Page 1

Energy-regenerative DC

Electronic Load

Series IT8300 Programming Guide

Model: IT8311/IT8312/IT8321/IT8322/IT8331/IT8332/

IT8341/IT8342/IT8351/IT8352/IT8361/IT8362/IT8371

/IT8372/IT8381/IT8382/IT8391/IT8392

Revision: V1.0

Page 2

IT8300 Programming Guide

Statement

© Itech Electronic, Co., Ltd. 2017 No

part of this manual may be reproduced

in any form or by any means (including

electronic storage and retrieval or

translation into a foreign language)

without prior permission and written

consent from Itech Electronic, Co., Ltd.

as governed by international copyright

laws.

Manual Part Number

IT8300-402227

Revision

1st Edition: APR 17, 2017

Itech Electronic, Co., Ltd.

Trademarks

Pentium is a registered trademark of

Intel Corporation in the United States.

Microsoft, Visual Studio, Windows and

MS Windows are trademarks of

Microsoft Corporation in the United

States and/or other countries/regions.

Warranty

Materials in the document are provided

talis qualis and may be changed in

future revisions without prior notice. In

addition, within the maximum allowable

extent of laws, ITECH is not committed

to any explicit or implied guarantee for

this manual and all information therein,

including but not limited to the implied

guarantee on marketability and

availability for some special purposes.

ITECH shall not be responsible for any

error or incidental or indirect losses

caused by the provision, use or

application of this documents and

information therein. If some guarantee

clauses in other written agreements

between ITECH and users are not

consistent with clauses herein, those

clauses in other written agreements

shall prevail.

Technology Licenses

Hardware and/or software in this

document cannot be provided without a

license and can only be used or copied

according to the license.

Restricted Rights Legend

Restricted permissions of the U.S.

government. Permissions for software

and technical data which are authorized

to the U.S. Government only include

those for custom provision to end users.

ITECH follows FAR 12.211 (technical

data), 12.212 (computer software).

DFARS 252.227-7015 (technical

data--commercial products) for national

defense and DFARS 227.7202-3

(permissions for commercial computer

software or computer software

documents) while providing the

customized business licenses of

software and technical data.

Safety Notices

A CAUTION sign denotes a

hazard. It calls attention to an

operating procedure or practice

that, if not correctly performed

or adhered to, could result in

damage to the product or loss of

important data. Do not proceed

beyond a CAUTION sign until

the indicated conditions are fully

understood and met.

A WARNING sign denotes

a hazard. It calls attention to

an operating procedure or

practice that, if not correctly

performed or adhered to, could

result in personal injury or death.

Do not proceed beyond a

WARNING sign until the

indicated conditions are fully

understood and met.

NOTE

A NOTE sign denotes important

hint. It calls attention to tips or

supplementary information that

is essential for users to refer to.

Page 3

IT8300 Programming Guide

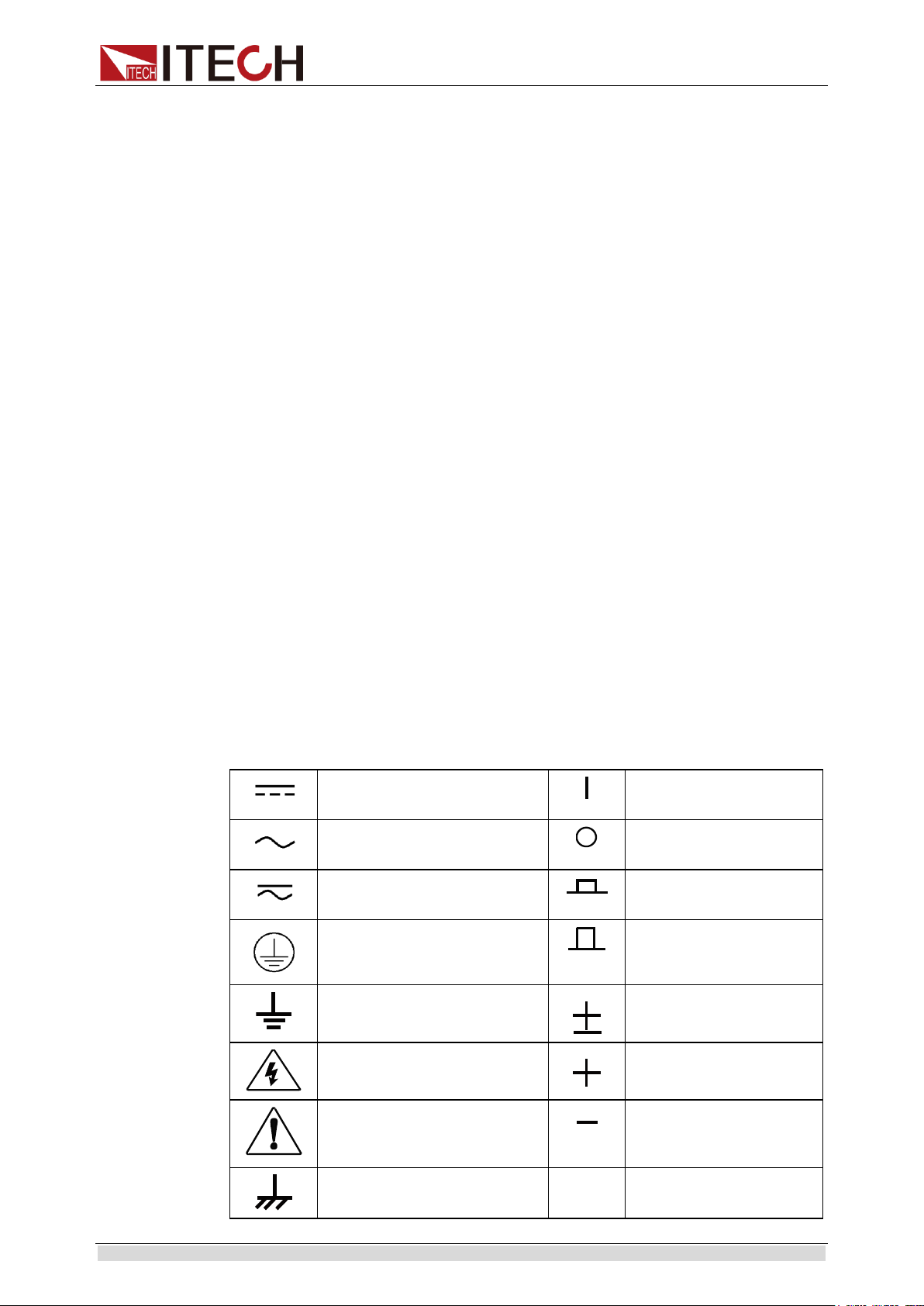

DC power

ON (with the power

switched on)

AC power

OFF (with the power

supply switched off)

Both DC and AC power supply

Power supply

switching-on status

Protective grounding terminal

Power supply

switching-off status

Grounding terminal

Reference terminal

Danger sign

Positive terminal

Warning sign (refer to specific

“Warning” or “Caution”

information in the manual)

Negative terminal

Ground wire connection end

sign

-

-

Certification and Quality Assurance

IT8300 series electronic load completely reaches nominal technical indicators

in the manual.

Warranty service

ITECH Company will provide one-year warranty services for the product

materials and manufacturing (excluding the following limitations).

When warranty service or repair is needed, please send the product to the

service unit specified by ITECH Company.

When the product is sent to ITECH Company for warranty service, the

customer must pay the one-way freight to the maintenance department of

ITECH, and ITECH will be responsible for return freight.

If the product is sent to ITECH for warranty service from other countries,

the customer will be responsible for all the freight, duties and other taxes.

Limitation of Warranty

Warranty service does not apply to the damage caused in the following

circumstances:

Damage resulting from customer-wired circuits or customer-supplied parts

or accessories;

Product which has been modified or repaired by the customer;

Damage caused by the circuit installed by the customer or damage caused

by operation of the product in non-specified environment;

The product model or serial number is altered, deleted, removed or made

illegible by customer;

Damage caused by accidents, including but not limited to lightning, water,

fire, abuse or negligence.

Safety signs

Copyright © ITECH Electronics Co., Ltd. i

Page 4

IT8300 Programming Guide

Environmental conditions

Requirement

Safety Precautions

General safety precautions below must be followed in each phase of instrument

operation. In case of failure to follow these precautions or specific warnings in

other parts of the manual, violation against the safety standards related to the

design, manufacture and purpose of the instrument will occur. If the user does

not follow these precautions, ITECH will bear no responsibility arising there

from.

Do not use the instrument if it is damaged. Before operation, check

the casing to see whether it cracks. Do not operate the instrument in

the presence of inflammable gasses, vapors or dusts.

The electronic load is provided with a power line during delivery and

should be connected to a junction box. Before operation, be sure that

the electronic load is well grounded.

Use electric wires of appropriate load. All loading wires should be

capable of bearing maximum short-circuit of electronic load without

overheating.

Check all marks on the instrument before connecting the instrument

to electronic load.

Ensure the voltage fluctuation of mains supply is less than 10% of the

working voltage range in order to reduce risks of fire and electric

shock.

Do not install alternative parts on the instrument or perform any

unauthorized modification.

Do not use the equipment when the removable cover is dismantled or

loose.

Please use the power adapter supplied by the manufacturer to avoid

accidental injury.

We do not accept responsibility for any direct or indirect financial

damage or loss of profit that might occur when using the instrument.

This instrument is used for industrial purposes, do not apply this

product to IT power supply system.

Do not use the equipment on the life support system or other

equipment with safety requirements.

Environmental conditions

Copyright © ITECH Electronics Co., Ltd. ii

If the equipment is not used in the manner specified by the

manufacturer, its protection may be damaged.

Always use dry cloth to clean the equipment housing. Do not clean

the inside of the instrument.

Do not block the air vent of the equipment.

The IT8300 series electronic load can only be used indoors or in low

condensation areas. The following table shows general environmental

requirements for this instrument.

Page 5

IT8300 Programming Guide

Operating temperature

0°C - 40°C

Operating humidity

20% - 80% (non condensing)

Storage temperature

-20°C - 70 °C

Altitude

Operating up to 2,000 meters

Installation category

Ⅱ

Pollution

Pollution degree 2

The CE tag shows that the product

complies with the provisions of all relevant

European laws (if the year is shown, it

indicates that the year when the design is

approved).

This instrument complies with the WEEE

directive (2002/96/EC) tag requirements.

This attached product tag shows that the

electrical/electronic product cannot be

discarded in household waste.

This symbol indicates that no danger will

happen or toxic substances will not leak or

cause damage in normal use within the

specified period. The service life of the product

is 10 years. The product can be used safely

within the environmental protection period;

otherwise, the product should be put into the

recycling system.

Waste electrical and electronic equipment (WEEE)

directive, 2002/96/EC

The product complies with tag requirements of the

WEEE directive (2002/96/EC). This tag indicates that the

electronic equipment cannot be disposed of as ordinary

household waste.

Product Category

According to the equipment classification in Annex I of

the WEEE directive, this instrument belongs to the

“Monitoring” product.

If you want to return the unnecessary instrument,

please contact the nearest sales office of ITECH.

Note

In order to ensure the accuracy of measurement, it is recommended to operate the

instrument half an hour after start-up.

Regulation tag

Waste electrical and electronic equipment (WEEE) directive

Copyright © ITECH Electronics Co., Ltd. iii

Page 6

IT8300 Programming Guide

IEC 61326-1:2012/ EN 61326-1:2013 ¹²³

Reference Standards

CISPR 11:2009+A1:2010/ EN 55011:2009+A1:2010 (Group 1, Class A)

IEC 61000-4-2:2008/ EN 61000-4-2:2009

IEC 61000-4-3:2006+A1:2007+A2:2010/ EN 61000-4-3:2006+A1:2008+A2:2010

IEC 61000-4-4:2004+A1:2010/ EN 61000-4-4:2004+A1:2010

IEC 61000-4-5:2005/ EN 61000-4-5:2006

IEC 61000-4-6:2008/ EN 61000-4-6:2009

IEC 61000-4-11:2004/ EN 61000-4-11:2004

Compliance Information

Complies with the essential requirements of the following applicable European

Directives, and carries the CE marking accordingly:

Electromagnetic Compatibility (EMC) Directive 2014/30/EU

Low-Voltage Directive (Safety) 2014/35/EU

Conforms with the following product standards:

EMC Standard

1. The product is intended for use in non-residential/non-domestic environments. Use of the

product in residential/domestic environments may cause electromagnetic interference.

2. Connection of the instrument to a test object may produce radiations beyond the specified

limit.

3. Use high-performance shielded interface cable to ensure conformity with the EMC standards

listed above.

Safety Standard

IEC 61010-1:2010/ EN 61010-1:2010

Copyright © ITECH Electronics Co., Ltd. iv

Page 7

IT8300 Programming Guide

Contents

Certification and Quality Assurance .......................................................................................................................... 1

Warranty service ........................................................................................................................................................ 1

Limitation of Warranty .............................................................................................................................................. 1

Safety signs ............................................................................................................................................................... 1

Safety Precautions ..................................................................................................................................................... 2

Environmental conditions .......................................................................................................................................... 2

Regulation tag............................................................................................................................................................ 3

Waste electrical and electronic equipment (WEEE) directive ................................................................................... 3

Compliance Information ............................................................................................................................................ 4

CHAPTER1 REMOTE CONTROL .................................................................................................................... 1

1.1 Overview ............................................................................................................................................................. 1

1.2 SCPI Command Introduction .............................................................................................................................. 1

1.3 Command Type of SCPI ..................................................................................................................................... 1

1.4 Message Type of SCPI ........................................................................................................................................ 3

1.5 Response Data Type ............................................................................................................................................ 4

1.6 Command Format ................................................................................................................................................ 5

1.7 Data Type ............................................................................................................................................................ 7

1.8 SCPI Command Complete .................................................................................................................................. 8

1.9 Remote Operation ................................................................................................................................................ 9

1.9.1 RS232 Interface ........................................................................................................................................... 9

1.9.2 USB Interface ............................................................................................................................................ 10

1.9.3 LAN Interface ............................................................................................................................................ 11

1.9.4 CAN Interface ............................................................................................................................................ 11

1.9.5 RS485 Interface ......................................................................................................................................... 12

1.10 Queue .............................................................................................................................................................. 12

1.11 Status byte and service request (SRQ) ............................................................................................................. 13

1.12 Serial poll and SRQ ......................................................................................................................................... 14

1.13 Trigger Model (GPIB Operation) .................................................................................................................... 14

CHAPTER2 SCPI REGISTER .......................................................................................................................... 16

2.1 Status Register ................................................................................................................................................... 16

2.2 Condition register .............................................................................................................................................. 18

2.3 Event register ................................ ................................ ................................ ..................................................... 18

2.4 Enable register ................................................................................................................................................... 19

CHAPTER3 ESSENTIAL COMMANDS ......................................................................................................... 20

STATus:QUEStionable[:EVENt]? .......................................................................................................................... 20

STATus:QUEStionable:ENABle ............................................................................................................................ 20

STATus:QUEStionable:PTRansition ...................................................................................................................... 21

STATus:QUEStionable:NTRansition ..................................................................................................................... 21

STATus:QUEStionable:CONDition? ...................................................................................................................... 22

STATus:OPERation[:EVENt]? ............................................................................................................................... 22

STATus:OPERation:ENABle ................................................................................................................................. 23

STATus:OPERation:CONDition? ........................................................................................................................... 23

STATus:PRESet ...................................................................................................................................................... 24

CHAPTER4 SYSTEM COMMANDS ............................................................................................................... 25

SYSTem:POSetup ................................................................................................................................................... 25

SYSTem:VERSion? ................................................................................................................................................ 25

SYSTem:ERRor? .................................................................................................................................................... 26

SYSTem:CLEar....................................................................................................................................................... 26

SYSTem:LOCal ...................................................................................................................................................... 26

SYSTem:REMote ................................ ................................ ................................ .................................................... 27

SYSTem:RWLock ................................................................................................................................................... 27

SYSTem:BEEPer:IMMediate ................................................................................................................................. 28

SYSTem:BEEPer[:STATe] ..................................................................................................................................... 28

SYSTem:KEY ................................................................................................................................ ......................... 28

SYSTem:COMMunicate:SELect ............................................................................................................................ 29

SYSTem:COMMunicate:RS232:BAUDrate ........................................................................................................... 29

SYSTem:COMMunicate:RS485:BAUDrate ........................................................................................................... 29

SYSTem:COMMunicate:LAN:CURRent:ADDRess .............................................................................................. 30

Copyright © ITECH Electronics Co., Ltd. v

Page 8

IT8300 Programming Guide

SYSTem:COMMunicate:LAN:CURRent:DGATeway........................................................................................... 30

SYSTem:COMMunicate:LAN:CURRent:SMASk ................................................................................................. 31

SYSTem:COMMunicate:LAN:SOCKetport ........................................................................................................... 31

SYSTem:COMMunicate:LAN:MACaddress? ........................................................................................................ 32

CHAPTER5 MEASURE COMMANDS ................................ ................................ ............................................ 33

FETCh:VOLTage[:DC]? ......................................................................................................................................... 33

MEASure:VOLTage[:DC]? .................................................................................................................................... 33

FETCh:VOLTage:MAX? ........................................................................................................................................ 33

MEASure:VOLTage:MAX? ................................................................................................................................... 33

FETCh:VOLTage:MIN? ......................................................................................................................................... 34

MEASure:VOLTage:MIN? ..................................................................................................................................... 34

FETCh:CURRent[:DC]? ......................................................................................................................................... 34

MEASure:CURRent[:DC]? ..................................................................................................................................... 34

FETCh:CURRent:MAX? ........................................................................................................................................ 34

MEASure:CURRent:MAX? .................................................................................................................................... 34

FETCh:CURRent:MIN? .......................................................................................................................................... 35

MEASure:CURRent:MIN? ..................................................................................................................................... 35

FETCh:POWer[:DC]? ............................................................................................................................................. 35

FETCh:CAPability? ................................................................................................................................................ 36

MEASure:CAPability? ............................................................................................................................................ 36

FETCh:TIME?......................................................................................................................................................... 36

MEASure:TIME? .................................................................................................................................................... 36

FETCh:ACMeter:EACStage? ................................................................................................................................. 36

FETCh:ACMeter:EACTotal? .................................................................................................................................. 37

CHAPTER6 TRIGGER SUBSYSTEM ............................................................................................................. 38

TRIGger[:IMMediate] ............................................................................................................................................. 38

TRIGger:SOURce ................................................................................................................................................... 38

TRIGger:TIMer ....................................................................................................................................................... 39

CHAPTER7 TRACE SUBSYSTEM .................................................................................................................. 40

TRACe:CLEar ......................................................................................................................................................... 40

TRACe:FREE? ........................................................................................................................................................ 40

TRACe:POINts ....................................................................................................................................................... 40

TRACe:FEED ......................................................................................................................................................... 41

TRACe:FEED:CONTrol ......................................................................................................................................... 41

TRACe:DATA?....................................................................................................................................................... 42

TRACe:FILTer[:STATe] ........................................................................................................................................ 42

TRACe:DELay ........................................................................................................................................................ 43

TRACe:TIMer ................................................................ ................................................................ ......................... 43

CHAPTER8 SOURCE SUBSYSTEM ............................................................................................................... 45

[SOURce:]INPut[:STATe] ...................................................................................................................................... 45

[SOURce:]INPut:SHORt[:STATe] ......................................................................................................................... 45

[SOURce:]INPut:TIMer[:STATe]........................................................................................................................... 46

[SOURce:]INPut:TIMer:DELay ............................................................................................................................. 46

[SOURce:]REMote:SENSe[:STATe] ..................................................................................................................... 47

[SOURce:]FUNCtion .............................................................................................................................................. 47

[SOURce:]FUNCtion:MODE ................................................................................................................................. 48

[SOURce:]TRANsient[:STATe] ............................................................................................................................. 49

[SOURce:]PROTection:CLEar ............................................................................................................................... 49

[SOURce:]CURRent[:LEVel][:IMMediate] ........................................................................................................... 49

[SOURce:]CURRent:RANGe ................................................................................................................................. 50

[SOURce:]CURRent:SLEW[:BOTH] ..................................................................................................................... 51

[SOURce:]CURRent:SLEW:POSitive .................................................................................................................... 51

[SOURce:]CURRent:SLEW:NEGative .................................................................................................................. 52

[SOURce:]CURRent:SLEWrate:STATe ................................................................................................................. 53

[SOURce:]CURRent:PROTection:STATe.............................................................................................................. 53

[SOURce:]CURRent:PROTection[:LEVel] ............................................................................................................ 54

[SOURce:]CURRent:PROTection:DELay .............................................................................................................. 54

[SOURce:]CURRent:TRANsient:MODE ............................................................................................................... 55

[SOURce:]CURRent:TRANsient:ALEVel ............................................................................................................. 56

Copyright © ITECH Electronics Co., Ltd. vi

Page 9

IT8300 Programming Guide

[SOURce:]CURRent:TRANsient:BLEVel.............................................................................................................. 56

[SOURce:]CURRent:TRANsient:AWIDth ............................................................................................................. 57

[SOURce:]CURRent:TRANsient:BWIDth ............................................................................................................. 57

[SOURce:]CURRent:HIGH .................................................................................................................................... 57

[SOURce:]CURRent:LOW ..................................................................................................................................... 57

[SOURce:]VOLTage[:LEVel][:IMMediate] ........................................................................................................... 58

[SOURce:]VOLTage:RANGe ................................................................................................................................. 58

[SOURce:]VOLTage[:LEVel]:ON .......................................................................................................................... 59

[SOURce:]VOLTage:LATCh[:STATe] .................................................................................................................. 60

[SOURce:]VOLTage:HIGH .................................................................................................................................... 60

[SOURce:]VOLTage:LOW ..................................................................................................................................... 60

[SOURce:]VOLTage[:LEVel]:ON:HYSTeresis .................................................................................................. 61

[SOURce:]RESistance[:LEVel][:IMMediate] ......................................................................................................... 61

[SOURce:]RESistance:RANGe............................................................................................................................... 62

[SOURce:]RESistance:HIGH .................................................................................................................................. 63

[SOURce:]RESistance:LOW .................................................................................................................................. 63

[SOURce:]POWer[:LEVel][:IMMediate] ............................................................................................................... 63

[SOURce:]POWer:RANGe ..................................................................................................................................... 64

[SOURce:]POWer:HIGH ........................................................................................................................................ 64

[SOURce:]POWer:LOW ......................................................................................................................................... 64

[SOURce:]POWer:PROTection[:LEVel] ................................................................................................................ 65

[SOURce:]POWer:PROTection:DELay.................................................................................................................. 66

[SOURce:]POWer:CONFig[:LEVel] ...................................................................................................................... 66

[SOURce:]INPut:CONTrol <EXTernal/INTernal> ................................................................................................ 67

[SOURce:]ACMeter:EACStage:CLEar .................................................................................................................. 67

CHAPTER9 LIST COMMANDS ....................................................................................................................... 68

[SOURce:]LIST:RANGe ........................................................................................................................................ 68

[SOURce:]LIST:COUNt ......................................................................................................................................... 68

[SOURce:]LIST:STEP ............................................................................................................................................ 69

[SOURce:]LIST:SLOWrate[:STATe] <LOW|HIGH> ............................................................................................ 69

[SOURce:]LIST:LEVel? ......................................................................................................................................... 70

[SOURce:]LIST:SLEW[:BOTH] ............................................................................................................................ 70

[SOURce:]LIST:WIDth .......................................................................................................................................... 71

[SOURce:]LIST:SAV ............................................................................................................................................. 71

[SOURce:]LIST:RCL .............................................................................................................................................. 72

CHAPTER10 CALIBRATION COMMANDS ................................................................................................... 73

CALibrate:SECure[:STATe] ................................................................................................................................... 73

CALibrate:INITial ................................................................................................................................................... 73

CALibrate:SAVe ..................................................................................................................................................... 74

CALibrate:CURRent:POINt ................................................................................................ .................................... 74

CALibrate:CURRent[:LEVel] ................................................................................................................................. 75

CALibrate:CURRent:METEr:POINt ...................................................................................................................... 75

CALibrate:CURRent:METEr[:LEVel] ................................................................................................................... 75

CALibrate:VOLTage:POINt ................................................................................................................................... 76

CALibrate:VOLTage[:LEVel] ................................................................................................................................ 76

CALibrate:VOLTage:METEr:POINt ...................................................................................................................... 77

CALibrate:VOLTage:METEr[:LEVel] ................................................................................................................... 77

CALibration:STRing ............................................................................................................................................... 78

CALibration:STRing? ............................................................................................................................................. 78

CHAPTER11 IEEE488.2 COMMANDS ............................................................................................................. 79

*CLS - Clear Status ................................................................................................................................................. 80

*ESE <NRf> - Event Enable ................................................................................................................................... 80

*ESR? ...................................................................................................................................................................... 81

*IDN? ...................................................................................................................................................................... 81

*OPC ....................................................................................................................................................................... 81

*PSC ................................................................................................................................ ................................ ........ 82

*RCL ....................................................................................................................................................................... 83

*RST ....................................................................................................................................................................... 83

*SAV ....................................................................................................................................................................... 83

*SRE ....................................................................................................................................................................... 84

Copyright © ITECH Electronics Co., Ltd. vii

Page 10

IT8300 Programming Guide

*STB? ...................................................................................................................................................................... 84

*TRG ....................................................................................................................................................................... 85

*TST? ...................................................................................................................................................................... 85

*WAI ....................................................................................................................................................................... 85

CHAPTER12 ERROR INFORMATION ................................................................ ............................................ 87

Copyright © ITECH Electronics Co., Ltd. viii

Page 11

Remote Control

Chapter1 Remote Control

1.1 Overview

This chapter will provide following remote configuration introductions:

SCPI Command Introduction

Command type

Command format

Data format

Remote operation

1.2 SCPI Command Introduction

Standard Command for Programmable Instrumentation (SCPI) is a

programming language for controlling instrument functions via GPIB, RS-232,

USB, and Ethernet interfaces. SCPI is placed on the top of the IEEE 488.2

hardware section. The same SCPI commands and parameters control the

same function of different machines.

1.3 Command Type of SCPI

SCPI has two types of commands, common and subsystem.

Common commands generally are not related to specific operation but to

controlling overallelectronic load functions, such as reset, status, and

synchronization. All commoncommands consist of a three-letter mnemonic

preceded by an asterisk: *RST *IDN? *SRE 8.

Subsystem commands perform specific electronic load functions. They are

organized into an inverted tree structure with the "root" at the top. The

following figure shows a portion of a subsyste command tree, from which

you access the commands located along the various paths.

Multiple commands in a message

Multiple SCPI commands can be combined and sent as a single

message with one message terminator. There are two important

considerations when sending several commands within a single

message:

Use a semicolon to separate commands within a message.

Head paths influence how the instrument interprets commands.

We consider the head path as a string which will be inserted in front of

Copyright © ITECH Electronics Co., Ltd. 1

Page 12

Remote Control

every command of a message. As for the first command of a message,

the head path is a null string; for each subsequent command, the head

path is a string which is defined to form the current command until and

including the head of the last colon separator. A message with two

combined commands: CURR:LEV 3;PROT:STAT OFF

The example indicates the effect of semicolon and explains the concept

of head path. Since the head path is defined to be "CURR" after "curr: lev

3", the head of the second command, "curr", is deleted and the

instrument explains the second command as: CURR:PROT:STAT OFF

If "curr" is explicitly included in the second command, it is semantically

wrong. Since combining it with the head path will become

"CURR:CURR:PROT:STAT OFF", resulting in wrong command.

Movement in the subsystem

In order to combine commands from different subsystems, you need to

be able to reset the header path to a null string within a message. You do

this by beginning the command with a colon (:), which discards any

previous header path. For example, you could clear the output protection

and check the status of the Operation Condition register in one message

by using a root specifier as follows:

PROTection:CLEAr;:STATus:OPERation:CONDition?

The following message shows how to combine commands from different

subsystems as well as within the same subsystem:

POWer:LEVel 200;PROTection 28; :CURRent:LEVel 3;PROTection:STATe ON

Note the use of the optional header LEVel to maintain the correct path

within the voltage and current subsystems, and the use of the root

specifier to move between subsystems.

Including Common Commands

You can combine common commands with subsystem commands in the

same message. Treat the common command as a message unit by

separating it with a semicolon (the message unit separator). Common

commands do not affect the header path; you may insert them anywhere

in the message.

VOLTage:TRIGgered 17.5;:INITialize;*TRG

OUTPut OFF;*RCL 2;OUTPut ONIT872X-3X SCPI Communication protocol 17

Case sensitivity

Common commands and SCPI commands are not case sensitive. You

can use upper or lower, for example:

*RST = *rst

:DATA? = :data?

:SYSTem:PRESet = :system:preset

Long-form and short-form versions

A SCPI command word can be sent in its long-form or short-form version.

The command subsystem tables in Section 5 provide the in the

long-form version. However, the short-form version is indicated by upper

case characters. Examples:

Copyright © ITECH Electronics Co., Ltd. 2

Page 13

Remote Control

:SYSTem:PRESet long-form

:SYST:PRES short form

:SYSTem:PRES long-form and short-form combination

Note that each command word must be in long-form or short-form, and

not something in between.

For example, :SYSTe:PRESe is illegal and will generate an error. The

command will not be executed.

Query

Observe the following precautions with queries:

Set up the proper number of variables for the returned data. For example, if

you are reading back a measurement array, you must dimension the array

according to the number of measurements that you have placed in the

measurement buffer.

Read back all the results of a query before sending another command to

the electronic load. Otherwise a Query Interrupted error will occur and the

unreturned data will be lost.

1.4 Message Type of SCPI

There are two types of SCPI messages, program and response.

Program message: A program message consists of one or more properly

formatted SCPI commands sent from the controller to the electronic load.

The message, which may be sent at any time, requests the electronic load

to perform some action.

Response message: A response message consists of data in a specific

SCPI format sent from the electronic load to the controller. The electronic

load sends the message only when commanded by a program message

called a "query."

The next figure illustrates SCPI message structure:

The Message Unit

The simplest SCPI command is a single message unit consisting of a command

header (or keyword) followed by a message terminator. The message unit may

include a parameter after the header. The parameter can be numeric or a

string.

VOLTage 20<NL>

Copyright © ITECH Electronics Co., Ltd. 3

Page 14

Remote Control

<CRD> Character Response Data. Permits the return of character strings.

<AARD> Arbitrary ASCII Response Data. Permits the return of undelimited 7-bit

ASCII. This data type has an implied message terminator.

<SRD> String Response Data. Returns string parameters enclosed in double quotes

Headers

Headers, also referred to as keywords, are instructions recognized by the

electronic load. Headers may be either in the long form or the short form. In the

long form, the header is completely spelled out, such as VOLTAGE, STATUS,

and DELAY. In the short form, the header has only the first three or four letters,

such as VOLT, STAT, and DEL.

Query Indicator

Following a header with a question mark turns it into a query (VOLTage?,

VOLTage:PROTection?). If a query contains a parameter, place the query

indicator at the end of the last header(VOLTage:PROTection?MAX).

Message Unit Separator

When two or more message units are combined into a compound message,

separate the units with a semicolon (STATus:OPERation?;QUEStionable?).

Root Specifier

When it precedes the first header of a message unit, the colon becomes the

root specifier. It tells the command parser that this is the root or the top node of

the command tree.

Message Terminator

A terminator informs SCPI that it has reached the end of a message. Three

permitted message terminators are:

newline (<NL>),decimal 10 or hexadecimal 0X0A in ASCII.

end or identify (<END>)

both of the above (<NL><END>).

In the examples of this guide, there is an assumed message terminator at the

end of each message.

Command execution rules

Commands execute in the order that they are presented in the program

message.

An invalid command generates an error and, of course, is not executed.

Valid commands that precede an invalid command in a multiple command

program message are executed.

Valid commands that follow an invalid command in a multiple command

program message are ignored.

1.5 Response Data Type

Character strings returned by query statements may take either of the following

forms, depending on the length of the returned string:

Copyright © ITECH Electronics Co., Ltd. 4

Page 15

Remote Control

Response messages

A response message is the message sent by the instrument to the computer in

response to aquery command.

Sending a response message

Afte sending a query command, the response message is placed in the Output

Queue. When the IT8300 series is then addressed to talk, the response

message is sent from the Output Queue to the computer.

Multiple response messages

If you send more than one query command in the same program message (see

the paragraph entitled, “ Multiple Command Messages “), the multiple response

messages for all the queries is sent to the computer when the IT8300 series is

addressed to talk. The responses are sent in the order that the query

commands were sent and are separated by semicolons (;). Items within the

same query are separated by commas (,). The following example shows the

response message for a program message that contains four single item query

commands:

0; 1; 1; 0

Response message terminator (RMT)

Each response is terminated with an LF (line feed) and EOI (end or identify).

The following example shows how a multiple response message is terminated:

0; 1; 1; 0; <RMT>

Message exchange protocol

Two rules summarize the message exchange protocol:

Rule 1.You must always tell the IT8300 series what to send to the computer.

The following two steps must always be performed to send information from the

instrument other computer:

1. Send the appropriate query command(s) in a program message.1.

2. Address the IT8300 series to talk.

Rule 2.The complete response message must be received by the computer

before another program message can be sent to the IT8300 series.

1.6 Command Format

Formats for command display are as follows:

[SOURce[1|2]:]VOLTage:UNIT {VPP|VRMS|DBM}

[SOURce[1|2]:]FREQuency:CENTer

{<frequency>|MINimum|MAXimum|DEFault}

Based on the command syntax, most commands (and certain Parameter) are

expressed in both upper and lower cases. Upper case refers to abbreviation of

commands. Shorter program line may send commands in abbreviated format.

Long-format commands may be sent to ensure better program readability.

For example, both formats of VOLT and VOLTAGE are acceptable in the above

syntax statements. Upper or lower case may be used. Therefore, formats of

VOLTAGE, volt and Volt are all acceptable. Other formats (such as VOL and

VOLTAG) are invalid and will cause errors.

Parameter options with given command strings are included in the brace

({ }). The brace is not sent along with command strings.

Copyright © ITECH Electronics Co., Ltd. 5

Page 16

Remote Control

Vertical stripes (|) separate several parameter options with given command

strings. For example, {VPP|VRMS|DBM} indicates that you may assign

"APP", "VRMS" or "DBM" in the above commands. Vertical stripes are not

sent along with command strings.

Angle brackets (< >) in the second example indicates that a value must be

assigned to the parameter in the brace. For example, the parameter in the

angle bracket is <frequency> in the above syntax statements. Angle

brackets are not sent along with command strings. You must assign a value

(such as "FREQ:CENT 1000") to the parameter, unless you select other

options displayed in the syntax (such as "FREQ:CENT MIN").

Some syntax elements (such as nodes and Parameter) are included in

square brackets ([ ]). It indicates that these elements can be selected and

omitted. Angle brackets are not sent along with command strings. If no

value is assigned to the optional Parameter, the instrument will select a

default value. In the above examples, "SOURce[1|2]" indicates that you

may refer to source channel 1 by "SOURce" or "SOURce1" or "SOUR1" or

"SOUR". In addition, since the whole SOURce node is optional (in the

square bracket), you can refer to the channel 1 by omitting the whole

SOURce node. It is because the channel 1 is the default channel for

SOURce language node. On the other hand, if you want to refer to channel

2, "SOURce2" or "SOUR2" must be used in the program line.

Colon (:)

It is used to separate key words of a command with the key words in next level.

As shown below:

APPL:SIN 455E3,1.15,0.0

In this example, APPLy command assigns a sine wave with frequency of 455

KHz, amplitude of 1.15 V and DC offset of 0.0 V.

Semicolon (;)

It is used to separate several commands in the same subsystem and can also

minimize typing. For example, to send the following command string:

TRIG:SOUR EXT; COUNT 10

has the same effect as sending the following two commands:

TRIG:SOUR EXT

TRIG:COUNT 10

Question mark (?)

You can insert question marks into a command to query current values of most

Parameter. For example, the following commands will trigger to set the count as

10:

TRIG:COUN 10

Then, you may query count value by sending the following command:

TRIG:COUN?

You may also query the allowable minimum or maximum count as follows:

TRIG:COUN?MIN

TRIG:COUN?MAX

Comma (,)

If a command requires several Parameter, then a comma must be used to

separate adjacent Parameter.

Copyright © ITECH Electronics Co., Ltd. 6

Page 17

Remote Control

Space

You must use blank characters, [TAB] or [Space] to separate Parameter with

key words of commands.

Generic commands (*)

Execute functions like reset, self inspection and status operation. Generic

commands always start with a asterisk (*) and occupy 3 character sizes,

including one or more Parameter. Key words of a command and the first

parameter are separated by a space. Semicolon (;) can separate several

commands as follows:

*RST; *CLS; *ESE 32; *OPC?

Command terminator

Command strings sent to the instrument must end with a <Newline> (<NL>)

character. IEEE-488 EOI (End or Identify) information can be used as <NL>

character to replace termination command string of <NL> character. It is

acceptable to place one <NL> after a <Enter>. Termination of command string

always resets current SCPI command path to root level.

NOTE

As for every SCPI message with one query sent to the instrument, the

instrument will use a <NL> or newline sign (EOI) to terminate

response of return. For example, if "DISP:TEXT?" is sent, <NL> will

be placed after the returned data string to terminate response. If an

SCPI message includes several queries separated by semicolon

(such as "DISP?;DISP:TEXT?"), <NL> will terminate response

returned after response to the last query. In all cases, the program

must read <NL> in response before another command is sent to the

instrument, otherwise errors will be caused.

1.7 Data Type

SCPI language defines several data types used for program message and

response messages.

Numerical parameter

Commands requiring numerical Parameter support the notations of all common

decimal notations, including optional signs, decimal points, scientific notation,

etc. Special values of numerical Parameter are also acceptable, such as MIN,

MAX and DEF. In addition, suffixes for engineering units can also be sent

together with numerical Parameter (including M, k, m or u). If the command

accepts only some specific values, the instrument will automatically round the

input Parameter to acceptable values. The following commands require

numerical Parameter of frequency value:

[SOURce[1|2]:]FREQuency:CENTer {<Frequency>|MINimum|MAXimum}

<NR1>: There is an implicit decimal point in the last bit,such as 273

<NR2>: There is an explicit decimal point,such as .273

<NR3>: There are an explicit decimal point and exponential,such as

2.73E+22.73E+2

<Nrf>:The extensible form includes <NR1>, <NR2> and <NR3>,such

as 273 273. 2.73E2273 273. 2.73E2

<Nrf+>: The extensible decimal form includes <NRf> and MIN MAX

DEF, such as 273 273. 2.73E2 MAX. MIN and MAX are the minimum

and maximum finite number. Within the range of the parameter

Copyright © ITECH Electronics Co., Ltd. 7

Page 18

Remote Control

definition, DEF is the default of the parameter.

Discrete parameter

Discrete Parameter are used for settings with limited number of programming

values (such as IMMediate, EXTernal or BUS). They can use short and long

format like key words of commands. They may be expressed in both upper and

lower case. The query response always returns uppercase Parameter in short

format. The following commands require discrete Parameter in voltage unit:

[SOURce[1|2]:]VOLTage:UNIT {VPP|VRMS|DBM}

Boolean parameter

Boolean Parameter refer to true or false binary conditions. In case of false

conditions, the instrument will accept "OFF" or "0". In case of true conditions,

the instrument will accept "ON" or "1". In query of Boolean settings, the

instrument will always return "0" or "1". Boolean Parameter are required by the

following commands:

DISPlay {OFF|0|ON|1}

ASCII string Parameter

String Parameter may actually include all ASCII character sets. Character

strings must start and end with paired quotation marks; and single quotation

marks or double quotation marks are both allowed. Quotation mark separators

may also act as one part of a string, they can be typed twice without any

character added between them. String parameter is used in the following

command:

DISPlay:TEXT <quoted string>

For example, the following commands display message of "WAITING..."

(without quotation marks) on the front panel of the instrument.

DISP:TEXT "WAITING..."

Single quotation marks may also be used to display the same message.

DISP:TEXT 'WAITING...'

1.8 SCPI Command Complete

SCPI commands sent to the electronic load are processed either sequentially

or in parallel. Sequential commands finish execution before a subsequent

command begins. Parallel commands allow other commands to begin

executing while the parallel command is still executing. Commands that affect

trigger actions are among the parallel commands.

*WAI, *OPC, and *OPC:Common commands provide different ways of

indicating when all transmitted commands, including any parallel ones, have

completed their operations. Some practical considerations for using these

commands are as follows:

*WAI: This prevents the electronic load from processing subsequent

commands until all pending operations are completed.

*OPC?: This places a 1 in the Output Queue when all pending operations have

completed. Because it requires your program to read the returned value before

executing the next program statement, *OPC? can be used to cause the

controller to wait for commands to complete before proceeding with its

program.

*OPC: This sets the OPC status bit when all pending operations have

completed. Since your program can read this status bit on an interrupt basis,

*OPC allows subsequent commands to be executed.

Note

The trigger system must be in the Idle state in order for the status OPC bit to be true.

Copyright © ITECH Electronics Co., Ltd. 8

Page 19

Remote Control

Therefore, as far as triggers are concerned, OPC is false whenever the trigger

system is in the Initiated state.

Using Device Clear

You can send a device clear at any time to abort a SCPI command that may be

hanging up the GPIB interface. The status registers, the error queue, and all

configuration states are left unchanged when a device clear message is

received. Device clear performs the following actions:

The input and output buffers of the electronic load are cleared.

The electronic load is prepared to accept a new command string.

The following statement shows how to send a device clear over the GPIB

interface using GW BASIC:

CLEAR 705 IEEE-488 Device Clear

The following statement shows how to send a device clear over the GPIB

interface using the GPIB command library for C or QuickBASIC.

IOCLEAR (705)

1.9 Remote Operation

IT8300 series have five standard communication interfaces: RS232, USB,

RS485, LAN and CAN. The customer can choose any one according to his

demands.

1.9.1 RS232 Interface

Cable connection load with both ends of COM interface (DB9) and computer.

Composite key [Shift] + 8(System) on front board can be used to enter system

menu for activation.

In RS-232 interface, all SCPI commands can be used for programming. If

RS-232 interface is selected, in accordance with internal connection of data

terminal equipment (DTE) and data communication equipment (DCE) as

defined in EIA RS-232, the load is connected to another DTE (e.g., PC COM

interface) with direct-connected Modem cable.

Note

The setup of RS232 in the program must be consistent with the system setup of the instrument.

Press [Shift] + 8(System) to modify the setup of the instrument if they don’t match.

RS-232 data format

RS-232 data comprises start bit, odd and even parity check bit, stop bit and

8-bit data bit. Start bit and stop bit are not editable. However, next odd or even

item can be selected by front board [Shift] + 8(System). The odd and even

items are saved in NVM.

Baud rate

Through front board [Shift] + 8(System), the user may select one Baud rate

saved in NVM: 4800 /9600 /19200 /38400 /57600 /115200

RS-232 Connection

Use RS-232 cable with DB-9 interface because the RS-232 serial port can be

connected controller (e.g. PC) serial port. Do not use modulating cable of

air-conditioner. Refer to Table 2-2 for plug pin.

If your computer is provided with a RS-232 interface with DB-25 plug, a cable

and a adapter with DB-25 plug (one end) and DB-9 plug (the other end) are

Copyright © ITECH Electronics Co., Ltd. 9

Page 20

Remote Control

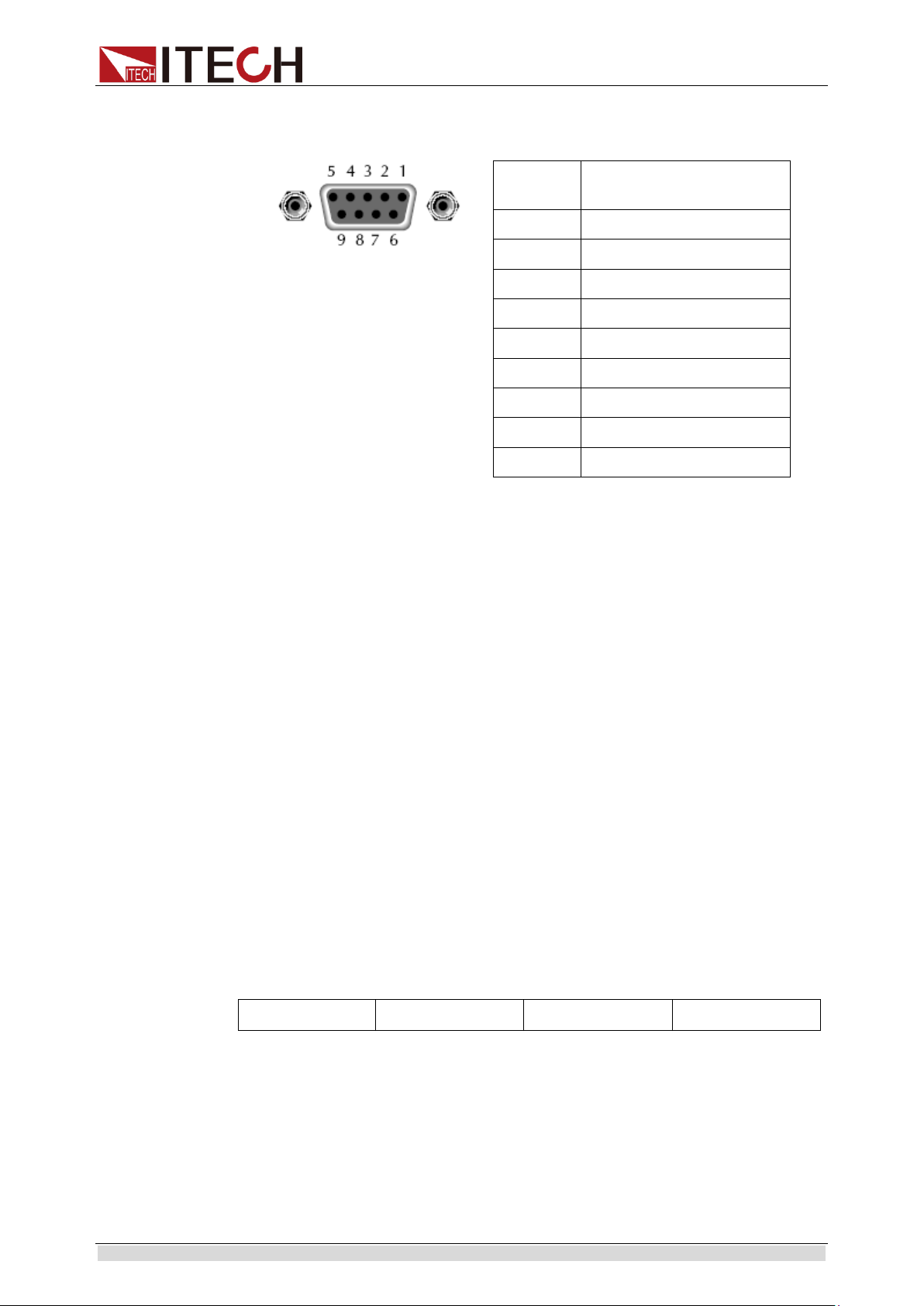

RS232 Pins of Plug

Base pin

number

Description

1

No conjunction

2

TXD, data transmission

3

RXD, data receiving

4

No conjunction

5

GND, grounding

6

No conjunction

7

CTS, clear to send

8

RTS, request to send

9

No conjunction

Start Bit

Parity=None

8 Data Bits

Stop Bit

required (not the modulating cable of the air-conditioner).

RS-232 troubleshooting:

In case of connection failure of RS-232, perform following check:

Check if the computer and load are provided with same Baud rate, parity

check bit, data bit and flow control. The power shall be configured with one

start bit (fixed) and one stop bit (fixed).

Just as described in the RS-232 connector, correct interface cable or

adapter shall be adopted. Note: even if the cable is equipped with right plug,

internal wiring may be incorrect.

The interface cable must be connected to the correct serial port (COM1,

COM2, etc.) of the computer.

Setting of communication

Before communication operation, be sure to match load and PC parameters (as

follows).

Baud rate: 9600 (4800/9600/19200/38400/57600/15200). You may enter

system menu through the board to set communication Baud rate.

Data bit: 8 bits

Stop bit: 1 bit

Check: (none, even, odd)

EVEN 8 data bits have even-parity check

ODD 8 data bits have odd-parity check

NONE 8 data bits have no check

Local address: (0-31, factory set value: 0)

1.9.2 USB Interface

Copyright © ITECH Electronics Co., Ltd. 10

Connect the load and the computer using a cable with two USB interfaces

(each end). All functions of the load can be programmed via USB.

The functions of load USB488 interface are as follows:

The interface is 488.2 USB488 Interface.

The interface receives requests of REN_CONTROL, GO_TO_LOCAL and

LOCAL_LOCKOUT.

Page 21

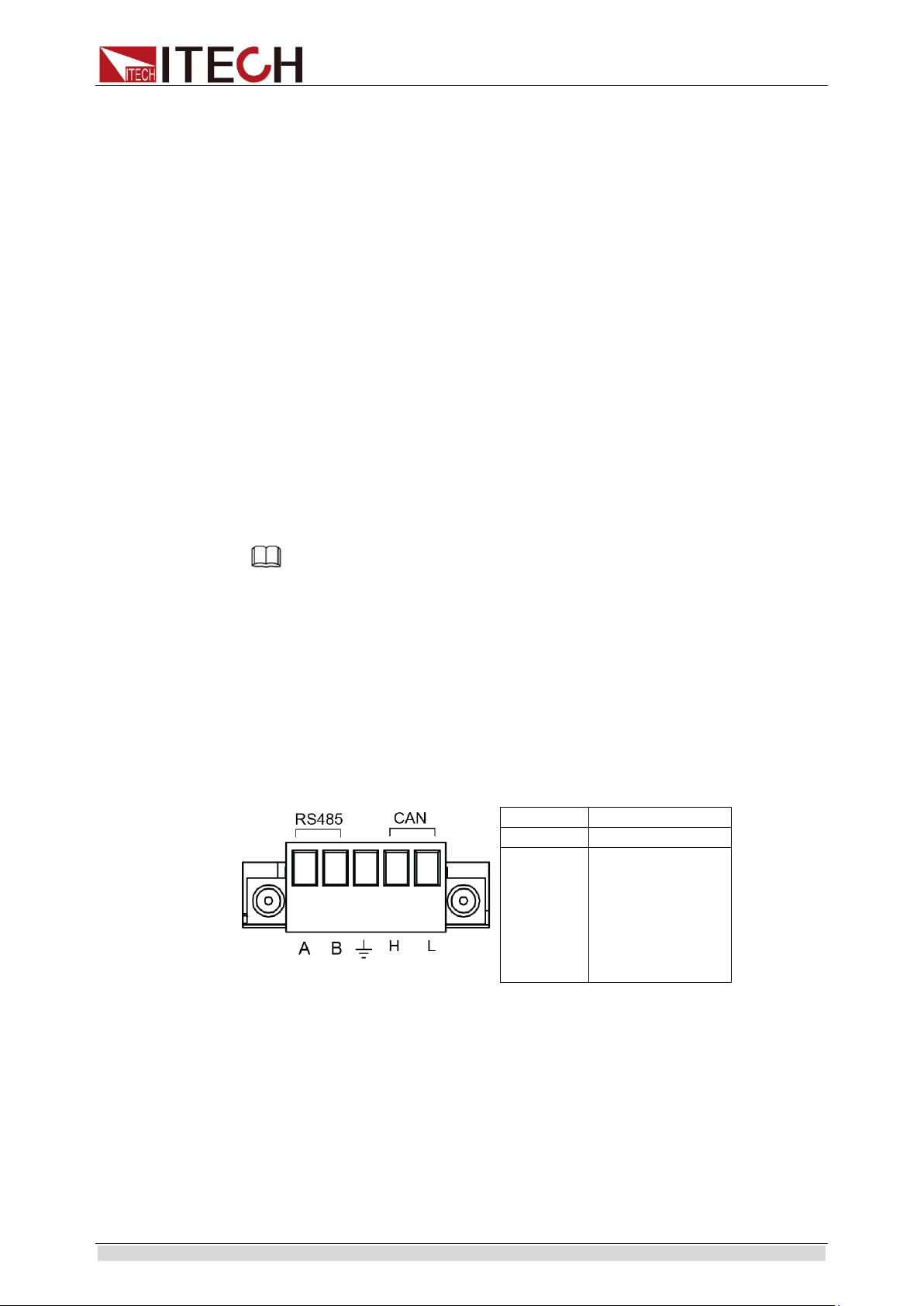

Remote Control

CAN INTERFACE PIN

PIN

DESCRIPTION

H

CAN_H

L

CAN_L

The interface receives the command MsgID=TRIGGER USBTMC and

conveys the TRIGGER command to the functional layer.

The functions of load USB488 device are as follows:

Capable to read all common SCPI commands.

SR1 enabled.

RL1 enabled.

DT1 enabled.

1.9.3 LAN Interface

Press [Shift] + 8(System) button to enter the system set. Please select “LAN”

in the Communication from System and then configure Gateway, IP, Mask and

Socket Port in the LAN option.

Connect the LAN interface of load to the computer with a reticle (crossed). The

gateway address should be consistent with that of the PC, and the IP address

should be at the same network segment with the PC’s IP address.

1.9.4 CAN Interface

There is one CAN interface at the rear panel. The user can use this terminal for

PC connection; to activate connection, be sure that the values set in the

System menu are same as the corresponding values set in PC.

Baud Rate

In the front panel [Shift] + 8(System), under the System menu, the user can

select one Baud rate stored in NVM:

20K|40K|50k|80k|100k|125k|150K|200k|250k|400K|500K|1000K

CAN Pin Definition

CAN interface pin is as follows.

Note

CAN setting in the program shall be consistent with the one set in the System menu of front

panel. To query and change, press the composite key [Shift] + 8(System) to enter the

setting screen in System menu for query and change. For details, refer to 3.6 System Menu.

CAN Troubleshooting:

Copyright © ITECH Electronics Co., Ltd. 11

If CAN connection fails, check that:

1. The PC and load have same Baud rate.

2. Appropriate interface pin or adapter is used, as described in CAN

connector.

3. The interface cable is correctly connected (CAN_H to CAN_H, CAN_L to

CAN_L).

Check whether 120 Ω terminal resistance is connected.

Page 22

Remote Control

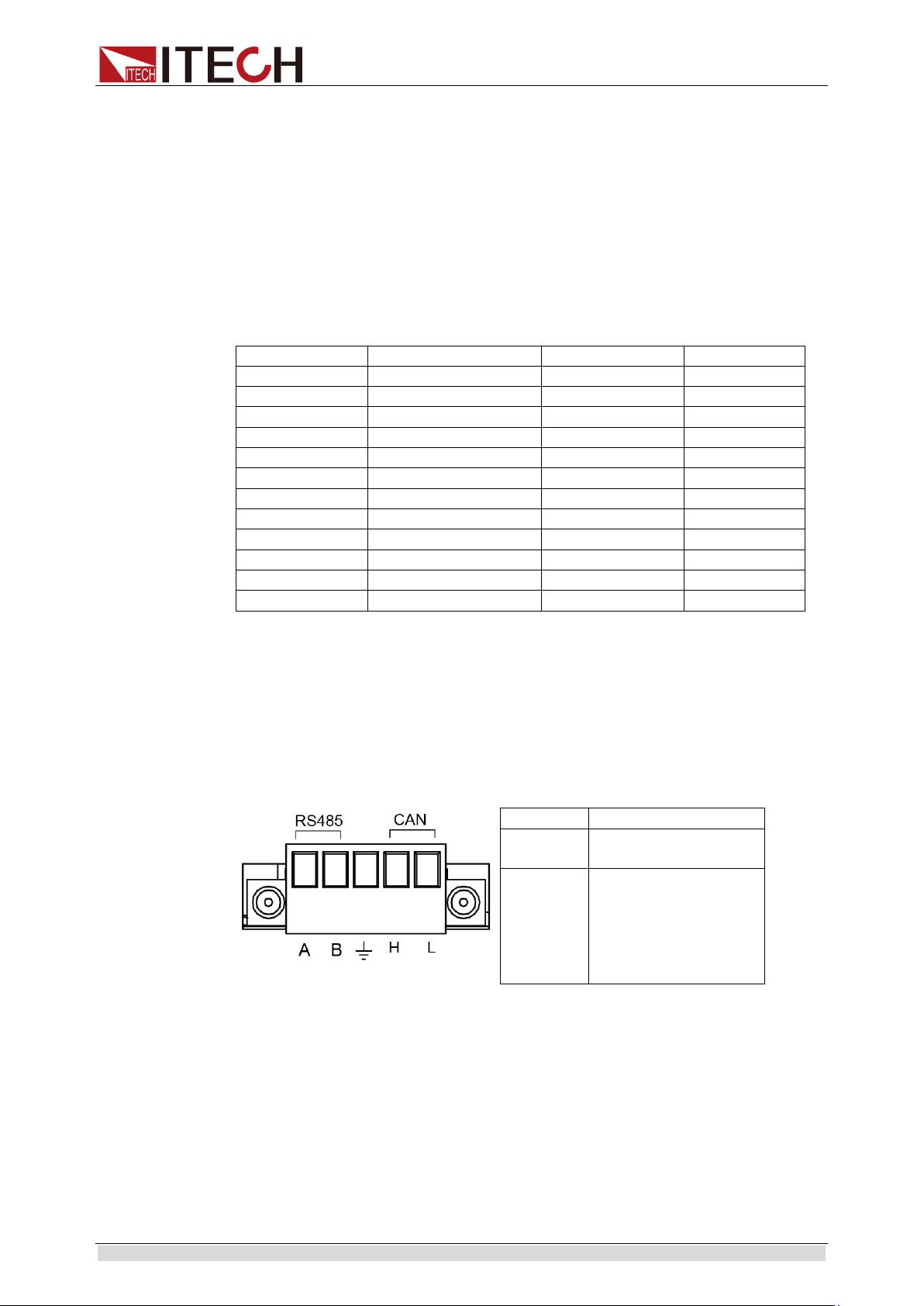

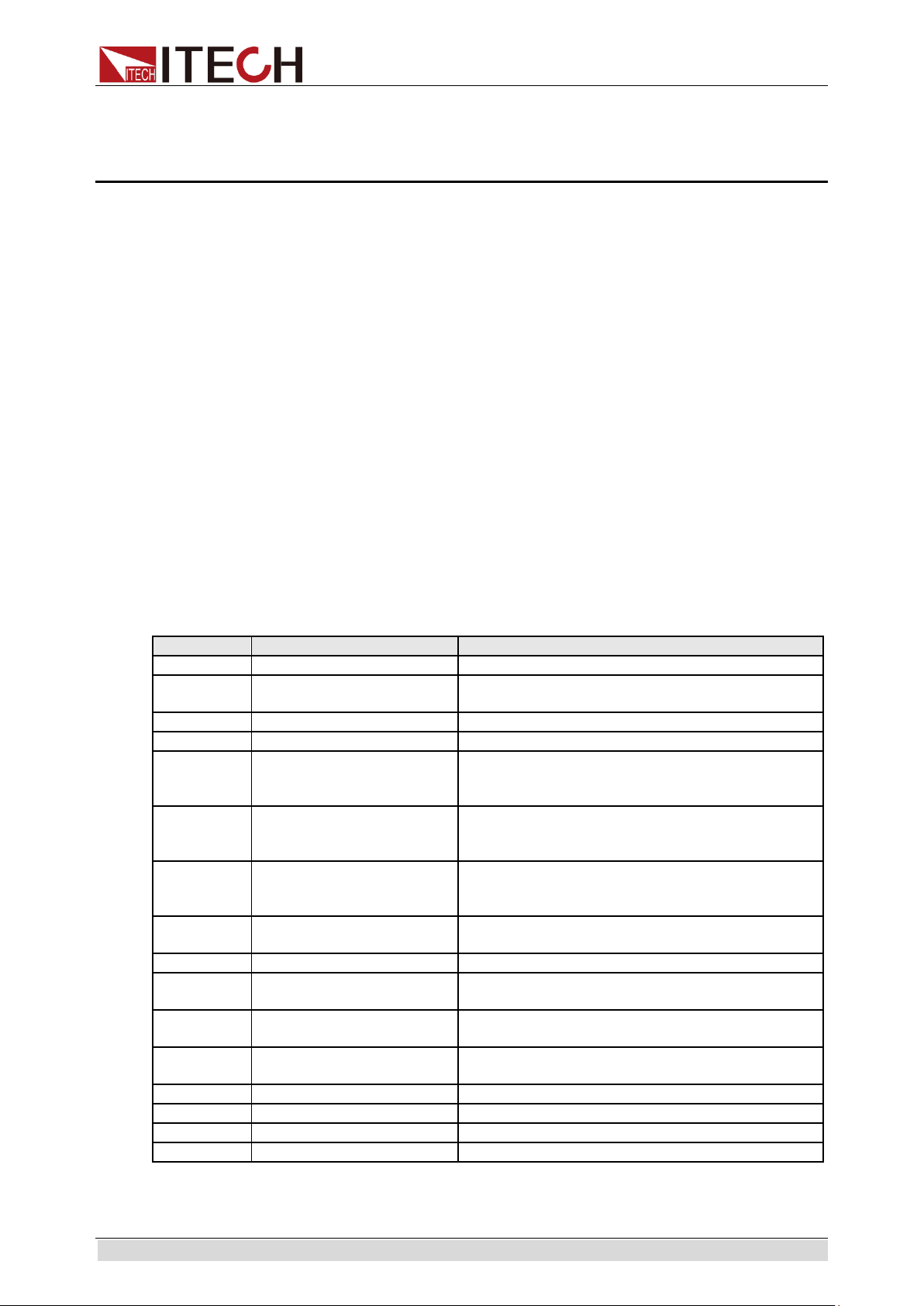

BAUD RATE

(PRESCALE)

PTS

PBS

20K

150

10

1

40K

75

10

1

50K

60

10

1

80K

75 4 0

100K

30

10

1

125K

24

10

1

150K

20

10

1

200K

15

10

1

250K

12

10

1

400K

15 4 0

500K

6

10 1 1000K

3

10

1

RS485 INTERFACE PIN

PIN

DESCRIPTION

A

A cable of RS485

interface

B

B cable of RS485

interface

Setting Communication

Before running communication, please match the load parameters with the PC

parameters as shown below.

Baud rate: 20K(40K, 50K, 80K, 100K, 125K, 150K, 200K, 250K, 400K, 500K,

1000K). You can enter the System menu through panel and set the

communication Baud rate

Addr.: 1-99

Prescale (Pres): Not settable. Change with Baud rate setting.

PTS (BS1): Not settable. Change with Baud rate setting.

PBS (BS2): Not settable. Change with Baud rate setting.

1.9.5 RS485 Interface

There is one RS485 interface at the rear panel. The user can use this terminal

for PC connection; to activate connection, be sure that the values set in the

System menu are same as the corresponding values set in PC.

Through front board [Shift] + 8(System), the user can set the Baud rate, Data

bit, Stop bit and check. And the operation method is same as RS232.

RS485 interface pin is as follows.

1.10 Queue

Copyright © ITECH Electronics Co., Ltd. 12

The IT8300 series uses two queues, which are first-in, first-out (FIFO) registers:

Output Queue - used to hold reading and response messages

Error Queue - used to hold error and status messages

The IT8300 series status model shows how the two queues are structured with

the other registers.

Page 23

Remote Control

Output queue

The output queue holds data that are related to the normal operation of the

instrument. For example, when a query command is sent, the response

message is placed on the output queue.

When data is placed in the output queue, the Message Available (MAV) bit in

the status byte register sets. A data message is cleared from the output queue

when it is read. The output queue is considered cleared when it is empty. An

empty output queue clears the MAV bit in the status byte register.

You can read a message from the output queue after a query is sent.

Error queue

The error queue holds error and status messages. When an error or status

event occurs, a message that defines the error/status is placed in the error

queue. This queue holds up to 31 messages.

When a message is placed in the error queue, the Error Available (EAV) bit in

the status byte register is set. An error message is cleared from the error/status

queue when it is read. The error queue is considered cleared when it is empty.

An empty error queue clears the EAV bit in the status byte register. Read an

error message from the error queue by sending :SYSTem:ERRor?command.

1.11 Status byte and service request (SRQ)

Service request is controlled by two 8-bit registers: the status byte register and

the service request enable register.

Status byte register

The summary messages from the status registers and queues are used to set

or clear the appropriate bits (B2, B3, B4, B5, and B7) of the status byte

register.These bits do not latch, and their states (0 or 1) are solely dependent

on the summary messages (0 or 1).For example, if the Standard event status

register is read, its register is cleared.As a result, its summary message will

reset to 0, which in turn will clear the ESB bit in the status byte register.Bit B6 in

the status byte register is called the MSS bit.

The Master Summary Status (MSS) bit, sent in response to the *STB?indicates

the enable status of the set bit.The Request for Service (RQS) bit, sent in

response to a serial poll, indicates which device was requesting service by

pulling on the SRQ line.

For a description of the other bits in the status byte register, see *STB?.

When reading the status byte register using the *STB? command, bit B6 is

called the MSS bit.None of the bits in the status byte register are cleared when

using the *STB? command to read them.

The IEEE-488.1 standard has a serial poll sequence that also reads the status

byte register and is better suited to detect a service request (SRQ).When using

the serial poll, bit B6 is called the RQS bit.Serial polling causes bit B6 (RQS) to

reset.Serial polling is discussed in more detail later.

Any of the following operations clear all bits of the status byte register:

Circulation power

Sending the *CLS command

Note: The MAV bit may or may not be cleared.

Service request enable register

This register is programmed by you and serves as a mask for the status

Copyright © ITECH Electronics Co., Ltd. 13

Page 24

Remote Control

summary message bits (B2, B3, B4, B5, and B7) of the status byte

register.When masked, a set summary bit in the status byte register cannot set

bit B6 (MSS/RQS) of the status byte register. Conversely, when unmasked, a

set summary bit in the status byte register sets bit B6.

A status summary message bit in the status byte register is masked when the

corresponding bit in the service request enable register is cleared.When the

masked summary bit in the status byte register sets, it is ANDed with the

corresponding cleared bit in the service request enable register.The logic “1”

output of the AND gate is applied to the input of the OR gate and, thus, sets the

MSS/RQS bit in he status byte register.

The individual bits of the service request enable register can be set or cleared

by using the following common command:

*SRE <NRf>*SRE <NRf>

To read the service request enable register, use the *SRE? query command.

The service request enable register clears when power is cycled or a parameter

(n) value of zero is sent with the *SRE command *SRE 0).

1.12 Serial poll and SRQ

Any enabled event summary bit that goes from 0 to 1 will set RQS and generate

a service request (SRQ). In your test program, you can periodically read the

status byte register to check if a service request (SRQ) has occurred and what

caused it. If an SRQ occurs, the program can, for example, branch to an

appropriate subroutine that will service the request. Typically, service requests

(SRQs) are managed by the serial poll sequence of the electronic load. If an

SRQ does not occur, bit B6 (RQS) of the status byte register will remain cleared

and the program will simply proceed normally after the serial poll is performed.

If an SRQ does occur, bit B6 of the status byte register will set and the program

can branch to a service subroutine when the SRQ is detected by the serial poll.

The serial poll automatically resets RQS of the status byte register. This allows

subsequent serial polls to monitor bit B6 for an SRQ occurrence generated by

other event types. After a serial poll, the same event can cause another SRQ,

even if the event register that caused the first SRQ has not been cleared.

A serial poll clears RQS but does not clear MSS. The MSS bit stays set until all

status byte event summary bits are cleared.

1.13 Trigger Model (GPIB Operation)

This section describes how the electronic load operates over the GPIB bus. It is

called the trigger model because operation is controlled by SCPI commands

from the Trigger subsystem. Key SCPI commands are included in the trigger

model.

Trigger Model Operation

Once the instrument is taken out of idle state, operation proceeds through the

trigger model down to the device action.

A control source is used to hold up operation until the programmed event

occurs. The control source options are explained as follows:

HOLD: only the FORCE:TRIG command will generate a trigger in HOLD

mode. All other trigger commands are ignored.

MANual: event detection is ended by pressing the TRIG key.

TIMer: this generates triggers that are in synchronization with the electronic

load's internal oscillator as the trigger source. The internal oscillator begins

running as soon as this command is executed. Send TRIG:TIM to program

Copyright © ITECH Electronics Co., Ltd. 14

Page 25

Remote Control

the oscillator period.

EXTernal: event detection is ended when an input trigger via the TRIGGER

LINK connector is received by the electronic load.

BUS: event detection is ended when a bus trigger (GET or *TRG) is

received by the electronic load.

Delay: The user can set the timing trigger delay time, the time range 0 to

999999.999S.

Copyright © ITECH Electronics Co., Ltd. 15

Page 26

SCPI Register

Bit

Signal

Description

Operation status group

6 CAL Calibrating: The electronic load iscalculated a new calibration constant.

5

TRG

Waiting:The electronic load is waiting for a trigger

Channel status group/Questionable status group

0

VF

Voltage Fault. Either an overvoltage or a reverse voltage has occurred This bit reflects