Page 1

OpenWay® Riva™ 500G Gas ERT Module,

Remote Mount

Installation Guide

Technical

Communications

knowledge to shape your future

Page 2

Identification

OpenWay Riva 500G Gas ERT Module Installation Guide, Remote Mount

01 May 2017

TDC-1678-000

Copyright

© 2017 Itron, Inc. All rights reserved.

Confidentiality Notice

The information contained herein is proprietary and confidential and is being provided

subject to the condition that (i) it be held in confidence except to the extent required

otherwise by law and (ii) it will be used only for the purposes described herein. Any third

party that is given access to this information shall be similarly bound in writing.

Trademark Notice

Itron is a registered trademark of Itron, Inc.

All other product names and logos in this documentation are used for identification purposes

only and may be trademarks or registered trademarks of their respective companies.

Suggestions

For more information about Itron or Itron products, see www.itron.com.

If you have questions or comments about the software or hardware product, contact Itron

Technical Support Services.

Contact

• Email: support@itron.com

• Internet: support.itron.com

• Telephone Itron Technical Support North America: 1-877-487-6602

For technical support contact information by region, go to www.itron.com and select your

country and language.

Page 3

Contents

Chapter 1 Important Safety and Compliance Information.............................. 1

U.S. and Canadian patent numbers..................................................................................................................... 1

USA, FCC Part 15 Rules....................................................................................................................................... 1

ISED rules............................................................................................................................................................. 2

Transportation classication................................................................................................................................. 3

Modications, repairs, installation, and removal...................................................................................................3

Lithium battery safety........................................................................................................................................... 3

Equipment repairs.................................................................................................................................................4

Intrinsic safety.......................................................................................................................................................4

Electrostatic ignition hazard..................................................................................................................................4

ERT module cleaning............................................................................................................................................ 4

Drop height limitation............................................................................................................................................4

Chapter 2 About the OpenWay Riva Remote 500G Gas ERT Module............ 5

Transmission modes............................................................................................................................................. 5

Remote OpenWay Riva 500G gas ERT module and Itron Security Manager....................................................... 6

Enabling 500G ERT module security......................................................................................................... 7

Remote OpenWay Riva 500G gas ERT module functional specications............................................................7

OpenWay Riva 500G gas ERT module operational specications.......................................................................7

Related documents...............................................................................................................................................8

Chapter 3 Mounting the Remote 500G ERT Module........................................9

Standard installation options................................................................................................................................ 9

Mounting the remote 500G ERT module on a pipe.............................................................................................. 9

Adapter plate mounting positions.......................................................................................................................11

Selecting a wall or at vertical mounting location.............................................................................................. 12

Chapter 4 500G Remote ERT Module Programming..................................... 14

Programming the remote ERT module............................................................................................................... 14

Itron programs and software variables............................................................................................................... 15

Chapter 5 Specific Meter Manufacturer Installation......................................19

Eagle Research meter installation.......................................................................................................................19

Eagle Research installation overview.......................................................................................................19

Eagle Research 500G product mounting instructions............................................................................. 20

Eagle Research mechanical and wiring installation instructions............................................................. 21

Connecting the 500G remote ERT module to the MPplus corrector................................................21

Connecting the 500G ERT module to the XARTU corrector.............................................................22

Eagle Research corrector programming and requirements notes........................................................... 23

Using Eagle Research Field Manager to change the MPplus settings.............................................24

Using Eagle Research Field Manager to change the XARTU corrector settings..............................26

Eagle Research programming note.................................................................................................. 27

Elster American meter installation...................................................................................................................... 27

Elster American 500G installation overview ............................................................................................27

Elster American meter 500G mounting instructions................................................................................ 28

OpenWay Riva 500G Gas ERT Module Installation Guide, Remote Mount TDC-1678-000 iii

Proprietary and Confidential

Page 4

Elster American mechanical and wiring installation instructions............................................................. 29

Installing the remote module cable...................................................................................................31

Galvanic Gas Micro Installation.......................................................................................................................... 31

Galvanic installation overview.................................................................................................................. 31

Galvanic product mounting instructions.................................................................................................. 32

Galvanic mechanical and wiring installation instructions.........................................................................32

Programming the Galvanic Gas Micro electronic volume corrector........................................................ 32

GE Oil and Gas meter installation.......................................................................................................................32

GE Oil and Gas 500G installation overview............................................................................................. 33

GE Oil and Gas custom mounting options.............................................................................................. 34

GE Oil and Gas ES3 or ETC ordered with the AMR-ready mounting kit.......................................... 34

GE Oil and Gas IMC/W2, or MC2 with the GE mounting bracket kit............................................... 35

GE Oil and Gas mechanical and wiring installation instructions .............................................................36

D800/D1000 wiring and installation.................................................................................................. 37

GE Oil and Gas meters with pulse output wiring..............................................................................39

GE Oil and Gas meter programming and requirements notes ................................................................41

Honeywell Instrument 500G installation............................................................................................................. 43

Honeywell Instrument installation overview............................................................................................. 43

Honeywell product mounting instructions............................................................................................... 44

Honeywell mechanical and wiring installation instructions......................................................................45

Connecting the remote ERT modules to a Honeywell Mini-AT, Mini-Max, or EC-AT ...................... 45

Connecting the remote ERT module to the Honeywell TCI.............................................................. 47

Honeywell Instrument programming and requirements...........................................................................49

Honeywell software settings............................................................................................................. 49

Programming the Honeywell Instrument parameters....................................................................... 50

Itron meter installation........................................................................................................................................ 51

National meter installation.................................................................................................................................. 52

Romet meter installation..................................................................................................................................... 52

Romet installation overview..................................................................................................................... 53

Romet product mounting instructions..................................................................................................... 54

Romet mechanical and wiring installation instructions............................................................................54

Romet corrector programming and requirements notes..........................................................................58

Sensus meter installation....................................................................................................................................60

Sensus meter installation overview..........................................................................................................60

Sensus product mounting instructions.................................................................................................... 60

Sensus meter mechanical and wiring installation instructions................................................................ 62

Sensus meter programming and requirements notes .............................................................................62

Chapter 6 Diaphragm Meter Installation.........................................................63

Diaphragm meter installation overview...............................................................................................................63

Product mounting installation instructions......................................................................................................... 64

Diaphragm meter mechanical and wiring installation instructions..................................................................... 65

Remote ERT module programming and requirements notes............................................................................. 69

Appendix A Using gel-cap connectors to complete wiring connections.....71

Appendix B Optional sealant application instructions ..................................72

OpenWay Riva 500G Gas ERT Module Installation Guide, Remote Mount TDC-1678-000 iv

Proprietary and Confidential

Page 5

Chapter 1 Important Safety and Compliance

Information

This section provides important information for your safety and product compliance.

U.S. and Canadian patent numbers

U.S. Patent numbers: 4,614,945; 4,753,169; 4,768,903; 4,799,059; 4,867,700

Canadian Patent numbers: 1,254,949; 1,267,936; 1,282,118

USA, FCC Part 15 Rules

This device complies with Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation.

Operation is subject to the following two conditions:

• This device may not cause harmful interference.

• This device must accept any interference that may cause undesirable operation.

This device must be permanently mounted such that it retains a distance of 20 centimeters

(7.9 inches) from all persons in order to comply with FCC RF exposure levels.

USA, FCC Class B-Part 15

This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and

used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or television

reception, which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver

is connected.

• Consult the dealer or an experienced radio or TV technician for help.

Compliance Statement Canada

This device complies with Innovation, Science

and Economic Development Canada (ISED)

license-exempt RSS standard(s). Operation is

Déclaration de Conformité

Le présent appareil est conforme aux CNR

d'Industrie Canada applicables aux appareils

radio exempts de licence. L'exploitation est

OpenWay Riva 500G Gas ERT Module Installation Guide, Remote Mount TDC-1678-000 1

Proprietary and Confidential

Page 6

Important Safety and Compliance Information

subject to the following two conditions: (1) this

device may not cause interference (2) this device

must accept any interference, including

interference that may cause undesired operation

of the device.

Under Innovation, Science and Economic

Development Canada (ISED) regulations, this

radio transmitter may only operate using an

antenna of a type and maximum (or lesser) gain

approved for the transmitter by Industry Canada.

To reduce potential radio interference to other

users, the antenna type and its gain should be so

chosen that the equivalent isotropically radiated

power (e.i.r.p.) is not more than that necessary

for successful communication.

Modifications and Repairs

To ensure system performance, this device and antenna shall not be changed or modified without

the expressed approval of Itron. Per FCC rules, unapproved modifications or operation beyond or in

conflict with these instructions for use could void the user's authority to operate the equipment.

autorisée aux deux conditions suivantes: (1)

l'appareil ne doit pas produire de brouillage, (2)

l'utilisateur de l'appareil doit accepter tout

brouillage radioélectrique subi, même si le

brouillage est susceptible d'en compromettre le

fonctionnement.

Conformément à la réglementation d'Industrie

Canada, le présent émetteur radio peut

fonctionner avec une antenne d'un type et d'un

gain maximal (ou inférieur) approuvé pour

l'émetteur par Industrie Canada. Dans le but de

réduire les risques de brouillage radioélectrique à

l'intention des autres utilisateurs, il faut choisir le

type d'antenne et son gain de sorte que la

puissance isotrope rayonnée équivalente (p.i.r.e.)

ne dépasse pas l'intensité nécessaire à

l'établissement d'une communication

satisfaisante.

ISED rules

Compliance Statement Canada Déclaration de Conformité

This device complies with Innovation, Science

and Economic Development Canada (ISED)

license-exempt RSS standard(s). Operation is

subject to the following two conditions: (1) this

device may not cause interference (2) this device

must accept any interference, including

interference that may cause undesired operation

of the device.

Under Innovation, Science and Economic

Development Canada (ISED) regulations, this

radio transmitter may only operate using an

antenna of a type and maximum (or lesser) gain

approved for the transmitter by Industry Canada.

To reduce potential radio interference to other

users, the antenna type and its gain should be so

chosen that the equivalent isotropically radiated

power (e.i.r.p.) is not more than that necessary

for successful communication.

Le présent appareil est conforme aux CNR

d'Industrie Canada applicables aux appareils

radio exempts de licence. L'exploitation est

autorisée aux deux conditions suivantes: (1)

l'appareil ne doit pas produire de brouillage, (2)

l'utilisateur de l'appareil doit accepter tout

brouillage radioélectrique subi, même si le

brouillage est susceptible d'en compromettre le

fonctionnement.

Conformément à la réglementation d'Industrie

Canada, le présent émetteur radio peut

fonctionner avec une antenne d'un type et d'un

gain maximal (ou inférieur) approuvé pour

l'émetteur par Industrie Canada. Dans le but de

réduire les risques de brouillage radioélectrique à

l'intention des autres utilisateurs, il faut choisir le

type d'antenne et son gain de sorte que la

puissance isotrope rayonnée équivalente (p.i.r.e.)

ne dépasse pas l'intensité nécessaire à

OpenWay Riva 500G Gas ERT Module Installation Guide, Remote Mount TDC-1678-000 2

Proprietary and Confidential

Page 7

Important Safety and Compliance Information

Compliance Statement Canada Déclaration de Conformité

l'établissement d'une communication

satisfaisante.

Modifications and Repairs

o ensure system performance, this device and antenna shall not be changed or modified without

T

the expressed approval of Itron. Per FCC rules, unapproved modifications or operation beyond or in

conflict with these instructions for use could void the user's authority to operate the equipment.

Transportation classification

The Federal A

commercial aircraft. When powered, the 100G series remote ERT module is considered an

operating transmitter and receiver and cannot be shipped by air. All product returns must be

shipped by ground transportation.

viation Administration prohibits operating transmitters and receivers on all

Modifications, repairs, installation, and removal

To ensure system performance, this device and antenna shall not be changed or modified

without the expressed approval of Itron. Any unauthorized modification will void the user's

authority to operate the equipment.

In the event of malfunction, all repairs should be performed by Itron. It is the responsibility of

users requiring service to report the need for service to Itron.

Lithium battery safety

Warning: Follow these procedures to avoid injury to avoid injury to yourself or

others:

•

The lithium battery may cause a fire or chemical burn if it is not disposed of

properly.

• Do not recharge, disassemble, heat above 100° Celsius (212° Fahrenheit),

crush, expose to water, or incinerate the lithium battery.

• Keep the lithium battery away from children.

• Fire, explosion, and severe burn hazard.

OpenWay Riva 500G Gas ERT Module Installation Guide, Remote Mount TDC-1678-000 3

Proprietary and Confidential

Page 8

Important Safety and Compliance Information

Equipment repairs

Warning: Only authorized Itron personnel should attempt repairs on Itron

equipment. Attempts to do so by others might void any maintenance contract

with your company. Unauthorized service personnel might also be subject to

shock hazard on some Itron equipment if removal of protective covers is

attempted.

Intrinsic safety

Warning: Substitution of components may impair intrinsic safety.

Electrostatic ignition hazard

Warning: Electrostatic Ignition Hazard. Ensure area is not hazardous when

installing, servicing, cleaning, or touching the ERT module.

ERT module cleaning

Warning: Clean only with a damp cloth.

Drop height limitation

Warning: ER

damaged if the module is dropped from heights greater than 36 inches. Product

warranty coverage is contingent on not exceeding this drop height limitation.

T modules contain sensitive electronic components which can be

OpenWay Riva 500G Gas ERT Module Installation Guide, Remote Mount TDC-1678-000 4

Proprietary and Confidential

Page 9

Chapter 2 About the OpenWay Riva Remote

500G Gas ERT Module

Itron remote 500G ERT modules are radio-frequency (RF) are IPv6 open standards based

gas modules designed to be read under Itron’s multi-purpose OpenWay Riva Network Mode

(RNM) or by legacy ChoiceConnect handheld, mobile and fixed network readers. In RNM,

the 500G gas ERT module offers firmware download, sub-hourly interval data, and

extended data storage. In 100 Series Mode, the ERT module operates identical to the 100G

DLS Dataglooging ERT module and can be ready by legacy ChoiceConnect handheld,

mobile, and network readers. The 500G gas ERT module continues Itron's tradition of

reliability, accuracy, and long battery life while meeting the industry's standards for security

and intrinsic safety.

The ERT module features tilt and cut cable-tamper reporting and security seals to indicate

physical tampering and minimize theft. Cut cable is reported when communications fail

between the meter or instrument and the ERT module, possibly from a cut or disconnected

cable. The ERT module circuitry senses an electrical current break to report a cut cable

tamper event.

Transmission modes

In Riva Network Mode, the module provides 3,840 buckets of interval data configurable from

1 minute to 1 hour (for example, 160 days of hourly data or 40 days of 15 minute data).

Interval options are 1-6, 10, 12, 15, 20, 30 or 60 minutes. Output power in RNM is +27 dBm

(500 milliwatts) and designed to transmit 4 times a day with a 20-year battery life

100G DLS Mode, the module provides 960 buckets of hourly interval data and can be set to

transmit in fixed network, mobile and handheld, hard to read mobile and handheld, or

cellular solutions mode (fixed network applications only).

• Fixed Network Mode. The remote 100G ERT module transmits a high-powered network

interval message (NIM) RF message every five minutes. Output power in this mode is

500 milliwatts or +27 dBm. Interspersed in the high power NIM, the remote 100G ERT

module transmits a medium power RF message at 10 milliwatts or +10 dBm every 60

seconds. In Fixed Network mode, the expected battery life is 20 years.

• Mobile High Power Mode. The remote 100G ERT module transmits a high-powered RF

message every 60 seconds. Output power in this mode is 250 milliwatts or +24dbm. In

Mobile High Power Mode, the expected battery life is 20 years.

• Mobile and Handheld Mode. The remote 100G ERT module transmits a medium-

powered RF message every 15 seconds. Output power in this mode is 10 milliwatts or

+10dBm. In Mobile and Handheld Mode, the expected battery life is 20 years.

• (Optional) Hard to Read Mobile and Handheld Mode. The remote 100G ERT module

transmits a high-powered RF message every 30 seconds. Output power in this mode is

250 milliwatts or +24dBm. In Hard to Read Mobile and Handheld Mode, the expected

OpenWay Riva 500G Gas ERT Module Installation Guide, Remote Mount TDC-1678-000 5

Proprietary and Confidential

Page 10

About the OpenWay Riva Remote 500G Gas ERT Module

battery life decreases to 15 years in this mode. The hard to read mobile and handheld

mode should only be used for exceptionally hard-to-read applications (such as meters

installed on roof tops or in sub-basements).

• Itron Cellular Solutions (ICS) Mode. The 100G DLS module is compatible with the Itron

Cellular Solution and can be programmed for optimum operation with FDM Endpoint

Tools Enhanced. In ICS mode, the 100G DLS transmits a high-powered RF network

interval message (NIM) every five minutes. Output power in this mode is 500 milliwatts or

+27 dBm. Interspersed in the high power NIM, the 100G transmits a medium power RF

message at 10 milliwatts or +10 dBm every 60 seconds. In ICS Mode, the expected

battery life is 20 years.

Note: ICS mode is for fixed network application only. ICS is optimized to work with the

ICS communications module in Itron’s electric meter. The 100G DLS must be in a full

security mode to work with ICS. This is not part of the ICS mode, but is a system level

requirement.

An FCC license is not required to read the 500G ERT modules.

Remote OpenWay Riva 500G gas ERT module and Itron Security Manager

The 500G ERT module is a component of Itron's OpenWay Riva system. The OpenWay

Riva system enhanced security, provided by Itron Security Manager (ISM), applies to the RF

communications between the collection device and the ERT module.

There are two fundamental security processes used in the Itron Security Manager to ensure

system communication confidentiality and validity.

• Authentication. Authentication is the process of confirming that an artifact is genuine or

valid. Authentication in the ERT module is the process of verifying a request is from a

valid source and in its original form.

• Encryption. Encryption is the process of transforming information to make it unreadable

to anyone who does not have a valid security key. There are two types of encryption,

symmetric and asymmetric. Symmetric encryption uses a shared key to decrypt or

encrypt information. Asymmetric encryption uses a private key to encrypt and a public

key to decrypt. Data transmissions over the network are protected using AES-256

encryption.

As a component of the Itron Openway Riva solution, the 500G gas module supports the

security model found in the OpenWay solution for both reading and programming. If the ERT

modules are shipped without enhanced security enabled (ready to secure), the utility can—

at a later date—configure the modules for ISM enhanced security.

Note: Enabling or working with Itron ISM enhanced security requires FDM Endpoint Tools

Enhanced.

OpenWay Riva 500G Gas ERT Module Installation Guide, Remote Mount TDC-1678-000 6

Proprietary and Confidential

Page 11

About the OpenWay Riva Remote 500G Gas ERT Module

Enabling 500G ERT module security

When 500G ERT modules ship from an Itron factory, each module contains utility factory

keys. The presence of these utility factory keys does not enable the enhanced security; the

installer enables the enhanced security at the time the ERT module is deployed or at a later

time using an Itron programming device, Field Deployment Manager Endpoint Tools

Enhanced, and programming commands. Initial key exchange commands are secured using

the utility factory keys. For more information about programming the 500G ERT module for

security, see the FDM Endpoint Tools Mobile Application Guide (TDC-0934).

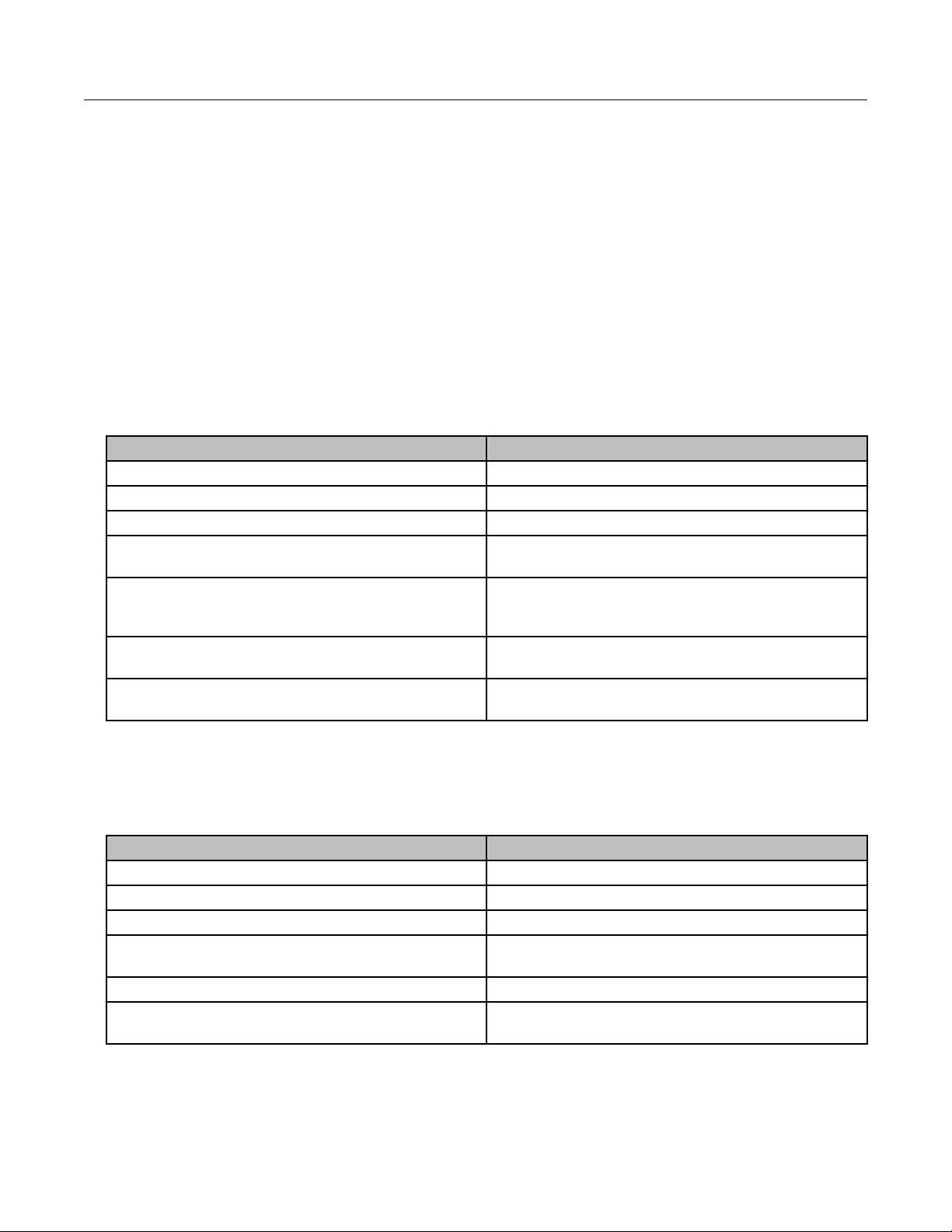

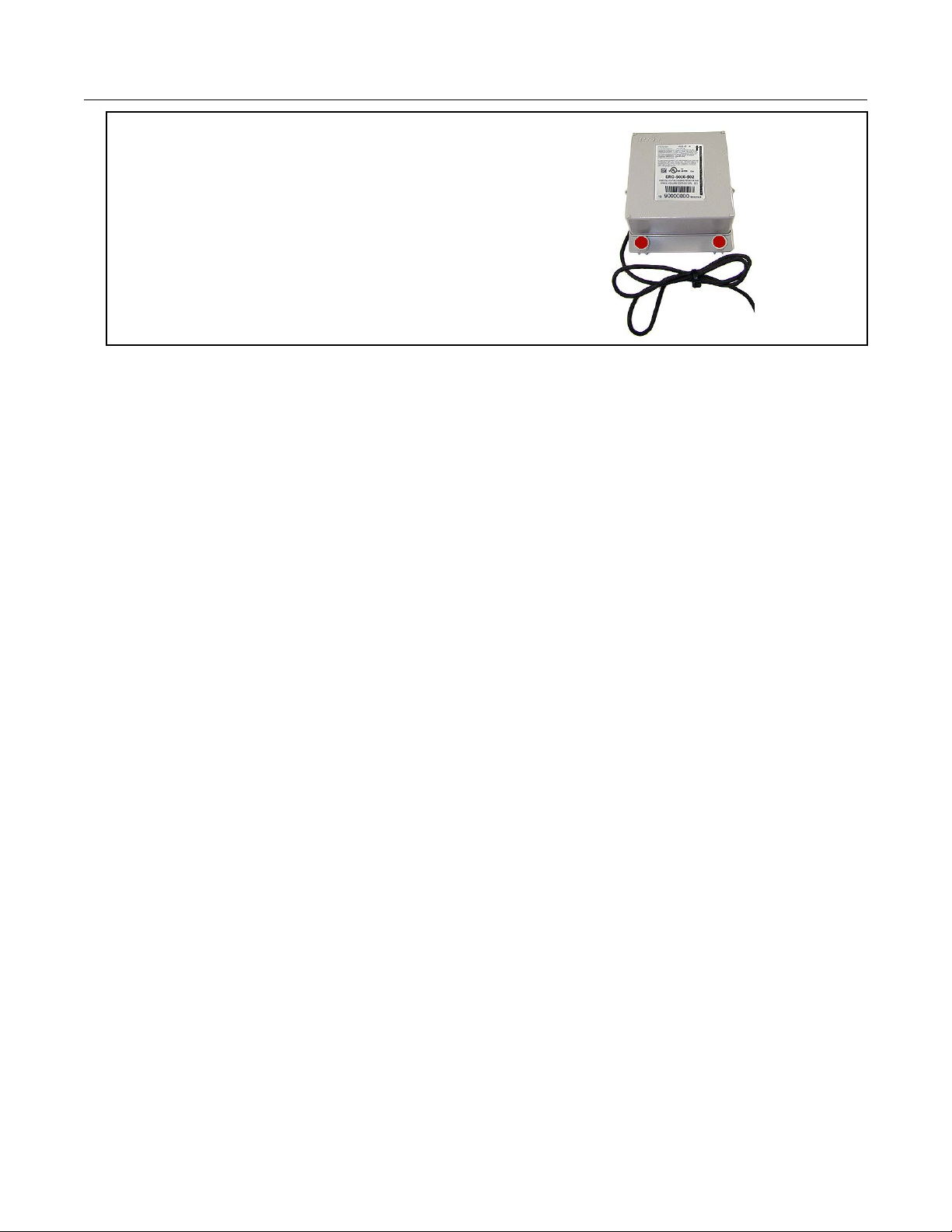

Remote OpenWay Riva 500G gas ERT module

functional specifications

Functional specification Description

Power source Two "A" cell lithium batteries

Tamper detection Tilt and cut cable

FCC compliance Part 15 certified

Innovation, Science and Economic

Development Canada (ISED) compliance

Intrinsically safe per Telemetering Equipment for use in Hazardous

Product identification Numeric and bar coded ERT type and serial

Construction materials Gray polycarbonate housing and back plate with

RSS-247 certified

Locations, for Cl I, Div 1, Gp D for Haz Loc,

emp Code T2, -40°C ≤ Ta ≤ +70°C.

T

number

encapsulated electronics

OpenWay Riva 500G gas ERT module operational

specifications

Operational specifications Description

Operating temperatures -40° to 158° F (-40° to +70° C)

Operating humidity 5 to 95 percent relative humidity

Program frequency 908 MHz

Transmit frequency Frequency hopping spread spectrum 903 to

926.85 MHz in the ISM band

Data integrity Verified in every data message

NIM message FM modulation; all other messages are AM

modulated

OpenWay Riva 500G Gas ERT Module Installation Guide, Remote Mount TDC-1678-000 7

Proprietary and Confidential

Page 12

About the OpenWay Riva Remote 500G Gas ERT Module

Related documents

Document title Document part number

OpenWay Riva 500G Gas ERT Module Installation Guide,

Direct Mount

OpenWay Collection Manager Operational Guidelines

OpenWay Riva Events and Exceptions Reference Guide

Gas and Telemetry Module Meter Compatibility List PUB-0117-002

Gas and Telemetry Module Ordering Guide PUB-0117-001

OpenWay Riva 500G Gas ERT Module Specification Sheet

Field Deployment Manager Endpoint Tools Mobile

Application Guide

Field Deployment Manager Field Representative's Guide TDC-0936-XXX

Note The last three digits of the user and installation guides represent the document's

revision level. The revision level is subject to change without notice.

TDC-1671-XXX

TDC-0934-XXX

OpenWay Riva 500G Gas ERT Module Installation Guide, Remote Mount TDC-1678-000 8

Proprietary and Confidential

Page 13

Chapter 3 Mounting the Remote 500G ERT

Module

This chapter provides the instructions to mount the remote 500G ERT module on a pipe or

other flat vertical surface (wall).

Standard installation options

Mount the remote ERT module using the pipe mount or wall mount (flat vertical surface)

procedure.

• Pipe mount. Itron offers a pipe installation kit (CFG-0005-003) to mount the remote ERT

module on a pipe.

• Flat vertical (wall) mount. Installation using the wall mount option places the module on

a wall or other vertical surface.

Select the mounting option that will best work for your system. For example, your setup may

provide the location for a pipe mount but not a wall mount. The preferred mounting location

is near the meter or instrument, but some installations may require an extended cable

length. For example, your installation may require mounting the ERT module around a

corner to avoid RF interference. The remote ERT module supports cable lengths up to 300

feet with a recommended one-splice limitation. Installers must mount the remote ERT

module in a vertical position with the ERT label directional arrow pointed upward.

Warning: Do not mount the 500G remote ER

than vertical (remote ERT module label arrow pointed upward). Violating the

mounting orientation requirements may void the product warranty.

Caution:

• The 500G series modules are optimized for communication and require

upright mounting. Any other mounting position could result in reduced RF

performance.

• The remote module tilt tamper sensor requires upright mounting. Any other

mounting position can cause issues with the module's tilt tamper detection.

Upright vertical positioning is critical because:

T module in an orientation other

Mounting the remote 500G ERT module on a pipe

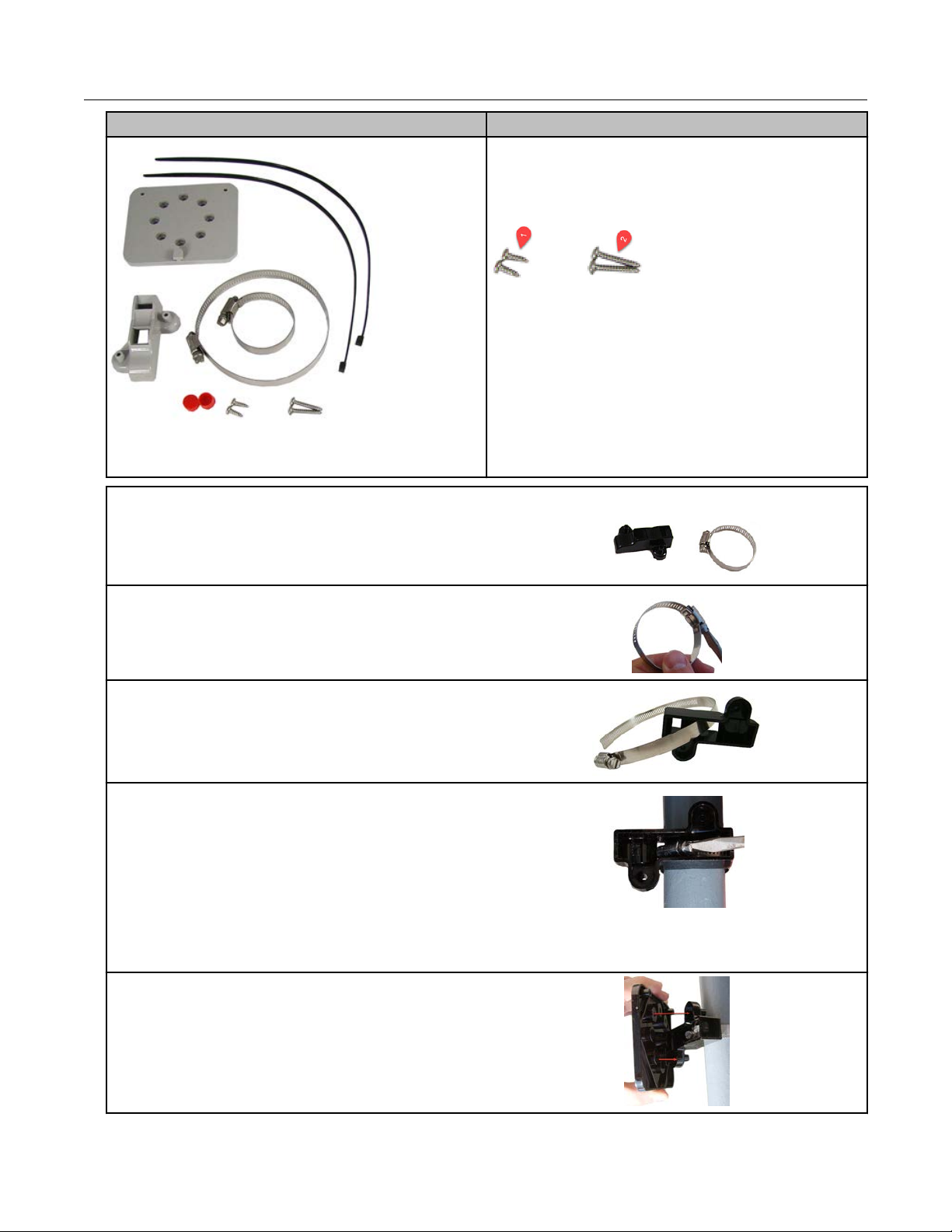

The following items are required to mount the remote ERT module on a pipe.

Itron part number Description

CFG-0005-003 Pipe mount kit contents:

OpenWay Riva 500G Gas ERT Module Installation Guide, Remote Mount TDC-1678-000 9

Proprietary and Confidential

Page 14

Mounting the Remote 500G ERT Module

Itron part number Description

2 band clamps, 2 tamper seals, pipe bracket, 2

cable ties, 1 adapter plate and the following

screws:

1. SCR-0215-001 (2) #8-16 x ½ inch slotted

pan-head tapping screw

steel. Attaches the adapter plate to the pipe

bracket.

2. SCR-0215-002 (2) #8-16 1-inch slotted panhead tapping screw, corrosion-resistant steel.

Attaches the ERT module to the adapter

plate.

1. Remove the pipe bracket and clamp from the

kit.

, corrosion-resistant

2. Loosen the band clamp screw until the end of

the band releases.

3. Push the end of the clamp's band through the

holes in the pipe bracket as shown.

4. Place the band clamp around the pipe. The

band will loosely wrap around the pipe.

Push the end of the band through the band

1.

clamp screw assembly.

2. Turn the band clamp's screw assembly to fit

into the pipe bracket opening.

3. Tighten the clamp screw until the band clamp

is secure on the pipe.

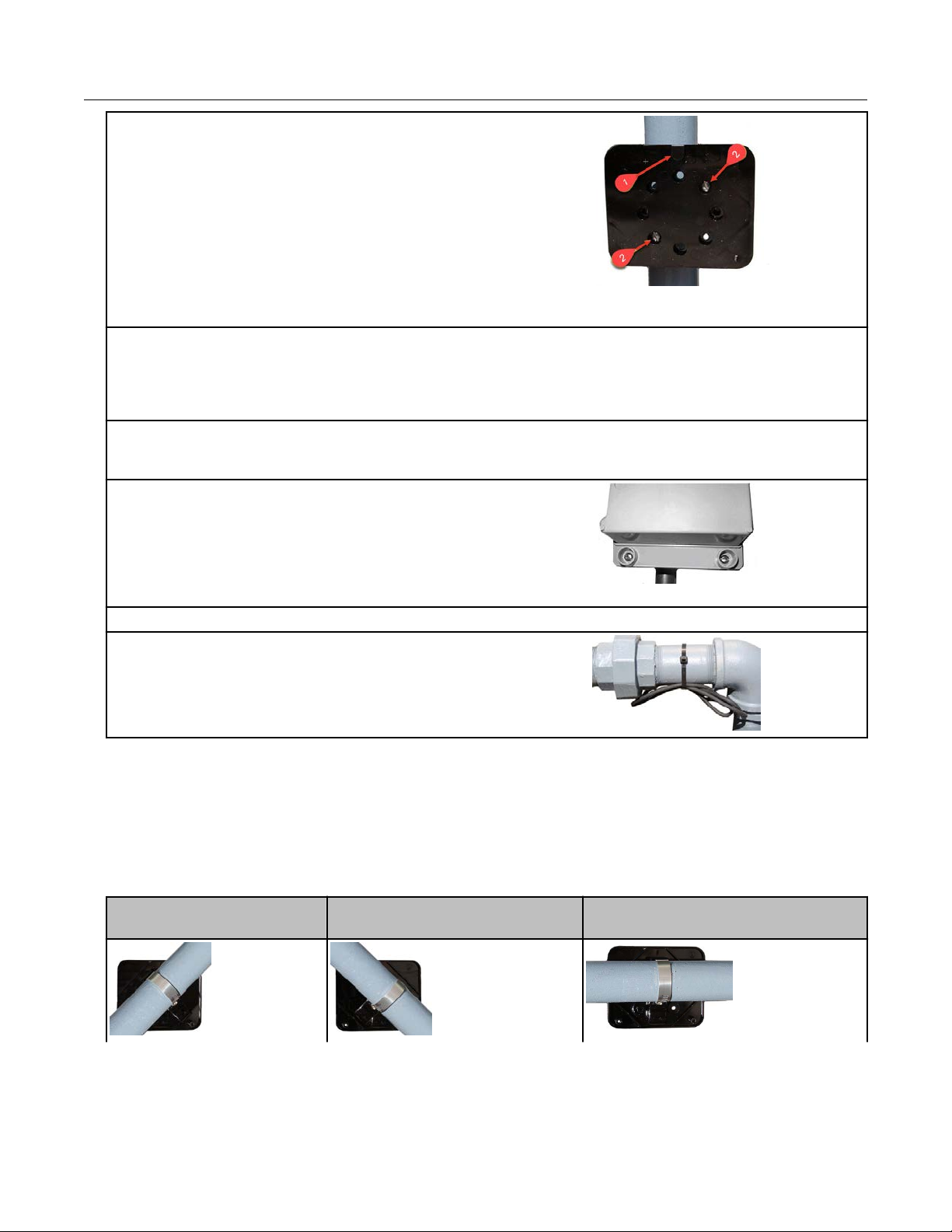

5. Place the adapter plate on the pipe bracket

with the mounting lug at the top. The adapter

plate screw bosses fit into the pipe bracket

recess.

OpenWay Riva 500G Gas ERT Module Installation Guide, Remote Mount TDC-1678-000 10

Proprietary and Confidential

Page 15

6. Ensure that the adapter plate is positioned as

shown with the mounting lug (1) at the top.

1. Install the adapter plate on the pipe mounting

bracket, use the two shortest (½-inch) screws

from the pipe mount kit.

2. Place the mounting screws into the holes as

shown (2).

Tighten both screws in an alternating pattern to 9

to 12 inch-pounds torque.

7. Position the back of the remote module

against the face of the adapter plate. The

adapter plate mounting lug (1) must be

positioned above the ER

recess (2).

8. Push up on the module until the adapter plate

mounting lug (1) is as far as possible inside the

module mounting lug recess (2).

9. Align the ERT module back-plate mounting

holes with the pipe mount adapter plate holes.

Install the two one-inch ERT module mounting

screws from the installation kit. Tighten the

module mounting screws evenly in an alternating

pattern. Tighten the screws to 9 to 12 inchpounds torque.

10. Insert the tamper seals.

11. Gather the excess ERT module cabling into a

loop and use the cable tie to secure the gathered

cable to the pipe.

T module mounting lug

Mounting the Remote 500G ERT Module

Adapter plate mounting positions

Note:

following illustrations show the various mounting configurations. The adapter plate mounting

screw locations are indicated (2).

45-degree angle with the

pipe running to the right

OpenWay Riva 500G Gas ERT Module Installation Guide, Remote Mount TDC-1678-000 11

The notch at the top of the adapter plate (1) must always be at the top position. The

45-degree angle with the pipe

running to the left

Proprietary and Confidential

Horizontal

Page 16

Mounting the Remote 500G ERT Module

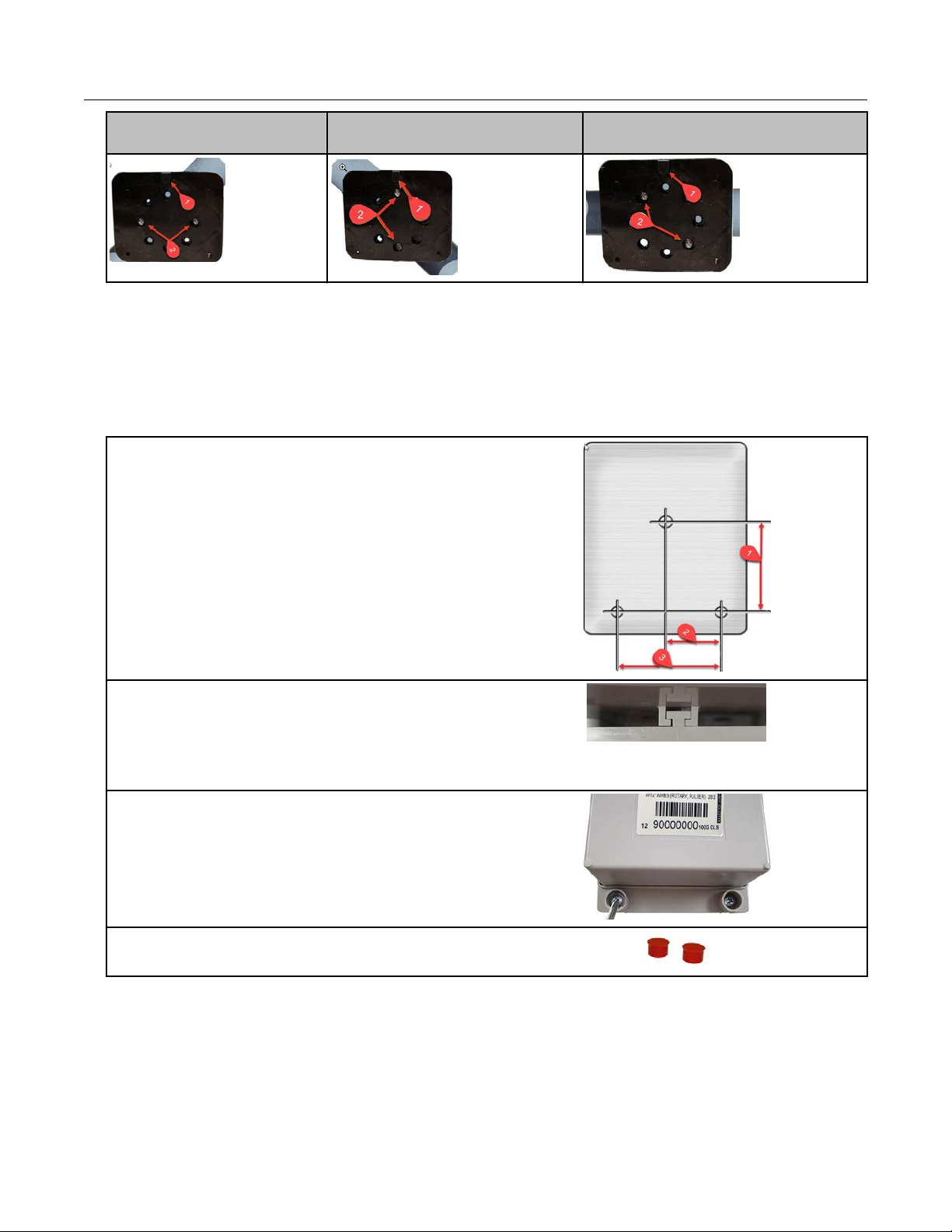

45-degree angle with the

pipe running to the right

45-degree angle with the pipe

running to the left

Horizontal

Selecting a wall or flat vertical mounting location

Carefully select a mounting location free from electrical wires. The mounting location must

have the proper clearance to accommodate the 1-1/2-inch module mounting screws so

nothing is damaged by the drill or mounting screws. Use a compatible mounting screw

1. Drill three pilot holes in the mounting surface.

The drilled pilot holes for the two bottom screws

must be on a horizontal line.

1. 3 inches

2. 1-11/16 inches

3. 3-3/8 inches

.

2. Screw the top mounting screw into the top pilot

hole drilled in step one, leaving enough of the

screw protruding so the ER

on the back plate slides over the screw head and

fits completely into the lug recess. Make

adjustments as necessary.

3. Install the two bottom mounting screws.

ighten the screws in an alternating pattern to

T

secure the module firmly in position.

4. Place a new tamper seal over each bottom

T module mounting screw as required.

ER

T module lug recess

OpenWay Riva 500G Gas ERT Module Installation Guide, Remote Mount TDC-1678-000 12

Proprietary and Confidential

Page 17

Note: To reduce the risk of cable damage,

secure any excess ERT module cabling with a

cable tie.

Mounting the Remote 500G ERT Module

OpenWay Riva 500G Gas ERT Module Installation Guide, Remote Mount TDC-1678-000 13

Proprietary and Confidential

Page 18

Chapter 4 500G Remote ERT Module

Programming

Caution: You must program the 500G remote ERT module before use.

Programming Itron gas ERT modules requires an understanding of:

• Your meter's drive rate and the number of dials

◦ The drive rate and number of dials is important for programming the module to count

correctly and roll over to zero at the correct time. For example, a four-dial, 2 cubic-feet

meter configuration will count two cubic-feet for each rotation and roll over to zero after

9999.99 where the one's place is equivalent to 100 cubic-feet.

• How your system interprets the meter reading

◦ Some systems modify the consumption reading with the collection software. Other

times, the billing system is used to make modifications. If modifications are made in

both systems, issues may cause consumption reading errors.

It is important to understand your system before the gas ERT modules are programmed.

Program the 500G gas ERT module in RVM mode using a compatible programming device

loaded with FDM version 4.0 or higher.

Program the 500G gas ERT module in 100S mode using an approved programming device

loaded with Field Deployment Manager (FDM) software version 3.3 or higher.

To enable enhanced security and for more complete programming information, see the Field

Deployment Manager Endpoint Tools Mobile Application Guide (TDC-0934).

Programming the remote ERT module

Program the meter drive rate into the remote ERT module using a compatible programming

device.

1. Verify that you have the correct programming mode (RNM, fixed network mode, mobile high

power mode, mobile/handheld mode, or hard-to-read mobile/handheld mode) for your application.

2. For all programming and Check Endpoint operations using a handheld computer

handheld as close to vertical as possible. For best success, keep the handheld within six feet of the

target ERT module.

3. Programming parameters are based on the configuration file loaded into the programming

device.

Read or Check the remote ERT module using a handheld computer or Belt Clip Radio.

• If the read result is higher than the number programmed in step 1, the module is counting

correctly.

• If the read result is not higher than the number programmed in step 1, replace the remote ERT

module.

, hold the

OpenWay Riva 500G Gas ERT Module Installation Guide, Remote Mount TDC-1678-000 14

Proprietary and Confidential

Page 19

500G Remote ERT Module Programming

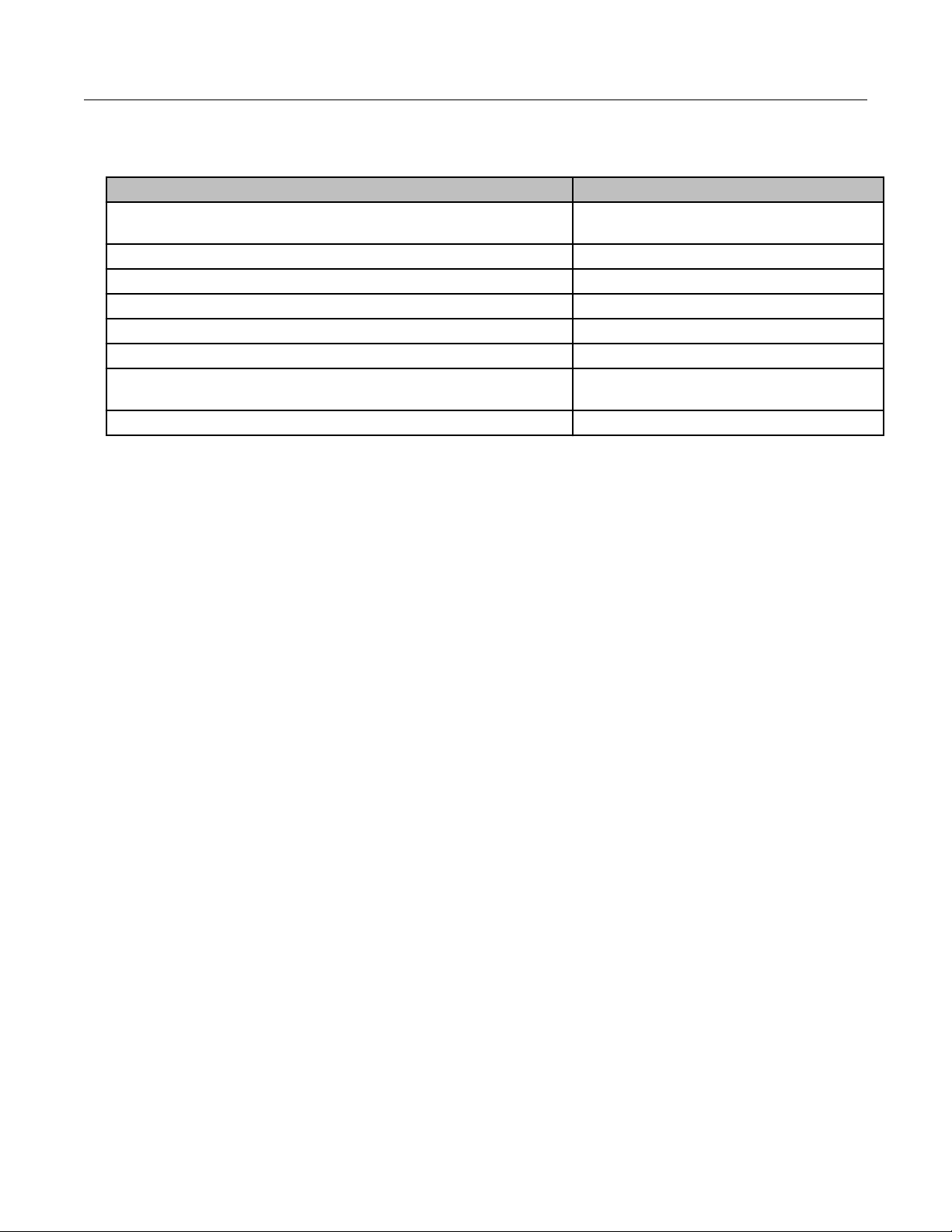

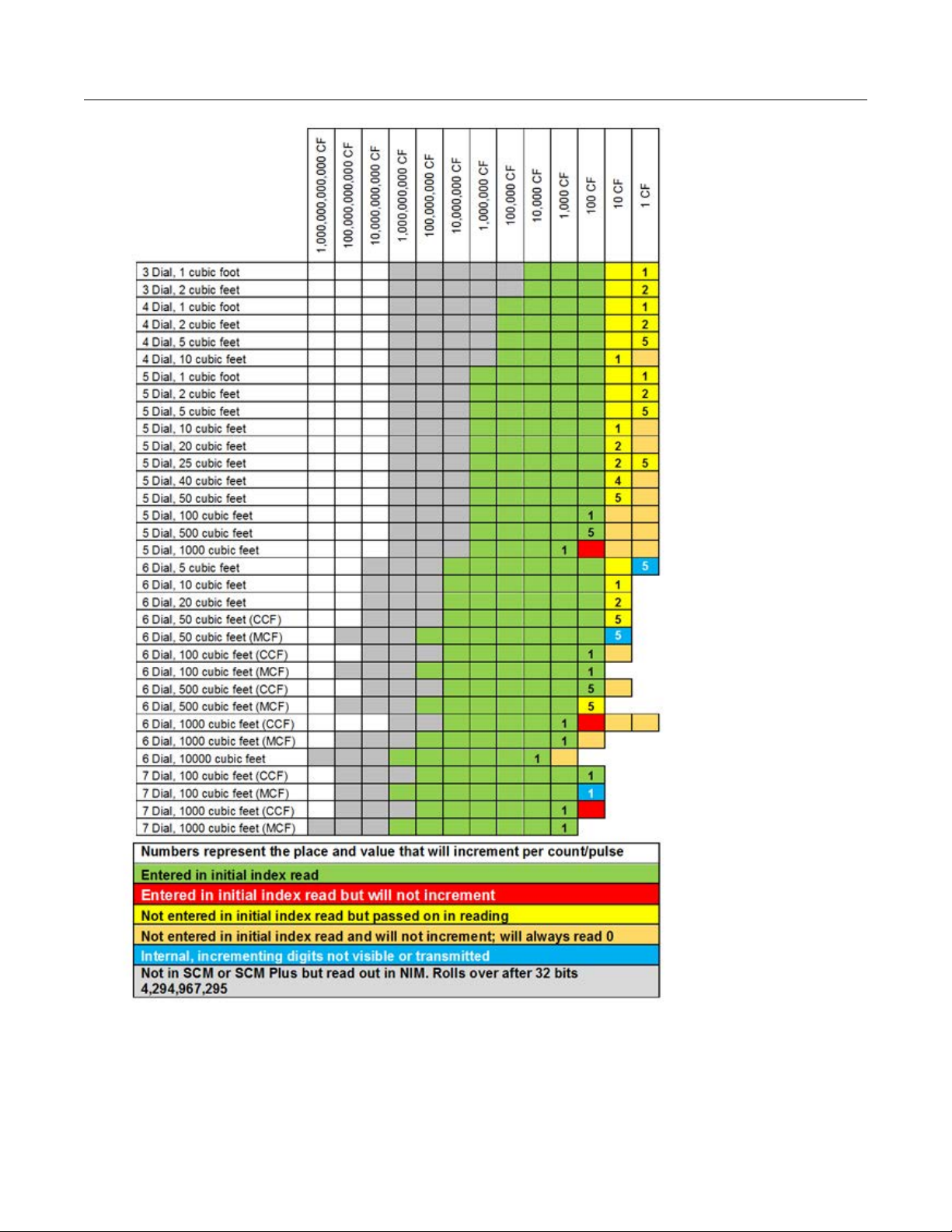

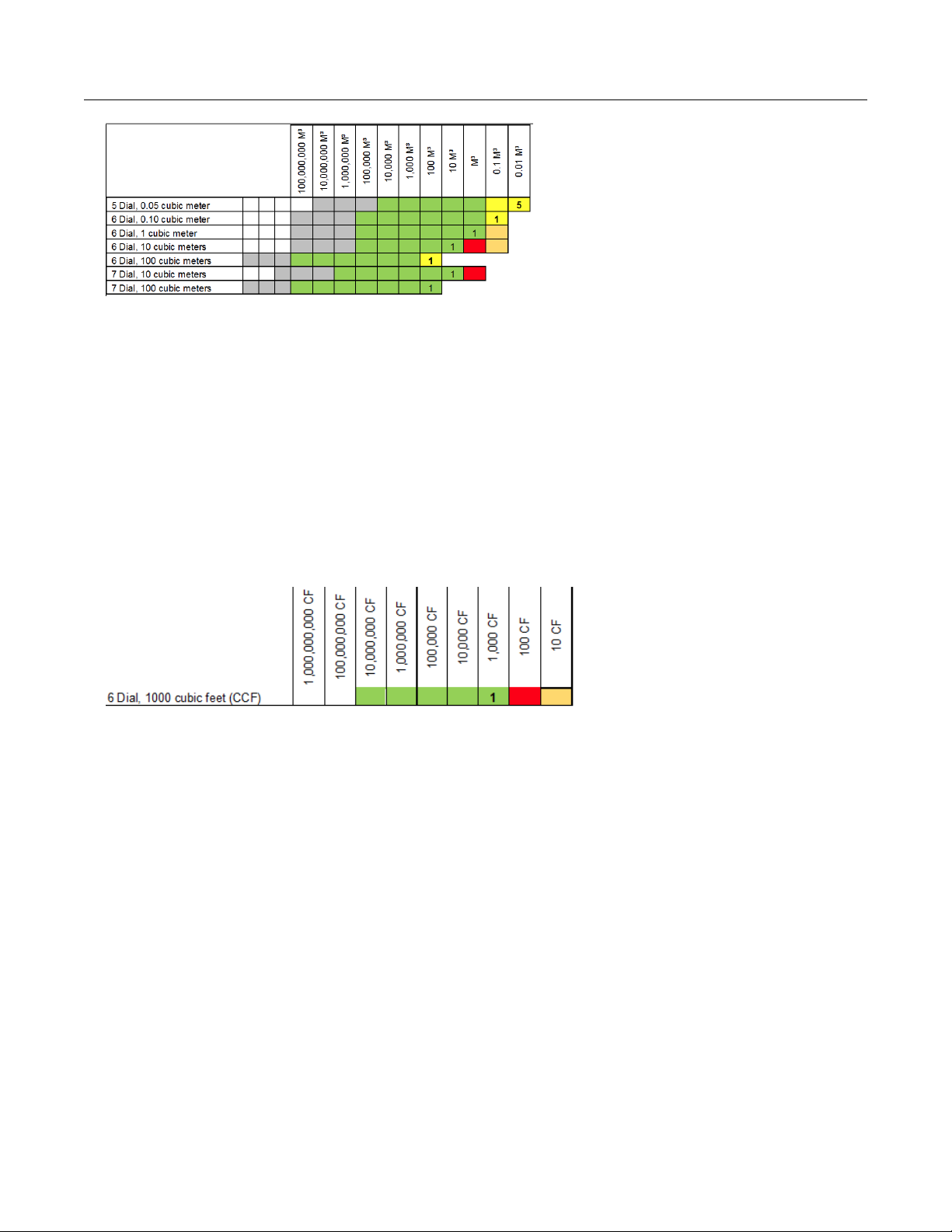

Itron programs and software variables

This section defines and clarifies possible system variables you may encounter in

programming Itron gas endpoints (ERT modules).

Field Deployment Manager (FDM)

The following tables illustrate various FDM programming configurations and the endpoint

response to each setting.

OpenWay Riva 500G Gas ERT Module Installation Guide, Remote Mount TDC-1678-000 15

Proprietary and Confidential

Page 20

500G Remote ERT Module Programming

OpenWay Riva 500G Gas ERT Module Installation Guide, Remote Mount TDC-1678-000 16

Proprietary and Confidential

Page 21

500G Remote ERT Module Programming

Programming example: Endpoint programmed for 6 dial, 1000 cubic feet.

1.

Enter the initial index read. For this example, the initial read is 123456 where 6 = 600

cubic feet. After the initial programming, an endpoint read will result in a reading of

1234560 where the least significant digit is in 10's of cubic feet. Since counting is with a

drive rate of 1000 cubic feet and the reading is transmitted in 10's of cubic feet, the last

two digits of the reading will not change.

2. Program the endpoint to 123456.

3. Read the endpoint. The result should be 1234560 with the zero added to put the reading

in 10's of cubic feet.

4. Add one count. The result should be 1234660. Notice the last two digits of 60 do not

change.

Mercury X-Blank options

Endpoints (ER

T modules) can be programmed with one of the Mercury X-Blank options.

There are 1, 2, 3, and 4 blank option available. Blank options are set up as a what-you-see-

is-what-you-get (WYSIWYG) configuration. The values are not set in cubic feet or cubic

meter standards. The Mercury X-Blank options are used in configurations where the system

receives pulses from a corrector or instrument that can change pulse values and has

configurable display digits. The Mercury-X Blank options allow users to program the

endpoint to match the configuration of the corrector or instrument.

Check Endpoint functions

The FDM Check Endpoint function triggers users to input the number of dials and drive rate

if a Check Endpoint is requested for an endpoint programmed for 5, 6, or 7-dial meter

configurations. The request to input the dial and drive rate information happens only if the

system has more than one option using the same count rate and rollover variable enabled in

their FDM business unit.

OpenWay Riva 500G Gas ERT Module Installation Guide, Remote Mount TDC-1678-000 17

Proprietary and Confidential

Page 22

500G Remote ERT Module Programming

Note: Itron recommends that users only enable the configurations used by your business

unit. Having only one meter configuration option enabled (with the endpoint variable being

checked in the FDM business unit) eliminates the need to enter the number of dials.

Field Collection System (FCS)

In FCS, a Read Type Code can be assigned to a meter session. The Read Type Code in

conjunction with the Endpoint Type is used to determine how the endpoint reading is

formatted using the Endpoint Translation table in FCS. The Endpoint Translation table is a

configurable table that is used to determine the truncation factor and multiplier for each

reading. A default Endpoint Translation is defined for each type of endpoint supported by

FCS (ReadType of 00 for each EndpointType). If the default Endpoint Translation is not

formatting the read correctly, an additional Endpoint Translation can be defined to properly

format the read.

Since the Endpoint Translation Code is based on the Read Type Code and the Endpoint

Type, changing from a 40-series endpoint to a 100-series endpoint can cause the reading to

be truncated differently. If you are having issues with your reading after a change out, check

your Read Type Codes and Endpoint Translation Codes.

OpenWay Collection Engine

The OpenWay Collection Engine collects the raw reading and passes it on without making

any formatting changes.

Note: If Collection Engine is collecting an NIM, the NIM will contain leading digits that are

not read in the SCM or SCM Plus (see the FDM programming configurations table). This

may cause the need to make adjustments in the upstream systems.

Itron Enterprise Edition (IEE) Meter Data Management

The standard unit of measure (UOM) in IEE is cubic feet for gas endpoints. The reading

passed on by the gas endpoint is not in cubic feet if endpoints with 6 and 7-dial meter

configurations are programmed so adjustments are required to set the correct unit of

measure. If you are having issues with your readings in IEE but your endpoint and meter

index match, check your unit of measure within IEE.

If your reading is from the OpenWay Collection engine and there are issues with the rollover

of the reading, it may be an additional digit is not expected in the reading due to the NIM

message. The NIM Read format must be taken into account in upstream systems to perform

the proper read formatting.

OpenWay Riva 500G Gas ERT Module Installation Guide, Remote Mount TDC-1678-000 18

Proprietary and Confidential

Page 23

Chapter 5 Specific Meter Manufacturer

Installation

This chapter provides the instructions to install the 500G remote ERT module to compatible

meters. Reference each section for compatible meters.

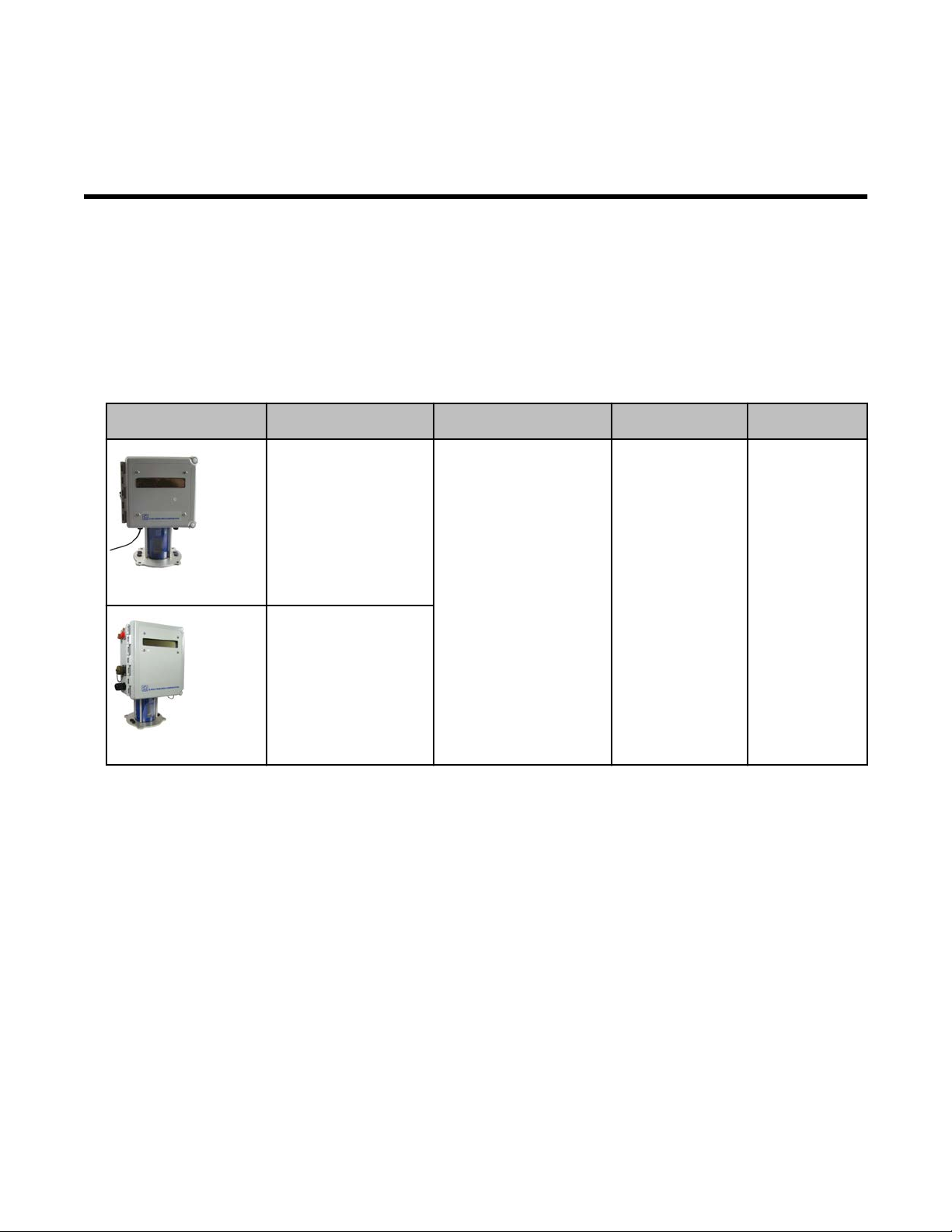

Eagle Research meter installation

This section provides the information to install the 500G remote ERT module on the

following compatible Eagle Research correctors.

Meter model Meter notes Module type Itron part number ERT module

Pulse width:

70mS and 500mS of

timing

Pulse output board

required

MPplus volume

corrector

Pulse width:

70mS on and 500mS off

timing

Corrector must have

Solid State relays

XARTU-1 volume

corrector

500G remote ERG-7000-502

f

notes

Eagle Research installation overview

Installing the 500G series remote ER

involves four tasks.

T module to an Eagle Research volume corrector

1. Programming or verifying that the volume corrector is set up to work with the 500G

remote ERT module.

Programming requires a computer loaded with the Eagle Research Software and an

Eagle Research computer-to-volume corrector communication cable.

2. Connecting the ERT module to the volume corrector.

Requires a wire stripper and flat-tip screwdriver sized to tighten the terminal connections

on the Eagle corrector.

3. Mounting the remote ERT module. Select the mounting option appropriate for your

installation. Mounting options include:

OpenWay Riva 500G Gas ERT Module Installation Guide, Remote Mount TDC-1678-000 19

Proprietary and Confidential

Page 24

Specific Meter Manufacturer Installation

• Wall mount on a sheet metal surface

• Pipe mount using the Itron pipe mount kit CFG-0005-003

• Custom Eagle Research mounting option using the Eagle research mounting rail

(Eagle Research part number 1010247)

Note: Itron recommends an optional sealant for installations where insect intrusion may

be a problem. For more information, see Optional sealant application instructions on

page 72.

4. Programming the 500G series remote ERT module. Programming requires an Itron ERT

programming device (for example, an FC300SR). For programming information, see

500G Remote ERT Module Programming on page 14

500G series module configuration with the meter is dependent on your system application.

See the Eagle Research meter product documentation for the Eagle Research Field

Manager database configuration information.

This mounting information describes installation for two 500G remote modules—one for

corrected reads and one for uncorrected reads. Installation is the same for both

configurations (corrected or uncorrected). Eagle Research meter outputs are optically

isolated from the meter control board and from each other. The volume corrector software

configuration controls the port operation. Follow the Eagle Research documentation and

these Itron instructions to ensure the correct compatibility and installation.

Eagle Research 500G product mounting instructions

Note: These instructions show the Eagle Research MPplus volume corrector. Installation is

the same for the XARTU-1 corrector.

1. Mount a remote ERT module on each end of the mounting rail using the mounting screws

supplied with the ERT modules.

Note: The notch in the mounting rail is the front bottom of the rail. The ERT modules mount to the

back of the mounting rail.

2. Insert tamper seals into the tamper seal

mounting cups on the remote ER

3. With the corrector facing forward, align the corrector mounting holes with the index drive

mounting holes.

4. Insert the corrector's mounting screws in the front corrector and index mounting holes. Loosely

tighten the front two mounting screws.

T modules.

OpenWay Riva 500G Gas ERT Module Installation Guide, Remote Mount TDC-1678-000 20

Proprietary and Confidential

Page 25

Specific Meter Manufacturer Installation

5. Align the inside mounting rail screw holes over the back index and corrector mounting screw

holes.

6. Insert the two remaining mounting screws in the corrector bracket mounting holes.

7. Tighten all four mounting screws.

Eagle Research mechanical and wiring installation instructions

This section provides wiring and connection information for compatible Eagle Research

products. Refer to the instruction for your product type.

Connecting the 500G remote ERT module to the MPplus corrector

1. With the MPplus door open, insert the flying leads from the remote ERT module into the

compression connector on the left of the MPplus housing.

2. Pull the lead wires through the compression connector until there is adequate wire to reach the

terminal blocks labeled 15, 16, 17, 18, 19, 20, 21, and 22.

3. Tighten the compression connector.

4. Twist the remote ERT module's blue and white wires together.

For uncorrected reads:

5. Connect:

• the twisted blue and white wires to terminal 17

on the MPplus terminal block.

• the red remote ERT module wire to terminal

18 on the MPplus terminal block.

For corrected reads:

6. Connect the twisted blue and white wires to terminal 15 on the MPplus terminal block.

7. Connect the red remote ERT module wire to

terminal 16 on the MPplus terminal block.

OpenWay Riva 500G Gas ERT Module Installation Guide, Remote Mount TDC-1678-000 21

Proprietary and Confidential

Page 26

Specific Meter Manufacturer Installation

8. Close and latch the MPplus corrector door.

Connecting the 500G ERT module to the XARTU corrector

For XARTU-1 uncorrected reads:

1. Insert the flying leads from the remote ERT

module into the compression connector on the

right of the XAR

TU-1 corrector housing.

2. Pull the lead wires through the compression connector until there is adequate wire to reach the

K2 terminal port.

3. Tighten the compression connector.

4. Connect the red remote ERT module wire to

pin 4 of the K2 terminal port.

5. Twist the remote ERT module's blue and white wires together and connect the twisted blue and

white wires to pin 5 of the K2 terminal port.

6. Plug the MTA battery connector from the battery pack into the VBAT1 connector to supply power

to the XAR

7. Close and latch the corrector door.

For XARTU-1 corrected reads:

8. With the XARTU door open, insert the flying

leads from the remote ERT module into the

compression connector on the left of the

corrector's housing.

TU-1 corrector.

OpenWay Riva 500G Gas ERT Module Installation Guide, Remote Mount TDC-1678-000 22

Proprietary and Confidential

Page 27

Specific Meter Manufacturer Installation

9. Pull the lead wires through the compression

connector until there is adequate wire to reach

the K1 terminal port.

1. K1

2. K2

3. K3

10. Tighten the compression connector.

11. Connect the red remote ERT module wire to pin 1 on the K1 terminal port.

12. Twist the remote ERT module's blue and white wires together.

13. Connect the twisted blue and white wires to

terminal 2 on the K1 terminal port.

Eagle Research corrector programming and requirements notes

Important: This information is subject to change without notice. Refer to the Eagle

Research product documentation to verify the most current programming and configuration

information for the 500G remote ER

Using Itron 500G series remote ERT modules with Eagle Research volume correctors

requires Eagle Research Field Manager software configured with the parameters for your

model of Eagle Research corrector.

T module.

OpenWay Riva 500G Gas ERT Module Installation Guide, Remote Mount TDC-1678-000 23

Proprietary and Confidential

Page 28

Specific Meter Manufacturer Installation

Using Eagle Research Field Manager to change the MPplus settings

1. Open the Eagle Research Field Manager from

the Start menu or the desktop shortcut.

2. Connect the communications cable from your computer into the MS connector on the side of the

MPplus corrector

front of the corrector.

3. Click Connect on the upper left corner of the

Field Manager window.

. After the MS connector is connected, take note of the baud rate displayed on the

A Connect to Remote window opens.

4. Select the following parameters:

Connection Type: Direct

•

• Communications Port: enter your computer's port number

• Baud Rate: enter the baud rate that displayed in Step. 2.

5. Click OK.

6. Click View/Config.

OpenWay Riva 500G Gas ERT Module Installation Guide, Remote Mount TDC-1678-000 24

Proprietary and Confidential

Page 29

The Field Manager window opens and displays

the settings for the current connection.

Specific Meter Manufacturer Installation

7. Click the Setup Parameters tab at the bottom of the parameters window

opens.

8. Enable POut 5 (17, 18) and set the additional

parameters as required in the Uncorrected

Pulse Output Setup at the lower right of the

window.

Important: If your software does not have an

option to use POut for the uncorrected pulse

output, contact Eagle Research to get the correct

software version.

9. Enter the parameters shown in the Corrected

Pulse Output Setup

section in the lower left of

the window.

10. Click Send All Changes.

11. Verify that all parameters are correct.

12. Click Disconnect.

. A parameters window

OpenWay Riva 500G Gas ERT Module Installation Guide, Remote Mount TDC-1678-000 25

Proprietary and Confidential

Page 30

Specific Meter Manufacturer Installation

Using Eagle Research Field Manager to change the XARTU corrector settings

1. Open the Eagle Research Field Manager from

the Start menu or the desktop shortcut.

2. Click Connect on the upper left corner of the

Field Manager window

.

3. Select the following parameters:

•

Connection Type: Direct

• Communications Port: Enter your computer's port number.

• Baud Rate: Enter the baud rate for the XARTU-1 corrector.

4. Verify that the time and station name are correct.

5. Click View/Config..

Click OK

6. Click the Setup Parameters tab at the bottom of the parameters window

The Meter Setup and Accumulation Multipliers

window opens. Set up the meter and

accumulation multipliers as appropriate for your

installation.

.

7. Enable K2 (4, 5, 6) and set additional

parameters are required in the Uncorrected

Pulse Output Setup section in the lower right of

the window.

OpenWay Riva 500G Gas ERT Module Installation Guide, Remote Mount TDC-1678-000 26

Proprietary and Confidential

Page 31

8. Set the Primary Pulse Output to Enable K1 (1,

2, 3) and the Optional Pulse Output to Disable

(unless it is used for another application) in the

Corrected Pulse Output Setup section in the

lower left of the window.

9. Click Send All Changes.

10. Verify that all parameters are completed and correct.

11. Click Disconnect.

Eagle Research programming note

Specific Meter Manufacturer Installation

During remote ER

T module programming for use with the Eagle Research corrector, verify

that the module drive rate settings match those set in the corrector. For example, set the

ERT module drive rate for 1000 CF when the Eagle Research corrector drive rate is set for

1000 CF.

Elster American meter installation

Some meter manufacturers provide ERT mounting kits and installation procedures for their

meters. If the Elster American RPM meter to the remote ERT module installation

instructions are not available, follow the installation procedures in this section.

Meter model Meter notes Module type Itron part number ERT module

10 Metric (10B) Originally manufactured

Elster American RPM

Series rotary meter

by Metric Metal W

Meter must have

factory-installed pulser

with connector output.

Purchase correct cable

interface from

manufacturer

orks

.

500G remote ERG-7000-501

500G remote ERG-7000-503

notes

Elster American 500G installation overview

Installing the 500G series remote ER

tasks.

1. Programming or verifying that the meter is set up to work with the 500G remote ERT

module. Programming requires a computer communication cable.

2. Connecting the ERT module to the meter. Connecting the module to the meter requires:

• a wire stripper

• a flat-tip screwdriver

OpenWay Riva 500G Gas ERT Module Installation Guide, Remote Mount TDC-1678-000 27

T module to an Elster American meter involves four

Proprietary and Confidential

Page 32

Specific Meter Manufacturer Installation

3. Mounting the remote ERT module (for mounting information, see Mounting the Remote

500G ERT Module on page 9. Select the mounting option appropriate for your

installation. Mounting options include:

• Wall mount on a sheet metal surface

• Pipe mount using the Itron pipe mount kit CFG-0005-003

• Custom Elster American meter mounting option

4. Programming the 500G series remote ERT module. For programming information, see

500G Remote ERT Module Programming on page 14. Programming requires an Itron

ERT programming device (for example, an FC300SR).

500G module configuration with the meter is dependent on your system application. See the

Elster American meter configuration information.

Elster American meter 500G mounting instructions

1. Remove the meter's top plate by removing the

two 5mm screws and carefully prying up on the

plate. The plate is secured with an O-ring seal.

Remove the O-ring from the plate.

Caution:

during removal, obtain a

replacement from Elster American

Meter Co.

2. Look into the meter tower and find the meter

switch lead and connector (4-pin).

3. If the lead and connector are not visible or

cannot be found, remove the four 5mm mounting

screws and the register cover. The meter switch

lead and connector will be visible inside the

cover.

If the O-ring is damaged

OpenWay Riva 500G Gas ERT Module Installation Guide, Remote Mount TDC-1678-000 28

Proprietary and Confidential

Page 33

Specific Meter Manufacturer Installation

4. Feed the lead and connector into the register

cover tower.

Note: Save any meter tags. You will re-install

them later in the installation process.

5. If you removed the register cover, replace the

cover using the four (4) 5mm mounting screws.

6. Attach the 4-pin male connector on the Elster American Meter adapter plate to the 4-pin female

connector inside the meter's tower

7. Carefully push the connectors and wires into

the meter tower housing.

. The connectors will slide together and latch.

8. Lubricate the O-ring with O-ring lubricant and install the O-ring on the adapter plate. Insert the

adapter plate into the tower and tighten the two 5 mm screws.

Elster American mechanical and wiring installation instructions

Caution:

commercial direct-drive modules. Use the information in the following tables to

program ERT modules connected to GE Dresser rotary meters.

Note: Connection to an Elster American meter requires a cable interface compatible to an

Elster American RPM rotary meter.

OpenWay Riva 500G Gas ERT Module Installation Guide, Remote Mount TDC-1678-000 29

Do not use these meter drive rates to program residential direct-drive or

Proprietary and Confidential

Page 34

Specific Meter Manufacturer Installation

1. Trim the ERT module wires to 3.5 inches.

2. Carefully strip the insulation covering from the meter cable (purchased from the meter

manufacturer) approximately 1-1/2-inches from the end.

Caution:

Do not cut through the individual wire insulation.

3. Separate the meter cable's black, white, and red wires for connection to the remote ERT module.

Cut off the unused wires even with the outer covering (insulation).

Caution:

Do not strip the individual wires.

4. Connect the meter cable to the remote module wires using 3M gel-cap connectors following the

American RPM meter to remote ER

T module wire connection information and wiring diagrams.

Important: Use a crimping tool compatible with gel-connectors. Do not use a standard pliers for

crimping gel-connects. For more information, see Using gel-cap connectors to complete wiring

connections on page 71.

Wire connection information

American meter wire Remote ERT module wire

Black Blue

White White

Red Red

5. Insert the meter cable through the slot on the ERT module backplate. Install a cable tie to the

meter cable wire below the meter cable insulation to provide strain relief.

OpenWay Riva 500G Gas ERT Module Installation Guide, Remote Mount TDC-1678-000 30

Proprietary and Confidential

Page 35

6. Tuck the connectors and cable tie into the ERT

module housing. Place backplate on the

assembly and tighten the four backplate screws

using a size T-10 Torx screwdriver.

Important: Verify that the cable tie and gel

connectors are inside the module housing and

that the cable extends out of the slot in the

backplate. Torque the backplate mounting

screws to 9 to 12 inch-pounds.

Installing the remote module cable

1. Insert the plug on the cable connected to the

T module into the receptacle on the meter

ER

adapter plate.

Specific Meter Manufacturer Installation

2. Tighten the threaded collar on the plug onto the American Meter interface receptacle. Verify the

connection is hand-tight.

Galvanic Gas Micro Installation

This section describes installation to Galvanic compatible correctors.

Meter model Meter notes Module type Itron part

GasMicro Electronic

olume Corrector

V

Must select 2 pulses/

second from pulse

output on the output

frequency menu.

500G remote ERG-7000-503 ERT module cut

Galvanic installation overview

Installing the 500G series remote ER

tasks.

T module to a Galvanic volume corrector involves four

number

ERT module notes

cable requires

customer-supplied

cable capable of

terminating the

module white and

blue wires at the

meter interface.

1. Programming or verifying that the volume corrector is set up to work with the 500G

remote ERT module. Programming requires a computer communication cable.

OpenWay Riva 500G Gas ERT Module Installation Guide, Remote Mount TDC-1678-000 31

Proprietary and Confidential

Page 36

Specific Meter Manufacturer Installation

2. Connecting the ERT module to the volume corrector. Completing the connections

requires a wire stripper and flat-tip screwdriver sized to tighten the terminal connections

on the Galvanic corrector.

3. Mounting the remote ERT module. Select the mounting option appropriate for your

installation. See Mounting the Remote 500G ERT Module on page 9. Mounting options

include:

• Wall mount on a sheet metal surface

• Pipe mount using the Itron pipe mount kit CFG-0005-003

4. Programming the 500G series remote ERT module. For programming information, see

500G Remote ERT Module Programming on page 14. Programming requires an Itron

ERT programming device (for example, an FC300SR).

500G series module configuration with the meter is dependent on your system application.

See the Galvanic corrector product documentation for configuration information.

Galvanic product mounting instructions

Note: See the Galvanic product documentation for custom mounting instructions.

Galvanic mechanical and wiring installation instructions

GAS Micro wiring connections

GAS Micro corrector P13 connection 100G ERT module wires

Pulse output1-C C1 Blue/white

Pulse output1-E C2 Red

Pulse output2-E C3

Pulse output2-C C4

Programming the Galvanic Gas Micro electronic volume

corr

ector

For more information about programming the Galvanic Gas Micro Electronic volume

corrector, see the GAS MICRO Operator's Manual, Galvanic part number MA1956. Contact

Galvanic Applied Sciences, Inc to obtain the operator's manual.

GE Oil and Gas meter installation

This section provides the instructions to install the 500G remote ERT module on the

following compatible GE Oil and Gas meters.

OpenWay Riva 500G Gas ERT Module Installation Guide, Remote Mount TDC-1678-000 32

Proprietary and Confidential

Page 37

Specific Meter Manufacturer Installation

Meter model Meter notes Module type Itron part

D800/D1000

B3 Series pulse output

meter

LMMA pulse output

meter

Integral Micro

Corrector IMC/W2

Pulse width must be set

greater than 100 ms.

Firmware version must

be 1.71 or higher

Rotary meters equipped

eighandWire

with W

solid state pulsers.

Meter must have

factory-installed pulser

with connector output.

Purchase correct cable

interface from GE

Dresser. Pulser must be

version 17 or higher.

Electronic volume

corrector for Series A

(LMMA) and Series B

(rotary meters). Must be

meter firmware version

1.94 or earlier

width must be set for

125ms.

.

. Pulse

500G remote ERG-7000-503

500G remote ERG-7000-503

500G remote ERG-7000-505

number

ERG-7000-505

ERT module notes

Both modules are

compatible with

these meter models.

Integral Micro

Corrector MC2

Series 3 ES3 meter

Electronic

T

emperature

Compensator (ETC)

Pulse width must be set

greater than 100ms.

Firmware version 1.71

or earlier

.

500G remote ERG-7000-503

ERG-7000-505

Both ERT modules

are compatible with

this meter model.

GE Oil and Gas 500G installation overview

Installing the 500G remote ER

1. Programming or verifying that the meter is set up to work with the 500G remote ERT

module.

• Programming may require a computer and communication cable.

2. Wiring the GE-supplied cable to the ERT module or wiring the ERT module to the GE

device.

T module to a GE Dresser meter involves the following tasks.

OpenWay Riva 500G Gas ERT Module Installation Guide, Remote Mount TDC-1678-000 33

Proprietary and Confidential

Page 38

Specific Meter Manufacturer Installation

Wiring may require a wire stripper, flat-tip screwdriver, Torx T-15 screwdriver, and wire

crimper. Requirements are dependent on your installation.

3. If your installation uses a GE supplied cable, connect the cable to the meter. If your

installation requires wiring directly to the GE device, move to the next step.

4. Mounting the remote ERT module. For more information, see Mounting the Remote 500G

ERT Module on page 9. Select the mounting option appropriate for your installation.

• Wall mount on a sheet metal surface

• Pipe mount using the Itron pipe mount kit CFG-0005-003

• Custom GE Dresser mounting

◦ D800/D1000 mounting solution requires the following materials

■ (1) 8-32 x ½" screw

■ (2) 8-32 x ¾" screws

■ (3) 8-32" Kep® nuts

5. Programming the 500G remote ERT module. Programming requires an Itron

programming device (for example, an FC300SR). For programming information, see

500G Remote ERT Module Programming on page 14. 500G module configuration with

the meter is dependent on your system application. See the GE Dresser meter product

documentation for configuration information.

GE Oil and Gas custom mounting options

Specific product mounting instructions for GE D800/D1000 meters are included in the D800/

D1000 installation section.

GE Oil and Gas ES3 or ETC ordered with the AMR-ready mounting kit

1. Score (cut) the cable jacket surrounding the

ES3 or ETC wires and carefully remove the cable

jacket to expose the ES3 or ETC wires.

2. Connect the wires to the ERT module following the installation instructions in the GE Oil and Gas

meters with pulse output installation section.

3. Align the ERT module mounting holes with the

ES3 or ETC bracket mounting holes. Use a T15

T

orx screwdriver to insert and tighten the

mounting screws. Tighten the screws in an

alternating pattern.

OpenWay Riva 500G Gas ERT Module Installation Guide, Remote Mount TDC-1678-000 34

Proprietary and Confidential

Page 39

Specific Meter Manufacturer Installation

Caution: Upright vertical positioning is critical because:

• The 500G series modules are optimized for communication and require upright

mounting. Any other mounting position could result in reduced RF performance.

• The remote module tilt tamper sensor requires upright mounting. Any other

mounting position may cause issues with the module's tilt tamper detection.

GE Oil and Gas IMC/W2, or MC2 with the GE mounting bracket

kit

Note: This mounting option requires that you follow the installation instructions to attach the

meter maufacturer cable prior to completing this mounting option. This configuration

requires the GE mounting bracket kit available from GE Oil and Gas (GE part number

057783-000). The kit includes the listed materials.

Quantity Description GE Dresser part number

1 Mounting bracket 015951-000

1 Screw, 8-32 x 7/16-inch 000163-277

2 Screw, 8-32 x 3/4-inch 000163-282

3 Nut, 8-32 012829-005

4 Spacer, #10 053669-001

5 ERT module/bracket mounting

, M6 x 20 mm

screw

013444-002

Important: The GE Oil and Gas mounting bracket kit does not include the cable required to

connect the remote module to the Amphenal connector on the IMC\W2.

1. Insert the 8-32 x 7/16-inch screw (1) into the

top of the mounting bracket. Insert the two 8-32 x

3/4-inch screws (2) into the bottom of the

mounting bracket.

2. Insert one 3/32-inch nut on the top 7/16-inch

bracket screw (A). Slide the 500G remote gas

module mounting lug over the top of the bracket

screw and nut.

3. Secure the bottom 500G remote gas module

mounting holes over the two 8-32 x 3/4-inch

screws with the remaining two 8-32 nuts.

OpenWay Riva 500G Gas ERT Module Installation Guide, Remote Mount TDC-1678-000 35

Proprietary and Confidential

Page 40

Specific Meter Manufacturer Installation

4. Insert the #10 spacers into the four mounting

holes on the back of the IMC\W2.

Caution:

• designed with the antenna in a vertical direction so the antenna is parallel to the

reading device (which has a vertical antenna). Matching antenna polarity can greatly

affect RF performance and enable easy ERT module reading.

• designed so the tilt tamper is vertical. It is important to maintain vertical positioning

in the field to enable tilt tamper stability.

• designed for installation with the batteries vertical (installed with the positive terminal

upward). Any other installation orientation will compromise battery life.

5. Secure the ERT module/bracket assembly on

the IMC\W2 using four ERT module/mounting

bracket screws (M6 x 20 mm). Install tamper

seals as required.

6. Connect the cable to the pulse output on the

IMC/W2 or MC2.

Upright vertical positioning is very important because the remote module is:

GE Oil and Gas mechanical and wiring installation instructions

This section describes mechanical installation to the GE Oil and Gas meter and wiring

connections.

OpenWay Riva 500G Gas ERT Module Installation Guide, Remote Mount TDC-1678-000 36

Proprietary and Confidential

Page 41

D800/D1000 wiring and installation

1. Loosen and remove the two screws holding

the mounting brackets to the meter

2. After the brackets are removed, the pulse

output cable is visible.

.

Specific Meter Manufacturer Installation

3. Loosen the cable gland and pull the cable out

until it extends 7.5 to 8" out of the cable gland.

4. Tighten the cable gland. Do not use a pliers or wrench to tighten the cable gland.

5. Rotate one bracket. Route the meter cable through the holes located at the bend of the mounting

brackets.

OpenWay Riva 500G Gas ERT Module Installation Guide, Remote Mount TDC-1678-000 37

Proprietary and Confidential

Page 42

Specific Meter Manufacturer Installation

6. Attach the brackets to the meter using the

previously removed screws.

7. Splice the meter pulse output wires to the ERT module wires using gel cap connectors. Follow

the wire connections for the D800/D1000 to 500G ER

T module wire connections below.

Note: Use a crimping tool compatible with gel-connectors. Details on using the crimping tool are

included in the mounting installation section of this document.

D800/D1000 meter ERT module

Pulse output Wire Pulse output 1 Pulse output 2 Pulse output 1

with fault

Pulse output 2

with fault

Output 1+ Brown White and blue White

Output 1- Green Red Red

Output 2+ White White and blue White

Output 2- Black Red Red

Output 3+ Red White White

Output 3- Blue Blue Blue

8. Install a cable tie strain relief on the cable

approximately 1/8" from the end of the cable

insulation.

9. Position the cable so the strain relief is just

inside the slot on the module's backplate.