Page 1

Internal Resistance Tester

IT5101 User Manual

Model:IT5101/IT5101E

Version:V1.0

Page 2

Notices

© Itech Electronic, Co., Ltd. 2016

No part of this manual may be

reproduced in any form or by any means

(including electronic stor age and

retrieval or translation into a foreig n

language) without prior permission and

written consent from Itech Electronic,

Co., Ltd. as governed by international

copyright laws.

Manual Par t Number

IT5101-402530

Revision

1st Edition: May 26, 2016

Itech Electronic, Co., Ltd.

Trademarks

Pentium is U.S. registered trademarks

of Intel Corporation.

Microsoft, Visual Studio, Windows and

MS Windows are registered trademarks

of Microsoft Corporation in the United

States and/or other countries and

regions.

Warranty

The materials contained in this

document are provided “as is”, and

is subject to change, without prior

notice, in future editions. Further, to

the maximum extent permitted by

applicable laws, ITECH disclaims

all warrants, either express or

implied, with regard to this manual

and any information contained

herein, including but not limited to

the implied warranties of

merchantability and fitness for a

particular purpose. ITECH shall not

be held liable for errors or for

incidental or indirect damages in

connection with the furnishing, use

or application of this document or of

any information contained herein.

Should ITECH and the user enter

into a separate written agreement

with warranty terms covering the

materials in this document that

conflict with these terms, the

warranty terms in the separate

agreement shall prevail.

Technology Licenses

The hardware and/or software

described herein are furnished under a

license and ma y be used or copied only

in accordance with the terms of such

license.

Restricted Rights Leg end

Restricted permissions of the U.S.

government. Permissions for software

and technical data which are authorized

to the U.S. Government only include

those for custom provision to end users.

ITECH provides this customary

commercial license in software and

technical data pursuant to FAR 12.211

(Technical Data) and 12.212 (Computer

Software) and, for the Department of

Defense, DFARS 252.227-7015

(Technical Data – Comm erci a l Items)

and DFARS 227.7202-3 (Rights in

Commercial Computer Software or

Computer Software Documentation).

Safety Notices

A CAUTION sign denotes a

hazard. It calls attention to an

operating procedure or practice

that, if not correctly performed

or adhered to, could result in

damage to the product or loss of

important data. Do not proceed

beyond a CAUTION sign until

the indicated conditions are fully

understood and met.

A WARNING sign denotes a

hazard.

It calls attention to an

operating procedure or practice

that, if not correctly performed

or adhered to, could result in

personal injury or death. Do not

proceed beyond a WARNING

sign until the indicated

conditions are fully understood

and met.

NOTE

A NOTE sign denotes important

hint. It calls attention to tips or

supplementary information that

is essential for users to refer to.

Page 3

IT5101 User Manual

Copyright© Itech Electronics Co ., Ltd. i

Quality Certification and Assurance

We certify that IT5101 internal resistance tester meets all the published

specifications at time of shipment from the factory.

Warranty

ITECH warrants that the product will be free from defects in material and

workmanship under normal use for a period of one (1) year from the date of

delivery ( except those descri bed in the Limitation of Warranty below).

For warranty service or repair, the product must be returned to a service center

designated by ITECH.

The product returned to ITECH for warranty service must be shipped

PREPAID. And I TECH will pay for return of the product to customer.

If the product is returned to ITECH for warranty service from overseas, all

the freights, duties and other taxes shall be on the account of customer.

Limitation of Warranty

This War ranty will be rendered invalid if the product is:

Damaged resul t i ng f rom cu sto mer-w i r ed cir cui t s or cust o mer-s uppl i ed par t s

or accessories;

Modified or repaired by customer without authorizati on;

Damaged resulting from customer-wired circuits or use in an environment

not designated by us;

The product model or serial number is altered, deleted, removed or made

illegi ble by customer;

Damaged as a result of accidents, including but not limited to lightning,

moisture, fire, improper use or negligence.

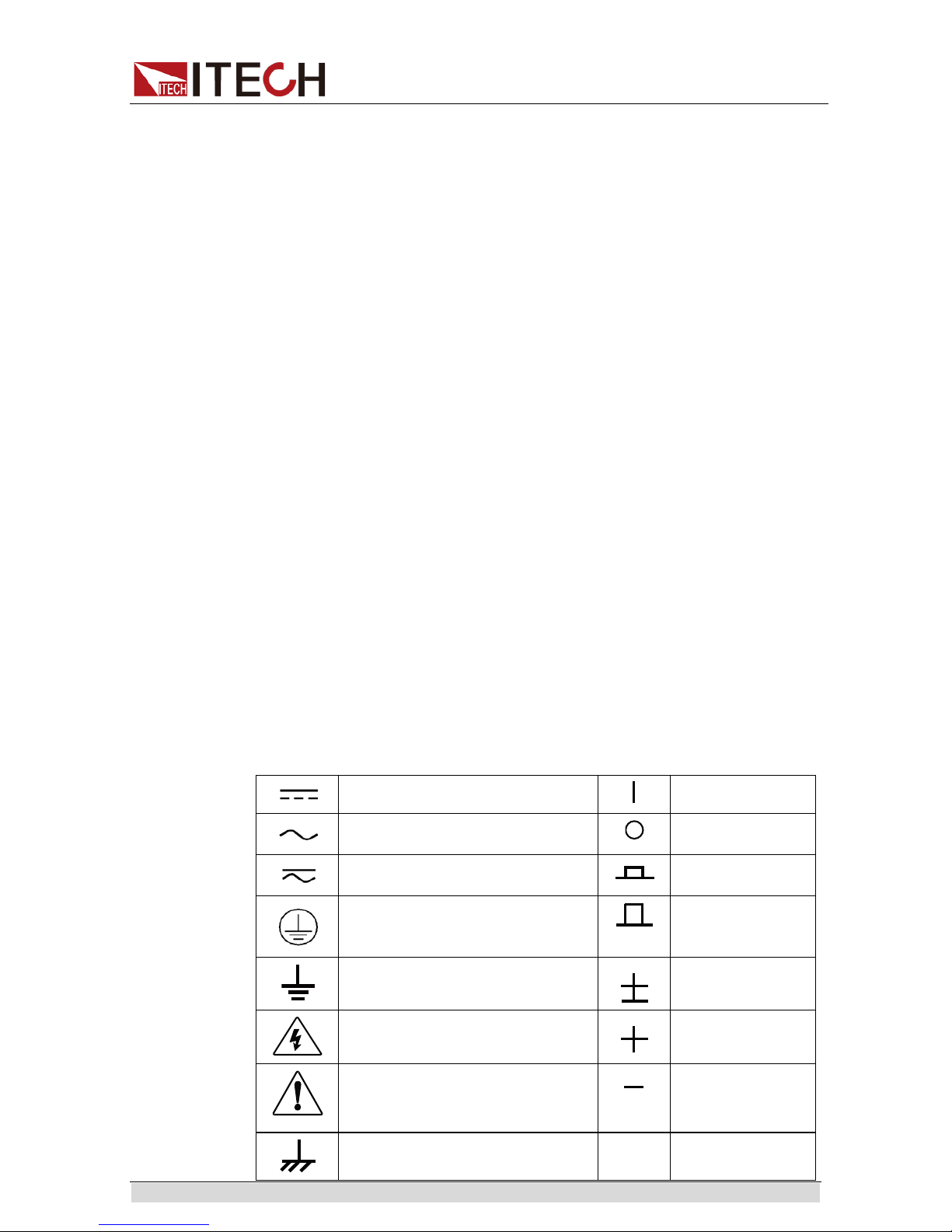

Safety Symbols

Direct current

ON (power)

Alternating current

OFF (power)

Both direct and alternating current

Power-on stat e

Chassis (earth ground) symbol.

Power-off state

Earth (ground) termi nal

Reference

terminal

Caution

Positive terminal

Warning (refer to this manual for

specific Warning or Caution

information)

Negati ve terminal

A chassis terminal

-

-

Page 4

IT5101 User Manual

Copyright© Itech Electronics Co ., Ltd. ii

Safety Precautions

The following safety precautions must be observed during all phases of

operation of this instrume nt. Failure to compl y wit h these pr ecaut i ons or sp eci fic

warnings elsewhere in this manual will constitute a default under safety

standards of design, manufacture and intended use of the instrument. ITECH

assumes no l iability for the customer’s failure t o comply with these preca utions.

Do not use the instrum ent if it is damaged. Before operation, check

the casing to see whether it cracks. Do not operate t he instrument in

the presence of inflammable gasses, vapors or du sts.

The internal resistance test er is provided with a three-cor e pow er line

during delivery and should be connected to three-core junction b ox.

Before operation, be sure t hat the internal resistance tester is well

grounded. M ake sure to use the power cord supplied by ITEC H.

Check all marks on t he instrumen t before connecting the instrument

to power supply.

Use electric wires of appropriate load. All loading wires should be

capable of b earing maximum short-circuit of electronic load without

overheat ing. If th ere are multi p le loads, each pai r of the load power

cord must be carr y out t he f ull rat ed short -ci rcui t out put cur r ent of the

power securel y.

Ensure the voltage fl uct uati on of mai ns supply i s less t han 10% of the

working voltage range in o rder to reduce risks of fire and ele ctric

shock.

Do not install alt ernative parts on the inst rument or per form any

unauthorized modifi cation.

Do not use the instrument if the detachable cover is removed or

loosen.

To prevent the possibility of accidental injuries, be sure to use the

power adapter supplied by the manufacturer only.

We do not accept responsibility for any direct or indi rect financial

damage or loss of profit that might occur when using the instrument.

This instrument is used for industrial purposes. Do not apply this

product to IT power supply system.

Never use the instrument with a life-support system or any other

equipment subject to safety requirements.

Failure to use the i n strument as directed by the manufacturer may

render its protective features void.

Always clean the casing w ith a dry cloth. Do not clean the internals.

Make sure the vent hole is alway s unblocked.

Environmental Conditions

The instrument is designed for indoor use and an area with low condensation.

The table below shows the general environmental requirements for the

instrument.

Environmental Conditions

Requirements

Operating tem perature

0°C to 40°C

Page 5

IT5101 User Manual

Copyright© Itech Electronics Co ., Ltd. iii

Operating humidity

20%-80% (non-condensation)

Storage temper ature

-20°C to 70 °C

Altitude

Operating up to 2,000 meters

Installation category

II

Pollution degree

Pollution degree 2

Note

To make accurate measurements, allow the instrument to warm up for 30 min.

Regulatory Markings

The CE mark indicates that the product

complies with all the relevant European

legal directives. The specific year (if any)

affixed refers to the year when the design

was approved.

The instrument complies with the WEEE

Directive (2002/96/EC) marking

requirement. This affix product label

indicates that you must not discard the

electrical/electronic product in domestic

househol d waste.

This symbol indicates the time period

during which no hazardous or toxic

substances are expected to leak or

deteriorate during normal use. The

expected useful life of the product is 10

years. The product can be used safely

during the 10-year Environment Friendly

Use Period (EFUP). Upon expiration of

the EFUP, the product must be

immediately recycled.

Waste Electrical and Electronic Equiment (WEEE)

Directive

2002/96/E C Waste Electrical and Electronic Equipment

(WEEE) Directive

This product complies with the WEEE Directi ve (2002/96/EC)

marking requirement. This affix product label indicates that you

must not discard the el ectrical/electronic product in domestic

househol d waste.

Product Category

With reference to the equipment classifications described in the

Annex 1 of the WEEE Direct ive, this instrument i s classified as

a “Monitoring and Control Instrument”.

To return thi s unwant ed i nst rument , cont a ct y our near est IT ECH

office.

Page 6

IT5101 User Manual

Copyright© Itech Electronics Co ., Ltd. iv

Compliance Information

Complies with the essential requirements of the following applicable European

Directives, and carries the CE marking accordi ngly:

Electromagnetic Compatibility (EMC) Directive 2014/30/EU

Low-Voltage Directive (Safety) 2014/ 35/EU

Conforms with the following product standards:

EMC Standard

IEC 61326-1:2012/ EN 61326-1:2013 ¹²³

Reference Standards

CISPR 11:2009+A1:2010/ EN 55011:2009+A1:2010 (Group 1, Class A)

IEC 61000-4-2:2008/ EN 61000-4-2:2009

IEC 61000-4-3:2006+A1:2007+A2:2010/ EN 61000-4-3:2006+A1:2008+A2:2010

IEC 61000-4-4:2004+A1:2010/ EN 61000-4-4:2004+A1:2010

IEC 61000-4-5:2005/ EN 61000-4-5:2006

IEC 61000-4-6:2008/ EN 61000-4-6:2009

IEC 61000-4-11:2004/ EN 61000-4-11:2004

1. The product is intended for use in non-residential/non-domestic environments. Use of the

product in residential/domestic environments may cause electromagnetic interference.

2. Connection of the instrument to a test object may produce radiations beyond the specified

limit.

3. Use high-performance shielded interface cable to ensure conformity with the EMC standards

listed above.

Safety Standard

IEC 61010-1:2010/ EN 61010-1:2010

Page 7

IT5101 User Manual

Copyright© Itech Electronics Co ., Ltd. v

CONTENT

Quality Certification and Assurance .........................................................................................................................i

Warranty .................................................................................................................................................................i

Limitation of Warranty ............................................................................................................................................i

Safety Symbols ........................................................................................................................................................i

Safety Precautions .................................................................................................................................................. ii

Environmental Conditions ...................................................................................................................................... ii

Regulatory Markings ............................................................................................................................................. iii

Waste Electrical and Electronic Equiment (WEEE) Directive ................................................................................... iii

Compliance Information ........................................................................................................................................ iv

Chapter1 Inspection and Installation ............................................................................................................... 1

1.1Verifying the Shipment ..................................................................................................................................... 1

1.2 Optional Accessories ....................................................................................................................................... 1

1.3 Instrument Size Introduction ........................................................................................................................... 5

1.4Dimension ........................................................................................................................................................ 5

1.5 Adjusting the Handle ....................................................................................................................................... 7

1.6 Removing the Handle ...................................................................................................................................... 7

1.7 Rack Mounting ................................................................................................................................................ 8

1.8 Connecting the Power Cord ............................................................................................................................. 8

1.9 Connecting Test Lines ( Optional) ..................................................................................................................... 8

Chapter2 Quick Start ...................................................................................................................................... 10

2.1Brief Introduction ........................................................................................................................................... 10

2.2 Features ........................................................................................................................................................ 10

2.3 Front Panel Introduction ................................................................................................................................ 11

2.4 Introduction to keyboard ............................................................................................................................... 11

2.5 Screen Indicator Lamps Description ............................................................................................................... 12

2.6 Rear Panel Introduction ................................................................................................................................. 12

2.7 Power-on Selftest .......................................................................................................................................... 12

Chapter3 Function and Features .................................................................................................................... 15

3.1 Range Setting ................................................................................................................................................ 15

3.2Sampling Rate Setting ..................................................................................................................................... 16

3.3 System Menu ................................................................................................................................................ 16

3.4Reset System .................................................................................................................................................. 18

3.5Frequency Filter Setting .................................................................................................................................. 19

3.6 Alarm Mode Setting ...................................................................................................................................... 20

3.7Compare Function .......................................................................................................................................... 21

3.8 Calculate Function ......................................................................................................................................... 22

3.9Average Function Setting ................................................................................................................................ 23

3.10Trigger Function Setting ................................................................................................................................ 24

3.11Statistics On/Off Setting ............................................................................................................................... 25

3.12Save/Recall Function .................................................................................................................................... 26

3.13 Screen Capture Function ............................................................................................................................. 27

3.14Statistics Function ........................................................................................................................................ 27

3.14.1View Statistic Results ........................................................................................................................ 28

3.14.2Display List ......................................................................................................................................... 28

3.14.3Display Normal Distribution Plot ....................................................................................................... 29

3.14.4Save/Recall Measureme nt Data ...................................................................................................... 29

3.15 Zero-Adjust Function ................................................................................................................................... 30

3.16 External Control(EXT I/O) ............................................................................................................................. 31

3.17 ERR Output .................................................................................................................................................. 35

3.18 Setting EOM Signal ...................................................................................................................................... 36

3.19 Timing Chart ................................................................................................................................................ 36

Chapter4 Routine Maintenance ..................................................................................................................... 38

Page 8

IT5101 User Manual

Copyright© Itech Electronics Co ., Ltd. vi

4.1 Self-test ......................................................................................................................................................... 38

4.2 Routine Maintenance .................................................................................................................................... 38

4.3 Contact ITECH Engineer ................................................................................................................................. 38

4.4 Return for Repair ........................................................................................................................................... 40

Chapter5 Remote Control .............................................................................................................................. 41

5.1 USB Interface ................................................................................................................................................. 41

5.2 GPIB Interface ............................................................................................................................................... 41

5.3 LAN Interface ................................................................................................................................................. 41

Chapter6 Specification ................................................................................................................................... 42

6.1 Main technical parameters ............................................................................................................................ 42

6.2 Supplemental characteristics ......................................................................................................................... 44

Page 9

Inspection and Installation

Copyright© Itech Electronics Co., Ltd. 1

Chapter1 Inspection and Installation

1.1Verifying the Shipment

Unpack the box and check the contents before operating the instrument. If

wrong items have been deliv ered, if items are missing, or if there is a defect

with the appearance of the items, contact the dealer from whi ch you purchased

the instr ume nt immediately. The package contents include:

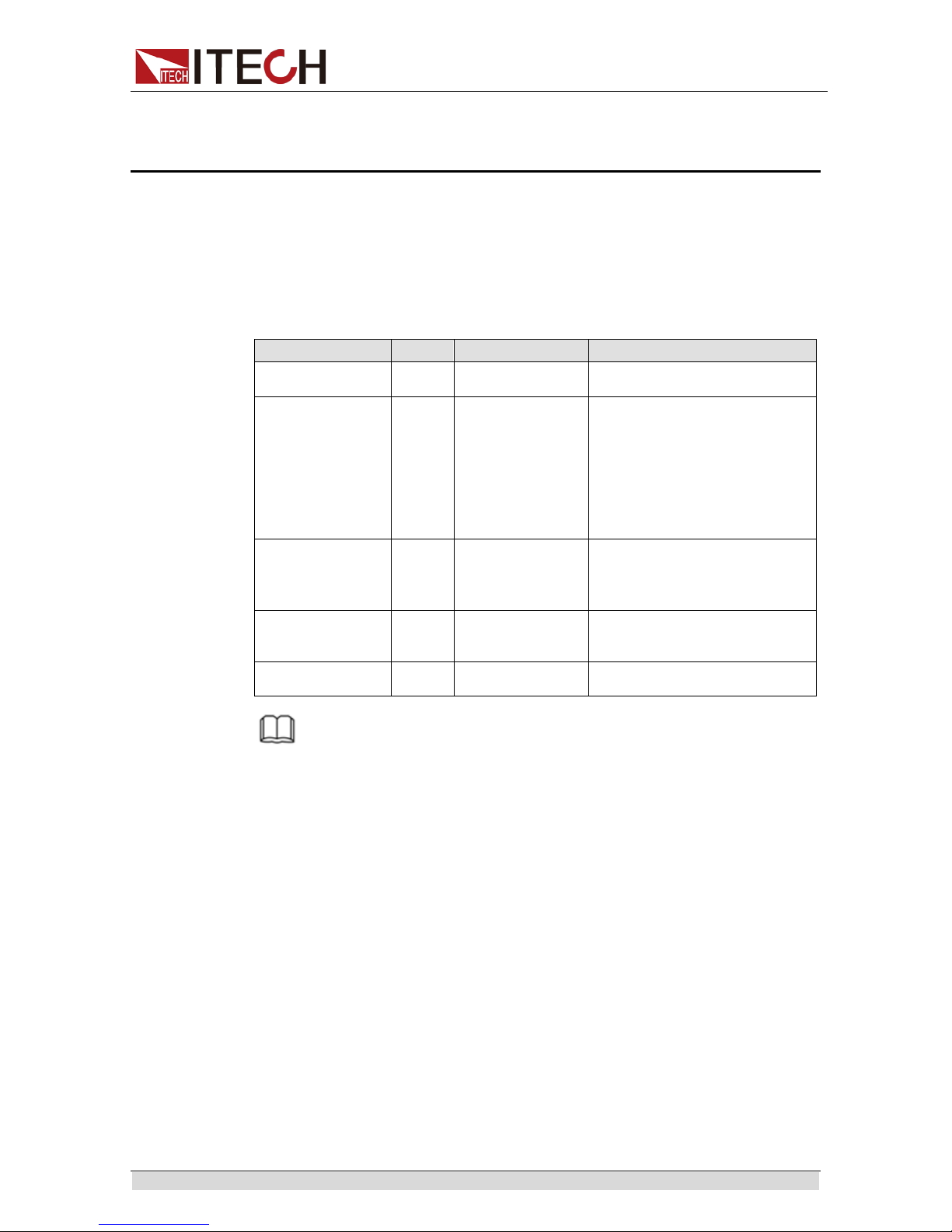

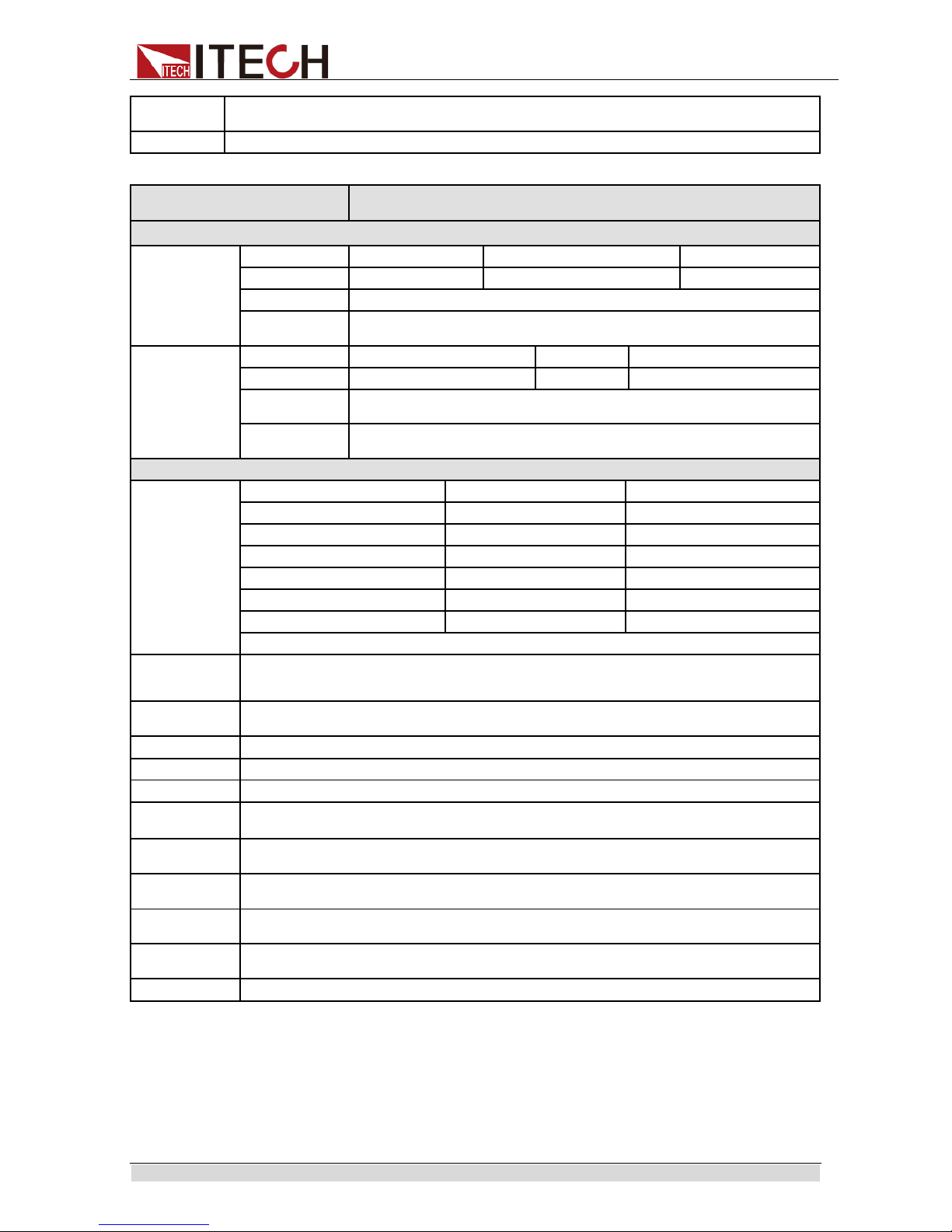

Checklist of Package Contents:

Item

Qty.

Model

Remarks

Internal

Resistance Tester

x1

IT5101/IT5101E

-

Power Cord

x1

IT-E171/IT-E172/

IT-E173/IT-E174

User may select an appropriate

power cord that matches the

specificat ions of power socket

used in the area. See the

Section

Connecting the Power Cord

for

details.

USB cable

x1

-

This accessory is selected

when the USB interface is used

for starting up rem ote

operation.

CD

x1 - It contains User’s Manual,

Programming Guide and other

user documentations.

Ex-factory Test

Report

x1 - It is the test report of the

instrument before delivery.

NOTE

Upon verification of the shipment, keep the package and relevant contents thereof in a

safe place. When returning the instrument for warranty service or repair, the specified

packing requirements shall be met.

1.2 Optional Accessories

IT5100 series internal resistance tester is supplied with the following optional

accessories (sold sep arately ):

Rack Mount Kit

This accessor y i s used t o mo unt t he i nst ru ment to sp eci al rack. ITECH provides

two models of rack mount kits: IT-E151 and IT-E151A. For detailed installation

process, refer to 1.7 Rack Mounting.

Test Lines

ITECH provides alone-sold test lines for professional measure. Test lines in

sold and related introduction are shown below. All lengths in the figure are in

mm.

IT-E601 IT-E601 Pin type lead (Under DC600V)

Page 10

Inspection and Installation

Copyright© Itech Electronics Co., Ltd. 2

Either for plane contacts or relay terminals that are not easy to clamp or small

objects like connectors, you j ust n ee d t o touc h the t est l i nes a gai nst the D U T f or

four-terminal measurement. The meter pen can be directly unscrewed for

changing For detailed length specif ication, see the figure above.

The central probe of the meter pen is Sense and the outer cylinder probe is

Source terminal. The schematic diagram is as shown below.

IT-E602 Large clip type lead for small component test ( Under DC600V)

It can be used to cl amp thick cylinder parts of DUT and is easy for operation. To

take four-terminal mea surement, directly clamp the DUT terminals. For det ailed

length specification, see the figure above.

The upper-jaw pr obe of al li gat or cli p i s Source terminal and t he low er -jaw probe

is Sense terminal. The schematic diagram is as shown below.

Page 11

Inspection and Installation

Copyright© Itech Electronics Co., Ltd. 3

IT-E603 Pin type lead for high-voltage bat tery test (Under DC600V)

The test lines are needle-type test lines with high dielectric strength designed

for DC300V (CATI) four-terminal structure, especially for high-voltage battery

packs or batteries with high docking ground potential. Two parallel pins are

designed at top for measurement through stable touch. The meter pins are

changeabl e. For detai led length specifications, see the figure above.

In the two meter pens, the one at the short corner side is Sense terminal and

the other is Source terminal. The schematic diagram is as s hown below.

IT-E604 4-terminal testing lead (Under DC600V)

The four-terminal test lines can connect and test DUT intuitively and

conviniently.

The alligator clip is Source terminal and rubber plug is Sense terminal. The

schemati c diagram is as shown below.

Page 12

Inspection and Installation

Copyright© Itech Electronics Co., Ltd. 4

Zero adjustment board

For zeroing, you need ITECH IT-E605 zeroing plate. The front and back sides

of the zeroing plate are as shown below.

Front side:

IT-E601: wiring area for zeroing by IT-E601 testing lines.

Or, the user can directly insert the crown-head meter pen to the

corresponding wiring holes in IT-E601. The outer circle corresponds to

Source terminal and the inner core corresponds to Sense terminal. There

is no positive and negative difference.

IT-E602: wiring area for zeroing by IT-E602 testing lines.

Directly clamp wiring end of IT-E602 area with the alligator clip, where the

Source and Sense terminals correspond to the gold-plated areas at front

and back. Pay attention to positive and negative identifications.

IT-E603: wiring area for zeroing by IT-E603 testing lines.

Directly insert two probes to corresponding holes of Source and Sense

terminals. Ther e is no positive and negative difference.

Page 13

Inspection and Installation

Copyright© Itech Electronics Co., Ltd. 5

IT-E604: wiring area for zeroing by IT-E604 testing lines.

Connect the four terminals of the test line to wiring areas respectively

based on identifications on the gold-plated area. Pay attention to positive

and negative identi fications.

Back side:

IT-E602: wiring area for zeroing by IT-E601 testing lines. The test line has

alligat or clips. Directly clamp the clips to connect Source and Sense terminals.

1.3 Instrument Size Introduction

The instrument should be installed at well-ventilated and rational-s ized space.

Please sel ect appropr i at e sp ace for i nst all ati on based on t h e internal resistance

tester size.

1.4Dimension

the detail size of the internal resistance tester is shown as below.

Dimension:

width:226mm

Height:105.18mm

Depth:383.92mm

Dimension

Page 14

Inspection and Installation

Copyright© Itech Electronics Co., Ltd. 6

Page 15

Inspection and Installation

Copyright© Itech Electronics Co., Ltd. 7

1.5 Adjusting the Handle

The instrument is equi pped with a handle for user to easily carry and place i t.

The handle can be adjusted in three manners as shown in the figure below. To

adjust the handle, first pull out the handle gently toward the left and right sides

of the inst rument, and then rotate it slowly to i ts alignment key s.

1.6 Removing the Handle

To mount the instrument on a r ack, fi rst remove the handle from the instrument.

The handl e can be removed following the procedure s below:

1. Rotate the handle to the position as shown in the following figure.

Page 16

Inspection and Installation

Copyright© Itech Electronics Co., Ltd. 8

NOTE

The handle can be easily removed from the alignment hole and key between the

handle and the instrument.

2. Pull out the handle toward the left and rights sides of the instrument from

the alignment hole.

NOTE

When mounting or removing the handle, do not squeeze it too hard and mind your

hand.

1.7 Rack Mounting

IT5101 can be mounted on a standard 19” rack. ITECH provides user with

IT-E151/IT-E151A rack, as an optional mount kit. The detailed operation please

refer to t he U ser Manual of your mount kit.

1.8 Connecting the Power Cord

Before connecting the power cord, please ensure the power switch of the

instrument is turned OFF. Only use the power cord supplied as a standard

accessory. The range of working vot age is AC100V~ AC 240V.

A summary of connection pr ocedures is given below.

Select from the flowing Schedule of Power Cord Specifications an appropriate

power cord that matches the voltage for the area in which you use the

instrument. If the power cord included in the instrument you purchased does

not match the voltage, co ntact the dealer or manufacturer f or change.

China

IT-E171

United States &

Canada & Japan

IT-E172

Europe

IT-E173

England

IT-E174

1.9 Connecting Test Lines ( Optional)

To avoid burning out, be sure to conf irm that power voltage matches

with supply voltage.

To avoid electrical shock, bef ore testing, please make sure the

ratingvalues of the testing lines, and do not measure t he voltage that

higher than t he rating v alue.

To avoid battery short cir cuit , be sur e to check t hat t he te st l ine e nd is

not connected when connecting or disassembling the test line. When

the test li n e end is connected with battery, short circuit may cause

severe acci dent.

E

N L

E

L N

E

N L

E

L N

Page 17

Inspection and Installation

Copyright© Itech Electronics Co., Ltd. 9

The test lines are not standard accessories of the instrument and are for

individual sales. Please select them based on actual usage. This

instrument has a socket terminal for resistance measurement that is

independent from four t erminals For details, refer to test line intr oduction in

“1.1 Verifying the Shipment ”

1. Before connecting the test lines, be sure that the instrument Power is

in Of f position.

2. Please check that the top of four-terminal test line is not connect ed.

3. Connect the 4-terminal test line to the input terminal.

Connect the red test line to the red terminal, and the black test line to

the black ter minal. Match the red sense ▼ symbol at the fr ont panel to

the ▲ symbol of red test line, and the black sense▼ symbol to the ▲

symbol of black test line.

4. Connect the other side to the DUT terminal based on current test line

type.

Red

Black

Page 18

Quick Start

Copyr ight © Ite c h Electronics Co., Ltd. 10

Chapter2 Quick Start

This chapter introduces power-on check steps of IT5101 to ensure normal

start-up and usage under ini tialization st atus. This part also introduces the front

panel, the rear panel, and key functions of inter nal resistance tester, make sure

that you can quickly know the appearance, instruction and the key function

before you operate the instrument. Help you make better use of this series of

internal resistance tester.

2.1Brief Introduction

IT5100 series is a series of battery internal resistance testers with high

precisi on, hi gh r esol uti on and hi gh sp eed. I T 5100 ado pts AC 4-terminal sensi ng,

that means the tester can test internal resistance and voltage simultaneously

with high precision. Resistance resolution is down to 0.1 μΩ, voltage resolution

is 10 μV. Combined with external USB disk, IT5100 series can be widely applied

in cellphone lithium batteries, electric vehicle batteries and other batteries

inspecti on and sorti ng.

2.2 Features

IT5100 Series internal resistance tester is featured with:

Support resistance & voltage simultaneously test and display

Measure accuracy of battery i nternal resistance: 0.4%;

Measurement accuracy of battery voltage: 0.01%;

Maximum volt age meas ure ment resol ut i on: 10uV

Maximum resistance measurement resolution of IT5101 model: 0.1uΩ

Maximum resistance measurement resolution of IT5101E model: 10uΩ

Supports VISA / USBTMC/ SCPI prot ocol

Automatically judge whether test results exceed set specifications based

on the maximum/mi ni mum limitation of test parameters

Built-in GPIB, USB, LAN i nterfaces

Select multi-measurem ent speed based on requirements

Statistics calculation and data USB storage f unction

Software mo nitoring via computer

Software-based calibration

4.3 inch LCD s creen

Page 19

Quick Start

Copyr ight © Ite c h Electronics Co., Ltd. 11

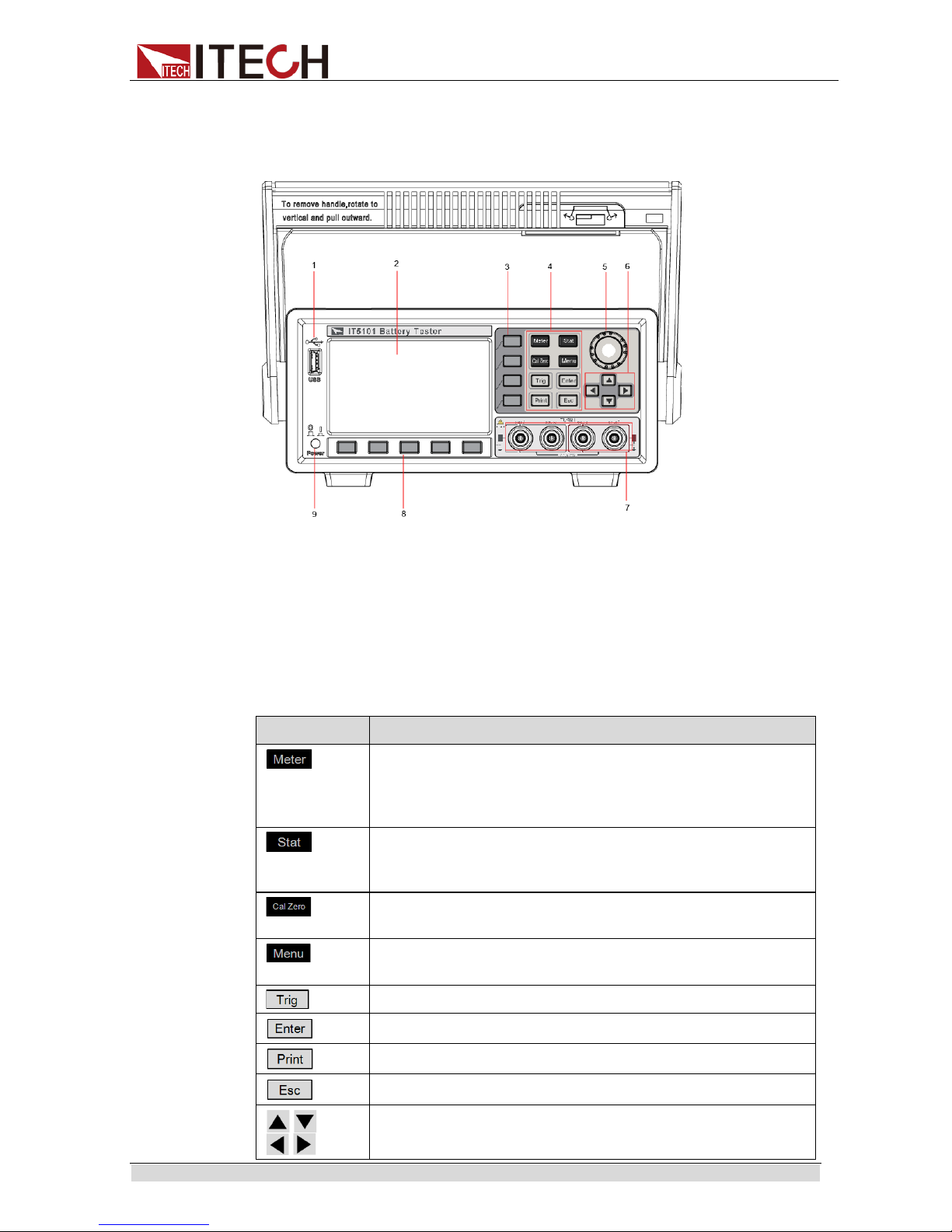

2.3 Front Panel Introduction

Schematic Diagr am of Front Panel of IT 5101 series internal resis tance test er is as

follow.

2.4 Introduction to keyboard

The functions of keys on the front panel of the IT5101 ser ies internal resistance

tester are shown in t he following table.

Key tag

Name and funct ion

Basic Measurement key When this key is pressed, the

measurement value

of voltage and resistance will be

displayed, and also displayed the config menu of

measurement.

Statistics key. When this key is pressed, the statistic

parameters (average, standard deviation) of measurement

data will be displayed.

Zero key. When this key is pressed, zeroing information will

be displayed.

Menu key, used for setting relevant measurement

parameters.

Used for manual trigger.

Enter key, used for confirming and saving the settings.

Used for sa ving screen images

Cancel/R eturn key

Up/Down key and Left/Right key

1 USB Interface

2 Display

3 Menu Ke ys

4 Functi on Keys

5 Setting knob

6 Arrow keys

7 Source terminals & Sense terminals

8 Menu Ke ys

9 Power Key

Page 20

Quick Start

Copyr ight © Ite c h Electronics Co., Ltd. 12

Key tag

Name and funct ion

Soft keys for correspon ding screen menu operations

Rotary knob: used for setting the value indicated by the cursor,

selecting the voltage and resistance range, adjusting the

waveform, etc.

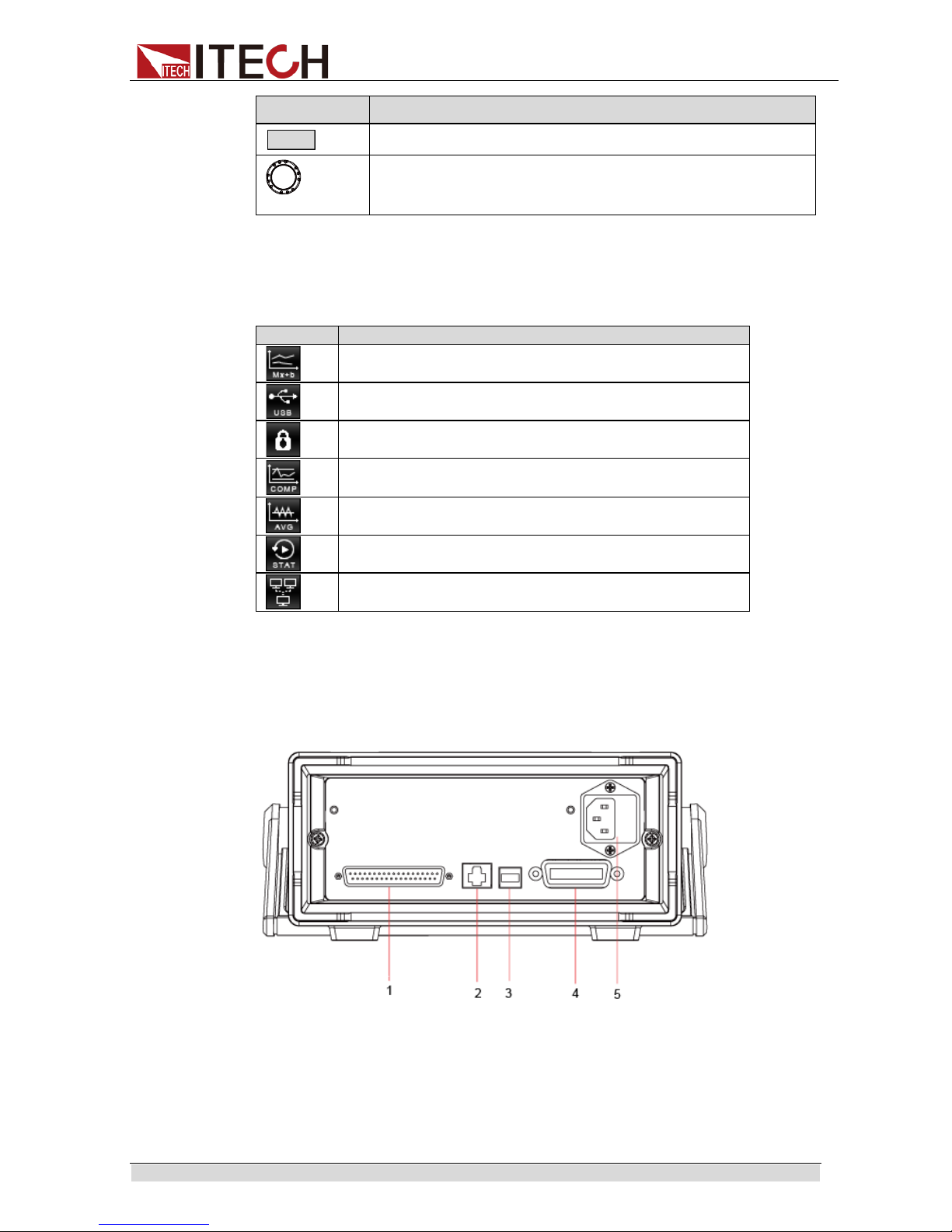

2.5 Screen Indicator Lamps Description

IT5101 series internal resistance tester screen indicator lamps description as

follows:

Flag

Function Description

Mx+B statistic function ON

Insert USB p eriphery device

Key lock. Press this key to disable all the keys except

Esc; press Esc key again for 5s to unlock all other key s.

Compare function ON.

Average fun ction ON.

Statistic functi on O N .

Used for turning on remot e control

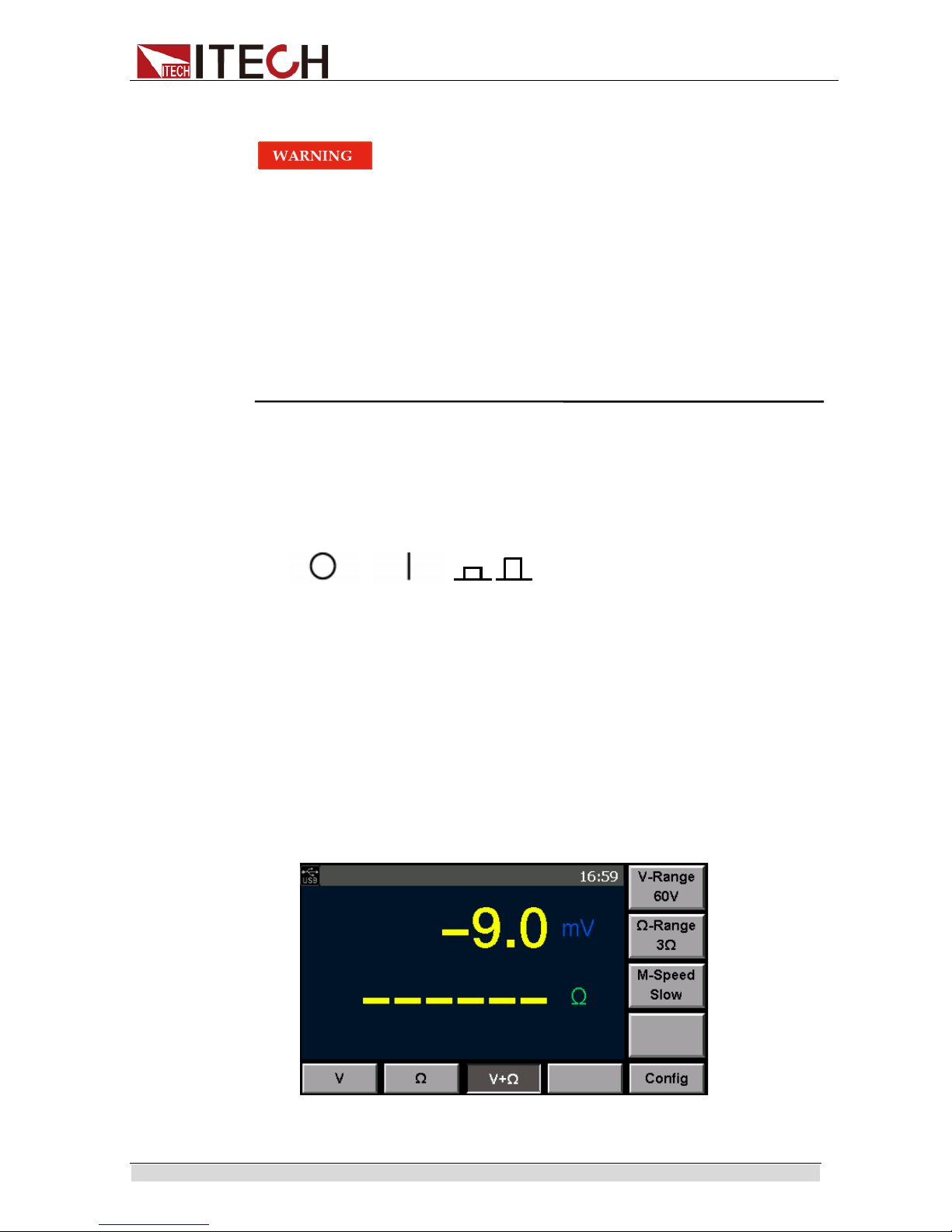

2.6 Rear Panel Introduction

Schematic diagram of rear panel of IT5101 series internal resistance tester is

as follow.

1 System I/O Interface

2 LAN Interface

3 USB Interface

4 GPIB Interface

5 AC Power Input

2.7 Power-on Selftest

A successful selft est indicates that the purchased power product meets delivery

standards and is available for normal usage.

Page 21

Quick Start

Copyr ight © Ite c h Electronics Co., Ltd. 13

Before operation, please confirm that you have fully understood the safety

instructions.

To avoid bur ning out, be sure to confirm that power voltage matches

with supply voltage.

The IT5101 supports 110V/220VAC input and no need t o sw itch.

Maximum voltage measurement r ange of instrument measurement

terminal: -300V-300V; max imum voltage between positiv e and

negative and ground: 300V. Do not connect overvoltage; otherwise,

the equipment will be burnt!

Be sure to connect the main power socket t o the power outl et of

protective grounding. Do not use termi nal board without protective

grounding. Before operation, be sure that the internal resistance

tester is well grounded.

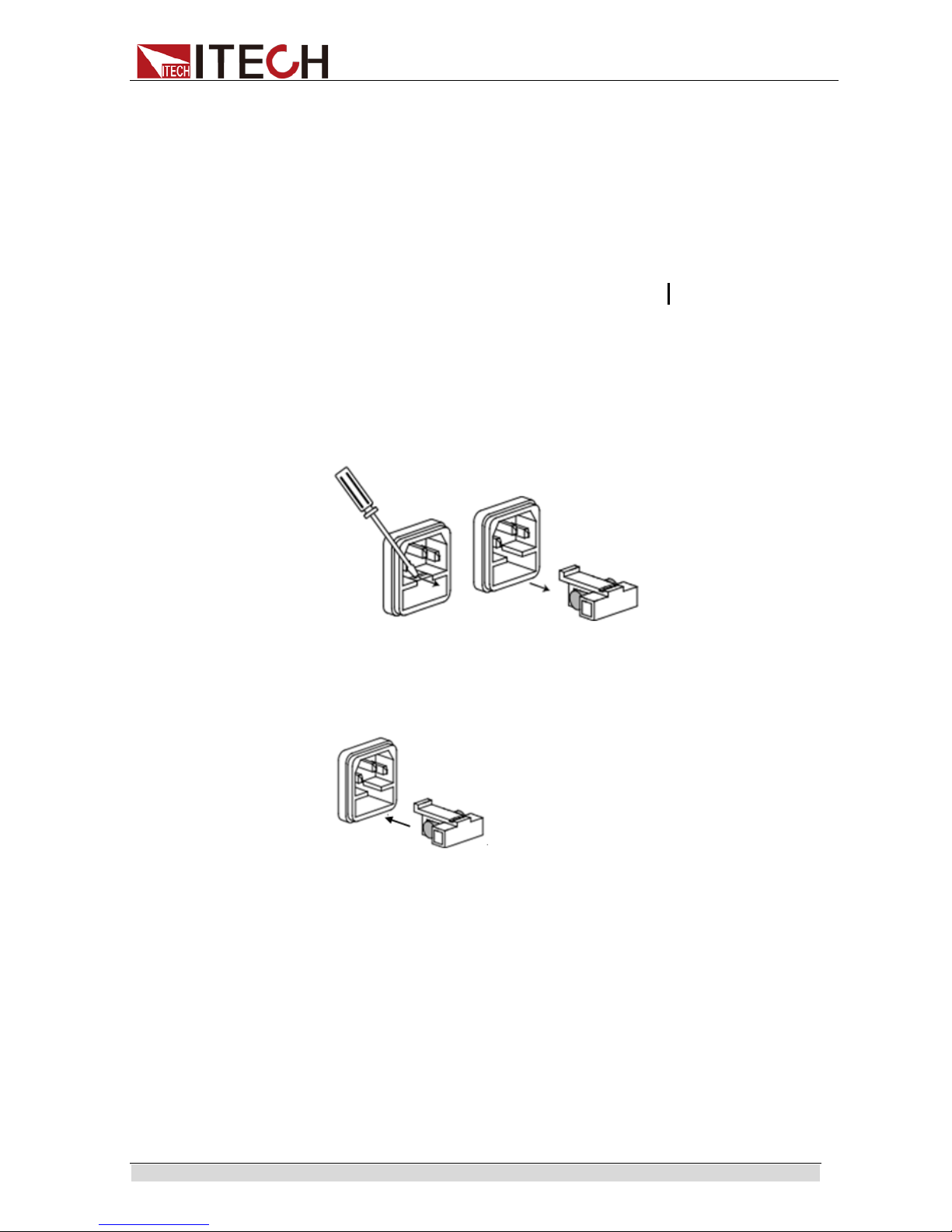

Power Switch Introduction

User can press the power switch of IT5101 series internal resistance tester

directl y to turn on or turn off t he instrument .

The status of Power switch is as follows.

Selftest steps

The normal pow er-on process of t h e IT 51 01 s eries internal resist ance test er ar e

as follows:

1. Properly connect the power cord and press [Power] to power on the

instrument.

2. The internal resistance test er will take s elf-test and the instr ument will complete

inter-CPU communication test and reading a nd wr iting test of memory.

3.

After ini tialization, the LCD scree n displays the following information.

Off On

On Of f

Page 22

Quick Start

Copyr ight © Ite c h Electronics Co., Ltd. 14

Exception handling

If the internal resistance tester cannot start normally, please check as below

steps.

1. Check whether the pow er cord is correctly conne cted and confirm whether

the internal resistance tester is powered.

Correct wiring of pow er cord = > 2

Incorrect wir ing of power cord = > Re-connect the power cord and check

whether the exception is removed.

2. Check whether the power in On. Power key is under “” On status.

Yes = > 3

No = > Please check the Power key to start power and check whether the

exception is removed.

3. Check whether the fuse of internal resist ance tester is burned out.

If yes, change fuse. Det ailed steps:

i. First pull out the power cord, and then take out the fuse block from the

power cord jack with a small screw driver, as shown below:

ii. Have a visual inspect ion of the fuse t o see whet her it is burnt out; if yes,

replace it with another f use of the sa m e specification.

iii. After replacement, mount the fuse block to the original position, as

illust rated below:

Page 23

Function and Features

Copyr ight © Ite c h Electronics Co., Ltd. 15

Chapter3 Function and Features

This chapter describes in detail the use of the front-panel keys and shows how they

are used to accomplish internal resist ance t

ester operation.

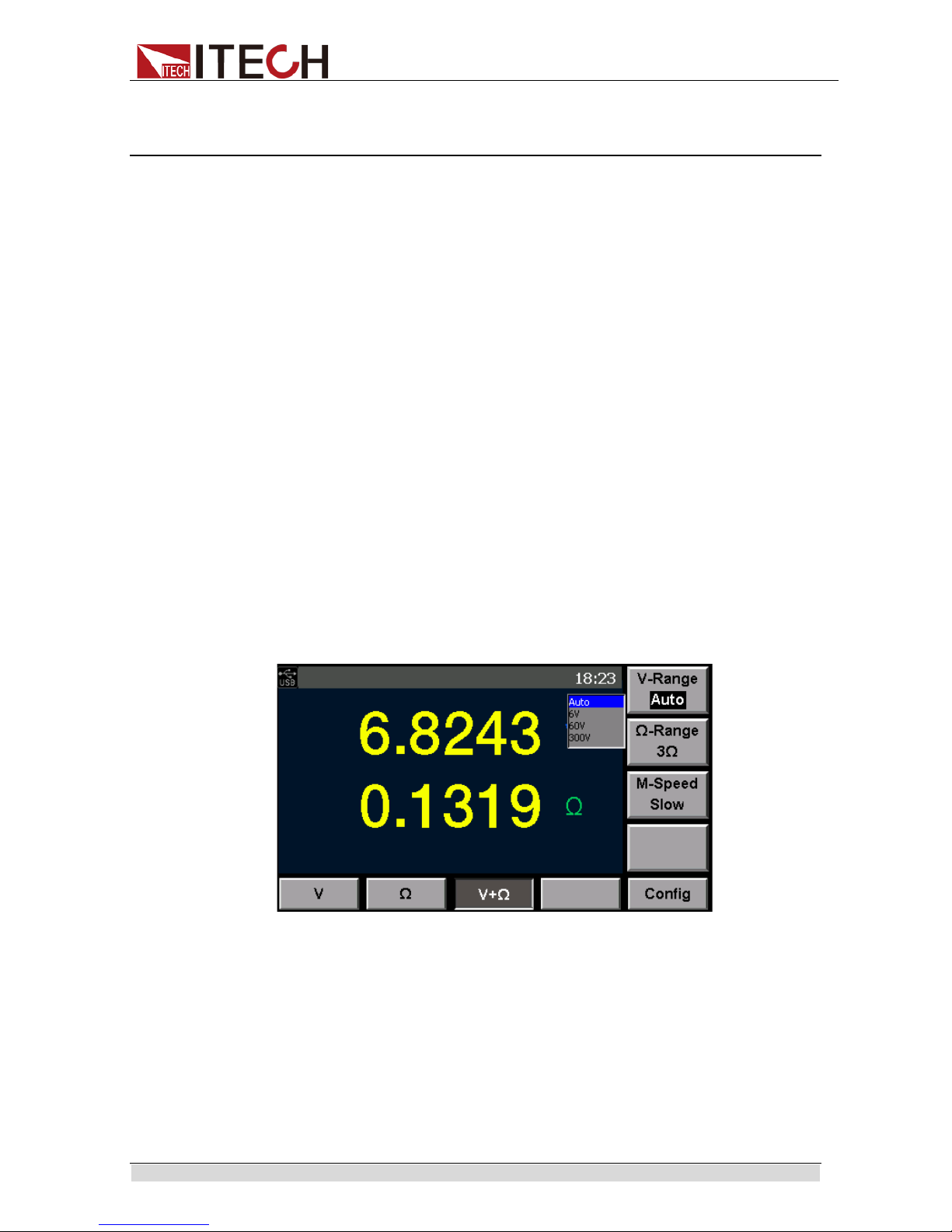

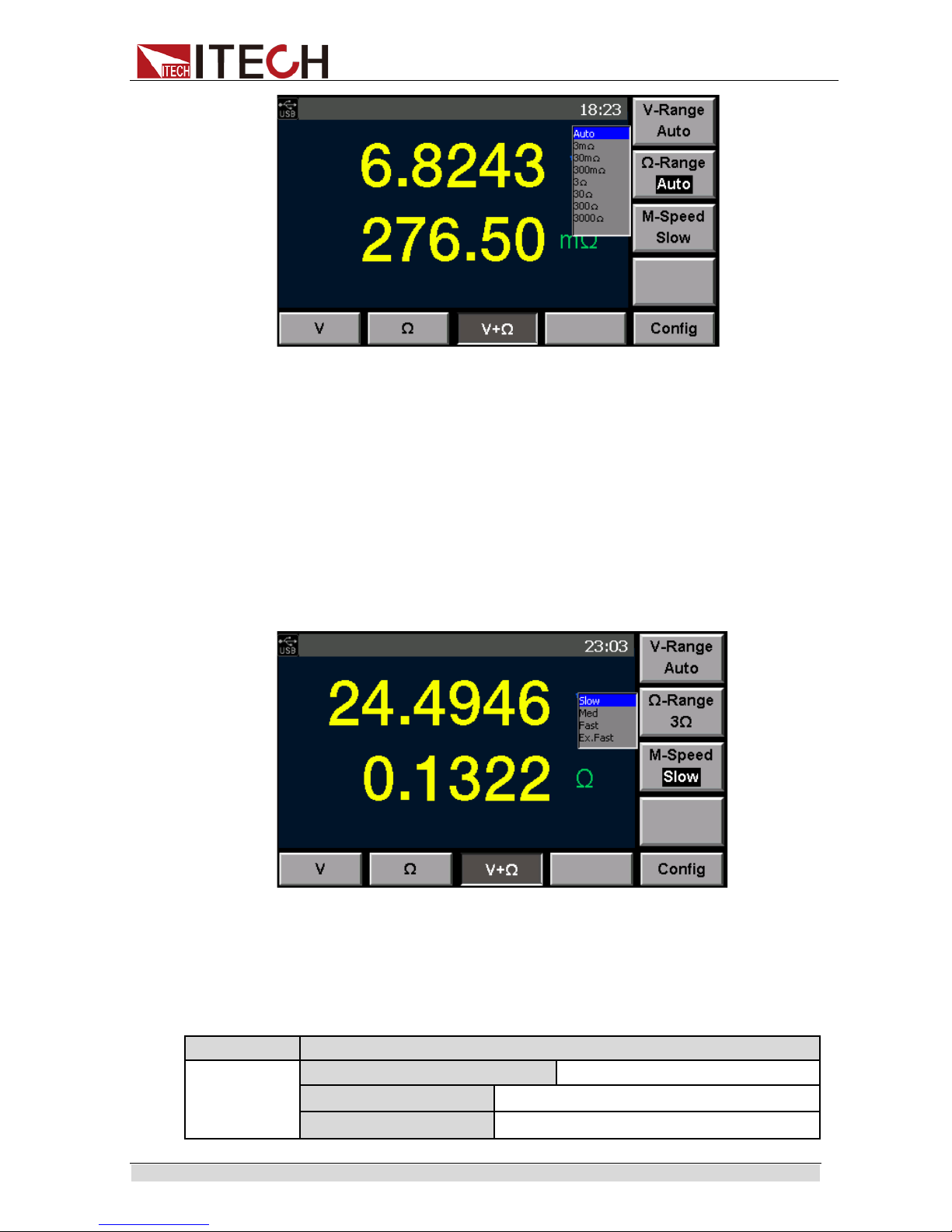

3.1 Range Setting

IT5101 Series internal resistance tester provides several ranges for measuring

voltage and internal resistance. If voltage/internal resistance scope of DUT is

known, appr opriate selection of range will improve measurement accuracy.

Voltage ranges of IT5101 Model: 6V, 60V and 300V; resistance ranges:

3mΩ, 30mΩ, 300mΩ, 3Ω, 30Ω, 300Ω and 3,000Ω. If voltage/internal

resistance scope is unknown, select Auto and the instrument will select

appropriate range auto m atically.

Voltage ranges of IT5101E Model: 6V, 60V and 300V; resistance ranges:

300mΩ and 3Ω. If voltage/internal resistance scope is unknown, select

Auto and the instrument will select appropriate range aut omatically.

You can directly select the measurement range on current Measurement

interface. Detailed operations are as follows:

1. Press [Meter] key. Display current measurement statu s.

2. Press corresponding soft key of V/Ω/V+Ω to select current measurement

situation.

3. Based on dif ferent situations, press corre sponding soft key of “V-Range” and

“Ω-Range” to select appropriate measure range.

Voltage range (V-R ange) setting diagram is as shown below .

Resistance range (Ω-Range) setting dia gram of IT5101 Model is as shown

below.

Page 24

Function and Features

Copyr ight © Ite c h Electronics Co., Ltd. 16

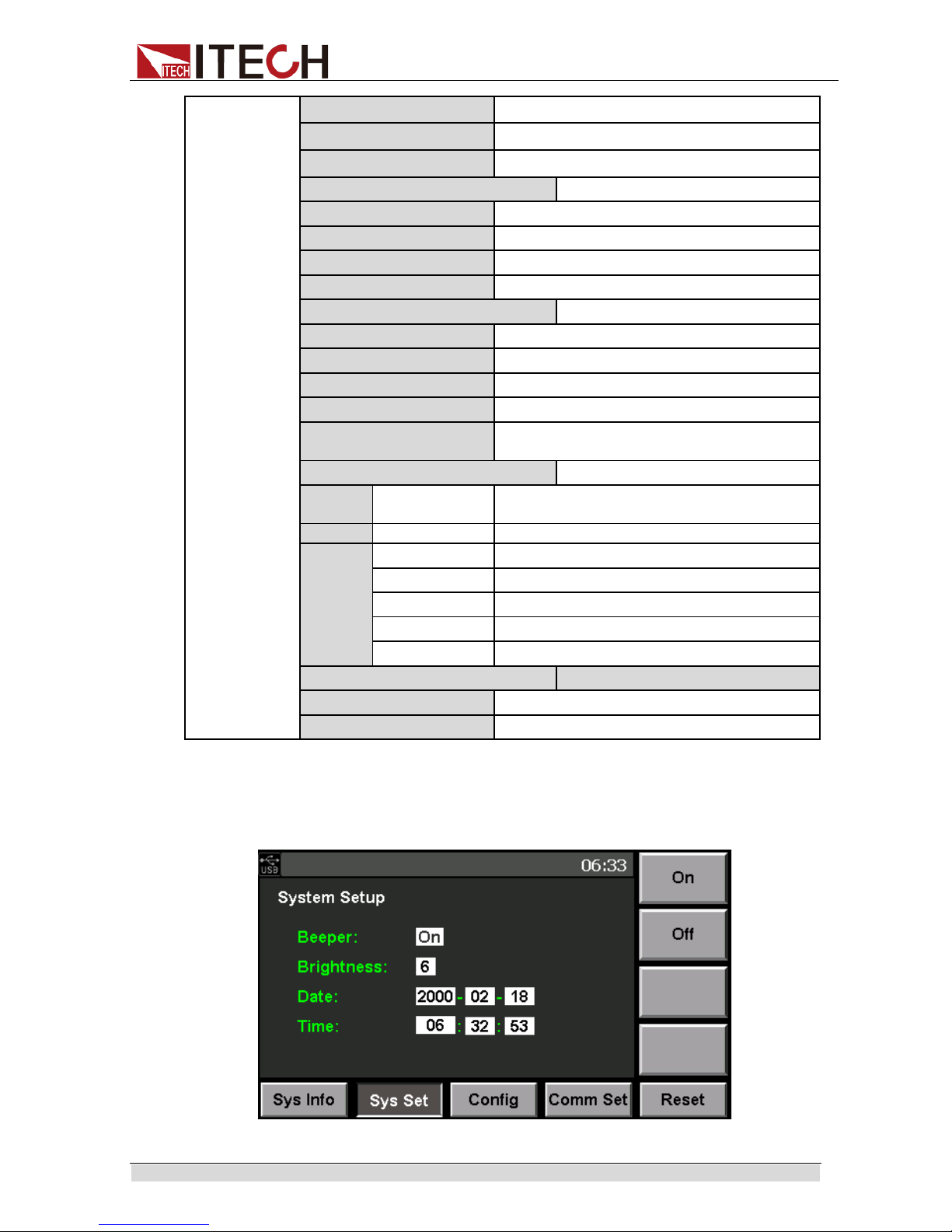

3.2Sampling Rate Setting

When measuring voltage or internal resistance with the IT5101 internal

resistance tester, the user can directly select a sampl ing speed from four gears:

Slow, Med, Fast and EX. Fast on the current Measurement interface. Detailed

operation st eps are show n below:

1. Press [Meter] key. Display current measurement statu s.

2. Press corresponding soft key of V/Ω/V+Ω to select current measurement

situation.

3. Under different situations, select appropriate sampling speed by pressing

corresponding soft key of “M-Speed”.

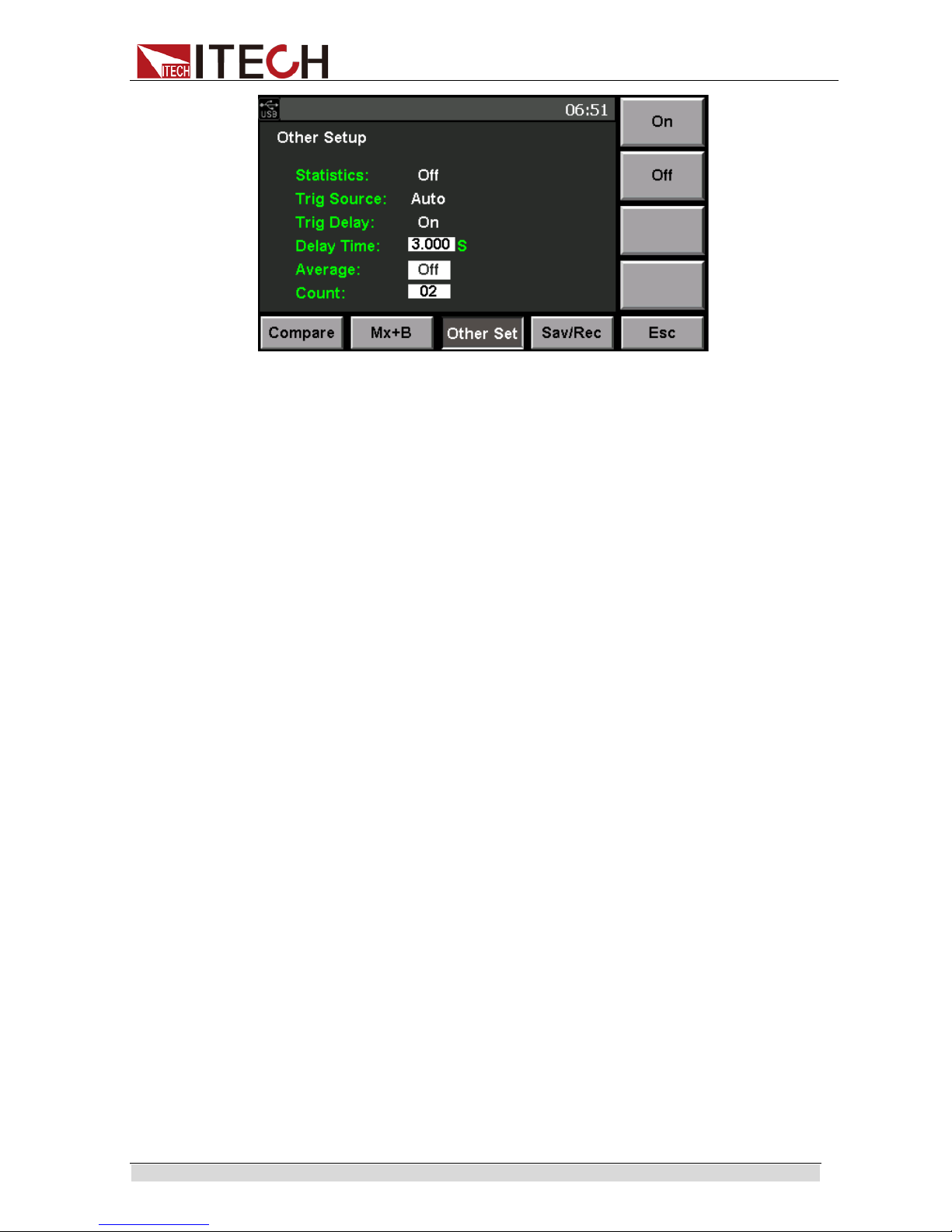

3.3 System Menu

Menu function include system setup and system configuration, Press “MENU ”

on the front panel to set the system menu. You can set the following menu

items.

Menu System Menu

Sys Info

System information

Model

Product Model

Version

software

Version

Page 25

Function and Features

Copyr ight © Ite c h Electronics Co., Ltd. 17

SN

Series Nu mb er

Cal Info

Calibration information

MAC Address

Network hardware address

Sys Set

System Setting

Beeper

Setting the buzzer function

Brightness

Setting the screen brightness.

Data

Setting system date: Year/ Mont h/Day

Time

Setting system time: Hour/Minute/Second

Config

System Conf iguration

Filter Freq

Setting the filter frequency

Alarm Set

Setting the mode of alarm

Err Out

Setting Err output mode

EOM Mode

Setting th EOM signal

Pulse Time

Setting the pulse time. It is effective when

“EOM Mode” set to “Pul se”

Comm Set

Communication configuration

USB

Type B

Connect

Select the USB communication interface.

GPIB

Address

The address c an be set within 1-31

LAN

IP Mode IP mode:MANU/DHCP

Port Set Setting port

IP Addre ss Setting IP address

IP Mask Setting IP mask

Gate Way Setting gatew ay

Reset

Reset syst em

SetReset Reset the configurat ion of system

SysReset Reset all of system configurati on

Press [Menu] key. The system, by default, displays System Information; press

the corresponding soft key of [Sys Set] to enter System Parameter Setting

page for sett i ng t he configurations below. (The schematic di agr am ta kes IT 51 01

Model as an ex ample)

Page 26

Function and Features

Copyr ight © Ite c h Electronics Co., Ltd. 18

Key Sound Set (>Beeper)

This item can set the buzzer state.On option indicates that when you push

buttons,the buzzer will sound.OFF option indicates that the buzzer function is

disabled.Factory default i s On option.

Adjust Screen Brightness

The user can adjust current screen brightness as required. Select “Sys Set” in

the menu and set Brightness value from 0-9, representing different brightness.

The larger is the value, the brighter is the screen.

Set System Date and Time

Set system d ate and ti me through this menu.

Extend Range (special for IT5101E)

The internal resistance tester of IT5101E Model has only two small ranges: 3Ω

and 300mΩ. However, the user can extend the range to make it consistent with

that of IT5101 Model. To extend range, select “Sys Set” in the menu and input

key in “Extend Range” sett ing item. Press [Enter] to extend range.

Range Extend is cont rolled by a key. To extend range, the user must ask for the

key from ITECH.

3.4Reset System

In Menu interface, press corresponding soft key of Reset for system reset. The

user can select reset range and then reset the sy stem:

SysReset: system reset.

The syste m w ill reset the parameters below t o ex-factory set ting.

Parameters

Default setting

Measurement mode

V+R

V-Range

300V

Ω-Range

IT5101:3mΩ

IT5101E:Auto

M-Speed

Slow

Sys Set

Beeper:On

Brightness:6

Date:2016-01-01

Time:00:00:00

Comm Set

USB

Delay (C al zero)

0s

Filter Freq

50HZ

Alarm Set

Display

Err Out

ASync

EOM Mode

Hold

Page 27

Function and Features

Copyr ight © Ite c h Electronics Co., Ltd. 19

Parameters

Default setting

Compare

Off

Mx+B

Off

Trig Source

Auto

Trig delay

Off

Delay Time(Trig)

0s

Average

Off

Statistics Off

SetReset: C onfiguration reset.

Parameters

Default setting

Measurement mode

V+R

V-Range

300V

Ω-Range

IT5101:3mΩ

IT5101E:Auto

M-Speed

Slow

Compare

Off

Mx+B

Off

Trig Source

Auto

Trig delay

Off

Average

Off

Statistics

Off

3.5Frequency Filter Setting

To remove noise, the user needs to set frequency for the internal resistance

tester. This item in the Menu is used to set frequency value of the frequency

filter. The user can set the frequency value for the frequency filter to 50Hz or

60Hz. This frequency must be consistent with the internal resistance tester

frequency. Incorrect internal resistance tester frequency may lead to unstable

measurement value.

1. Press [Menu] key. Display current me asurement status.

2. Press correspondi ng soft k ey of [ Config] to set fi l t er fr equency, alarm, E rr out

and EOM mode.

3. Press Up/down key to select “Filter Freq” and select corresponding

frequency value. The frequency value should be consistent with AC input

frequency.

Page 28

Function and Features

Copyr ight © Ite c h Electronics Co., Ltd. 20

4. Press Up/down key to select configuration item to be set and press

corresponding soft key for setting. Press [Enter] to confirm the set values.

Otherwise, the set value will not be effective.

After setting, press [Esc] to return to Measurement interface; when you

directly press [Esc] to return but fail to press the [Enter] key for confirmation,

the setti ng fails.

3.6 Alarm Mode Setting

This item is used to set alarm mode of Compare function:

Display means to display alarm where the Meter Interface will display

compari son result, and not gives beep alarm;

Beeper means to sound alarm where the Meter interface only gives beep

sound but not displays comparison r esults;

All means display al arm + sound alar m.

When All is selected, VFD displays comparison results (In, Low or High), and

gives sound.

1. Press [Menu] key to enter Menu Setting page.

2. Press correspondi ng soft k ey of [ Config] to set filter frequency, alarm, Err out

and EOM mode.

3. Press Up/down key to select “Alarm Set” and select corresponding alarm

mode of comp arison results.

Page 29

Function and Features

Copyr ight © Ite c h Electronics Co., Ltd. 21

4. Press Up/down key to select configuration item to be set and press

corresponding soft key for setting. Press [Enter] to confirm the set values.

Otherwise, the setting will not be effective.

3.7Compare Function

The IT5101 Series internal resistance tester provides Compare function. The

user can turn on this function and set comparison range or basis, and display

comparison results during measurement. This will help the user to detect the

specifications of products in batch. The Compare function of Series IT5101

internal resistance tester is divided into Absolute Comparison and Relative

Comparison.

Notes

When voltage or resistance range is in “Auto” status, Compare function is disabled and

the “Compare” interface under “Config” interface cannot be opened.

Absolute Comparison allows the user to set upper and lower limits of the

voltage and resistance. The instrument will check whether the measured

value is within the preset range. The comparative results will either be

displayed on the screen in the form of alarm information or be given by

giving a beeper alarm. There are three alarm types: screen display +

beeper, only screen display or only beeper.

Relative Comparison all ows t he user t o set basic value and r el ati ve percent

of voltage and resistance. For example, if basic v alue and percent are set

to 100V and 30% respe cti vely, it indicates that i f the measured value i s 30%

higher/lower than the basic value, the system will alarm.

Setting Method

1. Press [Meter] key. Display Measurement page.

In the Meter interface, select required Measurement mode: V/R/V+R, and

select appropriate me asurement range.

2. Press corresponding soft key of [Config] and select related measurement

configurations.

3. By default, the system displays configuration items related to Compare

function, as shown below.

Compare: On or Off, used for turning on or off Compare function.

Mode: Compare mode. It is divided into Manual (output comparer results

only when EXT I/O MANU input is ON) and Auto (always output comparer

results) . Default mode: Auto.

Page 30

Function and Features

Copyr ight © Ite c h Electronics Co., Ltd. 22

Abs: during judgment of comparer, read absolute value of voltage

measurement. Even in reversed polarity of battery, comparison still can be

realized based on absolute value.

V Mode: set voltage compare mode: Absolute (H/ L) and Relati ve (Ref%).

R Mode: set resistance compare mode: Absolute (H/L) and Relative

(Ref%).

H: set upper limit of voltage or resistance.

L: set lower limit of voltage or resi stance.

R: set basic value in comparison.

%: set percent of volt age/r esi st ance val ue in compari son.

4. Press Up/down key to select configuration item to be set and press

corresponding soft key for setting. Set values through knob. Press [Enter] to

confirm the set values. Otherwise, the setti ng w ill not be effective.

After setting, press [Esc] to return to Measurement interface; when you

directl y press [Esc] to return but fail to press t he [Enter] key for confir mation,

the setti ng fails.

5. After Compare function is on, if Alarm mode is set to Display, the Meter

interface will display comparison results. If set to Beeper, the instrument will

give beep alarm. Meter interface of display mod e is as follows:

V-Comp: voltage compare result: Low (lower than compare range)/High

(higher than compare range)/In (within compare range)

R-Comp: resistance compare result: Low (lower than compare range)/High

(higher than compare range)/In (within compare range)

3.8 Calculate Function

The IT5101 Series internal resistance tester provides Calculate function, and is

applied for instrument calibration or linear amplification of measured data.

Suppose that the current measured voltage is x, the value after liner

amplification is M*x+B, where M and B are set values.

In general, Calculate function is used to calculate other physical values related

to voltage and resistance. Suppose that there is a linear relationship between

resistance and temperature: T=M*R+B, where T means temperature, R means

resistance, and M and B are set coefficients, through measurement of

resistance val ue, you can displ ay temperature r esult.

Set amplification factor and offset value followi ng the steps below:

1. Press [Meter] key. Display current measurement statu s.

Page 31

Function and Features

Copyr ight © Ite c h Electronics Co., Ltd. 23

2. Press corresponding soft key of [Config] and select corresponding

configurat ion items related to current measurement.

3. Press corresponding soft key of [Mx+B] for related settings of Calculate

function. As shown below.

Mx+B: On/O ff, used to set on/off of the Calculate function.

M Value(V): set multiple of voltage linear amplification. Setting range:

-1,000.0000~1,000.0000.

B Value(V): set offset of voltage linear amplification. Setting range:

-10,000.00000~10,000.0000.

M Value(V): set multiple of resistance linear amplification. Setting range:

-1,000.0000~1,000.0000.

B Value(V): set offset of resistance linear amplification. Setting range:

-10,000.00000~10,000.0000.

4. Press Up/down key to select configuration item to be set and press

corresponding soft key for setting. Set values through knob. Press [Enter] to

confirm the set values. Otherwise, the setting will not be effective.

After setting, press [Esc] to return to Measurement interface; when you

directl y press [Esc] to return but fail to press t he [Enter] key for confir mation,

the setti ng fails.

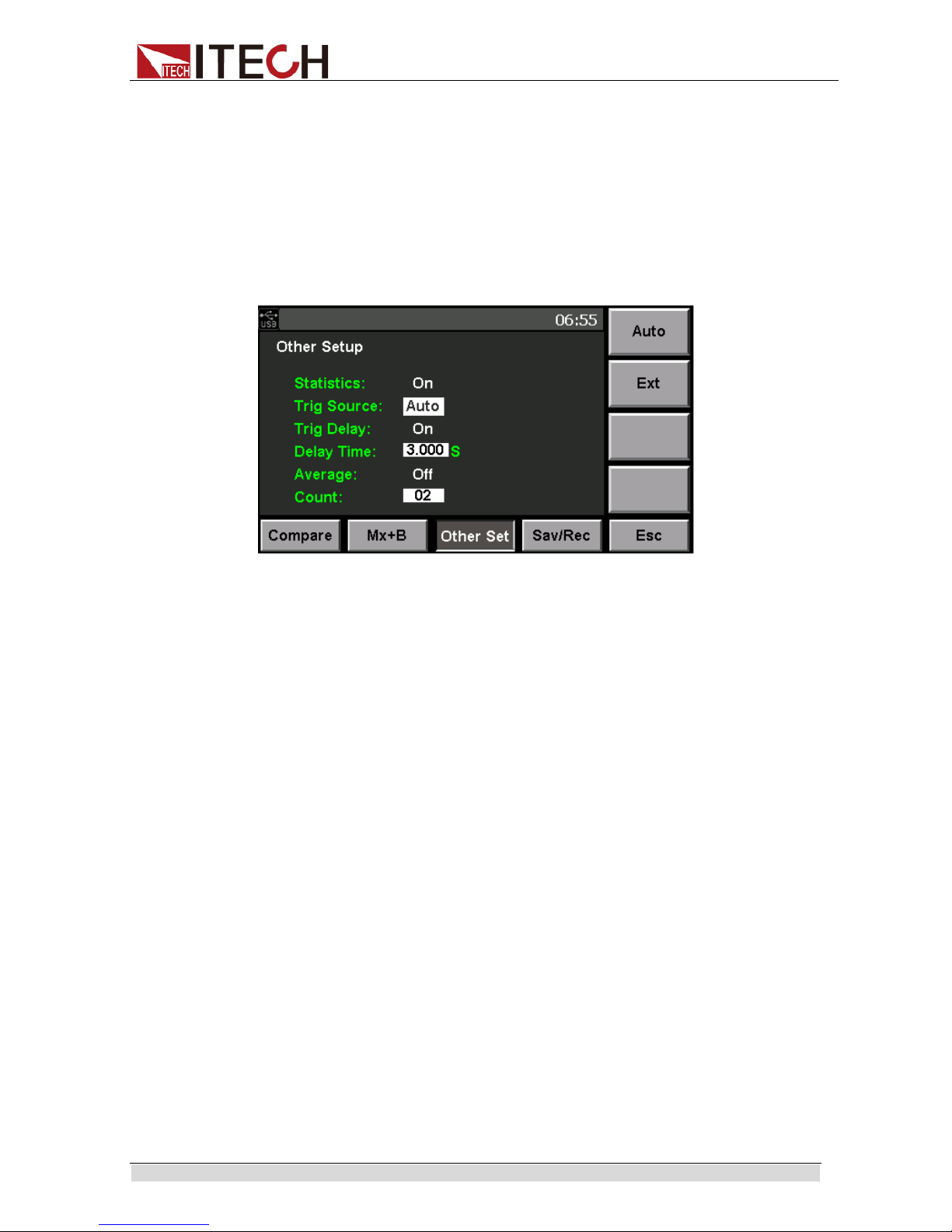

3.9Average Function Setting

To make measured value more accurate, the instrument provides Average

function, where the user can set total count of average as required. For

example, if the Count is set to 5, the measured result of each time will be the

average from 5 samplings.

1. Press [Meter] key. Display current measurem ent status.

2. Press corresponding soft key of [Config] and select corresponding

configurat ion items related to current measurement.

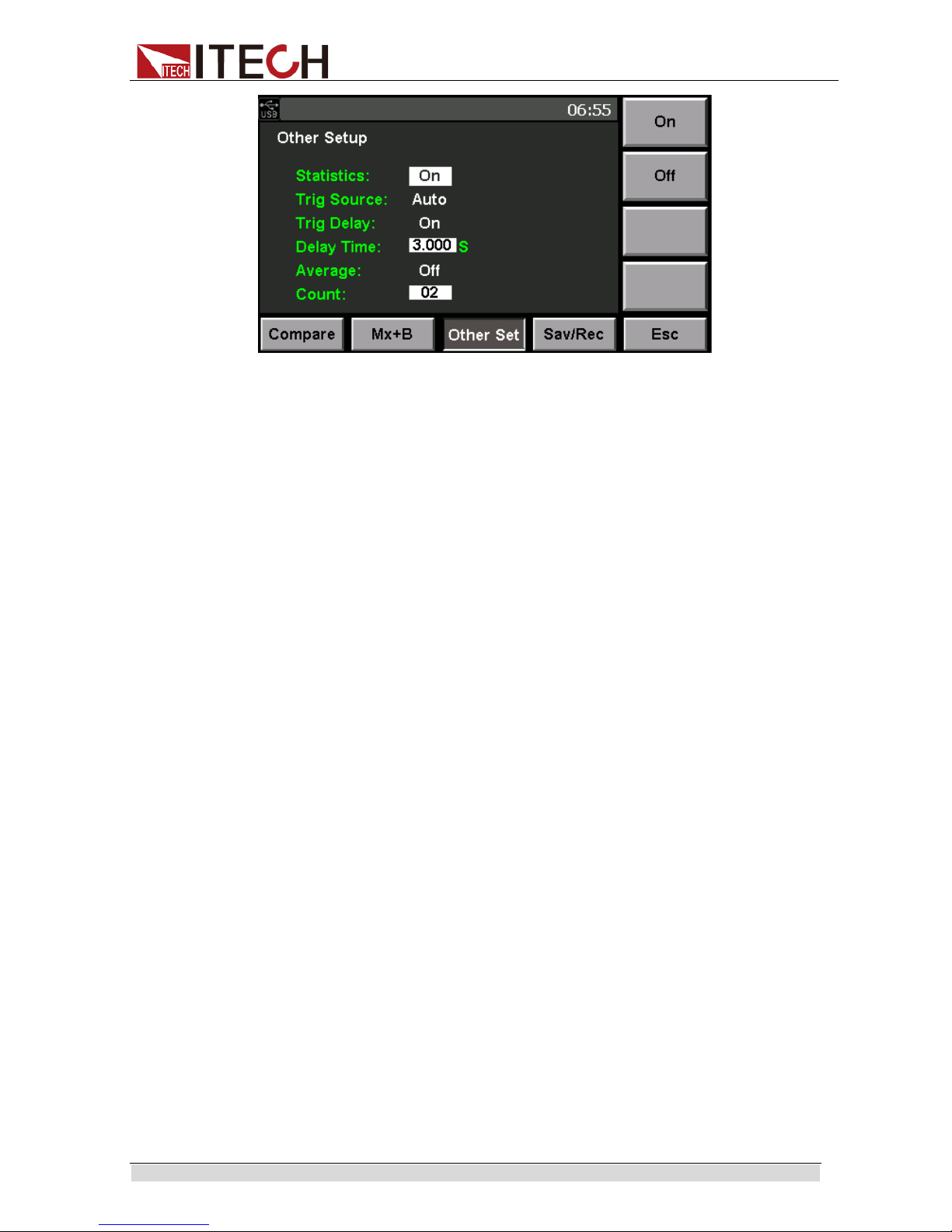

3. Press corresponding soft key of [Other Set] to set Filter, Average, Trigger

functions and Statistics On/Off.

4. Press Up/down key to select “Average” and select “On” to turn on Average.

Set total count of samplings for Average. As shown below.

Page 32

Function and Features

Copyr ight © Ite c h Electronics Co., Ltd. 24

Average: O n/Off, used to turn on or off Average function.

Count: set total count of sampli ngs for Average. Setting range: 2~16.

5. Press Up/down key to select configuration item to be set and press

corresponding soft key for setting. Set values through knob. Press [Enter] to

confirm the set values. Otherwise, the setti ng w ill not be effective.

After setting, press [Esc] to return to Measurement interface; when you

directl y press [Esc] to return but fail to press t he [Enter] key for confir mation,

the setti ng fails.

3.10Trigger Function Setting

Trigger Function Setting means to set the signal trigger mode for each

measurement. The instrument will sample and measure once after each trigger.

The user can set different trigger modes as required, i.e., triggering source

setting. U nder initial status of I T5101, the trigger source is Auto.

Trigger Source Setting

The user can s elect different trigger sources and set trigger waiting time. Select

“Trig Source” in the menu, and select corresponding soft key of trigger source

as required. IT5101 i nternal resistance tester has two trigger sources:

Auto

:the instrument will automatically generate trigger for auto

measurement.

Ext: external trigger, including keyboard [Trig], bus command trigger or

external trigger via the TRIG terminal input signal of EXT I/O port; when

TRIG signal is triggered once, the system will take 1 trigger and measure

once.

Trigger Delay Setting

The user can turn on/off Trigger Delay function and set the delay time from the

time to input tri gger si gnal to the time to st ar t measure as required. Thr ough this

function, the user can start measurement immediately after connection of DUT

or after measured value gets stable. Select this setting item and rotate t he knob

to set specific time val ue.

Setting Step

1. Press [Meter] key. Display current measurement statu s.

2. Press corresponding soft key of [Config] and select corresponding

Page 33

Function and Features

Copyr ight © Ite c h Electronics Co., Ltd. 25

configurat ion items related to current measurement.

3. Press corresponding soft key of [Other Set] to set Filter, Average, Trigger

functions and Statistics On/Off.

4. Press Up/down key to select “Trig Source” and select corresponding trigger

source. Press [Enter] for confi rmation.

5. Press Down key to select “Trig Delay” and set Delay Function On/off. Select

On and press [ Enter] for confirmation.

6. Press Down key to select “Delay Time” and set delay time through knob.

Press [Enter] for confirmation.

7. After setting, press [Esc] to return to Measurement interface; when you

directl y press [Esc] to return but fail to press t he [Enter] key for confir mation,

the setti ng fails.

3.11Statistics On/Off Setting

In measurement, the user can conveniently turn on Statistic function in

Measurement Configuration menu. When this function is enabled, each trigger

of measurement will be recorded as one piece of statistic data For detailed

statistic information, refer to Stati stic Function. When the tri gger source i s set at

Auto (auto measurement by the instrument) auto Statistic function will not be

enabled so that the user needs to press [Trig] key to trigger Statistic

measurement. If Statist ic function is off, even if the [Start] is pressed, statistics

still fails.

1. Press [Meter] key. Display current measurement statu s.

2. Press corresponding soft key of [Config] and select corresponding

configurat ion items related to current measurement.

3. Press corresponding soft key of [Other Set] to set Average and Trigger

functions and Statistics On/Off.

4. Press Up/down key to select “Statistics” to turn on/off this function.

Page 34

Function and Features

Copyr ight © Ite c h Electronics Co., Ltd. 26

5. Press [Enter] to confirm the set values. Otherwise, the setting will not be

effective.

6. After setting, press [Esc] to return to Measurement interface; when you

directl y press [Esc] to return but fail to press t he [Enter] key for confir mation,

the setti ng fails.

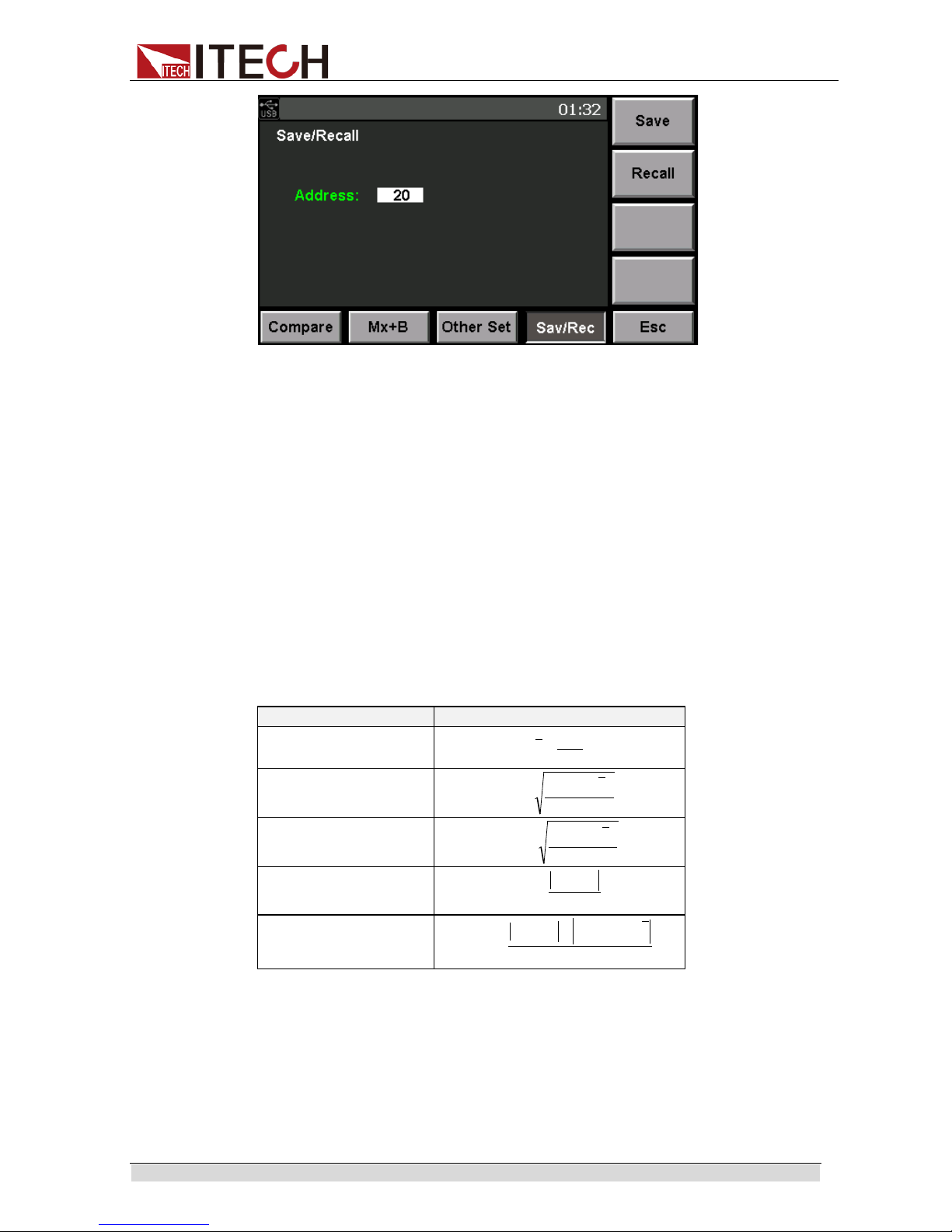

3.12Save/Recall Function

The user can save current measurement conditions in nonvolatile storage

space and recall these conditions from saving address. In IT5101 internal

resistance t est er, at maximum of 127 gr o ups of measur em ent c on di ti ons can b e

saved, including:

Measurement mode

Trig Source

V-Range&Ω-Range

Trig delay

M-Speed

Average

Filter Freq

Statistics

Compare

Mx+B

1. Press [Meter] key. Display current measurement statu s.

2. Press corresponding soft key of [Config] and select corresponding

configurat ion items related to current measurement.

3. Press corresponding soft key of [Sav/Rec] to save or recall measurement

conditions.

4. In “Address”, input address for saving or recalling. Setting range is 1-127.

5. Press corresponding soft key of [Save] or [Recall] for saving or r ecalling.

Page 35

Function and Features

Copyr ight © Ite c h Electronics Co., Ltd. 27

3.13 Screen Capture Function

The inter nal resi st ance test er has t h e fun c ti on of scre en c aptur e. I n sert t he US B

disk to USB i nt erf ace on fr ont panel, When [Print] on the front panel i s presse d,

the internal resist ance tester wi ll capture the present screen and save it into the

external storage devi ce.

3.14Statistics Function

The Statistics function enables batch record, statistics and analysis of batch

measurement results of battery. In Excel table, 1,000 pcs of measurement data

can be recorded. In IT5101 internal resistance tester, the user can take

statistics and analysis for measurement results, and calculate and display such

data as average, maximum value, minimum value, parent standard deviation,

sampli ng standard devi ation and pro cess capacity index .

The calculation formulas are as follows:

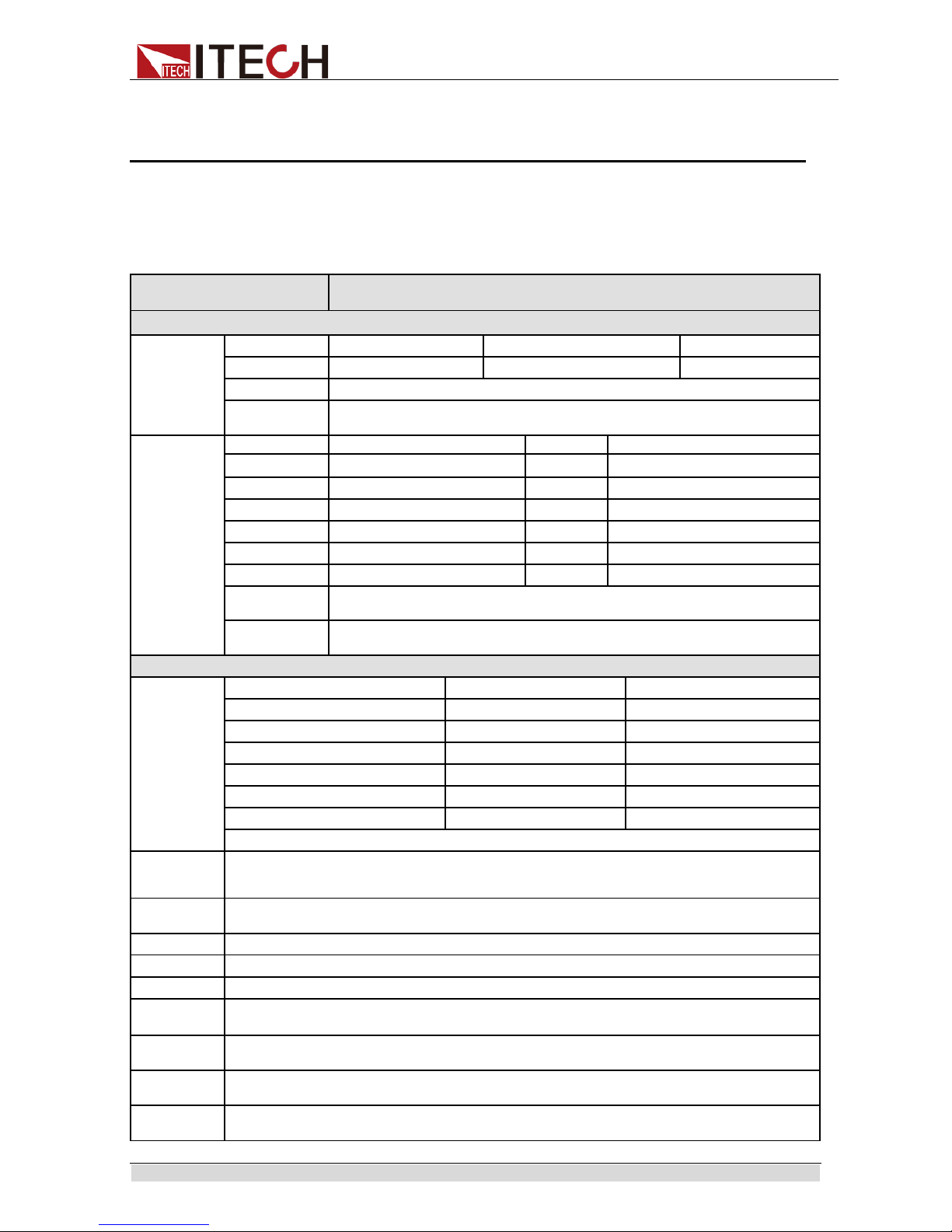

parameter

calculation formulas

Mean(x )

n

x

x

∑

=

Standard deviation of

population(σ)

n

xnx

n

∑

−

=

2

2

σ

Stand deviation of

sample(s)

1

2

2

1

−

−

=

∑

−

n

xnx

n

σ

Process capability

index( dispersion)

16−

−

=

n

p

LoHi

C

σ

Process capability

index(bias)

1

6

2

−

−+−−

=

n

p

xLoHiLoHi

KC

σ

In these for mul as, n r epre sents the number of valis dat a sa mples. Hi and Lo ar e

the upper an d lower thresholds of the comparator.

The process capability indices represent the quality achievement capability

vreated by a process, which is the breadth of thedispersion and bias of the

process’ quality. Generally, depending on the values of Cp and Cpk, process

capability is evaluat ed as follows:

Cp、CpK>1.33 Process capability is ideal

Page 36

Function and Features

Copyr ight © Ite c h Electronics Co., Ltd. 28

1.33≥Cp、CpK>1.00 Process capability is adequate

1.00≥Cp、CpK Process capability is inadequate

3.14.1View Statistic Results

Press [Start] key to enter Statistics page and view statistic information. In the

Statistics page, the user can display all statistic information through scrolling

display, or clear or sa ve/recall all statistic informati on.

Prev: page u p.

Next: page d own.

Clear: Clear statistic records. Press this soft key to clear records in Excel

and wave di splay at the same time.

The user can view such stati sti c items as

, σ, s, Cp, CpK, Max, Min, Index, etc.

3.14.2Display List

In Statistic Function page, select corresponding soft key of [Excel] to enter

Excel Table interface to view all current measurement data. The Excel displays

measurement serial number, measurement value, comparison results and

measurement time. In this interface, the user can select [Home], [Prev], [Next]

and [End] to view all data through scrolling display. In Statistics Function, at

maximum of 1, 000 data can be recorded.

Notes

Page 37

Function and Features

Copyr ight © Ite c h Electronics Co., Ltd. 29

Pass means to compare results;Y means that comparison is passed; N means that

comparison is not passed. When Compare function is Off and the “Pass“ in Statistics

information is also under Y status, for accurate comparison results, please turn on

Compare function at first and set related parameters. If the measured value exceeds

range, the N status will be displayed in regardless of whether Compare function is on or

off.

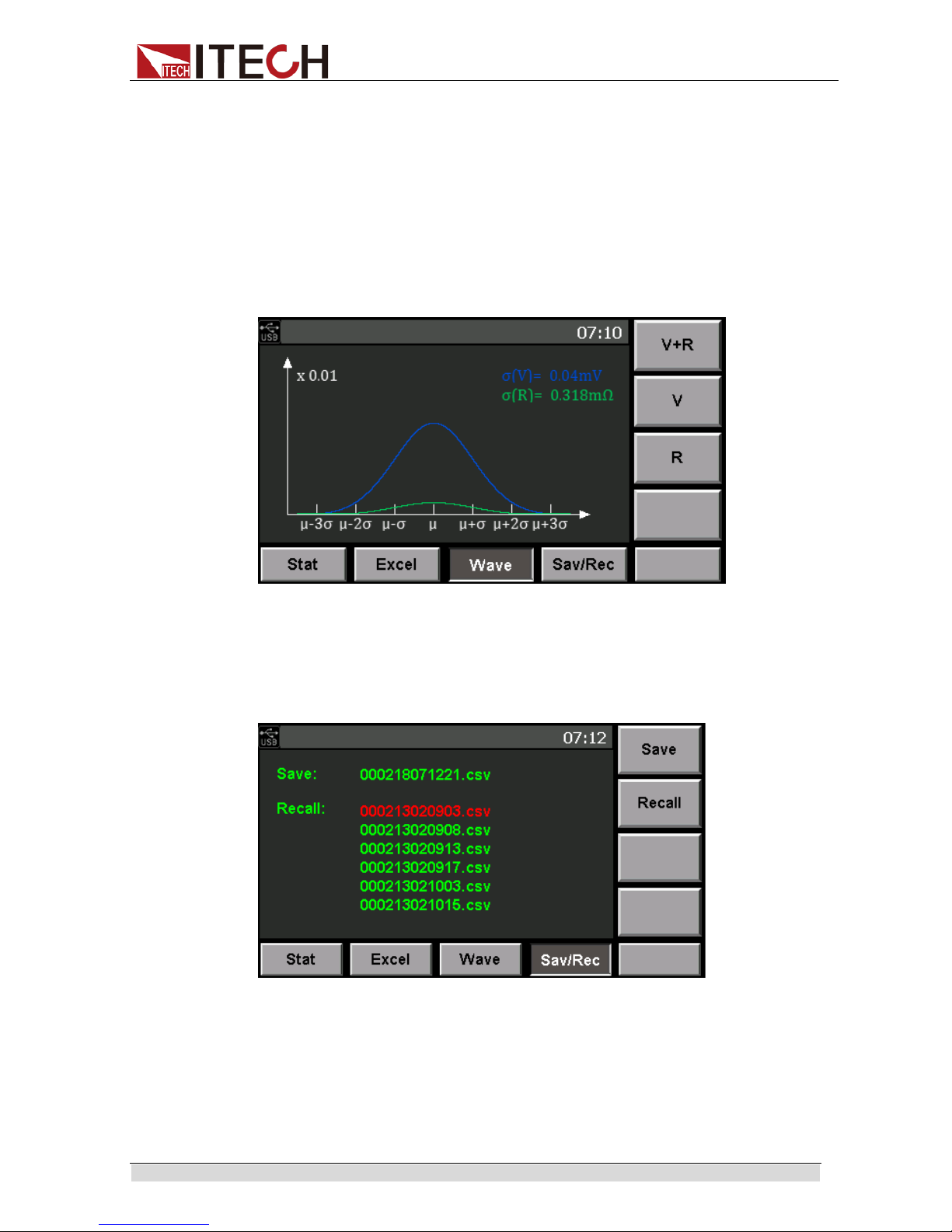

3.14.3Display Nor mal Distr i b uti on Plot

In Statistic Function page, select corresponding soft key of [Wave] to enter

Normal Di stribution Plot Display page to view normal distribution of voltage and

resistance. The user can increase or decrease wave display amplification

through the knob.

3.14.4Save/Recall Measurement Data

In Statistic Function page, select corresponding soft key of [Sav/Rec] to enter

Save inter f ace to save t he data t o USB or to ent er R ecal l i nter f ace to r ecall data

saved in USB. Before sa ving/recalling data, please insert USB.

Save Data

In Save/Recall page under Statistic Function, measurement data are saved in

USB in CSV format. The file is named after the current saving time. Press

corresponding soft key of [Save] to save Excel data to USB. CSV file contents

are as shown below.

Page 38

Function and Features

Copyr ight © Ite c h Electronics Co., Ltd. 30

Recall D ata

Insert USB with files to be recalled inside. The instrument will search for the

data file inside and display file list, as shown above. Press Down key to select

required fi le name and press [Recall] key to recall data records in the USB.

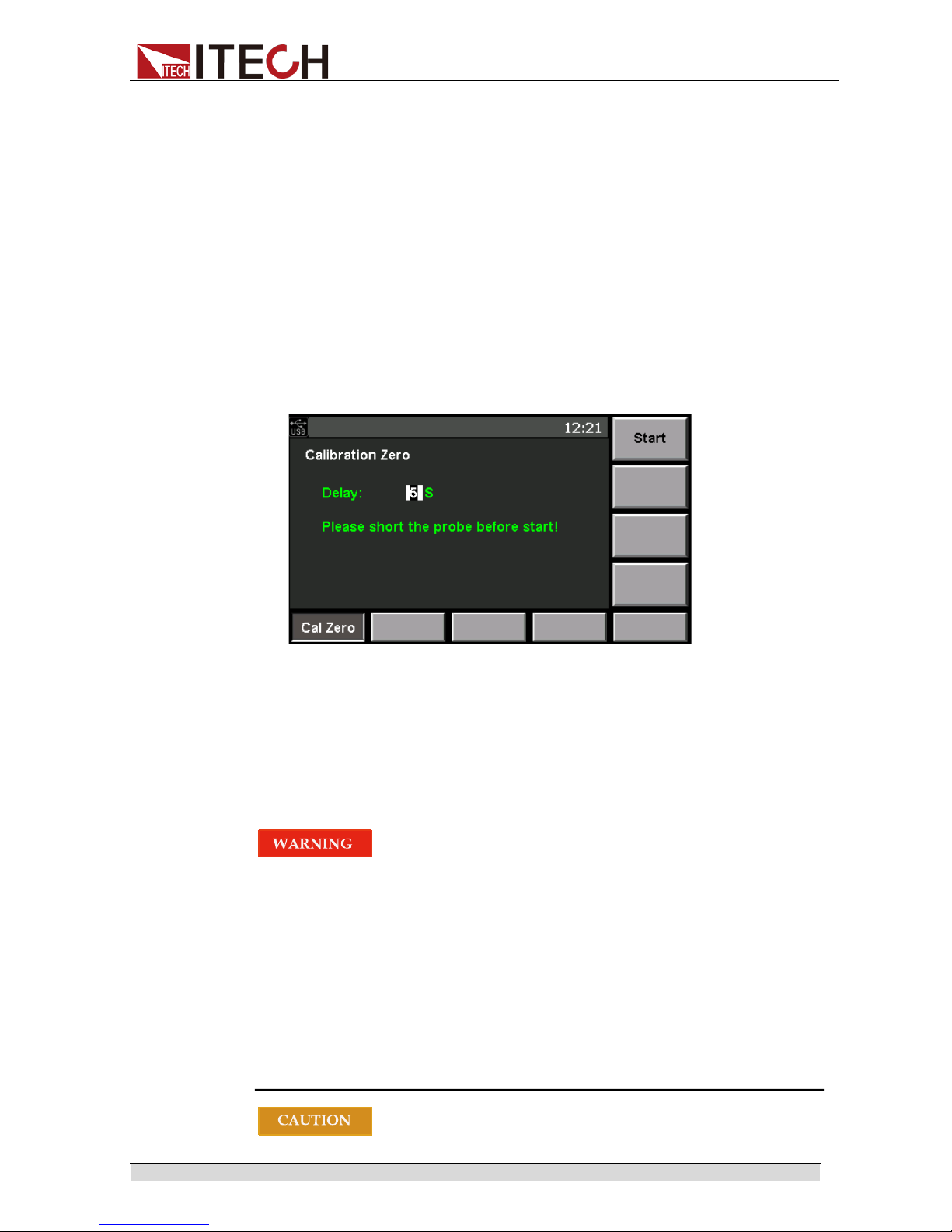

3.15 Zero-Adjust Function

Execute zero adjustment befor measuring to nullify any residual offset voltage

from the instrument or measurement environment. Measurement accuracy

specifications are applicable after zero adju stment.

Zero adjustment is a function which adjusts the zero point by deducting the

residual value obtained during 0Ω measurement. For this reason, zero

adjustment must be performed when connection is made to 0Ω. However,

connecting a sample with no resistance is difficult and therefore is not practical.

In this respect, when performing the actual zero adjustment, create a pseudo

connection to 0Ω and the adjust the zero point.

Wiring principle for Zero-Adjustment

The voltage between Sense(Red) and Sense(Black) becomes 0V according to

the Ohm’s Law of E=I*R. In other words, if you set the voltage between

Sense(Red) and Sense(Black) to 0V, this gives you the same state of 0Ω

connection.

Before executing zer o adjustment, connect the test leads ( probes) as follows:

1. Connect Sense (Red) to S ense (Black).

2. Connect Source (Red) to Source (Black).

3. Connect Snese(Bl ack) and Source(Black) .

Note

The detailed information for test leads probes, please refer to the test lines introduction.

Sine the amount of zero adjustment varies with the position and state of the

Page 39

Function and Features

Copyr ight © Ite c h Electronics Co., Ltd. 31

measurement leads (probes) (i.e., their length, shape, position, etc.), the

measurement leads must be positioned in the actual mea surement state befor e

performing zero adjustment.

Wiring Method for Zero-Adjustment

When execute zero adjustment, the four terminal short connection of test lines

provided by ITECH wi th the help of Zero adjustment board

Executing Zero-Adjustment

1. Connecting the test line probes to zero adjustment board correctl y.

2. Press [Cal Zero] in front panel and enter the Calibration zero page.

3. In calibration zero page, user can set the delay time and delay execute the

zero adjustment, the delay time can set from 0 to 9 se ncond.

4. Press [Start] softkey and start zero adjust m ent.

3.16 External Control(EXT I/O)

The EXT I/O interface in IT5101 rear panel is used to external output terminals

and external control terminals. Please pay attention to this alarm information

before connecting

To avoid electric shock or damage to the instr ument, always observe the

following precautions when connecting to the EXT/ I/O terminals.

Always turn off the power to the instr ument and to any d evices to be

connected before making con nections.

During operation, a wire becoming dislocated and contacting another

conductive ob ject can be serio us hazard. Make sure that

connections are secure and us e screws to secur e t he external

connectors.

Ensure that devices and systems to be connect ed to the EXT I/O

terminals are properly isolat ed.

Page 40

Function and Features

Copyr ight © Ite c h Electronics Co., Ltd. 32

Do not apply voltage or current t o the EXT I/O terminals that exceeds t heir

ratings.

When driving relays, be sure to install diodes to absorb

counter-electromotive force.

Be carefull not to short-cir cuit ISO_5V to ISO_COM.

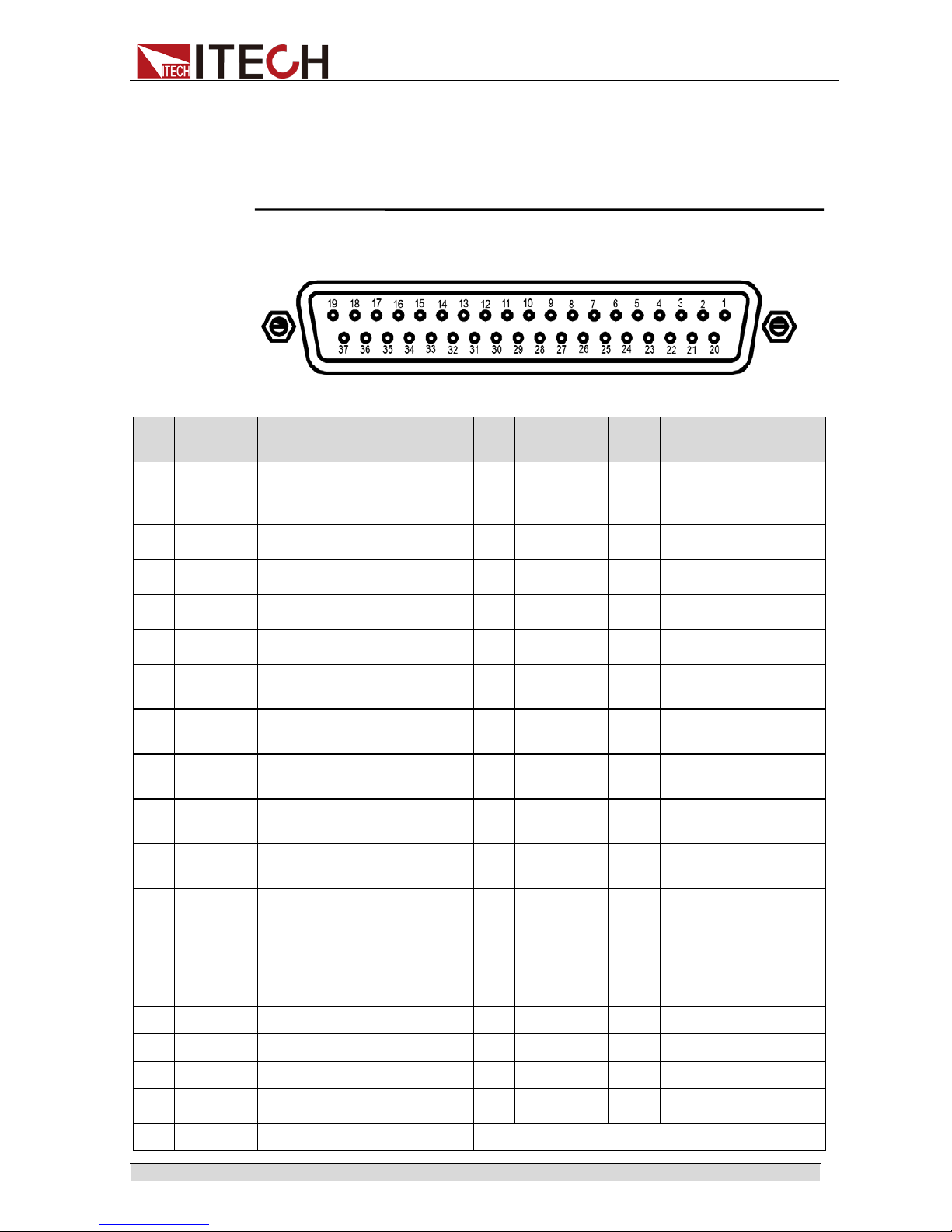

Pin definition

Pin Signal

name

I/O Function Pin Signal name I/O Function

1

TRIG

——————

IN External trigger 20

OADJ

___________

IN Zero adjustments

2 (Reserved) IN - 21 (Reserved) IN 3 (Reserved) IN - 22

LOAD0

____________

IN Load no. bit 0

4

LOAD1

____________

IN Load no. bit1 23

LOAD2

____________

IN Load no. bit 2

5

LOAD3

____________

IN Load no. bit 3 24

LOAD4

____________

IN Load no. bit 4

6

LOAD5

____________

IN Load no. bit 5 25

LOAD6

____________

IN Load no. bit 6

7

MANU

____________

IN

Comparator manual

control

26 (Reserved) IN -

8 ISO-5V - Isolated 5V power output 27 ISO-COM -

Isolated common signal

ground

9 ISO-COM - Isolated common signal

ground

28

EOM

________

OUT End of measurement

10

ERR

________

OUT Measurement fault 29

INDEX

___________

OUT

Analog measurement

finished

11

R_HI

________

OUT Hi

resistance judgment

result

30

R_IN

________

OUT IN

resistance judgment

result

12

R_LO

________

OUT Lo

resistance judgment

result

31

V_HI

________

OUT Hi

voltage judgement

result

13

V-IN

________

OUT IN

voltage judgement

result

32

V_LO

________

OUT Lo

voltage judgement

result

14 (Reserved) OUT - 33 (Reserved) OUT 15 (Reserved) OUT - 34 (Reserved) OUT 16 (Reserved) OUT - 35 (Reserved) OUT 17 (Reserved) OUT - 36 (Reserved) OUT 18

PASS

_________

OUT PASS judgement result 37

FAIL

_______

OUT Judgement result Fail

19 (Reserved) OUT - -

Page 41

Function and Features

Copyr ight © Ite c h Electronics Co., Ltd. 33

Signal Descriptions

The function descri ption of external control terminals as follows:

External trigger input(TRIG

——————

)

Select Panel No. to l oad(LOAD0

——————

~LOAD6

_________

)

Zero-adjust signal input(OADJ

________

)

Manual comparator judgment input(MANU

__________

)

External output terminal functions:

End-of-Conversion si gnal output(EOM

_____

)

Reference signal output (INDEX

________

)

Measurement Fault signal output(ERR

_______

)

Comparator decisi on si gnal output (R-Hi

________

、R-IN

_________

、R-Lo

_________

、V-Hi

_________

、V-IN

_________

、V-Lo

________

、

PASS

_________

、FAIL

_________

)

TRIG

——————

When the external trigger, one measurement is taken each time the TRIG

——————

signal tr ansitions from High to Low.

This tri gger signal is ignored when internal triggering is enabled.

Trigger functions are also available for statistical calculation, recording to

memory and output of measured val ues (valid also with internal triggering)

LOAD0

_______________

~ LOAD6

_________________

Select a Panel No. to load and apply a TRIG

——————

signal to load the select ed Panel

No. and measure. LOAD0

——————

is the LSB, and LOAD6

_________

is the MSB.

When a TRIG signal is applied, if LOAD0

——————

through LOAD6

_________

are unchanged

from the previous trigger event, panel settings are not loaded. In this case,

using external triggering, one measurement is taken as usual when the TRIG

——————

signal is applied.

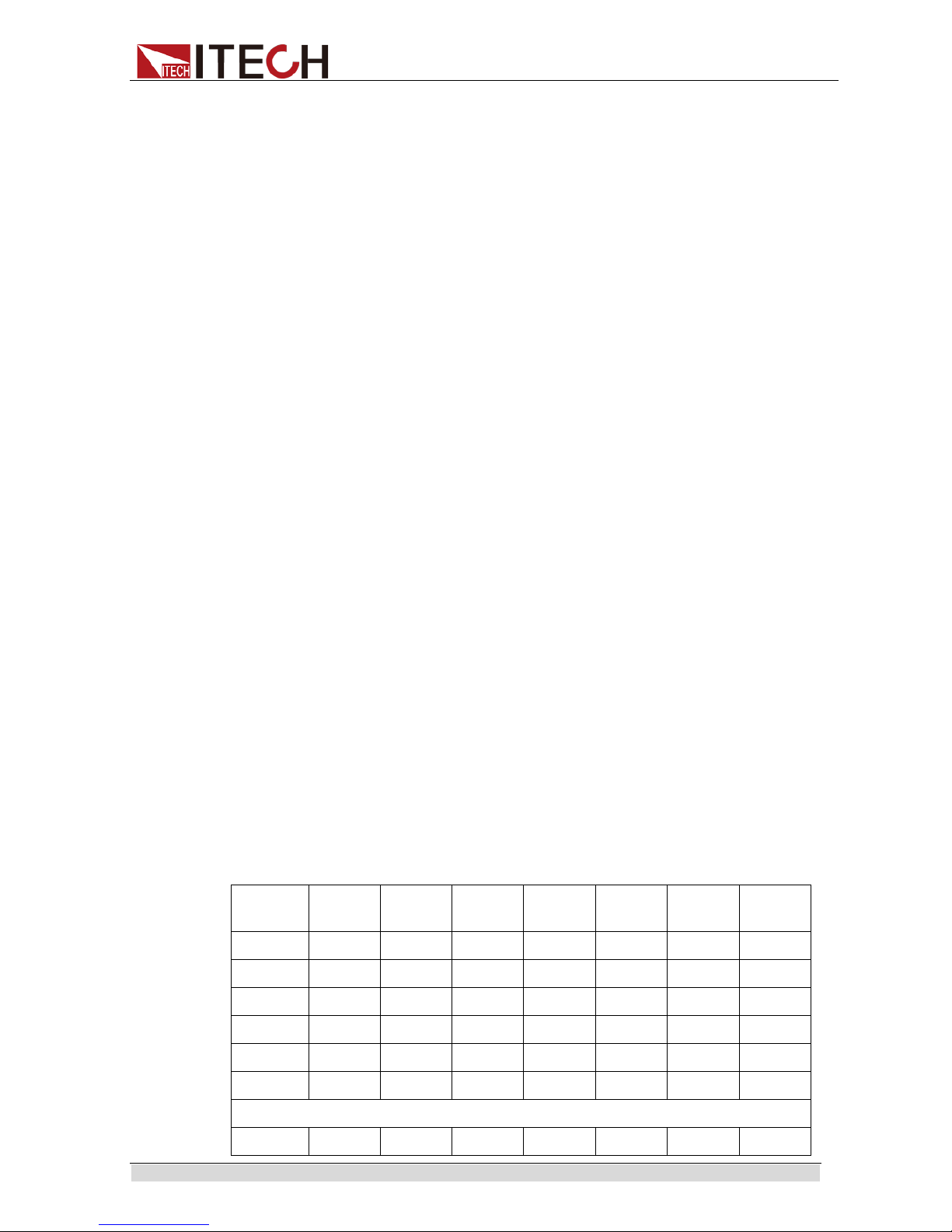

Panel

No.

LOAD6

____________

LOAD5

____________

LOAD4

____________

LOAD3

____________

LOAD2

____________

LOAD1

____________

LOAD0

____________

*

0 0

0 0 0 0 0

1

0 0

0 0 0 0 1

2

0 0 0 0 0 1 0

3 0 0 0 0 0 1 1 4 0 0 0 0 1 0

0

5 0 0 0 0 1 0

1

……

125 1 1 1 1 1 0

1

Page 42

Function and Features

Copyr ight © Ite c h Electronics Co., Ltd. 34

126 1 1 1 1 1 1

0

* 1 1 1 1 1 1

1

0:( HIGH: Open of from 5v to 24V 1: (LOW: 0V~0.9V)

* When a TRIG

——————

signal is applied with LOAD0

___________

~ LOAD6

______________

set to all 1’s or all

0’s, no Panel Load occurs.

At least 70 ms is r equi r ed for t he setti ngs to chan ge aft er execut i ng a Panel

Load (the actual time depends on the particular function, range and

sampli ng rate).

When set to external trigger mode, one measurement is taken upon load

completion.

OADJ

______________

Zero adjustment executes once when the OADJ

___________

signal transitions from High

to Low.

MANU

_________________

When the MANU comparator mode is selected, comparator judgment is

enabled while the MANU

__________

signal is Low.

ERR

__________

Indicates a measur e ment fault.

The Synchronous ERR

_______

output setting causes ERR

_______

output to be synchronous

with EOM

_________

output, while with the Asynchronous ERR

_______

output setting causes

ERR

_______

output to follow actual (asynchronous) contact of the probes with the test

object.

INDEX

_________________

The INDEX

___________

signal is output during the Trigger W ai t , Del ay, Self-Cali brati on and

Calculation states.

This signal is not output while measuring the resistance of test objects. This

signal transitions from Hi(Off) to Lo (On) to indicate that the test object can be

removed.

EOM

____________

This signal indicates the end of a measurement (End-Of-Conversion)

This signal indicates when comparator judgment results and ERR

_______

output

(when SYNC is enabled) are available.

R-Hi

__________

、R-IN

___________

、R-Lo

__________

、 V-Hi

____________

、V-IN

___________

、V-Lo

___________

These are the results of comparator decision.

Page 43

Function and Features

Copyr ight © Ite c h Electronics Co., Ltd. 35

PASS

_____________

This signal indicates when both resistance and voltage judgment results are IN

(ΩV mode).

It transitions to Low (ON) when both the resistance and voltage judgment

results ar e IN.

In the Ω and V modes, this signal is the same as R-IN and V-IN outputs,

respectively.

FAIL

____________

This signal transitions to Low (ON) when PASS

_____________

is Hi (OFF).

Note

The Sense terminal and source terminal introduction for test line refer to test lines

description.

The EOM

________

and INDEX

__________

signals are ini tialized HIGH( O FF) at power on.

If it is not necessary to change the measurement condit ions, set LOAD0

___________

through LOAD6

______________

to either Hi or Lo.

To avoid erroneous comparator judgments, both the PASS

_____________

and FAIL

____________

signals should be checked.

3.17 ERR Output

The ERR output signal indicates the occurrence of measurement fault

conditions (such as open test leads, or a bad conta ct).

There are two ERR output methods.

Synchronized with EOM Output (Sync)

Measurement faults detected while measuring (not while awaiting trigger or

during delay or calculation intervals) , are indicated by ERR output synchro nous

with EOM output(the end-of-measurement signal).

ERR output LOW (On): A measurement fault has prevented correct

measurement.

ERR output HIGH (Off): Correct measurement obtained (OF or –OF:

Out-of-range cases are included)

Asynchron ous with EOM Output (ASync)

Measurement faults (test lead connection conditions) are output in real time.

The output is asynchronous wit h the TRIG

——————

signal and EOM output .

ERR Output Low (On): Measurement fault condition(open test leads, or a bad

contact)

ERR Output High (Off): Test lead connections are normal

Setting Method