Page 1

P OS

c

SERIES 90PLUS

Receipt/Validation/Journal Printers

PROGRAMMER'S

GUIDE

Rev M

PN: 100-7586

Page 2

Page 3

Programmer's Guide PcOS Series 90PLUS Change History

Change History

Rev. M

Updated bookmarks in the Code Summary Table

Added Section 3.6.2.2 and Table 4

Updated MICR section

Added Euro Character on page 33

Corrected Cash Drawer Command on page 72

Updated “Service Information” section

Updated “Contacting Ithaca Peripherals” section

Rev. L

Clarified cash drawer connectors on page 144

Changed IEEE-1284 to IEEE 1284 and Code 3 of 9 to Code 39

Rev. K

Reformatted entire document

Corrected miscellaneous grammar and spelling mistakes

Rev. J Update for Firmware Rev. 2.24

Corrected Epson documentation

Added documentation for justified bar codes and readable printing of bar codes

Added documentation for Bar code 93

Rev. I Update for Firmware Rev. 2.21

Corrected documentation for ENQ 15, 17, and 20 commands; length was 40H changed to 40 decimal

Added [ESC] z (&%FR) from release commands

Added features to graphic-save

Added OCR overlay features

Corrected miscellaneous grammar and spelling mistakes

Rev. H Update for Firmware Rev. 2.15

Improved description of pass-through and multidrop

Added features to [ESC]a command

Added 90PLUS

Removed references to Ithaca Peripherals

Corrected description of Mechanical Test Mode

Updated several graphic examples

Rev. G Update for Firmware Rev. 2.13

Added narrow, 2.4 inch print zone

Added [ESC]mP, [ESC]q<n>, and [ENQ]<17> commands

Changed documentation on [ENQ] commands to reflect that they are no longer buffered

Documented Epson cash drawer option

Fixed right margin specifications

Rev. F Update for Firmware Rev. 2.11

Added functionality to the RESET commands

Enabled [DLE][ENQ] <3> EPOS

Added M50 extension commands

Added 270° rotated font and 5 x 7 fonts to [ESC]P commands

Changed IPCL command &%CC to accept 3 decimal digits, was 2 decimal digits

Corrected the description of the [ESC]J command. It does not start the next line at the left margin unless Auto-CR is on.

Updated the configuration table

Changed RS1284 references to IEEE-1284

Added Welsh and Thai character sets

Updated the cut command. The cutter does not have selectable cut. The cut command is now only 2 bytes.

Updated MICR section to include translation tables and field checking

Added 5 x 7 font to rotated print functions

Added sections on Windows Plug and Play

Added [ENQ]<20> (return all status) and [ENQ]<21> (return printer ID) commands

12/16/99 Rev M Page i

Page 4

Change History PcOS Series 90PLUS Programmer's Guide

Added commands to allow the host to define a unique code page

Added autocutter position information

Added multidrop addressing

Added, “The cash drawer will only provide 1.0 amp at 24V.”

Rev. E Update for Firmware Rev. 2.07

Added 50 international language code pages

Altered Character Sets I and II. The printer no longer supports Character Set I and II. The printer is always in Set II.

Changed IPCL &%CP to support 4-digit code page descriptions

Extended the EPOS [ESC]R to support enhanced language sets

Updated code page table descriptions

Removed the Prerelease Change History

Corrected minimum slip width specification in the text for Figure 4

Rev D Update for Firmware Rev 2.05

Updated and clarified descriptions in the communication section

Added description of CTS and DSR controls

Added MICR commands and references to MICR Programmer’s Guide

Updated configuration section to include MICR and communication CTS/RTS/DTR/DSR options

Added [ESC]y<2> and <3> commands to switch between EPOS and Normal modes

Added 4-inch resume on paper out

Rev C Update

Removed IPCL command for set rotated print line spacing

Shortened graphic-save buffer from 2014 characters to 2000

Removed second parameter of [ESC] [EM] B; set bar code height

Changed all validation and slip control IPCL commands to accept decimal parameters instead of binary

Removed set left and right margin IPCL commands

Removed set dynamic response from [ESC]y group and defined [ESC] to replace it

Updated inquire descriptions to reflect preprocessing of ENQ commands; previously, ENQ commands were processed with other commands.

Changed ENQ descriptions in the communication section to reflect command preprocessing

Reversed parallel port responses to ENQ 1, 2, 5, 6, and 11; updated CFG90 to match

Reversed serial port responses to ENQ 7 and 8; updated CFG90 to match

Redefined ENQ 9 to represent inquire buffer status

Added Epson mode [DLE] [EOT] and [DLE] [ENQ] commands

Rev B Update

Added eject wait and pause commands and configuration information

Added print suppress and display pass-through to both EPOS and Normal modes

Updated CFG90 to deal with the new modes

Rev A Initial Release

Page ii Rev M 12/16/99

Page 5

Programmer's Guide PcOS Series 90PLUS Disclaimer

Disclaimer

Information in this publication is subject to change without notice. However, as product improvements become

available, Ithaca Peripherals will make every effort to provide updated information for the products described in

this publication.

Ithaca Peripherals cannot guarantee that changes in software and equipment made by other manufacturers, and

referred to in this publication, do not affect the applicability of information in this publication.

Copyright

1995-1999 Ithaca Peripherals. All rights reserved.

November 1999

Printed in USA.

No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form or by any

means, mechanical, photocopying, recording, or otherwise, without the prior written permission of Ithaca

Peripherals.

Trademarks

PcOS is a registered trademark of Ithaca Peripherals. IBM is a registered trademark of International Business

Machines, Inc. Epson is a registered trademark of the Seiko Epson Corporation. Microsoft is a registered

trademark of Microsoft Corporation. Windows, Windows NT, and Plug and Play are trademarks of Microsoft

Corporation.

12/16/99 Rev M Page iii

Page 6

PcOS Series 90PLUS Programmer's Guide

Page iv Rev M 12/16/99

Page 7

Programmer’s Guide PcOS Series 90PLUS Table of Contents

Table of Contents

1 Overview of the Series 90PLUS Printer........................................................................................................... 1

1.1 Warranty Information............................................................................................................................ 1

1.1.1 Warranty Options.................................................................................................................. 1

1.1.2 Service Information............................................................................................................... 1

1.2 What is in this book? ............................................................................................................................. 1

1.2.1 Who should read this book?................................................................................................... 1

1.2.2 What does it cover?............................................................................................................... 1

1.2.3 Where can you find more information?.................................................................................. 2

1.2.4 Contacting Ithaca Peripherals................................................................................................ 2

1.2.4.1 Internet Support............................................................................................................ 2

2 General Descriptions ....................................................................................................................................... 3

2.1 Series 90PLUS Models .......................................................................................................................... 3

2.2 Standard Features.................................................................................................................................. 3

2.3 Receipt Printer ....................................................................................................................................... 3

2.4 Receipt/Journal Printer .......................................................................................................................... 4

2.5 Receipt/Journal/Validation Printer......................................................................................................... 4

2.6 Receipt/Validation Printer ..................................................................................................................... 4

3 General Specifications..................................................................................................................................... 5

3.1 Printing Specifications ........................................................................................................................... 5

3.1.1 Character Generation............................................................................................................ 5

3.2 Physical Specifications .......................................................................................................................... 7

3.2.1 Dimensions........................................................................................................................... 7

3.2.2 Weight.................................................................................................................................. 7

3.3 Electrical Characteristics ....................................................................................................................... 7

3.3.1 Self-powered AC................................................................................................................... 7

3.3.2 Interface Specifications ......................................................................................................... 8

3.3.2.1 Serial............................................................................................................................ 8

3.3.2.2 Parallel ......................................................................................................................... 8

3.3.2.3 Cash Drawer................................................................................................................. 8

3.4 Media Specifications.............................................................................................................................. 8

3.4.1 Ribbon .................................................................................................................................. 8

3.4.2 Receipt Paper........................................................................................................................ 8

3.4.3 Receipt/Journal Paper............................................................................................................ 9

3.4.4 Inserted Slips and Forms....................................................................................................... 9

3.5 Slip Sensor .......................................................................................................................................... 10

3.6 Printable Area ..................................................................................................................................... 11

3.6.1 Receipt Printing .................................................................................................................. 11

3.6.1.1 Receipt Printing without the Autocutter ...................................................................... 11

3.6.1.2 Receipt Printing with the Autocutter ........................................................................... 12

3.6.2 Validation Forms Printing................................................................................................... 13

3.6.2.1 Validation Forms Insertion ......................................................................................... 13

3.6.2.2 Validation Forms Sensing........................................................................................... 14

3.6.3 Inserted Forms Printing....................................................................................................... 14

3.6.3.1 Inserted Forms Guidelines........................................................................................... 15

3.6.4 MICR Reader...................................................................................................................... 16

4 Control Codes Overview ............................................................................................................................... 17

4.1 Nomenclature ...................................................................................................................................... 17

12/16/99 Rev M Page v

Page 8

Table of Contents PcOS Series 90PLUS Programmer's Guide

4.1.1 Standard Emulation ............................................................................................................ 18

4.1.2 EPOS Emulation................................................................................................................. 18

4.1.3 IPCL Codes ......................................................................................................................... 18

4.2 Application Development .................................................................................................................... 18

4.3 Tables and Charts................................................................................................................................ 18

5 Printer Control Codes.................................................................................................................................... 19

5.1 Print/Paper Motion .............................................................................................................................. 19

5.1.1 Low-level Paper Motion Control ......................................................................................... 19

5.1.2 Horizontal Motion Control.................................................................................................. 20

5.2 Vertical Motion Control ...................................................................................................................... 22

5.3 Character Font ..................................................................................................................................... 26

5.4 International Character Sets and Code Pages ....................................................................................... 28

1.5 Character Print Control ....................................................................................................................... 34

1.6 Character Pitch.................................................................................................................................... 35

1.7 Character Attribute Commands ........................................................................................................... 37

1.8 Print Rotation Commands.................................................................................................................... 43

1.9 Graphic Mode...................................................................................................................................... 49

1.9.1 Standard APA Graphics...................................................................................................... 49

1.9.2 Extended APA Graphics ..................................................................................................... 51

1.9.3 EPOS Bit Image Graphics................................................................................................... 52

1.9.4 Graphic Save....................................................................................................................... 53

1.9.4.1 Programming Considerations...................................................................................... 53

1.10 Bar codes............................................................................................................................................. 56

1.11 Station Control.................................................................................................................................... 59

1.11.1 Receipt Operation................................................................................................................ 59

1.11.1.1 Receipt Paper-error Sensor .......................................................................................... 60

1.11.2 Validation and Slip Operation............................................................................................. 62

1.11.2.1 Top Insertion Validation............................................................................................. 62

1.11.2.1.1 Validation Controlled by the Host System...................................................... 62

1.11.2.1.2 Validation Controlled by the Printer.............................................................. 62

1.11.2.2 Front Inserted Validation............................................................................................ 63

1.11.2.2.1 Slip Printing .................................................................................................. 63

1.11.2.3 Mode Selection ........................................................................................................... 63

1.11.3 Top Validation Operation.................................................................................................... 64

1.11.4 Front Slip Operation ........................................................................................................... 65

1.11.5 Validation and Slip Operation Control................................................................................ 66

1.12 MICR Reader ...................................................................................................................................... 72

1.12.1 Overview............................................................................................................................. 72

1.13 Miscellaneous Controls ........................................................................................................................ 77

1.14 Series 50 Compatibility Commands ..................................................................................................... 81

1.15 Printer Status Set/Inquire ..................................................................................................................... 82

1.15.1 Parallel, Non-IEEE 1284 Mode Inquire ............................................................................... 82

1.15.2 Serial Mode Inquire ............................................................................................................ 83

1.15.3 Parallel, IEEE 1284 Mode Inquire....................................................................................... 83

1.15.4 Dynamic Response Mode .................................................................................................... 83

1.15.5 Inquire Commands.............................................................................................................. 84

1.16 Extended Diagnostic Commands ......................................................................................................... 92

1.17 EPOS Codes ........................................................................................................................................ 94

1.17.1 Real-time Status.................................................................................................................. 94

1.17.2 EPOS Command Summary ................................................................................................. 94

Page vi Rev M 12/16/99

Page 9

Programmer's Guide PcOS Series 90PLUS Table of Contents

1.17.3 EPOS Deviations................................................................................................................. 97

1.17.3.1 Command Descriptions............................................................................................... 97

1.18 Control Codes Summary by Code .......................................................................................................104

1.19 Control Codes Summary by Function ..................................................................................................109

6 Operator Panel Controls...............................................................................................................................115

6.1 Push Buttons - Momentary Switches...................................................................................................115

6.2 Indicators ...........................................................................................................................................115

6.3 Fault Indicators ..................................................................................................................................116

7 Product Self Tests ........................................................................................................................................117

7.1 Level 0 Diagnostics ............................................................................................................................117

7.2 Extended Diagnostics .........................................................................................................................117

7.2.1 Self-test Mode....................................................................................................................117

7.2.2 Hex Dump Mode................................................................................................................118

7.2.3 Configuration Mode...........................................................................................................118

7.2.3.1 Initial Power On.........................................................................................................118

7.2.3.2 Manual Configuration ................................................................................................118

7.2.3.3 Enable Remote Configuration ....................................................................................120

7.2.3.4 Feature Configuration................................................................................................120

8 Communication Protocol and Print Buffers ..................................................................................................134

8.1 Overview............................................................................................................................................134

8.2 Parallel Port........................................................................................................................................137

8.2.1 Parallel Port Protocol .........................................................................................................137

8.2.2 Printer Buffer Size .............................................................................................................138

8.2.2.1 One-line Mode...........................................................................................................138

8.2.3 Parallel Port Inquire IEEE 1284.........................................................................................138

8.2.3.1 Buffer ........................................................................................................................139

8.2.3.2 Mode 4.......................................................................................................................139

8.2.3.3 Mode 0.......................................................................................................................139

8.2.3.4 Time outs ...................................................................................................................139

8.2.3.5 Active State................................................................................................................140

8.2.3.6 Inquire Responses......................................................................................................140

8.2.4 Parallel Port Inquire (Non-IEEE 1284)...............................................................................140

8.2.5 Parallel Port Plug and Play.................................................................................................141

8.2.6 Parallel Port Connector ......................................................................................................143

8.2.7 Signal Levels......................................................................................................................143

8.3 Serial Port ..........................................................................................................................................144

8.3.1 Serial Port Features............................................................................................................144

8.3.2 Serial Port Pin out..............................................................................................................144

8.3.2.1 Signal Levels .............................................................................................................145

8.3.3 Serial Port Protocol ............................................................................................................145

8.3.4 Print Buffer Flow ...............................................................................................................147

8.3.5 Printer Buffer Size .............................................................................................................149

8.3.5.1 One-line Mode...........................................................................................................149

8.3.6 Serial Mode Plug and Play .................................................................................................150

8.3.6.1 Using DSR .................................................................................................................150

8.3.6.2 Serial Device Identification........................................................................................150

8.3.7 Serial Port Inquire ..............................................................................................................151

8.4 Remote Printer Reset ..........................................................................................................................152

8.4.1 Reset in Serial Mode ..........................................................................................................152

12/16/99 Rev M Page vii

Page 10

Table of Contents PcOS Series 90PLUS Programmer's Guide

8.4.2 Reset in Parallel Mode .......................................................................................................152

8.5 Miscellaneous Communication Features .............................................................................................153

8.5.1 Power-cycle Recovery.........................................................................................................153

8.5.2 Data Pass-through..............................................................................................................153

8.5.3 Multidrop Configuration ....................................................................................................153

8.5.4 Off-line Active...................................................................................................................154

8.6 Programmer’s Notes...........................................................................................................................154

9 Cash Drawer Interface..................................................................................................................................155

9.1 Interface Description ..........................................................................................................................155

9.2 Interface Connectors...........................................................................................................................155

10 Printing Graphics.........................................................................................................................................156

10.1 Character Graphics.............................................................................................................................156

10.2 APA Graphics ....................................................................................................................................158

Page viii Rev M 12/16/99

Page 11

Programmer's Guide PcOS Series 90PLUS Table of Figures

Table of Figures

Figure 1 Single-wide character............................................................................................................................... 6

Figure 2 Character forming.................................................................................................................................... 6

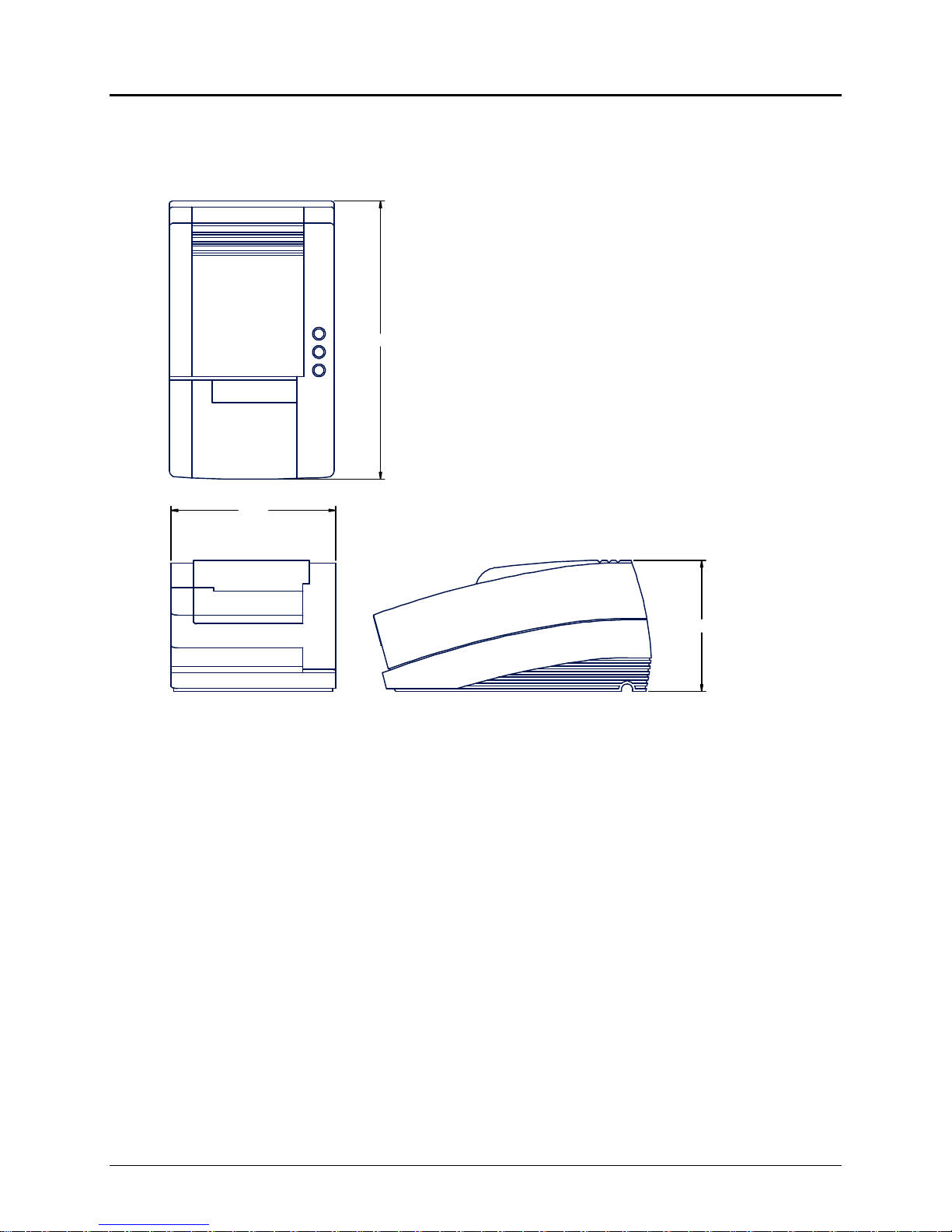

Figure 3 Physical dimensions................................................................................................................................. 7

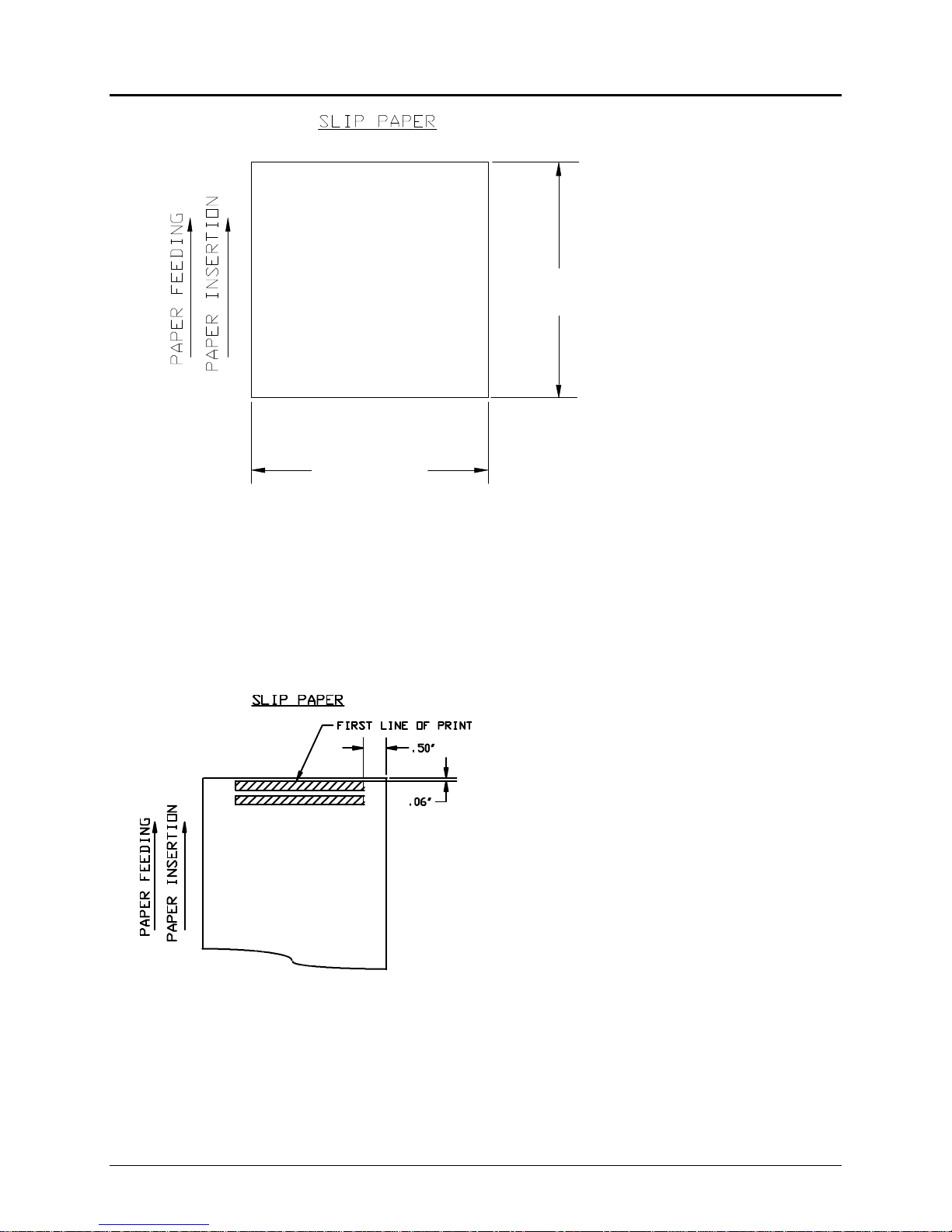

Figure 4 Slip form size......................................................................................................................................... 10

Figure 5 Slip paper print...................................................................................................................................... 10

Figure 6 Receipt printable area............................................................................................................................. 11

Figure 7 Receipt printable area............................................................................................................................. 11

Figure 8 Receipt autocutter position..................................................................................................................... 12

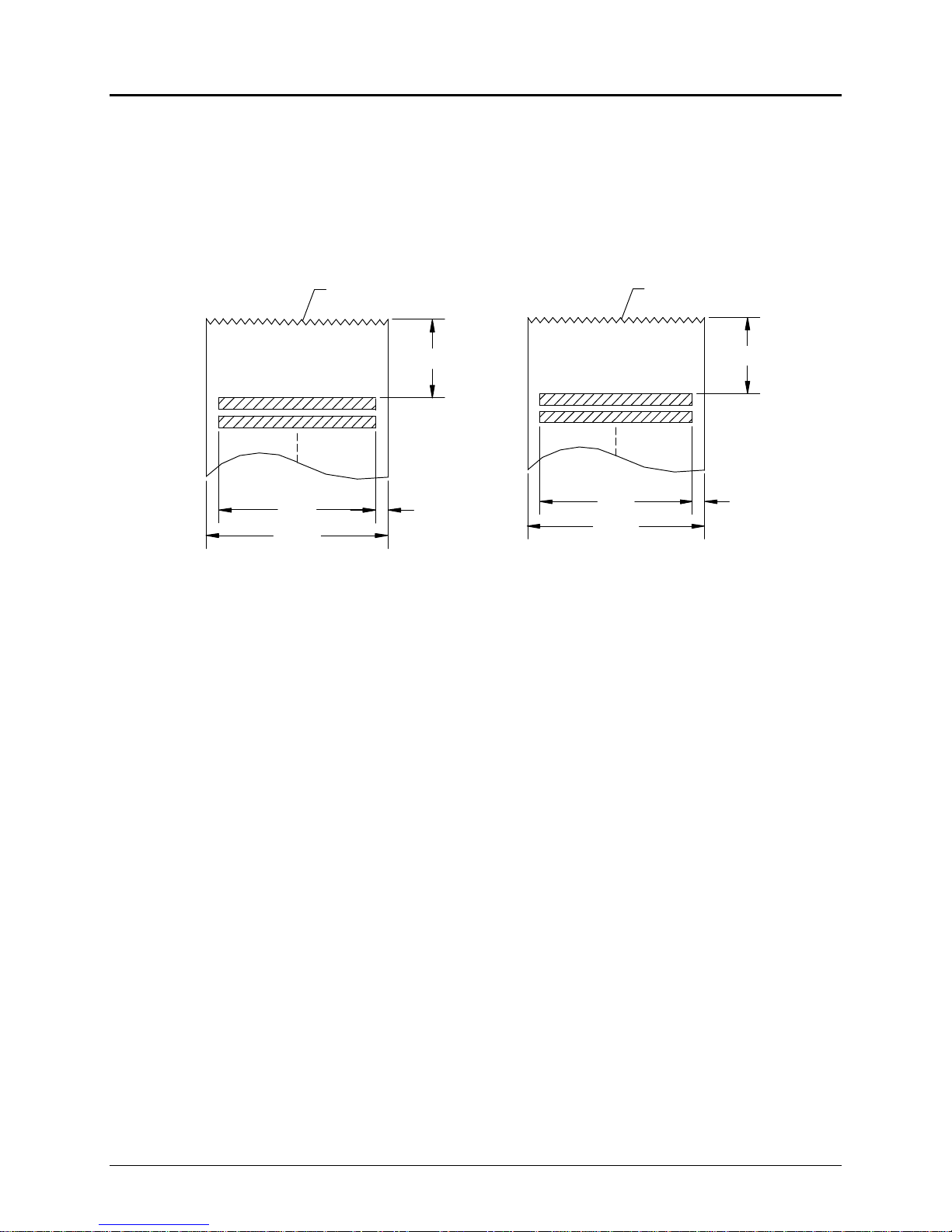

Figure 9 Validation print with normal and narrow print zones............................................................................. 13

Figure 10 Inserted slip using normal and narrow print zone ................................................................................. 14

Figure 11 Normal and narrow print zone rotated print ......................................................................................... 15

Figure 12 Multipart forms .................................................................................................................................... 15

Figure 13 Data sent to printer for a fine line feed ................................................................................................. 22

Figure 14 Example of fine line feed...................................................................................................................... 22

Figure 15 Examples of print at various character pitch ......................................................................................... 35

Figure 16 Data sent to printer for one-line double-wide print ............................................................................... 37

Figure 17 Example of one-line double-wide print................................................................................................. 37

Figure 18 Example of underline, enhanced, emphasized, superscript, and subscript print..................................... 42

Figure 19 ............................................................................................................................................................. 48

Figure 20 PE to ENQ request timing.................................................................................................................... 83

Figure 21 Typical POS system ............................................................................................................................134

Figure 22 Host to printer link ..............................................................................................................................134

Figure 23 Printer communications buffer flow.....................................................................................................135

Figure 24 Parallel port data timing......................................................................................................................137

Figure 25 ............................................................................................................................................................138

Figure 26 PE to ENQ request timing...................................................................................................................141

Figure 27 Serial port flow control using DTR......................................................................................................145

Figure 28 XON/XOFF serial port flow control ....................................................................................................146

Figure 29 Serial buffer operation.........................................................................................................................147

Figure 30 Print controller using data...................................................................................................................148

Figure 31 Inquire flow ........................................................................................................................................151

Figure 32 Receipt with extended graphic characters............................................................................................157

Figure 33 Receipt with APA graphics .................................................................................................................158

Figure 34 9-pin female to 9-pin female serial interconnect..................................................................................163

Figure 35 9-pin female to 25-pin female serial interconnect................................................................................163

12/16/99 Rev M Page ix

Page 12

Table of Tables PcOS Series 90PLUS Programmer's Guide

Table of Tables

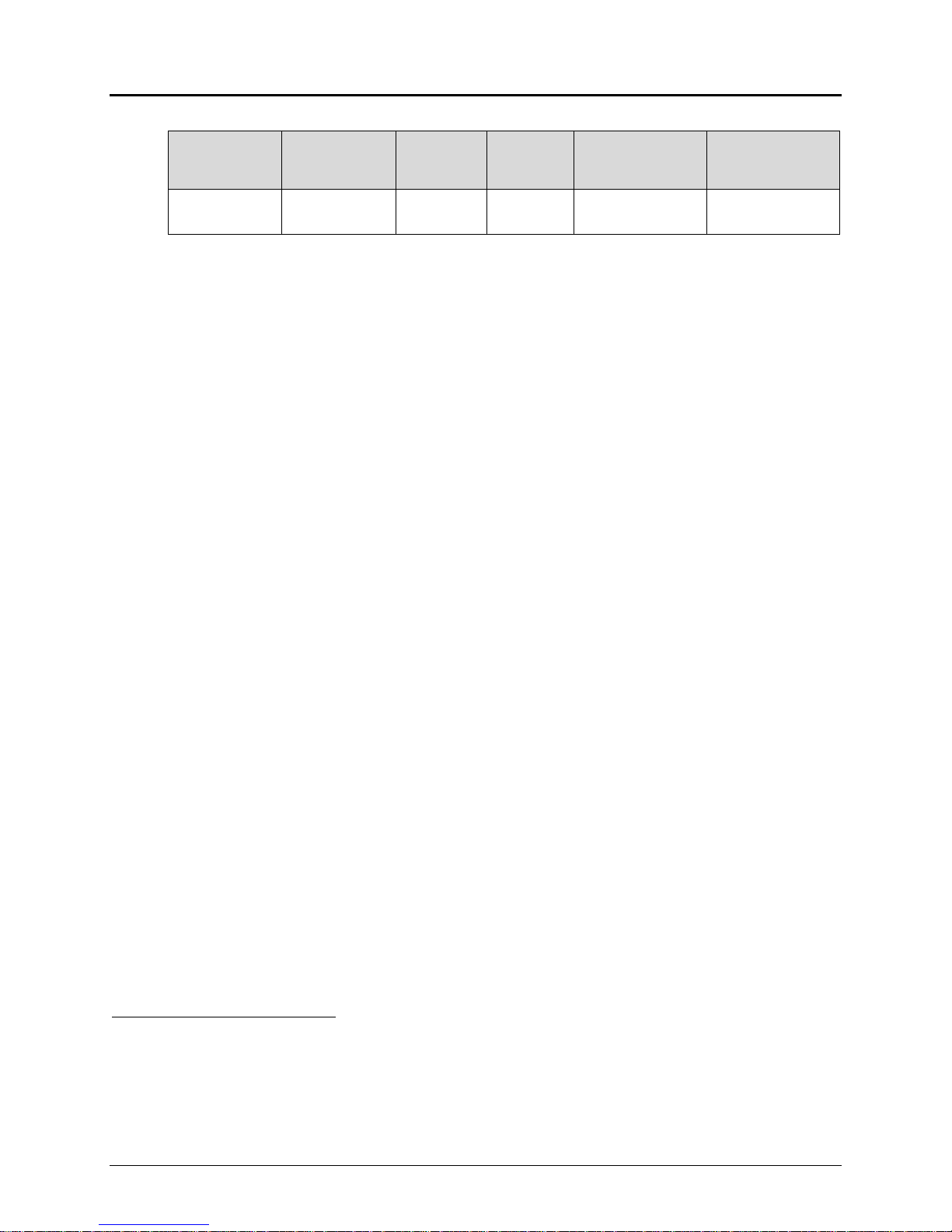

Table 1 Character specifications............................................................................................................................. 5

Table 2 Power input requirements.......................................................................................................................... 8

Table 3 Validation lines....................................................................................................................................... 13

Table 4 Ten line validation option........................................................................................................................ 13

Table 5 Language table identification................................................................................................................... 29

Table 6 EPOS language table identification.......................................................................................................... 29

Table 7 Code page definition table....................................................................................................................... 30

Table 8 EPOS code page definition table .............................................................................................................. 30

Table 9 OCR-MA2............................................................................................................................................... 32

Table 10 Euro character Substitution Matrix........................................................................................................ 33

Table 11 Print modes........................................................................................................................................... 34

Table 12 Intercharacter spacing table................................................................................................................... 36

Table 13 Rotated print spacing with 7 x 9 font..................................................................................................... 43

Table 14 Rotated print spacing with 5 x 7 font..................................................................................................... 44

Table 15 Amount of paper left when paper low is sensed...................................................................................... 60

Table 16 Values for the left and right print margins............................................................................................. 70

Table 17 MICR status fields................................................................................................................................. 74

Table 18 MICR translation characters.................................................................................................................. 76

Table 19 Printer states.........................................................................................................................................115

Table 20 Level 0 diagnostics...............................................................................................................................117

Table 21 Parallel port pin outs ............................................................................................................................143

Table 22 Serial bit rates ......................................................................................................................................144

Table 23 Serial port pin out.................................................................................................................................144

Table 24 Ithaca cash drawer connector................................................................................................................155

Table 25 Epson/Axiohm cash drawer connector..................................................................................................155

Table 26 Code page definitions...........................................................................................................................161

Table 27 ASCII code chart..................................................................................................................................162

Page x Rev M 12/16/99

Page 13

Programmer's Guide PcOS Series 90PLUS Overview

1 Overview of the Series 90PLUS Printer

1.1 Warranty Information

1.1.1 Warranty Options

All Ithaca Peripherals Series 90PLUS printers come with a standard 24-month warranty covering both

parts and labor. An optional warranty, covering both parts and labor for an additional 12 months, may be

purchased separately.

For more information concerning the warranty options, please contact your dealer or the Sales Department

at Ithaca Peripherals. See “Contacting Ithaca Peripherals” on page 2.

1.1.2 Service Information

Ithaca Peripherals has a full service organization to meet your printer service and repair requirements.

If your printer needs service, please directly contact Ithaca Peripherals’ Technical Support Department at

(607) 257-8901 for a return authorization.

Ithaca Peripherals offers the following service programs to meet your needs:

• Extend Warranty

• Depot Repair

• Maintenance Contract

1.2 What is in this book?

1.2.1 Who should read this book?

This book is intended for system engineers or integrators. It contains the information needed to integrate

the Series 90PLUS Printer with a point-of-sale terminal and to program the terminal to communicate with

the printer.

1.2.2 What does it cover?

The programmer's guide provides the following material:

• Start-up information including diagnostics and fault conditions;

• Command descriptions;

• Character fonts;

• Printer features;

• Parallel and RS-232 interface information;

• Communications and buffers; and

• Command code reference tables.

12/16/99 Rev M Page 1

Page 14

Overview PcOS Series 90PLUS Programmer's Guide

1.2.3 Where can you find more information?

An Operator's Guide is available that describes the set up and use of the Series 90PLUS Printer. It

describes basic procedures such as changing paper; printing on a slip or form; and replacing the ribbon

cassette. A Maintenance Manual is also available. It shows how to repair the Series 90PLUS Printer and

lists the replacement parts. The Maintenance Manual is intended for trained, service technicians. For

information about ordering these books or programs, refer to the next section.

In addition, there are a number of drivers available that will support various environments.

Windows 95 Print Driver with Documentation Part No. 100-9167

Windows NT 4.0 Print Driver with Documentation Part No. 100-9170

OPOS Drivers with Documentation Part No. 100-9732

MICR Programmer’s Guide Part No. 100-9094

Master Character Set Definitions Part No. 100-9785

1.2.4 Contacting Ithaca Peripherals

The Sales and Technical Support Departments will be able to help you with most of your questions.

Contact the Technical Support Department to receive technical support, order documentation, receive

additional information about the Series 90PLUS Printer, obtain information about your warranty, or send

a printer in for service. To order supplies or receive information about other Ithaca Peripherals products,

contact the Sales Department.

You may reach both the Sales and Technical Support Departments at the following address and telephone

or fax numbers:

Ithaca Peripherals

20 Bomax Drive

Ithaca, NY 14850

Main telephone (607) 257-8901

Main fax (607) 257-8922

Sales fax (607) 257-3868

Technical Support fax (607) 257-3911

Technical Support E-mail techsupport@ithper.com

1.2.4.1 Internet Support

Ithaca Peripherals maintains an Internet web site. The address is http://www.ithper.com. On the

technical support page, you will find support information on all of our printers. The Series 90PLUS

Printer support pages offer the latest information. They include the current version of this manual;

program examples; test procedures; programming instructions; and all supported print drivers.

Page 2 Rev M 12/16/99

Page 15

Programmer's Guide PcOS Series 90PLUS General Descriptions

2 General Descriptions

2.1 Series 90PLUS Models

There are four basic models of the Series 90PLUS Printer. They are:

Model 91PLUS Receipt printer;

Model 92PLUS Receipt/Journal printer;

Model 93PLUS Receipt/Journal/Validation printer; and

Model 94PLUS Receipt/Validation printer.

2.2 Standard Features

The following features are common to the entire family of printers:

• 340 cps logic-seeking print speed;

• 5 inches per second paper feed speed;

• 2.4 and 2.8 inch print zones;

• Snap on ribbon cassettes;

• Dual cash drawer drivers with status;

• Centronics parallel, IEEE 1284 or serial RS-232C interfaces;

• Configurable receiver buffers;

• Standard and Epson command emulations1;

• Standard all-points-addressable (APA) or EPOS bit-image graphics;

• Standard and EPOS International Character Sets;

• 8, 10, 12, 15, 17.1, 20, and 24 characters per inch (cpi) selections;

• Custom logo graphic print buffer in nonvolatile memory;

• Emphasized, enhanced, double-wide, double-high, double-wide double-high, half-high, underline,

subscript, superscript, and rotated printing;

• Operator-visible print zones;

• Self-diagnostics; and

• Setup and configuration utility programs.

2.3 Receipt Printer

The Model 91PLUS receipt printer only provides receipt functions. The last line printed on the receipt is

within 0.7 inch of the tear-off or cut-off edge of the receipt. The receipt printing appears right-side up with the

total at the bottom as the receipt appears from the top of the printer and is presented to the operator.

The receipt printer handles one-, two-, or three-ply paper. The optional cutter is able to cut one- and two-ply

paper.

1

Other emulation’s can be made available. Contact Ithaca Peripherals’ Sales Department for more information.

12/16/99 Rev M Page 3

Page 16

General Descriptions PcOS Series 90PLUS Programmer's Guide

The receipt printer does not have the ability to validate or handle slips. Commands that operate validation and

slip modes of other Series 90PLUS Printers will not function.

2.4 Receipt/Journal Printer

The Model 92PLUS receipt/journal printer adds the journal feature to the Model 91PLUS receipt printer. The

journal take-up is able to rewind the second copy of the 3.5-inch diameter 2-ply paper roll (125 feet).

The receipt/journal printer does not have the ability to validate or handle slips. Commands that operate

validation and slip modes of other Series 90PLUS Printers will not function.

2.5 Receipt/Journal/Validation Printer

The Model 93PLUS printer adds an independent validation capability to the Model 92PLUS. There are two

methods of form validation on the Model 93PLUS.

1. Top insertion validation. The form is inserted from the top and extends out the left side and/or top of the

printer. It rests on a fixed form stop. Under software control, printing can be from a minimum of two lines

to a maximum of 17 lines at 42 characters. Throughout this manual, top insertion will be termed

“Validation Mode.”

2. Front inserted validation. The form is inserted from the front and extends out the left side and/or front of

the printer. In front insertion mode, the form is loaded to the first line of print under firmware control.

Printing then begins from the top of the form down. Throughout this manual, front insertion will be

termed “Slip Mode.”

All Series 90PLUS validation printers have both validation and slip modes. The validation/slip movement is

independently controlled from the movement of the receipt and journal. Either can be moved alone or in sync

with the receipt/journal movement. The validation/slip movement will be under software control but set to

independent validation by default.

2.6 Receipt/Validation Printer

The Model 94PLUS receipt/validation printer adds validation to the Model 91PLUS described above. The

Model 94PLUS is a Model 93PLUS without journal take-up.

Page 4 Rev M 12/16/99

Page 17

Programmer's Guide PcOS Series 90PLUS General Specifications

3 General Specifications

3.1 Printing Specifications

Printing method Impact dot matrix

Head wire arrangement 9 pins in a line

Print wire diameter 0.34 mm (0.012 inch)

Print wire pitch 0.353 mm (0.013 inch)

Printing directions Bidirectional, logic-seeking

Print zone 59.5 mm (2.4 inches) or 71.12 mm (2.83 inches)

Characters per second (cps) Refer to Table 1.

Characters per line (cpl) Refer to Table 1.

Characters per inch (cpi) Refer to Table 1.

Print Pitch Capability

(in characters per inch)

8 22 19 220

10 28 24 275

12 34 28 330

15 42 36 340

17.1 (condensed) 48 41

20 (super-condensed) 56 48 340

24 (super-condensed) 68 57 340

5 (double-wide) 14 12 130

6 (double-wide) 17 14 160

7.5 (double-wide) 21 18 170

8.5 (condensed, double-wide) 24 20 170

10 (condensed, double-wide) 28 24 170

12 (super-condensed, double-wide) 34 28 170

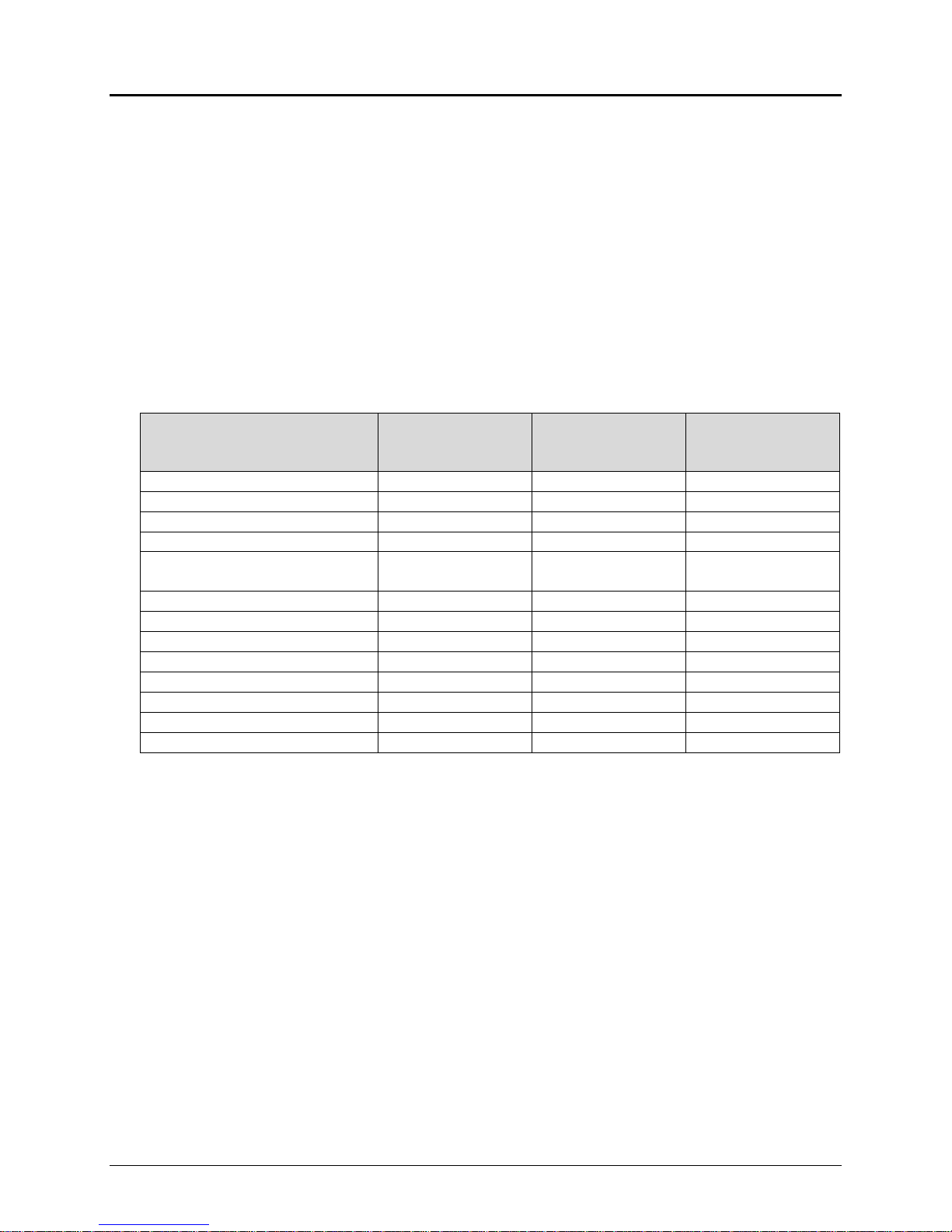

Table 1 Character specifications

Normal 2.8”

Maximim

Characters per Line

Narrow 2.4”

Maximum

Characters per Line

(40 in M50 mode)

Series 90PLUS

Characters per

Second

340

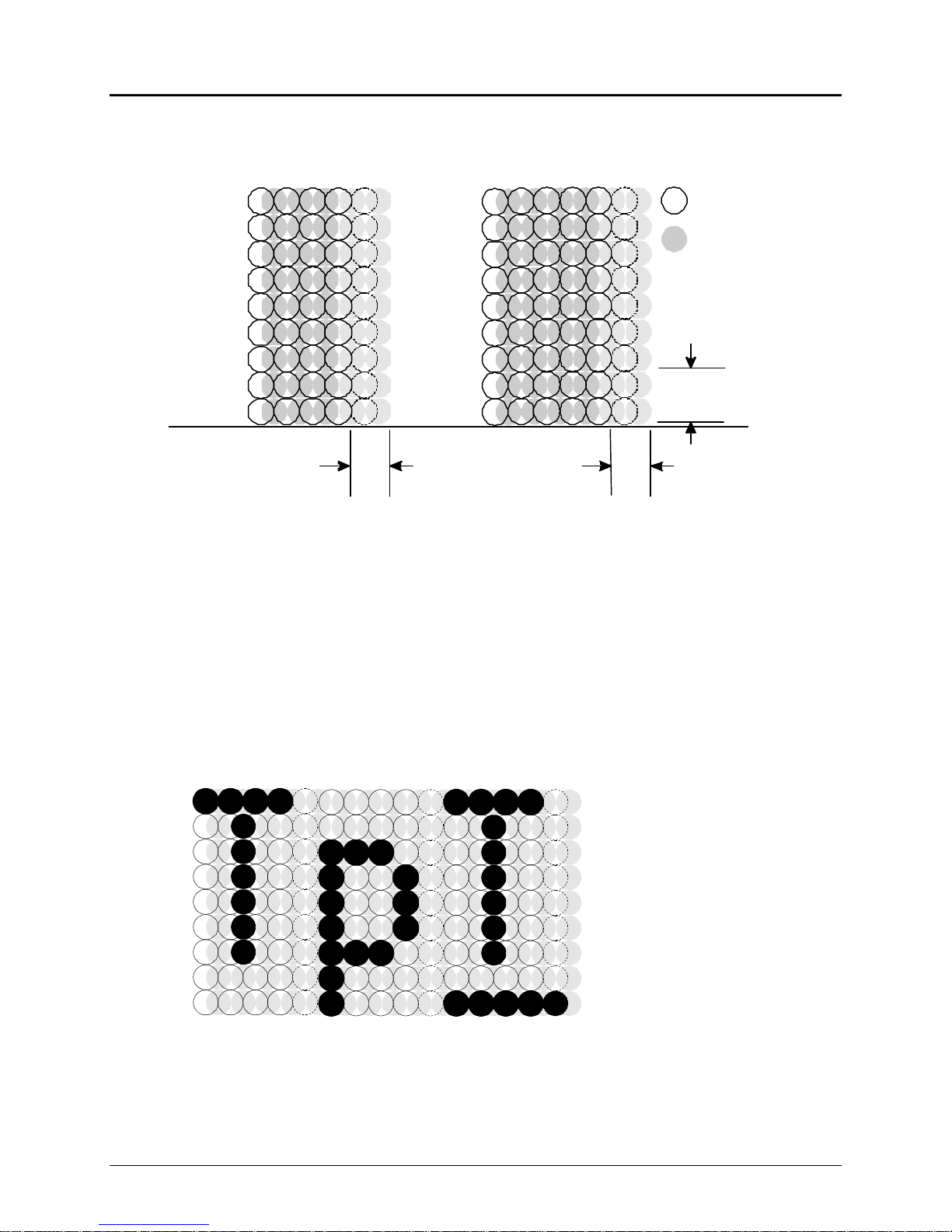

3.1.1 Character Generation

All the character sets and modes are based on one of two character cells, 10 wide x 9 high or 12 wide x 9

high. Double-wide mode is twice the width of normal mode, 20 wide x 9 high or 24 wide x 9 high.

In utility print mode, the character cell consists of five full-dots and five half-dots horizontally by nine

full-dots vertically. The character is a 9 x 9 character. In high speed draft (HSD) mode, the character cell

is shortened by one half-dot and one full-dot column yielding a 7 x 9 character.

Each character is justified to the left of the cell. The first four columns of the full dots and the first three

columns of half dots are used to generate the character in high speed draft. In utility mode, the first five

columns of the full dots and the first four columns of the half dots are used. The last full-dot and the last

two half-dots are used for character spacing in both modes.

12/16/99 Rev M Page 5

Page 18

General Specifications PcOS Series 90PLUS Programmer's Guide

1 3 5 7 9 11

1 3 5 7 9

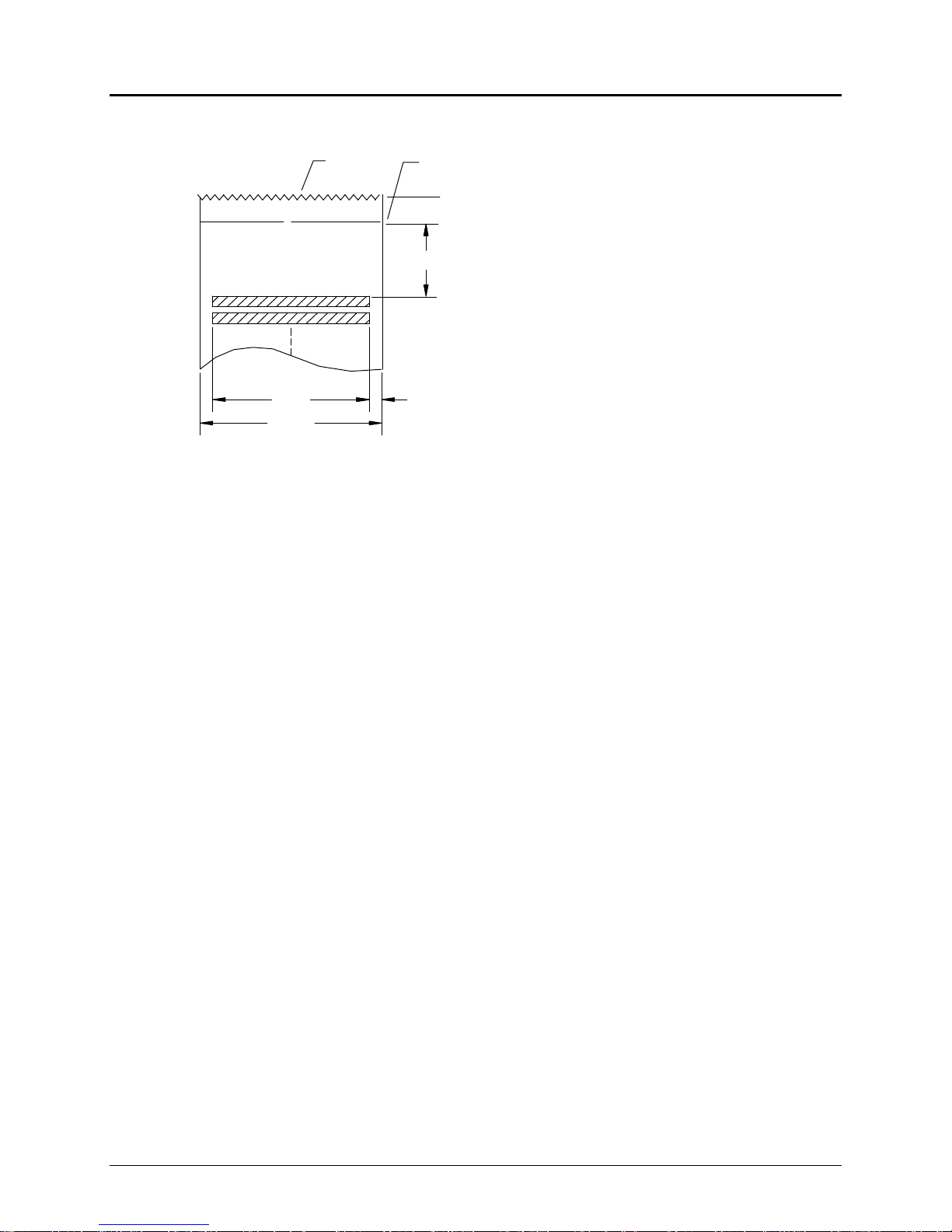

The following illustration shows a single-wide character cell.

2 4 6 8 10

1

2

3

4

5

6

7

8

9

Character

spacing

High Speed Draft Mode

Figure 1 Single-wide character

The example above, which only holds true for the 12 cpi mode, shows full dots adjacent to each other in

the character cell. The 10 cpi mode allows a gap between adjacent full rows; 17 and 24 cpi allow an

overlap of full rows. The printer cannot print adjacent full and half dots in any single row. Some graphics

(double-density, half-speed) allow adjacent rows to be printed by slowing the print speed by half. Slowing

the print speed allows the time between half and full columns to be the same as the time between full

columns in full speed operation.

2 4 6 8 10 12

1

2

3

4

5

6

7

8

9

Character

spacing

Utility Mode

Full Dots

Half Dots

Descender (Rows 8 and 9)

and Underline (Row 9)

The following illustration shows the use of full and half dots as well as descenders to form characters.

1 3 5 7 9

2 4 6 8 10

1

2

3

4

5

6

7

8

9

Figure 2 Character forming

1 3 5 7 9

2 4 6 8 10

1 3 5 7 9

2 4 6 8 10

Page 6 Rev M 12/16/99

Page 19

Programmer's Guide PcOS Series 90PLUS General Specifications

3.2 Physical Specifications

3.2.1 Dimensions

12.25” (311.2 mm)

7.30”

(185.4 mm)

6.0” (152.4 mm)

Figure 3 Physical dimensions

3.2.2 Weight

Approximate weight 10 pounds (4.5 kg)

Shipping weight 13 pounds (5.9 kg)

3.3 Electrical Characteristics

3.3.1 Self-powered AC

The Series 90PLUS Printer is designed to be AC self-powered in domestic and international markets. The

printer is equipped with a universal input power supply that is designed to operate worldwide without

modification.

12/16/99 Rev M Page 7

Page 20

General Specifications PcOS Series 90PLUS Programmer's Guide

Supply

Voltage

Rating (VAC)

100 - 240 90 - 264 47 - 63 45 0.08 @ 120VAC

Table 2 Power input requirements

Supply

Voltage

Range (VAC)

Frequency

(Hz)

Rated

Power

(watts)

Current Idle

(amps)

0.04 @ 240VAC

Current Printing

(amps)

0.5 @ 120VAC

0.25 @ 240VAC

3.3.2 Interface Specifications

3.3.2.1 Serial

The serial interface is a standard RS-232 interface on a 9-pin, D-shell connector. It is defined as a

standard DTE device. A null modem cable is required to interface the printer to another DTE device

(a personal computer). See the serial port description later in this manual.

3.3.2.2 Parallel

The parallel port is a standard 25-pin, D-shell as defined in the IEEE 1284-A Standard. See the

parallel port description later in this manual.

3.3.2.3 Cash Drawer

The Series 90PLUS Printer supports dual cash drawers with status. The interface will provide status

and 24 VDC at up to 1.5 amps to the cash drawer. See the cash drawer interface description later in

this manual.

3.4 Media Specifications

3.4.1 Ribbon

Inking method cartridge type, 70.9-inch (1.8 m) seamless ribbon with reinker

Ink color black or purple

Ribbon life at 25°C 3 million (black) or 4.5 million (purple) characters to ink depletion

Manufacturer Only Ithaca Peripherals approved ribbons should be used.

3.4.2 Receipt Paper

Paper feed method friction feed

Paper feed pitch default, 1/8 inch; can be set in units of 1/216 inch by software command

Paper width 2.5, 3.0, or 3.25 inches (63.5, 76.2, or 82.6 mm)

Roll diameter 3.5 inches (88.9 mm)

Paper thickness at 25°C 0.003 - 0.0035 inch (0.076 - 0.089 mm)

Roll paper core inside diameter 7/16 inch or more

2

Ribbon must be from an approved manufacturer and tested with a rolling ASCII test pattern using 15 cpi in HSD

mode.

2

Page 8 Rev M 12/16/99

Page 21

Programmer's Guide PcOS Series 90PLUS General Specifications

Roll footage 240 feet (7315.2 cm) typical

Paper low indicator striping starts at approximately 8 - 10 feet (243.8 - 300.5 cm) from end of roll

Receipt paper out Paper exhaust is sensed, and printing is prevented at end of roll.

3.4.3 Receipt/Journal Paper

Paper feed method friction feed

Paper feed pitch default, 1/8 inch; can be set in units of 1/216 inch by software command

Paper width 2.5, 3.0, or 3.25 inches (63.5, 76.2, or 82.6 mm)

Roll diameter 3.5 inches (88.9 mm)

Paper thickness at 25°C

Two-ply 0.006 - 0.007 inch (0.15 - 0.18 mm)

Three-ply 0.009 - 0.0105 inch (0.23 - 0.27 mm)

Roll paper core inside diameter, 7/16 inch

Typical roll footage

Two-ply 110 feet (3352.8 cm)

Three-ply 70 feet (2133.6 cm)

Paper low indicator striping starts at approximately 8 - 10 feet (243.8 - 300.5 cm) from end of roll

Receipt paper low The paper level is sensed by software with an adjustable end of roll monitor

that prevents printing.

3.4.4 Inserted Slips and Forms

Paper width 2.50 - 9.0 inches (63.5 - 228.6 mm)

Length 3.375 - 11.0 inches (85.7 - 279.4 mm)

Paper thickness a. one sheet: 0.0035 - 0.016 inches (0.089 - 0.41 mm) at 25°C

b. combination of copy paper and carbon copy paper:

4 sheets maximum (one original and three copies)

c. maximum form thickness: 0.016 inches (0.41 mm) at 25°C

12/16/99 Rev M Page 9

Page 22

General Specifications PcOS Series 90PLUS Programmer's Guide

3.375 - 11.00”

(85.7 - 279.4 mm)

2.50 - 9.00”

(63.5 - 228.6 mm)

Figure 4 Slip form size

3.5 Slip Sensor

Once an inserted form has been properly aligned and sensed by the slip sensor, it is positioned at the top of the

form by the slip load command.

Figure 5 Slip paper print

The position of the first line of print can be adjusted by ± 0.050 inch (± 1.27 mm) during printer installation.

Page 10 Rev M 12/16/99

Page 23

Programmer's Guide PcOS Series 90PLUS General Specifications

3.6 Printable Area

3.6.1 Receipt Printing

3.6.1.1 Receipt Printing without the Autocutter

Tear-off

0.70” (7.8 mm)

2.80” (71.1 mm)

3.25” (82.6 mm)

Figure 6 Receipt printable area Figure 7 Receipt printable area

The paper tear-off is 0.7 inch (17.78 mm) above the last line of print. To place the last line printed

above the tear-off point, the paper should be fed 0.8 inch (20.32 mm). The paper can then be torn-off

from either the left or right side. The first line of the next print will be 0.7 inch (17.78 mm) from the

top of the form.

0.225” (5.7 mm)

2.40” (61.0 mm)

2.50” (63.5 mm)

Tear-off

0.70” (17.8 mm)

0.225” (5.7 mm)

The paper should not be reverse fed back into the printer. If a double-high line of print is the first line

of a receipt, it will be reverse fed 0.1 inch (2.54 mm). If any more paper is reverse fed, the paper will

become unloaded from the tear-off bar.

12/16/99 Rev M Page 11

Page 24

General Specifications PcOS Series 90PLUS Programmer's Guide

3.6.1.2 Receipt Printing with the Autocutter

Tear-off

2.80” (71.1 mm)

3.25” (82.6 mm)

Figure 8 Receipt autocutter position

Cut-off

0.60” (15.2 mm)

0.90” (22.9 mm)

0.225” (5.7 mm)

The autocutter has a cut point and a tear-off point. The tear-off is used to separate the partial cut

cleanly from the next receipt.

The autocutter is positioned 0.9 inch (22.9 mm) from the top of the last line of print to the cut point.

The paper should be fed 1.0 inch (25.4 mm) after the last line is printed and before the cutter is

activated. After the cut, the paper automatically feeds 0.6 inch (15.2 mm) to allow the receipt cut

point to be at the tear-off point.

The first line of print is 1.5 inches (38.1 mm) from the cut. If the first line of the next receipt is to be

closer to the top of the receipt, the receipt can be reversed up to 0.4 inch (10.2 mm). The previous

receipt must, however, be removed before the reverse feed. If the receipt is not to be removed but is to

remain attached to the next receipt, the paper should not be reversed.

The paper should not be fed back into the printer more than 0.4 inch (10.2 mm). If a double-high line

of print is the first line of a receipt, it will be reverse fed 0.1 inch (2.54 mm). If any more paper is

reverse fed, the paper will become unloaded from the knife.

Page 12 Rev M 12/16/99

Page 25

Programmer's Guide PcOS Series 90PLUS General Specifications

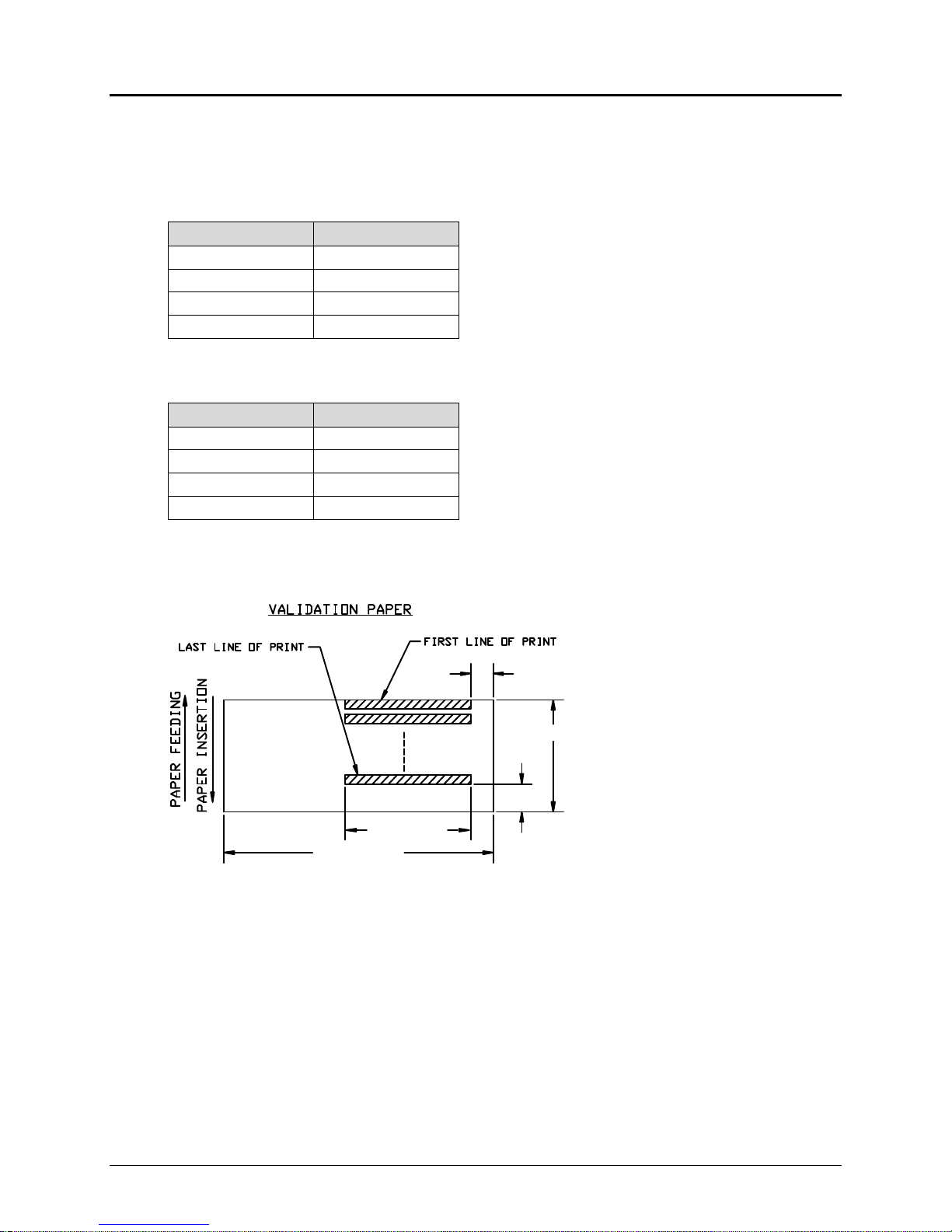

3.6.2 Validation Forms Printing

The Models 93PLUS and 94PLUS are both equipped with independent validation. The movement of the

validation form is under software or firmware control and allows the form to move either independent of

the receipt (or receipt/journal) or in sync with the receipt (or receipt/journal).

Lines per inch Lines

9 18

8.5 17

8 16

6 13

Table 3 Validation lines

Lines per inch Lines

9 11

8.5 10

8 10

6 7

Table 4 Ten line validation option

0.50” (12.7 mm)

2.50 - 4.25” (63.5 - 108.0 mm)

0.625”

(15.9 mm)

2.40”/2.80”

(61.0/71.1 mm)

6.00 - 10.00”

(152.4 - 254.0 mm)

Figure 9 Validation print with normal and narrow print zones

3.6.2.1 Validation Forms Insertion

Form insertion is from the top or the left side of the printer. Automatic form location is under

software or firmware control. Character rotation under software control will allow check validation to

appear right-side up when the check is removed.

12/16/99 Rev M Page 13

Page 26

General Specifications PcOS Series 90PLUS Programmer's Guide

3.6.2.2 Validation Forms Sensing

The printer has a sensor that is used to detect the presence of a validation form. This sensor may be

queried by an application to check on the presence of a form. It is located approximately 0.5 inch

(12.7 mm) below the print line and to the far right of the paper path.

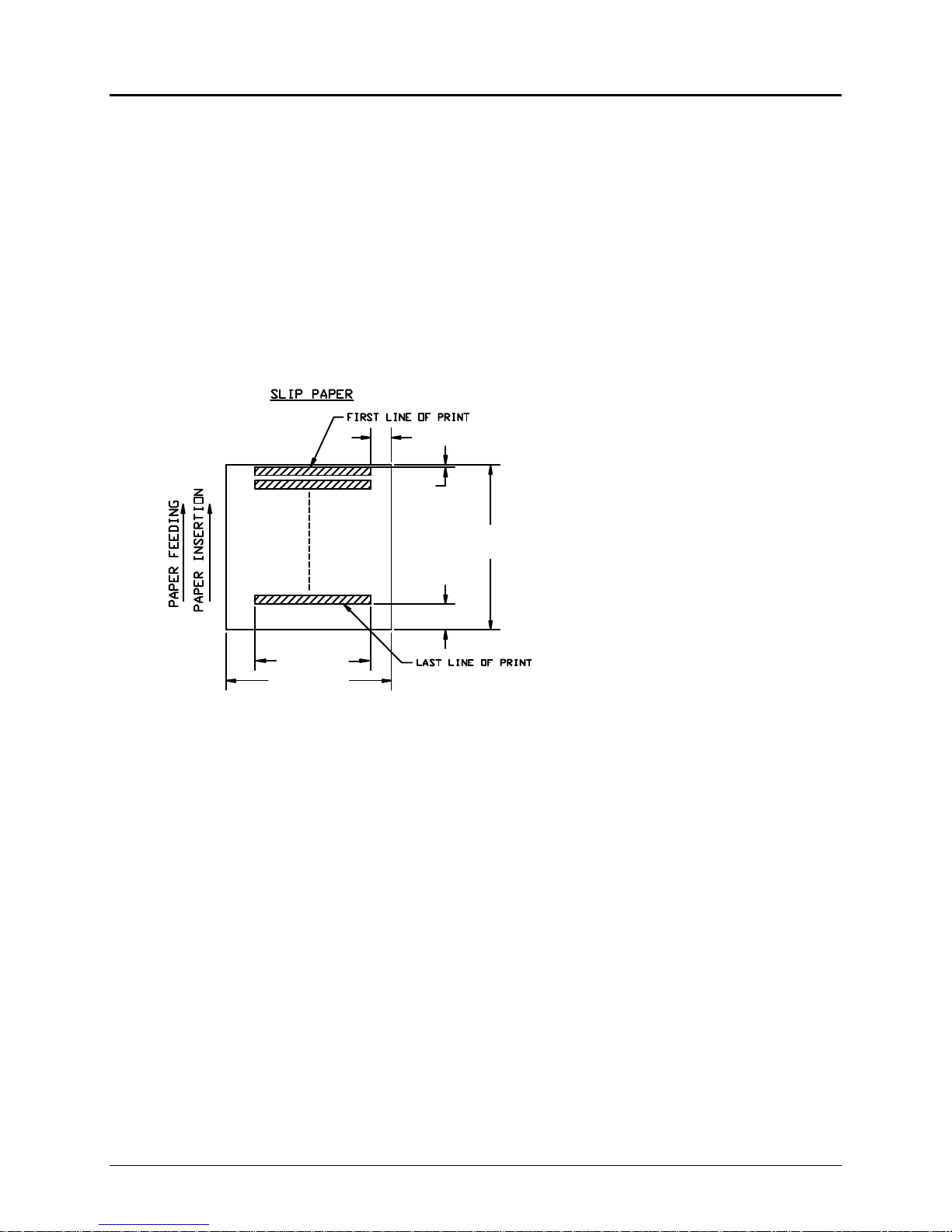

3.6.3 Inserted Forms Printing

Top of form to top of print line 0.06 inch (1.52 mm)

Minimum form length 3.375 inches (85.7 mm)

Minimum form width 2.5 inches (63.5 mm)

Bottom of form to bottom wire 0.625 inch (15.9 mm)

0.50” (12.7 mm)

0.06”

(1.52 mm)

3.375 - 11.00”

(85.7 - 279.4 mm)

0.625” (15.9 mm)

2.40”/2.80”

(61.0/71.1 mm)

2.50 - 9.00”

(63.5 - 228.6 mm)

Figure 10 Inserted slip using normal and narrow print zone

Page 14 Rev M 12/16/99

Page 27

Programmer's Guide PcOS Series 90PLUS General Specifications

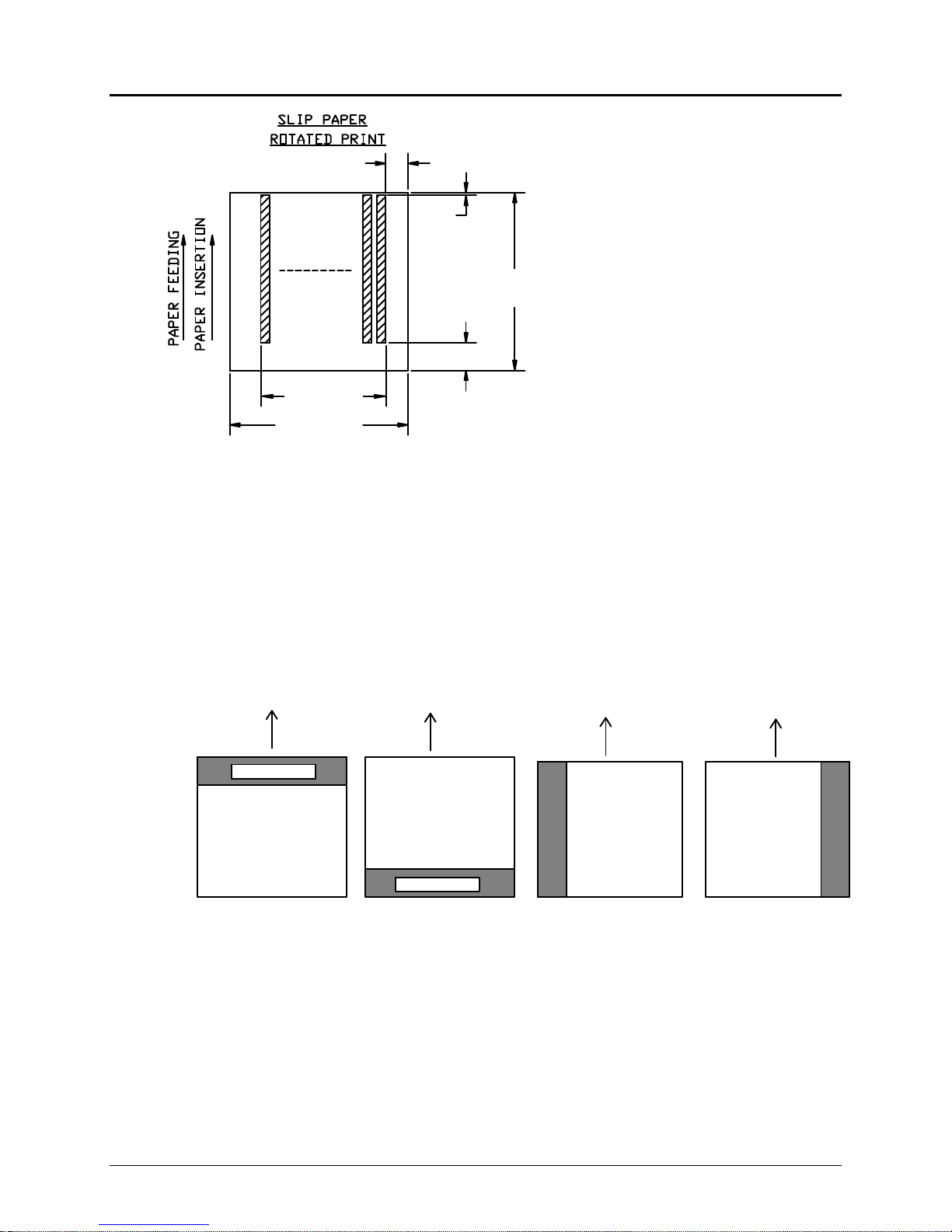

Insertion Direction

0.50” (12.7 mm)

0.06”

(1.52 mm)

3.375 - 11.00”

(85.7 - 279.4 mm)

0.625” (15.9 mm)

2.40/2.80”

(61.0/71.1 mm)

2.50 - 9.00”

(63.5 mm - 228.6 mm)

Figure 11 Normal and narrow print zone rotated print

3.6.3.1 Inserted Forms Guidelines

• Use forms with a paper roll loaded.

• Use forms that are flat and without curls, folds, warps, or wrinkles.

• Glue should not be on the bottom edge of the form.

• Use of multipart forms with thick middle plies will decrease copy visibility.

Glue Area

Glue Area

Glue Area

Recommended

Figure 12 Multipart forms

Not Recommended

Use Carefully

Glue Area

Use Carefully

12/16/99 Rev M Page 15

Page 28

General Specifications PcOS Series 90PLUS Programmer's Guide

3.6.4 MICR Reader

The MICR reader is an option for the Series 90PLUS Printer. It is attached to the front of the printer and

allows a document having MICR data on it to be read and positioned for print.

The MICR reader recognizes the magnetic ink on the bottom of checks; it is not an optical reader. Any

nonmagnetic data will not be read. The Series 90PLUS MICR reader is based on a technique which uses a

magnetic read head to pick up a signal from a document containing magnetic ink which is passed beneath

the read head.

The Series 90PLUS MICR reader recognizes E13-B characters. It does not read CMC-7 characters. CMC7 characters are used in Latin America and Europe.

Page 16 Rev M 12/16/99

Page 29

Programmer's Guide PcOS Series 90PLUS Control Codes

4 Control Codes Overview

This programmer's guide is designed to help users of the Series 90PLUS slip printer develop applications. Series

90PLUS printers are specialized, point-of-sale printers that have several features not normally found on general

purpose printers. Because of these special features, Series 90PLUS printers have specialized control codes. This

guide documents all of the control codes with an emphasis on those codes that are unique to the Series 90PLUS

Printer.

All PcOS Series 90PLUS Printers have both a serial and parallel interfaces. Both interfaces provide the same

printer control3 and use the same codes.

4.1 Nomenclature

When describing control codes, there is often confusion as to whether the description is decimal, hexadecimal,

or ASCII. To minimize the confusion, this guide will use the following nomenclature when describing control

code sequences:

[ ] encloses a control character. This is a single, 8-bit value as defined in the standard ASCII

tables. The ASCII chart in Appendix A lists control codes. An example would be [ESC],

which would represent a 1BH or 27 decimal.

< > encloses an 8-bit value in decimal format. The value will be from 0 to 255. An example

would be <2>, which would represent 02H or 2 decimal.

<n> indicates a variable parameter. <n> can have a value from 0 to 255. The meaning of <n> is

described and defined in the description of the command.

<n1> <n2> indicates that there are two parameters, n1 and n2, where both can have values from 0 to 255.

<m1> <m2> is an Ithaca Peripherals’ Control Language (IPCL) parameter consisting of two digits where

m1 and m2 are ASCII characters from 0 to 9. The parameter will be combined to form a

value from 0 to 99. If m3 is included, the parameter will be combined to form a value from 0

to 999. If two values are specified, there must be two bytes added to the IPCL code. In other

words, if the command specifies <m1> <m2> and the desired value is 5, the value must be

specified as 05.

x represents all other ASCII characters in control strings. For example, [ESC] 1 would

represent 1BH followed by 31H.

The CFG90 configuration and demonstration program4 uses the same nomenclature. All print examples

shown in this guide are available for CFG90.

In many cases, applications require that control sequences be specified in hexadecimal or decimal codes. In

most cases, commands are specified in ASCII, hexadecimal, and decimal. There is an ASCII chart in

Appendix A that lists ASCII, hexadecimal, and decimal equivalents.

3

The serial and parallel, IEEE 1284 interfaces provide a few additional interface capabilities over the standard

parallel interface. Both serial and parallel, IEEE 1284 interfaces provide a bidirectional data path.

4

The CFG90 distribution disk is included in a jacket on the back cover. The program runs on IBM personal

computers and compatibles. For more information, see the CFG90/150 User’s Guide following this manual.

12/16/99 Rev M Page 17

Page 30

Control Codes PcOS Series 90PLUS Programmer's Guide

4.1.1 Standard Emulation

The standard control codes for the Series 90PLUS Printer are extensions and subsets of the IBM

emulation provided on other PcOS products. In some cases, an application designed for a Series 50 Printer

with IBM code sets will function with a Series 90PLUS Printer. There are, however, significant

differences in the operation of the Series 90PLUS Printer that may impact existing applications.

4.1.2 EPOS Emulation

ESC/POS5 is referred to here as EPOS. The Series 90PLUS Printer supports an EPOS emulation with

extensions. The emulation is designed to allow the Series 90PLUS Printer to be used with Seiko Epson

printer applications. It is intended that the standard emulation be used for new applications. Not all

features of the Series 90PLUS Printer are supported by EPOS.

This guide will include the EPOS code equivalent for features of the Series 90PLUS Printer that are

supported by EPOS. When EPOS commands are significantly different from the standard emulation, an

independent EPOS description is provided.

4.1.3 IPCL Codes

Ithaca Printer Control Language (IPCL) codes are designed to control a printer without using control

characters, i.e., characters less than 20H. Only the standard emulation supports IPCL. Not all commands

are supported by IPCL codes. For the commands that are supported, the IPCL code is listed.

In rare cases, an IPCL code will interfere with the text that is to be printed. The IPCL translator can be

disabled with an [ESC] y <4> command.

4.2 Application Development

To aid in application development, there are several sections in this guide that are designed to help the

programmer understand the Series 90PLUS Printer. The first is a detailed description of each of the

commands. The second section is an explanation of how the printer works. It explains the internal print buffer,

the communication link, and how the host computer and printer interact. The third is a description on how to

use the CFG90 program to help develop applications.

4.3 Tables and Charts

Throughout this guide, there are charts and tables that list commands and features. In most cases, these charts

cross-reference the page that describes the command. Commands are grouped by function and can at times be

hard to find. To minimize the time it takes to find commands, there are two code summary charts in the

following section, one ordered by code and one by function.

5

ESC/POS is a registered trademark of the Seiko Epson Corporation.

Page 18 Rev M 12/16/99

Page 31

Programmer's Guide PcOS Series 90PLUS Printer Control Codes

Print/Paper Motion

5 Printer Control Codes

5.1 Print/Paper Motion

5.1.1 Low-level Paper Motion Control

Function Carriage return

ASCII [CR]

Hexadecimal 0DH

Decimal <13>

IPCL &%CR

EPOS 0DH

Description The [CR] command prints the contents of the print buffer (if any) and resets the

next character print position to the left margin. A line feed is not performed

unless autofeed was activated. The left margin is defined by the current print

station, the print rotation direction, and the left margin command.

Note In single line mode, the [CR] is used to terminate all lines. The printer will go

busy6 after the [CR] is received. The printer will not be ready to accept data

until the previous data is printed.

Function Line feed

ASCII [LF]

Hexadecimal 0AH

Decimal <10>

IPCL &%LF

EPOS 0AH

Description The [LF] command prints the contents of the buffer (if any) and advances the

paper one line at the current default line spacing. The next character print

position is not reset to the left margin unless auto-CR was active.

6

In one-line mode, the parallel-port busy signal will occur as a result of receiving the [CR].

In serial mode, the busy indication will be delayed until the [CR] is processed by the input software. Data sent to

the printer after the [CR] will not be lost unless the printer is power-cycled.

12/16/99 Rev M Page 19

Page 32

Printer Control Codes PcOS Series 90PLUS Programmer's Guide

Print/Paper Motion

5.1.2 Horizontal Motion Control

There are several commands that control the horizontal position of the characters. Many applications use

space control to position fields. However, the Series 90PLUS Printer has the ability to control character

position with horizontal tab stops. To move tabs, use the horizontal tab, [HT].

Function Horizontal tab

ASCII [HT]

Hexadecimal 09H

Decimal <9>

IPCL &%HT

EPOS [HT]

Description The [HT] command inserts spaces in the print buffer up to the next tab stop.

The default tab locations are every eight spaces.

Function Back space

ASCII [BS]

Hexadecimal 08H

Decimal <8>

IPCL &%BS

EPOS [BS]

Description The [BS] command prints the data in the print buffer and shifts the current

horizontal position by one character width to the left. If the current position is

at the left margin, the [BS] is ignored.

Function Set horizontal tab stops

ASCII [ESC]D<n1><n2><n3>...<ni>0

Hexadecimal 1BH 44H <n1> <n2> <n3> ... <ni> 00H

Decimal <27> <68> <n1> <n2> <n3> ... <ni> <0>

IPCL none

EPOS [ESC] D <n1> <n2> <n3> ... <ni> 0

Description The [ESC] D <n1> <n2> <n3> ... <ni> 0 command sets tab stops at the

character columns specified by <n>. The end of the setting is specified by a

<0>. All previously set tabs will be cleared by the command. There is no

default restore procedure other than to respecify the tabs. The power up default

is every eight spaces, i.e., 9, 17, 25, and so forth.

Column sizes are in accordance with the current character pitch.

Setting tabs that are beyond the station width is possible. A [CR] will be

inserted if the tab is used. Printing will begin at the home position.

Function Reset horizontal and vertical tab stops

ASCII [ESC] R

Hexadecimal 1BH 52H

Decimal <27> <82>

IPCL &%HV

EPOS none

Description The [ESC] R command resets horizontal and vertical tab stops to power up

configuration.

The power up horizontal default is every eight spaces, i.e., 9, 17, 25, and so

forth. The vertical default is every line.

Page 20 Rev M 12/16/99

Page 33

Programmer's Guide PcOS Series 90PLUS Printer Control Codes

Print/Paper Motion

Function Set justification

ASCII [ESC] a <n>

Hexadecimal 1BH 61H <n>

Decimal <27><97><n>

IPCL &%JL, &%JC, &%JR

EPOS [ESC] a <n>

Description The [ESC] a <n> command sets the horizontal justification.

Where <n> 0 left justified &%JL

1 center justified &%JC

2 right justified &%JR

8 left justified (no LF) none

9 center justified (no LF) none

10 right justified (no LF) none

The print format can be right, center, or left justified. The value of <n>

specifies the justification.

The power on default is left justified.

Notes 1. Lines that have mixed size characters within them cannot be centered. For

example, a line with mixed single- and double-high text cannot be

centered. If a line of print is to be double-high and centered, the change to

single-high print must be done after the line terminator for the double-high

line.

For example, [ESC] W <3> Centered [ESC] W <0> [CR] will not print

correctly because the printer assumes that more data will follow the [ESC]

W <0>. The correct line would be: [ESC] W <3> Centered [CR] [ESC] W

<0>.

2. Justify commands do not effect graphics.

12/16/99 Rev M Page 21

Page 34

Printer Control Codes PcOS Series 90PLUS Programmer's Guide

Vertical Motion

5.2 Vertical Motion Control

Function Fine line feed

ASCII [ESC] J <n>

Hexadecimal 1BH 4AH <n>

Decimal <27> <74> <n>

IPCL &%FM <m1> <m2> <m3>

EPOS [ESC] J <n>

Description The [ESC] J <n> function command prints the contents of the buffer (if any) and

performs a line feed of n/216 inch. The command does not change the default line

spacing value. The next character print position is reset to the left margin if the

auto-CR mode is set.

EPOS Note In EPOS mode, the command performs line feeds in n/144-inch increments.

Example of Fine Line Feed[CR]

[ESC]J<54>

This line is 1/4" below the first.

[CR][LF]

This line is spaced at the default

of 1/8". [CR][LF]

Figure 13 Data sent to printer for a fine line feed

Figure 14 Example of fine line feed

Function Set variable line space n/216 inch

ASCII [ESC] 3 <n>

Hexadecimal 1BH 33H <n>

Decimal <27><51><n>

IPCL &%SV <m1> <m2><m3>

EPOS [ESC] 3 <n>

Description The [ESC] 3 <n> command sets the default line spacing to n/216 inch. Set n = 1 to

255. The command takes effect immediately and sets the line feed spacing used by

[LF] to values other than 1/8 or 7/72 inch.

EPOS Note Line spacing of n/144 inch is used.

Function Set line space 27/216 inch

ASCII [ESC] 0

Hexadecimal 1BH 30H

Decimal <27><48>

IPCL &%ST

EPOS [ESC] 2

Description The [ESC] 0 command sets the default line spacing to 1/8 or 27/216 inch, which is

the standard eight lines per inch line spacing at initial power up.

EPOS Note In EPOS mode, the command sets 1/6-inch spacing or six lines per inch.

Page 22 Rev M 12/16/99

Page 35

Programmer's Guide PcOS Series 90PLUS Printer Control Codes

Vertical Motion

Function Set line space 21/216 or 7/72 inch

ASCII [ESC] 1

Hexadecimal 1BH 31H

Decimal <27> <49>

IPCL &%SG

EPOS none

Description The [ESC] 1 command sets the default line spacing to 21/216 inch. The line

spacing is for all-points-addressable (APA) graphic printing.

Function Set variable line space n/72 inch

ASCII [ESC] A <n>

Hexadecimal 1BH 41H <n>

Decimal <27> <65> <n>

IPCL none

EPOS none

Description The [ESC] A <n> command sets the default line spacing to n/72. Set n = 1 to 85.

The line spacing does not take effect until enabled by the [ESC] 2 command. The

command is provided to maintain backward compatibility with the Series 50,

OKIDATA, IBM, and other printers. It can also be used to print on preprinted

forms.

Function Enable [ESC] A <n> line spacing

ASCII [ESC] 2

Hexadecimal 1BH 32H

Decimal <27> <50>

IPCL none

EPOS none

Description The [ESC] 2 command enables [ESC] A <n> line spacing. [ESC] 2 is a companion

to the [ESC] A <n> command and puts the specified line spacing into effect. It will

remain in effect until another line spacing command is issued.

Function Feed <n> lines at current spacing

ASCII [ESC] d <n>

Hexadecimal 1BH 64H <n>

Decimal <27> <100> <n>

IPCL &%FL <m1> <m2>

EPOS [ESC] d

Description The [ESC] d <n> command prints the contents of the buffer (if any) and performs

<n> line feeds at the current line spacing. The command does not change the

default line spacing value. The next character print position is reset to the left

margin.

Note The IPCL command will print from 00 to 99 lines. For example, if you wish to feed

12 lines, the IPCL command would be as follows: &%FL12.