Page 1

C

3

HAPTER

Sensus/Rockwell Meter Installation

This chapter provides instructions to install the 100G Datalogging Gas Endpoint on a

Sensus/Rockwell Meter. These instructions apply to 11-tooth, 16-tooth, and 18-tooth Sensus

100G Datalogging Gas Endpoints.

Note Sensus meters are also known as Invensys, Equimeter, and Rockwell. For

these instructions, all meter types are referred to as Sensus meters.

100G Datalogging Gas Endpoint Sensus 11-tooth

Sensus 16-tooth

Sensus 18-tooth

100G Datalogging Installation G uide - Direct Mount 21

Page 2

Chapter 3 Sensus/Rockwell M eter Installati on

To Remove the Index from the Meter

1. Remove the four index cover screws and the index cover from the Sensus meter.

Alternate screw removal following the numbered pattern as shown in the photo.

2. Examine the mounting screws. If they are 5/8" long and not corroded, keep them to

attach the 100G Datalogging Gas Endpoint assembly. If the screws are not the correct

length or if the screws are corroded, discard.

Note You may use the removed index cover as a temporary storage container for

screws. Properly dispose all unused screws, old index covers, gaskets, tamper

seals, and other leftover materials. Do not leave materials on customer premises.

3. Unscrew one index mounting screw completely. Hold one hand under the index to

catch the screw. While removing the other mounting screw, pull the index away from

the meter to keep the index backplate against the back of the screw. Remove the screw

completely after the index is free of the meter.

Set the index aside where it will not be damaged or fill with dirt, rain or snow. The

index will be mounted in the endpoint later in this procedure. Verify the index

mounting screws are 5/8" long and not corroded. If the screws are the correct length

and not corroded, retain for later use. If the original screws are discarded, use the

correct replacement screws (see Installation Prerequisites on page 8.)

22 100G Datalogging Installation Guide - Direct Mount

Page 3

Attaching the 100G Datalogging Gas Endpoint Assembly to the Elster American Meter

4. Remove the old gasket, gasket residue, and dirt from the meter (if applicable). The

meter face must be free of gasket residue or dirt before you install the 100G

Datalogging Gas Endpoint.

To Assemble the 100G Datalogging Gas Endpoint and Index

1. Separate the 100G Datalogging Gas Endpoint housing from the cover by pulling the

cover straight out from the housing. Set the endpoint cover aside where it will not be

damaged or fill with rain, dirt or snow. The cover will be used later in this installation

procedure.

2. Place the index drive gear (1) in the housing wriggler gear cup (2) of the endpoint.

The example shows an 11-tooth drive gear. Your index may be a 16- or 18-tooth gear.

Use the appropriate 100G Datalogging Gas Endpoint for your specific meter. See the

Meter Compatibility List on page 2 for more information.

100G Datalogging Installation G uide - Direct Mount 23

Page 4

Chapter 3 Sensus/Rockwell M eter Installati on

3. After the drive gear is aligned with the wriggler gear, the mounting holes will line up.

4. Using the original index mounting screw or a replacement screw (if necessary), place

one 6 - 32 5/8" screw into the index's right mounting screw hole. Attach the screw to

the endpoint housing's right-index mounting post just enough to hold the screw and

the right end of the index in place. Install and tighten the left index mounting screw.

Tighten the right index mounting screw completely.

24 100G Datalogging Installation Guide - Direct Mount

Page 5

Programming the 100G Datalogging Gas Endpoint Assembly

5. Slide the endpoint cover over the index and housing. Verify the cover is installed

correctly. The endpoint label should be clearly visible and easily read.

Programming the 100G Datalogging Gas Endpoint Assembly

The 100G Datalogging Gas Endpoint must be programmed with the FC200SR

handheld computer loaded with EndPoint-Link

5.3 or later. See the Endpoint-Link v5.3 (or later) Endpoint Programming Guide

(TDC-0744) for more complete programming information.

®

or Point-Link Pro® software version

Caution The 100G Datalogging Gas Endpoint must be programmed before use.

Follow the steps in this section to properly program the endpoint.

100G Datalogging Installation G uide - Direct Mount 25

Page 6

Chapter 3 Sensus/Rockwell M eter Installati on

Take note of the index drive rate shown on a lower left dial on the index. The endpoint is

programmed based on the drive rate. Sensus meter index drive rates are typically 2-cubic

feet.

To Program the 100G Datalogging Gas Endpoint

1. Program the index drive rate into the 100G Datalogging Gas Endpoint using the

FC200SR. For all programming and "Check Endpoint" operations, hold the FC200SR

as close to vertical as possible. For best success, keep the FC200SR within 6 feet of

the target endpoint. Verify you have the correct programming mode (Fixed Network

Mode, Mobile/Handheld Mode, or Hard to Read Mobile/Handheld Mode) for your

application. Programming parameters are based on the mode defined by your system

administrator.

During programming, the 100G Datalogging Gas Endpoint is set to the nearest 100

cubic feet; the last two digits (tens and units) are programmed as zeros (0). After

programming is complete, the endpoint assembly will read to the nearest cubic foot.

2. Slowly turn the endpoint's drive wriggler two turns in the direction shown on the

index drive rate. This verifies the endpoint is counting properly after assembly.

Caution Do not turn the drive wriggler faster than one turn per second.

26 100G Datalogging Installation Guide - Direct Mount

Page 7

Attaching the 100G Datalogging Gas Endpoint Assembly to the Sensus Meter

3. Read the 100G Datalogging Gas Endpoint using the FC200SR.

• If the read result is higher than the number programmed in Step 1, the 100G

Datalogging Gas Endpoint is counting correctly.

• If the read result is not higher than the number programmed in Step 1, replace

the 100G Datalogging Gas Endpoint.

Attaching the 100G Datalogging Gas Endpoint Assembly to

the Sensus Meter

After 100G Datalogging Gas Endpoint programming is complete, attach the endpoint

assembly to the Sensus meter.

To Attach the 100G Datalogging Gas Endpoint

1. Gently place the ERT module assembly against the front of the meter at angle.

Endpoint-to-meter mounting screws are installed and tightened in an alternating

fashion. Align the top right mounting screw-hole on the meter with the top right

screw-hole on the endpoint. Insert the top-right cover mounting screw and tighten the

screw enough to hold it in place. Do not completely tighten. Rotate the Endpoint

assembly counterclockwise until the remaining three endpoint screw holes line up

with the holes in the meter. Use the original mounting screws if they were the correct

size and not corroded. If the original screws were discarded, use the correct

replacement screws (see Installation Prerequisites on page 8.)

100G Datalogging Installation G uide - Direct Mount 27

Page 8

Chapter 3 Sensus/Rockwell M eter Installation

Install the remaining three mounting screws and tighten in the pattern shown.

• Insert lower left mounting screw and tighten to snug position.

• Tighten upper right mounting screw to snug position.

• Insert upper left mounting screw and tighten to snug position.

• Insert lower right mounting screw and tighten to snug position.

Each mounting screw should be tightened evenly.

Important Meter manufacturers should torque the mounting screws 15 to 20

inch-pounds.

2. Place a new tamper seal over the two screws with tamper seal cups. Press the new

tamper seals into place using the 11/32-inch nut driver (or similar blunt tool).

3. Complete any necessary paperwork and properly dispose excess installation materials

and scrap from the customer premises.

28 100G Datalogging Installation Guide - Direct Mount

Page 9

Attaching the 100G Datalogging Gas Endpoint Assembly to the Sensus Meter

100G Datalogging Gas Endpoint installation on the Sensus Meter is complete.

100G Datalogging Installation G uide - Direct Mount 29

Page 10

Chapter 3 Sensus/Rockwell M eter Installati on

30 100G Datalogging Installation Guide - Direct Mount

Page 11

C

4

HAPTER

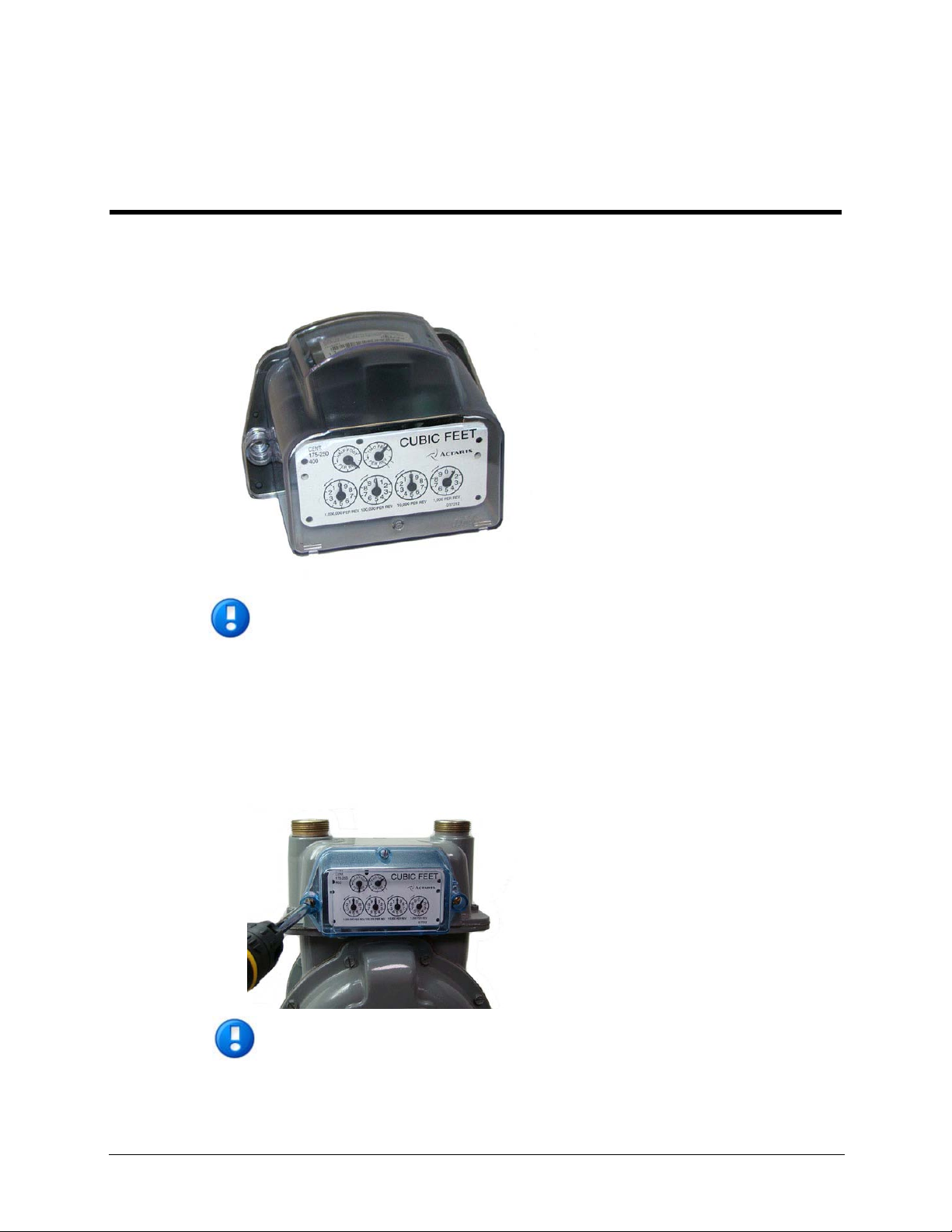

Itron/Actaris Meter Installation

This chapter provides instructions to install the 100G Datalogging Gas Endpoint on an

Itron/Actaris Meter.

Note Itron/Actaris meters are also known as Sprague and Schlumberger meters.

For these instructions, all meters will be referred to as Itron/Actaris meters.

To remove the index from the meter

1. Remove the index cover screws and the index cover from the Itron/Actaris meter.

Examine the mounting screws. If they are 5/8" long and not corroded, keep them to reattach the 100G Datalogging Gas Endpoint assembly. If the screws are not the correct

length or if the screws are corroded, discard.

Note Use the removed index cover as a temporary storage container for

screws. Properly dispose all unused screws, old index covers, gaskets, tamper

seals, and other leftover materials. Do not leave materials on customer premises.

100G Datalogging Installation G uide - Direct Mount 31

Page 12

Chapter 4 Itron/Actaris Meter Installation

2. Loosen the index mounting screws 1/2 to one turn. Slide the index to the left and off

the mounting screws and remove from the meter.

Set the index aside where it will not be damaged or fill with dirt, rain or snow. The

index will be mounted in the endpoint later in this procedure. Verify the index

mounting screws are 1/4" long and not corroded. If the screws are the correct length

and not corroded, retain for later use. If the original screws are discarded, use the

correct replacement screws (see Installation Prerequisites on page 8.)

3. Remove the old gasket, gasket residue, and dirt from the meter (if applicable). The

meter face must be free of gasket residue or dirt before you install the 100G

Datalogging Gas Endpoint.

To assemble the 100G Datalogging Gas Endpoint and index

1. Separate the 100G Datalogging Gas Endpoint housing from the cover by pulling the

cover straight out from the housing. Set the endpoint cover aside where it will not be

damaged or fill with rain, dirt or snow. The cover will be used later in this installation

procedure.

32 100G Datalogging Installation Guide - Direct Mount

Page 13

Attaching the 100G Datalogging Gas Endpoint Assembly to the Sensus Meter

2. Screw the 10 - 24 x 1/4" screws into the index mounting posts two turns. Do not

tighten the screws.

3. Align the index wriggler (1) with the endpoint drive post (2). Carefully slide the index

onto the mounting screws. Verify the 100G Datalogging Gas Endpoint's housing drive

post makes positive engagement with the index wriggler. Hold the index in place and

tighten the index mounting screws.

Caution Indexes have varying drive mechanism styles. The diagrams show a bartype (left) and "Scottish Yoke" type (right). Failure to align the endpoint wriggler

with the index drive post can cause binding and lead to poor registration or meter

failure. To verify proper engagement of the index to the endpoint housing, spin the

wriggler one clockwise rotation, then one-counterclockwise rotation. Do not spin

more than one complete rotation. The wriggler should spin freely, with little or no

resistance.

100G Datalogging Installation G uide - Direct Mount 33

Page 14

Chapter 4 Itron/Actaris Meter Installation

4. Slide the endpoint cover over the index and housing. Verify the cover is installed

correctly. The endpoint label should be clearly visible and easily read.

Programming the 100G Datalogging Gas Endpoint Assembly

The 100G Datalogging Gas Endpoint must be programmed with the FC200SR

handheld computer loaded with EndPoint-Link

5.3 or later. See the Endpoint-Link v5.3 (or later) Endpoint Programming Guide

(TDC-0744) for more complete programming information.

®

or Point-Link Pro® software version

Caution The 100G Datalogging Gas Endpoint must be programmed before use.

Follow the steps in this section to properly program the endpoint.

34 100G Datalogging Installation Guide - Direct Mount

Page 15

Programming the 100G Datalogging Gas Endpoint Assembly

Take note of the index drive rate shown on the drive dial on the index. The endpoint is

programmed based on the drive rate. Itron/Actaris meter index drive rates are typically 2cubic feet.

To program the 100G Datalogging Gas Endpoint

1. Program the index drive rate into the 100G Datalogging Gas Endpoint using the

FC200SR. For all programming and "Check Endpoint" operations, hold the FC200SR

as close to vertical as possible. For best success, keep the FC200SR within 6 feet of

the target endpoint. Verify you have the correct programming mode (Fixed Network

Mode, Mobile/Handheld Mode, or Hard to Read Mobile/Handheld Mode) for your

application. Programming parameters are based on the mode defined by your system

administrator.

During programming, the 100G Datalogging Gas Endpoint is set to the nearest 100

cubic feet; the last two digits (tens and units) are programmed as zeros (0). After

programming is complete, the endpoint assembly will read to the nearest cubic foot.

2. Slowly turn the endpoint's drive wriggler two turns in the direction shown on the

index drive rate. This verifies the endpoint is counting properly after assembly.

Caution Do not turn the drive wriggler faster than one turn per second.

100G Datalogging Installation G uide - Direct Mount 35

Page 16

Chapter 4 Itron/Actaris Meter Installation

3. Read the 100G Datalogging Gas Endpoint using the FC200SR.

• If the read result is higher than the number programmed in Step 1, the 100G

Datalogging Gas Endpoint is counting correctly.

• If the read result is not higher than the number programmed in Step 1, replace

the 100G Datalogging Gas Endpoint.

Attaching the 100G Datalogging Gas Endpoint Assembly to

the Itron/Actaris Meter

After the 100G Datalogging Gas Endpoint has been programmed, attach it to the

Itron/Actaris meter.

To attach the 100G Datalogging Gas Endpoint

1. Align the white wriggler (1) so one of its four drive slots lines up with the meter's

drive dog (2).

2. Carefully place the 100G Datalogging Gas Endpoint on the meter.

Warning Failure to correctly align the meter drive post and endpoint drive slot

can cause binding and lead to poor registration or meter failure. If there is a gap

between the endpoint gasket and the meter, it may be the drive slot of the

endpoint assembly's wriggler is not correctly aligned with the meter drive slot.

Remove the 100G Datalogging Gas Endpoint assembly and repeat the

alignment procedure. You must establish proper engagement of the meter drive

dog within the endpoint wriggler slot.

36 100G Datalogging Installation Guide - Direct Mount

Page 17

Attaching the 100G Datalogging Gas Endpoi

nt Assembly to the Itron/Actaris Meter

3. Endpoint to meter mounting screws must be installed in an alternating fashion. Use

the original mounting screws if they were the correct size and not corroded. If the

original screws were discarded, use the correct replacement screws (see Installation

Prerequisites on page 8.) Insert the right index cover mounting screw and tighten the

screw enough to hold it in place. Do not completely tighten. Install the left index

cover mounting screw and tighten to a snug fit. Finish by tightening the right

mounting screw to a snug fit. Each mounting screw must be tightened evenly.

Important Meter manufacturers should torque the mounting screws 15 to 20

inch-pounds.

1. Place a new tamper seal over the two screws in the tamper seal cups. Press the new

tamper seals into place using the 11/32-inch nut driver (or similar blunt tool).

2. Complete any necessary paperwork and properly dispose excess installation materials

and scrap from the customer premises.

100G Datalogging Installation G uide - Direct Mount 37

Page 18

Chapter 4 Itron/Actaris Meter Installation

100G Datalogging Gas Endpoint installation on the Itron/Actaris Meter is complete.

38 100G Datalogging Installation Guide - Direct Mount

Page 19

Attaching the 100G Datalogging Gas Endpoint Assembly to the Itron/Actaris Meter

Attaching the 100G Datalogging Gas Endpoint Assembly to

Flat-faced Itron/Actaris Meters

100G Datalogging Gas Endpoint installation on a flat-faced Itron/Actaris meter requires the

Itron Adapter Shim Kit (CFG-0015-001).

Itron Adapte r Shim Kit (CFG-0015-001)

1 Adapter Shim Plate

2 Clear Cover Mounting Screws

3 Drive Dog

4 Adapter Plate Mounting Screws

To Attach the 100G Datalogging Gas Endpoint Assembly

1. Verify the kit includes the materials listed in the Itron Adapter Shim Kit Table.

100G Datalogging Installation G uide - Direct Mount 39

Page 20

Chapter 4 Itron/Actaris Meter Installation

Warning The Adapter Shim Plate must fit flush against the meter face. Some

older Schlumberger/Sprague meters are not compatible with the adapter plate.

The following examples illustrate the potential obstruction (problem) areas

between the adapter plate and meter. Failure to mount adapter plate flush on

the front of a meter could result in a binding condition and lead to poor

registration or meter failure.

2. Remove the drive dog from the flat-faced Itron/Actaris meter. Replace it with the

extended drive dog included in the kit. Hand-tighten to snug.

Warning The meter drive dog shaft is surrounded by a gasket. A gas leak could

result if the gasket is damaged. Do not use a tool to install or tighten the new drive

dog. Hand-tighten only.

40 100G Datalogging Installation Guide - Direct Mount

Page 21

Attaching the 100G Datalogging Gas Endpoint Assembly to the Itron/Actaris Meter

s Endpoint and

3. Attach the Adapter Shim Plate to the meter with the gasket against the meter face.

Secure with the two adapter plate mounting screws in an alternating fashion.

• Insert the right adapter plate screw and tighten the screw enough to hold it in

place.

• Install the left mounting screw and tighten to a snug fit.

• Finish by tightening the right mounting screw to a snug fit.

Each adapter plate screw must be tightened evenly.

Note 100G Datalogging Gas Endpoints must be assembled and programmed

following the instructions in

To Assembe the 100G Datalogging Ga

Index on page 32 and Programming the 100G Datalogging Gas Endpoint

Assembly on page 34 prior to installation on the meter.

4. Align the white wriggler (1) so one of its four drive slots lines up with the meter's

drive dog (2).

5. Carefully place the 100G Datalogging Gas Endpoint assembly on the meter.

Warning Failure to correctly align the meter drive post and endpoint drive slot

can cause binding and lead to poor registration or meter failure. If there is a gap

between the endpoint gasket and the meter, remove the 100G Datalogging Gas

Endpoint assembly and repeat the alignment procedure. You must engage the

meter drive dog in the endpoint wriggler slot.

6. Secure the endpoint to the meter by installing mounting screws in an alternating

fashion. Use the original index cover mounting screws if they were the correct size

and not corroded. If the original screws were discarded, use the correct replacement

screws (see Installation Prerequisites on page 8.)

• Insert the right index cover mounting screw and tighten the screw enough to

hold it in place. Do not completely tighten.

• Install the left index cover mounting screw and tighten to a snug fit.

• Finish by tightening the right mounting screw to a snug fit.

Each mounting screw must be tightened evenly.

Important Meter manufacturers should torque the mounting screws 15 to 20

inch-pounds.

100G Datalogging Installation G uide - Direct Mount 41

Page 22

Chapter 4 Itron/Actaris Meter Installation

1. Place a new tamper seal over the two screws with tamper seal cups. Press the new

tamper seals into place using the 11/32-inch nut driver or similar blunt tool.

2. Complete any necessary paperwork and properly dispose excess installation materials

and scrap from the customer premises.

100G Datalogging Gas Endpoint installation on the Itron/Actaris Meter is complete.

42 100G Datalogging Installation Guide - Direct Mount

Page 23

Attaching the 100G Datalogging Gas Endpoint Assembly to the Itron/Actaris Meter

Attaching the 100G Datalogging Gas Endpoint to

Securing Brass Meter Tags to Flat-faced Meters

Some older Sprague meters have metal index covers with brass meter tags attached (by

screws or rivets) to metal index covers.

Typically, brass meter tags have mounting (screw/rivet) holes on each end of the tag.

Note If the brass meter tag will be secured to the meter utilizing the endpoint-to-

meter mounting hole, it must be attached during the endpoint installation

procedure described in Step 1 of

the Itron/Actaris Meter on page 36.

100G Datalogging Installation G uide - Direct Mount 43

Page 24

Chapter 4 Itron/Actaris Meter Installation

To Secure Brass Meter Tags to Flat-faced Meters

1. After the metal index cover is removed from the meter, carefully remove the brass

meter tag from the meter index cover. Do not damage the meter tag mounting holes.

The Itron Adapter Shim Plate was designed with a tag mounting hole in the lower

right corner. After the 100G Datalogging Gas Endpoint assembly is attached to the

meter, secure the meter tag to the Shim Plate meter tag mounting hole with a utilityapproved wire security seal. Itron acceptable meter tag mounting methods are shown

in the photos.

44 100G Datalogging Installation Guide - Direct Mount

Page 25

Attaching the 100G Datalogging Gas Endpoint Assembly to the Itron/Actaris Meter

2. If the meter tag mounting holes were damaged during removal so a wire security seal

cannot be used, remove the 100G Datalogging Gas Endpoint index cover and place

the meter tag inside the endpoint assembly to maintain meter security. (See To

Assemble the 100G Datalogging Gas Endpoint on page 32.)

Warning Placing the brass meter tag inside the 100G Datalogging Gas

Endpoint assembly is not the preferred method of securing the tag to the meter.

Use this method only if the brass meter tag mounting holes are damaged and

cannot be used for mounting. This method does not secure the tag inside the

endpoint. The brass meter tag may move out of view if the meter is bumped or

jarred.

100G Datalogging Installation G uide - Direct Mount 45

Page 26

Chapter 4 Itron/Actaris Meter Installation

46 100G Datalogging Installation Guide - Direct Mount

Page 27

C

5

HAPTER

National/Lancaster Meter Installation

This chapter provides instructions to install the 100G Datalogging Gas Endpoint on 175 250 CFH National/Lancaster meters.

To Remove the Index from the Meter

1. Remove any tamper seals from the index cover screws. Remove the index cover

screws and the index cover from the meter. Discard the index cover mounting screws

and index cover. The 100G Datalogging Gas Endpoint includes new, different-size

endpoint mounting screws

Note You may use the removed index cover as a temporary storage container for

screws. Properly dispose all unused screws, old index covers, gaskets, tamper

seals, and other leftover materials. Do not leave materials on customer premises.

100G Datalogging Installation G uide - Direct Mount 47

Page 28

Chapter 5 National/Lancaster Meter Installation

2. Unscrew one index mounting screw completely. Hold one hand under the index to

catch the screw. While removing the other mounting screw, pull the index away from

the meter to keep the index backplate against the back of the screw. Remove the screw

completely after the index is free of the meter.

Set the index aside where it will not be damaged or fill with dirt, rain or snow. The

index will be mounted in the endpoint later in this procedure. Discard the index

mounting screws. The 100G Datalogging Gas Endpoint for National/Lancaster meters

includes new, different-sized index mounting screws (see Installation Prerequisites on

page 8 for screw information).

3. Remove the old gasket, gasket residue, and dirt from the meter (if applicable). The

meter face must be free of gasket residue or dirt before you install the 100G

Datalogging Gas Endpoint assembly.

48 100G Datalogging Installation Guide - Direct Mount

Page 29

Attaching the 100

G Datalogging Gas Endpoint Assembly to the Itron/Actaris Meter

To Assemble the 100G Datalogging Gas Endpoint and Index

1. Separate the 100G Datalogging Gas Endpoint housing from the cover by pulling the

cover straight out from the housing.

2. Set the endpoint cover aside where it will not be damaged or fill with rain, dirt or

snow. The cover will be used later in this installation procedure.

100G Datalogging Installation G uide - Direct Mount 49

Page 30

Chapter 5 National/Lancaster Meter Installation

to mount the index on the

Note National/Lancaster meter indexes are available in different models:

Some National/Lancaster Meter indexes have index legs

meter or endpoint. Some indexes have both legs and index mounting holes and

some have just mounting holes. Mounting methods are dependent on the index.

Index types require different mounting screws to attach the index to the 100G

Datalogging Gas Endpoint housing (see

Indexes with legs must be mounted to the endpoint housing mounting posts.

Indexes with mounting holes must be attached to the endpoint housing's bracket

mounting posts.

Installation Prerequisites on page 8).

1 Bracket mounting posts (indexes with legs)

2 Housing mounting posts (indexes without legs)

50 100G Datalogging Installation Guide - Direct Mount

Page 31

Attaching the 100G Datalogging Gas Endpoint Assembly to the Itron/Actaris Meter

If your index has legs with mounting screw slots, skip steps 3 and 4. If your index has

mounting screw holes in the index back plate (no legs), perform steps 3 and 4, and

skip steps 5 and 6.

3. For indexes with mounting screw holes in the index back plate (no legs), use

replacement index mounting screws (SCR-0037-001 - see Installation Prerequisites on

page 8). Place one screw into the index's right-hand mounting screw hole.

Note National/Lancaster index mounting screws are thread-forming screws and

may require more torque.

4. Attach the screw to the endpoint housing's right-index mounting post just enough to

hold the screw and the right end of the index in place.

5. For indexes with legs (mounting slots), screw one 6 - 19 x 3/16" screw (SCR-0015-

001 - see Installation Prerequisites on page 8 for screw information) into the right

index mounting post one or two turns. Do not completely tighten the screw.

6. Place the right index mounting screw slot under the screw head. Do not completely

tighten the screw.

7. Carefully slide the index drive post into the endpoint wriggler. Verify positive

engagement of the index wriggler to the endpoint drive dog. (The following photos

show three types of index/wrigglers with positive engagement.)

Caution Verify the index drive slot engages with the 100G Datalogging Gas

Endpoint wriggler. Failure to mate the endpoint wriggler with the index drive post

(or slot) can cause binding and lead to poor registration or meter failure.

100G Datalogging Installation G uide - Direct Mount 51

Page 32

Chapter 5 National/Lancaster Meter Installation

8. Install and tighten the left index mounting screw (for indexes with either mounting

screw slots or holes). Tighten the right index mounting screw. Each index mounting

screw must be tightened evenly.

9. Slide the endpoint cover over the index and housing. Verify the cover is installed

correctly. The endpoint label should be clearly visible and easily read.

52 100G Datalogging Installation Guide - Direct Mount

Page 33

Programming the 100G Datalogging Gas Endpoint Assembly

Programming the 100G Datalogging Gas Endpoint Assembly

The 100G Datalogging Gas Endpoint must be programmed with the FC200SR

handheld computer loaded with EndPoint-Link

5.3 or later. See the Endpoint-Link v5.3 (or later) Endpoint Programming Guide

(TDC-0744) for more complete programming information.

®

or Point-Link Pro® software version

Caution The 100G Datalogging Gas Endpoint must be programmed before use.

Follow the steps in this section to properly program the endpoint.

Take note of the index drive rate shown on a top right dial on the index. The endpoint is

programmed based on the drive rate. National/Lancaster meter index drive rates are

typically 2-cubic feet.

100G Datalogging Installation G uide - Direct Mount 53

Page 34

Chapter 5 National/Lancaster Meter Installation

To Program the 100G Datalogging Gas Endpoint

1. Program the index drive rate into the 100G Datalogging Gas Endpoint using the

FC200SR. For all programming and "Check Endpoint" operations, hold the FC200SR

as close to vertical as possible. For best success, keep the FC200SR within 6 feet of

the target endpoint. Verify you have the correct programming mode (Fixed Network

Mode, Mobile/Handheld Mode, or Hard to Read Mobile/Handheld Mode) for your

application. Programming parameters are based on the mode defined by your system

administrator.

During programming, the 100G Datalogging Gas Endpoint is set to the nearest 100

cubic feet; the last two digits (tens and units) are programmed as zeros (0). After

programming is complete, the endpoint assembly will read to the nearest cubic foot.

2. Slowly turn the endpoint's drive wriggler two turns in the direction shown on the

index drive rate. This verifies the endpoint is counting properly after assembly.

Caution Do not turn the drive wriggler faster than one turn per second.

3. Read the 100G Datalogging Gas Endpoint using the FC200SR.

• If the read result is higher than the number programmed in Step 1, the 100G

Datalogging Gas Endpoint is counting correctly.

• If the read result is not higher than the number programmed in Step 1, replace

the 100G Datalogging Gas Endpoint.

54 100G Datalogging Installation Guide - Direct Mount

Page 35

Attaching the 100G Datalogging Gas Endpoint Assembly to the National/Lancaster Meter

Attaching the 100G Datalogging Gas Endpoint Assembly to

the National/Lancaster Meter

After the 100G Datalogging Gas Endpoint has been programmed, attach it to the

National/Lancaster meter.

To Attach the 100G Datalogging Gas Endpoint

1. Align the white wriggler (1) so one of its four drive slots lines up with the meter's

drive dog (2).

2. Carefully place the 100G Datalogging Gas Endpoint on the meter.

Warning Failure to correctly align the meter drive post and endpoint drive slot

can cause binding and lead to poor registration or meter failure. If there is a gap

between the endpoint gasket and the meter, it may be the drive slot of the

endpoint assembly's wriggler is not correctly aligned with the meter drive slot.

Remove the 100G Datalogging Gas Endpoint assembly and repeat the

alignment procedure. You must engage endpoint wriggler in the meter drive

dog.

3. Install endpoint to meter mounting screws in an alternating fashion. 100G

Datalogging Gas Endpoints for National/Lancaster meters come with new, differentsize endpoint mounting screws (SCR-0014-004 - see Installation Prerequisites on page

8 for screw information.) Insert the right index cover mounting screw and tighten the

screw enough to hold it in place. Do not completely tighten. Install the left index

cover mounting screw and tighten to a snug fit. Finish by tightening the right

mounting screw to a snug fit. Each endpoint mounting screw must be tightened

evenly.

Important Meter manufacturers should torque the mounting screws 15 to 20

inch-pounds.

100G Datalogging Installation G uide - Direct Mount 55

Page 36

Chapter 5 National/Lancaster Meter Installation

4. Place new tamper seals over the screws. Press the new tamper seals into place using

the 11/32-inch nut driver or similar blunt tool.

5. Complete any necessary paperwork and properly dispose excess installation materials

and scrap from the customer premises.

100G Datalogging Gas Endpoint installation on the National/Lancaster Meter is complete.

56 100G Datalogging Installation Guide - Direct Mount

Loading...

Loading...