Page 1

The WindowWasher™ by ITR

Installation and

Operating Manual

Diesel Fired Continuous Output

Window Cleaning Water Heater

Page 2

Copyright © February 2012

International Thermal Research

IN CANADA: IN THE UNITED STATES:

2431 Simpson Road 11915 NE 56

Richmond, BC, Canada V6X 2R2 Vancouver, WA, USA 98682

Tel: 1-800-755-1272 or 604-278-1272 Tel: 1-800-993-4402 or 360-993-4877

Fax: 604-278-1274 Fax: 360-993-1105

Email: info@itrheat.com Email: info@itrheat.com

th

Circle, Suite B

Website: http://www.itrheat.com

All rights reserved. No part of this manual may be reproduced or

transmitted in any form by any means, electronic or mechanical,

including photocopying and recording, information storage,

retrieval, or transmission, without permission in writing from

International Thermal Research

Right to Modify:

Due to our commitment for quality and ongoing product

improvement, ITR reserves the right to modify or change

without notice, any materials, applications, equipment,

accessories, and/or prices. All measurements and weights are

approximate.

Page 3

Table of Contents

Table of Contents

Section 1, Overview .................................................. 1-1

1.1 Unpacking The WindowWasher™ by ITR ........... 1-2

1.2 Protect Your Warranty ................................... 1-2

1.3 The WindowWasher™ by ITR Features ............. 1-3

1.4 Critical Factors ............................................. 1-4

1.5 Equipment, Tools and Skills ............................ 1-4

1.6 Testing and Inspection .................................. 1-5

Section 2, Mounting - The WindowWasher™ ............ 2-1

2.1 Before You Begin .......................................... 2-1

2.2 Your Mounting Location ................................. 2-2

2.3 Procedure .................................................... 2-4

Section 3, Installing the Exhaust System .................. 3-1

3.1 Before You Begin .......................................... 3-1

3.2 Mounting Location ........................................ 3-1

Recommended Exhaust Outlet Locations ............ 3-1

Recommendation for Installation ...................... 3-2

What NOT to Do ............................................. 3-4

3.3 Procedure .................................................... 3-4

Section 4, Installing the Fuel System ........................ 4-1

4.1 Before You Begin .......................................... 4-1

4.2 Fuel System Operation .................................. 4-1

Recommendation for Installation ...................... 4-1

4.3 What NOT to Do ........................................... 4-2

4.4 Procedure .................................................... 4-3

Section 5, Wiring the Electrical System ..................... 5-1

5.1 Before You Begin .......................................... 5-1

5.2 12 VDC ....................................................... 5-1

5.3 Remote Operating Panel Cable ........................ 5-2

5.4 Main Electronic Control Board ......................... 5-2

5.5 What NOT to Do ........................................... 5-3

iv WindowWasher by ITR Installation Manual

Page 4

Table of Contents

Section 6, Plumbing the System ................................ 6-1

6.1 Before You Begin ......................................... 6-1

6.2 Plumbing Installation .................................... 6-2

6.3 What NOT to Do ........................................... 6-4

6.4 Installation Procedure ................................... 6-4

Section 7, Operating The WindowWasher™ by ITR .... 7-1

7.1 Operating Instructions for

The WindowWasher™ by ITR ......................... 7-1

7.2 Turning the Power to

The WindowWasher™ by ITR ON .................... 7-2

7.3 Activing the Burner (Primary) ........................ 7-2

7.4 Functions of the Remote Operating Panel ......... 7-2

7.5 Functions of The WindowWasher™ by ITR

Control Panel ............................................... 7-3

7.6 Maintenance ................................................ 7-5

7.7 Protect The WindowWasher™ by ITR™ ............ 7-8

7.8 General Troubleshooting ............................... 7-8

Section 8, Warranty and Service ................................ 8-1

8.1 Warranty .................................................... 8-1

8.2 Installations ............................................... 8-1

8.3 Limited Warranty ......................................... 8-2

8.4 Owner’s Responsibility .................................. 8-2

8.5 Not Covered Under Warranty ......................... 8-3

8.6 Customer Service Calls ................................ 8-4

8.7 Returns ...................................................... 8-4

8.8 Telephone Service ........................................ 8-5

International Thermal Research International Thermal Research Ltd. February 2012

Page 5

Table of Contents

List of Figures

Figure 1-1 Window Washer ......................................... 1-1

Figure 2-1 Dimensions ............................................... 2-3

Figure 2-2 Location of Mounting Brackets

Insets: Bracket/Nut/Bolt Configurations ........ 2-4

Figure 3-1 Installing the Exhaust System (Up Exhaust) ... 3-4

Figure 5-1 System Wiring ........................................... 5-3

Figure 6-1 Plumbing Fittings ........................................ 6-1

Figure 7-1 The WindowWasher™ by ITR – Fittings .......... 7-1

Figure 7-2 Remote Operating Panel .............................. 7-3

Figure 7-3 The WindowWasher™ by ITR – Control Panel .. 7-4

vi WindowWasher by ITR Installation Manual

Page 6

Table of Contents

International Thermal Research International Thermal Research Ltd. February 2012

Page 7

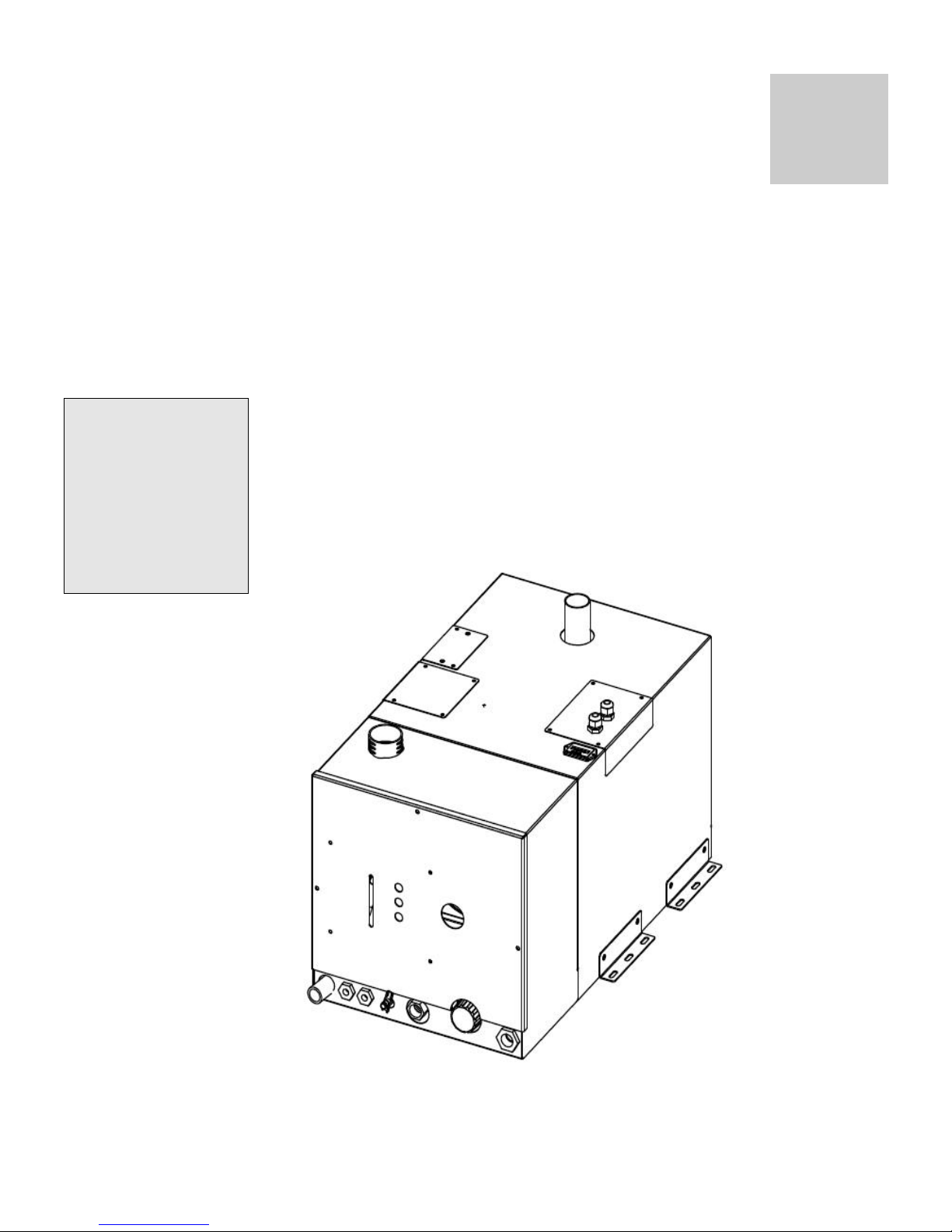

Section

1

Overview

Thank you for purchasing The WindowWasher™ by ITR for portable hot

water window cleaning.

Some of the figures

in this manual

represent a typical

installation, but

other configurations

or methods may be

acceptable. If in

doubt, obtain

approval from ITR.

This section describes features of The WindowWasher™ by ITR and

covers critical information you need to know before beginning the

installation, including how to protect your warranty, and tools and

equipment needed.

Figure 1-1

International Thermal Research 1-1

Page 8

Section 1, Overview

1.1 Unpacking The WindowWasher™ by ITR

When you receive The WindowWasher™ by ITR:

1 Unpack it carefully.

2 Check each component against the provided parts list to ensure that

you have everything and that all parts arrived undamaged.

3 If you discover any missing or defective parts, call ITR immediately.

4 If you are not installing The WindowWasher™ by ITR right away,

secure all components so none will be misplaced.

5 Before installing The WindowWasher™ by ITR, read the rest

of Section 1 – Overview. It contains critical information for a

proper installation.

A properly installed WindowWasher™ by ITR is essential for several

reasons:

• To ensure that you and/or your customers receive satisfactory

results.

• To ensure a trouble-free installation, a successful inspection and

testing process and ease of future maintenance.

NOTICE

• To protect your Warranty.

1.2 Protect Your Warranty

This document reflects approved installation techniques, methods, and

materials, and applies only to ITR equipment. The WindowWasher™ by

ITR is only guaranteed by ITR if the entire system has been installed

according to the requirements and recommendations set out here.

Any modification must be approved in writing by qualified ITR

personnel, prior to the installation.

This includes:

• Deviations from the instructions in this Manual.

• Changes to any piece of ITR-supplied equipment.

• Substitution of a non-ITR-approved component.

1-2 The WindowWasher™ by ITR

Page 9

Section 1, Overview

No warranty will be extended to improper installations. Use of any

unapproved materials, equipment, or installation procedures will result

in a voided warranty for the entire heating system. ITR accepts no

liability for any

damage or loss of service resulting from unapproved

modifications.

• Efficient

• Clean

• Quiet

• Compact

• Safe

• Rugged

• Reliable

• Economical

1.3 The WindowWasher™ by ITR Features

The WindowWasher™ by ITR uses a patented diesel burner (12 VDC)

controlled by a multi-functional electronic controller as the primary

source of heating water. The WindowWasher™ by ITR heats water to

provide a continuous supply for all domestic hot water needs.

Other features of The WindowWasher™ by ITR include:

• A high-temperature, stainless steel burner and stainless steel

jacket.

• 5.3 US gallon ( 20.5 l) welded stainless steel insulated wate r tank

that minimizes heat loss and optimizes heat recovery.

• Low water level switch in the tank.

• Easy to install with hookups and connections easily accessible

from the top and front of The WindowWasher™ by ITR.

• Quiet operation and low power consumption.

• Low pressure fuel system with built-in fuel pump.

• Fuel efficient burner capable of burning a wide variety of diesel-

• Exhaust has minimal smoke or smell.

• Fan assisted sealed combustion chamber is designed to use

• Simple, low amperage draw ignition.

• Electronically-controlled system with:

International Thermal Research 1-3

based fuels.

outside air.

o Automatic Safety Shutdown.

o Manual reset aquasta ts for safety overheat protection.

o LED indicators on the Control Panel for diagnostics.

Page 10

Section 1, Overview

o Patented, proprietary flame sensor.

• The WindowWasher™ by ITR Remote Operating Panel with

ON/OFF switch for the diesel burner and indicator LED’s for

operational and diagnostic information.

1.4 Critical Factors

Pay attention to the

notices of “Danger”

“Warning” “Caution”

and “Notice” in this

manual.

The key factors to keep in mind when planning and carrying out the

installation are:

• Mounting location restrictions for The WindowWasher™ by ITR,

exhaust outlet (to reduce noise, vibration, heat loss, etc.)

• Length, routing, and sizing of fluid lines, fuel lines, air flow tubing,

exhaust piping and wiring.

• Unrestricted intake required to draw in outside air for combustion.

• Ability to easily access and service the product, especially fuel,

plumbing, and electrical systems.

• After installation, requirement to purge water and fuel lines and

inspect/test entire system using the ITR-supplied Inspection

Check Sheet.

1.5 Equipment, Tools and Skills

As the user and/or installer, you must be qualified and authorized to do

the installation, which requires mechanical aptitude and electrical

knowledge. Make sure you comply with existing industry practices,

using the highest and most recent standards and codes. Good

workmanship is essential. Please refer back to Section 1.2, Protect Your

Warranty.

You will need the following equipment and tools (not supplied) to install

the heating system. This list does not include optional equipment and

accessories:

• Standard tools normally available in a well-equipped shop.

• Appropriate fasteners for mounting the heater unit.

1-4 The WindowWasher™ by ITR

Page 11

Section 1, Overview

• Stainless steel 1-1/2” ID exhaust piping, maximum 12’ with no

bends (see Section 3 – Installing the Exhaust System, for details

when bends are present).

• ITR muffler.

• 1/4” supply and return fuel line, approved rubber or copper.

• Domestic water hose and/or tubing to connect The

WindowWasher™ by ITR hose fittings to the domestic water

system.

1.6 Testing and Inspection

After all components have been properly installed according to standard

practices, RVIA or ABYC standards, and the recommendations of this

Installation and Operating Manual, The WindowWasher™ by ITR should

be test-operated for inspection purposes.

For your convenience, you can use the pullout Inspection Check Sheet in

this Manual. The Inspection Check Sheet is divided into progressive

sections, allowing each phase of the inspection to be carried out

systematically, and then signed off by authorized persons.

International Thermal Research 1-5

Page 12

Section 1, Overview

1-6 The WindowWasher™ by ITR

Page 13

Section

2

Mounting - The WindowWasher™

2.1 Before You Begin

Plan the location of The WindowWasher™ by ITR and all its major

components in advance to ensure the chosen locations are feasible

and within the technical specifications.

Consider the following factors to help you decide exactly wher e best

to mount The WindowWasher™ by ITR:

• The WindowWasher™ by ITR weight when full.

! WARNING

• Ventilation requirements.

• Exhaust outlet location and maximum acceptable length.

• Thru hull location.

• Potential for vibration and jarring.

• Fuel storage location.

• Most efficient plumbing runs.

• Safe and convenient access for maintenance.

• Location of other equipment to be installed or connected to

The WindowWasher™ by ITR.

Make sure you are familiar with Section 1 – Overview of this M anual.

If the system is not installed according to specifications and with the

correct equipment, The WindowWasher™ by ITR may not operate

properly, safety may be compromised, and your Warranty may be

voided.

International Thermal Research 2-1

Page 14

Section 2, Mounting The WindowWasher™ by ITR

2.2 Your Mounting Location

Your mounting location should consider the following:

• Mounting location must be able to support double the gross

weight of The WindowWasher™ by ITR (i.e. 150 lbs. x 2 =

300 lbs/68 KG x 2 = 136 KG).

• The WindowWasher™by ITR is 14”H x 14”W x 24”D

(35.6 cm x 35.6 cm x 60.9 cm). See Figure 2-1:

Dimensions.

! CAUTION

The WindowWasher™ by ITR must not be installed in any compartment with flammable gases.

• The WindowWasher™ by ITR must be completely isolated

from living spaces. Combustion air must be drawn from a

100% outside source and cannot contain any combustible

gases.

• The WindowWasher™ by ITR must be mounted in an area

that provides unrestricted access to the front panel

mounted fuel and water connections, and top mounted

power and exhaust connection (minimum of 10” top

clearance – top exhaust version; and 3” clearance to all

other WindowWasher™ surfaces.

• The WindowWasher™ by ITR must not be installed in any

compartment with flammable gases.

• The WindowWasher™ by ITR must be mounted horizontal

and level using eight (8) x 1/4” through bolts using 1”

diameter fender washers, lock washers and nuts.

• It is recommended that a catchpan be placed under The

WindowWasher™ by ITR for containing any unexpected

leakage.

NOTICE

2-2 The WindowWasher™ by ITR

If The WindowWasher™ by ITR is going to be mounted in the engine

compartment, check for adequate ventilation. When the engine is

running, this area could be under a negative pressure. Make sure the

air intake and exhaust hoses have no leaks and are well-fastened to

the heater, muffler and thru hull fitting. Assembly parts that may

cause injury through accidental contact should be protected.

Page 15

Section 2, Mounting The WindowWasher™ by ITR

Isolate the unit in a closed compartment so that no air from the

heater will infiltrate the vehicle cab.

• Choose a sturdy surface in a location that won’t be unduly

affected by vibration and the jarring of rough roads or rough

seas.

• Mount the unit with the front panel side facing out and

accessible. Facing out simplifies installation and maintenance.

• Open access is required to properly service the heater. Leave

room at the front, and top of the unit.

• Ensure that the exhaust tubing can be properly and safely

routed to the outside. The maximum exhaust run for the

system is 12’.

Figure 2-1: Dimensions

2.3 Procedure

After choosing the mounting location for The WindowWasher™ by ITR:

International Thermal Research 2-3

Page 16

Section 2, Mounting The WindowWasher™ by ITR

1

Mount The WindowWasher™ by ITR horizontally and level.

2 Secure The WindowWasher™ by ITR in place (against the wall,

floor, or a mounting platform) using eight (8) x 1/4” through bolts

using 1” diameter fender washers, lock washers and nuts (See

Figure 2-2: Location of Mounting Brackets.).

Figure 2-2: Location of Mounting Brackets.

Insets: Bracket/Nut/Bolt Configurations

2-4 The WindowWasher™ by ITR

Page 17

Section

3

Installing the Exhaust System

3.1 Before You Begin

For efficient and safe operation of The WindowWasher™ by ITR

follow all recommendations for properly installing the exhaust.

Any deviations from these must be approved in advance by ITR.

Although the heater’s exhaust produces very low carbon

! DANGER

monoxide emissions, caution is still advised:

• Do not operate The WindowWasher™ by ITR in an

enclosed area unless there is adequate ventilation.

• Isolate The WindowWasher™ by ITR in a closed

compartment so that no air from the unit will infiltrate the

living areas.

Never place any exhaust parts close to combustible material or

through a combustible wall or ceiling without fireproof p rotection.

The exhaust can reach high temperatures.

3.2 Mounting Location

If you can’t meet the technical specifications for mounting the

exhaust, don’t use The WindowWasher™ by ITR. The unit may

perform poorly or become damaged if not installed according to

specifications.

Recommended Exhaust Outlet Locations

The following is recommended for a van exhaust outlet location:

• Mount the exhaust o utlet outside the van, not inside the

heater compartment. Otherwise, exhaust fumes could

infiltrate the van from The WindowWasher™ by ITR

compartment.

International Thermal Research 3-1

Page 18

Section 3, Installing the Exhaust System

• In a van, the typical mounting location for the exhaust

outlet is under the floor of the heater compartment, or on

the other side of the van, directly across from the heater

unit. Keep in mind you cannot exceed 12’ of exhaust

piping, including bends.

• Position the outlet of the exhaust pipe so that the exhaust

exits off the side of the van, not towards the front, back,

directly underneath the van, or under an openable

window, vent or sliding door.

Recommendation for Installation

• You may use sweep bends but each 90° bend is equ ivalent

to two feet of exhaust piping. For example, if you use two

90° bends you must deduct two feet per bend from the

maximum allowed 12’ straight exhaust pipe length.

Therefore you will be restricted to 8’ of straight exhaust

piping plus the two bends. Do not exceed these

recommendations.

! DANGER

• The combustion air-intake must use 100% outside air.

• Use an ITR-manufactured muffler or silencer; no other is

acceptable.

• Exhaust outlet is on the top or bottom of The

WindowWasher™ by ITR, towards the back.

The exhaust and outlet are HOT and the surrounding areas

must be thermally shielded and protected from the hot

surfaces and heat buildup by insulation. Nothing can come

into inadvertent contact with any part of the exhaust system

• Exhaust pipe must have a minimum of 3” (7.6 cm)

clearance from all surfaces.

• Ensure that the exhaust cannot be plugged or restricted.

• The exhaust fitting on The WindowWasher™ by ITR is

1.5” O.D. and the exhaust pipe used must have a

minimum of 1.5” I.D throughout its length.

• All exhaust elbows must be of a large radius design

(minimum radius 2.0”).

3-2 The WindowWasher™ by ITR

Page 19

Section 3, Installing the Exhaust System

• The exhaust must be supported a minimum of e very 3’ of

its installed length.

• The exhaust and The WindowWasher™ by ITR connection

point must use appropriate clamps and sealing compound

to ensure that the connections are tight and leak free. The

WindowWasher™ by ITR exhaust outlet pipe and the

exhaust pipe itself must not be distorted or damaged

during this process.

• With The WindowWasher™ by ITR running, the connection

points and the system must be checked for leaks and any

found must be corrected. Periodically, check the exhaust

fittings, connections, exhaust tube and insulation for leaks

and integrity and correct if required.

• Install an exhaust collar on the exhau st pipe to isolate the

pipe from the van.

What NOT to Do

Don’t mount the exhaust pipe inside the heater compartment.

Don’t use more than 12’ of total exhaust length (including

bends)

Don’t use mufflers with any flow restrictions.

Don’t over tighten exhaust clamps or you may crush The

WindowWasher™ by ITR’s exhaust spout.

3.3 Procedure

Figure 3-1 shows a standard setup for the up exhaust. To install

the exhaust system:

1 Leave suitable air spacing to protect combustible

materials; use an exhaust collar and metal shields where

required.

2 Securely seal the exhaust piping to The WindowWasher™

by ITR fitting using an approved exhaust clamp.

3 Connect the exhaust piping in series with the muffler,

using heavy-duty exhaust clamps. If you use vibration

isolation mounts they must be high temperature.

International Thermal Research 3-3

Page 20

Section 3, Installing the Exhaust System

4 Connect the air-intake tubing (2” I.D.) to the air-intake

fitting on top of the heater, and to an outside air-intake

fitting or dual thru hull (outside air only). Ensure t he run

of tubing is as short as possible to facilitate air flow.

5 Secure both ends of the air-intake tubing with properly

sized hose clamps to prevent air leaks.

6 Make sure the air-intake and exhaust hoses have no leaks

and are not touching each other.

Figure 3-1: Installing the Exhaust System (Up Exhaust)

3-4 The WindowWasher™ by ITR

Page 21

Section

4

Installing the Fuel System

4.1 Before You Begin

For efficient and safe operation of The WindowWasher™ by ITR,

follow all recommendations for properly installing the fuel system.

Any deviations from these recommendations must be approved in

advance by ITR.

! DANGER

! WARNING

Never use gasoline in The WindowWasher™ by ITR. Use only d iesel

I or diesel II fuel oil.

Keep fuel lines away from any heat source above 100°F (38°C).

Keep gasoline and any equipment that uses gasoline away from The

WindowWasher™ by ITR location. The WindowWasher™ by ITR is

not rated for use in an explosive environment.

Never share the fuel supply to The WindowWasher™ by ITR with

any other fuel-burning device.

4.2 Fuel System Installation

Recommendation for Installation

The WindowWasher™ by ITR’s fuel connections are accessed from

the front panel of the heater. The fuel inlet and fuel return are

labelled and located on the front lower face of The WindowWasher™

by ITR and are not interchangeable. These fittings consist of 1/8”

female NPT that connect to the fuel pump inside the units’ front

cover.

The following is recommended for the fuel system installation:

International Thermal Research 4-1

Page 22

The fuel supply

requires a dedicated

pickup line from the

main fuel tank. The

pickup must allow the

heater to run out of

fuel before the tank

itself is empty.

Section 4, Installing the Fuel System

• The fuel supply from the fuel storage tank to the fuel inlet

must be from a dedicated fuel pickup on the top of the tank.

• The fuel supply line should be installed with minimal rise

from the fuel tank. In no event should The WindowWasher™

by ITR be more than 60” above the fuel tank.

• The fuel return line should be installed from The

WindowWasher™ by ITR to the fuel tank.

• The fuel line must be run and secured so as to prevent

damage, chafing and kinking dur ing normal operation.

• All fuel line connection points and hoses must use suitable

clamps and/or sealant and must be checked for leaks on the

initial installation and also periodically as part of normal

maintenance.

• A primary, 10 micron UL and/or CSA approved fuel oil filter

(not provided) must be installed inline in the fuel su pply hose

between the tank and The WindowWasher™ by ITR, in a

manner that ensures easy access for maintenance. There is

also a small fuel filter behind the nozzle in the fuel block

inside The WindowWasher™ by ITR. Both filters must be

inspected and replaced as required as part of normal

maintenance.

• Fuel line hose used must be appropriate for your

requirements. It is strongly recommended that the hoses

have permanently installed end fittings.

4.3 What NOT to Do

• Don’t allow the fuel or the fuel lines to become con taminated

with foreign material.

• Don’t allow the fuel lines to become damaged or constricted.

4-2 The WindowWasher™ by ITR

Page 23

Section 4, Installing the Fuel System

Ensure that fuel lines are always protected from contamination by

foreign material. When installing or servicing, seal off ends to

prevent contamination. After installing, you may also wish to flush

the fuel line to rid of it air and any foreign material.

! CAUTION

Be sure that all fuel lines are secured and will not become pi nched,

kinked or damaged during normal operation.

4.4 Procedure

To complete the fuel system installation:

1 Install the inline fuel filter. The optimal location is on a

compartment wall next to The WindowWasher™ by ITR,

inline between the fuel tank and The WindowWasher™ by

ITR.

2 Connect the fuel line to the dedicated fitting on the main

diesel fuel tank.

3 Inspect the supply and return fuel line for any loose

connections or damage. Fittings must be airtight.

4 If desired, install a shut-off valve on the tank side of the

fuel filter to allow shutdown and filter service.

International Thermal Research 4-3

Page 24

Section 4, Installing the Fuel System

4-4 The WindowWasher™ by ITR

Page 25

Wiring the Electrical System

! WARNING

Section

5

5.1 Before You Begin

The WindowWasher™ by ITR and its electrical Control Board are

pre-wired and have been thoroughly tested together as a unit.

To review the wiring system for The WindowWasher™ by ITR, refer

to the schematic in this Section 5, Figure 5-1: System Wiring.

All electrical connections and wiring must comply with normallyaccepted 12 VDC wiring practices, local regulations and standards.

Only a qualified electrical installer should complete the wiring.

! WARNING

5.2 12 VDC

The following apply to the 12 VDC connections to the The

WindowWasher™ by ITR:

• There is one paired set of 12 VDC electrical connections on

the top right of The WindowWasher™ by ITR. They consist of

the primary DC positive (red) and negative (black) connection

and are 14 gauge stranded copper wires.

Primary DC power should originate from a dedicated connection on

the house battery bank. A 20 amp fuse or breaker must be included

inline from the battery to the positive (red) connection on The

WindowWasher™ by ITR. The primary power wire gauge must be

sized to permit no more than a 3% voltage drop from the battery to

The WindowWasher™ by ITR.

• A properly-shielded power system is required for safe,

trouble-free operation.

International Thermal Research 5-1

Page 26

Section 5, Wiring the Electrical System

5.3 Remote Operating Panel Cable

• The other connection on the top right of The WindowWasher™

by ITR is a short four (4) wire remote operating panel cable

with a four (4) pin connector. This connects to a matching

25’ connector cord that plugs directly into the Remote

Operating Panel. Refer to Figure 6-1: System Wiring.

NOTICE

Figure 5-1: System Wiring

5.4 Main Electronic Control Board

• The main electronic Control Board is mounted on board The

WindowWasher™ by ITR itself. It has no user adjustable

components.

5.5 What NOT to Do

Never shut off The WindowWasher™ by ITR power via an inline

battery or master switch while the system is running. Never

disconnect the battery when The WindowWasher™ by ITR is

running, and never disconnect the battery while the inverter is

charging.

5-2 The WindowWasher™ by ITR

Page 27

Section 5, Wiring the Electrical System

Doing either will severely damage The WindowWasher™ by ITR

because it fails to automatically purge the combustion chamber.

Such damage is detectable upon inspection and will not be covered

under warranty. Always shut the system off using the normal

system controls, after it has completed its purge.

International Thermal Research 5-3

Page 28

Section 5, Wiring the Electrical System

5-4 The WindowWasher™ by ITR

Page 29

Section

6

Plumbing the System

6.1 Before You Begin

For efficient and safe operation of The WindowWasher™ by ITR,

follow all recommendations for properly installing the plumbing

system. Any deviations from these must be approved in advance by

ITR.

6.2 Plumbing Installation

NOTICE

Do not operate The

WindowWasher™ by

ITR until water is in

the WindowWasher™

and heating system,

and all trapped air

has been bled.

Figure 6-1: Plumbing Fittings

International Thermal Research 6-1

Page 30

NOTICE

All fittings on the

WindowWasher™

require two

wrenches when

tightening.

Section 6, Plumbing the System

The plumbing installation should consider the following:

• All fittings on The WindowWasher™ by ITR require two

wrenches when tightening. One wrench must be placed on

the tank fitting and held in place to prevent this fitting from

being overstressed. The other wrench can be used to tighten

the matching half of the fitting onto it. Failure to follow this

procedure will damage The WindowWasher™ by ITR and the

fittings.

NOTICE

All fittings, hose

and/or tubing

involving the

domestic water

component of the

distribution module

(optional) must be

approved for use with

domestic water

• All fittings, hose and/or tubing involving the domestic water

must be approved for use with domestic water and rated for

the domestic water system pressure. The working pressure

limit of The WindowWasher™ by ITR tank is 150 psi.

• All plumbing lines must be run and secured so as to preven t

damage, chafing and kinking.

• The WindowWasher™ by ITR sh ould be filled and flushed prior

to operation to remove any foreign debris.

• The WindowWasher™ by ITR is supplied with a

temperature/pressure relief valve and drain fitting. This

valve drains through the drain relief hose located at an

opening on the left front lower face of The WindowWasher™

by ITR and is labeled “Temp/Pressure Relief Valve”. Do not

block or plug the valve or the hose. See the label attached

onto the drain relief hose for the proper utilization and

routing of this hose (see next page).

6-2 The WindowWasher™ ITR

Page 31

Section 6, Plumbing the System

NOTICE

The WindowWasher™

is supplied with a

temperature and

pressure relief valve

and drain relief hose.

This valve drains

through the drain

relief hose located at

an opening on the

left front lower face

of the

WindowWasher™ and

is labeled

“Temp/Pressure

Relief Valve”. Do not

block or plug the

valve or the hose.

See the label

attached onto the

drain relief hose for

the proper utilization

and routing of this

hose.

IT IS CONNECTED TO THE COMBINATION TYPE TEMPERATURE AND

PRESSURE SAFETY RELIEF VALVE AT THE TANK. PROPER INSTALLATION IS

REQUIRED.

Discharge line should terminate through plain (unthreaded) pipe with at least a 6”

(152mm) air gap from a location where any discharge will be clearly visible. In no

case may a discharge line be directly conne cted to a sewer line . No reduc ing coupling

or other restriction shall be installed in the discharge line. The discharge line shall be

installed to allow complete drainage of both the v alve and the discharge line. The

discharge line must be installed in a continuously downward direction a nd in a frost

free environment. Water may drip from the discharge line. The discharge line must be

left open to atmosphere. Discharge line material must conform to local plumbing

codes or ASME requirements. Excessive length over 30’ (9.14m), use of more then

four elbows, or reducing discharge line size will cause a restriction and reduce the

discharge capacity of the valve. The pressure re lief valve is to be operated regulare ly

to remove lime deposits and to verify that it is not blocked. Temperature and

pressure safety relief valve should be inspected at least once every three years and

replaced, if necessary. See tag attached to the valve for additional instructions.

CAUTION! THIS IS A DISCHARGE LINE!

• Heater hose — PEX tubing. Slip-on foam insulation

coverings may be used over the hose fittings to reduce

heat loss. Secure all hose connections with spring clamps.

• Air vents — Air vents for the fluid circu lation system are

not supplied, but may be optionally installed to help bleed

air from the system.

NOTICE

6.3 What NOT to Do

Don’t use low-quality heater hose.

Don’t let the hose come into contact with solvents, which may

cause it to soften and swell. If there is any risk that solvents may

contact the hose, insert it into PVC plastic tubing for protection.

6.4 Installation Procedure

To install and connect The WindowWasher™ by ITR:

1 The supply and return plumbing connections are on the front

lower face of The WindowWasher™ by ITR and are 1/2” female

NPT fittings. The supply input is labeled “Cold Water Inlet” and

the hot water output is labeled “Hot Water Outlet”. Ensure

proper direction of flow.

International Thermal Research 6-3

Page 32

Section 6, Plumbing the System

r

The

r

f

2 Two male 1/2” NPT PEX tube fittings (not supplied) must be fit

into the supply and return fittings and tightened to a leak free

condition.

3 Connect the domestic water holding tank to the Cold Wate

Inlet. In some installations, a check valve may have to be

obtained and installed on the cold input line to

WindowWasher™ by ITR to prevent warm water from

backfilling to the water storage tank. Check the appropriate

standards and regulations. Ensure there are no kinks or sharp

bends that might restrict the fluid flow. If bends are required

for PEX tubing, fit the tubing into a plastic bend support. Do

not use rubber heater hose for potable water plumbing.

4 Connect the hot water supply line to the Hot Water Outlet.

Ensure there are no kinks or sharp bends that might restrict

the fluid flow. If bends are required for PEX tubing, fit the

tubing into a plastic bend support. Do not use rubber heater

hose for potable water plumbing.

5 A drain point, labeled “Drain” is provided on the front lowe

middle face of The WindowWasher™ by ITR and consists of a

thumb valve.

6 A suggested procedure for filling The WindowWasher™ by ITR

is to close The WindowWasher™ by ITR drain valve, open the

highest hot water faucet in the domestic water system, open

the valve to the cold water inlet to The WindowWasher™ by ITR

and then allow to fill. Once the water is flowing in a steady

stream from the hot water faucet, close the faucet.

7 To drain the WindowWasher™ by ITR, have the outlet of the

pressure relieve valve and the outlet of the drain valve go into

a bucket or to a drain where it will not create a mess. Open the

drain valve and open the pressure relief valve and allow all o

the water to drain from the tank. Once the water has been

drained, close the pressure relief valve and the drain valve.

6-4 The WindowWasher™ ITR

Page 33

Section

7

Operating The WindowWasher™

7.1 Operating Instructions for The

WindowWasher™ by ITR

This section describes the operation and maintenance of your new

WindowWasher™ by ITR.

The WindowWasher™ by ITR must be installed and connections

NOTICE

made in accordance with the recommendations in the Installation

and Operating Manual prior to operating The WindowWasher™ by

ITR.

Figure 7-1: The WindowWasher™ by ITR - Fittings

International Thermal Research 7-1

Page 34

Section 7, Operating the WindowWasher

7.2 Turning the Power to The

WindowWasher™ by ITR “ON”

• The WindowWasher™ by ITR’s Control Panel located on the

WindowWasher™ itself contains three push buttons: ON/OFF

power, Bypass and Reset. The power switch must be pushed

ON (power LED will turn ON) to turn the DC electrical power

to the main Control Board and WindowWasher™ ON and is

required to be left ON during any period where heat is

requested. When The WindowWasher™ by ITR is shut down

for any extended period or the season it is recommended that

the power switch be turned OFF.

7.3 Activating the Burner

NOTICE

Do not operate the

WindowWasher™

until it is filled

with water and all

trapped air has

been bled.

Activating the Burner

The burner switch on the Remote Operating Panel controls the

ON/OFF of the diesel burner (primary heat source). When the

burner switch is turned ON, the diesel portion of The

WindowWasher™ by ITR will turn on after ten seconds. The Burner

LED on the Remote Operating Panel will turn ON when the diesel

burner has been activated. The burner will continue to operate until

the water in The WindowWasher™ by ITR reaches the set operating

temperature range. At this point, the diesel burner will turn OFF. If

The WindowWasher™ by ITR water should cool to outside of this

temperature range, the burner will again come on and will continue

until either the burner switch on the Remote Operating Panel is

turned OFF or the temperature range is again achieved. If the

burner switch on the Remote Operating Panel is turned OFF, the

burner stops and The WindowWasher™ by ITR enters a two minute

cool down stage prior to completely shutting down.

7.4 Functions of the Remote Panel

• The WindowWasher™ by ITR’s Remote Operating Panel,

Figure7-2: Remote Operating Panel, contains one ON/OFF

burner switch and three LED’s indicating Burner activation,

AC element activation(not available), and service.

7-2 The WindowWasher™ by ITR

Page 35

Section 7 , Operating the WindowWasher

Figure 7-2: Remote Operating Panel

Burner Switch

• The burner switch controls the ON/OFF of the diesel burner.

The Burner LED will turn ON when the diesel burner has been

activated.

Burner LED (Green)

• When ON, indicates the diesel burner has been activated.

AC Heat LED (Green)

• Not used

Service LED (Red)

• When ON, indicates T he WindowWasher™ by ITR has faulted.

The specific fault can be identified by examining the

WindowWasher™ Control Panel located on the

WindowWasher™. There are three red and six green indicator

LED’s on this panel. Refer to the description of the

WindowWasher™ Control Panel for further details.

7.5 Functions of The Control Panel

The WindowWasher™ by ITR’s Control Panel, Figure 7-3:

WindowWasher™ Control Panel, contains three push buttons:

ON/OFF power, Bypass and Reset. In addition, it contains nine

LED’s indicating Power, AC Heat, Air Compressor, Fuel Pump,

Combustion Fan, Igniter, Flame Fault, Voltage Fault and Low Water

Level Fault.

International Thermal Research 7-3

Page 36

Section 7, Operating the WindowWasher

Figure 7-3: The WindowWasher™ by ITR - Control Panel

Power On/off Button

• The Power On/Off button turns ON/OFF the power to the

WindowWasher™ Control Board. The Power LED (green)

turns ON when the power to the control board is ON.

Bypass Button

• The Bypass button is for authorized service personnel only.

Reset Button

• The Reset button when pressed resets the WindowWasher™

Control Board.

Power LED (Green)

• The Power LED (green) turns ON when the power to The

WindowWasher™ by ITR Control Board is ON. The LED flashes

when the WindowWasher™ is in bypass mode.

7-4 The WindowWasher™ by ITR

Page 37

Section 7 , Operating the WindowWasher

AC Heat LED (Green)

• Not installed

Compressor,Fuel Pump, Combustion Fan, Igniter LED (Green)

• The air Compressor, Fuel Pump, Combustion Fan an d Igniter

LED’s (green) turn ON when the component is ON, and will

flash if the component is electrically open or shorted.

Flame Out LED (Red)

• The Flame Out fault LED (red) turns ON when a flame fault

has been detected.

Voltage LED (Red)

• The Voltage fault LED (red) turn s ON wh en a voltage fault has

been detected.

Low Water LED (Red)

• The Low Water level fault LED (red) turns ON when a low

water level in the WindowWasher™ has been detected.

7.6 Maintenance

Customer Monthly Maintenance: Check the following and

correct as required:

• Water hoses and fittings for leaks and integrity.

• Exhaust fittings, connections, tubes for leaks, and integrity.

• Exhaust and air-intake checked for no obstructions.

• Fuel lines, fittings for leaks and integrity.

• External fuel filter for clogging.

Annual Factory Maintenance: Perform the following:

• Factory Service Tune-up (DC power is disconnected):

• Prior to operation for the season, a factory service

International Thermal Research 7-5

tune-up of the modular system should be performed by

trained service personnel. Only personnel familiar with

the equipment modules should perform the service tune-up.

It is recommended that the dealer be contacted for this

service or if not available, contact ITR for further instructions.

Page 38

Section 7, Operating the WindowWasher

• As a general guide, the regular maintenance items such as

the igniter, fuel nozzle, fuel filters (internal and external) and

air filter (internal) should be replaced as opposed to inspected

and cleaned. Their performance may be deteriorating and/or

their remaining service life ending without any apparent

visual signs or operating symptoms.

• The major components such as the air compressor, fuel

pump, and combustion air fan should be examined for wear

and should be replaced by the service technician as required.

They are not serviceable and must be replaced.

• The combustion tube should be inspected by the service

technician for wear and replaced if necessary. If the tube is

satisfactory, a thorough cleaning of the tube and burner

chamber should be performed.

• The domestic water mixing valve on the WindowWasher™

should be inspected every year and replaced if necessary.

See the tag attached to the valve for additional instructions

(see below).

This ____ Mixing Valve must be installed and adjusted per the supplied instruction sheet.

It must be installed in accordance with applicable plumbing codes. To insure that the

valve keeps working properly, periodically turn the handwheel a full number lower

(higher) than the set number. If yo u do not detect a noticeable decrease ( increase)

in the discharge temperature, service the valve immediately. Otherwise, turn the

handwheel back to the original setting.

This ____ valve was installed _______. The handwheel was set to number : ______.

Any change in the setting to a higher numb er may raise the discharge temperature

to an unsafe temperature which may lead to scalds.

• The temperature and pressure safety relief valve on the

WindowWasher™ should be inspected every year and

replaced if necessary. See the tag attached to the valve for

additional instructions (see below).

DO NOT REMOVE THIS TAG FROM VALVE.

WARNING:

FAILURE TO COMPLY WITH THESE INSTURCTIONS REGARDING THIS VALVE CAN

RESULT IN SERIOUS PERSONAL INJURY OR DEATH AND/OR SEVERE

PROPERTY DAMAGE.

WARNING: Following installation, the valve lever MUST be operated AT LEAST ONCE A

YEAR by the water heater owner to ensure that waterways are clear. Certain

naturally occurring mineral deposits may adhere to the valve, blocking waterways,

rendering it inoperative. When the lever is operated, hot water will discharge if the

waterways are clear. PRECAUTIONS MUST BE TAKEN TO AVOID PE RSONAL INJURY

FROM CONTACT WITH HOT WATER AND TO AVOID PROPERTY DAMA GE. BEFORE

operating lever, check to see that a discharge line is connected to this valve,

directing the flow of hot water from the valve to a proper place of disposal. If no

7-6 The WindowWasher™ by ITR

ANNUAL OPERATION OF T& P RELIEF VALVES

Page 39

Section 7 , Operating the WindowWasher

water flows when the lever is operated, replacement of the valv e is required. TURN

THE WATER HEATER “OFF” (see instruction manual) AND CALL A PLUMBER

IMMEDIATELY.

REINSPECTION OF T & P RELIEF VALVES:

WARNING: Temperature and Pressure Relief Valves should be inspected AT LEAST ONCE

EVERY THREE YEARS, and replaced, if ne cessary, by a licensed plumbing contractor

or qualified service technician, to ensure that the product ha s not been affected by

corrosive water conditions and to ensure that the valve and discharge l ine have not

been altered or tampered with illeg ally. Certain naturally occurring condition s may

corrode the valve or its components over time, rendering the valve inoperative.

Such conditions can only be detected if the valve and its componen ts are physically

removed and inspected. Do not attempt to conduct an inspection on your own.

Contact your plumbing contractor for a reinspection to assure continuing safety.

WARNING: FAILURE TO REINSPECT THIS VALVE AS DIRECTED COULD RESULT

IN UNSAFE TEMPERATURE OR PRESSURE BUILD-UP WHICH CAN RESULT IN

SERIOUS INJURY OR DEATH AND/OR SEVERE PROPERTY DAMAGE.

If discharge occurs, CALL A PLUMBER IMMEDIATELY. Discharge may ind icate that a n

unsafe temperature or pressure condition exists whi ch requires immediate attention

by a qualified service technician or licensed plumbing contractor.

SEE WATER HEATER INSTRUCTION MANUAL FOR ADDITIONAL INFORMATION

REGARDING THE TEMPERATURE AND PRESSURE RELIEF VALVE.

See other side for important information

WARNING: To avoid water damage and/or scalding due to valve operation, a d ischarge

line must be connected to valve outlet and run to a safe place of disposal. The

discharge line shall be installed to allow complete drainage of both the valve and the

discharge line. No reducing coupling or other restriction shall be installed in the

discharge line. The discharge line must pitch downward from the valve and

terminate with a 6" (152mm) air gap from an approved location or building drain.

The discharge line must terminate through plain (unthreaded) p ipe. Discharge line

material must conform to local plumbing code or A.S.M.E. requirements. Excessive

length – more than 30 feet (9.14m), use of more than four elbows or bends in

discharge piping, or reduction of discharge line size will cause a restriction and

reduce the discharge capacity of the valve. No shut-off valve should be installed

between the relief valve and tank, or in the discharge line.

To ensure proper operation, this valve must be installed by a qualified service technician

or licensed plumbing contractor in accordance with these instructions and local

plumbing codes and standards.

WARNING:

FAILURE TO COMPLY WITH THESE INSTRUCTINS REGARDING THIS VALVE CAN

RESULT IN SERIOUS PERSONAL INJURY OR DEATH AND/OR SEVER

PROPERTY DAMAGE.

Combination temperature and pressure relief valves with extension thermostats must b e

installed so that the temperature-sensing ele ment is immersed in the water in the

top 6" (152mm) of the water storage tank. They must be installed either in the hot

outlet service line or directly in a tank tapping. Valves must be located so as to

assure isolation from flue gas heat or other ambient conditions that are not indicative

of stored water temperature. See other instructions regarding the discharge line.

This device is designed for emergency safety relief and must not be used as an operating

Repair or alteration of valve in any way is pro hibited by national safety standards/local

International Thermal Research 7-7

control.

codes.

Page 40

Section 7, Operating the WindowWasher

• Regular inspection and maintenance are a necessary part of a

properly operating module and satisfactory performance.

7.7 Protect the WindowWasher™

• Protect The WindowWasher™ by ITR from temperature

extremes and any dusty, dirty, corrosive environment.

• Protect The WindowWasher™ by ITR from cold temperatures

and corrosion.

• Note that any domestic water in The WindowWasher™ by ITR

will freeze in cold temperatures and will damage the

components. The WindowWasher™ by ITR and all associated

components must be completely drained of the domestic wa ter

and emptied before freezing temperatures are encountered.

7.8 General Troubleshooting

Insure that The WindowWasher™ by ITR has both

sufficient battery voltage and water level as The

WindowWasher™ is designed not to allow operation if

either are incorrect (indicated by lit Voltage Fault or Low

Water Level Fault LED’s on The WindowWasher™ Control

Panel) .

Burner Does Not Start Up

• WindowWasher™ connected to 12 VDC power?

• Power On/Off button on WindowWasher™ Control Panel pushed

ON? Power LED lit on Remote Operating Panel?

• Burner switch on Remote Operating Panel ON?

• Fuses or circuit breakers blown or tripped?

Burner Starts but Flame Faults

• Fuel supply present and adequate?

• Air-intake or exhaust not blocked or obstructed?

• Air in fuel line (White smoke from exh aust)?

• Fuel filter (external) dirty?

• Component LED’s all glowing green on T he WindowWasher™

Control Panel?

7-8 The WindowWasher™ by ITR

Page 41

Section

8

Warranty And Service

8.1 Warranty

Warranty cards must be filled in completely, signed by the

Owner and Dealer and returned to ITR within 30 days of the

date of the original installation.

ITR warrants the HURRICANE®II/IIL/COMBI, SCH25, Water

Heater and WindowWasher by ITR (referred to as

“heater(s)”) and all accessories or other supplied components with

the original purchase to be free of defects in materials and

workmanship under design usage and service conditions for two (2)

years from the heater serial number label manufacturing date.

Warranty replacement parts are covered for the remainder of the

heater’s warranty.

This warranty does not apply to damage or failure of the

heater, or the vessel or vehicle into which it was installed,

due to improper installation, assembly, maintenance, or

abuse, accident, or the use of parts not supplied by ITR.

8.2 Installations

The purchaser and installer are advised that specific rules and

regulations may be in effect with respect to the installation of the

“heater”. It is the installer’s responsibility to review and comply with

all such rules and regulations.

Non-standard installations, that is, those requiring a departure from

published installation instructions, should not be undertaken without

first having consulted and obtained the written approval of ITR.

Coverage for warrantable parts will, at the discretion of ITR, be

made to the claimant in the form of repair, replacement, or credit.

“Heaters” installed using non standard, industry accepted

procedures and without ITR’s or an authorized Dealer’s

approval will be limited to a 90 day warranty measured from

the heater serial number label manufacturing date.

International Thermal Research 8- 1

Page 42

Section 8, Warranty

8.3 Limited Warranty

The following warranties are in lieu of all other warranties

and conditions. ITR makes no other warranties,

representations, or conditions, express or implied, and there

are expressly excluded all implied or statutory warranties or

conditions of merchantability of fitness for a particular

purpose and those arising by statute or otherwise in law of

from a course of dealing or usage of trade.

The stated express warranties are in lieu of all liabilities or

obligations for damages arising out of or in connection with

the delivery, use, performance, or licensing of the product or

in connection with any services performed. In no event

whatsoever, shall ITR be liable for indirect, consequential,

exemplary, incidental, special or similar damages including

but not limited to lost profits, lost business revenue, failure

to realize expected savings, other commercial or economic

loss of any kind or any claim against ITR by any other party

arising out of or in connection with the sale, delivery, use,

performance, or repair or in connection with any services

performed, even if ITR has been advised of the possibility of

such damages, whether based upon warranty, contract, or

negligence. ITR’s maximum liability shall not in any case

exceed the contract price for the products claimed to be

defective. ITR warranties its products; ITR authorized

dealers/service centers and installers provide warranty for

installation. Any warrantable service and or labour is the

responsibility of ITR and should be performed by an authorized

dealer unless other arrangements are authorized.

No one is authorized to increase, alter, or enlarge ITR’s

responsibilities or obligations under these warranties.

Warranties are void if the original serial number has been

removed or altered, or cannot be readily determined.

8-2 Installation Manual for Window Washer by ITR

Page 43

Section 12, Warranty

8.4 Owner’s Responsibilities

Before the expiration of the warranty, the Owner must give

notice to a registered ITR Dealer of failures, if any,

considered to be warrantable and deliver the defective

“heater” to such dealer. The Owner is responsible for all repairs

made to the engine, equipment, vessel, or vehicle in which the

“heater” is installed, other than the “heater”. The Owner is

responsible for lodging, meals, and other incidental costs incurred by

the Owner as a result of a warrantable failure. The Owner is

responsible for “down time” expenses, and all business costs and

losses resulting from a warrantable failure.

ITR IS NOT RESPONSIBLE FOR INCIDENTAL OR

CONSEQUENTIAL DAMAGES.

8.5 Not Covered Under Warranty

This warranty will not apply to:

• Normal usage, wear, and tear on parts, including but not limited to,

fuel filter, air filter, nozzle, fuses, igniter, and carbon brushes.

• Parts or products which malfunction due to improper installation

including but not limited to malfunctions causing inadequacies in;

air, fuel or coolant flow, voltage due to wiring, shock or vibration.

• Any progressive damage to the engine, vessel, or vehicle arising out

of failure of the “heater”.

• “Heaters” which have been modified or use of non-standard parts

not approved by ITR.

• “Heaters” that have been abused, damaged, vandalized, or received

improper maintenance.

• Removal and re-installation expenses of the “heater” unless

specific written permission has been obtained from ITR.

,

• Travel time and expenses incurred by an ITR dealer or other

personnel to perform warranty related work on the “heater”

International Thermal Research 8 - 3

Page 44

Section 8, Warranty

• Diagnosis or repairs when caused by problems not directly related to

the “heater” or due to empty fuel tanks or poor fuel quality, fuel

additives, acidic water, electrolysis, incorrect vessel bonding leading

to abnormal corrosion.

• Running the system dry or without appropriate preservatives

(antifreeze), causing damage to the heat exchanger, pump seals,

etc.

• Exposing the heater to an environment detrimental to its effective

operation (such as excessively wet, dirty, or hot areas).

• Other products which ITR does not manufacture.

• Any products or parts which have been used in a manner contrary

to ITR’s printed instructions.

PLEASE FOLLOW THE RECOMMENDATIONS INCLUDED IN THIS

MANUAL.

8.6 Customer Service Calls

Normal service calls are at the owner’s expense.

CHECK THE TROUBLESHOOTING CHAPTER OF THIS MANUAL

TO SEE IF YOUR PROBLEM IS ADDRESSED.

When calling with a service problem, please have the following

information at hand:

• The model number and serial number of your heater and main

electronic control board.

• If your heater is already installed, ensure you are familiar with

the design and installation setup.

• Have ready a detailed description of the problem and keep the

manual handy to refer to.

8.7 Returns

To obtain warranty service, the owner must:

• Provide a full description of the problem to your dealer and ITR.

ITR will determine if the problem is covered under the ITR

warranty.

8-4 Installation Manual for Window Washer by ITR

Page 45

Section 12, Warranty

• If ITR determines that the problem is covered under warranty,

they will provide you with a Repair or Return Goods Authorization

(RGA) number for any warranty return, repair or service.. ITR will

refuse any return package without a proper RGA number.

• If ITR determines that “heater” repairs will be covered under

warranty under in-field conditions, ITR will authorize the in-field

warranty service personnel as to specific conditions and limits for

parts and labor used in the repair. Any other incurred costs will not

be covered under the warranty.

• When shipping your product, pack securely to prevent damage,

indicate the RGA and serial number of the heater on the outside of

the shipping container, and ship prepaid and insured to ITR.

• In the shipping container, provide written details of the problems,

RGA number, manufacturing date as indicated by the serial

number label, serial number, proof of purchase, and a return

address.

After repair or replacement

of products under warranty, ITR will

return the product to the customer via standard (non expedited)

delivery. Factory repairs or replacement will be done as quickly as

possible, with an estimated five working day turn around.

8.8 Telephone Service

There is no charge for help or service information given over the

telephone or by fax. Any recommendation or advice from ITR or any of

its employees, or Dealers, is given only in good faith as an

accommodation to the customer. Such information should not be relied

upon by the customer without an independent verification of its

applicability to the customer’s particular situation. For customer service

or other information:

Call the Dealer from whom you bought the heater, or call ITR

IN CANADA: IN THE UNITED STATES:

th

2431 Simpson Road, 11915 NE 56

Circle Suite B

Richmond, BC Canada V6X 2R2 Vancouver, WA USA 98682

Tel: 1-800-755-1272 or 604-278-1272 Tel: 1-800-993-4402 or 360-993-4877

Fax: 604-278-1274 Fax: 360-993-1105

Email: info@itrheat.com Website: http://www.itrheat.com

International Thermal Research 8 - 5

Page 46

Section 8, Warranty

PLEASE FILL OUT FOR YOUR OWN REFERENCE

8-6 Installation Manual for Window Washer by ITR

Loading...

Loading...