Page 1

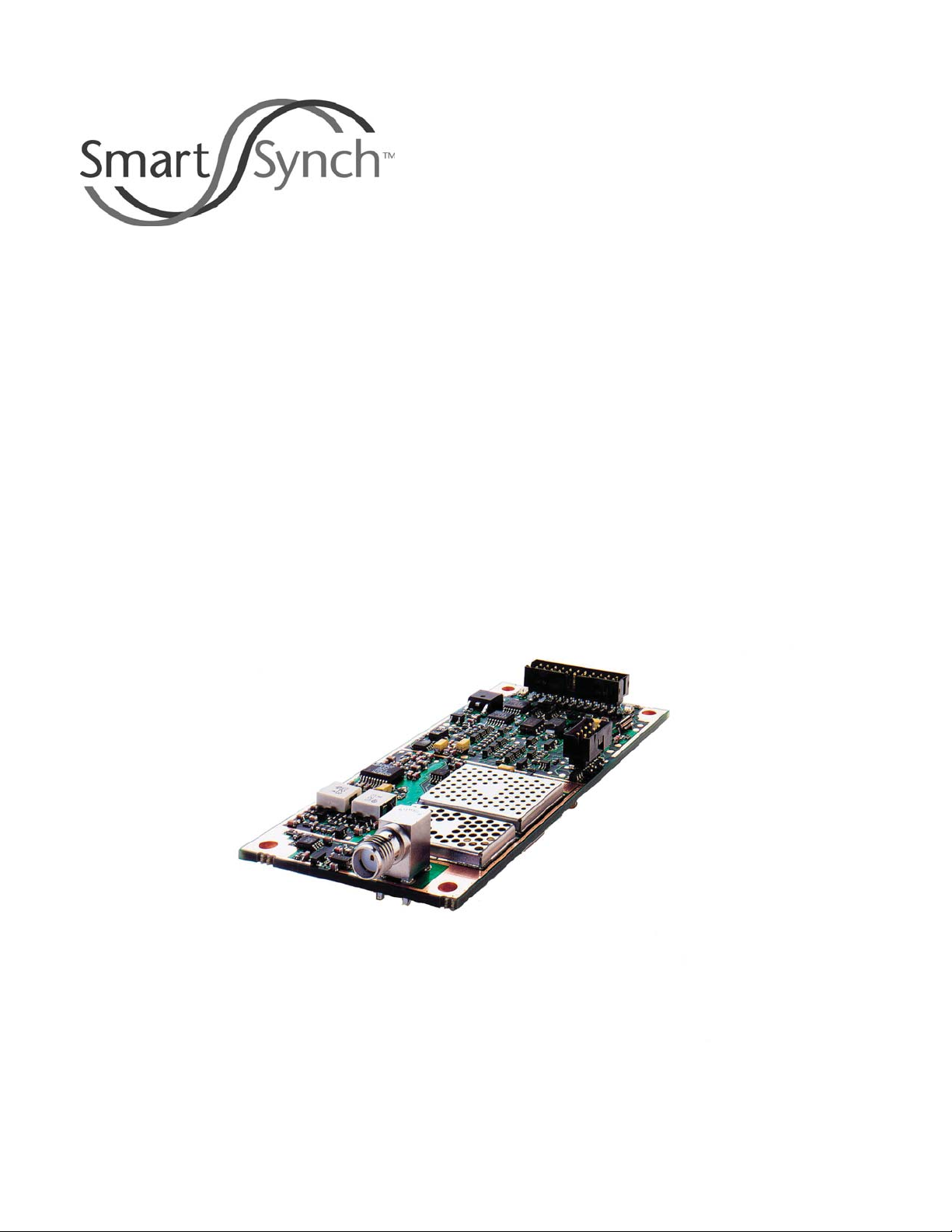

Hardware

Integrator's Guide

CreataLink™ 2XT

ReFLEX 25 and 50 Technologies

Page 2

Page 3

CreataLink2 XT Hardware Integrator’s Guide Foreword

91B

1Foreword

1Foreword

Foreword

Foreword

Customer Information

The information in this manual has been reviewed for accuracy. However, no

responsibility is assumed for inaccuracies. SmartSynch, Inc., reserves the right to

make changes to any products discussed h erein. The inf ormation in th is document

is subject to change without notice. SmartSynch, Inc. assumes no liability for

hardware or software damage or loss of data due to errors or omissions in this

manual. SmartSynch, Inc. does not assume any liability arising from the application

or use of any products or circuits described here in. Neither do es SmartSynch, Inc.

convey any license under its patents or right of others.

For technical support and questi ons concerning the Creat aLink2 XT and documentation, refer to our web site at www.smartsynch.com.

Computer Software Copyrights

The SmartSynch products described in this manual include copyrighted SmartSynch computer software stored in semiconductor memories and other media . Laws

in the United States and other countries preserve for SmartSynch, Inc. certain

exclusive rights for copyrighted computer programs, including the exclusive right

to copy or reproduce in any form the copyrighted computer software.

Trademarks

Accordingly, any copyrighted SmartSynch computer software contained in the

SmartSynch products described in this manual cannot be copied or reproduced in

any manner without the express written permission of SmartSynch, Inc..

Furthermore, the purchase of SmartSynch products doe s not grant, either directly

or by implication, estoppel, or otherwise, any license under the copyrights, patents

or patent applications of SmartSynch, Inc., except for the normal, non-exclusive,

royalty-free license to use that arises by operation of law in the sale of a product.

Portions of the software described in this manual are copyrighted by Motorola, Inc.

CreataLink®2 XT is a registered trademark of Sma rtSynch, Inc.

Motorola, the stylized M logo, CLP™, FLEX™, FLEXsuite™, and ReFLEX™ are

trademarks or registered trademarks of Motorola, Inc.

Microsoft®, Windows®, and Windows NT® are registered trademarks of Micro soft

Corporation.

Solaris™ is a trademark of Sun Microsystems Inc.

UNIX® is a registered trademark of X/Open Compan y Ltd.

July 23, 2002 1-1

Page 4

Foreword CreataLink2 XT Hardware Integrator’s Guide

Important Safety Information

Important Safety Information

The installation, maintenance, and/or operation of this equipment could present

potentially unsafe conditions , including, but not limited to, electr ical shock, improp

er voltage to components. Improper o peration could cause personal injury, death or

damage to property.

Read Instructions

Read all safety instructions before you operate the Data Transceiver or maintenance equipment. Retain these safety instructions for future reference. Specialized

procedures and instructions are required and must be followed. All applicable safety

procedures, such as Occupational, Safety, and Health Administration (OSHA)

requirements, Nation al Elect ric Cod e Require ments, local code req uirements, safe

working practices and good judgement must be used by personnel.

Heed Admonitions

Adhere to all warnings on the equipment and in the operating instructions. Follow

all operating and usag e instructions. The follow ing two safety admonitions are used

in this manual:

-

Caution: Emphasizes information about actions which could result in

G

E

equipment damage.

Warning: Emphasizes information about actions which could result in

personal injury.

Mounting

Mount the equipment only as recommended by the manufacturer. Situate the

equipment away from heat sources such as radiators, heat registers, stoves, or other

equipment (including amplifiers) that produces heat.

Power Sources and Grounding

Connect the equipment to the type of power source described in the installation

instructions, or as marked on the equipment. Do not defeat the grounding or

polarization provisions of the equipment. Turn the circuit b reaker off when equip

ment is to be left unused for long periods of time.

-

1-2 July 23, 2002

Page 5

CreataLink2 XT Hardware Integrator’s Guide Foreword

Important Safety Information

Damage Requiring Service

Do not attempt to perform service functions that are not described in the operating

instructions. Refer all such servicing to qualified service personnel.

Motorola, Inc. is not responsi ble for static damag e to equipment not sold under the

Motorola logo.

FCC Compliance Statement

This product generates, uses and can radiate radio frequency (RF). If it is not

installed and used in accordance with the instruction manual, it can cause harmful

interference to radio communications. It has been tested and c omplies with the

limits for a Class B digital device, pursuant to Part 15 of the Federal Communica

tions Commission (FCC) code of federal regulations, which are designed to provide

reasonable protection against harmful interference in a residential installation.

However, there is no guarantee that interference will not occur in a particular

installation. If this equipment causes harmful interference to radio or television

reception, the user should try and correct the interference by one or more of the

following measures:

Reorient or relocate the receiving/transmitting antenna.

-

Increase the separation between the equipment and the CreataLink2 XT device.

Connect the equipment into an outlet on a circuit di ff erent from t hat to which t he

CreataLink2 XT device is connected.

Interference must be corrected at the user’s expense. Consult the dealer or an

experienced radio/TV technician for help.

July 23, 2002 1-3

Page 6

Foreword CreataLink2 XT Hardware Integrator’s Guide

Important Safety Information

1-4 July 23, 2002

Page 7

GENERAL

Page 8

Page 9

CreataLink2 XT Hardware Integrator’s Guide General

91B

2General

Contents

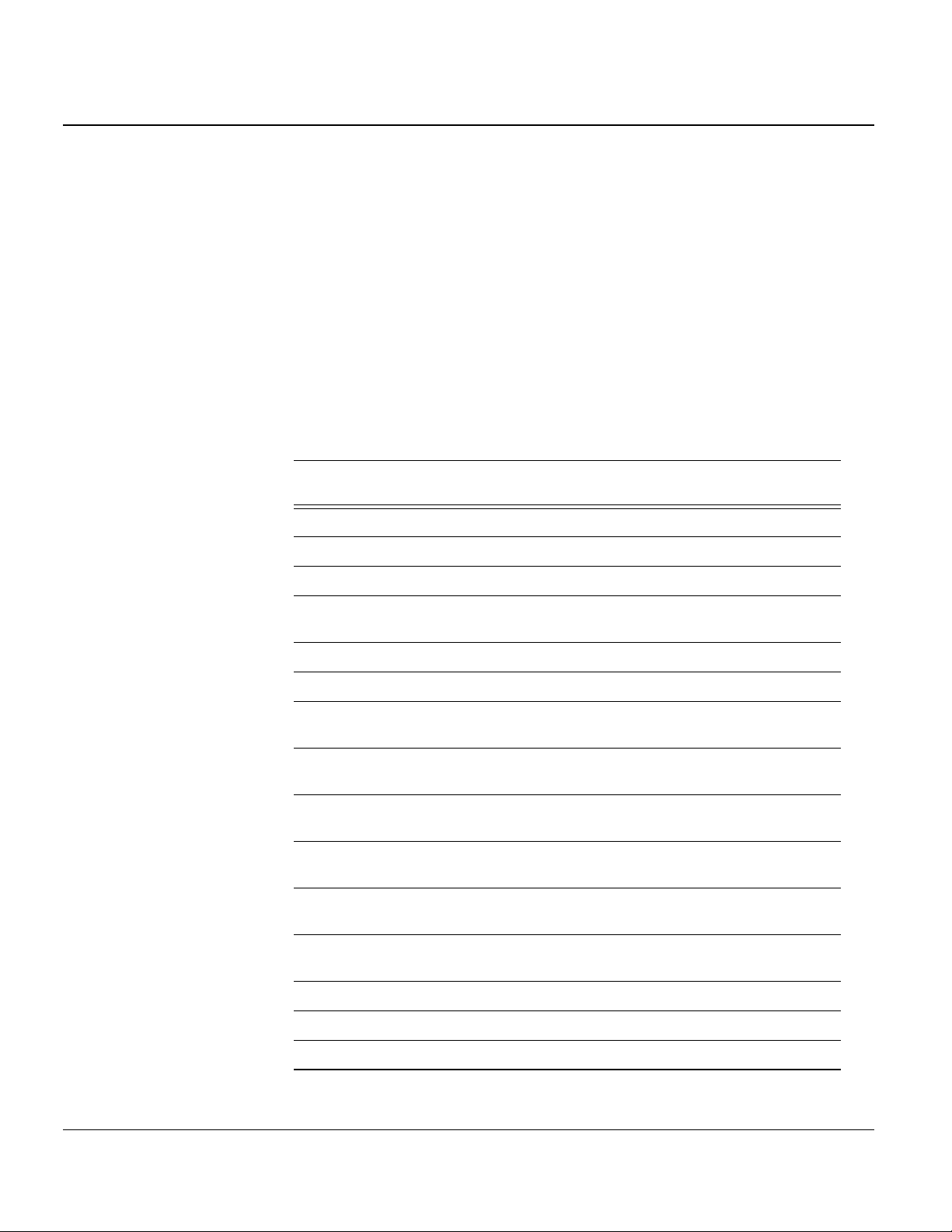

Contents

About this Document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Related Publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Environmental Constraints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

Connectors Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-13

Typical Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-14

Air Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-16

Air Interface Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-16

ReFLEX Network Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-17

Product Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-18

Operating System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 -18

Power-up Operating Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-18

Message-Search Operating Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-18

Address Capability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-19

Duplicate Message Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-19

Message Deletion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-19

Unit IDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-19

Message Storage and Lengths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-20

Acknowledgment of Received Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-21

Registration Request . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-21

Configuration Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-21

PPS Utility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-21

End-User Application Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 -22

Serial Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-22

June 18, 2002 2-i

Page 10

General CreataLink2 XT Hardware Integrator’s Guide

Contents

2-ii June 18, 2002

Page 11

CreataLink2 XT Hardware Integrator’s Guide General

2General

About this Document

About this Document

This document summarizes the product features and describes how to install and

integrate the CreataL ink2 XT data transc eiver into an off-board a pplication. If you

are developing an on-board/embedded application, use the Software Integrator’s

Guide listed in the Related Publications Section in conjunction with this manual.

This document is organized in sections as follows:

• Section 1: Foreword - A brief introduction to this document, licensing information, safety guidelines, and a general description of the data transceiver.

• Section 2: General - Information about this document, references, installation

instructions, troubleshooting tips an d product features.

• Section 3: The Integration Overview - Integration (interface) overview.

• Section 4: Hardware Integration - The development environment, accessories,

and options.

• Section 5: Testing - installation, troubleshooting, and diagnostic mode.

• Section 6: Parts information - Part numbers and ordering information.

• Appendix A: Abbreviations and Acronyms

• Appendix B: Desense - A discussion of desense, EMI testing procedures, and

EMI control.

• Appendix C - FLEXsuite of Application Protocols - FLEX technology explained,

licensing information, and licensee form.

Audience

Conventions

This document was created for third-party developers who install the CreataLink2

XT data transceiver and deve lop app lication pro grams that co mmunicate wit h the

unit. Use of this manual to build applications for separate sale or license in

connection with data transceivers NOT purchased from SmartSynch, Inc. is unau

thorized and requires separate written permission from SmartSynch, Inc.

Special characters and typefaces, listed and described below, are used in this

publication to emphasize certain types of information.

Note: Emphasizes additional information pertinent to the subject matter.

➧

Caution: Emphasizes informa tion abo ut actio ns which may resu lt in equi pment

G

E

damage.

Warning: Emphasizes information about actions which may result in personal

injury.

Commands are shown like this

-

July 23, 2002 2-1

Page 12

General CreataLink2 XT Hardware Integrator’s Guide

Related Publications

Related Publications

The following documents provide additional information to integrators and application developers:

• Communication Linking Protocol Reference Manual,

publication 6881033B20

• CreataLink2

publication 6881033B45

• CreataLink2

publication 6881036B30

• Software Integrator’s Guide, publication 6881033B65

®

XT R50 Programming Software Guide - Integrators,

®

XT R25 Programming Software Guide,

2-2 July 23, 2002

Page 13

CreataLink2 XT Hardware Integrator’s Guide General

Product Description

Product Description

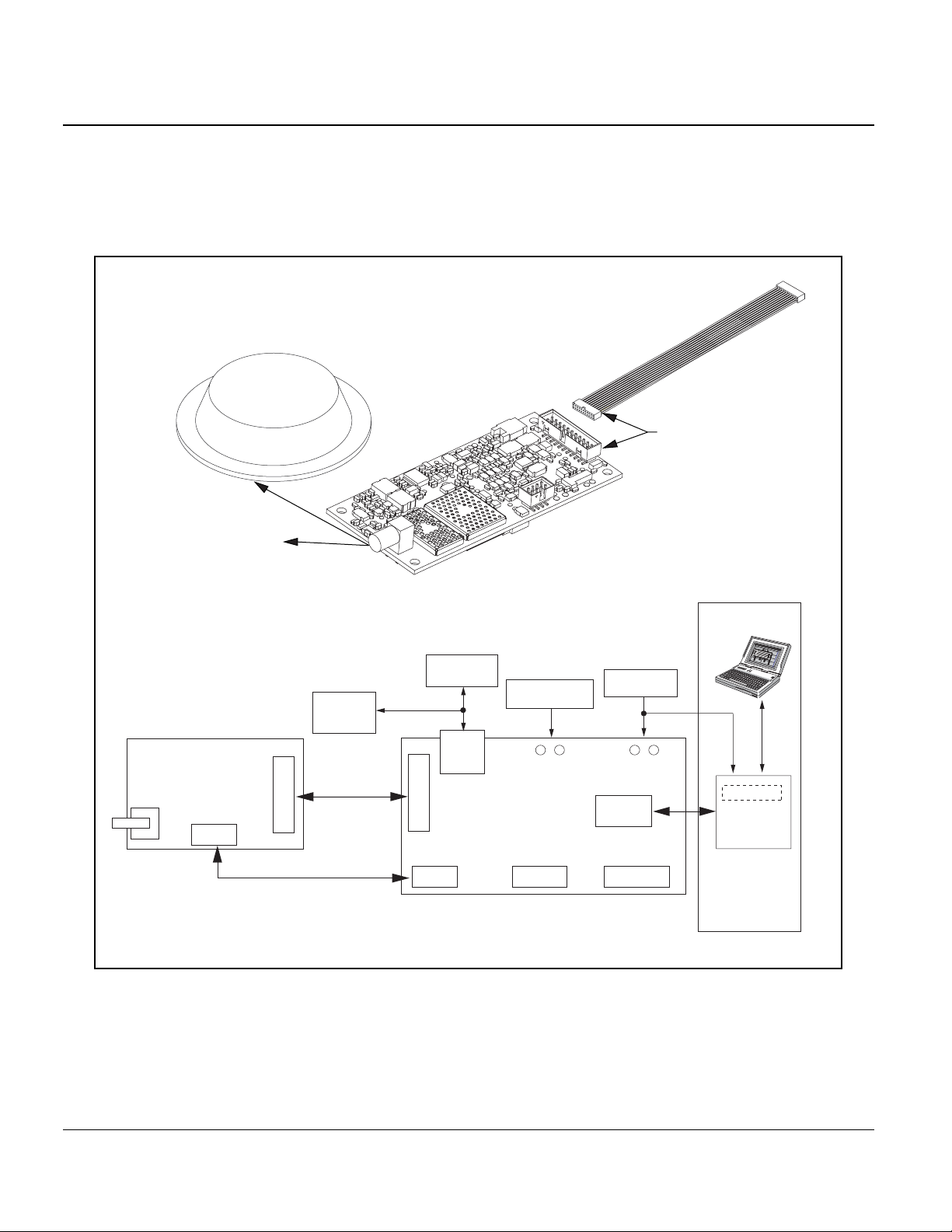

The CreataLink2 XT device is a two-way data transceiver that supports the

ReFLEX protocol. The CreataLink2 XT device can initiate transmissions into a

ReFLEX Narrow Band Personal Communications System (NBPCS) network, re

ceive and decode data, and store it. It can forward messages it receives from the

ReFLEX network to an interconnected hos t device via an RS-232 level or TransistorTransistor Logic (TTL) level serial port. The CreataLink2 XT device performs all

necessary ReFLEX protocol processing to maintain connection to the ReFLEX

network, accurately receives and acknowledges messages, and delivers messages

in conformance with protocol requirements.

The CreataLink2 XT provides an 8-bit, bi-directional parallel Input/Output (I/O)

port. Each bit can be configured individually as an input or output by the integrator

or end-user. The product also has two Analog-to-D igital (A/D) input ports for

customer use.

An additional pin is provi ded for a secondary battery so urce. This secondary source

can be used to back-up RAM contents in the event of a power failure and can be

selected through software to power the transmitter.

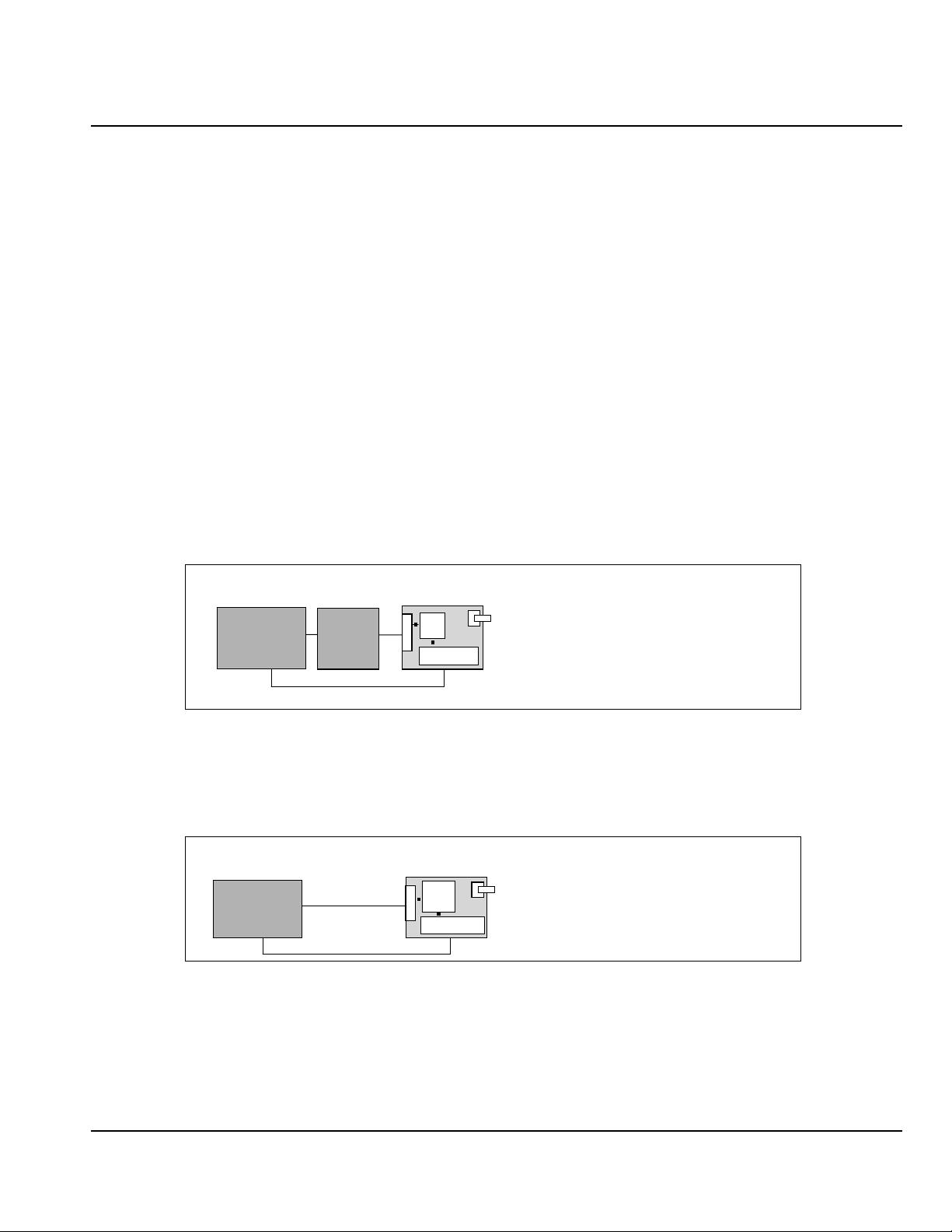

The CreataLink2 XT device can support an off-board application configuration (see

Figure 2-1 below). Off-board applications communicate with the CreataLink2 XT

using the Communications Linking Protocol (CLP).

-

Data collection

pt -machine,

meter, car, etc.

Discret e signals

Data collection

pt -machine,

meter, car, etc.

Discret e signals

CreataLink2 XT

Interface

Board for

proto col

translation

CLP

SERIAL

CLP

APP

I/O, A/D Port

SMA

Off-board host control over serial

port interface. Platform acts as

modem. Parallel I/ O and A/D port

control via host over serial link.

990441

Figure 2-1. Off-board Configuration

The CreataLink2 XT also supports an on-board application configuration which

enables third parties to write custom resident applications. This usually eliminates

the need for an external application board.

CreataLi nk2 XT

Custom Serial

Interface

SERIAL

3rd

PARTY

APP

I/O, A/D Port

SMA

On-board host operation via 3rd party

application.

990442

Figure 2-2. On-board Configuration

July 23, 2002 2-3

Page 14

General CreataLink2 XT Hardware Integrator’s Guide

Product Description

Architecture

The data transceiver’s software architecture is based upon the FLEX Kernel realtime operating system. With the addition of ReFLEX stack software, a message

manager, and the CLP default application, it provides a third-party embedded

messaging Application Programmer Interface (API). Ownership of the serial port

can be passed to a third-party application in place of the CLP application via an

application framework provided by SmartSynch, Inc. An ARM core based micropro

cessor provides the following features:

• 32-bit addressi ng

• 8, 16, and 32-bit data

• State-of-the-art softwar e development tools

• Industry standard Joint Test Action Group (JTAG) port

• Debugging support tools and environment via JTA G port

The serial port data interface supports the CLP application. The CLP serial

interface commands the data transceiver to obtain status information about the

network, transmit messages, and download received messages.

Components

-

The CreataLink2 XT hardware incorporates RF, digital, and analog circuitry on one

Printed Circuit Board (PCB). The product contains no housing and is sold as an

Original Equipment Manufacturer (OEM) product. The data transceiver has an

industry-standard Sub-Miniature connector (SMA) connection for cabling to a

remote antenna.

2-4 July 23, 2002

Page 15

CreataLink2 XT Hardware Integrator’s Guide General

Features

Features

The CreataLink2 XT device incorporates the following features.

• Compact package with four mounting holes

• External SMA female coaxial connector

• Configurable battery-save mode for reduced a verage power consumption

• Selectable transmi t power at antenna connector

NUF3902: 0.5W, 0.75W, 1.0W, 1.5W and 2.0W

NUF8006: 0.25W, 0.5W, 1.0W, 1.5W, and 2.0W

• Asynchronous transistor-transistor logic (TTL) or RS-232 serial port interface

that supports standard baud

• Alternate transmitter power source connection

• 8 Bi-directional I/O lines available for external interfacing; 2 driven outputs

and 6 open collectors

• 2 A/D input lines available for reading analog signals

• Receive frequency range:

NUF3902: 940-941 MHz

NUF8006: 929-941 MHz

• Transmit frequency range:

NUF3902: 901-902 MHz

NUF8006: 896-902 MHz

• Two-way paging protocols:

NUF3902: ReFLEX 50 (R50)

NUF8006: ReFLEX 25 (R25)

• Duplicate message detection/deletion

• Out-of-range indication

• Individual and broadcast message addressing

• 2000-byte uplink message length

• Single fragment, approximately 1000-byte downlink message length

• Backup battery option for SRAM

• FLASH for third-party on-board application or non-volatile st orage

•32KB RAM for messages

• JTAG interface for software debugging

•External reset

Although the data transceiver can receive messages of up to 1000 bytes in length,

➧

the carrier might not send this amount of data in a single transmission. Obtain

maximum single fragment message length from your carrier.

July 23, 2002 2-5

Page 16

General CreataLink2 XT Hardware Integrator’s Guide

Specifications

Specifications

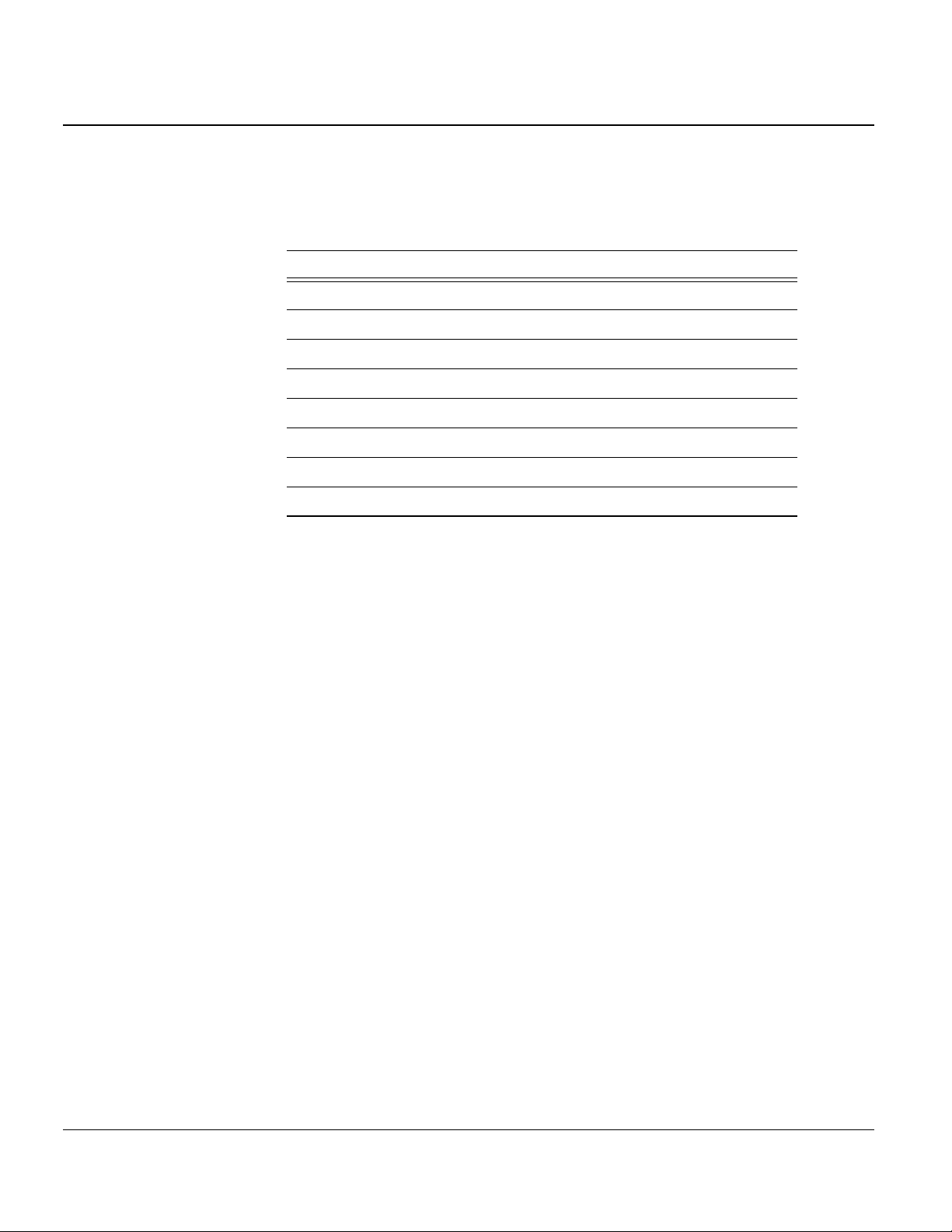

T able 2-1. General Specifications

Item Specification Specification

Board Kit Number NUF3902 NUF8006

Coding format ReFLEX 50 ReFLEX 25

Serial Protocol CLP or third-party application CLP or third-party application

Operating temperature -40oC to +85oC -40oC to +85oC

22-pin vertical shroud ed header for combined

Interface

Power supply

requirements

Backup battery/

alternate transmit

power supply

requirements

Physical dimensions

Antenna Connector 50 Ohm SMA female connector 50 Ohm SMA female connector

Transm itter spec ific ation s:

Frequency 901–902 MHz 896-902 MHz

RF power output (at

antenna port)

power supply, serial , and p arallel I/O in terface.

8-pin vertical shrouded header for JTAG

interface; SMA connector for antenna

5-12 Vdc, 2.5A minimum, 100 mVpp ripple up

to 5 MHz (worst case estimate if sourcing/

sinking I/O at max values)

3-9 Vdc, 1 mA if used for RAM backup only.

5-9Vdc, 1.4A minimum, 10 0 mVpp ripple up to

5 MHz if used for transmitter supply (Battery

voltage must b e equal to or less t han the main

supply voltage)

Length: 3.75 in (95.25 mm) Length: 3.75 in (95.25 mm)

Width: 1.75 in (44.45 mm) Width: 1.75 in (44.45 mm)

Height: 0.7 in (17.78 mm) Height: 0.7 in (17.78 mm)

Weight: 1.5 oz. (42.5 grams) Weight: 1.5 oz. (42.5 grams)

0.5W, 0.75W, 1.0W, 1.5W, and 2.0W 0.25W, 0.5W, 1.0W, 1.5W, and 2.0W

22-pin vertical shrouded header for combined

power supply, serial, and parallel I/O interface.

8-pin vertical shrouded header for JTAG

interface; SMA connector for antenna

5-16 Vdc, 2.5A minimum, 100 mVpp ripple up

to 5 MHz (worst case estimate if sourcing/

sinking I/O at max values)

3-9 Vdc, 1 mA if used for RAM backup only.

5-9 Vdc, 1.4A minimum, 100 mVpp ripple u p to

5 MHz if used for transmitter supply (Battery

voltage must be equal to or less than the main

supply voltage)

Transmit data bit rate 9600 bits per second (bps) 800, 1600, 6400, 9600 bps

Modulation 4-level Frequency Shift Keying (FSK) 4-level FSK

Frequency stability 1 ppm on transmit 1 ppm on transmit

Receiver specifications:

Frequency 940–941 MHz 929-941 MHz

Sensitivity -115 dBm into SMA antenna connector -115 dBm into SMA antenna connector

2-6 July 23, 2002

Page 17

CreataLink2 XT Hardware Integrator’s Guide General

Specifications

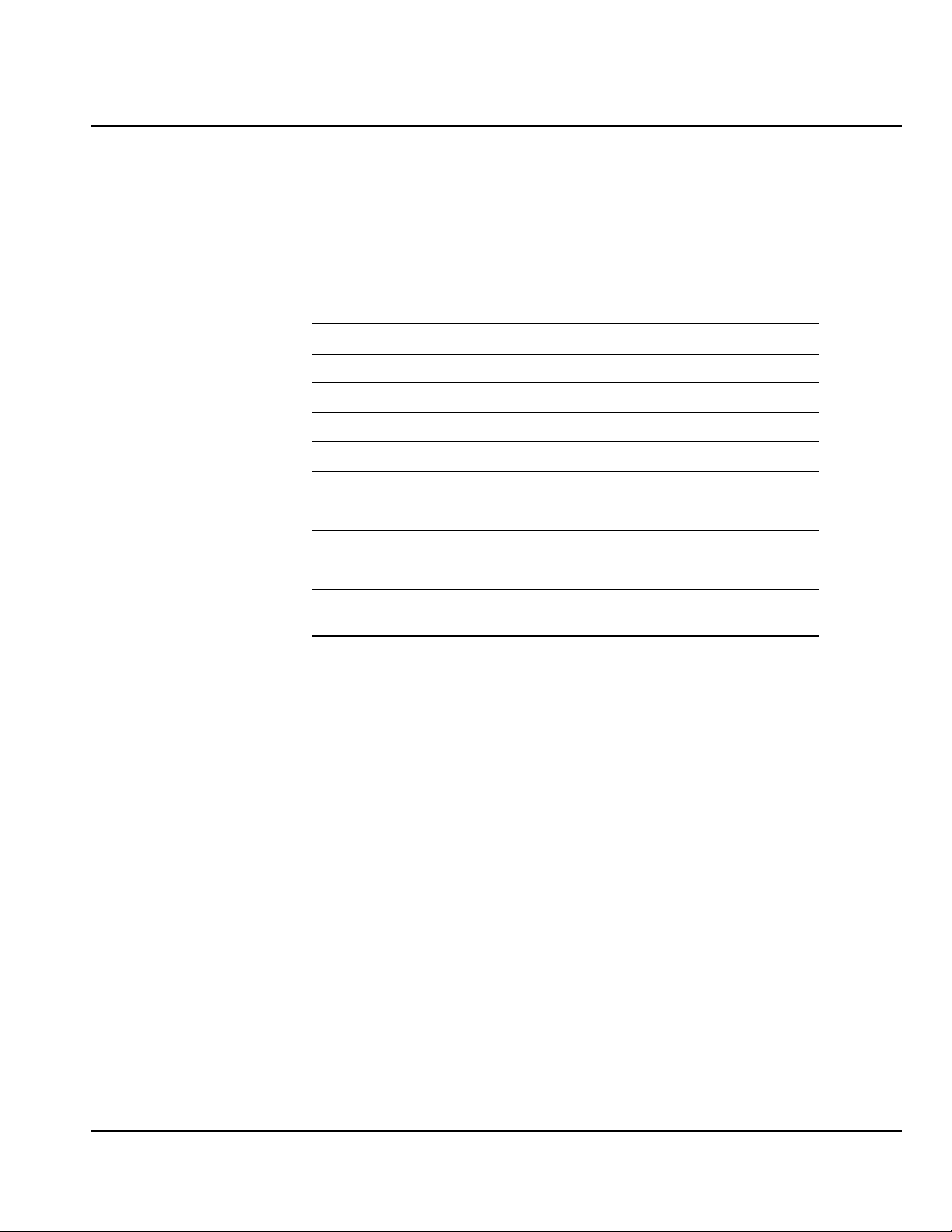

Table 2-1. General Specifications (Continued)

Item Specification Specification

Receive data bit rate 6400 bps

Modulation 4-level FSK 2-level and 4-level FSK

Channel Spacing 50 kHz 25 kHz

I/O

HVIO-0 – HVIO-5

(configured as outputs)

HVIO-0 – HVIO-5

(configured as inputs)

HVIO-6 & HVIO-7

(configured as outputs)

HVIO-6 & HVIO-7

(configured as inputs)

12 Vdc maximum pullup voltage. 25 mA

maximum sink current (@12 Vdc pullup)

12 Vdc maximum input 16 Vdc maximum inp ut

Driven to supply voltage (12 Vdc maximum)

Maximum sourcing/sinking current is 350 mA

Maximum input limited to that of supply

voltage

1600 and 3200 bps using 2-level FSK

3200 and 6400 bps using 4-level FSK

16 Vdc maximum pullup voltage. 25 mA

maximum sink current (@16Vdc pullup)

Driven to supply voltage (16 Vdc maximum)

Maximum sourcing/sinking current is 350mA

Maximum input limited to that of supply voltage

Environmental Constraints

The CreataLink2 XT devi ce me ets t he fo ll ow in g enviro nment al sp eci fica tions (se e

Table 2-2):

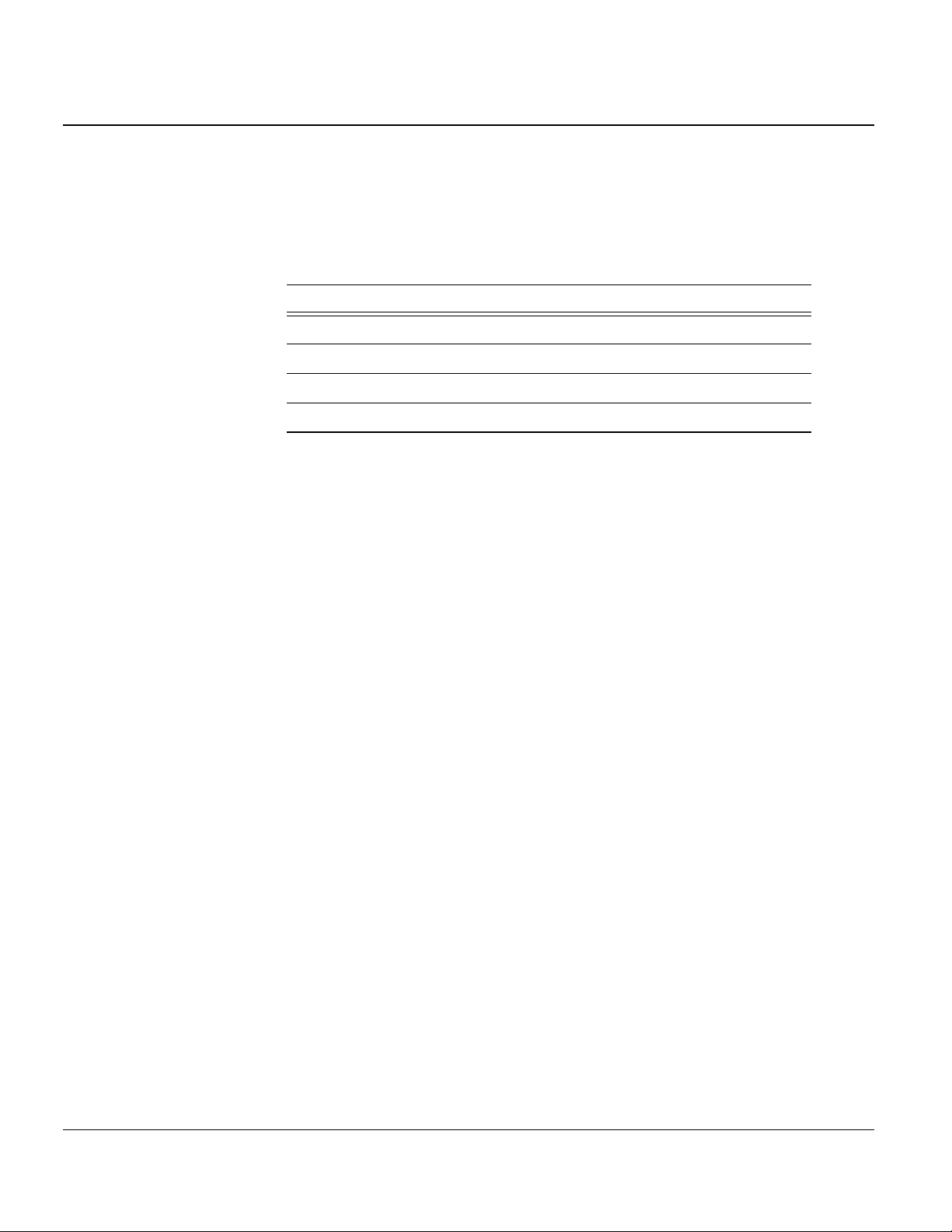

Table 2- 2. Environm ental Specifications

Item Requirement

Humidity 90% relative humidity at 50oC non-condensing onto pcb

Drop/shock test Compliant with TIA/EIA 603 specifications

Vibration TIA/EIA 603, Section 3.3.4.

FCC requirements for radiated and conducted emissions,

Emissions

per Parts 2, 15, and 24 of title 47 Code of Federal

Regulations.

July 23, 2002 2-7

Page 18

General CreataLink2 XT Hardware Integrator’s Guide

Specifications

Power Requirements

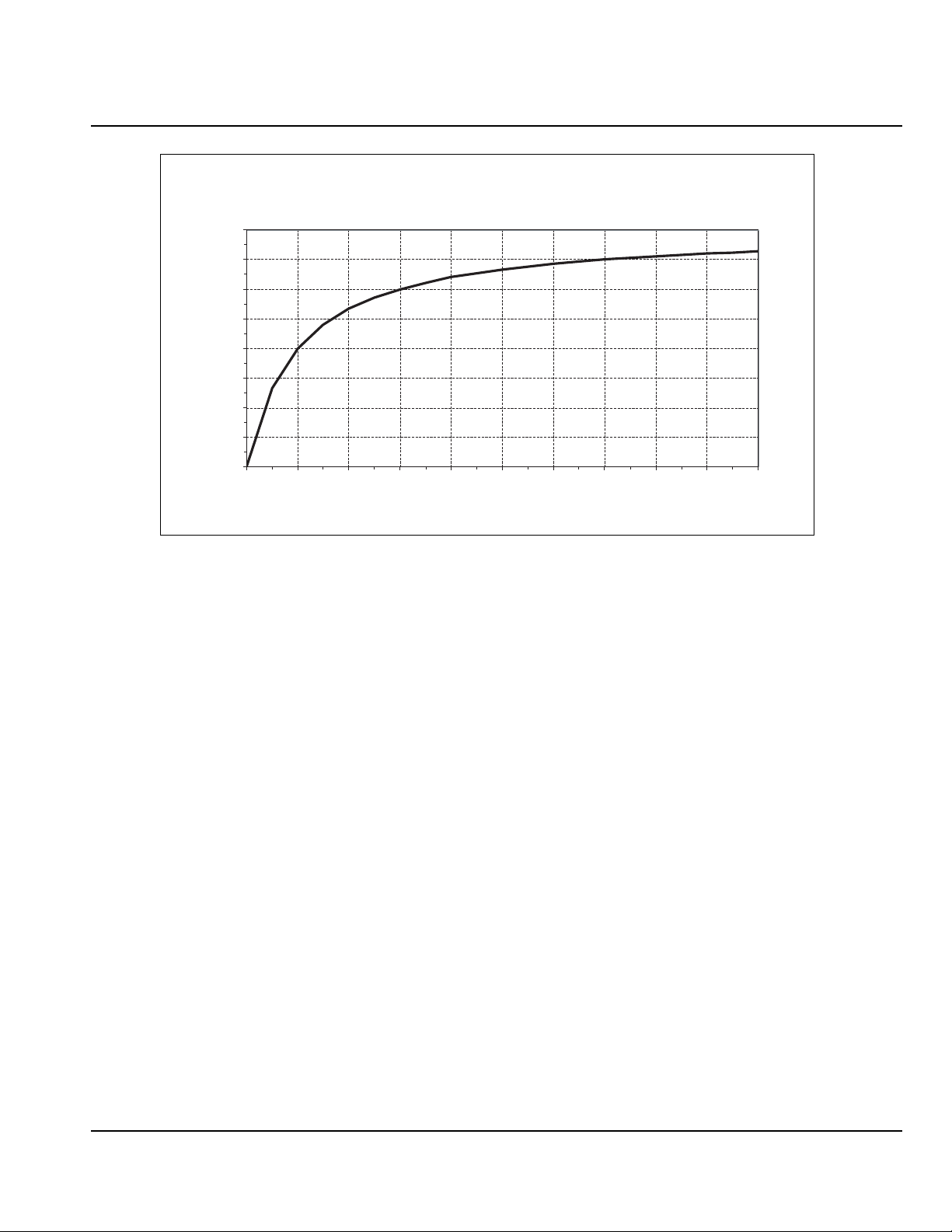

To conserve power, the FL EX protocol for two-way paging provides low power modes

of operation. In receive mode, all logic and receive circuits are powered while waiting

to receive a message. In standby mode, all circuits are in a low power state for power

economy. In transmit mode, all logic circuits and the power amplifier are active and

consume large amounts of current for short durations.

Table 2-3. Power Consumption

Item NUF3902 NUF8006

Operating Mode Current Drain (approxim ate) Current Drai n (approxi mate)

b

a

a

Standby 3 - 5 mA

Receive 65 - 90 mA

Transmit (2 W setting) 1250 - 1400 mA

b

a

1 - 5 mA

See Figure 2-3 for typical

performance

25 - 90 mA

See Figure 2-4 for typical

performance

a

350 - 1400 mA

See Figure 2-5 for typical

performance

RS-232 Communication 3 - 4 mA 3 - 4 mA

HVIO_0 - HVIO_5, configured as

outputs, driven to the low state, sinking

max current

HVIO_6 and HVIO_7, configured as

outputs, driven to high state, sourcing

max current.

25 mA each 25 mA each

350 mA each 350 mA each

a. Does not include current due to RS-232 communications.

b. No Valid RS-232 voltages and all 8 I/O lines configured as inputs.

2-8 July 23, 2002

Page 19

General CreataLink2 XT Hardware Integrator’s Guide

Specifications

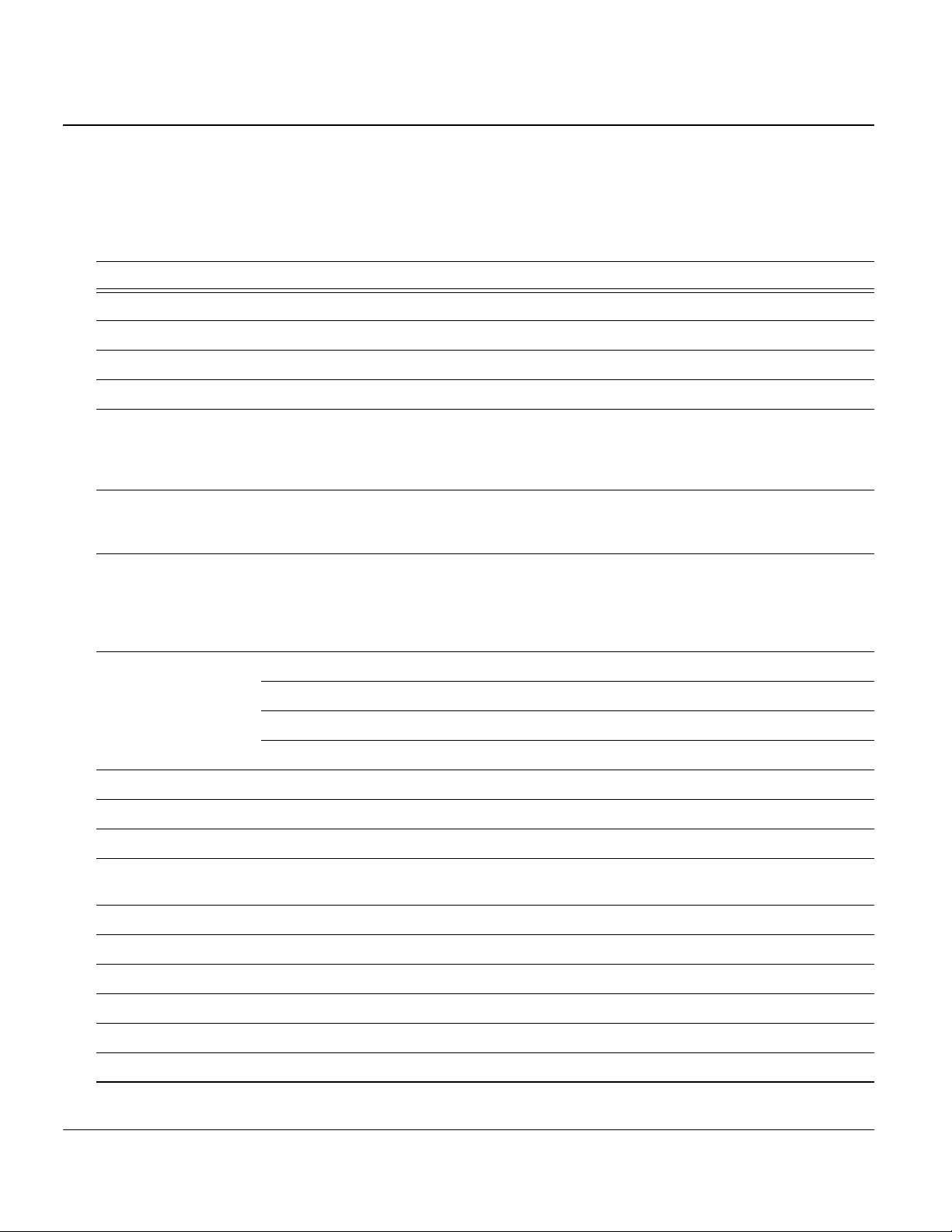

6

5

4

3

2

SUPPLY CURRENT (mA)

1

0

5 6 7 8 9 10 111213141516

SUPPLY VOLTAGE (V)

000159

Figure 2-3. NUF8006: Average Sleep Current versus Supply Voltage

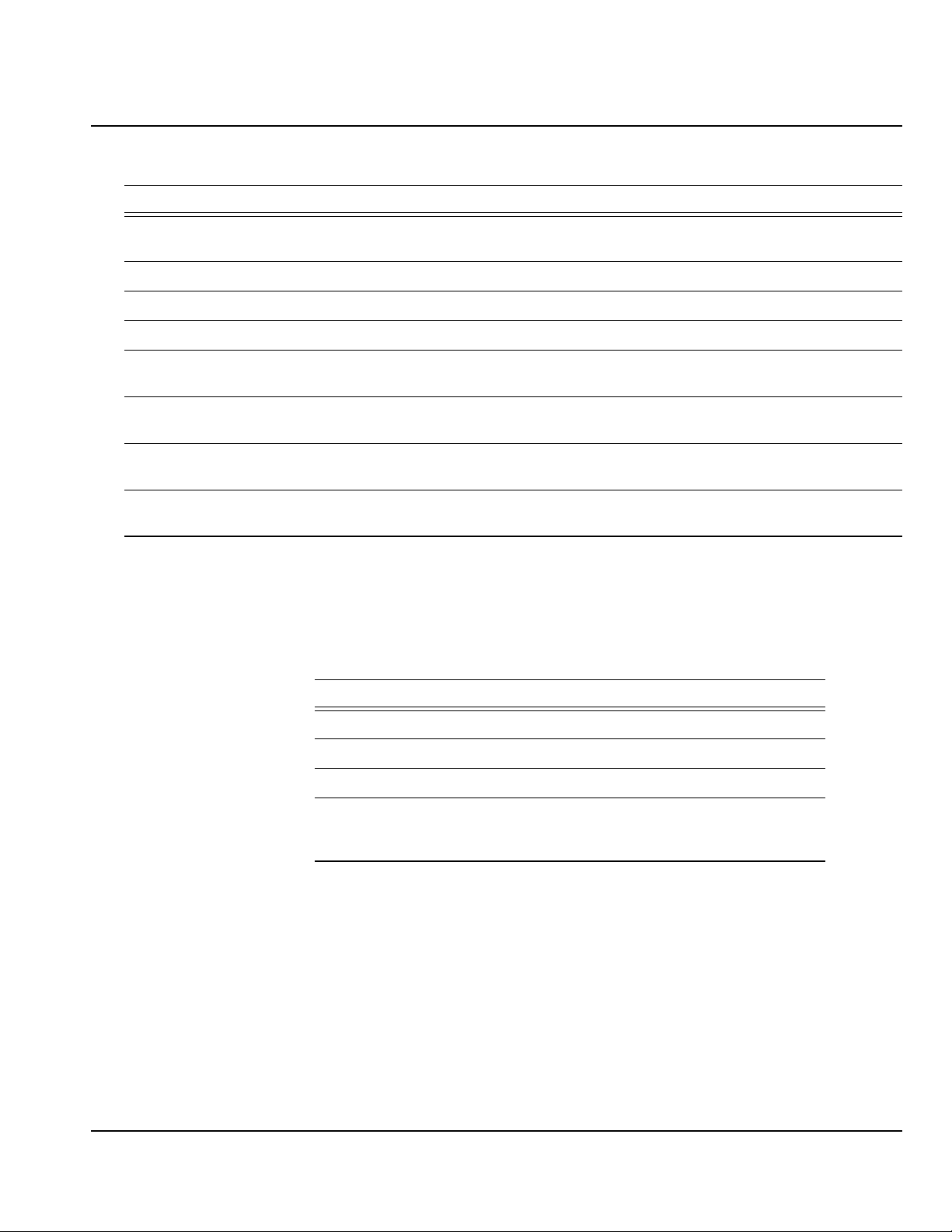

80

70

60

50

40

30

SUPPLY CURRENT (mA)

20

10

0

56

8 9 10 11 12 13 14 15 16

7

SUPPLY VOLTAGE (V)

Figure 2-4. NUF8006: Average Receive Current

versus Supply Voltage

000121

2-9 July 23, 2002

Page 20

CreataLink2 XT Hardware Integrator’s Guide General

Specifications

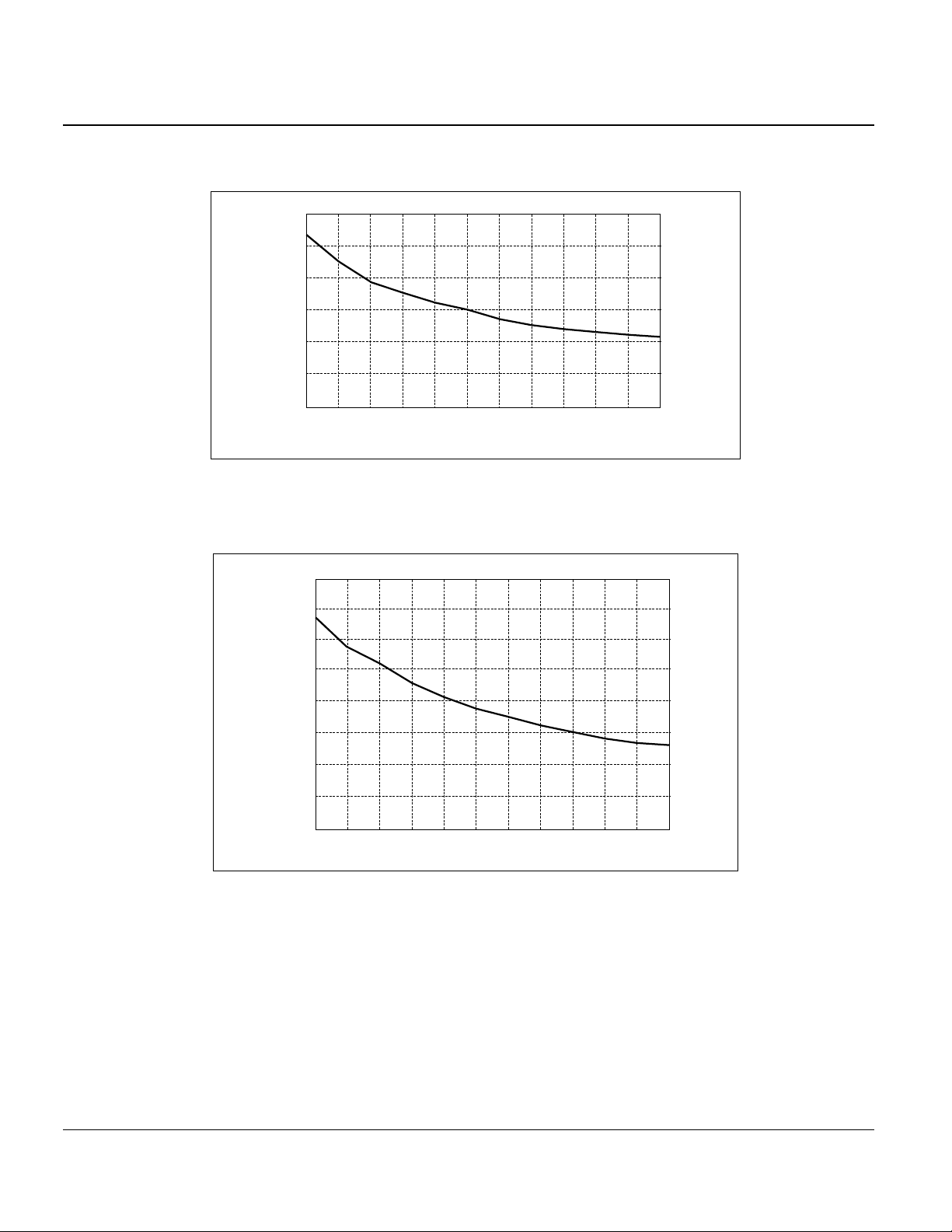

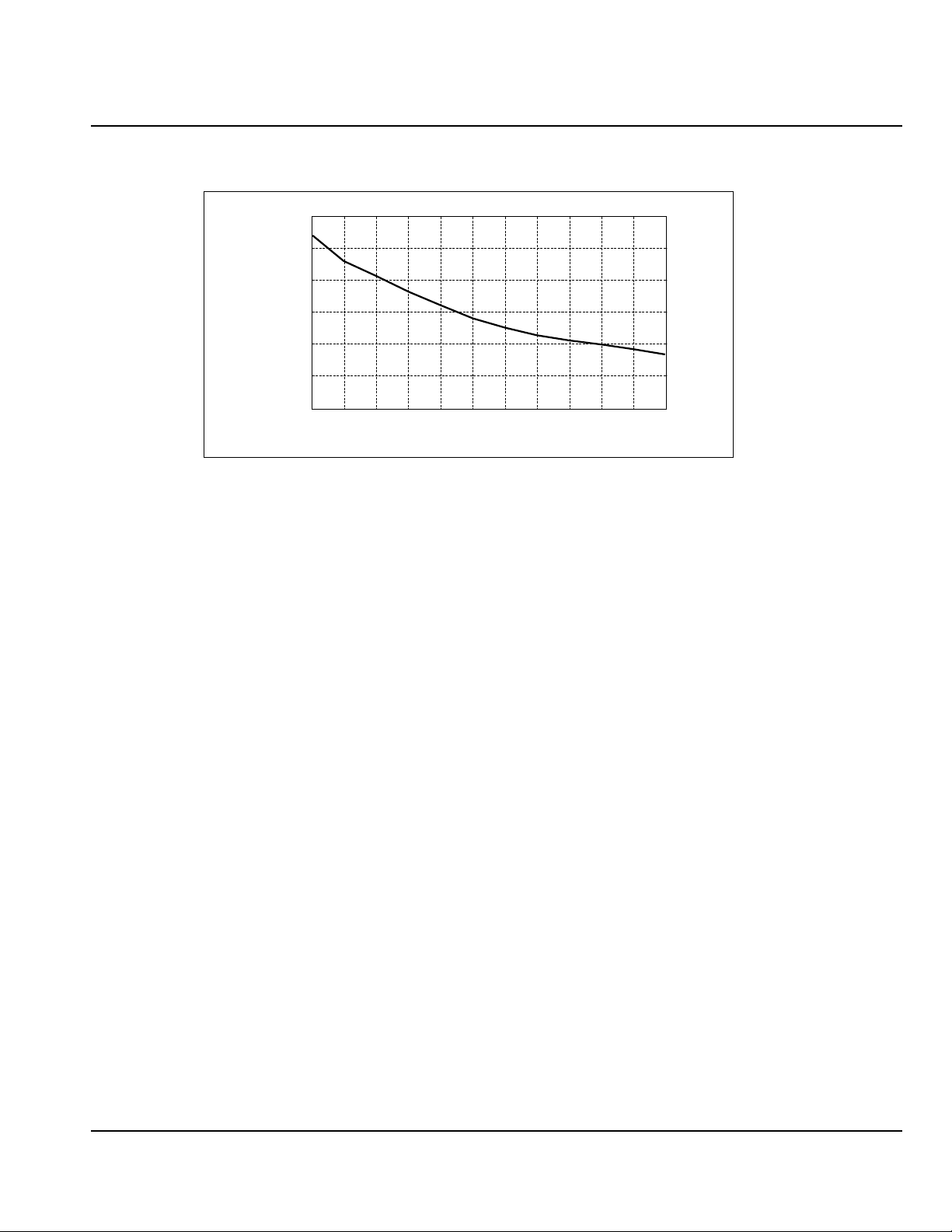

1.2

1

0.8

0.6

SUPPLY CURRENT (A)

0.4

0.2

0

56

8 9 10 11 12 13 14 15 16

7

SUPPLY VOLTAGE (V)

000122

Figure 2-5. NUF8006: Average Transmit Current versus Supply Voltage

July 23, 2002 2-10

Page 21

General CreataLink2 XT Hardware Integrator’s Guide

Specifications

Connectors Description

The CreataLink2 XT device features the following connectors:

External Antenna Connector

The external antenna connector is a succoplate, tin-dipped, SMA female co nnector.

It provides a 50-ohm connection to the CreataL ink2 XT board.

Power/Serial/Parallel I/O

The 22-pin connector provides electrical power, serial, and parallel I/O capability

for the CreataLink2 XT device. Connectors are rated at 2A per contact.

(See Section 6, "Parts Information" for part numbers of mating connectors).

Table 2-4. 22-Pin Vertical Header Connector Signals

Pin

Number

1 Supply Power Supply Connection

2 GND Ground

3 TXDO 3.3V TTL Serial Data from CreataLink2 XT device

4 RS232_TXDO

5 BATT Backup Battery / Alternate Transmit Power Supply

6 BATT_GND Ground

7 RXDI

8 RS232_RXDI

9 RESET_ENABLE

10 EXT_RESET

11 RX_ACTIVE

Signal Name Description

+/- 5V RS-232 Serial Data from CreataLink2 XT

device

TTL Serial Data received by CreataLink2 XT

device

RS-232 Serial Data received by CreataLink2 XT

device

3.3V active-high input used to enable external

reset capability (no connect if no t used)

3.3V active-low in put used to reset Creat aLink2 XT

(no connect if not used)

3.3V when CreataLink2 XT device is receiving a

message

12 TX_ACTIVE

13 A/D_EXT1 Externally supplied analog input

14 A/D_EXT2 Externally supplied analog input

15 HVIO_0 Open collector output/High voltage input

3.3V when Creat aLink2 XT device is tran smitting a

message

2-11 July 23, 2002

Page 22

CreataLink2 XT Hardware Integrator’s Guide General

Specifications

Table 2-4. 22-Pin Vertical Header Connector Signals (Continued)

Pin

Number

16 HVIO_1 Open collector output/High voltage input

17 HVIO_2 Open collector output/High voltage input

18 HVIO_3

19 HVIO_4 Open collector output/High voltage input

20 HVIO_5 Open collector output/High voltage input

21 HVIO_6

22 HVIO_7 Driven output/High voltage input

Signal Name Description

Open collector output/High voltage input

NUF8006 only: Input Capture 2

Open collector output/High voltage input

NUF8006 only: Input Capture 1

July 23, 2002 2-12

Page 23

General CreataLink2 XT Hardware Integrator’s Guide

Specifications

JTAG Communication Port

Table 2-5 shows the 8-pin vertical header connector signals.

T able 2-5. 8-Pin Vertical Header Connector Signals

Pin Number Signal Name Description

1 B++ ICE power source

2 TMP1 Mode select

3 ARM_TDI JTAG Data in

4 ARM_TRST JTAG reset

5 ARM_TCK JTAG clock

6 GND3 Ground

7 ARM_TDO JTAG Data out

8 ARM_TMS JTAG I/O

Accessories

It is assumed that the Embedded ICE or JEENI is used to drive these signals for

➧

on-board/embedded applications only.

The following accessory options are available for the CreataLink2 XT device:

• External antenna kit

• CreataLink2 XT device interface kit

See Section 6, "Parts Information" and the inside of the back cover for part numbers

and ordering information.

2-13 July 23, 2002

Page 24

CreataLink2 XT Hardware Integrator’s Guide General

Specifications

External Antenna Kit

The external antenna kit includes a low profile antenna and coaxial cable with

connector (see

See Section 6, "Parts Information" and the inside of the back cover for part numbers

and ordering information.

Property Description

Type Low profile with radome

Transmit frequ ency 896-902 MHz

Receive frequency 929-941 MHz

Impedance 50 ohms nominal

VSWR 1.5:1 maximum

Table 2-6).

Table 2-6. External Antenna Specifications

Typical Configurations

Polarization Linear, vertical

Gain 0 dBi

Maximum power 5 watts continuous

Coaxial cable

6-foot long RG58/U with SMA male

connector

Interface Kit

The interface kit contains a PCB assembly and two cables. The interface PCB

assembly takes the signals on the 22-pin connector and brings them out for easy

access during hardware and software development. F or a deta iled des cription, see

the Software Integrator’s Guide listed in "Related Publication" section, for develop

ment of an on-board/embedded application or Section 5 of this manual for development of an off-board CLP application.

See Section 6, "Parts Information" and the inside of the back cover for part numbers

and ordering information.

End-User Configuration

The CreataLink2 XT data transceiver has an antenna connected to the SMA

connector on the board and a customer-developed cable to the 22-pin header on the

board for main supply power, alternate power for transmitter/backup battery

supply, I/O, A/D, and serial interface (see

Figure 2-6, top).

-

July 23, 2002 2-14

Page 25

General CreataLink2 XT Hardware Integrator’s Guide

Specifications

Software Development Configuration

The CreataLink2 XT data transceiver is connected to an interface board, which can

be connected to a PC, another device or an embedded ICE or JEENI box (see

2-6, bottom).

Main supply power, alternate

power for transmitter/backup

battery supply, I/O, A/D, and

serial interface connection to

CreataLink2 XT.

Figure

Optional Antenna Kit

or Customer-supplied

connection to SMA connector

on CreataLink2 XT

Creatalink2 XT

SMA

JTAG

(Optional)

Serial

Protocol

Analyzer

22-pin Header

Ribbon Cable

JTAG Cable

(Required for ICE Box

PC or device

under test

DB-9

22-pin Header

Backup Batt. or

Transmit Supply

Backup

Power

Interface Board

JTAG Probe Blk Terminal Blk

but not for JEENI Box)

3-Amp

Power Supply

Main

Power

ICE Box

Connect

Embedded

ICE or

JEENI

Box

(This setup

enclosed in

the dotted box

is only used

for on-board

application

development)

990137-O

Figure 2-6. Configuration Options

2-15 July 23, 2002

99137O

Page 26

CreataLink2 XT Hardware Integrator’s Guide General

Air Interface

Air Interface

Data transport between the host application and the network requires data exchange protocols. In the radio porti on of the network, between the data trans ceiver

and the base stati on, specialized R F protocols carry t he data. Thes e radio protocols

are typically transparent in wireless applications. The FLEXsuite of application

protocols must be used to transport data between applications on either side of

network. FLEXsuite is available from Motorola, Inc. via a license agreement.

Air Interface Protocol

The data transceiver communicates across radio frequency channels via the ReFLEX protocol and an internal 900 MHz radio to operat e across the 12.5 kHz

(ReFLEX 25) or 10 kHz (ReFLEX 50) RF sub-channels in the 900 MHz band. The

network-specific configuration is constant for all like data transceivers on the

network, and includes the network ID, channel list , base f rame, and ho me cont rol

channel.

On ReFLEX ne tworks, the dat a transceive r automatic ally scans avai lable channe ls

to locate an area channel that supports reliable communications. The data trans

ceiver then performs a registration on the channel to establish a connection with

the network. The registration process can be disabled via codeplug configuration

for fixed location applications. The default configuration is Registration Off

(always considered registered). A data transceiver operating in a typica l network,

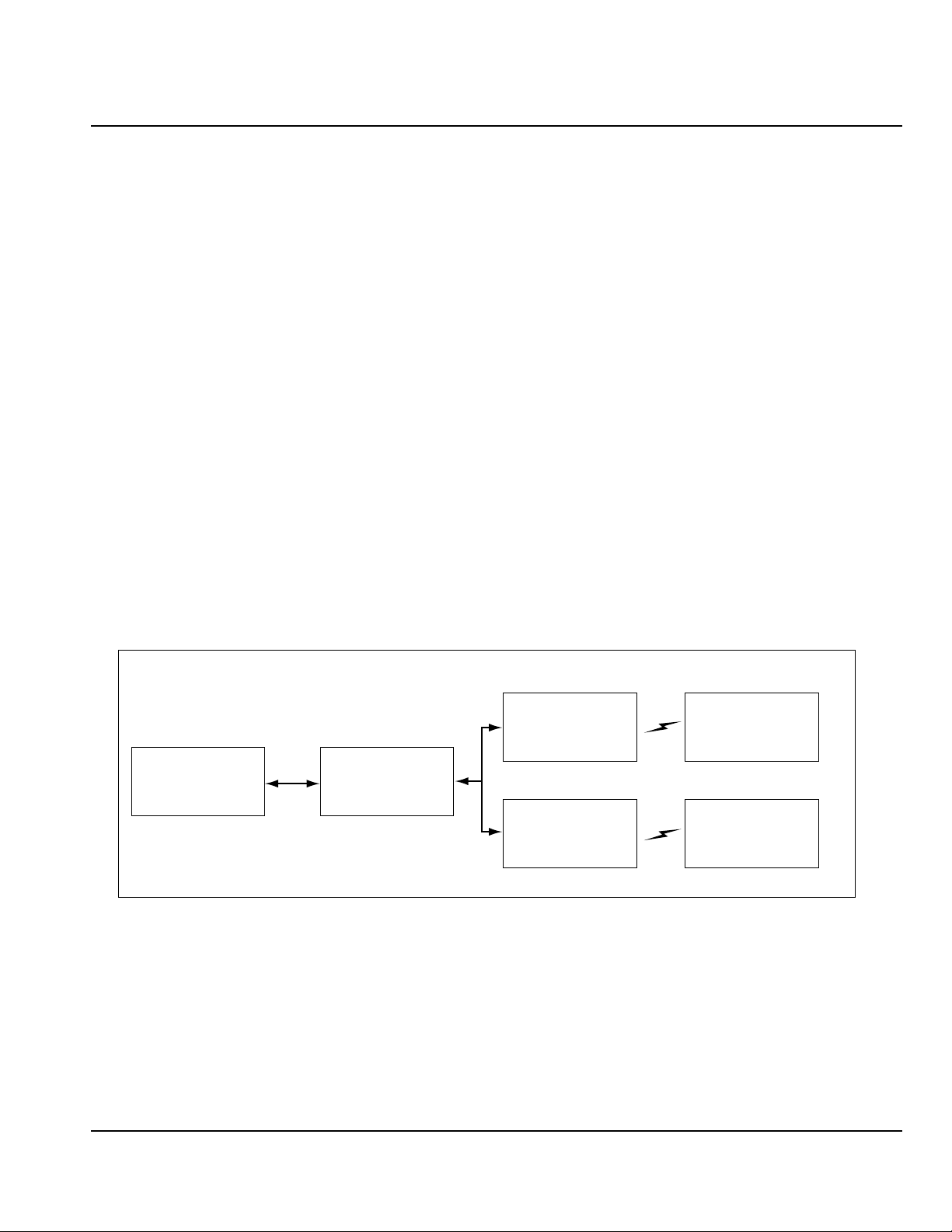

integrated into a product, is shown in

operation, contact your network operator (paging carrier).

Figure 2-7. For more details on network

-

Application

Host or Server

Network

Controller

Figure 2-7. Network Routing

Base Transmitter

or Base Receiver

Base Transmitter

or Base Receiver

(Specific Example)

Vending Machine

with Integrated

Data Transceiver

Host Product

with Integrated

Data Transceiver

(Generic Example)

807SRH-02

990007

July 23, 2002 2-16

Page 27

General CreataLink2 XT Hardware Integrator’s Guide

Air Interface

ReFLEX Network Operation

All two-way messaging networks that support two-way data communications with

CreataLink2 XT device use the ReFLEX protocol. The network can be viewed as

two separate one-way ne tworks. For messages dire cted to the data trans ceiver, the

network controller rout es the messages to one of many high po wer transmitter sites.

For messages from the data transceiver, a higher density of receiver sites are

provided to compensate for the lower transmit power of the data transceiver.

The Global Positioni ng System (GPS) synchroni zes the downlink and upl ink paths,

allowing downlink control of the uplink communications path. The network control

ler schedules all transmissions from the data transceiver for optimal utilization of

the uplink communications path.

Downlink messages are deli vered at a time when the data transceiver is guara nteed

to be listening, as de fined by the data transcei ver battery-save mode/colla pse value.

Each unit is assigned certain frames in which its messages can be received. The

personal address collapse and information services collapse values are used to

schedule those frames a uni t mus t deco de f or mess ag es. If y ou u se the se coll apse d

frames, you are trading battery life for the more frequent delivery of messages.

Therefore, collapse frame use provides a battery-save mode and defines the per

centage of the time the data transceiver is listening to the channel for messages.

The remainder of the time the data transceiver is in a low-power state, and is not

listening to the carrier channel for messages. It is important for the data transceiver

and network controller to remain synchronized in order for mes sages to be delivered

successfully.

-

-

The downlink is also referred to as the forward path. The uplink is also referred to

➧

as the reverse path.

2-17 July 23, 2002

Page 28

General CreataLink2 XT Hardware Integrator’s Guide

Product Functionality

Product Functionality

The data transceiver relies on system software for basic operational instructions,

and on configura tion parameter values to meet data transceiver and network

interface requirements.

Operating System

The data transcei ver operating system is based on the FLEX Kernel operating

system. It can be reloaded or upgraded by the service center. For third-party

software developers, tools are available to load in main operating code.

Power-up Operating Mode

The data transceive r operates in one of two power-up modes, depending on the

condition of the supply voltage. If the supply voltage is not present, the data

transceiver does not power up. Minimize cable length to limit the voltage drop across

the cable during RF transmissions.

Supply Voltage At or Below Minimum Voltage

If the supply voltage level is less than or equal to 4V, the condition is detected and

the data transceiver does not power up.

If the supply voltage is greater than 4V, but less than 5V, the data transceiver

powers up but the performance will not be optimal. In this state, the data trans

ceiver can still communicate with the resident host but:

• attempts to initiate messages are likely to fail.

• receive sensitivity is drast icall y affecte d.

• transmit power and the corresponding FCC spectral mask are degraded.

When the supply volt age rises above 5V, the data transcei ver turns on and the unit

sucessfully enters the message-search mode.

Adequate Supply Voltage

A normal power-up occurs when the supply volta ge is above 5V. The data transcei ver automatically enters the message-search mode.

Message-Search Operating Mode

The message-search mode is the data tr ansceiv er’s main operat ing mode . When it

powers up, the transceiver turns ON, and the unit begins to search for a valid

ReFLEX frame. When the unit detects what appears to be a valid ReFLEX frame,

it synchronizes with this channel and begins to decode the contents of the frame.

The unit then attempts to register with the network (if the auto-registration feature

is enabled). The default configuration is Regist ration Off (alway s considered reg is

tered). After successful registration, the un it begins normal message de coding and

searches for its assigned ReFLEX address(es).

If the data transceiver does not detect a valid ReFLEX frame wit hin approximately

1.5 minutes, the unit enters a low current cons umption mode. This mode conserves

power for a pre-programmed length of time. When the time has elapsed, the unit

attempts, once again, to acquire a valid ReFLEX frame. The unit alternates between

-

-

2-18 July 23, 2002

Page 29

General CreataLink2 XT Hardware Integrator’s Guide

Product Functionality

searching for a valid ReFLEX frame and low current mode until it detects a valid

ReFLEX frame.

If the data transceiver detects a valid ReFLEX frame and has become synchronized,

but does not detect its address, the unit stays on the channel. It continuously

decodes frame data and waits for its address(es).

Address Capability

The data transceiver can receive the following addresses:

• ReFLEX 25: 1 personal service address and 6 information service addresses

• ReFLEX 50: 2 personal service address and 1 information service address

Additionally, for the ReFLEX 50 network only, each information service address

can have up to 32 subaddresses.

Duplicate Message Detection

To ensure proper message delivery, the data transceiver detects and cancels

duplicate messages sent via the pagi ng system. If it finds a dupli cate message , the

data transceiver discards it in a manner transparent to the host application.

Message Deletion

Unit IDs

When all message slots are occupied, or unused message memory is insufficient,

the data transceiver deletes the oldest message to make room for a new message.

Read messages are deleted before unread messages.

The data transceiver contains the following user identification strings within the

codeplug:

• Serial number

• Electronic serial number (ESN)

The strings are unique to each data transceiver.

Serial Number

The serial number consists of ten bytes of data stored in the data transceiver

codeplug. It is factory-programmabl e only.

Electronic Serial Number (ESN)

The ESN consists of four bytes of data stored in the data transceiver codeplug. Each

data transceiver is equipped with a unique serial number which serves as the

reverse channel address of the data transceiver.

The serial number and ESN are data transceive r-specific. If the unit is changed for

service, these numbers als o change. Th e carrier must be notified to make the PIN

number point to the new serial number and ESN.

2-19 July 23, 2002

Page 30

General CreataLink2 XT Hardware Integrator’s Guide

Product Functionality

Message Storage and Lengths

Messages are s tored in approx imately 32 kbyte s of RAM. Messa ge downlink le ngth

is a maximum of 1 kbyte, and uplink length is a maximum of to 2 kbytes. Consult

your carrier to determine message lengths supported on the network (see " Handling

Large Messages", in Section 2 - Getting Started, in the Software Integrator’s Guide).

2-20 July 23, 2002

Page 31

General CreataLink2 XT Hardware Integrator’s Guide

Product Functionality

Acknowledgment of Received Messages

System Acknowledge

The data transceiver transmits an Acknowledge Transmission signal (ACK) to

acknowledge automatically the receipt of a message. The data transceiver also

transmits a Nega ti ve Ack nowl ed ge Tra nsmi ssi on si gnal ( NAK) whe n me ssage s are

not received correctly. If the data transceiver transmits a NAK, the system resends

the message.

Registration Request

Registration enables nat ionwide systems to t rack the data tran sceiver from region

to region. The sys tem then transmits messa ges only to that regi on. The Enable Auto

Registration codeplug option enables automatic registration. The default registra

tion is OFF, because it is considered always registered for fixed applications.

The data transceiver genera tes th e regi st rati on reques t mes sa ge an d the regist ra tion request ALOHA packet with the current zone on the following occasions:

• A valid zone change: The data transceiver monitors the Zone ID field in the

ReFLEX frame header. When it recognizes that the frame header has changed,

the unit automatically sends a registration message after a delay.

• Power-Up: The data transceiver automatically transmits a registration request

only if automatic registration is enabled. Automatic registration is only

required if the application is mobile. SmartSynch, Inc. does not recommend

automatic registration for fixed location installations.

• A change from out-of-range to in-range: When the data transceiver goes out of

forward-channel range, and then returns within forward-channel range, the

data transceiver automatically transmits a registration request after a delay.

-

Configuration Parameters

Data transceiver configuration data is categorized as follows:

• The service provider establishes the network-specific parameters for the data

transceiver configuration. Typically, parameters are constant for all like

devices on the network. The parameters include the default channel list, roam

ing parameters, and other service provider protocol-related parameters.

• Only the factory or authorized service depot sets fixed device-specific parameters. These parameters indicate the type of radio installed, the type of data

transceiver , and the hardware revision level. Significant configuration items in

this category include the ESN, device type, hardware revision level, protocol

type, and low voltag e thresholds.

PPS Utility

Product Family 91B Programming Software (PPS) is a configuration utility that

enables some codeplug options to be programmed into the data transceiver. This

application runs on a stand-alone PC with the Windows 95®, Windows 98®, or

Windows NT® operating environment. The PPS interacts with the data transceiver

via the serial port. Because the 22-pin connector that contains the serial I/O is not

standard, you must connect the DB9 connector on the interface kit or a custom cable

to the PC serial port. The Programming Software Guide-Integrators, listed in

"Related Publications", provides instructions for configuring data.

-

2-21 July 23, 2002

Page 32

General CreataLink2 XT Hardware Integrator’s Guide

Product Functionality

For user-configured items, see Programming Software Guide-Integrators, listed in

➧

"Related Publications."

End-User Application Software

To develop your own embedded application r efer to the Software I ntegrator’s Guide

listed in "Related Publications."

Serial Interface

External host devices communicate with the data transceiver across the serial

interface via the asynchronous Communication Linking Protocol (CLP

mands.

The data transceiver supports a default serial baud of 9600 bps, no parity, eight

data bits, one star t bit, and one stop bit. The host product must provide a full duplex

(both directions at the same time) pass-through link at this speed.

TM

) com-

Communication Linking Protocol (CLP)

The CLP application contains a set of commands that enable the host to send and

retrieve messages, retrieve and modify select configuration information, and re

trieve status info rmation from the data transc eiver. When longer transmissio ns are

required to transfer da ta, the XMODEM file-t ransfer protocol provides error check

ing during transmission across the serial link.

The CLP application provides general wireless messaging services that are independent of the underlying RF protocol.

For a detailed descri ptio n of se rvi ces prov id ed, s ee t he Communicati on Linking

Protocol R eference Man u al listed in "Related Publications.".

-

-

2-22 July 23, 2002

Page 33

INTEGRATION OVERVIEW

Page 34

Page 35

91B

CreataLink2 XT Hardware Integrator’s Guide Integration Overview

3Integration Overview

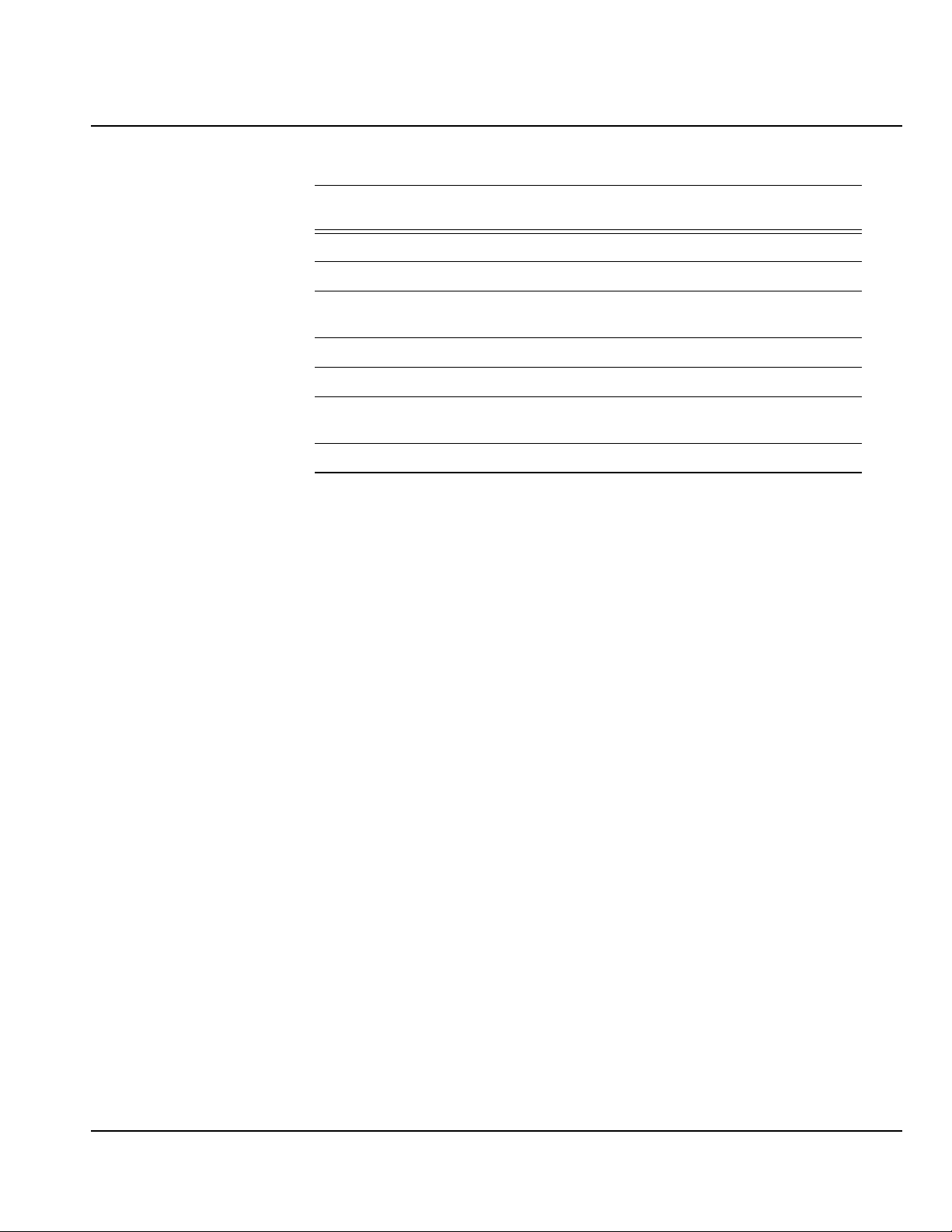

Contents

Contents

Integration Goal and Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Usage Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Message Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Service Strategy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

System Design of Integrated Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Hardware Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Antenna Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Software Applications Development . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

EMI and Desense Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Regulatory Approval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Final Assembly Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Installation and Field Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Customer Problem Isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Wireline and Wireless Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Power Conservation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Network Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Throughput . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Design Tips for Serviceability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Data Transceiver Accessibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

SmartSynch Software Utilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Developing Diagnostic Software Utilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Environmental Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Coasting Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

ESD Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Regulatory Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

June 18, 2002 3-i

Page 36

Integration Overview CreataLink2 XT Hardware Integrator’s Guide

Contents

3-ii June 18, 2002

Page 37

CreataLink2 XT Hardware Integrator’s Guide Integration Overview

3Integration Overview

Integration Goal and Objectives

Integration Goal and Objectives

SmartSynch, Inc. recommends that you consider the impact of each task on the

development plan and allow sufficient time for required activities. Try to identify

critical path activities early in product development. The following list summarizes

the development ta sks. These tasks are disc ussed in detail in the following chapters.

• Define a usage model.

• Define a message model that specifies how many messages will be sent/

received and how often.

• Define a service strategy.

• Define system design of integrated product

• Design the hardware.

• Consider power supply options.

• Identify the source antenna.

• Design, code, and t est an end-to-end application between the data transceiver

and host device.

• Obtain regulatory approval.

• Set up an assembly and final test environment.

• Perform a field installation functional verification procedure.

• Develop an in-the-field problem isolation test strategy and the necessary test

tools.

Usage Model

Message Model

As a developer, you must have, above all, a clear understanding of the end-use of

the product. End-use directs the devel opment process; all design considerations aim

to meet the needs of the final customer.

Design issues related to a mo bile device, such as altern ator noise and vibration and

handling of changing RF cond itions, are different from design issues required for a

fixed-point telemetry application powered by line power, battery, or solar panel.

End-user priorities should determine the critical engineering tradeoffs in the

product design.

You are responsible for defining the usage model. SmartSynch, Inc. is available to

provide assistance and answer questions but is not directly involved in this phase

of the project.

The message model is related to the usage model. Create the message model to

determine how much and how often d ata is sent in each of the up link and downlink

directions. Power supply requirements and network message routing selection

depend on this data determination. The amount of data sent and received is also

relevant in calculating the cost of airtime. Many engineeri ng decisions req uire the

message model as source data.

You are also responsible for defining the message model. A typical approach to

creating the message model is to define the peak and average throughput

requireme nts b ased on th e ty pe o f ap plic at ion. Take into acc oun t bo th no rmal and

unique conditions. Typical current consumption figures for each of the various

models of operation (transmit, receive, standby) are provided in this manual.

For ReFLEX networks, message latency is inherently longer than in circuitswitched connections. Use shorter messages to minimize latency and increase

reliability.

July 10, 2002 3-1

Page 38

Integration Overview CreataLink2 XT Hardware Integrator’s Guide

Integration Goal and Objectives

Service Strategy

The objective of the service strategy is to define processes by which to ident ify the

cause of a user’s problem and keep the customer operational during repair.

Diagnostics

It is best to test the data transceiver while it is integrated with the host at the user’s

site. To provide this function, the product must include a pass-through mode of

communications for the data transceiver. SmartSynch, Inc. recommends that you

incorporate a test mode that extracts details of the status of the data transceiver

in the host application.

Customer Support

For uninterrupted service, SmartSynch, Inc. recommends that you install a spare

unit and call the service provider to update its database with the spare unit

information. Return the defective unit to the SmartSynch, Inc. warranty repair

center for repair and return.

System Design of Integrated Product

Power source, RFI/EMI issues, and end-user environment are crucial

considerations that you must address while meeting CreataLink2 XT device

environmental and power supply requirements.

CreataLink2 XT device is a board-level product. It is your responsibility to protect

➧

the device from environmental hazards such as dust, rain, condensing humidity,

ESD, etc.

Hardware Design

To integrate a wireless data transceiver into a hardware design, you must consider

power supply, battery size (where applica ble), heat dissipation, isolation from EMI,

and physical mounting of the unit for proper groundi ng. SmartSynch, Inc. can

provide recommendations for hardware design, where applicable.

Power Supply

Power supply requirements vary according to the needs defined by the usage and

message models. Consider the following when you design a power su pply:

• Current drain of the data tra nsceiver in its various operating modes

• Ripple and noise on the power lines

• Supply instantaneous curren t (up to 1400 mA) to allow proper transmitter

operation (2.5 A supply if using the I/O)

These requirements define the type of power supply (linear or switched) to use with

the wireless d ata t rans cei ver. See Sec tion 2, Tabl e 2- 1 " Gene ral Spe cif icat ion s" for

power supply requirements.

3-2 July 10, 2002

Page 39

CreataLink2 XT Hardware Integrator’s Guide Integration Overview

Integration Goal and Objectives

Antenna Configuration

The data transceiver is available with an optional antenna from SmartSynch, Inc.

See Section 4, "Hardware Integration" for other antenna s uppliers.

Use the following guidelines when you mount the data transceiver:

• Mount the device away from any metallic or conductive enclosures.

• Mount the device away from items that produce RF noise, such as a poorlyshielded PC.

• Use an antenna with a gain of 0 dBi to +3 dBi to maximize the effective

radiated power (ERP) of the antenna.

• Mount the antenna according to the guidelines in Section 4.

• If you must mount the device in a metallic or conductive enclosure, mount the

antenna outside the enclosure and connect it to the data transceiver via the

female SMA connector with the coaxial cable (RG58).

Software Applications Development

In addition to the specific software application, SmartSynch, Inc. encourages you

to incorporate wireless-specific reporting and monitoring features into the

application, so as to make it more sensitive to the wireless environment

(registration states and messaging status information, for example). The data

transceiver uses a packetized serial interface (CLP) to enable the application to

monitor wireless link-related information and application-specific data

simultaneously. T he Communication Linking Pr otocol Reference Manual describes

this interface in more detail. If you use an on-board application configuration, the

required information is available via the API in the Software Integrator’s Guide.

EMI and Desense Testing

Data transceiver operation requires that there is minimum electromagnetic

interference radiating from the product platform. Exces s noise significantly reduces

the effectiveness of the wireless data transceiver, making it less likely to receive

network messages.

Regulatory Approval

Every commercial RF device must display an FCC regulatory label on the outside

host case. The FCC also requires the wireless data transceiver to transmit random

data patterns on specific freque ncies whi le incorpo r ated in the host platform. The

data transceiver incorporates special debug modes to help test for regulatory

compliance with this requirement. For most applications, no additional FCC

certification is required.

Final Assembly Test

To verify proper assembly of the final product (ant enna connection and opera tional

serial and/or parallel port) perform an end-to-end test. This test verifies that the

final product can receive and transmit at the required signal levels and has

operational I/O ports.

July 10, 2002 3-3

Page 40

Integration Overview CreataLink2 XT Hardware Integrator’s Guide

Integration Goal and Objectives

Installation and Field Test

A product shipped to a site might be mounted in a location that restricts RF

communications. To verify that the data transceiver is located in an area of good

coverage, and that an end-to-end loopback message is possible, the product needs

a software application to perform the test or a pass-through mode that enables a

message to be sent and received. Work with your carrier to determine exactly how

to do this on the network.

The most effective approach to field testing is to include an installation test

procedure as part of the standard host application software. SmartSynch, Inc. can

recommend the specific network information available from the data transceiver

and how to best implement an end-to-end loopback t est.

3-4 July 10, 2002

Page 41

CreataLink2 XT Hardware Integrator’s Guide Integration Overview

Customer Problem Isolation

Customer Problem Isolation

When a customer reports a pro blem from th e field, you must i solat e the so urce. To

isolate the prob lem, determine if it is the network , the wireless data transceive r, or

the host product that is causing the p roblem. Of ten, th e custo mer misunde rstands

the use of the product. Off-site troubleshooting reduces the number of returned

products and service costs, particularly if the host must be disassembled to remove

the data transceiver.

SmartSynch, Inc. recommends that the product application (both at the terminal

and host ends) incorporate diagnostic software that enables you to identify problems

from a remote site. One method is to incorporate progressively deeper loopback

tests. Use progressively longer message lengths to determine when the

communication link fails.

Make this diagnostic function part of the standard software load. SmartSynch, Inc.

can indicate the types of failure condition reporting mechanisms present in the data

transceiver and recommend implementations.

July 10, 2002 3-5

Page 42

Integration Overview CreataLink2 XT Hardware Integrator’s Guide

Wireline and Wireless Communications

Wireline and Wi reless Communications

Consider the similarities and differences between wireline and wireless

communications: Wireline data communications involve two data transceivers that

use a dial-up telephone link to send and rece ive da ta. This t ype of communi cati on

is known as "full duplex, circuit-switched communications." Full duplex indicates

both sides can send and receive simultaneously. Circuit-switched indicates the

sender and receiver have access to the entire communications line at all times

without sharing wit h ot her use r s. T he wirel ine me tho d o f co mmunicat ions wa stes

air time in a wireless setting because, typically, one side does mo st of the

transmitting while the other side is listening.

In wireless packet communications, the sender and receiver can share the

communication media with other users by sending packets, or bursts of data. This

method of communication enables other users to send their packets between the

gaps. To reduce data transmission cost, the communications are usually sent half

duplex; the sender does not listen while it transmits.

Some data communications protocols (XMODEM and YMODEM) are designed to

be used on a full dup lex, circuit-switched co nnection. The user p ays for the number

of minutes the circuit is open, regardless of the amount of data sent. Short timers,

numerous link level acknowledgments, and error correction help speed the data

transfer. With wireless packet data, the user is billed only for the data actually sent.

It makes more sense to consider communications in terms of datagrams ( similar to

what is used in IP). Much of the error correction and acknowledgment information

sent in wireline communications becomes an extra cost burden because the packet

data protocol already provides for forward error correction and link level

acknowledgments.

Determine which applications are best suited f or wireless and which applications

need to be modified before you use wireless. Message-based applications such as

database lookup, e-mail without attachments, and point-of-sale transactions are

suited to wireless communication, often without modification. Applications that

send handshaking messages or applications with timers that resend too quickly are

unsuitable for wireless communica tions because of the unnecessary overhead traffic

they generate.

Power Conservation

For installations that require power conservation (battery or solar cell powered),

consider data transceiver power consumption in the various operating states and

how data transceiver configuration affects power consumption. The data

transceiver uses the ReFLEX protocol battery-save cycle configuration, a customerordered option, for low po wer cons umption. To reduce ave rage power co nsumption

further, activate the data transceiver only when needed (see Table 2-3, "Power

Connection" section, and "Power Supply Circuit Details" section).

Network Communication

There are two ways to communicate with a network:

• Connection

• Connectionless

Most packet communication is connectionless and does not require call setup and

teardown for communications. For the most efficient airt ime solution, SmartSynch,

Inc. recommends a connectionless communications model.

3-6 July 10, 2002

Page 43

CreataLink2 XT Hardware Integrator’s Guide Integration Overview

Wireline and Wireless Communications

Throughput

The network throughput of the device de pends on several factors:

• Raw throughput of the radio channel

• Overhead involved in forward error correction

• Support for packet headers

• Number of active users on a shared RF channel

• Network configuration

July 10, 2002 3-7

Page 44

Integration Overview CreataLink2 XT Hardware Integrator’s Guide

Design Tips for Serviceability

Design Tips for Serviceability

Consider the concept of serviceability early in the design. Create a functional service

strategy that includes procedures fo r performing unit-level screening. The test must

determine whether a fault lies with the data transceiver or with the product into

which the data transcei ver is integrated. The test must also screen for network

problems and human error.

Data Transceiver Accessibility

Locate the data transceiver so that the serial I/O, parallel I/O, and antenna

connections are accessible. Quick access to the data transceiver enables easy

removal and installation, troubleshooting, and functional testing.

SmartSynch Software Utilities

SmartSynch, Inc. provides the programming software utility with which to

configure the data tran sceiver. The PPS operates with Windows 95, Windows 98 and

Windows NT and communicates via the RS-232 serial connection. For

microprocessor-based host pla tforms, provide a pass-through mode that enables the

programming software utility to run while the data transceiver is connected to the

end-user’s host design or system.

Developing Diagnostic Software Utilities

A thorough serviceability plan includes a needs assessment for developing software

utilities that help you to identify communication problems among the product, the

data transceiver, and the RF network. These utilities must send commands to the

data transceiver, evaluate responses, perform network connectivity testing, and

verify data communications with the network.

Develop these utilities via the CLP command set or the internal CLP API if you are

developing an on-board/embedde d application. The CLP API provides t he capability

to monitor and evaluate data transceiver operating conditions and all

communications to and from the wireless network host.

The CLP command set and CLP API supports reading of a diagnostic buffer that

provides the view of the network from the data transceiver. This utility is essential

for field service engineers and service center technicians attempting to diagnose

product problems, and trace such probl ems to failed assemblies or mismanaged

communications links. See the "Diagnostic Mode" subsection of the "Off-Board

Application Development" chapter in the Software Integrators Guide for details.

Pager to/from e-mail and pager-to-pager communication is supported in the

ReFLEX protocol, which SmartSynch, Inc. reco mmends for diagnostics. An example

of this feature is sending a message to a pager worn by the technician servicing the

equipment. This enables you to perform local troubleshooting.

3-8 July 10, 2002

Page 45

CreataLink2 XT Hardware Integrator’s Guide Integration Overview

Environmental Issues

Environmental Issues

The CreataLink2 XT device is designed as an OEM module. Any data transceiver

applications are house d i n a host p roduct . T he d ata trans cei ver ha s been t es ted t o

environmental specifications that meet the applications of most inte grators.

As an integrator, you must meet the following guidelines:

1. The data transceiver must be housed in an enclosure to protect the board

assembly from condensation and water/dust/salt fog intrusion. Any

condensation on board assembly will cause CreataLink2 XT device to be

non-functional.

2. Provide mechanical support of the PCB to withstand drops, transport stress,

and handling.

3. Power supply must be clean per Table 2-1.

4. Ambient air temperature around the CreataLink2 XT device must be

maintained between -40 degrees C and +85 degrees C.

Coasting Performance

Coasting is the process by which the data transceiver remains synchronized to the

ReFLEX network during periods when ReFLEX information (i.e. frames) is not

being received by the data transceiver. The absence of ReFLEX frames can be

caused by the data transcei ver being in an RF fade or by the network being

configured to intentionally st op transmi tting ReFL EX fra mes for a p eriod o f time .

Synchronization, in this case, has both timing and frequency elements.

Maintaining timing synchronization with the ReFLEX system is critical for both

network and data t ransceive r operation. When the da ta transcei ver has a me ssage

to transmit into the network, it first informs the network that it has data to send.

The network then schedules the data transceiver transmission and informs the data

transceiver of the specif ic time to tra nsmit its data. Failure on the part of the data

transceiver to remain very closely synchronized to the network will result in the

transmission occurring at an incorrect time and an in creased p robabilit y of a failed

message delivery.

Maintaining frequency synchronization is critical for both receive and transmit

operations on the data transceiver. Algorithms deployed in the data transceiver

firmware use received ReFLEX frames for frequency correction. Following the

absence of ReFLEX frames, should the tune d frequency of t he receive r drift too far

from the target, messages directed to the data transceiver will not be received.

Moreover, the network wi ll not receive messages transmitted by the data

transceiver if the frequency of the data transceiver transmitter has drifted out of

tolerance.

For a data transceiver in a constant ambie nt temperature environment, timing and

frequency errors are very small and can be largely ignored. However, in a dynamic

temperature environment, temperature variation of component tolerances can

cause synchronization to be lost. Algorithms in the data transceiver firmware have

been developed to track, predict, and correct both timing and frequency errors

within certain design limits.

A data transceiver in an open air environment (i.e. not in a housing) can maintain

timing and frequency synchronization with the network in the presence of a

temperature gradient not excee ding 1°C/minute. The addition of a housing a round

the data trans ceiver provides an insulating layer which re duces the grad ient of the

temperature change experien ced by t he co mponen ts on t he da ta tr anscei ve r PCB.

It is up to the integrator to select appropriate housing material and thickness, and/

July 10, 2002 3-9

Page 46

Integration Overview CreataLink2 XT Hardware Integrator’s Guide

Environmental Issues

or provide another mean s of insula ting the data transceive r sufficientl y to achieve

a temperature gradient at the board level not exceeding 1°C/minute.

General Precautions

Failure to provide adequate protection will void the device warranty.

G

Take the following general precautions to prevent damage to the data transceiver:

• Handle the data transceiver as little as possible.

• Wear a grounded antistatic wrist strap while you handle the data transceiver.

• Do not bend or stress the data transceiver.

• Insert connectors straight and evenly to avoid bending pins.

3-10 July 10, 2002

Page 47

CreataLink2 XT Hardware Integrator’s Guide Integration Overview

Environmental Issues

ESD Precautions

This data transceiver contains components that are sensitive to ESD. People

typically experience up to 35 kV ESD while walking on a carpet in low humidity

environments. Many electronic compone nts can b e damaged by few er than 10 00V

of ESD. Observe handling precautions when you service this equipment:

• Eliminate static generators (plastics, styrofoam, etc.) in the wo rk area.

• Remove nylon or double knit polyest er jackets , roll up long sl eeves , and remove

or tie back loose-hanging nec kties.

• Store and transport all static-sensitive components in ESD protective

containers.

• Disconnect all power from the unit before ESD sensitive components are

removed or inserted, unless otherwise noted.

• Use a static safeguarded workstation. Such safeguards includes a conductive

wrist strap, ground cords, and static control table mat.

When antistat ic facilities are not available, use the following techn ique to minimize

the chance of ESD damage to equipment:

• Place the static-sensitive components on a conductive surface when not in use.

• Make skin contact and maintain the contact with a conductive work surface

before you handle the static-sensitive component.