Page 1

Water Solutions

100W Datalogging Endpoint Installation

Guide

TDC-0909-000

Page 2

Identification

Warning Follow these procedures to avoid injury to yourself or others:

•The lithium battery may cause a fire or chemical burn if it is not disposed of

properly.

• Do not recharge, disassemble, heat above 100° Celsius (212° Fahrenheit), or

incinerate the lithium battery.

• Keep the lithium battery away from children.

• Replace the lithium battery only with batteries meeting Itron specifications. Any

other battery may cause a fire or explosion.

Warning This unit cannot be modified and is not repairable. Modification of this

device could cause non-compliance with FCC rules. Attempts to modify this device

will void the warranty.

100W Datalogging Endpoint Installation Guide

04/26/2010 TDC-0909-000

Copyright

© 2010 Itron, Inc. All rights reserved.

Confidentiality Notice

The information contained herein is proprietary and confidential and is being provided subject to the condition that (i) it be held in confidence except to the extent required otherwise by

law and (ii) it will be used only for the purposes described herein. Any third party that is given access to this information shall be similarly bound in writing.

Compliance Statement

This device complies with Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmfu l interference in a residential installation. Operation is

subject to the following two conditions:

This device may not cause harmful interference.

This device must accept any interference that may cause undesirable operation.

This device must be permanently mounted such that it retains a distance of 20 centimeters (7.9 inches) from all persons in order to comply with FCC RF exposure levels.

Compliance Statement

This equipment has been tested and found to comply with the limits, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference in a residential installation. Operation is subject to the following conditions:

This device may not cause interference.

This device must accept any interference that may cause undesired operation of the device.

Compliance Statement

This equipment complies with policies RSS-210 and RSS-GEN of the Industry Canada rules.

Operation is subject to the following two conditions: (1) this device may not cause interference, and (2) this device must ac cept any interference, including interference that may cause

undesired operation of the device.

Note: Changes or modifications not expressly approved by the party responsible for compliance could void the user's authority to operate the device.

Trademark Notice

Itron is a registered trademark of Itron, Inc.

All other product names and logos in this documentation are used for identification purposes only and may be trademarks or registered trademarks of their respective companies.

Transportation Classification

The Federal Aviation Administration prohibits operating transmitters and receivers on all commercial aircraft. When powered, endpoints are considered operating transmitters and

receivers and cannot be shipped by air. All product returns must be shipped by ground transportatio n to Itron.

Suggestions

If you have comments or suggestions on how we may improve this documentation, send them to TechnicalCommunicationsManager@itron.com

If you have questions or comments about the software or hardware product, contact Itron Technical Su pport:

Contact

Internet: www.itron.com

E-mail: support@itron.com

Phone: 1 800 635 8725

Page 3

TDC-0909-000 100W Datalogging Endpoint Installation Guide iii

Proprietary and Confidential

Chapter 1 Before You Begin ...................................................................................... 1

Contents

How This Document is Organized ...................................................................................................... 1

Document Conventions ............................................................................................................ 2

Chapter 2 About the 100W Datalogging Endpoint .................................................... 3

Battery Life .......................................................................................................................................... 3

Operating Modes ................................................................................................................................ 4

Chapter 3 Initializing and Connecting the 100W Datalogging Endpoint ................. 5

To initialize the 100W ......................................................................................................................... 5

Connecting to a Meter Register Using the Inline Connector .............................................................. 5

Connecting to a Meter Register Using a 5-foot Cable ........................................................................ 5

Using an Extension Cable .................................................................................................................. 6

Verifying Operation of the 100W ........................................................................................................ 7

Chapter 4 Installing the 100W Datalogging Endpoint ............................................... 9

100W Datalogging Endpoints with Integral Connectors ..................................................................... 9

Rod Mount Installation ...................................................................................................................... 10

Required Tools and Hardware ............................................................................................... 11

Wall Mount Installation ...................................................................................................................... 14

Required Tools and Hardware ............................................................................................... 14

Base Mount Installation .................................................................................................................... 16

Required Base Mounting Tools and Hardware ...................................................................... 16

Shelf Mount Installation .................................................................................................................... 17

Required Tools and Hardware ............................................................................................... 17

Optional Leak Sensor Installation ..................................................................................................... 20

Required Equipment ............................................................................................................... 20

Pipe Preparation .......................................................................................................... 23

Chapter 5 Optional Remote Antenna Installation .....................................................29

Mounting the Remote Antenna ......................................................................................................... 29

Appendix A Using an Inline Connector ....................................................................33

Index .............................................................................................................................35

Page 4

Contents

iv TDC-0909-000 100W Datalogging Endpoint Installation Guide

Proprietary and Confidential

Page 5

TDC-0909-000 100W Datalogging Endpoint Installation Guide 1

Proprietary and Confidential

This document provides the installation instructions for the 100W datalogging endpoint and

Caution Installing an integrated 100W endpoint and meter register in

a water pit box reduces the endpoint's RF signal distance significantly.

If read reliability is a problem, install a remote antenna or select a new

installation method.

Chapter

Description

1. Before You Begin

Information about this publication.

2. About the 100W

Overview of 100W installation.

3. Initializing and Connecting the

100W

Instructions to initialize the 100W endpoint and

connect the endpoint to the water meter.

4. Installing the 100W

Step-by -step endpoint installation instructions for:

Rod mount

Wall mount

Remote antenna (CFG-0900-001)

Pit lid shelf mount (kit CFG-1300-001)

Base mount

5. Optional Remote Mount Antenna

Installation

Step-by -step remote mount antenna installation

instructions.

Appendix

Step-by -step instructions to install inline

connectors.

C H A P T E R 1

Before You Begin

includes rod mount, wall mount, through-lid (remote antenna), and shelf mount installation.

The 100W is available with the following configurations:

Integral connector

5-foot open-end cable

20-inch open-end cable

An optional Itron Leak Sensor is available for all three configurations to provide leak

monitoring capability. 100W endpoint configurations provide an easy interface to several

register types. The 20-inch cable variant allows meter manufacturers to mount the endpoint

directly to their respective meter registers before delivery to the installer.

How This Document is Organized

This document is organized into the following chapters:

Page 6

Chapter 1 Before You Begin

2 TDC-0909-000 100W Datalogging Endpoint Installation Guide

Proprietary and Confidential

Convention

Example

Itron product part numbers are noted in

parentheses.

To install the endpoint (ERW-0000-000), do the

following steps.

Hypertext links are in blue.

See the Copyright Page for identification information.

Note A Note indicates neutral or positive information that stresses or

supplements important points of the main text. A note supplies information that

may apply only in special cases.

Tip A Tip helps users apply the techniques and procedures described in the

text to their specific needs.

Caution A Caution advises users that failure to take or avoid a specified action

could result in a loss of data.

Warning A Warning advises users that failure to take or avoid a specified

action could result in physical harm to the user or the hardware.

Document Conventions

Page 7

TDC-0909-000 100W Datalogging Endpoint Installation Guide 3

Proprietary and Confidential

The 100W datalogging endpoint is a high-power radio frequency automatic meter reading

Caution Failure to initialize the endpoint may delay the initial reading up to 1

hour.

C H A P T E R 2

About the 100W Datalogging Endpoint

(AMR) device that attaches to a water meter to collect consumption usage and tamper data

that it transmits to a data collection device. The endpoint operates in both bubble-up mode

and two-way modes.

The 100W ships in Factory Mode. The endpoint will acquire and transmit meter register

data within one hour following register connection. The endpoint will transfer meter data

immediately if the unit is initialized with a handheld computer during installation (see To

initialize the 100W on page 5).

The 100W supports protocols for a variety of meter manufacturer's registers. Refer to the

Water Meter Compatibility List (PUB-0063-002), for the list of supported meters and

registers.

100W s feature the following capabilities:

Leak Detection: The 100W indicates (by meter reading software) that a potential

system leak exists if a zero consumption value does not occur over a programmed

period of hourly register reads. Upon detecting a zero consumption, the leak test

period is reset. The optional Itron Leak Sensor provides advanced leak monitoring

through data collections analyzed using a unique mlogonline™ portal.

Tamper Indicators: To minimize the possibility of theft, the 100W features cut cable

Reverse Flow Detection: To detect reverse flow, the 100W compares the register’s

Battery Life

Powered by two non-replaceable, long-life lithium batteries, the 100W has an expected

battery life of 20 years when the endpoint operates in default Mobile or Fixed Network

Operating mode.

tamper reporting as well as a security seal to indicate physical tampering. Either a cut

cable or a register/endpoint communication error will set a cable tamper flag. This flag

will remain set for one day after communication is restored when the endpoint is

programmed to Network mode, or 40 days after communication is restored when the

endpoint is programmed to Mobile mode.

current consumption reading to the reading obtained at the previous hourly update. If

the register value is less, the endpoint signals the meter reading software to report a

reverse flow condition for the next 40 days. The 40 day time limit is continually reset

if another reverse flow event occurs before the period has timed out.

Page 8

Chapter 2 About the 100W Datalogging Endpoint

4 TDC-0909-000 100W Datalogging Endpoint Installation Guide

Proprietary and Confidential

Operating Modes

The 100W has three standard operating modes.

1. Factory Mode

100W endpoints are shipped from the factory in Factory Mode.

The endpoint's transmitter is turned off.

The endpoint's receiver is bubbling-up to listen for a programming command.

100W encoder models will attempt to read the register every hour.

Last good read and cut tamper flags may be set when a register is not

connected.

If the 100W reads a connected register, the endpoint automatically moves to

Run Mode.

2. Run Mode

100W endpoint’s normal operation mode.

The 100W transmitted message is dependent on its factory settings for standard

consumption messages (SCM), standard consumption messages 30 (SCM30),

network interval message (NIM), or network consumption message (NCM).

For SCM and SCM30, the 100W default bubble-up rate is 9 seconds.

For NIM and NCM, the 100W default bubble-up rate is 5 minutes. When the

endpoint is set for NCM or NIM, the 100W transmits a contingency SCM

message every minute. NCM or NIM mode is configured when the endpoint

detects an attached register or by programming NCM or NIM mode with a

programming device.

3. Audit Mode

Audit Mode is configured by sending a Check ERT command or a Set Mode

command #119 with a programming device.

The 100W operates as if in Run Mode but also transmits an SCM every 4

seconds and bubbles up the receiver every 4 seconds.

The 100W exits Audit Mode automatically after 1 hour or by configuring Run

Mode with a programming device.

Page 9

TDC-0909-000 100W Datalogging Endpoint Installation Guide 5

Proprietary and Confidential

This chapter provides the instructions to initialize the 100W datalogging endpoint and

Caution To obtain an immediate reading, initialize the 100W with an approved

handheld computer. Failure to initialize the endpoint may delay the initial

reading up to 1 hour.

Caution The wire terminations must be properly sealed with a non-conductive

gel material to prevent water intrusion (otherwise, this configuration should not

be used in a pit box environment). Itron recommends the 5-foot cable

configuration for OEM users only.

C H A P T E R 3

Initializing and Connecting the 100W Datalogging Endpoint

connect the endpoint to the water meter register. The 100W initializes immediately when

the endpoint is programmed with an approved handheld computer or the endpoint

recognizes the meter register and activates itself after connection to a register.

To initialize the 100W

To initialize the 100W immediately, use one of the following handheld computers

running Field Deployment Manager (FDM) version 1.0 or later.

FC200SR handheld computer (Itron part number FC2-0005-004 or FC2-0006-

004)

FC300 with SRead

For normal activation, connect the 100W to the water meter register. The endpoint

polls for a register every hour. After a register is detected, the 100W automatically

activates.

Connecting to a Meter Register Using the Inline Connector

The inline connector system easily allows a separation of the endpoint and meter register

and provides for general maintenance or system troubleshooting (see Using an Inline

Connector on page 33).

Connecting to a Meter Register Using a 5-foot Cable

The 100W may be connected to the water meter register using the 5-foot cable.

Page 10

Chapter 3 Initializing and Connecting the 100W Datalogging Endpoint

6 TDC-0909-000 100W Datalogging Endpoint Installation Guide

Proprietary and Confidential

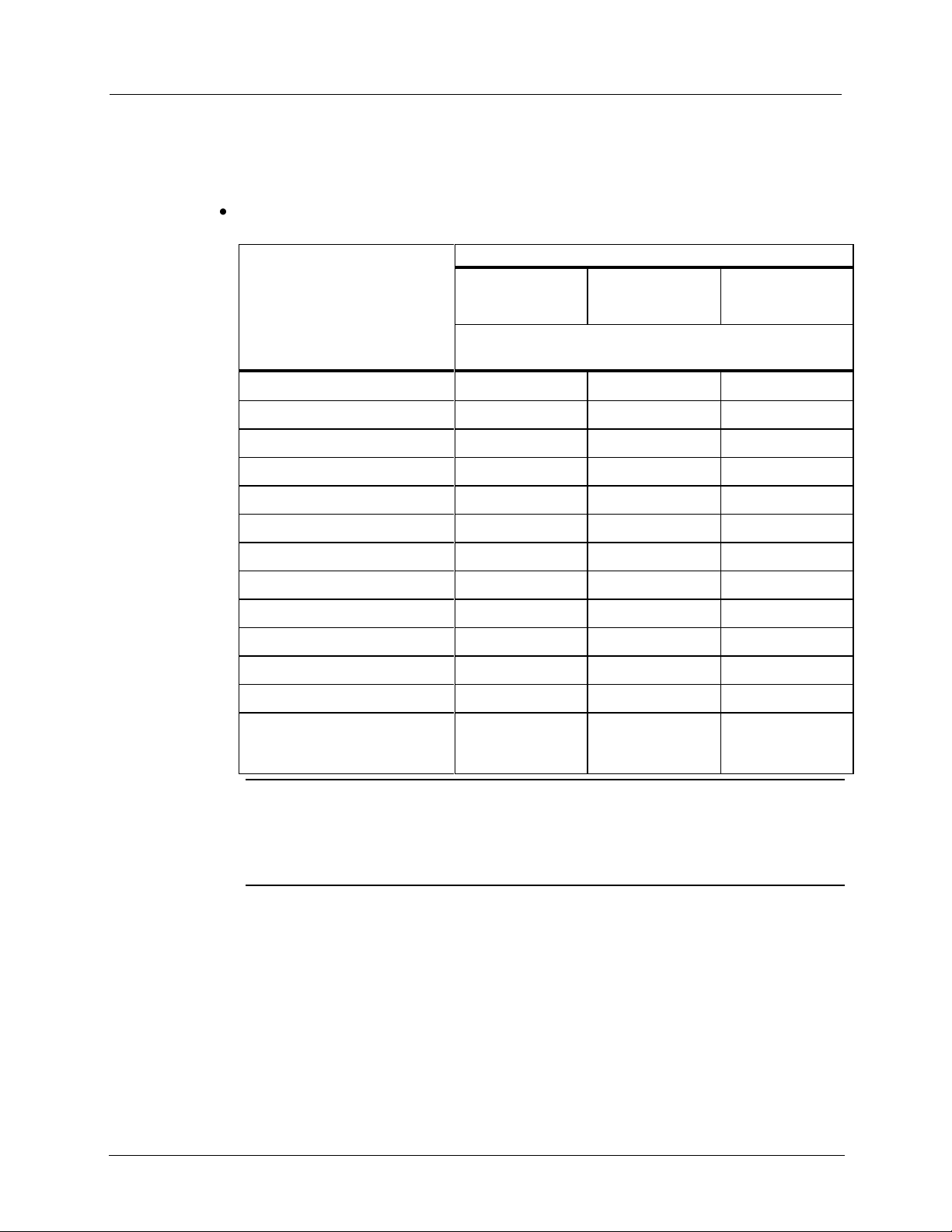

Register Manufacturer

100W wire color

Red

(data)

Black

(power/clock)

White

(ground)

Register screw terminal

Elster AMCO Invision

R

G

B

Elster AMCO Scancoder

R

G

B

Elster AMCO evoQ4 (Q4000)

R W B

Hersey Translator

G R B

Badger ADE

G R B

Sensus ECR

G R B

Sensus ICE

G R B

Metron Farnier

G R B

Itron (Actaris) Coder

G R B

ProRead

R B G

ARB V

R B G

Performance ETR

G R B

Severn Trent SM700

SmartMeter

(Sensus Protocol)

G R

B

To connect the 100W to the register

Connect the 100W wires to the register screw terminals according to the following

table.

Caution Wire should wrap one complete revolution around register screw.

Completely tighten register screws and verify wire insulation is not under screw

terminal heads or intermittent electrical connection may occur. You must use a

moisture-proof sealant if the meter is used outdoors or in any environment where

moisture can collect on the screw terminals.

Using an Extension Cable

Order the 25-foot inline connector extension cable assembly (CFG-0151-401) to extend the

100W with the inline connector.

Page 11

Verifying Operation of the 100W Datalogging Endpoint

TDC-0909-000 100W Datalogging Endpoint Installation Guide 7

Proprietary and Confidential

Verifying Operation of the 100W Datalogging Endpoint

NOTES

Each handheld radio requires special setup and configuration parameters to

successfully read and program 100W products. Refer to the respective

meter reading application for specific instructions.

When comparing the actual register value to that reported by the 100W ,

please keep in mind the endpoint's consumption value is updated once an

hour when it is in a Run Mode.

Caution Do not use ReadOne Pro, FS2PN, FS3PN, or FC200 readers to read

the 100W endpoint. These readers do not keep their receivers on long enough

or at the right frequency to reliably capture a 100W transmission.

Use one of the following handheld computers to verify consumption:

FC200SR handheld computer (Itron part number FC2-0005-004 or FC2-0006-004)

FC300 with SRead

Page 12

Chapter 3 Initializing and Connecting the 100W Datalogging Endpoint

8 TDC-0909-000 100W Datalogging Endpoint Installation Guide

Proprietary and Confidential

Page 13

TDC-0909-000 100W Datalogging Endpoint Installation Guide 9

Proprietary and Confidential

This chapter provides the instructions to install the 100W. Install the 100W using one of the

Caution Observe the following guidelines for mounting the 100W:

Endpoint positioning other than upright could negatively affect

radio performance and battery life.

Do not use gel connectors in pit environments.

Use only Itron-approved splice kits or inline connectors.

Warning If a dual-port 100W is installed but the Leak Sensor is not

attached, the environmental cap (MSC-0019-005) must remain in place on

the blue connector (Leak Sensor connector) to protect the connector from

damage.

C H A P T E R 4

Installing the 100W Datalogging Endpoint

following methods:

Rod mount. The endpoint mounts on a 1/2 inch outside diameter rod.

Wall mount. The endpoint mounts to a wall or other vertical surface.

Base mount. The endpoint mounts on a horizontal, flat surface.

Shelf Mount. The endpoint mounts in pre-fabricated pockets or shelves within the pit

lid using a shelf mount accessory kit.

For water pit boxes, the type of installation method is based on two factors: the lid material

and the current lid configuration. Metal lids may require a through-lid remote mount

antenna for optimal endpoint radio performance. Plastic lids and other composite materials

accept any installation methods described above. The 100W is temperature rated from -20º

C to +60º C. Do not install the 100W in locations that may exceed the temperature rating.

100W Datalogging Endpoints with Integral Connectors

If 100W s with integral connectors (ERW-1300-X0X) and the registers are not installed at

the same time, secure the protective connector cover on the endpoint using a cable tie (Itron

part number MSE-0005-002). Cable ties are not shipped with the 100W , but can be ordered

from Itron. Use the protective cover (on the endpoint side) in the field for up to one year.

Page 14

Chapter 4 Installing the 100W Datalogging Endpoint

10 TDC-0909-000 100W Datalogging Endpoint Installation Guide

Proprietary and Confidential

To install a cable tie to the connector

Warning The rod installation area must be free from other pipes, wires, or

facilities that may be damaged by driving a rod into the ground.

Caution You must follow local codes when using the rod mount installation method.

Failure to use 1/2-inch rod and follow instructions may result in an unreliable installation.

Caution Observe the following guidelines for mounting the 100W using the

wall mount procedure:

Endpoint positioning other than upright could negatively affect

radio performance and battery life.

Do not use gel connectors in pit environments.

Use only Itron-approved splice kits or inline connectors.

1. Thread the cable tie through the security holes in the connector and protective cover.

2. Thread the cable tie end through the eye of the cable tie. Pull the cable tie tight to

secure it (as shown).

Rod Mount Installation

100W s can mount below the pit lid on a customer-supplied 1/2-inch OD rod. The example

installation described in this section uses a fiberglass rod. For more information, see the

Compatibility Chart at the following Itron website address:

http://www.itron.com/pages/products_detail.asp?ID=itr_000428.xml&pgtype=&subID=ar

Page 15

Rod Mount Installation

TDC-0909-000 100W Datalogging Endpoint Installation Guide 11

Proprietary and Confidential

Required Tools and Hardware

Hammer

1/2-inch outside diameter rod (either a square or round rod may be used)

Tape measure

Rod-driving tool (optional)

Cutting tool to adjust rod length

The 1/2-inch diameter rod hole is shown in the following bottom and side view of the

100W.

To install the 100W endpoint on a rod

1. Remove the pit lid. Inspect the area to make sure there are no buried cables, pipes, or

other obstructions.

2. Measure the depth of the pit box from the top of the lip (where the lid will rest) to the

bottom of the pit. Be sure to measure the depth at the point where the rod will be

driven into the ground.

3. Add 12 inches to the pit box depth measurement taken in step 2. The resulting total

represents the minimum length of rod needed. Soil types and moisture conditions may

require longer rod lengths to ensure the endpoint is well supported and remains

vertical.

Page 16

Chapter 4 Installing the 100W Datalogging Endpoint

12 TDC-0909-000 100W Datalogging Endpoint Installation Guide

Proprietary and Confidential

4. Without touching the meter body or adjacent pipes, position the rod as close to the

center of the pit as possible. Drive the rod into the ground. Ensure the rod remains

vertical.

Note The rod shown has a protective end cap to protect the rod while driving it into

the ground.

5. Drive the rod into the ground so the top of the rod is approximately three and one-half

inches below the bottom of the pit lid.

If the rod cannot be driven in enough to equal the necessary spacing, cut the

remaining rod length to the proper height using an abrasive cut off tool.

If the rod is driven to the correct depth but remains loose in the soil, replace the

rod with a longer version.

Caution Cutting fiberglass creates dust particles. Practice proper safety precautions

when using cut-off tools to prevent exposure to fiberglass dust particles.

Page 17

Rod Mount Installation

TDC-0909-000 100W Datalogging Endpoint Installation Guide 13

Proprietary and Confidential

6. The top of the rod should be three and one-half inches below the bottom of the lid.

Place the endpoint on the rod. Completely insert the rod into the endpoint's rod mount

hole. Do not force the endpoint onto the rod. If the endpoint does not slide freely on

the rod, remove the endpoint and examine the endpoint rod hole and rod for burrs or

obstructions. You may secure the endpoint to the rod with a self-drilling screw

through the hole in the top of the 100W rod mount cavity. The screw mounting hole is

shown in the following product image.

7. Installation is complete when the endpoint is perpendicular to the underside of the lid.

The endpoint must not contact the pit structure or lid.

Caution Verify the pit lid does not come in contact with the endpoint when the lid is

replaced. There must be a 1 to 2 inch space between the top of the endpoint and the

bottom of the pit lid. If the 100W is installed too high, too low, or is touching any of

the surrounding surfaces, adjust as necessary.

Page 18

Chapter 4 Installing the 100W Datalogging Endpoint

14 TDC-0909-000 100W Datalogging Endpoint Installation Guide

Proprietary and Confidential

Wall Mount Installation

Caution Observe the following guidelines for mounting the 100W using the

wall mount procedure:

Endpoint positioning other than upright could negatively affect

radio performance and battery life.

Do not use gel connectors in pit environments.

Use only Itron-approved splice kits or inline connectors.

Select a flat vertical mounting surface. Install the endpoint in an upright position; locate the

endpoint as high as possible. To mount the endpoint to the wall in a water pit box, select a

mounting location on the inside of the pit box and try to maintain a distance of one to two

inches from the bottom of the pit box lid.

The 100W is suitable for use with up to 300 feet of Itron approved cable.

Required Tools and Hardware

Itron 100W Shelf Mount Kit

To install the 100W endpoint using the wall mount procedure

1. Select a vertical surface in the pit box or on a wall (for example, endpoints mounted in

basements).

2. Position the endpoint vertically so the top of the endpoint is between one and two

inches below the bottom of the lid.

3. Mark the location of the top mounting hole.

4. Drill a pilot hole in the pit box wall. Follow the screw manufacturer's recommendation

for the size of the pilot hole.

Page 19

Wall Mount Installation

TDC-0909-000 100W Datalogging Endpoint Installation Guide 15

Proprietary and Confidential

5. For concrete-type pit boxes, it may be necessary to use a screw anchor. Choose an

anchor appropriate for a #10 pan head screw.

Caution Do not over-tighten the mounting screws. Over-tightening the mounting

screws may break the endpoint mounting tabs.

6. Start a screw into the pilot hole. Using the top hole of the endpoint, set the endpoint

over the screw head and slide it down so the screw is now at the top of the notch (as

shown). Carefully tighten the screw until snug. Over-tightening the mounting screw

could crack the endpoint housing.

Note If mounting requires a screw anchor, mark the location of the bottom anchor and

remove the endpoint. Drill the required mounting hole, insert the anchor, and re-attach

the endpoint.

7. Holding the 100W in the upright position, drill the second pilot hole. Use the bottom

mounting hole as a template.

Caution Any endpoint position other than upright may negatively affect radio

performance and battery life.

8. Screw the bottom screw into the pilot hole until snug. Do not over-tighten the

mounting screw.

Page 20

Chapter 4 Installing the 100W Datalogging Endpoint

16 TDC-0909-000 100W Datalogging Endpoint Installation Guide

Proprietary and Confidential

Base Mount Installation

Caution Observe the following guidelines for mounting the 100W using the

wall mount procedure:

Endpoint positioning other than upright could negatively affect

radio performance and battery life.

Do not use gel connectors in pit environments.

Use only Itron-approved splice kits or inline connectors.

The 100W may be mounted to a flat surface using the base tab.

Required Base Mounting Tools and Hardware

Drill and drill bits appropriate for mounting location material.

Common hand tools for the selected fastening method.

Mounting screws: #10 size pan head screws appropriate for the wall or pit box

material.

To install the 100W using the base mount procedure

1. Select a flat surface.

2. Position the endpoint vertically.

3. Mark the location of the mounting hole.

4. Drill a pilot hole in the mounting location material. Follow the screw manufacturer's

recommendation for the size of the pilot hole.

5. Position the 100W and insert a #10 pan head screw in the base mounting tab.

Carefully tighten the mounting screw until the 100W is secure.

Caution Do not over-tighten the mounting screws. Over-tightening the mounting

screws may break the endpoint mounting tabs.

Page 21

Shelf Mount Installation

TDC-0909-000 100W Datalogging Endpoint Installation Guide 17

Proprietary and Confidential

Shelf Mount Installation

Caution Observe the following guidelines for mounting the 100W using the

wall mount procedure:

Endpoint positioning other than upright could negatively affect

radio performance and battery life.

Do not use gel connectors in pit environments.

Use only Itron-approved splice kits or inline connectors.

The pit lid and slot must have the correct dimensions for the 100W assembly to

fit properly.

Pit Lid Slot Dimensions

Dimension

Minimum

(inches)

Maximum

(inches)

A

6 3/4

N/A B 2

5 3/4

C

3/4

1

This section describes 100W installation using a Shelf Mount Adapter to mount the

endpoint in a pit lid slot.

The following illustration and the accompanying table give pit lid slot dimensions for the

shelf mount installation method.

Required Tools and Hardware

Itron 100W Shelf Mount Kit

Page 22

Chapter 4 Installing the 100W Datalogging Endpoint

18 TDC-0909-000 100W Datalogging Endpoint Installation Guide

Proprietary and Confidential

To install using the shelf mount adapter

1. With the foam spacers facing up, insert the shelf mount adapter into the opening in the

disk.

2. Push the adapter into the opening gently until the adapter snaps into place. Insert the

shelf mount adapter into the 100W antenna slot pushing firmly with your thumb until

the adapter tab locks into place in the opening of the 100W antenna slot.

Page 23

Shelf Mount Installation

TDC-0909-000 100W Datalogging Endpoint Installation Guide 19

Proprietary and Confidential

3. Slide the adapter assembly into the pit lid with the foam spacers positioned on each

Caution Do not install the adapter assembly in a manner that provides little or

no support under disk's edge.

side of the pit lid slot.

Correct position for foam spacers

Incorrect mounting position for foam spacers.

4. The installed position of the endpoint should be vertical and upright when the lid is

replaced on the pit.

Caution When placing the pit lid on to the pit box after shelf mount adapter

installation, use care to avoid pinching or damaging the 100W meter cable. Any

endpoint position other than upright may negatively affect radio performance and

battery life.

Page 24

Chapter 4 Installing the 100W Datalogging Endpoint

20 TDC-0909-000 100W Datalogging Endpoint Installation Guide

Proprietary and Confidential

Optional Leak Sensor Installation

Equipment

Itron Part Number

Description

Leak Sensor

LDS-0001-002

LDS with inline connector, environmental

connector cap; 5-foot cable, and mounting bolt

(fits up to 1 1/2-inch OD pipe).

Optional mounting bracket

CFG-0349-002

Mounting bolt fits up to 2 1/2-inch OD pipe.

100W datalogging endpoint

ERW-1300-002

Dual port 100W for LS and environmental

connector caps.

25-foot extension cable

CFG-0349-101

25-foot cable with coordinating connectors (LS

blue connector, register black connector).

100W LS environmental

replacement cap

MSC-0019-005

Protects Leak Sensor connector when the Leak

Sensor is not connected to the 100W endpoint.

Warning When the 100W is installed but the Leak Sensor is not attached,

the blue Leak Sensor port must be protected with the environmental cap

(MSC-0019-005).If the Leak Sensor is removed from the 100W, the

environmental cap must be replaced to protect the connector.

Leak Sensors analyze water flow sound patterns to detect new, evolving, and pre-existing

leaks. LS analysis data is uploaded to mlogonline™ Network Leak Monitoring for data

analysis accessed through a secure Internet portal unique to your utility.

The 100W endpoint stores 20 days of Leak Sensor data. On the 21st day, the 100W begins to

write over stored data in a first in, first out manner, maintaining current data on the status of

the surrounding water pipes.

The 100W automatically detects the presence of connected Leak Sensors. The 100W will

automatically detect the Leak Sensor within 22.5 minutes and begin reading leak sensor

data. To immediately detect the Leak Sensor and begin reading data, perform a Check ERT

with a handheld computer running FDM software.

This section describes installation of the Leak Sensor (LS) in a 100W system. The LS is

used in both indoor (basement) and outdoor (water meter pit) locations. LS devices are

mounted on a water service pipe or meter insetter (meter horn) and connect to the blue, top

connector of the 100W endpoint. The mounting bracket shipped with the Leak Sensor

accommodates an (up to) 1 1/2-inch OD pipe. An optional mounting bracket is available for

pipe sizes (up to 2 1/2-inch OD.

Required Equipment

Leak Sensor Mounting bracket 100W endpoint Optional mounting bracket

Page 25

Optional Leak Sensor Installation

TDC-0909-000 100W Datalogging Endpoint Installation Guide 21

Proprietary and Confidential

To connect the Leak Sensor to the 100W

Caution Verify you have the correct 100W endpoint. Leak Sensors must

mount to Port B (top port) of the 100W. Connecting the LS to Port A (bottom port)

will cause electrical damage to the LS and 100W endpoint.

1. Remove the environmental cap from the 100W endpoint blue connector (B).

B. 100W blue connector: Leak Sensor connection

A. 100W black connector: Register connection

2. Remove the environmental cap from the Leak Sensor connector. Verify the connectors

(100W LS connector and the Leak Sensor connector) are clean and dry.

3. Align the Leak Sensor connector with the endpoint's blue connector and insert.

Page 26

Chapter 4 Installing the 100W Datalogging Endpoint

22 TDC-0909-000 100W Datalogging Endpoint Installation Guide

Proprietary and Confidential

4. Rotate the connector locking ring until the security holes align.

Caution Do not force the connector ends together. While holding the LS connector,

engage the 100W connector by rotating the locking ring until both connectors securely

connect. Twist only the connector locking ring, not the body of the connector.

Twisting the connector body could damage the connector's pins.

Attaching an Itron Security Seal

Required Materials

Itron Security Seal (MSC-0018-001)

Page 27

Pipe Preparation

TDC-0909-000 100W Datalogging Endpoint Installation Guide 23

Proprietary and Confidential

To attach an Itron Security Seal through the connector security hole

1. Insert the pointed end of the Security Seal through the inline connector and the 100W

connector security holes.

2. Insert the pointed end of the security seal into the capped end and push until the seal

locks.

This completes 100W and Leak Sensor connections.

Pipe Preparation

Clean any dust or dirt from the pipe to facilitate direct contact with the LS surface.

Page 28

Chapter 4 Installing the 100W Datalogging Endpoint

24 TDC-0909-000 100W Datalogging Endpoint Installation Guide

Proprietary and Confidential

To install the Leak Sensor on a pipe or meter insetter

1. Select a Leak Sensor mounting location within 5 feet of the 100W endpoint. Mount

the sensor on the water input side of the meter.

Caution The Leak Sensor must be mounted on the water input side of the meter.

Failure to follow this mounting requirement could result in errors in the leak detection

data. Installation requires Itron mounting hardware. Repair costs and service charges

relating to the use on non-compliant mounting hardware will be charged to the

customer. Contract Itron Support for more information.

2. Verify the pipe’s mounting surface is free from dirt and debris. Place the curved

surface of the LS against the pipe.

3. Insert the mounting U-bolt over the pipe and into the LS mounting holes.

Caution Do not mount the Leak Sensor on a pipe coupler, joint, or nut.

Page 29

Pipe Preparation

TDC-0909-000 100W Datalogging Endpoint Installation Guide 25

Proprietary and Confidential

4. Insert the mounting plate over the U-bolt's threaded screw ends. Attach the two wing

nuts over the clamp screw ends and tighten the wing nuts until snug (to a minimum of

5-inch pounds) to prevent device rotation on the pipe. After the second wing nut is

tightened, check the Leak Sensor to verify the device is snug. If the sensor moves,

tighten the wing nuts until there is no movement.

Caution Do not tighten the Leak Sensor to more than 20 inch-pounds. Overtightening could damage the Leak Sensor housing and/or the pipe.

Note Leak Sensor mounting orientation is not critical. Orient the Sensor to best

accommodate your installation. The most important installation practice is to mount

the Sensor securely to the pipe.

Page 30

Chapter 4 Installing the 100W Datalogging Endpoint

26 TDC-0909-000 100W Datalogging Endpoint Installation Guide

Proprietary and Confidential

To install the Leak Sensor on a pipe (up to 2 1/2-inch OD)

1. Select a Leak Sensor mounting location within 5 feet of the 100W endpoint.

Note Leak Sensor mounting orientation is not critical. Orient the Sensor to best

accommodate your installation. The most important installation practice is to fasten

the Sensor securely to the pipe.

Caution The Leak Sensor must be mounted on the water input side of the meter.

Failure to follow this mounting requirement could result in errors in the leak detection

data. Installation requires Itron mounting hardware. Repair costs and service charges

relating to the use on non-compliant mounting hardware will be charged to the

customer. Contract Itron Support for more information.

2. Insert the mounting plate screws into the holes on the Leak Sensor's curved surface.

3. Secure the mounting plate to the Leak Sensor.

Page 31

Pipe Preparation

TDC-0909-000 100W Datalogging Endpoint Installation Guide 27

Proprietary and Confidential

4. Verify the pipe’s mounting surface is free from dirt and debris. Place the curved

surface of the LS against the pipe.

Caution Do not mount the Leak Sensor on a pipe coupler, joint, or nut.

5. Insert the U-bolt around the pipe and into the holes in the plate/Leak Sensor assembly.

Secure the U-bolt with the wing nuts. Tighten the wing nuts until snug (to a minimum

of 5-inch pounds) to prevent device rotation on the pipe. After the second wing nut is

tightened, check the Leak Sensor to verify the device is snug. If the sensor moves,

tighten the wing nuts until there is no movement.

Caution Do not tighten the Leak Sensor to more than 20 inch-pounds. Overtightening could damage the Leak Sensor housing and/or the pipe.

Page 32

Chapter 4 Installing the 100W Datalogging Endpoint

28 TDC-0909-000 100W Datalogging Endpoint Installation Guide

Proprietary and Confidential

Page 33

TDC-0909-000 100W Datalogging Endpoint Installation Guide 29

Proprietary and Confidential

The optional 900 MHz remote mount antenna provides increased RF range coverage for:

C H A P T E R 5

Optional Remote Antenna Installation

Meters located deep in a pit boxes.

Meters submerged in water for extended periods of time.

Meters in Fixed Network systems.

This section provides antenna mounting instructions through a pit lid and the instructions to

connect the antenna to the 100W.

Mounting the Remote Antenna

Metal lids on water pit boxes require a through-lid solution for optimal endpoint radio

performance. The remote antenna is designed to fit in a pit lid hole with a diameter between

1 3/4-inch to 2-inches and a lid thicknesses from 1/4-inch to 1 3/4-inch.

To mount the optional remote antenna through a pit lid

1. Insert the remote antenna into the hole in the pit lid with the convex surface on the top

of the pit lid. (These instructions show a simulated pit lid material.)

Page 34

Chapter 5 Optional Remote Antenna Installation

30 TDC-0909-000 100W Datalogging Endpoint Installation Guide

Proprietary and Confidential

2. From the bottom side of the lid, screw on the threaded collar two or three turns. Turn

the threaded collar until it is tight against bottom of the pit lid. Verify the antenna

dome does not move up and down or shift laterally .

Note Ensure the beveled edge (1) of the threaded collar is toward the top of the lid

(2). The Itron-recommended placement centers the remote antenna and takes up the

extra space in mounting holes up to 2 1/2-inches.

To connect the remote antenna coupler to the 100W

1. Insert the remote antenna cable coupler into the 100W s antenna slot with the flat side

of the coupler against the 100W housing.

2. Push the antenna coupler into the antenna slot until the coupler locks into the tabs of

the antenna slot.

Page 35

Mounting the Remote Antenna

TDC-0909-000 100W Datalogging Endpoint Installation Guide 31

Proprietary and Confidential

Important Verify the antenna coupler locks with the antenna slot's tabs.

Remote antenna installation is complete.

Page 36

Chapter 5 Optional Remote Antenna Installation

32 TDC-0909-000 100W Datalogging Endpoint Installation Guide

Proprietary and Confidential

Page 37

TDC-0909-000 100W Datalogging Endpoint Installation Guide 33

Proprietary and Confidential

This section describes the connections of the 100W to the water meter register using the

Note If an inline connector is not used and the 100W is already connected to

the water meter register, skip this step.

A P P E N D I X A

Using an Inline Connector

inline connector assembly. Follow the manufacturer's recommended procedure for installing

the water meter register on the meter.

To connect the inline connector

1. Remove the protective cover from the connector by twisting the two halves in opposite

directions. Pull the halves apart.

Caution Verify the connector halves are clean and dry before assembly.

If any of the following conditions occur, do not install the endpoint:

Any of the three pins are damaged or missing.

The O-ring is missing.

The cable is cut or nicked

2. Connect the register cable to the endpoint connector. Holding the connectors by the

back shells, rotate one end to align the keyed slots. Push until snug. Slide the black

coupling nut over the O-ring. Make sure the O-ring stays seated. If the O-ring does not

stay seated, disconnect and try again.

Page 38

Appendix A Using an Inline Connector

34 TDC-0909-000 100W Datalogging Endpoint Installation Guide

Proprietary and Confidential

3. Twist the register cable's black coupling nut to align the two tabs.

4. Install the security seal as shown. Push it until it snaps into place.

Note For future meter or endpoint servicing, break the security seal by pulling apart.

The original protective connector covers can be reused if kept clean and dry. Install a

new security seal after servicing either device. To order more parts, see the Water

Endpoint Ordering Guide (PUB-0063-001).

Caution Shield connectors with protective environmental covers. Do not leave an

exposed connector in the field.

Leak Sensor connector environmental cover: MSC-0019-005

Register connector environmental cover: MSC-0019-001, 1-year life.

The Leak Sensor environmental Cap employs multiple seals to increase cap life. The

Leak Sensor's cap design allows utilities to install the endpoint and install the Leak

Sensor at a later date.

Page 39

TDC-0909-000 100W Datalogging Endpoint Installation Guide 35

Proprietary and Confidential

Symbols & Numbers

Index

100W Datalogging Endpoints with Integral

Connectors • 9

A

About the 100W Datalogging Endpoint • 3

B

Base Mount Installation • 16

Battery Life • 3

Before You Begin • 1

C

Connecting to a Meter Register Using a 5-foot

Cable • 5

Connecting to a Meter Register Using the Inline

Connector • 5

H

How This Document is Organized • 1

I

Initializing and Connecting the 100W

Datalogging Endpoint • 5

Installing and Connecting • 5

Installing the 100W Datalogging Endpoint • 9

M

Mounting the Remote Antenna • 29

O

Operating Modes • 4

Optional Leak Sensor Installation • 20

Optional Remote Antenna Installation • 29

P

Pipe Preparation • 23

Required Equipment • 20

Required Tools and Hardware • 11, 14, 17

Rod Mount Installation • 10

S

Shelf Mount Installation • 17

T

To connect the 100W to the register • 6

To connect the inline connector • 33

To connect the Leak Sensor to the 100W • 21

To connect the remote antenna coupler to the

100W • 30

To initialize the 100W • 5

To install a cable tie to the connector • 10

To install the 100W on a rod • 11

To install the 100W using the base mount

procedure • 16

To install the 100W using the wall mount

procedure • 14

To install the Leak Sensor on a pipe (up to 2 1/2-

inch OD) or meter insetter • 26

To install the Leak Sensor on a pipe or meter

insetter • 24

To install using the shelf mount adapter • 18

U

Using an Extension Cable • 6

Using an Inline Connector • 33

V

Verifying Operation of the 100W Endpoint • 7

W

Wall Mount Installation • 14

R

Required Base Mounting Tools and Hardware •

16

Loading...

Loading...