Page 1

P OS

Ithaca

A Subsidiary of Tridex Corporation

PROGRAMMER'S

06/09/94

c

SERIES 60

GUIDE

Multi-Station Slip Printers

Rev C

Peripherals

Incorporated

PN: 10-2071

Rev. C

Page 2

Programmer's Guide PcOS Series 60

Ithaca Peripherals Incorporated

Changes for Rev C:

1) [ESC] b and [ESC] B commands have been added to aid handling forms that are to be printed tword the

operator.

2) Fine Line feed ([ESC] J <n> has been enabled in journal mode to allow graphics on the journal.

3) Expanded discussion of ENQ commands.

4) Included CFG60 and Demo Edit users guides

5) Referance to Quad Density graphics has been removed. [ESC] Z <n>1 <n>

2

Changes for Rev B:

1) [ESC] N and [ESC] M commands have been added to aid handling of small forms.

2) [ESC] Q command has been added to help synchronize the host application with the printer.

3) The command summary sheets have been updated with all new commands.

4) The command summaries have been corrected.

5) The parallel port timing specification has been updated

6) A self test diagnostics flow chart has been added.

7) A vertical alignment procedure has been added to diagnostics.

Disclaimer

Information in this publication is subject to change without notice and does not represent a commitment on the part of

Ithaca Peripherals Incorporated. However, as product improvements become available, Ithaca Peripherals Incorporated will

make every effort to provide updated information for the products described in this publication.

Copyright

Copyright 1993, 1994

Ithaca Peripherals Incorporated

A Subsidiary of Tridex Corporation

20 Bomax Drive

Ithaca, New York

All Rights Reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form or by any means, mechanical, photocopying, recording, or otherwise, without the prior written permission of Ithaca

Peripherals Incorporated.

Third Edition, June 1994

Printed in USA

Rev C 7/8/2008 Page i

Page 3

PcOS Series 60 Programmer's Guide

Ithaca Peripherals Incorporated

Trademarks

PcOS is a registered trademark of Ithaca Peripherals Incorporated. IBM is a registered trademark of the International

Business Machines Corporation. Epson is a registered trademark of Seiko Epson Corporation. Ithaca Peripherals

Incorporated is a subsidiary of Tridex Corporation.

Federal Communications Commission Radio Frequency

Interference Statement

This equipment complies with the limits for Class A computing device in accordance with the specifications in Part 15 of

FCC rules which are designed to minimize radio frequency interference in the installation; however, there is no guarantee

that radio or television interference will not occur in any particular installation. If this equipment does cause interference to

radio or television reception, which can be determined by turning the equipment off and on while the radio or television is

on, the user is encouraged to try to correct the interference by one or more of the following measures:

• Reorient the radio or television receiving antenna

• Relocate the printer with respect to the receiver

• Move the printer away from the receiver

• Plug the printer into a different outlet so that the printer and receiver are on different outlets.

If necessary the user should consult the dealer or an experienced radio/television technician for additional suggestions. The

user may find the following booklet prepared by the Federal Communications Commission helpful: How to Identify and

Resolve Radio/TV Interference Problems.

This booklet is available from the US Government Printing Office, Washington, DC 20402. Order stock number 004-00000345-4.

Page ii Rev B 7/8/2008

Page 4

Programmer's Guide PcOS Series 60 Control Codes

Ithaca Peripherals Incorporated Paper Motion

Table of Contents

Changes for Rev C: ....................................................................................................................................i

Changes for Rev B: ....................................................................................................................................i

Disclaimer ..................................................................................................................................................i

Copyright....................................................................................................................................................i

Trademarks.................................................................................................................................................ii

Federal Communications Commission Radio Frequency Interference Statement .....................................ii

Overview of the Series 60 Printer ..............................................................................................................1

Warranty Information ..................................................................................................................1

Options...........................................................................................................................1

Service Information .......................................................................................................1

What is in this book?....................................................................................................................1

Who is it For? ................................................................................................................1

What Does it Cover?......................................................................................................1

Where Can You Find More Information?......................................................................2

Contacting Ithaca Peripherals ........................................................................................2

Description of the Series 60 Printer .............................................................................................3

Series 60 Models............................................................................................................3

PcOS Model 61 Slip Printer ............................................................................3

PcOS Model 62 Slip and Receipt Printer ........................................................4

PcOS Model 63 Slip, Receipt, and Journal Printer..........................................4

PcOS Model 64 Slip and Journal Printer .........................................................4

Standard Features ............................................................................................4

Optional Features...........................................................................................................4

Reliability ......................................................................................................................4

Print Characteristics.......................................................................................................5

Character Information .....................................................................................5

Character Generation.......................................................................................5

Control Codes Overview ............................................................................................................................7

Nomenclature...............................................................................................................................7

IPCL Codes....................................................................................................................7

Application Development ............................................................................................................8

Tables and Charts.........................................................................................................................8

Printer Control Codes.................................................................................................................................9

Print / Paper Motion.....................................................................................................................9

Low Level Paper Motion Control ..................................................................................9

Special Paper Motion.....................................................................................................9

Horizontal Motion Control...........................................................................................................14

Character Pitch.............................................................................................................................15

Character Font..............................................................................................................................18

Print Rotation Commands...........................................................................................................21

Character Attribute Commands....................................................................................................26

Graphics Mode.............................................................................................................................28

Station Control .............................................................................................................................29

Miscellaneous Control .................................................................................................................34

Printer Status Set/Inquire .............................................................................................................36

Extended Diagnostics Commands................................................................................................42

Control Codes Summary (by Code) .............................................................................................43

Control Codes Summary (by Function) .......................................................................................46

How to use the Series 60 Features..............................................................................................................49

How to use the Slip Station..........................................................................................................49

Printing on forms. ..........................................................................................................49

Rev C 7/8/2008 Page iii

Page 5

Control Codes PcOS Series 60 Programmer's Guide

Paper Motion Ithaca Peripherals Incorporated

How to use rotated print on the Slip Station ..................................................................53

How to endorse a check .................................................................................................55

How to fill out a personal check. ...................................................................................58

How to use the Receipt Station ....................................................................................................60

How to use rotated print in the Receipt Station .............................................................62

How to use the Journal Station.....................................................................................................63

Special Tricks...............................................................................................................................66

How to make a coupon ..................................................................................................66

Printing Graphics........................................................................................................................................68

Character Graphics.......................................................................................................................68

APA Graphics ..............................................................................................................................69

Communications Protocol and Print Buffers..............................................................................................71

Overview......................................................................................................................................71

Parallel Port..................................................................................................................................73

Parallel Port Protocol.....................................................................................................73

Parallel Port Inquire.......................................................................................................74

Parallel Port [ESC] Q ....................................................................................................74

Parallel Port Connector..................................................................................................75

Serial Port.....................................................................................................................................76

Serial Port Features........................................................................................................76

Serial Port Pin-out..........................................................................................................76

Serial Port Protocol........................................................................................................77

Serial Port [ESC] Q .......................................................................................................80

Serial Port Inquire..........................................................................................................81

Remote Printer Reset ...................................................................................................................82

Reset in Serial Mode......................................................................................................82

Reset in Parallel Mode...................................................................................................82

Power Cycle Recovery.................................................................................................................82

How to Interpret Printer Error Codes .........................................................................................................83

Operator Correctable Errors:........................................................................................................83

Unrecoverable Printer Errors .......................................................................................................83

Application Errors........................................................................................................................84

Diagnostic Indicators ...................................................................................................................84

Series 60 Configuration and Test Program Overview................................................................................85

CFG60 Program .........................................................................................................................................85

System Requirements...................................................................................................................85

Installing the Software................................................................................................................................86

Running CFG60...........................................................................................................................87

Configuring Printers...................................................................................................................................88

Configuring Series 60 Printers .....................................................................................................88

Testing and Adjusting Series 60 Printers .....................................................................................90

Creating Configuration files for CFG60 ......................................................................................92

PC Configuration...........................................................................................................92

Default Printer Configuration ........................................................................................92

CFG60 Feature Control .................................................................................................92

Running Demonstrations............................................................................................................................94

Selecting the DEMO Menu..........................................................................................................94

Running the Slip Demo..................................................................................................94

Running the Journal Demo ............................................................................................94

Running the Receipt Demo............................................................................................94

Creating and Editing Demonstration files ....................................................................................95

Demo Scripts .................................................................................................................95

Demo Nomenclature........................................................................................96

Demo Commands ............................................................................................96

Page iv Rev C 7/8/2008

Page 6

Programmer's Guide PcOS Series 60 Control Codes

Ithaca Peripherals Incorporated Paper Motion

Pause .................................................................................................97

Stop ...................................................................................................97

Echo ..................................................................................................97

RV.....................................................................................................97

RPT ...................................................................................................97

Date and Time...................................................................................97

DO.....................................................................................................98

REM..................................................................................................98

Counters ............................................................................................98

Sensor and Front ...............................................................................99

Reset..................................................................................................99

Demo Command Control Summary ..............................................................................100

Demo Example ..............................................................................................................101

Using CFG60 to Test Printers ....................................................................................................................102

Using CFG60 to Develop Applications .......................................................................................102

Using CFG60 to Monitor Serial Communications.......................................................................103

Demo Editor ...............................................................................................................................................104

Help..............................................................................................................................................104

Editor Function Keys ...................................................................................................................104

Short Cut Keys.............................................................................................................................105

Open File......................................................................................................................................105

Save File As .................................................................................................................................105

Search for Text.............................................................................................................................105

New File.......................................................................................................................................105

Block Operations .........................................................................................................................106

Searching/Replacing ....................................................................................................................106

Save File.......................................................................................................................................106

Series 60 Diagnostics .................................................................................................................................107

Level 0 Diagnostics......................................................................................................................107

Level 1 Diagnostics......................................................................................................................108

Test Communications Interface .....................................................................................108

Journal Test....................................................................................................................109

Receipt Test ...................................................................................................................109

Slip Test, Sensor Calibration, and Vertical Alignment..................................................110

Configuration ...............................................................................................................................111

Initial Power ON............................................................................................................111

Manual Configuration....................................................................................................111

Enable Remote Configuration .......................................................................................112

Diagnostics Flow Chart................................................................................................................113

Character Sets.............................................................................................................................................122

Print Character Codes Set I ..........................................................................................................122

Print Character Codes Set II.........................................................................................................123

ASCII Code Chart........................................................................................................................124

Character Mode Specifications ....................................................................................................125

Appendix A ................................................................................................................................................126

CFG60 Selection Keys.................................................................................................................126

Appendix B ................................................................................................................................................127

CFG60 Configuration Command Summary. ...............................................................................127

Appendix C ................................................................................................................................................128

Configuring Serial Ports...............................................................................................................128

Appendix D ................................................................................................................................................128

Configuring Parallel Ports............................................................................................................128

Appendix E.................................................................................................................................................129

Graphic..............................................................................................99

Rev C 7/8/2008 Page v

Page 7

Control Codes PcOS Series 60 Programmer's Guide

Paper Motion Ithaca Peripherals Incorporated

Configuring CFG60 for specific PC's ..........................................................................................129

Appendix F.................................................................................................................................................129

Demo Command Summary:.........................................................................................................129

Appendix G ................................................................................................................................................130

Control Command Summary: ......................................................................................................130

Appendix H ................................................................................................................................................131

Trouble Shooting the CFG60 Program ........................................................................................131

Appendix I..................................................................................................................................................133

Ordering Information ...................................................................................................................133

Index...........................................................................................................................................................134

Overview of the Series 60 Printer

Warranty Information

Options

All Ithaca Peripherals Incorporated (Ithaca) PcOS Series 60 Printers come with a standard 12 month warranty covering both

parts and labor.

An optional warranty, covering both parts and labor for 24 months, may be purchased separately.

For more information concerning the warranty options, please contact your dealer or the Sales department at Ithaca

Peripherals:

Sales:

Ithaca Peripherals Incorporated

Page vi Rev C 7/8/2008

Page 8

Programmer's Guide PcOS Series 60 Control Codes

Ithaca Peripherals Incorporated Paper Motion

20 Bomax Drive

Ithaca, NY 14850

(607) 257-8901

Service Information

The printer may be serviced by a dealer, an independent service contractor, or by Ithaca Peripherals. If the printer is to be

serviced by Ithaca Peripherals, a return authorization is required. Call Field Engineering at (607)257-8901 and ask for a

return authorization.

The printer will need to be packed in the original packing material and box and sent to Ithaca Peripherals. Information on

shipping the printer will be provided with the return authorization.

What is in this book?

Who is it For?

This book is intended for system engineers or system integrators. It contains the information you need to integrate the

Series 60 printer with a point-of-sale terminal and to program the terminal to communicate with the printer.

What Does it Cover?

This programmer's guide provides the following information:

• Start up information including diagnostics and fault conditions.

• Command descriptions.

• Character Fonts.

• How to use the printer features.

• Parallel and RS-232 interface information.

• Communications and buffers.

• Command code reference tables.

Rev C 7/8/2008 Page vii

Page 9

Control Codes PcOS Series 60 Programmer's Guide

Paper Motion Ithaca Peripherals Incorporated

Where Can You Find More Information?

An Operator's Guide is available that describes setting up the printer and all the operating procedures such as changing

journal and receipt paper, printing on a slip or form, and changing the ribbon cassette.

A Service Guide is available1. It's intended for trained technicians who will be servicing the printer.

For information about ordering these books, refer to the next section.

Contacting Ithaca Peripherals

The Sales department and Field Engineering department will be able to help you with most of your questions.

Contact the Sales Department for technical support, to order documentation or receive additional information about the

Series 60 Printer, to order supplies, or to receive information about other products by Ithaca Peripherals.

Contact the Field Engineering department if you would like information about your warranty, or if you need to send a

printer in for service.

You can contact both the Sales department and the Field Engineering department at the following address and phone or fax

numbers:

Ithaca Peripherals Incorporated

20 Bomax Drive

Ithaca, NY 14850

Main phone: (607)257-8901

Main fax: (607)257-8922

Sales/Field Engineering fax: (607)257-3868

1

The Service Guide will be available in 1993.

Page viii Rev C 7/8/2008

Page 10

Programmer's Guide PcOS Series 60 Control Codes

Ithaca Peripherals Incorporated Paper Motion

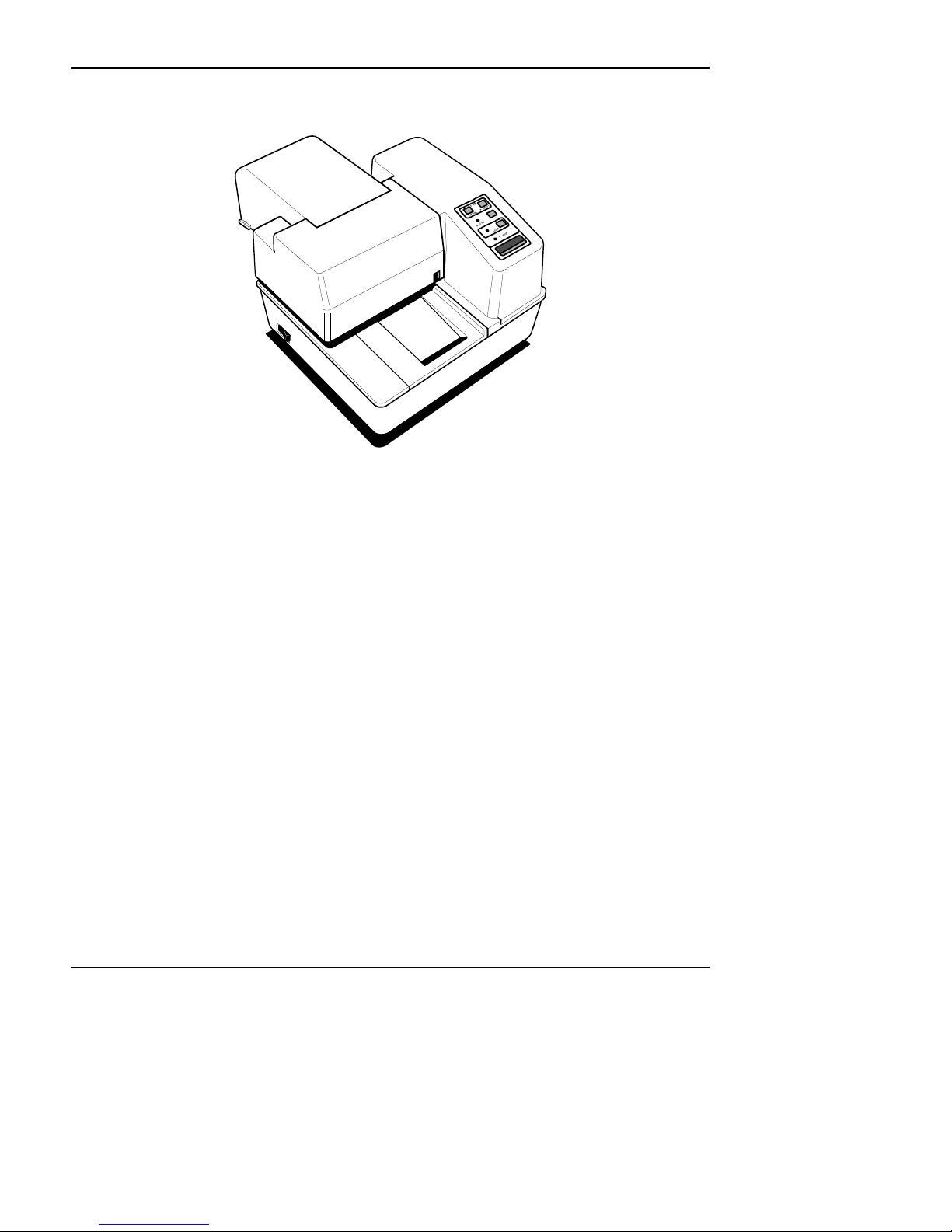

Description of the Series 60 Printer

The Ithaca PcOS (personal computer, point-of-sale) Series 60 Printer can be ordered in several configurations to perform a

variety of functions in any point-of-sale operation. The standard model (Model 63) is equipped with all three print stations:

slip, receipt, and journal.

Other models come as either slip, slip and receipt, or slip and journal.

The slip station prints (or validates) on receipts, credit slips, and multi-part forms. The receipt station prints on standard

receipt paper to provide your customers with a record of their purchases. The journal station prints a permanent record of all

your business transactions on standard journal paper.

The unique modular design of the Series 60 Printer allows it to be upgraded or downgraded to perform the same functions

as any other model in the series.

Series 60 Models

There are four models in the Series 60 line of printers, all with the slip station and their own unique set of features. Models

62, 63, and 64 are multi-station printers.

• Ithaca PcOS Model 61 Slip Printer

• Ithaca PcOS Model 62 Slip and Receipt Printer

• Ithaca PcOS Model 63 Slip, Receipt, and Journal Printer

• Ithaca PcOS Model 64 Slip and Journal Printer

PcOS Model 61 Slip Printer

• Prints (or validates) on a variety of forms, such as receipts, credit slips, and multi-part forms (up to four

forms in a multi-part form)

• Prints up to 60 characters at 17 characters per inch

• Prints up to 80 characters at 24 characters per inch on single- or multi-part forms

• Prints rotated characters in 90 degree increments

• Senses the top and bottom of forms

• Ejects forms from either the front or rear of the printer

Rev C 7/8/2008 Page ix

Page 11

Control Codes PcOS Series 60 Programmer's Guide

Paper Motion Ithaca Peripherals Incorporated

PcOS Model 62 Slip and Receipt Printer

• Adds receipt station to Model 61 Slip Printer

• Prints receipts at 10, 12, 17, or 24 characters per inch

• Prints receipts up to 48 columns at 17 characters per inch

• Cuts receipt automatically

• Prints rotated characters in 90 degree increments

PcOS Model 63 Slip, Receipt, and Journal Printer

• Adds receipt and journal stations to Model 61 Slip Printer

• Prints receipts at 10, 12, 17, or 24 characters per inch

• Prints receipts up to 48 columns at 17 characters per inch

• Cuts receipts automatically

• Prints journal up to 40 columns at 17 characters per inch

• Prints rotated characters in 90 degree increments

• Includes standard automatic journal take-up

PcOS Model 64 Slip and Journal Printer

• Adds journal function to Model 61 Slip Printer

• Prints journal up to 40 columns at 17 characters per inch

• Prints rotated characters in 90 degree increments

• Includes standard automatic journal take-up

Standard Features

• Interfaces

• Centronics Parallel Interface, 2K buffer

• RS-232 Serial Interface, 19.2K Baud, 2K buffer

• Up to 7 lines printed per second

• Dual cash drawer drivers with drawer OPEN/CLOSED status

• Snap-on ribbon cassette

• All points addressable graphics

• IBM/Epson compatible

• Self test

• IBM character sets I and II

Optional Features

• Custom PROMS to allow operation in various computer or simulation environments

• Most common languages (number of resident languages depends on language mix

Reliability

• Mean time between failure: 25,000 hours (except printhead)

• Printhead life: 200 million characters

• Auto cutter life: 1 million cuts

• Auto cutter mean time between failure: 300,000 cuts

• Mean time to repair: 15 minutes

Page x Rev C 7/8/2008

Page 12

Programmer's Guide PcOS Series 60 Control Codes

Ithaca Peripherals Incorporated Paper Motion

Print Characteristics

Character Information

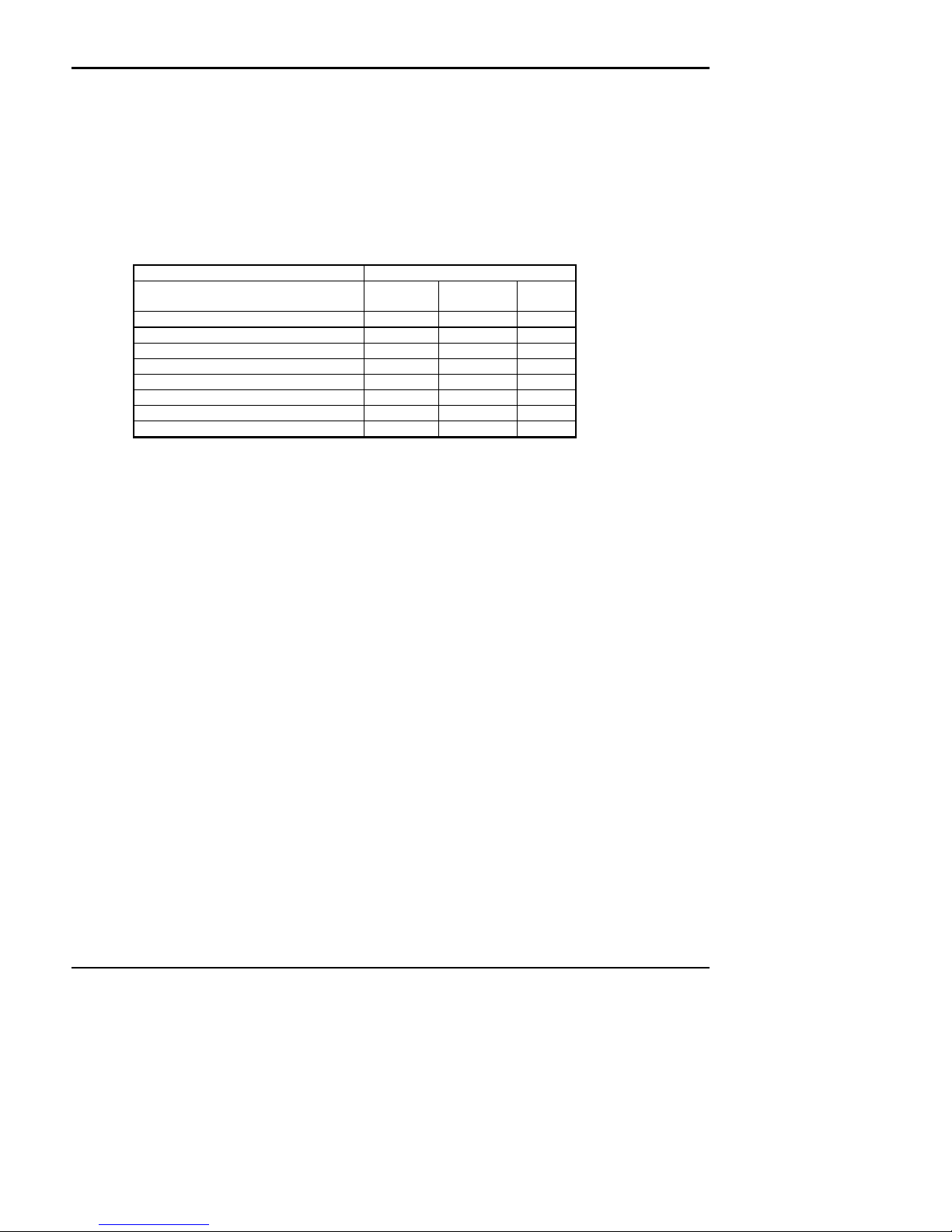

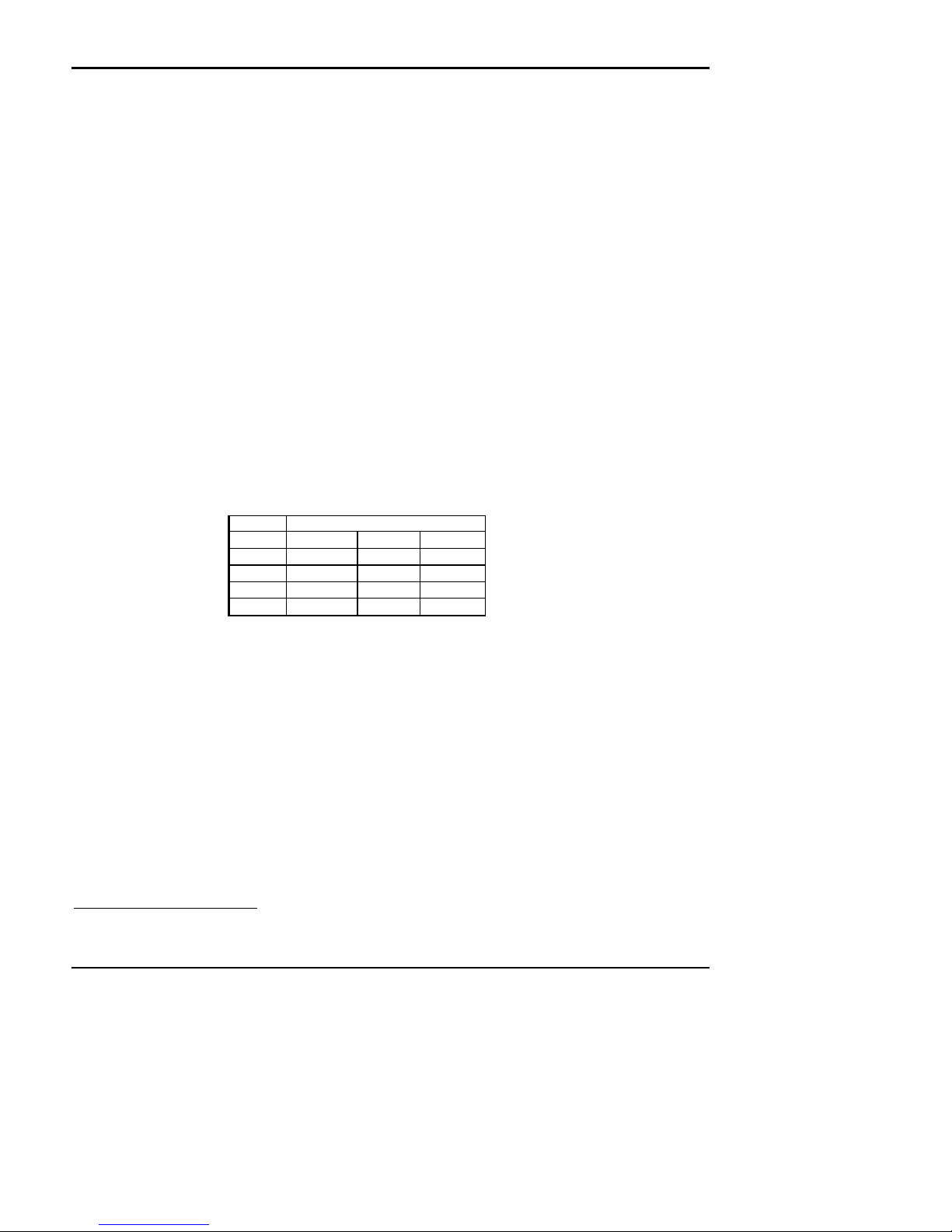

The Ithaca PcOS Series 60 Printers prints characters in a variety of pitches as shown in the following table and print

samples. Each pitch can also be printed in a variety of styles affecting the appearance of the characters and the speed of the

printer.

For information about programming the printer to print a particular pitch or style, please refer to the "Programming" section

on page 29.

Pitch (Characters per inch) Slip

Print Pitch Capability

10 CPI 34 28 24

12 CPI 42 32 28

17 (Condensed) 60 48 40

24 (Super Condensed) 84 66 56

5 (Double Wide) 17 14 12

6 (Double Wide) 21 16 14

8.5 (Condensed Double Wide) 30 24 20

12 (Super Condensed Double Wide) 42 33 28

Note: 10 Characters per inch is sometimes referred to a Pica, 12 CPI is sometimes referred to as

Elite

Rotated Print: The printer can be programmed to rotate characters in 90 degree increments. All rotated print is in the 12

CPI format. For information about programming the printer to rotate characters, please refer to the "Control Codes and

Features sections"

Maximum Characters per Line

Station

Receipt

Station

Journal

Station

Character Generation

All the character sets and modes are based on one of two character cells, 10 wide by 9 high or 12 wide by 9 high. Double

wide mode, is twice the width of the normal mode or 20 wide by 9 high or 24 wide by 9 high.

In utility print mode he character cell consists of five full dots and five half dots horizontally by nine full dots vertically,

the character is a 9 by 9 character I High Speed Draft mode the character cell is shortened by one half and one full dot

column. This yields a 7 by 9 character.

Each character is justified to the left of the cell. The first four columns of the full dots and the first three columns of half

dots are used to generate the character in high speed draft, while the first five columns of the full dots and the first four

columns of the half dots are used in utility mode. The last full dot and the last two half dots are used for character spacing

in both modes.

Rev C 7/8/2008 Page xi

Page 13

Control Codes PcOS Series 60 Programmer's Guide

Paper Motion Ithaca Peripherals Incorporated

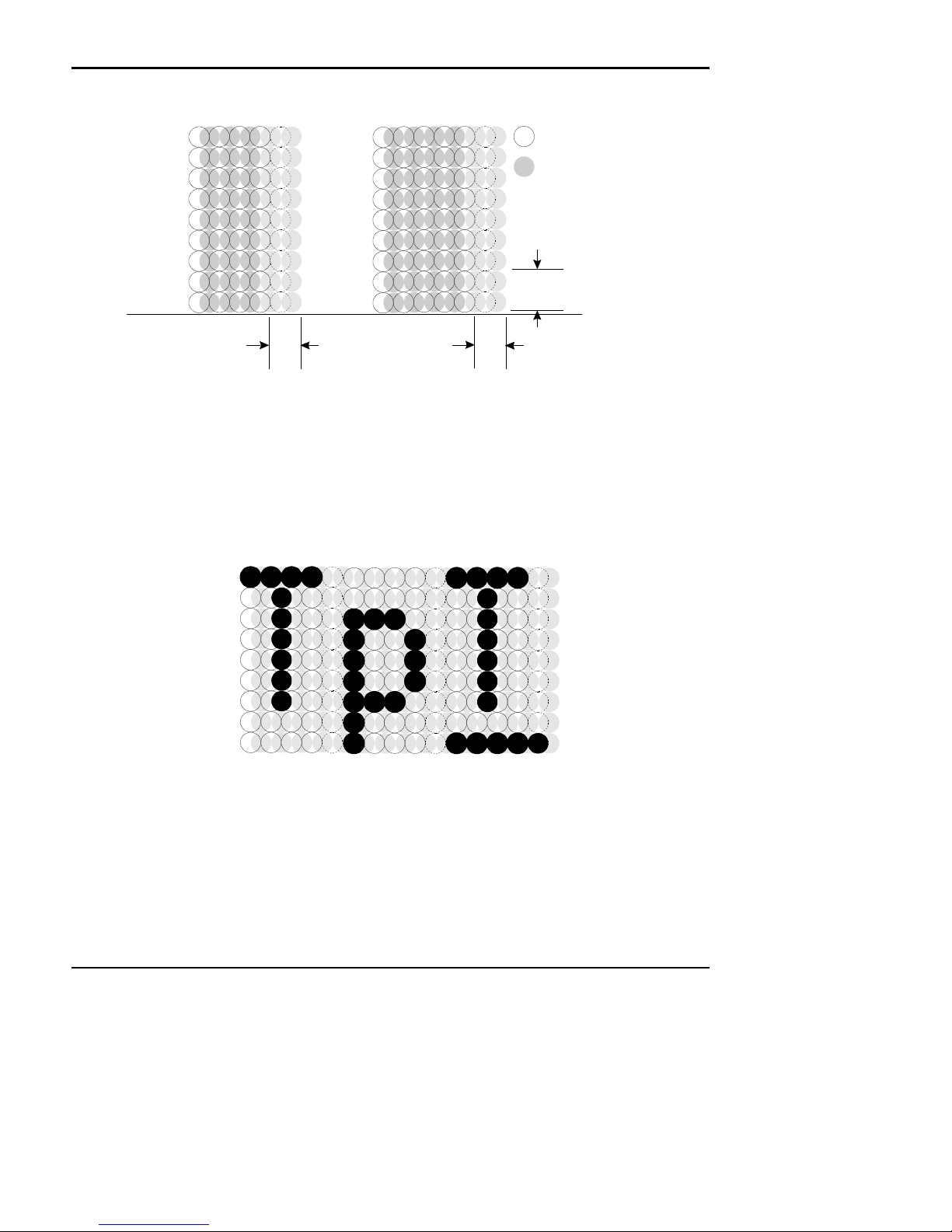

The following illustration shows a single wide character cell:

1 3 5 7 9

2 4 6 8 10

1

2

3

4

5

6

7

8

9

1 3 5 7 9 11

2 4 6 8 10 12

1

2

3

4

5

6

7

8

9

Full Dots

Half Dots

Descender (Row 8 & 9)

& Underline (Row 9)

Character

Spacing

High Speed Draft

Single Wide Character

The example above shows the full dots as adjacent to each other in the character cell. This is true for the 12 CPI mode

only. The 10 CPI mode allows a gap between adjacent full rows, 17 and 24 CPI allow an overlap of full rows.

The printer can not print adjacent full and half dots in any single row. Some graphics (Double Density Half Speed) allow

adjacent rows to be printed by slowing the print speed by half. This allows time between half and full columns to be the

same as between full columns in full speed operation.

The following illustration shows the use of full and half dots as well as descenders to form characters:

1 3 5 7 9

2 4 6 8 10

1

2

3

4

5

6

7

8

9

Character

Spacing

Utility Mode

1 3 5 7 9

2 4 6 8 10

1 3 5 7 9

2 4 6 8 10

Page xii Rev C 7/8/2008

Page 14

Programmer's Guide PcOS Series 60 Control Codes

Ithaca Peripherals Incorporated Paper Motion

Control Codes Overview

This programmer's guide is designed to help users of Ithaca Peripherals Series 60 Slip Printer develop applications. The

Series 60 printers are specialized Point Of Sale POS printers that have several features not normally found on general

purpose printers. Because of these special features, the Series 60 printers have some specialized codes that control these

features. This programmer's guide documents all the control codes with emphases on those codes that are unique to the

Series 60 printer.

All Ithaca Peripherals Series 60 printers have both a serial and parallel interface. Both interfaces provide the same printer

control2 and use the same codes.

Nomenclature

Whenever describing control codes there is confusion as to whether the description is decimal, hex, or ASCII. To minimize

this problem, this users guide will use the following nomenclature when describing control code sequences:

[ ] Enclose a control character. This is a single 8 bit value as defined in the standard ASCII tables. The

< > Enclose an 8 bit value in decimal format. This value will be from 0 to 255

An example would be <2> which would represent 02H or 2 decimal

<n> This indicates a variable parameter. In this case a variable parameter "n" that can have a value of from 0

<n>1 <n>2 This indicates that there are 2 parameters, n1 and n2 where both can have values from 0 to 255.

x All other characters in control strings represent ASCII characters.

For example " [ESC] 1 " Would represent 1BH followed by 31H.

ASCII chart in Appendix A lists all the control codes. An example would be [ESC] which would

represent a 1BH or 26 Decimal

to 255. The meaning of "n" is described and defined in the description of the command.

The CFG60 Configuration and demonstration program3 uses the same nomenclature. All print examples shown in this

manual are available for CFG60.

In many cases, applications require that control sequences be specified in Hex or Decimal codes. In most cases all

commands are specified in ASCII, Hex and Decimal. There is an ASCII chart in the Appendix that lists ASCII, Decimal,

and Hex Equivalents.

IPCL Codes

IPCL (Ithaca Printer Control Language) codes are designed to control a printer without using control characters. Not all

commands are supported by IPCL codes. For those commands that are the IPCL code is listed.

Occasionally an IPCL code will interfere with the text that are to be printed, the IPCL translator can be disabled with an

[ESC]y<4> command.

2

The Serial Interface does provide a few additional interface capabilities because of the ability of the serial interface to be

bi-directional.

3

CFG60 is available from Ithaca Peripherals at no cost. This program runs on IBM PC or compatible.

Rev C 7/8/2008 Page xiii

Page 15

Control Codes PcOS Series 60 Programmer's Guide

Paper Motion Ithaca Peripherals Incorporated

Application Development

To aid in application development there two sections in this manual that are designed to help the programmer understand

the series 60 printer.

The first is a how to section that explains ways to use the special features and get the most out of the printer.

The second section is an explanation of how the printer, it's print buffer, the communications link, and the host computer

interact.

Tables and Charts

Throughout this programmer's guide there are charts and tables that list commands and features. In most cases these charts

cross reference the page that describes the command. Commands are grouped by function and can at times be hard to find.

To minimize the time it takes to find commands, there are two code summary charts in the following section, one ordered

by code and one ordered by function.

Printer Control Codes

Print / Paper Motion

Page xiv Rev C 7/8/2008

Page 16

Programmer's Guide PcOS Series 60 Control Codes

Data Sent to printer

Ithaca Peripherals Incorporated Paper Motion

Low Level Paper Motion Control

Function: Carriage Return

ASCII: [CR]

Hexadecimal: 0DH

Decimal: <13>

IPCL: &%CR

Description: Print contents of print buffer (if any) and reset the next character print position to the left margin. A line

Function: Line Feed

ASCII: [LF]

Hexadecimal: 0AH

Decimal: <10>

IPCL: &%LF

Description: Print contents of buffer (if any) and advance paper one line at the current default line spacing. The next

NOTE: The journal feeds only from back to front.

feed is NOT performed. The left margin is defined by the current print station, the print rotation direction

and the left margin command.

character print position is reset to the left margin. The direction moved is defined by the current print

station, the rotated print command, and the paper motion set by the [ESC] r, [ESC] n or [ESC] o

commands.

Special Paper Motion

Function: Fine Line Feed

ASCII: [ESC] J <n>

Hexadecimal: 1BH 4AH <n>

Decimal: <27> <74><n>

IPCL: (None)

Description: Print contents of buffer (if any) perform line feed of n/216" . This command does not change the default

NOTE: The journal feeds only from back to front.

line spacing value. The next character print position is reset to the left margin.

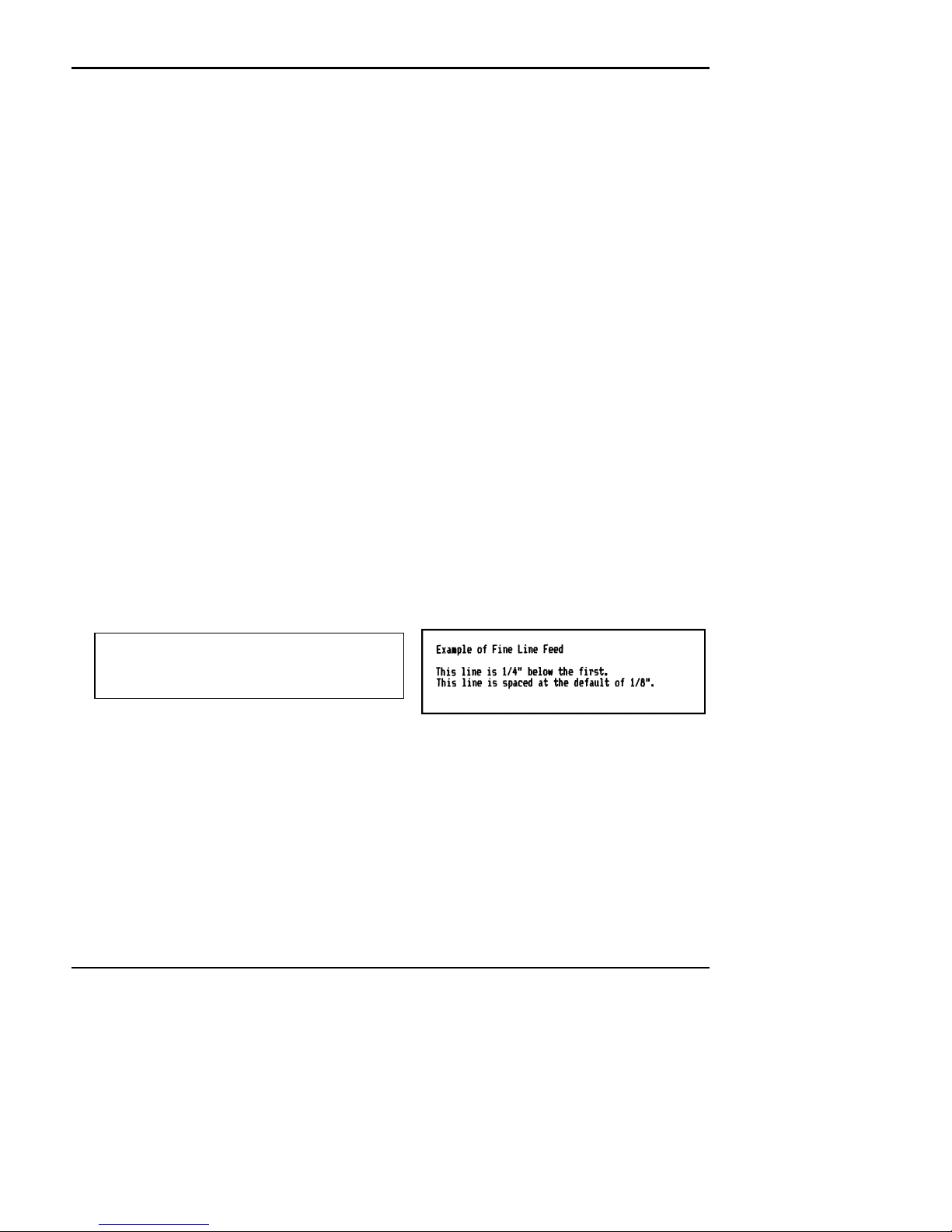

Example of Fine Line Feed[CR]

[ESC]J<54>

This line is 1/4" below the first.[CR][LF]

This line is spaced at the default of

1/8".[CR][LF]

Resulting Print

Rev C 7/8/2008 Page xv

Page 17

Control Codes PcOS Series 60 Programmer's Guide

Paper Motion Ithaca Peripherals Incorporated

Function: Feed 2 Inches

ASCII: [ESC] e

Hexadecimal: 1BH 65H

Decimal: <27><101>

IPCL: &%LC

Description: Feed receipt tape 2.0". This command will feed the Receipt out after a cut until there are 3 print lines left.

This command will also work for the slip station in either front to back or back to front direction. It will

Function: Feed 7 Inches

ASCII: [ESC] d

Hexadecimal: 1BH 64H

Decimal: <27><100>

IPCL: &%LC

Description: Feed form 7". This command will feed the Receipt or Slip 7 inches in the last direction selected.

This command does not function in journal mode

Function: Feed to Mark

ASCII: [ESC] k

Hexadecimal: 1BH 6BH

Decimal: <27><107>

IPCL: &%LK

Description: Feed receipt tape 7" or to mark.". This command will feed the Receipt out until a black mark is found on

When the mark is found it will be about 1.75" from the print line. There will be about 14 lines of print (at

NOTE: The knife will not operate if the mark is under the rear slip sensor. The knife safety logic thinks

The Mark must be at least 0.1875" long and 0.75" from the left side of the Receipt. The mark must not

Typically this command is issued to feed the receipt after the receipt is complete.

feed the slip 2.0".

Typically this command is issued to feed the receipt after the receipt is complete, or to eject a form from

the printer

the right side of the receipt tape. Typically this command is issued to feed the receipt to locate a marker

on a pre printed tape.

1/8" spacing ) to the mark.

that the receipt is not loaded and will not cycle. Feed the paper past the mark before cutting. Use an

[ESC] q command before the [ESC] v to force the knife safety logic to wait for the line feeds before

checking the sensors.

reflect IR. light.

Note: This command does not function in journal mode.

Function: Feed to End of Slip

ASCII: [ESC] m

Hexadecimal: 1BH 6DH

Page xvi Rev C 7/8/2008

Page 18

Programmer's Guide PcOS Series 60 Control Codes

Ithaca Peripherals Incorporated Paper Motion

Decimal: <27><109>

IPCL: &%LE

Description: Feed the slip to the edge. This command feeds the slip until either the front or the rear slip sensor no

When the form is fed from front to back the print line will be about 0.375" from the edge. When the form

NOTE: This command does not function in journal mode

Function: Set Variable Line Space n/216"

ASCII: [ESC] 3 <n>

Hexadecimal: 1BH 33H <n>

Decimal: <27><51><n>

IPCL: &%SV <n>

Description: Set default line spacing to n/216". Set n =1 to

NOTE: This command does not affect journal

Function: Set Line Space 27/216"

ASCII: [ESC] 0

Hexadecimal: 1BH 30H

Decimal: <27><48>

IPCL: &%ST

Description: Set default line spacing to 27/216". This is a standard 8 lines per inch line spacing. This is the default

NOTE: The journal is always printed at 8 lines per inch. This command is accepted and will affect

longer sees the slip. The slip will be fed in the direction last specified. The feed will be a maximum of 7"

and then stop. The ENQ <5> and <6> commands can be used to verify the operation of this command.

A second [ESC] m command can be issued to feed more than 7". If the second command is issued after

the end is found it will not cause any paper motion.

is fed from back to front the print line will be about 1.75" from the edge.

255. This command sets the line feed spacing

used by [LF] to values other than 1/8 or 7/72

inch. This command takes effect immediately as

opposed to the set variable line spacing.

Resulted in this print

spacing. The journal is always 8 lines per inch.

This command is accepted and will affect receipt

and slip mode.

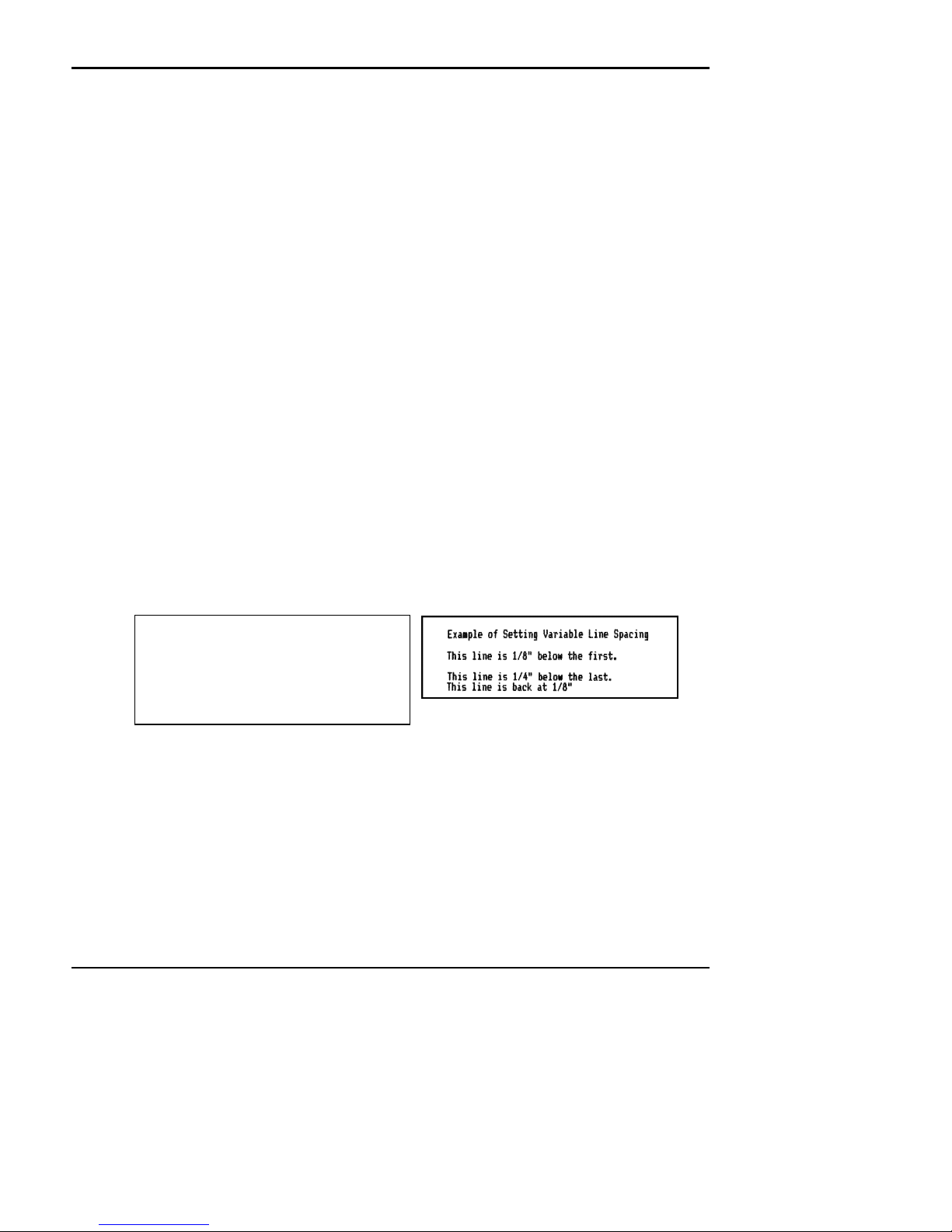

[ESC]3<54>

Example of Setting Fine Line Feed[CR][LF]

This line is 1/4" below the first.[CR][LF]

This l ine is also 1/4" below the

last.[CR][LF]

Data Sent to the printer

text line spacing at power up.

receipt and slip mode.

Rev C 7/8/2008 Page xvii

Page 19

Control Codes PcOS Series 60 Programmer's Guide

Paper Motion Ithaca Peripherals Incorporated

Function: Set Line Space 21/216" or (7/72")

ASCII: [ESC] 1

Hexadecimal: 1BH 31H

Decimal: <27><49>

IPCL: &%SG

Description: Set default line spacing to 21/216". This line spacing is for APA (All Points Addressable) Graphics

NOTE: This command will not affect the journal station. This command is accepted in journal mode and

Function: Set Variable Line Space n/72"

ASCII: [ESC] A <n>

Hexadecimal: 1BH 41H <n>1

Decimal: <27><65><n>

IPCL: (None)

Description: Set default line spacing to n1/72. Set n1 =1 to 85. This line spacing does not take effect until enabled by

NOTE: This command will not affect the journal station. This command is accepted and will affect

Function: Enable [ESC] A <n> line spacing.

ASCII: [ESC] 2

Hexadecimal: 1BH 32H

Decimal: <27><50>

IPCL: (None)

Description: Enable [ESC] A <n> line spacing. This is a companion to the [ESC] A <n> command and puts to

NOTE: This command will not affect the journal station. This command is accepted and will affect

printing.

will affect receipt and slip mode when selected.

1

the [ESC] 2 command. This command is provided to maintain backward compatibility with Series 50 and

OKIDATA IBM compatible printers. It can be used to print on pre-printed forms.

receipt and slip mode.

specified line spacing into effect. It will remain in effect until another line spacing command is issued.

receipt and slip mode.

[ESC]A<18>

Example of Setting Variable Line

Spacing[CR][LF]

This line is 1/8" below the first.[CR]

[ESC]2[LF]

This line is 1/4" below the last.[CR]

[ESC]0[LF]

This line is back at 1/8"[CR][LF]

Data Sent to printer

Page xviii Rev C 7/8/2008

Resulting Print

Page 20

Programmer's Guide PcOS Series 60 Control Codes

Ithaca Peripherals Incorporated Paper Motion

Function: Set Line Feed Direction Back to Front

ASCII: [ESC] n

Hexadecimal: 1BH 6EH

Decimal: <27><110>

IPCL: &%LR

Description: Set slip spacing direction from the back to the front of printer. This command sets the feed direction and

NOTE: This command is overridden by a station select command. Selecting the slip station defines the

NOTE: This command will not affect the journal station. This command is excepted and will affect

NOTE: Whenever the slip is moved in the opposite direction of the intended print direction, the feed in

Function: Set Line Feed Direction Front to Back

ASCII: [ESC] o

Hexadecimal: 1BH 6FH

Decimal: <27><111>

IPCL: &%LB

Description: Set slip spacing direction from front to back of printer. This command sets the feed direction and will

NOTE: This command is overridden by a station select command. Selecting the slip station defines the

NOTE: Although this command will work on the receipt station, no more than 1/8 inch should be fed,

NOTE: This command will not affect the journal station. This command is excepted and will affect

NOTE: Whenever the slip is moved in the opposite direction of the intended print, the feed in the non-

will operate in Slip and Receipt mode. This and its companion command [ESC] o can be used to move a

slip into any print position.

feed direction to be from front to back. Selecting the receipt station defines feed direction to be from

back to front. Once the station is selected the [ESC] n command can be used to change the direction.

receipt and slip mode.

the non-print direction should be moved one unit too far. The form should then be repositioned in the

intended print direction. This will minimize positioning errors caused by any mechanical backlash.

operate in Slip and Receipt mode. This and its companion command [ESC] n can be used to move a slip

into any print position.

feed direction to be from front to back. Selecting the Receipt station defines feed direction to be from

back to front. Once the station is selected the [ESC] o command can be used to change the direction.

in the front to back direction. It is possible to cut the receipt, feed the receipt to cut with the [ESC] e

command, and then reverse feed. this will in effect make a slip out of a receipt.

receipt and slip mode.

print direction should be moved one unit too far. The form should then be repositioned in the intended

print direction. This will minimize positioning errors caused by mechanical backlash.

Rev C 7/8/2008 Page xix

Page 21

Control Codes PcOS Series 60 Programmer's Guide

Horizontal Motion Ithaca Peripherals Incorporated

Horizontal Motion Control

There are two commands that can control the horizontal position of characters. Many applications use space control to

positions fields, however, there is the ability to control character position with horizontal tab stops and using the horizontal

tab [HT] to move to those tab stops.

Function: Horizontal Tab

ASCII: [HT]

Hexadecimal: 9H

Decimal: <9>

IPCL: NONE

Description: Inserts spaces in the print buffer up to the next tab stop. The default tab locations are every 8 spaces.

Function: Set Horizontal Tab Stops

ASCII: [ESC] D <n>1 <n>2 <n>3 ... <n>i 0

Hexadecimal: 1BH 75H <n>1 <n>2 <n>3 ... <n>i 00H

Decimal: <27><117><n>1 <n>2 <n>3 ... <n>i <0>

IPCL: NONE

Description: Set tab stops at the character columns specified by <n>. The end of the settings is specified by a <0>.

Column sizes are in accordance with the current character pitch.

Setting tabs that are beyond the station width is possible. A [CR] will be inserted if the tab is used.

The power up default is every 8 spaces, i.e. 9, 17, 25 and so on.

All previously set tabs will be cleared by this command. There is no restore defaults procedure other than

to re specify the tabs.

Printing will begin at the home position.

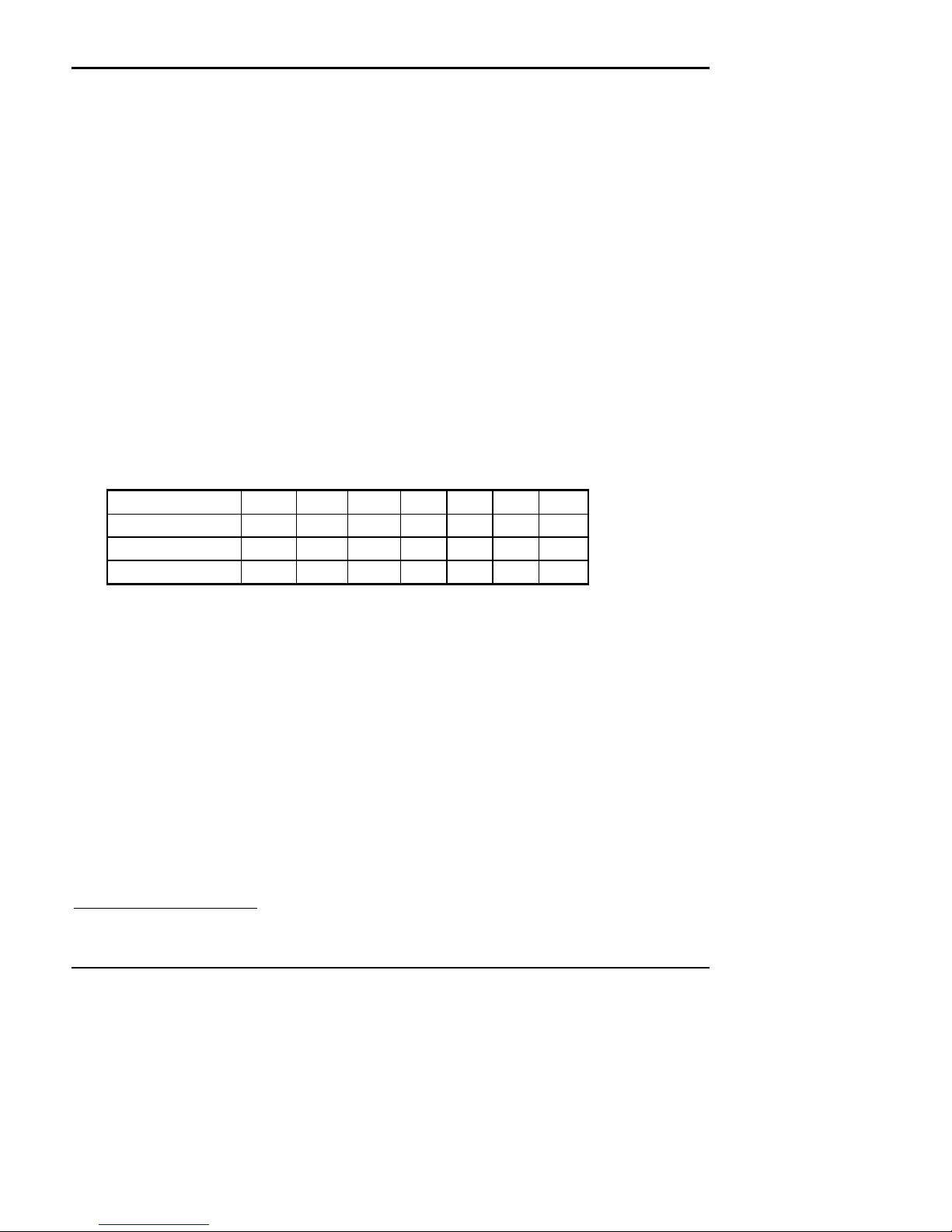

Pitch Print Station

CPI4

24

17.1

12

10

Slip Receipt Journal

1≤n≤84 1≤n≤66 1≤n≤56

1≤n≤60 1≤n≤48 1≤n≤40

1≤n≤42 1≤n≤32 1≤n≤28

1≤n≤34 1≤n≤28 1≤n≤24

Valid tab stops

4

CPI - Characters Per Inch

Page 20 Rev C 7/8/2008

Page 22

Programmer's Guide PcOS Series 60 Control Codes

Ithaca Peripherals Incorporated Character Pitch

Character Pitch

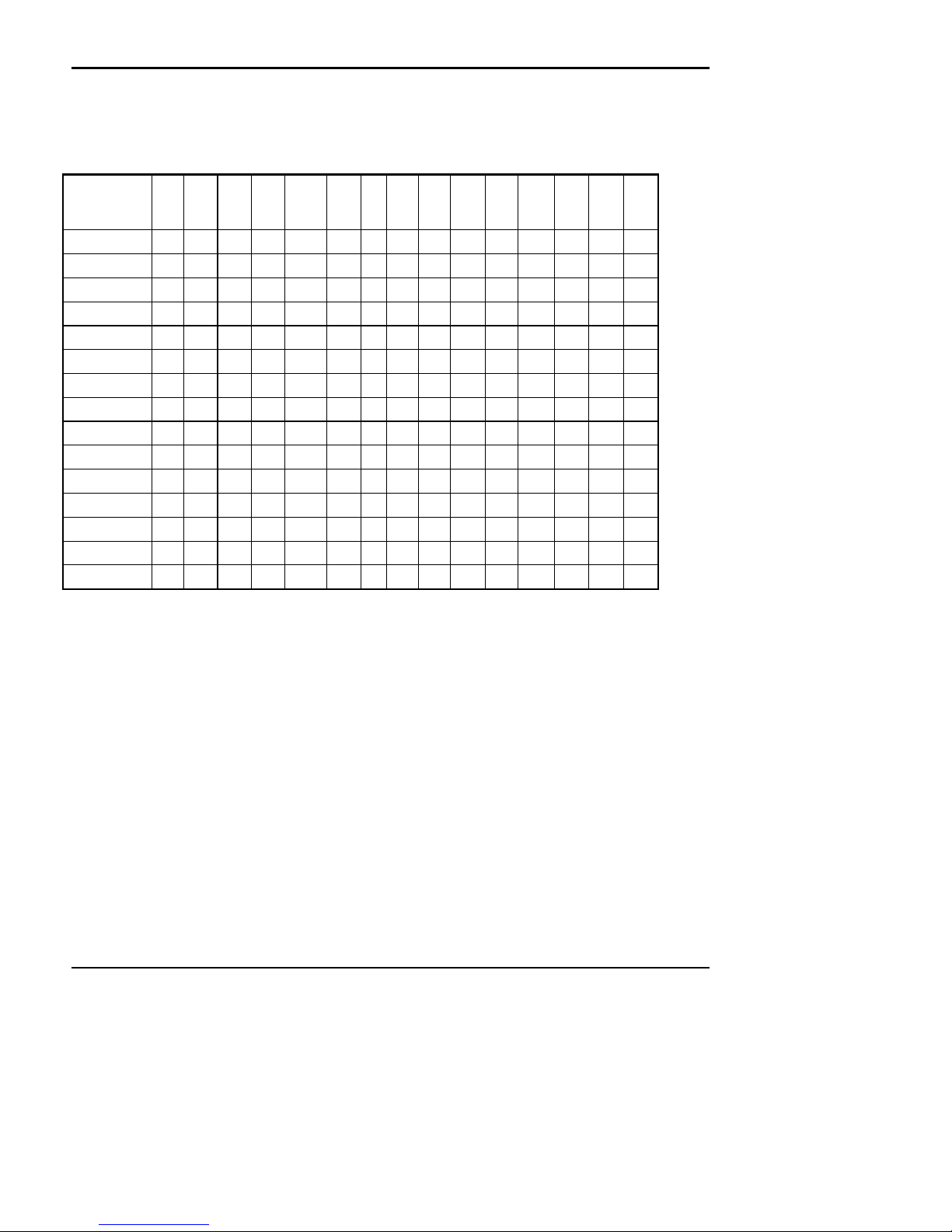

There are a number of Character pitch and print mode operations that are possible and a few that are not. The following

table lists the operations that are possible in matrix form.

Operation 10

10 cpi

12 cpi

17 cpi

24 cpi

Line Graphics

Super / Sub

Util

NLQ

HSD

Emphasize

Enhanced

Double wide

Underline

Rotate 180°

Rotate 90°/270°

NOTE: Feature Available

Feature NOT Available

Switches to 10 CPI Emphasize. If 17 or 24 CPI was set previously to the emphasize command, the

Prints half high full width utility script.

In rotated 90° or 270° mode the print is done in APA Graphics. The print is in 12 CPI character cell size.

12 cpi 17 cpi 24 cpi Line

cpi

Graphic

s

Super

Util NLQ HSD Emph

/ Sub

asize

Enha

nced

Double

wide

Under

line

Rotate

180

Rotate

90°

/270°

characters will be printed at 10 CPI with Emphasize. When Emphasize is terminated, the print will revert

to 17 or 24 CPI.

The inter-character spacing can be adjusted with the normal line spacing commands.

Rev C 7/8/2008 Page 21

Page 23

Control Codes PcOS Series 60 Programmer's Guide

Character Pitch Ithaca Peripherals Incorporated

Function: Begin 10 CPI character pitch

ASCII: [DC2]

Hexadecimal: 12H

Decimal: <18>

IPCL: &%F3

Description: Set 10 character per inch print pitch.

Function: Begin 12 CPI character pitch

ASCII: [ESC] :

Hexadecimal: 1BH 3AH

Decimal: <27><58>

IPCL: &%F2

Description: Set 12 character per inch print pitch

Function: Begin 17 CPI character pitch

Mode: Global

ASCII: [SI]

Hexadecimal: 0FH

Decimal: <15>

IPCL: &%F1

Description: Set 17 character per inch print pitch

Function: Begin 24 CPI character pitch

Mode: Global

ASCII: [ESC] [SI]

Hexadecimal: 1BH 0FH

Decimal: <27><15>

IPCL: &%F4

Description: Set 24 character per inch print pitch

[DC2]

This line is 10 CPI[CR][LF]

[ESC]:

This line is 12 CPI[CR][LF]

[SI]

This line is 17 CPI[CR][LF]

[ESC][SI]

This line is 24 CPI[CR][LF]

Data sent to the printer

Page 22 Rev C 7/8/2008

Resulting print

Page 24

Programmer's Guide PcOS Series 60 Control Codes

Ithaca Peripherals Incorporated Character Pitch

Function: Begin one line double wide print

ASCII: [SO]

Hexadecimal: 0EH

Decimal: <14>

IPCL: &%MW

Description: This command causes subsequent characters to

be printed at twice the currently selected

character width. For example 10 cpi becomes 5

cpi, 17 cpi becomes 8.5 cpi etc. This

command remains in effect until :

a. - a valid line terminator is received ( CR,

LF, or Fine Line Feed)

b. - The command is canceled

c. - The maximum number of characters per

line is reached and the printer performs an auto print

Function: Cancel one line double wide print

ASCII: [DC4]

Hexadecimal: 14H

Decimal: <20>

IPCL: &%MN

Description: Cancel one line double wide mode set by [SO] command. This command allows single and double wide

characters to be printer on the same line.

Function: Begin Multi line double wide print

ASCII: [ESC] W <1>

Hexadecimal: 1BH 57H 01H

Decimal: <27><87><1>

IPCL: &%FD

Description: Begin Multi-line line double wide mode. This command is similar to the [SO] command except that the

printer will remain in double wide mode until the Cancel Multi Line double wide command is received.

Function: Cancel Multi-line line double wide print

ASCII: [ESC] W <0>

Hexadecimal: 1BH 57H 00H

Decimal: <27><87><0>

IPCL: &%FE

Description: Cancel Multi-line line double wide mode set by [ESC] W <1> command

Example of one line Double Wide[CR][LF]

This is normal 12 CPI Print[CR][LF]

[SO]

Double Wide[CR][LF]

This is back to normal[CR][LF]

Data Sent To Printer

Resulting Print

Rev C 7/8/2008 Page 23

Page 25

Control Codes PcOS Series 60 Programmer's Guide

Character Font Ithaca Peripherals Incorporated

Character Font

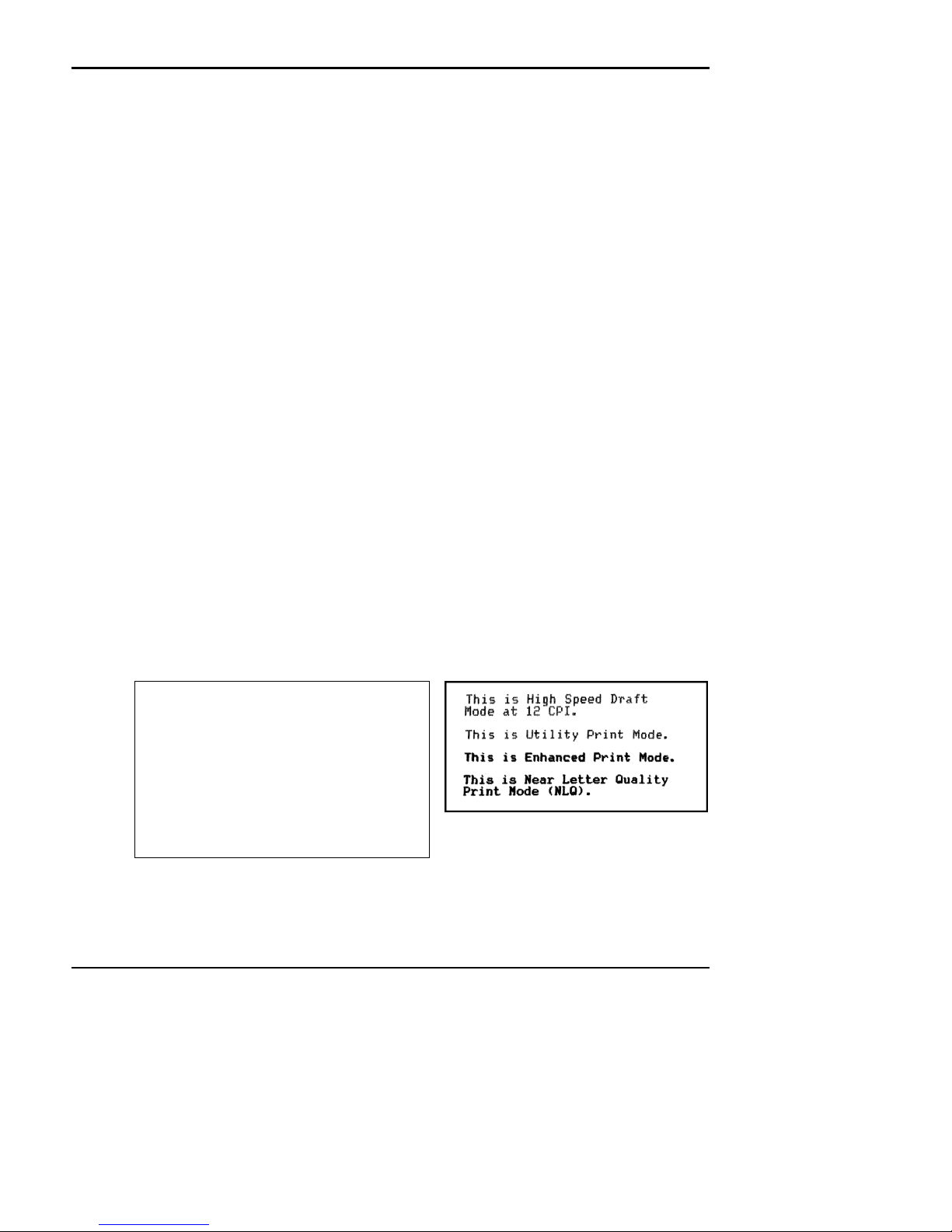

Function: Begin High Speed Draft Mode (HSD) (Power on Default)

ASCII: [ESC] # <0>

Hexadecimal: 1BH 23H 00H

Decimal: <27><35><0>

IPCL: &%QT

Description: Begin Draft print mode (1 pass 7x7 font). Enhanced, Emphasized, Subscript, Superscript, and

To maintain optimum print speed the printer should be returned to High Speed Draft mode when

Function: Begin Utility Print

ASCII: [ESC] I <1>

Hexadecimal: 1BH 49H 01H

Decimal: <27><73><1>

IPCL: &%QU

Description: Begin Utility print mode (1 pass 9x7 font). Utility print mode enables Enhanced, Emphasized,

Function: Begin Enhanced Print

ASCII: [ESC] I <2>

Hexadecimal: 1BH 49H 02H

Decimal: <27><73><2>

IPCL: &%QE

Description: Begin Enhanced print mode (2 pass 9x7 font). Print speed is reduced approximately 40% over the High

Function: Begin NLQ Print

ASCII: [ESC] I <3>

Hexadecimal: 1BH 49H 03H

Decimal: <27><73><3>

IPCL: (None)

Description: Begin NLQ print mode ( 2 pass 9x7 font). This is generally regarded as a Near Letter Quality print node.

Underline character attributes are not available in this mode.

enhanced print is not required.

Subscript, Superscript, and Underline character attributes. Print speed is reduced approximately 20%

over the High speed Mode (HSD).

speed Mode (HSD). The effect is to darken the resulting print

The print speed is reduced and character features are added to the font to enhance the appearance.

[ESC]f[ESC]:

{rpt:5}[LF]

[ESC]v

[ESC]#<0>

This is High Speed Draft [CR][LF]

Mode at 12 CPI.[CR][LF][LF]

[ESC]I<1>

This is Utility Print Mode.[CR][LF][LF]

[ESC]I<2>

This is Enhanced Print Mode.[CR][LF][LF]

[ESC]I<3>

This is Near Letter Quality[CR][LF]

Print Mode (NLQ).[CR][LF][LF]

[ESC]z

Data sent to the printer

Page 24 Rev C 7/8/2008

Resulting Print

Page 26

Programmer's Guide PcOS Series 60 Control Codes

Ithaca Peripherals Incorporated Character Font

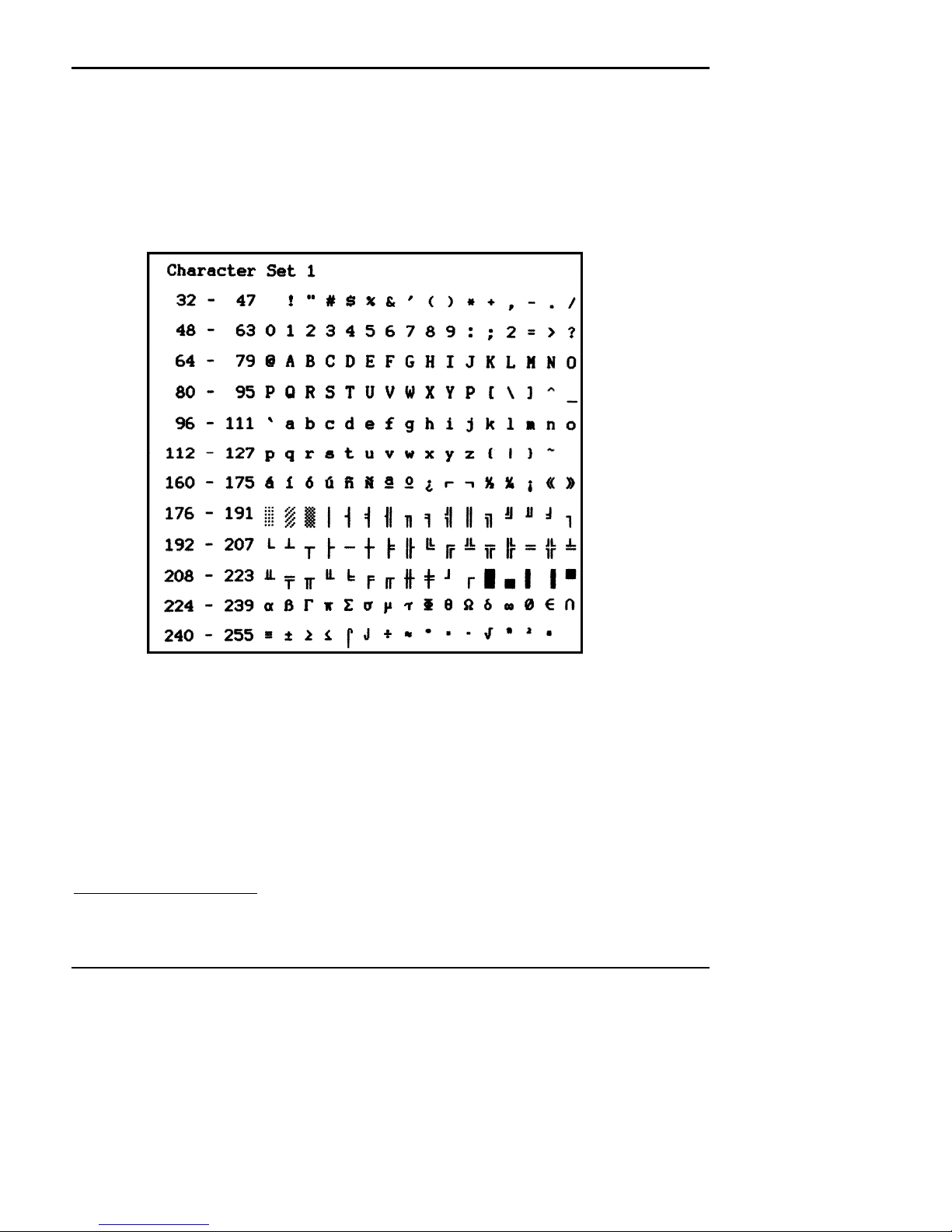

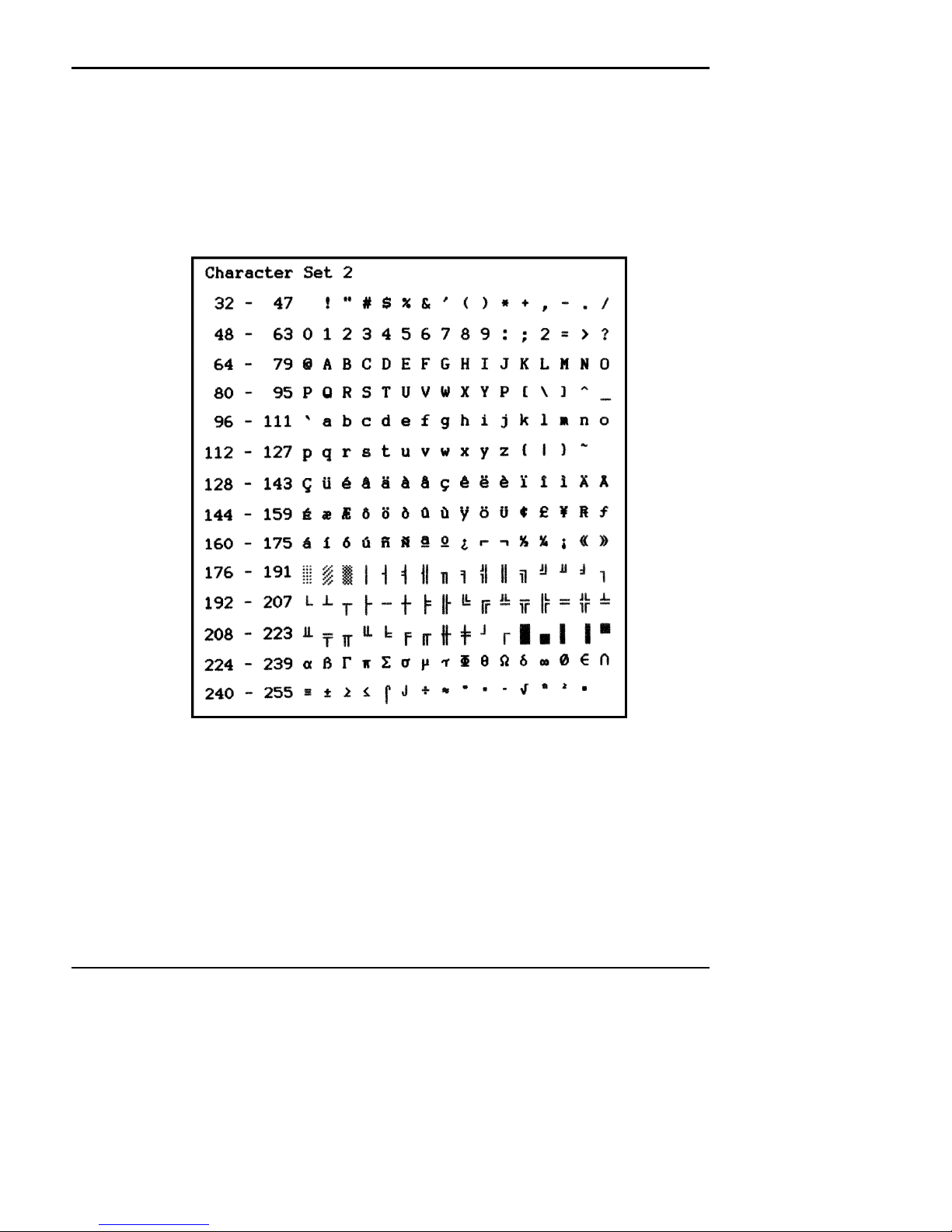

Function: Select Character Set 1 (Default Character set)

ASCII: [ESC] 7

Hexadecimal: 1BH 37H

Decimal: <27><55>

IPCL: &%C1

Description: Select character set 1. This character set consists of characters 32 through 127 and 160 through 255 in

the character chart below. Characters 128 through 1595 are not implemented and should not be sent to

the printer.

NOTE: Characters 176 through 228 (Block Graphics) and 244 should not be used in journal mode as they

are multiple pass fonts that will not print well on the journal.

5

Because of limited code space the validity of characters between 128 and 159 are not checked in character set 1. In most

cases sending these values to the printer will have unexpected effects.

Rev C 7/8/2008 Page 25

Page 27

Control Codes PcOS Series 60 Programmer's Guide

Character Font Ithaca Peripherals Incorporated

Function: Select Character Set 2

ASCII: [ESC] 6

Hexadecimal: 1BH 36H

Decimal: <27><54>

IPCL: &%C2

Description: Select character set 2. This is a full character set. It includes characters between 32 and 255 from the

NOTE: Characters 176 through 228 (Block Graphics) and 244 should not be used in journal mode as they

chart below.

are multiple pass fonts that will not print well on the journal.

Page 26 Rev C 7/8/2008

Page 28

Programmer's Guide PcOS Series 60 Control Codes

Ithaca Peripherals Incorporated Print Rotation

Print Rotation Commands

To provide flexibility in printing on preprinted and various size forms, rotated print capability is provided in slip and receipt

mode. This mode will rotate the print in any of three 90 degree orientations.

In 90° and 270° rotated mode, the print data is first buffered by the printer, processed (rotated) and then printed. This

causes the print process to be delayed slightly as it takes some time to process the data before it is printed. In 180° mode,

the print is simply inverted.

Because the rotated 90° and 270° print buffer is limited to 1024 characters, the amount of rotated print is limited. The

technique used by the Series 60 printer is to receive all the print to be rotated and convert it into graphics. This requires

buffer space for all possible characters in each print line. Each line has a fixed length buffer regardless of how much data is

actually sent to the printer. The printer will space fill the buffer for each line to the maximum size. This means that a short

line of two characters will take as much buffer space as a long line.

To make the most efficient use of buffer space the line length is pre defined. The default line length is 48 characters which

leaves room for 21 lines. To allow longer lines to be printed the line length can be changed, however no more than 25 lines

are allowed and no more than 80 characters per line are allowed. For example if the line length is expanded to 80 there is

buffer space for 1024/80 or 12 lines.

The spacing between lines is controlled by a line spacing table. This table is defined by the rotated print line spacing

([ESC] u ... ) command. This command specifies the number of dots between each printed line. Each line has an entry in

the table. There is room for 25 lines in the table. The default and minimum is one dot or 1/60 of an inch between lines or 6

2/3 lines per inch.

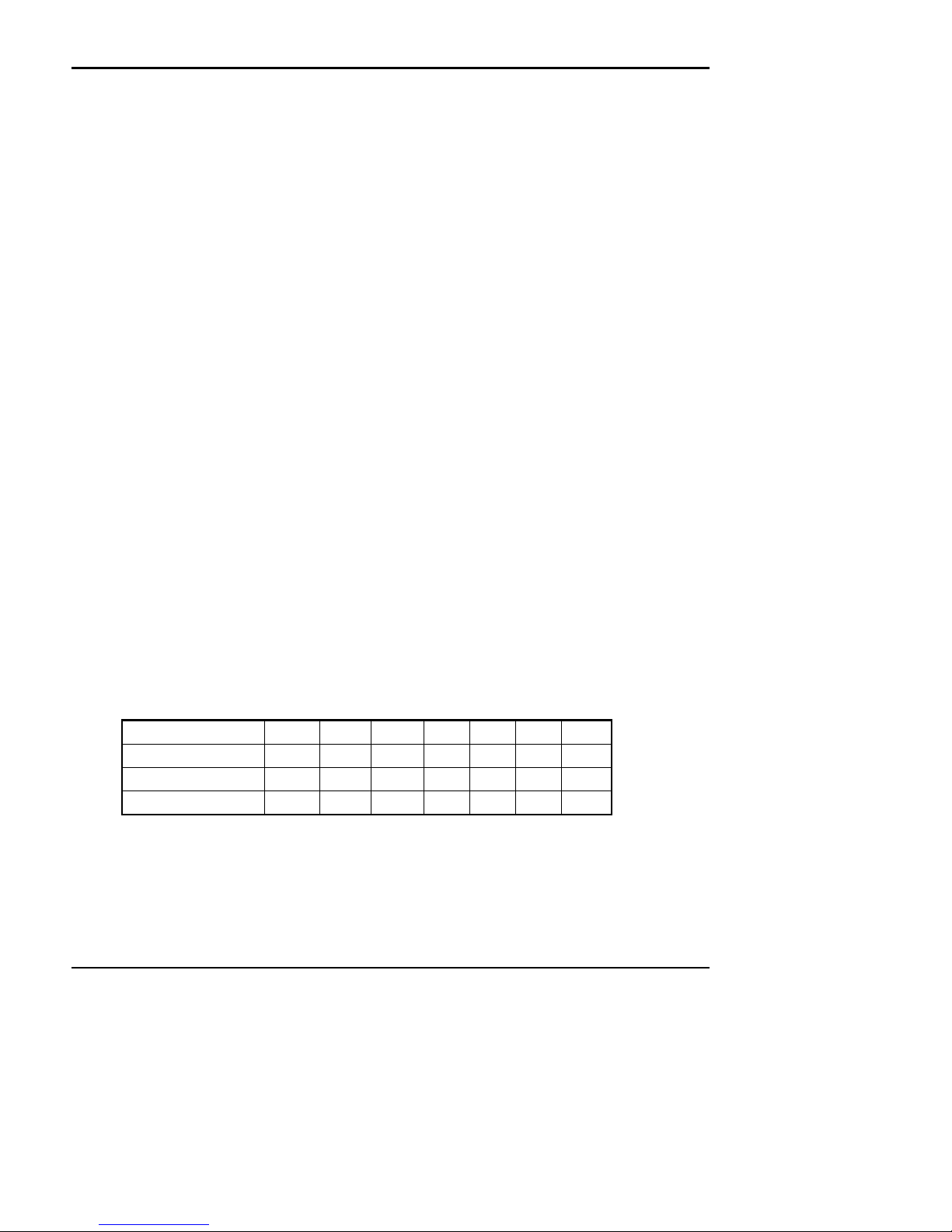

The character cell is a 5x8 with one dot of white space min. If the spacing between lines is set to 1 the character cell will be

5x9. If the spacing is set to 2 dots the cell will be 5 x 10 and so on. The following table specifies lines per inch for various

numbers of inserted dots.

Number of dots added 1 2 3 4 5 6 7

Cell Size 5x9 5x10 5x11 5x12 5x13 5x14 5x15

Line spacing (inches) 0.15" 0.167 0.183 0.20 0.22 0.23 0.25

Number Lines/inch 6.667 6 5.45 5 4.62 4.29 4

In rotated 90° or 270° mode the print is done in APA6 Graphics. The print is in a modified 12 CPI character cell size. The

inter-character spacing is adjusted with the normal line spacing commands. The [ESC]3<n> command is the most

effective command for adjusting inter character spacing. Because the character is close to a 12 CPI cell, much less than 12

CPI will force the characters to overlap. (Spacing of 12 CPI is obtained with an [ESC] 3 <18>.)

When rotate 90° or 270° is selected only normal text can be printed. Underline, Enhanced, Emphasized and other attributes

will not function. See chart on page 21 for a list of available features.

In rotated 180° mode the 10, 12, 17, and 24 CPI spacing commands are effective. This mode of operation simply inverts

and mirrors the print operation. All line spacing and print features are available. It should be noted that the feed direction

is not affected by any of the rotate commands.

6

APA - All Points Addressable

Rev C 7/8/2008 Page 27

Page 29

Control Codes PcOS Series 60 Programmer's Guide

Print Rotation Ithaca Peripherals Incorporated

Function: Begin 90 Degree Rotated Print

ASCII: [ESC] r <1>

Hexadecimal: 1BH 72H 01H

Decimal: <27><114><1>

IPCL: &%R1

Description: Print data is entered in normal left to right, top to bottom format. When an End Rotated Print ([ESC] r

NOTE: Do not use this command in journal mode. It will not function correctly.

Function: Begin 270 Degree Rotated Print

ASCII: [ESC] r <3>

Hexadecimal: 1BH 72H 03H

Decimal: <27><114><3>

IPCL: &%R3

Description: Print data is entered in normal left to right, top to bottom format. When an End Rotated Print ([ESC] r

NOTE: In receipt mode this rotation requires that the text be sent to the printer in reverse. The feed

NOTE: Do not use this command in journal mode. It will not function correctly.

Function: Begin 180 Degree Rotated Print

ASCII: [ESC] r <2>

Hexadecimal: 1BH 72H 02H

Decimal: <27><114><2>

IPCL: &%R2

Description: All subsequent lines will be rotated 180 degrees and positioned at the opposite margin. This command is

NOTE: The last line of print must be terminated with a line terminator before the END rotated command

NOTE: The definition of normal is rotated 180° on the slip station.

<0>) command is received, the printer will format and print the data. The print will be rotated 90

degrees according to the current stored format parameters. In slip mode, the rotated pattern will be 180

degrees different than in receipt mode. However, the resulting print will be the same provided the feed

direction is correct.

<0>) command is received, the printer will format and print the data. The print will be rotated 270

degrees according to the current stored format parameters.

direction in receipt mode must always be from back to front. It is recommended that only rotate 90° be

used on the receipt.

effective on all stations including the journal. This command will remain in effect until rotation is

canceled with an End Rotated Print ([ESC] r <0>) command, or a station select command is issued.

is issued. Any characters in the print buffer that have not been printed will not be printed. They will be

printed un-rotated when a line terminator is received.

Page 28 Rev C 7/8/2008

Page 30

Programmer's Guide PcOS Series 60 Control Codes

Ithaca Peripherals Incorporated Print Rotation

Function: End Rotated Print

ASCII: [ESC] r <0>

Hexadecimal: 1BH 72H 00H

Decimal: <27><114><0>

IPCL: &%R0

Description: Print contents of rotated print buffer ( if 90 or 270 degree mode) and return to normal print orientation.

In 180 degree mode the printer will return to normal mode. Characters in the print buffer that have not

NOTE: The definition of normal is rotated 180 on the slip station.

Function: Set Rotated Print Line Length

ASCII: [ESC] s <n>

Hexadecimal: 1BH 73H <n>

Decimal: <27><115><n>

IPCL: &%RL <n>

Description: Sets the print line length to be used in Auto Format rotated print mode. The maximum number of

The number of available print lines is found by dividing 1024 by the number of characters per line and

Function: Set Rotated Print Line spacing

ASCII: [ESC] u <n>1 <m>1 <n>2 <m>2... <n>i <m>i 0

Hexadecimal: 1BH 75H <n>1 <m>1 <n>2 <m>2 ... <n>i <m>i 00H

Decimal: <27><117><n>

IPCL: &%RP <n>1<m>1 <n>2 <m>2 ... <n>i <m>i 0

Description: Adjust line spacing for each rotated print line. Where ni is the line number, mi is the spacing in dot

For the first print line the distance is calculated from the margin. An ni value of 0 is used to terminate the

The value of m can be from 1 to 127, n can be from 1 to 25.

NOTE: When this command is used ENQ processing must be disabled. This will prevent unwanted ENQ

been printed will NOT be printed.

characters is 80 per line. The power on default line length is 48 characters.

rounding down to the nearest whole number. The minimum number is 40 characters. Any value less

than 40 will not allow any additional print lines to be printed.

1

<m>1 <n>2 <m>2 ... <n>i <m>i <0>

columns (1/60") from the previous line.

command. Any unspecified spacing will be set to 1. This allows data to be accurately positioned on an

inserted form. These values will be used as a template for all subsequent rotated print. On power up, all

spacings are preset to 1/60" (n=1, 6.667 Lines per inch) for all lines. This command is only effective in

90° and 270° degree rotation. It will remain in effect until a new table is received or until the printer is

power cycled. An [ESC] u <0> will have the effect of setting all lines to 1.

responses.

Number of dots added 1 2 3 4 5 6 7

Cell Size 5x9 5x10 5x11 5x12 5x13 5x14 5x15

Line spacing (inches) 0.15" 0.167 0.183 0.20 0.22 0.23 0.25

Number Lines/inch 6.667 6 5.45 5 4.62 4.29 4

The following chart illustrates the line spacing command.

Rev C 7/8/2008 Page 29

Page 31

Control Codes PcOS Series 60 Programmer's Guide

Print Rotation Ithaca Peripherals Incorporated

Left Margin

n=1, m

n=2, m

The print example on the right is an example of rotated print. It was obtained with the following print codes:

[ESC]h

[ESC]m[ESC]m[ESC]n[ESC]e[ESC]h

[ESC]1

[ESC]r<1>

Ithaca Peripherals Incorporated [CR][LF]

20 Bomax Drive [CR][LF]

Ithaca, New York, 14850 [CR][LF]

[CR][LF]

{date:0} {time:1}[CR][LF]

Series 60 Slip Printer [CR][LF]

Rotated Print Mode [CR][LF]

[CR][LF]

*************************************[CR][LF]

* INNOVATIVE *[CR][LF]

* SOLUTIONS *[CR][LF]

* FOR *[CR][LF]

* RETAIL *[CR][LF]

* AND *[CR][LF]

* FINANCIAL *[CR][LF]

* APPLICATIONS *[CR][LF]

*************************************[CR][LF]

[ESC]r<0>[ESC]0[ESC]n

{rpt:32}[LF]

[ESC]z

Data Sent to the printer

Edge of form

First line

Second Line

Third Line

Page 30 Rev C 7/8/2008

Resulting Print

Page 32

Programmer's Guide PcOS Series 60 Control Codes

Ithaca Peripherals Incorporated Character Attributes

Character Attribute Commands

Function: Begin Underline

ASCII: [ESC] - <1>

Hexadecimal: 1BH 2DH 01H

Decimal: <27><45><1>

IPCL: &%MU

Description: Begin Underline print mode. All subsequent text and leading spaces will be underlined. Trailing spaces

NOTE: Underline is not available in Enhanced Print Modes. See page 21 for available modes.

Function: End Underline

ASCII: [ESC] - <0>

Hexadecimal: 1BH 2DH 00H

Decimal: <27><45><0>

IPCL: &%CU

Description: Ends Underline print mode.

Function: Begin Enhanced Print

ASCII: [ESC] G

Hexadecimal: 1BH 47H

Decimal: <27><71>

IPCL: &%ME

Description: All subsequent text will be printed in enhanced print mode (2 pass w/ vertical offset). Enhanced printing

NOTE: This mode is not available on the journal.

Function: End Enhanced Print Mode

ASCII: [ESC] H

Hexadecimal: 1BH 48H

Decimal: <27><72>

IPCL: &%CE

Description: Cancel Enhanced print mode and return to currently selected font.

Function: Begin Emphasized Print

ASCII: [ESC] E

Hexadecimal: 1BH 45H

Decimal: <27><69>

IPCL: &%MM

Description: Begin Emphasized print mode (1 pass w/ horizontal offset). This print is bolder than normal print.

Function: End Emphasized Print

ASCII: [ESC] F

Hexadecimal: 1BH 46H

Decimal: <27><70>

IPCL: &%CM

Description: Cancel Emphasized print mode

Function: Select Superscript

ASCII: [ESC] S <0>

Hexadecimal: 1BH 53H 00H

Decimal: <27><83><0>

IPCL: &%SP

are also underlined.

provides a deeper resolution of each character and may enhance multiple part form printing.

Rev C 7/8/2008 Page 31

Page 33

Control Codes PcOS Series 60 Programmer's Guide

Character Attributes Ithaca Peripherals Incorporated

Description: Selects Superscript. All following characters will be printed half size on the upper side of the print line.

NOTE: This feature is not available in all print modes. See page 21 for available modes.

Function: Select Subscript

ASCII: [ESC] S <1>

Hexadecimal: 1BH 53H 01H

Decimal: <27><83><1>

IPCL: &%SB

Description: Selects Subscript. All following characters will be printed half size on the bottom side of the print line.

NOTE: This feature is not available in all print modes. See page 21 for available modes.

Function: End Superscript or Subscript

ASCII: [ESC] T

Hexadecimal: 1BH 53H

Decimal: <27><84>

IPCL: &%SE

Description: Ends Superscript or Subscript.

[ESC]f

[ESC]:

[ESC]I<1>

[ESC]v

{RPT:5}[LF]

This is an example of [ESC]-<1>Underline[ESC]<0>.[CR][LF][LF]

[ESC]G

This is Enhanced Mode[CR][LF][LF]

[ESC]H

[ESC]E

This is Emphasized Mode[CR][LF][LF]

[ESC]F

This is [ESC]S<0>Superscript[ESC]T[CR][LF][LF]

This is [ESC]S<1>Subscript[ESC]T[CR][LF][LF]

[ESC]z

Data Sent to the printer

Resulting Print

Page 32 Rev C 7/8/2008

Page 34

Programmer's Guide PcOS Series 60 Control Codes

Ithaca Peripherals Incorporated Graphics

Graphics Mode

NOTE: Be sure to disable ENQ commands before sending graphics data.

NOTE: The journal feeds only from back to front.

Function: Begin Unidirectional Print

ASCII: [ESC] U <1>

Hexadecimal: 1BH 55H 01H

Decimal: <27><85><1>

IPCL: &%GU

Description: Print all data in unidirectional print mode to improve line to line registration for graphics data.

NOTE: This command should be canceled before normal text is printed. It will slow print if it is not

Function: Begin Bi-directional Print

ASCII: [ESC] U <0>

Hexadecimal: 1BH 55H 00H

Decimal: <27><85><0>

IPCL: &%GB

Description: Print all data in bi-directional, logic seeking print mode.

Function: Print Single Density Graphics ( 60 72dpi)

ASCII: [ESC] K <n>1 <n>2

Hexadecimal: 1BH 4BH <n>

Decimal: <27><75><n>1 <n>2

IPCL: &%GS <n>1 <n>2

Description: Print n1 + 256*n2 bytes of single density graphics (60 dpi).

Function: Print Double Density Graphics ( 120 x 72dpi)

ASCII: [ESC] L <n>1 <n>2

Hexadecimal: 1BH 4CH <n>1 <n>2

Decimal: <27><76><n>1 <n>2

IPCL: &%GD <n>1 <n>

Description: Print n1 + 256*n2 bytes of double density graphics (120 dpi)

Function: Print Double Density Graphics ( 120 x 72 dpi)

ASCII: [ESC] Y <n>1 <n>2

Hexadecimal: 1BH 59H <n>1 <n>2

Decimal: <27><89><n>1 <n>2

IPCL: &%GF <n>1 <n>2

Description: Print n1 + 256*n2 bytes of double density graphics (120 dpi) full speed, no consecutive dots.

canceled.

1

<n>2

2

Rev C 7/8/2008 Page 33

Page 35