Page 1

High Resolution and High

Spe e d Pr o gr a m mable Power

Supply

Series IT6100 User’s Manual

Model: IT6121/IT6122/IT6123/IT6151/IT6152/

IT6153/IT6154

Version: V 1.1

Page 2

Notices

© Itech Electronics, Co., Ltd. 2015

No part of this manual may be

reproduced in any form or by any means

(including electronic stor age and

retrieval or translation into a foreig n

language) without prior permission and

written consent from Itech Electronics,

Co., Ltd. as governed by international

copyright laws.

Manual Par t Number

IT6100-402196

Revision

1st Edition: May 26, 2015

Itech Electronics, Co., Ltd.

Trademarks

Pentium is U.S. registered trademarks

of Intel Corporation.

Microsoft, Visual Studio, Windows and

MS Windows are registered trademarks

of Microsoft Corporation in the United

States and/or other countries and

regions.

Warranty

The materials contained in this

document are provided “as is”, and

is subject to change, without prior

notice, in future editions. Further, to

the maximum extent permitted by

applicable laws, ITECH disclaims

all warrants, either express or

implied, with regard to this manual

and any information contained

herein, including but not limited to

the implied warranties of

merchantability and fitness for a

particular purpose. ITECH shall

not be held liable for errors or for

incidental or indirect damages in

connection with the furnishing, use

or application of this document or of

any information contained herein.

Should ITECH and the user enter

into a separate written agreement

with warranty terms covering the

materials in this document that

conflict with these terms, the

warranty terms in the separate

agreement shall prevail.

Techn ology Licenses

The hardware and/or software

described herein are furnished under a

license a nd m a y be use d or cop ie d o nly

in accordance with the terms of such

license.

Restricted Rights Legend

Restricted permissions of the U.S.

government. Permissions for software

and technical data which are authorized

to the U.S. Government only include

those for custom provision to end users

ITECH provides this customary

commercial license in software and

technical data pursuant to FAR 12.211

(Technical Data) and 12.212 (Computer

Software) and, for the Department of

Defense, DFARS 252.227-7015

(Technical Data – Commercial Item s)

and DFARS 227.7202-3 (Rights in

Commercial Computer Software or

Computer Software Documentation).

Safety Notices

A CAUTION sign denotes a

hazard.

It calls attention to an operating

procedure or practice that, if not

correctly performed or adhered

to, could result in damage to the

product or loss of im port ant dat a.

Do not proceed beyond a

CAUTION sign until the

indicated conditions are fully

understood and met.

A WARNING sign denotes a

hazard.

It calls attention to an

operating procedure or practice

that, if not correctly performed

or adhered to, could result in

personal injury or death. Do not

proceed beyond a WARNING

sign until the indicated

conditions are fully understood

and met.

NOTE

A NOTE sign denotes important

hint. It calls attention to tips or

supplementary information that

is essential for users to refer to.

Page 3

IT6100 User’s Manual

Direct current

ON (power on)

Alternating current

OFF (power off)

Both direct and alternating

current

Power-on state

Protective conductor terminal

Power-off state

Caution, risk of elect ric shock

Positive terminal

to this manual for specific

Warning or Caution

information)

Frame or chassis termi nal

-

-

Quality Certification and Assurance

We certify that IT6100 series power supply meets all the published specifications.

Warranty

ITECH warrants that the product will be free from defects in material and

workmanship under normal use for a period of one (1) year from the date of

delivery (except those descri bed in the Limitation of Warranty below).

For warranty service or repair, the product must be returned to a service center

designate d by ITECH.

The product returned to ITECH for warranty servi ce must be shipped

PREPAID. And ITECH will pay for return of the product to customer.

If the product is returned to ITECH for warranty service from over seas, all the

freights, duties and other taxes shall be on the account of customer.

Limitation of Warranty

This Warranty w ill be rendered invalid if the product is:

Damage caused by circuit installed by customer or using customer own

product s or accessor ies;

Modified or repai red by customer without author ization;

Damage caused by circuit installed by customer or not operating our products

under desi gnated environment;

The product m odel or serial number i s modified, deleted, removed or illegible;

Damaged as a result of accidents, including but not limited to lightning,

moistur e, fire, improper use or negl igence.

Safety Symbols

Earth (ground) termi nal

Warning, risk of danger (refer

Reference t erminal

Negati ve terminal

Copyright © ITECH Electronics Co., Ltd. i

Page 4

IT6100 User’s Manual

Environmental Conditions

Requirements

Operating temperature

0°C to 40°C

Operating humidity

20%-80% (non-condensation)

Storage temperature

-20°C to 70 °C

Safety Precautions

The following safety precautions must be observed during all phases of operation

of this instrument. Failure to comply with these precautions or specific warnings

elsewher e in this manual will constitute a default under saf ety standards of design,

manufacture and intended use of the instrument. ITECH assumes no liability for

the custo mer’s f ailure to comply with these precautions.

Do not use the instrument if it is damag ed. Before operation, check the casi ng

to see whether it cracks. Do not operat e the instrument in the presence of

inflammable gasses, vapors or dusts.

The power supply is provided with a three-core power line during delivery and

should be connected to a thr ee-core junction box. Before operat ion, be sure

that the power supply is well grounded. Make sure to use the power cord

supplied by ITECH.

Check all marks on the instrument before connect ing the instrument to pow er

supply.

Use electric wires of appropriat e load. All loading wires should be capable of

bearing maximum short -circuit of electronic load without overheating. If there

are multiple loads, each pair of the load power cord must be carr y out the full

rated short-circuit output current of the power securely.

Ensure the voltage fluctuati on of mains supply is less than 10% of the working

voltage range in order to reduce risks of fire and electric shock.

Do not install alternative parts on the instrument or perform any unauthorized

modification.

Do not use the instrument if the detachable co ver is removed or loosen.

To prevent the possibility of accidental injuries, be sure to use the power

adapter su pplied by the m anufacturer only.

Never use the instrument with a li fe-support syst em or any other equipment

subject to safety requirements.

Failure to use the instrument as directed by the manuf acturer may render its

protecti ve featur e s void.

Always clean the casing with a dry cloth. Do not clean t he internals.

Make sure the vent hole is always unblocked.

Environmental Conditions

The instrum ent is designed for indoor use and an area with low condensation. The

tabl e below shows the general environmental requirements for the instrument. The

speed of fan will change intelligently by the temperature of radiator. When the

temperature is up to 40°C, the fan will be on and adjust intelligently when

temperature ch ang es.

Copyright © ITECH Electronics Co., Ltd. ii

Page 5

IT6100 User’s Manual

Altitude

≤2,000m

Pollution degree

Pollution degree 2

Installation category

The CE mark is a registered

trademark of the European

the product complies with all the

relevant European Legal Direct ives.

The instrument complies with the

WEEE Directive (2002/96/EC)

product label indicates that you must

This symbol indicates the time period

during which no hazardous or toxic

substances are expected to leak or

deteriorate during normal use. The

t can be used

Friendly Use Period (EFUP). Upon

expiration of the EFUP, the product

must be immediately recycled.

(WEEE) Directive

This pr oduct compli es with the WEEE Directive (2002/96/EC)

household waste.

Product Cat egory

To return thi s unw ant ed i nstr u ment , co nt act y our ne ar est I T ECH

office.

Ⅱ

NOTE

To make accurate measurements, allow the instrument to warm up for 30 min before

operation.

Regulatory Markings

Community. This CE mark shows that

marking requirement. This affixed

not discard the electrical/electronic

product in domestic household w aste.

expected service life of the product is

10 years. The produc

safely during the 10-year Environment

Waste Electrical and Electronic Equipment (WEEE)

Directive

2002/96/E C Waste Electrical and Electronic Equipment

marking r equirement. Thi s affix product label indicates that you

must not discard the el ectrical/ electronic product in domestic

With ref erence to the equipment classif ications described in the

Annex I of the WEEE Directive, this instrument is classified as a

Copyright © ITECH Electronics Co., Ltd. iii

“Monitoring and Control Instrument” product.

Page 6

IT6100 User’s Manual

IEC 61326-1:2012/ EN 61326 -1:2013 ¹²³

Reference St andards

CISPR 11:2009+A1:2010/ EN 55011:2009+A1:2010 (Group 1, Class A)

IEC 61000-4-2:2008/ EN 61000-4-2:2009

IEC 61000-4-3:2006+A1:2007+A2:2010/ EN 61000-4-3:2006+A1:2008+A2:2010

IEC 61000-4-4:2004+A1:2010/ EN 61000-4-4:2004+A1:2010

IEC 61000-4-5:2005/ EN 61000-4-5:2006

IEC 61000-4-6:2008/ EN 61000-4-6:2009

IEC 61000-4-11:2004/ EN 61000-4-11:2004

Compliance Information

Complies with the essential requirements of the following applicable European

Directives, and carries the CE marking accordingly:

Electroma gnetic Compatibility (EMC) Directive 2014/30/EU

Low-Voltage Directive (Safety) 2014/35/EU

Conforms with the following product standards:

EMC Standard

1. The product is intended for use in non-residential/non-domestic environments. Use of the

product in residential/domestic environments may cause electromagnetic interference.

2. Connection of the instrument to a test object may produce radiations beyond the specified limit.

3. Use high-performance shielded interface cable to ensure conformity with the EMC standards

listed above.

Safety Standard

IEC 61010-1:2010/ EN 61010-1:2010

Copyright © ITECH Electronics Co., Ltd. iv

Page 7

IT6100 User’s Manual

Copyright © ITECH Electronics Co., Ltd. v

CONTENTS

Quality Certific ation and A ssura nce ................................................................................................................ i

Warranty ........................................................................................................................................................... i

Limitat ion of Warranty ..................................................................................................................................... i

Safety Symbol s ................................................................................................................................................. i

Safety Precautions ........................................................................................................................................... ii

Environmental Conditions .............................................................................................................................. ii

Regulatory Markings ...................................................................................................................................... iii

Waste Electrical and Electronic Equipment (WEEE) Directive .................................................................... iii

Compl i ance Information ................................................................................................................................ iv

Chapter1 Ins talling the Instrume nt .............................................................................................................. 1

1.1 Verify i ng the Shi pment.............................................................................................................................. 1

1.2 Instrument Size Introduction ..................................................................................................................... 1

1.3 Adjusting the Carrying Handle ................................................................................................................. 3

1.4 Ra cking Mo unt the Instrument ................................................................................................................. 3

1.5 Connecting the Power Cord ...................................................................................................................... 3

Chapter2 Quick Start ..................................................................................................................................... 5

2.1 Brief Intr o d uct io n ...................................................................................................................................... 5

2.2 Fro nt Panel Introduction ........................................................................................................................... 5

2.3 Keyboard Introduction .............................................................................................................................. 7

2.4 Re ar Panel Introduction ............................................................................................................................. 8

2.5 Power -on Sel ftest ...................................................................................................................................... 9

2.6 Output Checkout ..................................................................................................................................... 11

Chapter3 Functions a nd Characteristics .................................................................................................. 13

3.1 Front-panel Operation Overview ............................................................................................................ 13

3.2 Setti ng Vol t age ......................................................................................................................................... 13

3.3 Setting Current ........................................................................................................................................ 14

3.4 Saving and Recalling Operation ............................................................................................................. 14

3.5 Menu Operation ....................................................................................................................................... 15

3.6 Over Voltage Protection Function ........................................................................................................... 22

3.6 Out put Operation ..................................................................................................................................... 23

3.7 Remote Sense .......................................................................................................................................... 23

3.8 Mill io hm Met er ....................................................................................................................................... 24

3.9 Voltag e M et er .......................................................................................................................................... 24

Chapter4 Technical Specification .............................................................................................................. 26

4.1 Specifications .......................................................................................................................................... 26

4.2 Supplemental Characteristics .................................................................................................................. 27

Chapter5 Remote Oper ation Mode ........................................................................................................... 29

5.1 Communication Cable ............................................................................................................................. 29

5.2 Communication betwe e n Pow e r Su p pl y and Com pu t er ......................................................................... 30

Appendix ............................................................................................................................................................... 31

Specifi c at io n s of Re d and Bl a ck Test Lines .................................................................................................. 31

Page 8

Installing the Instrument

The IT6100 series include:

IT6151/IT6152/IT6153/IT6154

User may select an appropr iate

Cord for details.

x1

It contains IT6100 power supply

documentations.

Ex-factory Test

Report

It is the test report of the

instrument before delivery.

Model IT6120 Series

Chapter1 Installing the Instrument

1.1 Verifying the Shipment

Unpack the box and check the contents before operating the instrument. If wrong

items have been delivered, if items are missing, or if there is a defect with the

appearance of the items, contact the dealer from which you purchased the

instrume nt immediat ely. The package contents include:

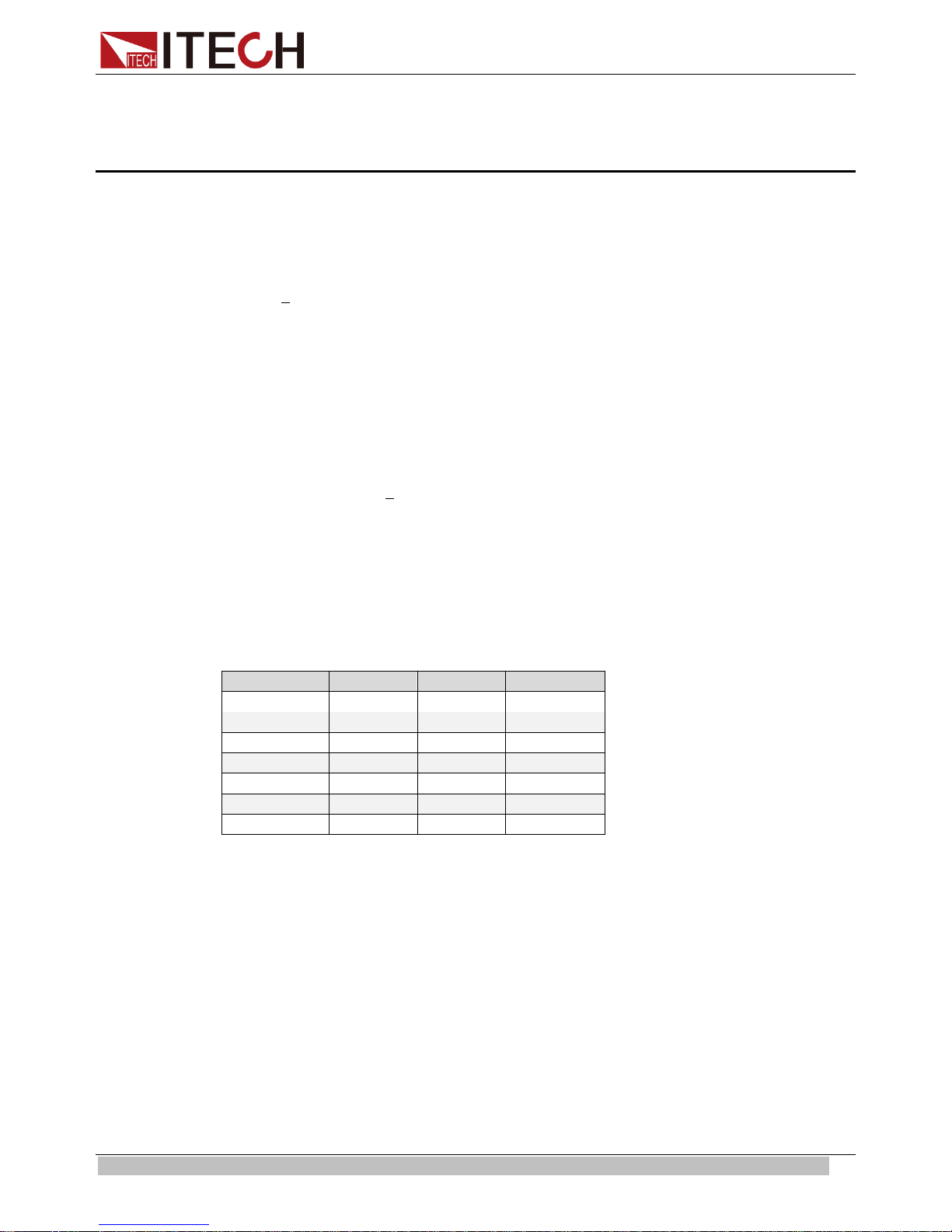

Checklist of Package Contents

Item Qty. Model Remarks

IT6100 power

supply

Power cord

USB cable

CD x1 -

Note

Upon verification of the shipment, keep the package and relevant contents thereof in a safe

place. When returning the instrument for warranty service or repair, the specified packing

requirements shall be met. Refer to IT6100 User’s Manual for detailed requirements on

returns.

x1 IT6100 series

IT-E171/IT-E172

x1

x1 -

/IT-E173/IT-E17

4

- -

IT6121/IT6122/IT6123/

power cord that matc hes the

specifications of power socket

used in the area. See the

Section Connecting the Power

User’s Manual, Programming

Guide and other user

IT6100 series power supply has the following optional accessory:

IT-E151:19 inch rac k m ount

IT-E121:RS232 communication cable

IT-E122:USB communi cation cable

IT-E135:GPIB connector

IT-E123:RS485 communication cable

1.2 Instrument Size Introduction

The instrument should be installed at well-ventilated and rational-sized space.

Please select appropriate space f or inst allation based on t he power supply size.

Copyright © ITECH Electronics Co., Ltd. 1

Page 9

Installing the Instrument

Detailed dimensional drawings

Model IT6150 Series

Detailed dimensional drawings

Overall dimensions

Width: 214.5 mm

Height: 88.2 mm

Depth: 354.6 mm

(Unit: mm)

Overall dimensions

Width: 429 mm

Height: 88.2 mm

Depth: 354.6 mm

Copyright © ITECH Electronics Co., Ltd. 2

Page 10

Installing the Instrument

1.3 Adjusting the Carrying Handle

To adjust the po si tion, grasp the handle by t he si des and pul l outw ar d. Then, r otat e

the handl e to the desired position.

Bench-top viewing positions Carrying position

1.4 Racking Mount the Instrument

You can mount the IT6120 and IT6150 series power supply in a standard 19-inch

rack cabinet. For details, please see the corresponding rack mounting installation

instruction.

1.5 Connecting the Power Cord

Before connecting the power cord, please ensure the power switch of the

instrument is turned OFF. Only use the power cord supplied as a standard

accessory. A summary of connection procedures is given below.

AC power input level

IT6120/IT6150 series power supply working voltage is 110V and 220V. Please pay

Copyright © ITECH Electronics Co., Ltd. 3

Page 11

Installing the Instrument

E

N L

E

L N

E

N L

E

L N

IT-E172

attention to the AC power input level as below.

AC power input level:

Option Opt .01: 220VAC ± 10%, 47 to 63 Hz

Option Opt .02: 110 VAC ± 10%, 47 to 63 Hz

Categories of power cords

IT6100 series power supply provides the standard power cords as bel ow.

Please selec t appropriate power cords appropriate to local voltage based on the

specifications of power cords below. If purchased model fails to meet local voltage

requireme nts, please conta ct distri butor or factor y for change.

China

IT-E171

America,

Canada,Japan

Europe

IT-E173

Britain

IT-E174

Copyright © ITECH Electronics Co., Ltd. 4

Page 12

Quick Start

Model

Voltage

Current

Power

IT6121

20V

5A

100W

IT6122

32V

3A

96W

IT6123

72V

1.2A

86W

IT6151

5.2V

60A

312W

IT6152

20V

27A

540W

IT6153

30V

18A

540W

IT6154

60V

9A

540W

2.1 Brief Introduction

IT6100 Series power supplies are high resolution and high speed programmable

DC power supplies. This series have very small size of 2U, and they are equipped

1

with 5

invest extra money to purchase digital meter. This series offer flexible solution to

general laboratory and workshop requirement.

VFD displ ay

Liner programmable power supply with low ripple and noise

Very high accuracy and resolution of 0.1mV/0.1mA

High rise speed<30mS

Equipped with 5

2

digital voltage meter and mΩ meter. That means you don’t need to

1

2

digital voltage meter and mΩ meter

Chapter2 Quick Start

Small size can be installed in standard 19’’ rack or bench top

Remote contr ol via USB/RS232/GPIB

Limit voltage protection

Over curre nt/temperature protection

Free sof tware for control the machine on computer

2.2 Front Panel Introduction

IT6120 Series’ Front Panel as shown below.

Copyright © ITECH Electronics Co., Ltd. 5

Page 13

Quick Start

1

2

3

4

5

6

7

8

6

7

2

1

534

1

2

3

Fig 1.1 IT6120 series’ front panel

VFD display

Rotary knob

Power switch

Numeric keys and ESC key

Function keys

Up , down key and ENTER key

Output termi nals

IT6150 Series’ Front Panel as shown below.

Fig 1.2 IT6150 series’ front panel

VFD display

Rotary knob

Power switch

Copyright © ITECH Electronics Co., Ltd. 6

Page 14

Quick Start

4

5

6

7

8

keys

Name and functions

Power

Power on the instrument.

0~9

Numeric button

Dot mark.

V-setV-set

Set the voltage val ue

I-setI-set

Set the current value

Save

Save the curr entl y data of the power supply to inter nal register

Recall

Recall the data from the internal register

On/Off

Set the output state of power supply

Shift

Use it with multiple key

Up key. Select menu items or increase output voltage in menu

operation.

Down key. Select menu items or decrease output voltage in

menu operati on.

Enter

Shift

Shift

key to realize menu

n and set the corresponding parameters

of power supply.

Shift

Set LIST operation parameters.

Numeric keys and ESC key

Function keys

Up, down key and ENTER key

Input terminals

Output termi nals

2.3 Keyboard Introduction

Detailed descri ption of keys:

Esc key. Exit under any conditions.

Enter key.

Combination keys. Press

(Shift ) button first and then other keys to achieve all

kinds functions in the following table.

+ ( Menu)

Combine with

operatio

+ ( List)

Copyright © ITECH Electronics Co., Ltd. 7

Page 15

Quick Start

Shift

+ ( Trigger)

Cause an immediate tr igger.

Shift

Shift

+ (0.1W)

Shift

+ (1W)

Shift

+ (10W)

Shift

+ ( Local)

Local key. Remote mode switch to local mode.

+ ( V/mΩ)

Voltmeter/Milliohm meter

Milliohm meter 0.1W range.

Milliohm meter 1W range.

Milliohm meter 10W range.

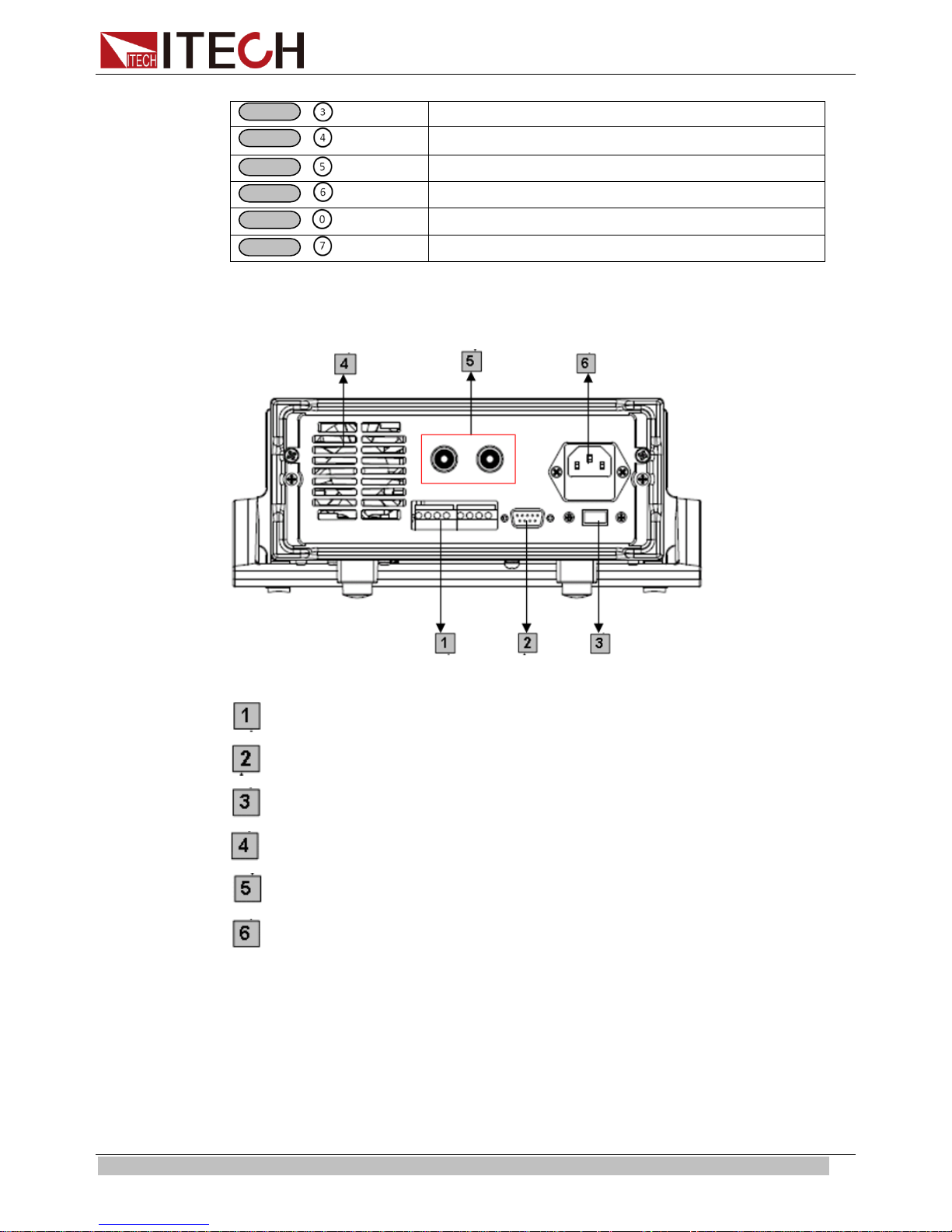

2.4 Rear Panel Introduction

IT6120 Series’ Rear Panel as shown below.

8-Pin Trigger and Remote sensing connector s

9-Pin COM port interface connector

Power switch (110V / 220V)

Cooling window

Voltage measurement terminals

Power socket

IT6150 Series’ Rear Panel as shown below.

Copyright © ITECH Electronics Co., Ltd. 8

Page 16

Quick Start

1

2

3

4

5

0.000V 3.000V

9-Pin COM port interface connector

4-Pin Trigger and Remote sensing connectors

Power socket

Power switch (110V / 220V)

Cooling window

2.5 Power-on Selftest

A successful selftest indicates that the purchased power product meets delivery

standar ds and is avai lable for normal usage.

Before operation, please confirm that you have fully understood the safety

instructions.

To avoid burni ng out, be sure to confirm that power voltage matches with

supply voltage.

Be sure to con nect the main power socket to the power outlet of pr otective

groundi ng. Do not use terminal boar d w ithout protective grounding. Before

operation, be sure that the power supply is well grounded.

To avoid burni ng out, pay at tention to marks of positive and negative polarities

before wiring.

Selftest steps

Normal selftest procedures:

1. Correctly connect the power cor d. Press Power key to start up.

After selftest, VFD display the output voltage and current st atus as below:

2.

0.000V 0.00000A OFF

Copyright © ITECH Electronics Co., Ltd. 9

Page 17

Quick Start

Model

Fuse Sepcification

(110VAC)

Fuse Sepcification

(220VAC)

IT6121

T2.5A 250V

T1.25A 250V

IT6122

T2.5A 250V

T1.25A 250V

IT6123

T2.5A 250V

T1.25A 250V

IT6151

T10A 250V

T5A 250V

IT6152

T10A 250V

T5A 250V

IT6153

T10A 250V

T5A 250V

IT6154

T10A 250V

T5A 250V

Error Information References

The following error information may occur when an error occurs during Power On

self-test:

If the EEPROM was damaged, the V FD will display “EEPROM Error”.

If the last est operation data in EEPROM is lost, then VFD will display “Error

Config Data”.

If the calibration data in EEPROM is lost, then VFD will display “Error

Calibration Data”.

If the fact ory calibration data in EEPROM is lost, and then the VFD will display

“Error Factory Cal.Data”.

Exception handling

If the power supply cannot start normally, please check and take measures by

reference to steps below.

1. Check whether the power cord is correctly connected and confirm whether the

power supply is powered.

Correct wiring of pow er cord => 2

Incorrect wiring of power cord => Re-connect the power cord and check

whether t he excepti on is removed.

2. Check whether the power in On. Power key is under “

” On stat us.

Yes => 3

No => Please check the Power key to start power and check whether the

exception is removed.

3. Check whether the fuse of power supply is bur ned out.

If yes, change fuse. Detailed steps:

1. Use a screwdriver to push and turn the fuse box on the rear panel of the

power supply, refer to the below picture.

Fuse speci fication list

Copyright © ITECH Electronics Co., Ltd. 10

Page 18

Quick Start

On/Off

Out on/off

2. After the fuse box is opened, you can see the fuse in it. Please replace

with a fuse of the same specification..

2.6 Output Checkout

The following procedur es check to ensure that the power supply de velops its rat ed

outputs and properly responds to op eration from the front panel.

2.6.1 Voltage Output Checkout

The following steps verify basic voltage functions without load.

1. Turn on t he power supply.

2. Enable t he outputs

Press key to let the CV announciator turn on to li ght.

3. Set the voltage value

Set some different voltage values, then wait till the Meter mode to check if the

VFD displ ayed voltage value is the s a me as t he set vol t age value, and to check if

the VFD displayed current value is nearly zero.

4. Ensure t hat the voltage can be adjust ed from zero t o the full r ated value.

2.6.2 Current Output Checkout

The following steps check basic current functions with a short across the power

supply ’s output.

1. Turn on t he power supply.

2. Disable the output

Press

3. Connect a short across (+) and (-) output terminals with an insulated test lead.

Use a wire size sufficient to handle the maximum current.

4. Enable t he output

5. Adj ust the vol tage value to 1.0 volt

Adjust the voltage to 1.0 volt to ens ur e t he p ow er supply is in CC operati on mode.

The CC announciator will turn on.

6. Adjust the current value

Set some different voltage values, then wait till the Meter mode to check if the

VFD displ ayed curr ent val ue i s the sa me as t he s et vol t age value, and to c he ck i f

the VFD displayed voltage value is nearly zero

Copyright © ITECH Electronics Co., Ltd. 11

key to ensur e that the output is disabled.

Page 19

Quick Start

7. Ensure t hat the current can be adjusted from zero to the full rated value

8. Turn off the power suppl y and remove the short wire from the output terminals

Copyright © ITECH Electronics Co., Ltd. 12

Page 20

Functions an d Characteristics

On/Off

Chapter3 Functions and Char ac t er istics

This chapter elaborates on the functions and characteristics of IT6100 series

power supply. Contents following sections:

Front-Panel Operation Overview

Setting Voltage

Setting Current

Saving and Recalling Operation

Menu Operation

Output Operation

Remote Sense

Milliohm Meter

Voltage Meter

3.1 Front-panel Operation Overview

The following section describes an overview of the front-panel keys before

operating your power supply.

1. The power supply is shipped from the factory configured in the front-panel

operation mode. At power-on, the power supply is automatically set to operate in

the front-panel operation mode. When in this mode, the front panel keys can be

used.

2. When the power supply is in remote operation mode, you cannot use the

front-panel. A change between front-panel and remote operation modes will not

result in any change in the output parameters. You can change the front-panel and

remote operation modes by computer.

3. The output of the power supply can be enabled or disabled from the front panel

by pressing

4. The VFD display shows the present operating status of the power supply with

announciators. Turn on the power supply, VFD displays two lines data. The first

line show s the act ual out put vol tage value, current value an d t he st at e of t he pow er

supply. The second line shows the voltage value tested by the voltage meter and

the output value of the pow er supply.

key.

3.2 Setting Voltage

The constant voltage range is from 0V to the maximum voltage value of each

model. It is very easy for you to set the constant voltage output. You have 2

solutions to set the constant voltage value.

Solution1:

Step1: Power on the IT6100 series instrument.

Step2: Press the ▲ and ▼ keys to c hange the value.

Solution2:

Step1: Power on the IT6100 series instrument.

Copyright © ITECH Electronics Co., Ltd. 13

Page 21

Functions an d Characteristics

V-setV-set

Enter

V-setV-set

Enter

Save

Recall

Save

Enter

Recall

Enter

9

0

0

I-Set

Enter

9

I-Set

Enter

Step2: Press

.

St ep3: Use the nu meric keys to or ▲ and ▼ keys t o chang e the vol t age

value.

Step4: Press

to confirm.

Solution3:

Step1: Power on the IT6100 ser ies instrument.

Step2: Press

.

Step3: Use rotar y knob to adjust the voltage val ue.

Setp4: Pre ss

to confirm.

3.3 Setting Curr ent

The const ant cur rent o utput r ange is from 0A t o t he m aximum current val ue of ea ch

type. It is very easy for you to set the constant current output.

Solution1:

Step1: Power on the IT6100 series instrument.

Step2: Press key.

Step3: Use the numeric keys to or use ▲and ▼keys to change the

current value.

Step4: Press key to confirm the value.

Solution2:

Step1: Power on the IT6100 series instrument.

Step2: Press key.

Step3: Use rotary knob

to adjust the voltage value.

Step4: Press key to confirm the value.

3.4 Saving and Recal l ing Operation

You can use

50 different output states in storage register locations(1 to 50). If the fast recall

function is turned on, you can recall the saved settings by pressing numerical ke y

(0~9). You can store the followings: the maximum output voltage value, the

voltage setting value, the current setting value and the step value of voltage.

Saving Operation: You can use

and store t he parameter of IT6100 series int o the register.

Recalling Operation: You can use

and recal l the parameter stored before from the register.

or

or use the SCPI order *SAV、*RCL to store up to

and 0~50 numeric key, press

and 0~50 numer i c key, press

,

,

Copyright © ITECH Electronics Co., Ltd. 14

Page 22

Functions an d Characteristics

MENU

ESC

MENU

Config

Config Init.

Return to t he factory default setup value.

Out Recall

Setting Power-on state of power supply.

On

When users turn on the power supply; its setup value will

power

supply.

Off<Default>

Disable this funct ion.

PWR-ON Recall

Setting power-on parameter of power supply

On

When users turn on the power supply; its setup value will

power

supply.

Off<Default>

Disable this funct ion.

Key Sound Set

Keypad sound setting.

On<Default>

Enable key sound.

Off

Disable key sound

Knob Lock Set

Setup Rotary knob lock state .

On

Lock Rotary knob.

Off< Default >

Unlock Rotary knob.

Remote Sense

Setup voltage measurement Mode.

On

The electronic load will measure input voltage fr om t he

remote sense connector.

Off< Default >

The power supply will measure input value from the

front panel connector.

ShortCut Recall

Quickly recall t he data stored before

On

Enable this function

Off<Default>

Disable this funct ion

OVP Set

Setting over voltage protection

On

Enable this function

Off< Default >

Disable this funct ion

Meter Rate Set

Setting the speed of power supply

High

High speed

Low< Default >

Low speed

Baudrate set

Setting baud rate

Baudrate 4800 <

Default >

Baudrate 9600

Baudrate 19200

Baudrate 38400

Comm. Parity

Communication parity bit set.

None< Default >

ENTER

3.5 Menu Operation

Menu Description

Press

to indicate operation mode. View the menu in VFD, and use ▲ and

▼to scroll through the com plete menu list as following. If press , you could

get the selected menu function. Press

back to the previous menu selection

page.

keep the state of last time as use r s t ur ned off the

keep the state of last time as use r s t ur ned off the

Copyright © ITECH Electronics Co., Ltd. 15

Page 23

Functions an d Characteristics

Even

Odd

Address Set

Setting communication address(range from 0to 254)

Address=**

Port Mode

Select function of port

Trigger< Def >

RI/DIF

DIGITAL I/O

Trig Source

Setting trigger mode

Immediat<Def>

Shift

+

Trigger

External

Trigger signals from the TRIG connector in the rear

panel.

Bus

Communication command trigger mode.

RI Mode

Control the output mode

Off< Default >

Disable this funct ion

Latching

Live

DFI Source

Discrete Fault Indic ator

Off< Default >

QUES

Question Bit

OPER

Operation Bit

ESB

Event State Bit

RQS

Require Bit

Key Lock Set

Setting keypad password.

Press

ENTER

directly to disable the key lock function.

Exit

System Set

Max Volt. set

Setup the Maximum Voltage.

Step Volt Set

Set voltage step

Exit

List Set

Call ListFile

Recall list oper ation file.

Edit ListFile

Edit list operation file.

Continuous

Once

Repeat

Step

Once

Repeat

Save Mode Set

Users can choose 4 k inds of memory space to sav e the list

file.

8 X 25 Steps

4 X 50 Steps

2 X 100 Steps

Password= ﹡﹡﹡﹡

Max= ﹡﹡﹡﹡

Trigger signals from

key

Step=﹡﹡﹡﹡

Copyright © ITECH Electronics Co., Ltd. 16

Page 24

Functions an d Characteristics

1 X200 Steps

Exit

Out On

Timer

Output timer,i f you st art thi s func tion, t he pow er sup ply wil l tur n off after the

time you set.

Timer State

Setting POWER ON timer state

On

When users choose the timer state ON, and then tur n

ON TIMER

ON TIMER is

put will

turn off automatically.

Off< Default >

Timer Set

Setting time of POWER ON timer.

Exit

Exit

Shift

Esc

Esc

Shift

MENU

ENTER

ENTER

ENTER

ESC

V-setV-set

I-setI-set

ENTER

Save

0

0

9

9

on the power supply’s outp ut, the POWER

will start working, and when the POWER

reach the setup time, the power supply’s out

Timer= ﹡﹡S

Note:

Press

operations, press

Output Recall

This function can help you set the output state when the power supply is powered

on. If you select On, the power supply will keep the st ate of last time as it is turned

off. If you select Off, this function is disabled. D efault is On.

Key Sound

This inst r ucti on can sw i tch on/ of f the buz z ing so un d w hen y ou pre ss a ny key, if you

select On, the buzzer will sound when any k ey was pressed. If you select Off, the

buzzer wi ll not sound whe n the keys wer e pressed. Default is On.

ShortCut Recall

This f unction can help you recall the data stored before.

Option:

1. Press

2. Press▲ and ▼to select ShortCut Recall, press

press

+1(Menu) to enter menu operation, then press

key to exit the current operation state.

+

into menu operation, VFD displays Config,

to confirm.

to exit. During any function

to confirm.

3. Press▲ and ▼to select On, press

4. Press

5. Press

press

6. Press

Copyright © ITECH Electronics Co., Ltd. 17

two times to escape menu operation.

or

, select to to set volt age value or current value,

to confirm.

, VFD displays Store 1, select to to set the register

to confirm.

Page 25

Functions an d Characteristics

ENTER

Shift

MENU

ENTER

ENTER

ESC

1

Trigger in

Inhibit Input

Digital I npu t

2

GND

GND

GND

3

No Use

Fault Out put

Digital Output

4

No Use

GND

GND

0

9

number(range from 1 to 50), press

to confirm.

7. You can recall the data stored before by pressing the register number.

Setting Communica t ion Baud Rate (>BAUDRATE)

This function can help you set communication baud rate. There are 4 kinds of

baud rate, 4800HZ, 9600HZ, 19200HZ and 38400HZ. Make sure that power ’s

baud rate i s as t he sa me as y our co mput e r bef ore co mm uni cation. Default baud

rate is 4800 HZ.

Setting Commun ication Parity Bit (>Comm.Parity)

This function can set communication parity bit. There are three kinds of

communication parity bit, None, Even and Odd. Make sure that the communi cation

parity bit set to None during remote communication operation. Default

communication parity bit is None.

Setting A ddress (>ADDRESS)

This instruction can set the communication address for each power supply. The

address ran ge i s from 0 to 30. Before t he co mm uni cation, you must make sure that

there is same address between the power supply and the computer. Default

address is 0.

Option:

1. Press

press

2. VFD displays Address= **, select to and set address,

press

3. Press

Setting Port Mode

The level of the port on the rear panel is TTL, and the port has 3 kinds of function

as follows:

TRIGGER: pin1 and pin 2 can be used as the external trigger source for power

supply, and can control the list operation.

RI/DFI: Inhibit Input can control the output state of power supply, Fault Output can

find fault of power supply.

DIG ITAL I/O: It can read and control output and input state.

Pin

+

into menu operation, VFD displays Config,

to confirm.

to confirm.

two times to escape menu operation.

mode

Trigger RI/DFI DIG ITAL I/O

Copyright © ITECH Electronics Co., Ltd. 18

Page 26

Functions an d Characteristics

Shift

Trigger

Shift

Setting Trigger Operation (Shift+Trigger)

The power supply has 3 kinds of trigger mode. You m ust choose trigger source

before trigger operating.

Trigger Key: If this function is enabled, press

will start trigger operation once.

External trigger signal (TTL): There is a trigger input port on the rear panel.

When this function is enabled, please give this trigger input port a pulse about 5

mS, and the power suppl y will start trigger operation once.

Bus: When this function is enabled, and the power supply receives order*TRG or

TRIgger, t he power supply will st art trigger operation once.

Setting Remote Inhibit

RI input has 3 modes: LATCHING, L IVE, OFF

LATCHING: When the level of RI port changes from high to low, the output of

power supply is off.

LIVE: The output state of power supply changes along with the level of RI p ort. If

the level of RI is high, the output is on; and the level of RI is low, the output of

power supply is off.

OFF: The level state of RI do not affect the output st ate of power supply.

Setting Discrete Fault Indicator

DFI source contains QUES、OPER 、ESB、RQS、OFF.

+

, the power supply

QUES: The output lev el of DFI changes along with the state of QUES bit. When

QUES bit is 1, DFI output s low level. When QUES bit is 0, DFI outputs high level.

OPER: The out put level of DFI changes along with the stat e of OPER bit.

ESB: The output level of DFI changes along with the state of ESB bit.

RQS: The output level of DFI changes along with the state of RQ S bit.

OFF: The output level of DFI remains high.

Setting KEY LOCK

This instruction can set a password (1 through 4 digits) to lock the function keys

operation. After setting the p assw or d, al l the funct i on key s on th e f r ont p anel wil l be

locked except the OUT on/off key. You must enter the correct password to unlock

them, then you can continue to do the function key operation. If you don’t want to

lock the function keys, please don’t press any number key when you enter

the >KEY LOCK instruction, just press ENTER key to unlock it.

Note: When shipped from factory, there is no password and function keys are unlocked. The

start bit of your desired password shouldn’t be 0.

Setting Maximum Output Voltage (>Max Volt. Set)

The range of maximum voltage value is from 0V to full rated output voltage, the

steps ar e as follows:

1. Press

Copyright © ITECH Electronics Co., Ltd. 19

+1(Menu) to enter menu function. VFD displays >Config,

Page 27

Functions an d Characteristics

ENTER

ENTER

0

ENTER

Esc

Shift

Menu

Enter

Enter

Enter

Shift

Menu

Enter

Enter

Enter

Enter

Enter

Enter

Enter

List Set

Press and to select>System Set, then press

2. Press

3. VFD displays Max=73.000V, select

press

4. Press

and to select>Max Volt. Set, then press

-9 to set maximum voltage value,

to confirm.

twice ti me to exit menu oper ation. Default value of M ax Volt. Set is

to confirm.

to confirm.

full rat ed output voltage.

Before you e dit the list file, please set trigger source as “immediate” in the menu.

Action:

1. Press

2. Press up or down key to sel ect “Config”, press

3. Press up or down k ey to select “Trig Source”, press

4. Press up or down key to sel ect “Immediat”, press

+

into the me nu.

to confirm.

to confirm.

to confirm.

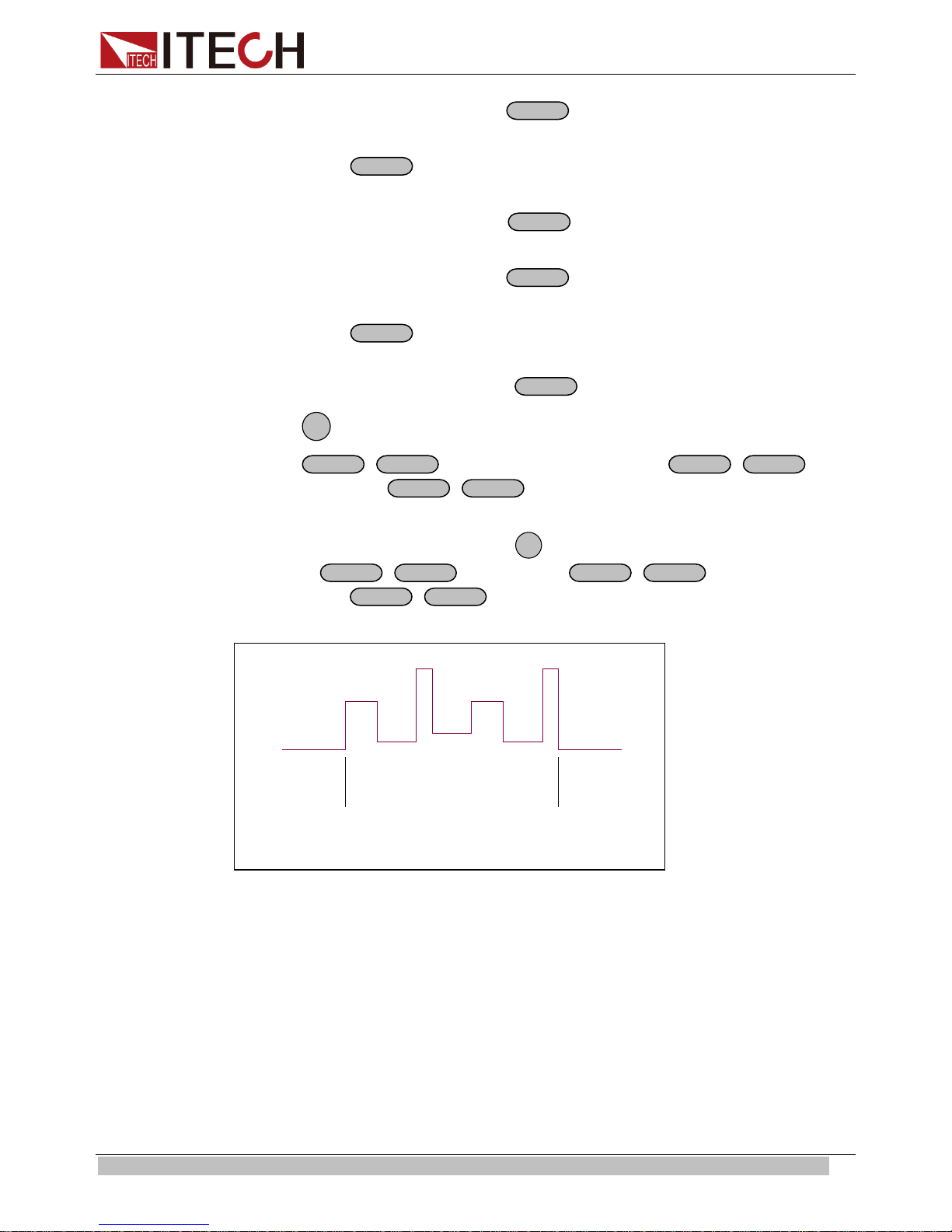

You can make the input change order by editing every step value of list operation.

The parameter of list operation includes the name of list file, input step (no more

than 400 step s), step time (the minimum is 1mS) and every step value. The list file

can be stored in ROM whose capacity is 4K, and it can be fast recalled. This store

area is di vi ded i nto A, B, C and D f our ar e as. I n area A, there is onl y 1 gr oup w hose

capacity is 4Kb. In ar ea B, there are 2 groups and each group’ s capacity is 2Kb. In

area C, there 4 groups and each group’s capacity is 1Kb. In area D, there are 8

groups and each group’s capacity is 512b.

If the li st operation mode i s CONTINIOUS, when you receiving a tr igger signal, the

power supply will star t lis t operation until the list operation is over or a trigger is

received a gain.

Operation:

1. Press

2. VFD displays Config, press ▼to select List Set, press

3. VFD displays Call ListFile , press ▼to select Edit ListF ile, press

+

into menu operation.

to confirm.

to

confirm.

4. VFD displays Continuous, press

5. VFD displays Once, press ▼to select Repeat, press

to confirm.

to confirm,

select circle operation.

6. VFD displays Second, press ▼to select MilliSecond, press

to confirm,

select time unit.

7. VFD displays List Count= _, press numeric key or move the rotary knob, set

circle times ( in this example, count is 2),press

to confirm.

8. VFD displays1th=*.****V, press numeric key or move the rotary knob,

set the maximum vol t age, press

to confirm.

9. VFD displays 1th=*.****A, press numeric key or move the rotary knob,

Copyright © ITECH Electronics Co., Ltd. 20

Page 28

Functions and Characteristics

Enter

Enter

Enter

Enter

Enter

Enter

Esc

Shift

List

Shift

Trigger

Shift

List

Esc

Shift

List

Shift

Trigger

Shift

List

Trigger

Trigger

set the maximum current, press

to confirm.

10. VFD displays 1th=*mS, press numeric key or move the rotary knob, set delay

time, press

to confirm.

11. VFD displays 2th=*.****V, press numeric key or move the rotary knob,

set the maximum vol t age, press

to confirm.

12. VFD displays 2th=*.****A, press numeric key or move the rotary knob,

set the maximum current, press

to confirm.

13. VFD displays 2th=*mS, press numeric key or move the rotary knob, set delay

time, press

to confirm.

14. VFD display Store File_, press numeric key or move the rotary knob, set the

register number(1 to 8), pr ess

15. Press

16. Press

two times to escape menu o peration.

+

to set the list file, then press

the list file. Press

+

to stop.

to confirm.

+

to run

If you have edited several list files, you can call the list file that you need by “Call

ListFile” function in the menu. Press

then press

you call. Press

+

to set it, press

+

to stop running.

two times to exit menu operation. And

+

to run the file that

When the list operation mode is STEP, the power supply will go to the next step

when receive a trigger signal.

Copyright © ITECH Electronics Co., Ltd. 21

Page 29

Functions an d Characteristics

Trigger

Trigger

Trigger

Trigger

Trigger

Trigger

Trigger Trigger

Shift

Enter

Enter

Enter

Esc

Shift

Enter

Enter

0

Enter

Esc

Setting Output Timer Function (>Out On Timer)

The loading time of IT6100 power supply can be set. When the timer state is ON,

the power supply output opens and starts with load. When the loading time

reaches the set time, the output will be turned off automatically. W hen the timer

state is OFF, the timer function will be disabled. Default value is OFF.

The detai led operations are as fol lows:

Set timer state:

Digital I/O

1. Press

press

2. Press

and to select>Out On Tim er, then press

and to select>Timer State, then press

3. VFD displays Off<Default> (or On), press

press

4. Press

+1(Menu) to enter menu function, VFD displays>Config,

to confirm.

to confirm.

and to select On or Off, then

to confirm.

twice time to exit the operation.

Set the time of output timer:

1. Press

press

2. Press

and to select>Out On Tim er, then press

and to select>Timer Set, then press

3. VFD displays Timer=20S, press

+1(Menu) to enter menu function, VFD displays>Config,

to confirm.

to confirm.

-9 to set time, then press

to

confirm.

4. Press

twice time to exit the operation.

When the digital port of the power supply mode is DIGITALI/O and power supply is

under remote sense, you could send SCPI order (DIGital:INPut[:STATe?] and

DIGital:OUTPut[:STATe?]) to read and set the state of out put and input port.

3.6 Over Voltage Protection Function

When the output voltage exceeds the constant voltage by 5%, or the connection is

unsuccessful under remote sense mode, the power supply will protect itself

automatically. The power supply must be turned on again. When the power is in

overvoltage protection, the output is off, and buzzer is mooing. VFD displays Over

Voltage.

Copyright © ITECH Electronics Co., Ltd. 22

Page 30

Functions an d Characteristics

On/Off

+S

-

S

+

-

INH GND FLT GND

Over Voltage

When the power supply with other power supply is in paralle l connection, please

disable this functi on.

3.6 Output Operat ion

If you control the power supply by front panel, you can press

the state of output. If power supply is under remote sense, you can send SCPI

order (OUTPut ON|OFF) t o change the state of output.

3.7 Remote Sense

The wire connected the power supply and electronic load will produce voltage

difference when the current of the power supply is so big. In order to make the

measurem ent accuracy mu ch accurate, there are 4 pin trigger and remote s ensing

connectors on the rear panel and you can use it to measure the output voltage of

the tested instrument. You must set remote sense mode before you start remote

test function.

IT6120 8 pin connector in rear panel

+,-: Output port, they are as the same as the output in front panel

+S,-S: Sense port

INH: this port hat multi ple function

and switch

When “Port Mode” in the me nu is set with “Trigger”, INH is trigger por t.

When “Port Mode” in the menu is set with “RI/DIF”, INH can set the output status

on/off. Here INH port has 3 worki ng mo de to choose.

LATCHING: W hen the level of INH port changes from high to low, the output of

power supply is off.

LIVE: The output state of power supply changes along with the level of INH port. If

the level of INH is 1, the output is on; and the level of INH is 0, the output of power

supply is off.

OFF: The level state of INH do not affect the output state of power supply.

When “Port Mode” in the menu is set with “DIGITAL I/O”, INH port becomes the

digital input por t to read input status by communication order.

FLT: This port hat multiple function

When “Port Mode” in the me nu is set with “Trigger”, FLT is an invalid port.

When “Port Mode” in the me nu is set with “RI/DIF”, FLT port can fi nd fault of power

supply.

FLT source contains QUES, OPER, ESB, RQS, OFF.

QUES: The output lev el of FLT changes along with the state of QUES bit. When

Copyright © ITECH Electronics Co., Ltd. 23

Page 31

Functions an d Characteristics

TRIN

-

+

GND

+

-

+

OUTPUT

-

5 ½ DVM

R

+

-

+

OUTPUT

-

5 ½ DVM

R

+

-

+

OUTPUT

-

5 ½ DVM

R

Shift

Shift

Shift

QUES bit is 1, FLT outputs low level. When QUES bit is 0, FLT outputs high level .

OPER: The out put level of FLT changes along with the state of OPER bit.

ESB: The out put level of FLT changes along with the stat e of ESB bit.

RQS: The output level of FLT changes along with the stat e of RQS bit.

OFF: The output level of FLT remains high.

When “Port M ode” i n menu is set with “DIGITAL I/O”, FLT port become s outp ut port

to control the output status by com m unication order.

IT6150 4 pin connector in rear panel

GND, TRIN: Tri gger port

-, +: Remote sense port

3.8 Milliohm Meter

SOURCE METER can measure resistant value accurately and the biggest

resistance it can measure is 1kΩ. In order to protect the resistor, please select the

power range of the resis tor bef ore you measure it. Wiring diagram as follows:

There are 3 r anges to be chosen: 0.1W、1W、10W.

The accuracy of the measurement is <1%, the higher range you select, the more

accurate result you can g et.

Option:

1. Press

m:

**, you can measure resistance value.

2. Press

3.9 Voltage Meter

Copyright © ITECH Electronics Co., Ltd. 24

Wiring diagram as follows:

+V/mΩ(if VFD displays**.**V, press

+0.1W /1W /10W, you can s et different range of milliohm meter.

+V/mΩ), set

Page 32

Functions and Characteristics

+

-

5 ½ DVM

待测物待测物

+

-

5 ½ DVM

待测物

Load

Shift

Ω

Shift

Press

press

voltage val ue.

The accuracy is <0.1%.

+V/m

+V/mΩ), VFD displays**.**V, you can begin to test the

( if VFD displays Range: **,please

Copyright © ITECH Electronics Co., Ltd. 25

Page 33

Technical Specification

Parameter

IT6121

IT6122

IT6123

( 0 °C~40 °C)

Voltage

0 ~20V

0 ~32V

0~72V

Current

0~5A

0~3A

0~1.2A

LVP

0 ~21V

0 ~33V

0 ~73V

±(%of output+offset)

Voltage

Current

≤0.05%+1mA

≤0.05%+0.3mA

±

Voltage

≤0.01%+1mV

≤0.01%+2mV

≤0.05%+0.05m

A

Voltage

0.5mV

2mV

Current

0.1mA

0.02mA

Voltage

0.1mV

0.5mV

Current

0.05mA

0.01mA

0.01mA

Setup

±(%of output+offset)

Readback a ccuracy

±(%of output+offset)

Temperature coefficient,

±(%of output+offset)

Readback temperature,

±(%of output+offset)

Parameter

IT6151

IT6152

IT6153

IT6154

Voltage

<0.05%+20mV<0.05%+15mV

Chapter4 Technical Specification

4.1 Specifications

IT6120 Series DC Power Supply

Output Ratings

Load Regulation

Line Regulation

(%of output+offset)

Setup resolution

Readback resolution

accuracy, 12months,

(25 °C ± 5 °C)

12months,

(25 °C ± 5 °C)

Ripple

(20Hz ~20MHz)

(0 °C~40 °C)

≤0.01%+2mV ≤0.01%+2mV

Current

Voltage

Current

Voltage

Current

Voltage

Current

Voltage

Current

≤0.05%+0.1mA

≤0.03%+3mV ≤0.03%+6mV

≤0.05%+2mA ≤0.05%+1mA

≤0.02%+3mV ≤0.02%+5mV

≤0.05%+2mA ≤0.05%+1mA

≤3mVp-p ≤4mVp-p ≤5mVp-p

≤3mArms ≤3mArms ≤3mArms

≤0.02%+3mV ≤0.02%+5mV

≤0.05%+2mA ≤0.05%+0.5mA

coefficient,

Dimension(mm)

Weight

IT6150 Series High Re solution Power Supply

Output Ratings

( 0 °C~40 °C)

The model of

remote

sense±(%ofoutput

Copyright © ITECH Electronics Co., Ltd. 26

Current

LVP

Voltage

Current

Voltage

Current

0~5.2V 0~20V 0~30V 0~60V

0~60A 0~27A 0~18A 0~9A

0~5.5V 0~21V 0~31V 0~61V

<0.05%+30mV

<0.1%+10mA <0.1%+5mA <0.1%+2mA

≤0.02%+3mV ≤0.02%+5mV

≤0.05%+2mA ≤0.05%+0.5mA

214.5mmW×88.2mmH×354.6mmD

8 kg

<0.05%+10mV

Page 34

Technical Specification

+offset)

Line Regulation

output+offset)

resolution

Voltage

0.1mV

0.5mV

0.5mV

Current

1mA

1mA

1mA

Readback

resolution

Voltage

0.1mV

0.1mV

0.5mV

Current

1mA

0.1mA

0.1mA

Setup

+offset)

Readback

output+offset)

Ripple

(20Hz~20MHz)

Voltage

≤4mVp-p

≤4mVp-p

≤5mVp-p

Current

<15mArms

<5mArms

<3mArms

Temperature

output+offset)

Readback

output+offset)

Dimension(mm)

429mmW×88.2mmH×458.9mmD

IT6120 Series

IT6150 Series

±(%of

Setup

accuracy,12

months±(%of

output

accuracy

±(%of

Coefficient

( 0 °C~40 °C)

±(%of

Voltage

Current

Voltage

Current

Voltage

Current

Voltage

Current

<0.02%+1mV <0.02%+1mV <0.02%+2mV

<0.1%+1mA <0.01%+1mA <0.01%+0.1mA

0.02%+2mV <0.02%+6mV ≤0.02%+12mV

<0.1%+30mA <0.1%+15mA <0.05%+10mA

0.02%+1.5mV 0.02%+3mV 0.02%+6mV

<0.05%+15mA <0.05%+10mA <0.05%+5mA

<0.02%+2mV <0.02%+5mV <0.02%+10mV

<0.1%+30mA <0.1%+15mA <0.05%+5mA

temperature

coefficient±(%of

Weight

Voltage

Current

* The above specifications may be subject to change without prior notice.

<0.02%+2mV <0.02%+5mV <0.02%+10mV

<0.1%+30mA ≤0.05%+10mA ≤0.05%+5mA

29 kg

4.2 Supplemental Char acteristics

State Stor age Memory: Fifty (50) user-configurable stored states

Recomm ended Calibration Interval: Once a year

AC Input Ratings (selectable vi a sw itch on the rear panel):

Option Opt .01: 220VAC ± 10%, 47 to 63 Hz

Option Opt .02: 110 VAC ± 10%, 47 to 63 H

Maximum power:

300VA 1000VA

Cooling: Fan cooled

Operating Tem perat ure: 0 to 40 °C

Storage Temper atur e: -20 to 70 °C

Copyright © ITECH Electronics Co., Ltd. 27

Page 35

Technical Specification

Environmental Conditions

Designed for indoor use in an installation category II, pollution degree 2

environment. Designed to operate at maximum relative humidity of 95% and at

altitudes of up to 2000 meters.

Copyright © ITECH Electronics Co., Ltd. 28

Page 36

Remote Operation Mode

PC Load

IT-E131 communication cable

COMPUTER

INSTRUM ENT

RX

TX

IT-E131 ISOLATED

COMMUNICATION CABLE

TTL(5V)RS232 ISOL ATION

859666668889942311

IT

COMPUTER

INSTRUM ENT

RX

TX

IT-E131 ISOLATED

COMMUNICATION CABLE

TTL(5V)RS232 ISOL ATION

859666668889942311

IT

Power

supply

PC

PC Load

IT-E131 communication cable

COMPUTER

INSTRUM ENT

RX

TX

IT-E131 ISOLATED

COMMUNICATION CABLE

TTL(5V)RS 232 ISOLATION

859666668889942311

IT

COMPUTER

INSTRUM ENT

RX

TX

IT-E131 ISOLATED

COMMUNICATION CABLE

TTL(5V)RS 232 ISOLATION

859666668889942311

IT

Power

supply

PC

IT-E132 communication cable

Chapter5 Remote Operation Mode

The DB9 interface connector on the rear panel of the power supply can be

transferred to RS-232 interface, the following information will tell you how to use

the computer to control the output of t he power supply.

5.1 Communication Cable

IT-E131 RS232 Communicat ion Cable

The DB9 int erf ace connector on the rear p anel of pow er supply is TTL voltage level;

you can use the communication cable (IT-E131) to connect the DB9 interface

connector of the power supply and the RS-232 interface connector of computer for

the communication.

Computer side TTL→RS232 Cable (IT -E131) PS side

IT-E132 USB Communication Cable

The DB9 interface connector on the r ear panel of power suppl y i s TTL volt age l evel;

you can use the communication cable (IT-E132) to connect the DB9 interface

connector of t he p ow er sup pl y and t he US B i nt erf ace co nnect or of c o mput er f or t he

communication.

IT-E135 GPIB Communication Cable

The DB9 int erf ace connector on the rear p anel of pow er supply is TTL voltage level;

you can use t h e GPIB communication cable ( IT-E135) to connect the D B9 interface

Copyright © ITECH Electronics Co., Ltd. 29

Page 37

Remote Operation Mode

IT-E135 ISOLATED

Serial /IEEE 488 Controller

IT-E135 outer communication ad apter

COM interface of

Power supply

GPIB line

connector of the power supply, and then connect the GPIB interface of the IT-E135

and computer with GPIB /IEEE 488 line for the communication.

Copyright © ITECH Electronics Co., Ltd. 30

Page 38

Appendix

Model

Specification

Cross section

Length

IT-E301/10A

10A

-

1m

IT-E301/30A

30A

6mm2

1.2m

IT-E301/30A

30A

6mm2

2m

IT-E301/60A

60A

20mm2

1.5m

IT-E301/120A

120A

50mm2

2m

IT-E301/240A

240A

70mm2

1m

IT-E301/240A

240A

70mm2

2m

IT-E301/360A

360A

95mm2

2m

AWG

10

12

14

16

18

20

22

24

26

28

The

value( A)

40

25

20

13

10 7 5

3.5

2.5

1.7

Appendix

Specifications of Red and Black Test Lines

ITECH provides you with optional red and black test lines, which individual sales

and you can select for test. For specifications of ITECH test lines and maximum

current values, refer to the table below.

For maximum current of AWG copp er wire, refer to table blow.

Maximum

current

Note: AWG ( American Wire Gage), it means X wire ( marked on the wire). The

table above lists current capacity of single wire at working temperature of 30°C.

For reference only.

Copyright © ITECH Electronics Co., Ltd. 31

Page 39

Contact US

Thank you for purchasi ng ITECH products. If you have any doubt about this product, please

contact us as follow.

1. Please refer to the CD-ROM of related user’ s manual in package.

2.

Visit ITECH webs it e www.itechate.com .

3. Select the most convenient contact for further consultation.

Loading...

Loading...