Page 1

TM

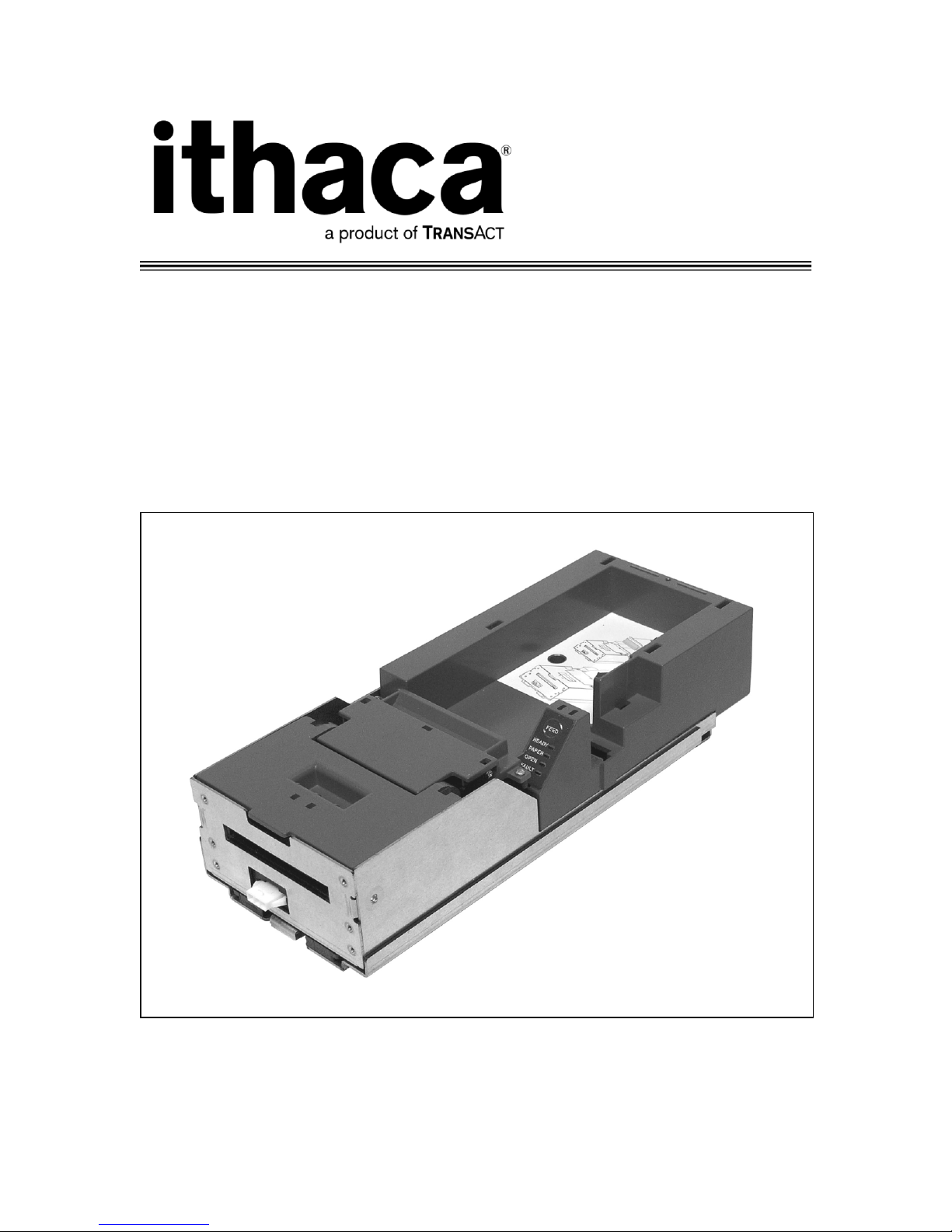

Epic 950

OEM Integration Manua l

P/N 95-05245

Rev G

Feb. 2007

Page 2

Page 3

This page intentionally left blank

Page 4

Page 5

Change History

Rev A Initial release July 2004

Rev B Add index, table of page numbers, new commands March 2005

Rev C Add additional communications interface descriptions March 2006

Rev D Added internal/external bezel s to bezel mounting section May 2006

Rev E Pg 22 – 95-06003L was 95-06003 May 2006

Rev F Revised ticket specification information Sept 2006

Rev G Pg 13 updated max operating temp values Feb 2007

95-05245 Rev G Page i

Page 6

Important:

Before installing any equipment be sure to consult the specifications in this manual.

Failure to do so may cause integration problems. Portions of this integration manual may

be changed without prior notice.

Note:

Losses that can be attributed to improper installation and working procedures are not the

responsibility of TransAct Technologies Inc. No part of this manual may be used to

recreate any part of the Epic 950TM Printer. This manual is to be used for integration

purposes only. If this manual contains any questionable information or mistakes please

contact TransAct for assistance.

Disclaimer

NOTICE TO ALL PERSONS RECEIVING THIS DOCUMENT:

The information in this document is subject to change without notice. No part of this

document may be reproduced, stored or transmitted in any form or by any means,

electronic or mechanical, for any purpose, without the express written permission of

TransAct Technologies, Inc. ("TransAct"). This document is the property of and contains

information that is both confidential and proprietary to TransAct. Recipient shall not

disclose any portion of this document to any third party.

TRANSACT DOES NOT ASSUME ANY LIABILITY FOR DAMAGES INCURRED,

DIRECTLY OR INDIRECTLY, FROM ANY ERRORS, OMISSIONS OR

DISCREPANCIES IN THE INFORMATION CONTAINED IN THIS DOCUMENT.

TransAct cannot guarantee that changes in software and equipment made by other

manufacturers, and referred to in this publication, do not affect the applicability of

information in this publication.

Copyright

© 2007 TransAct Technologies, Inc. All rights reserved.

Revision Level G

February 2007

Printed in USA

Trademarks

Some of the product names mentioned herein are used for identification purposes only

and may be trademarks and/or registered trademarks of their respective companies.

BANKjet, 50Plus, Insta-Load, Ithaca, "Made to Order. Built to Last", Magnetec, PcOS,

POSjet, PowerPocket and TransAct are registered trademarks and Epic 950, Flex-Zone,

imPort, ithaColor, iTherm, KITCHENjet, Momentum, QDT and TicketBurst are

trademarks of TransAct Technologies, Inc.

Page ii Rev G 95-05245

Page 7

Table of Contents

Change History..........................................................................................i

Disclaimer................................................................................................ii

Copyright................................................................................................. ii

Trademarks..............................................................................................ii

Table of Contents ......................................................................................iii

Figures ................................................................................................... vi

Tables .................................................................................................... vi

Introducing Your Epic 950 Printer.........................1

About Your Epic 950 Printer.........................................................................3

Who Should Read This Guide?.....................................................................4

What Is Included in This Guide?....................................................................4

Warranty Options ......................................................................................4

Technical and Sales Support........................................................................5

On-line Technical Support........................................................................5

Telephone Technical Support....................................................................5

Return Materials Auth orization and Return Policies........................................6

Service Programs ...................................................................................6

Sales Support........................................................................................6

Contact Information................................................................................7

Epic 950 Specifications and Requirements .............9

Epic 950 Specifications and Requirements .....................................................11

Standard Features.................................................................................11

Optional Features..................................................................................12

Dimensions..........................................................................................13

Interface..............................................................................................13

Printer................................................................................................13

Printer Environmental Conditions..............................................................13

Power Requirements..............................................................................13

Test Standards.....................................................................................14

Mechanism Characteristics ......................................................................14

Printing Specifications ............................................................................15

Ticket Specifications..............................................................................15

Design Envelope: Ticket Clearance ...........................................................16

Black Dot Position and Presentation Scheme...............................................17

Ticket Stack Orientation..........................................................................18

Mounting Requirements.................................... 19

Mounting Requirements .............................................................................21

Outer Chassis to Final Product.................................................................21

Custom Bezel Specifications and Recommendations.....................................22

Epic 950 Printer Sensors................................... 25

Printer Sensors........................................................................................27

Cover Open Switch................................................................................27

Ticket Low Sensor.................................................................................27

Ticket Burst Sensor...............................................................................27

Top-of-Form/Ticket Out Sensor................................................................28

95-05245 Rev G Page iii

Page 8

Ticket Taken Sensor ..............................................................................28

Chassis Open Sensor/Audible Alarm .........................................................28

Printer Status LED.................................................................................28

Electrical Connections ...................................... 31

Interface Connections................................................................................33

RS232 Serial Communications Interface PCB..............................................34

Default Communication Settings...............................................................34

USB Communications Interface PCB .........................................................35

NETPLEX Communications Interface PCB..................................................36

Universal USB/NETPLEX Communications Interface PCB..............................37

Dual Port NETPLEX Communications Interface PCB.....................................38

Dual Port RS232 Comm unications Interface PCB .........................................39

Bezel Lamp Connector..............................................................................40

Firmware Download Port............................................................................41

Printer Block Diagram................................................................................42

Operational Procedures .................................... 43

Racking/Unracking the Inner Chassis............................................................45

Loading Tickets into Feeding Mechanism.......................................................47

Removing Loaded Tickets..........................................................................49

Cleaning the Print Head.............................................................................51

Purchasing Cleaning Cards.....................................................................52

Printing a Self-test Ticket ............................................................................53

Programming for the Epic 950 ........................... 55

Programming for the Epic 950.....................................................................57

Resetting the Printer..............................................................................57

Command Parameters...........................................................................57

Character Evaluation ..............................................................................57

16-bit Character Parameters....................................................................58

Conversions.........................................................................................58

Font Statistics.......................................................................................59

Objects..................................................................................................59

Print Modes.............................................................................................59

Bitmap Graphics Mode...........................................................................59

Portrait Printing Mode.............................................................................60

Landscape Printing Mode........................................................................60

General Notes......................................................................................61

Text Objects.........................................................................................62

Bar Code Objects..................................................................................63

Graphic Objects....................................................................................64

Line Objects .........................................................................................64

The POR.INI File......................................................................................65

POR.INI File Parameter Definitions ...........................................................66

DIP Switch Settings ..................................................................................68

Flash Memory and Firmware Download Port...................................................70

Firmware Memory Features.....................................................................70

Non-Firmware Memory Features...............................................................71

Smart Suite Features ................................................................................72

Command Reference........................................ 73

BEL – Audio Alert..................................................................................76

Page iv Rev G 95-05245

Page 9

HT – Horizontal Tab ...............................................................................77

LF – Line Feed.....................................................................................78

FF – Form Feed....................................................................................79

CR – Carriage Return .............................................................................80

SO – Set Font to Double-wide..................................................................81

DC4 – Ca ncel Double-wide Mode.............................................................82

ENQ – Request Combined Printer Status....................................................83

20h – FFh – Printable Characters..............................................................84

ESC ENQ 1 – Return Version Information ...................................................85

ESC BEL – Configure Audio Alert .............................................................86

ESC SP – Set Right-Side Character Spacing...............................................87

ESC ! – Select Print Mode(s)...................................................................88

ESC $ – Set Absolute Horizontal Position in page mode.................................89

ESC * – Reset to Defaults .......................................................................90

ESC @ – Reset to Power-up Condition......................................................91

ESC B – Print Bitmap (BMP) Image...........................................................92

ESC E – Form Feed...............................................................................93

ESC F – Select Fonts.............................................................................94

ESC G – Turn Double-strike Mode On/Off...................................................95

ESC J – Feed n Sublines ........................................................................96

ESC M – Set Font to 12 cpi .....................................................................97

ESC P – Set Font to 16 cpi......................................................................98

ESC S – Set Font to 20 cpi......................................................................99

ESC T – Set Font to 7 cpi......................................................................100

ESC U – Set Font to 10 cpi....................................................................101

ESC V – Return Firmware Revision.........................................................102

ESC W – Wrap Data............................................................................103

ESC X – Set Horizontal Starting Position..................................................104

ESC Y – Set Vertical Starting Position...................................................... 105

ESC c – Select Color...........................................................................106

ESC t – Set Print Direction in Page Mode .................................................107

GS DC2 – Set Font to Double-high..........................................................108

GS DC3 – Cancel Double-high Font ........................................................109

GS RS – Set Inverse Print Mode............................................................. 110

GS US – Cancel Inverse Print Mode........................................................111

GS ! – Select Character Size.................................................................112

GS $ – Set Absolute Vertical Position in Page Mode.................................... 113

GS * – Landscape Mode Graphics..........................................................114

GS ? – CRC Verification.......................................................................115

GS 0 – Print User Defined Image............................................................116

GS 1 – Enter Download Image Mode.......................................................117

GS 3 – Image Status Handler.................................................................118

GS A – Starting Position of Bar Code.......................................................119

GS E – Set Validation Number Field........................................................120

GS F – Set Field in Page Mode..............................................................121

GS G – Print Custom Graphic ................................................................123

GS L – Set Feed Length.......................................................................124

GS S – Return Printer Status ................................................................. 125

GS T – Select Line Wrap/Truncate Modes .................................................126

GS V – Set Print Orientation..................................................................127

GS W – Set Bar Code Element Width......................................................128

95-05245 Rev G Page v

Page 10

GS d – Feed n Text Lines ......................................................................129

GS h – Set Bar Code Height ..................................................................130

GS k – Print Bar Code..........................................................................131

GS l – Draw Line in Landscape Mode ......................................................132

GS t – Set Characters per Line in Landscape.............................................133

GS u – Set Characters per Line in Portrait................................................. 134

GS w – Set Bar Code Module Width........................................................135

GS y – Request Combined Printer Status .................................................136

GS z – Request Printer Status................................................................ 137

Available Commands ..............................................................................139

Appendix A: Character Codes.......................... 141

Supported Non-Printable Control Characters................................................142

Supported Printable Characters.................................................................143

Index.......................................................... 145

Figures

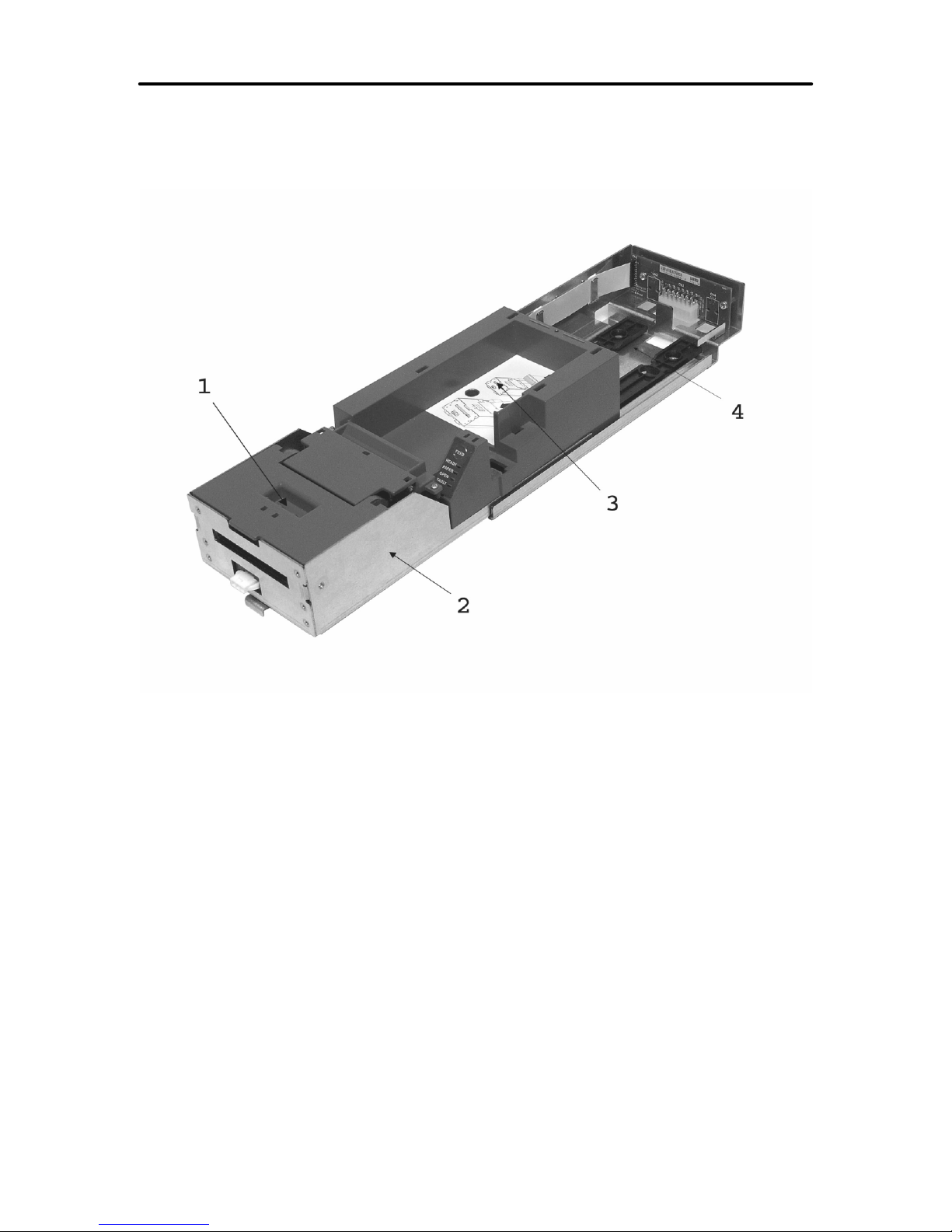

Figure 1. Epic 950 Printer Component Overview.................................................11

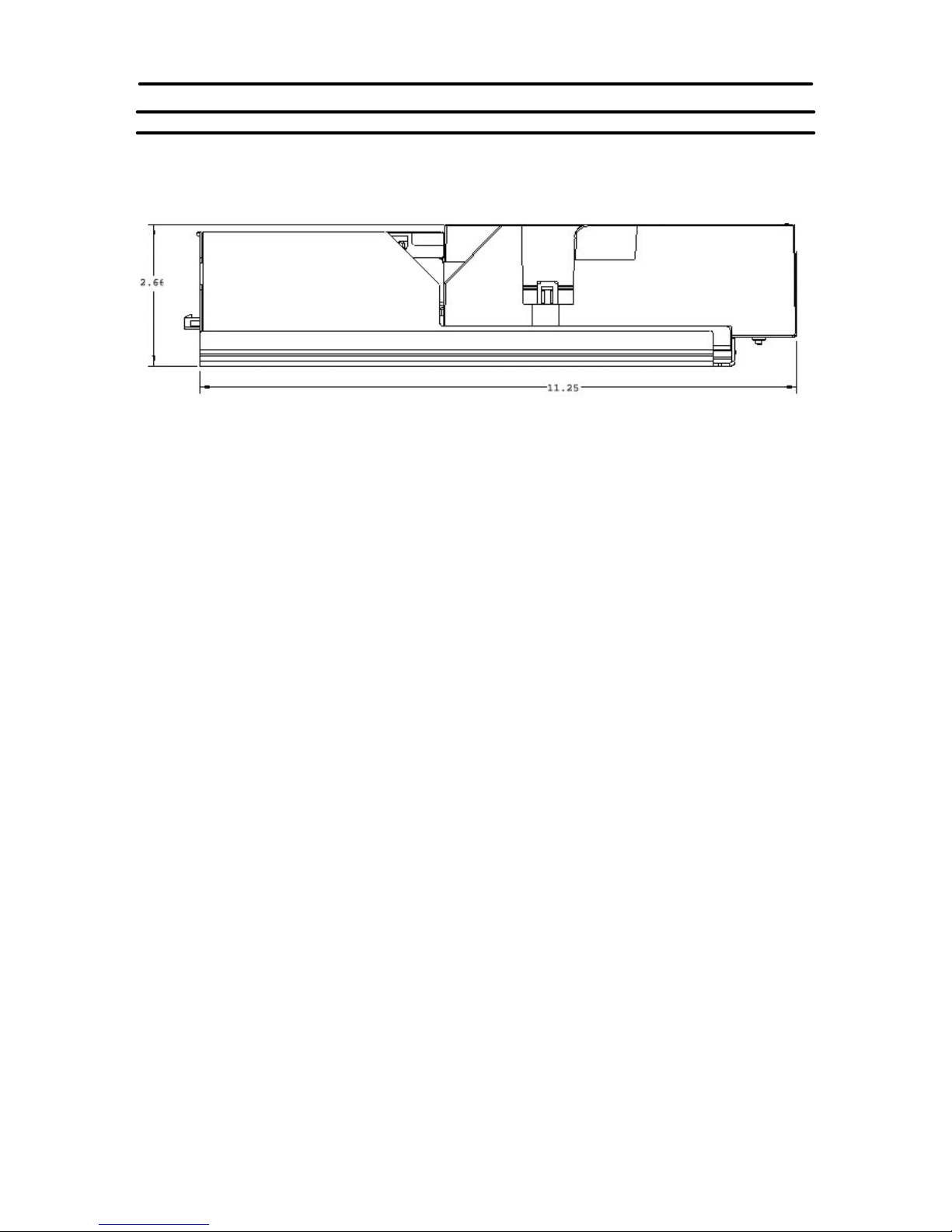

Figure 2. Epic 950 Printer: Dimensions .............................................................13

Figure 3. Maximum Mechanism Operating Angle................................................14

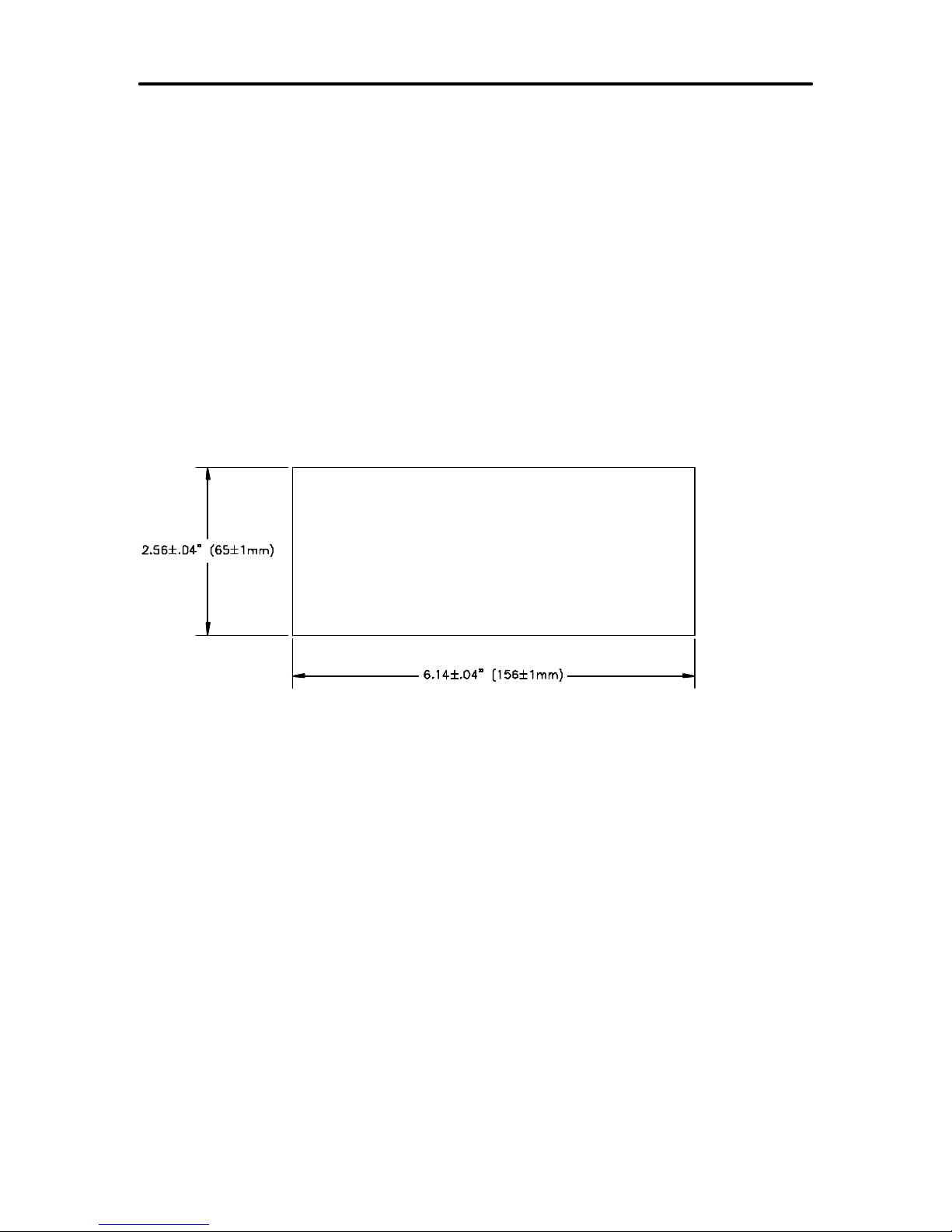

Figure 4. Sample Ticket Size..........................................................................15

Figure 5. Design Envelope: Ticket Clearance .....................................................16

Figure 6. Location of Black Dot/Top of Form Indicator on Back of Ticket...................17

Figure 7. Ticket Stack Orientation ....................................................................18

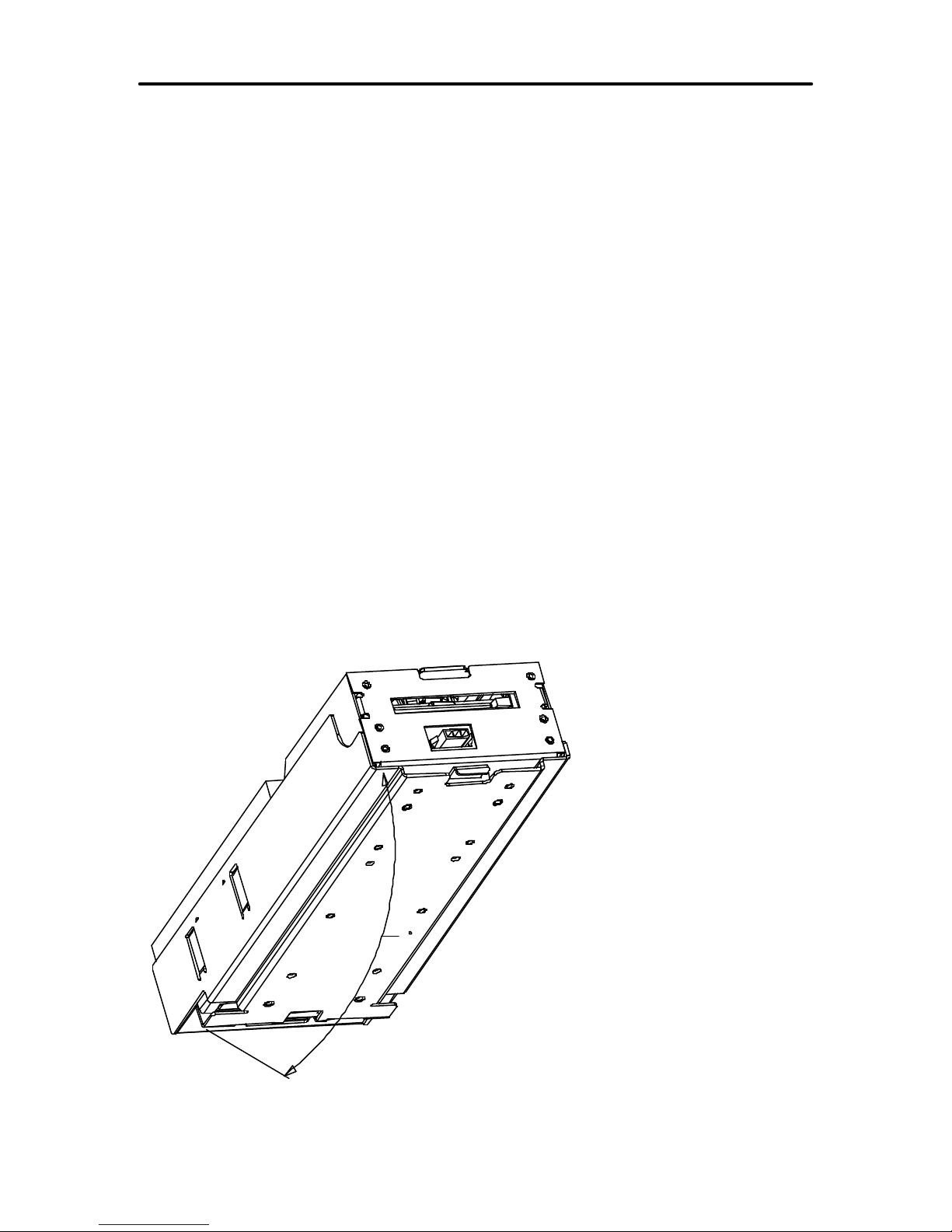

Figure 8. Outer Chassis to Final Product...........................................................21

Figure 9. Custom Bezel Mounting and Hardware Requirements..............................22

Figure 10. Epic 950 Shown with Optional Internal Bezel Assembly..........................23

Figure 11. Epic 950 Shown with Optional External Bezel Assembly.........................23

Figure 12. Sensor Breakdown and Locations .....................................................27

Figure 13. Open/Close Position/Audible Alarm....................................................28

Figure 14. Interface PCB Location (Dual Port RS232 Shown).................................33

Figure 15. Firmware Download Port.................................................................41

Figure 16. Epic 950 Electrical Operations Diagram ..............................................42

Figure 17. Racking/Unracking the Inner Chassis .................................................45

Figure 18. Ticket Loading and Ticket Feed Mechanism.........................................47

Figure 19. Ticket Cover Shown Open for Ticket Removal......................................49

Figure 20. Cleaning the Print Head..................................................................51

Figure 21. Sample self-test ticket. ....................................................................54

Figure 22. Portrait and Landscape Print Modes...................................................60

Tables

Table 1. Serial Communication PCB Pin-Outs....................................................34

Table 2. USB Communication PCB Pin-Outs......................................................35

Table 3. NETPLEX Communication PCB Pin-Outs ..............................................36

Table 4. Universal USB/NETPLEX Communication PCB Pin-Outs ..........................37

Page vi Rev G 95-05245

Page 11

Table 5. Dual Port NELTPLEX Communication PCB Pin-Outs...............................38

Table 6. Dual Port RS232 Communication PCB Pin-Outs......................................39

Table 7. Bezel Power Connector Pin-Outs.........................................................40

Table 8. Conversion from Dots to Inches ...........................................................58

Table 9. Font Statistics..................................................................................59

95-05245 Rev G Page vii

Page 12

Page 13

chapter 1

Introducing Your Epic 950 Printer

95-05245 Rev G Page 1

Page 14

This page intentionally left blank

Page 2 Rev G 95-05245

Page 15

Introducing Your Epic 950 Printer Epic 950 OEM Integration Manual

About Your Epic 950 Printer

The Ithaca Epic 950TM printer represents the very latest technology for use in gaming

ticket printing applications. It features full backward compatibility for previous users of

Ithaca Series 800 printers, together with a host of new features designed to improve the

performance of your gaming operations, including:

• TicketBurstTM, a unique buffered transport system that prints and bursts the entire

ticket internally before presenting it to the operator, solving the problem of

premature ticket removal.

• Internal separation of tickets, providing consistently perfect single tickets

accurately separated along perforation lines.

• QDTTM (Quick Disconnect Technology) lets you remove the printer without the

need to disconnect power from the unit, incorporating a one-touch hot swappable

design that lets you remove and replace your printer at the touch of a frontmounted latch.

• Expanded status LEDs, giving you immediate visibility on printer, paper and fault

status.

• The ability to upgrade your firmware completely via download, with no hardware

modification required.

• 2-color ticket printing with user-programmable images and layout, to turn your

tickets into a key part of your brand identity and marketing program.

Above all, the Epic 950 is designed for ease of programming and ease of use in your

gaming operations. While supporting the full command language and macro features of

the Series 800 printer, the Epic 950 introduces a new higher-level command interface

which lets you quickly and easily integrate more layout and printing options than ever –

while giving you the reliability, durability and uptime you have come to expect from

Ithaca printers.

95-05245 Rev G Page 3

Page 16

Introducing Your Epic 950 Printer Epic 950 O EM Integration Manual

Who Should Read This Guide?

This document provides information useful to original equipment manufacturers (OEM)

who will integrate the Epic 950 printer into their products.

Wh at Is Included in This Guide?

This Integration Manual includes information on the mechanical, electrical and command

language requirements of the Epic 950 printer. It provides the following information to

support your integration efforts:

• Warranty and technical support information.

• Specifications and functionality description.

• Mounting requirements and mounting locations.

• Power and interface connections.

• Operational procedures.

• Programming information, including documentation of low-level and high-level

command interfaces, as well as sample scripts to guide your own implementation

efforts.

We want you to have a trouble-free implementation with your Ithaca printer. For any

issues not covered in this guide, quality technical support is available on-line at

www.transact-tech.com, or by telephone at (607) 257-8901 or (877) 7ithaca – consult

the following pages for more details about our support services.

Warranty Options

All Epic 950 Printers come with a standard 24-month standard warranty covering both

parts and labor that starts upon shipment from the factory. An optional extended

warranty, covering both parts and labor for an additional 12 months, may be purchased

separately. For more information concerning the warranty options, please contact the

Sales Department at TransAct’s Ithaca facility. You are responsible for insuring any

product returned for service, and you assume the risk of loss during shipment to Ithaca

C.O.D. packages are not accepted and warranty repairs are subject to the terms and

conditions as stated on the Ithaca warranty policy.

Page 4 Rev G 95-05245

Page 17

Introducing Your Epic 950 Printer Epic 950 OEM Integration Manual

Technical and Sales Support

Your Ithaca printer is backed by the resources of TransAct Technologies, a global

technology firm with dedicated technical support and sales assistance. Here is how we

can help you:

On-line Technical Support

Our web site at www.transact-tech.com is your on-line portal to obtaining technical

assistance with your Ithaca printer. Click on the Technical Support link to find

documentation for your Epic 950 printer, including a current copy of this OEM Integration

Manual featuring:

o Command codes and descriptions.

o Character fonts.

o Printer features.

o Communication specifics.

o Ticket specifications.

Our on-line support site also includes a convenient e-mail assistance request form,

where you can submit support requests 24 hours a day, and receive a return contact

from a TransAct support technician during regular business hours.

Telephone Technical Support

Live telephone support is available Monday through Friday from 8 AM to 5 PM Eastern

US time, excluding holidays. We can provide general information about integrating Epic

950 printers with your system, technical support, documentation, or assistance in

sending a printer for service. To obtain telephone support, call TransAct's Ithaca Facility

at (607) 257-8901 and ask for Technical Support. To help us serve you faster, please

have the following information ready when you call:

• The Model Number and Serial Number of the printer.

• A list of any other peripheral devices attached to the same port as the printer.

• What application software, operating system, and network (if any) you are using.

• What happened and what you were doing when the problem occurred.

• How you tried to solve the problem.

95-05245 Rev G Page 5

Page 18

Introducing Your Epic 950 Printer Epic 950 O EM Integration Manual

Return Materials Au thorization and Return Policies

If the technical support person determines that the printer should be serviced at our

facility, and you want to return the printer for repair, we will issue you the Returned

Materials Authorization (RMA) number that is required before returning the printer.

Repairs are warranted for 90 days from the date of repair or for the balance of the

original warranty period, whichever is greater. Please prepare the printer being returned

for repair as follows:

• Pack the printer to be returned in the original packing material.

• Packing material may be purchased from TransAct's Ithaca Facility.

• Do not return any accessories unless asked to do so by a support technician.

• Write the RMA number clearly on the outside of the box.

Service Programs

TransAct Technologies Incorporated has a full service organization to meet your printer

service and repair requirements. If your printer needs service, please contact your

service provider first. If any problems still persist, you can directly contact the Ithaca

facility’s Technical Support Department at (607) 257-8901 or (877) 7ithaca for a return

authorization. International customers should contact your distributor for services.

TransAct offers the following service programs to meet your needs.

• Extended Warranty.

• Depot Repair.

• Maintenance Contract.

• Internet Support.

Sales Support

To order supplies, receive information about other Ithaca products, or obtain information

about your warranty, contact our Sales Department at the contact telephone or fax

numbers listed below. To receive information on International distribution, visit our web

site at www.transact-tech.com.

Page 6 Rev G 95-05245

Page 19

Introducing Your Epic 950 Printer Epic 950 OEM Integration Manual

Contact Information

TransAct Technologies Incorporated

Ithaca Facility

20 Bomax Drive

Ithaca, NY 14850 USA

Telephone (877) 7ithaca or (607) 257-8901

Main fax (607) 257-8922

Sales fax (607) 257-3868

Technical Support fax (607) 257-3911

Web site www.transact-tech.com

95-05245 Rev G Page 7

Page 20

Page 21

chapter 2

Epic 950 Specifications and Requirements

95-05245 Rev G Page 9

Page 22

This page intentionally left blank

Page 10 Rev G 95-05245

Page 23

Epic 950 Specifications and Requirements Epic 950 OEM Integration Manual

Epic 950 Specifications and Requirements

Figure 1. Epic 950 Printer Component Overview

1. Printer Mechanism

2. Inner Chassis Assembly

3. Printer Ticket Bucket Assembly

4. Outer Chassis Assembly

Standard Features

The following features are common to the Epic 950 Printers:

Key features:

• Perforated fan folded tickets in a stack of 200, 300 or 400 tickets.

• Barcode and total ticket cash-out capabilities.

• TicketBurstTM – incorporating print, burst and transport zones, where the ticket is

completely printed and burst before transport to operator.

• HotSwap QDTTM (Quick Disconnect Technology), a hot swappable printer

mechanism design for easy service.

• Modular interface PCB.

95-05245 Rev G Page 11

Page 24

Epic 950 Specifications and Requirements Epic 950 OEM Integration Manual

Other standard features:

• Selections of 7.5, 10, 12, 16.5 and 20 characters per inch printing.

• Selectable printing of Normal, Double-high, Double-wide and Double-

high/Double-wide.

• Sensors for Burst Ticket, Ticket Low, Top-of-Form/Ticket Out, Chassis Open,

and Ticket Taken.

• Cover Open switch.

• Modular printer mechanism, ticket tray and sliding unit for easy maintenance.

• Open ticket path for ticket jam clearing.

• Operator interface: FEED button, status LED’s (Ready/Paper/Open/Fault).

• Bezel lamp connection.

• imPortTM firmware and graphics download port.

• Print face down.

• Page mode printing.

• Audible Buzzer.

Optional Features

• 600 count ticket capacity using optional extender walls.

• Dual port interface capable.

• RS-232 interface capable.

• USB interface capable.

• Bezels (Internal and external).

Page 12 Rev G 95-05245

Page 25

Epic 950 Specifications and Requirements Epic 950 OEM Integration Manual

(Dimensions reflect use of 200 unit ticket bucket unless otherwise noted)

Dimensions

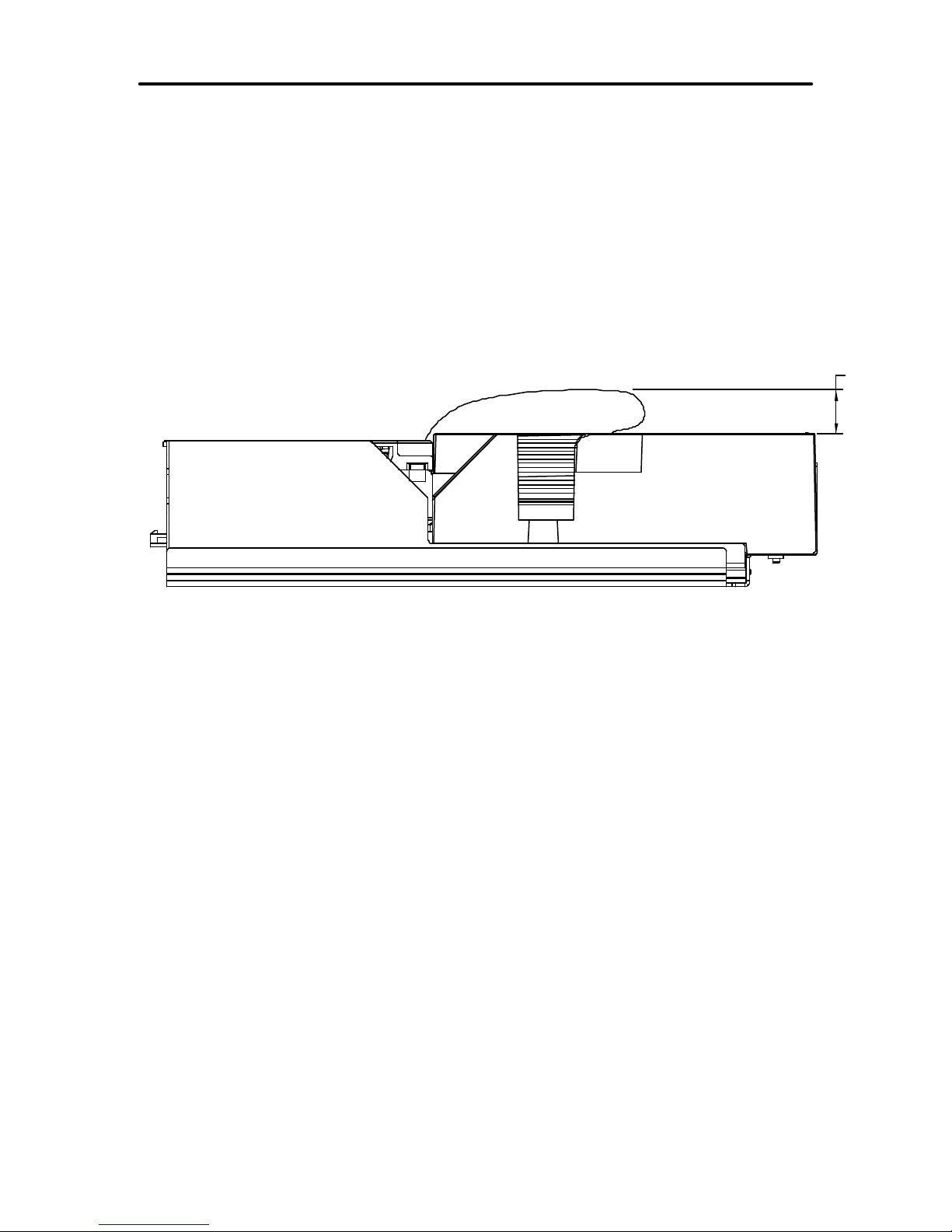

Figure 2. Epic 950 Printer: Dimensions

Stationery Module Size: H: 2.66" (66.6mm) W: 4.66" (112.5 mm) D: 11.25" (284.2 mm)

The Epic 950 is a stationery module, and is designed to work with any of the three

interchangeable ticket capacities using extender walls. Please be sure to specify the desired box

size when making your selections.

200 ticket setup: H: 2.66" (66.6mm) W: 4.66" (112.5 mm) D: 11.25" (284.2 mm)

400 ticket setup: H: 4.04" (102.6 mm) W: 4.66" (112.5 mm) D: 11.25" (284.2 mm)

600 ticket setup: H: 5.54" (140.7 mm) W: 4.66" (112.5 mm) D: 11.25" (284.2 mm)

Weight: 3.8 lbs.

Interface

Type Bi-Directional, serial RS-232 using transmit, receive, and ground.

Protocol Ready/Busy or XON/XOFF, 9600 baud, 8 data bits, no parity,

1 start bit, 1 stop bit.

Printer

Printer Type: Fixed linear thermal head.

Printer Environmental Conditions

Operating Temperature Range: 5º ~ 60ºC (41º ~ 140ºF)

Shipping/Storage Temperature Range: –10º ~ 50ºC (14º ~ 122ºF)

Operating Humidity Ra nge: 10% ~ 90% Noncondensing only

Shipping/Storage Humidity Range: 5% ~ 90% Noncondensing only

Power Requirements

24 Vdc ± 10%.

2.2 Amps max. @ 24 Vdc @ 25% print ratio.

95-05245 Rev G Page 13

Page 26

Epic 950 Specifications and Requirements Epic 950 OEM Integration Manual

Test Standards

EN50081-1-1992

EN55022-1998, Class A

FCC CFR-47, Part 15, Class A

EM55082-1-1998

EN55024-1998

EN61000-4-2, Level 3

EN6100-4-3, Level 2

EN61000-4-4, Level 2

EN61000-4-5, Level 2

EN61000-4-6, Level 2

ESD IEC 1000-4-2, 6kv direct discharge and 8kv air discharge.

Radiated RF IEC 1000-4-3, 3 v/m from 27 MHz to 1 GHz.

Fast transit (burst) IEC 1000-4-4, 2kv powerline, 1kv I/O lines (level 3, Industrial environment).

Acoustic Noise: Less than 65 decibels max . while printing a 30/30 format.

(measured in 10 positions @ operator level with distance of 1 meter, per ISO 779).

Mechanism Characteristics

Drawer Slide Force: TBD lbs. max.

Opening Distance: 190mm (7.5") (approximate ).

Drawer Holding Force: 4.5 lbs. (out of detents).

Mechanism Operating Angle: Horizontal to 45º inclination (ticket exit slot up).

45

Figure 3. Maximum Mechanism Operating Angle

Page 14 Rev G 95-05245

Page 27

Epic 950 Specifications and Requirements Epic 950 OEM Integration Manual

Printing Specifications

Print Method: Thermal Sensitive Line Dot System.

Ticket Handling: TicketBurstTM ticket buffering with burst.

Print Speed: 125 mm/sec. (5" per sec.) max. (monochrome) (in text mode).

Presentation Speed: 125 mm/sec. (10" per sec.) min.

Resolution: 203dpi x 203dpi.

Dot Pitch-Horizontal: 0.125 mm (8 dots/mm).

Dot Pitch-Vertical: 0.125 mm (8 dots/mm).

Line Feed Pitch: 3.2 mm (.125").

No. of Elements: 496 dots in -line.

Print Width: 62.0 mm (2.44" ).

Ticket Specifications

Dimension: (same size as US dollars)

Figure 4. Sample Ticket Size

Ticket Width: 65 ± 1mm (2.56" ± .03").

Ticket Length: 156 ± 1mm (6.14" ± .04") between perforations.

Ticket Thickness: 4.5-5.0 mils (.114-.127 mm).

Ticket Weight: 27# (102 g/m) Ave.

Brightness: 89% Ave. (84%Min.), Test method TAPPI T-525

Printing Colors: Black (visible light absorption: 600 ~ 700 nm), Red, Green, Blue

Quantities Available: Fan-folded stacks of 200, 300, 400 and 600 tickets.

Contract Transact for complete ticket specifications and approved suppliers

Bar Code Specifications

Standard Bar Code: Interleaved. 2 of 5

Minimum Bar Width: 0.5 mm min./0.6 max.

W : N Ratio: 3 : 1 (recommended, with 12:4 wide bar width (dots):narrow bar

width (dots)).

95-05245 Rev G Page 15

Page 28

Epic 950 Specifications and Requirements Epic 950 OEM Integration Manual

# of Characters: 6 min./18 max.

Symbol Contrast Value: 70% min.

Applicable Standards: ANSI X3.182

gsa-p0038.001.01

Design Envelope: Ticket Clearance

A minimum paper clearance distance of .75" is required above the printer’s ticket

buckets. The minimum clearance for all ticket buckets will vary, but should fall within the

.75" minimum clearance measurement.

.75

Figure 5. Design Envelope: Ticket Clearance

Page 16 Rev G 95-05245

Page 29

Epic 950 Specifications and Requirements Epic 950 OEM Integration Manual

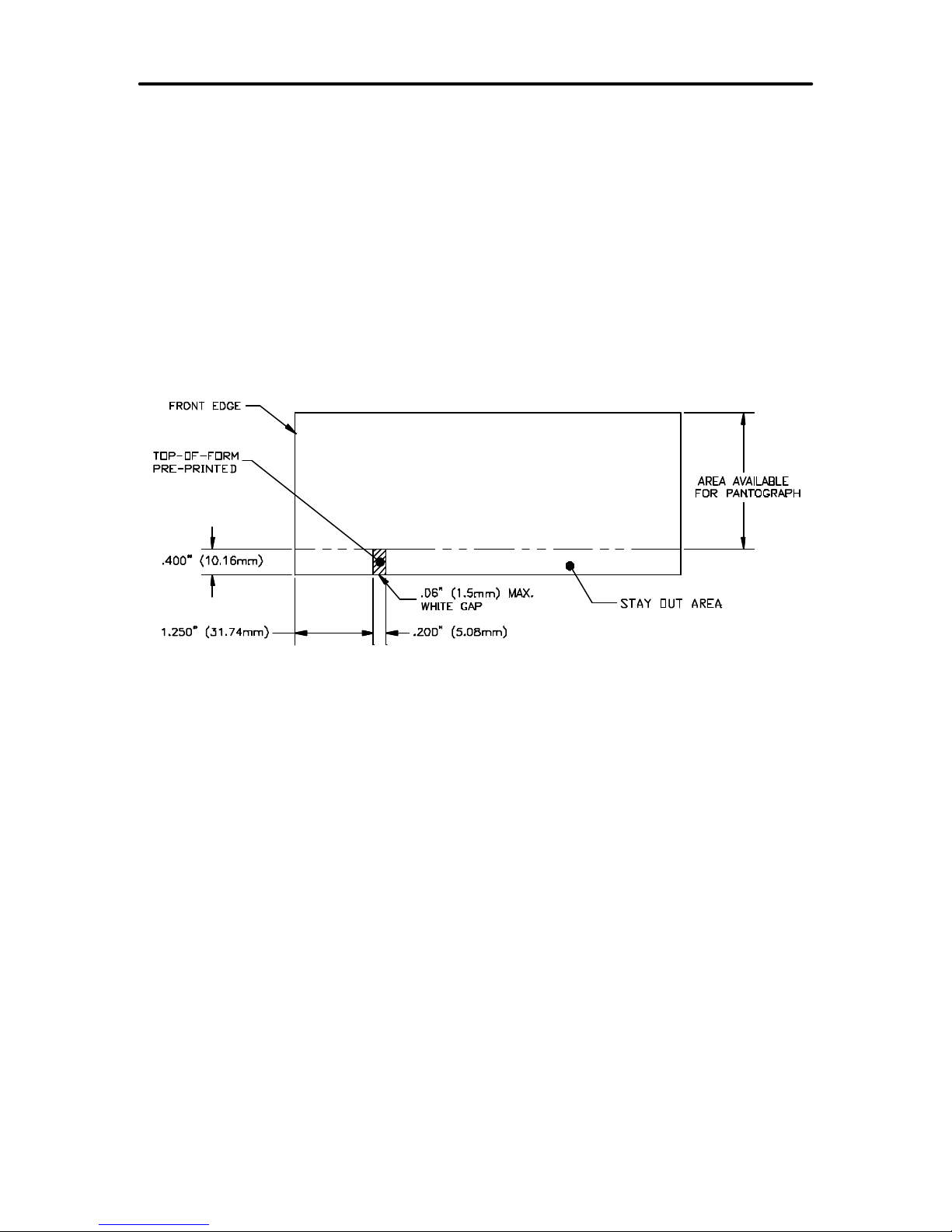

Black Dot Position and Presentation Scheme

All graphics preprinted on the ticket must be in thermal paper compatible ink.

Black Dot Position

The back of the ticket is used for the Black Dot/Top of Form indicator. For the printer to

sense when a ticket has been indexed to the printing position, a Black Dot/Top of Form

sensor is needed. It must be printed in black, thermal paper compatible, infrared

readable ink. The 10.16mm area in line with the Black Dot/Top of Form indicator and

the ticket edge (keep-out zone) must remain clear, as the Ticket Out Sensor will read

that area while the ticket is printed and presented. The remaining area on the back of the

ticket may be used for rules and disclaimer.

Figure 6. Location of Black Dot/Top of Form Indicator on Back of Ticket

95-05245 Rev G Page 17

Page 30

Epic 950 Specifications and Requirements Epic 950 OEM Integration Manual

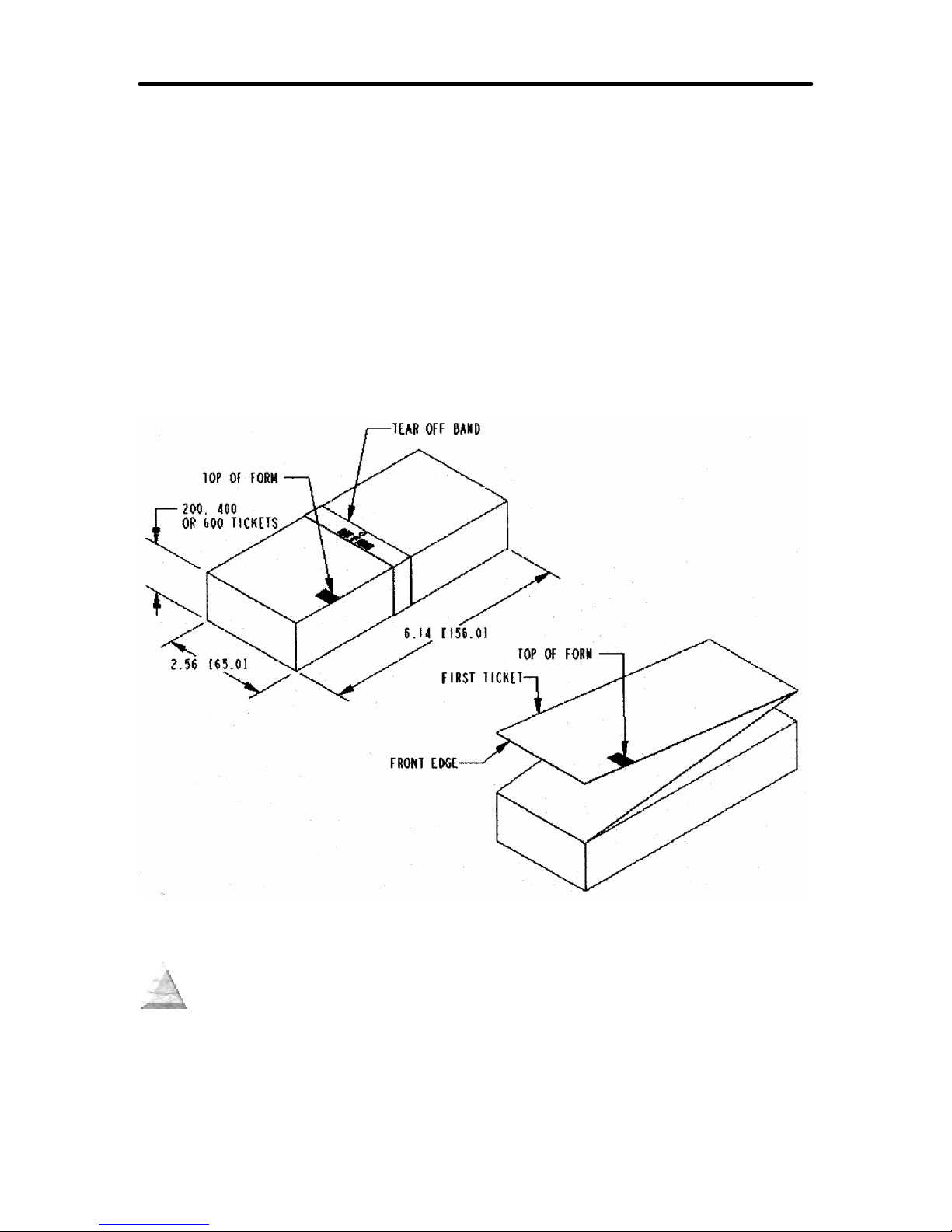

Ticket Stack Orientation

To ensure the ticket is loaded correctly into the printer, the ticket stack must be properly

loaded in the ticket box. The stack must be oriented so that the Black Dot/Top of Form

mark of the tickets is on the leading edge of the ticket, not near the perforation of the

next ticket. If the top ticket on the stack has the back facing upward, the perforation

attaching the next ticket will be toward the front of the Ticket Tray with the Black Dot/Top

of Form indicator in the rear right corner. If the print area is facing upward, the

perforation attaching the next ticket will be toward the rear of the Ticket Tray. For

instructions on inserting the first ticket into the printer, see the section “Loading Tickets

into Feeding Mechanism”.

Figure 7. Ticket Stack Orientation

Page 18 Rev G 95-05245

Page 31

chapter 3

Mounting Requirements

95-05245 Rev G Page 19

Page 32

This page intentionally left blank

Page 20 Rev G 95-05245

Page 33

Mounting Requirements Epic 950 OEM Integration Manual

Mounting Requirements

Outer Chassis to Final Product

Bottom: 4x M4x 0.7 press nuts.

4x ? .180" thru holes .

2.024

1.904

M4x0.7

PEM NUTS

4PLS

.180

4PLS

4.430

Figure 8. Outer Chassis to Final Product

4.500

7.875

3.500

1.250

95-05245 Rev G Page 21

Page 34

Mounting Requirements Epic 950 OEM Integration Manual

Bezel Specifications and Recommendations

Bezel to Printer Mechanism mounting points

Epic 950 printers are designed to accommodate a TransAct or customer-supplied bezel

assembly that is mounted following the hardware and mounting dimensions as listed.

The following drawing shows the positioning and dimensions of the Epic 950 printer’s

mounting points.

Bezel assemblies available from TransAct include internal bezels (part nos. 95-06003L

(yellow) and 95-06005 (blue), with other colors available) and an external bezel (part no.

85-04645L). Part specifications are described in the Epic 950 Maintenance Manual,

document no. 95-05140. For further details, contact your TransAct sales representative.

Front: 6x M3x 0.5 press nuts and interface with bezel .

TOP OF SLIDING MODULE

SIDE OF SLIDING MODULE

4.430

3.662

.940

1.831

C OF TICKET

L

Figure 9. Bezel Mounting and Hardware Requirements

2.409

.337

.258

.499

.500

M3x0.5

PRESS NUTS

6PLS

.497

2.176

Page 22 Rev G 95-05245

Page 35

Mounting Requirements Epic 950 OEM Integration Manual

Figure 10. Epic 950 Shown with Optional Internal Bezel Assembly.

Figure 11. Epic 950 Shown with Optional External Bezel Assembly.

95-05245 Rev G Page 23

Page 36

Page 37

Mounting Requirements Epic 950 OEM Integration Manual

chapter 4

Epic 950 Printer Sensors

95-05245 Rev G Page 25

Page 38

This page intentionally left blank

Page 26 Rev G 95-05245

Page 39

Epic 950 Printer Sensors Epic 950 OEM Integration Manual

Printer Sensors

The Epic 950 printers use several sensors to provide feedback to the host system. The

Communications PCB handles all power and interface communications.

(Covers not shown for clarity)

Figure 12. Sensor Breakdown and Locations

Cover Open Switch

The Cover Open switch detects the case where the Ticket Cover is open, and halts the

printing and ticket feeding process until the Ticket Cover is closed.

Ticket Low Sensor

A Ticket Low Sensor optically senses the number of tickets remaining in the printer’s

ticket bucket. The sensor will detect when the number of tickets reaches below 5-10

tickets. The ticket low status will be reported on the status byte, when the host issues a

status request.

Ticket Burst Sensor

A Ticket Burst sensor is used to detect that the ticket has been separated before it is

presented. Note that the Epic 950 printer incorporates a TicketBurstTM feature which

automatically burst tickets prior to presentation to the operator.

95-05245 Rev G Page 27

Page 40

Epic 950 Printer Sensors Epic 950 OEM Integration Manual

Top-of-Form/Ticket Out Sensor

A Top of Form/Ticket Out Sensor is used to control ticket loading and printing.

Ticket Taken Sensor

A Ticket Taken Sensor is used to determine when customers have actually taken the

printed ticket.

Chassis Open Sensor/Audible Alarm

The printer has a Chassis Open sensor to determine if the Inner Chassis is in the fullracked position. If the Inner Chassis is not in the fully racked position, then the printer

status LED will blink, indicating the printer is not ready.

1. Chassis Open Sensor (Sliding Module).

2. Audible Alarm Buzzer (PIEZO - game controlled).

Figure 13. Open/Close Position/Audible Alarm

Printer Status LED

The printer has been outfitted with a LED panel system that provides the condition of the

printer by using solid or blinking status LEDs to communicate status information. The

following table lists the different LED states for specific conditions within the printer.

Page 28 Rev G 95-05245

(Ticket Bucket not shown for clarity)

Page 41

Epic 950 Printer Sensors Epic 950 OEM Integration Manual

Condition Ready LED Paper LED Open LED Fault LED

Unit Ready On Off Off Off

Cover Open On Off On Off

Chassis Open On Off Blink Off

Ticket Out On On Off Off

Ticket Low On Blink Off Off

Temperature Error Blink Off Off Blink

Paper Jam On Off Off Blink

Ram Error 2-Blink Off Off On

Checksum Error 4-Blink Off Off On

Table 2 Printer Status LED Indication Descriptions

95-05245 Rev G Page 29

Page 42

Page 43

chapter 5

Electrical Connections

95-05245 Rev G Page 31

Page 44

This page intentionally left blank

Page 32 Rev G 95-05245

Page 45

Electrical Connections Epic 950 OEM Integration Manual

Interface Connections

The Epic 950 printer is equipped with one of several communication interface options. In

all cases power and communication connections are made to a connector or

connectors located at the rear of the printer.

1. RS232 Serial

2. USB

3. NETPLEX

4. Universal USB / NETPLEX

5. Dual Port – NETPLEX

6. Dual Port – RS232

Communications interface options 3-6 utili ze communications protocols that are

proprietary to specific manufacturers and are subject to licensing requirements. In these

cases only the interface pin connections are described in this manual.

Figure 14. Interface PCB Location (Dual Port RS232 Shown)

95-05245 Rev G Page 33

Page 46

Electrical Connections Epic 950 OEM Integration Manual

RS232 Serial Communications Interface PCB

T he RS232 Serial interface connector is a 14 position Molex Minifit Jr®., part number 3930-1140, which mates with Molex part number 39-01-2140 or equivalent.

1 2 3 4 5 6 7

8 9 10 11 12 13 14

Serial Communication PCB Pin-Outs

PIN # FUNCTION I/O

1 MRESET (Active low) I

2 Not Connected N/C

3 +12 VDC I

4 Not Connected N/C

5 GND 6 +24VDC 7 GND 8 +24VDC 9 Bezel Lamp – Switched +24VDC O

10 FGND 11 RS232 RXD I

12 RS232 TXD O

13 DTR O

14 RTS O

Table 1. Serial Communication PCB Pin-Outs

Default Communication Settings

The RS -232C interface default configuration settings are:

Baud Rate: 9600 BPS

Data Bits: 8 Bits

Parity: None

Stop Bits: 1

Handshaking: XON/XOF

Receive Error: Prints

Input Buffer 8,192 bytes

These communications settings may be altered only through the use of the CONFIG

program, special printer configuration software available from TransAct. Contact

TransAct Technical Support for further information on this utility.

Page 34 Rev G 95-05245

Page 47

Electrical Connections Epic 950 OEM Integration Manual

USB Communications Interface PCB

The USB Communications PCB contains two connectors.

§ Power - 4 position Molex Minifit Jr®., part number 39-30-1040, which mates with

Molex part number 39-01-2040 or equivalent .

§ USB Communications - Type B USB connector

1 2

3 4

12

3 4

USB Comm unications PCB Pin-Outs

USB Connector

Pin # FUNCTION I/O

1 VBUS 2 D - I/O

3 D+ I/O

4 GND Power Connector

Pin # FUNCTION

1 +24VDC 2 GND 3 GND 4 FGND -

Table 2. USB Communication PCB Pin-Outs

95-05245 Rev G Page 35

Page 48

Electrical Connections Epic 950 OEM Integration Manual

NETPLEX Communications Interface PCB

The NETPLEX Communications interface connector is a 10 position Molex Minifit Jr®.,

part number 39-30-1100, which mate s with Molex part number 39-01-2100 or equivalent.

1 2 3 4 5

6 7 8 9 10

NETPLEX Communication PCB Pin-Outs

PIN # FUNCTION I/O

1 MRESET (Active low) I

2 RXD I

3 +12 VDC I

4 TXD O

5 SGND 6 +24VDC 7 GND 8 +24VDC 9 Bezel Lamp – Switched +24VDC O

10 GND -

Table 3. NETPLEX Communication PCB Pin-Outs

Page 36 Rev G 95-05245

Page 49

Electrical Connections Epic 950 OEM Integration Manual

Universal USB/NETPLEX Communications Interface

PCB

The Universal USB/NETPLEX interface supports both USB and NETPLEX

communications. This interface contains three connectors:

§ Power - 4 position Molex Minifit Jr®., part number 39-30-1040, which mates with

Molex part number 39-01-2040 or equivalent.

§ NETPLEX communications- 6 position Molex Minifit Jr®., part number 39-301060, which mates with Molex part number 39-01-2060 or equivalent.

§ USB Communications - Type B USB connector.

1 2

3 4

1 2 3

4 5 6

12

3 4

Universal USB/NETPLEX Communication PCB Pin-Outs

USB Connector

Pin # FUNCTION I/O

1 VBUS 2 D - I/O

3 D+ I/O

4 GND Power Connector

Pin # FUNCTION

1 +24VDC 2 GND 3 GND 4 FGND NETPLEX Connector

Pin # FUNCTION

1 MRESET (Active low) I

2 RXD I

3 +12 VDC I

4 TXD O

5 SGND 6 Bezel Lamp – Switched +24VDC O

Table 4. Universal USB/NETPLEX Communication PCB Pin-Outs

95-05245 Rev G Page 37

Page 50

Electrical Connections Epic 950 OEM Integration Manual

Dual Port NETP LEX Communications Interface PCB

The Dual Port NETPLEX Communications interface contains three connectors

§ NETPLEX Communications. - 10 position Molex Minifit Jr®., part number 39-301100 for NETPLEX connections which mates with Molex part number 39-012100 or equivalent.

§ I2C Communications - 2 modular RJH connections The connectors are

electrically connected to allow daisy chaining of multiple devices.

1 2 3 4 5

6 7 8 9 10

1 2 3 41 2 3 4

NETPLEX Communication PCB Pin-Outs

NETPLEX Connector

Pin # FUNCTION I/O

1 MRESET (Active low) I

2 Not Connected N/C

3 +12 VDC I

4 Not Connected N/C

5 GND 6 +24VDC 7 GND 8 +24VDC 9 Bezel Lamp – Switched +24VDC O

10 GND -

I2C Port

Pin # FUNCTION

1 RESET I

2 SCL I

3 SDA I/O

4 GND

Table 5. Dual Port NELTPLEX Communication PCB Pin-Outs

Page 38 Rev G 95-05245

Page 51

Electrical Connections Epic 950 OEM Integration Manual

Dual Port RS232 Communications Interface PCB

The Dual Port RS232 Communications interface contains three connectors

§ RS232 Communications14 position Molex Minifit Jr®., part number 39-30-1140

which mates with Molex part number 39-01-2040 or equivalent.

§ I2C Communications -2 two modular RJH connections for a secondary I2C port.

The two modular connectors are electrically connected to allow daisy chaining of

multiple devices.

1 2 3 4 5 6 7

1 2 3 4

8 9 10 11 12 13 14

1 2 3 4

NETPLEX Communication PCB Pin-Outs

RS 232 Connector

Pin # FUNCTION I/O

1 MRESET (Active low) I

2 Not Connected N/C

3 +12 VDC I

4 Not Connected N/C

5 GND 6 +24VDC 7 GND 8 +24VDC 9 Bezel Lamp – Switched +24VDC O

10 FGND 11 RS232 RXD I

12 RS232 TXD O

13 DTR O

14 RTS O

I2C Port

Pin # FUNCTION

1 RESET I

2 SCL I

3 SDA I/O

4 GND

Table 6. Dual Port RS232 Communication PCB Pin-Outs

95-05245 Rev G Page 39

Page 52

Electrical Connections Epic 950 OEM Integration Manual

Bezel Lamp Connector

The bezel connector is a Molex Minifit Jr®, part number 39-01-4032 and will mate with a

Molex part number 39-01-4030 or equivalent.

123

Figure 11. Bezel Lamp Connector Location and Connector Information

Bezel Lamp Connector Pin-Outs

PIN # FUNCTION

1 Modulated +24VDC

2 Not Connected

3 GND

Table 7. Bezel Power Connector Pin-Outs

Page 40 Rev G 95-05245

Page 53

Electrical Connections Epic 950 OEM Integration Manual

Firmware Download Port

The Epic 950 printer features an imPortTM firmware and graphics download port, as

shown in the figure below. This port uses a 4-pin Molex connector with an RS -232

interface. For further details on this use of this proprietary download port, please contact

TransAct Technical Support.

Figure 15. Firmware Download Port.

95-05245 Rev G Page 41

Page 54

Electrical Connections Epic 950 OEM Integration Manual

Printer Block Diagram

Figure 16. Epic 950 Electrical Operations Diagram

Page 42 Rev G 95-05245

Page 55

chapter 6

Operational Procedures

95-05245 Rev G Page 43

Page 56

This page intentionally left blank

Page 44 Rev G 95-05245

Page 57

Operational Procedures Epic 950 OEM Integration Manual

Racking/Unracking the Inner Chassis

All Epic 950 printers use a slider/detent/latch system with latch arms to retain the Inner

Chassis from accidentally being separated from the Outer Chassis. The Epic 950 is

opened for service by simply pulling on the ticket cover, pulling the Inner Chassis

forward from the Outer Chassis as you would a filing cabinet. If accessible, a frontmounted release lever can also be pulled on to disengage and slide the Inner Chassis.

Figure 17. Racking/Un racking the Inner Chassis

To remove the Inner Chassis, perform the following steps:

• Pull on the Ticket Cover to release the rear detents, pulling the Inner Chassis

towards you until its latches catch the forward detent slots in the Outer Chassis

Slides.

• Pull on the Release Lever and pull forward on the Inner Chassis to disconnect

from the Outer Chassis. (This assembly incorporates a HotSwap QDT (Quick

Disconnect Technology) design, which may be removed while power is still on to

the unit.)

To return the Inner Chassis to its base, perform the following steps:

95-05245 Rev G Page 45

Page 58

Operational Procedures Epic 950 OEM Integration Manual

• Align the base of the Inner Chassis with the outer walls of the Outer Chassis,

seating it within side walls A and B as shown in Figure 17.

• While pulling outwards on the Release Lever, slide the Inner Chassis towards the

rear of the Outer Chassis until it latches at the rear of the Outer Chassis.

Page 46 Rev G 95-05245

Page 59

Operational Procedures Epic 950 OEM Integration Manual

Loading Tickets into Feeding Mechanism

When loading new ticket stacks, be sure that there is power to the printer. The first ticket

of the stack must be inserted into the printer by hand. The Epic 950 printers’ ticket tray is

integrated with a guide to direct the ticket into the printer mechanism. Once the leading

ticket enters the Top of Form sensor, the ticket will be automatically fed into the Printer

Mechanism.

Figure 18. Ticket Loading and Ticket Feed Mechanism

95-05245 Rev G Page 47

Page 60

Operational Procedures Epic 950 OEM Integration Manual

Loading tickets into the ticket supply box: (Refer to the label on printer)

• Load tickets into the ticket supply tray, making sure that the Black Dot is

positioned as shown in Figure 18.

• Orient the tickets so that the Black Dot is towards the leading edge of the ticket.

Feeding tickets into the Printer Mechanism: (Refer to the label on printer)

• Check to ensure that the tickets have been placed in the ticket tray with the

proper black dot orientation.

• Insert the leading ticket into the Printer Mechanism’s insertion guide area. The

ticket should be fed about a ½" into the mechanism; at this time, the machine

automatically completes the feeding process.

• If printer has been slid out from rack, make sure that the printer is closed.

• The printer is ready to receive information.

Page 48 Rev G 95-05245

Page 61

Operational Procedures Epic 950 OEM Integration Manual

Removing Loaded Tickets

The Epic 950 printers have two ways to remove unused tickets from the printer

mechanism:

• The first way is to release the Ticket Cover by lifting and rotating backward, this

will relieve pressure to the platen and tickets can be removed. This also will allow

an opening that provides space to check the printer for ticket jams, or prepare the

paper path for ticket replenishing.

• The second way is to use the feed button, which will feed out tickets from within

the printer mechanism.

Figure 19. Ticket Cover Shown Open for Ticket Removal

Unloading Tickets from the Printer by opening the Ticket Cover

1. Pull Inner Chassis away from the Outer Chassis until it stops in the open

position.

2. Lift and rotate the Ticket Cover backwards, towards the rear of the printer.

3. Remove all tickets from the ticket path and check for any debris.

4. Remove any remaining tickets from the ticket tray.

5. Rotate the Ticket Cover into its original closed and latched (Magnetic) position.

95-05245 Rev G Page 49

Page 62

Operational Procedures Epic 950 OEM Integration Manual

6. Proceed with ticket loading procedure.

Page 50 Rev G 95-05245

Page 63

Operational Procedures Epic 950 OEM Integration Manual

Cleaning the Print Head

Two kinds of periodic cleaning operations will ensure continued high print quality from

your Epic 950 printer:

1. Paper dust removal. Use a soft brush to clean the paper dust from inside the printer

and chassis area. The paper dust should also be removed from the sensor optics.

2. Cleaning thermal print head. If streaking on the printed ticket is evident, the thermal

print head may need to be cleaned. This can be done by inserting a thermal printer

cleaning card, as shown in the instructions below:

Figure 20. Cleaning the Print Head

Detailed instructions

1. Open the cover and remove all tickets from ticket feed path.

2. Close the cover.

3. Open cleaning card pouch and remove cleaning card.

4. Insert cleaning card into feed path.

5. The cleaning card will automatically be drawn into the feed path.

95-05245 Rev G Page 51

Page 64

Operational Procedures Epic 950 OEM Integration Manual

6. Open the cover and then remove the cleaning card by gently pulling it back.

7. Repeat process if necessary.

8. Properly dispose of used cleaning card.

Purchasing C leaning Cards

Cleaning cards are available through TransAct – consult Chapter 1 for contact

information by telephone or the Internet. Cards can also be purchased direct from

Enefco International Ltd. at (888) 578-0141.

Description: Part Number:

2.5" x 6" Thermal Cleaning Card (box of 25) 100-03322 (TransAct)

2.5" x 6" Thermal Cleaning Card (box of 25) GTP250PB (Enefco)

Page 52 Rev G 95-05245

Page 65

Operational Procedures Epic 950 OEM Integration Manual

Printing a Self-test Ticket

The Epic 950 printer has the ability to print a pre-defined self -test ticket, to test the

normal printing functionality of the unit, and create a printout of the current printer

configuration. To print a self-test ticket, perform the following steps:

1. Unrack the Inner Chassis.

2. Open the Ticket Cover. Do not remove a currently loaded ticket.

3. Press and hold the feed button until the Open LED goes out, then release this button.

4. Now close the Ticket Cover, and the self-test ticket will then print.

5. Close the Inner Chassis to resume normal operation.

Figure 21 shows an example of the information printed. Your printer may print more or

less information, depending on the version and revision of the printer.

95-05245 Rev G Page 53

Page 66

Operational Procedures Epic 950 OEM Integration Manual

Figure 21. Sample self-test ticket.

Page 54 Rev G 95-05245

Page 67

chapter 7

Programming for the Epic 950

95-05245 Rev G Page 55

Page 68

This page intentionally left blank

Page 56 Rev G 95-05245

Page 69

Programming for the Epic 950 Epic 950 OEM Integration Manual

Programming for the Epic 950

NOTE: This programming guide applies only to printers equipped with RS232 interface

and running standard RS232 firmware.

The first step in programming the Epic 950 is to understand how the printer works. This

section covers all the points that need to be understood to program the Epic 950 Printer

correctly, including both basic and advanced topics.

As an ASCII-based printer, the Epic 950 accepts 8-bit ASCII characters as both data and

commands. The ASCII table in the Character Codes section shows the relationship

between the 8-bit values and the characters they represent. Most environments either

use the ASCII character table as the default for character values or support an ASCII

mode where characters are interpreted by the ASCII values.

The following subsections discuss general information that is needed for programming

the Epic 950 Printer.

Resetting the Printer

Each print job should begin with a printer reset command. This ensures that the printer

always begins in a known state.

T he command characters used to reset the Epic 950 are ESC (decimal value 27) and *

(decimal value 42).

Command Parameters

When sending a command, all of the command characters and parameters that make up

a command must be sent. Thi s is especially important when using the bar code and

graphics commands. Sending too few characters to fill the required parameters for a

command will either cause the command to fail or result in subsequent data being lost.

Character Evaluation

Most of the parameters that are sent to the Epic 950 Printer are evaluated based on their

decimal value.

Some commands accept parameters by either their decimal value or the representative

character. For example, the set print orientation command (GS V) interprets both a

NULL (ASCII decimal value of 0) and the ‘0’ character as meaning the same thing.

95-05245 Rev G Page 57

Page 70

Programming for the Epic 950 Epic 950 OEM Integration Manual

16-bit Character Parameters

The maximum value a single 8-bit character can represent is 255. Some com mands,

though, can take values that are greater than 255. The set horizontal starting position

command (ESC X), for example, specifies a distance (in dots) that the next text object

will print from the left margin. Because a dot is only 1/8 of a millimeter, a value of 255

would place the object only a little over 31 mm from the left margin. To allow for longer

distances to be specified, two 8-bit characters are used to specify the value, by

combining them into one 16-bit character. Though the calculations are all done within the

Epic 950 Printer, it is important to understand how the characters are handled.

For two specified 8-bit parameter values n1 and n2, the resulting 16-bit value is

computed as follows:

Value = (n1 * 256) + n2

In other words, the decimal value of the first character that is sent (n1) is multiplied by

256, and then the decimal value of the second character sent (n2) is then added to this.

To send a value under 256 to a command that takes the n1 and n2 parameters, simply

send the first character with a 0 value. For values greater than 255 but less than 512, the

first parameter should be sent with a value of 1. For values greater than 511 but less

than 768, the first parameter should be set to 2, and so on.

Conversions

The table below lists some common values and their relationship for converting from

dots to inches using the n1 n2 parameters.

Inches Dots n1 n2

0.5 101 0 101

1.0 203 0 203

1.5 304 1 48

2.0 406 1 150

2.5 507 1 251

3.0 609 2 97

3.5 710 2 198

4.0 812 3 44

Table 8. Conversion from Dots to Inches

Page 58 Rev G 95-05245

Page 71

Programming for the Epic 950 Epic 950 OEM Integration Manual

Font Statistics

The information below lists the statistics for the five internal fonts the Epic 950 Printer

supports. Height and width are expressed in terms of dots.

Font Height Width Horizontal cpi Vertical cpi

ESC S 24 10 20.0 8.4

ESC P 24 12 16.9 8.4

ESC M 32 16 12.7 6.4

ESC U 32 20 10.2 6.4

ESC T 56 28 7.3 3.6

Table 9. Font Statistics

Objects

Objects are t he basic units that the Epic 950 prints. An object can be either a line of text

characters, a bar code, a landscape graphic, a landscape line, or a bitmap dot line. Each

of these objects has different rules relating to them, as discussed below.

Objects ca n also be either active or complete. An active object is one that is still

receiving the data that composes it. A completed object is one that has been terminated.

A line of text that has not yet received a line feed or carriage return is a good example of

an active object. Until a terminator character, like a line feed, is sent, more text

characters can be added to the text object. Bar code and graphic objects do not require

special terminator characters (such as line feeds). Instead they are considered complete

as soon as they receive the correct amount of data.

Print Modes

The Epic 950 provides three modes of printing: bitmap graphics mode, portrait printing

mode, and landscape printing mode. Each mode operates under very different rules.

These rules are detailed below.

Bitmap Graphics Mode

At its most basic level, a Epic 950 Printer is a direct thermal printer that creates images

on a ticket by heating the individual elements of its print head. The print head has 496

elements (or dots). When it prints, some of these dots will be turned on (heated), and the

printer’s motor will advance the ticket by a step. The ticket stock that is under a heated

element will then turn black. For each motor step, a dot line is printed in 203 x 203 dpi

resolution. Each dot line is a complete object and is printed by the Epic 950 as soon as it

is processed. Because of this, a bitmap dot line should not be sent while a portrait object

or a landscape page is being constructed.

95-05245 Rev G Page 59

Page 72

Programming for the Epic 950 Epic 950 OEM Integration Manual

INSERT THIS SIDE UP

INSERT THIS SIDE UP

Figure 22. Portrait and Landscape Print Modes

Portrait Printing Mode

On power-up, the Epic 950 Printer is set for portrait printing. In portrait printing mode,

text characters exit the printer from the top of the character to the bottom. It is also

possible to switch to this mode using the set print orientation command (GS V).

Portrait printing mode is also referred to as immediate mode printing, because each

object that is sent to the printer while the printer is in portrait printing mode is printed as

soon as the object is completed. No two objects may be printed on the same line in this

mode because the ticket is advanced as each object is completed and printed.

Certain comm ands are disabled or work differently while the Epic 950 is in portrait

printing mode. Exact details can be found under each command’s description.

Landscape Printing Mode

By using the set print orientation command (GS V), th e Epic 950 Printer can be

configured for landscape printing. In landscape printing, text characters exit the printer

from the left side of the character to the right. Before the Epic 950 Printer can be

switched to landscape printing mode, the set characters per line command (GS t) must

be set. This command defines the width of the landscape page. A landscape page is

defined as the area allocated by the Epic 950 in which landscape text, graphics, bar

codes, and line objects may be printed. The height of this landscape page always equals

the width of the Epic 950’ print head. The width of the landscape page is calculated

when the set characters per line command (GS t) is sent. The width of the page is equal

to the number of characters per line multiplied by the width of the current font. The

default font is 16 dots wide (2 mm), and the default number of characters per line is 80.

In landscape printing mode, completed objects are placed within a memory buffer in the

Epic 950 and are only printed when the landsc ape page is terminated. A form feed (FF)

character is usually used to terminate a landscape page. This causes the Epic 950 to

print the objects that have been placed on the landscape page and advance to the next

ticket. After a landscape page is printed, t he Epic 950 will remain in landscape printing

mode. If more objects are sent to the Epic 950, a new landscape page will be allocated

with a width equal to the previous page. To change the width of a landscape page, you

Page 60 Rev G 95-05245

Page 73

Programming for the Epic 950 Epic 950 OEM Integration Manual

must send the set characters per line command (GS t) followed by the set print

orientation command (GS V). Because the Epic 950 does not print objects immediately

in landscape mode, multiple objects can be placed on the same line. The set horizontal

starting position (ESC X) and set vertical starting position (ESC Y) commands allow

objects to be placed at any location within a landscape page. In the case of objects

positioned to overlap each other, the first object that is sent to the printer will be printed

in the overlapping area.

Objects that would normally print below the bottom of the landscape page can be either

wrapped to the next ticket or truncated by using the select line wrap/truncate modes

command (GS T). Unless the set vertical starting position command (ESC Y) is used,

the first object sent will be printed at the top of the landscape page.

General Notes

The Epic 950 Printer may be in only one print mode at a time. Multiple areas may be

printed in different print modes on a single ticket, but these areas may only be adjacent

to one another, they may not overlap.

In any mode, the set feed length command (GS L) is used to determine how far the Epic

950 will feed in search of a Black Dot/Top of Form indicator. If the Epic 950 finds a Black

Dot/Top of Form indicator before the maximum feed distance is reached, it will stop at

that point, rather than continuing. This command is only needed when dealing with

continuous-feed tickets.

95-05245 Rev G Page 61

Page 74

Programming for the Epic 950 Epic 950 OEM Integration Manual

Text Objects

A text object is simply a line of printable characters. A text object is created whenever

the Epic 950 receives a printable character that is not otherwise part of a command.

Once it is created, a text object will remain active until it is terminated.

While a text object is active, any printable characters sent to the Epic 950 will be added

to that text object. The only exceptions are printable characters that are sent as part of a

command. While a text object is active, commands that alter text line attributes (such as

font and double-high character commands) are ignored. Commands that alter text

character attributes (such as double-wide and inverse) may be sent at any time, though.

Line attributes include the five basic fonts (P, M, U, and T), plus the double-high font

command (GS DC2 ). These commands may not be issued while a text object is active;

instead they should be issued before a text object is begun. The font line attribute

persists until another font command is received. The double-high line attribute persists

either until the cancel double-high command (GS DC3) is sent or the current font is

changed. The character attribute commands include the set font to double wide (SO)

and set inverse print mode (GS RS ) commands. These commands may be issued or

canceled at any time. Character attributes persist only until the end of a text object.

A text object can be terminated with a carriage return, a line feed, or both, in either

combination. If the length of the text object exceeds the space allowed for printing, it will

either wrap to the next line or truncate at the end of the printable area. The decision to

wrap or truncate is determined by the select line wrap/truncate mode command (GS T).

By default, text objects will wrap to the next line.

Page 62 Rev G 95-05245

Page 75

Programming for the Epic 950 Epic 950 OEM Integration Manual

Bar Code Objects

A bar code obj ect is created by the print bar code command (GS k). Specified within the

command is the symbology to be used, amount of data to be encoded, and data itself.

Other attributes of the bar code, such as height and width, can be set using other

commands.

The set bar code height command (GS h) specifies the height of the bar code in dots, or

1/8 mm. The maximum height for a bar code is 256 dots or 32 mm. In cases where a

taller bar code is needed, a second bar code can be printed below the first at the same

left offset. The set bar code module width (GS w) and set bar code element width (GS

W) commands can be used to alter the width of the bar code. See the command

descriptions later in the next section for a full explanation of the differences between

these two commands.

The limitations of each symbology must be adhered to when sending data for a bar

code. For example, you should not send alphabetic characters to symbologies that only

accept numeric data (like the UPC/EAN symbology).

Other items must also be considered when printing bar codes:

(If any of these items are ignored, the printed bar code may be unreadable.)

• Sufficient blank space on either side of the bar code must be left to create a quiet

zone.

• A good ratio/element size must be selected if the default values are not being

used.

• Adequate room must be available for the bar code to be printed on the ticket.

• Bar codes may only be printed in black, for accurate infrared scanning, using

thermal media with a visible light absorption of 600-700 nm for black printing.

A bar code object is self-terminating and will be processed as soon as the proper

amount of data has been sent to it. The print bar code command’s (GS k) second

parameter specifies whether a fixed amount of data will be sent or whether delimiters will

be used. In either case, the data sent must match the parameter setting. If a fixed

number of characters are specified, then the exact number of characters specified must

be sent. If delimiters are indicated, then matching characters must be sent before and

after the bar code data to specify the beginning and end of the data. If an incorrect

number of characters or delimiters are sent, the Epic 950 will not print correctly.

Bar codes that are too long to fit within the printable area of a ticket are truncated. This

usually results in an unreadable bar code being printed. To correct this condition, a

narrower ratio must be set, fewer digits encoded, or a more compact symbology used.

Bar codes

Codabar

Code 3 of 9

Code 128-A

Code 128-B

Code 128-C

95-05245 Rev G Page 63

Page 76

Programming for the Epic 950 Epic 950 OEM Integration Manual

Code 128-Auto

EAN-8

EAN-13

Interleaved 2 of 5

UPC-A

UPC-E

Code93

Graphic Objects

Graphic objects are created by the landscape printing mode graphics command (GS *).

Graphic objects may only be printed as part of a landscape page. To print a graphic

without entering landscape printing mode, you must use bitmap graphics mode.

No landscape graphic may be wider than 256 dots, though they may be as tall as the

width of the Epic 950’ print head. If a graphic needs to be printed wider than 256 dots,

either subdivide it into narrower sections or print it using bitmap graphics commands.

Line Objects

Line objects are created using the draw line in landscape printing mode command (GS

l).

Line objects may only be printed as part of a landscape page. If the length of a line

object is set to exceed the printable area of a ticket, the line will be truncated at the end

of the printable area.

Page 64 Rev G 95-05245

Page 77

Programming for the Epic 950 Epic 950 OEM Integration Manual

The POR.INI File

The POR.INI file contains system/printer initializ ation parameters. This file follows the

standard INI file format of sections defined in brackets (ie. [POR]) followed by single-line

parameter settings.

The main section of this file is the [POR] section, which contains default initialization

information that the printer will use when it powers on or does a reset. In addition to the

[POR] section, the file may contain other sections that are specific to individual dip

switches, of the form [Dipswitchn] where n is the number of the dip switch.

Example

; Lines in this file must be cr+lf terminated.

; Use no tabs.

[POR]

; There may be additional information here that initializes various internal

; functions. These parameters should not be altered.

PeriodicStatusOn = n

ColorMode = Off

DemoMode = Off

ErrorLog = Off

ZstatusBit3AlwaysHigh = Off ; Set to off for older versions of the Series 800

CommSave = Off

[Dipswitch3]

DemoMode = On

[Dipswitch4]

ErrorLog = On

[Dipswitch5]

CommSave = On

[Dipswitch7]

PeriodicStatusOn = y

[Dipswitch8]

ColorMode = On

95-05245 Rev G Page 65

Page 78