HOLEMAKER HMP45

Holemaker Portable Magnetic Drilling Machine

OPERATOR’S MANUAL

WARNING!

BEFORE USE, ENSURE EVERYONE USING THIS MACHINE READS AND UNDERSTANDS

ALL SAFETY AND OPERATING INSTRUCTIONS IN THIS MANUAL .

EYE PROTECTION

REQUIRED

HEARING PROTECTION

REQUIRED

NEVER PLACE

FINGERS NEAR

CUTTING AREA OR

MACHINE ARBOR

LINE VOLTAGE

PRESENT

BEWARE OF

ROTATING

MACHINE PARTS

Ver: 1.10 18/08/2015

esahcruP fo etaD # laireS

®

HMP45 OPERATOR’S MANUAL

LIMITED WARRANTY

Industrial Tool & Machinery Sales (hereinafter refered to as ITMS) will, within twelve (12)

months from the original date of purchase, repair or replace any goods found to be defective

in materials or workmanship.

This warranty is void if the item has been damaged by accident, neglect, improper service or

other causes not arising out of defects in materials or workmanship. This warranty does not

apply to machines and/or components which have been altered, changed, or modified in any

way, or subjected to overloading or use beyond recommended capacities and specifications.

Worn componentry due to normal wear and tear is not a warranty claim. Goods returned

defective shall be returned prepaid freight to ITMS or agreed repair agent, which shall be the

buyer’s sole and exclusive remedy for defective goods. ITMS accepts no additional liability

pursuant to this guarantee for the costs of travelling or transportation of the product or parts to

and from ITMS or the service agent or dealer, such costs are not included in this warranty.

Our goods come with guarantees which cannot be excluded under the Australian Consumer

Law. You are entitled to replacement or refund for a major failure and to compensation

for other reasonably foreseeable loss or damage. You are also entitled to have the goods

repaired or replaced if the goods fail to be of acceptable quality and the failure does not

amount to a major failure.

THE MANUFACTURER RESERVES THE RIGHT TO MAKE IMPROVEMENTS AND

MODIFICATIONS TO DESIGN WITHOUT PRIOR NOTICE.

PRODUCTS IMPORTED AND DISTRIBUTED NATIONALLY BY:

INDUSTRIAL TOOL & MACHINERY SALES

18 BUSINESS ST, YATALA QLD 4207

T: 07 3287 1114 E: sales@industrialtool.com.au

F: 07 3287 1115 W: www.industrialtool.com.au

2 www.holemaker.com

®

HMP45 OPERATOR’S MANUAL

CONTENTS

1. GENERAL SAFETY ADVICE..............................................................................4

2. START UP AND OPERATION............................................................................6

3. ADJUSTMENTS, MAINTENANCE & SERVICE................................................16

4. TECHNICAL DATA............................................................................................19

The Holemaker HMP45 Package consists of:

• metal box 1pc

• HMP45 drilling machine 1pc

• #2 Morse Taper arbor 1pc

• coolant system 1pc

• chip guard 1pc

• spoke handles 3pcs

• hex wrench s=4 1pc

• hex wrench s=5 1pc

• drill drift, MT2 1pc

• safety chain with snap hook 1pc

• operator’s manual 1pc

BEFORE YOU START WORK WITH THE MACHINE, PLEASE READ THESE

INSTRUCTIONS CAREFULLY AND USE ALL RECOMMENDATIONS.

www.holemaker.com 3

®

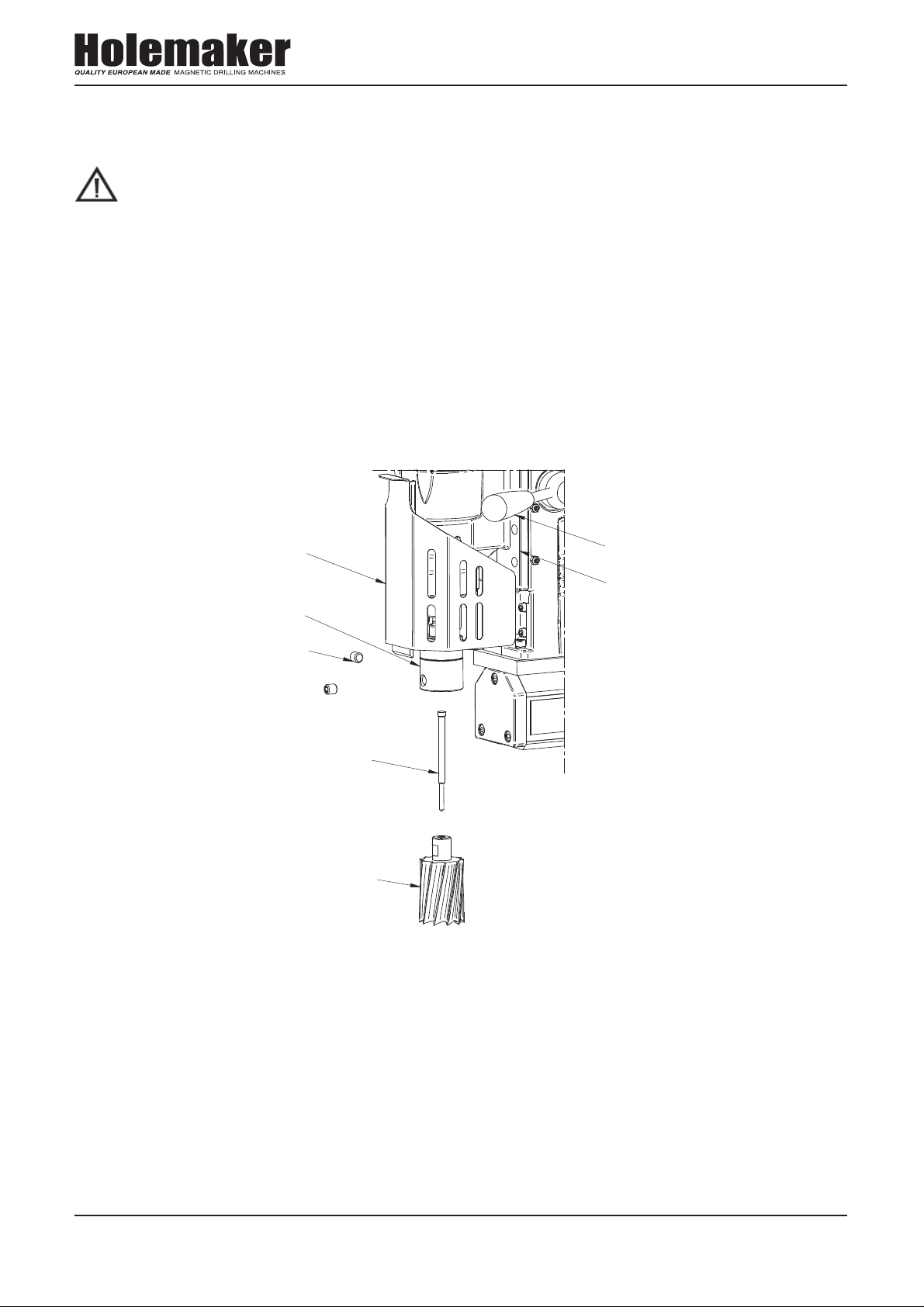

rawing 1.

xamples how safety chain should be fastened.

.

HMP45 OPERATOR’S MANUAL

1. GENERAL SAFETY ADVICE

Drilling machine must not be used when:

1. The operator has not read the Operator’s Manual.

2. The work to be done is not in agreement with the recommendations in this Manual.

3. Drilling machine is not complete or has been repaired with non-original parts.

4. Power supply parameters do not conform to those stated on the motor’s plate.

5. Machines operator has not checked condition of the drilling machine, condition of air hose,

control panel or cutting tool.

6. Machine is not secured with safety chain as a protection from falling down especially when

used at heights or in vertical or upside-down positions.

7. Bystanders are present in the immediate vicinity of machine.

Important rules of safe use of drilling machine

1. Before attempting to work with the machine check condition of air hose and coupling.

2. Make sure that the drill is supplied with purified air and oiled.

3. Machine can be used outdoors, but is not weatherproof. Do not expose to rain, snow or

frost.

4. Machine should not be used on: rusty surfaces, steel plates covered with paint, uneven

surfaces, or steel plate which is being welded on.

5. In all cases always use a safety chain/strap. See drawing 1. The safety chain must not be

loose!

6. Do not use the machine in explosion hazard zones.

7. Do not start work if the machine has excessive play on guide slides.

8. Always wear safety goggles and ear protection.

Drawing 1.

Examples how safety chain should be fastened.

4 www.holemaker.com

®

HMP45 OPERATOR’S MANUAL

9. Do not remove metal chips with bare hands, always use gloves.

10. Do not touch the spindle and cutting tool during work.

11. Cutting Tools must be fastened firmly.

12. Do not drill with blunt of damaged cutting tools.

13. Do not use annular cutters without a pilot pin, and arbors without an ejection spring.

Do not touch or replace the cutting tool with power source on

14. After use, always clean drilling machine from metal chips and cutting fluid.

15. Any maintenance and repair should be performed only when the machine is disconnected

from the air supply.

16. Before each use the machine should be checked for the presence of damage. Check

whether any of the parts are broken and all the that all parts are fasten properly.

17. In the case that the machine falls on a hard surface, from a height, is wet or is subjected

to other unfortunate events that could affect its technical state - work should be terminated

immediately and the machine should be sent to service for inspection as soon as possible.

This machine is not recommended to be used to drill on steel thinner than 10mm (3/8”).

On thin steel less than 10mm (3/8”) magnet’s adhesive power would be significantly

reduced which can cause machines failure or personal injury.

The pneumatic motor used in Holemaker HMP45 drilling machine is ATEX II2 G/D C IIC

T6;T4 certified, which is required for usage in explosion risk zones.

CAUTION: Never carry the drill by the motor’s air supply hose!

www.holemaker.com 5

®

D

D

HMP45 OPERATOR’S MANUAL

2. START UP AND OPERATION

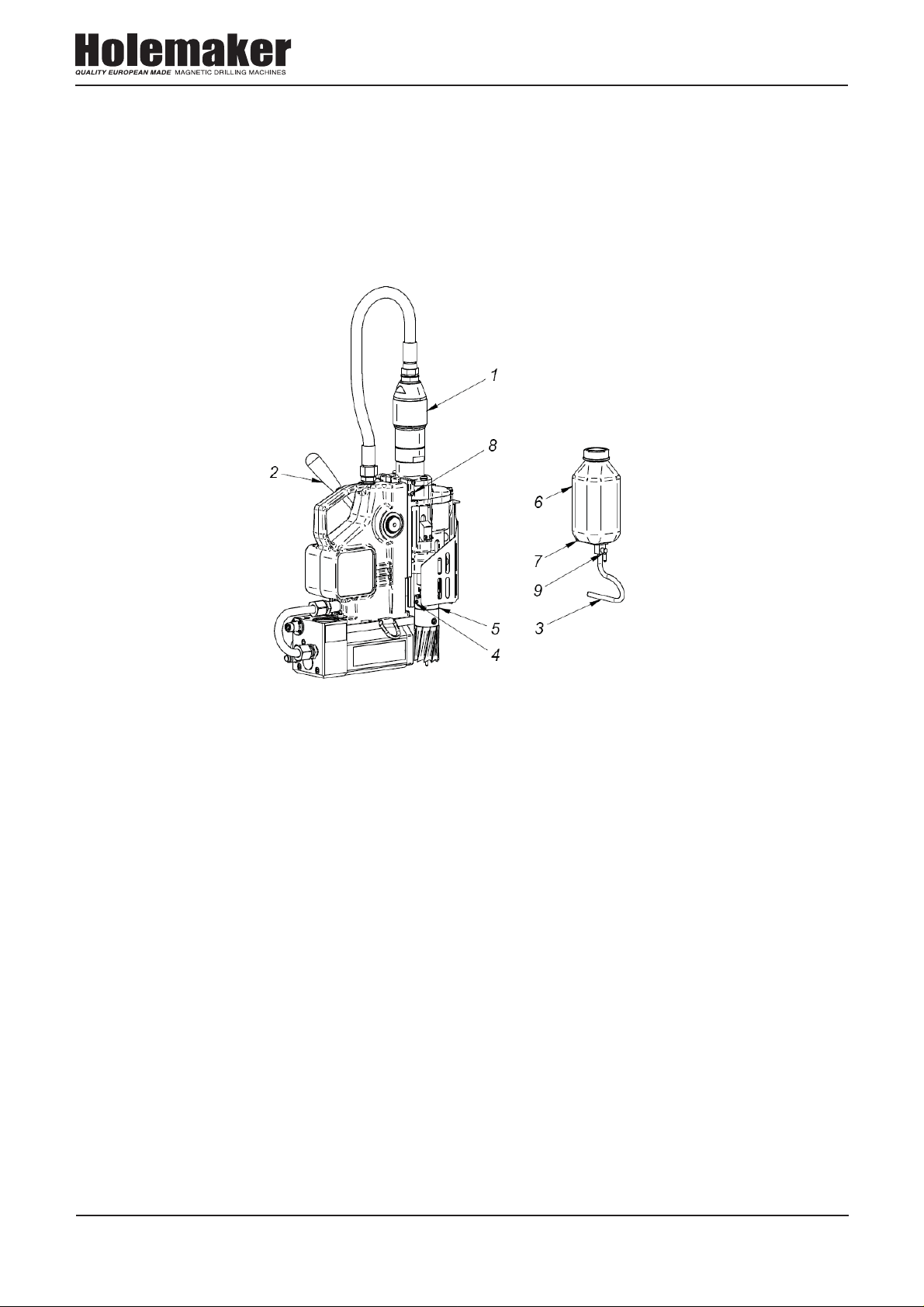

Cutters and optional equipment features

The Holemaker HMP45 has a #2 Morse Taper spindle which can be used with twists drills,

annular cutters, tapping heads and reamers etc. that have a #2 Morse Taper shank.

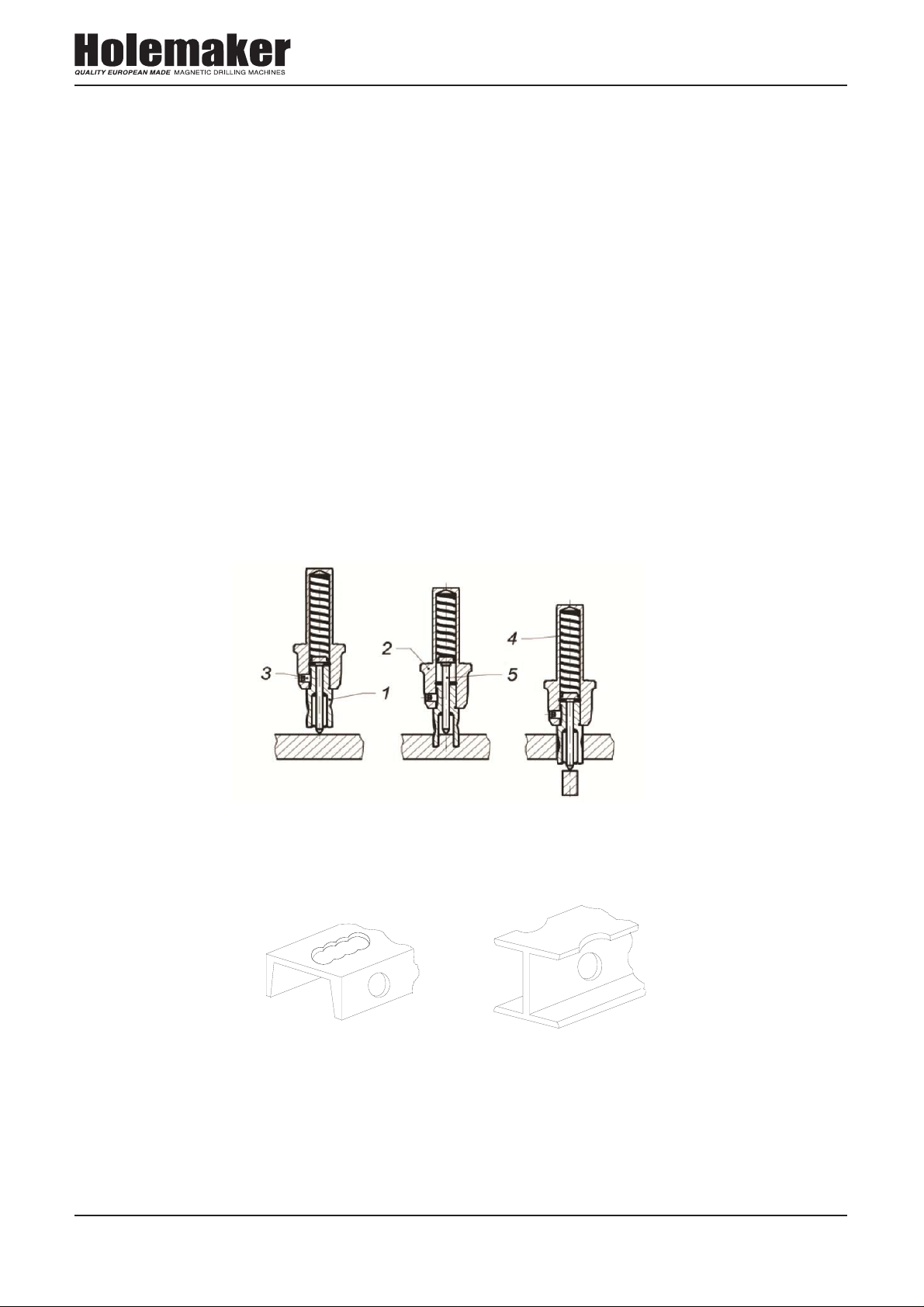

The Annular cutter (1) is located inside arbor body (2) and is fastened with grub screws (3).

When fastening the cutter in the arbour, ensure that the grub screws are firmly tightened to

avoid them coming loose during operation. It is important to position the cutter in relation to

the arbour in such a way that fixing flats on the cutter shank are positioned opposite to the

grub screws (3). Both grub screws(3) should be used to fasten the cutter. The Pilot Pin (5) is

located inside the cutter to easily position the annular cutter over centre of a planned hole.

During drilling as the cutter goes into the material, the pilot pin moves back into the arbour

body and pressurizes the discharge spring (4).That spring ejects the slug which is a byproduct of drilling the hole with a centre free cutter.

rawing 2. Principle of annular cutter’s work

rawing 3. A few types of holes that can be done with an annular cutter.

6 www.holemaker.com

®

HMP45 OPERATOR’S MANUAL

2.1 Installing and uninstalling the arbor

The arbor installation and uninstallation should be carried out when the machine is

turned off and disconnected from the air supply.

Installing the arbor:

a) Raise the cutter guard (2) to the maximum height

b) Clean the inside of the spindle using a cotton cloth,

c) Before mounting, clean off the lubricant from the new arbor (3),

d) Place the arbor with the tang on top, and place it in the spindle,

e) By turning the arbor, align the tang to the appropriate slot in the spindle,

f) Using a light impact from the bottom side, drive the arbor into the spindle.

1

2

3

Uninstalling the arbor:

a) Raise the guard, turn the spindle so that the opening in the spindle (1) is lined up with

the opening in the reducer body,

b) Place the drill drift (included as standard equipment) into the uncovered spindle

opening (1),

c) Hold down the arbor (3) with one hand,

d) Strike the drill drift with a hammer, taking care to not to damage the arbor,

e) Carefully remove the arbor from the socket in the spindle,

f) Remove the drill drift

www.holemaker.com 7

®

HMP45 OPERATOR’S MANUAL

2.2 Installing and uninstalling an annular cutter

Annular cutter installation and uninstallation should be carried out when the machine is

turned off and disconnected from the air supply!

Installing the annular cutter:

1. Raise the drive and the slide (2) up using the feed handles (3);

2. Raise the guard (1) to the maximum height in order to attain access to the arbor (4) grub

screws (5);

3. Insert the appropriate type of pilot (6) into the annular cutter (7);

4. Position the annular cutter (7) with the cutter facing up, so that the flat sides of the milling

cutter are found facing the grub screws (5)

5. Put the annular cutter (7) into the arbor socket (4);

6. Tighten the grub screws securely (5), locking onto the flat sections of the annular cutter.

1

4

5

6

7

3

2

Uninstalling the annular cutter:

1. Raise the drive and the slide (2) up using the feed handles (3);

2. Raise the guard (1) to the maximum height in order to attain access to the arbor (4) grub

screws (5).

3. Loosen the grub screws (5);

4. Remove the annular cutter (7) and the pilot pin (6) from the arbor socket (4).

8 www.holemaker.com

®

HMP45 OPERATOR’S MANUAL

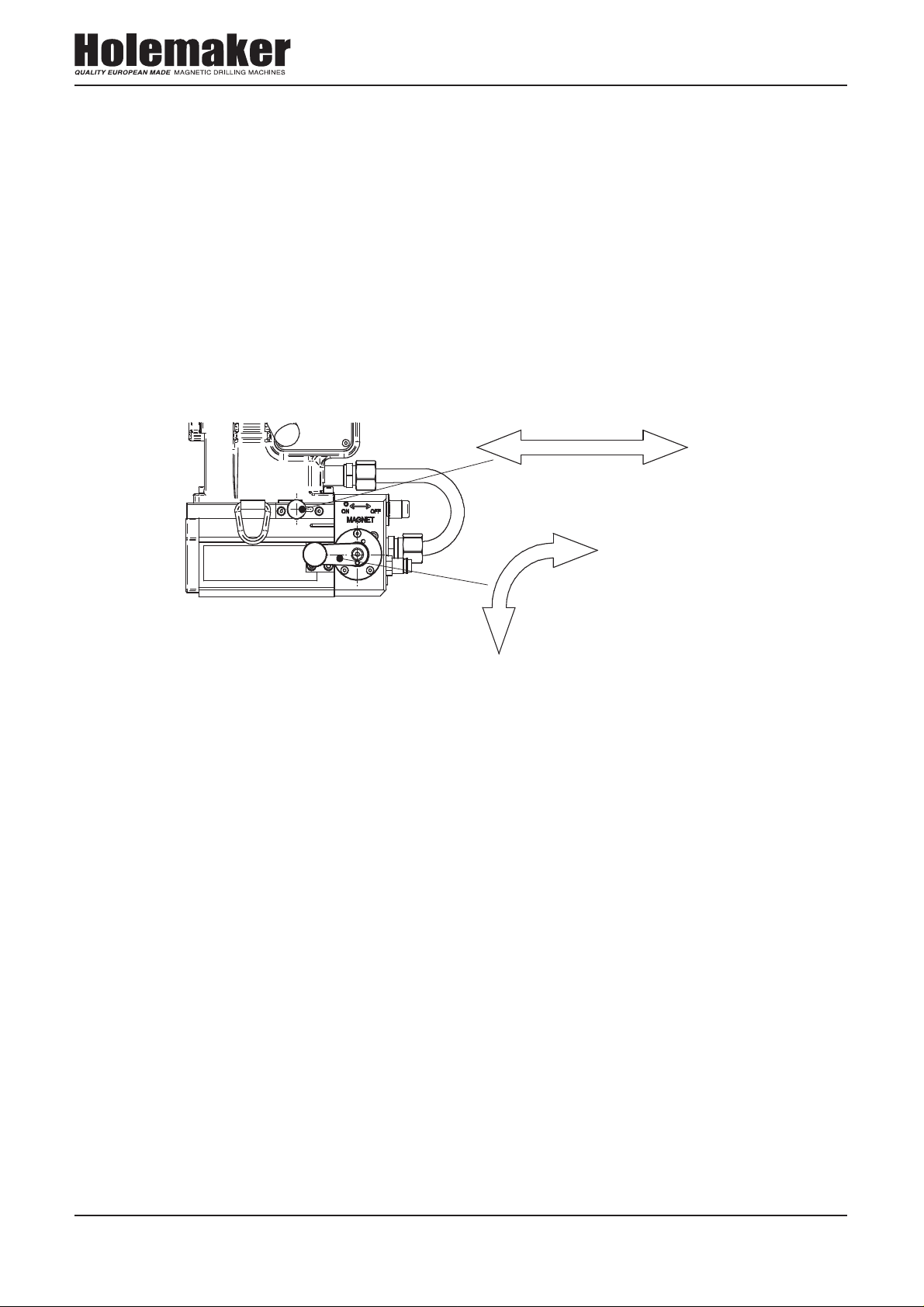

2.3 Installing and uninstalling the coolant system

1. Place the machine in the vertical position,

2. Slide the drive and the slider (1) up using feed handles (2),

3. Place coolant bracket (7) with cooling unit (6) onto screws (8)

4. Connect the cooling conduit ending (3) with the coupling (4) found in the cooling ring (5).

Before starting the machine:

• Remove the bottle’s cap,

• Fill it with soluble cutting fluid,

• Replace bottle cap.

After fulfilling the above actions and making sure, that the system has been appropriately

fixed, and the cooling conduit (3) is placed correctly on the coolant coupling (4), the bottle cap

should be loosened by 1/3 of a turn. Turn on the valve (9), so that liquid travels to the hose,

after which the machine can be started (see II pt. 3)

After finishing work, one must remember to tighten the bottle cap and turn off the valve (9) (to

prevent liquid from leaking during the time that the machine is not being used) and uninstall

the cooling system (6) before placing the machine in the box.

Uninstalling the cooling system:

1. Place the machine in the vertical position,

2. Slide the drive and the slider (1) up using feed handles (2),

3. Disconnect the cooling conduit ending (3) and the coolant coupling (4) found in the cooling

ring (5).

4. Remove the cooling system.

www.holemaker.com 9

®

HMP45 OPERATOR’S MANUAL

2.4 Before first use:

• Steel elements of the drilling machine are protected for transit and storing with grease film.

• Before first start up of the machine all grease should be removed before each use all

handles should be screwed into pinion.

2.5 Before you cut

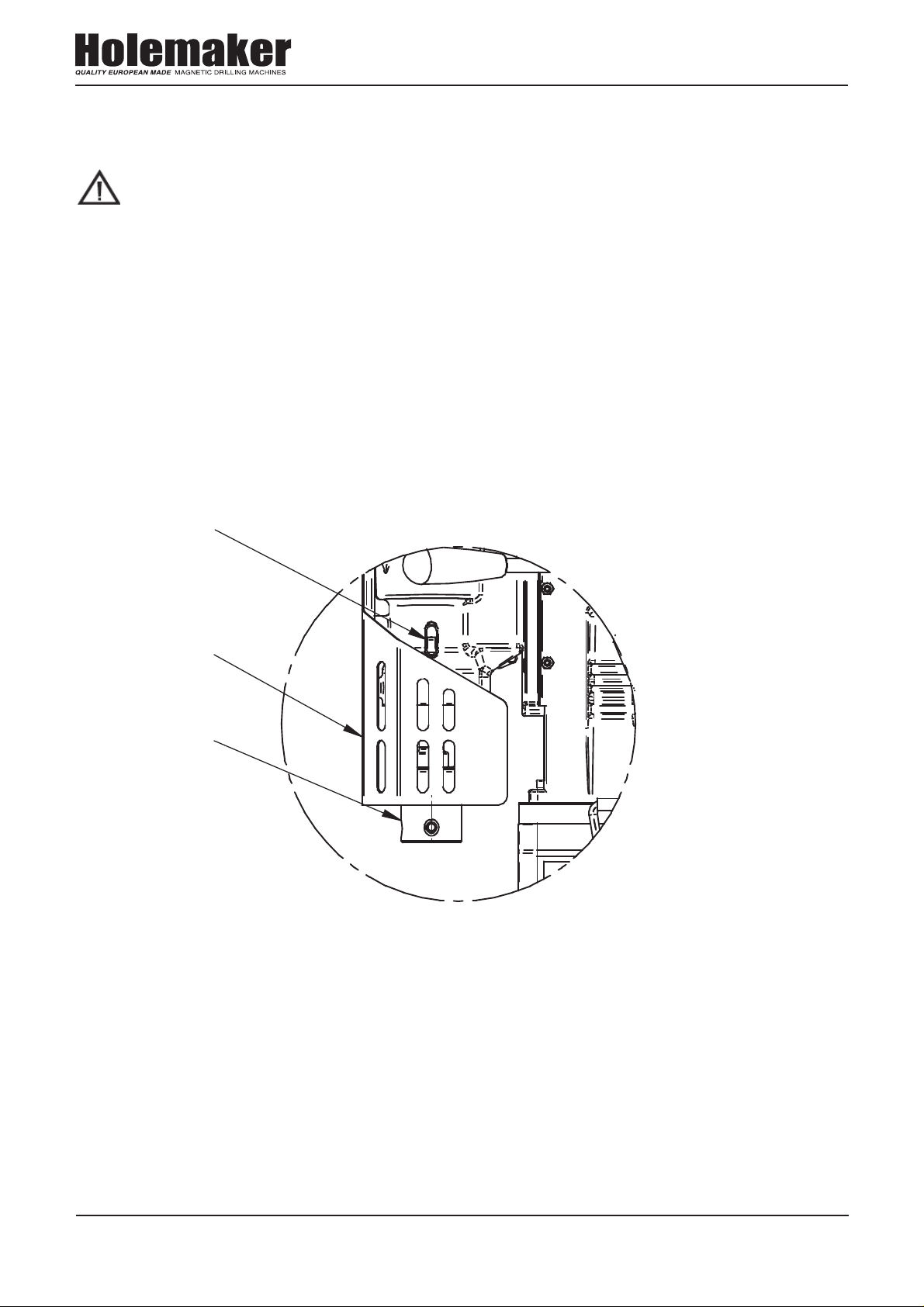

Control elements include:

• MAGNET switch,

• MOTOR switch.

ON

MAGNET

OFF

ON

MOTOR

OFF

To start the machine, follow these steps:

• Make sure that both the motor and magnet ON/OFF switch are in the OFF position.

• Plug machine into air supply, and position drill

• Slide the magnet ON/OFF switch to the ON position.

• Toggle the motor switch to ON position, after pulling back the safety latch of the switch.

• Once cut has been completed, toggle the motor ON/OFF switch to the off position.

• To position the machine in a new drilling spot, the magnetic base switch has to be toggled

to OFF position.

READ THE WHOLE INSTRUCTIONS MANUAL BEFORE ATTEMPTING TO START UP

2.6 Before you cut

• Before positioning the machine on work piece always make sure that:

• Work piece is made of ferrous steel (some grades of stainless or acid resistant steel

do not conduct magnetic flux)

10 www.holemaker.com

®

HMP45 OPERATOR’S MANUAL

• thickness of work piece is at least 10mm (3/8”)

• surface of steel under the magnet is flat

• wipe, brush or sand down clean surface where you intended to place the drilling machine,

so that you remove rust, paint, dirt etc. which would reduce adhesive power of the

electromagnetic base.

• Install drill bit, annular cutter or other tooling such as tapping head or reamer into the

machine before plugging it air supply. Then plug into air supply (see paragraph 2) and

position where you wish to drill. Place the machine so that the tool is over the centre of the

hole you intend to make and turn the magnetic base ON.

Prior to use always make sure that the machine is secured from falling down with

original chain

2.7 Cutting

• Select the right speed for the tool you intend to use (see the speeds chart in this manual).

Do not use water as the cutting fluid.

The coolant system is an integral part of the machine and should always be used.

Warning: The coolant system can only be used when drilling machine is in vertical

position. In other positions additional external source of coolant should be used, for

example: a pressure feed coolant bottle.

• Check working of cooling system. Open coolant reservoir’s tap and apply pressure on the

pilot by turning the feed handles counter clockwise. As the pilot pin starts to retract up into

the annular cutter, cutting fluid should start to run down cutters inner wall and onto the

workpiece. If there is no cutting fluid flowing down check if the tap is fully opened. It may

take a few seconds for cutting fluid to fill the whole system.

• Connect air pressure hose with feeding air of appropriate parameters (6 bar / 90 PSI,

1400 l/min).

• Position an axis of the spindle precisely above drilling point

• Switch on magnetic action using the MAGNET switch.

• Turn the motor on.

• Making a hole with an annular cutter should ideally be done in one pass. It makes

the cutter work better and easier to eject the slug after the hole is completed. If you

experience slugs getting stuck inside a cutter after hole is complete try to reduce pressure

on the cutter. Do not allow excessive swarf build up around the annular cutter and arbor.

WARNING: when the annular cutter goes through the material, the slug can be pushed

out often with considerable strength. Pay attention to avoid injury.

www.holemaker.com 11

®

HMP45 OPERATOR’S MANUAL

• After a hole is made the cutter should be withdrawn back and both the motor and the

electromagnet should be switched OFF.

• When work with the machine is finished the air supply should be disconnected, the

machine should be cleaned up from swarf, coolant etc and the cutter should be removed

and cleaned.

2.8 Workpiece Material

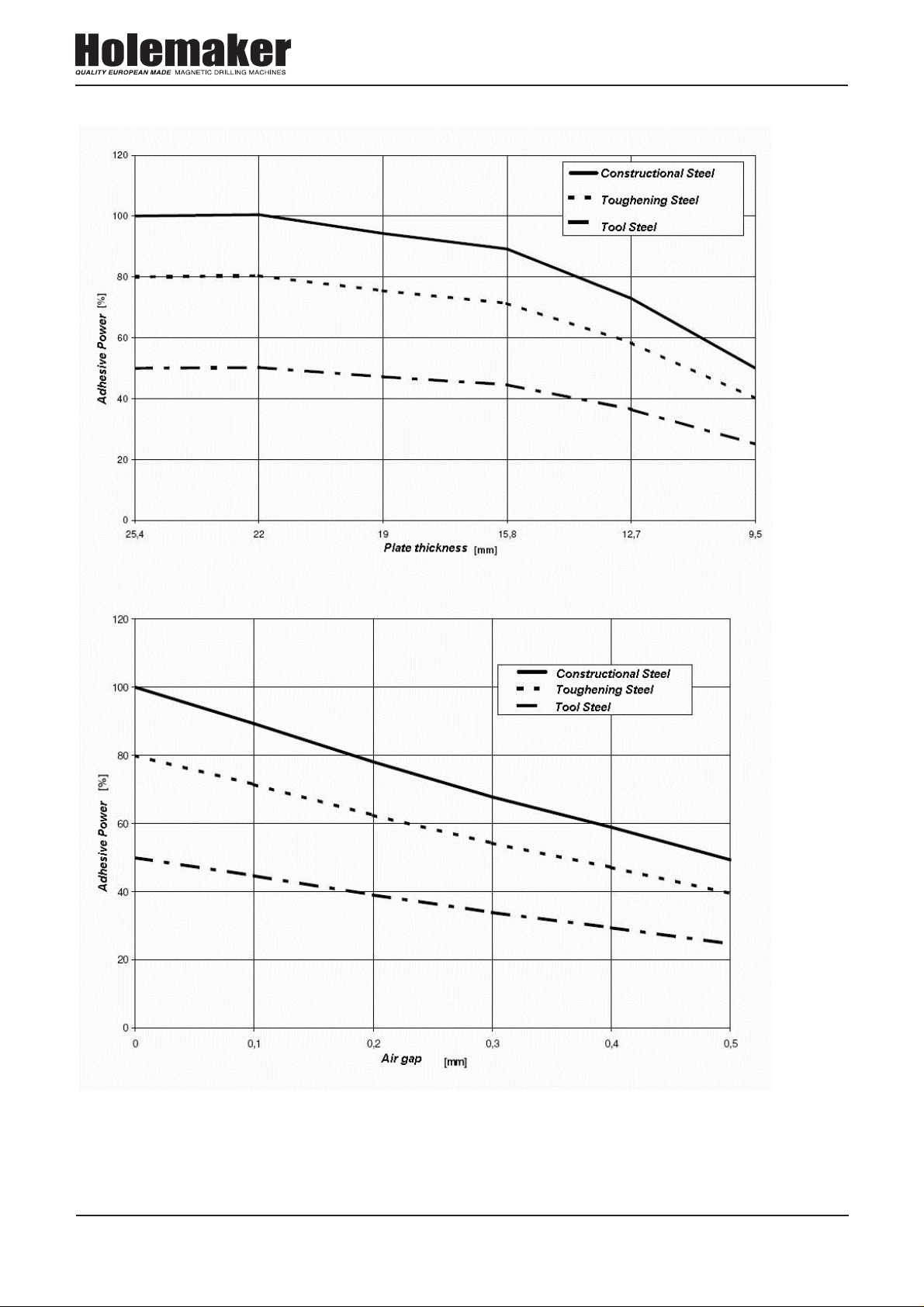

As shown on the graphs [Drawing 4] magnetic clamping force of the electromagnetic base

to the ferrous material depends on its magnetic properties. Steel with increased carbon

content and some other alloying ingredients have lower magnetic permeability, which causes

a decrease in the clamping force. Also the thickness of the work piece, on which the drill is

placed, is significant.

If material less than 10mm (3/8”) is to be drilled, a thick (10mm or more) piece of

material must be placed underneath the workpiece, directly below the machines

magnet, to ensure enough magnetic adhesion is present.

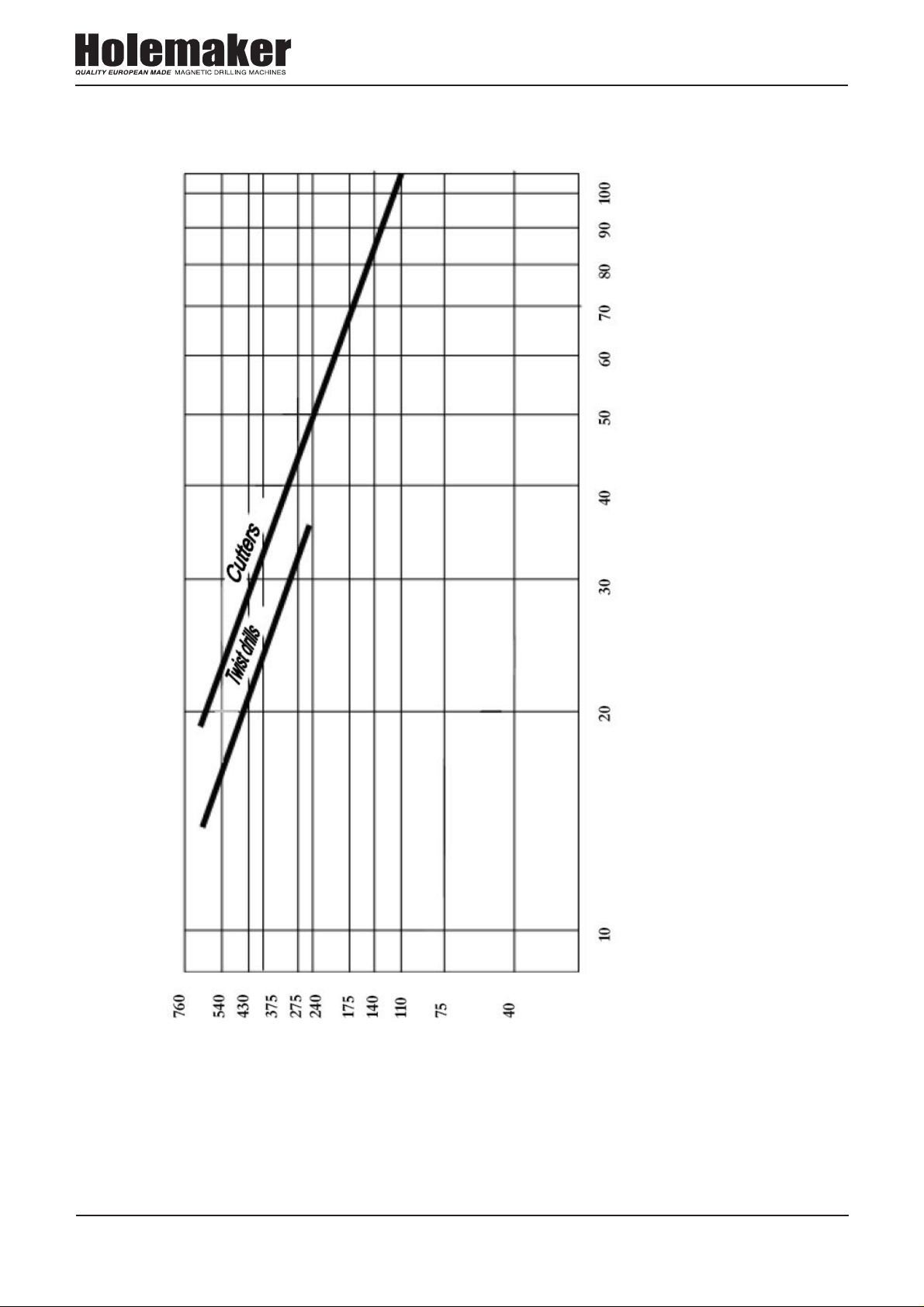

Appropriate rpm should be adjusted depending on if drilling would be carried out with a drill

bit, or annular cutter, and also the cutting tool’s diameter. The HMP45 is equipped with a

mechanical 2-step reducing gearbox. A general dependence between drilling diameter and

drilling speed is shown in graphs [Drawing 5]. Detailed guides should also be available from

the cutting tool manufacturer. The graph is just a general guide and applies to average mild

steel.

2.9 Working in difficult areas

The feed handles of the machine can be moved from one side to the other, by removing the

entire pinion shaft from the machine, and re-inserting into the opposite side of the drill.

Please keep all recommendations

12 www.holemaker.com

®

HMP45 OPERATOR’S MANUAL

Drawing 4. Clamping force depending on the thickness of the substrate and the value gap.

www.holemaker.com 13

®

HMP45 OPERATOR’S MANUAL

Relationship between machine speed and cutter diameter

The cutter diameter Rotary speed

(inch) (mm)

(rpm)

0.04 ÷ 0.43 3.5 ÷ 13 290

0.44 ÷ 0.78 14 ÷ 20 190

Relationship between machine speed and twist drill diameter

The twist drill diameter Rotary speed

(inch) (mm)

(rpm)

0.04 ÷ 0.43 3.5 ÷ 13 290

0.44 ÷ 0.78 14 ÷ 20 190

14 www.holemaker.com

®

HMP45 OPERATOR’S MANUAL

Diameter (mm)

Revolutions of spindle (rpm)

Drawing 5. Dependence of rotational speed on drilling diameter

www.holemaker.com 15

®

HMP45 OPERATOR’S MANUAL

3. ADJUSTMENT, MAINTENANCE AND SERVICE

• After every days work position of gear lever (used for selection of gearbox speed) should

be changed. For example if machine worked with 190 rpm speed, it should be switched to

290rpm.

• Regularly Lubricate brass slide guide inserts with grease as well as the rack and pinion.

• To prevent the machine from rusting (especially when used outdoors) all steel parts

should be covered with thin layer of grease film.

• When working with a pneumatic motor it is necessary to use an air lubrication unit.

• Damaged machine parts to be exchanged only to original parts.

• All repair work should be done only by authorized service points, appointed by distributor.

CAUTION: The warranty conditions for the pneumatic motor do not apply when

occurred damages and wear are caused by impurities from air supply, or an

appropriate lubrication wasn’t used.

Lubrication of the pneumatic motor.

• It is necessary to use the air lubrication unit in the air supply system.

• Inspections and maintenance of the air supply system should be carried out when needed

depending on level of air pollution; clean the filter and maintain the amount of oil in the

lubrication unit to ensure an oil drop every 2 to 5 seconds.

• The oil used in the air supply unit must have an ignition temperature higher than 260°C.

CAUTION: The HMP45 is designed to be supplied with an air of pressure 4 to 6 bar/60

to 90 PSI/. Maintaining the machine’s parameters and its condition strictly depend on

the air purity and its preparation level, and a proper servicing.

16 www.holemaker.com

®

HMP45 OPERATOR’S MANUAL

3.1 Slides Adjustment

Use the feed handles (1) to move the sliding section of the drill to a position where the screws

(2) align with the holes (5) in the sliding section. Loosen each of these screws slightly, and

then using the feed handles slide the sliding section up and down several times until any

clearance between the pressure strip and the slider is even and aligned.

Canceling clearance

1

5

2

3, 4

A

Once this has been completed, tighten screws (2) starting from the middle screw. The slider

should be located symmetrically relative to the middle screw. Next, tighten the neighboring

screws (2) moving the slider in the degree necessary for making them visible.

Then, tighten screws (3) until any noticeable resistance is felt. Tighten counter nut (4). The

screws (3) counteract the machining force and protect the pressure strip from shifting during

operation.

www.holemaker.com 17

®

HMP45 OPERATOR’S MANUAL

Then, tighten screws (3) until any noticeable resistance is felt. Tighten counter nut (4). The

screws (3) counteract the machining force and protect the pressure strip from shifting during

operation.

Caution: In the case that the machine falls on a hard surface, from a height, is wet or is

subjected to other unfortunate events that could affect its technical state - work should

be terminated immediately and the machine should be sent to service for inspection as

soon as possible.

18 www.holemaker.com

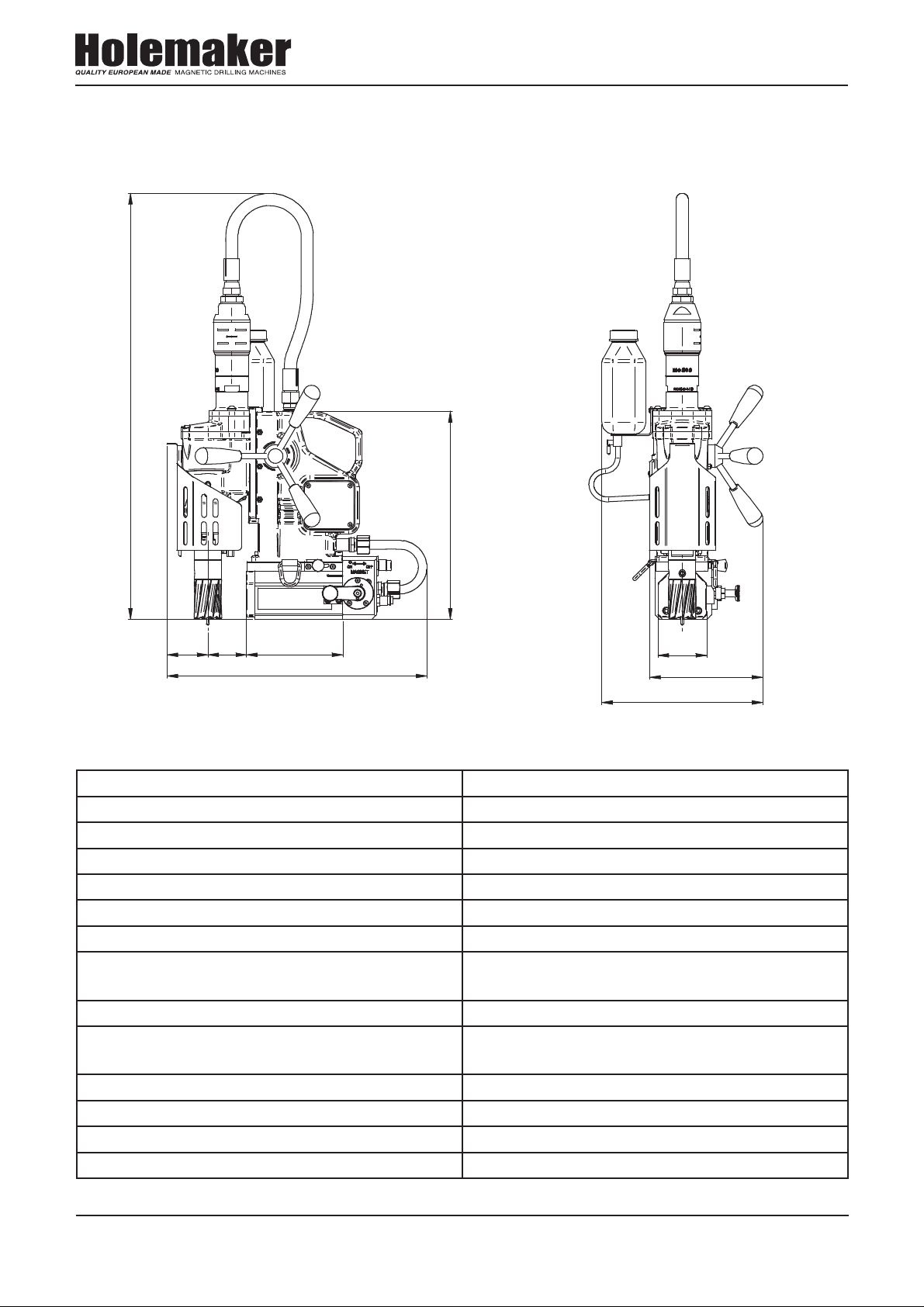

4. TECHNICAL DATA

690 / 750

®

HMP45 OPERATOR’S MANUAL

340

63 15766,5

424

Nominal pressure 6 bar

Air consumption 1400 l/min

Motor power 800 W

Tool holder 19 mm (3/4") Weldon

Max. twist drill diameter 20 mm

Max. annular drilling diameter 45 mm

Max. milling depth 51 mm (2”)

Standard adhesive force of electromagnet

7500 N

(for steel 7/8” (22 mm) thick and Ra < 1.25)

Slide stroke 150 mm

Machine speeds /under load/ I – 190 rpm

II – 290 rpm

Electromagnetic base 80 x 80 x 143mm

Total weight 19kg

Noice level 70 dB

Surrounding temperature -20°C ÷ +40°C

79

185

263

www.holemaker.com 19

PRODUCTS IMPORTED AND DISTRIBUTED NATIONALLY BY:

INDUSTRIAL TOOL & MACHINERY SALES

18 BUSINESS ST, YATALA QLD 4207

T: 07 3287 1114 E: sales@industrialtool.com.au

F: 07 3287 1115 W: www.industrialtool.com.au

HOLEMAKER HMP45

BREAKDOWN

HMP45 BREAKDOWN

1

Main Body Assembly

ITEM PART NUMBER DESCRIPTION Q-TY

2.1

2.2

2.3

2.4

2.5

2.6

2.7

2.8

2.9

2.1

2.11

2.12

2.13

2.14

2.15

SPP45201 MAIN FRAME BODY 1

SPP45202

SPP45203

SPP45204

SPP45205

SPP45206

SPP45207

SPP45208

SPP45209

SPP45210

SPP45211

SPP45212

SPP45213

SPP45214

SPP45215

PRESSURE PLATE

SLIDE INSERT -LEFT

SELF LUBRICATING SLEEVE

28,05H7x32x16,

SPRING, 1,6x8x14,5

HEX SOCKET BOLT-M5X20

ROUND WASHER 5,3

MAIN FRAME BODY PIPE I

MAIN FRAME BODY PIPE II

MAIN FRAME BODY BLOCK

SCR,SHCS M5 x 25 DIN 912

EXTERNAL RETAINING RING-20Z

SOCKET SET SCREW M5 x 10

NUT M5

SEAL WASHER 3/8 "

1

1

2

4

5

5

1

1

1

4

2

3

3

2

2.16

SPP45216

SPRING WASHER

4

2

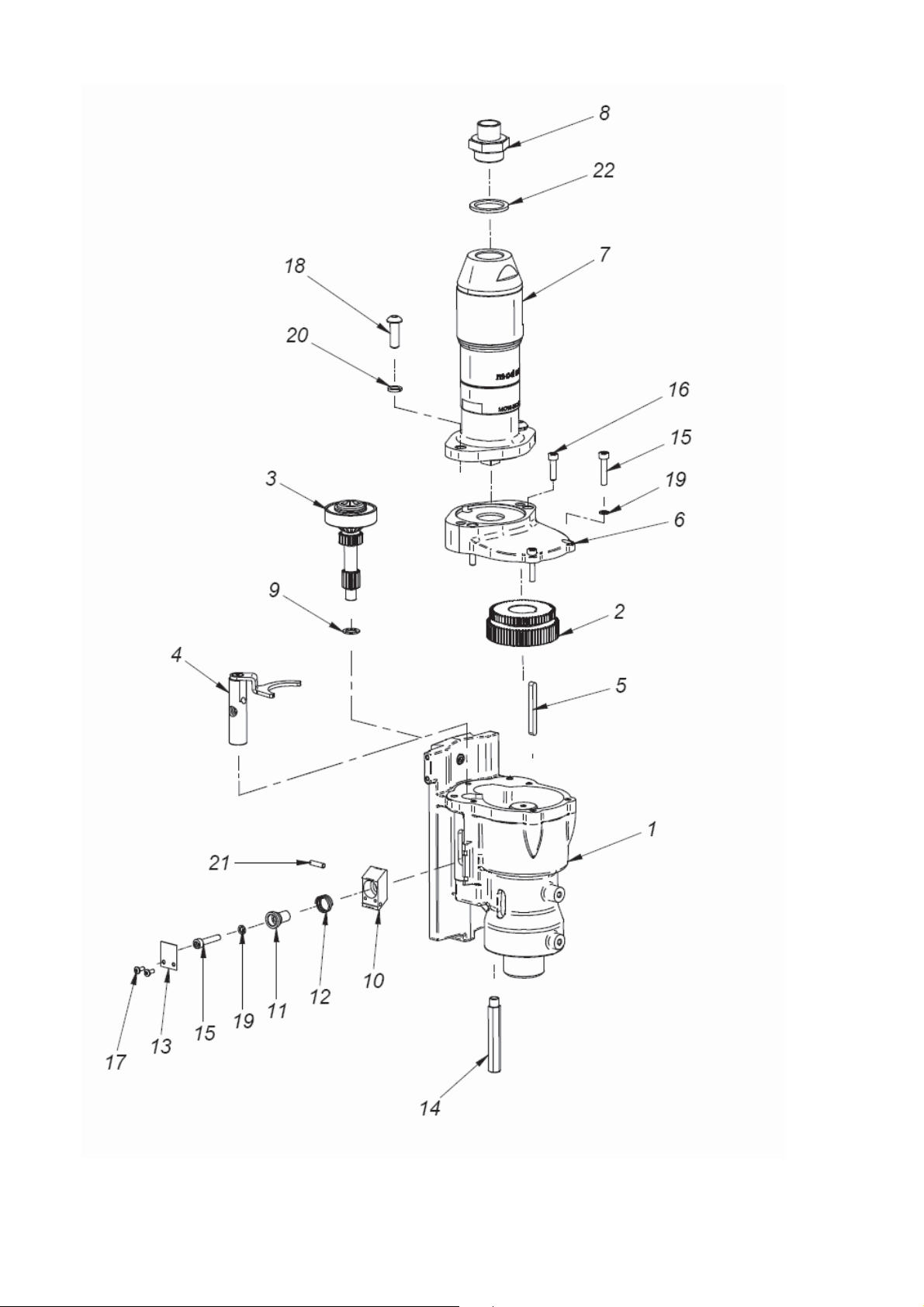

HMP45 BREAKDOWN

Drilling Machine HMP45

ITEM PART NUMBER DESCRIPTION Q-TY

1

2

3

4

5

6

7

8

9

10

11

12

13

14

SPP4501 MAGNET BASE ASSY 1

SPP4502

SPP4503

SPP4504

SPP4505

SPP4506

SPP4507

SPP4508

SPP4509

SPP4510

SPP4511

SPP4512

SPP4513

SPP4514

MAIN BODY ASSY

MOTOR ASSY

PINION SHAFT,

SPOKE HANDLE INCLUDING

KNOB (ASSY),

PANEL PLATE ASSY

GUARD'S SLIDE

D-RING STRAP

COOLANT SYSTEM

ARBOR SET -AMT2-C19/2-2

HEX. SOCKET BOLT M6x20

HEX SOCKET BOLT-M6X25

SPRING WASHER 6,1

SOCKET BUTTON HEAD CAP

SCREW M4x10

1

1

1

3

1

1

1

1

1

2

1

3

6

15

16

17

18

19

20

23*

SPP4515

SPP4516

SPP4517

SPP4518

SPP4519

SPP4520

SPP4523

SCR, M5 x 16 FHSCS

EXTERNAL RETAINING RING

28z

GUARD ASSEMBLY

MOTOR HOSE ASSY

VALVE HOSE ASSY

STRAIGHT COUPLING 1/2" -3/8"

METAL BOX

2

1

1

1

1

2

1

HMP45 BREAKDOWN

3

4

HMP45 BREAKDOWN

Magnet Base Assembly

ITEM PART NUMBER DESCRIPTION Q-TY

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.9

1.1

1.11

1.12

1.13

1.14

1.15

SPP45101 VALVE ASSEMBLY 1

SPP45102

SPP45103

SPP45104

SPP45105

SPP45106

SPP45107

SPP45108

SPP45109

SPP45110

SPP45111

SPP45112

SPP45113

SPP45114

SPP45115

MOUNTING PLATE

MOUNTING PLATE INSERT

MAGNET 1

TURN ON/OFF GEAR

GEAR PLUG

STRAIGHT COUPLING 1/2 -3/8" "

HEX. SOCKET BOLT M4x6

HEX. SOCKET BOLT M6X16

HEX. SOCKET BOLT M6x65

HEX. SOCKET BOLT M8x16

SCR, M4 x 06 FHSCS

HEX SET SCREW-M6 x 6

SPRING WASHER 6,1

SPRING WASHER 8.2

1

1

1

1

1

1

2

2

2

2

1

2

2

1.16

1.17

1.18

SPP45116

SPP45117

SPP45118

OVAL KNOB ASSY

HEX SOCKET BOLT-M5X16

STOP BLOCK

1

2

1

HMP45 BREAKDOWN

5

Valve Assembly

ITEM PART NUMBER DESCRIPTION Q-TY

1.1.1

1.1.2

1.1.3

1.1.4

1.1.5

1.1.6

1.1.7

1.1.8

1.1.9

1.1.10

1.1.11

1.1.12

1.1.13

1.1.14

1.1.15

1.1.16

1.1.17

1.1.18

1.1.19

1.1.20

1.1.21

1.1.22

1.1.23

1.1.24

1.1.25

1.1.26

1.1.27

1.1.28

1.1.29

1.1.30

1.1.31

1.1.32

1.1.33

1.1.34

1.1.35

1.1.36

1.1.37

1.1.38

SPP451101 VALVE HOUSING 1

SPP451102

SPP451103

SPP451104

SPP451105

SPP451106

SPP451107

SPP451108

SPP451109

SPP451110

SPP451111

SPP451112

SPP451113

SPP451114

SPP451115

SPP451116

SPP451117

SPP451118

SPP451119

SPP451120

SPP451121

SPP451122

SPP451123

SPP451124

SPP451125

SPP451126

SPP451127

SPP451128

SPP451129

SPP451130

SPP451131

SPP451132

SPP451133

SPP451134

SPP451135

SPP451136

SPP451137

SPP451138

PISTON ASSY

PISTON PLUG

STOP PLUG ASSY

LOCKING RING

SPRING 1

SOCKET BUTTON HEAD CAP SCREW WITH

FLANGE M6x10

EXTERNAL RING

HANDLE HOLDER

WASHER 1

HANDLE SHAFT

HANDLE 1

SEAL COVER

COVER 1

DIVIDING SHAFT

SLEEVE I

CENTER SLEEVE

SLEEVE II

SHAFT RING

COVER 1

SILENCER G1/4

SCR, M3 x 8 FHSCS

SCR, M4 x 16 FHSCS

HEX. INSERT SCREW M5x8

HEX. INSERT SCREW M12x8

PIN 4x8

BALL LOCK GN 614-8-NI

RETAINING RING INTERNAL 21w

RETAINING RING INTERNAL 24w

INTERNAL RETAINING RING-47W

PIN 4x10

O-RING 15,3x2,4

O-RING 17x2

O-RING 42x2

SEAL, 4x8,2x4

SEAL U2 012x18.4

MALE PLUG, G3/8 10mm "

INDEXING PLUNGER

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

8

3

1

4

1

1

1

1

1

1

1

2

1

1

4

1

1

6

HMP45 BREAKDOWN

HMP45 BREAKDOWN

7

Motor Assembly

ITEM PART NUMBER DESCRIPTION Q-TY

3.1

3.2

3.3

3.4

3.5

3.6

3.7

3.8

3.9

3.1

3.11

3.12

3.13

3.14

3.15

3.16

3.17

3.18

3.19

3.2

3.21

3.22

3.23

3.24*

SPP45301 GEARCASE ASSY 1

SPP45302

SPP45303

SPP45304

SPP45305

SPP45306

SPP45307

SPP45308

SPP45309

SPP45310

SPP45311

SPP45312

SPP45313

SPP45314

SPP45315

SPP45316

SPP45317

SPP45318

SPP45319

SPP45320

SPP45321

SPP45322

SPP45323

SPP45324

CLUSTER GEAR z64/z58

PINION SHAFT T=14, T=20 ASSY

SHIFT FORK ASSY

KEY 5X5X50

GEARBOX COVER

AIR MOTOR

COUPLING 3/4 -3/8" "

WASHER, THRUST 10x1 (2x2)

SHIFT LEVER

SHIFT DRIVE PIN (USA-5)

COMPRESSION SPRING (USA 5)

LABEL, SHIFT LEVER

STOP PIN L=70,

SCR,SHCS M5 x 25 DIN 912

HEX SOCKET BOLT-M5X20

SOCKET BUTTON HEAD CAP SCREW

M3x8,

SCREW M8x25

SPRING WASHER 5,1

SPRING WASHER 8.2

SPRING PIN 4x16

PIN 5x14

SEAL WASHER, 3/4 "

GREASE LUBRIPLATE BP1

1

1

1

1

1

1

1

1

1

1

1

1

1

3

3

2

2

3

2

1

2

1

0,2kg

8

HMP45 BREAKDOWN

HMP45 BREAKDOWN

9

Gear Case Assembly

ITEM PART NUMBER DESCRIPTION Q-TY

3.1.1

3.1.2

3.1.3

3.1.4

3.1.5

3.1.6

3.1.7

3.1.8

3.1.9

3.1.10

3.1.11

3.1.12

SPP453101 GEARCASE 1

SPP453102

SPP453103

SPP453104

SPP453105

SPP453106

SPP453107

SPP453108

SPP453109

SPP453110

SPP453111

SPP453112

SPINDLE 1

GEAR RACK,

HEX. SOCKET BOLT M5x14

HEX. SOCKET BOLT M5X20

SPRING WASHER 5,1

EXTERNAL RETAINING RING 30z

INTERNAL RETAINING RING 62W

UPPER SPINDLE BEARING 6005 25x47x12

LOWER SPINDLE BEARING 6206 2Z

30x62x16

BEARING, NEEDLE RHNA 10x16x10

EXTERNALE RETAINING RING 25z

1

1

1

3

1

1

1

1

1

1

10

HMP45 BREAKDOWN

HMP45 BREAKDOWN

11

Pinion Shaft T=14, T=20 Assembly

ITEM PART NUMBER DESCRIPTION Q-TY

3.3.1

3.3.2

3.3.3

SPP453301 PINION SHAFT T=14, T=20 1

SPP453302

SPP453303

BEARING BALL 6005 2RS

EXTERNALE RETAINING RING 25z

1

1

12

HMP45 BREAKDOWN

Coolant System

ITEM PART NUMBER DESCRIPTION Q-TY

9.1

9.2

9.3

9.4

9.5

SPP45901 COOLANT VALVE, 1

SPP45902

SPP45903

SPP45904

SPP45905

COOLANT BRACKET

BOTTLE, 1

NUT M8x1

PLASTIC HOSE 4MM

1

1

0,27

HMP45 BREAKDOWN

13

Arbor Set - AMT2-C19/2-2

ITEM PART NUMBER DESCRIPTION Q-TY

10.1

10.2

10.3

10.4

10.5

10.6

10.7

10.8

10.9

10.1

10.11

10.12

10.13

SPP451001 ARBOR BODY 1

SPP451002

SPP451003

SPP451004

SPP451005

SPP451006

SPP451007

SPP451008

SPP451009

SPP451010

SPP451011

SPP451012

SPP451013

PLUNGER 1

SPRING 2x2 MT2

COOLANT RING

WASHER II

BAR L=25,

WASHER 1

SEAL 1

CONNECTOR 4x11,5

HEX SET SCREW M10X10

INTERNAL RETAINING RING 19W

EXTERNALE RETAINING RING 25z

SEAL O-RING 25.2x3

1

1

2

1

1

2

1

1

2

14

HMP45 BREAKDOWN

Loading...

Loading...