ITRON CENTRON C1SR, CENTRON C1S, CENTRON C1ST, CENTRON C1SL, CENTRON C1SC Technical Reference Manual

...Page 1

FCC Part 15 Transmitter Certification

Test Report

FCC ID: SK9C1A-2

FCC Rule Part: 15.247

ACS Report Number: 04-0396-15C

Manufacturer: Itron Electricity Metering, Inc.

Equipment Type: Electricity Meter With Dual RF Transmitters

Trade Name: CENTRON ™ ICARe

Model: C1A-2

Manual

5015 B.U. Bowman Drive Buford, GA 30518 USA Voice: 770-831-8048 Fax: 770-831-8598

Page 2

CENTRON® Meter

Technical Reference Guide

Effective: January 2005

Page 3

Proprietary Rights Notice

This manual is an unpublished work and contains the trade secrets and confidential information of Itron, Inc., which are not to be divulged to third parties and may not be reproduced or transmitted in whole or part, in any form or by any means, electronic or

mechanical for any purpose, without the express written permission of Itron, Inc. All rights

to designs or inventions disclosed herein, including the right to manufacture, are reserved to

Itron, Inc.

The information contained in this document is subject to change without notice. Itron, Inc.

reserves the right to change the product specifications at any time without incurring any

obligations.

Trademarks Used in This Manual

CENTRON, PC-PRO+, PRO-READ, and ReadOne are registered trademarks of Itron, Inc.

Windows is a trademark of Microsoft Corporation.

Cellnet is a registered trademark of Cellnet Technologies, Inc.

CENTRON® Meter Technical Reference Guide

Part Number: 100299GM-01

Itron, Inc.

Corporate Headquarters

2818 North Sullivan Road

Spokane, WA 99216

U.S.A.

Tel: (509) 924-9900

Fax: (509) 891-3355

www.itron.com

Copyright© 2004-2005

Itron, Inc.

All rights reserved.

Oconee Electricity Metering

313-B North Highway 11

West Union, SC 29696

Tel: (864) 638-8300

Fax: (864) 638-4950

Itron, Inc.

U.S.A.

ii CENTRON Meter Technical Reference Guide

Page 4

Compliance With FCC Regulations

FCC Part 15, Class B

This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to Part 15 of the FCC rules. These rules are designed to provide reasonable

protection against harmful interference when the equipment is operated in a residential/

commercial environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions, may cause harmful

interference to radio communications. However, there is no guarantee that interference will

not occur in a particular installation. If this equipment does cause harmful interference to

radio or television reception, which can be determined by turning the equipment off and on,

the user is encouraged to try to correct the interference by one or more of the following

measures:

• Re-orient or relocate the receiving antenna.

• Increase the separation between the equipment and the receiver.

• Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help. This device complies

with Part 15 of the FCC rules.

THIS DEVICE COMPLIES WITH PART 15 OF THE FCC RULES. OPERATION IS SUBJECT

TO THE FOLLOWING TWO CONDITIONS: (1) THIS DEVICE MAY NOT CAUSE HARMFUL

INTERFERENCE, AND (2) THIS DEVICE MUST ACCEPT ANY INTERFERENCE

RECEIVED, INCLUDING INTERFERENCE THAT MAY CAUSE UNDESIRED OPERATION

FCC Part 15, Subpart C

When equipped with a radio transmitter option, this equipment has been tested and found to

comply with the limits for an intentional radiator, pursuant to Part 15, Subpart C of the FCC

Rules. This equipment generates, uses, and can radiate radio frequency energy. If not

installed and used in accordance with the instructions, it may cause interference to radio

communications.

The limits are designed to provide reasonable protection against such interference in a residential situation. However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause interference to radio or television reception.

which can be determined by turning the equipment on and off, the user is encouraged to try

to correct the interference by one of more of the following measures:

• Reorient or relocate the receiving antenna of the affected radio or television.

• Increase the separation between the equipment and the affected receiver.

• Connect the equipment and the affected receiver to power outlets on separate circuits.

• Consult the dealer or an experienced radio/TV technician for help.

Changes or modifications not expressly approved by Itron, Inc. could void the user’s authority to operate the equipment.

RF Exposure Information

This equipment complies with the FCC RF radiation requirements for uncontrolled environments. To maintain compliance with these requirements, the antenna and any radiating elements should be installed to ensure that a minimum separation distance of 20 cm is

maintained from the general population.

Canadian Interference Causing Equipment Regulations

This Class B digital apparatus meets all requirements of the Canadian Interference Causing

Equipment Regulations. Operation is subject to the following two conditions: (1) this device

may not cause harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation.

CENTRON Meter Technical Reference Guide iii

Page 5

Cet appareillage numérique de la classe B répond à toutes les exigences de l'interférence

canadienne causant des règlements d'équipement. L'opération est sujette aux deux conditions suivantes: (1) ce dispositif peut ne pas causer l'interférence nocive, et (2) ce dispositif

doit accepter n'importe quelle interférence reçue, y compris l'interférence qui peut causer

l'opération peu désirée.

Factory Repair of Meters

Itron recommends that all repairs be performed at the factory. Certain repairs may be performed by the user; however, unauthorized repairs will void any existing warranty. All surface mounted parts must be replaced by the factory.

Repair of Meters Under Warranty

If the meter is under warranty, then Itron, Inc. will repair the meter at no charge if the meter

has failed due to components or workmanship. A return authorization number must be

obtained before the equipment can be sent back to the factory. Contact your Itron Sales

Representative for assistance.

Repair of Meters Not Under Warranty

The same procedure as above applies. Itron will charge for the necessary repairs based on

the failure.

Service Return Address

Itron, Inc.

Customer Repair Department

313 North Highway 11 Dock C

West Union, SC 29696

Recycling Information:

The product you have purchased contains a battery (or batteries), circuit boards, and switches. The

batteries are recyclable. At the end of the meter’s useful life, under various state and local laws,

it may be illegal to dispose of certain components into the municipal waste system. Check with

your local solid waste officials for details about recycling options or proper disposal.

Although polycarbonate is not a commonly recycled plastic, the recycling number for the polycarbonate base is seven (7).

iv CENTRON Meter Technical Reference Guide

Page 6

TABLE OF CONTENTS

Chapter 1 General Information

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Physical Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Meter Base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Personality Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Product Availability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Display Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Operating Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Characteristic Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Burden Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

C1SD/C1ST/C1SL Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Shipping Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Chapter 2 Installation

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Selecting a Site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Installing the Meter into Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Programming the C1SD,T,L Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Retrofitting with Personality Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Chapter 3 Operation: Base Metrology

CENTRON 1S, 2S CL200, and 3S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

CENTRON 2S CL320, 4S, 12/25S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Chapter 4 Operation: C1S Version

Physical Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Kilowatt Hours . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Resetting Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

LCD Display Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

CENTRON Meter Technical Reference Guide v

Page 7

Table of Contents

Pre-June 2003 LCDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Post-June 2003 LCDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Non-Detented Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Detented Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Net Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Segment Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Factory Programming Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Chapter 5 Operation: C1SD, C1ST, and C1SL Versions

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Controls and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Modes of Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Normal Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Alternate Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Test Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Low Power Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Programmable Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Register Display Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Self Reading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Last Season Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Operating Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Informational Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Test Mode Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

Programming the Meter With a 200 Series Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

Demand Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

Time-of-Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

TOU Schedules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

Calendar Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

Rate Schedules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

Daily Schedules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

Seasonal Schedules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

Daylight Savings Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

Current Season Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

Last Season Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

Load Profile Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

Bit Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

Interval Lengths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

Power Outage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

Channel Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

Data Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

Recording Duration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

Optional Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

Electronic Detent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

Expansion Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

Security Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

Calculations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

vi CENTRON Meter Technical Reference Guide

Page 8

Table of Contents

Energy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

Demand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

Demand Calculations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

Power Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-23

Applying Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-23

Battery Life (Load Profile & TOU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-23

Example 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

Example 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-25

Example 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-26

Low Battery Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-26

Effectivity Date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-27

Three Button Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-27

Option Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-27

CENTRON R300CD Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-27

Programming the R300CD Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-28

Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-29

Chapter 6 Operation: C1SR Version

Physical Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Electronic Detent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Resetting Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Transmission Scheme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

FCC Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Tamper Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Testing the CENTRON C1SR Tamper Counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Retrofitting the C1SR Personality Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Chapter 7 Operation: C1SC Version

Physical Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Transmission Scheme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

FCC Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Display Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Resetting Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Programming the C1SC/CN1SC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Chapter 8 Testing, Troubleshooting, and Maintenance

Testing Support Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Infrared Test LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Pulse Detector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Annunciators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Watthour Annunciators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

TOU Rate Annunciators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Test Mode Annunciator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Testing with the Infrared Test LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Testing Using the Disk Emulation Annunciator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

CENTRON Meter Technical Reference Guide vii

Page 9

Table of Contents

Recommended Energy Testing Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

AEP Test Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Field Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Required Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Error Codes (R300) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Non-Fatal Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Fatal Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Error Codes (Demand, TOU, and Load Profile) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Non-Fatal Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

Fatal Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

Inspecting and Troubleshooting—General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-8

Blank Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-8

Time and Date Wrong (TOU or Load Profile Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-8

No Accumulation of kWh or kW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-8

Software Cannot Communicate with Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

Reed Switch Does Not Activate the Alternate Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

Reset Mechanism Does Not Initiate Demand Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

Demand Reset Cannot be Initiated Through PC or Handheld . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

Test Mode Switch Does Not Place Module in Test Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

Inspecting and Troubleshooting—C1S LCD and C1SR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

Blank Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

Chapter 9 Specifications and Drawings

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

viii CENTRON Meter Technical Reference Guide

Page 10

LIST OF FIGURES

Figure Figure Titles Page

1.1 Personality Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.2 Form 1S, 120 Volt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.3 Form 2S, CL200 240 Volt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.4 Form 4S, 20 Amp Transformer-Rated . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.5 Personality Module Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.6 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1.7 C1SD/C1ST/C1SL Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

2.1 Removing the Board-to-Board Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.2 Removing the Register Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.3 New Module Snap-in . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.4 Circuit Board Notches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.5 Board-to-Board Connector, Bottom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.6 Board-to-Board Connector, Top . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

3.1 Power Measurement Principle in 2S. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.2 Simplified CENTRON Architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.3 Hall Cells and ADCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

4.1 C1S LCD Personality Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 Mounted LCD Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.3 ZRO-C2A Resetter Connected to the CENTRON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.4 Reverse Side of ZRO Resetter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.5 Pre-June 2003 LCD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.6 LCD Display without Segment Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.7 LCD Display with Segment Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.8 Post-June 2003 LCD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.9 Non-Detented Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.10 Delivered kWh with Detent Enabled. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

4.11 Net kWh . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

4.12 Segment Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

5.1 C1SL Meter with Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2 C1SL Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.3 Test Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.4 Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5.5 Program File Export . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

5.6 Program File Export Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

5.7 Import Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

5.8 CENTRON C1ST/L Battery Life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

5.9 Example 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-25

5.10 Example 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-25

5.11 Example 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-26

5.12 CENTRON TOU Personality Module with R300CD Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-28

6.1 C1SR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2 C1SR LCD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.3 CENTRON C1SR Transmission Cycle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

6.4 C1SR FCC Label Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

7.1 C1SC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.2 CellNet Telemetry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

7.3 C1SC LCD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

7.4 C1SC/CN1SC Programming Port Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

CENTRON Meter Technical Reference Guide ix

Page 11

List of Figures

Figure Figure Titles Page

8.1 LED Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8.2 Pulse Detector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

8.3 TOU Rate Annunciators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

9.1 Form 1S Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

9.2 Form 2S Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

9.3 Form 3S Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

9.4 Form 4S Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

9.5 Form 12S Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

9.6 Form 25S Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

x CENTRON Meter Technical Reference Guide

Page 12

LIST OF TABLES

Table Table Titles Page

1.1 Outer Cover Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

5.1 LCD Display Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

5.2 Register Display Formats. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

5.3 Programmable Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

5.4 Information Data Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

5.5 Test Mode Data Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

5.6 Recording Duration for 32Kb . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

6.1 ReadOne Pro Tamper Count . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

8.1 AEP Test Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

8.2 Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

8.3 Non-Fatal Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

8.4 Fatal Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

CENTRON Meter Technical Reference Guide xi

Page 13

List of Tables

Notes:

xii CENTRON Meter Technical Reference Guide

Page 14

Chapter 1 General Information

This technical reference guide explains the installation, operation, and

maintenance of the Itron CENTRON® meter family. Itron urges you to read the

entire manual before attempting installation, testing, operation, or maintenance of

a meter. To operate the Itron PC-PRO+® Programming Software and the

PRO-READ® handheld reader programmer discussed in this manual, refer to their

respective user manuals.

About This Manual

This manual contains the following information as listed in the chapter

descriptions below:

Chapter 1

General Information

Chapter 2

Installation

Chapter 3

Operation: Base

Chapter 4

Operation: C1S

Chapter 5

Operation:C1SD, C1ST,

C1SL

Chapter 6

Operation: C1SR

Chapter 7

Operation: C1SC

Chapter 8

Testing, Troubleshooting,

and Maintenance

Chapter 9

Specification Numbers and

Drawings

Provides a general description, operation, physical and

functional descriptions, and complete meter specifications.

Gives instructions for the proper handling and installation.

Describes the measurement technique used for the base on

the CENTRON meter.

Provides a physical description and operational

characteristics of the basic watthour (kWh) only meter.

Provides detailed information and theoretical operation for

Demand (C1SD), Time-of-Use (C1ST), and Load Profile

(C1SL) versions. Gives step-by-step procedures for

accessing the three operational modes and associated

displays.

Provides a physical description and the operational

characteristics of the R300 900 MHz radio frequency

personality module.

Provides a physical description and the operational

characteristics of the CellNet personality module.

Provides an explanation of the testing, troubleshooting, and

maintenance of the CENTRON meter.

Provides a reference to meter part numbers as well as

CENTRON wiring diagrams.

CENTRON Meter Technical Reference Guide 1-1

Page 15

General Information

General Description

The CENTRON meter family is a solid-state, singlephase and network meter used

for measuring electrical energy consumption. The CENTRON incorporates a twopiece design combining a base metrology with a variety of personality modules

that snap on the standard meter base. Utilizing the Hall Effect technology for

accurate power measurement, the metrology portion of the meter contains all

measurement circuitry and calibration information, while the personality modules

contain the register functionality and communication mediums.

Each version of the meter is distinguished by the various personality modules that

mount to the standard meter metrology base (see Figure 1.1) The personality

modules available include the following versions:

• Energy only—C1S (LCD)

• Demand—C1SD

• Time-of-Use (TOU) with Demand—C1ST

• Load Profile with TOU and Demand—C1SL

• Energy only with radio frequency AMR—C1SR

• CellNet Fixed Network—C1SC

• Energy plus demand with radio frequency AMR - R300CD

Figure 1.1 Personality Modules

1-2 CENTRON Meter Technical Reference Guide

Page 16

Physical Description

Meter Base

General Information

The CENTRON meter features a common meter base to which various personality

modules are attached. The covers come in configurations of polycarbonate and

glass.

The CENTRON meter base contains all of the measurement circuitry and

calibration information on the metrology board.

The meter base assembly includes two current conductors, a flux-directing core, a

Hall Effect device, the metrology circuit board, and the ultrasonically welded

module support. The base also contains a MOV, metal oxide varistor, which is used

to protect the meter from line surges.

Meter bases are built specific to the metering form and are available in Form 1S, 2S

CL200, 2S CL320, 3S 120V, 3S 240V, 4S, and 12/25S configurations.Examples are

shown in Figure 1.2, Figure 1.3, and Figure 1.4.

Figure 1.2 Form 1S, 120 Volt Figure 1.3 Form 2S, CL200 240 Volt

Figure 1.4 Form 4S, 20 Amp Transformer-Rated

CENTRON Meter Technical Reference Guide 1-3

Page 17

General Information

Personality Modules

All of the personality modules in the CENTRON meter family snap into the module

holder located on the standard meter base (see Figure 1.5). From the base

metrology, the energy data is transmitted to the personality modules, which

contain the meter display, communication mediums, and register functionality.

Product Availability

Battery

Figure 1.5 Personality Module Assembly

The current offerings for the CENTRON are:

Metrology Class 100, 120V, Form 1S

Class 200, 240V, Form 2S

Class 320, 240V, Form 2S

Class 20, 120V, Form 3S

Class 20, 240V, Form 3S

Personality

Modules

Option Boards R300CD

The CENTRON C1ST and C1SL modules contain a battery that powers the clock

circuit during a power outage. The battery is permanently soldered to the module

and is expected to last the life of the module.

Refer to Chapter 5,"Operation: C1SD, C1ST, and C1SL Versions" for detailed battery

information.

C1S—LCD (5x1 or 4x10)

C1SR—R300C (Radio

Frequency)

C1SC—CellNet Data System

Class 20, 240V, Form 4S

Class 200, 120V, Form 12S

Class 200, 120V, Form 25S

C1SD—Demand

C1ST—Time-of-Use (TOU)

C1SL—Load Profile

1-4 CENTRON Meter Technical Reference Guide

Page 18

Covers

Outputs

Display Functions

General Information

The outer cover configurations available for CENTRON meter family are described

in Table 1.1.

Table 1.1 Outer Cover Configurations

Meter Versions Cover Options

Polycarbonate Glass

C1S, C1SR, C1SC Standard Optional

C1SD, C1ST, C1SL Including Demand Reset+ Optical Tower Not Available

The C1SD, C1ST, and C1SL personality modules are available input/output-ready

(I/O-ready). These modules contain circuitry that allows future functionality

expansion through I/O modules.

The C1S and C1SR modules can display kWh readings in either a 5x1 or 4x10

configuration.

The C1SD, C1ST, and C1SL modules can display a maximum of 32 Normal, 32

Alternate, and 8 Test display items, up to a total of 48 items.

Specifications

Electrical

Operating Environment

Voltage Rating 120V, 240V

Operating Voltage ± 20% (60 Hz); ± 10% (50 Hz)

Frequency 60 Hz, 50 Hz

Operating Range ± 3 Hz

Battery Voltage 3.6 V nominal (C1ST, C1SL only)

Operating Range 2.7V - 3.8V

Carryover 8 year cumulative and 15 year shelf life

Temperature -40°C to +85°C

Humidity 0% to 95% non-condensing

Accuracy ± 0.5% @ unity power factor

± 0.5% @ 50% power factor

Transient/Surge Suppression ANSI C37.90.1 - 1989

IEC 61000-4-4

ANSI C62.45 - 1992

CENTRON Meter Technical Reference Guide 1-5

Page 19

General Information

Characteristic Data

Burden Data

Starting Watts

2S CL200 5W

1S, 2S CL320, 12S, 25S 10W

3S CL20 1.2W

4S CL20 2.4W

Temperature Rise Meets ANSI C12.1 Section 4.7.2.9

Metrology Voltage Watt Loss VA

1S 120 0.45 3.7

2S Class 200 240 0.45 7.2

2S Class 320 240 0.65 10.2

3S 240 0.65 10.2

4S 240 0.65 10.2

12S/25S 120 0.65 5.4

240V

Register

Watt Loss 0.01 1.34 1.34 0.90

VA — 0.25 0.25 14.76

120V

Register

Watt Loss 0.01 0.62 0.62 0.90

VA — 0.14 0.14 11.1

LCD R300 CellNet D/T/L

LCD R300 CellNet D/T/L

120V Option Board R300CD

Watt Loss 2.2

VA 23

240V Option Board

Watt Loss 2.2

VA 42

To get the watt loss or VA of the overall product, add the metrology watt loss to the

register watt loss and option board watt loss.

VA (Meter) VA (Metrology) VA (Register) + VA (Option Board)+=

Watt Loss (Meter) Watt Loss (Metrology) Watt Loss (Register) + Watt Loss (Option Board)+=

1-6 CENTRON Meter Technical Reference Guide

Page 20

Technical Data

Dimensions

General Information

Meets applicable standards:

• ANSI C12.1-1995

•ANSI C12.10-1997

• ANSI C12.16 (Solid State Meters)

• ANSI C12.18 (Optical Communications Protocol)

• ANSI C12.20 (Class 0.5) - 1998

• IEC 61000-4-4

• IEC 61000-4-2

The following dimensional measurements are shown in inches and (centimeters).

Figure 1.6 Dimensions

A B C D E

Polycarbonate

6.29 (16.00) 6.95 (17.70) 2.70 (6.90) 3.16 (8.00) 4.53(11.50)

Glass

6.42 (16.30) 6.95(17.70) 3.17 (8.10) 3.64 (9.20) 5.01 (12.70)

CENTRON Meter Technical Reference Guide 1-7

Page 21

General Information

C1SD/C1ST/C1SL Dimensions

The following dimensional measurements are shown in inches and (centimeters).

Figure 1.7 C1SD/C1ST/C1SL Dimensions

ABCDEFGH

6.95 (17.70) 6.29 (16.00) 2.70 (6.90) 3.16 (8.00) 4.53(11.50) 4.98(12.70) 6.29(16.00) 6.95 (17.70)

Shipping Weights

Polycarbonate

The following weight measurements are shown in pounds and (kilograms).

Polycarbonate Glass

Meter 1.375 (0.623) 2.75 (1.247)

4 Meters and Carton 8.90 (4.04) 13.96 (6.35)

96 Meter Pallets 214 (97.30) 335 (152.30)

1-8 CENTRON Meter Technical Reference Guide

Page 22

Chapter 2 Installation

This chapter of the guide gives instructions for the proper handling and installation

of the CENTRON meter.

Inspection

Perform the following inspections when you receive the meter:

• Inspect for obvious damage to the cover, base, and meter assembly.

• Be sure the optical connector is free of debris.

• Compare the meter and register nameplates to the record card and invoice.

Verify the type, class, voltage, form number, and other pertinent data.

• Save the original packing materials.

Battery

The lithium battery is soldered to the register module circuit board (C1ST and

C1SL only). A low-power mode for the battery preserves the capacity of the

battery. Factory-programmed C1ST and C1SL meters should be put into service in

a timely manner to avoid degradation of the battery. Programmed meters are not in

low-power mode.

Storage

The product you have purch ased co ntain s a recyclable lithiu m b attery, circuit boards, and

switches. At the end of its useful life, under various state and local laws, it may be illegal

to dispose of this battery into the municipal waste s tream. Check with y our local area

solid waste officials for details about recycling options or proper disposal.

The C1SR also contains a tilt switch that may contain mercury. Please dispose of

properly.

Store the meter in a clean, dry (Relative Humidity < 50%) environment between

-40° C to +85° C (-40° F to +185° F). Avoid prolonged storage (more than one year)

at temperatures above +70° C(+158° F). Store the meter in the original packing

material. The lithium battery has a shelf life of approximately fifteen (15) years.

CENTRON Meter Technical Reference Guide 2-1

Page 23

Installation

Unpacking

Selecting a Site

As with all precision electronic instruments, the meter should be handled with care

in an outdoor environment. Follow these precautions when handling the meter:

• Avoid damaging the meter base, cover, reset mechanism (if supplied), and

optical connector (if supplied).

• When handling personality modules, grip the circuit board by its edges. Do not

touch the liquid crystal display.

The meter is designed and manufactured to be installed in an outdoor

environment, at operating temperature ranges between -40° C and +85° C (-40° F to

+185° F). Operation in moderate temperatures increases reliability and product

life.

When using a Demand, TOU, or Load Profile meter where the line frequency is not

stable, Itron recommends using either the C1ST or C1SL meter version with

Crystal Time synchronization if a clock is needed (TOU or Load Profile).

Installing the Meter into Service

Install the meter base using standard meter installation practices.

The current and potential terminals extend as blades, or bayonets, from the back

of the meter. The meter is plugged into the socket so that the bayonets engage the

main socket jaws that connect to the service lines. Clamping pressure on the

bayonets is provided by the heavy spring pressure of the socket jaws. In some

heavy-duty sockets, jaw clamping pressure is provided by a handle or wrench.

On meters equipped with LCD displays, verify register operations by observing the

display:

• LCD displays the correct number of digits (4 or 5).

• If the test mode annunciator is flashing, depress the Test mode button to

return the meter to the Normal mode (C1S D/T/L only).

• If the register only displays a Segment Test (all display items shown) and

flashes “CNTRON”, the register has not been programmed.

• Verify that no errors are displayed.

2-2 CENTRON Meter Technical Reference Guide

Page 24

The practice of knowingl y install ing Form 12S/25 S meters into meteri ng sock ets wi th

either missing or disconnected fifth terminal jaws in the meter socket is NOT

recommended for CENTRON Form 12S/25S meters.

The following guidance should be followed when using the Form 12S/25S CENTRON

meter:

• This version of the meter should not be used in a non-Form 12S or 25S metering

service.

• The meter's 5th terminal should be properly installed on the meter in a location

defined in the CENTRON Technical Reference Guide.

• The fifth terminal jaw in the meter socket should be properly connected to the

service neutral and installed in the correct location.

• The metering service should match the class, form and voltage rating on the meter's

nameplate.

Failure to follow these recomme ndations will result in damage to the CENTRON Form

12S/25S meter and void all product warranties.

Programming the C1SD,T,L Meter

Installation

The personality module should be powered prior to programming. The module can

be programmed using the optical connector. The default communications rate

when programming through the optical tower is 4800 baud; 9600 baud is

selectable. Refer to PC-PRO+ documentation for detailed programming

information.

Retrofitting with Personality Modules

CENTRON meters can be upgraded to increase functionality by changing the

Personality Modules.

Do not power ON the meter without the inner cover in place. Power the meter OFF before

removing the inner cover. Personality modules are sensitive to ESD damage. Take

appropriate grounding measures before retrofitting!

To change or add a Personality Module:

1 Remove power from the meter.

2 Remove the outer (polycarbonate or glass) cover.

3 Remove plastic inner cover by holding the meter with both hands and applying

equal pressure on either side of the three and nine-o’clock positions. The inner

cover is held in place by four plastic tabs on the meter base.

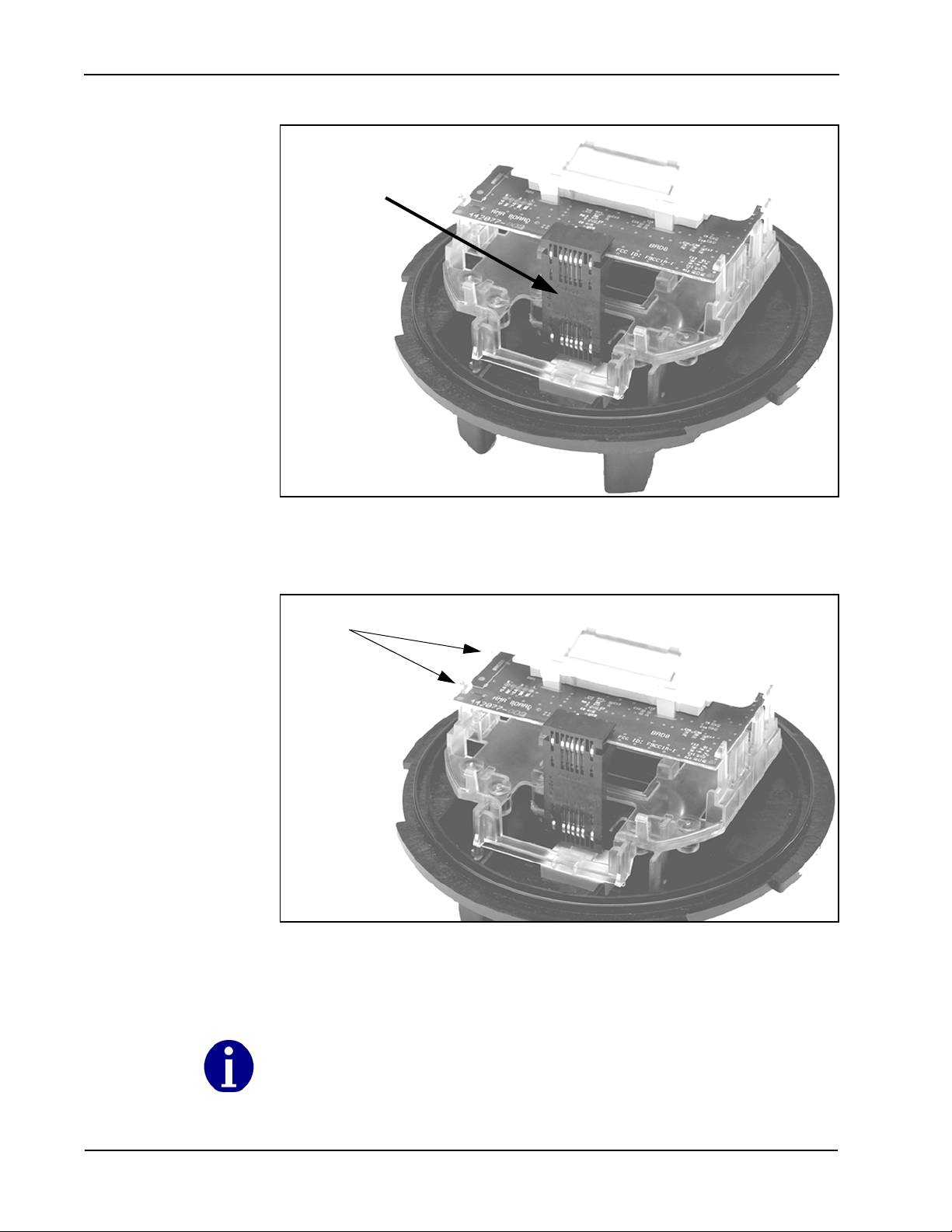

4 Remove the black board-to-board connector between the circuit board and the

metrology board by pulling it by its middle while moving it side-to-side (see

Figure 2.1). To maintain the integrity of the connector, only remove it when

you are upgrading the meter.

CENTRON Meter Technical Reference Guide 2-3

Page 25

Installation

Board-to-Board

Connector

Figure 2.1 Removing the Board-to-Board Connector

5 Remove the register module, one side at a time, by pulling gently outward on

the meter frame snaps (see Figure 2.2) while lifting the module up.

Meter Frame

Snaps

Figure 2.2 Removing the Register Module

6 Snap the new module into the meter frame by aligning the notches at bottom

of the circuit board with the lower two snaps (see Figure 2.3).

The module must be aligned properly in the snaps to avoid damaging the connector or circuit

board.

2-4 CENTRON Meter Technical Reference Guide

Page 26

Figure 2.3 New Module Snap-in

Installation

7 Replace the board-to-board connector by aligning the top of the connector

with the notches in the circuit board (see Figure 2.4) and pressing gently at the

bottom of connector to mate the connector to metrology board (see Figure

2.5). Then, gently press the top of the connector to mate it to the register

module (see Figure 2.6). The connector is seated correctly when you hear it

snap into place.

Notches (2)

Figure 2.4 Circuit Board Notches

CENTRON Meter Technical Reference Guide 2-5

Page 27

Installation

Be sure to use the meter base for leverage instead of the LCD holder (see Figure 2.5). Pressure

on the LCD holder may damage the personality module.

Figure 2.5 Board-to-Board Connector, Bottom

8 Ensure the board-to-board connector is fully seated by pressing firmly in on

the middle of the connector.

Figure 2.6 Board-to-Board Connector, Top

9 Carefully replace the inner protective cover. Engage the top snaps first, taking

care to place the slot at the top of the cover over the IR light pipe. Failure to do

so could break the light pipe. Ensure that all four meter base tabs are engaged

with the slots at the top and bottom of the inner cover.

2-6 CENTRON Meter Technical Reference Guide

Page 28

Installation

10 Place the cover over the meter base until the flange on the cover is flush with

the flange on the meter base.

11 Turn the cover clockwise until the locking tabs are fully engaged with the

meter base.

12 If the cover has a Demand Reset or an Optical Connector, be sure these are

properly aligned with their corresponding accessory on the register faceplate.

If not aligned correctly, the Demand Reset or Optical Connector will not

function properly. If the Demand Reset plunger is not in the retracted position

before turning the outer cover, the mechanism may be damaged.

CENTRON Meter Technical Reference Guide 2-7

Page 29

Installation

Notes:

2-8 CENTRON Meter Technical Reference Guide

Page 30

Chapter 3 Operation: Base Metrology

This chapter describes the measurement technique used for the base metrology on

the CENTRON meters.

CENTRON 1S, 2S CL200, and 3S

The CENTRON meter is a solid-state meter which uses the inherent multiplication

properties of the Hall Effect to measure power. The Hall Effect principle relies on a

physical property: a conductor which carries a current in a magnetic field

generates a voltage difference across the conductor proportional to the product of

the current and the magnetic field.

The voltage V

Where

i

is the biasing current (derived from the line voltage)

b

B is the magnetic field density (derived from the line current)

K is the Hall coefficient (analogous to a gain factor in any meter)

K could be viewed as the Hall sensor intrinsic gain and is maximized by the

appropriate choice of semiconductor materials that have been uniquely optimized

by Itron for the CENTRON meter.

For the metering application, the biasing current i

generated from the line voltage (V) using a resistor (R).

created at the output of the Hall device:

out

V

KibB×=

out

applied to the sensor is

b

VR⁄=

i

b

The magnetic field (B) is generated by the line currents (I = I

+ I2) that flow

1

through two conductors looped around the core.

B CI× CI1I2+()×==

Where

C is a constant that is dependent upon the geometric and magnetic properties

of the coil

This field is focused to flow through the Magnetic Core’s air gap where the Hall

sensor is precisely positioned. The voltage, Vout, which is formed on the Hall

Effect device is proportional to the input watts (see Figure 3.1).

CENTRON Meter Technical Reference Guide 3-1

Page 31

Operation: Base Metrology

The output voltage of the Hall Effect device is then:

V

V= out GIV GPower==

hall

Where G C R⁄()K=

G is the combined gain factor of the entire system (Voltage to biasing current, line

Current to flux density, Hall sensor).

i

b

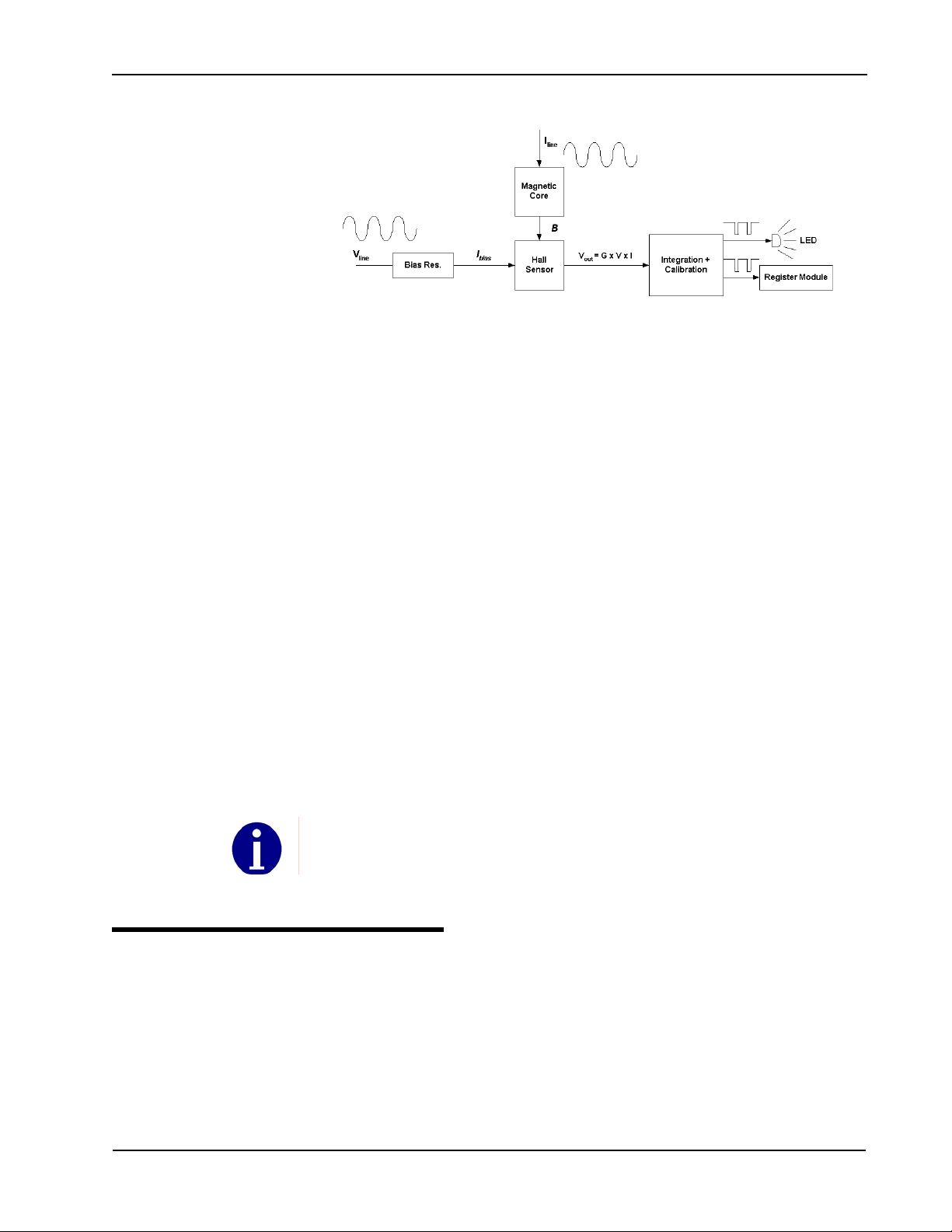

Figure 3.1 Power Measurement Principle in 2S

From the power information available at the output voltage of the sensor, the

meter architecture is simplified over previous designs as the multiplication has

already taken place (see Figure 3.2).

The Hall sensor output voltage is amplified by a differential amplifier in order to

bring the signal within the nominal level of the analog to digital converter (ADC).

The output of the ADC is integrated over time to get the energy information and

generates a pulse stream that is accumulated into a counter. When the

accumulated pulses reach a threshold set by meter calibration, a Wh pulse is

emitted and the meter LED is flashed. The counter threshold is programmed at the

factory and serves as the permanent gain calibration for the life of the product. The

calibration is a digital feature and has no variation or adjustment. All the

processing steps described above are integrated into an Application Specific

Integrated Circuit (ASIC) to improve reliability and reduce cost.

3-2 CENTRON Meter Technical Reference Guide

Page 32

Operation: Base Metrology

Figure 3.2 Simplified CENTRON Architecture

The custom ASIC cancels all the offset generated by the meter and removes the

need for a light load adjustment of the metrology. This allows the meter to have

excellent accuracy over a very large dynamic range, especially at the low current

levels. For this reason, no offset adjustment is needed or provided for the

CENTRON meter.

There is a slight phase shift in the current to flux density conversion due to eddy

currents in the magnetic core material. This shift causes a small power factor error

that is uniform across the dynamic range (load curve) of the meter. Itron

compensates for this shift in the CENTRON by the use of a capacitor in the biasing

current circuit. This correction is permanent.

The custom ASIC provides:

• Wh pulses to drive the Test LED

The same signal is also provided to the electronic register attachments.

• energy direction (sign)

• 60Hz clock signal synchronized with the line voltage (for time keeping)

• pulse that drives the stepper motor for the mechanical register attachment (1

pulse every 10 watthours)

The metrology board, which houses the measurement components described

above, passes the Wh pulse, energy direction, and 60Hz clock signals to the

personality module attached to the meter base. The two line voltages (one is

referred to as meter ground), and power supply references are also supplied for

reference purposes.

An inherent feature built into the design of each CENTRON ensures that the calibration of the

product is not affected by any electronic board (existing or planned) added to the meter. This is

achieved by a distributed power supply and documented design requirements in the CENTRON

developer’s kit.

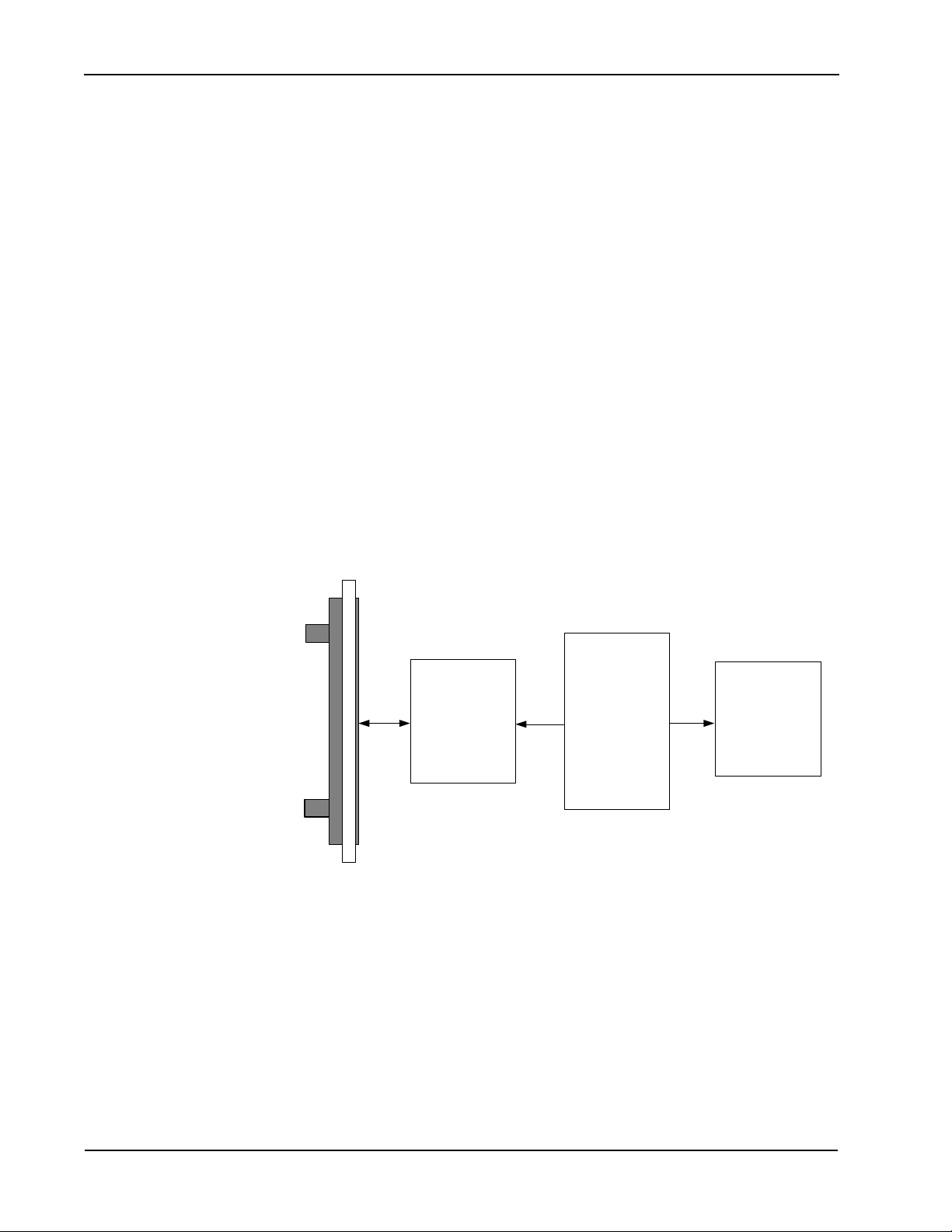

CENTRON 2S CL320, 4S, 12/25S

The advanced metering forms of the CENTRON (2S CL320, 4S, and 12/25S) meter

use the same Hall Effect measurement principle that is used in the form 1S, 2S, and

3S metering forms described earlier in this chapter.

The major difference with these metering forms is the presence of two Hall cells,

magnetic cores, and ADCs (see Figure 3.3).

CENTRON Meter Technical Reference Guide 3-3

Page 33

Operation: Base Metrology

For these metering applications, the biasing current Ibias (I

each sensor is generated from the line voltage (V

magnetic field is generated by the line current (I

conductor looped around each core. The voltage (V

line1

line1

and V

and I

and V

out1

line2

line2

and I

bias1

) using a resistor. The

) that flows through the

) that is formed on

out2

) applied to

bias2

each Hall Effect device is proportional to the watts produced by each phase.

Each Hall sensor output voltage is amplified by a differential amplifier in order to

bring the signal within the nominal level of the ADC. ADC 1 sums the signal from

ADC 1 and ADC 2. The output of ADC 1 is integrated over time to get the energy

information. Each time the integrated signal exceeds a predetermined amount of

energy, a pulse is generated. The pulse stream is accumulated into a counter. When

the accumulated pulses reach a threshold, a Wh pulse is emitted and the meter

LED is flashed. The counter threshold is programmed at the factory and serves as

the permanent gain calibration for the life of the product. The calibration is a

digital feature and has no variation or adjustment. ADCs 1 and 2 are calibrated

independently, which means that each phase is calibrated independently.

Figure 3.3 Hall Cells and ADCs

3-4 CENTRON Meter Technical Reference Guide

Page 34

Chapter 4 Operation: C1S Version

The kWh only version of the CENTRON meter is available with an LCD personality

module to register energy accumulation:

The LCD module may be ordered with a 5x1 or 4x10 register for self-contained

meters, and a 5xTR or 4xTR register for transformer-rated meters.

The kWh only version of the CENTRON provides very accurate measurement for

energy accumulation for today’s needs, but also provides a platform for easy

upgrade to higher functionality in the future.

Figure 4.1 C1S LCD Personality Module

Physical Description

The CENTRON Personality Modules snap into the meter register mounting

brackets to ease installation of the board.

The LCD module is connected to the metrology board using the board-to-board

connector. The following information is sent to the LCD module from the

metrology board:

• Line voltage

• Reference voltage

• Energy flow direction

• Energy pulse data

• Line frequency

A connector is located at the 12 o'clock position behind the LCD for resetting the

energy register. This is done using the ZRO-C2A Resetter.

CENTRON Meter Technical Reference Guide 4-1

Page 35

Operation: C1S Version

Registers

Kilowatt Hours

Resetting Values

Figure 4.2 Mounted LCD Register

The modules display energy in increments of whole values of kWh. Standard

operation for all modules is to add forward and reverse energy flow. Therefore, if

the meter is inverted, the registers will accumulate in the forward direction, thus

providing uni-directional operation. At the time of order, the LCD module can be

selected to have a detent register. Programmed at the factory, this feature will

cease registration while the meter is inverted, or power flow is otherwise reversed.

The module can also be selected to have a net register. This feature is factory

programmable and will subtract registration while the meter is inverted, or power

flow is otherwise reversed.

The ZRO-C2A (see Figure 4.3) resets the energy register through a direct

connection to the connector at the 12 o’clock position on the LCD and R300

modules.

4-2 CENTRON Meter Technical Reference Guide

Page 36

Figure 4.3 ZRO-C2A Resetter Connected to the CENTRON

Operation: C1S Version

The ZRO-C2A Resetter works with both pre-June 2003 and Post-June 2003 LCDs.

The ZRO-C2A is a pocket-sized handheld device for resetting the electronic meter

readings in the CENTRON LCD kWh meter (C1S) and the R300 meter (C1SR). The

ZRO-C2A also resets the tamper indicators in the C1SR.

The ZRO-C2A requires that the meter Not Be Powered. The device connects to

the CENTRON meter through a hole in the plastic inner cover located at the 12

o’clock position on the meter (see Figure 4.3). Extending from the ZRO-C2A is a

cable terminating in a connector which mates to the programming connector of

the CENTRON.

Beginning February 20, 2002, the C1SR module for the CENTRON meter uses a

new EEPROM component. This new EEPROM operates at a different voltage level

requiring revision to the CENTRON resetter.

Use of a ZRO-C or ZRO-C2 resetter without the C2A upgrade WILL CAUSE DAMAGE to

the personality modules on both the C1S LCD and C1SR me ters produc ed after the ne w

EEPROM implementation date; damaged modules will show “Error” on the display.

CENTRON Meter Technical Reference Guide 4-3

Page 37

Operation: C1S Version

All current production resetters and resetters produced after June of 2001 were

built with the C2A upgrade and are labeled accordingly as shown in Figure 4.4

below. Although personality modules with the new EEPROM are only compatible

with the C2A version of the CENTRON resetter (ZRO-C2A), the older revisions of

the personality modules are also compatible with the ZRO-C2A.

Figure 4.4 Reverse Side of ZRO Resetter

LCD Display Function

Pre-June 2003 LCDs

The CENTRON LCD has been updated as of June 2003. All CENTRON C1S meters

built after this date will incorporate the new LCD. The following sections describe

both the new LCD and the old LCD. The information on the pre-June 2003 LCD is

provided for users who purchased meters prior to the change. This display is no

longer available for order.

The pre-June 2003 LCD module is shown in Figure 4.5. Two separate versions of

the LCD are available. Both versions may be configured for either four or five digits

and will roll over at 100,000 kWh. The LCD is automatically adjusted for contrast

over the operating temperature range.

Figure 4.5 Pre-June 2003 LCD

4-4 CENTRON Meter Technical Reference Guide

Page 38

Operation: C1S Version

The non-segment check version displays only the kWh reading. A downward

pointing arrow on the LCD pulses at a rate equal to the energy consumption. The

arrow flashes on for 1 watthour and off for 1 watthour. This effectively produces

an equivalent Kh of 2.0.

Infrared LED Kh is 1.0.

Figure 4.6 LCD Display without Segment Check

A second version of the LCD is available which displays the kWh reading and a

segment check (see Figure 4.7). The display scrolls between the kWh reading and

segment check with 7 seconds of on-time for each display item.

Figure 4.7 LCD Display with Segment Check

The three triangle segments in the bottom right corner of the display represent a

watt disk emulator. This electronic load indicator will advance with each pulse,

since each pulse is equivalent to one watthour. Reverse power is indicated by a

reversal in the direction of the electronic load indicator.

CENTRON Meter Technical Reference Guide 4-5

Page 39

Operation: C1S Version

Post-June 2003 LCDs

The post-June 2003 LCD module is shown in Figure 4.8. This display uses five

7-segment digits, four icons to indicate the type of displayed data, and three icons

to represent a watt disk emulator. The display may be configured for either four or

five digits and will roll over at 100,000 kWh.

This module is compatible with the ZRO-C2A Resetter.

Figure 4.8 Post-June 2003 LCD

Non-Detented Register

The Non-Detented Register displays the delivered energy plus received energy.

Figure 4.9 Non-Detented Register

4-6 CENTRON Meter Technical Reference Guide

Page 40

Operation: C1S Version

Detented Register

The Detented Register addresses applications requiring the reading of delivered

kWh only. Received energy is discarded.

Figure 4.10 Delivered kWh with Detent Enabled

Net Register

The Net (kWh) Register addresses applications requiring residential net metering

points. Net kWh is the delivered kWh to the customer minus any received kWh