Page 1

Power meter

IT9121 Series User Manual

Model: IT9121

Version:V1.4

Page 2

IT9121 User Manual

Notices

© ItechElectronic, Co., Ltd. 2017

No part of this manual may be

reproduced in any form or by any means

(including electronic stor age and

retrieval or translation into a foreig n

language) without prior permission and

written consent from Itech Electronic,

Co., Ltd. as governed by international

copyright laws.

Manual Par t Number

IT9121-402145

Revision

1

st

Edition: June 27, 2017

Itech Electronic, Co., Ltd.

Trademarks

Pentium is U.S. registered trademarks

of Intel Corporation.

Microsoft, Visual Studio, Windows and

MS Windows are registe red trad em arks

of Microsoft Corporation in the United

States and/or other countries and

regions.

Warranty

The materials contained in this

document are provided “as is”, and

is subject to change, without prior

notice, in future editions. Further, to

the maximum extent permitted by

applicable laws, ITECH disclaims

all warrants, either express or

implied, with regard to this manual

and any information contained

herein, including but not limited to

the implied warranties of

merchantability and fitness for a

particular purpose. ITECH shall not

be held liable for errors or for

incidental or indirect damages in

connection with the furnishing, use

or application of this document or of

any information contained herein.

Should ITECh and the user enter

into a separate written agreement

with warranty terms covering the

materials in this document that

conflict with these terms, the

warranty terms in the separate

agreement shall prevail.

Technol ogy Licenses

The hardware and/or software

described herein are furnish ed under a

license and may be used or cop ied only

in accordance with the terms of such

license.

Restricted Rights Leg end

U.S. Government Restricted Rights.

Software and technical data rights

granted to the federal government

include only those rights customarily

provided to end user customers. ITECH

provides th is custo mary comme rcial

license in software and technical

data pursuant to FAR 12.211

(Technical Data) and 12.212

(Computer Software) and, for the

Department of Defense, DFARS

252.227-7015 (Technical Data –

Commercial Items) and DFARS

227.7202-3 (Rights in Commercial

Computer Software or Computer

Software Documentation).

Safety Notices

A CAUTION sign denotes a

hazard. It calls attention to an

operating procedure or practice

that, if not correctly performed

or adhered to, could result in

damage to the product or loss of

important data. Do not proceed

beyond a CAUTION sign until

the indicated conditions are fully

understood and met.

A WARNING sign denotes a

hazard. It calls attention to an

operating procedure or practice

that, if not correctly performed

or adhered to, could result in

personal injury or death. Do

not proceed beyond a

WARNING sign until the

indicated conditions are fully

understood and met.

NOTE

A NOTE sign denotes important

hint. It calls attention to tips or

supplementary information that

is essential for users to refer to.

.

Page 3

IT9121 User Manual

Copyright © Itech Electronics Co., Ltd. i

Quality Certification and Assurance

We certify that T9121 power m eter meets al l the published specifications.

Warranty

ITECH warrants that the product will be free from defects in material and

workmanship under normal use for a period of one (1) year from the date of

delivery ( except those described in the Limi tation of Warranty below).

For warranty service or repair, the product must be r eturned to a s ervice center

designated by ITEC H.

The product returned to ITECH for warranty service must be shipped PREP AID.

And ITECH will pay for return of the product to customer.

If the product is returned to ITECH for warranty service from overseas, all the

freights, duties and other taxes shall be on the acc ount of customer.

Limitation of Warranty

This War ranty will be rendered invalid if the product is:

Damage d resulting from cus tom er-wired circuits or customer-supplied parts or

accessories;

Modified or repaired b y customer without authorization;

Damage d resulting from cus tom er-wired circuits or use in an envi ronment not

designated by us;

The product model or serial number is altered, deleted, removed or made

illegible by customer;

Damaged as a result of accidents, includi ng but not limited to lightning,

moisture, fir e, improper use or negligence.

Safety Symbols

Direct current

ON (power)

Alternating current

OFF (power)

Both direct and alternating

current

Power-on state

Protective earth (ground)

terminal

Power-off state

Earth (ground) termi nal

Reference terminal

Caution

Positive terminal

Warning (refer to this manual

for specific Warning or

Caution informati on)

Negati ve terminal

A chassis terminal

-

-

Page 4

IT9121 User’s Manual

Copyright © Itech Electronics Co., Ltd. ii

Safety Precautions

The following safety precautions must be observed during all phases of

operation of this instrume nt. Failure to comply with these pr e cautions or speci f i c

warnings elsewhere in this manual will constitute a default under safety

standards of design, manufacture and intended use of the instrument. ITECH

assumes no l iability for the custom er’ s failure to comply with these preca utions.

Do not use the instrument if it is damaged. Before operation, check the

casing to see whether it cracks or is not appli ed w ith suf ficient plastics. Do

not operate the instrum ent in the pr esence of inflammable gasses, vapor s

or dusts.

The max imum operating voltage and current of the inst rument are 600V

and 20A respectively. Exceeding these limits will l ead to burnout of the

instrument.

Make sure to use the power cord supplied by ITECH.

Check all marks on the instrument before connecting the instrument to

power supply.

Tur n off the instrument and the operation system before connecting to the

I/O terminal.

Do not use the instrument if t he detachable cover is remo ved or loosen.

Do not connect the instrument to any cable or terminal block bef ore

self-testing.

To prevent the pos sibility of accidental injuries, be sure to use the power

adapter supplied by the manufacturer only.

We do not accept responsibility for any direct or indirect financial damag e

or loss of pr ofit that might occur when using the instrument.

This instrument is used for industrial purposes. Do not apply t his product to

IT power supply system.

Never use t he i nst rum ent with a life-support syst em or any ot her equi pment

subject to saf ety requirements.

Fail ure to use the instrument as directed by the manufacturer may render

its protective features void.

Always clean the casing with a dry cloth. Do not clean the internals.

Make sure the vent hole is always unblocked.

Environmental Conditions

The instrum ent is designed for indoor use and an area with low condensation.

The table below shows the general environmental requirements for the

instrument.

Enviro nmental Cond iti ons

Requirements

Operating tem perature

5°C-40°C

Operating humidity

humidity 20%-80%

(non-condensation)

Storage temper ature

-20°C-50 °C

Altitude

Operating up to 2,000 meters

Page 5

IT9121 User’s Manual

Copyright © Itech Electronics Co., Ltd. iii

Install ation category

II

Polluti on degree

Polluti on degree 2

NOTE

To m ake accurate measurements, allow the instrument to warm up for 30 min.

Regulatory Markings

The CE mark indicates that the product

complies with all the relevant European

legal

directives. The specific year (if any)

affixed refers to the year when the design

was approved.

The instrum ent complies with the WEEE

Directive (2002/96/EC) marking

requirement. This affix product label

indicates that you must not discard the

electrical

/electronic product in domestic

househol d waste.

This symbol indicates the time period

during which no hazardous or toxic

substances are expected to leak or

deteriorate during normal use. The

expected useful life of the product is 10

years. The product

can be used safely

during the 10-

year Environment Friendly

Use Period (EFUP). Upon expiration of

the EFUP, the product must be

immediately recycled.

Waste Electrical and Electronic Equiment (WEEE)

Directive

2002/96/E C Waste Electrical and El ectronic Equipment

(WEEE) Directive

This product complies with the WEEE Directive (2002/96/EC)

marking requirement. Thi s affix product label indicates that you

must not discard the el ectrical/electronic product in domestic

househol d waste.

Product Category

With

reference to the equi pment classifications described in the

Annex 1 of the WEEE Directive, this instrument is classified as

a “Monitoring and Control Instr ument”.

To return thi s unw anted instrument, contact your ne ar est I TE CH

office.

Page 6

IT9121 User’s Manual

Copyright © Itech Electronics Co., Ltd. iv

Compliance Information

Complies with the essential requirements of the following applicable European

Directives, and carries the CE marking accordingly:

Electromagnetic Compatibility (EMC) Directive 2014/30/EU

Low-Voltage Directive (Safety) 201 4/35/EU

Conforms with the following product standards:

EMC Standard

IEC 61326-1:2012/ EN 61326-1:2013 ¹²³

Reference Standards

CISPR 11:2009+A1:2010/ EN 55011:2009+A1:2010 (Group 1, Class A)

IEC 61000-4-2:2008/ EN 61000-4-2:2009

IEC 61000-4-3:2006+A1:2007+A2:2010/ EN 61000-4-3:2006+A1:2008+A2:2010

IEC 61000-4-4:2004+A1:2010/ EN 61000-4-4:2004+A1:2010

IEC 61000-4-5:2005/ EN 61000-4-5:2006

IEC 61000-4-6:2008/ EN 61000-4-6:2009

IEC 61000-4-11:2004/ EN 61000-4-11:2004

1. The product is intended for use in non-residential/non-domestic environments. Use of the

product in residential/domestic environments may cause electromagnetic interference.

2. Connection of the instrument to a test object may produce radiations beyond the specified

limit.

3. Use high-performance shielded interface cable to ensure conformity with the EMC standards

listed above.

Safety Standard

IEC 61010-1:2010/ EN 61010-1:2010

Page 7

IT9121 User’s Manual

Copyright © Itech Electronics Co., Ltd. v

Content

Quality Certification and Assurance ....................................................................................................................... 1

Warranty ............................................................................................................................................................... 1

Limitation of Warranty .......................................................................................................................................... 1

Safety Symbols ...................................................................................................................................................... 1

Safety Precautions ................................................................................................................................................. 2

Environmental Conditions ..................................................................................................................................... 2

Regulatory Markings ............................................................................................................................................. 3

Waste Electrical and Electronic Equiment (WEEE) Directive ................................................................................... 3

Compliance Information ........................................................................................................................................ 4

Chapter1 Introduction ..................................................................................................................................... 1

1.1 Brief Introduction ............................................................................................................................................ 1

1.2 Introduction of front panels............................................................................................................................. 2

1.3 Introduction to keyboard ................................................................................................................................. 2

1.4 Introduction of Menu Function........................................................................................................................ 3

1.5 Introduction of Interface Display Information .................................................................................................. 5

1.6 Introduction of Interface Symbols.................................................................................................................... 5

1.7 Introduction of rear panels .............................................................................................................................. 6

Chapter2 Measurement Conditions ................................................................................................................. 7

2.1 Setting of Measurement Range ....................................................................................................................... 7

2.2 Setting of Measurement Interval ..................................................................................................................... 9

2.3 Setting of Filter and Crest Factor .................................................................................................................... 11

2.4 Setting of Averaging Function ........................................................................................................................ 12

Chapter3 Basic Measurement Functions ....................................................................................................... 15

3.1 Basic Concepts .............................................................................................................................................. 15

3.2 Setting of Measurement Function and Interface Display ................................................................................ 16

Chapter4 Waveform Display Function ........................................................................................................... 18

4.1 Basic Concepts .............................................................................................................................................. 18

4.2 Adjustment of Measurement Parameters ...................................................................................................... 21

4.3 Setting of Trigger Configuration ..................................................................................................................... 21

Chapter5 Integral Operation Function ........................................................................................................... 23

5.1 Basic Concepts .............................................................................................................................................. 23

5.2 Setting of Integral Measurement Configuration ............................................................................................. 27

5.3 Integration..................................................................................................................................................... 29

Chapter6 Harmonic Measurement Function .................................................................................................. 32

6.1 Basic Concepts .............................................................................................................................................. 32

6.2 Setting of Harmonic Measurement Configuration .......................................................................................... 35

Chapter7 Routine Maintenance ..................................................................................................................... 38

7.1 Self-inspection ............................................................................................................................................... 38

7.2 Error Information References ........................................................................................................................ 38

7.3 Daily maintenance ......................................................................................................................................... 40

7.4 Contact of ITECH Engineers............................................................................................................................ 40

Chapter8 Technical Specifications .................................................................................................................. 42

8.1 General Specification ..................................................................................................................................... 42

8.2 Screen Display ............................................................................................................................................... 42

8.3 Input Parameters ........................................................................................................................................... 42

8.4 Voltage and Current Accuracy ........................................................................................................................ 44

8.5 Active Power Accuracy .................................................................................................................................. 44

8.6 Voltage Current and Power measurements.................................................................................................... 45

8.7 Frequency Measurement............................................................................................................................... 47

8.8 Harmonic Measurement ................................................................................................................................ 47

Page 8

IT9121 User’s Manual

Copyright © Itech Electronics Co., Ltd. vi

8.9 Fundamental Frequency ................................................................................................................................ 48

8.10 Accuracy ...................................................................................................................................................... 48

8.11 Oscilloscope Function .................................................................................................................................. 49

8.12 Interface Specification ................................................................................................................................. 49

Page 9

Introduction

Copyright © Itech Electronics Co., Ltd. 1

Chapter1 Introduction

1.1 Brief Introduction

The IT9121 power meter can provide the maximum input of 600Vrms and

20Arms and the measurement bandwidth of 100KHZ and thus can be easily

used for measuring the parametersincluding voltage, current, power, frequency

and harmonics. Standard configuration includes USB, GPIB, RS232 and LAN

communication interfaces and also the interface for USB peripherals. The user

can store the measured parameters in the external storage medium. The

voltage and current precision is 0.1%. The instrument also has many integral

functions, such as the active power. The product can be widely applied in

motors, household appliances, UP S and other test fields.

Features

4.3-inch color liquid crystal displ ay (TFT)

The number of matrix columns to be displayed on the screen and the

commonly used measurement parameters can be set freely.

Input range:600Vrms/20Arms

The voltage, current, power, harmonics and other parameters can be

measured at the same time.

The precision of voltage and current m easurement is up to 0.1%.

It has the harmonic measuring function and can measure 50-order

harmoni c components at most.

With the interface for USB peripherals, the user can store the interface in

the external storage medium.

With many powerful integral functions, the bought/sold electricity can be

calculated.

Frequency me asurement function

Built-in USB, GPIB, RS232 and LAN communication interfaces

Application advantages

Analysis of UPS power quality:

As an important backup power supply in the communication industry, the

steady-state characteristics, dynamic characteristics, power quality and

other parameters of UPS should be analyzed. With internal nonlinear

elements, the UPS power supply will generate a large number of harmonic

components during operation, which may affect operation of the

communication system. The IT9121 power meter can measure such

parameters as the AC/DC signal, power factor, harmonics, frequency and

distortion factor, and systematically and comprehensively analyze the

performance of the UPS power supply.

Test of performance of household appliances:

With promotion of the concept of using energy in a rational and

environmentally friendly manner, more and more household appliances

adopt the variable frequency control technology to reduce the power

consumption. The IT9121 power meter can measure the inrush current,

active power, crest factor, etc.

Page 10

Introduction

Copyright © Itech Electronics Co., Ltd. 2

1.2 Introduction of front panels

Schematic Diagram of Front Panel of IT9121 Series Power Meter and Diagram

of Key Functions.

1 USB Interface

2. Displ ay

3. Menu key

4. Waveform Display key

5 Basic fu nctions

6. Harmonic key

7. Integrator key

8. Setting knob

9. Arrow keys

10. Hold/Esc key

11. Enter key

12. Image Save key

13 Parameter setting key

14. Menu key

15 Power switch

1.3 Introduction to keyboard

The functions of keys on the front panel of the IT9121 series power meter are

shown in the following table.

Key tag

Name and funct ion

Waveform Display key When this key is pressed,the waveform

corresponding to current measurement data will be displayed.

Harmonic Measurement key When this key is pressed, the

harmonic measurement results and the menu of harmonic

measurement parameter configuration will be displayed.

Basic Measurement key When this key is pressed, the

measurement data of various it ems w ill be displayed.

Integral Measurement key When this key is pressed, the integral

measurement results and the menu of integral measurement

parameter configuration will be displayed.

Menu key, used for setting relevant measurem ent parameters of

the power met er.

Enter key, used for savi ng the settings.

Image Save key

Cancel/E SC key

The front panel keyboard can be locked/unlocked when the ESC

key is constant ly pressed for 5s.

The remote control m ode of the power meter can be switched to

the panel operation mode when

the ESC key is constantly

pressed for 5s.

Page 11

Introduction

Copyright © Itech Electronics Co., Ltd. 3

Key tag

Name and funct ion

Up/Down key and Left/Right key

List Edi t: t hose l i nes w hich are not displayed c an be di spl ay ed by

operating t he Left /R i ght key. Those rows w hi ch are not di spl ay ed

can be displayed by operating the Up/Down key.

Menu Edit: the programming items can be rolled by operating

the Up/Down key. Prompts of corresponding options are

displayed on the right and options can be selected v ia the soft

key.

Digit Edit: the programming items can be rolled by operating the

Up/

Down key. The digit to be edited is selected by operating the

Left/Right key or via the knob. Carrying can be completed

automatically.

Soft key The contents on the left of the key and the menu

function displayed above the key on the display screen may be

subject to changes.

Knob key, used for setting the value indicated by the cursor,

selecting the voltage and current range, adjusting the waveform,

etc.

1.4 Introduction of Menu Function

Press this key to enter the system menu function. Menu is described as

follows.

Menu

Menu setting

SYSTEM

SYSTEM INFO

Instrument system

information

Model

Instrument model

Serial

Instrument SN

Cpu Version

The version of CPU

Dsp Version

The version of Digital Sig nal Processing

MAC address

Network hardware address

Socket Port

Port number

COMM CONFIG

Communication

configuration

R232

BAUD Rate

Set the communication baud

rate:4800/9600/19200/38400/57600/115200

Parity Chack

Communication parity check bit: Default:

NONE

Data bit

Communication data bit: 8 (default)

Stop bit

Communication st op bit : 1 (default)

USB T y pe B Conne ct

Select the USB communicat ion interface.

GPIB GPIB Address

The address is adjustable between 1 and 30.

LAN

IP mode

IP mode: MANU/DHCP

IP Addre ss

IP address setting

Subnet mask

Set the subn etmask.

Gateway

Set the gateway.

Page 12

Introduction

Copyright © Itech Electronics Co., Ltd. 4

SYSTEM CONFIG

System conf iguration

Date (YY/MM/DD)

System date: Year/Month/Day

Ti me (hh:mm:ss)

System time: Hour/Minute/Second

Brightness

Set the screen brightne ss.

Beep

Set the keyboard sound

SELF TEST

Self test

SYSTEM SELF_T EST

Self test

INITIAL

Initialize

SYSTEM INITIAL

System initialization

SETUP

SETUP INFO

Configuration information

Averag

Average

Sync Source

Synchronization

Line Filt er

Line fil ter

Update Rate

Data updating rate

Freq Filter

Frequency filter

Crest Factor

Crest factor

ExSensor1

External current sensor 1 (range:

CF=3:2.5V,5V,10V; CF=6:1.25V, 2.5V,5V.)

ExSensor2

External current sensor 2 (range:

CF=3:50mV,100mV,200mV,500mV,1V,2V;

CF=6:25 mV,50mV,100mV,250mV,0.5V,1V.)

Rate(V/A)

Conversion ratio of external cur rent sensor 1

Rate(mV/A)

Conversion ratio of external cur rent sensor 2

U_Range

Voltage range

I_Range

Current range

AVERAG SET

Average f unction setting

State

Status

Mode

Mode

Type

Loading Type

Count

Counti ng cycle

EXT SEN SET

External current sensor

setting

EXSENSOR 1

Set the external current sensor 1: ON/OFF

Ratio(V/A)

Set the con version ratio of the external

current sensor 1

EXSENSOR 2

Set the external current sensor 2: ON/OFF

Ratio(mV/A)

Set the con version ratio of the external

current sensor 2

OTHER SET

Other settings

Sync Source

Select the synchroni zation source: U/I/OFF

Freq Filter

Set the frequency filter: ON/OFF

Line Filt er

Set theline filter : ON /OFF

Crest Factor

Set the crest factor: CF3/CF6

Update Rate

Set the data updating rate:

0.1s/0.25s/0.5s/1s/2s/5s

INRUSH SET

Inrush sett ing

Page 13

Introduction

Copyright © Itech Electronics Co., Ltd. 5

State

Status

Trig le vel(A)

Trigger level

Delay time(ms)

Delay time

Measure time(s)

Measuri ng time

CAL ZERO

Calibration Zero

Zero point calibration

Calibration Zero

Zero point calibration

1.5 Introduction of Interface Display Information

The IT9121 power meter has four measurement modes. Below is the

introduction of basic interface information, with the basic measurement

interface as an example.

Basic measurement interface

Select the “Meter” button, and the initial interface of basic measurement as

shown bel ow will appear.

1.6 Introduction of Interface Symbols

The interface of the IT9121 power meter will display the following symbols.

Status Bar icon

Status descri ption

This icon appears when the line filter is

switched on.

This icon appears when the frequency filter is

switched on.

This icon appears when USB is insert ed.

Over-voltage protection icon: this icon appears

when over-voltage occurs.

Over-current protection icon: this icon appears

when over-current occurs.

Page 14

Introduction

Copyright © Itech Electronics Co., Ltd. 6

Status Bar icon

Status descri ption

Key Lock: this icon appears when the keyboard

is locked.

Remote Lock: this icon appears in remote

operation and then local keys fail.

This icon appears in remote network

connection.

1.7 Introduction of rear panels

Schemati c D iagram of Rear Panel of IT9121 Power Meter.

1. GPIB interface

2 Ethernet interface

3 USB Interface

4. RS232 i nterface

5. External synchronization signal interface

6 Power i nterface

7. External sensor interface

8. Voltage input terminal

9. Current input terminal

Warning: The external sensor interface (as shown in Fig. 7 above) of IT

9121 power meter is installed with a protective jacket at ex-factory, which

should be correctly installed at all circumstances unless an external sensor

permitted by ITEC H is used.

Page 15

Measurement Conditions

Copyright © Itech Electronics Co., Ltd. 7

Chapter2 Measurement Condi t i ons

This chapter describes details of relevant work to be finished before use of the

IT9121 power meter.

2.1 Setting of Measurement Range

The appropriate measurement range (v oltage and current range) must be set

for accurate measurement. The selected range is effective for different

measurement modes, such as waveform display, integral measurement and

harmoni c me asurement.

Operation steps

1. In the “Meter” interface Press the soft key corresponding to “V-RANGE” or

“A-RANGE”, and us e the knob or “ ” to select the voltage or current

range.

2. Press the “Enter” key to confirm the setting. The instrument will

automatically confirm and exit the setting in case of no operation on the

interface for more than 5s.

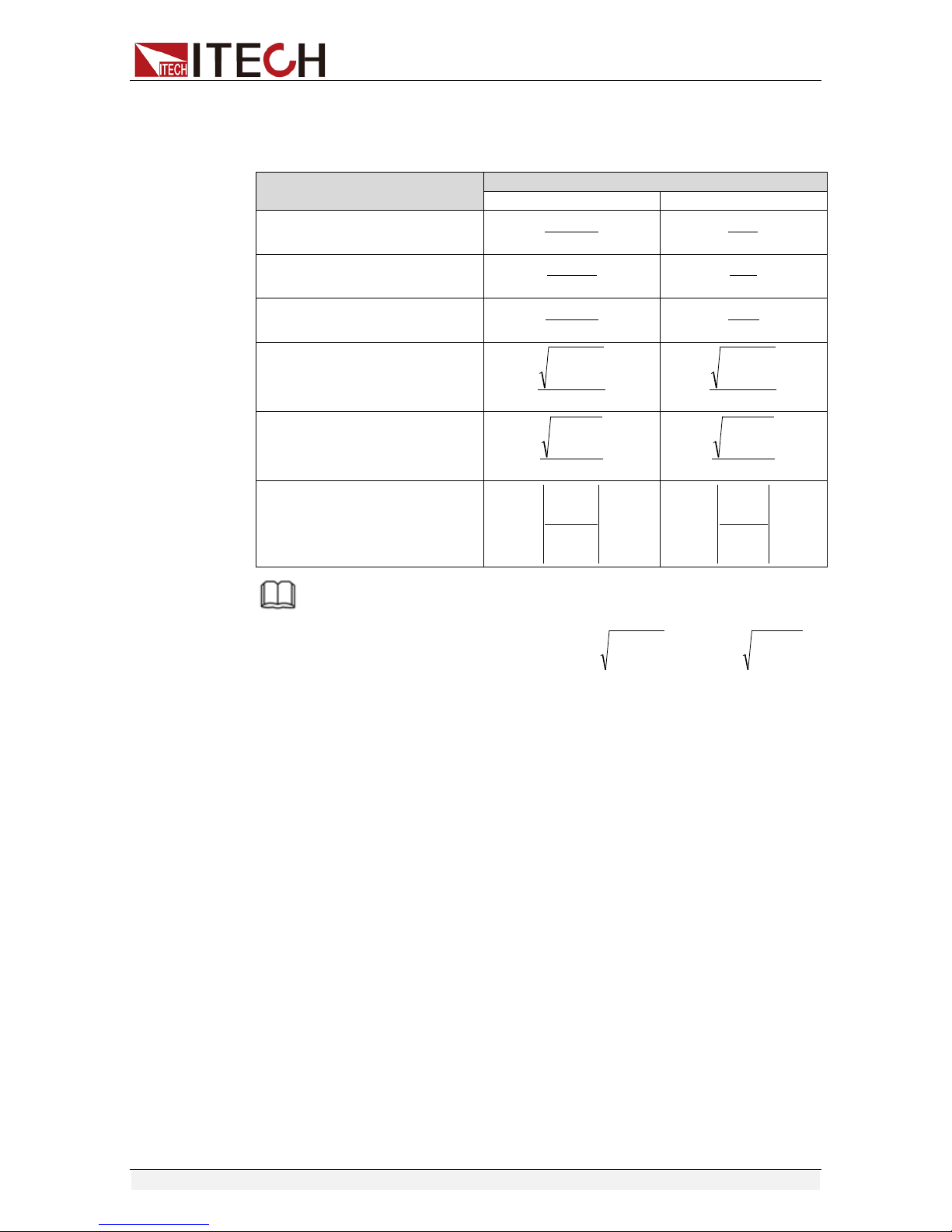

When the crest factor is 6:

Figure: Voltage Range

Figure: Current Range

Page 16

Measurement Conditions

Copyright © Itech Electronics Co., Ltd. 8

When the crest factor is 3:

Figure: Voltage Range

Figure: Current Range

NOTE

When EX1 or EX2 is installed, the power meter has more current range options. See details

in IT9121 Installation Instructions.

Voltage and current range

Set the measurement range according to the lev el of the effective value. When

the voltage or current signal is input into the input unit, there are two types of

range: fixed and automatic.

Fixed range

Select the required range from a number of options. After selection, the range

will not change with the input signal. For the voltage range, when the crest

factor is 3, the maximum option is “600V” and the minimum option is “15V”.

When the crest factor is 6, the maximum option is “300V” and the minimum

option is “7.5V”.

Page 17

Measurement Conditions

Copyright © Itech Electronics Co., Ltd. 9

NOTE

During measurement of the distortion waveform and other non-sinusoidal wave signals, the

accuracy of measurement can be improved by selecting the minimum range on the premise

that the measured value does not exceed the range.

Auto-measuring span

The range is switched automatically according to the input signal. The range

types for switching are the same as those of the fixed range.

Principles of automatic range l evel increase:

The range level is increased when any one of the following conditions is

satisfied.

Urms or Irms exceeds 110% of the current range setting.

The crest fa ct or is 3. The value Upk or Ipk of t he i nput si gnal ex cee ds 33 0%

of the current range setting.

The crest factor is 6. The value Upk or Ipk of the input signal exceeds 660 %

of the current range setting.

Principles of automatic range l evel decrease:

The range level is decreased when all of the following conditions are satisfi ed.

Urms or Irms is less than or equal to 30% of the current measurement

range.

The crest factor is 3. The v alue Upk or Ipk of the input signal is less than

300% of the ra nge at the following l evel.

The crest factor is 6. The v alue Upk or Ipk of the input signal is less than

600 % of the ran ge at the following l evel.

NOTE

The selected automatic range may change when the input waveform is a pulse waveform of uncertain

cycle. In this case, the fi xed range should be selected.

2.2 Setting of Measurement Interval

The time for acquisition of sampling data is determined by the measurement

interval during measurement. The measurement interval is determined by the

data updating rate and synchronization source. The synchronization source

provides reference signals for measurement, and the data updating rate

determines the updating cycle of sampling data.

Measurement interval

The measurement interval is determined by the data updating rate and

synchronization source. (see “2.3 Setting of Filter and Crest Factor” for specific

settings)

Synchronization

IT9121 adopts the frequency measurement circuit to t est the input signal cycle

set in the measurement interval. The measurement inter val is the integer times

of the test cy cle. The measured value of IT9121 is calculated by averaging

sampli ng data in the measurement i nterval. The reference input signal used for

defining the input signal measurement interval is called the synchronization

source.

Measurement inter val for conventional measurement

The measurement interval of the reference input signal is the time fro m the

Page 18

Measurement Conditions

Copyright © Itech Electronics Co., Ltd. 10

starti ng part of the rising slope (or descending sl ope) through the zero point

(intermediate value of amplit ude) to the ending point of the rising slope (or

descendi ng slope) through the zero point (intermediate value of amplitude).

However, the measurement int erval which det ermines the maximum

voltage or current is within the overall data updating cycle. Therefore, the

measurement of Ipk+, I pk-, Upk+, Upk-, Ucf and Icf cal cul ated base d on t he

maximum voltage and current also adopts the data updating cycle as the

measurement interval.

The rising or descending edge is selected automatically to prolong the

measurement interval.

If there i s only one or no rising slope or descending slope wit hin the data

updating cycle, the data updating cy cle is taken as the measurement

interval.

The input signal to be used as the synchronization source can be set in

each unit (for synchronizati on with the zero point of that input signal). The

overall interval of the signal voltage, current or data updating cycle can be

selected as the synchronization source for mea surement.

NOTE

The data updating cycle refers to the cycle used for calculating sampling data of the

measurement function. It is identical to the set value of the data updating rate.

The slope refers to signal changes from low level to high level (rising edge) or from high level to

low level (descending edge).

Measurement interval for harmonic measurement

At the sampling frequency of harmonic m easur e ment , t he meas ure ment i nt erval

refers to t he first point 1024 from the data updating cycle. The sampling

frequency of harmonic measure me nt is determined automatically by the signal

cycle set as t he P LL source in the instrument. The sampling data or

measurement interval for calculation may be differ ent from the sampling data or

measurement interval of the measur ement function in conventional

measurement.

Page 19

Measurement Conditions

Copyright © Itech Electronics Co., Ltd. 11

2.3 Setting of Filter and Crest Factor

Operation steps

1. Select Menu > SET UP > OTHER SET and enter the OTHER configuration

page.

2. Press to select the param eter to be config ured (bl ue fo nt bac kgr ound),

and then press the soft key corresponding to the paramet er on the right to set

the required value, as shown in the following diagram.

Character

Function description

Sync Source

Select the synchronization source: U/I/OFF. The overall

interval of the signal voltage, current or data updating cycle

can be selected as the synchronization source for

measurement.

Freq Filter

Set the status of the frequency filter. When “ON” is selected,

the frequency filter is turned on. When “OFF” is selected, the

frequency filter is turned off.

Line Filt er

Set the status of theline filter. When “ON” is selected, the line

filter is turned on. When “OFF” is selected, the line filter is

turned off.

Crest Factor

Set the crest factor: CF3/CF6

Update Rate

Data Updating Rate Setting key: when this key is pressed, the

capture interval of the voltage, current, power and other data,

i.e. data updating rate, can be set. When the data updating

rate is increased, rapid load changes of the power system can

be obtained. When the data updating rate is decreased,

relative low-

frequency signals can be measured. Options of

the data updating rate: 0.1s/0.25 s/0.5s/1s/2s/5s

3. Press the Enter key to save the settings.

Filter

Frequency filter: it is inserted in the frequency measurement circuit and may

affect frequency measurement. It can be used for filtering high-frequency

components of interference to make the measured frequency parameter more

accurate. W hen the frequency filter is switched on, the voltage or current of no

more than 200Hz can be mea sured. The cutoff frequency is 500HZ.

Page 20

Measurement Conditions

Copyright © Itech Electronics Co., Ltd. 12

Line filter: it is inserted in the voltage and current m easurement circuit and has

direct influence on measurement of the voltage, current and power. When the

line filt er is swit ched on, noi se and high-frequency component s fr om t he invert er

or distortion waveform can be fil tered. The cutoff frequency is 500HZ.

Crest factor

The crest factor is the ratio of the waveform peak to the effective value. The

crest factor of IT9121 is specified as the times of the crest value which can be

input under the rated input conditions. The crest factor CF3 or CF6 can be

selected in the interface “Menu > SETUP > OTHER SET”.

ranget Measuremen

input be can whichPeak value

)(factor Crest =CF

The crest factor can be set as 3 or 6. The crest factor can be measured under

the foll ow ing conditions:

{ }

value)(effective valueMeasured

6)or (3 CF of Set valueranget Measuremen

factorCrest

×

=)(CF

NOTE

The crest value of the input signal must be no more than the maximum allowable

input value.

When the crest factor of the measured signal is larger than the crest factor in

instrument specifications (based on the crest value of rated input), the signal

with the crest factor larger than the specified value can be measured by setting

a range including the value of the measured signal.

For example, when CF is set as 3 but the measured value (effective value) is

less than 60% of the range, the signal w ith CF more than 5 can be measured.

When CF is 3, the signal with CF equal to 300 can be measured under

minimum effective input (1% of the range) conditions.

The voltage range, current range, effective input range and measurement

accuracy de pend on the set crest factor.

2.4 Setting of Averaging Function

The user can set the averaging function via this menu. When the input signal

frequency is low, the value is displayed unstably and cannot be read easily. In

this case, the averaging function can be enabled to calculate and display the

average value of several measurements.

Operation steps

1. Select Menu > SET UP > AVERAG SET to enter the configuration page of

the averaging function.

2. Press to select the parameter to be configured (blue font

background), and then press the soft key corresponding to the parameter on

the right to set the required value, as shown in t he followi ng diagram.

Page 21

Measurement Conditions

Copyright © Itech Electronics Co., Ltd. 13

Parameter descriptions:

Character

Function description

State Set the status of the averaging function. When “ON” is selected,

the averaging function is enabled. When “OFF” is selected, the

averaging function is disabled.

Type

Set the linear averaging type. EXP: index averaging, often used

for analy sis of t he non-st ationary process. LINE: li near averaging,

often used for measurement and analysis of the stationary

random process. The deviation relative to the standard can be

reduced by increasing the averaging times.

Tcontrol

Set the mode of the averaging function. MOVING: moving

averaging R EP EAT: repeate d averaging

Count

Set the times of the averaging function. If the mode of the

averaging function is set as EXP (index averaging), the

attenuation constant can be set. If the mode of the averaging

function is set as LINE (linear averaging), the averaging times

can be set.

3. Press the Enter key to confir m the setting.

Averaging mode

Index averaging:

Computing formula:

k

DM

DD

nn

nn

11−

−

−

+=

Dn: the value displayed after the nth index averaging (D1, the value

displayed after the first averaging, is equal t o M1)

Dn-1: the value displayed after the (n-1)th index averaging

Mn: the nth measured data.

K: attenuation constant (1-64)

Linear averaging

Computing formula:

( )

m

MMMM

D

nnnmn

n

+++

=

−−−− 121

....

Dn: the value displayed after linear averaging of m values from the

(n-(m-1))th to nth val ue

Page 22

Measurement Conditions

Copyright © Itech Electronics Co., Ltd. 14

Mn-(m-1): the (n-(m-1))th measured data

Mn-2: the (n-2)th measured data

Mn-1: the (n-1)th measured data

Mn: the nth measured data.

M: the number of average values (1-64)

When m can be divided exactly by n, the calculated value is the moving

average; when there is no particular relationship between m and n, the

calculated value is the repeated averag e.

NOTE

When index averaging is set, averaging is implemented under the harmonic

measurement function.

When linear averaging is set, averaging can only be implemented in the conventional

measurement function and this mode is not applicable to the harmonic measurement

function.

Averaging function

Measurement function in conventional measurement

The following measurement functions are subject to di rect averaging. Data of

the foll owing mea sure ment funct i ons ar e obtained via operation in ot her modes,

and the obtained measurement function is affected averaging.

Urms, Umn, Udc, Urmn, Uac, Irms, Imn, Idc, Irmn, Iac, P, S and Q.

Ucf, Icf, PF and WPAV are calculated by operation of the a veraged Urms,

Irms, P and S.

Measurement function in harmonic measureme nt

The following measurement functions are subject to di rect averaging. Data of

the foll owing mea sure ment funct i ons ar e obtained via operation in ot her modes,

and the obtained measurement function is affected averaging.

U(k), I(k), P(k), S(k) and Q(k).

PF(k) is calculated via operation of the average d P(k) and Q(k).

U(%r), I(%r), P(%r) , U(%f), I(%f) and P(%f ) are calculated via operation of

the averaged U (k), I(k) and P(k).

(k indicates t he harm onic t imes.)

NOTE

When the averaging function is enabled, the average of a number of measurements

are calculated and displayed. Therefore, in case of drastic changes of the input signal,

the measured value will slowly affect these changes.

For both the attenuation constant of index averaging and the number of averaged

values of linear averaging, the larger the set value is, the more stable the measured

value is.

The following measurement functions will not be affected by averaging.

Conventional measurement functions:fU, fI, Ipk+, Ip k-, Upk+, Upk-, Time, WP, WP+,

WP-, q+, q-, q and Fsyn.

Harmonic measurement functions: φ(k) , φUU(k) and φII(k) (k indicates the harmonic

times).

Page 23

Basic Measurement Functions

Copyright © Itech Electronics Co., Ltd. 15

Chapter3 Basic Measurement Funct ions

This chapter describes the features and use of the basic measurement

functions of the IT9121 power meter in details.

3.1 Basic Concepts

The IT9121 power meter has rich basic power measurement functions and can

be used for accurately measuring the voltage, current, power, AC/DC signal,

power factor, harmonics, frequency, distortion factor and other parameters. The

reliable data can prov ide a scientific basis for analysis of the power quality and

performance of equipment.

Introduction of soft keys on the interface

Menu soft key

Instruction

U-RANGE

Set the voltage range.

I-RANGE

Set the current range.

RUN/HOLD

Running/holding

RESET Reset soft key When this key is pressed, the instrument

can immedi ately carry out measurem ent again.

VIEW 1

View (1): displaying 1 large value and 6 small values.

VIEW 4

View (4): displaying 4 large value and 6 small values.

VIEW 12

View (2): displaying 12 large values.

MAXHOLD

(OFF/ON)

Maximum value holding (OFF/ON): the maximum value

(MAX) of data can be held.

CONFIG

Basic measur ement configuration

Measured parameters

Parameters

Parameter descriptions

Parameters

Parameter descriptions

P

Active power [W]

Imn

Average rectified val ue after

the

current is calibrated to

the effective value

Q

Reactive power [var]

Idc

Average current

S

Apparent power [VA]

Ipk+

Positive current peak value

[A]

PF

Power factor

Ipk-

Negative current peak value

[A]

Page 24

Basic Measurement Functions

Copyright © Itech Electronics Co., Ltd. 16

Parameters

Parameter descriptions

Parameters

Parameter descriptions

φ

Phase difference of voltage

and current

Ipp

Current peak-to-peak value

[A]

Fsyn

Synchronization source

frequency

Icf

Current crest factor

Irms

Current effective value [VA]

fI

Current frequency (Hz)

Iac

AC current component

Irush

Inrush current

Irmn

Average rectified current [A]

Urms

Voltage effective value [VA]

Umn

Average rectified value after

the voltage is calibrated to the

effective value

Urmn

Average rectified value of

voltage [V]

Udc

Average voltage [V]

Uac

AC voltage component

Upk+

Positive voltage peak value

[V]

Upk-

Negative vo ltage peak va lue

[V]

Upp

Voltage peak-to-peak value

[V]

Ucf

Voltage crest factor

fU

Voltage frequency (Hz)

3.2 Setting of Measurement Function and Interface

Display

The power meter has three interface display styles for measurement of basic

parameters. At most five pages are displayed in each style. When one or more

important measurement parameter(s) should be highlighted, the View1 or

View4 mode can be freely enabled to design the humane display style. W hen

you need to view all parameters at the same time in one interface, the View12

mode can be enabled.

Take power measurement as an example. The interface can display four

parameters in the large font form: effective voltage, effective current, active

power and power factor. Operating procedures ar e as below:

Operation steps

1. In the “Meter” interface when the soft key corresponding to “VIEW 4” is

pressed, 10 measurement parameters can be displayed in total, 4 of which

are displayed in an amplified manner. Other measurement parameters can

be viewed by pressing key to turn pages, as shown in the figure

below.

2. When the soft key corresponding to “CONFIG” is pressed, the

measurement function can be selected and the interface display

Page 25

Basic Measurement Functions

Copyright © Itech Electronics Co., Ltd. 17

information can be set.

3. W hen the soft key corresponding to “FUNC” is pressed, the measurem ent

function can be s elected. For exam ple, when the “FUNC” key is pressed

once, the displayed measurement function will be switched once in the

W/I/V sequence. Different measurement parameters are displayed when

different functions are selected. As power measurement is taken as an

example in this operat ion, P is selected.

P (power): P, Q, S, PF, φ and Fsyn

I (current): Irms, Imn, Irmn, Idc, Iac, Ipk+, Ipk-, Ipp, Icf,

fI and Irush

U (voltage): Urms, Umn, Urmn, Udc, Uac, Upk+, Upk-, Upp, Ucf and

fU

4. Press the “ ” key and move the cursor to select the parameter

displayed in the interface (blue font background). Press the right soft key

corresponding to the parameter to adjust the parameter displayed at

present. P, Q, S and PFare set in sequence.

NOTE

When the soft key corresponding to the parameter is pressed once, the parameter will be

selected in sequence.

5. You can also press the “INSER T PAGE” to add a display page. At most five

pages are all owabl e. Press t he “DELET E P AGE” to del ete the di splay page.

At least one page should be left.

Page 26

Waveform Display Function

Copyright © Itech Electronics Co., Ltd. 18

Chapter4 Waveform Display Function

This chapter describes the features and use of the waveform display function of

the IT9121 power meter in details.

4.1 Basic Concepts

The IT9121 power meter has a waveform display function based on sampling

data. The voltage and current waveform of the input unit can be displayed or

hidden. Only the necessary waveform is displayed to facilitate observation. The

wavefor m display interface includes the vertical axis and the horizontal axis.

Introduction of soft keys on the interface

When the button is pressed, the initial waveform display interface

below appear s.

Description of information of w aveform display interf ace:

Parameter name

Parameter descriptions

U_RANGE

Voltage range setting: press the soft key

corresponding to this parameter to set the voltage

range.

I_RANGE

Current range setting: press the soft key

corresponding to this parameter to set the current

range.

RUN/STOP

Run/stop: press the soft key corresponding to this

parameter to run or stop the waveform status.

SINGLE

Single measurement key: when single

measurement is performed under stop conditions,

the stop status will be enabled again after one

measurement according to the curre

nt data

updating rate. When single measurement is

performed under running conditions, one

measurement will be performed immediately by

the instrument and then the stop status will be

enabled.

SCOPE(U/I/UI)

Select the waveform to be displayed on the

screen: voltage/current/voltage and current.

Page 27

Waveform Display Function

Copyright © Itech Electronics Co., Ltd. 19

Parameter name

Parameter descriptions

KNOB SEL

(U/I/TL/TD/Td)

Knob selection: the following variables can be

adjusted by rotating the knob: vertical voltage

position/vertical current position/trigger

level/t rigger delay/level calibration.

AUTO

Automatic adjustment key: when the soft key

corresponding to this parameter is pressed, the

power meter will automatically calibrate the input

signal to display the best effect of t he input signal.

TRIG SET

Trigger setting

MEASURE SET

Measurement setting

Introduction of waveform display interface

The trigger status is described as follows:

Trigger

status

Instruction

Auto

When the trigger mode is set as Auto, the trigger status Auto

will be di splayed after triggering.

Auto?

When the trigger mode is set as Auto, the trigger status will be

Auto in the case of no triggering?

Trig

When the trigger mode is set as Normal, the trigger status Trig

will be di splayed after triggering.

Trig?

When the trigger mode is set as Normal, the trigger status will

be Trig in the case of no triggering?

Stop

When the “Stop” soft key in the waveform display interface is

pressed, the t rigger status Stop will be displayed.

Vertical calibration

When the crest factor CF is 3, the selected vol tage range and current range will

Page 28

Waveform Display Function

Copyright © Itech Electronics Co., Ltd. 20

be subject to vertical calibration (voltage/grid, current/grid). When CF is 6, the

selected voltage range and current range will be subject to two-time vertical

calibration (voltage/grid, current/grid).

Horizontal calibration

When the “KNOB SEL” soft key is pressed and “T/d” is selected, horizontal

calibration (scanning speed) adjusted by rotating the knob. In this case,

time/grid information changes can be observed on the screen by rotating the

knob and changing the horizontal (time/grid) setting. When acquisition is run,

the sampling rate can be changed by adjusting the horizonta l calibration knob.

When acquisition is stopped, sampling data can be amplified by adjusting the

horizontal calibration knob.

Trigger delay

When the KNOB SEL s of t key is pr essed and “T D” is selected, the trigger delay

can be adju sted by rotating the knob. In this case, when the knob is rotated, the

trigger point will move horizontally and the delay time will be displayed on the

screen. When the delay time is changed, the trigger point ( ) will move

horizontally, and the distance between the trigger point and the horizontal

center will be indicated. The trigger point is displayed along the top of the

display grid.

Trigger waveform

When the specified trigger conditions are satisfied, the trigger waveform will be

displayed, and the triggering time point is called trigger point. The trigger point

is general ly di spl ay ed in t he l ef t of the display screen. Foll owi ng t he tr i gger poi nt ,

the waveform is displayed on the display screen from left to right over time.

Before using the trigger function, the user needs to configure the following

parameters:

Trigger mode

The trigger mode refers to conditions for updating the contents displayed

on the screen. Including the Auto model and Normal mode Auto mode: the

displayed waveform is updated in case of triggering in the pause time and

automatically updated in case of no triggering in the pause tim e. Normal

mode: the displayed content is updated in case of triggering and not

updated in case of no triggering.

Trigger source

The trigger source is used for generating triggering conditions. The user

can select the trigger source from the input signal of the input unit and the

external clock signal.

Trigger slope

The slope refers to signal changes from low level to high level (rising edge)

or from high level to low level (descending edge). When used as a

triggering condition, the slope is called trigger slope.

Trigger level

Level of trigger slope: triggering occurs when the level of the signal of the

trigger source reaches the set trigger level under t he specified trigger slope

conditions. When the “KNOB SEL” soft key is pressed and “ TL” is selected,

the trigger level can be adjusted by rotating the knob. In this case, the

trigger level can be changed by rotating the knob, and changes in the

Page 29

Waveform Display Function

Copyright © Itech Electronics Co., Ltd. 21

trigger level can be observed on the screen.

4.2 Adjustment of Measurement Parameters

You can rotate the knob to adjust the vertica l calibration, horizontal calibration,

trigger delay and trigger level of the waveform display interface. Detailed steps

are as follows:

Operation steps

1. Press “ ” to enter the w aveform display interface.

2. In the waveform dis play interface Press the soft key corresponding to the

“KNOB SEL” parameter and select the parameter to be adjusted. When

“KNOB SEL” is pressed once, the parameter to be adjusted via the knob

will be switched in sequ ence among U/I/TL/TD/Td.

3. When the parameter is adjusted by rotating the knob, the interface will

display changes of the corresponding value.

4.3 Setting of Trigger Configuration

When you need to enable the trigger function, you should select the trigger

source, trigger mode, trigger slope and other trigger-related configuration.

Detailed steps are as follows:

Operation steps

1. Press “ ” to enter the w aveform display interface.

2. In the waveform dis play interface Press the soft key corresponding to the

“TIRG SET” parameter to enter the trigger setting interface, as shown

below.

3. Press the right soft key corresponding to the parameter to select the

required trigger configuration.

Source: trigger source

Mode: trigger mode

Slope: trigger slope

Page 30

Waveform Display Function

Copyright © Itech Electronics Co., Ltd. 22

External trigger input (Ext)

When the trigger source is set as Ext, input the trigger signal into the external

signal input interface (Synchr onous) of the rear panel according to the following

specifications.

Projects

Specification

Interface t ype

BNC inter face

Input level

TTL

Minimum pulse width

1µs

Trigger delay time

Within (1μs + 3 sampling cycles)

NOTE

When the voltage higher than 0-3.3V is applied on the external signal input interface

(Synchronous), the instrument may be damaged.

Minimum pulse width: refers to the width of the high or low trigger level, at least 1µs.

Trigger delay time: refers to the delay between the appearance of the trigger level and the

response of CPU, within (1μs + 3 sampling cycles).

Page 31

Integral Operation Function

Copyright © Itech Electronics Co., Ltd. 23

Chapter5 Integral Operation Function

This chapter describes the features and use of the integral function of the

IT9121 power meter in details.

5.1 Basic Concepts

The IT9121 power meter can be used for integral operation of the current and

power of the input un it. Technical indic ators can be calculated. In addition, the

range can be swi tched auto mati cally in the Buy and Sell modes accor ding t o the

input level so as to accurately compl et e integr ate mea sur e ment .

During operation of the air-conditioner, refrigerator, induction cook and other

household appliances, the working status will change frequently, resulting in

changes of the working current in a large scale. The current m ay decrease of

dozens of amperes to a few milliamperes. Ordinary power measuring

instruments can only be used for integral measurement within one range. If the

measured value exceeds the current maximum range, the measurem ent result

is inaccurate. You need to manually switch the range before integral

measurement. Integral measurement of equipment subject to large current

changes cannot be performed continuously. The IT9120 series power meter

can automatically switch the range in the integral mode. Therefore, errors of

integral measurement caused by manual range switching can be elim inated,

and the power consumption of household appliances can be measured more

accurately. See the schematic diagram below.

Introduction of soft keys on the interface

When the “Integ” button is pressed, the initial integral measurement interface

below will appear.

Page 32

Integral Operation Function

Copyright © Itech Electronics Co., Ltd. 24

Description of information of integral measurement interface:

Parameter name

Parameter descriptions

U_RANGE

Vol t age r ang e set ting: press the soft key c orr esp ondi ng

to this paramet er to set the voltage range.

I_RANGE

Current rang e s ett i ng: press t he soft key cor r esponding

to this par ameter to set the current range.

RUN/HOLD

Run/hold: press the soft key corresponding to this

parameter to run or hold the integral function.

RESET

Reset.

FUNC(WP/q/AV)

Selection of the integral function: active power integral

(WP

), current integral (q) and average active power

integral (AV).

LARGE(WP/WP+/WP

-, q/q+/q-, WPAV)

Selection of the item to be displayed in a amplified

manner: WP (watt hour, the sum of positive and minus

watt hours), WP+ (the consumption of positive watt

hours), WP-

(the negative watt hours of feedback

power), q (ampere hour, the sum of positive and

ne

gative ampere hours), q+ (the consumption of

positive ampere hours), q- (the negative ampere hours

of feedback power) and WPAV (average active

powerintegral).

START

Integral Star t key In t he manu al st art mode, the integral

function can be enabled by press

ing the soft key

corresponding to this parameter.

STOP

Integral Stop key In the manual stop mode, the integral

function can be disabled by pressing the soft key

corresponding to this parameter.

SETUP

Set relevant parameters of integral measurement.

Page 33

Integral Operation Function

Copyright © Itech Electronics Co., Ltd. 25

Integral measurement display information

Description of measurement information:

Character

Function description

Mode

Display the integral start and stop mode. Start mode: MANUAL

and TIME

Stop mode: MANUAL, T I M E and TIN Terval.

State

Display the current status of the integral function.

Start: di splayed when the integral function is working.

Stop: displayed when the integral function is interrupted,

canceled or stopped.

Ready: displayed in the ready state of the real-time start mode.

Time Up: displayed wh

en it reaches the specified time of the

integral timer.

Reset: displayed when the integral value and integral time are

reset via integral resetting.

Error: when the power supply is recovered, the integral funct ion is

stopped and the integral result before power failure is displayed.

This integral state is called Error state.

Time

Display the integral time.

St

Display the set integral time.

Et

Display the set integral ending time.

Timer

Display the fixed integral time.

Integral operation

Active pow er integral

In watt hour, displ ayed as WP ( w at t hour s, t he su m of p osi t i ve and n egat i ve w att

hours), WP+ (the consumption of positive watt hours) and WP- (the negative

watt hours of feedback power).

Current integral

In q, displayed as q (ampere hours, the sum of positive and negative ampere

hours), q+ (the consumption of positive ampere hours) and q- (the negative

ampere hours of feedba ck power)

Average act ive power integral

In watt, displayed as WPAV (average active power integral)

Page 34

Integral Operation Function

Copyright © Itech Electronics Co., Ltd. 26

Integration time

Displayed as Time, in the format of hhhh:mm:ss.

Specification

Save in case of power failure

The integral result can be kept in the memory even in case of power failure

during operation of the integral function. When the power supply is recovered

and the integral function is disabled, the integral result before power failure is

displayed. When the power supply is recovered and the integral is rest, the

integral function is enabled again.

Display resolution

The maximum display resolution of the integral value is 99999. When the

integral v alue reaches 100000, the decimal point will move automatically. For

example, when 0.01mwh is added to 999.99mwh, 1.0000wh will be displayed.

Display in case of overflow

When the integral value meets the following overflow conditions, the integral

function w i ll be di sabl ed, and the integral time and integral value at t hi s poi nt wil l

be kept.

The integral time reaches the maximum value (10000 hours).

The integral values of WP, q and WPAV reach the maxi mum/mini mum

display integral values.

Maximum/minimum display integral value

Active pow er integral (WP): ±99999 Mwh

Current integral (q): ±99999 MAh

Average power integral (WPAV): ± 99999 Mw

Restricted implementation

Settings of the following functions cannot be changed during integral operation.

Function

Integration status

Integral

resetting

Current

integral status

Integral

interruption

Functions r elated to settings of m easurement parameters

Wiring

Executable

Unenforceable

Unenforceable

Measurement range

Executable

Unenforceable

Unenforceable

Filter

Executable

Unenforceable

Unenforceable

Averagi ng function

Executable

Unenforceable

Unenforceable

Synchronization

Executable

Unenforceable

Unenforceable

Data updating rate

Executable

Unenforceable

Unenforceable

Integral function parameter setting

Integral mode

Executable

Unenforceable

Unenforceable

Integral timer

Executable

Unenforceable

Unenforceable

Integral operation

Integral start

Executable

Unenforceable

Executable

Integral stop

Unenforceable

Executable

Unenforceable

Integral resetting

Executable

Unenforceable

Executable

Other operati ons

Save operat ion

Executable

Executable

Executable

Hold operation

Executable

Executable

Executable

Single measurement

operation

Executable

Executable

Executable

Page 35

Integral Operation Function

Copyright © Itech Electronics Co., Ltd. 27

NOTE

In addition to the above items, other settings (such as self-testing and date/time setting) or

operations with influence on the integral cannot be executed; otherwise, errors may be

caused.

5.2 Setting of Integral Measurement Configuration

You can set the start mode, stop mode, automatic zero setting, automatic

calibration, watt-hour integration, current integration and other parameters of

integral measurement. Specific steps are as fol lows:

Operation steps

1. Press “Integ” to enter the integral measurement interface.

2. Press the soft key corresponding to the “SETUP” parameter in the integral

measurement interface to enter the integral parameter configuration

interface. Press the “ ” key to select the required parameter, as

shown in the figure below.

Parameter descriptions:

Start: set in the MANUAL mode or TIME mode via the right soft key.

MANUAL: press the “START” soft key in the integral measurement

interf ace i n t he manual st art mode t o tr i gger the m anual start of the int egral

function.

TIME: the date on which the integral mode is started can be set in the

real-tim e start mode. Integration will be started on the set date. When the

time/date combination is set in the real-time start mode, integration will not

be started before the current time and date. Integration will be started

when the screen is updated once at l east before the start time.

Stop: set in the MANUAL mode, TIME mode and TINTerval mode via the right

soft key.

MANUAL: press the “STOP” soft key in theintegral measurement interface

in the manual st op mode t oman ual l y stop i nt egr ati on. When the integration

time reaches the maximum integration time (10,000 hours) or the integral

Page 36

Integral Operation Function

Copyright © Itech Electronics Co., Ltd. 28

value reaches the maximum/minimum display value, integration will be

stopped, and the current integral time and integral value will be kept.

TIME: The date for stop of the integral mode can be set in the real-time

stop mode. Int egrat i on w i ll be stop ped on the s et date. When i t reach es the

set time or the integral value reaches the maximum/minimum display

integral value, i nt egrati on w il l be st opped, and t he c urr ent integral time and

integral value will be kept.

TINTerval: the integral measurem ent tim e can be set in the set-time stop

mode. When it reaches the set ending date and time or the integral value

reaches the maximum/minimum display integral value, integration will be

stopped, and the current integral time and integral value will be kept.

Page 37

Integral Operation Function

Copyright © Itech Electronics Co., Ltd. 29

Auto Clear: used for enabling (ON) or disabling (OFF) the function of automatic

zero clearing of the integral. On: i ntegration is restarted when the ST A RT key is

pressed to start integration. OFF: integration is restarted based on the integral

value at the end of previous integration when the START key is pressed to start

integration.

Auto Cal: used for enabling (ON) or disabling (OFF) the function of automatic

integral calibration. W hen automatic integral calibration is enabled, zero setting

is implemented. In this case, the power and current measured just now are

subject to integration.

WP type: used for selecting the integral mode for positiv e and negative watt

hours. There are four integral mod es:

Charge/Discharge: used for measuring the DC positive and negative watt

hours (integration of sampling data).

Sold/Bought: used for measuring the AC positive and negative watt hours

(value integration in each data updating cycle).

q type: used for selecting the current integration mode. Options of the current

integration mode are as f ollows:

rms: Effective value;

mn: Calibration to t he average rectified value of the effective value.

dc: Simple averaging;

rmn: Average rectified value;

ac: AC component

5.3 Integration

When the integral measurement function is enabled, you can keep the current

integral information and carry out the following operations: exit, start and stop.

Specific steps are as follows:

Operation steps

1. Press “Integ” to enter the integral display interface.

2. In the integral measurement display interface Press the soft key

corresponding to the “START” parameter to start or recover integral

operation. T he Star t st at us and integral operati on val ue ar e di splayed in the

Page 38

Integral Operation Function

Copyright © Itech Electronics Co., Ltd. 30

interface.

3. W hen you need to keep the current integral status and integral result, you

can press the soft key corresponding to the “RUN HOLD” parameter. Then

the current status of the integral result display and communication output

will be kept no matter whether integral operation is running.

4. When you need to continue to implement integral operation, double-press

the soft key correspon ding to the “RUN HOLD” parameter to exit the HOLD

status. The power meter will display the integral result after exiting the

HOLD status. The schematic diagram of display of the HOLD/RUN integral

result i s shown below.

5. When you need to suspend integral operation, press the soft key

corresponding to the “Stop” parameter to suspend integral operation.

6. Press the soft key corresponding to the “RESET” parameter to reset the

integral value and integral time. The relationship diagram of start,

suspension and resetting of the integral operation status is shown below.

Auto Clear: when ON is selected.

Auto Clear: when OFF is selected.

Page 39

Integral Operation Function

Copyright © Itech Electronics Co., Ltd. 31

Page 40

Harmonic Measurement Function

Copyright © Itech Electronics Co., Ltd. 32

Chapter6 Harmonic Measurement Funct ion

This chapter describes the features and use of the harmonic measurement

function of the IT9121 power meter i n details.

6.1 Basic Concepts

With the 100kHZ bandwidth, the IT9121 power meter can realize harmonic

measurement of high speed and wide dynamic range. The voltage, current,

active power, reactive power and phase of harmonics and total harmonic

distortion (THD) factor can be tested in the harmonic mode. In addition, the

IT9121 power meter can be used for multiple harmonic measurements,

50-order harmonics of the fundamental frequen cy at most.

The IT9121 power meter displays harmonic parameters in the list or bar chart

form so as to provide cl ear analysis of test results.

Introduction of soft keys on the interface

Select the “ ” button, and the initial harmonic measurement interface

below will appear.

Description of information of harmonic measur ement interface:

Parameter

name

Parameter descriptions

U_RANGE

Voltage range setting: press the soft key corresponding to

this parameter to set the voltage range.

I_RANGE

Current range setting: press the soft key corresponding to

this parameter to set the current range.

RUN/HOLD

RUN/HOLD: press the soft key corresponding to this

parameter to run/hold the harmonic status.

RESET

Reset.

FUNC(P/I/U)

Function options (power/current /voltage)

BAR

Displayed in the bar char t form

LIST

Displayed in the list form

SETUP

Parameter setting.

Page 41

Harmonic Measurement Function