Page 1

MAGNETIC TAPE

WORD

PROCESSOR

UD002441-1

FIELD

ENGINEERING

DIVISION

SEPT., 1972

Page 2

Page 3

This information

is

current

as

of

September 1972.

ITEL

CORPORATION

FIELD

ENGINEERING

DIVISION

Technical Support Operations

10435 North Tantau Avenue

Cupertino,

California 95014

Tel: (408) 257-6220 TWX 910-338-0280

Printed

in

U.S.A.

September

1972

Copyright(£)

1972

Page 4

Page 5

Chapter

1

2

3

4

2441-1

CONTENTS

GENERAL

INFORMATION.

1. 1 Introduction

1. 2 Manual

Content

1.

2.

1

Chapter

1,

General

Information.

1.

2.2

Chapter

2,

Installation.

1.

2. 3

Chapter

3,

Operation

.

1.

2. 4

Chapter

4,

Theory

of

Operation.

1.

2. 5

Chapter

5,

Maintenance

1.

2.

6

Chapter

6,

Checks

and

Adjustments

1.

2.7

Chapter

7,

Error

Analysis

1.

2.8

Chapter

8,

Replacement

Procedures

1.

2.9

Chapter

9,

Diagrams

1. 3 System

Description

1.

3.1

Microprocessor

1.3~2

Keyboard

.

1.

3.

3

1.

3.4

1.4

Printer.

Ma

gnetic

Tape

Transports

Specifications.

INS TA

LLA

TION .

2. 1

Unpacking.

2.1.

1

Unpacking

the

Typewriter

Unit

2.1.2

Unpacking

the

Console

Unit

.

2. 2

System

Interconnections

2. 3 Preoperational

Checkout

.

2.3.1

Power

Supply

Voltage

Checkout.

2.3.2

System

Diagnostic

Checkout

.

OPERATION

.

3.1

Keys,

Controls,

Indicators

and

Alarms

.

3.

1.

1

Basic

Operation

Keys

.

3.

1.

2 Mode

Keys

.

3.

1.

3

Action

Keys

3.

1.

4

Encoded

Function

Keys.

3.

1.

5

Console

Controls

and

Indicators.

3.

1.

6

Alarms.

3.2

Operating

Instructions

.

THEORY

OF

OPERA

TION .

4. 1

Functional

Description

.

4. 2 Microprocessor.

4.2.1,

Read

Only

Memory

(ROM)

Program

4.2.2

ROM

Address

Register.

Page

1-1

1-1

1-1

1-1

1-2

1-2

1-2

1-2

1-2

1-2

1-2

1-2

1-2

1-3

1-3

1-4

1-4

1-5

2-1

2-1

2-1

2-1

2-3

2-5

2-5

2-7

3-1

3-1

3-1

3-4

3-6

3-8

3-11

3-12

3-13

4-1

4-1

4-1

4-1

4-6

i

Page 6

CONTENTS (CONT)

Chapter

5

4.2.3

4.2.4

4.2.5

4. 3 Buffer

4.4

4.5

4.6

4.7

4.8

4.9

4.10

4.11

4.12

4.13

MAINTENANCE .

5. 1

5.2

5.2.1

5.2.2

5.

3

5.3.1

5.

3.2

5.4

5.4.1

5.4.2

5.4.3

Return

General

Arithmetic

Tape

Write

Read

Tape

Motor

Keyboard

Printer

Miscellaneous,

Display

DC

Power

Safety

Maintenance

Objectives.

Basic

Tools

Tools

Test

Power

Voltage

Logic

Use

Address

I/O

and

Control

Encode

Decode

Read/Write

Control.

Interface

Interface.

Panel

Supplies

Precautions

Considerations

and

Servicing

Equipment

Supply

Levels

Levels

of

Probes

Purpose

Logic

Buffer

.

.

and

Clock

.

Philosophy

Voltage

.

Register

(GP)

and

Unit

(ALU) .

Control

Tape

.

and

Aids

.

Read

IC .

.

Main

(M)

Only.

Registers

Page

4-7

4-8

4-8

4-8

4-9

4-9

4-9

4-10

4-10

4-12

4-12

4-13

4-13

4-13

5-1

5-1

5-1

5-1

5-1

5-2

5-2

5-2

5-6

5-6

5-6

5-7

ii

6

CHECKS AND

6.1

6.2

6.3

6.4

6.5

6.6

6. 7

6.8

6.9

6.10

6.11

6.12

6.13

6.

6.

6.

General.

PDA

ROM

Branch

Branch

PDA

G-Registers

H-Registers

ALU

Buffers

Data

Data

Keyboard

14

Printer

15

Transport

15.1

Installation

Test

Test

Test

Bus

Bus

Run

ADJUSTMENTS

·

Test

on

Data

·

Test

Test

.

Test

·

Test

Test

Forward

.

Out

(Lamp)

In

(Thumbwheel)

Strobe

Tests

Test

.

. . .

Normal

Test.

Test

Test

6-1

6-1

6-1

6-6

6-7

6-9

6-10

6-10

6-11

6-12

6-13

6-14

•

6-15

6-16

6-17

6-18

6-18

2441-1

Page 7

CONTENTS (CONT)

Chapter

7

8

6.15.2

6.15.3

6.15.4

6.15.5

6.15.6

ERROR

7.1

7.2

Run

Reverse

Run

Forward

Run

Reverse

Speed

Normal

ANALYSIS .

General.

Recommended

REPLACEMENT

8.1

8. 2

8.3

8.4

8.4.

8.4.2

8.4.3

8.4.4

8.4.5

General.

Printer

Keyboard

Transport

1

Head

Motor

Lock

BOT/EOT

Cassette

and

Removal

Assembly

Solenoid

Installation

Normal

Fast

Fast

Tests

Write

.

Forward

Troubleshooting

PROCEDURES

and

Removal

Removal

and

and

Removal

Removal

and

Removal

Sensor

In

Place

Assembly

Switch

Test

Test

Test

.

Test

Installation

Installation.

Installation

and

Installation.

and

and

Sequence.

Installation.

Installation

Removal

File

Protect

and

Installation.

Switch

Page

6-20

6-21

6-22

6-23

6-26

7-1

7-1

7-1

8-1

8-1

8-1

8-1

8-2

8-4

8-6

8-6

8-7

Removal

8-8

9 DIAGRAMS

9. 1

9.2

Figure

1-1

1-2

2-1

2-2

2-3

2-4

2-5

3-1

3-2

3-3

3-4

3-5

4-1

4-2

4-3

Magnetic

Simplified

Typewriter

Console

Typewriter

System

Power

Basic

Mode

Action

Encoded

Console

Console,

Detailed

K-Page

General.

System

Tape

Wire

Word

System

Unit

Packaging

Unit

Packaging

Cover

Interconnections

Supply

Operation

Interconnect

Keys

Keys.

Keys

Function

Controls

Keys.

and

Right-Hand

System

Memory

Block

Structure

List

ILLUSTRATIONS

Processor.

Block

Removal

Diagram

Panel

Indicators.

Interior

View.

Diagram.

9-1

9-1

9-24

Page

1-1

1-3

2-2

2-2

2-4

2-4

2-6

3-1

3-4

3-6

3-8

3-11

4-2

4-4

4-5

2441-1

iii

Page 8

ILLUSTRATIONS

(CONT)

Figure

4-4

4-5

4-6

4-7

4-8

4-9

5-1

6-1

Major-Page

12-Bit

ROM

Bi-Phase

Motor

System

PDA

PDA

Schematics:

Address

Address

Control

Clock

Controls

Installation

Printer

Keyboard

Miscellaneous,

ROM

ROM

Return

Main

Arithmetic

Buffer

Buffer

Tape

Read

Write

Motor

Cassette

Tape

Display

DC

Keyboard

PDA

PDA

Memory

Word

Register

Serial

Power

Data

Block

Timing

and

Indicators,

Interface

Interface

Program

Address

Address

and

General

Logic

I/O

(Read

Control

Control

Decode

Encode

Control

Heat

Read/Write,

Panel

Supply

Logic

ROM

and

Switch

and

Structure

Format

Diagram

,

(socket

(socket

Clock,

(sockets

Register

Register

Purpose

Unit

Only & Read/Write)

(Read

(Read/Write & Read

(Read/Write & Read

(Read/Write)

(sockets

Sink

Tape

.

Controls

Indicator.

1)

3),

and

IC

(socket

5,

6, 7,

(socket

(socket

(socket

Only & Read/Write)

R/WJ1

,

Read

9)

Register

12) ,

(socket

and

Only

and

8)

,

10) ,

(socket

Only)

Only)

19)

ROJl).

(sockets

4)

11),

(sockets

(sockets

(sockets

(sockets

R/WJ2

13

and

17

18

14

and

and

and

15) .

and

16)

20)

21).

ROJ2)

Page

4-5

4-6

4-7

4-10

4-11

4-14

5-4

6-1

9-2

9-3

9-4

9-5

9-6

9-7

9-8

9-9

9-10

9-11

9-12

9-13

9-14

9-15

9-16

9-17

9-18

9-19

9-20

9-21/9-22

9-23

Table

1-1

2-1

3-1

3-2

iv

Dual

Station

Power

Encoded

Encoded

MTWP

Supply

Function

Function

Voltages.

TABLES

Specifications

Codes

Keys.

Page

.

1-5

2-7

3-5

3-8

2441-1

Page 9

TABLES (CONT)

Table

4-1

4-2

6-1

6-2

6-3

6-4

6-5

6-6

6-7

6-8

6-9

6-10

6-11

7-1

7

-2

8-1

8-2

8-3

Card

Other

PDA

Error

ROM

Branch

Branch

ALU

Buffers

Data

Transport

Speed

Normal

PWA's

Troubleshooting

Transport

Head

BOT/EaT

Cage

Routine

Test

Bus

Assembly

PWA's

Console

Addresses

Tests.

Tests

on

Data

"Error

Test

Out

Tests

Conversions

Write

Affected

Power

Sensor

PWA's

Addresses

.

Test

"Error

Addresses"

"Error

(Lamp)

Forward

Addresses"

Error

.

According

Chart

Connections

Connections

Assembly

Test

Analysis

"Error

.

Addresses"

Sequence

Addresses"

to

Priority.

.

Connections.

Page

4-3

4-3

6-4

6-5

6-7

6-8

.

6-9

6-13

6-14

6-15

6-20

6-24

6-27

7-2

7-3

8-3

8-4

8-7

9-1

Diagrams.

9-1

2441-1

v

Page 10

/

Page 11

CHAPTER 1

1.1

INTRODUCTION

This

manual

single

Both

printer,

form

ports

and

systems

and

an

automatic

are

attractive

provides

dual

station

combine

one

(single

contained

case

suitable

GENERAL

installation,

Magnetic

the

functions

station)

writing

in a compact

system.

for

secretarial

INFORMATION

operation,

Tape

Word

of a Microprocesflor,

or

two (dual

The

Microprocessor

console.

use.

and

Processor

station)

The

keyboard

service

(MTWP) ,

magnetic

instructions

shown

an

electronic

tape

and

magnetic

and

printer

for

both

in

Figure

keyboard

transports

tape

trans-

are

housed

the

to

1-1.

and

in

an

Console

Figure

1.2

This

ided

MANUAL

Magnetic

into

nine

CONTENT

Tape

Word

chapters.

The

chapter.

1.2.1 Chapter 1, General Information

This

ment

chapter

description,

provides

and

introductory

the

2441-1

1-1.

Magnetic

Processor

following

material, a description

specifications

\

Tape

Operation,

paragraphs

for

the

Word

Service,

briefly

system.

Typewriter

Processor

and

Diagrams

describe

of

manual

Manual

the

contents

contents,

is

of

an

diveach

equip-

1-1

Page 12

1.2.2 Chapter 2, Installation

Chapter 2 discusses

installing a system.

vided

1.2.3 Chapter

in

this

chapter

3,

Chapter 3 identifies

and

indicator

1.2.4 Chapter

The

theory

and

timing

1.2.5 Chapter

on

4,

of

operation

diagrams

5,

Chapter 5 outlines

required

1.2.6 Chapter 6, Checks and Adjustments

Electrical

special

and

mechanical

unpacking,

A

preoperation

to

verify

Operation

and

describes

the

console,

Theory of Operation

is

provided

are

used,

Maintenance

safety

tools

precautions,

and

test

inspection,

that

and

where

equipment.

checks

the

the

system

in

and

and

checks

and

system

function

alarm.

this

chapter.

necessary,

presents

adjustments

the

interconnections

adjustments

is

operating

of

each

key

Block

to

support

maintenance

are

contained

procedure

properly.

on

the

keyboard,

diagrams,

the

text.

philosophy,

in

required

is

simplified

and

Chapter

when

also

control

lists

6.

pro-

drawings,

1.2.7 Chapter 7, Error Analysis

This

chapter

1.2.8 Chapter 8, Replacement Procedures

Chapter 8 presents

1.2.9 Chapter 9, Diagrams

This

chapter

Programmed

1.3 SYSTEM DESCRIPTION

The

ITEL

tronic

only

the

system

the

capabilities

single

dual

• A

contains

information

removal

contains

the

Diagnostic

or

dual

for

automatic

station

of

system

the

single

Microprocessor.

and

schematic

Aid

(PDA). The

station

writing.

will

station

designed

installation

Magnetic

be

discussed.

to

diagrams

system

Tape

The

functions

system.

assist

in

procedures.

for

the

wire

Word

Processor,

of

The

dual

The

major

troubleshooting.

system

list

is

as

also

well

included.

(MTWP)

both

are

identical;

station

does,

components

as

those

is

therefore,

however,

of

the

for

an

elec-

extend

system

the

are:

• A

full

duplex

1-2

electronic

keyboard.

2441-1

Page 13

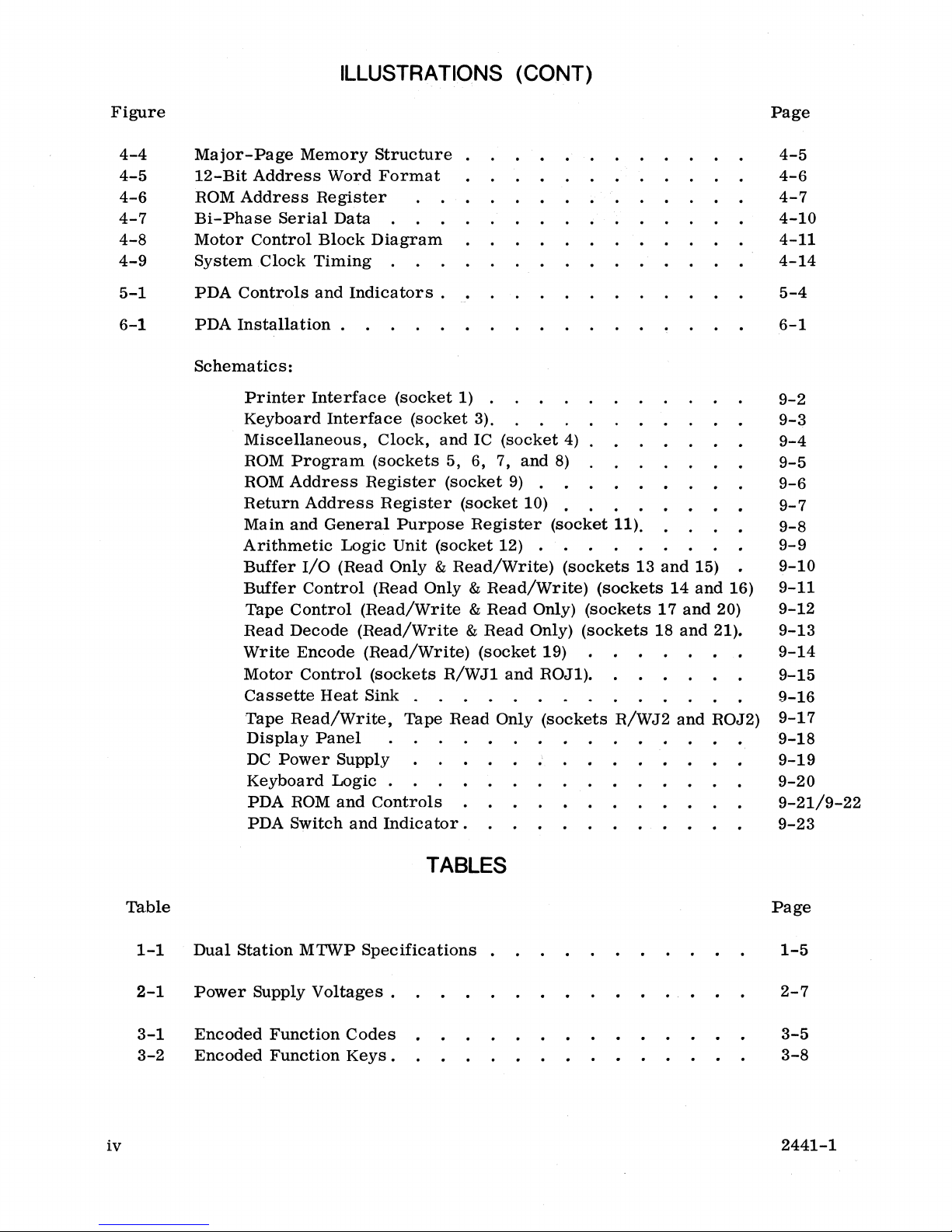

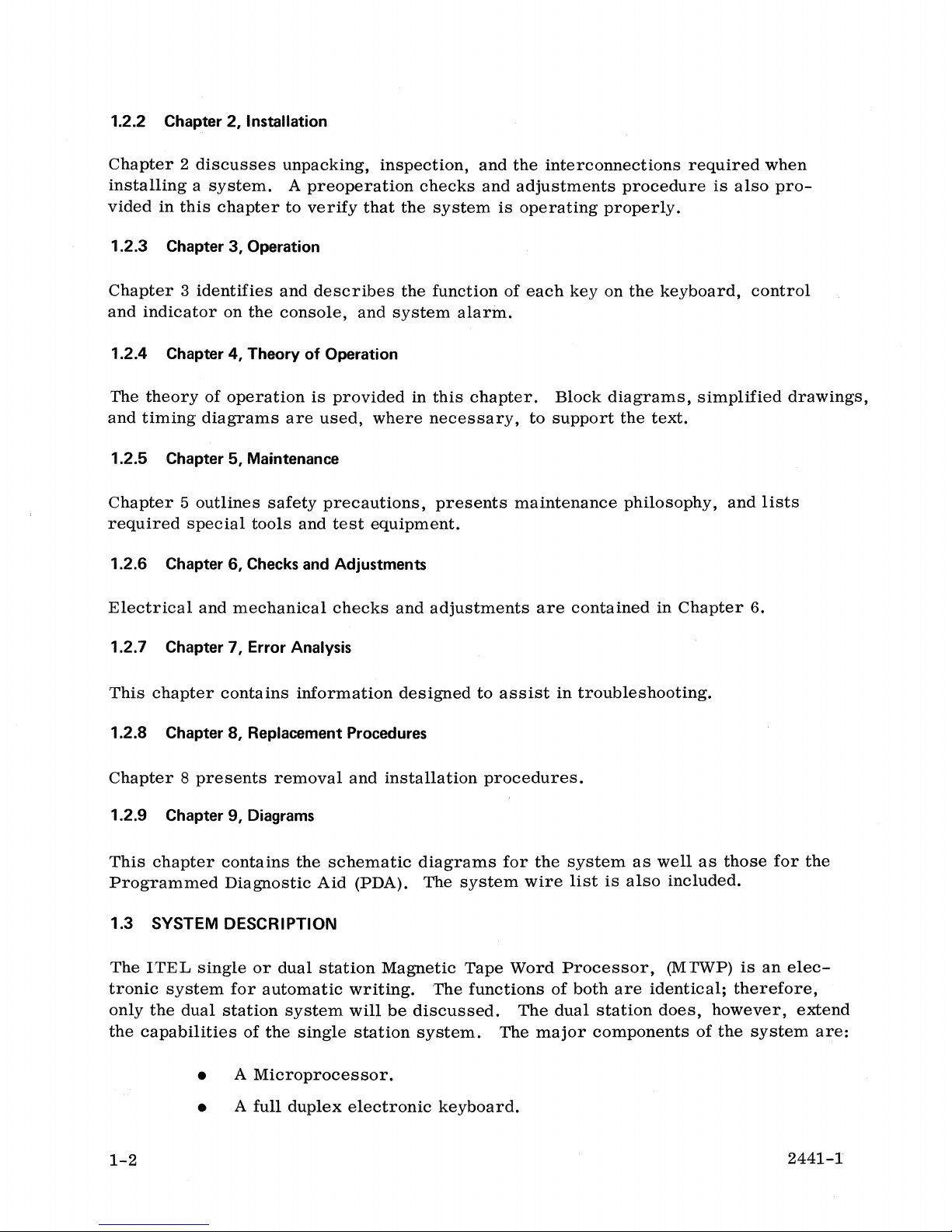

•

An

electronic

printer.

Figure

• Two

1-2

provides a simplified

TYPEWRITER

magnetic

~~

..

alT

DATA

FLOW

tape

transports.

block

1-------1

TYPOWRITER INTERFACE

r-----

LSlNGLE

STATlDN

SYSTEM

-----

diagram

-

__

~

MAGNETIC TAPE

TRANSPORTS

DUAC

...

"ON

ovm.

of

the

system.

CONSOLE

~----------l

II

, , I

k::j

Ii'

, , I

MICROPROCESSOR

L ________ j

----:

___

I .

, I

! i

! i

~

i---

L

__

BUFFERS

_

---l

-~

'

i

I

i

1.3.1 Microprocessor

Microprocessor

The

These

It

is

keyboard,

mation

Memory

1.3.2 Keyboard

The

of

rather

from

system

to

sixteen-bit

also

has

processed

is

gated

portion

keyboard

this

type

than

the

keyboard.

during

indicate

an

eight-bit

is

processed

I?rinter,

on

of

used

of

keyboard,

directly

normal

the

present

Figure

has

instruction

and

and

the

in

to

A

1-2.

the

parallel

on

both

off

the

Microprocessor.

this

system

signals

the

printer.

standard

typing

operation.

Simplified

capability

words

this

magnetic

data

operations.

are

data

bus

data

bus

is a full

are

All

44-key

These

routed

System

of

storing

used

(DB.0

bus.

tape

by

The

transports

the

duplex

through

system

typewriter

Certain

lighted

16 BtT

Block

4096

to

control

through

instruction

functions

keys

DB7). Any

data

bus

together

electronic

the

array

keys

also

INSTRU~TlON

WORD

BUS

Diagram

sixteen-bit

the

operation

links

words

keyboard.

Microprocessor

are

inputs

are

lighted,

monitor

instruction

information

the

Microprocessor,

into one

stored

controlled

information

the

words.

of

the

system.

which

unit.

in

Through

when

Microprocessor

Infor-

the

Read

to

the

by

the

into

depressed,

Only

the

use

printer,

operator

the

2441-1

1-3

Page 14

and

flash

to

key

on

the

keyboard

1.3.3 Printer

The

printer,

character

text

such

six

lines

at a time).

as

per

display

used

letters,

inch

input, output, and

and

each

alarm

as

the

output

It

operates

device

specifications,

(single

space)

or

system

is

discussed

for

at

speeds

contracts,

three

the

up

lines

error

conditions.

in

detail

system,

to 30

characters

etc.

per

inch (double

is

of a serial

The

15-inch

The function

in

Chapter 3 of

per

long

space).

this

type

(prints a single

second

platen

of

manual.

on

general

indexes

each

at

There

feed.

controls

ASCII

direction

1/60

line

1/48

Character

wheels

Two

by

are

code

of

spaces

of

types

the

operator.

Each

are

and

an

an

are

three

motion

for

inch),

(indexes)

inch).

sets

easily

of

carbon.

1.3.4

The

Magnetic

dual

station

store a single

8-bit

word

enroute

these

of

in

the

on

to

the

8-bit

buffer

tape.

basic

is

sent

down

the

next

number

or

an

are

provided

interchanged

ribbon

cartridges

The

Tape

Transports

system

line

of

the

data

printer.

characters.

and

then

printer

motions;

controlled

the

eleven

character

of

printing

ll-bit

that

the

word

paper

in

the

by

are

styles

has

available

two

typewritten

bus,

comes

A

single

Information

outputed, a

carrier,

by

the

system

data

to

be

spaces

which

is

to

form

the

operator.

available

include

lines.

printed,

to

be

of

The

be

moved

specifies

moved

an

88-character

and

single

circulating-type,

information.

from

line

line

either

of

typewritten

from

at a time,

the

the

print

wheel

through

an

data

ii-bit

the

lines

by

the

direction

by

the

these

too

reusable

live-memory,

This

information,

keyboard

information

keyboard

onto

the

(character),

printer

transmit

word

which

the

carrier

paper

feed

print

are

easily

fabric

or

magnetic

is

stored, a line

read/write

and

interface.

either

specifies

(in

multiples

and

number

(in

multiples

wheel.

These

interchangeable

and a single-use

MOS

buffers

in

the

form

tape

can

contain

(R/W)

paper

These

the

7-bit

the

of

of

vertical

of

print

which

of

an

storage

up

to 256

at a time,

magnetic

The

magnetic

20

inches

the

read

directionally

per

second.

the

system,

per

only

tape

transports

second

magnetic

reading

The

functions

are

controlled

and

bidirectionally

tape

at

20

1-4

are

transport

inches

of

each

by

the

capable

searching

(dual

per

second

magnetic

operator

of

unidirectionally

at

70

station

and

tape

from

system

bidirectionally

transport,

the

keyboard.

reading

inches

only)

like

and

per

second.

is

only

searching

any

other

writing

Naturally,

capable

at

70

functions

at

of

uni-

inches

2441-1

of

Page 15

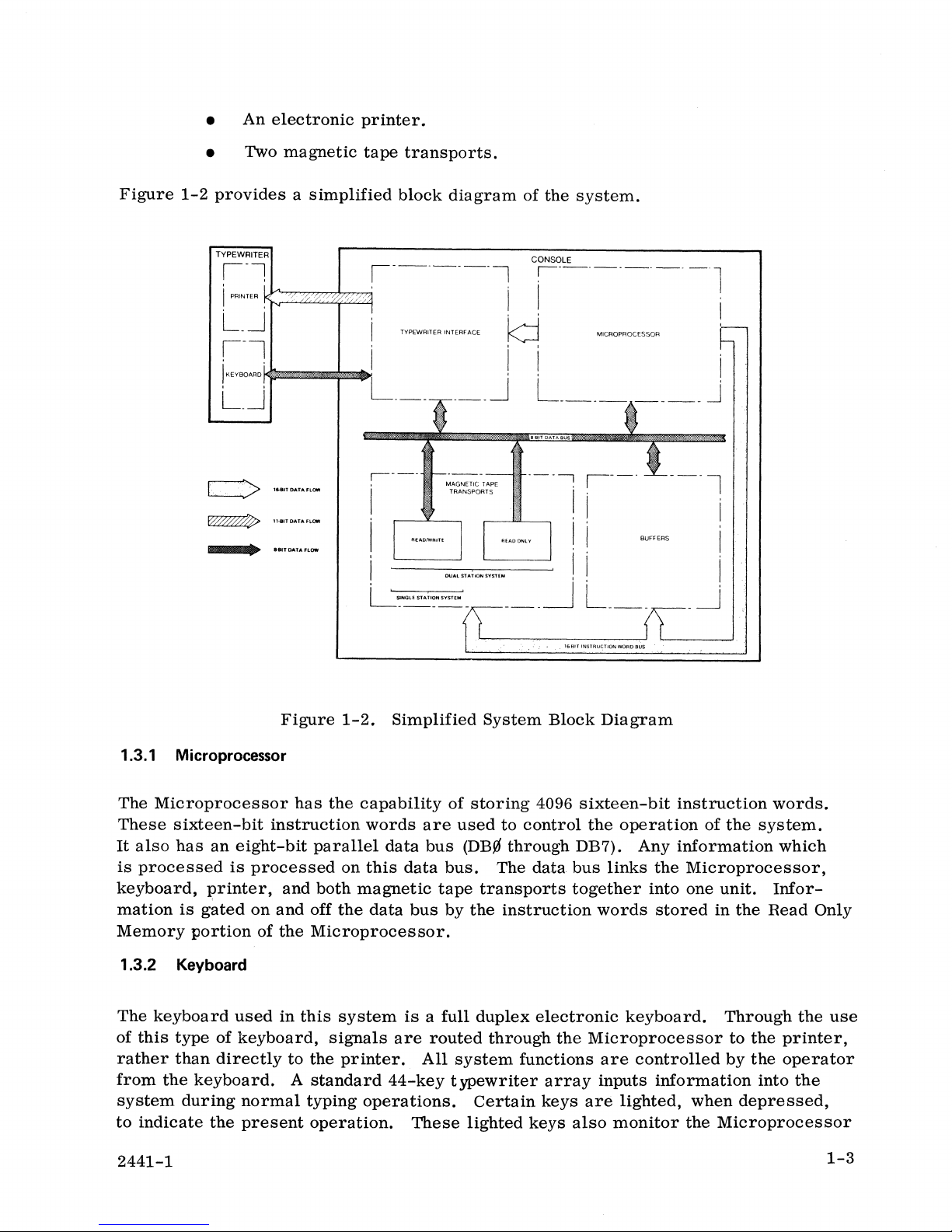

1.4 SPECIFICATIONS

The

specifications

listed

in

Table

for

1-1.

the

dual

station

Magnetic

Tape

Word

Processor

(MTWP)

are

Table

CHARACTERISTICS

MICROPROCESSOR:

Type

of

storage

Storage

Instruction

Memory

capacity

cycle

access

KEYBOARD:

Typewriter

Lighted

array

Function

Non-Lighted

Repeat

keys

1.1.

Dual

time

time

keys

Function

Station

keys

MTWP

Specifications

SPECIFICA

Read

Only

65,536

(4096

words)

2

J.1.s

1

J.1.s

maximum

44

keys

12

4

Hyphen,

index,

rier

reverse

return,

period.

TIONS

Memory

16-bit

backspace,

index,

space

(ROM)

instruction

forward

X,

car-

bar

and

2441-1

Maximum

PRINTER:

Number

Print

Print

Line

Print

Paper

input

of

characters

speed

line

length

spacing

quality

feed

rate

500

characters

88

>30

characters

(on

general

132

characters

(10-pitch)

12

per

inch

6

per

inch

per

inch

Standard

15-inch

per

text)

at

or

158

(12-pitch)

(single

(double

typewriter

platen

fed

second

per

second

10

per

characters

spaced)

spaced)

inch

or

1-5

at

3

Page 16

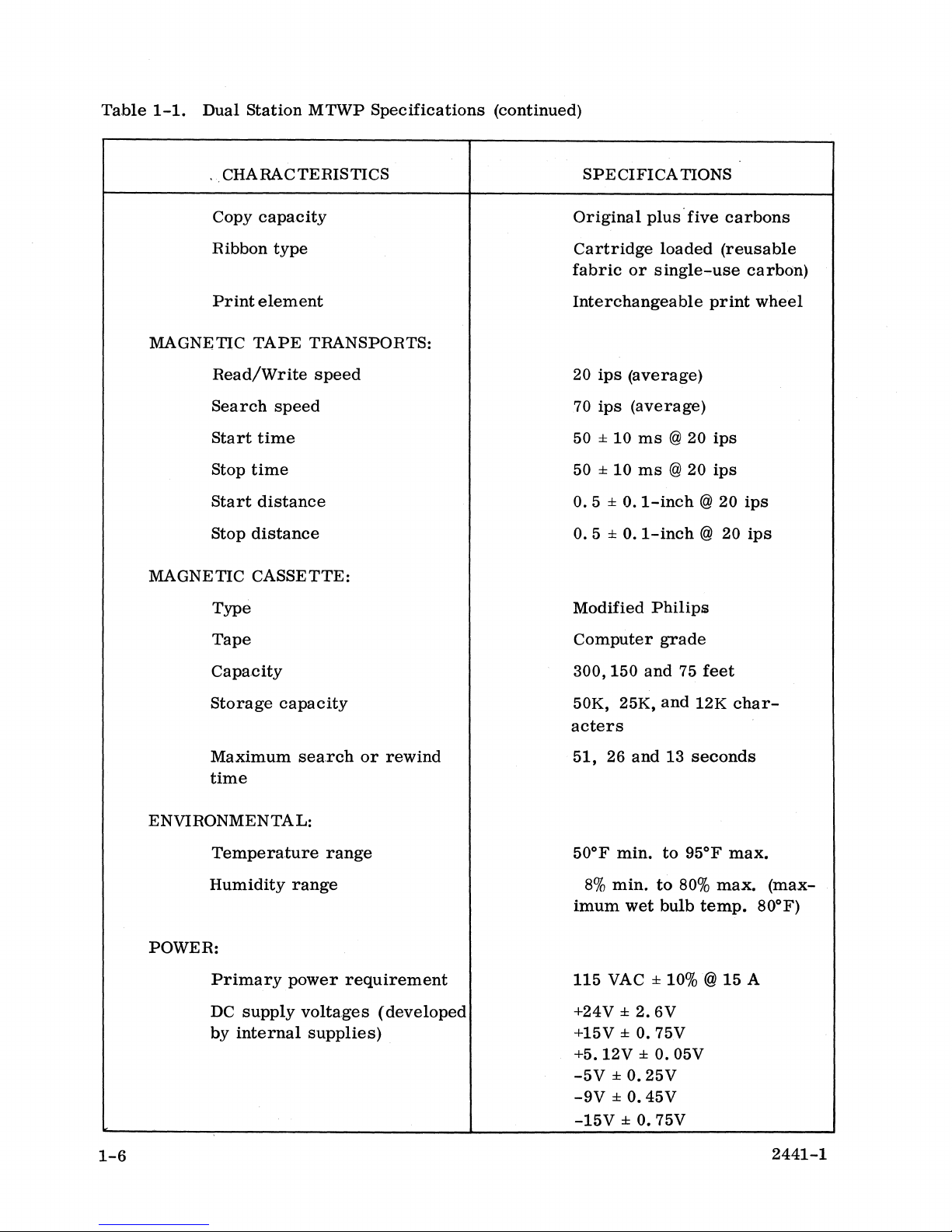

Table

1-1.

Dual

Station

..

CHARACTERISTICS

Copy

capacity

MTWP

Specifications

(continued)

Original

SPECIFICA

plus·

TIONS

five

carbons

Ribbon

Print

MAGNETIC

Read/Write

Search

Start

Stop

Start

Stop

MAGNETIC

Type

Tape

Capacity

type

element

TAPE

TRANSPORTS:

speed

speed

time

time

distance

distance

CASSETTE:

Cartridge

fabric

loaded

or

single-use

Interchangeable

20

ips

(average)

70

ips

(average)

50 ±

10

ms @ 20

50 ±

10

ms @ 20

0.5

±

O.

I-inch @ 20

O.

5 ±

O.

I-inch @ 20

Modified

Computer

300,150

Philips

grade

and

75

(reusable

print

ips

ips

feet

carbon)

wheel

ips

ips

1-6

Storage

Maximum

capacity

search

time

ENVIRONMENTAL:

Temperature

Humidity

range

POWER:

Primary

DC

by

internal

supply

power

voltages

or

range

requirement

supplies)

rewind

(developed

50K, 25K,

acters

51,

26

and

8%

min.

imum

115

+24V ±

+15V

+5.12V

-5V

-9V

-15V

wet

VAC ±

2.

±

O.

±

±

O.

±

O.

±

O.

and

13

to

bulb

10%@

6V

75V

O.

25V

45V

75V

12K

seconds

80%

temp.

05V

char-

max.

15

(max-

80°F)

A

2441-1

Page 17

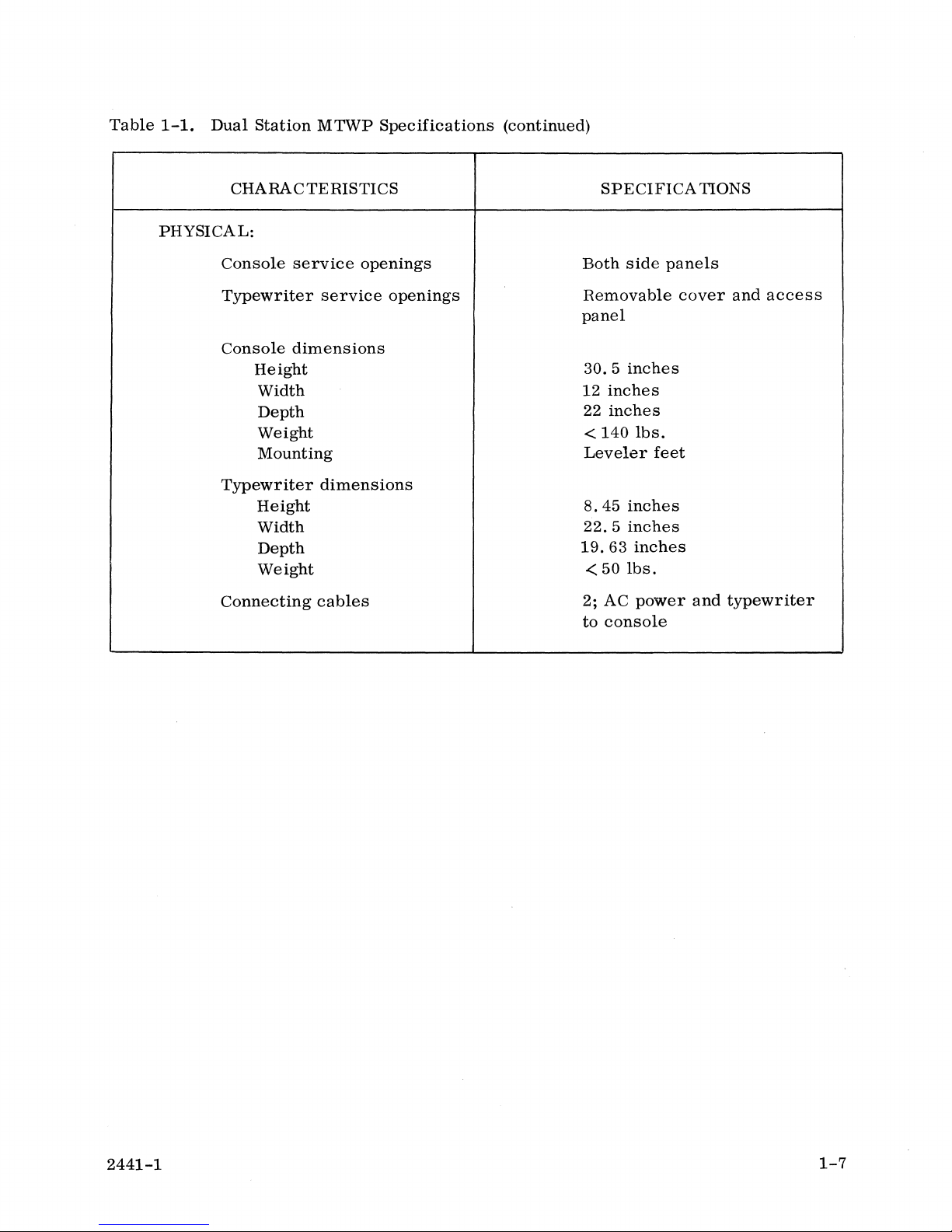

Table

1-1.

Dual

Station

MTWP

Specifications

(continued)

CHARACTERISTICS

PHYSICAL:

Console

Typewriter

Console

Typewriter

Connecting

service

dimensions

Height

Width

Depth

Weight

Mounting

Height

Width

Depth

Weight

openings

service

dimensions

cables

openings

SPECIFICA

Both

side

Removable

panel

30.5

inches

12

inches

22

inches

<

140

lbs.

Leveler

8.45

inches

22.5

inches

19.63

< 50

2; AC

to

inches

lbs.

power

console

panels

cover

feet

TIONS

and

typewriter

and

access

2441-1

1-7

Page 18

Page 19

2.1

UNPACKING

The

Magnetic

prior

console)

to

shipment.

are

procedures

containers,

If

damage

units

from

any

return

Tape

separately

to

attain

examine

is

evident,

their

packaging.

shipment.

Word

Processor

Individual

packaged

optimum

each

for

contact

INSTALLATION

units

that

into two

system

broken

the

transportation

Original

CHAPTER 2

is

inspected

comprise

containers.

performance.

bands,

packaging

for

crushed

company

material

mechanical

part

of

Perform

Before

walls,

and

the

system

the

removing

or

other

involved

should

be

electrical

(the

following

units

signs

before

retained

operation

typewriter

unpacking

from

of

their

damage.

removing

to

facilitate

and

the

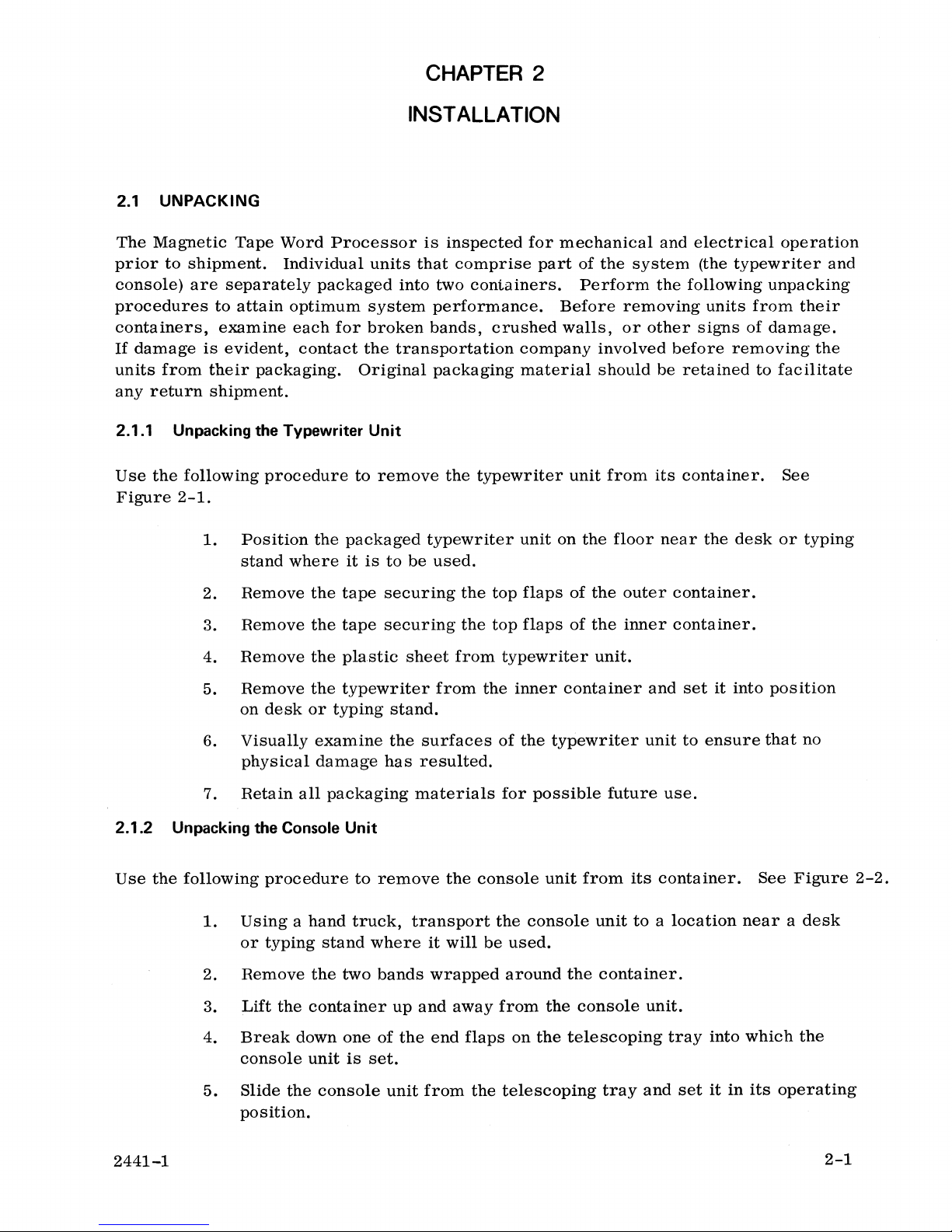

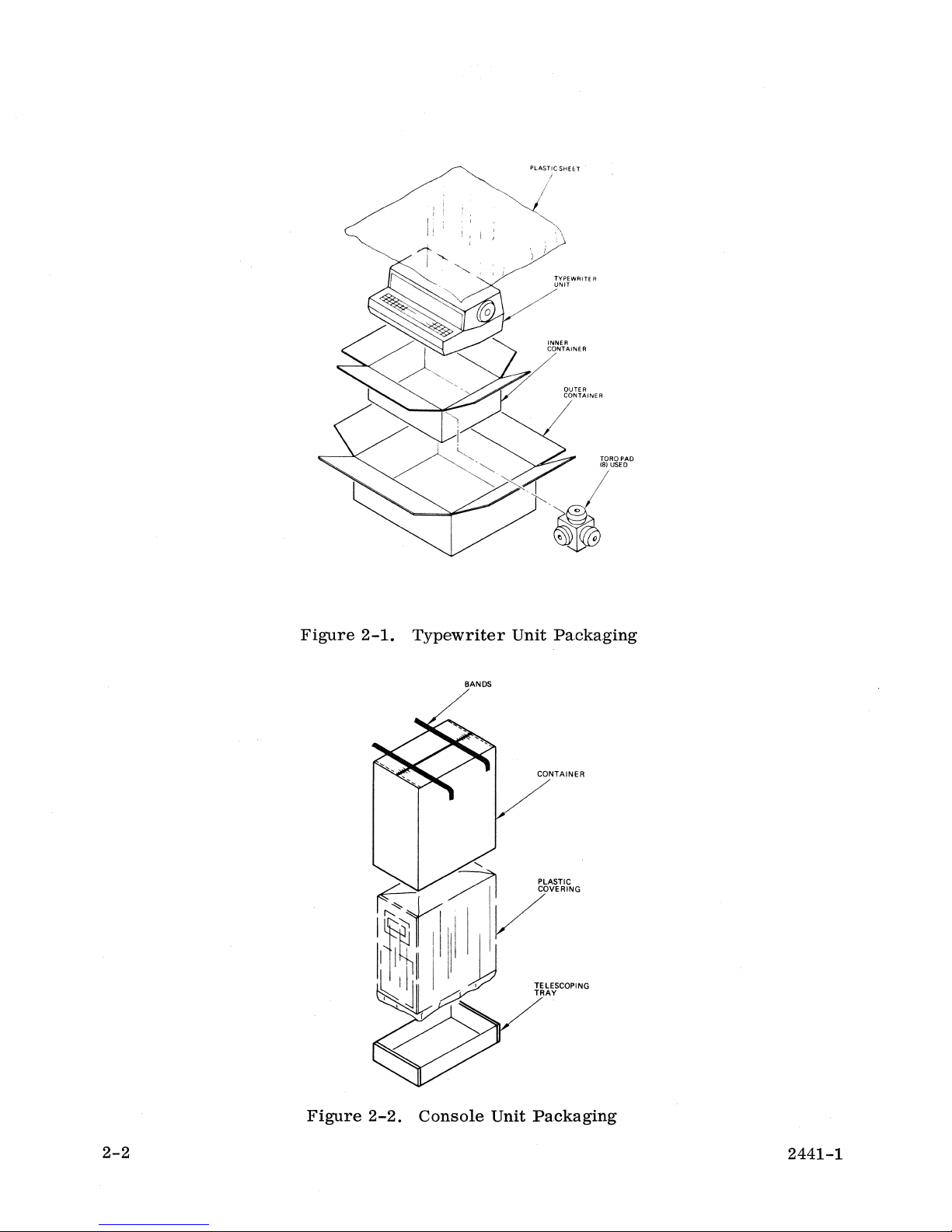

2.1.1 Unpacking

Use

the

following

Figure

2-1.

1.

2. Remove

3.

4.

5.

6.

7.

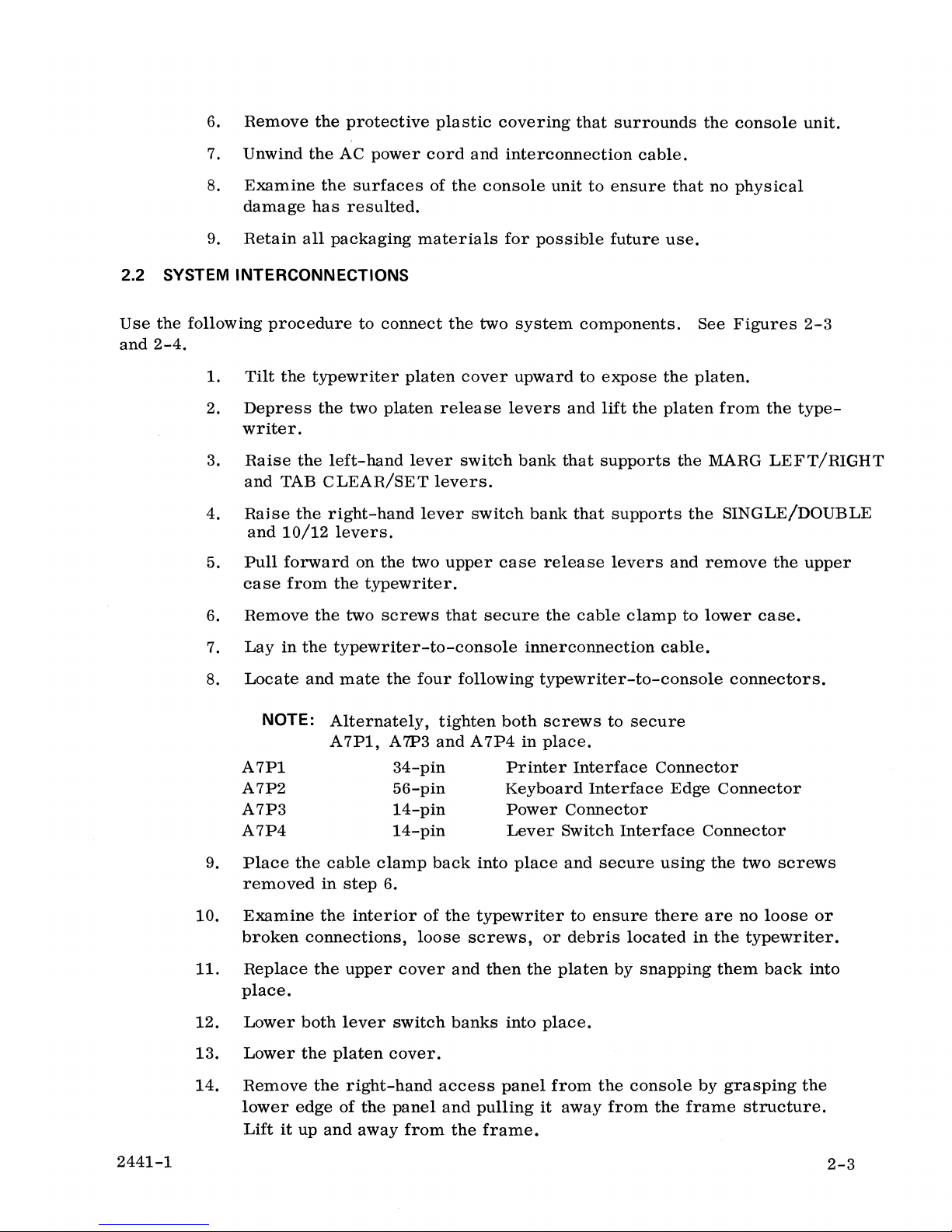

2.1.2

Use

Unpacking

the

following

the

Typewriter Unit

procedure

Position

stand

where

Remove

Remove

Remove

on

desk

or

Visually

physical

Retain

the

all

Console

procedure

to

the

packaged

it

is

the

tape

the

tape

the

plastic

the

typewriter

typing

examine

damage

packaging

Unit

to

remove

typewriter

to

be

securing

securing

sheet

stand.

the

surfaces

has

resulted.

materials

remove

the

used.

the

the

from

from

the

typewriter

unit

top

flaps

top

flaps

typewriter

the

inner

of

the

for

possible

console

unit

unit

from

on

the

floor

of

the

outer

of

the

inner

unit.

container

typewriter

future

from

its

near

container.

container.

and

unit

use.

its

container.

container.

the

desk

set

it

into

to

ensure

See

or

typing

position

that

no

See

Figure

2-2.

1.

Using a hand

or

typing

2. Remove

3.

Lift

4.

Break

console

5.

Slide

the

the

container

down

unit

the

console

pOSition.

2441-1

truck,

stand

two

one

is

where

bands

up

of

the

set.

unit

transport

it

will

wrapped

and

away

end

flaps

from

the

the

console

be

used.

around

from

the

on

the

telescoping

unit

to a location

the

container.

console

unit.

telescoping

tray

and

tray

set

near a desk

into

which

it

in

its

the

operating

2-1

Page 20

2-2

PLASTIC

SH£E:T

/

Figure

2-1.

Typewriter

Unit Packaging

BANDS

CONTAINER

TELESCOPING

TRAY

Figure

2-2.

Console

Unit Packaging

2441-1

Page 21

6.

Remove

the

protective

plastic

covering

that

surrounds

the

console

unit.

7. Unwind

S.

Examine

damage

9.

Retain

2.2 SYSTEM INTERCONNECTIONS

Use

the

following

and

2-4.

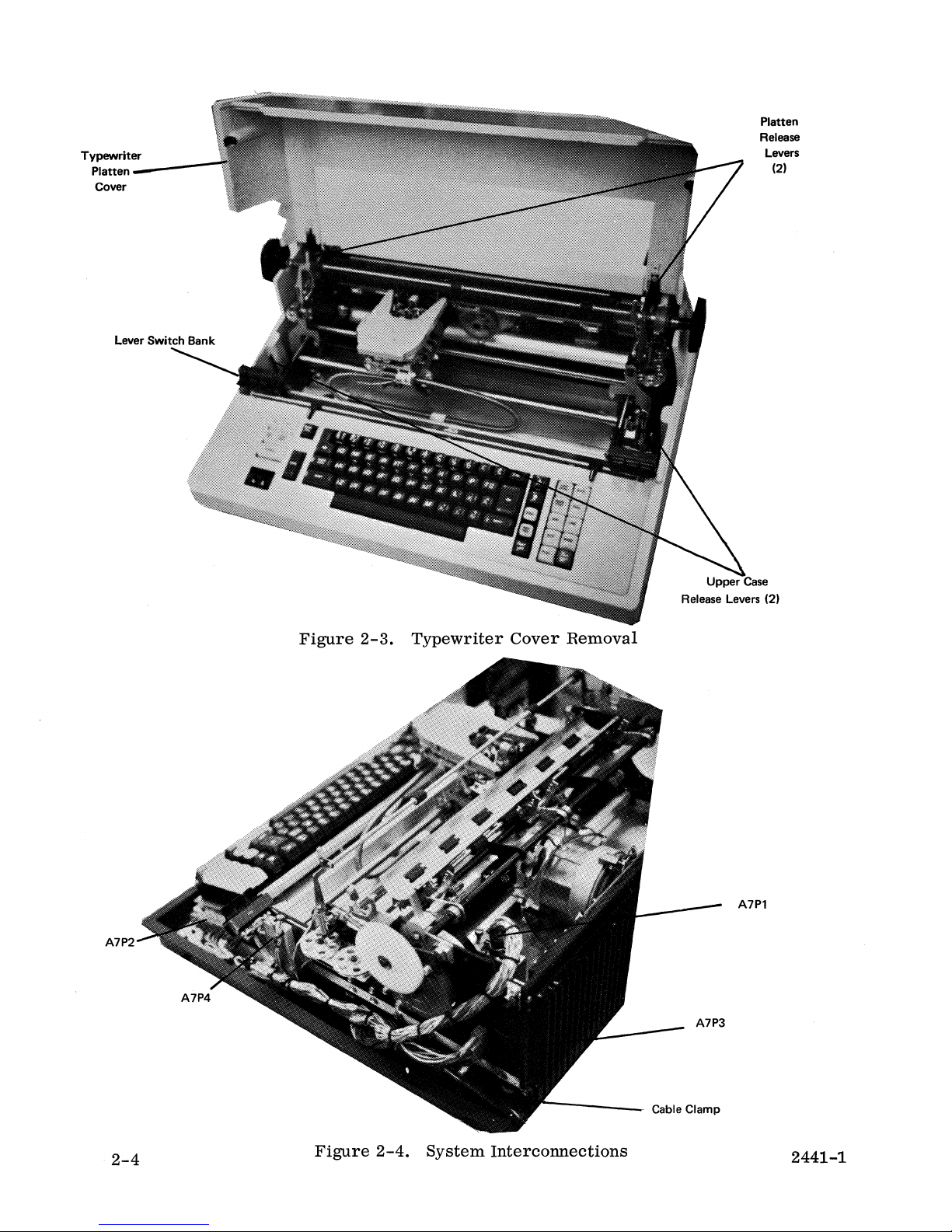

1.

Tilt

2.

Depress

the

the

has

all

packaging

procedure

the

typewriter

the

AC

power

surfaces

resulted.

to

connect

two

platen

writer.

3.

4.

5.

Raise

and

Raise

and

Pull

case

the

left-hand

TAB

CLEAR/SET

the

right-hand

10/12

forward

from

levers.

on

the

the

typewriter.

cord

of

the

materials

the

platen

release

lever

levers.

lever

two

upper

and

interconnection

console

for

two

system

cover

upward

levers

switch

bank

switch

case

unit

possible

components.

to

and

that

bank

that

release

to

ensure

future

expose

lift

the

supports

supports

levers

cable.

that

use.

the

platen

and

no

physical

See

Figures

platen.

from

the

the

MARG

the

remove

LEFT/RIGHT

SINGLE/DOUBLE

the

2-3

type-

upper

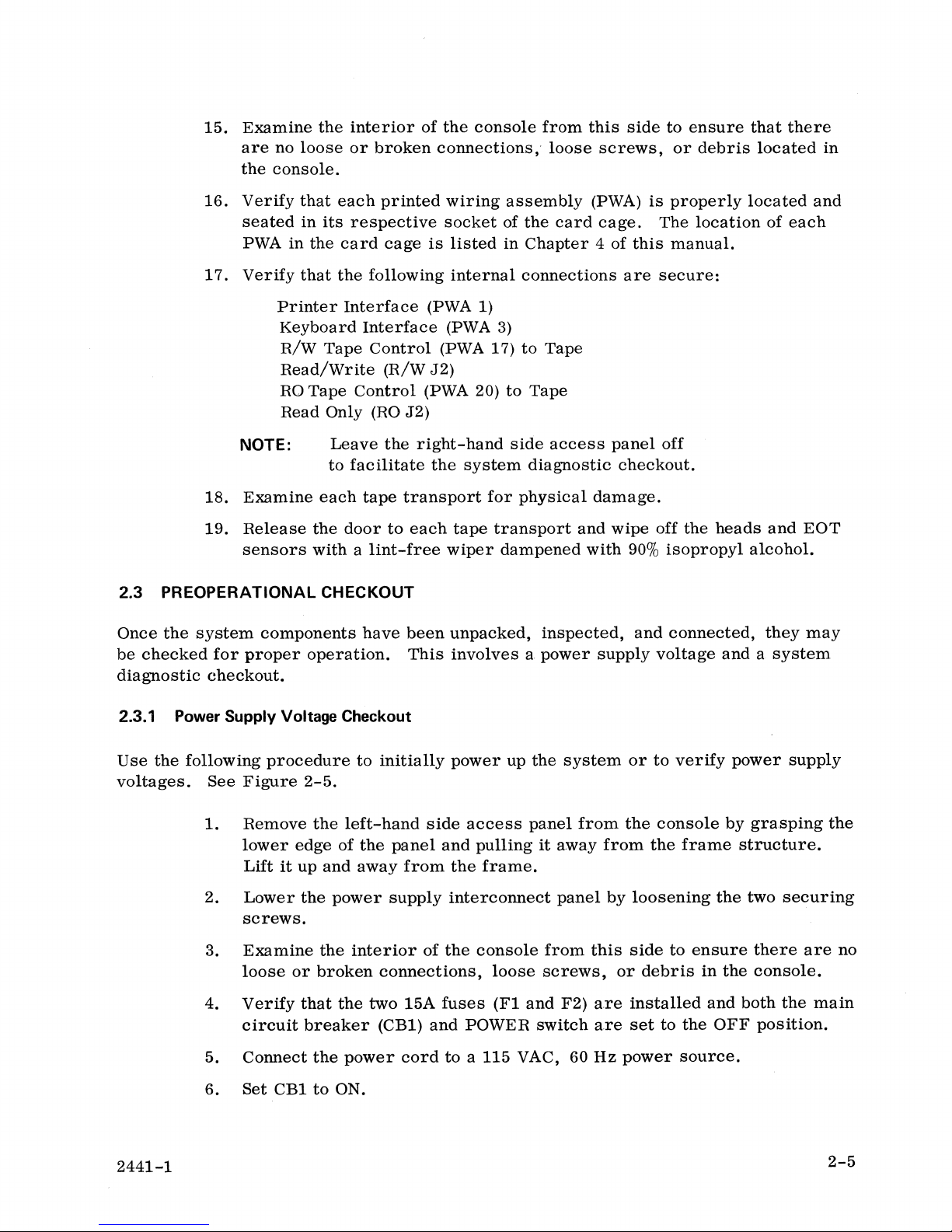

6.

7.

S.

9.

10.

11.

12.

13.

Remove

Lay

in

Locate

NOTE:

A7P1

A7P2

A7P3

A7P4

Place

the

removed

Examine

broken

Replace

place.

Lower

Lower

the

two

screws

the

typewriter-to-console

and

mate

the

four

Alternately,

A

7P1,

A 7P3

34-pin

56-pin

14-pin

14-pin

cable

in

the

connections,

the

both

the

step

interior

upper

lever

platen

clamp

6.

of

loose

cover

switch

cover.

that

secure

following

tighten

and A 7P4

back

into

the

typewriter

screws,

and

then

banks

the

cable

innerconnection

typewriter-to-console

both

screws

in

place.

Printer

Keyboard

Power

Lever

place

or

the

platen

into

place.

to

Interface

Interface

Connector

Switch

and

to

Interface

secure

ensure

debris

by

clamp

cable.

secure

Connector

Edge

using

there

located

snapping

to

lower

connectors.

Connector

Connector

the

are

in

the

them

case.

two

screws

no

loose

typewriter.

back

or

into

14.

Remove

lower

Lift

it

the

edge

up

2441-1

right-hand

of

the

and

away

panel

from

access

and

pulling

the

panel

frame.

from

it

away

the

from

console

the

by

frame

grasping

structure.

the

2-3

Page 22

Typewriter

-----

Platten

Cover

Platten

Release

Levers

(2)

A7P2

Figure

2-3.

Typewriter

Cover

Removal

A7Pl

A7P3

2-4

Figure

2-4.

System

------

Interconnections

Cable Clamp

2441-1

Page 23

15.

16.

17.

Examine

are

no

the

console.

Verify

that

seated

PWA in

Verify

the

loose

in

its

the

that

interior

or

broken

each

printed

respective

card

cage

the

following

of

the

console

connections,

wiring

socket

is

listed

internal

from

loose

assembly

of

the

card

in

Chapter 4 of

connections

this

side

screws,

(PWA)

cage.

are

is

this

to

ensure

or

debris

properly

The

location

manual.

secure:

that

there

located

located

of

each

in

and

Printer

Keyboard

R/W

Read/Write

RO

Read

NOTE:

18.

Examine

19.

Release

sensors

2.3 PREOPERATIONAL CHECKOUT

Once

the

be

checked

diagnostic

system

for

checkout.

components

proper

Interface

Interface

Tape

Control

(R/W

Tape

Control

Only (RO

Leave

to

each

the

the

facilitate

tape

door

to

with a lint-free

have

operation.

2.3.1 Power Supply Voltage Checkout

(PWA 1)

(PWA

(PWA 17)

J2)

(PWA 20)

J2)

right-hand

the

system

transport

each

tape

wiper

been

unpacked,

This

involves a power

3)

to

Tape

to

Tape

side

diagnostic

for

physical

transport

dampened

inspected,

access

and

with

panel

checkout.

damage.

wipe

90%

and

supply

off

off

the

heads

isopropyl

connected,

voltage

and

EOT

alcohol.

they

may

and a system

Use

the

voltages.

2441-1

following

See

Figure

1.

Remove

lower

Lift

2.

Lower

screws.

3.

Examine

loose

4.

Verify

circuit

5.

Connect

6.

Set

procedure

2-5.

the

edge

it

up

and

the

power

the

or

broken

that

breaker

the

CB1

to

ON.

to

initially

left-hand

of

the

panel

away

supply

interior

connections,

the

two

(CB1)

power

power

side

access

and

pulling

from

the

frame.

interconnect

of

the

console

15A

fuses

and

POWER

cord

to a 115 VAC, 60

up

loose

(F1

and

the

system

panel

it

away

panel

from

screws,

F2)

switch

from

from

by

this

are

are

Hz

or

to

the

console

the

loosening

side

or

debris

installed

set

to

power

verify

frame

to

ensure

in

and

the

source.

power

by

grasping

structure.

the

two

there

the

console.

both

OFF

supply

securing

are

the

main

pOSition.

the

no

2-5

Page 24

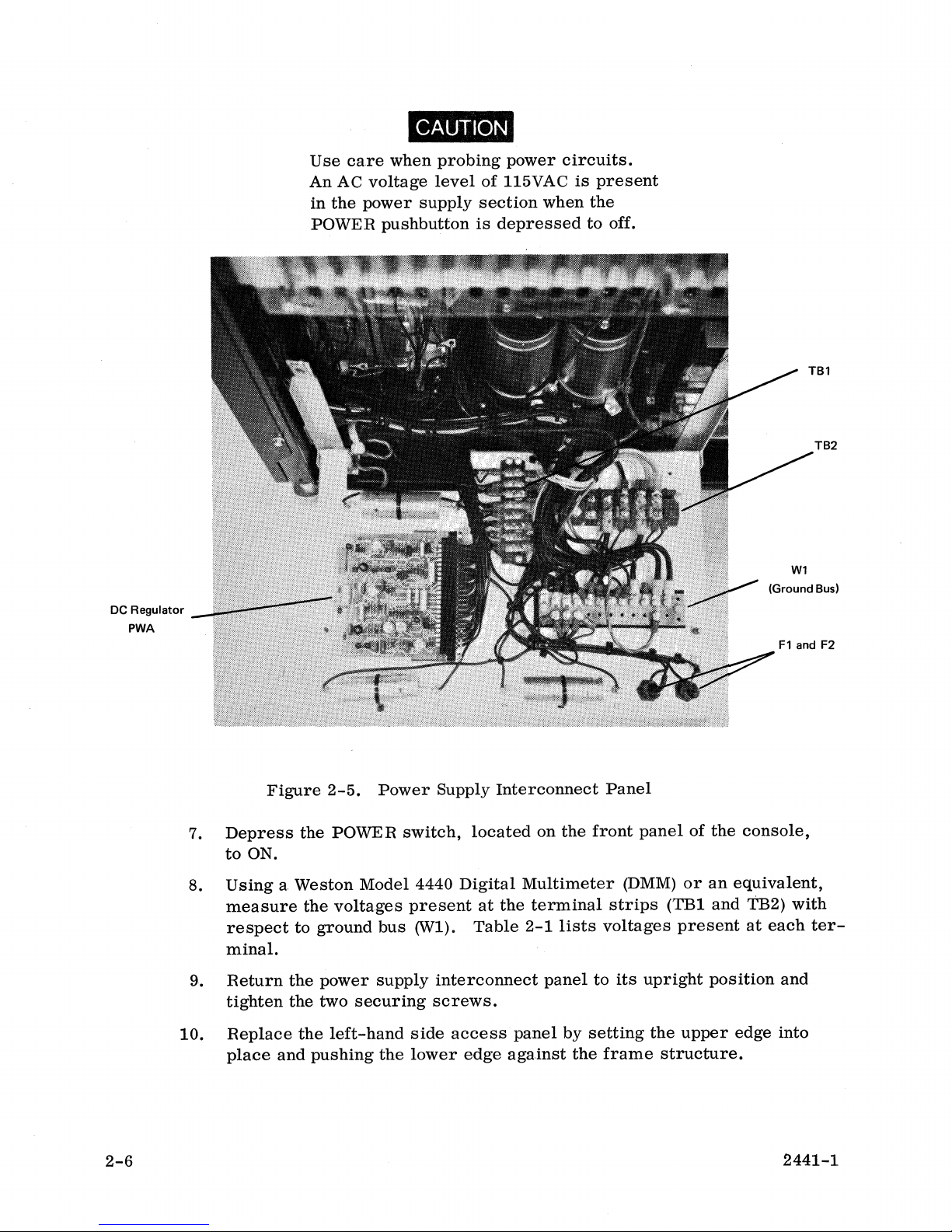

DC Regulator

PWA

Use

care

An

AC

in

the

power

POWER

CAUTION

when

voltage

supply

pushbutton

probing

level

of

section

is

power

circuits.

115VAC

when

depressed

is

present

the

to

off.

TB2

W1

(Ground Bus)

Figure

7.

Depress

to

ON.

8.

Using a Weston

measure

respect

the

the

to

ground

minal.

9.

10.

Return

tighten

Replace

place

the

the

and

the

pushing

2-6

2-5.

POWER

Model

voltages

power

two

securing

left-hand

Power

switch,

4440

present

bus

(WI),

supply

side

the

lower

Supply

Interconnect

located

Digital

at

the

Table

interconnect

screws.

access

edge

panel

against

on

the

front

Multimeter

terminal

2-1

lists

panel

by

to

setting

the

Panel

panel

(DMM)

strips

voltages

its

upright

the

frame

structure.

of

or

(TB1

present

upper

the

console,

an

equivalent,

and

TB2)

at

position

edge

with

each

and

into

2441-1

ter-

Page 25

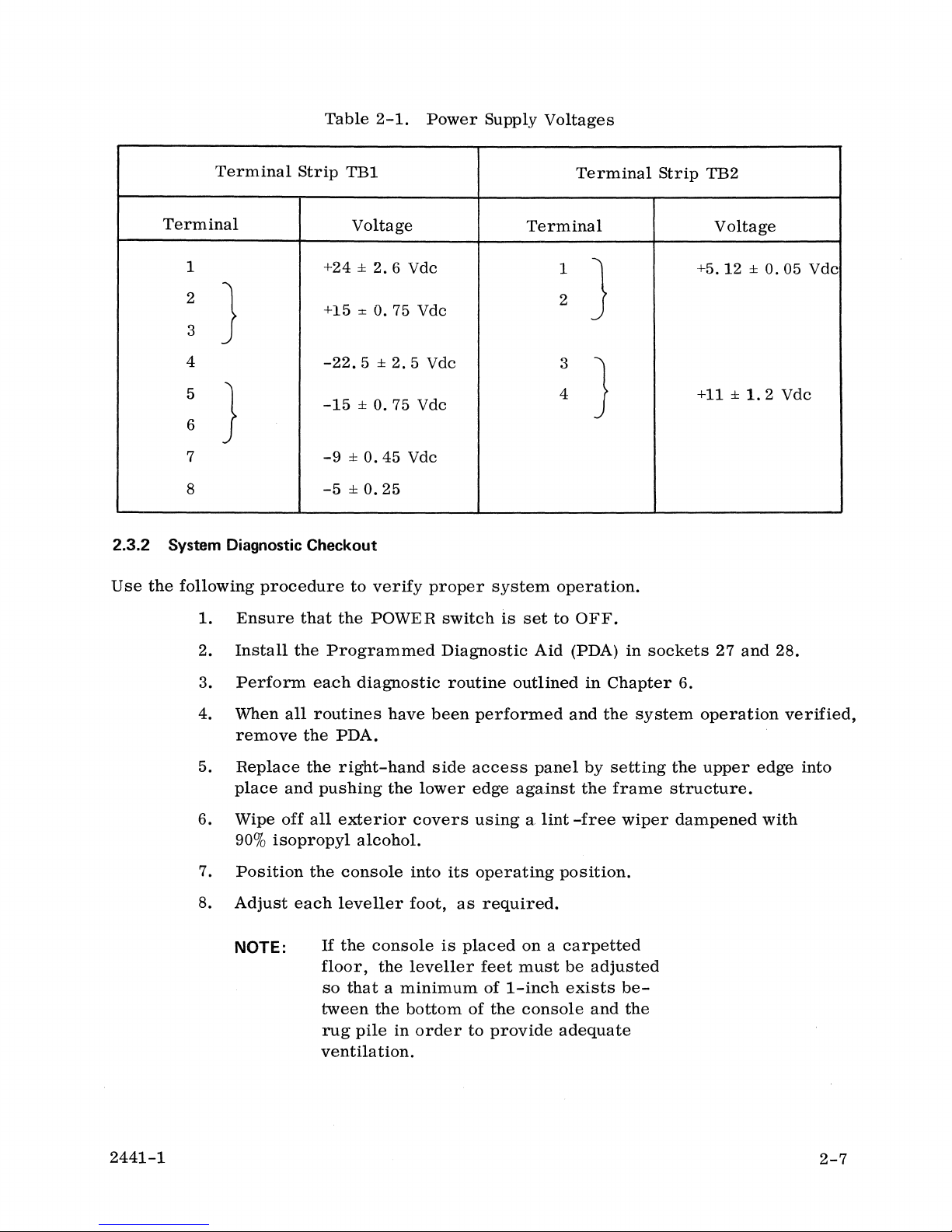

Table

2-1.

Power

Supply

Voltages

Terminal

Terminal

1

2

)

3

4

5

}

6

7

8

2.3.2 System Diagnostic Checkout

Use

the

following

1.

Ensure

Strip

+24 ±

+15

-22.5 ± 2.5

-15 ± 0.75

-9

-5

procedure

that

TB1

Voltage

:!:

±0.45

±0.25

to

the

2.6

Vdc

0.75

Vdc

Vdc

Vdc

Vdc

verify

POWER

proper

switch

Terminal

system

is

set

Terminal

1

2

}

3

4

}

operation.

to

OFF.

Strip

TB2

Voltage

+5.12 ± 0.05

+11 ±

1.

Vdc

2 Vdc

2.

3.

4.

5.

6.

7.

8.

Install

Perform

When

remove

Replace

place

Wipe

90%

Position

Adjust

NOTE:

all

and

off

isopropyl

the

Programmed

each

routines

the

PDA.

the

right-hand

pushing

all

exterior

the

console

each

leveller

If

the

floor,

so

that a minimum

tween

rug

ventila

diagnostic

have

the

lower

covers

alcohol.

into

foot,

console

the

leveller

the

bottom

pile

in

order

tion.

Diagnostic

routine

been

performed

side

access

edge

using a lint

its

operating

as

required.

is

placed

feet

of

of

the

to

provide

Aid

(PDA)

outlined

panel

against

on a carpetted

must

1-inch

console

in

and

by

the

-free

position.

be

adjusted

exists

and

adequate

in

sockets

Chapter

the

system

setting

frame

wiper

be-

the

27

6.

operation

the

upper

structure.

dampened

and

edge

28.

verified,

into

with

2441-1

2-7

Page 26

Page 27

CHAPTER 3

OPERATION

3.1

KEYS, CONTROLS, INDICATORS AND ALARMS

Each

key

on

the

understanding

•

• Mode

•

•

In

each

classification, a key

illustration

The

controls

a

description

is

keyboard

as

to

Basic

Action

Encoded

provided

and

indicators

of

each

their

has

functions:

Operation

Keys

Keys

Function

is

for

each

located

system

been

Keys

Keys

first

group

alarm

classified

identified,

to

on

the

is

presented.

and

assist

Console

presented

and

then

in

the

are

as

its

function

location

then

identified

follows

is

of

each

to

provide a better

defined.

discussed

and

defined

An

key.

and

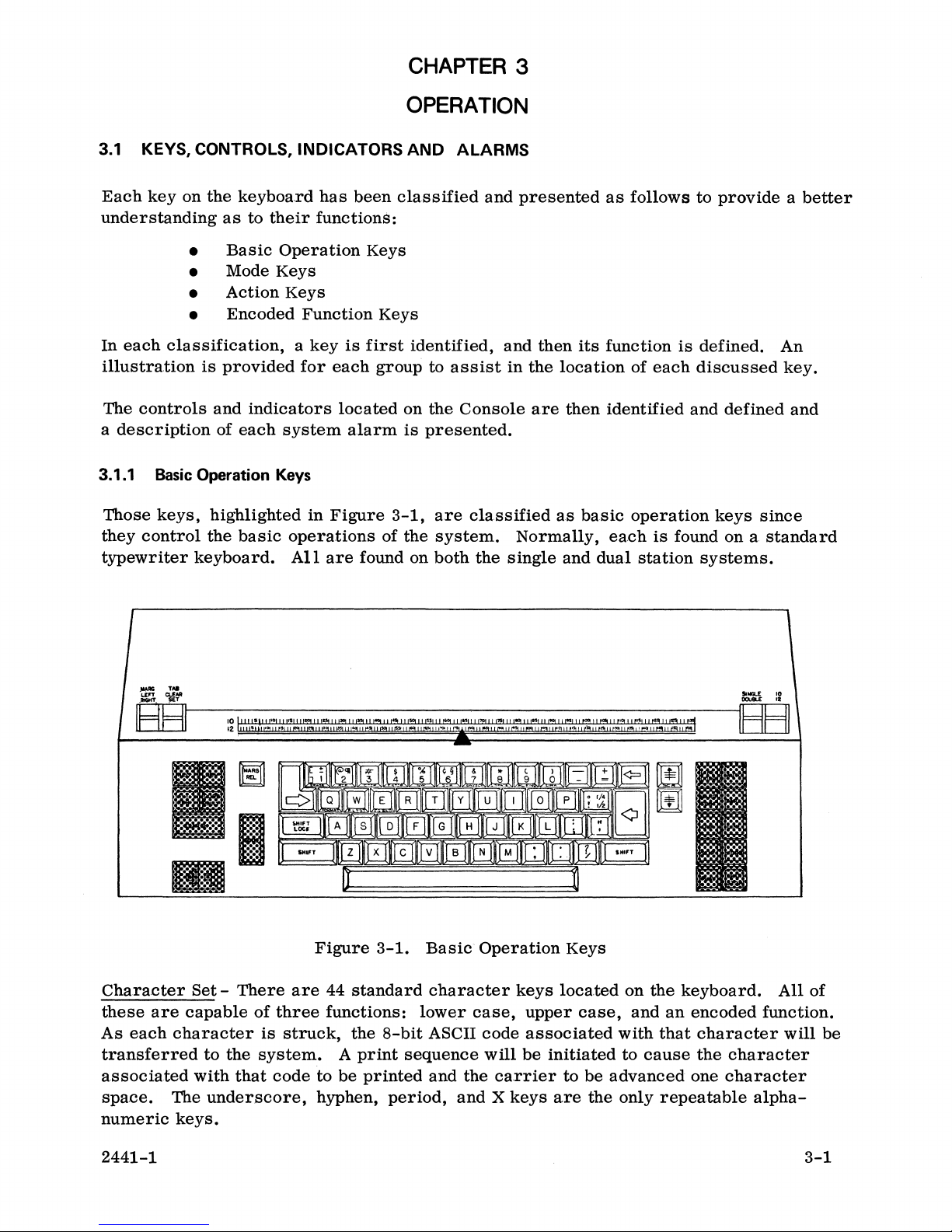

3.1.1

Those

they

Basic

keys,

control

typewriter

Operation

highlighted

the

basic

keyboard.

Keys

in

Figure

operations

All

are

3-1,

of

the

found on

are

classified

system.

both

the

as

Normally,

single

and

basic

each

dual

operation

is

found on a

station

keys

since

systems.

Sutal

.. ! 10

DCIUILE

IBBI

standard

..

Figure

Character

these

As

each

transferred

associated

space.

numeric

Set -There

are

capable

character

with

The

keys.

of

three

is

struck,

to

the

system.

that

code

underscore,

are

to

hyphen,

2441-1

3-1.

44

standard

functions:

the

8-bit

A

print

be

printed

period,

Basic

character

lower

ASCII

sequence

and

the

and X keys

Operation

keys

case,

code

will

upper

associated

be

carrier

Keys

located

case,

initiated

to

be

are

the

on

the

and

an

with

that

to

cause

advanced

only

repeatable

keyboard.

encoded

character

the

character

one

character

All

of

function.

will

alpha-

3-1

be

Page 28

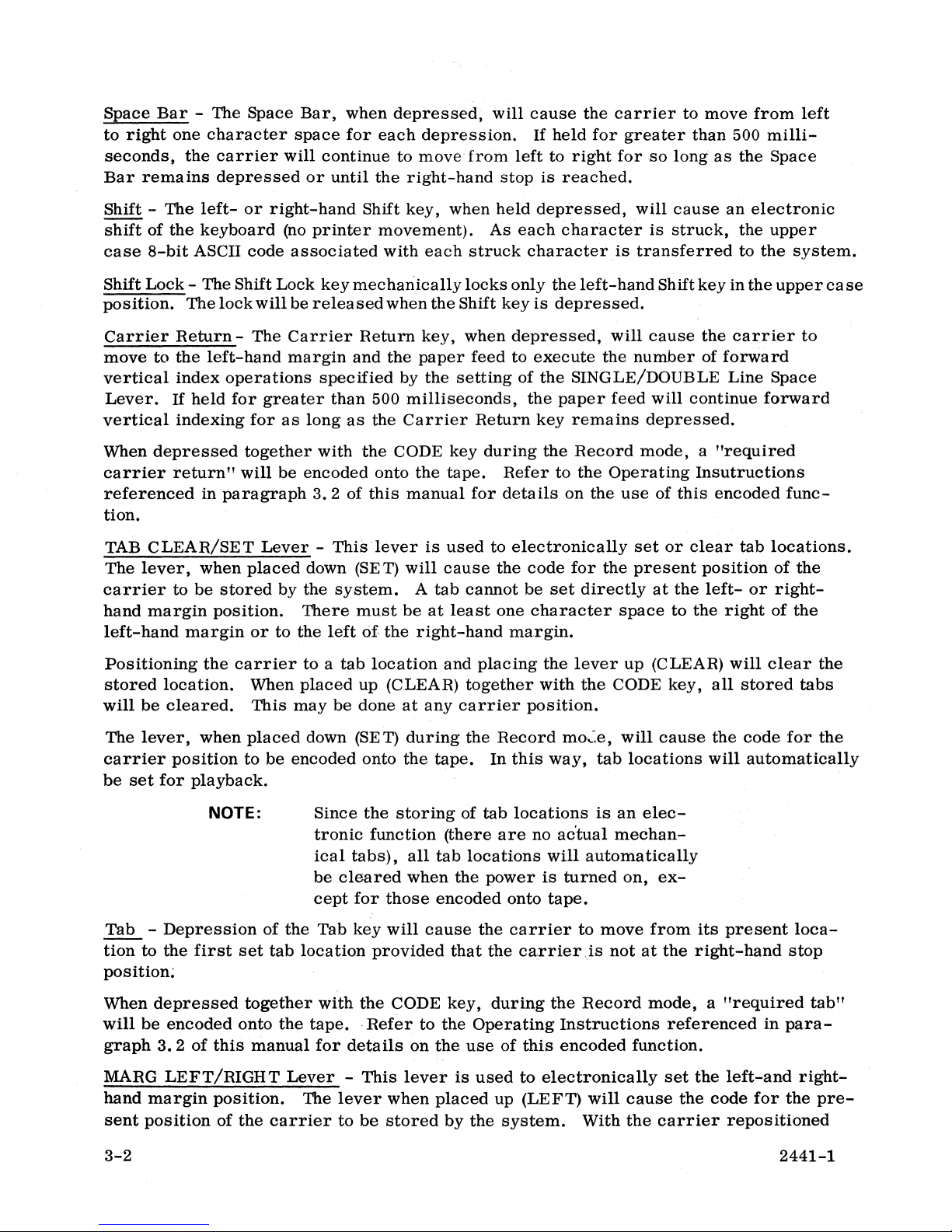

Space

to

Bar

right

seconds,

Bar

remains

- The Space

one

character

the

carrier

depressed

Bar,

space

will

or

when

for

each

continue

until

the

depressed,

depression.

to

move

from

right-hand

will

left

stop

cause

If

held

to

is

reached.

the

for

right

carrier

greater

for

so

to

than

long

move

500

as

the

from

milli-

Space

left

Shift - The

shift

of

case

8-bit

left-

the

keyboard

ASCII

or

right-hand

(no

code

associated

Shift Lock - The Shift Lock

position.

Carrier

move

vertical

Lever.

vertical

When

carrier

referenced

The

lock

Return-

to

the

left-hand

index

If

held

indexing

depressed

return"

in

paragraph

will

be

The

Carrier

margin

operations

for

greater

for

as

together

will

be

encoded

tion.

TAB

CLEAR/SET

The

lever,

carrier

hand

margin

left-hand

when

to

be

margin

pOSition.

Lever -This

placed

stored

or

to

by the

There

the

printer

key

mechanically

released

and

specified

than

long

as

with

3.2

of

down

(SE

system.

must

left

Shift

key,

movement).

with

each

when the Shift

Return

the

key,

paper

by the

500

milliseconds,

the

Carrier

the

CODE key

onto

the

this

manual

lever

T)

is

will

A

be

at

of

the

right-hand

when

setting

tape.

used

cause

tab

least

held

As

each

struck

locks

only

key

when

depressed,

feed

to

of

Return

during

Refer

for

details

to

electronically

the

cannot

one

margin.

depressed,

character

character

the

left-hand

is

depressed.

execute

the

SINGLE/DOUBLE Line Space

the

paper

key

remains

the

Record

to

the

on

code

for

be

set

directly

character

will

is

transferred

will

the

number

feed

mode, a "required

Operating

the

use

set

the

present

space

cause

is

struck,

Shift

key

cause

the

of

will

continue

depressed.

Insutructions

of

this

encoded

or

clear

position

at

the

left-

to

the

an

electronic

the

upper

to

the

in the

upper

carrier

forward

forward

tab

locations.

of

or

right-

right

of

system.

ca

to

func-

the

the

se

POSitioning

stored

will

be

The

lever,

carrier

be

set

the

location.

cleared.

when

pOSition

for

playback.

NOTE:

carrier

When

This

placed

to

Tab -Depression

tion

to

the

first

set

position;

When

will

graph

depressed

be

encoded

3.2

of

onto

this

together

manual

MARGLEFT/RIGHT

hand

sent

margin

position

pOSition. The

of

the

to a

tab

placed

may

be done

down (SET)

be

encoded

Since

tronic

ical

be

cleared

cept

of

the

Tab

tab

location

with

the

tape

for

Lever -This

lever

carrier

to

location

up (CLEAR)

at

during

onto

the

the

storing

function

tabs),

all

when

for

those

key

will

provided

the

CODE

..

Refer

details

to

on

lever

when

be

stored

and

together

any

carrier

the

tape.

of tab

(there

tab

locations

the

encoded

cause

that

key,

the

the

use

is

placed

by

the

placing

the

with

position.

Record

In

this

locations

are

noac'tual

power

is

onto

the

carrier

the

carrier

during

Operating

of

this

used

to

electronically

up

(LEFT)

system.

lever

the

CODE

mo:.e,

way,

tab

is

will

an

mechan-

will

automatically

turned

tape.

to

move

is

not

the

Record

Instructions

encoded

will

With

up

(CLEAR)

key,

cause

locations

will

all

the

will

stored

elec-

on,

ex-

from

at

its

the

right-hand

present

mode, a "required

referenced

function.

set

the

left-and

cause

the

the

carrier

code

repositioned

clear

the

tabs

code

for

the

automatically

loca-

stop

tab"

in

para-

right-

for

the

pre-

3-2

2441-1

Page 29

for

the

margin

The

lever,

the

left-

left-

and

right-hand

position.

NOTE:

when

and

right-hand

right-hand

margin,

used

margins

the

The

reach

system

that

right-hand

during

margin

lever

keyboard

the

right-hand

buzzer

five

spaces

the

Record

positions

will

automatically

can

be

does

will

remain

margin

mode,

to

placed

not

down (RIGH

lock

margin.

sound

to

before

is

encountered.

will

be

encoded

be

set

when

The

indicate

the

cause

onto

for

T)

to

you

the

codes

the

tape.

playback.

store

the

associated

In

this

right-hand

with

way,

the

During

position

stored

margin

with

tions

MARG

the

the

initial

and

then

and

in a

positions

8-1/2" x 11"

or

setting

NOTE:

REL

- The

present

left-hand

Backspace -The

right

to

left

one

seconds,

key

remains

When

space"

paragraph

the

carrier

depressed

depressed

will

be

3.2

encoded

of

power

spaced

similar

(10/70

paper.

the

desired

margin

margin.

Backspace

character

will

together

this

manual

on

sequence,

to a

standard

the

left-hand

manner a right-hand

for

The

margin

Since

is

an

actual

will

power

encoded

release

key,

space

continue

or

until

with

onto

the

10-pitch

operator

the

electronic

automatically

the

for

or

12/84

then

positions

storing

mechanical

is

turned

onto

tape.

key,

when

when

for

the

tape.

each

to

move

left-hand

CODE

details

depressed,

key,

Refer

on

function

on

carrier

is

margin

margin

for

12-pitch)

has

the

as

previously

of

margin

(there

stops),

be

cleared

except

depressed,

will

depression.

from

right

margin

during

to

the

Opera

the

use

positioned

position.

position

option

positions

are

all

margins

when

for

those

permits

cause

If

held

to

left

is

reached.

the

Record

ting

of

this

encoded

to

the

left

The

is

stored.

are

typical

of

using

these

described.

no

the

the

operator

the

carrier

for

greater

for

as

long

mode, a "required

Instructions

function.

most

position

These

settings

standard

to

move

than

as

the

referenced

is

stored

for

use

posi-

to

bypass

from

500

milli-

Backspace

back-

in

Forward

to

execute

the

key

During

read

vertical

Reverse

to

execute

the

paper

key

Index

paper

remains

the

during

index

Index

remains

(£)

forward

feed

will

depressed.

Record

playback,

operation.

(i=)

reverse

feed

will

depressed.

- The

vertical

continue

mode,

the

-

The

vertical

continue

2441-1

Forward

index

forward

the

Forward

paper

Reverse

index

reverse

Index

operations.

vertical

Index

feed

will

Index

key,

operations.

vertical

key,

when

If

held

depressed,

indexing

code

will

automatically

when

depressed,

If

held

indexing

for

for

be

execute

for

for

will

greater

as

long

recorded

each

will

greater

as

long

cause

than

as

the

onto

cause

than

as

the

the

500

milliseconds,

Forward

the

tape.

recorded

the

500

milliseconds,

Reverse

paper

forward

paper

Index

feed

Index

When

feed

3-3

Page 30

During

read

vertical

the

Record

during

index

mode,

playback,

operation.

the

the

paper

Reverse

feed

Index

will

code

automatically

will

be

recorded

execute

onto

each

the

tape.

recorded

When

reverse

SINGLE/DOUBLE

spacing

10/12

ten

3.1.2

Those

the

to

system

this

of

Pitch

characters

Mode

keys,

mode

of

indicate

error

manual.

the

printer

Lever -This

per

Keys

highlighted

system

the

present

conditions.

Line

Space

to

six

lever

inch

(10)

in

operation.

system

Lever -This

lines

per

is

used

or

twelve

Figure

3-2,

Each

operation.

These

alarms

lever

inch

(SINGLE)-

to

electronically

characters

are

classified

is a lighted

Certain

are

discussed

is

used

per

key

keys

to

or

three

set

inch

as

mode

which

flash

in

electronically

lines

per

the

pitch

(12).

keys

since

illuminates,

to

signal

detail

in

paragraph

set

the

line

inch (DOUBLE).

of

the

printer

they

establish

when

depressed,

input, output,

3.

1.

6

to

or

of

Record

In

this

automatically

EOR (end

mode

(REC) -

mode,

of

is

turned

This

the

read/write

searched

record)

off.

lighted

for a recordable

is

located.

In

this

tape.

Revise

This

be

activated

of

CODE

writer

(REV) -

mode

made

within

during

an

RO

to

PRINT -This

character

is

used

R/W

This

lighted

to

make

the

prerecorded

this

mode.

transfer.

lighted

that

is

associated

3-4

Figure

key,

when

(R/W)

way,

key,

magnetic

An

EOR

old

data

when

corrections

line

plus

In

this

way,

key,

when

with

3-2.

Mode

Keys

depressed,

tape

transport

area.

is

is

depressed,

A

recordable

recorded

preserved

selects

on a prerecorded

50

characters.

minor

depressed,

an

revisions

will

encoded

selects

the

is

Record

actuated

area

on

the

tape

and

new

the

Revise

tape.

SKIP

and

can

be

cause

the

function. An

is

detected

each

data

can

mode

The

corrections

PLAY

made

printing

automatic

mode

and

time

the

be

added

may

without

of

of

operation.

the

tape

is

when

an

Record

to

the

of

operation.

must

also

be

the

need

the

type-

overprinting

2441-1

Page 31

of

this

character

not a regular

tion

will

also

the

encoded

with a slash

typed

be

functions

character.

printed,

they

(/)

Those

but

not

represent.

will

follow to

numeric

slashed.

indicate

codes

Table

3-1

that

that

accompany

lists

this

those

is

an

encoded

an

slashed

function,

encoded

characters

func-

and

When

will

will

depressed

automatically

occur

together

print

as

specified,

CODE ENCODED FUNC TION KEY

i

$

I:

~

¢

'I

g

or

1

~

with

the CODE

out

on

the

paper.

but

no

slashed

Table

3-1.

Reference

Stop

Transfer

Switch

Search

Switch and

SINGLE/DOUBLE

First

Line

Encoded

Stop

Search

Find

key,

all

If

CODE

character

Function

Line

prerecorded

PRINT

will

print.

Codes

Space L SPACE

is

margin

not

on, the

and

REF

STOP

TSTOP

SW

SCH

SW/SCH

FL

FIND

tab

settings

encoded

function

fQ

VI

t

Margin

will

zone.

Instructions

mode

Duplicate

cause a high

R/W

the

licated.

all

address

next

Depressing

Control

automatically

This

and

the

(PUP) -

without

AUTO

data

key

If

from

will

sequential

f5

(MARG CONT) -

cause

zone

may

referenced

zone

adjustment

This

speed

printing

a

block

the

be

the

transfer

is

depressed,

address

present

duplicated.

block

PARA, LINE, WORD,

Track

Format

First

Page

the

be

adjusted

in

paragraph

lighted

on

paper.

location

address

Link LINK

Line

End

This

right-hand

from

technique.

key

(dual

of

data

(1000

If

a 00

all

data

is

set

into

up

When

and

the

stop

FORMAT

Set

(line count) PG END

lighted

margin

0 to 7

3.2

is

from

the

to

but

block

without

or

key,

when

to

readjust

character

of

this

manual

station

characters

set

the

thumbwheels

CHAR/STOP

systems

into the

present

not

including

address

duplicating

depressed

spaces.

for

only),

per

second)

block

location

and

that

is

located,

key

within a five

details

address

the

data

that

will

FL

during

Refer

when

from

to

an

AUTO

specified

the

block

then

SET

character

to

on

the

depressed,

the

thumbwheels

EOR

will

key

R/W

will

of

information.

cause

the

Play

the

Operating

use

of

RO

to

be

is

depressed,

by

the

write

only

that

mode,

space

this

will

the

and

dup-

block

the

2441-1

3-5

Page 32

selected

which

portion

is

lower

duplication

When

key

the

will

extinguish.

of

than

of

data

will

duplication

the

data

that

for

only

is

completed,

to

be

duplicated.

the

present

terminate

the

location,

after

all

system

If

the

no

selected

buzzer

thumbwheels

duplication

conditions

will

sound

are

will

and

set

take

have

the

to a

place.

been

lighted

block

address

The

fulfilled.

action

SKIP coded

key

and

PIA

mode,

This

functions,

operates

CHAR/STOP.

Y -

This

the

R/W

commanded

The

PIA Y key,

will

cause

data

paper.

When

be

for

3.1.3 Action

Those

action,

used

read

this

from

operation

keys,

when

lighted

to

in

conjunction

lighted

magnetic

by

the

depression

when

to

be

in

conjunction

the

RO

to function.

Keys

highlighted

depressed.

key,

be

read

key,

used

read

and

when

without

with

when

tape

in

from

with

printed

in

Figure

depressed,

printing

the

action

depressed,

transport

of

an

action

conjunction

the

RO

and

the

ALT

RDR

on

paper.

3-3,

are

will

or

keys,

selects

is

activated

key.

with

written

key

The

classified

cause

recorded

performing

i.

e.,

AUTO, PARA, LINE, WORD,

the

and

the

REC

into

(dual

station

system

as

Play

data

key

the

must

action

data,

the

encoded

mode

is

(dual

R/W,

systems

not

of

read

station

as

be

keys

including

function.

operation.

and

printed

systems

well

as

printed

only),

in

the

Record

since

they

any

data

cause

en-

This

In

this

as

only)

on

will

mode

an

SEARCH loaded

tape

responds

lighted

until

3-6

This

transport

to

the

the

lighted

key,

and

particular

block

address

Figure

when

3-3.

depressed

automatically

block

address

is

located

Action

search

set

into

and

Keys

during

the

the

then

it

the

Play

mode,

tape

for a block

thumbwheels.

will

extinguish.

will

actuate

address

The

key

SING...!

10

D<lUIU "

the

which

will

2441-1

cor-

remain

Page 33

When

RO

to

used

R/W

in

conjunction

transfer,

the

with

RO

the

tape

ALT

will

RDR

be

searched

key

(dual

for

station

the

block

systems

address.

only)

during

an

Block

address

into

ALT

the

the

cause

iated

are

Address

ranging

the

tape,

RDR - The

Play

mode,

R/W

(standard

the

reading

with

the

located

Thumbwheels -These

from

particular

alternate

will

selected

on

the

LINE CORR - The

cause

the

will

not

rewind

line.

over

AUTO modes,

information.

that

line

carrier

not

returned

appear

transferred

the

tape

The

tape,

any

portion

This

will

cause

of

on the

from

and

in

of

lighted

These

00 to 99. Since

segments

reader

cause

reader

to

be

the

in the

returned

reader,

console.

line

correct

information

to

the

left-hand

tape,

the

buffer

reverse

this

case,

the

existing

key,

when

the

system

blocks

are

can

key

reading

Play

to

will

key,

presently

nor

will

onto

vertical

will

be

information.

depressed

to

play

separated

thumbwheels

block

addresses

easily

(dual

station

of

information

mode)

the

light

when

to

R/W.

when

depressed

being

margin

the

the

index

erased

position

tape

tape.

the

and

during

and

print,

by

are

used

are

be

searched

systems

from

the

RO. A

The

Active

the

reader

during

stored

in the

without

be

erased

Each

paper

or

subsequent

feed

rerecorded

the

Play,

skip,

or

prerecorded,

to

set a two-digit

sequentially

or

located.

only),

the

when

tape

subsequent

READ

is

Station

activated.

the

Record

buffer

to

prerecorded

depressed

to

be

switched

depression

Indicator

These

mode,

be

cleared,

indexing. The

rewound,

since

depression

to

the

beginning

as

the

operator

Revise,

Skip,

duplicate a single

sequential

block

block

will

assoc-

indicators

will

and

information

that

line

will

merely

of

each

previous

retypes

or

Duplicate

block

of

addresses.

during

from

was

During

by

the

PARA modes,

of

operation

the

block

thumbwheels

This

will

information.

or a required

LINE modes,

This

will

information.

line

and