Page 1

PCOS

SERIES 90PLUS

MAINTENANCE

MANUAL

PN: 100-9067

Page 2

Page 3

WARNING: To prevent fire or shock hazard, do not expose this printer to rain

or moisture.

Page 4

Disclaimer

Information in this publication is subject to change without notice. However, as product improvements become

available, Ithaca Peripherals will make every effort to provide updated information for the products describ ed

in this publication.

Ithaca Peripherals cannot guarantee that changes in software and equipment made by other manufacturers, and

referred to in this publication, do not affect the applicability of the information in this publication.

Copyright

© 1996, 1998, 1999 Ithaca Peripherals. All Rights Reserved.

Revision C, June 1999

Printed in the United States of America.

No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form or by

any means, mechanical, photocopying, recording, or otherwise, without the prior written permission of Ithaca

Peripherals.

Trademarks

Ithaca and PcOS are registered trademarks of Ithaca Peripherals. Ithaca Peripherals is a Transact Technologies

Incorporated Company. IBM is a registered trademark of the International Business Machines Corporation.

Page 5

Federal Communications Commission Radio Frequency Interference

Statement

The Series 90PLUS printer complies with the limits for a Class A computing device, in accordance with the

specifications in Part 15 of the FCC rules, which are designed to minimize radio frequency interference during

installation. However, there is no guarantee that radio or television interference will not occur in any particular

installation. If the equipment does cause interference to radio or television reception, which can be determined

by turning the equipment off and on while the radio or television is on, the user is encouraged to try to correct

the interference by one or more of the following measures:

♦ Reorient the radio or television receiving antenna;

♦ Relocate the printer with respect to the receiver; or

♦ Plug the printer and receiver into different outlets.

If necessary, the user should consult their dealer or an experienced radio/television technician for additional

suggestions.

The user may find the following booklet prepared by the Federal Communications Commission helpful: How to

Identify and Resolve Radio/TV Interference Problems. This booklet is available from the United States

Government Printing Office, Washington, DC 20402. Ask for stock number 004-000-00345-4.

Canadian Department of Communications Radio Interference Statement

The Series 90PLUS printer does not exceed Class A limits for radio noise emissions from digital apparatus set

out in the Radio Interference Regulations of the Canadian Department of Communications.

UL, CSA, VDE, CE Statement

Ithaca Peripherals’ printers are UL and CSA listed, VDE certified, and carry the CE mark.

Page 6

Page 7

Table of Contents

TABLE OF CONTENTS

PRODUCT INFORMATION 1

What is in this book? ................................................................................................ 1

Who should read this book?....................................................................... 1

What does it cover?.................................................................................... 1

Where can you find more information?...................................................... 1

Contacting Ithaca Peripherals..................................................................... 1

Warranty Information............................................................................................... 2

Options.......................................................................................................2

Ordering Supplies..................................................................................................... 2

Paper........................................................................................................... 2

Ribbon Cassettes........................................................................................3

Take-up Spool............................................................................................ 3

Print Head and Clamp................................................................................ 3

Cables......................................................................................................... 3

i

Description of the Series 90PLUS Printer................................................................ 4

Series 90PLUS Models .............................................................................. 4

Standard Features....................................................................................... 6

Optional Features ....................................................................................... 6

Technical Specifications........................................................................................... 7

Printing Specifications................................................................................ 7

Print Characteristics ................................................................................... 7

Reliability................................................................................................... 8

Dimensions................................................................................................. 8

Weight........................................................................................................ 8

Power Requirements................................................................................... 8

Environmental Conditions.......................................................................... 8

Communication Interfaces and Cash Drawer Connectors......................................... 9

Serial Cable................................................................................................ 9

Parallel Cable ........................................................................................... 10

Cash Drawer Pin Assignments..................................................................11

CLEANING AND ADJUSTMENTS 13

Cleaning the Printer................................................................................................ 13

Making Adjustments............................................................................................... 13

Diagnosing the Print Quality.................................................................... 13

Necessary Tools ....................................................................................... 14

Adjusting the Platen Gap.......................................................................... 15

Adjusting the Platen Parallel to the Print Head........................................ 16

Page 8

Table of Content

ii

ASSEMBLY/DISASSEMBLY 17

Precautions for Disassembly................................................................................... 17

Necessary Tools ....................................................................................... 17

Disconnecting the Power Cord ............................................................................... 18

Disconnecting the Communication Cable............................................................... 19

Disconnecting the Serial Cable................................................................. 19

Disconnecting the Parallel Cable.............................................................. 20

Disconnecting the Cash Drawer Cables.................................................... 20

Removing the Ribbon Cassette ............................................................................... 21

Installing the Ribbon Cassette.................................................................. 21

Print Head............................................................................................................... 23

Removing the Used Print Head ................................................................ 23

Installing the New Print Head................................................................... 25

Removing the Covers.............................................................................................. 26

Take-up Motor Assembly Kit................................................................................. 28

Mechanical Base Assembly.................................................................................... 30

Knife Disassembly.................................................................................................. 32

25-pin Parallel Interface Cable............................................................................... 34

9-pin Serial Interface Cable.................................................................................... 35

Cash Drawer Harnesses .......................................................................................... 36

Power Supply Assembly......................................................................................... 37

Power Switch and AC Inlet Assembly.................................................................... 38

Controller Board Assembly.................................................................................... 39

Keypad PC Board................................................................................................... 40

Carrier/Cam Plate................................................................................................... 41

Cam Plate................................................................................................................ 44

Carrier Assembly .................................................................................................... 47

Removing the Print Mechanism Assembly............................................................. 49

Print Mechanism Assembly.................................................................................... 50

Carriage Assembly.................................................................................................. 51

Carriage Motor ....................................................................................................... 52

Line Feed Motor..................................................................................................... 53

TROUBLESHOOTING 55

Determining the Problem........................................................................................ 55

LED Indicators ....................................................................................................... 71

Printer Fault Indicators........................................................................................... 72

Checking Connections and Resistance.................................................................... 74

Page 9

Table of Contents

Print Head................................................................................................. 74

Space Motor Assembly.............................................................................75

Line Feed Motor (Slip)............................................................................. 75

Line Feed Motor (Receipt)....................................................................... 76

APPENDIX A: THEORY OF OPERATION 77

Electrical Operation................................................................................................ 78

Circuit Operation...................................................................................... 78

Microprocessor and Peripheral Circuits ................................................................. 79

Microprocessor (U1: 80C154) ................................................................. 79

Program ROM (U4).................................................................................. 79

Program RAM (U2).................................................................................. 79

RAM (U5)................................................................................................ 79

LSI (M7U042-026) .................................................................................. 79

Initialization............................................................................................................ 80

Interface Control..................................................................................................... 80

Parallel Interface ...................................................................................... 80

Serial Interface ......................................................................................... 80

iii

Print Head Drive Circuit......................................................................................... 81

Carriage Drive........................................................................................................ 81

Space Motor Control................................................................................ 81

Slit Encoder.............................................................................................. 82

Line Feed................................................................................................................ 82

Alarm Circuits........................................................................................................ 83

Drive Circuit Fault Alarm Circuit............................................................. 83

Head Overheat Alarm Circuit................................................................... 83

Power Supply.......................................................................................................... 83

AC Input................................................................................................................. 83

Mechanical Operation............................................................................................. 84

Print Head Mechanism and Operation...................................................... 84

Space Mechanism and Operation............................................................. 84

Ribbon Feed Mechanism and Operation .................................................. 85

Paper Feed Mechanism and Operation..................................................... 86

Paper-low Detection Mechanism and Operation...................................... 86

APPENDIX B: PARTS LISTS 87

Packing Materials/Publications............................................................................... 88

Printer Assembly..................................................................................................... 90

Paper Cover Assembly............................................................................................92

Paper Cover Assembly with Lock........................................................................... 93

Right Cover Assembly (90-7464)........................................................................... 94

Right Cover Assembly with Lock (90-7470) .......................................................... 95

Base Cabinet and Take-up Motor........................................................................... 96

Page 10

Table of Content

iv

Take-up Motor Assembly (90-7462)...................................................................... 97

Mechanical/Electrical Base Assembly.................................................................... 98

Mechanical/Electrical Base Assembly (continued)................................................. 99

Mechanism Base Assembly - Models 91PLUS and 92PLUS............................... 100

Mechanism Base Assembly - Models 93PLUS and 94PLUS............................... 102

Mechanism Base Assembly - Models 93PLUS and 94PLUS (continued)............ 103

Knife Assembly .................................................................................................... 105

Cam Plate Assembly............................................................................................. 107

Carrier Assembly (Standard) ................................................................................ 108

Carrier Assembly (3” Paper Option) .................................................................... 109

Print Mechanism Assembly.................................................................................. 110

Carriage Assembly................................................................................................ 111

Carriage Motor Assembly..................................................................................... 112

Electronic Base Assembly .................................................................................... 113

APPENDIX C: SCHEMATICS 115

Page 11

Product Information

PRODUCT INFORMATION

WHAT IS IN THIS BOOK?

WHO SHOULD READ THIS BOOK?

This book is a maintenance guide intended for trained, service technicians.

WHAT DOES IT COVER?

This book only covers the Series 90PLUS printer, not the entire point-of-sale system, but it will tell

you all you need to know about properly maintaining and servicing the printer. You will learn how to

clean and adjust the printer, troubleshoot problems, and disassemble the printer.

This book also provides some general and technical information about the printer, so you will learn

what the features are, how reliable it is, and what its printing capabilities are.

1

WHERE CAN YOU FIND MORE INFORMATION?

A Programmer’s Guid e is available if you need to know how to program a point-of-sale terminal or a

PC to work with the printer. It describes the commands the printer recognizes to perform its functions.

An Operator’s Guide is also available and is intended for new and experienced operators. It covers

setting up and using the Series 90PLUS printer with any point-of-sale system. For information about

ordering these books, refer to the next section.

CONTACTING ITHACA PERIPHERALS

Contact your dealer first for general information about the Series 90PLUS printer and how it works

with your system. If you need more specific information about the printer, you may contact Ithaca

Peripherals directly. The Sales and Technical Support Departments will be able to help you with most

of your questions.

To order supplies or send a printer in for service, the Technical Support Department can help. Also,

contact the Technical Support Department to receive information about your warranty, technical

advice, or additional information about the Series 90PLUS printer. To order supplies or receive

information about other products by Ithaca Peripherals, contact the Sales Department.

You may reach both the Sales and Technical Support Departments at the following address and phone

or fax numbers:

Ithaca Peripherals

20 Bomax Drive

Ithaca, NY 14850

Page 12

Series 90PLUS Maintenance Manual

2

Main phone (607) 257-8901

Main fax (607) 257-8922

Sales fax (607) 257-3868

Technical support fax (607) 257-3911

Technical support E-mail techsupport@ithper.com

Web site http://www.ithper.com

WARRANTY INFORMATION

OPTIONS

All Ithaca Peripherals PcOS Series 90PLUS printers come with a standard 24-month warranty

covering both parts and labor. An optional warranty, covering both parts and labor for an additional 12

months, may be purchased separately.

For more information concerning the warranty options, please contact your dealer or the Sales

Department at Ithaca Peripherals. See “Contacting Ithaca Peripherals” on page 1.

ORDERING SUPPLIES

You may order supplies by calling Ithaca Peripherals or by faxing the order form that was shipped in the

box with the printer. If you would like more forms, call Ithaca Peripherals at (607) 257-8901, and ask for

the Sales Department. If you already have forms, fax the order to (607) 257-3868.

You may order the following supplies:

♦ Paper,

♦ Ribbon cassettes,

♦ Take-up spool,

♦ Print head and clamp, and

♦ Cables.

PAPER

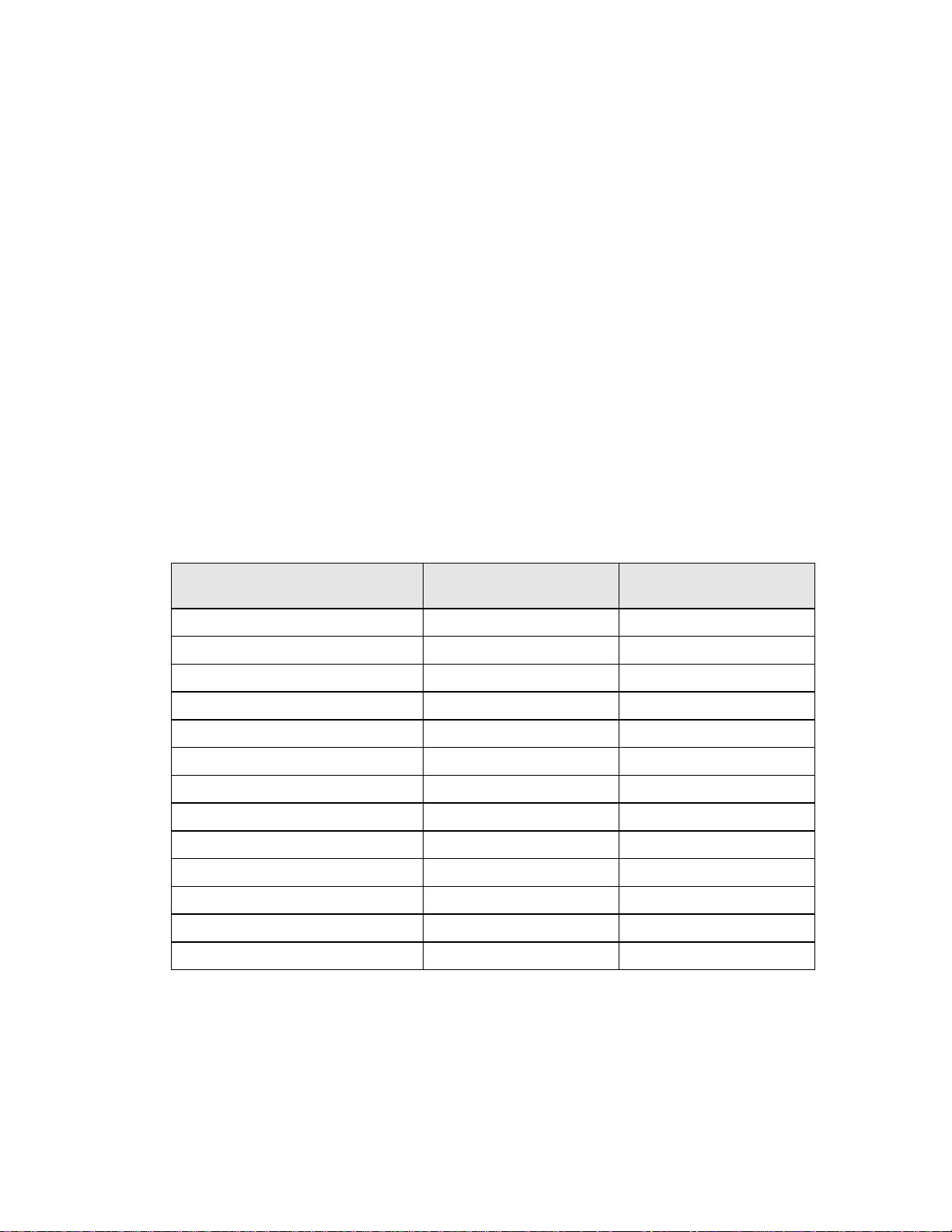

Paper Type Dimensions Stock Number

Receipt paper Single-ply 3.25 inches (width)

3.5 inches (diameter)

240 feet (length)

Receipt-journal

paper

Double-ply 3.25 inches (width)

3.5 inches (diameter)

125 feet (length)

100-2203

100-2206

Receipt-journal

paper

Triple-ply 3.25 inches (width)

3.5 inches (diameter)

85 feet (length)

100-2207

Page 13

Product Information

RIBBON CASSETTES

Color Supplier Stock Number

Black Ithaca Peripherals 100-7565

Purple Ithaca Peripherals 100-7859

Note: The warranty may be voided if other than genuine Ithaca Peripherals ribbons are used.

TAKE-UP SPOOL

Take-up Spool Stock Number

Journal take-up spool 90-6415

PRINT HEAD AND CLAMP

Print Head and Clamp Stock Number

3

Print head 90-7337

Print head clamp 06-0571

CABLES

Cables Stock Number

110V power cable 06-0561

230V power cable 06-0806

Parallel-communication cable 253-9800007

Serial-communication cable

PC, 9-pin female to 9-pin female

PC, 9-pin female to 25-pin female

10-2020

10-2021

Page 14

Series 90PLUS Maintenance Manual

4

DESCRIPTION OF THE SERIES 90PLUS PRINTER

The PcOS (personal computer, point-of-sale) Series 90PLUS printer is a stand-alone, 40-column, highspeed impact printer. The Series 90PLUS printer performs a variety of functions in a point-of-sale

environment and is available in the following models:

♦ Model 91PLUS: Receipt only

♦ Model 92PLUS: Receipt and Journal

♦ Model 93PLUS: Receipt, Journal, and Slip/Validation

♦ Model 94PLUS: Receipt and Slip/Validation

SERIES 90PLUS MODELS

Each of the four models in the Series 90PLUS line of printers has its own unique set of features.

PcOS Model 91PLUS Receipt Printer

The Model 91PLUS is a receipt printer used for applications requiring high-speed printing of

receipts and single-line validation.

♦ 300 characters per second bidirectional printing

♦ 42-column printing at 15 characters per inch

Page 15

Product Information

PcOS Model 92PLUS Receipt and Journal Printer

The Model 92PLUS is a receipt and journal printer used for applications requiring a transaction

audit trail (journal) in addition to high-speed printing of receipts and single-line validation.

♦ 300 characters per second bidirectional printing

♦ 42-column printing at 15 characters per inch

♦ Journal take-up

PcOS Model 93PLUS Receipt, Journal, and Slip/Validation Printer

The Model 93PLUS is a receipt, journal, and slip/validation printer used for applications

requiring up to 17 lines of print on inserted forms such as checks (in validation mode) or charge

slips, guest checks, or personal checks (in slip mode). In addition, it provides the same high-speed

journal and receipt printing as the Model 92PLUS.

♦ 300 characters per second bidirectional printing

♦ 42-column printing at 15 characters per inch

♦ Journal take-up

♦ Form insertion sensor

♦ 17-line validation

♦ Front slip insertion

5

PcOS Model 94PLUS Receipt and Slip/Validation Printer

The Model 94PLUS is a receipt and slip/validation printer used for applications requiring up to

17 lines of print on inserted forms such as checks (in validation mode) or charge slips, guest

checks, or personal checks (in slip mode). It does not include the journal take-up assembly.

♦ 300 characters per second bidirectional printing

♦ 42-column printing at 15 characters per inch

♦ Form insertion sensor

♦ 17-line validation

♦ Front slip insertion

Page 16

Series 90PLUS Maintenance Manual

6

STANDARD FEATURES

The following features and items are standard on all Series 90PLUS printers:

♦ Centronics parallel interface with 2K buffer

♦ Internal international power supply (95 to 265 VAC)

♦ Operating controls and lights

Power ON/OFF switch and indicator

Paper feed button

Forms release button

Resume button

Alarm and form LED’s

♦ Paper-low sensor

♦ Operator controlled self-test

♦ Cash drawer connector (RJ12) and driver (24V, 1.5 amp pulse for approximately 150 ms;

drawer open/closed status reporting)

♦ Nine-pin stored energy print head

♦ Short line-seeking logic

♦ Characters and graphics

Lowercase characters with descenders

300 characters per second bidirectional printing

42-column printing at 15 characters per inch

Emphasized and enhanced print

IBM compatible all-points-addressable (APA) graphics

♦ Software controlled vertical spacing

♦ Snap-on ribbon cassette

♦ Steel receipt tear-off bar

OPTIONAL FEATURES

The optional features either replace a standard feature or enhance the operation of the printer. All

optional features are installed at the factory and must be selected when the printer is ordered.

♦ RS-232C serial communication interface

♦ RS-422 serial communication interface

♦ Journal cover lock

♦ Custom colors and logo

Page 17

Product Information

TECHNICAL SPECIFICATIONS

PRINTING SPECIFICATIONS

♦ Printing method impact dot matrix

♦ Head wire arrangement 9 pins in line

♦ Print wire diameter 0.012 inch (0.34 mm)

♦ Print wire pitch 0.013 inch (0.35 mm)

♦ Print directions bidirectional, logic-seeking

♦ Print zone 2.80 inches (71.12 mm)

PRINT CHARACTERISTICS

The Series 90PLUS printer prints characters in a variety of pitches as shown in the following table.

Each pitch can also be printed in a variety of styles affecting the appearance of the characters and the

speed of the printer.

7

For information about programming the printer to print a particular pitch or style, please refer to the

Programmer’s Guide. You can order the Programmer’s Guide from Ithaca Peripherals. See

“Contacting Ithaca Peripherals” on page 1.

Pitch (in characters per inch) Maximum Characters per

Line

8 22 250

10 28 270

12 32 300

15 42 300

17.1 (condensed) 48 300

20 (super-condensed) 56 300

24 (super-condensed) 66 300

4 (double-wide) 11 150

6 (double-wide) 16 150

7.5 (double-wide) 21 150

8.5 (condensed, double-wide) 24 150

10 (condensed, double-wide) 28 150

Characters per Second

12 (super-condensed, double-wide) 33 150

Page 18

Series 90PLUS Maintenance Manual

8

RELIABILITY

♦ Mean time between failure 30,000 hours (Model 91PLUS)

(except print head)

♦ Print head life 200 million characters

♦ Mean time to repair 15 minutes

DIMENSIONS

♦ Width 7.30 inches (185.42 mm)

♦ Length 12.25 inches (311.15 mm)

♦ Height 6.00 inches (152.40 mm)

WEIGHT

♦ Approximate weight 10 pounds

♦ Approximate shipping weight 13 pounds

POWER REQUIREMENTS

The Model 90PLUS printer is designed to b e AC self-powered in domestic and international markets.

The printer is equipped with a universal, input power supply that is designed to operate worldwide

without modification.

Supply

Voltage

Rating (VAC)

100 - 240 90 - 264 47 - 63 45 0.08 @ 120VAC

Supply

Voltage

Range (VAC)

Frequency

(Hz)

Rated Power

(watts)

Current Idle

(amps)

0.04 @ 240VAC

Current

Printing (amps)

0.9 @ 120VAC

0.4 @ 240VAC

ENVIRONMENTAL CONDITIONS

The printer will run its best when stored and operated in an environment that meets the following

temperature and humidity conditions:

♦ Operating temperature 0° to 50°C (32° to 122°F)

♦ Storage temperature -10° to +60°C (-14° to +140°F)

♦ Operating relative humidity 10% to 90% (noncondensing)

♦ Storage relative humidity 5% to 90%

Page 19

Product Information

COMMUNICATION INTERFACES AND CASH

DRAWER CONNECTORS

SERIAL CABLE

Cable Requirements

The PcOS Series 90PLUS printer requires an RS-232C shielded cable, no more than 50 feet long.

The cable must be UL and CSA approved.

RS-232C Communication

The RS-232C interface uses the following protocol and communication characteristics:

♦ Up to 19.2K baud

♦ Up to 6K buffer

♦ Ready/Busy or XON/XOFF protocol

♦ Communications diagnost i c mode

9

Pin Assignments for 9-pin Printer Connector

Pin Name Description

1 DCD Data carrier detect

2 RX Receive data

3 TX Transmit data

4 DTR Data terminal ready

5 GND Signal ground

6 DSR Data set ready

7 RTS Request to send

8 CTS Clear to send

9 SSD Secondary data

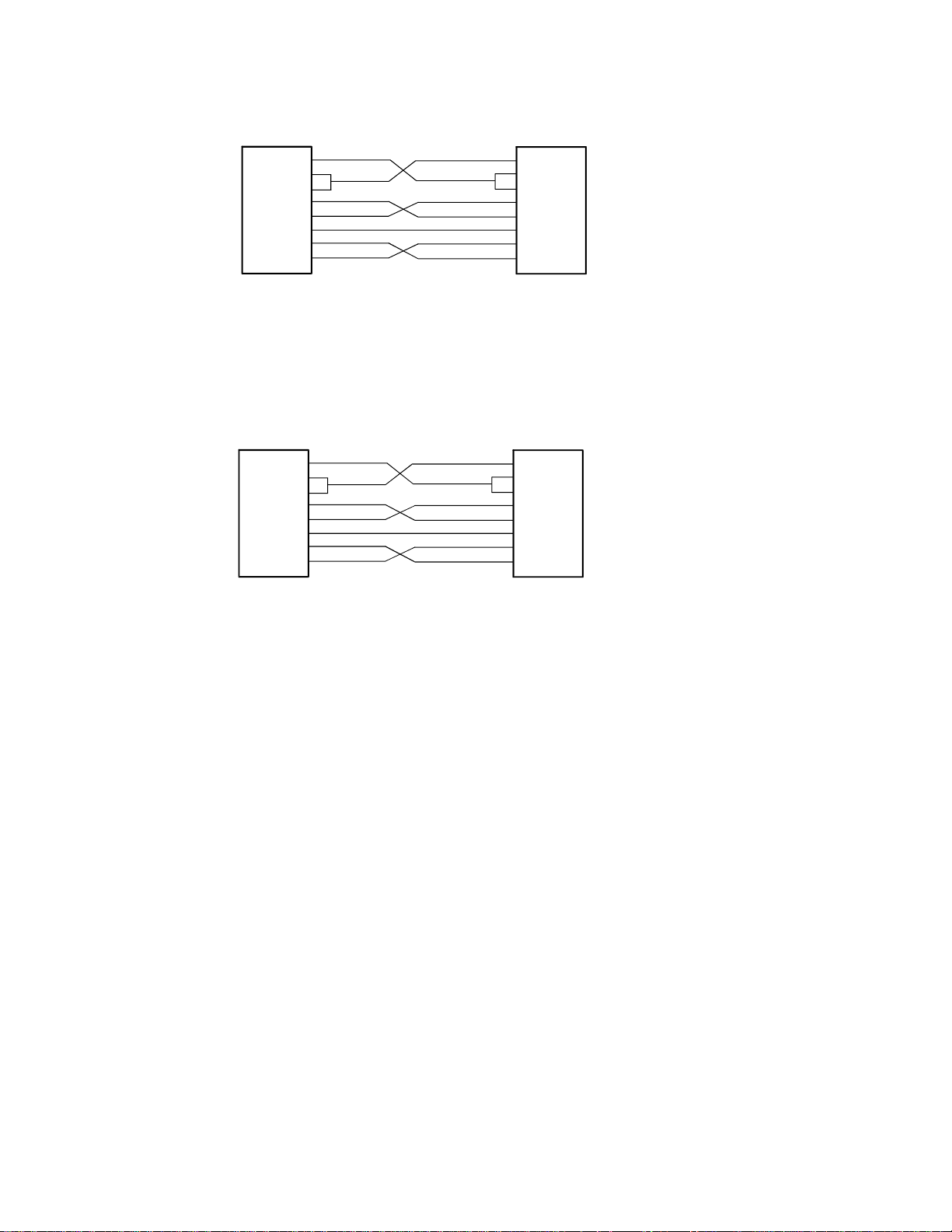

Serial Cable Configurations

The following cable configurations are for different host requirements.

Serial PC to Series 90PLUS (null modem)

Use the Ithaca Peripherals cable, part number 10-2020, for PcOS Series 90PLUS printers

connected to PC’s or PS/2’s with 9-pin serial ports.

Page 20

Series 90PLUS Maintenance Manual

10

Nine-pin

Female

PC

DTR

DSR

DCD

TXD

RXD

GND

RTS

CTS

PN 10-2020

4

6

1

3

2

5

7

8

Nine-pin

Female

Printer

DTR

DSR

DCD

TXD

RXD

GND

RTS

CTS

4

6

1

3

2

5

7

8

Serial AT to Series 90PLUS (Null Modem)

Use the Ithaca Peripherals cable, part number 10-2021, for PcOS Series 90PLUS printers

connected to PC’s or PS/2’s with 25-pin serial ports.

Twenty-five-pin

Female

PC

DTR

20

DSR

6

DCD

8

TXD

2

RXD

3

GND

7

4

RTS

5

CTS

PN 10-2021

Nine-pin

Female

Printer

DTR

DSR

DCD

TXD

RXD

GND

RTS

CTS

4

6

1

3

2

5

7

8

PARALLEL CABLE

Cable Requirements

The PcOS Series 90PLUS printer requires a 25-pin male D-shell connector at the printer. To

connect the printer to most PC’s, use Ithaca Peripherals part number 253-9800007, 25-pin male to

25-pin male parallel interconnect cable.

Page 21

Product Information

Pin Assignments

Pin(s) Signal Description Direction

1 STROBE Clock data to printer Host to printer

2 through 9 D0 - D7 Data Host to printer

10 ACK\ Printer accepted data Printer to host

11 BUSY Printer is busy Printer to host

12 PE Paper out/status Printer to host

13 SLCT Printer selected Printer to host

14 AUTOFD Autofeed paper Host to printer

15 ERR\ Printer error Printer to host

16 INIT\ Initialize the printer Host to printer

17 SLIN Select printer Host to printer

18 through 25 GND Ground

11

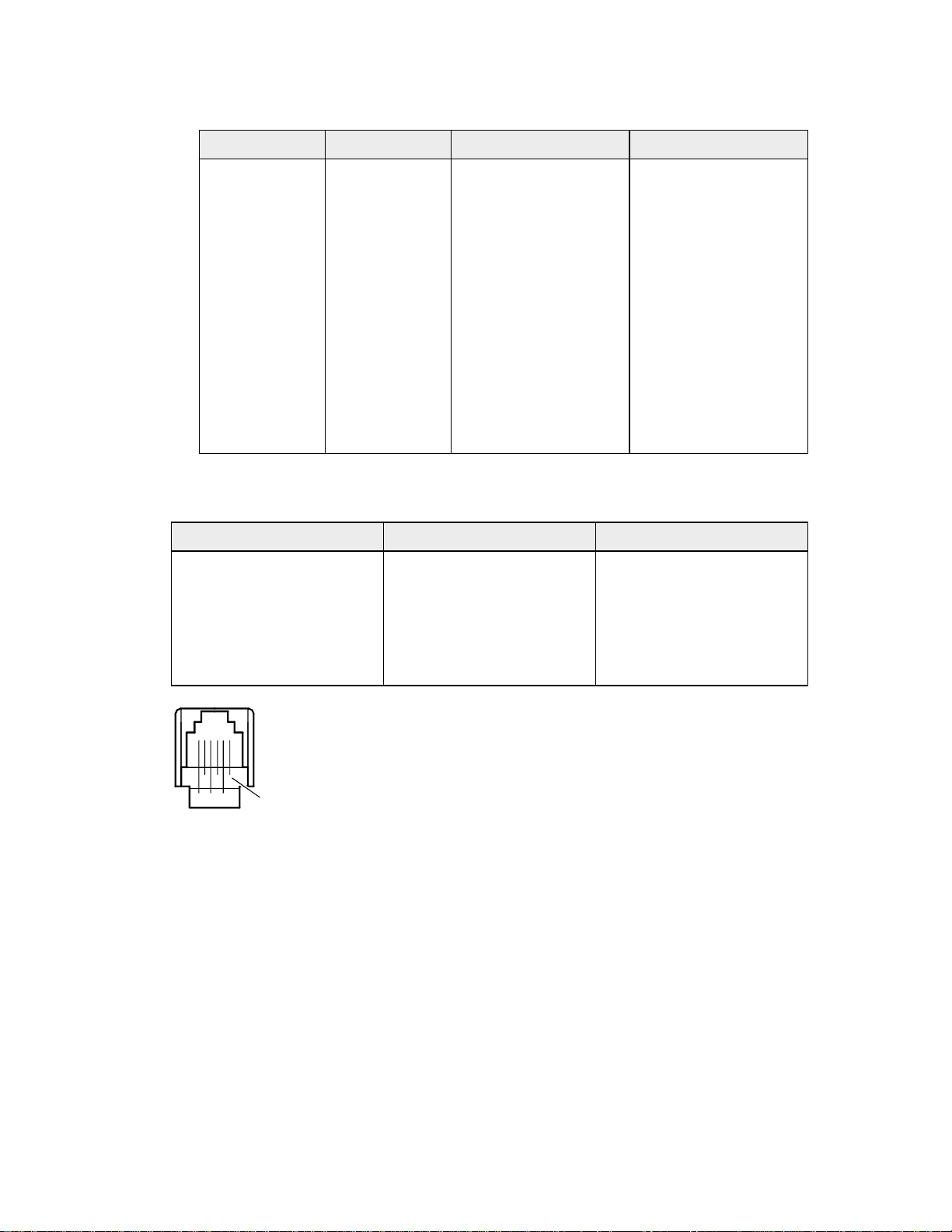

CASH DRAWER PIN ASSIGNMENTS

Function Drawer 1 Drawer 2

Drawer Drive + Pin 4 Pin 4

Drawer Drive - Pin 5 Pin 1

Status Signal Pin 2 Pin 2

Status Ground Pin 3 Pin 3

Frame Ground Pin 6 Pin 6

Pin 1

Page 22

Series 90PLUS Maintenance Manual

12

Page 23

CLEANING AND

ADJUSTMENTS

CLEANING THE PRINTER

Remove paper dust periodically by using a vacuum cleaner or air compressor.

Caution: Do not use alcohol or petroleum-based chemicals to clean the printer as these will damage

the plastic parts. The carriage rack is particularly sensitive and will be permanently damaged if

exposed to these chemicals. Take special care not to get the cleaner on any electronic components.

Cleaning and Adjustments

13

None of the internal parts of the printer require lubrication or routine maintenance. Apply a common

cleaner such as fantastik

keypad.

®

or Formula 409® to a damp cloth and gently wipe the surface of the printer and

MAKING ADJUSTMENTS

The adjustments described in this section are required only to correct print head drag or print quality flaws.

If the print density on a print sample is consistent from top to bottom and the print head does not drag, no

adjustment is necessary. If the print head drags, adjust the platen gap for the thickness of paper being used.

If the print sample is inconsistent, adjust the print head parallelism.

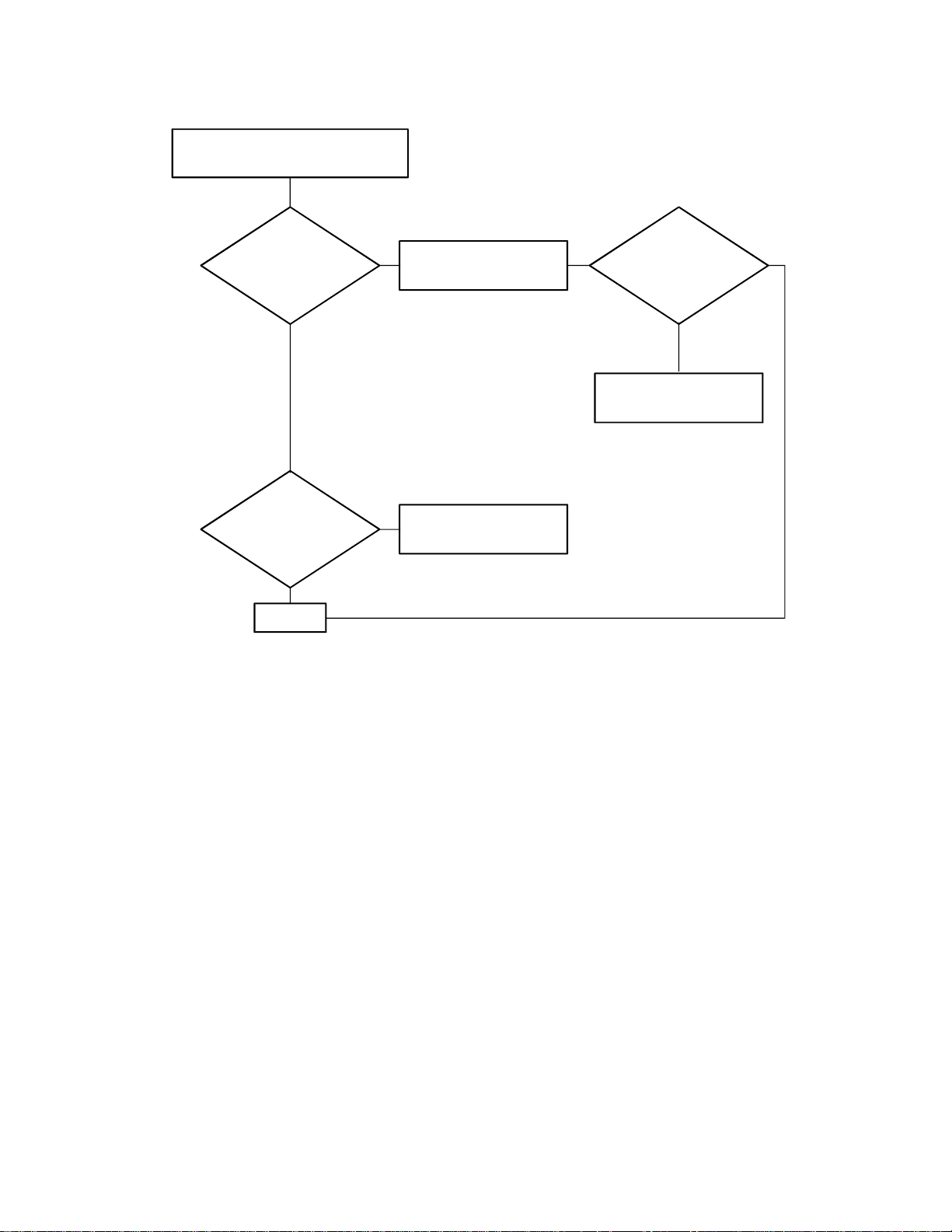

DIAGNOSING THE PRINT QUALITY

Use the flowchart on the following page to determine which procedure to use to correct a specific print

problem.

Page 24

Series 90PLUS Maintenance Manual

14

Print Quality Diagnosis.

Examine print sample.

Prints

too

light?

No

Prints on

either top or bottom, but

not both?

No

End

Yes

Replace ribbon.

Check parallelism.

Still

light?

Yes

Check platen gap.

NoYes

Note: For additional print problems not covered in this flow chart, refer to the troubleshooting chart

on page 55.

NECESSARY TOOLS

The following list provides the tools needed to adjust the platen gap.

♦ #1 Phillips screwdriver

♦ Thickness gauge: 0.016 inch (0.406 mm)

♦ Paper clip

Caution: Using the wrong tools may cause personal injury or printer damage. Be sure to use the

proper tools when maintaining or servicing the Series 90PLUS printer.

Page 25

Cleaning and Adjustments

15

ADJUSTING THE PLATEN GAP

Blue

Lever

The gap between the print head and the platen can be adjusted to accommodate the thickness of

different paper. If the gap is not set properly, the characters may smudge, the print head may jam, and

the density of the characters may be less than ideal.

Adjust the print head gap by moving the blue lever, located to the left of the ribbon cassette, to one of

three positions.

Set the gap to one of the following:

♦ Position 1 One-ply paper

♦ Position 2 Two-ply paper

♦ Position 3 Three-ply paper

Page 26

Series 90PLUS Maintenance Manual

16

ADJUSTING THE PLATEN PARALLEL TO TH E PRINT HEAD

1

3

4

5

6

2

1. Turn off the printer.

2. Remove all paper from the printer.

3. Remove the ribbon cassette (1).

4. Set the range adjustment lever (2) to position 1 (towards the rear of the printer). The range

adjustment lever (2) is the blue lever on the print head (4).

5. Sight along the length of the platen (3) from the side of the printer to observe the parallelism

of the air gap between the platen (3) and the print head (4).

6. Press down on the outer ring of the adjusting gear (6) with the straightened end of a paper

clip, and turn the adjusting screw (5) with a #1 Phillips screwdriver until the gap measures

0.016 ± 0.003 inch (0.406 ± 0.0762 mm).

Page 27

Assembly and Disassembly

ASSEMBLY/DISASSEMBLY

PRECAUTIONS FOR DISASSEMBLY

Before disassembling any part of the printer, be sure the power is turned off. Disconnect the AC power

cord, the communication cable, and the cash drawer cables.

Caution: The controller board and PC board keypad can easily be damaged by static electricity.

Observe ESD precautions. Wear a grounded wrist strap, and use a static mat or other protected work

surface. Do not place the printed circuit boards directly on the printer or floor.

NECESSARY TOOLS

The following list provides the necessary tools for properly maintaining the Series 90PLUS printer.

♦ Screwdrivers

#0 Phillips

#1 Phillips

#2 Phillips

Small flat blade

Large flat blade

♦ Nut driver

3 mm

♦ Miscellaneous

Thickness gauge: 0.016 inch (0.406 mm)

Hobby knife

Small needle-nose pliers

17

Caution: Using the wrong tools may cause personal injury or printer damage. Be sure to use the

proper tools when maintaining or servicing the printer.

Page 28

Series 90PLUS Maintenance Manual

18

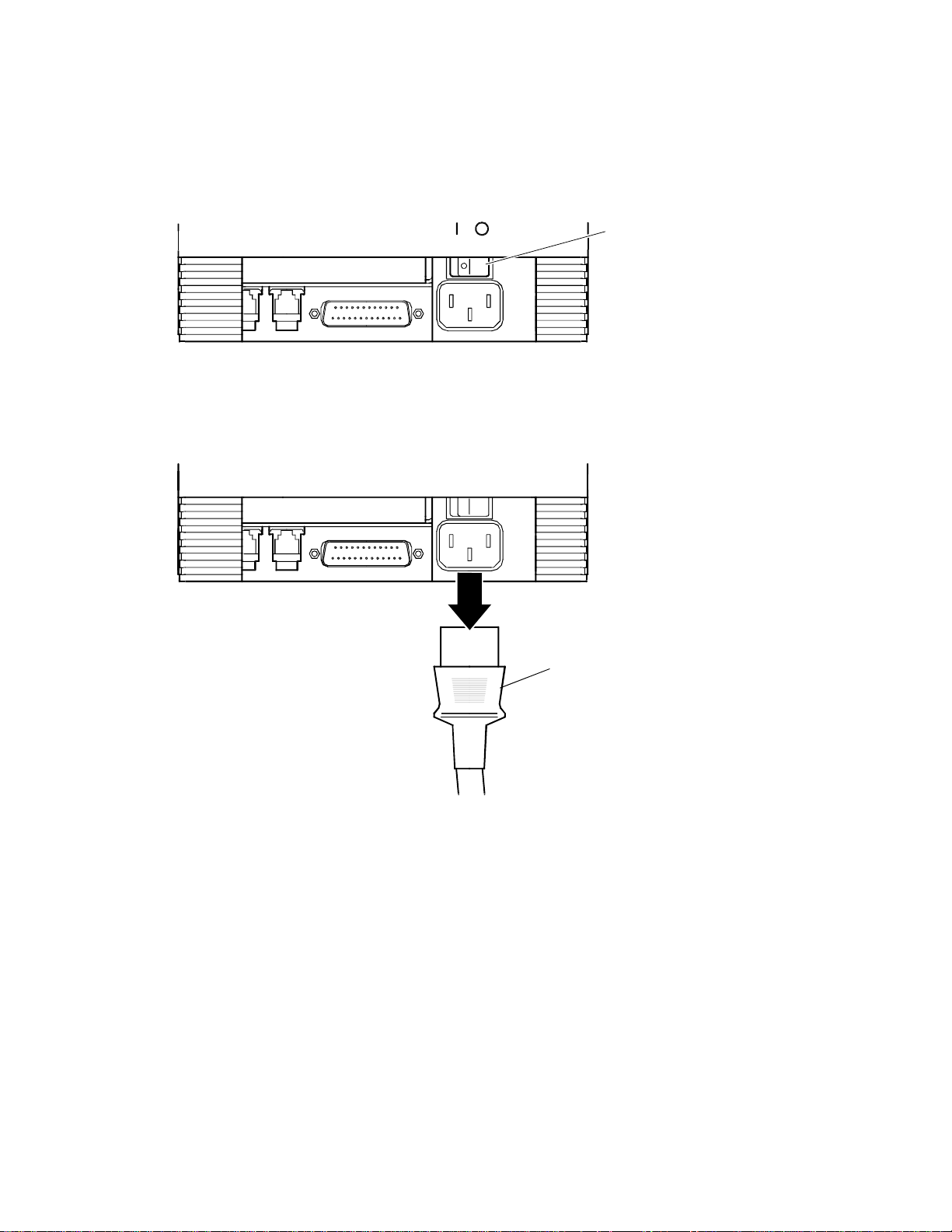

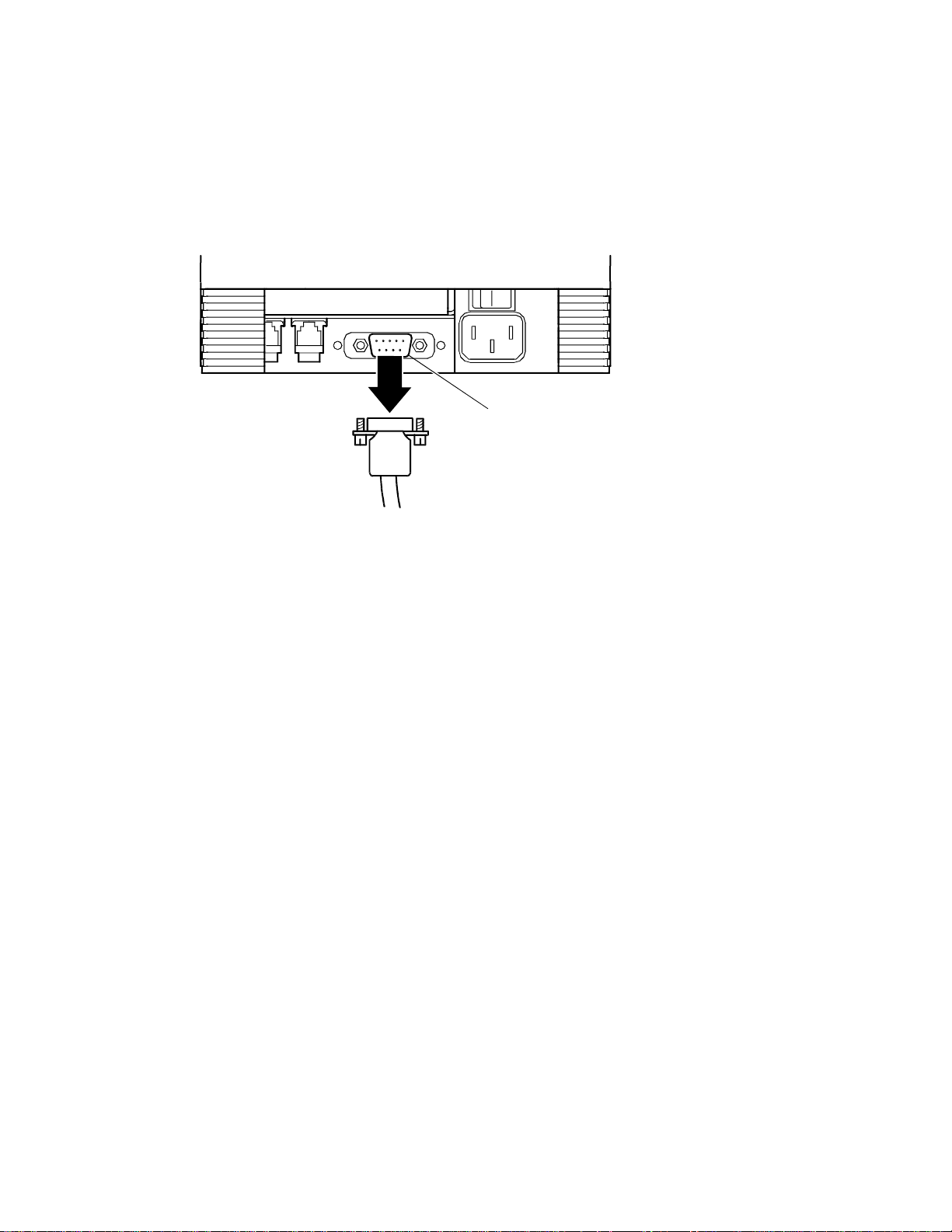

DISCONNECTING THE POWER CORD

Caution: The printer must be grounded through the three-prong power connector. Do not use a

ground-defeating adapte r.

On Off

Backof

Prin ter

1. Be sure the power switch is turned off.

Power

Switch

Back of

Printer

Power

Cord

Disconnect the external AC power source and the power cord from the power socket located on

2.

the back of the printer.

Page 29

Assembly and Disassembly

19

DISCONNECTING THE COMMUNICATION CABLE

Depending on the interface your system uses, either disconnect the serial or parallel communication cable

from the appropriate connector on the back of the printer.

DISCONNECTING THE SERIAL CABLE

Back of

Printer

9-pin Serial

Interface Connector

1. Turn off the printer and the host system or PC.

2. Loosen the two mounting screws on each side of the cable connector.

3. Disconnect the 9-pin serial interface cable from the connector located on the back of the

printer.

Refer to “Communication Interfaces and Cash Drawer Connectors” on page 9 for

information on the serial cable requirements.

Page 30

Series 90PLUS Maintenance Manual

20

DISCONNECTING THE PARALLEL CABLE

Back of

Printer

1. Turn off the printer and the host system or PC.

25-pin Parallel

Interface Connector

2. Loosen the two mounting screws on each side of the cable connector.

3. Disconnect the 25-pin parallel interface cable from the connector located on the back of the

printer.

Refer to “Communication Interfaces and Cash Drawer Connectors” on page 9 for

information on the parallel cable requirements.

DISCONNECTING THE CASH DRAWER CABLES

Cash Drawer

Connector 2

Backof

Printer

Cash Drawer

Connector 1

1. Turn off the printer.

2. Disconnect the cash drawer cables from the connectors located on the back of the printer.

Adapters are available for connecting cash drawers equipped with BNC-style connectors. (A

modular, telephone-style connector is standard). If you need an adapter, contact the Technical

Support Department at Ithaca Peripherals. See “Contacting Ithaca Peripherals” on page 1.

Page 31

Assembly and Disassembly

21

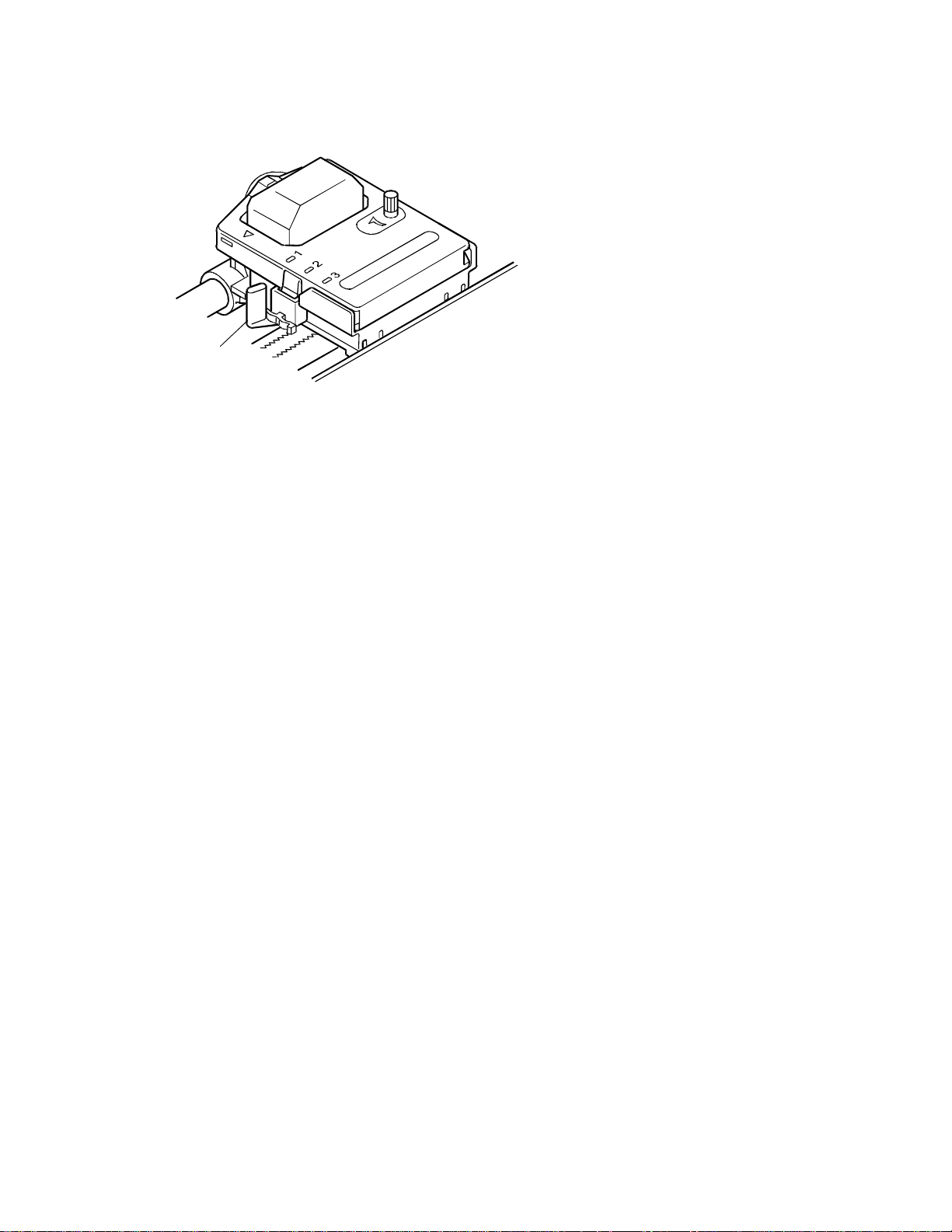

REMOVING THE RIBBON CASSETTE

Grasp both sides of the cassette. Lift and rock the cassette towards you. Do not pull the cassette straight up.

INSTALLING THE RIBBON CASSETTE

Cassette

Print head

Tabs

Carriage

Groove

1. Holding the ribbon cassette with the Mylar guide facing away from you, insert the front of the

cassette into the carriage.

Note: It is important to fit the front edge of the ribbon cassette into the carriage first. Do not place

the ribbon cassette flat on the carriage.

Print head

Tab

Ribbon

Cassette

Clamp

Carriage

Rock the ribbon cassette forward, toward the print head, and then press down on it until the

2.

tabs on the cassette snap into the clamps on the carriage.

Page 32

Series 90PLUS Maintenance Manual

22

Tighten the ribbon by turning the knob on the cassette clockwise.

3.

Close the cassette cover.

4.

Turn the printer back on (if already installed).

5.

Knob

Cassette

Page 33

PRINT HEAD

Replace the print head when the characters are consistently misprinting.

REMOVING THE USED PRINT HEAD

Caution: The print head can get very hot.

On Off

Backof

Print er

1. Turn off the printer, and allow the print head to cool for at least three minutes before

replacing it.

Assembly and Disassembly

Power

Switch

23

2. Open the cassette cover.

3. Remove the ribbon cassette.

Cassette

Cover

Page 34

Series 90PLUS Maintenance Manual

24

Note: In the following illustrations, the heat sink is not shown for clarity.

4. Open the print head clip by grasping the tab on the right side of the clip and rotating it from

right to left.

5. Lift the print head straight up out of the carriage.

Page 35

INSTALLING THE NEW PRINT HEAD

Note: In the following illustration, the heat sink is not shown for clarity.

Assembly and Disassembly

25

1. Slide the black wire guide on the back of the print head into the slot on the carriage. Make

sure the tabs on the wire guide hold the print head against the carriage.

2. Align the PC board on the bottom of the print head with the receptacle on the carriage.

3. Press the print head into the carriage. Do not force the PC board into the receptacle. Make

sure it is lined up properly.

4. Close the print head clip by rotating it from left to right and latching it into place.

5. Replace the ribbon cassette, and then close the cassette cover.

Page 36

Series 90PLUS Maintenance Manual

26

REMOVING THE COVERS

3

1

5

6

4

8

1. Unlock the optional journal lock (1) located on the right cover (2).

2. Open the paper cover (3) until it unsnaps from the base cabinet (6).

2

7

3. Remove the take-up spindle (4).

4. Remove the clip (5). Use needle-nose pliers to squeeze the open ends on the clip, and carefully

pull it out. Move the back corner of the right cover (2) to the right until the star stud clears the

tower on the base cabinet (6). Rotate the back corner up and to the front until it is free from the

base cabinet.

5. Open the cassette cover (7). Pull the hinge pin (8) out from the right, and remove the cassette

cover.

Page 37

10

Assembly and Disassembly

6

10

9

27

11

12

13

8

13

6. From the bottom of the mechanical/electrical base assembly (8), insert a flat blade screwdriver

through the holes in the front, and unlatch the tabs (13 ) holding the cabinet bezel (9) to the base

cabinet (6). Push on the left side of the cabinet bezel (9) to free the pin from the cabinet base.

7. Remove the four screws (10) holding the base cabinet (6) to the mechanical/electrical assembly

(8). Lift the back of the base cabinet up and slide forward.

8. Models 92PLUS and 93PLUS, disconnect the take-up harness (11) from the take-up extension

cable (12).

Page 38

Series 90PLUS Maintenance Manual

28

TAKE-UP MOTOR ASSEMBLY KIT

Models 92PLUS and 93PLUS

2

3

1

1. Remove the covers. See page 26.

2. Remove the E-ring (1) and slide off the arm (2) from the take-up motor assembly (3).

Page 39

Assembly and Disassembly

29

4

5

3

3. Remove the screw (4) holding the take-up assembly (3) to the base cabinet (5).

4. Release the take-up motor assembly (3) from the base cabinet (5). Move the bottom of

the take-up motor assembly to the right until it clears the tab on the back wall of the base

cabinet.

Page 40

Series 90PLUS Maintenance Manual

30

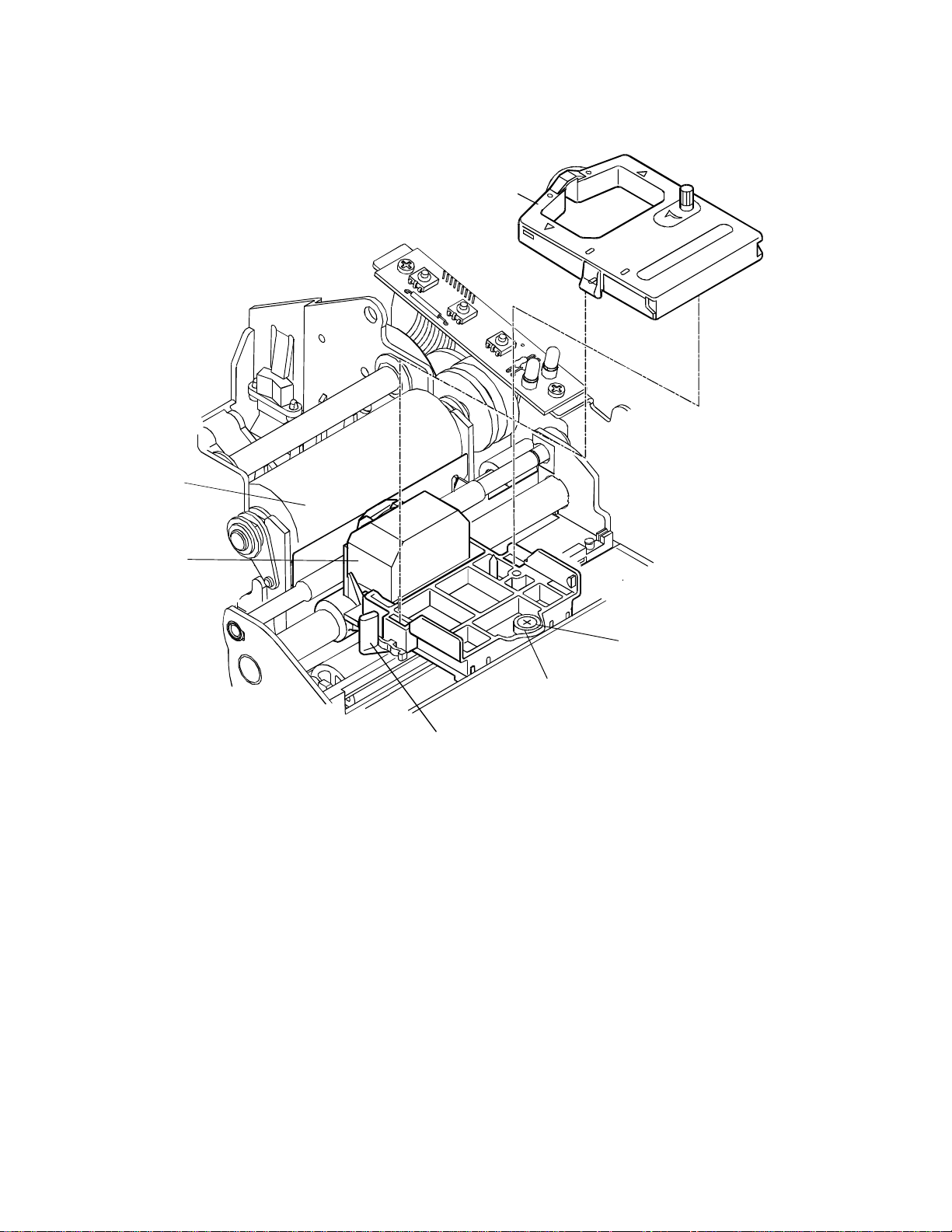

MECHANICAL BASE ASSEMBLY

9

2

10

11

4

1

1

6

8

1

1

7

9

5

3

Page 41

Assembly and Disassembly

31

1. Remove the covers. See page 26.

2. Remove the four screws (1), two in front and two in back, holding the mechanical base (2) to the

electronic base assembly (3).

3. Lift the mechanical base (2), and disconnect the following harnesses from the controller board

assembly (4): cam plate motor (6); head cable (5); slip-in sensor (7); paper-low sensor (8); takeup motor extension (9); keypad (10); and receipt line feed stepper-motor (11). Refer to the chart

below for connector locations on the controller board.

4. Remove the slip-in sensor harness (7) and paper-low sensor harness (8) from the tabs on the left

and back of the insulator.

5. Remove the receipt line feed stepper-motor harness (11) from the tab on the right side of the

insulator.

Type of Harness Controller Board Location

Head cable CN8

Cam plate motor CN7

Slip-in sensor CN9

Paper-low sensor CN15

Take-up motor extension

(Models 92PLUS and 93PLUS)

Keypad CN5

Receipt line feed stepper-motor CN3

CN4

Page 42

Series 90PLUS Maintenance Manual

32

KNIFE DISASSEMBLY

1

See Detail B.

5

17

14

6

15

16

4

3

12

7

10

20

8

9

See Detail B.

11

18

13

2

Page 43

Assembly and Disassembly

14

Assemble with curve

faci ng t he stud

shoulder as shown.

33

9

Stud shoulder

Detail B

Scale 2 = 1

19

Approximate location

of f er r ite bead.

Detail A

Bottom view

Connecting rod must be

assembled in this orientation.

Detail C

Caution: The knife blade is extremely sharp.

1. Turn the cutter assembly upside down, remove the screw (12), and pull out the knife guide (2). If

necessary unsnap and remove the tear-off (13).

2. Remove the screw (18) and the E-ring (11), and separate the knife plate assembly (3) from the

knife frame.

3. Remove the connecti ng rod (7) a nd the compound ge ar (17) fr om the knife pin ( 6). Remove t he

knife gear (5) and the knife pin from the knife frame.

4. Disconnect the knife motor connector (16) from the PCB assembly (15). Unthread the knife motor

harness from the wire retainer (19), and remove the knife motor.

5. Pull the PCB assembly out of the knife frame (1).

6. To remove the knife blade (4), unscrew the drive stud (9). This will also release the Teflon film

(10), spring washer (14), knife slider (8), and shear blade (20).

Installation notes

1. Position the ferrite bead on the knife motor harness as shown in Detail A.

2. Refer to Detail C for the correct orientation of the connecting rod. Lubricate the four points on the

knife frame with Teflon Anti-Seize Lube.

3. Install the spring washer with the curve facing the stud shoulder as shown in Detail B.

4. The slider must be replaced if disassembled. The stud must be retorqued to 4.5 ± 1 in. lbs. and

then loosened one-quarter turn.

Page 44

Series 90PLUS Maintenance Manual

34

25-PIN PARALLEL INTERFACE CABLE

3

1

4

2

1. Remove the mechanical base assembly. See page 30.

2. Disconnect the 25-pin parallel interface cable (1) from the connector, CN13, on the controller

board (2).

3. Unscrew the two jack screws (3) holding the cable to the electronic base (4).

Page 45

9-PIN SERIAL INTERFACE CABLE

3

6

5

Assembly and Disassembly

4

7

7

35

1

2

1. Remove the mechanical base assembly. See page 30.

2. Disconnect the 9-pin serial interface cable (1) from the connector, CN14, on the controller board

(2).

3. Unscrew the two jack screws (3) holding the cable to the adapter plate (4).

4. Remove the adapter plate (4) from the electronic base (5) by unscrewing the two screws (6) from

the two nuts (7).

Page 46

Series 90PLUS Maintenance Manual

36

CASH DRAWER HARNESSES

1

3

4

2

1. Remove the mechanical base assembly. See page 30.

2. Disconnect Cash Drawer Harness #1 (1) from the connector, CN11, on the controller board (2).

3. Pull the harness up and out of the electronic base assembly (3).

4. Disconnect Cash Drawer Harness #2 (4) from the connector, CN12, on the controller board (2).

5. Pull the harness up and out of the electronic base assembly (3).

Page 47

POWER SUPPLY ASSEMBLY

1

2

Assembly and Disassembly

4

3

37

3

6

3

5

1. Remove the mechanical base assembly. See page 30.

2. Disconnect the DC power harness (1) from the connector, CN10, on the controller board (2).

3. Unscrew the three screws (3) holding the power supply (4) to the electronic base (5).

4. Depress and push t he power assembly standoff (6 ) through the side of the electronic base (5).

5. Lift the power supply assembly (4) up, and disconnect the power switch harness (7).

7

1

Page 48

Series 90PLUS Maintenance Manual

38

POWER SWITCH AND AC INLET ASSEMBLY

1

2

3

4

6

5

7

6

White

Black

Black

White

Green with

Reference Wire Orientation

Yellow Stripe

1. Remove the power supply. See page 37.

2. Unplug the AC inlet assembly wires (7) from the power switch assembly (1).

3. Remove the power switch assembly (1) by squeezing the tabs on the sides of the switch and

pushing it out of the electronic base (2).

4. Unscrew the nut (3) ho l ding the ground wire ( 4) to the stud (5) on the electronic base (2). Remove

the lock washer (6) from the stud.

5. Remove the AC inlet assembly (6) by squeezing the tabs on the top and bottom of the assembly.

Page 49

CONTROLLER BOARD ASSEMBLY

1

8

Assembly and Disassembly

39

5

2

3

8

8

7

1. Remove the mechanical base. See page 30.

4

6

2. Disconnect the DC power harness (1), left cash drawer harness (2), right cash drawer harness (3),

and the interface cable (4) from the connectors on the controller board (5). See the chart below for

locations on the controller board.

3. Remove the snap rivet (6) from the electronic base assembly (7). To remove the snap rivet, locate

it on the bottom of the electronic base, push the center pin up into the outer jacket, depress the

tabs on the oute r jacket, and push it through the e l ectronic ba se.

4. Remove the three screws (8) holding the controller board (5) to the electronic base assembly (7).

Type of Harness Controller Board Location

DC power CN10

Left cash drawer (Cash Draw Harness #1) CN11

Right cash drawer (Cash Draw Harness #2) CN12

Interface cable (25-pin parallel) CN13

Interface cable (9-pin serial) CN14

Page 50

Series 90PLUS Maintenance Manual

40

KEYPAD PC BOARD

1

1

2

4

5

2

4

3

1. Remove the mechanical base assembly. See page 30.

2. Remove the two screws (1) holding the keypad PC board (2) to the mechanical base assembly (3).

3. Lift the keypad PC board (2) from the mechanical base assembly (3), and disconnect the keypad

harness (4).

4. Cut the Ty-wrap (5) to remove the keypad harness (4).

Installation note

3

When replacing the Ty-wrap (5), the knot and trimmed end should be positioned towards the

inside of the base wall.

Page 51

CARRIER/CAM PLATE

Models 93PLUS and 94PLUS

7

8

Do not include

keypad harness in

Ty-wrap bundle.

Assembly and Disassembly

41

2

1

5

6

8

4

3

1. Remove the mechanical base assembly. See page 30.

2. Disassemble the cam sensor flag (1) from the carrier/cam assembly (2), located under the

mechanical base assembly (3). To remove, securely grab the narrow portion of the flag

and pull down. Tip the flag to the right and wiggle out to the left.

3. Remove the slip-stop sensor flag or bank validation flag (4) from the carrier/cam

assembly (2).

4. Remove the screw and pull off the magnet mounting bracket (6).

Page 52

Series 90PLUS Maintenance Manual

42

2

3

5. Release the lock tabs, and slide the carrier/cam assembly (2) backwards until it is

released from the mechanical base assembly (3).

6. Carefully pull the cables (7) out of the mechanical base assembly (3).

Installation note

1. To reinsert the cam sensor flag, wiggle in the flag on the left side. Lift up on the flag and

snap into place.

Page 53

Models 91PLUS and 92PLUS

Assembly and Disassembly

1

43

2

1. Remove the mechanical base. See page 30.

2. Release the lock tabs, and slide the carrier/cam assembly (1) backwards until it is

released from the base (2).

Page 54

Series 90PLUS Maintenance Manual

44

CAM PLATE

Models 93PLUS and 94PLUS

2

4

3

1

4

5

1. Remove the carrier/cam plate. See page 41.

2. Partially remove the pin (1) to the left until the motor shroud (2) is free from the cam

plate (5).

Caution: Do not pull the pin all the way out or the gear drive will not be

functional.

3. Separate the tabs and lift out the cam plate motor (3).

4. The cam lobes must face downward (toward the cam plate). Rock the carrier assembly

forward (4), and slide it backwards until is released from the cam plate (5).

Page 55

Assembly and Disassembly

45

7

6

1

5

8

5. Push back on the tab behind the cam shaft (6), and lift the cam shaft out of the cam plate

(5).

6. Slide the cam shaft gear (7) off the left end of the cam shaft (6).

7. Slide the pin (1) to the left, and remove the compound gear (8).

Page 56

Series 90PLUS Maintenance Manual

46

Models 91PLUS and 92PLUS

1. Remove the carrier/cam plate. See page 41.

2. Slide the carrier assembly (2) backward until it is released from the cam plate (1).

Page 57

CARRIER ASSEMBLY

Assembly and Disassembly

47

3

12

6

7

2

14

5

1

8

4

11

12

13

14

15

13

Shown

Removed

for Clarity

11

2

10

9

Ty Warp

.50 Approx.

Page 58

Series 90PLUS Maintenance Manual

48

1. Remove the cam plate. See page 44.

2. Unsnap the receipt roller (1) from the forms comp carrier (2).

3. Rotate the bearings (3 and 4) on each side of the platen assembly (5) forward until the platen

assembly can be lifted out.

4. Remove the left platen bearing (3) from the platen assembly (5).

5. Lift the pressure shaft (6) up, and slide it through the hole on t he right side of the forms comp

carrier (2).

6. Unsnap the spring plate (7) from the forms comp carrier (2).

7. Models 93PLUS and 94PLUS only. Unsnap the forms comp springs (8) from the forms comp

carrier (2).

8. Cut the Ty-wrap (9) securing the motor wires and sensor harnesses (11 and 14).

9. Unscrew the two screws (12) and two hex nuts (13) holding the line feed motor assembly (15) to

the forms comp carrier (2).

10. Unsnap the paper-low sensor (14) from the forms comp carrier (2) by pushing the tab to the right.

11. Models 93PLUS and 94PLUS only. Unsnap the forms-in sensor (11) assembly from the forms

comp carrier (2) and slide out.

Page 59

Assembly and Disassembly

REMOVING THE PRINT MECHANISM ASSEMBLY

49

3

See Installation Note.

5

1. Remove the carrier/cam plate. See page 41.

2. Remove the carriage shaft screw (1) from the right side of the base assembly (2).

2

1

4

3. Remove the screw (3) holding the print mechanism (5) to the base assembly (2).

4. Remove the screw (4) holding the carriage rail to the base assembly (2).

5. Remove the head cable tape from the bottom of the print mechanism frame.

6. Lift the print mechanism (5) o ut of the ba se assembly (2). Gently pull the he ad cabl e through the

slot.

Installation note

When installing the screw (3), torque to 5 ± 1 inch per pound.

Page 60

Series 90PLUS Maintenance Manual

50

PRINT MECHANISM ASSEMBLY

1. Remove the print mechanism assembly. See page 49.

2. Lift the left side of the carriage rail (15), and slide it out of the print mechanism frame (3).

3. Slide the carriage shaft (14) to the right, and pull out of the print mechanism frame (3) and carriage

assembly (16).

4. Remove the carriage assembly (16). Be careful when pulling the ribbon cable out of the frame.

5. Release the tab on the left side of the frame, and lift out the space rack (5).

6. Remove the idler gear (7) from the frame by squeezing the tabs together with pliers and pushing

the gear to the right.

7. Remove the two clips (13) from the validation shaft assembly (12), and slide the validation shaft

assembly right until it is free from the frame. Slide the feed-roll bearing (2) out of the frame.

8. Snap the slip-drive shaft (4) out of the actuator (9).

9. Remove the actuator (9) and idler gear (1) by removing the small pin (6) from the left side of the

frame and sliding the large pin (8) out of the frame and idler gear (1).

10. T urn the print mechanism assembly upside down to remove the shaft before releasing the actuator

from the frame. Flip right-side up, and gently slide the actuator out of the frame.

11. To remove the actuator bearings (10) and actuator compression springs (11) from the actuator (9),

turn the actuator over. Rotate the bearings 90°. They will easily pop out.

Page 61

CARRIAGE ASSEMBLY

Assembly and Disassembly

51

Cut Mylar

fro m c a b le

as shown.

1. Disassemble the print mechanism assembly. See page 50.

2. Remove the print head (2). See page 23.

3. Release the four tabs holding the ribbon feed gear assembly (3) to the carriage motor assembly

(6). Use caution not to separate the ribbon feed gear assembly parts.

4. Remove the print head connector (1).

5. Remove the head cable (5) and the rubber pressure contact (4) from the bottom of the ribbon feed

gear assembly (3).

Page 62

Series 90PLUS Maintenance Manual

52

CARRIAGE MOTOR

1. Disassemble the carriage assembly. See page 51.

2. To remove the print head clamp (5), gently pry the back of the clamp over the pin on the back of

the carriage roller (3).

3. Remove the front screw (4), and take off the slider (1).

4. Remove the back two screws (4) to separate the spacer motor assembly (2) from the carriage

roller (3).

Page 63

LINE FEED MOTOR

Assembly and Disassembly

4

53

3

2

Shown

removed for

clarity

1. Remove the print mechanism assembly. See page 49.

2. Remove the line feed motor ( 2) by prying off the Tinne rman clip (1) and r emoving the hex nut

holding the motor to the base assembly (4).

1

Page 64

Series 90PLUS Maintenance Manual

54

Page 65

Troubleshooting

55

TROUBLESHOOTING

This chapter provides solutions to problems that may occur with the printer. Use the table to determine the

problem, then refer to the specified flow chart that describes the corrective action for that problem.

Following the flow charts is a section that describes checking the connection circuits and resistance for the print

head, space motor, and line feed motor.

DETERMINING THE PROBLEM

When Problem

Occurs

Trouble at power on Switches or lights do not function on the keypad, and the

Trouble during data Spacing or printing does not occur. 5

reception or printing Spacing operates normally, but printer does not print. 6

Forms handling Receipt does not line feed. 11

Description of Problem Refer to Flow

chart

carriage does not move.

Carriage does not move, and the power LED is lit. 2

Carriage does not operate normally; runaway, vibration, or

incomplete homing occurs.

Carriage homes normally, but indicator display does not

operate normally.

Printer stops printing. 7

Wrong characters are printed or some characters are not

printed.

Some dots do not print. 9

Print is not dark enough. 10

Slip does not line feed. 12

Carrier assembly does not open or close. 13

1

3

4

8

Slip will not load from the front of the printer. 14

Top validation failure occurs. 15

Page 66

Series 90PLUS Maintenance Manual

56

1

Is AC cord

fully seated?

Yes

Is primary

wiring loose or

broken?

No

Is AC switch

damaged or

open?

No

Is secondary

wiring loose or

broken?

No

Yes

Yes

Yes

Reseat AC power

cord.

Repair/replace

primary wiring

harness.

Replace AC switch.

Repair/replace

secondary wiring

harness.

No

Replace power

supply.

Voltages n ow

present?

Yes

End

No

2

Page 67

2

When the po we r i s

turned on, the

carriage does not

move.

Troubleshooting

57

No

Yes

Do LED’s

illuminate?

Yes

Can the

carriage be moved

easily by

hand?

Yes

Is the

carriage cable

damaged or

unplugged?

No

Are +40V

present at

emitter of Q14?

No

Is fuse,

F2, on the

controller board

open?

No

Yes

Replace/

reseat the

carriage cable.

Yes

2-2

Remove the

ribbon cassette.

Can the

carriage be

moved easily by

hand?

No

Is

the space rack

okay?

Yes

Remove the ribbon

feed gear assembly.

Replace the ribbon

Yes

Replace the space

No

cassette.

rack.

No

Replace the

controller board.

Replace fuse.

Can

the carriage

be moved easily by

hand?

No

Replace space motor.

Replace the ribbon

Yes

feed gear assembly.

Page 68

Series 90PLUS Maintenance Manual

58

3

When power is turned on, carriage oper ation is

abnormal; runaway, vibration, or incomplete

homing occurs.

Runaway?

No

Vibration?

Yes

Are

phase A&B

being output to US pins

75, 76 on controller

board?

Yes

Replace controller

board.

Is printer

operation

normal?

No

Yes

No

Replace controller

board.

Proceed to

No

2-2.

Is

the ribbon

feed assembly

attached

correctly?

Yes

Is

the carriage

cable broken or

unplugged?

No

Yes

Reassemble.

Replace/reseat

carriage cable.

Yes

End

No

Replace space motor

assembly.

Page 69

4

When the power is turned on,

the homing operation is

normal, but the READY LED

is flashing.

Troubleshooting

59

Flashing

green?

Yes

Is the paper

cover closed?

Yes

Is the

magnet present

in the paper

cover?

Yes

Replace the

switch assembly.

No

No

Close the paper

cover.

Flashing

orange?

Yes

Is the paper

installed in the

printer?

Yes

Replace the paper-

low sensor.

No

Flashing red

indicates printer fault.

Refer to Table 2

Fault Indicators.

No

Install paper.

Page 70

Series 90PLUS Maintenance Manual

60

During data reception, neither carriage

movement nor printing occurs.

Verify that data is

being transmitted to

5

the printer.

No

Replace controller

board.

Can self -test be

performed?

Yes

Is interface

cable connected

correctly?

Yes

Is printer

interface

configured

correctly?

Yes

No

No

Reconnect interface

cable.

Run configuration

routines.

Replace the

controller board.

Page 71

6

During data reception

and printing, carriage

motion is normal but

nothing prints.

Replace print head.

6A

Troubleshooting

61

Is print

operation

normal?

Yes

End

No

Is the ribbon

feed assembly

attached

correctly?

Yes

Is carriage

cable broken?

No

Is the contact

pin of print head

connector

deformed?

No

Yes

Yes

Reassemble.

Replace carriage cable.

Replace the connector.

No

Replace controller

board.

Page 72

Series 90PLUS Maintenance Manual

62

7

During data reception and printing,

printing stops.

Are any

LED’s

flashing?

No

Is the interface

cable connected

securely?

Yes

Replace the print head.

Is printer

operation normal?

Yes

Yes

No

Refer to Table 1 LED

No

Replace controller

Indicators.

Reconnect the

interface cable.

board.

End

Page 73

8

Wrong c haract e r s are printed, or

some characters are not printed.

Troubleshooting

63

Is interface

cable connected

properly?

Yes

Does self-test

print normally?

Yes

Is printer

configured

correctly?

Yes

Replace controller

board.

No

No

No

Connect the cable

properly.

Replace controller

board.

Run configuration

utility.

Page 74

Series 90PLUS Maintenance Manual

64

9

Some dots are not

printed.

Is the ribbon

properly

seated?

Yes

Remove the

print head.

No

Seat the ribbon.

Are any pins

broken or

misaligned?

No

Check resistance of

the print head coil.

Is resistance

approximately

20 ohms?

Yes

Proceed to

6A.

No

Yes

Replace the

print head.

Page 75

10

Print is not dark

enough.

Troubleshooting

65

Is the ribbbon

feed operating

properly?

Yes

Is ribbon wear

excessive?

No

Is head gap

set correctly?

Yes

Are power

supply

voltages

correct?

No No

Yes

No

No

Replace ribbon

cassette.

Replace ribbon

cassette.

Adjust head gap.

Replace power

supply.

Is operation

normal?

Yes

Replace ribbon feed

END

gear assembly.

Yes

Replace printhead.

Is p rinter

operation

normal?

Yes

END

No

Replace controller

board.

Page 76

Series 90PLUS Maintenance Manual

66

11

Receipt feed is not

performed.

Is paper

installed

properly?

Yes

Is receipt feed

step motor

plugged in?

Yes

Check resistance of

step motor windings.

Is resistance 6.8

ohms?

Yes

No

No

No

Install paper correctly.

Reconnect motor t o

controller board.

Replace receipt feed

step motor.

Bind in paper

feed gear

train?

No

Is fuse, F1, on

the controller

board open?

Yes

Replace fuse.

Yes

No

Correct bind

condition.

Replace controller

board.

Page 77

12

y

Slip feed is not

performed.

Troubleshooting

67

Is carrier

assembly

closed?

Yes

Do step motor

pins contact

controller

board?

Yes

Check resistance of

step motor windings.

Is resistance 70

ohms?

Yes

12A

No

No

No

Depress RELEASE

button.

Correct bent pins and

reinstall controll er

board.

Replace slip-feed st ep

motor.

Does carrier

assembl

close?

No

Proceed to

13.

Correct

operation?

Yes

No

Bind in paper

feed gear train?

No

Replace controller

board.

Yes

Correct bind condition.

Yes

End

12A

Page 78

Series 90PLUS Maintenance Manual

68

13

Carrier will not

open/close properly.

Does

carrier move when

RELEASE button is

depressed?

No

Check for 12V at

terminals of cam

plate motor when

RELEASE button is

depressed.

Yes

sensor flag

properly

installed?

Yes

Replace controller

board.

I

s

No

Correctly

install flag.

Voltage

present?

No

Motor

connections

okay?

Yes

Replace controller

board.

No

Yes

Repair motor

harness.

Unplug motor

from controller

board, and check

terminal

resistance.

Is

resistance 12

1 ohm?

±

No

Replace motor.

Yes

Check assembly for

mechanical bind

condition.

Page 79

Troubleshooting

69

14

Slip will not load from

the front of the printer.

Does

carrier assembly

open and close

properly?

Yes

Does slip

stepper motor activate

when slip is

inserted?

Yes

Yes

Is slip fed into

printer?

No

Check slip-drive shaft for

bind condition.

No

Proceed to

No

Check slip-drive

step motor.

Are

the slip-sensor

flag and spring

positioned

properly?

Yes

13.

No

Readjust sensor flag.

Check TOF sensor.

Is the

TOF sensor

okay?

Yes

Replace controller

board.

Replace controller

board.

No

Replace TOF sensor.

Page 80

Series 90PLUS Maintenance Manual

70

15

Carrier does not

operate correctly.

Does

carrier assembly

open and close

properly?

Yes

No

Proceed to

13.

Does carrier

close when form

is inserted?

No

Are

sensor flag and

spring positioned

properly?

Yes

Replace controller

board.

No

Readjust sensor flag.

Page 81

Troubleshooting

71

LED INDICATORS

There are two indicators. One is READY and the other is STATUS (Form). The READY indicator is

tricolored: red, green, or orange.

The printer can be in any of the following states.

STATE READY

Indicator

1. Ready

The printer is ready to receive data and print.

2. Printer not ready

Cover is open.

3. Ready but waiting for a form Orange (status)

Request slip form Slow flash

Request validation form Fast flash

Request form be removed Medium flash

4. Ready, but low on receipt paper Flashing orange/green OFF

5. Printer errors

Out of paper Flashing orange OFF

Slip-load failed Slow flash

Printer fault (See page 72.) Flashing red OFF

6. Menu mode Flashing orange/green/red OFF

7. Test mode Flashing red/orange OFF

8. Printer failure Orange OFF

Green OFF

Flashing green OFF

FORM

Indicator

9. Watchdog fault (printer resets)

Table 1 LED Indicators

Page 82

Series 90PLUS Maintenance Manual

72

PRINTER FAULT INDICATORS

If the printer indicates printer fault, the error is not recoverable. The printer must be restarted and may lose

information. To aid in printer troubleshooting, the RESUME key will activate an extended diagnostic

indication. This key will blink the status indicator a number of times. The number of blinks indicates the

fault.

The printer fault errors are as follows.

Faults during operation

1 Motor move time out

2 Motor move retry fault

3 Motor move fault (moved in wrong direction)

4 Space motor locked

5 Motor homing fault

6 Motor acceleration fault

7 Printing fault

8 Fault while centering

9 Forms compensation fault

Faults during Level 0 diagnostics

10 ROM check-sum failure

11 RAM failure

12 Configuration EEPROM failure

13 Processor test fault

14 EEPROM check-sum failure

Faults that can happen anytime

15 Firmware control fault (loss of program control)

Table 2 Fault indicators

After the fault code is displayed, restart the printer by pressing the RESUME and RELEASE keys

simultaneously.

If the EEPROM check-sum fault occurs (Fault Code 14), the EEPROM can be set to defaults by pressing

the RESUME and LF keys simultaneously. The printer will be functional but must be reconfigured. This

procedure is only to allow reconfiguration and not to recover printer function in the field.

If the indication is pri nte r fail ure , t he p r int co ntr o lle r is no t r unning a nd is b ei ng hel d in r ese t. If thi s fa ilur e

occurs, the printer is not functional and should be serviced.

If the printer appe ars to go through a po wer cycle by itself, the hard ware watchdog has detected a fault.

This fault is generally a hardware failure or an external interference. If the fault is a hardware failure, the

printer will continue to cycle through its diagnostics and then reset. If this happ ens, the printer must be

serviced. If the fault is caused by external interference like electrostatic discharge (ESD), the printer will

generally recover. (Note: The parallel-port INIT pin causes a soft reset.)

Page 83

CN10

CN4

CN12

CN11

CN14

CN13

CN5

CN3

Troubleshooting

73

CN7

CN15

CN9

CN8

Note: This illustration is referenced by the letters in the troubleshooting flow charts and in the

illustrations on the following three pages.

Page 84

Series 90PLUS Maintenance Manual

74

CHECKING CONNECTIONS AND RESISTANCE

PRINT HEAD

The following illustration shows the connection circuit for the print head. To check the circuit of Wire

#1 on the print head, use Pin 5, 6, or 7 and measure with a meter to Pin 14 at Location A. The

resistance should read approximately 20 ohms.

Pins at Connection Signals Pins on

Print head

Common

Wire #1

Wire #2

Wire #3

Wire #4

Wire #5

Wire #6

Wire #7

Wire #8

Wire #9

5, 6, 7

14

13

1

12

2

11

1

10

4

Rear of Print head

Page 85

Troubleshooting

75

SPACE MOTOR ASSEMBLY

The following illustration shows the connection circuit for the space motor assembly and the pins on

the space motor. The resistance should be approximately 21 ohms between pads 17 and 16, 16 and 18,

and 17 and 18 on the space motor.

Pins at Connection Signals Pins on Space Motor

V

U

W

A

B

15

14

16

LINE FEED MOTOR (SLIP)

The following illustration shows the connection circuit for the line feed motor. The resistance of each

coil should be approximately 70 ohms between pads 38 and 39, 39 and 40, 37 and 36, and 36 and 35

on the line feed motor.

Pins at Connection Signals Pins on Line Feed Motor

Phase 1

3

Common

Phase 3

Phase 2

Common

Phase 4

2

1

4

5

6

Page 86

Series 90PLUS Maintenance Manual

76

LINE FEED MOTOR (RECEIPT)