Page 1

DRAFT

Natural Gas Solutions

100G Installation Guide for Mercury

Electronic Volume Correctors

Revision A3

Natural Gas Solutions

Page 2

DRAFT

Identification

100G Remote ERT Module Installation Guide

Part number: PUB-0200-002 Revision A 02/08

ERT Part Numbers: ERG-5000-502 (100G with 5-ft. cable)

Copyright

© 2008 Itron, Inc. All rights reserved.

Your company has the right to reproduce this contract document, provided that such reproduction shall be subject to the same use and disclosure restrictions contained in the

Confidentiality and Non-Disclosure paragraphs in the Sales Contract.

Applicable Patents

U.S. Patent Numbers: TBD

Canadian Patent Numbers: TBD

Transportation Classification

The Federal Aviation Administration prohibits operating transmitters and receivers on all commercial aircraft. When powered, the 100G Remote ERT Module is considered an operating

transmitter and receiver and cannot be shipped by air. All product returns must be shipped by ground transportation.

WARNING! Only authorized Itron personnel should attempt repairs on Itron

equipment. Attempts to do so by others might void any maintenance contract

with your company. Unauthorized service personnel might also be subject to

shock hazard on some Itron equipment if removal of protective covers is

attempted.

WARNING! Substitution of components may impair intrinsic safety.

WARNING! To prevent ignition of flammable or combustible atmospheres,

disconnect power before servicing.

Compliance Statement

This device complies with Part 15 of the FCC Rules. Operation of this device is subject to the following two conditions:

• This device may not cause harmful interference.

• This device must accept any interference that may cause undesirable operation.

This device must be permanently mounted such that it retains a distance of 20 centimeters (7.9 inches) from all persons in order to comply with FCC RF exposure levels.

Modification and Repairs

To ensure FCC compliance and system performance, this device and antenna shall not be changed or modified without the expressed approval of Itron. Any unauthorized modification

will void the user’s authority to operate the equipment.

Meter Installation/Removal

In the event of malfunction, all repairs should be performed by Itron. It is the responsibility of users requiring service to report the need for service to Itron.

WARNING! Follow these procedures to avoid injury to yourself or

others.

• The lithium battery may cause a fire or chemical burn if it is

not disposed of properly.

• Do not recharge, disassemble, heat, or incinerate the lithium

battery.

• Keep the lithium battery away from children.

Related Documents

Endpoint-Link Endpoint Programming Guide (TDC-0744)

Trademark Notice

Enscan, ERT, Itron, ReadOne, and Endpoint-Link are registered trademarks of Itron, Inc. All other product names and logos in this documentation are used f or identification purposes

only and may be trademarks or registered trademarks of their respective companies.

Suggestions

If you have comments or suggestions on how we may improve this documentation, send them to

If you have questions or comments about this application, contact Itron Technical Support:

Itron, Inc.

• Mail: Itron, Inc. Attention: Customer Care, 2111 N Molter Road, Liberty Lake, WA 99019

• E-mail: support@itron.com

• Phone: 1 800 635 8725

TechnicalCommunicationsManager@itron.com.

Page 3

DRAFT

Contents

Chapter 1 Getting Started...........................................................................................1

Tools and Materials Supplied By You.................................................................................................1

Materials Supplied by Itron..................................................................................................................2

Screw Specifications.................................................................................................................3

Code Settings......................................................................................................................................3

Chapter 2 Installing the 100G Remote ERT Module ..................................................7

Mount the Corrector ............................................................................................................................7

Pipe Mounting .....................................................................................................................................8

Adapter Plate Mounting Positions...........................................................................................12

Program the ERT....................................................................................................................15

Flat Surface Mounting.......................................................................................................................22

Program the ERT....................................................................................................................25

Functional Specifications...................................................................................................................30

Physical Specifications......................................................................................................................31

Operational Specifications.................................................................................................................31

Natural Gas Solutions 100G Installation Guide for Mercury Electronic Volume Correctors iii

Page 4

Contents

DRAFT

iv Natural Gas Solutions 100G Installation Guide for Mercury Electronic Volume Correctors

Page 5

DRAFT

C HAPTER 1

Getting Started

The 100G is Itron's latest gas encoder-receiver-transmitter (ERT®) module.

ERT modules are radio-frequency (RF) devices that transmit meter data. The RF meter data

can be received by a reading device that is within transmission distance of the ERT. Itron's

100G ERT module has increased output power over legacy gas ERT modules for increased

RF transmission distance.

This installation guide shows you how to install the 100G Remote ERT Module on the

Mercor Mini, Mini-AT, Mini-Max, and EC-AT meter correctors.

Mini-AT

Mini-Max

EC-AT

Tools and Materials Supplied By You

You must supply the following tools and material to install, program, and check the 100G

Remote ERT Module:

• Medium flat-blade screwdriver for band clamps

• Small flat-blade screwdriver for installing Phoenix connector

• Medium flat-blade, torque-measuring screwdriver for the screws used to attach

adapter plates to pipe brackets and the screws used to attach ERT modules to adapter

plates. Torque to be measured is 9 to 12 inch-pounds

• Medium Philips screwdriver for opening and closing Mini-Max cover, and, if

necessary, for attaching ERT modules to flat surfaces

• Pliers for pulling cable ties tight

• 1" wrench for tightening compression connector nut

• Side-cutting pliers ("dykes") or similar tool for cutting off the excess length of cable

tie straps

• 1/4-inch nut driver or other blunt tool for seating ERT-module tamper seals

• Rubber tape for sealing compression connector

Natural Gas Solutions 100G Installation Guide for Mercury Electronic Volume Correctors 1

Page 6

Chapter 1 Getting Started

DRAFT

• FC200R unit for programming and checking ERT modules.

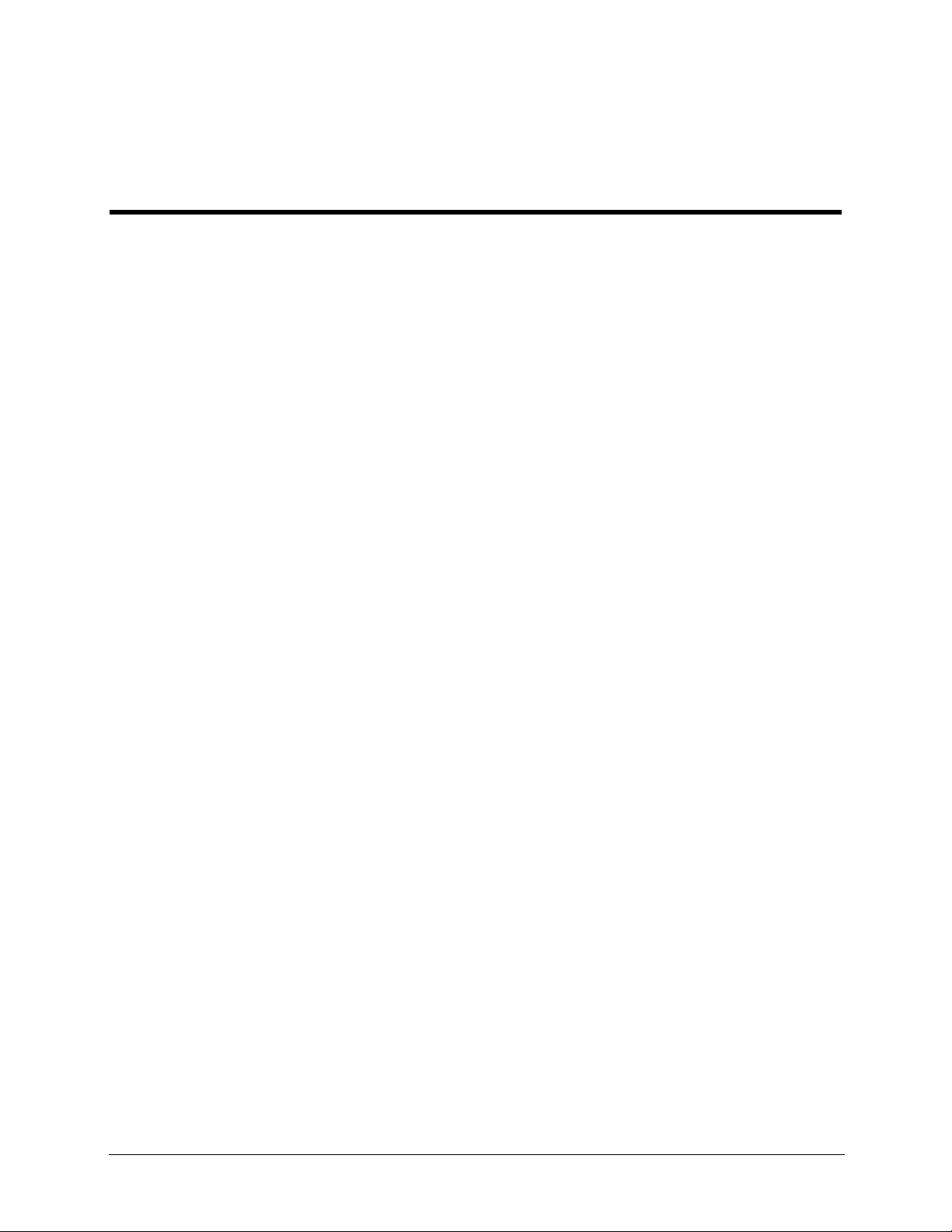

Materials Supplied by Itron

The following items are supplied with each 100G Remote ERT Module installation:

• 100G Remote ERT Module with 5-foot cable (ERG-5000-502)

• A pipe bracket installation kit

Two cable ties for

securing the ERT cable

Two band clamps for attaching

the pipe bracket to a pipe

Three screws to attach

the ERT to a fla t su rfac e

Adapter plate

Pipe bracket

Two tamper seals

Two screws to attach

the adapter plate to

the pipe bracket

Two screw s to attach the

ERT to the adapter plate

2 Natural Gas Solutions 100G Installation Guide for Mercury Electronic Volume Correctors

Page 7

Code Settings

DRAFT

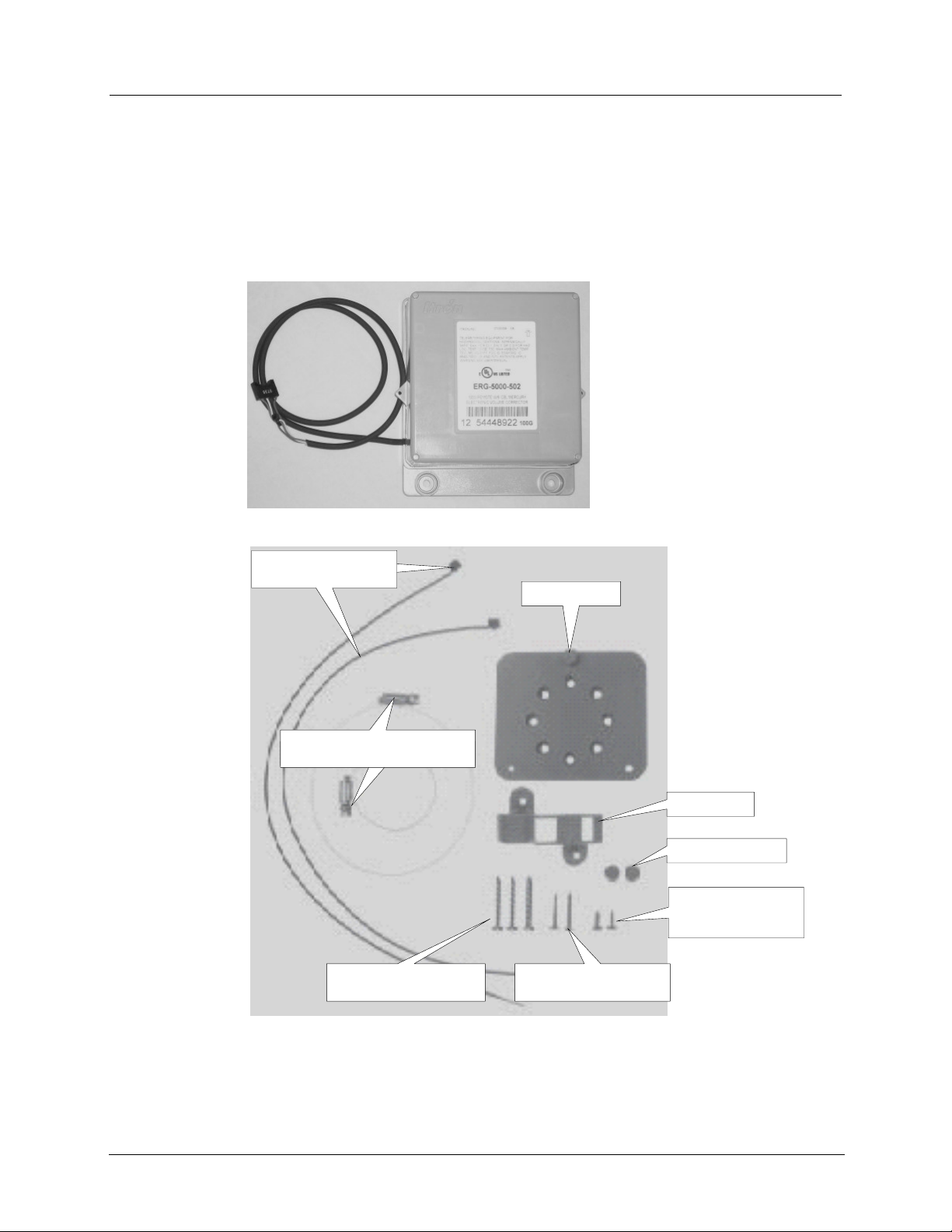

Screw Specifications

For mounting adapter plates on

pipe brackets

8–15 x 1/2 Type A slotted pan

head tapping screw,corrosion

resistant steel

For mounting ERTs on adapter

plates

8–15 x 1 Type A slotted panhead

tapping screw, corrosion resistant

steel

For mounting ERTs on wood or

sheet metal surfaces

10–16 x 1 1/2 Type AB Phillips

panhead tapping screw, corrosion

resistant steel

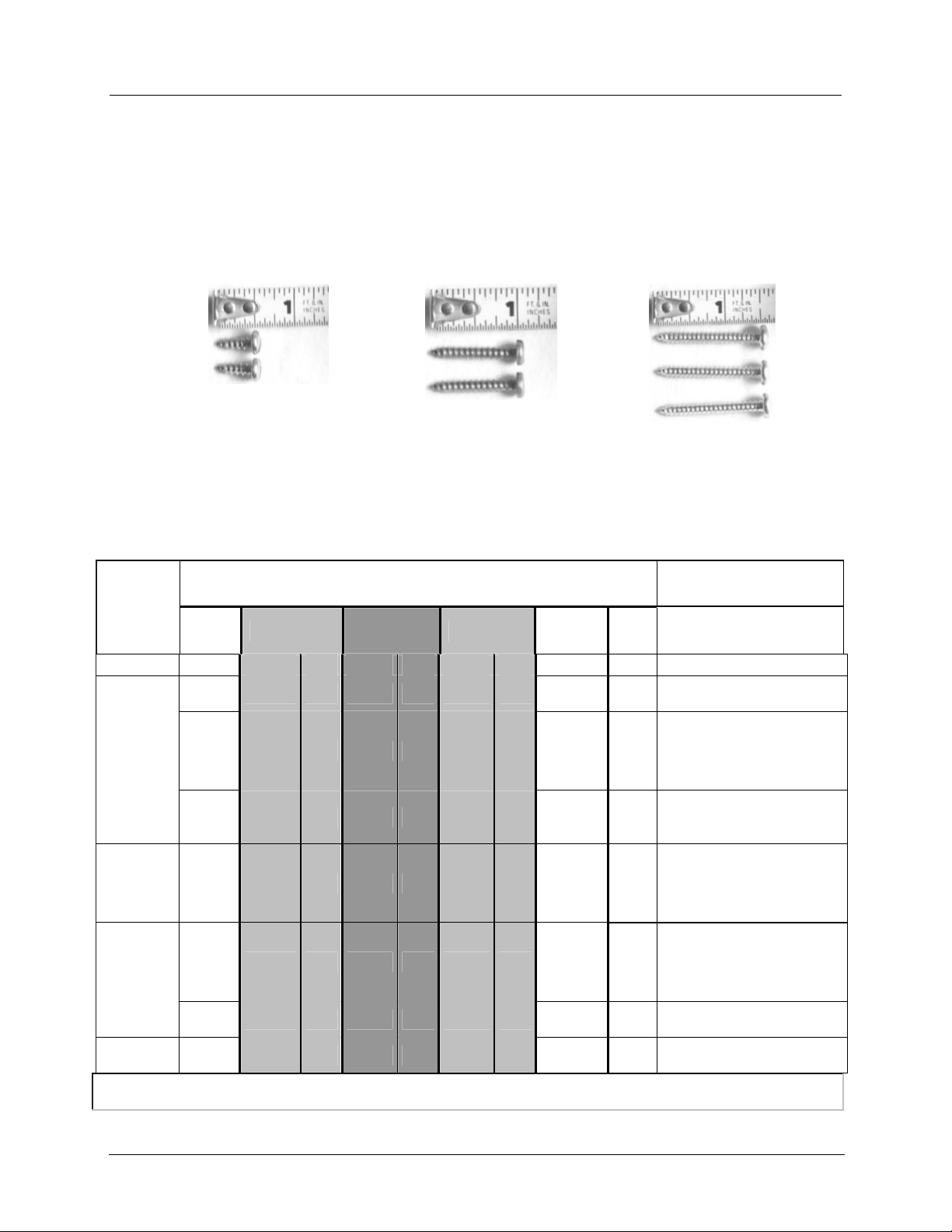

Code Settings

Item Code Settings and Corresponding Terminal Board Channel Terminal Board Connections*

Instrument

Type

Form A Channel A Channel B Channel C

0 n/a n/a n/a n/a n/a n/a n/a n/a

ECAT:

Mini with

Form A

Mainboard:

Mini-AT:

Mini-Max: 2 2.0000 0 2.0000 0 n/a n/a 1, 2, 3 or 4 1 or 2

* For more information, see pages 11-20 of the "Basic Pulse Information for Mercury Instruments, Inc., Electronic Volume Correctors" manual, or

contact Mercury Instruments at 513-272-1111.

3 2.0000 0 2.0000 0 2.0000 0 1, 2, 3 or 4 1 or 2

1

1

2 2.0000 0 2.0000 0 n/a n/a 1, 2, 3 or 4 1 or 2

0

#056 #093 #057 #094 #058 #095 #096 #115

n/a n/a n/a n/a 2.0000 0 1, 2, 3 or 4 1 or 2

2.0000 0 n/a n/a n/a n/a 1, 2, 3 or 4 1 or 2

n/a n/a n/a n/a n/a n/a n/a n/a

Ka, Ya = Channel A Kb, Yb =

Channel B Kc, Yc = Channel C

ERT does not support a Form-C

Pulse Output Board

Ka, Kb, Kc (Red Wire) Ya, Yb, Yc

(Blue & White Wire). Connection

must be on same terminal board

channel (i.e., Ka/Ya; Kb/Yb;

Kc/Yc).

Kc (Red Wire) Yc (Blue & White

Wire) For this option, ERT must be

connected to Channel C.

K (Red Wire) Y (Blue & White

Wire) Jumper settings must be on

J1-B as stated in the Mercury Quick

Reference Guide (page 45) for

Form-A.

K (Red Wire) Y (Blue & White

Wire) Jumper settings must be on

J1-B as stated in the Mercury Quick

Reference Guide (page 45) for

Form-A.

ERT does not support a Form-C

Pulse Output Board

K (Red Wire) Ya OR Yb (Blue &

White Wire)

Natural Gas Solutions 100G Installation Guide for Mercury Electronic Volume Correctors 3

Page 8

Chapter 1 Getting Started

DRAFT

4 Natural Gas Solutions 100G Installation Guide for Mercury Electronic Volume Correctors

Page 9

Code Settings

DRAFT

Natural Gas Solutions 100G Installation Guide for Mercury Electronic Volume Correctors 5

Page 10

DRAFT

Page 11

DRAFT

C HAPTER 2

Installing the 100G Remote ERT Module

The 100G Remote ERT Module can be mounted on a pipe, using the pipe bracket

installation kit, or a flat surface. The 100G Remote ERT Module must always be mounted

with the printed label right-side-up, and the encoder wires and tamper seals at the bottom, as

shown.

Top of ERT

Cable comes

out the bottom

Mount the Corrector

Mount the corrector on the meter according to the Mercury installation manual.

Enter the specified code settings for the corrector.

Tamper seals at

the bottom

Natural Gas Solutions 100G Installation Guide for Mercury Electronic Volume Correctors 7

Page 12

Chapter 2 Installing the 100G Remote ERT Module

DRAFT

Pipe Mounting

To mount the adapter plate on vertical a pipe

1. Get the pipe bracket from remote mount kit and a proper size band clamp.

2. Loosen the clamp screw until the end of the band is released.

3. Push the end of the band through this hole in the pipe bracket.

8 Natural Gas Solutions 100G Installation Guide for Mercury Electronic Volume Correctors

Pass end of

band clamp

through the hole

Page 13

Pipe Mounting

DRAFT

4. Place the band clamp around the pipe.

5. Push the end of the band through the hole in the band clamp and into the entrance to

the screw assembly.

Entrance to screw

assembly

Pass end of the band

through this hole

6. Tighten the band clamp until the end of the band can be pushed into the hole in the

pipe bracket.

Put the end of

the ban d in t h is

hole

Natural Gas Solutions 100G Installation Guide for Mercury Electronic Volume Correctors 9

Page 14

Chapter 2 Installing the 100G Remote ERT Module

DRAFT

7. Tighten the clamp screw three or four more turns to make sure the end of the band

does not pop back out on this side of the pipe bracket.

8. Position the band clamp as shown then fully tighten the band clamp screw.

9. Place the adapter plate on the pipe bracket. The adapter-plate screw boss goes into this

pipe-bracket recess.

Screw boss

Screw boss

10 Natural Gas Solutions 100G Installation Guide for Mercury Electronic Volume Correctors

Page 15

Pipe Mounting

DRAFT

When the adapter plate is properly positioned on the pipe bracket, it looks like this.

10. Obtain two adapter-plate mounting screws (shown here actual size) from the

installation kit.

11. Install the adapter plate mounting screws in these holes.

Put screws in

these holes

12. Tighten both screws to 9 to 12 inch-pounds of torque.

Natural Gas Solutions 100G Installation Guide for Mercury Electronic Volume Correctors 11

Page 16

Chapter 2 Installing the 100G Remote ERT Module

DRAFT

Adapter Plate Mounting Positions

The installation procedure in this section shows how to mount the adapter plate on vertical

pipes. The following pictures show how to mounting the adapter plate on pipes that are

either horizontal or at 45 degree angles. Regardless of which direction the pipe goes, the

adapter plate mounting lug must always be at the top.

If the pipe is at a 45 degrees angle up to the right, install the adapter plate as shown.

Mounting lug

Screws

If the pipe is at a 45 degrees angle up to the left, install the adapter plate as shown.

Mounting lug

Screws

If the pipe is horizontal, install the adapter plate as shown.

12 Natural Gas Solutions 100G Installation Guide for Mercury Electronic Volume Correctors

Page 17

Pipe Mounting

DRAFT

Mounting lug

Screws

To mount the 100G Remote ERT Module on the adapter plate

1. Get the 100G Remote ERT Module and two 1-inch mounting screws from the

installation kit.

2. Place the back of the ERT module against the face of the adapter plate.

Natural Gas Solutions 100G Installation Guide for Mercury Electronic Volume Correctors 13

Page 18

Chapter 2 Installing the 100G Remote ERT Module

DRAFT

The adapter-plate mounting lug should be just above the ERT-module mounting lug

recess.

Mounting lug

Mounting lug

recess

3. Raise the ERT module until the adapter-plate mounting lug is as far as possible inside

the ERT-module mounting lug recess.

14 Natural Gas Solutions 100G Installation Guide for Mercury Electronic Volume Correctors

Page 19

Pipe Mounting

DRAFT

4. Install the two ERT module mounting screws you got from the installation kit.

When the ERT module is properly mounted on the adapter plate, it should look like

this.

5. Tighten the screws to 9 to 12 inch-pounds of torque.

Program the ERT

The ERT must be programmed using the FC200SR with EndPoint-Link software. See the

Endpoint-Link ERT Programming Guide (TDC-0411) for more information.

IMPORTANT You must perform the following programming procedure for

the ERT module to function properly.

When programming the ERT module, you must take note of the drive rate shown on the

index of the meter. Program the meter based on the drive rate shown on the index.

Natural Gas Solutions 100G Installation Guide for Mercury Electronic Volume Correctors 15

Page 20

Chapter 2 Installing the 100G Remote ERT Module

DRAFT

To program the ERT module

1. Using the FC200SR, program the reading of the index that was on the meter into the

ERT module assembly.

• For initial programming, hold the FC200SR approximately 1 foot away from

the 100G.

• For reprogramming (30 days or more past initial programming), hold the

FC200SR approximately 4 to 5 feet away from the 100G.

Be sure to program the 100G to the correct mode for the reading technology that will

be used (for example, Fixed Network Mode, Mobile/Handheld Mode, or Hard to Read

Mobile/Handheld Mode). In Endpoint-Link Pro v5.0, you will have access to the one

mode that was defined by your system administrator.

2. Read the ERT module assembly using the FC200SR. Consult the

Programming Guide

read an ERT.

• If this reading is higher than the one you programmed in step 1 above, the ERT

module assembly is counting correctly.

• If the ERT module assembly reading is

in step 1, replace the ERT module with a new one.

To connect the ERT cable to the corrector

1. Insert the ERT cable into the compression connector.

(TDC-0411) or other applicable instructions for details on how to

not higher than what was programmed

EndPoint-Link ERT

16 Natural Gas Solutions 100G Installation Guide for Mercury Electronic Volume Correctors

Page 21

Pipe Mounting

DRAFT

2. Strip one inch from the outer insulation and about 1/4-inch from the red,white and

blue wires. Twist the blue and white wires together.

3. Install the Phoenix connector (supplied by Mercury). Connect the red, blue and white

wires to the Phoenix connector terminals as directed in

Code Settings on page 3.

NOTE In EC-AT units, the connector might be soldered to the pulse board.

Natural Gas Solutions 100G Installation Guide for Mercury Electronic Volume Correctors 17

Page 22

Chapter 2 Installing the 100G Remote ERT Module

DRAFT

4. Install the connector so that the"K" terminal is topmost, leaving some slack in the

cable.

5. To hold the cable in place, wrap and stretch some rubber tape at the compression

connector.

18 Natural Gas Solutions 100G Installation Guide for Mercury Electronic Volume Correctors

Page 23

Pipe Mounting

DRAFT

6. Install and tighten compression nut. This provides strain relief and seals the

connection.

To install tamper seals and cable ties

1. Get two new tamper seals from the installation Kit.

2. Place anew tamper seal over each ERT module mounting screw.

Natural Gas Solutions 100G Installation Guide for Mercury Electronic Volume Correctors 19

Page 24

Chapter 2 Installing the 100G Remote ERT Module

DRAFT

3. Push both tamper seals all the way into place with a 1/4-inch nut driver or similar

tool.

The100G Remote ERT Module should look like this after the tamper seals have been

installed.

20 Natural Gas Solutions 100G Installation Guide for Mercury Electronic Volume Correctors

Page 25

Pipe Mounting

DRAFT

4. Loop a cable tie around the pipe and the ERT cable.

5. Pull the cable tie tight and cut off excess length. Dispose of the cut-off piece properly.

When finished, the cable tie should look like this.

Natural Gas Solutions 100G Installation Guide for Mercury Electronic Volume Correctors 21

Page 26

Chapter 2 Installing the 100G Remote ERT Module

DRAFT

6. Push any excess wire up between the back of the ERT module and the face of the

adapter plate.

Flat Surface Mounting

To mount the 100G Remote ERT Module on a flat surface

1. Drill three pilot holes in the mounting surface the proper size for the mounting screws,

as shown in the drilling template.

WARNING! Do not strike electrical wires or damage anything on the other side

of the surface you are going to mount the ERT module on when you drill the

holes and install the screws.

22 Natural Gas Solutions 100G Installation Guide for Mercury Electronic Volume Correctors

Page 27

Flat Surface Mounting

DRAFT

The holes for the bottom two screws must be on a horizontal line.

If you mount the ERT module on a wood surface, use the mounting screws included

with the ERT module or screws with the same size heads.

2. Get the three 1 1/2 inch mounting screws from the installation kit.

3. Turn the top mounting screw part way into the mounting surface.

Natural Gas Solutions 100G Installation Guide for Mercury Electronic Volume Correctors 23

Page 28

Chapter 2 Installing the 100G Remote ERT Module

DRAFT

4. Get an ERT module assembly.

5. Turn the screw into the mounting surface until the back side of the ERT module

mounting lug recess at the top of the ERT module will just barely slide under the

screw head.

6. Push the ERT module upward until the screw head is all the way into the screw-head

mounting recess at the top of the ERT module.

24 Natural Gas Solutions 100G Installation Guide for Mercury Electronic Volume Correctors

Page 29

Flat Surface Mounting

DRAFT

7. Install and fully tighten the two bottom ERT module mounting screws.

Program the ERT

The ERT must be programmed using the FC200SR with EndPoint-Link software. See the

Endpoint-Link ERT Programming Guide (TDC-0411) for more information.

IMPORTANT You must perform the following programming procedure for

the ERT module to function properly.

When programming the ERT module, you must take note of the drive rate shown on the

index of the meter. Program the meter based on the drive rate shown on the index.

To program the ERT module

1. Using the FC200SR, program the reading of the index that was on the meter into the

ERT module assembly.

• For initial programming, hold the FC200SR approximately 1 foot away from

the 100G.

• For reprogramming (30 days or more past initial programming), hold the

FC200SR approximately 4 to 5 feet away from the 100G.

Be sure to program the 100G to the correct mode for the reading technology that will

be used (for example, Fixed Network Mode, Mobile/Handheld Mode, or Hard to Read

Mobile/Handheld Mode). In Endpoint-Link Pro v5.0, you will have access to the one

mode that was defined by your system administrator.

Natural Gas Solutions 100G Installation Guide for Mercury Electronic Volume Correctors 25

Page 30

Chapter 2 Installing the 100G Remote ERT Module

DRAFT

2. Read the ERT module assembly using the FC200SR. Consult the EndPoint-Link ERT

Programming Guide

read an ERT.

• If this reading is higher than the one you programmed in step 1 above, the ERT

module assembly is counting correctly.

(TDC-0411) or other applicable instructions for details on how to

• If the ERT module assembly reading is

in step 1, replace the ERT module with a new one.

To connect the ERT cable to the corrector

1. Insert the ERT cable into the compression connector.

2. Strip one inch from the outer insulation and about 1/4-inch from the red,white and

blue wires. Twist the blue and white wires together.

not higher than what was programmed

26 Natural Gas Solutions 100G Installation Guide for Mercury Electronic Volume Correctors

Page 31

Flat Surface Mounting

DRAFT

3. Install the Phoenix connector (supplied by Mercury). Connect the red, blue and white

wires to the Phoenix connector terminals as directed in

NOTE In EC-AT units, the connector might be soldered to the pulse board.

4. Install the connector so that the"K" terminal is topmost, leaving some slack in the

cable.

Code Settings on page 3.

Natural Gas Solutions 100G Installation Guide for Mercury Electronic Volume Correctors 27

Page 32

Chapter 2 Installing the 100G Remote ERT Module

DRAFT

5. To hold the cable in place, wrap and stretch some rubber tape at the compression

connector.

6. Install and tighten compression nut. This provides strain relief and seals the

connection.

28 Natural Gas Solutions 100G Installation Guide for Mercury Electronic Volume Correctors

Page 33

Flat Surface Mounting

DRAFT

To install tamper seals and cable ties

1. Get two new tamper seals from the installation kit.

2. Place a new tamper seal over each ERT module mounting screw and push both seals

all the way into place with a 1/4-inch nut driver or similar tool.

3. Secure extra cable with a cable tie.

Natural Gas Solutions 100G Installation Guide for Mercury Electronic Volume Correctors 29

Page 34

Chapter 2 Installing the 100G Remote ERT Module

DRAFT

4. Pull the cable tie tight and cut off excess length. Dispose of the cut-off piece properly.

When finished, the tamper seals and cable should look like this.

Functional Specifications

Power source: Lithium battery

Radio programming parameters: LCD reading, number of digits, count rate, security

level

Mercury corrector programming parameters:

• Correctors must have Form A board. Form C is NOT supported.

• Item # 056: Pulse A Scaling. Set at 2.0000 for a form A switch.

• Item #057: Pulse A Scaling. Set at 2.0000 for a form A switch.

• Item #058: Pulse A Scaling. Set at 2.0000 for a form A switch.

30 Natural Gas Solutions 100G Installation Guide for Mercury Electronic Volume Correctors

Page 35

Physical Specifications

DRAFT

• Item # 093: Type of gas volume information to be sent. For CorVol selected, must be

set at 0.

• Item # 094: Type of gas volume information to be sent. For CorVol selected, must be

set at 0.

• Item # 095: Type of gas volume information to be sent. For CorVol selected, must be

set at 0

• Item # 096: Corrected Volume Display: Must be set at 1, 2, 3 or 4 blanks. ERT does

not support a setting of 0 blanks.

• Item # 115: Output Pulse Code: Must be set at 1 or 2.

Operating temperatures: –40°F to + 158°F (–40°C to +70°C)

Operating humidity: 5 to 95 percent non-condensing relative humidity

Product identification: Numeric and bar-coded ERT module type and serial number

FCC compliance: Part 15 certified

Intrinsically safe per: Factory Mutual and UL Class 1, Division 1, Groups C and D

Physical Specifications

Materials of construction: Black polycarbonate housing; encapsulated electronics

Operational Specifications

Receive frequency: 952 and 956 MHz (MAS Bands)

Transmit frequency: 910 to 920 MHz

Data integrity: Verified in every data message

Natural Gas Solutions 100G Installation Guide for Mercury Electronic Volume Correctors 31

Page 36

Chapter 2 Installing the 100G Remote ERT Module

DRAFT

32 Natural Gas Solutions 100G Installation Guide for Mercury Electronic Volume Correctors

Loading...

Loading...