ITech IT6036C-500-180, IT6018C-500-90, IT6006C-500-30, IT6012C-500-60, IT6126C-500-630 User Manual

...Page 1

Bi-directional Programmable

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

DC Power Supply

IT6000C Series User Manual

Model: IT6000C Series

Version: V1.0/01,2019

Page 2

Notices

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

© Itech Electronic, Co.,

Ltd. 2019

No part of this manual

may be reproduced in any

form or by any means (including electronic storage

and retrieval or translation

into a foreign language)

without prior permission

and written consent from

Itech Electronic, Co., Ltd.

as governed by international copyright laws.

Manual Part Number

Trademarks

Pentium is U.S. registered

trademarks of Intel

Corporation.

Microsoft, Visual Studio,

Windows and MS Windows are registered

trademarks of Microsoft

Corporation in the United

States and/or other countries and regions.

Warranty

The materials contained in this document are provided “as is”, and is subject to change, without prior notice, in

future editions. Further, to the maximum extent permitted by applicable

laws, ITECH disclaims all warrants, either express or implied, with regard to

this manual and any information contained herein, including but not limited

to the implied warranties of merchantability and fitness for a particular purpose. ITECH shall not be held liable

for errors or for incidental or indirect

damages in connection with the furnishing, use or application of this

document or of any information contained herein. Should ITECH and the

user enter into a separate written

agreement with warranty terms covering the materials in this document that

conflict with these terms, the warranty

terms in the separate agreement shall

prevail.

Technology Licenses

The hardware and/or software described herein are furnished under a license and may be used or copied only

in accordance with the terms of such

license.

Restricted Rights Legend

Restricted permissions of the U.S.

government. Permissions for software

and technical data which are authorized to the U.S. Government only include those for custom provision to

end users. ITECH follows FAR 12.211

(technical data), 12.212 (computer

software). DFARS 252.227-7015

(technical data–commercial products)

for national defense and DFARS

227.7202-3 (permissions for commercial computer software or computer

software documents) while providing

the customized business licenses of

software and technical data.

Safety Notices

A CAUTION sign denotes

a hazard. It calls attention

to an operating procedure

or practice that, if not correctly performed or adhered to, could result in

damage to the product or

loss of important data. Do

not proceed beyond a

CAUTION sign until the indicated conditions are

fully understood and met.

A WARNING sign denotes

a hazard. It calls attention

to an operating procedure

or practice that, if not correctly performed or adhered to, could result in

personal injury or death.

Do not proceed beyond a

WARNING sign until the

indicated conditions are

fully understood and met.

A NOTE sign denotes important hint. It calls attention to tips or

supplementary information that is essential for

users to refer to.

Page 3

IT6000C Series User Manual

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

Quality Certification and Assurance

We certify that series instrument meets all the published specifications at time

of shipment from the factory.

Warranty

ITECH warrants that the product will be free from defects in material and workmanship under normal use for a period of one (1) year from the date of delivery

(except those described in the Limitation of Warranty below).

For warranty service or repair, the product must be returned to a service center

designated by ITECH.

• The product returned to ITECH for warranty service must be shipped PRE-

PAID. And ITECH will pay for return of the product to customer.

• If the product is returned to ITECH for warranty service from overseas, all

the freights, duties and other taxes shall be on the account of customer.

Limitation of Warranty

This Warranty will be rendered invalid in case of the following:

• Damage caused by circuit installed by customer or using customer own

products or accessories;

• Modified or repaired by customer without authorization;

• Damage caused by circuit installed by customer or not operating our prod-

ucts under designated environment;

• The product model or serial number is altered, deleted, removed or made il-

legible by customer;

• Damaged as a result of accidents, including but not limited to lightning, mois-

ture, fire, improper use or negligence.

Copyright © Itech Electronic Co., Ltd.

I

Page 4

Safety Symbols

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

IT6000C Series User Manual

Direct current ON ( power)

Alternating

current

Both direct and

alternating

current

Chassis (earth

ground) symbol.

Earth ( ground)

terminal

Caution Positive terminal

Warning ( refer to

this manual for

specific Warning

or Caution

information)

OFF ( power)

Power-on state

Power-off state

Reference

terminal

Negative terminal

Safety Precautions

The following safety precautions must be observed during all phases of operation of this instrument. Failure to comply with these precautions or specific warn-

ings elsewhere in this manual will constitute a default under safety standards of

design, manufacture and intended use of the instrument. ITECH assumes no liability for the customer’s failure to comply with these precautions.

Copyright © Itech Electronic Co., Ltd.

A chassis

terminal

- -

II

Page 5

IT6000C Series User Manual

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

• Do not use the instrument if it is damaged. Before operation, check the

casing to see whether it cracks. Do not operate the instrument in the

presence of inflammable gasses, vapors or dusts.

• The instrument is provided with a power cord during delivery and should

be connected to a socket with a protective earth terminal, a junction box

or a three-phase distribution box. Before operation, be sure that the instrument is well grounded.

• Please always use the provided cable to connect the instrument.

• Check all marks on the instrument before connecting the instrument to

power supply.

• Ensure the voltage fluctuation of mains supply is less than 10% of the

working voltage range in order to reduce risks of fire and electric shock.

• Do not install alternative parts on the instrument or perform any unau-

thorized modification.

• Do not use the instrument if the detachable cover is removed or loosen.

• To prevent the possibility of accidental injuries, be sure to use the power

adapter supplied by the manufacturer only.

• We do not accept responsibility for any direct or indirect financial dam-

age or loss of profit that might occur when using the instrument.

• This instrument is used for industrial purposes, do not apply this product

to IT power supply system.

• Never use the instrument with a life-support system or any other equip-

ment subject to safety requirements.

Copyright © Itech Electronic Co., Ltd.

III

Page 6

IT6000C Series User Manual

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

• SHOCK HAZARD Ground the Instrument. This product is provided with

a protective earth terminal. To minimize shock hazard, the instrument

must be connected to the AC mains through a grounded power cable,

with the ground wire firmly connected to an electrical ground (safety

ground) at the power outlet or distribution box. Any interruption of the

protective (grounding) conductor or disconnection of the protective earth

terminal will cause a potential shock hazard that could result in injury or

death.

• Before applying power, verify that all safety precautions are taken. All

connections must be made with the instrument turned off, and must be

performed by qualified personnel who are aware of the hazards involved.

Improper actions can cause fatal injury as well as equipment damage.

• SHOCK HAZARD, LETHAL VOLTAGES This product can output the

dangerous voltage that can cause personal injury, and the operator must

always be protected from electric shock. Ensure that the output electrodes are either insulated or covered using the safety covers provided, so

that no accidental contact with lethal voltages can occur.

• Never touch cables or connections immediately after turning off the in-

strument. Verify that there is no dangerous voltage on the electrodes or

sense terminals before touching them.

• Failure to use the instrument as directed by the manufacturer may ren-

der its protective features void.

• Always clean the casing with a dry cloth. Do not clean the internals.

• Make sure the vent hole is always unblocked.

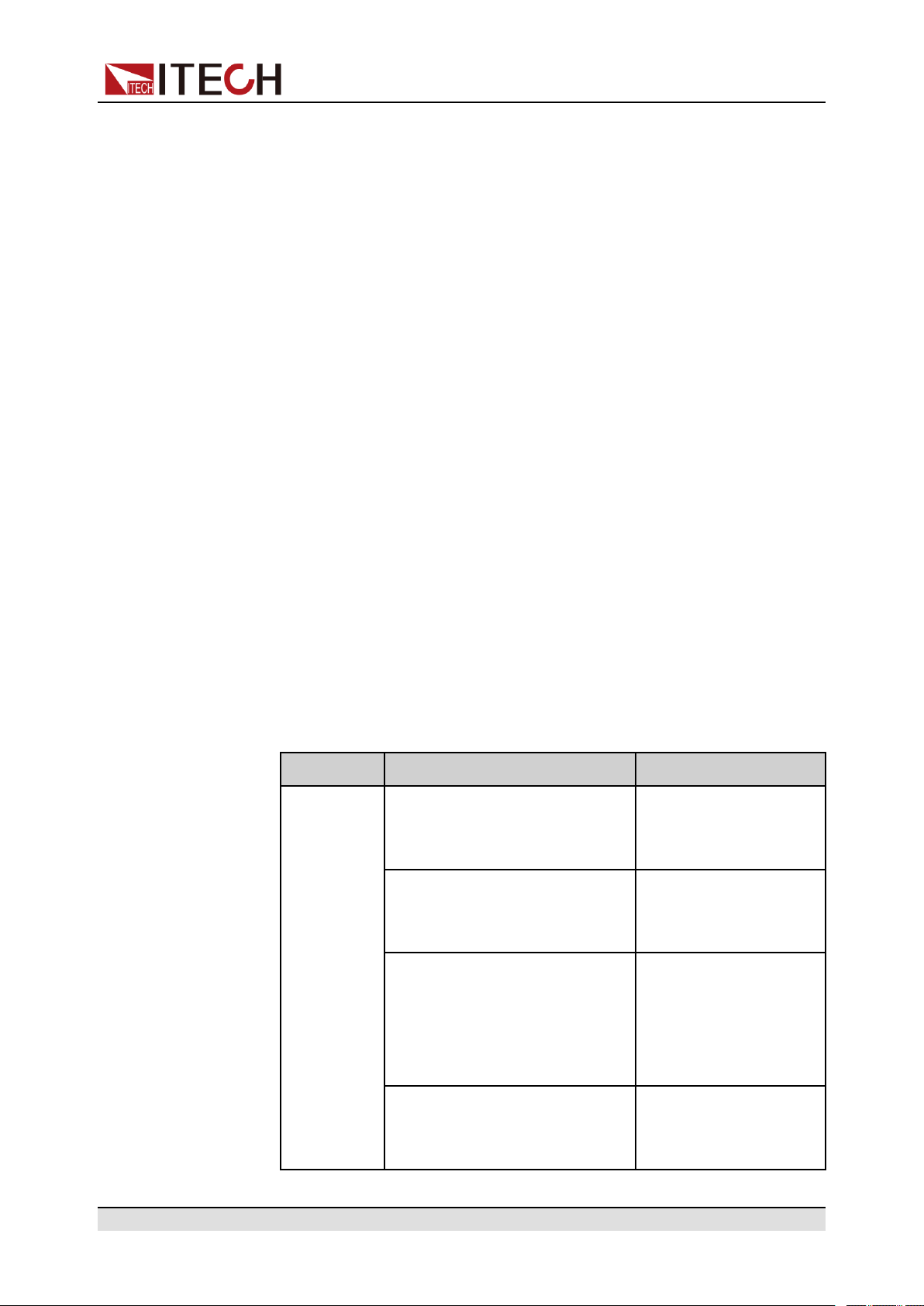

Environmental Conditions

The instrument is designed for indoor use and an area with low condensation.

The table below shows the general environmental requirements for the

instrument.

Environmental Conditions Requirements

Operating temperature 0°C~40°C

Operating humidity 20%~80%( non-condensation)

Storage temperature -10°C~70 °C

Copyright © Itech Electronic Co., Ltd.

IV

Page 7

Environmental Conditions Requirements

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

Altitude Operating up to 2,000 meters

Installation category II

Pollution degree Pollution degree 2

In order to ensure the accuracy of measurement, it is recommended to operate the instrument half an hour after start-up.

Regulation Tag

IT6000C Series User Manual

The CE tag shows that the product

complies with the provisions of all relevant European laws (if the year is

shown, it indicates that the year when

the design is approved).

This instrument complies with the

WEEE directive (2002/96/EC) tag requirements. This attached product

tag shows that the electrical/electronic product cannot be discarded in

household waste.

This symbol indicates that no danger

will happen or toxic substances will

not leak or cause damage in normal

use within the specified period. The

service life of the product is 10 years.

The product can be used safely within

the environmental protection period;

otherwise, the product should be put

into the recycling system.

Copyright © Itech Electronic Co., Ltd.

V

Page 8

IT6000C Series User Manual

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

Waste Electrical and Electronic Equipment (WEEE) Directive

Waste electrical and electronic equipment (WEEE) directive, 2002/96/EC

The product complies with tag requirements of the WEEE directive

(2002/96/EC). This tag indicates that

the electronic equipment cannot be

disposed of as ordinary household

waste. Product Category

According to the equipment classification in Annex I of the WEEE directive, this instrument belongs to the

“Monitoring” product.

If you want to return the unnecessary

instrument, please contact the nearest sales office of ITECH.

Copyright © Itech Electronic Co., Ltd.

VI

Page 9

Compliance Information

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

Complies with the essential requirements of the following applicable European

Directives, and carries the CE marking accordingly:

• Electromagnetic Compatibility (EMC) Directive 2014/30/EU

• Low-Voltage Directive (Safety) 2014/35/EU

Conforms with the following product standards:

EMC Standard

IEC 61326-1:2012/ EN 61326-1:2013 ¹²³

Reference Standards

CISPR 11:2009+A1:2010/ EN 55011:2009+A1:2010 (Group 1, Class A)

IEC 61000-4-2:2008/ EN 61000-4-2:2009

IT6000C Series User Manual

Safety Standard

IEC 61000-4-3:2006+A1:2007+A2:2010/ EN 61000-4-3:2006+A1:2008+A2:2010

IEC 61000-4-4:2004+A1:2010/ EN 61000-4-4:2004+A1:2010

IEC 61000-4-5:2005/ EN 61000-4-5:2006

IEC 61000-4-6:2008/ EN 61000-4-6:2009

IEC 61000-4-11:2004/ EN 61000-4-11:2004

1. The product is intended for use in non-residential/non-domestic environments. Use of the

product in residential/domestic environments may cause electromagnetic interference.

2. Connection of the instrument to a test object may produce radiations beyond the specified

limit.

3. Use high-performance shielded interface cable to ensure conformity with the EMC standards

listed above.

IEC 61010-1:2010/ EN 61010-1:2010

Copyright © Itech Electronic Co., Ltd.

VII

Page 10

IT6000C Series User Manual

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

Content

Quality Certification and Assurance .................................................................................. I

Warranty ............................................................................................................................ I

Limitation of Warranty ........................................................................................................ I

Safety Symbols ................................................................................................................. II

Safety Precautions............................................................................................................ II

Environmental Conditions................................................................................................ IV

Regulation Tag..................................................................................................................V

Waste Electrical and Electronic Equipment (WEEE) Directive .......................................VI

Compliance Information.................................................................................................. VII

1 Inspection and Installation.................................................................................................. 1

1.1 Verifying the Shipment ............................................................................................. 1

1.2 Instrument Size Introduction .................................................................................... 2

1.3 Connecting the Power Cord..................................................................................... 3

1.4 Connecting the Device Under Test (DUT) ............................................................... 5

2 Quick Start.......................................................................................................................... 9

2.1 Brief Introduction...................................................................................................... 9

2.2 Front-Panel Overview .............................................................................................11

2.2.1 Keyboard Introduction ................................................................................. 12

2.2.2 Push-on Knob .............................................................................................. 14

2.2.3 VFD Indicator Lamps Description................................................................ 15

2.3 Rear Panel Introduction ......................................................................................... 16

2.4 Power-on Self-Test................................................................................................. 17

3 Basic Operation................................................................................................................ 20

3.1 On/Off Control ........................................................................................................ 20

3.2 Local/Remote Mode Switch ................................................................................... 20

3.3 Key Lock Function ................................................................................................. 21

3.4 Save and Recall Operations .................................................................................. 21

3.4.1 Save Operation............................................................................................ 22

3.4.2 Recall Operation.......................................................................................... 22

3.5 Data Logging Function........................................................................................... 22

3.6 System Menu Function .......................................................................................... 25

3.6.1 Set the Beeper Status (Beep)...................................................................... 30

3.6.2 Set the Power-on State (PowerOn) ............................................................. 31

3.6.3 Sense Function (Sense) .............................................................................. 32

3.6.4 Select Trigger Source (Trig Source) ............................................................ 33

3.6.5 Set the Communication Information (I/O Con) ............................................ 34

3.6.6 Set Parallel Operation Mode (Parallel)........................................................ 34

3.6.7 Digital I/O Function (Digital Port)................................................................. 37

3.6.8 (Optional) Analogue Function (Ext-Program).............................................. 56

3.6.9 Restored to Factory Setting (System Reset)............................................... 57

3.6.10 View the System Information (System Info) .............................................. 60

3.7 System Upgrade .................................................................................................... 60

4 Power Supply Function .................................................................................................... 64

4.1 Set the Output Voltage........................................................................................... 64

4.2 Set the Output Current ........................................................................................... 64

4.3 Set the Output Power............................................................................................. 65

4.4 Configuration Menu Function for Power Supply .................................................... 65

4.4.1 Set the CC/CV Priority Mode....................................................................... 67

4.4.2 Set the Internal Resistance ......................................................................... 70

4.4.3 Set the Output-On/Output-Off Delay ........................................................... 70

4.5 Protection Function for Power Supply ................................................................... 70

4.5.1 Set Over-Voltage Protection (OVP)............................................................. 73

4.5.2 Set Over-Current Protection (OCP)............................................................. 74

4.5.3 Set Over-Power Protection (OPP)............................................................... 75

4.5.4 Set Under-Current Protection (UCP)........................................................... 76

Copyright © Itech Electronic Co., Ltd.

VIII

Page 11

IT6000C Series User Manual

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

4.5.5 Set Under-Voltage Protection (UVP)........................................................... 77

4.5.6 Over-Temperature Protection (OTP) ........................................................... 78

4.5.7 Sense Reverse Protection........................................................................... 78

4.6 Function Menu for Power Supply........................................................................... 79

4.6.1 LIST Function .............................................................................................. 79

4.6.2 Battery Charging/Discharging Test Function............................................... 85

4.6.3 Built-in Waveform Function ......................................................................... 86

4.6.4 Solar Photovoltaic Curve Simulation Function (SAS) ................................111

5 Remote Interface Connection .........................................................................................116

5.1 USB Interface........................................................................................................116

5.2 LAN Interface ........................................................................................................117

5.3 CAN Interface....................................................................................................... 120

5.4 GPIB Interface (Optional) .................................................................................... 121

5.5 RS–232 Interface (Optional) ................................................................................ 122

5.6 Web Server .......................................................................................................... 123

6 Technical Specification................................................................................................... 125

6.1 Main Specification................................................................................................ 125

6.1.1 IT6006C-500-30 ........................................................................................ 126

6.1.2 IT6012C-500-60 ........................................................................................ 128

6.1.3 IT6018C-500-90 ........................................................................................ 130

6.1.4 IT6018C-1500-30 ...................................................................................... 132

6.1.5 IT6006C-800-20 ........................................................................................ 134

6.1.6 IT6012C-800-40 ........................................................................................ 136

6.1.7 IT6018C-800-60 ........................................................................................ 138

6.1.8 IT6036C-800-120 ...................................................................................... 140

6.1.9 IT6018C-2250-20 ...................................................................................... 142

6.2 Supplemental Characteristics.............................................................................. 145

A Appendix ........................................................................................................................ 146

A.1 Specifications of Red and Black Test Lines......................................................... 146

A.2 Fuse Replacement .............................................................................................. 147

Copyright © Itech Electronic Co., Ltd.

IX

Page 12

Inspection and Installation

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

1 Inspection and Installation

♦ Verifying the Shipment

♦ Instrument Size Introduction

♦ Connecting the Power Cord

♦ Connecting the Device Under Test (DUT)

1.1 Verifying the Shipment

Unpack the box and check the contents before operating the instrument. If

wrong items have been delivered, if items are missing, or if there is a defect with

the appearance of the items, contact the dealer from which you purchased the

instrument immediately.

The package contents include:

Item Qty. Model Remarks

Bi-directional Pro-

grammable DC Power

Supply

Power cord x1 - Depending on the instru-

USB communication

cable

x1 IT6000C

Series

x1 - This accessory is se-

For the specific models in-

cluded in this series, refer

to 2.1 Brief Introduction.

ment model.

The power cord is

adapted to the power outlet specifications in this

area. For details, see 1.3

Connecting the Power

Cord.

lected when the USB in-

terface is used for starting

up remote operation.

Copyright © Itech Electronic Co., Ltd.

1

Page 13

Inspection and Installation

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

Item Qty. Model Remarks

CD x1 - It contains User Manual,

Programming Guide and

other user

documentations.

Ex-factory Test Report x1 - It contains the test report

and calibration report of

the instrument before

delivery.

Upon verification of the shipment, keep the package and relevant contents

thereof in a safe place. When returning the instrument for warranty service or

repair, the specified packing requirements shall be met.

1.2 Instrument Size Introduction

The instrument should be installed at well-ventilated and rational-sized space.

Please select appropriate space for installation based on the instrument size.

The detailed dimension drawings of the IT6000C series are as follows:

3U Models

Copyright © Itech Electronic Co., Ltd.

2

Page 14

1.3 Connecting the Power Cord

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

Precautions

To prevent electric shock and damage to the instrument, observe the following

precautions.

• Before connecting power cord, be sure to confirm that the power voltage

matches with the rated input voltage of the instrument.

• Before connecting power cord, be sure to switch off the instrument. Veri-

fy that there is no dangerous voltage on the connection terminals.

• To avoid fire or electric shock, make sure to use the power cord supplied

by ITECH.

• Be sure to connect the power cord to the AC distribution box with protec-

tive grounding. Do not use terminal board without protective grounding.

• Do not use an extended power cord without protective grounding, other-

wise the protection function will fail.

Inspection and Installation

• Be sure to perform related operations and connections to feed energy

back to grid in accordance with related regulations, and meet all necessary conditions.

• Ensure that the power cord connection terminals are either insulated or

covered by the supplied protective cover so that no accidental contact

with lethal voltage can occur.

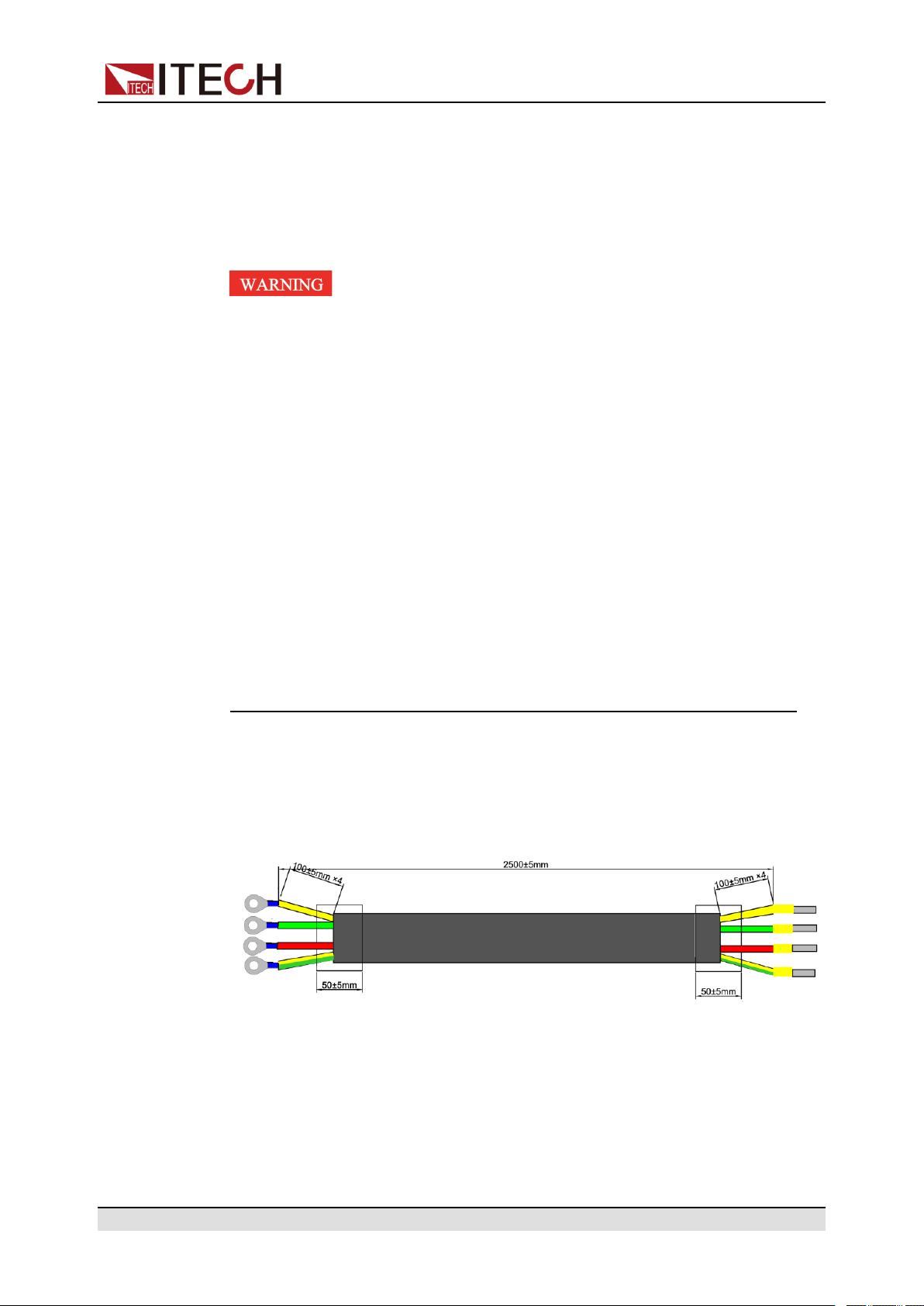

Categories of Power Cords

The power cord specifications of this series of instruments are as follows:

The red, green and yellow wires are live wires, which are correspondingly con-

nected to the L1, L2 and L3 terminals of power input on the rear panel of the instrument; the yellow-green wire is grounding wire, which is connected to the PE

terminal of power input on the rear panel.

Copyright © Itech Electronic Co., Ltd.

3

Page 15

AC Power Input Level

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

The input of this series is a three-phase AC power of 380V. (Line voltage: such

as the voltage between L1 and L2).

• Voltage: 380V±10% (Three-phase four-wire)

• Frequency: 47Hz to 63Hz

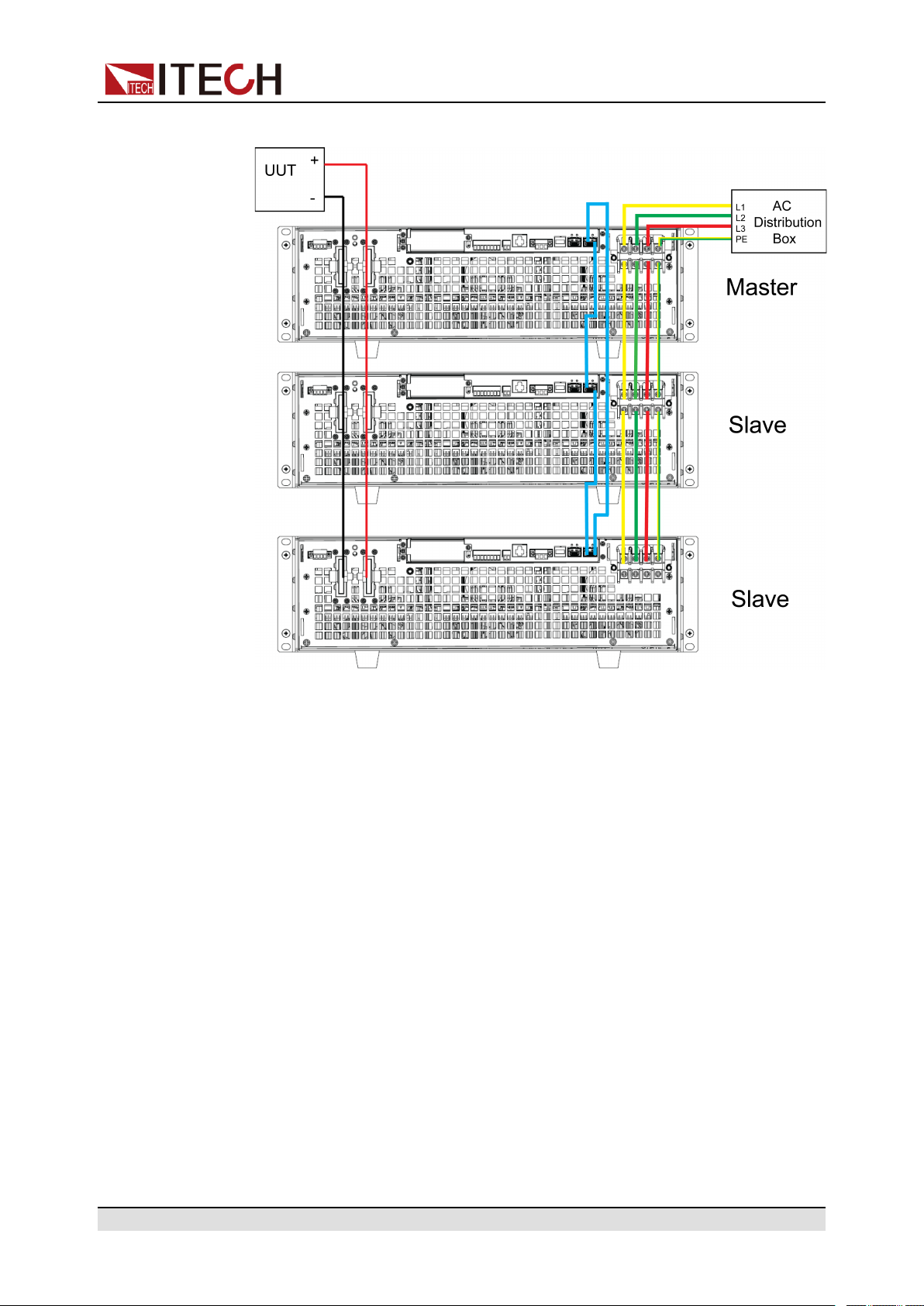

Connecting the Power Cord

• For 3U model, see the steps below to connect the power cable.

• For units already assembled into a cabinet during ex-factory, if one end of

the power cable is connected, the user needs to connect the other end of

the power cable to the distribution box. The connection method is same as

that for the 3U model;

• For models to be assembled in parallel by the user, see contents related to

power cable connection in Cabinet Assembly Guide.

Inspection and Installation

1. Confirm that the switch of the AC power distribution box is off.

2. Confirm that the power switch is in the OFF position and verify that there is

no dangerous voltage on the connection terminals.

3. Remove the protective cover outside the AC input terminal on the rear

panel.

4. Connect one end of the power cable’s round terminal to the AC power input

terminal on the instrument’s rear panel.

a. You only need to connect the red, green and yellow live wires to the ter-

minals on the rear panel, which are not required to correspond to L1, L2

and L3 terminals one by one.

b. The yellow-green wire is grounding wire, which is connected to the pro-

tective grounding terminal (PE).

5. Mount the protective cover back to its original position.

6. Connect the other end of the power cable to the required AC distribution

box.

The schematic is shown below.

Copyright © Itech Electronic Co., Ltd.

4

Page 16

Inspection and Installation

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

1.4 Connecting the Device Under Test (DUT)

Precautions

This section describes how to connect the test cables between the instrument

and DUT.

To prevent electric shock and damage to the instrument, observe the following

precautions.

Copyright © Itech Electronic Co., Ltd.

5

Page 17

Inspection and Installation

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

• Before connecting test cables, be sure to switch off the instrument.

Power switch is in Off position, otherwise touching the output terminals

on the rear panel may result in personal injury or death due to electric

shock.

• To avoid electrical shock, before testing, please make sure the rating val-

ues of the testing cables, and do not measure the current that higher

than the rating value. All test cables shall be capable of withstanding the

maximum short circuit current of the instrument without causing

overheat.

• If several loads are provided, each pair of load wires shall safely with-

stand the rated short circuit output current of the power supply under full

load.

• Do not short the battery when connecting or disconnecting the battery

testing circuit. Short circuit may cause severe accident.

• Because the instrument can be used to sink current, hazardous voltages

from an external energy source such as a battery may be present on the

output terminals even with the instrument power off. Provision must be

made to disconnect the external energy source before touching the output or sense terminals.

• Always use test cables provided by ITECH to connect the equipment. If

test cables from other factories are used, please confirm the maximum

current that the test cables can withstand.

• During wiring, check that the positive and negative poles of the test ca-

bles are properly and tightly connected. Do not connect the positive pole

and disconnect the negative pole.

• Ensure that the output terminals are either insulated or covered using

the safety covers provided, so that no accidental contact with lethal voltages can occur.

Specification for Test Cables

Test cables are not standard accessories for the instrument. Please select op-

tional red and black test cables for individual sales based on the maximum current value. For specifications of test cables and maximum current values, refer

to A.1 Appendix→Specifications of Red and Black Test Lines.

Connecting the DUT (Local Measurement)

The instrument supports two kinds of wiring methods with the DUT: local measurement and remote measurement (SENSE). The default test mode is local

measurement.

The connection diagram and steps of local measurement are as follows:

Copyright © Itech Electronic Co., Ltd.

6

Page 18

Inspection and Installation

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

1. Confirm that the power switch is in the OFF position and verify that there is

no dangerous voltage on the connection terminals.

2. Remove the output terminals cover of the power supply.

3. Loosen the screws of the output terminals and connect the red and black

test cables to the output terminals. Re-tighten the screws.

When maximum current that one test cable can withstand fails to meet the

rated current, use multiple pieces of red and black test cables. For example,

the maximum current is 1,200A, then 4 pieces of 360A red and black cables

are required.

4. Thread the red and black test cables through the output terminals cover of

the power supply and install the cover.

5. (Optional) According to the actual situation of DUT, connect the grounding

terminal on the rear panel of the instrument to the DUT to ensure the safe

grounding.

For the location information, see 2.3 Rear Panel Introduction.

6. Connect the other end of the red and black cables to the DUT. The positive

and negative poles must be properly connected and fastened when wiring.

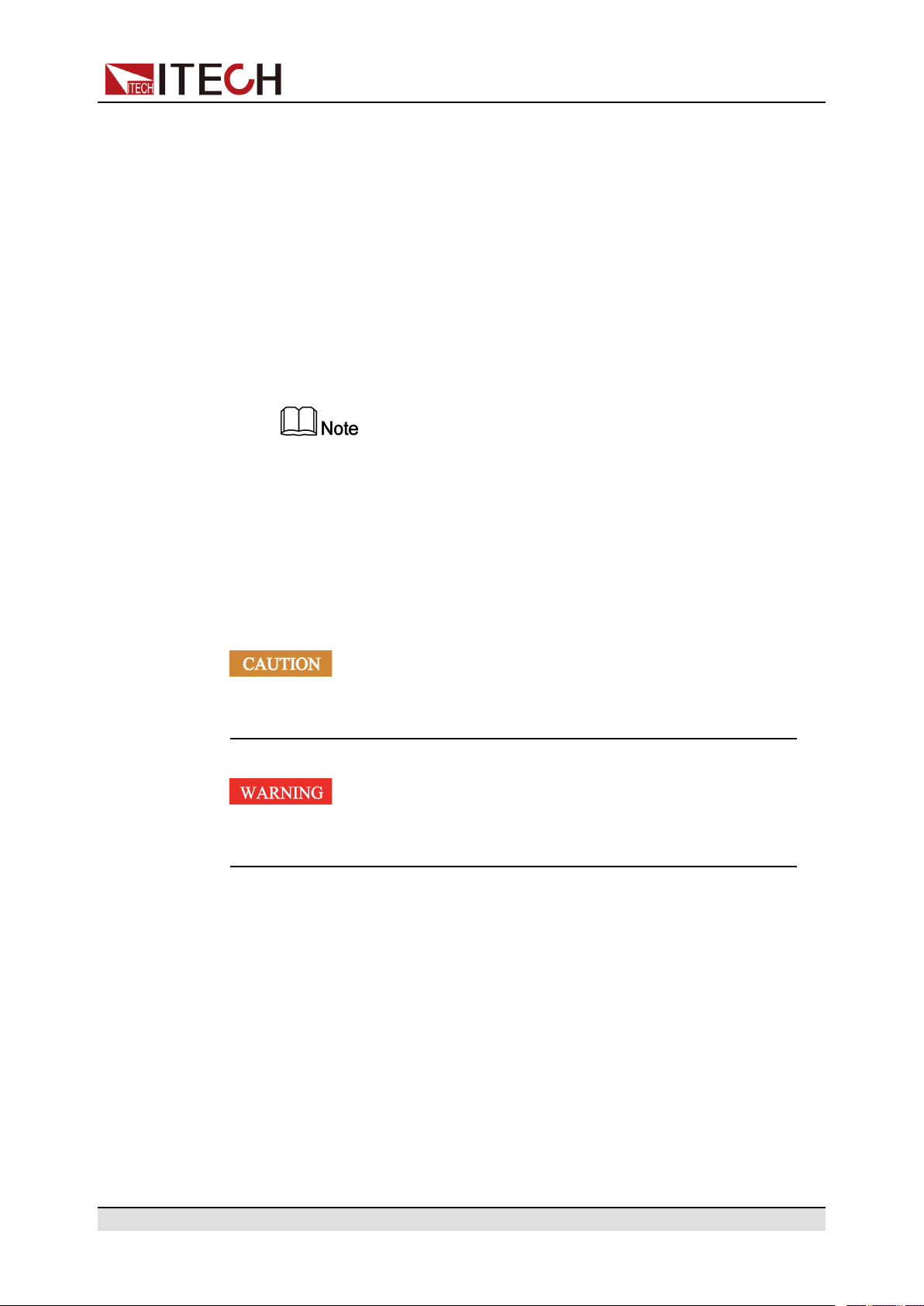

Connecting the DUT (Remote Sensing)

Remote measurement is available for the following scenarios:

When the DUT consumes large current or the wires are too long, there is a voltage drop on the wires between DUT and output terminals of the power supply.

To maximize measurement accuracy, the power supply provides the remote

measurement terminals VS+ and VS- on the rear panel, which can be used to

measure the terminal voltage of the DUT.

When the power supply is used for battery testing in actual applications, the

voltage drop of the wire will lead to voltage inconsistency of both ends and inconsistency of the cutoff voltage of power supply and the actual voltage of bat-

tery, resulting in inaccurate measurement.

The connection diagram and steps of remote measurement are as follows:

Copyright © Itech Electronic Co., Ltd.

7

Page 19

Inspection and Installation

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

1. Confirm that the power switch is in the OFF position and verify that there is

no dangerous voltage on the connection terminals.

2. Refer to the wiring diagram and connect the Vs+ and Vs- with armored

twisted-pair cables.

To ensure the stability of the system, use armored twisted-pair cables between the remote sense terminals and the DUT. Pay attention to the positive and negative poles when wiring, otherwise it will damage the

instrument.

3. Remove the output terminals cover of the power supply.

4. Loosen the screws of the output terminals and connect the red and black

test cables to the output terminals. Re-tighten the screws.

When maximum current that one test cable can withstand fails to meet the

rated current, use multiple pieces of red and black test cables. For example,

the maximum current is 1,200A, then 4 pieces of 360A red and black cables

are required.

5. Thread the red and black test cables through the output terminals cover of

the power supply and install the cover.

6. (Optional) According to the actual situation of DUT, connect the grounding

terminal on the rear panel of the instrument to the DUT to ensure the safe

grounding.

For the location information, see 2.3 Rear Panel Introduction.

7. Connect the other end of the remote sense cables to the DUT.

8. Connect the other end of the red and black cables to the DUT. The positive

and negative poles must be properly connected and fastened when wiring.

9. Power on the instrument and turn on the Sense function of the instrument.

For details, see 3.6.3 Sense Function (Sense).

Never touch cables or connections immediately after turning off the instrument at the end of the test. Lethal voltages may remain at the output terminals after turn-off. Verify that there is no dangerous voltage

on the output or sense terminals before touching them.

Copyright © Itech Electronic Co., Ltd.

8

Page 20

2 Quick Start

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

This Chapter will introduce power-on check steps of this series to ensure normal

start-up and usage under initialization status of the power. Besides, to facilitate

usage, this part also displays the functions of front board, rear board and keyboard keys as well as display functions to a quick view of power appearance,

structure and key usage functions before operation.

♦ Brief Introduction

♦ Front-Panel Overview

♦ Rear Panel Introduction

♦ Power-on Self-Test

2.1 Brief Introduction

Quick Start

The IT6000C series Bi-directional Programmable DC Power Supply is designed

with the module concept. The voltage class of each module is 80V/200V/360V/

500V/800V. A single module can realize up to 800V/20A/6kW DC output capacity, and modules can be run in series or in parallel. At most of three modules

can be connected in series or in parallel for a single unit (3U) with input of three-

phase 380V AC power supply. The 3U model on sales supports 500V/90A/

18kW and 1500V/30A/18kW output to satisfy different test requirement such as

high current and low voltage or high voltage and low current. Meanwhile, units

can be run in parallel to deliver stronger output capacity.

In addition to the above powerful and diverse output capability, based on conventional features (such as List function, comprehensive protection and other

functions), the IT6000C series Bi-directional Programmable DC Power Supply

also supports a variety of unique features, such as digital I/O, data logging, energy regeneration, and the selective upgrade of system files. More functions,

technical indicators and technical innovations are described below:

• The standard 3U chassis of the IT6000C series instruments can accommo-

date up to 3 modules.

• Internal modules can be run in series or in parallel for voltage sharing or cur-

rent sharing.

• Single module output voltage ranges from 80V to 800V, and current ranges

from 20A to 170A.

• For the whole instrument, the output voltage ranges from 80V to 2250V, and

current ranges from 20A to 2040A.

Copyright © Itech Electronic Co., Ltd.

9

Page 21

Quick Start

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

• The instrument supports bi-directional energy transmission and feeds elec-

tric energy back to the grid in a pollution-free manner, thus cutting electricity

and heat dissipation costs and meeting energy-saving and environmental

protection demands;

• It supports optional system file upgrade and one-click check of such informa-

tion as system version, module version and system configuration;

• Support List, battery test, comprehensive protection and parallel function.

• During the test, the instrument can record specific data type (such as voltage

value) and save it in the USB memory device;

• The front panel can be inserted with the USB memory device to support

such functions as system file upgrade, import/export of List files and data

record;

• Strong Digital I/O Function: In addition to general digital signal I/O functions,

it can also be customized by supporting the wiring through different pins to

meet different special needs through different pin wirings;

• Select CC loop priority or CV loop priority. If voltage and current parameters

are to be changed frequently during test, the user can directly set related parameters through [V-set] and [I-set] on the front panel, which is very

convenient;

• Built-in voltage curves comply with multiple automotive standards for quick

user recall.

• Built-in maximum power point tracking (MPPT) mechanism to provide solar

photovoltaic curve simulation.

• High visible vacuum fluorescent display (VFD)

• Support optical fiber communication, which is applicable for loop control be-

tween units under parallel mode.

• Built-in USB/CAN/LAN communication interface

• Optional GPIB/RS–232 communication interface

• Optional external analog interface, and share an interface position with RS-

232.

• Strong trigger system;

• Use a virtual resistor to realize paralleled current sharing and series voltage

sharing between units;

• Enable a true seamless switch between positive current and negative cur-

rent while avoiding overshoot current and overshoot voltage;

• When the Sense function is turned on, it can ensure that the DUT is safe in

case of reverse connection or open circuit of the Sense line.

Copyright © Itech Electronic Co., Ltd.

10

Page 22

The models included in the IT6000C series are as follows:

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

Quick Start

500V 1,500V Height (with

bare machines

overlapped)

IT6006C-500-30 –

IT6012C-500-60 –

IT6018C-500-90 IT6018C-1500-30

IT6036C-500180

IT6054C-500270

IT6072C-500360

IT6090C-500-

450

IT6108C-500540

IT6036C-1500-60 6U

IT6054C-1500-90 9U 15U

IT6072C-1500120

IT6090C-1500-

150

IT6108C-1500180

3U

12U

15U 27U

18U

Height (constituting cabinet)

–

IT6126C-500630

IT6144C-500720

Naming rules for each series of model are as follows: IT 6XXXC-YYY-ZZZ,

wherein, XXX means rated power; YYY means rated voltage; and ZZZ

means rated current.

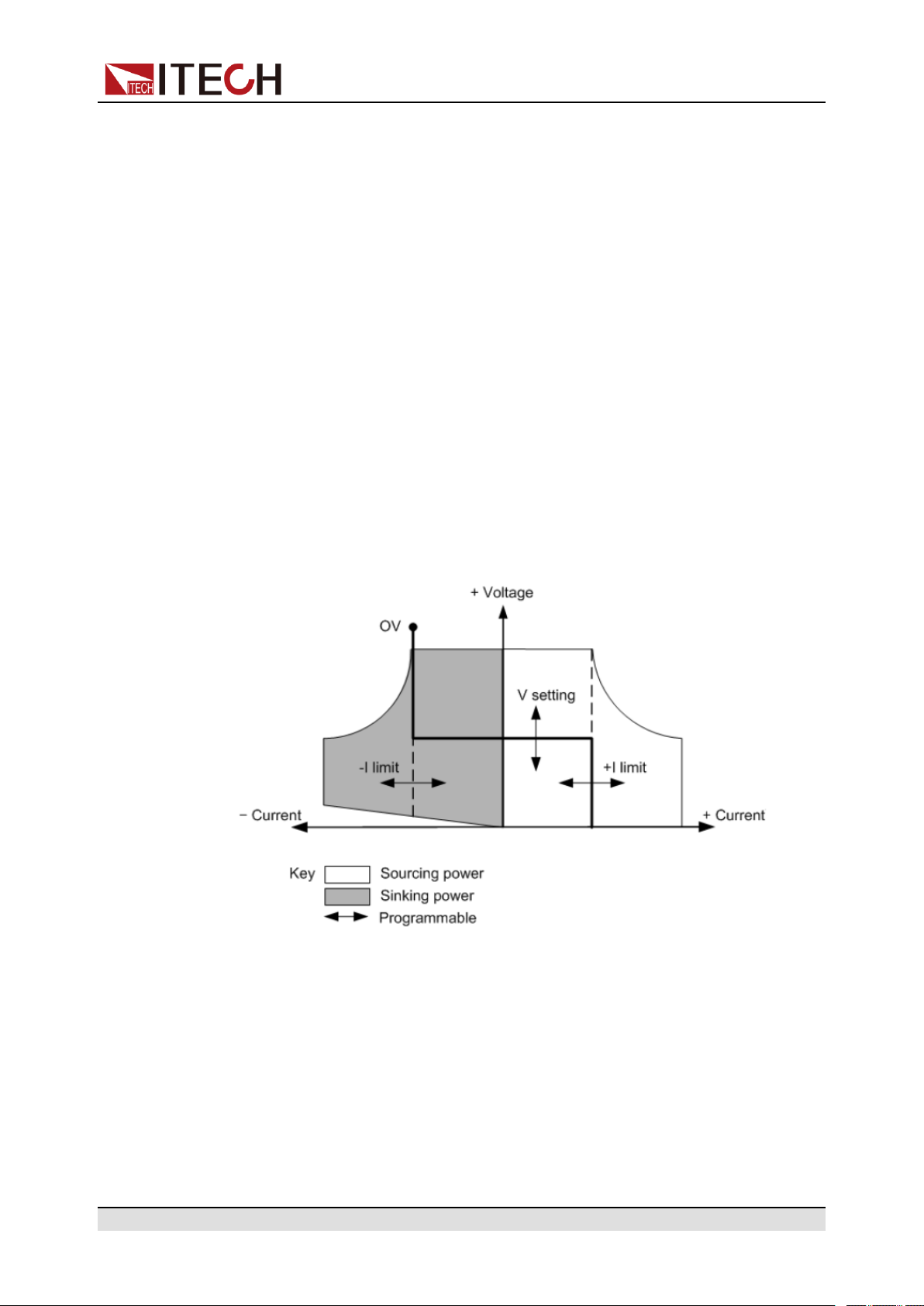

As a bipolar power supply, this series can output and absorb electric energy.

The current and power input capacity is same as the output capacity. For example, the maximum rated value of the output power of the IT6018C-500-90

model is 18,000W, and the maximum rated value of input power is also

18,000W.

IT6126C-1500210

IT6144C-1500240

2.2 Front-Panel Overview

For the IT6000C series Bi-directional Programmable DC Power Supply, all front

panels of the 3U model are the same, and the operation panels of other models

are the same as those of the 3U model. The following is the front panel schematic of the 3U model.

21U

24U

Copyright © Itech Electronic Co., Ltd.

11

Page 23

3U Model

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

Quick Start

1 Power On/Off switch

2 Vacuum fluorescent display

(VFD)

3 Function and composite keys

4 Numeric and composite keys

2.2.1 Keyboard Introduction

The keyboard introduction of IT6000C series Bi-directional Programmable DC

Power Supply is shown as follows.

5 Up, down, left, and right cursor navigation

keys and Enter key

6 Push-on knob

7 Vent hole

8 USB storage device connection port

Table 2–1 Keys Description

Keys Description

[Esc] Press this key to exit the current operation interface.

[V-set] / Config Set the output voltage value / Enter the Config menu of

the power supply

Copyright © Itech Electronic Co., Ltd.

12

Page 24

Quick Start

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

Keys Description

In CV priority (default) mode, press [V-set], the inter-

face displays “Vs=0.00V” (Setting value of voltage).

In CC priority mode, press [V-set], the interface dis-

plays “Vh=0.00V” (Upper limit of voltage), and press

[V-set] again, the interface displays “Vl=0.00V”

(Lower limit of voltage).

[I-set] / Function Set the output current value / Enter the Function menu

of the power supply

In CV priority (default) mode, press [I-set], the inter-

face displays “I+=0.00A” (Upper limit of current) ,

and press [I-set] again, the interface displays “I-= –

0.00 A” (Lower limit of current). In CC priority mode,

press [I-set], the interface displays “Is=0.00A” (Set-

ting value of current).

[P-set] / System Set the output power value / Enter the System menu

Press [P-set], the interface displays “P+=0.00W”

(Upper limit of power) , and press [P-set] again, the

interface displays “P- = – 0.00W” (Lower limit of

power) .

[Recall] / Protect Returns the instrument to the specified setup. / Enter the

Protect menu of the power supply

[Shift] Composite key, combined with other keys to realize func-

tions marked above keys.

[On/Off] / Trigger

• Turn the power supply output on or off. When lit, indi-

cates that the output is enabled or on.

• Generate a local trigger signal.

[0]-[9] Numeric keys

[Shift]+[1] (Log) Enter the data logging function menu.

[Shift]+[2] (Lock) Turn the keyboard lock on or off.

[Shift]+[3] (Local) Switch remote control mode to local control mode.

Copyright © Itech Electronic Co., Ltd.

13

Page 25

Keys Description

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

Quick Start

[Shift]+[+/–]

(Save)

+/– Positive and negative signs

. Decimal point

Left / Right navigation keys

Up / Down navigation keys

[Enter] Operation confirmation key

2.2.2 Push-on Knob

The IT6000C series Bi-directional Programmable DC Power Supply provides a

knob on the front panel as shown in the next figure.

Save the common parameter settings.

The left and right navigation keys are used to adjust the

cursor to the specified position or scrolls pages to view

menu items.

The up and down navigation keys are used to scroll page

up and down to view menu items.

The functions of the posh-on knob is described as follows.

• Adjust the value setting

• Select menu item

• Confirm the set value or the selected menu item

Adjust the Value Setting

In the value setting interface, rotate the knob clockwise to increase the set value

and anticlockwise to decrease the set value.

Select Menu Item

The knob can also be used to view menu items. In the menu item display interface, turning the knob clockwise indicates that the next menu item is selected,

and turning the knob anticlockwise indicates that the previous menu item is

selected.

Copyright © Itech Electronic Co., Ltd.

14

Page 26

Confirm settings

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

After completing the value setting or selecting a menu item, pushing the knob

acts like pressing [Enter] key to confirm the operation.

2.2.3 VFD Indicator Lamps Description

The IT6000C series Bi-directional Programmable DC Power Supply VFD indicator lamps description is as follows:

Table 2–2 VFD Indicator Lamps Description

Quick Start

Flag Function

Description

OFF The output of the

power supply is

turned off.

CV The power supply is

in a state of constant voltage

output.

CC The power supply is

in a state of con-

stant current output.

* The keyboard lock

is turned on.

CR None Rmt Indicates that the instrument

Flag Function Description

Auto None

Sense Sense function of the power

supply is enabled.

Rear Analog function begin to

work.

Addr When received command

successfully, the flag will display 3 seconds.

is working in remote control

mode.

Shift Using composite

function key

SRQ Indicates that the

internal status request event occurs.

CW The power supply is

in a state of con-

stant power output.

Copyright © Itech Electronic Co., Ltd.

Error Error occur

Prot The instrument enters the

protection state.

Trig The instrument is in a state

of waiting for a trigger.

15

Page 27

2.3 Rear Panel Introduction

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

The rear panel of the 3U model of the IT6000C series Bi-directional Programmable DC Power Supply (after removing the protective cover) is shown below.

3U Models

1. Sense terminals (Vs+, Vs-)

Quick Start

2. DC output terminals of the power supply

3. Optional communication interface: RS-232 or GPIB

4. Digital I/O interface: P-IO

5. CAN communication interface

6. LAN communication interface

7. External control interface CTRL

This interface is used for cabinet self-assembling scenarios. Connect the

interface on the rear panel of each unit to be connected in parallel, and

the master can offer synchronous control over the power-on/off of the

slave.

8. USB communication interface

9. Communication interface of inner ring optical fiber (F-TX and F-RX)

This interface is used for cabinet self-assembling scenarios for realizing

communication of units in parallel.

10.Communication interface of outer ring optical fiber (TX and RX)

Copyright © Itech Electronic Co., Ltd.

16

Page 28

This interface is used for parallel scenarios of common units for the com-

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

munication of units in parallel.

11. AC power input terminals (L1, L2, L3, and PE)

12.Chassis ground terminal

2.4 Power-on Self-Test

A successful self-test indicates that the purchased product meets delivery

standards and it is available for normal usage.

Before operation, please confirm that you have fully understood the safety

instructions.

Quick Start

• Before connecting power cord, be sure to confirm that the power voltage

matches with the rated input voltage of the instrument.

• Before connecting power cord, be sure to switch off the instrument. Veri-

fy that there is no dangerous voltage on the connection terminals.

• To avoid fire or electric shock, make sure to use the power cord supplied

by ITECH.

• Be sure to connect the power cord to the AC distribution box with protec-

tive grounding. Do not use terminal board without protective grounding.

• Do not use an extended power cord without protective grounding, other-

wise the protection function will fail.

• Be sure to perform related operations and connections to feed energy

back to grid in accordance with related regulations, and meet all necessary conditions.

• Ensure that the power cord connection terminals are either insulated or

covered by the supplied protective cover so that no accidental contact

with lethal voltage can occur.

Power Switch Introduction

User can adjust the power switch directly to turn on or turn off the instrument.

The status of Power switch is as follows.

Copyright © Itech Electronic Co., Ltd.

17

Page 29

Quick Start

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

On Off On Off

If the instrument is the cabinet type, the rear panel of the cabinet provides a

master power switch. The relationships between the device status and switch

status are listed in the following table.

Master switch status Desperate switch

On On On

On Off Off

Off On Off

Off Off Off

Self-Test Procedures

Normal self-test procedures:

1. Correctly connect the power cord and power on the instrument.

The instrument starts the self-test.

2. After the instrument is self-tested normally, the VFD shows the output voltage, current, power and other information (CV mode).

If an error occurs during the self-test, an error message is displayed. The following table lists the error messages you might see.

Device status

status

Error message Error Description

Eeprom Failure The EEPROM is damaged.

Main FrameInitializeLost The system setting data is lost.

Calibration Data Lost The factory calibration data in EE-

PROM is lost.

Config Data Lost The latest operation state of the in-

strument is lost.

NETWORKING… The parallel operations are abnormal

and cannot finish the networking.

Copyright © Itech Electronic Co., Ltd.

18

Page 30

Exception Handling

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

If the instrument cannot start normally, please check and take measures by

reference to steps below.

1. Check whether the power cord is correctly connected and confirm whether

the instrument is powered.

2. Check whether the power in On. The power switch is under “|” On status.

3. Check whether the power voltage matches with the supply voltage. Please

refer to 1.3 Connecting the Power Cord to select proper AC input.

4. If you need additional assistance, contact ITECH technical support engineer.

Quick Start

Copyright © Itech Electronic Co., Ltd.

19

Page 31

3 Basic Operation

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

This chapter describes the basic functions and features of the instrument. Divided into the following sections:

♦ On/Off Control

♦ Local/Remote Mode Switch

♦ Key Lock Function

♦ Save and Recall Operations

♦ Data Logging Function

♦ System Menu Function

♦ System Upgrade

3.1 On/Off Control

Basic Operation

You can press the [On/Off] key on the front panel to control the output status of

the power supply. If the [On/Off] key light is on, indicates that the output is

turned on. If the [On/Off] key light is off, indicates that the output is turned off.

When the output of the power supply is on, the operating status flag (CV/CC/

CW) on the VFD will be illuminated.

It is recommended that you turn on the [On/Off] after the power supply is

connected to the DUT. If the power supply has no output after the output is

turned on, check the voltage and current setting value, set the voltage and

current to a non-zero value, and then turn on the output.

3.2 Local/Remote Mode Switch

The power supply provides both local and remote operation modes. The default

mode of the power supply is local operation mode.

• Local operation mode: Use the front panel keys to control the power supply.

• Remote operation mode: The power supply is connected to PC, and the user

uses the software in PC to control the power supply remotely.

– During remote control operation, the remote symbol “Rmt” is displayed.

All panel keys, except the [On/Off] and [Shift]+[3] (Local) keys, are

locked.

Copyright © Itech Electronic Co., Ltd.

20

Page 32

– You can press [Shift]+[3] (Local) to switch the remote control to local

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

control. The mode modification will not affect the output parameters of

the power supply.

3.3 Key Lock Function

This function can prevent the power supply from the panel keys misoperation

during usage. Press the composite keys [Shift]+[2] (Lock) to lock front panel

keys and the lock symbol “*” is shown on the front panel display. All panel keys,

except the [On/Off] and [Shift]+[2] (Lock) keys, are locked. You can repress

[Shift]+[2] (Lock) to unlock the front panel.

3.4 Save and Recall Operations

Basic Operation

The power supply can save up to 10 common parameters in nonvolatile memory

(No. 1 to No. 10) for user to recall conveniently. The saved settings include the

following parameters.

Category Parameter

Main interface

Config menu CC/CV loop priority mode: Mode

Voltage setting: Vs

Current setting: Is

Upper limit of voltage: Vh, and lower limit of voltage: Vl

Upper limit of current: I+, and lower limit of current: I-

Upper limit of power: P+, and lower limit of power: P-

The output status of the instrument: [On/Off]

CC/CV loop speed: Speed

Voltage/Current rise time: V-Rise Time/I-Rise Time

Voltage/Current fall time: V-Fall Time/I-Fall Time

On/Off switch delay: On Delay/Off Delay

Internal resistance of the power supply: Output Res

Protect menu OCP/OVP/OPP/UCP/UVP switch status: On/Off

OCP/OVP/OPP/UCP/UVP limit setting: Level

Copyright © Itech Electronic Co., Ltd.

21

Page 33

Category Parameter

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

You can do the save and recall operations by the following two methods.

• Press the composite keys [Shift]+[+/-] (Save) to save the parameters. Press

the [Recall] key to recall the parameters.

• SCPI commands: *SAV and *RCL

3.4.1 Save Operation

The save operation procedures are as follows:

1. Press the composite keys [Shift]+[+/-] (Save) to enter the parameter save

interface.

Basic Operation

OCP/OVP/OPP/UCP/UVP delay time: Delay

UCP/UVP warm-up time: Warm-up

2. Set the storage location.

Enter a number in the "Save data to bank=0" to set the storage location in

non-volatile memory.

3. Press [Enter] to save the parameters.

3.4.2 Recall Operation

You can recall the parameters you saved in the specified memory location as

the setting values.

1. Press the [Recall] key to enter the parameter recall interface.

2. Set the storage location.

Enter a number in the “Recall data from bank=0” to set the storage location

in non-volatile memory.

3. Press [Enter] to recall the parameters.

3.5 Data Logging Function

The IT6000C series Bi-directional Programmable DC Power Supply supports

the recording and saving of test data. This Chapter introduces how to use this

function in details.

Copyright © Itech Electronic Co., Ltd.

22

Page 34

The user can select the following data sources for recording:

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

• Voltage

Only records voltage data during the data acquisition period.

• Current

Only records current data during the data acquisition period.

• Voltage and current

Records current and voltage data during the data acquisition period.

Configure the Function Menu

1. Press the composite button [Shift]+[1] (Log) on the front panel to enter the

configuration menu of the data logging function.

The parameters are described as follows:

Basic Operation

Menu Item Description Setting

Sample

Period

Duration This parameter indicates the time for

Source This parameter indicates the source

This parameter indicates the data

sampling interval (unit: s), that is, the

test data is recorded once every X

seconds.

The input range supported by the in-

strument is: 0 - 9

data recording (unit: s), namely, the

data recording will be completed in Y

seconds and be ready for the next

data record.

The input range supported by the in-

strument is: 0 - 3600

of recorded data, including voltage

(V), current (I), voltage and current

(V/I).

Set the value by in-

putting the value

through the number

key or rotating the

knob.

Use the Left and

Right arrow key or

the rotation knob to

select.

Copyright © Itech Electronic Co., Ltd.

23

Page 35

Basic Operation

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

Menu Item Description Setting

Data Type This parameter indicates the type of

recorded data, including:

• Average: This is the default se-

lected data type, namely, the

average of all data acquired in the

data recording period as indicated

in the table of saved data.

• Max/Min: If this option is se-

lected, it means the maximum

value and minimum value of data

acquired in the data recording period as indicated in the data saving table.

2. Set the value of Sample Period and press [Enter].

3. Set the value of Duration and press [Enter].

4. Set the value of Source and press [Enter].

5. Set the value of Data Type and press [Enter].

At this point, the VFD screen returns to the main interface of the system.

Select the Trigger Method

See the steps in the 3.6.4 Select Trigger Source (Trig Source) section to set

how the data logging is triggered.

This setting result is only valid for data recording function. When List function

is used, the method for triggering the running of List files needs to be addi-

tionally set (by default, triggered by the panel).

Copyright © Itech Electronic Co., Ltd.

24

Page 36

Start Data Logging

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

• Manual

• Bus

Basic Operation

Before this operation, make sure to connect the USB memory device

to the memory port on the front panel (The USB interface on the rear

panel can only be used for connecting the PC) so that the recorded

data can be stored in the external storage device. Otherwise, the Data

Recording function is not available for usage.

Press the composite button [Shift] + [On/Off] (Trigger) on the front panel to

trigger.

Triggered by the SCPI instruction, for example, when the instrument receives the trigger command *TRG, a trigger operation is performed.

• External

Connect to pin 4 of the digital I/O interface (P-IO) and set pin 4 to Ext-Trig→Trig-In→Dlog to trigger.

For details, see 3.6.7.4 IO–4. Ext-Trig, Not-Invert.

After the data recording function is started, the lower right corner of the main interface displays Logging, indicating that the data is recorded. The recorded data is saved in USB memory device in .csv format. The user can get access to

these files for analysis based on needs.

3.6 System Menu Function

This Chapter offers a general introduction of system menus, allowing users to

have a preliminary understanding of system functions of this IT6000C series.

The steps of the system menu function are as follows:

1. Press the composite keys [Shift]+[P-set] (System) on the front panel to enter the system menu.

At this point, the VFD screen displays the system menu items. Each menu

item has a numbering identifier. The user can press Up and Down buttons or

use the knob for scrolling display of other menu items.

2. Press [Enter] on a menu interface to enter the setting interface.

Copyright © Itech Electronic Co., Ltd.

25

Page 37

3. After the menu items are set, press [Enter] again to save the modified

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

contents.

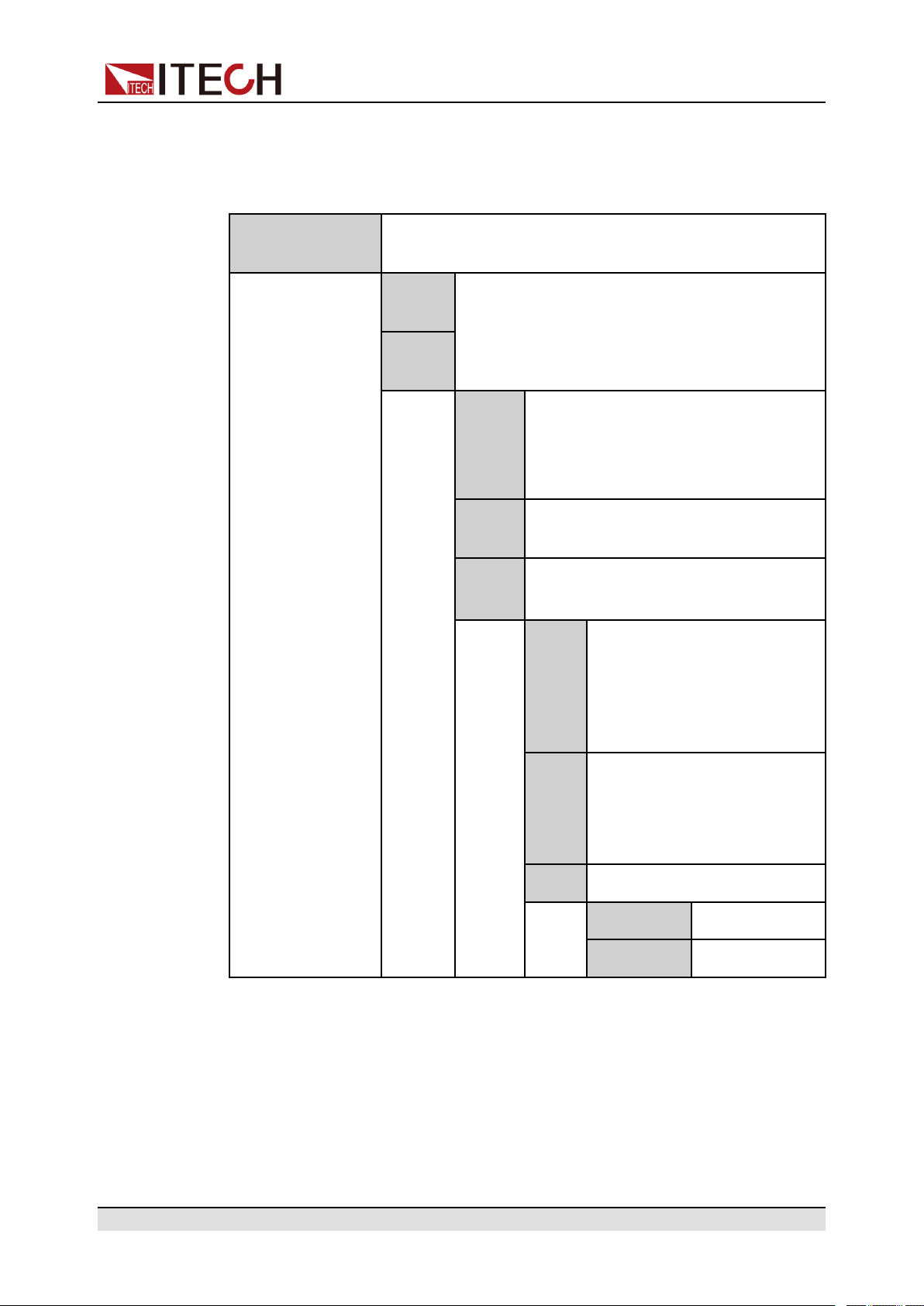

The description of the menu items is shown in the table below.

System System Menu

Beep Set the beeper state.

Basic Operation

You can press [Esc] to return to the previous menu.

Turn the beeper on.

Turn the beeper off.

PowerOn

On

Off

Select the power-on state.

When the instrument is powered on, the instru-

Reset

ment will initialize some settings and [On/Off]

state.

When the instrument is powered on, the instru-

Last

ment will remain the same settings and

[On/Off] state as last time you turned off the

instrument.

When the instrument is powered on, the instru-

Last+Off

ment will remain the same settings as last time

you turned off the instrument, but the [On/Off]

is OFF state.

Sense Set the sense function state.

Off Turn the sense function off.

On Turn the sense function on.

ListTrig Source Set the trigger method for the List files running.

DataLogger Trig

Source

I/O Con

Manual

Bus

External

Manual trigger

Bus trigger

External trigger

Set the trigger method for the data logging.

Manual

Bus

External

Manual trigger

Bus trigger

External trigger

Set the communication information between instrument and

PC.

USB USB communication interface

LAN LAN communication interface

Copyright © Itech Electronic Co., Ltd.

26

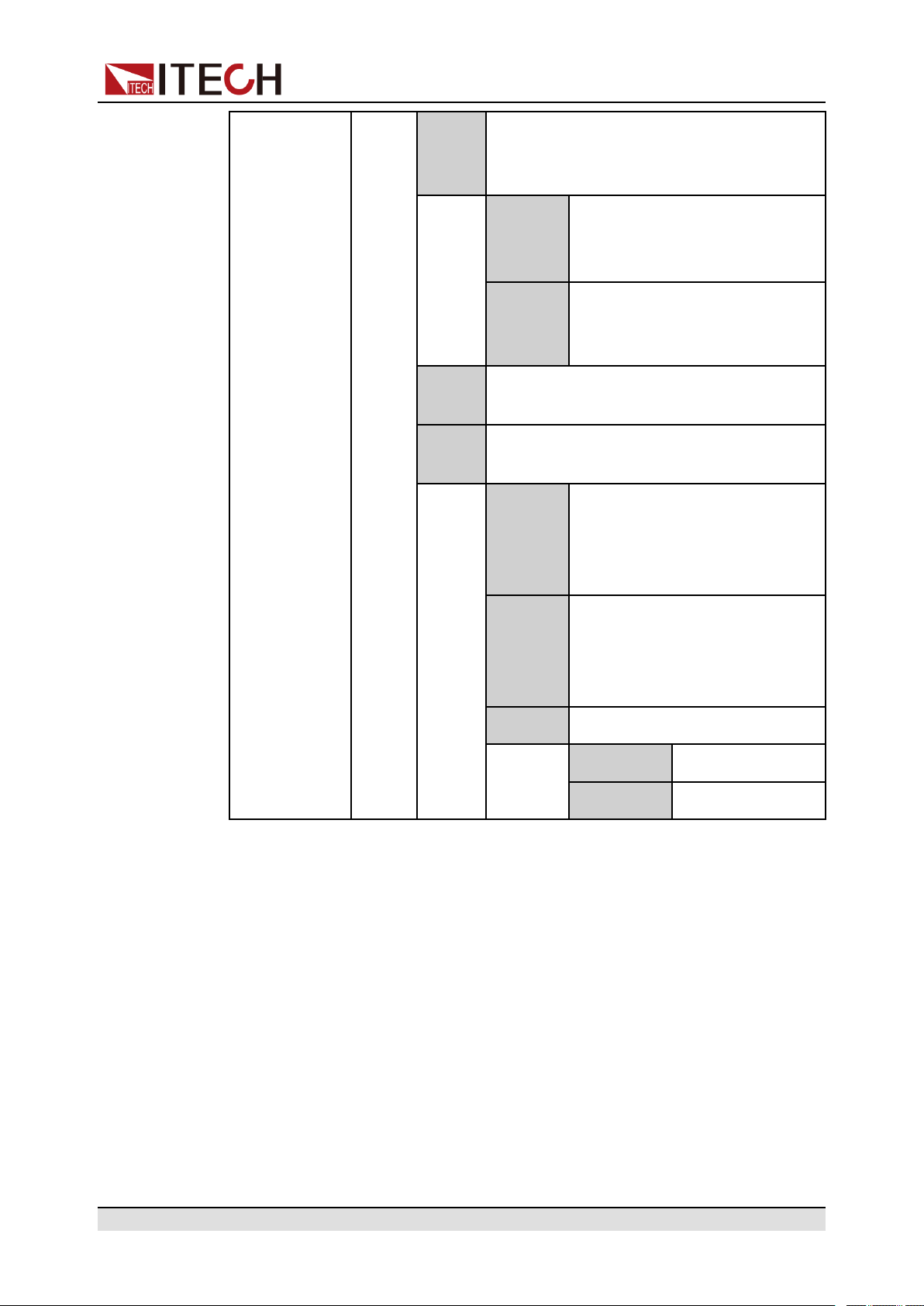

Page 38

Basic Operation

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

Info View the LAN information.

LAN Status: Down

IP Mode: Disconnect

IP Addr: 0.0.0.0

SubNet: 0.0.0.0

Gateway: 0.0.0.0

DNS1: 0.0.0.0

DNS2: 0.0.0.0

MAC: 8C:C8:F4:40:01:E1

MDNS Status:

HostName:

HostDesc:

Domain:

TCPIP::INSTR:

Socket Port: 30000

IP-Conf

Configure LAN IP information.

Auto: automatically configure the

address of the instrument.

Manual: manually configure the address of the instrument.

• IP Addr: 0.0.0.0

Set the IP address.

• SubNet: 0.0.0.0

Set the subnet mask.

• Gateway: 0.0.0.0

Set the gateway address.

• DNS1: 0.0.0.0

Set the preferred address of the

DNS server. If it is not involved,

there is no need to set it.

• DNS2: 0.0.0.0

Set the DNS server alternate

address. If it is not involved,

there is no need to set it.

• Socket Port: 30000

Set the port number.

ServConf

Configure the LAN services.

MDNS: MDNS service state.

• On

• Off

PING: PING service state.

• On

Copyright © Itech Electronic Co., Ltd.

27

Page 39

Basic Operation

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

• Off

Telnet-scpi: telnet-scpi service

state.

• On

• Off

Web: Web service state.

• On

• Off

VX-11: VX-11 service state.

• On

• Off

Raw-socket: Raw-socket service

state.

• On

• Off

Reset

CAN CAN communication interface.

Baudrate

Address

Prescal-erPrescale

BS1

Value

BS2

Value

VCP Select virtual serial communication interface.

Baudrate

Databit Data bit: 5/6/7/8

Select whether to confirm the LAN

setting or not.

Select the baud rate from the following options: 20k, 40k, 50k, 80k,

100k, 125k, 150k, 200k, 250k,

400k, 500k, 1000k.

Set the instrument address to a

number from 1 to 65535.

PTS

PBS

Baud rate: 4800/9600/19200/

38400/57600/115200

Parity

Stopbit Stop bit: 1/2

Display RS232

or GPIB according to optional interface. In

addition, RS232

RS232 Select RS-232 communication interface.

Baudrate

Databit Data bit: 5/6/7/8

Copyright © Itech Electronic Co., Ltd.

Parity bit: N (No parity) / E (Even

parity) / O (Odd parity)

Baud rate: 4800/9600/19200/

38400/57600/115200

28

Page 40

Basic Operation

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

interface and the

analog interface

share an interface position.

Parallel

Digital Port

Parity

Stopbit Stop bit: 1/2

GPIB Select GPIB communication interface.

Address

Set the instruments to parallel operation mode.

Single

Master Set the instrument to master mode.

Slave Set the instrument to slave mode.

Set Digital I/O

By default, the menu item displays 7 options. You can set

parameters for each option respectively. After setting, the

corresponding change to each option becomes valid immediately. When re-entering DigPort, the interface can display

the changed option. For detailed introduction of menus and

functions, see 3.6.7 Digital I/O Function (Digital Port).

Set the instrument to single mode, i.e., disable

the parallel operation mode.

Total: Number of parallel instruments.

Parity bit: N (No parity) / E (Even

parity) / O (Odd parity)

Set the communication address (1

to 30).

IO-1. Ps-Clear, NotInvert

IO-2. Ps, Not-Invert

IO-3. Off-Status, NotInvert

IO-4. Ext-Trig, NotInvert

IO-5. INH-Living, NotInvert

IO-6. Sync-On, NotInvert

IO-7. Sync-Off, NotInvert

External Analog Function. This function is optional. The

Ext-Program

System Reset Select whether to restore the factory default settings or not.

System Info View the system information.

menu can only display when corresponding board card is inserted. For detailed menu settings, see 3.6.8 (Optional)

Analogue Function (Ext-Program).

Function setting of pin 1

Function setting of pin 2

Function setting of pin 3

Function setting of pin 4

Function setting of pin 5

Function setting of pin 6

Function setting of pin 7

Model

MAC Addr

SN

Copyright © Itech Electronic Co., Ltd.

Display the instrument model.

Display the MAC address, that is, the physical

address.

Display the serial number.

29

Page 41

Basic Operation

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

Main-Ver Display the system version information.

Ctrl-Ver Display the version information for a single

module.

FPGA-Ver Display the FPGA version information.

INV-Ver Display the control board version information.

2017/6/22

00:00:00

Press the composite button [Shift]+[P-set] (System) to enter the system

menu, and press [Esc] to exit the menu.

Display the system time.

3.6.1 Set the Beeper Status (Beep)

The user can turn the instrument beeper sound on or off base on personal

requirement.

The beeper sound works in the following scenarios:

• A beeper sound produced when the front panel key is pressed.

• When an error is generated inside the instrument, such as when the instru-

ment receives an unprocessable command in the remote state. At this time,

the instrument produces a beeper sound, and the flag “Error” appears on the

VFD.

• When the instrument is under protection status, such as over-temperature

protection. At this time, the instrument produces the beeper sound.

The setting procedures are as follows:

1. Press the composite keys [Shift]+[P-set] (System) on the front panel to enter the system menu.

The first displayed menu item Beep is used to set the beeper status.

2. Press [Enter] key to enter the parameter setting interface.

3. Press the Left / Right key or turn the knob to adjust the value of this

parameter.

• On: Default value, indicates the beeper is on.

• Off: Indicates the beeper is off.

4. After the parameter settings are complete, press [Enter].

At this point, the beeper status takes effect immediately.

Copyright © Itech Electronic Co., Ltd.

30

Page 42

3.6.2 Set the Power-on State (PowerOn)

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

This menu item is used to control the settings and output state when the power

supply is powered on.

The detailed power-on parameters and output state are as follows.

• The voltage, current, power setting values displayed on the main interface

when the instrument is powered on.

• Parameter setting values in the Config and Protect menus.

• The output state of the power supply, i.e., the [On/Off] key state.

The procedures to set the menu item are as follows.

1. Press the composite keys [Shift]+[P-set] (System) on the front panel to enter the system menu.

2. Press the Up/Down key or turn the knob to select the [PowerOn] and press

[Enter].

Basic Operation

3. Press the Left / Right key or turn the knob to adjust the value of this

parameter.

• Reset: Default value, indicates when the instrument is powered on, the

instrument will initialize some parameter settings or state.

The affected parameters and the reset information are as shown in Table

3–1 Initial value of the parameter.

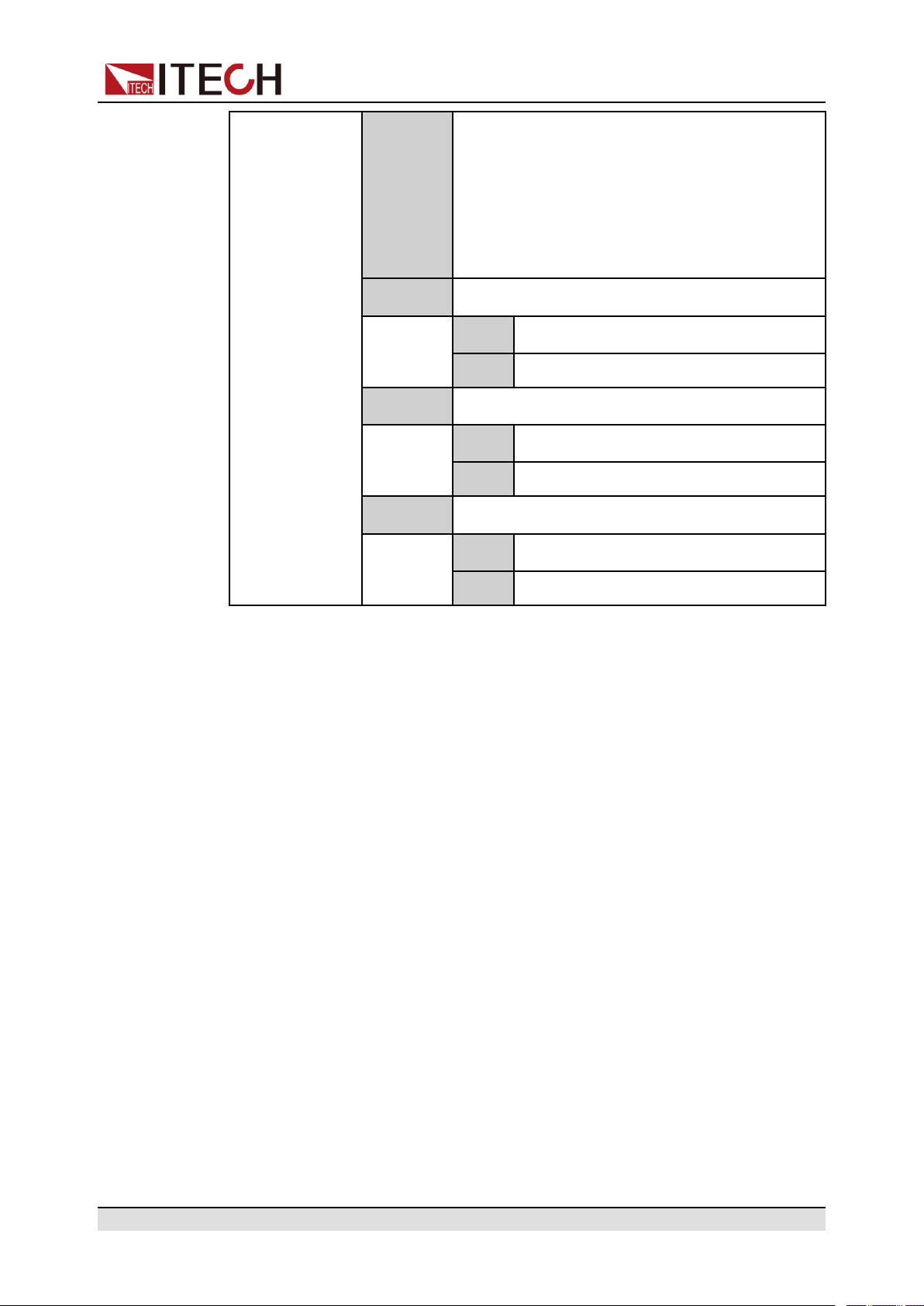

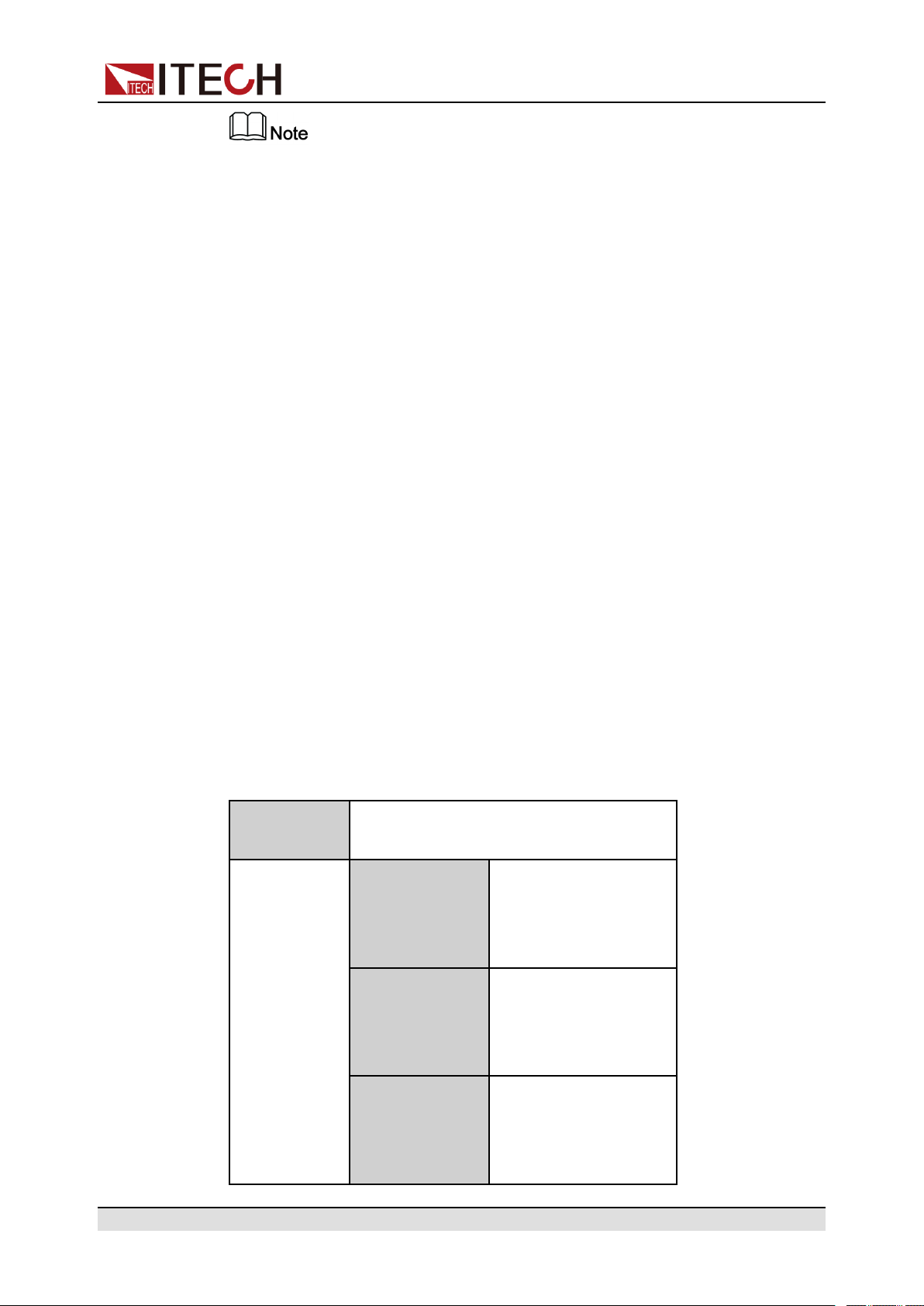

Table 3–1 Initial value of the parameter

Category Parameter Initial Value

Main

interface

Voltage setting: Vs One percent of the

rated voltage of the

instrument

Current setting: Is One percent of the

rated current of the

instrument

Upper limit of voltage: Vh, and

lower limit of voltage: Vl

Upper limit value: One

percent of the rated

voltage of the

instrument

Lower limit value: 0

Upper limit of current: I+, and

lower limit of current: I-

Copyright © Itech Electronic Co., Ltd.

One percent of the

rated current of the

instrument

31

Page 43

Basic Operation

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

Category Parameter Initial Value

Config

menu

Upper limit of power: P+, and

lower limit of power: P-

[On/Off] status Off

Mode CV

Speed High

V-Rise Time/I-Rise Time 0.1s

V-Fall Time/I-Fall Time

Output Res 1000

On Delay/Off Delay 0

Rated power value of

the instrument

• Last: Indicates when powered on, the instrument will remain the same

parameter settings (i.e., the parameters controlled by the *SAV 0 command, see 3.4 Save and Recall Operations) as last time you turned off

the instrument.

• Last+Off: Indicates when powered on, the instrument will remain the

same settings as last time you turned off the instrument, but the output

state is Off.

Under the condition of Last+Off, the output switch state is not con-

strained by the *SAV 0 instruction.

4. After the parameter settings are complete, press [Enter].

For example, Last is selected, and the voltage value is set to 20V. After the

instrument is powered off and then powered on, the voltage displayed on the

interface is 20V.

3.6.3 Sense Function (Sense)

This menu item is used to switch the power supply to local measurement or remote sensing.

The IT6000C series power supply supports two connection methods: Local

measurement and Remote sensing. The remote sensing is used for maximizing

measurement accuracy. (Refer to 1.4 Connecting the Device Under Test (DUT))

The procedures to set the menu item are as follows.

Copyright © Itech Electronic Co., Ltd.

32

Page 44

1. Press the composite keys [Shift]+[P-set] (System) on the front panel to en-

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

ter the system menu.

2. Press the Up/Down key or turn the knob to select the Sense and press

[Enter].

3. Press the Left / Right key or turn the knob to adjust the value of this

parameter.

• Off: Default value, indicates turn the sense function off.

• On: Indicates turn the sense function on.

4. After the parameter settings are complete, press [Enter].

3.6.4 Select Trigger Source (Trig Source)

For the IT6000C series power supply, the List and data logging functions can be

triggered for running by the following methods:

Basic Operation

• Manual: Default value, indicates the trigger occurs when the

[Shift]+[On/Off] (Trigger) keys are pressed from the front panel.

• Bus: Indicates the trigger occurs via the communication cables. When the

trigger command *TRG is received, the IT6000C instrument generates a

trigger.

• External: Indicates the trigger occurs via the pin 4 of the digital I/O interface

(P-IO).

For details, see 3.6.7.4 IO–4. Ext-Trig, Not-Invert.