Ceiling gas radiators

0694

n°

BL3197

- FORCED -

PS40

R2

PS60

R2

PS80

R2

PS90

R2

PS40

R2

PS60

R2

PS80

R2

PS90

R2

INSTRUCTION BOOKLET:

INSTALLATION AND

AFTER-SALES SERVICE

2

CONFORMITY

Our appliances are in conformity with:

Gas Directive 90/396/EEC

Electromagnetic Compatibility Directive 89/336/EEC

Low-Voltage Directive 73/23/EEC 0694

0694

RANGE

Poster 40

Poster 60

PS40R2 M0000

PS60R2 M0000

Poster 70

PS80R2 M0000

Poster 90

PS90R2 M0000

MODEL CODE

Dear Technician,

Congratulations on having chosen a POSTER PS CONVECTOR. This unit is able to provide many

years of well-being with extremely high standards of efficiency, reliability, quality and safety.

By means of this booklet, we intend providing you with all the information we consider necessary

for correct and easy installation.

Thank you once again

The Manufacturer

3

GARANZIA

The radiator comes with a specified warranty from the manufacturer. We invite

you to apply to the above-mentioned Technical service that with no payment will:

Make a free service on the convector

Ratify the warranty certificate furnished with apparatus that we like to advice

you to read.

GENERAL

General Information page 5

Fundamental safety rules 5

Description of the appliance 6

Safety devices 6

Identification 6

Structure 7

Technical details 8

Accessories 8

Functional wiring diagram 9

Control panel 10

INSTALLER

Receipt of product 11

- Pipe kit Ø 32 or Ø 54 mm with COMBINED end piece 11

- Pipe kit Ø 32 or Ø 54 mm SEPARATE end piece 13

Dimensions and weights 14

Installation area 14

Installation and masonry works 15

- CEILING installation with COMBINED end piece 17

- BRACKET installation with COMBINED end piece 20

- Fitting the CONVECTOR 22

- Installation with SEPARATE end pieces 23

- Fitting the stack 26

- Checking Pressure Loss (Pa) 26

Power connections 28

Gas supply connections 29

TECHNICAL AFTER-SALES SERVICE

Preliminary operations before initial startup 30

Initial startup 30

Control unit malfunctions 31

Controls during and after the initial startup 32

Switching from one type of gas to another 33

Settings 35

Routine maintenance 38

Removing and refitting the casing 45

Troubleshooting 46

This booklet consists of 48 pages.

- After removing the packaging, check the integrity and completeness of the

supply and in case of any discrepancies, contact the Agency that sold the

appliance.

4

CONTENTS

In same parts of the book there are used these symbols:

Attention: it used to underline particular caution or actions.

Prohibited: it used to underline the actions that don’t half to

be executed.

CONTENTS

-children and unassisted disabled persons must not

use the appliance.

- do not start electric appliances or equipment, such

as switches, household appliances etc in case of a

smell of fuel or of combustion fumes.

In this case:

o ventilate the premises by opening the doors and

windows;

o close the fuel opening/closing device;

o promptly call the After-Sales service or professionally qualified personnel.

-do not touch the appliance with wet or damp parts of

the body or if your feet are wet.

- do not close or reduce sizes of venting opening in

the installation area o on the appliance

- cleaning is forbidden without first disconnecting the

appliance from the power mains by turning the

master switch, if fitted, to "OFF" or taking out the

plug.

- It is forbidden to change or tamper with safety or

setting devices without prior manufacturer agreement

- do not pull, disconnect or twist the power cables

exiting from the appliance even when this is disconnected from the power mains. Do not place objects,

such as towels, rags, etc., on the appliance which

could cause malfunctions or prove to be a hazard

- Never leave packaging material (cartons, plastic

bags, etc.) within reach of children as this could be a

potential hazard source.

- After removing the packaging, check the integrity

and completeness of the supply and in case of any

discrepancies, contact the Agency that sold the

appliance.

- The appliance must be installed by companies

approved pursuant to Law no. 46 dated 5 March

1990. Upon completing the installation, such companies must issue a declaration of installation conformity in accordance with applicable national laws and

the instructions provided by the Manufacturer in the

installer's booklet attached to the product.

- The appliance must only be used for the purpose

intended by the Manufacturer and for which it has

been expressly designed. The Manufacturer

disclaims any contractual and non-contractual liability for injuries caused to people or animals and

damage to things, due to installation errors, wrong

settings, bad maintenance or improper use.

If the appliance is not used for a long period of time,

the following operations must be performed:

- position the master switch (if fitted) on "off" or

disconnect the plug from the power mains;

- close the gas tap.

Once in the year you must service the appliance.

- This booklet and that of the User are an integral

part of the appliance and must therefore be carefully

looked after and ALWAYS accompany the appliance

even when this is sold to another person or user or

transferred to another system. In case of damage or

loss, ask the Area After-Sales Service for another

copy.

5

GENERAL

GENERAL INFORMATION

FUNDAMENTAL SAFETY RULES

Please remember that the use of products involving fuels and electricity requires the enforcement of a number of

fundamental safety rules such as:

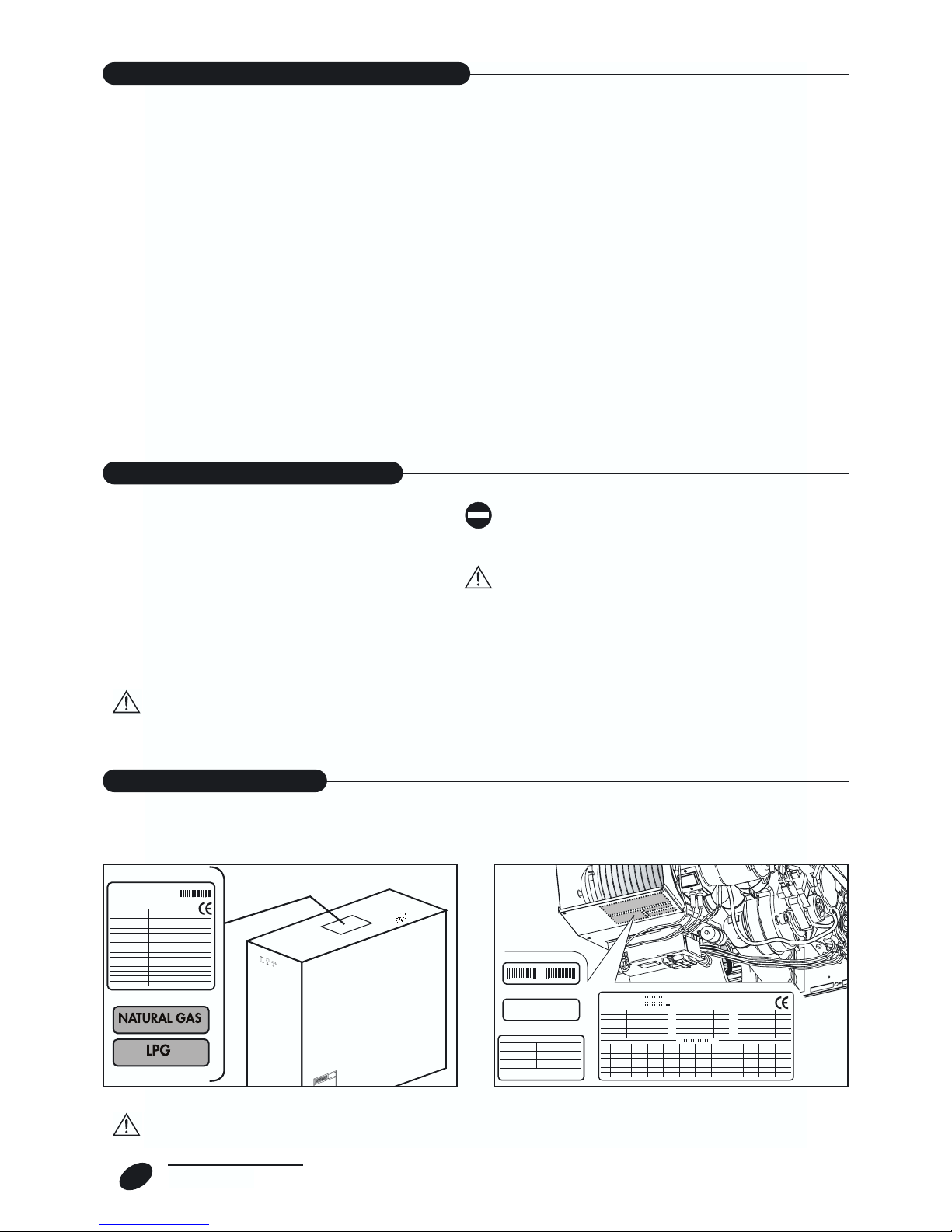

The appliance is identifiable by means of:

- the packaging label

- the Technical Plate

which shows the serial number, the model and the

main technical/performance data.

CONVECTOR units are independent gas appliances

for heating environments.

They use an atmospheric burner with combustion

chamber of the C TYPE, sealed with respect to the

place of installation, offering utmost safety as the

return is prevented of exhaust fumes or fuel into the

environment.

The combustion air is taken from outside the place of

installation and the combustion products are conveyed outside by means of the centrifugal fan fitted

to the appliance.

In view of their compact dimensions, the appliances

can be installed in small spaces.

The appliances are factory set for running on NATURAL GAS and can be transformed for LPG

(G30/G31) thanks to the nozzle kit provided as standard

.

The heat exchanger, consisting of aluminium die

casting with fins, ensures high combustion efficiency.

The tangential fan ensures rooms are quickly heated

up after switch-on.

An electronic board controls all the main appliance

functions and automatically interrupts the gas supply

in case of a fault.

The control panel permits starting or stopping the

appliance in "manual" mode and restoring normal

operation after a fault.

- The remote control permits programming weekly

operating periods, setting the temperature and starting summer ventilation.

6

GENERAL

TERMOCONVETTORE

TERMOCONVETTORE

DESCRIPTION OF THE APPLIANCE

The appliance features the following safety devices:

- Safety thermostat: this trips and switches the

appliance to stop mode if the temperature in the

exchanger exceeds the set limit (107°C).

- Pressure switch: this trips and switches the

appliance to safety standby in case of faults in the

fume extraction circuit.

- Protection fuse: this protects the electrical parts of

the appliance from any power surges.

The engagement of the safety devices points to a

potentially hazardous appliance malfunction; contact

the Manufacturer's After-Sales Service immediately.

The appliance must never ever be operated with the

safety devices not engaged or tampered with.

The safety devices must only be replaced by the

Manufacturer's After-Sales Service, using only original spare parts. Refer to the attached spare parts

catalogue.

To order spare parts and/or perform technical jobs,

the exact model of the appliance must be known.

After making the repairs, perform a start-up test and

check correct operation.

SAFETY DEVICES

IDENTIFICATION

Tampering with and removing the Technical Plate will make it impossible to identify the product with any certainty and

make any installation and maintenance job difficult.

7

GENERAL

1 Safety thermostat

2 Technical plate Gas Valve

3 Control unit

4 Protection fuse

5 Digital remote control

6 Main switch

7a "Integrated" room heat probe

7b "Split" room heat probe

8 Display

9 Battery holder (buffer batteries)

10 Condenser (mod. 70 and 90)

11 Convection fan

12 Power plug

13 Gas valve

14 Combustion fan

15 Room thermostat

16 Burner unit

17 Heat exchanger

16

14

15

13

3

4

5

6

1

2

7b

891011

17

12

7a

STRUCTURE

On request, the following accessories are available:

8

GENERAL

MODEL

II 2H3+

mbar

kW

kW

%

-

V~Hz

W

-

n°

Ø mm

mbar

m

3

/h

kg/h

kg/h

m

3

m3/h

kg

1

230 ~ 50

135

IP20

3

20

C13 / C33 / C53 / C63

80

G20

G30/G31

7,4 / 5,07

8 / 5,6

92,5 / 90,7

196

335

39,5

12 28,5/35,8

1,42 0,82

60

G20

G30/G31

5,85 / 4,0

6,5 / 4,55

90,2 / 88,4

155

265

32

12 28,8/36,7

1,30 0,74

40

G20

G30/G31

3,5 / 2,4

3,85 / 2,7

90,5 / 88,5

95

160

23,5

12 28,8/36,8

1,02 0,58

90

G20

G30/G31

9,1 / 6,2

10 / 7,0

91 / 83

245

410

47,5

10 27,2/34,5

1,65 0,95

0,407

0,285

0,688

0,481

0,847

0,593

1,06

0,742

0,303

0,212

0,512

0,358

0,630

0,441

0,788

0,552

G20

0,299

0,209

0,505

0,354

0,621

0,435

0,777

0,544

G30

G31

Fuel

Mains gas supply pressure (nominal) G20

Category of appliance

Type of appliance

Nom. heat output / min. HI

Nom. heat input /min. HI

Working efficiency Pn

Efficiency class*

Power supply

NOM power input

Insulation standard

Nozzles

Pressure at nozzles

Gas consumption (15°C) nom. / red

.

Quantity of heated air (approximate figure)

Gross weight (with packaging)

* Efficienc

y

class obtained according to prEN 1266 dated 6/1997.

MAX volume, room heated by a

convector (approximate figure)

Wall spacer bracket 30

DESCRIPTION CODE

Wall spacer bracket 50

90° curves _Ø 32mm pipe union

Extension Ø 32mm L = 500mm

Extension Ø 32mm L = 1000mm

Outer protection grille "GP" for separate end piece Ø 32mm

Griglia prot. esterna "GPu" per Term. Unico Ø 32mm

Stack for pipe Ø 32mm

90° curve _Ø 54mm pipe union

Extension Ø 54mm L = 500mm

Extension Ø 54mm L = 1000mm

90°__curve Ø 54mm cast

Outer protection grille "GP" for separate end piece Ø 54mm

Recessed screen "SDP" for separate end piece Ø 54mm

Stack for pipe Ø 54mm

Weekly TIMER

Wall spacer bracket 70

Wall spacer bracket 90

Daily TIMER

INSULATION for pipe Ø 54mm L = 1000mm (pack of 4 pcs.)

INSULATION for pipe Ø 32mm L = 1000mm (pack of 5 pcs.)

Inlet/Outlet end piece Ø 54mm L = 6 cm

Inlet/Outlet end piece Ø 32mm L = 5 cm

135° curves _Ø 54mm

135° curves _Ø 32mm

Recessed screen "SDP" for separate end piece Ø 32mm

Outer protection grille "GPu" for combined end piece Ø 54mm

70000666 00

70000676 00

70000700 00

70000720 00

70000710 00

70000350 00

70000600 00

70000730 00

70000370 00

70000390 00

70000380 00

70000755 00

70000350 00

70000365 00

70000740 00

70000280 00

70000686 00

70000696 00

70000270 00

70000850 00

70000840

70000465 00

70000466

70000375 00

70000705 00

70000365 00

70000610 00

TECHNICAL SPECIFICATIONS

ACCESSORIES

9

GENERAL

TA

T1

CN1

3 2 1

CN2

1 2

CN6

3 2 1

CN3

4 3 2 1

VC

S I T

7530108_0B

CN9

1 2 3 4 5 6

CN7

1 2

CN8

1 2 3

CN5

1 2 3 4

1

2

EV2

4

3

TX

+

RX

PP

SAS

SE

PS

F 2AL 250V

TL

LN

CL

230V~

EV1

SAI

CR

DDS 174

General wiring diagram

PS-R2

CVT

V.T.

BL

RD

WH

PP BATTERY HOLDER

SIT CONTROL BOARD

EA IGNITION ELECTRODE

ER DETECTION ELECTRODE

EV1 ELECTRIC GAS VALVE

F FUSE

CL LINE CONNECTOR

EV2 POWER MODULATOR

L PHASE LINE

N NEUTRAL LINE

CRD DIGITAL REMOTE CONTROL

PS PRESSURE SWITCH

TL LIMIT THERMOST AT

SA I INTEGRATED ROOM PROBE

SAS SPLIT ROOM PROBE

SE OUTSIDE PROBE (optional)

VC COMBUSTION FAN

VT TANGENTIAL FAN

CN... CONNECTOR

T1 POWER TERMINAL

VT TANGENTIAL FAN

TA IGNITION TRANSFORMER

GND/+24V REMOTE POWER SUPPLY

TX/RX TRANSMISSION/SIGNAL RETURN

BL BLUE WIRE

WH WHITE WIRE

RD RED WIRE

ER

WIRING DIAGRAM

12345

DESCRIPTION OF KEYS

a - Switch on the appliance (key 3);

b - Press MENU key (key 5);

c - Press DOWN key (key 2) to move the cursor onto the required menu

line;

d - Press SELECT key (key 5);

note: keys 1, 2, 4 and 5 acquire different functions in the different

menus.

• required setting

e - Press keys 1 and 2 to set the required parameter;

f - Press key 4 to store the parameter just set and pass onto the next;

g - Press OK key (key 5) to store all the set parameters and return to

main menu;

10

GENERAL

CONTROL PANEL

Loading...

Loading...