TECHNICAL AND INSTALLATION MANUAL

Cod. MTEBT03

APPARECCHI RADIOLOGICI ELETTROMEDICALI

VIA DEL PARLAMENTO EUROPEO 9D - 50010 SCANDICCI (FI) - TEL. ++39-0557228511 - FAX ++39-0557228512

www.italray.it info@italray.it

BT MTEBT03

MANUAL DATA

REVISIONE RELEASE MTEBT03 - VALIDITY FROM S/N 11-130-06

PREPARATO PREPARED LEANDRO BETTACCINI, RICCARDO SARTI

VERIFICATO CHECKED STEFANO BALDINI

APPROVATO APPROVED STEFANO BALDINI

DATA DI EMISSIONE DATE OF EMISSION 15/03/2006

REVISION RECORD

MTEBT01

24/04/2003 MTEBT02 - New Italray’s telephone number

15/03/2006

MTEBT03 - General device revision.

THIS DOCUMENT ACCOMPANIES THE FOLLOWING PRODUCT

Part Number:

S/N.

TYPE CODE / PART NUMBER REVISION

Cassette Tray

Potter Bucky manual

ENCLOSED DOCUMENTATION

TECHNICAL AND INSTALLATION MANUAL Pag. I di

27

BT MTEBT03

WARNING

Read the content of this manual carefully before setting up and adjusting the equipment.

Although this equipment is designed and manufactured in compliance with current safety

standards, any source of X rays always represents a hazard in the hands of an operator

who is not suitably qualified or properly informed. An excessive exposure to X rays can

cause bodily harm.

As a result, all necessary precautions must be taken to avoid unauthorized and unqualified

persons operating this equipment, thus creating a hazard for themselves and others.

Before taking any action, the people qualified and authorized to operate this equipment

must be duly informed on the protective measures specified by the International

Commission on Radiological Protection and on the relevant national norms.

The manufacturer can accept no liability for the effects of any action taken by unauthorized

staff.

The equipment must not be used for any purposes other than those for which it was

intended.

!

The manufacturer declines all responsibility for any failure by authorized technicians to

comply, in the performance of their tasks, with the requirements contained in this manual.

In the event of any anomalies or malfunctions that cannot be overcome by following the

indications given in this manual, the authorized staff must consult the manufacturer of the

equipment to obtain instructions on how to deal with the problem.

This equipment satisfies the requirements of the EEC 89/336 electromagnetic compatibility

directive and subsequent revisions.

To meet said needs, special technical solutions have been adopted, such as the

application of noise filters and the establishing of specific earthing connections. The metal

covers and their closing mechanisms have been manufactured and tested using fixing

devices and special linings made of conducting materials, designed to guarantee both the

equipment's immunity to sources of outside noise and to contain the level of any noise

generated by the equipment's electric circuits.

TECHNICAL AND INSTALLATION MANUAL Pag. II di

27

BT MTEBT03

Technicians performing any maintenance or repairs are consequently strongly

recommended to avoid altering the path of the connections and to scrupulously

reconnect all the earthing connectors relating to the covers, if these are removed

during any maintenance or fault-finding operations, paying the utmost attention to

return the protective covers in the same conditions and with the same fixing

devices as originally installed.

The maximum allowable weight on the patient-positioning table-top is 200 kg.

The manufacturer accepts no liability for the proper operation of the equipment in the

event of its installation or maintenance being handled by unauthorized persons.

The manufacturer reserves the right to make changes to the product described in this

manual at any time, without notice.

Do not stand patients on the table top, or allow them to sit on the end of the table when it

is fully extended.

ITALRAY s.r.l.

Via del Parlamento Europeo 9/D – 50010 - Scandicci – Firenze - ITALY

Telefono +39 055 7228511 Fax +39 055 7228512

Email info@italray.it Web www.italray.it

TECHNICAL AND INSTALLATION MANUAL Pag. III di

27

BT MTEBT03

INDEX

1

1. INTRODUCTION ........................................................................................................................................... 4

1.1. GENERAL................................................................................................................................................... 5

1.2. IMPORTANT ADVICE AND GENERAL NOTES........................................................................................ 5

2

2. FEATURES AND PERFORMANCE.............................................................................................................. 7

2.1. TECHNICAL DATA..................................................................................................................................... 8

2.1.1. TRANSPORT AND STORAGE CONDITIONS ....................................................................................... 8

2.1.2. AMBIENT CONDITIONS ......................................................................................................................... 8

2.1.3. ELECTRICAL FEATURES ...................................................................................................................... 8

2.2. IDENTIFICATION ....................................................................................................................................... 9

2.3. DISPOSING OF THE EQUIPMENT........................................................................................................... 9

2.4. OVERALL DIMENSIONS ......................................................................................................................... 10

2.5. PERFORMANCE...................................................................................................................................... 10

2.5.1 MECHANICAL ........................................................................................................................................ 10

2.5.2. POTTER BUCKY................................................................................................................................... 10

2.5.3. TABLE TOP ........................................................................................................................................... 11

3

3. ACCESSORIES........................................................................................................................................... 12

3.1. ON REQUEST .......................................................................................................................................... 13

4

4. TRANSPORT AND HANDLING .................................................................................................................. 14

4.1. PACKAGING ............................................................................................................................................ 15

4.2. UNPACKING AND HANDLING................................................................................................................ 15

5

5. PRIOR TO INSTALLATION......................................................................................................................... 16

5.1. PREPARING THE ROOMS...................................................................................................................... 17

5.2. CONNECTIONS TO THE GENERATOR................................................................................................. 17

6

6. INSTALLATION ........................................................................................................................................... 18

6.1. INSTRUCTIONS FOR ASSEMBLY OF THE EQUIPMENT AND ACCESSORIES................................. 19

6.1.1. MECHANICAL ASSEMBLY................................................................................................................... 19

6.1.2. ELECTRIC CONNECTIONS ................................................................................................................. 23

7

7. MAINTENANCE AND REPAIRS ................................................................................................................. 24

7.1. MAINTENANCE........................................................................................................................................ 25

8

8. SPARE PARTS............................................................................................................................................ 26

9

9. WIRING DIAGRAMS ..................................................................................................................................... 5

TECHNICAL AND INSTALLATION MANUAL Pag. IV di

27

BT MTEBT03

1. INTRODUCTION

TECHNICAL AND INSTALLATION MANUAL Pag. 1 di

27

BT MTEBT03

1.1. GENERAL

The BT is a HORIZONTAL X-RAY TABLE that allows for the four-way movement of the

bucky table, thus facilitating patient positioning for centering them with respect to the X-ray

beam. The surface of the bucky table is perfectly smooth for improved comfort and to

facilitate the transfer of patients on stretchers. The table is floated by means of a foot

pedal which can be placed on the left- or right-hand size, as preferred. The table-top is

fitted with guides on both sides for attaching any accessories. The equipment is fitted with

a longitudinally sliding Potter Bucky (with a mobile grid).

1.2. IMPORTANT ADVICE AND GENERAL NOTES

This manual serves the purpose of providing the manufacturer's staff, or other technicians

authorized by the manufacturer, with instructions for the proper installation and

maintenance of the appliance.

2. FEATURES AND PERFORMANCE

TECHNICAL AND INSTALLATION MANUAL Pag. 2 di

27

BT MTEBT03

2.1. TECHNICAL DATA

2.1.1. DIRECTIVES AND TECHNICAL STANDARDS

The equipment meets the following directives :

♦ Directive 93/42/EEC (Class I)

♦ Directive 89/336/EEC and later amendments.

and the following technical standards:

♦ IEC EN 60601-1 (Class I type B) and later amendments.

♦ IEC EN 60601-1-2

♦ IEC EN 60601-1-3

♦ IEC EN 60601-2-32

The device meets the European Environmental Directives 2002/95/EC, 2002/96/EC and

2003/108/EC

Technical features

Dimensions of the x-ray table 2200 x770 mm

Height from floor 750 mm

Longitudinal travel 1000 mm

Transversal travel 130 + 130 mm

Distance x-ray table - film 68 mm

Longitudinal travel of potter 400 mm

Maximum allowable weight 190 Kg

Weight of the device 140 Kg

Power supply 220Vac +/- 10% 50/60 Hz

Absorption 1 A

Al equivalence (stratified table standard) 0,85 mm aluminium

Al equivalence (carbon fibre table top) (optional) 0,4-0,5 mm aluminium

2.1.2. TRANSPORT AND STORAGE CONDITIONS

Temperature : -10° to +70° C

Humidity : 20 to 80%

2.1.3. AMBIENT CONDITIONS

Temperature : +10° to +40° C

Humidity : 30 to 75%

2.1.4. ELECTRICAL FEATURES

power supply 220-240 Vac 50/60 Hz – 1 A

2.1.5. BUCKY

- Motorized grid movement (with variable speed in factory)

- Grid ratio 1:10 D.F.F. 120. Inch scales 103 (standard grid)

- Cassette holder, manual self-centring.

TECHNICAL AND INSTALLATION MANUAL Pag. 3 di

27

BT MTEBT03

2.2. IDENTIFICATION

An identification data plate is positioned above left indicating equipment code, serial

number and other necessary information.

LABE

Fig. 1

Via del P. Europeo 9/D - 50010

SCANDICCI (Firenze) ITALY

tel.+39 055 7228511 fax.+39 055 7228512

e-mail: info@italray.it web: www.italray.it

Type B

EN60601-1

class I

Device name

Type

Serial n°

Power supply

Manuf. year

TRO+IR101/A-A

220Vac +/- 10% 50/60 Hz

BT

nn-nnn-nn

2006

When requesting maintenance or replacement parts it is always necessary to give this

information.

2.3. DISPOSING OF THE EQUIPMENT

- Packing:

Wood and bubble sheet 100% recyclable

- Assembly materials :

Carbon steel 100% recyclable

Elastomers and plastic materials 100% recyclable

Cables and other electrical materials

Printed circuits made of FR4 epoxy glass and electronic components

TECHNICAL AND INSTALLATION MANUAL Pag. 4 di

27

BT MTEBT03

The equipment must not be disposed of as normal urban solid waste, it must be taken to

an expert waste disposal centre and in conform with the local laws in force.

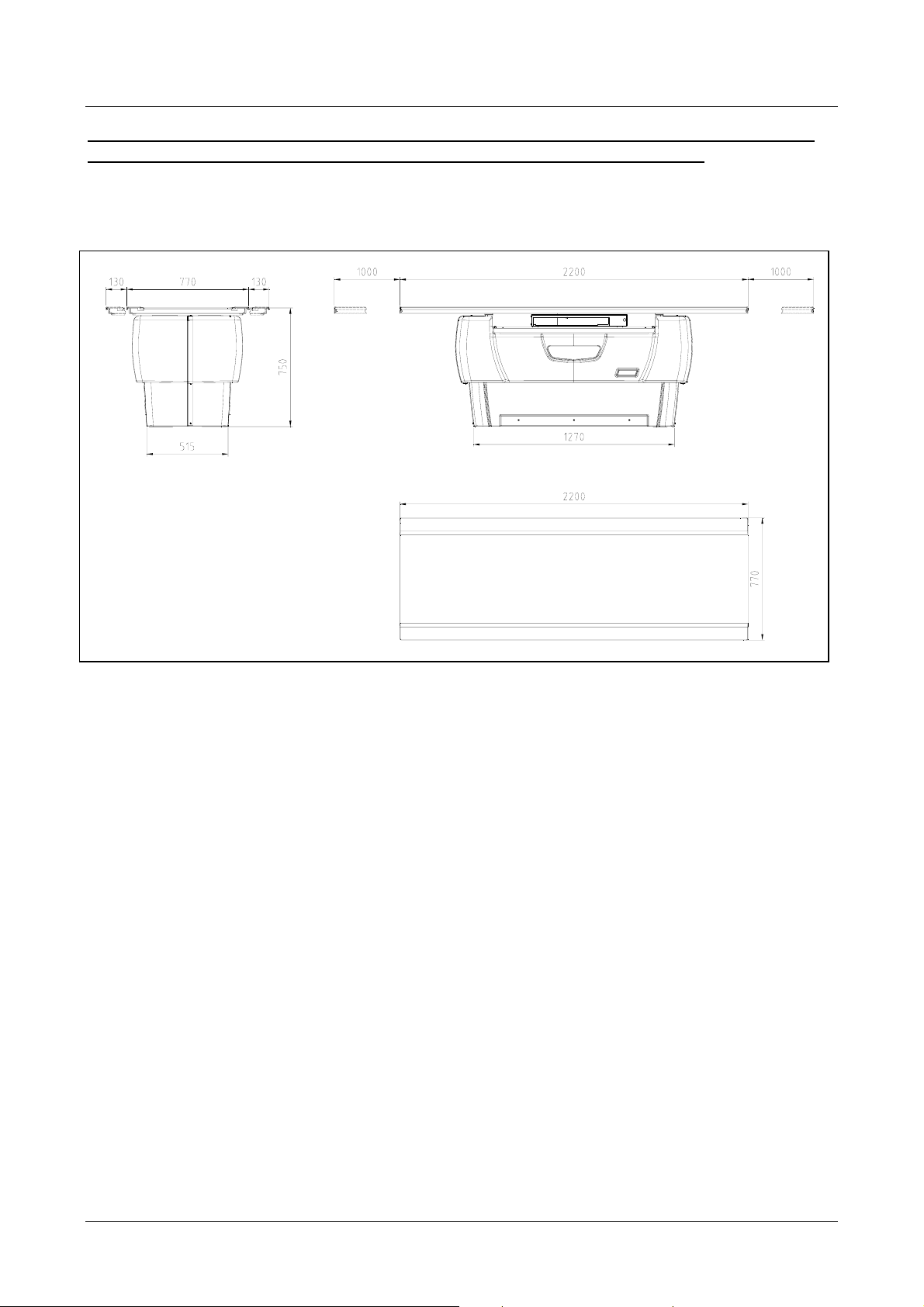

2.4. OVERALL DIMENSIONS

Fig. 2

weight: 260 kg

2.5. PERFORMANCE

2.5.1 MECHANICAL

) Dimensions of table-top 2200x770 mm.

) Distance from table top to plane of FILM: 68 mm with standard POTTER.

) Longitudinal excursion of table top: 1000 mm

) Lateral excursion of table top: 130+130 mm.

) Longitudinal stroke of POTTER: 400 mm.

TECHNICAL AND INSTALLATION MANUAL Pag. 5 di

27

BT MTEBT03

2.5.2. POTTER BUCKY

The BT is fitted (unless requested otherwise) with the standard Potter Bucky with the

following features:

• Motor-driven grid movement, the speed can be adjusted by means of the trimmer R7,

see diagram PTRS001.

• D.F.F. focused anti-scatter grid D.F.F. 120 cm., ratio 1:12, 103 strips per inch. A

different grid can be installed, to the customer specifications.

• Manual stainless steel self-centering cassette holder for X-ray cassettes in sizes from

13x18 cm to 35x43 cm.

• Power supply 24V dc.

• Grid movement starter 24V dc.

• Overall dimensions 570x585x68mm.

• Weight 12.5kg.

2.5.3. TABLE TOP

• Applied part type B to CEI EN 60601-1

• Radiolucent laminate with white surface, contrast media stain-proof

• Maximum weight allowable on table-top: 190 kg

• ATTENUATION EQUIVALENT: less than 1.7 mm Al.

3. ACCESSORIES

TECHNICAL AND INSTALLATION MANUAL Pag. 6 di

27

BT MTEBT03

3.1. ON REQUEST

• Automatic Potter with motor-driven insertion, centering and extraction of the X-ray

cassettes.

• Option for installing a non-standard grid to prevent scatter, with technical specifications

to customer's order.

• Table-top in carbon fiber with attenuation equivalent of about 0.40-0.45 mm Al.

• Compression band.

• Lateral cassette holders for inserting in the side guides on the table-top.

• Pair of handles for patient support, for inserting in the side guides on the table top.

• Head rest with fixing elements for inserting in the guides on the table top.

• Intravenous drip-stand holder.

4. TRANSPORT AND HANDLING

TECHNICAL AND INSTALLATION MANUAL Pag. 7 di

27

BT MTEBT03

1

4.1. PACKAGING

The BT is packed in a wood case with dimensions of 236x98x108 cm, total weight 400Kg,

(with singularly packing)

The box can be moved by crane or transpallet (fig. 3)

4.2. UNPACKING AND HANDLING

The packages can be handled with a crane as illustrated in fig. 3, or with a fork-lift (the

overall weight is 350 kg approx.).

It is important to comply strictly with the recommendations printed on the crates.

Open the box in this sequence 1→ 2→ 3→ 4 → 5 (fig.4)

•

Remove the fixed support.

•

Remove from the box the device.

•

Remove the “Ball in Ball Film”.

•

Fig. 3

P = 400 kg

A

2

I

5

B

Fig. 4

4

3

Î in the event of dispatch by sea, the same case is used as for air transport, with the

difference that the equipment is first inserted in damp-barrier bags.

Î in all other cases, unless specifically requested otherwise by the customer, the

equipment is packaged on a pallet with bubble pack polythene film.

TECHNICAL AND INSTALLATION MANUAL Pag. 8 di

27

BT MTEBT03

5. PRIOR TO INSTALLATION

TECHNICAL AND INSTALLATION MANUAL Pag. 9 di

27

BT MTEBT03

5.1. PREPARING THE ROOMS

1. The minimum useful opening through the doors for accessing the X-ray room must be

cm. 78. If the opening is smaller, the table-top can be removed, in which case the

minimum opening required becomes cm. 74.

2. The ducting needed for the installation is as follows (see fig. 5):

• Bring up to point A (floor outlet) a duct having a minimum diameter of 30 mm from

the X-ray generator.

5.2. CONNECTIONS TO THE GENERATOR

From the generator come up to point A with the following conductors:

a) Multiple cable size 3x1.5mm²

b) Multiple cable size 7x1.5 mm²

c) Earthing connection with green/yellow conductor size 10 mm²

TO THE X-RAY GENERATOR

Fig. 5

TO THE X-RAY GENERATOR

TECHNICAL AND INSTALLATION MANUAL Pag. 10 di

27

BT MTEBT03

6. INSTALLATION

TECHNICAL AND INSTALLATION MANUAL Pag. 11 di

27

BT MTEBT03

AAA

6.1. INSTRUCTIONS FOR ASSEMBLY OF THE EQUIPMENT

AND ACCESSORIES

The unit is delivered dismantled in several parts, as follows

• Technical documentation.

BT horizontal X-ray table structure.

•

Tabletop

•

Carter ABS.

•

6.1.1. MECHANICAL ASSEMBLY

The following list indicates the sequence of operations involved in the positioning and

installation of the equipment.

1. Position the equipment as explained in the pre-assembly instructions, making sure to

keep the Potter centered, along its entire stroke, in relation to the X-ray tube.

2. Mark the position of the holes “A” for attaching the unit to the floor (see fig. 6)

Fig. 6

A

TECHNICAL AND INSTALLATION MANUAL Pag. 12 di

27

BT MTEBT03

A

3. Move the equipment aside and drill suitable holes for the screw anchors you are using,

depending on the type of floor. The screw anchors provided with the equipment require

a hole 12 mm in diameter. Insert the anchors and bring the equipment into position

once again.

4. Before definitively fixing the caisson for the table top in place, check that it is perfectly

level and centered in relation to the X-ray tube. To get the leveling use the special

thickness on equip.

5. Fix the bucky table base to the floor.

6. Remove the screws “A” fig. 7 to release the potter and table support

Fig. 7

A

TECHNICAL AND INSTALLATION MANUAL Pag. 13 di

27

BT MTEBT03

7. Fit the bottom ABS cover in place and fix with screws (fig. 8)

8. Fit the top ABS cover in place and fix with screws (fig. 9)

Fig. 8

Fig. 9

TECHNICAL AND INSTALLATION MANUAL Pag. 14 di

27

BT MTEBT03

9. Dismantle the table-top by removing the 4 screws (Pos. A fig.10) on the supporting

element for attaching the two side guides . The supporting element pos. B fig.10 can be

removed either from the right or from the left, depending on the space available for its

re-assembly.

A

B

A

Fig. 10

10. Fit the table top in place again, proceeding as in item 9 but in reverse order.

11. Check the proper operation of the table-top brakes.

12. Check the proper operation of the Potter.

TECHNICAL AND INSTALLATION MANUAL Pag. 15 di

27

BT MTEBT03

6.1.2. ELECTRIC CONNECTIONS

Referring to the diagram Block BT “BTFZ10A”:

The system is connected to the mains power supply by means of the connector M1 on the

BTFZ10A panel, using the following pin/out:

M1 TERMINAL BLOCK (BTFZ10A panel)

INPUT 220/240 Vac POWER SUPPLY PHASE FROM X-RAY GENERATOR

1

INPUT 220/240Vac POWER SUPPLY NEUTRAL FROM X-RAY GENERATOR

2

GND

3

The system is connected to the X-ray generator by means of the CN8 terminal block on

the BTFP02A board using the following pin/out:

CN8 TERMINAL BLOCK (BTFP02A board)

OUTPUT GRID START CONTACT

1

OUTPUT GRID START CONTACT

2

OUTPUT X X-RAY CONTACT

3

OUTPUT X X-RAY CONTACT

4

5

6

NC

NC

The power and control lines for the X-ray commands are connected to the X-ray generator

by means of the cable prepared during the pre-installation operations. The equipotential

ground node must be connected to the general ground GND node in the X-ray room. The

other electric connections form part of the system wiring, so it is not necessary to provide

further wiring during the installation phase.

The tube stand device STATIX is connected to the BT by connector CN1 on the BTFP02A

board according to the BTFZ10A wiring diagram and using the wires provided.

IMPORTANT!

• The electric system for powering the equipment must be in compliance with the current

regulations applicable to the country where the equipment is installed.

• The manufacturer accepts no liability for any failure to comply with the above

recommendation.

TECHNICAL AND INSTALLATION MANUAL Pag. 16 di

27

BT MTEBT03

7. MAINTENANCE AND REPAIRS

TECHNICAL AND INSTALLATION MANUAL Pag. 17 di

27

BT MTEBT03

7.1. MAINTENANCE

Before taking any action, it is compulsory for the maintenance technician to stop

the equipment in such conditions that it cannot be started again without his consent

(equipment disabled).

There are cases in which the maintenance technician has to verify the results of certain

operations he has performed or to proceed with a fault-finding session while the equipment

is running. In such cases, specific and indispensable instructions must be given to ensure

that:

• The operator at the controls and the maintenance technician can see each other so that

their communications are easy and unequivocal.

• The operator must act according to the instructions received from the maintenance

technician.

• All maintenance must be done under conditions of adequate lighting.

The maintenance technician must be informed of the exact function of all parts of the

equipment. In the event of any doubts, he must consult the RELEVANT sections of this

manual; he must also pay attention to the signal labels attached to the equipment itself.

Any welding operations on the equipment are likely to cause damage to the

instrumentation and to the electrical and/or electronic devices if these are powered. It is

therefore advisable in this case to disconnect the equipment electrically.

For the first 6 months, and every 12 months thereafter, make the following checks and

adjustments:

⇒ After removing the ABS cover (fig. 8 and fig. 9 par.6.1.1) accurately clean the inside

of the equipment and check that the screws that hold it attached to the floor are tight.

⇒ Check that the moving parts are working properly and lubricate as necessary.

⇒ Check the preservation of the electrical and earthing connections.

⇒ Remove the table-top and accurately clean all the upper parts of the appliance and

lubricate (fig.10 par.6.1.1). Remove any remains of contrast medium from the table

top and Potter cover.

⇒ Potter bucky, clean and lubricate the moving parts (greed support). Remove any

foreign bodies, such as lead numbers and letters.

⇒ Check and, if necessary, adjust the electromagnetic brakes.

⇒ Check the state of wear on the rubber end-of-stroke shock absorbers.

⇒ Check the optical switch brake alignment and function.

⇒ Check and, if necessary, adjust the bearings and their tightness.

Re-install the table-top and any covers that have been removed and check the general

operation of the equipment. Make a mechanical and radiographic test.

TECHNICAL AND INSTALLATION MANUAL Pag. 18 di

27

BT MTEBT03

8. SPARE PARTS

TECHNICAL AND INSTALLATION MANUAL Pag. 19 di

27

BT MTEBT03

TECHNICAL AND INSTALLATION MANUAL Pag. 20 di

27

BT MTEBT03

TECHNICAL AND INSTALLATION MANUAL Pag. 21 di

27

BT MTEBT03

TECHNICAL AND INSTALLATION MANUAL Pag. 22 di

27

BT MTEBT03

TECHNICAL AND INSTALLATION MANUAL Pag. 23 di

27

BT MTEBT03

9. WIRING DIAGRAMS

TECHNICAL AND INSTALLATION MANUAL Pag. 24 di

27

A

B

C

D

E

CN2

6

4 4

CN1

1

2

3

4

5

6

4

3 3

CN7

- +

3

D4

1

12

C1

+

2

4700µF 63V

5

4

3

2

1

+24Vcc

+24Vcc

D2

1 2

D3

1N4007

8

1

3

6

1 2

2K2 1/4W

RL1

4

2

5

7

R1

12

D5

1 2

BYW29E-150

1

12

D19

2 2

JP1

12

R11

2K2 1/4W

JP2

3

2

1

+24Vcc

1

2

3

1

2

3

JP3

a termini di legge è severamente vietato riprodurre o comunicare a terzi il contenuto

del presente disegno

+24Vcc

8

15

7

14

6

13

5

12

4

11

3

10

2

9

1

1

2

CN3

3

4

1

2

CN4

3

4

2

CN6

1

1

CN5

2

CN12

1

2

3

CN8

4

5

6

1 1

-

2

C-1/2

1

A

REV. ZONA DESCRIZIONE VARIAN TI

Rimosso CN11, CN13, RL6 , D1, D17, D18, R10, F1, F2

AGGIUNTO RELE' RL6 PIU ' DIODI

PRIMA EMISSIONE

-

B

Disegnato

C

S.B.

F.B.

S.B.

F.B.

S.F.0

F.B.

Controll. Approv. Data

S.B.

S.B.

S.B.

25.10.05

05.05.1998

Title

29.05.01

BT INTERFACE

Size Document Number Rev

A4

BTFS02A

D

Sheet of

1 1

E

2

A

B

C

D

E

1

CN6

CN5

2

3

4

1

2

3

4

2

1

1

2

8

15

7

14

6

13

5

12

4

11

3

10

2

9

1

15

14

13

12

11

10

CN3

CN4

8

7

6

5

4

3

2

9

1

4 4

M1

FASE

220-240Vac POWER

LINE

SUPPLY

NEUTRAL

3 3

2 2

1

2

F1

2A

THERMAL

OVERLOAD

TR1

200Vac

220Vac

240Vac

1 CN3

2 CN3

STXP04A BOARD

F2

80VA

18Vac

20Vac

F3

170VA

24Vac

27Vac

BTFP02A2

2A

5A

BOARD

6

5

4

CN2

3

2

1

1

2

3

CN1

4

5

6

CN12

3 BLUE (-0Vdc)

1 BROWN (+10-30Vdc)

4 BLACK OUT (250mA MAX)

RECEIVER

3 BLUE (-0Vdc)

1 BROWN (+10-30Vdc)

SENDER

SEE POTTER

SCHEMATIC

0 Vac

24 Vac

GRID START

GRID START

X X-RAY CONTACT

X X-RAY CONTACT

P1

UNLOCK

BRAKE

SBLOCCO

FRENO

12

ET1

12

ET3

ET5

1 2

BRAKE

POTTER

FRENO

POTTER

PHOTOCELLS

CONTROL BRAKE

12

ET2

TRASV.

AND LONG.

TABLE TOP

12

ET4

POTTER

STATIX

1

CN7

1

2

3

CN8

4

5

6

1 1

2

1

PRIMA EMISSIONE

REV. ZONA DESCRIZIONE VARIANTI

A

B

-

C

GRID START

GRID START

X X-RAY CONTACT

X X-RAY CONTACT

X-RAY GENERATOR

S.B.

S.F.0

F.B.

Disegnato

Controll. Approv. Data

D

25.10.05

a termini di legge è severamente vietato riprodurre o comunicare a terzi il contenuto

del presente disegno

Title

DIAGRAM BLOCK BT

Size Document Number Rev

A3

BTFZ10AA

Sheet of

E

1 1

0

Loading...

Loading...