Natural Gas Solutions

100G Installation Guide

Revision A

Identification

100G Installation Guide -- DRAFT

Part number: PUB-0200-001 Revision A 10/06

ERT Part Numbers: ERG-aaaa-bbb, CCCC-ddd, etc.

Copyright

© 2006 Itron, Inc. All rights reserved.

Your company has the right to reproduce this contract document, provided that such reproduction shall be subject to the same use and disclosure restrictions contained in the

Confidentiality and Non-Disclosure paragraphs in the Sales Contract.

Applicable Patents

U.S. Patent Numbers: XXXXXXXXXXXXXXXX XXXXXXXXXXXXXXXX XXXXXXXXXXXXXXXX????

Canadian Patent Numbers: XXXXXXXXXXX XXXXXXXXXX XXXXXXXXX?????????

Transportation Classification

Itron classifies and ships model 100G ERT modules as a non-hazardous material. The proper shipping name is Lithium Batteries contain in Equipmen t, Class 9, UN3091, Packing

Group II

.

The Federal Aviation Administration prohibits operating transmitters and receivers on all commercial aircraft. When powered, the 100G ERT module is considered an operating

transmitter and receiver and cannot be shipped by air.

Compliance Statement

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference in a residential installation. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance

with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation.

If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct

the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio or TV technician for help.

This device complies with Subpart C of Part 15 of FCC Rules. Operation of this device is subject to the following two conditions:

• This device may not cause harmful interference.

• This device must accept any interference that may cause undesirable operation.

This device must be permanently mounted such that it retains a distance of 20 centimeters (7.9 inches) from all persons in order to comply with FCC RF exposure levels.

Modification and Repairs

To ensure FCC compliance and system performance, this device and antenna shall not be changed or modified without the expressed approval of Itron. Any unauthorized modification

will void the user’s authority to operate the equipment.

Meter Installation/Removal

In the event of malfunction, all repairs should be performed by Itron. It is the responsibility of users requiring service to report the need for service to Itron.

Related Documents

EndPoint-Link ERT Programming Guide (TDC-tbd-tbd)

Trademark Notice

ERT and Itron are both registered trademarks of Itron, Inc. All other product names and logos in this documentation are used for identification purposes only and may be trademarks or

registered trademarks of their respective companies.

Suggestions

If you have comments or suggestions on how we may improve this documentation, send them to TechnicalCommunicationsManager@itron.com.

If you have questions or comments about this application, contact Itron Technical Support:

Itron, Inc.

• Mail: Itron, Inc. 2401 North State Street, Waseca, MN 56093

• E-mail: support@itron.com

• Phone: 1 800 392 3185; Fax: 507 837 4451

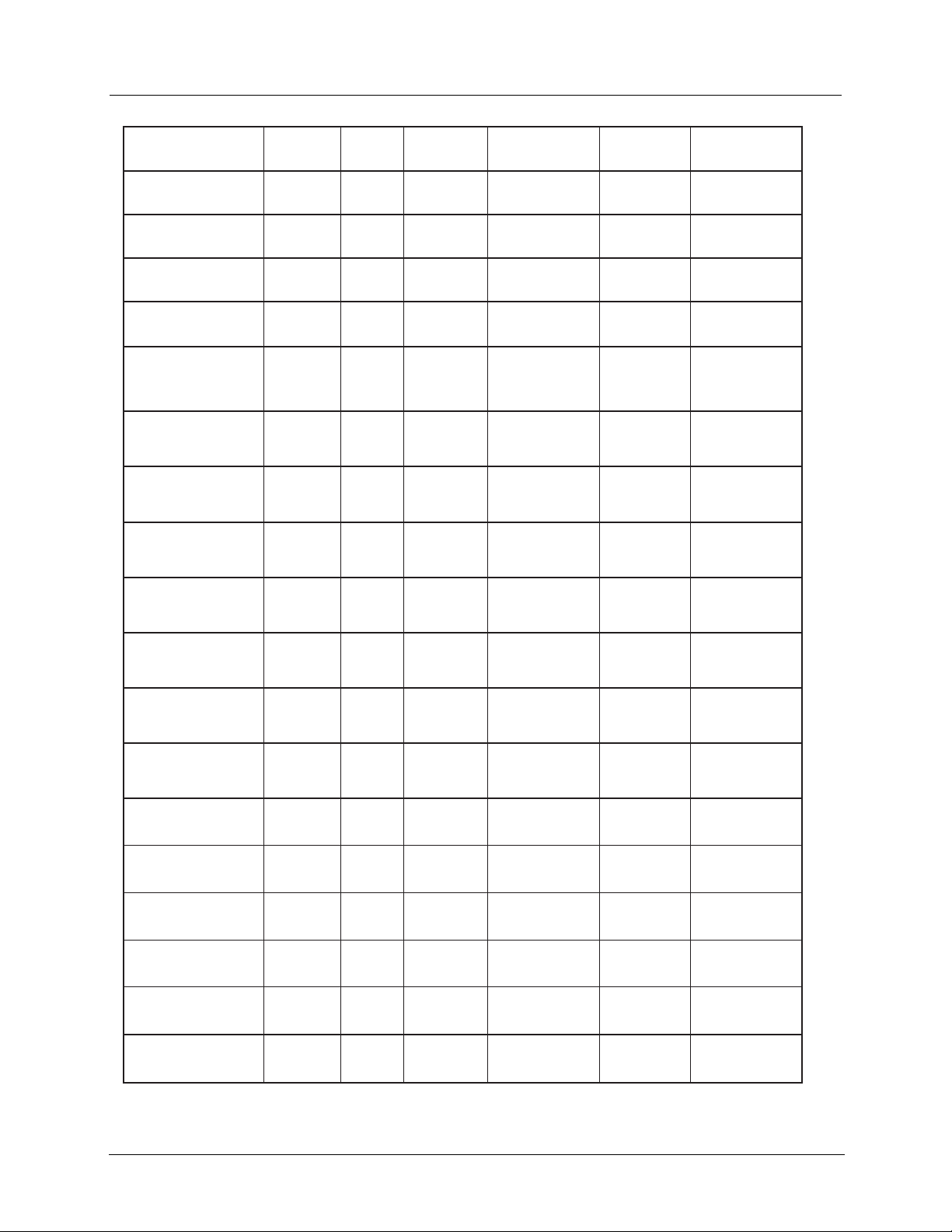

Table of Contents

Chapter 1 Getting Started...........................................................................................1

Transmission Modes...........................................................................................................................1

Specifications ......................................................................................................................................1

Meter Compatibility List.......................................................................................................................2

Chapter 2 American Meter Installation .......................................................................5

Installation Prerequisites.....................................................................................................................5

Materials Supplied By Itron.......................................................................................................5

Materials Supplied By You........................................................................................................5

Replacement Screws......................................................................................................6

Preinstallation Preparations......................................................................................................6

Installing the 100G on an American Meter..........................................................................................6

Remove the Existing Index.......................................................................................................6

Assemble the ERT Module.......................................................................................................9

Program the ERT Module.......................................................................................................13

Attach the ERT Module to the Meter ......................................................................................15

Chapter 3 Sensus Meter Installation.........................................................................19

Introduction........................................................................................................................................19

Installation Prerequisites...................................................................................................................19

Materials Supplied By Itron.....................................................................................................19

Materials Supplied by You......................................................................................................19

Replacement Screws....................................................................................................19

Preinstallation Preparations ..............................................................................................................20

Installing the 100G on a Sensus Meter.............................................................................................20

Remove the Existing Index.....................................................................................................20

Assemble the ERT Module.....................................................................................................22

Program the ERT....................................................................................................................24

Attach the ERT to the Meter ...................................................................................................25

100G Installation Guide iii

Table of Contents

iv 100G Installation Guide

C HAPTER 1

Getting Started

The 100G is Itron's latest high-powered gas encoder-receiver-transmitter (ERT) module.

ERTs are meter-installed devices that transmit meter data using radio communications. That

information may be received by a reading device that is within transmission distance,

meaning that multiple devices may receive data from a single endpoint. Itron's 100G ERT is

a high-powered device with a wide transmission distance.

This installation guide shows you how to install the 100G ERT module on meters from a

variety of manufacturers. To ensure you have a meter that is compatible with the 100G ERT

module, please see the

Transmission Modes

Once installed, the 100G ERT module has two standard available transmission modes:

Meter Compatibility List on page 2.

Fixed Network Mode In this mode, a 100G ERT module transmits a high-powered

•

RF message every 60 seconds.

•

Mobile and HandHeld Mode In this mode, a 100G ERT module transmits a

medium-powered RF message every 15 seconds.

An FCC license is not required to read 100G ERT modules.

Specifications

The functional and operational specifications for the 100G are listed below.

Functional Specifications Description

Power Source

Tamper Detection

FCC Compliance

Industry Canada Compliance

Measurement Canada Approval

Intrinsically Safe per

Product Identification

Contstruction Materials

"A" cell lithium battery

Tilt tamper and magnetic tamper

Part 15 certified

RSS-210 certified

Yes

Factory Mutual and UL Class I, Division 1, Groups C

and D

Numeric and barcoded ERT module type and serial

number

Gray polycarbonate back plate with Santoprene®

gasket; clear polycarbonate front cover; encapsulated

electronics

100G Installation Guide 1

Chapter 1 Getting Started

Operational Specifications Description

Operating Temperatures

Operating Humidity

Program Frequency

Transmit Frequency

Data Integrity

-40° to 158° F (-40° to +70° C)

5 to 95percent relative humidity

908 MHz

Spread spectrum 908 to 924 MHz ISM band

Verified in every data message

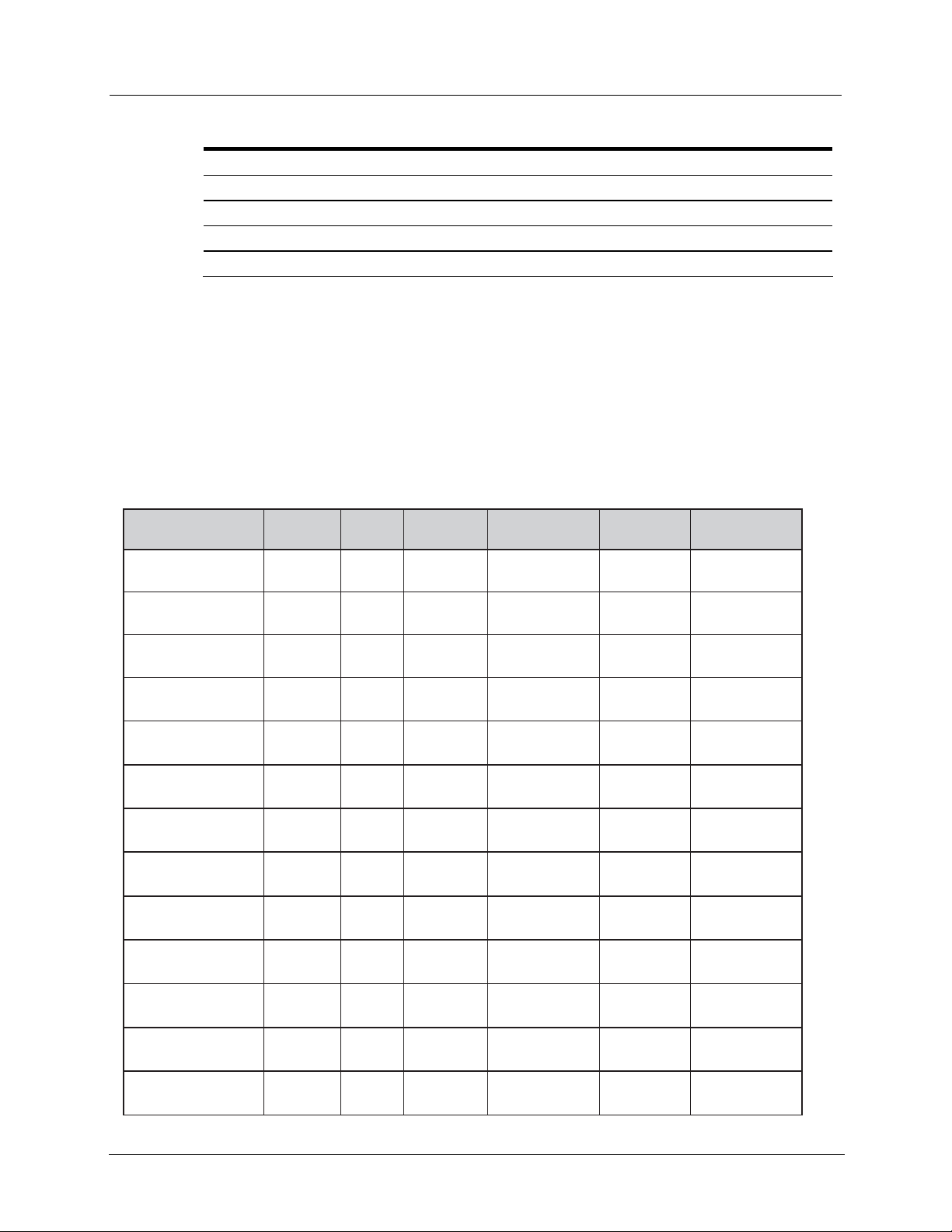

Meter Compatibility List

The following meters are compatible with the 100G. Due to continuous research, product

improvements, and enhancements, Itron reserves the right to change this list at any time.

To ensure you have the latest Meter Compatibility list available, contact your Itron

representative.

Mfgr. Model Desc. Class Comments ERT Type ERT Part No.

American/ Canadian W75AL

American/ Canadian AL-175

American/ Canadian AC-175

American/ Canadian AT-175

American/ Canadian ALC-175

Residential Aluminum case

Meters Only

Residential Aluminum case

meters only

Residential Aluminum case

meters only

Residential Aluminum case

meters only

Residential Aluminum case

meters only

100G ERG-5000-001

100G ERG-5000-001

100G ERG-5000-001

100G ERG-5000-001

100G ERG-5000-001

American/ Canadian AT-210

American/ Canadian AL-225 Canada

American/ Canadian AL-250

American/ Canadian AR-250

American/ Canadian AC-250

American/ Canadian AT-250

American/ Canadian AM-250

American/ Canadian AL-310

only

Residential Aluminum case

meters only

Residential Aluminum case

meters only

Residential Aluminum case

meters only

Residential Aluminum case

meters only

Residential Aluminum case

meters only

Residential Aluminum case

meters only

Residential Aluminum case

meters only

Residential Aluminum case

meters only

100G ERG-5000-001

100G ERG-5000-001

100G ERG-5000-001

100G ERG-5000-001

100G ERG-5000-001

100G ERG-5000-001

100G ERG-5000-001

100G ERG-5000-001

2 100G Installation Guide

Meter Compatibility List

American/ Canadian AL-350

Residential Aluminum case

meters only

American/ Canadian AT-350

Residential Aluminum case

meters only

American/ Canadian AL-425

Residential Aluminum case

meters only

American/ Canadian AC-630

Residential Aluminum case

meters only

American/ Canadian 5B 225 Residential Aluminum case

Sensus/Invensys/

Equimeter/ Rockwell

R-175 11 Tooth Residential Compatible with 2

foot drive index; 1

foot drive has 24

teeth

Sensus/Invensys/

R-200 11 Tooth Residential

Equimeter/ Rockwell

Sensus/Invensys/

RT-200 11 Tooth Residential

Equimeter/ Rockwell

Sensus/Invensys/

RT-230 11 Tooth Residential

Equimeter/ Rockwell

Sensus/Invensys/

R-275 11 Tooth Residential

Equimeter/ Rockwell

100G ERG-5000-001

100G ERG-5000-001

100G ERG-5000-001

100G ERG-5000-001

100G ERG-5000-001

100G ERG-5000-002

100G ERG-5000-002

100G ERG-5000-002

100G ERG-5000-002

100G ERG-5000-002

Sensus/Invensys/

Equimeter/ Rockwell

Sensus/Invensys/

Equimeter/ Rockwell

Sensus/Invensys/

Equimeter/ Rockwell

Sensus/Invensys/

Equimeter/ Rockwell

Sensus/Invensys/

Equimeter/ Rockwell

Sensus/Invensys/

Equimeter/ Rockwell

Sensus/Invensys/

Equimeter/ Rockwell

Sensus/Invensys/

Equimeter/ Rockwell

Sensus/Invensys/

Equimeter/ Rockwell

RT-275 11 Tooth Residential

R-315 11 Tooth Residential

250 11 Tooth Residential

310 11 Tooth Residential

S-110 11 Tooth Residential

S-200 11 Tooth Residential

175-S 11 Tooth Residential

RT-100 18 Tooth Residential

S-190 11 Tooth Residential

100G ERG-5000-002

100G ERG-5000-002

100G ERG-5000-002

100G ERG-5000-002

100G ERG-5000-002

100G ERG-5000-002

100G ERG-5000-002

100G ERG-5000-004

100G ERG-5000-002

100G Installation Guide 3

Chapter 1 Getting Started

Sensus/

Invensys/ Equimeter/

Rockwell

Sensus/Invensys/

Equimeter/ Rockwell

Sensus/Invensys/

Equimeter/ Rockwell

Sensus/Invensys/

Equimeter/ Rockwell

Sensus/Invensys/

Equimeter/ Rockwell

Sensus/Invensys/

Equimeter/ Rockwell

Sensus/Invensys/

Equimeter/ Rockwell

S-120 11 Tooth Residential

T-120 11 Tooth Residential

T-110 11 Tooth Residential

R-415 18 Tooth Residential

RT-360 18 Tooth Residential

MR8

(R-275

Metric)

MR12

(R-415

Metric)

16 Tooth Residential

16 Tooth Residential

100G ERG-5000-002

100G ERG-5000-002

100G ERG-5000-002

100G ERG-5000-004

100G ERG-5000-004

100G ERG-5000-003

100G ERG-5000-003

4 100G Installation Guide

C HAPTER 2

American Meter Installation

This chapter shows you how to install a 100G gas ERT module on an American meter.

Before installing the 100G ERT module, verify that you have:

• A compatible meter. See the the

information.

• A compatible index. Itron 100G gas ERT modules can be used with standard dial and

direct read (odometer) indexes on American Meters.

• The list of materials defined under

Installation Prerequisites

The following items are required to install Itron's 100G gas ERT.

Materials Supplied By Itron

The following items are supplied by Itron.

Materials Supplied By You

• 100G gas ERT modules

• Tamper plugs

Meter Compatibility List on page 2 for more

Installation Prerequisites on page 5.

You must supply the following items to successfully install the 100G gas ERT on the

American Meters listed in the Meter Compatibility above.

• Small and medium flat-blade screwdrivers Used to remove and tighten index and

index-cover screws.

• Side-cutting plier/wire snips Used for cutting wire seals, if necessary.

Small putty knife Used to remove all traces of old gaskets from the meter.

•

Meter seals, wire seals, and seal press Used to secure the meter from tampering, if

•

necessary.

• 1

1/32-inch nut driver or other blunt tool Used to securely seat new tamper plugs

over screw holes.

FC200SR unit with EndPoint-Link or EndPoint-Link Pro software Used to

•

program and check ERT assembly.

•

Replacement screws Used to mount ERT assembly to meter and index to ERT

assembly backlates; see

100G Installation Guide 5

Replacement Screws on page 6 for more information).

Chapter 2 American Meter Installation

Replacement Screws

Replacement screws used in this procedure must be slotted, zinc-plated, steel machine

screws. Sizing options are shown below.

• Use 1/4 - 20 x 5/8-inch slotted, Fillister head screws for mounting 100G ERT module

assemblies on meters.

• Use 8 - 32 x 3/16-inch slotted, round head screws for mounting indexes on 100G ERT

module backplates.

Preinstallation Preparations

Before installing the 100G gas ERT module on a meter, verify that:

• All ERTs are type 100G modules for American Meter Company gas meters.

• The model numbers of all meters on which the 100G modules will be installed are

included in the

Meter Compatibility see "Meter Compatibility List" on page 2 list.

Installing the 100G on an American Meter

There are four major steps to installing the 100G gas ERT on an American Meter:

• Remove the Existing Index

• Assemble the ERT Module

• Program the ERT Module

• Attach the ERT Module to the Meter

These procedures are described in the following sections.

NOTE Be sure to properly dispose of all unused screws, old index covers,

gaskets, and other left-over materials. Do not leave any materials on customer

premises.

Remove the Existing Index

The first major step when installing a 100G gas ERT on an American meter is to remove the

existing index from the meter.

To Remove the Existing Index

1. Remove any tamper seals from the meter.

6 100G Installation Guide

2. Detach the index cover from the meter by removing the four screws holding it in

place.

3. Examine the index cover screws you just removed. Verify that they are 5/8-inch long

and are not corroded.

• If the screws are 5/8-inch long, and are not corroded, keep them for later use.

• If the screws are an incorrect length or are corroded, dispose of them properly.

Use 1/4 - 20 x 5/8-inch screws as described in

Replacement Screws on page 6

instead.

TIP You can use the index cover you just removed as a temporary storage

location for screws.

4. Unscrew one index mounting screw completely.

Hold one hand beneath the index to catch the screw when it falls out of the index

assembly. If it does not fall out by itself, be sure to remove it.

5. Unscrew the other index mounting screw.

100G Installation Guide 7

Chapter 2 American Meter Installation

While removing this screw, pull the index away from the meter to keep its backplate

(1) against the back of the screwhead (2). This prevents the screw from falling out

prematurely.

6. Remove the screw from the index once it is completely free of its hole.

7. Set the index aside for the moment. Place it where it will not be damaged; get filled

with dirt, rain, or snow; or fall to the ground or floor. The index will be used later in

this procedure.

1

2

8. Examine the index screws you just removed. Verify that they are 3/16-inch long and

are not corroded.

• If the screws are 3/16-inch long and are not corroded, keep them for later use.

• If the screws are an incorrect length or are corroded, dispose of them properly.

Use 8 - 32 x 3/16-inch screws as described in

Replacement Screws on page 6

instead.

9. Use a putty knife or similar object to completely remove the old index gasket from the

meter (if applicable). All traces of the gasket must be removed before athe ERT can be

installed.

8 100G Installation Guide

Assemble the ERT Module

When installing a 100G gas ERT, the next major step is to create the ERT module assembly

by combining the ERT backplate and cover with the meter index. Follow the procedure

below to do so.

To Assemble the ERT Module

1. Obtain a new 100G ERT and index cover.

2. Separate the ERT module backplate from the cover.

3. Set the new ERT index cover aside for the moment. Place it where it will not be

damaged; get filled with dirt, rain, or snow; or fall to the ground or floor. The ERT

index cover will be used later in this procedure.

IMPORTANT Before continuing with the installation, note the following

information about American Meter idexes:

• Index wrigglers on one-foot meters have drive slots.

100G Installation Guide 9

Chapter 2 American Meter Installation

• Index wrigglers on two-foot meters have drive posts.

• An index may have mounting screw holes.

• An index may have mounting screw slots.

If the index has mounting screw

If the index has mounting screw

slots, skip steps 4 and 5 below. Continue with step 6.

holes, perform steps 4 and 5 below, and then skip

steps 6 and 7.

10 100G Installation Guide

4. If the index has mounting screw holes, place an index mounting screw (1) in the right-

hand mounting screw hole (2). Use one 8 - 32 3/16-inch screw for this step (you can

use an original mounting screw if it was the correct size and not corroded; otherwise,

use the correct size replacement screw).

1

2

5. Attach the screw to the ERT backplate's right-hand index mounting post just far

enough to hold the screw and end of the index in place.

6. If the index has mounting screw

slots, screw an index mounting screw (1) one to two

turns into the ERT backplate's right-hand index mounting post (2). Use one 8 - 32

3/16-inch screw for this step (you can use an original mounting screw if it was the

correct size and not corroded; otherwise, use the correct size replacement screw).

1

100G Installation Guide 11

2

Chapter 2 American Meter Installation

7. Place the index mounting screw slot under the screw head. Do not tighten the screw

yet.

8. Attach the wriggler to the index and backplate.

• If the index wriggler has a drive slot (1), place the backplate wriggler's drive

post (2) in the index wriggler's drive slot.

1

2

• If the index wriggler has a drive post (1), place the index wriggler's drive post

in the backplate wriggler's drive slot (2).

1

2

12 100G Installation Guide

9. Install and tighten the left-hand index mounting screw (for indexes with either

mounting screw slots or holes). Use one 8 - 32 3/16-inch screw for this step (you can

use an original mounting screw if it was the correct size and not corroded; otherwise,

use the correct size replacement screw).

10. Tighten the right-hand index mounting screw.

11. Slide the ERT cover (1) over the index and backplate, making sure the ERT label (2)

is visible through the window.

1 2

Next, program the ERT module.

Program the ERT Module

Once the ERT module has been assembled, the ERT must be programmed using the

FC200/SR with EndPoint-Link software. See the

(TDC-tbd-xxx

) for more information.

IMPORTANT You must perform the following programming procedure for

the ERT module to function properly.

EndPoint-Link ERT Programming Guide

100G Installation Guide 13

Chapter 2 American Meter Installation

When programming the ERT module, you must take note of the drive rate shown on the

index of American meters. Examples of 1-foot (1) and 2-foot (2) drive rates are shown

below. Be sure to program the ERT based on the indicated drive rate.

1

2

To Program the ERT Module

1. Using the FC200/SR, program the reading of the index that was on the meter into the

ERT module assembly. Be sure to hold the FC200/SR unit by the battery pack and

within a few inches of the ERT during programming and reading; this will ensure

proper communication between unit and the ERT.

During programming, the 100G ERT module is programmed to the

feet

; the last two digits (the tens and units) are programmed as zeros (0). Once

programming is complete, however, the ERT module assembly can be read to the

nearest cubic foot.

2. Slowly turn the ERT module drive wriggler two turns in the direction indicated on the

index drive rate. This lets you verify the ERT module is counting properly after

assembly.

nearest 100 cubic

14 100G Installation Guide

IMPORTANT Do not turn the drive wriggler faster than one turn per second.

1 2

3. Read the ERT module assembly using the FC200SR. Consult the

Programming Guide

(TDC-tbd-tbd) or other applicable instructions for details on how

EndPoint-Link ERT

to read an ERT.

• If this reading is higher than the one you programmed in step 1 above, the ERT

module assembly is counting correctly.

• If the ERT module assembly reading is

not higher than what was programmed

in step 1, replace the ERT module with a new one.

Attach the ERT Module to the Meter

After the ERT has been programmed and is reading correctly, it must be attached to the

meter. Follow the steps below to do this.

To Attach the ERT to the Meter

5B 225 Meters Only If you are installing the ERT on a 5B 225 aluminum meter, cut

1.

1/16-inch off each post of the ERT wriggler to prevent it from rubbing on the face of

the nut that holds the wriggler in place. If you are not installing on a 5B 225 meter,

continue to step 2 below.

1 2

100G Installation Guide 15

Chapter 2 American Meter Installation

2. Set the wriggler to the desired position for mounting the ERT module assembly to the

meter.

• For One-Foot Meters: Align the ERT module assembly wriggler with the meter

drive post (as shown below). Make sure the ERT wriggler is perpendicular to

the meter drive post.

• For Two-Foot Meters: Align the ERT module assembly wriggler with the

meter slot (as shown below). Make sure the ERT wriggler is perpendicular to

the meter slot.

3. Gently place the ERT module assembly on the meter. Align the four screw holes on

the ERT module assembly with the holes on the meter.

1 2

16 100G Installation Guide

4. Install and tighten all ERT module assembly mounting screws, working in a diagonal

pattern as shown below. Tighten the mounting screws to 15 to 20 inch-pounds of

torque. Use the 1/4 - 20 x 5/8-inch screws for this step (you can use the original

mounting screws if they were the correct size and not corroded; otherwise, use the

correct size

Replacement Screws on page 6).

3

2

41

5. Place a new tamper seal over two of the mounting screws as shown below.

2

1

6. Press the new tamper seals into place using the 11/32-inch nut driver (or another

similar blunt tool).

2

1

100G Installation Guide 17

Chapter 2 American Meter Installation

7. Complete any necessary paperwork. Make sure no excess material is left on the

customer premises; dispose of it properly.

The ERT is now installed on the meter.

18 100G Installation Guide

C HAPTER 3

Sensus Meter Installation

Introduction

This chapter shows you how to install a 100G gas ERT on a compatible Sensus meter.

Sensus meters are also known by the following names: Invensys,

Equimeter,

be referred to as Sensus meters for this installation procedure.

Installation Prerequisites

Materials Supplied By Itron

and Rockwell. For consistency, all of these meter types will

The following items are supplied by Itron.

• 100G gas ERT modules

• Tamper plugs

Materials Supplied by You

You must supply the following items to successfully install the 100G gas ERT on the

Sensus meters listed in the

• Small and medium flat-blade screwdrivers (used for index and index-cover screws)

• Side-cutting plier (used for cutting wire seals, if necessary)

• Small putty knife (to remove old gaskets)

• Meter seals, wire seals, and seal press (if necessary)

• 11/32-inch nut driver or other blunt tool (to securely seat new tamper plugs)

• ReadOne Pro unit (used to program and check ERT assembly)

Replacement screws (used to mount ERT assembly to meter and index to ERT assembly

backlates; see

Replacement Screws on page 19 for more information).

Replacement Screws

Meter Compatibility List on page 2.

Replacement screws used in this procedure must be slotted, zinc-plated, steel machine

screws. Sizing options are shown below.

For mounting 100G ERT module assemblies on meters:

• 10 - 24 x5/8-inch slotted, Fillister head

100G Installation Guide 19

Chapter 3 Sensus Meter Installation

For mounting indexes on 100G ERT module backplates:

• 6 - 32 x 5/8-inch slotted, round head

Preinstallation Preparations

Before installing the 100G gas ERT module on a meter, verify that:

• All ERTs are type 100G modules for Sensus gas meters.

• The model numbers of all meters on which the 100G modules will be installed are

included in the

Meter Compatibility List on page 2.

Installing the 100G on a Sensus Meter

There are three major steps to installing the 100G gas ERT on a Sensus meter:

• Remove the Existing Index

• Assemble the ERT Module

• Program the ERT

• Attach the ERT to the Meter

These procedures are described in the following sections.

Be sure to properly dispose of all unused screws, old index covers, gaskets, and

other left-over materials. Do not leave any materials on customer premises.

Remove the Existing Index

The first major step when installing a 100G gas ERT on a Sensus meter is to remove the

existing index from the meter.

To Remove the Existing Index

1. Remove any tamper seals from the meter.

20 100G Installation Guide

2. Detach the index cover from the meter by removing the four screws holding it in

place.

4

1

2

3

3. Examine the index cover screws you just removed. Verify that they are 5/8-inch long

and are not corroded.

• If the screws are 5/8-inch long and are not corroded, keep them for later use.

• If they are an incorrect length or are corroded, dispose of them properly. Use 10

- 24 x 5/8-inch screws as described in

Replacement Screws on page 19 instead.

TIP You can use the index cover you just removed as a temporary storage

location for screws.

4. Unscrew one index mounting screw completely.

5. Remove the other index mounting screw.

6. Set the index aside for the moment. Place it where it will not be damaged; get filled

with dirt, rain or snow; or fall to the ground or floor. The index will be used later in

this procedure.

7. Examine the index screws you just removed. Verify that they are 5/8-inch long and

are not corroded.

100G Installation Guide 21

Chapter 3 Sensus Meter Installation

• If the screws are 5/8-inch long and are not corroded, keep them for later use.

• If the screws are an incorrect length or are corroded, dispose of them properly.

Use 6 -32 x 5/8-inch screws as described in

instead.

8. Use a putty knife or similar object to completely remove the old index gasket from the

meter (if applicable). All traces of the gasket must be removed before the ERT can be

installed.

Replacement Screws on page 19

Assemble the ERT Module

When installing a 100G gas ERT, the next major step is to create the ERT module assembly

by combining the ERT backplate and cover with the meter index. Follow the procedure

below to do so.

To Assemble the ERT

1. Obtain a new 100G ERT and index cover.

2. Separate the ERT module backplate from the cover.

3. Place the index drive gear (1) in the backplate wriggler gear cup (2) of the ERT

(please note that the following example uses an 11-tooth drive gear; your index may

be slightly different).

1

2

22 100G Installation Guide

Once properly installed, the index drive gear and backplate wriggler cup should look

similar to the following example.

4. Attach the right-hand mounting screw to the index and meter, just far enough to hold

the index in place. Use one 6 - 32 x 5/8-inch screw for this step (you can use an

original mounting screw if it was the correct size and not corroded; otherwise, use the

correct size

Replacement Screw see "Replacement Screws" on page 19).

5. Install and tighten the left-hand index mounting screw.

6. Tighten the right-hand index mounting screw completely.

100G Installation Guide 23

Chapter 3 Sensus Meter Installation

7. Slide the ERT cover over the index and backplate.

8. Verify that the cover is installed correctly; the cover's clear window should be over

the backplate label.

Once combined, the ERT backplate, meter index, and ERT cover create an "ERT

Module Assembly."

Next, program the ERT module.

Program the ERT

Once the ERT module has been assembled, the ERT must be programmed using the

FC200/SR with EndPoint-Link software. See the

(TDC-tbd-xxx

) for more information.

EndPoint-Link ERT Programming Guide

IMPORTANT You must perform the following programming procedure for

the ERT module to function properly.

When programming the ERT module, you must take note of the drive rate shown on the

index of Sensus meters. Sensus meters have a 2-foot drive rate, as indicated in the example

below (1).

1

To Program the ERT Module

1. Using the FC200/SR, program the reading of the index that was on the meter into the

ERT module assembly. Be sure to hold the FC200/SR unit by the battery pack and

within a few inches of the ERT during programming and reading; this will ensure

proper communication between unit and the ERT.

24 100G Installation Guide

During programming, the 100G ERT module is programmed to the nearest 100 cubic

feet

; the last two digits (the tens and units) are programmed as zeros (0). Once

programming is complete, however, the ERT module assembly can be read to the

nearest cubic foot.

2. Slowly turn the ERT module drive wriggler two turns in the direction indicated on the

index drive rate. This lets you verify the ERT module is counting properly after

assembly.

IMPORTANT Do not turn the drive wriggler faster than one turn per second.

3. Read the ERT module assembly using the FC200SR. Consult the

Programming Guide

(TDC-tbd-tbd) or other applicable instructions for details on how

EndPoint-Link ERT

to read an ERT.

• If this reading is higher than the one you programmed in step 1 above, the ERT

module assembly is counting correctly.

• If the ERT module assembly reading is

in step 1, replace the ERT module with a new one.

not higher than what was programmed

Attach the ERT to the Meter

After the ERT has been programmed and is reading correctly, it must be attached to the

meter. Follow the steps below to do this.

100G Installation Guide 25

Chapter 3 Sensus Meter Installation

To Attach the ERT to the Meter

1. Gently place the ERT module assembly against the front of the meter as shown. Make

sure all four mounting screw holes in the ERT module assembly line up with the

corresponding holes on the meter.

2. Insert the top-right cover mounting screw. Tighten the screw just enough to hold the

ERT module assembly in place. Use the 10 - 24 5/8-inch screws for this and the

following step (you can use the original mounting screws if they were the correct size

and not corroded; otherwise, use the correct size as described in

on page

19).

Replacement Screws

26 100G Installation Guide

3. Install and tighten the remaining three mounting screws. Tighten the mounting screws

to 15 to 20 inch-pounds of torque.

2

3

1

4. Tighten the top-right mounting screw.

5. Place a new tamper seal over two of the mounting screws as shown below.

1

2

100G Installation Guide 27

Chapter 3 Sensus Meter Installation

6. Press the new tamper seals into place using the 11/32-inch nut driver (or another

similar blunt tool).

7. Complete any necessary paperwork. Make sure no excess material is left on the

customer premises.

The ERT is now installed on the meter.

28 100G Installation Guide

Loading...

Loading...