IB-P01 CIRCUIT BOARD

TECHNICAL DOCUMENTATION

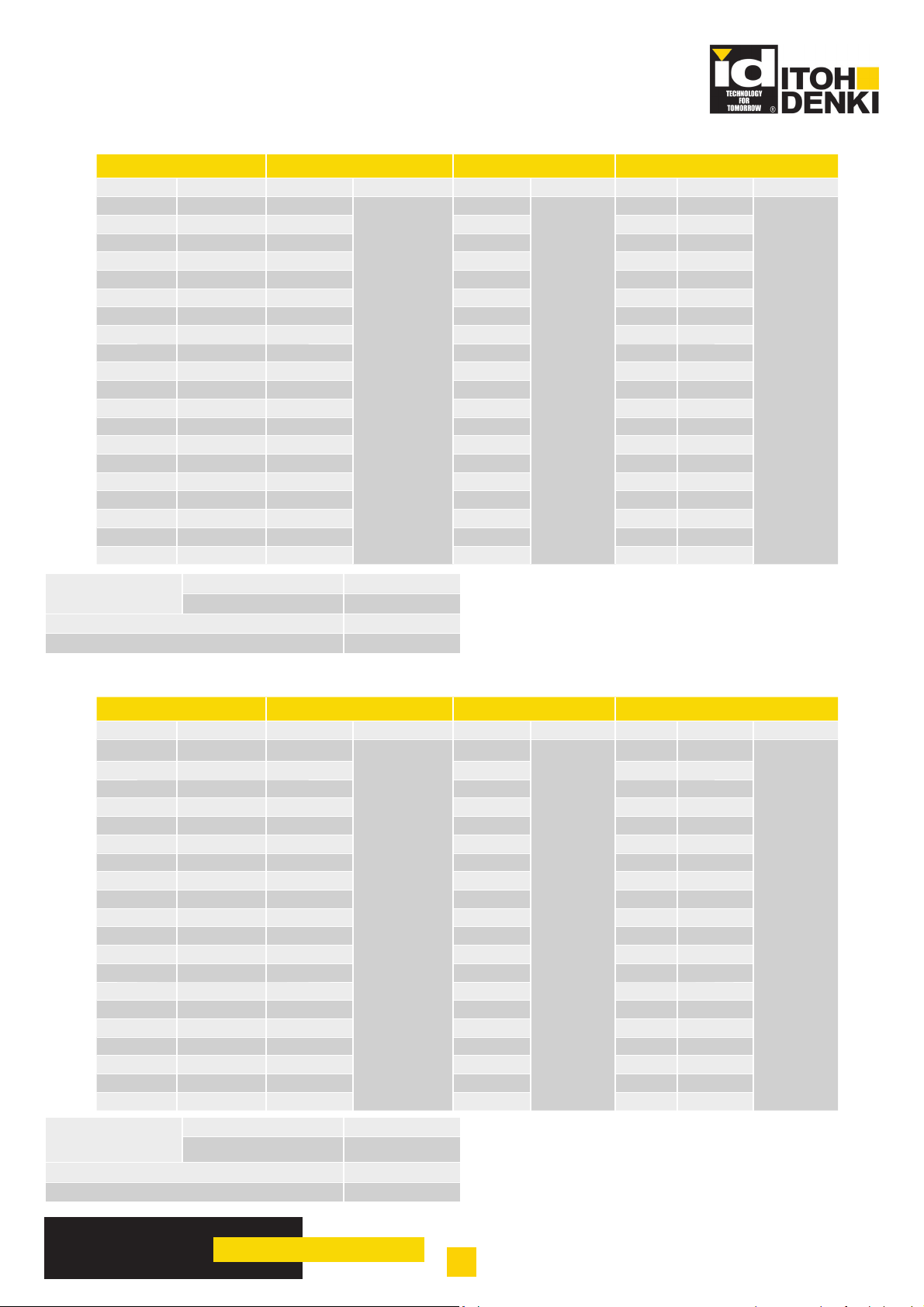

1 - PRESENTATION OF THE POWER MOLLER

®

PRODUCT RANGE

(ඔඍඋගකඖඑඋ 0ගකඑජඍඌකඔඔඍකඛ 0ඌඝඔඍ

Standard circuit board

CB016

CBM-105

CBK-109

CB018

CBV-108

CB016B

New version of CB030

ZPA circuit board

HB510 HB510B

HBK-608

Module circuit board

HBR-605

External

circuit board

Ø50

PM500 FE

PM500 VE

PM500 FE-B

Ø60,5

DC Brushless

B

CBM-105

HB510

IB-E

CBV-108

IB-P

CB016B

HB510B

Integrated

circuit board

Ø50

PM500 XE

PM500 XP

PM500 XK

PM500 XC

90° transfer

F-RAT-S250

F-RAT-S300

F-RAT-U225

45° transfer

POP-UP

B&W AS-i 3.0

Wenglor

Molex

B&W AS-i 3.0

Wenglor

Molex

PEPPERL-FUCHS

AS-Interface

Molex

PEPPERL-FUCHS

AS-Interface

Molex

HBR-605

CBM-105

CBR-306

HBR-605

CBM-105

CBR-306

HBR-605

CBM-105

CBR-306

CBM-105

CBR-306

CBR-306

Network controller

IB-E

IB-P

IB-P01

PM605 FE

PM605 VE

PM605 FE-B

PM605 KT

B

Ø32

PM320 HS

TECHNICAL DOCUMENTATION

CBM-105

HB510

IB-E

CBV-108

IB-P

CB016B

HB510B

CBK-109

HBK-608

IB-P

CB018

2

Ø60,5

PM605 XE

PM605 XP

B&W AS-i 3.0

Wenglor

Molex

B&W AS-i 3.0

Wenglor

Molex

Corresponding circuit board

Compatible module / sensor

Max load to be conveyed

Mechanical brake version

Original notice - T1.4

2 - SUMMARY

1. Presentation of the PowerMoller product range Page 2

2. Summary Page 3

3. Presentation of the IB-P01 circuit board Page 4

3.1 - General description

3.2 - Dimensions

*HQHUDOVSHFL¿FDWLRQV

3.4 - Location of items

4. Wiring Page 7

4.1 - Circuit diagram

4.1.1 - Remote Output interface circuit

4.1.2 - Remote Input interface circuit

4.2 - CN1 connector - 24 VDC power supply

4.3 - CN301 connector - Control supply

4.4 - CN302 connector - Inputs / outputs (I/O)

4.5 - CN305 and CN304 Connectors - Sensors

4.6 - CN101 and CN201 Connectors - Motor

4.7 - CN401 and CN402 - RJ45 connector

6ZLWFKHVFRQ¿JXUDWLRQ 3DJH

'LSVZLWFKHVFRQ¿JXUDWLRQ6:

5.2 - Factory reset

6. Warning light LED Page 14

6.1 - List of errors that can occur in an IB-P01 circuit board

7. Technical data depending on the motorized roller Page 16

7.1 - With PM500VE motorized roller

7.2 - With PM605VE motorized roller

1HWZRUNFRQ¿JXUDWLRQ 3DJH

8.1 - Cascade connection

8.2 - Star connection

9. Controlling IB-P01 circuit board Page 23

9.1 - When the PROFINET capable PLC controls IB-P01 circuit board

9.2 - In case of controlling the local ‘own’ zone by IB-P01 circuit board, and monitoring each zone by PROFINET capable PLC

:KHQWKHQHWZRUNLVFRQ¿JXUHGRQO\ZLWK,%3FLUFXLWERDUG

9.4 - When one IB-P01 circuit board controls multiple connected IB-P01 circuit boards

Annex1: Incorporation declaration Page 25

IB-P01

TECHNICAL DOCUMENTATION

3

Original notice - T1.4

3. PRESENTATION OF THE IB-P01 CIRCUIT BOARD

3.1 - GENERAL DESCRIPTION

• Fasteners

- 2 M4 x 15 cross-head screws

- 2 M4 washers

- 2 M4 nuts

• 1 connector 2 pins (231-302/026-000)

• 1 connector 3 pins (734-103)

• 2 connectors 4 pins (733-104)

• 1 connector 10 pins (733-110) (Optional)

Compatible motorized rollers series :

- Serie PM500VE

- Serie PM605VE

• 2 motorized rollers can be connected to each IB-P01 circuit board.

• 24VDC power supplies for motor power and control are separate.

• 2 communication cables (Optional)

Use PROFINETFHUWL¿HGFDEOHVRQO\

Wago 2 pin motor power connector

supplied with circuit board

Ref 231-302-026-000

24V control

power supply

24V motor

power supply

HMI

Network

M8 5 pin male profiled

cable length 300mm

IB-P01 Profinet card

2 zone programmable

circuit board for VE series

Wago 3 pin control power connector

supplied with circuit board

Ref 734-103

35

Controller

Wago 4 pin sensor connectors

supplied with circuit board

2 x Ref 733-104

24

M8 5 pin female profiled

connector prewired with

cable length 200mm

Use only Profinet

certified network cables

(see separate guidelines)

Optional Wago 10 pin

I/O connector Ref 733-110

Optional motor extension cables

1m ref ECMF-IDK-5P-1000

2m ref ECMF-IDK-5P-2000

PD-2P

2 pole, 4 way power

distribution connector 32A

IB-P01

TECHNICAL DOCUMENTATION

4

Original notice - T1.4

3.2 - DIMENSIONS

30.5

170

137

84.3

160 fixing hole centres

2 x 4.2 dia

200

3.3 - GENERAL SPECIFICATIONS

Power Supply TBTS 24VDC ± 10% - ripple < 10%

A stabilised power supply is recommended

Absorbed current without motorized roller 0.5A

Start current limitation 4.0A

Motor start time after signal 43.2ms

Protection index (IP) IP20

Environment Temperature range -20 / +40 °C

SPECIFICATIONS

A switching mode power supply is recommended as the DC power supply (24VDC±10%) for IB-P01 circuit

boards. Use a stabilized power supply that has an adequate capacity of 24VDC and 10A or higher and does

QRWÀXFWXDWHGXHWRORDGYDULDWLRQ

Relative humidity < 90% condensation-free (avoid thermal shocks)

Neither corrosive nor explosive atmosphere

Vibrations <1 G

Indoor use

The power supply shall have a capacity larger than the total of the MDR rated values.

A transformer type power supply cannot be used.

Secure a voltage of 24VDC±10% at the power supply terminal of the IB-P01 circuit board.

If the capacity of the power supply is lower than the total of the rated power of the MDR and circuit boards, it

may cause the supply voltage to drop and damage MDR and IB-P01 circuit board.

In addition, the power supply should not activate protection with peak current 20A, 1ms or below.

Wiring between power supply and IB : Excessive volt drop can occur with longer cable lengths between the

power supply and the IB-P01 circuit board. Ensure that cable size is large enough to carry the full load current

without exceeding the recommended 10% volt drop, which might cause malfunctions or damages.

Use recommended wire gauge, 2~2.5mm² AWG:14-12 and secure 24VDC±10%.

Separation of power control and power motor : The power supplies for control power and motor power should

be different.

Ensure that all 0v terminals of all power supplies are grounded to the main earth terminal inside the control

cabinet.

IB-P01

TECHNICAL DOCUMENTATION

5

Original notice - T1.4

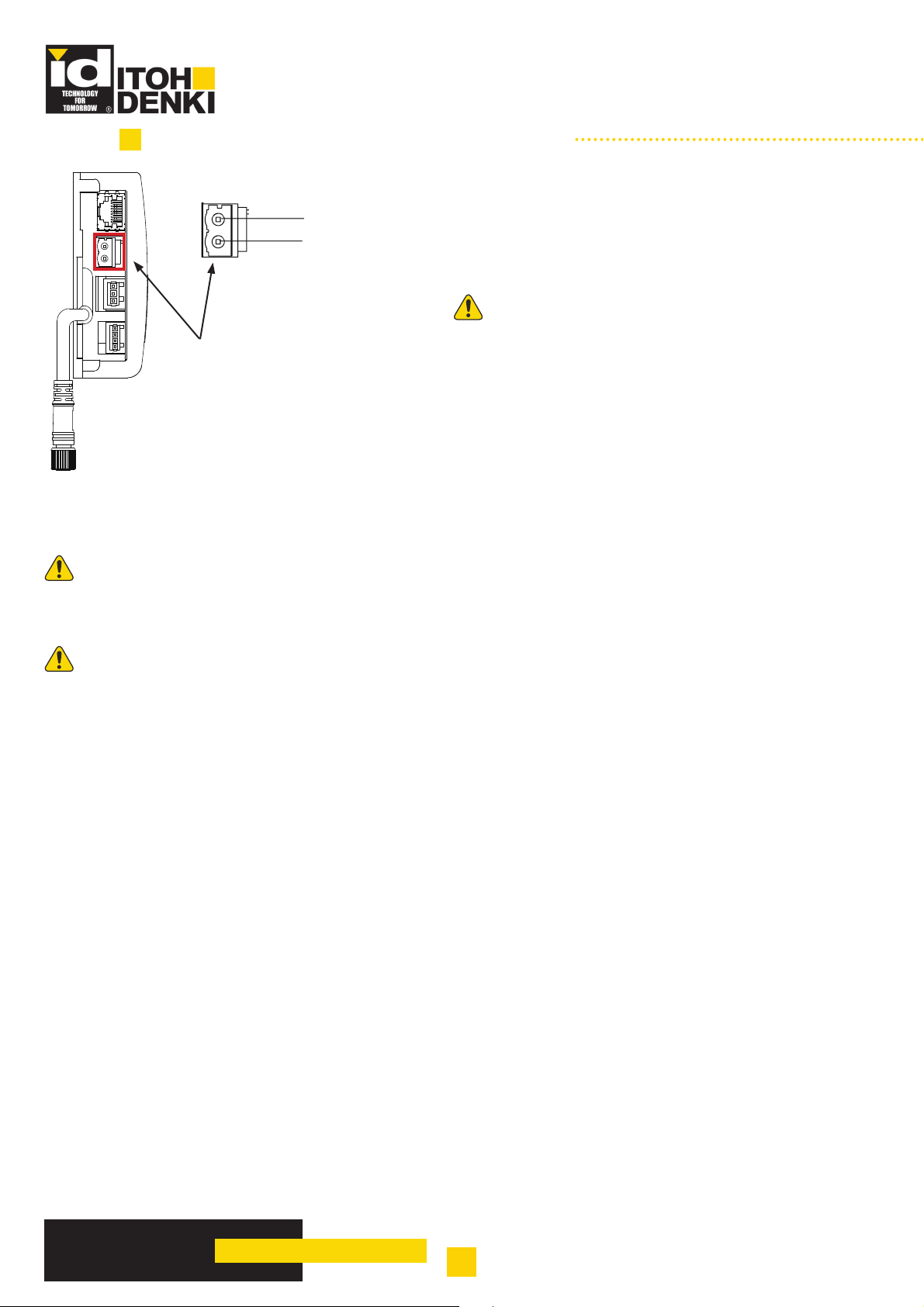

3.4 - LOCATION OF ITEMS

CN401 LAN 1 RJ45

Use only PROFINET

certified cables

CN1 Wago 231-302-026-000

Motor power connector

included with board

CN301 Wago 734-103

Control power connector

included with board

SW1 dip-switches

for synchronising motors

CN402 LAN 2 RJ45

Use only PROFINET

certified cables

CN302

Wago 733-110

Optional

Connector I/O

4 x inputs

4 x outputs

CN304 Wago 733-104

Sensor A connector included

with board (24V, sensor input,

0V & sensor alarm if required)

CN101 Motor A

5 pin M8 connector

CN305 Wago 733-104

Sensor B connector

included with board

CN201 Motor B

5 pin M8 connector

IB-P01

TECHNICAL DOCUMENTATION

6

Original notice - T1.4

4. WIRING

4.1 - CIRCUIT DIAGRAM

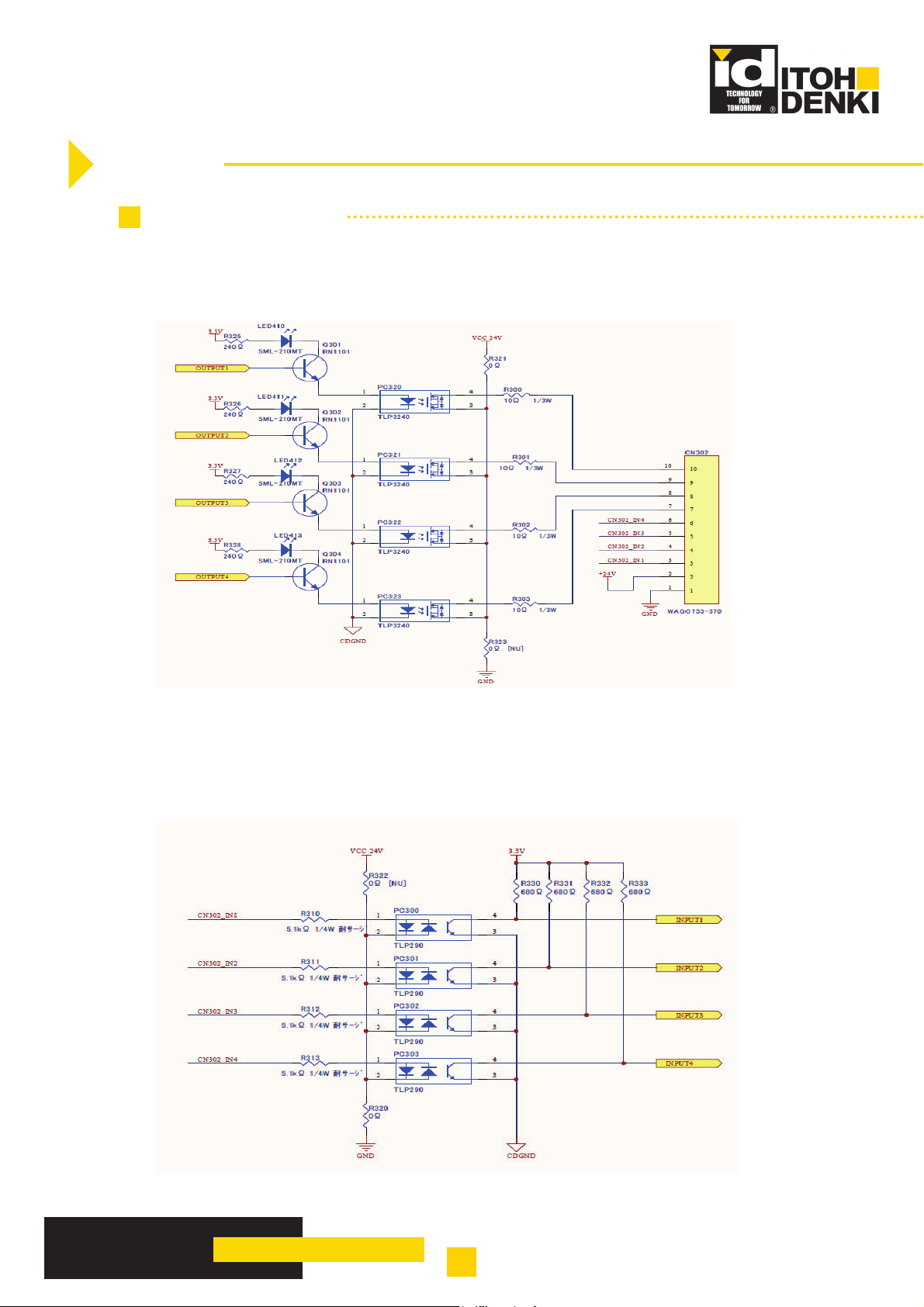

4.1.1 - Remote Output interface circuit

4.1.2 - Remote Input interface circuit

IB-P01

TECHNICAL DOCUMENTATION

7

Original notice - T1.4

4.2 - CN1 CONNECTOR - 24 VDC POWER SUPPLY

1 - 24 VDC

2 - 0 VDC

• Solid wire or Braided wire

• Minimum cross-section : 2-2.5mm

2

(AWG:14~12)

• The length of stripped wire : 8-9mm

3URYLGHDSRZHUVXSSO\ WKDW LV VXI¿FLHQWO\SRZHUIXO

• (Connecting cable side) WAGO 231-302/026-000

in function of the type and number of motorized rollers to

CN1

be powered.

The stabilized power supplies 24V shall be sized according to the number of motorized rollers that shall work.

It is possible to link some group of motorized rollers to the power supplies. These groups being linked together

thanks to communication cable.

It is mandatory to link the 0v of ALL power supplies together by ensuring that all the 0v terminals are grounded to

the main earth terminal inside the control cabinet. They shall be controlled simoultaneously to avoid creating problem

in transition point.

Make sure that the power supply is turned OFF before plugging / unplugging the motor connector CN101/201.

IB-P01

TECHNICAL DOCUMENTATION

8

Original notice - T1.4

4.3 - CN301 CONNECTOR - CONTROL SUPPLY

3 - FG

2- 0 VDC

1- 24 VDC

CN301

• (Connecting cable side) WAGO 734-103

• Solid wire or Braided wire

• Minimum cross-section : 0.08-1.5mm

• The length of stripped wire : 6-7mm

2

(AWG:28~14)

4.4 - CN302 CONNECTOR - INPUTS / OUTPUTS (I/O)

1

CN302

10

Connector Designation

10V

2 24V

3 INPUT1

4 INPUT2

5 INPUT3

6 INPUT4

7OUTPUT4

8OUTPUT3

9OUTPUT2

10 OUTPUT1

• (Connecting cable side) WAGO 733-110

• Solid wire or Braided wire

• Minimum cross-section : 0.08-0.5mm

• The length of stripped wire : 5-6mm

• Inputs & outputs are PNP only

• Remote Input : 25mA max

• Remote output : 100mA max

2

(AWG:28~20)

IB-P01

TECHNICAL DOCUMENTATION

9

Original notice - T1.4

4.5 - CN305 AND CN304 CONNECTORS - SENSORS

STS B

LAN1

IB-P01F-UL

ACT 2

OUT 1

Motor Power

24V

0V

MOTOR

A

Control Power

FG

0V

24V

Sensor A

ALM

0V

SEN

24V

ACT 1

LAN 1

MOT A

STS A

SEN A

LED400

LED400

LED408

LED408

LED415

LED415

LED406

LED406

LED417

LED417

MAC: 00-22-21-XX-XX-XX

DEVICE: 0x15A001

RIN: 0301 R8C: 51

IN 1

POWER

IN 2

LAN 2

OUT 2

BF

IN 3

MOT B

OUT 3

MB-SYN

MA-SYN

SF

IN 4

R494

R494

R495

R495

R469

R469

34

34

34

2

1

2

1

2

1

LED402

LED402

LED419

LED419

LED403

LED403

LED404

LED421

LED404

LED421

LED405LED420

LED405LED420

SEN B

STS B

OUT 4

R476

R476

R475

R475

R464

R464

RG300

RG300

LED407

LED407

LED410

LED410

LED401

LED401

LED411

LED411

LED409

LED409

LED416

LED412

LED416

LED412

LED41

LED413

LED413

CN304 CN305

Sensor B

IN/OUT

OUT4

OUT3

OUT1

LAN2

0V

24V

IN1

IN2

IN3

IN4

MOTOR

OUT2

B

24V

SEN

0V

ALM

4 - Optional sensor alarm input

3 - 0V

2 - Sensor input

1 - 24 VDC

• (Connecting cable side) WAGO 733-104

• Solid wire or Braided wire

2

• Minimum cross-section : 0.08-0.5mm

(AWG:28~20)

• The length of stripped wire : 5-6mm

N° Designation

1 24VDC

2 Sensor input

30V

4 Optional sensor alarm input

1 - 24 VDC

2 - Sensor input

4 - Optional sensor alarm input

3 - 0V

IB-P01

TECHNICAL DOCUMENTATION

10

Original notice - T1.4

4.6 - CN101 AND CN201 CONNECTORS - MOTOR

STS B

LAN1

IB-P01F-UL

ACT 2

OUT 1

ACT 1

Motor Power

24V

0V

MOTOR

A

Control Power

FG

0V

24V

Sensor A

ALM

0V

SEN

24V

LAN 1

MOT A

STS A

SEN A

LED400

LED400

LED408

LED408

LED415

LED415

LED406

LED406

LED417

LED417

MAC: 00-22-21-XX-XX-XX

DEVICE: 0x15A001

RIN: 0301 R8C: 51

CN101 CN201

IN 1

POWER

IN 2

LAN 2

OUT 2

BF

IN 3

MOT B

MB-SYN

34

34

34

2

2

2

OUT 3

SF

IN 4

R495

R495

R469

R469

LED402

LED402

LED419

LED419

LED403

LED403

LED404

LED421

LED404

LED421

LED405LED420

LED405LED420

SEN B

STS B

OUT 4

R476

R476

R475

R475

R464

R464

RG300

RG300

LED407

LED407

LED410

LED410

LED401

LED401

LED411

LED411

LED409

LED409

LED416

LED412

LED416

LED412

LED41

LED413

LED413

MA-SYN

R494

R494

1

1

1

Sensor B

IN/OUT

OUT4

OUT3

OUT1

LAN2

0V

24V

IN1

IN2

IN3

IN4

MOTOR

OUT2

B

24V

SEN

0V

ALM

4

Black

3

Blue

2

White

1

Brown

N° Color

For the motor output setting

CN101

For the motor port setting

CN201

1 Brown Motor coil U Motor port output (U-phase)

2 White Motor coil V Motor port output (V-phase)

5

Gray

3 Blue Hall sensor signal N/A

4 Black Motor coil W N/A

5 Grey +12VDC N/A

• Switching the motor output setting to motor port output, allows the use of the U and V coil outputs as remote

output.

• “Motor output “and “Motor port” setting are selectable by iCEP or PLC.

Setting method by iCEP: Please refer to «iCEP user» manual.

6HWWLQJPHWKRGE\3/&3OHDVHUHIHUWR©&RQQHFWLRQZLWKWKH3UR¿QHWFDSDEOH3/&ªPDQXDO

7KHRXWSXWVDUH¿[HGWR131

• The maximum output current value is 4 A per motor with IB-P01 circuit board.

The motor port output cannot be changed with NPN open drain output.

IB-P01

TECHNICAL DOCUMENTATION

11

Original notice - T1.4

4.7 - CN401 AND CN402 - RJ45 CONNECTOR

STS B

LAN1

IB-P01F-UL

ACT 2

OUT 1

ACT 1

Motor Power

24V

0V

Control Power

FG

0V

24V

MOTOR

A

Sensor A

ALM

0V

SEN

24V

CN401 CN402

LAN 1

MOT A

STS A

SEN A

LED400

LED400

LED408

LED408

LED415

LED415

LED406

LED406

LED417

LED417

MAC: 00-22-21-XX-XX-XX

DEVICE: 0x15A001

RIN: 0301 R8C: 51

IN 1

POWER

IN 2

LAN 2

OUT 2

BF

IN 3

MOT B

MB-SYN

34

34

34

2

2

2

OUT 3

SF

IN 4

R495

R495

R469

R469

LED402

LED402

LED419

LED419

LED403

LED403

LED404

LED421

LED404

LED421

LED405LED420

LED405LED420

SEN B

STS B

OUT 4

R476

R476

R475

R475

R464

R464

RG300

RG300

LED407

LED407

LED410

LED410

LED401

LED401

LED411

LED411

LED409

LED409

LED416

LED412

LED416

LED412

LED413

LED413

LED41

MA-SYN

R494

R494

1

1

1

N° Designation

1 Tx+ (transmission data +)

2 Tx- (transmission data -)

81

3 Rx+ (reception data +)

4 Not used

5 Not used

6 Rx- (reception data -)

7 Not used

8 Not used

Sensor B

IN/OUT

OUT4

OUT3

OUT1

LAN2

0V

24V

IN1

IN2

IN3

IN4

MOTOR

OUT2

B

24V

SEN

0V

ALM

LAN cable can be either straight through or crossover type cable.

ONLY use PROFINETFHUWL¿HG/$1FDEOHVQRW(WKHUQHWFDEOHV

IB-P01

TECHNICAL DOCUMENTATION

12

Original notice - T1.4

5. SWITCHES CONFIGURATION

5.1 - DIP-SWITCHES CONFIGURATION SW1

STS B

LAN1

IB-P01F-UL

ACT 2

OUT 1

Motor Power

24V

0V

MOTOR

A

Control Power

FG

0V

24V

Sensor A

ALM

0V

SEN

24V

ACT 1

LAN 1

MOT A

STS A

SEN A

LED400

LED400

LED408

LED408

LED415

LED415

LED406

LED406

LED417

LED417

MAC: 00-22-21-XX-XX-XX

DEVICE: 0x15A001

RIN: 0301 R8C: 51

IN 1

POWER

BF

MB-SYN

MA-SYN

SF

R494

R494

R495

R495

34

34

34

2

1

2

1

2

1

LED419

LED419

LED421

LED421

LAN 2

IN 2

OUT 2

IN 3

MOT B

OUT 3

IN 4

R469

R469

LED402

LED402

LED403

LED403

LED404

LED404

LED405LED420

LED405LED420

SEN B

STS B

OUT 4

R476

R476

R475

R475

R464

R464

RG300

RG300

LED407

LED407

LED410

LED410

LED401

LED401

LED411

LED411

LED409

LED409

LED416

LED416

LED412

LED412

LED413

LED413

LED41

SW1

To perform a synchronization of motors, make the settings using these switches.

Sensor B

IN/OUT

OUT4

OUT3

OUT1

LAN2

0V

24V

IN1

IN2

IN3

IN4

MOTOR

OUT2

B

24V

SEN

0V

ALM

SW1-1 SW1-2 Motor A Motor B

OFF OFF Regular operation Regular operation

OFF ON Regular operation Synchronize with Motor A

ON OFF Synchronize with Motor B Regular operation

ON ON Factory reset (see chapter 5.2)

5.2 - FACTORY RESET

To reset the circuit board as factory setting, refer to the bellow procedure:

1 Turn off the power supply to the IB-P01 circuit board.

2 Set the dip switches (SW1 #1 “MA-SYN” and #2 “MB-SYN”) to ON. Set IN1 and IN4 inputs to ON.

3 The initialization will start when the power to the IB-P01 Circuit board is turned on.

4

5 Turn off the power supply to the IB-P01 circuit board.

When the initialization is complete, the LEDs of SenA, SenB, IN1, IN2, IN3, IN4, RUN, SF, and BF

become on.

6

IB-P01

Return the dip switches (SW1 #1 “MA-SYN” and #2 “MB-SYN”) to the state prior to the

initialization.

TECHNICAL DOCUMENTATION

13

Original notice - T1.4

6. WARNING LIGHT LED

R494

R494

LED400

ACT1

LAN1

MOTA

STSA

SENA SENB

LED408

LED408

LED415

LED415

LED406

LED406

LED400

LED417

LED417

1

1

1

R476

R464

R464

LED410

LED410

LED411

LED411

LED412

LED412

LED413

LED413

R476

R475

R475

LED401

LED401

LED409

LED409

LED416

LED416

LED41

LED407

LED407

RG300

RG300

R495

R495

R469

R469

34

34

34

2

2

2

LED402

LED402

LED419

LED419

LED421

LED421

LED403

LED403

LED404

LED404

LED405LED420

LED405LED420

If an error occurs in an IB-P01 circuit

board, it indicates the state of the error in

LED display.

POWER IN2 OUT2 LAN2

BF IN3 OUT3 MOTB

SF IN4 OUT4 STSB

IN1 OUT1 ACT2

LED display error

LED

SENSOR (SEN A/SEN B)

(LED 406 / 407)

Remote IN (IN1~4)

(LED 402 ~ 405)

Remote OUT (OUT1~4)

(LED 410 ~ 413)

POWER (POWER)

(LED 419)

System Fault (SF)

(LED 420)

Bus Fault (BF)

(LED 421)

LINK (LAN1 / LAN2)

(LED 408 / 409)

ACT (ACT1 / ACT2)

(LED 400 / 401)

MOTOR

(MOTA / MOTB / STSA /

STSB)

(LED 415 / 416 / 417 / 418)

Green Red

ON - Sensor input detected

OFF - Sensor input not detected

ON - Remote input detected

OFF - Remote input not detected

ON - Remote output detected

OFF - Remote output not detected

ON - Control power supply ON

Flashing (6Hz) - Power supply of motor power OFF

OFF - Control power supply OFF

- OFF No error

- ON System fault error

- OFF No error

- ON Bus fault error

OFF - Disconnected LAN cable

ON - Connected LAN cable

OFF - No sending/receving data

Flashing - Sending/receving data

OFF OFF Motor stop (No error)

ON OFF

ON Flash (6Hz) Blown fuse

OFF Flash (1Hz) Motor unplugged error

ON Flash (1Hz) Lock error

OFF ON

ON Flash (1.7s 6Hz×2times) Back EMF error

Flash Alternately (1Hz) Flash Alternately (1Hz) JAM error

Flash Alternately (6Hz) Flash Alternately (6Hz) Software error 1

Flash Alternately (2Hz) Flash Alternately (2Hz) Software error 2

LED pattern

Motor or IB-P01 circuit board

*Motor green LED illuminates by any output from UV (W), when motor port is used.

Description

Rotation of a motor

(common to CW and CCW)

Motor port output(*)

thermal error

IB-P01

TECHNICAL DOCUMENTATION

14

Original notice - T1.4

6.1 - LIST OF ERRORS THAT CAN OCCUR IN AN IB-P01 CIRCUIT BOARD

The table shown below summarizes error occurrence conditions and reset conditions for an IB-P01 circuit

board, as well as states of the ladder logic and motor in which an error is occurring. Occurrence of errors

can be checked with iCEP and PLC. Refer to table “LED display error” on Paragraph 6 “PROFINET I/O”, for

information on LED display of errors.

Error type

Motor Power

OFF

Under Voltage

Error

Blown fuse

Motor

Disconnected

Motor Lock 4

PCB Thermal 5

Motor Thermal 6

Back EMF

Error

Motor Port

current limit

Jam Error 8

Soft Error 1 9

Soft Error 2 10

Sensor Alarm 11

Priority

(*1)

1

2

3 Motor disconnected Connect motor Auto/Manu Run Stop

7

Error occurrence

condition

Motor power voltage of

lower than 6 V

Motor power voltage of

6V ~ 15 V

Fuse has been blown on

the motor driver board

Continuously-unchanged

hall signal

Higher than the IB-P01

circuit board temperature

threshold

Higher than the motor

temperature threshold

Continuous back EMF of

40 VDC or higher for 2

seconds

Continuous back EMF of

60 VDC or higher for 0.1

seconds

Continuous motor port

current of 4 A or higher

for 0.1 seconds

Output coils Y7 and Y37

are ON

Output coils Y8 and Y38

are ON

Output coils Y9 and Y39

are ON

Alarm input is ON

(CN304 CN305)

Error reset condition

(*2)

Power supply voltage 18

V or higher

Power supply voltage 18

V or higher

Impossible to reset

Automatic reset: Pulse

change

Reset instruction by upper

level

Manual reset: Reset

instruction by upper level

Lower than the IB-P01

circuit board temperature

threshold

Lower than the motor

temperature threshold

Back EMF of lower than

40 VDC

Motor port current of

lower than 4 A

Output coils Y7 and Y37

are OFF

Output coils Y29 and Y30

are OFF

Output coils Y9 and Y39

are OFF

Sensor alarm input is OFF

(CN304, CN305)

Type of error

reset method

Auto Run Stop

Auto/Manu Run Stop

IB-P01 circuit

board

replacement

Auto/Manu Run Stop

Auto/Manu Run Stop

Auto/Manu Run Stop

Manu Run Stop

Manu Run Stop

Ladder Run Run

Ladder Run Run

Ladder Run Run

Signal input Run Run

Ladder Motor

Run Stop

(*1) If more than one error occurs, the LED display shows the error of the highest priority. If the error of the

highest priority among multiple errors is reset, the errors with the lower priority will be also reset. However, if

thecause of an error remains, the error will be displayed again.

(*2) For manual reset, the error can be reset by the instruction from the higher level, only if the error reset

condition is met. Manual reset is carried out by using iCEP or PLC.

1. Reset by iCEP: Refer to the «iCEP user manual», Chapter 6 Section 2, “Error monitor.”

5HVHWE\3/&5HIHUWR©&RQQHFWLRQZLWKWKH3UR¿QHWFDSDEOH3/&ªPDQXDO3DUDJUDSK³352),1(7,2´

IB-P01

TECHNICAL DOCUMENTATION

15

Original notice - T1.4

7. TECHNICAL DATAS ACCORDING MOTORIZED ROLLER

7.1 - WITH PM500VE MOTORIZED ROLLER

PM500VE - SPEED CODE 17

V (m/min)+/-3% Tangential force (N) Torque (Nm) Current (A)

No load Nominal Nominal Start-up Nominal Start-up No load Nominal Start-up

17.4 17.4 101.1

15.9 15.9 106.4 2,6 0,6 2,7

15.2 15.2 108.9 2,7 0,6 2,7

14.5 14.5 111.7 2,8 0,5 2,7

13.7 13.7 114.2 2,9 0,5 2,7

13.0 13.0 114.5 2,9 0,5 2,6

11.6 11.6 115.2 2,9 0,4 2,4

10.9 10.9 115.5 2,9 0,4 2,3

10.1 10.1 115.5 3,0 0,4 2,2

9.4 9.4 115.8 3,0 0,4 2,1

8.7 8.7 116.1 3,0 0,4 2.0

335

8.0 8.0 116.4 3,0 0,3 1,9

7.2 7.2 116.7 3,0 0,3 1,7

6.5 6.5 117.0 3,0 0,3 1,6

5.8 5.8 117.4 3,0 0,3 1,5

5.1 5.1 117.7 3,0 0,3 1,4

4.3 4.3 118.0 3,0 0,3 1,3

3.6 3.6 118.3 3,0 0,2 1,2

2.9 2.9 118.6 3,0 0,2 1,1

2.2 2.2 118.9 3,0 0,2 1,0

2,5

8.4

0,7 2,8

4,0

Servo brake

Tangential force 5.0~102N

Absorbed current 0,1~1,0A max

Reduction ratio 1/44,95

Stage 3 stage

Speed

(m/min)

Area of continuous

operation

Speed vs Tangential force

17.4 m/min

13.0 m/min

7,2 m/min

2.2 m/min

Current vs Tangential force

Current(A) Current(A) Current(A)

Current (A)

IB-P01

TECHNICAL DOCUMENTATION

Tangential force (N)

16

Original notice - T1.4

PM500VE - SPEED CODE 25

/

V (m/min)+/-3% Tangential force (N) Torque (Nm) Current (A)

No load Nominal Nominal Start-up Nominal Start-up No load Nominal Start-up

29.1 29.1 68.1

26.7 26.7 71.7 1.8 0.6 2.7

25.4 25.4 73.4 1.8 0.6 2.7

24.2 24.2 75.3 1.9 0.5 2.7

23.0 23.0 77.0 1.9 0.5 2.7

21.8 21.8 77.2 1.9 0.5 2.6

19.4 19.4 77.6 1.9 0.4 2.4

18.2 18.2 77.8 2.0 0.4 2.3

17.0 17.0 77.8 2.0 0.4 2.2

15.7 15.7 78.1 2.0 0.4 2.1

14.5 14.5 78.3 2.0 0.4 2.0

226

13.3 13.3 78.5 2.0 0.3 1.9

12.1 12.1 78.7 2.0 0.3 1.7

10.9 10.9 78.9 2.0 0.3 1.6

9.7 9.7 79.1 2.0 0.3 1.5

8.5 8.5 79.3 2.0 0.3 1.4

7.3 7.3 79.5 2.0 0.3 1.3

6.1 6.1 79.7 2.0 0.2 1.2

4.8 4.8 80.0 2.0 0.2 1.1

3.6 3.6 80.2 2.0 0.2 1.0

1.7

5.7

0.7 2.8

4.0

Servo brake

Tangential force 5.0~78.0N

Absorbed current 0,1~1,0A max

Reduction ratio 1/26,67

Stage 2 stage

Speed

(m/min)

Speed vs Tangential force

29.1 m/min

Area of continuous

operation

21.8 m/min

12.2 m/min

3.6 m/min

Current vs Tangential force

Current (A)

Tangential force (N)

IB-P01

TECHNICAL DOCUMENTATION

17

Original notice - T1.4

PM500VE - SPEED CODE 60

/

V (m/min)+/-3% Tangential force (N) Torque (Nm) Current (A)

No load Nominal Nominal Start-up Nominal Start-up No load Nominal Start-up

61.7 61.5 32.3

56.6 56.6 34.0 0.8 0.6 2.7

54.0 54.0 34.8 0.8 0.6 2.7

51.4 51.4 35.7 0.9 0.5 2.7

48.9 48.9 36.5 0.9 0.5 2.7

46.3 46.3 36.6 0.9 0.5 2.6

41.1 41.2 36.8 0.9 0.4 2.4

38.6 38.6 36.9 0.9 0.4 2.3

36.0 36.0 36.9 0.9 0.4 2.2

33.4 33.4 37.0 0.9 0.4 2.1

30.9 30.9 37.1 0.9 0.4 2.0

107

28.3 28.3 37.2 0.9 0.3 1.9

25.7 25.7 37.3 0.9 0.3 1.7

23.1 23.1 37.4 0.9 0.3 1.6

20.6 20.6 37.5 0.9 0.3 1.5

18.0 18.0 37.6 0.9 0.3 1.4

15.4 15.4 37.7 0.9 0.3 1.3

12.9 12.9 37.8 0.9 0.2 1.2

10.3 10.3 37.9 0.9 0.2 1.1

7.7 7.7 38.0 0.9 0.2 1.0

0.8

2.7

0.7 2.8

4.0

Servo brake

Tangential force 4.5~42.0N

Absorbed current 0,1~1,0A max

Reduction ratio 1/12,64

Stage 2 stage

Speed

(m/min)

Area of continuous

operation

Speed vs Tangential force

61.7 m/min

1

46.3 m/min

25.7 m/min

7.7 m/min

Current vs Tangential force

Current (A)

Tangential force (N)

IB-P01

TECHNICAL DOCUMENTATION

18

Original notice - T1.4

PM500VE - SPEED CODE 90

/

V (m/min)+/-3% Tangential force (N) Torque (Nm) Current (A)

No load Nominal Nominal Start-up Nominal Start-up No load Nominal Start-up

104.0 104.0 21.8

95.4 95.4 22.9 0.6 0.6 2.7

91.0 91.0 23.5 0.6 0.6 2.7

86.6 86.6 24.1 0.6 0.5 2.7

82.4 82.4 24.6 0.6 0.5 2.7

78.0 78.0 24.7 0.6 0.5 2.6

69.4 69.4 24.8 0.6 0.4 2.4

65.1 65.1 24.9 0.6 0.4 2.3

60.7 60.7 24.9 0.6 0.4 2.2

56.3 56.3 24.9 0.6 0.4 2.1

52.1 52.1 25.0 0.6 0.4 2.0

72

47.7 47.7 25.1 0.6 0.3 1.9

43.3 43.3 25.2 0.6 0.3 1.7

38.9 38.9 25.2 0.6 0.3 1.6

34.7 34.7 25.3 0.6 0.3 1.5

30.3 30.3 25.4 0.6 0.3 1.4

26.0 26.0 25.4 0.6 0.3 1.3

21.7 21.7 25.5 0.6 0.2 1.2

17.4 17.4 25.6 0.6 0.2 1.1

13.0 13.0 25.6 0.6 0.2 1.0

0.6

1.8

0.7 2.8

4.0

Servo brake

Tangential force 4.0~33.0N

Absorbed current 0,1~1,0A max

Reduction ratio 1/7,5

Stage 1 stage

Speed

(m/min)

Area of continuous

Speed vs Tangential force

104.0 m/min

operation

78.0 m/min

43.3 m/min

13.0 m/min

Current vs Tangential force

Current (A)

Tangential force (N)

IB-P01

TECHNICAL DOCUMENTATION

19

Original notice - T1.4

7.2 - WITH PM605VE MOTORIZED ROLLER

PM605VE - SPEED CODE 17

V (m/min)+/-3% Tangential force (N) Torque (Nm) Current (A)

No load Nominal Nominal Starting Nominal Starting No load Nominal Starting

21,1 21,1 83,6

19,2 19,2 87,9 2,6 0,6 2,7

18,4 18,4 90,0 2,7 0,6 2,7

17,5 17,5 92,3 2,8 0,5 2,7

16,6 16,6 94,4 2,9 0,5 2,7

15,7 15,7 94,6 2,9 0,5 2,6

14,0 14,0 95,2 2,9 0,4 2,4

13,2 13,2 95,5 2,9 0,4 2,3

12,2 12,2 95,5 3,0 0,4 2,2

11,4 11,4 95,7 3,0 0,4 2,1

10,5 10,5 96,0 3,0 0,4 2,0

9,7 9,7 96,2 3,0 0,3 1,9

8,7 8,7 96,4 3,0 0,3 1,7

7,9 7,9 96,7 3,0 0,3 1,6

7,0 7,0 97,0 3,0 0,3 1,5

6,2 6,2 97,3 3,0 0,3 1,4

5,2 5,2 97,5 3,0 0,3 1,3

4,4 4,4 97,8 3,0 0,2 1,2

3,5 3,5 98,0 3,0 0,2 1,1

2,7 2,7 98,3 3,0 0,2 1

277

2,5

8.4

0,7 2,8

4,0

Servo brake

Tangential force 4.1~84.3N

Absorbed current 0,1~1,0A max

Reduction ratio 1/44,95

Stage 3 stage

PM605VE - SPEED CODE 25

V (m/min)+/-3% Tangential force (N) Torque (Nm) Current (A)

No load Nominal Nominal Starting Nominal Starting No load Nominal Starting

35,2 35,2 56,3

32,3 32,3 59,3 1,8 0,6 2,7

30,7 30,7 60,7 1,8 0,6 2,7

29,3 29,3 62,2 1,9 0,5 2,7

27,8 27,8 63,6 1,9 0,5 2,7

26,4 26,4 63,8 1,9 0,5 2,6

23,5 23,5 64,1 1,9 0,4 2,4

22,0 22,0 64,3 2,0 0,4 2,3

20,6 20,6 64,3 2,0 0,4 2,2

19,0 19,0 64,5 2,0 0,4 2,1

17,5 17,5 64,7 2,0 0,4 2,0

16,1 16,1 64,9 2,0 0,3 1,9

14,6 14,6 65,0 2,0 0,3 1,7

13,2 13,2 65,2 2,0 0,3 1,6

11,7 11,7 65,4 2,0 0,3 1,5

10,3 10,3 65,5 2,0 0,3 1,4

8,8 8,8 65,7 2,0 0,3 1,3

7,4 7,4 65,9 2,0 0,2 1,2

5,8 5,8 66,1 2,0 0,2 1,1

4,4 4,4 66,3 2,0 0,2 1

187

1,7

5.7

0,7 2,8

4.0

Servo brake

Tangential force 4.1~64.5N

Absorbed current 0,1~1,0A max

Reduction ratio 1/26,67

Stage 2 stage

IB-P01

TECHNICAL DOCUMENTATION

20

Original notice - T1.4

PM605VE - SPEED CODE 60

V (m/min)+/-3% Tangential force (N) Torque (Nm) Current (A)

No load Nominal Nominal Starting Nominal Starting No load Nominal Starting

74,7 74,9 26,7

68,5 68,5 28,1 0,8 0,6 2,7

65,3 65,3 28,8 0,8 0,6 2,7

62,2 62,2 29,5 0,9 0,5 2,7

59,2 59,2 30,2 0,9 0,5 2,7

56,0 56,0 30,2 0,9 0,5 2,6

49,7 49,9 30,4 0,9 0,4 2,4

46,7 46,7 30,5 0,9 0,4 2,3

43,6 43,6 30,5 0,9 0,4 2,2

40,4 40,4 30,6 0,9 0,4 2,1

37,4 37,4 30,7 0,9 0,4 2,0

34,2 34,2 30,7 0,9 0,3 1,9

31,1 31,1 30,8 0,9 0,3 1,7

28,0 28,0 30,9 0,9 0,3 1,6

24,9 24,9 31,0 0,9 0,3 1,5

21,8 21,8 31,1 0,9 0,3 1,4

18,6 18,6 31,2 0,9 0,3 1,3

15,6 15,6 31,2 0,9 0,2 1,2

12,5 12,5 31,3 0,9 0,2 1,1

9,3 9,3 31,4 0,9 0,2 1

88

0,8

2.7

0,7 2,8

4.0

Servo brake

Tangential force 3.7~34.7N

Absorbed current 0,1~1,0A max

Reduction ratio 1/12,64

Stage 2 stage

PM605VE - SPEED CODE 90

V (m/min)+/-3% Tangential force (N) Torque (Nm) Current (A)

No load Nominal Nominal Starting Nominal Starting No load Nominal Starting

125,8 125,8 18,0

115,4 115,4 18,9 0,6 0,6 2,7

110,1 110,1 19,4 0,6 0,6 2,7

104,8 104,8 19,9 0,6 0,5 2,7

99,7 99,7 20,3 0,6 0,5 2,7

94,4 94,4 20,4 0,6 0,5 2,6

84,0 84,0 20,5 0,6 0,4 2,4

78,8 78,8 20,6 0,6 0,4 2,3

73,4 73,4 20,6 0,6 0,4 2,2

68,1 68,1 20,6 0,6 0,4 2,1

63,0 63,0 20,7 0,6 0,4 2,0

57,7 57,7 20,7 0,6 0,3 1,9

52,4 52,4 20,8 0,6 0,3 1,7

47,1 47,1 20,8 0,6 0,3 1,6

42,0 42,0 20,9 0,6 0,3 1,5

36,7 36,7 21,0 0,6 0,3 1,4

31,5 31,5 21,0 0,6 0,3 1,3

26,3 26,3 21,1 0,6 0,2 1,2

21,1 21,1 21,2 0,6 0,2 1,1

15,7 15,7 21,2 0,6 0,2 1

60

0,6

1.8

0,7 2,8

4.0

Servo brake

Absorbed current 0,1~1,0A max

Reduction ratio 1/7,5

Stage 1 stage

Tangential force 3.3~27.3N

IB-P01

TECHNICAL DOCUMENTATION

21

Original notice - T1.4

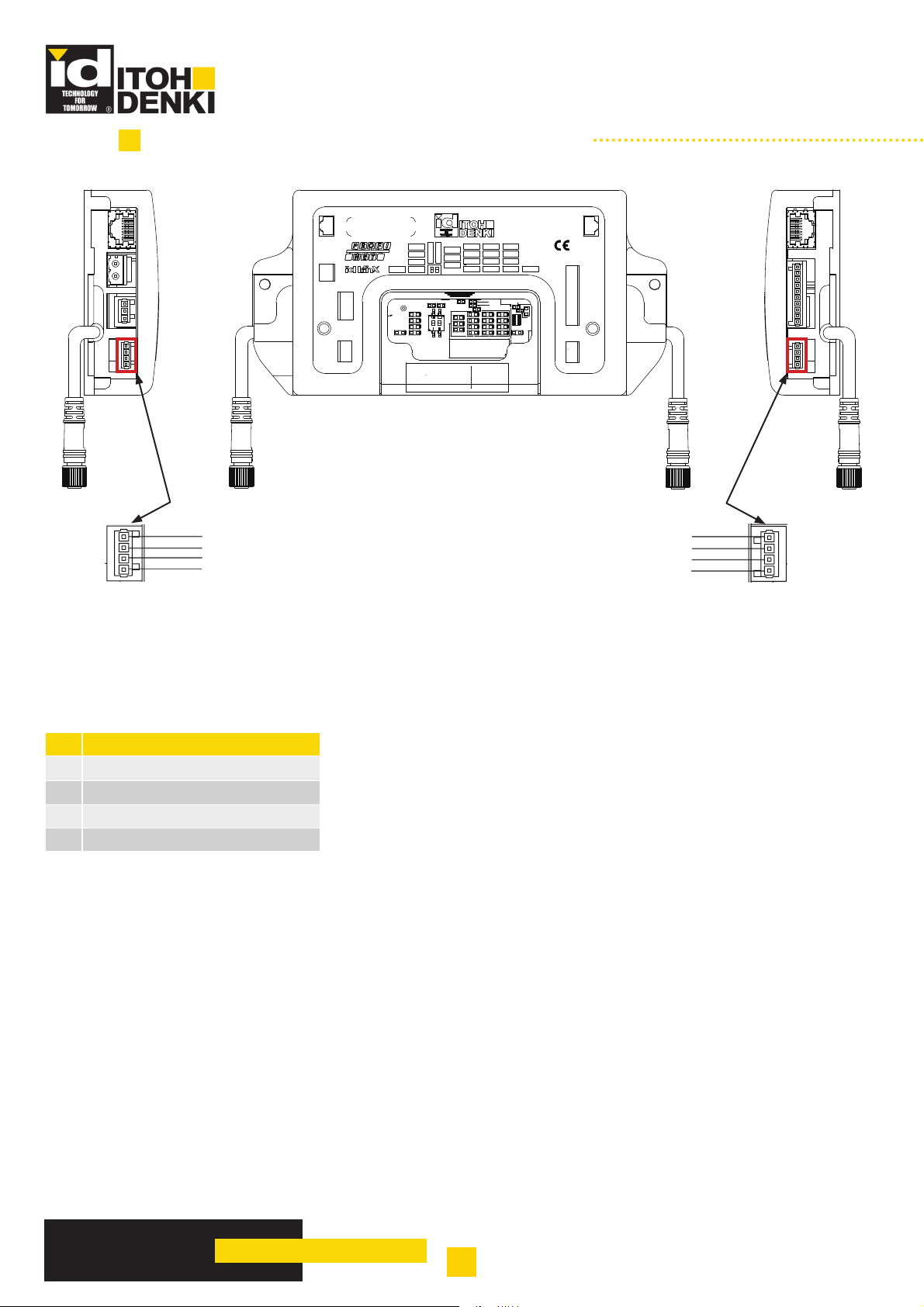

8. NETWORK CONFIGURATION

To use iCEP, you need to connect the PC and IB-P01 circuit boards.

8VHWKH¿JXUHVVKRZQEHORZIRU\RXUUHIHUHQFHZKHQZLULQJ,%3FLUFXLWERDUGV<RXFDQXVHHLWKHUVWUDLJKW

through or crossover cables as a LAN cable used between IB-P01 circuit boards.

For further information refer to iCEP user manual.

8.1 - CASCADE CONNECTION

iCEP (PC application)

PROFINET

IB-P01 IB-P01 IB-P01 IB-P01

192.168.1.1

192.168.1.2

192.168.1.3

8.2 - STAR CONNECTION

iCEP (PC application)

Hub

IB-P01 IB-P01 IB-P01 IB-P01

192.168.1.4

IB-P01

192.168.1.1

TECHNICAL DOCUMENTATION

192.168.1.2

22

192.168.1.3

192.168.1.4

Original notice - T1.4

9. CONTROLLING IB-P01 CIRCUIT BOARD

,%FLUFXLWERDUGVFDQEHFRQ¿JXUHGLQHLWKHUDV0$67(5RU6/$9(PRGHV,IDQ,%3FLUFXLWERDUGLVVHWWR

a master, the motor RUN and remote output on the board can be controlled by its own board. If IB-P01 circuit

boards are set to slaves, the motor RUN and remote output on each IB-P01 circuit board cannot be controlled

by its own board, and they will be controlled by the master. For further information refer to iCEP user manual.

This section introduces four typical or example usages as follows:

9.1 - WHEN THE PROFINET CAPABLE PLC CONTROLS IB-P01 CIRCUIT BOARD

Set the PLC to be the master and IB-P01 circuit boards to be slaves to make a PROFINET I/O between the PLC

and IB-P01 circuit boards. The PLC will control all the IB-P01 circuit boards.

PROFINET capable PLC

PROFINET I/O (obtaining sensor and error information)

Motor RUN

instruction, etc...

IB-P01 (Slave) IB-P01 (Slave) IB-P01 (Slave) IB-P01 (Slave)

Ladder N/A

Ladder N/A

Ladder N/A

Ladder N/A

9.2 - IN CASE OF CONTROLLING THE LOCAL ‘OWN’ ZONE BY IB-P01 CIRCUIT BOARD, AND

MONITORING EACH ZONE BY PROFINET CAPABLE PLC

Set each IB-P01 circuit board as a master, and download ladder logic onto each of them. Each IB-P01 circuit

board controls its own zone. The PLC monitors the status of each PROFINET I/O zone. In this case, it is possible

to write data from the PLC into the data register of each IB-P01 circuit board.

PROFINET capable PLC

PROFINET I/O (obtaining sensor and error information)

PROFINET I/O

Writing data into the

data registrer

Communication

between boards

(sensor information,

etc...)

IB-P01

IB-P01 (Master) IB-P01 (Master) IB-P01 (Master) IB-P01 (Master)

With ladder

TECHNICAL DOCUMENTATION

With ladder

23

With ladder

With ladder

Original notice - T1.4

9.3 - WHEN THE NETWORK IS CONFIGURED ONLY WITH IB-P01 CIRCUIT BOARD

Set each IB-P01 circuit board as a master, and download ladder logic onto each of them. Each IB-P01 circuit

board controls its own zone. The control can be performed without connecting the PC or PLC.

Communication between boards

(sensor information, etc...)

IB-P01 (Master) IB-P01 (Master) IB-P01 (Master) IB-P01 (Master)

With ladder

With ladder

With ladder

With ladder

9.4 - WHEN ONE IB-P01 CIRCUIT BOARD CONTROLS MULTIPLE CONNECTED

IB-P01

Download ladder logic onto the master IB-P01 circuit board. Set other IB-P01 circuit boards as slaves. The

master IB-P01 circuit board controls its own zone and the zones of the slaves. Up to seven slave IB-P01 circuit

boards can be controlled by one master IB-P01 circuit board.

With ladder

IB-P01 (Master)

Communication

between boards

(motor RUN instruction)

CIRCUIT BOARD

Communication between boards

(sensor information, etc...)

IB-P01

IB-P01 (Slave) IB-P01 (Slave) IB-P01 (Slave) IB-P01 (Slave)

Ladder N/A

Ladder N/A

Ladder N/A

Ladder N/A

Up to 7 IB-P01 circuit boards

TECHNICAL DOCUMENTATION

24

Original notice - T1.4

ANNEX 1

AKASHI, G

to

INCORPORATION DECLARATION

ACCORDANCE WITH THE EC MACHINERY DIRECTIVE 2006/42/EC, ANNEX II B

IN

The manufacturer :

ITOH DENKI CO., Ltd

1146-2 Asazuma-Cho, Kasai, Hyogo 679-0105 Japan

Distributed in Europe by :

ITOH DENKI Europe SAS

490 avenue des Jourdies - PAE les Jourdies - BP 323

74807 St Pierre en Faucigny Cedex - France

hereby declares that the product series:

IB-P01

LVDQLQFRPSOHWHPDFKLQHDVGH¿QHGLQWKH(&0DFKLQHU\'LUHFWLYHDQGWKHUHIRUHGRHVQRWIXOO\PHHW

WKHUHTXLUHPHQWVRIWKLV'LUHFWLYH6HUYLFHHQWU\LVSURKLELWHGXQWLOWKHZKROHPDFKLQHV\VWHPLQZKLFK

LWLVLQFRUSRUDWHGLVGHFODUHGWREHLQFRPSOLDQFHZLWKWKH(&0DFKLQHU\'LUHFWLYH

The health and safety requirements of Annex I have been applied. The special technical documents in

accordance with Annex VII have been drawn up (and, if appropriate, submitted to the competent authorities).

Person authorized to compile the technical documentation :

ITOH DENKI CO., Ltd

Toshiyuki TACHIBANA

1146-2 Asazuma-Cho, Kasai, Hyogo 679-0105 Japan

ITOH DENKI EUROPE SAS

Makoto MITSUYOSHI

490 Avenue des Jourdies, 74800 St Pierre en Faucigny - France

(&'LUHFWLYHVDSSOLHG

• Machinery Directive 2006/42/EC

• European EMC Directive 2014/30/EC

• European RoHS Directive 2011/65/EU

CIRCUIT BOARD

ITOH DENKI EUROPE SAS, undertakes to forward, following a duly motivated request from the national

authorities, the relevant information concerning the quasi-machine.

Saint Pierre en Faucigny, 15 December 2017

T. AKASHI, General Director

.

eneral Direc

IB-P01

TECHNICAL DOCUMENTATION

25

Original notice - T1.4

,72+'(1.,(8523(6$6

UK BRANCH OFFICE

GERMAN BRANCH OFFICE

490 Av. des Jourdies

P.A.E. les Jourdies

74800 St Pierre en Faucigny - France

Tél. : +33 (0)4 50 03 09 99

Fax : +33 (0)4 50 03 07 60

E-mail : info@itoh-denki.com

Suite 1 Trinity Space Centre

Waldorf Way

:DNH¿HOG:)'+8.

Tel : +44 (0)1924 366 539

Fax : +33 (0)4 50 03 07 60

E-mail : info@itoh-denki.com

:::,72+'(1.,&20

26

Lebacher Strasse 4

66113 Saarbrücken - Deutschland

Tel : +49 911 25 26 - 200

Fax : +49 911 25 26 - 201

E-mail : info@itoh-denki.de

Loading...

Loading...