Italkero Fiammella Installation Manual

2

GENERAL

COMPLIANCE

RANGE

Our appliance are compliance at:

Gas directive 90/396/CEE

Electromagnetic directive compatible 89/336/CEE

Low-tension directive 73/23/CEE

0694

MODEL CODE

Fiammella

FM40R2 M0000

Kind Technical

We thank you for choosing the appliance. We can assure you its performance will be long lasting,

reliable when it is installed and used properly (manufacturer’s guidelines are followed).

Good work and thanks

The Manufacturer.

3

GENERAL

WARRANTY

Provided that it is fitted in accordance with the Manufacturer's instructions, this

appliance benefits from the statutory warranty.

GENERAL

General informations pag.5

Safety rules pag.5

Appliance description pag.6

Identification pag.6

Structure pag.7

Technical data pag.8

Accessories pag.8

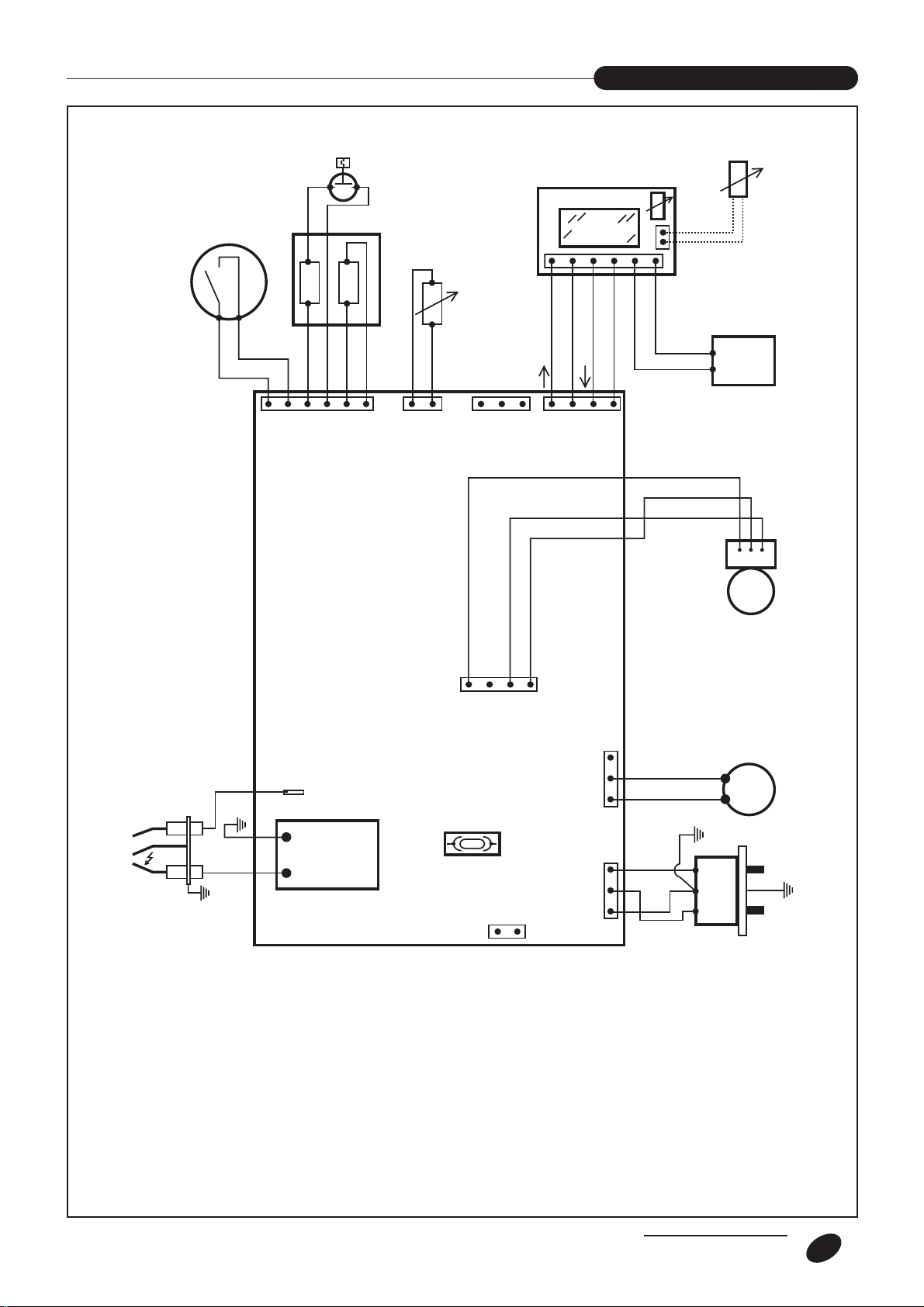

Electrical scheme pag.9

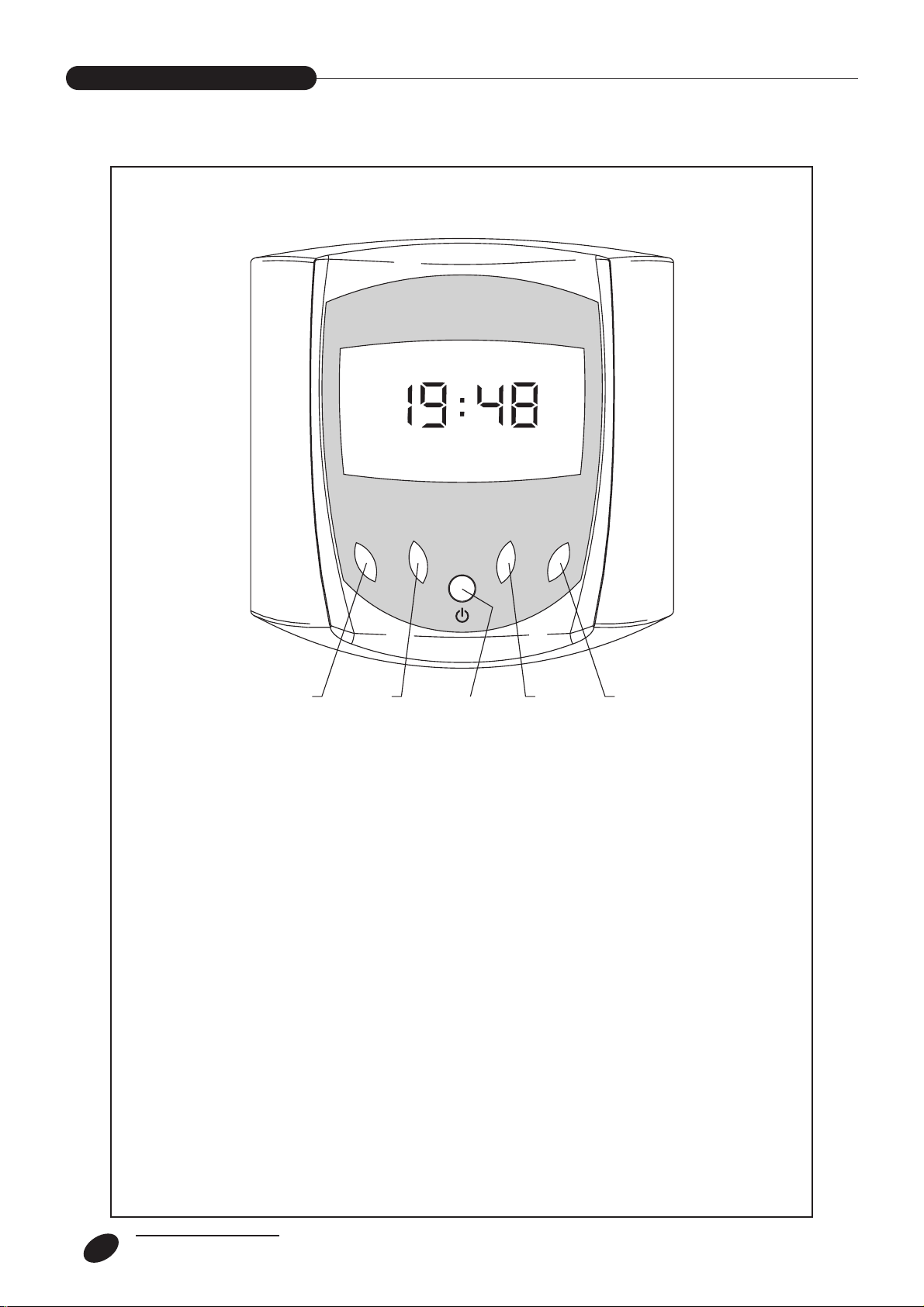

Control panel pag.10

INSTALLATION

Receiving the product pag.11

Weight and dimension pag.13

Installation

- Apparatus choice location pag.14

- Intake & exhaust tube fumes assemblage pag.16

-- Tube Kit Ø 54 mm with unique term. (Standard) pag.17

-- Tube Kit Ø 54 mm with single term. (Speciale) pag.18

- Appliance assemblage pag.23

Electrical collegaments pag.25

Gas connection pag.26

CUSTOMER SERVICE

Preliminary operations pag.26

First service start pag.27

Processor control box malfunction pag.28

Controls during the first & after starting service pag.28

Gas transformation pag.29

Regolation pag.30

Ordinary maintenance pag.31

Appliance clean out pag.31

Components replacement pag.32

Disassembly & reassembly of the skirt pag.36

Eventual anomalies & remedies pag.36

Useful information pag.38

This Manual is composed by 40 pages.

4

GENERAL

INDEX

In same parts of the book there are used these symbols:

Attention: it used to underline particular caution or actions.

Prohibited: it used to underline the actions that don’t half to

be executed.

We like to remember that, products that use combustion

or electrical energy there is security rule to observe

before operating.

Do not allow children to be near the appliance.

It is prohibited to turn on an electrical device if there

is a gas smell.

In this case:

- Open windows and door.

- Close the gas tap.

- Call a Technical Service Assistance.

It is prohibited to touch the appliance with wet hand

or other parts of your body.

-Electrical Hazard: Do not touch the appliance with

wet feet or other part of your body.

It is prohibited to clean the appliance when it is running.

It is prohibited to pull, remove and wring electric

wires outside the appliance also if the electrical

supply is turned off.

It is prohibited place over the appliance, towels, tea

clothes and other could be cause of inefficiency or

also source of hazard.

It is prohibited to leave paper, plastic, or other things

of the appliance box outside within a child’s reach.

After removing the packaging, check the integrity of

the contents. In case of discrepancies, contact the

Agency that sold the appliance.

The appliance must be installed by an authorised

company pursuant to Law no. 46 dated 5 March

1990. After installation, such company should issue

the owner with a declaration of conformity of proper

installation, according to current national regulations

and any local regulations pursuant to Art. 17 of law

no. 46/90 and the instructions provided by the

Manufacturer in the installer's booklet that accompanies the product.

The APPLIANCE must be used as intended by the

Manufacturer and for the purpose for which it was

expressly built.

The Manufacturer disclaims any contractual and

non-contractual liability for injury to persons and animals and damage to things caused by installation,

adjustment and maintenance errors or improper

appliance use.

If the APPLIANCE is not used for a long period of

time, the following operations will have to be performed:

- position the master switch of the appliance on

"OFF"

- position the master switch of the system, if fitted, on

"OFF" or disconnect the plug from the power socket.

- close the gas tap

The appliance should be serviced at least once a

year.

This booklet is an integral part of the appliance and

must therefore be carefully looked after and

ALWAYS accompany the APPLIANCE, including

when this is sold to another user or transferred to

another system.

In case of damage or loss, ask the Area After Sales

service of the Manufacturer for another copy.

Always make sure that curtains or other objects do

not obstruct the suction filter and the room air outlet

vent.

Only connect the appliance to properly earthed

power sockets.

Only install the appliance in dry environments (protection IP 20)

The appliance must not be operated wherever there

are hazardous materials, vapours or liquids.

Install the appliance on a flat surface to prevent any

malfunction.

5

GENERAL

GENERAL INFORMATIONS

SAFETY RULES

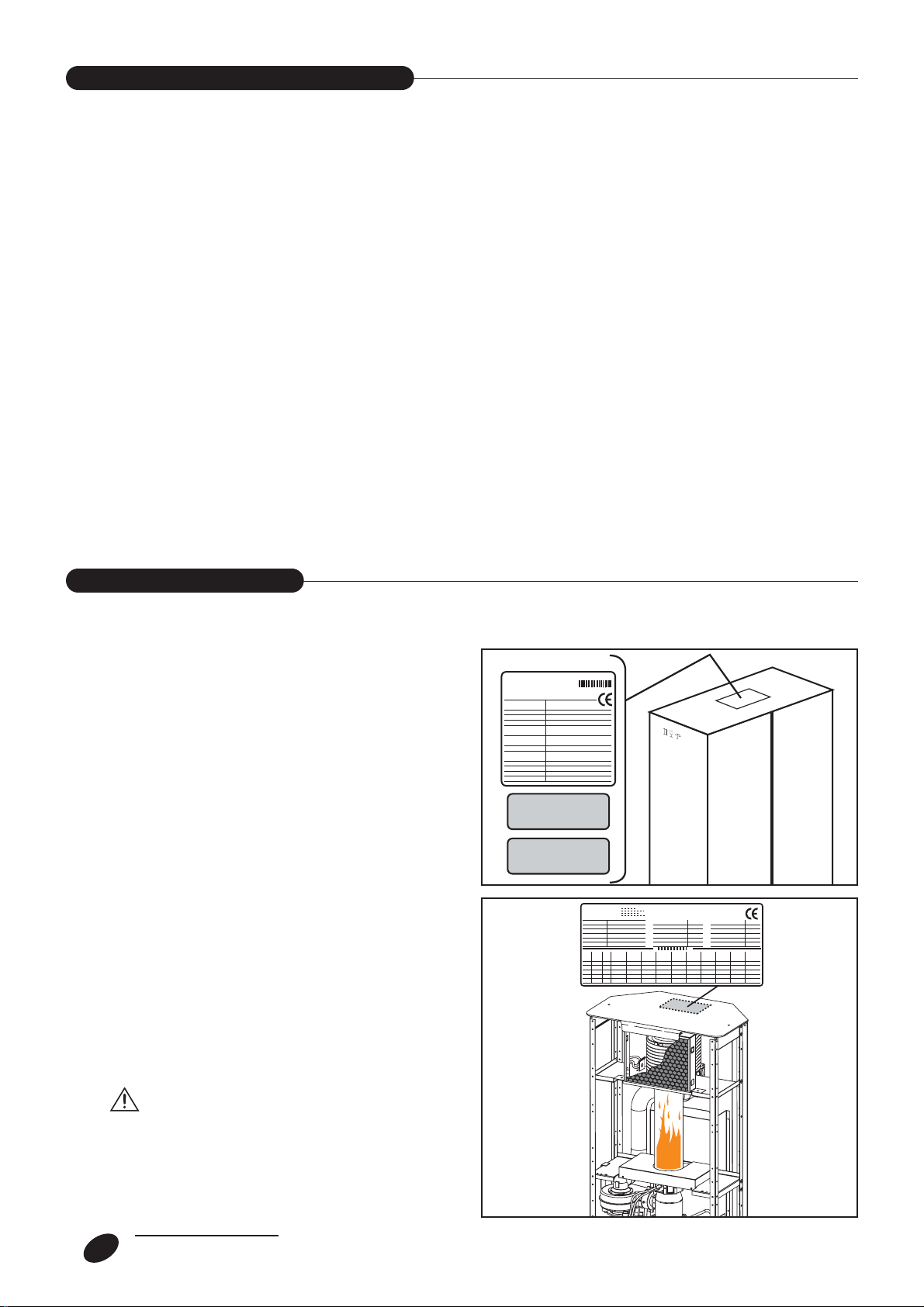

The appliance is identified through:

- Packed label:

A label that indicates the code and the combustion it

uses to identifies the appliance.

- Technical label:

The technical label reports the matrices numbers,

the gas prearrangement, and technical observation.

-Gas prearrangement label:

It reports the kind of gas the appliance has to use,

and if there is a transformation from one kind of gas

to another you have to change the old label.

Spare parts, or technical operation require, a

precise identification of the type of model.

If there is going to be any tampering of the technical

label, this will not consent the right identification of

the apparatus.

The appliance is a gas radiator that heat up the

atmosphere.

It has an intake of air that goes in the combustion

chamber type C.

The appliance is made with an aluminium body that

allows a high efficiency of heat; it also has a fan that

allows the dispersal of air faster in the rooms.

The convectors are arranged in factory for the function at gas methane and they can be transformed to

GPL(G30/G31) using the furnished nozzle kit.

Note: At request the apparatus can be furnished

already arranged at GPL.

It also has an electrical device that allows you to do

a series of things.

There also is a Processor Control Box (P.C.B

assy) that controls all the principals’ function of

the apparatus.

After there is the Control Panel that has other

options.

6

GENERAL

APPLIANCE DESCRIPTION

IDENTIFICATION

Metano

Methane

G.P.L.

L.P.G.

7

GENERAL

STRUCTURE

3

2

1

4

19

18

5

6

17

16

15

7

8

2324

9

10

20

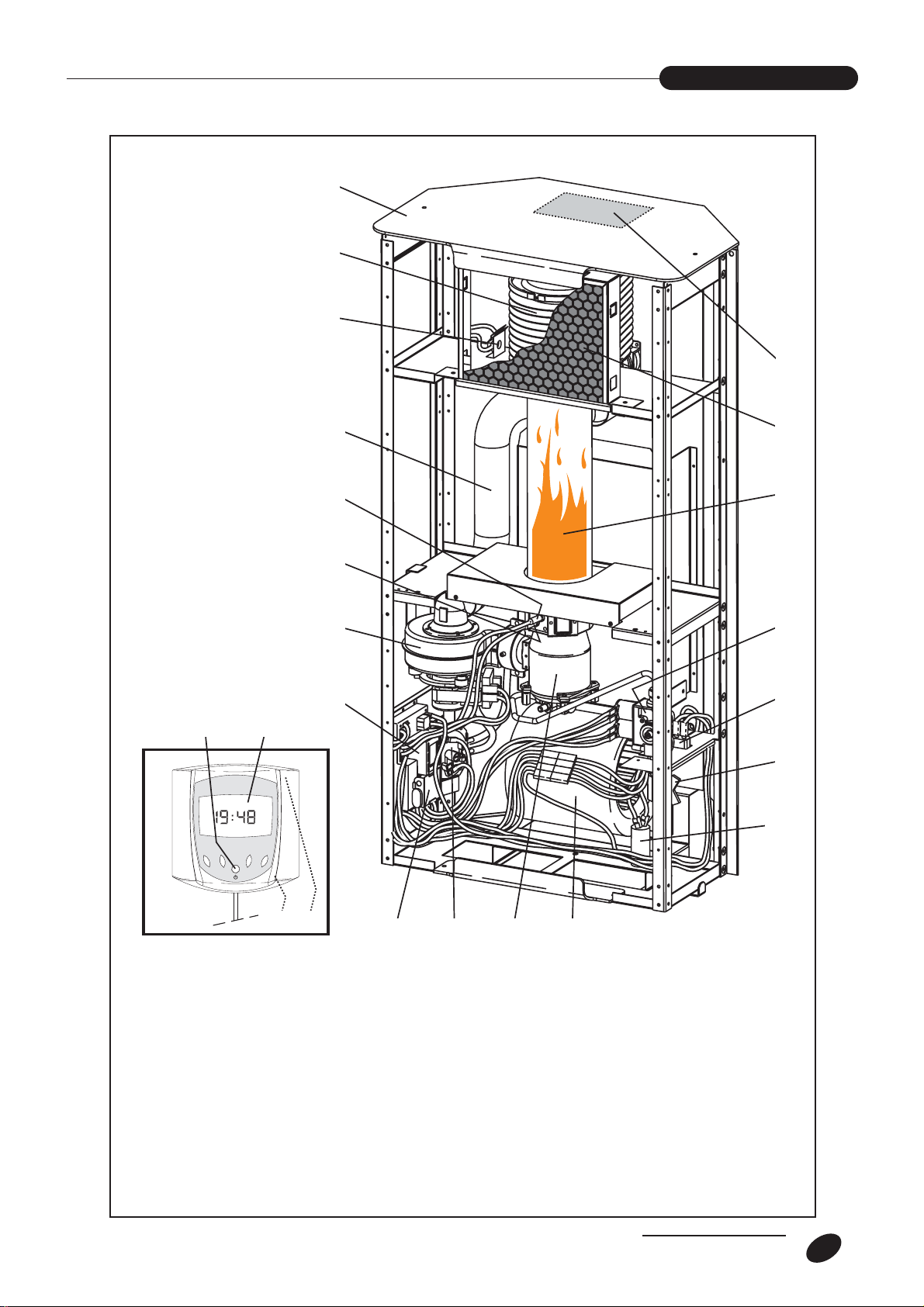

1 Safety thermostat

2 Heat exchanger

3 Upper cover

4Technical data plate

5 Exchanger cover

6 Glass pipe

7 Gas valve

8 Power plug

9 Gas tap

10 Condenser

11 Convection fan

12 Combustion chamber

21 22

11121314

13 Pressure switch

14 Battery holder (buffer batteries)

15 Control unit

16 Combustion fan

17 Ignition electrode

18 Detection electrode

19 Air extraction pipe

20 Digital control

21 “Split” environment heat probe

22 “Integrated” environment heat probe

23 Display

24 ON/OFF key

The following options are available upon request:

8

GENERAL

TECHNICAL DATA

ACCESSORIES

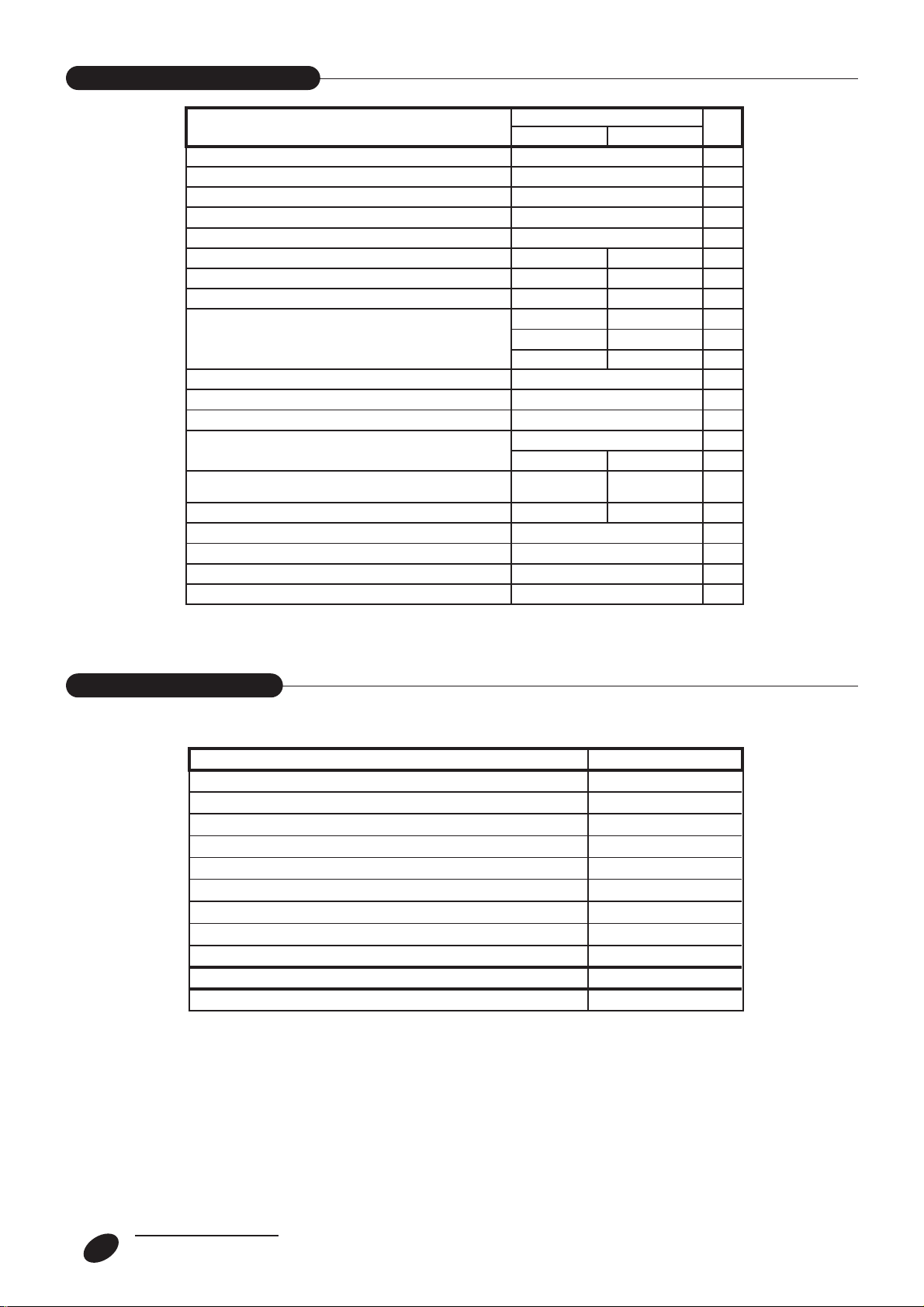

MODEL

Terminal capacity nomination (Qn)

Terminal power convector nomination (Pn)

Terminal capacity reduction (Qn)

Terminal power convector reduction (Pn)

Right efficiency

Main pressure (nomination)

Nozzle pressure

Reduce nozzle pressure

Gas consumption (15°C) (nom./red.)

Type of apparatus

Combustion category

Efficiency class

Nozzle

Max/min value Atmospheric

heated by a convector

Quantity of air heated

Electrical alimentation

Power absorbed when in function

Protection degree

Weight with the convector in box

Methane

G30

G31

fiammella

Methane

12,0

7,5

0,407/0,285

C13 - C33 - C53

1,10

95

160

4,5

3,96

3,41

2,9

88

2H 3+

II

1

3

230~50

135

IP20

43

LPG

29/3720

28,8/36,4

17/21

0,354/0,228

0,349/0,225

0,62

95

160

kW

kW

kW

kW

kW

kW

%

mbar

mbar

mbar

3

m

kg/h

kg/h

n°

Ø

m

m3/h

V~Hz

W

kg

/h

3

DESCRIPTION CODE

90° curve _Ø 54mm pipe union

Extension Ø 54mm L = 500mm

Extension Ø 54mm L = 1000mm

90°__curve Ø 54mm cast

135° curves _Ø 54mm

Outer protection grille "GP" for separate end piece Ø 54mm

Outer protection grille "GPu" for combined end piece Ø 54mm

Recessed screen "SDP" for separate end piece Ø 54mm

Stack for pipe Ø 54mm

INSULATION for pipe Ø 54mm L = 1000mm (pack of 4 pcs.)

Inlet/Outlet end piece Ø 54mm L = 6 cm

70000370 00

70000390 00

70000380 00

70000755 00

70000375 00

70000350 00

70000610 00

70000365 00

70000740 00

70000850 00

70000465 00

9

GENERAL

ELECTRICAL SCHEME

TL

2

PS

1 2 3 4 5 6

EV1

1

CN9

3

EV2

4

SE

1 2

CN7

1 2 3

CN8

CR

DDS 174

TX

RX

+

1 2 3 4

CN5

SAS

SAI

-

II

BL

I

RD

0

WH

PP

II I O

V.T.C.

S I T

7530108_0B

T1

ER

TA

SAI INTEGRATED ENVIRONMENT PROBE

SAS SPLIT ENVIRONMENT PROBE

SE EXTERNAL PROBE (optional)

VC COMBUSTION FAN

VTC TANGENTIAL-CENTRIFUGAL FAN

CN... CONNECTOR

T1 POWER TERMINAL

VT TANGENTIAL FAN

TA IGNITION TRANSFORMER

GND/+24V

TX/RX SIGNAL TRANSMISSION/RETURN

BL BLUE LEAD

WH WHITE LEAD

RD RED LEAD

REMOTE CONTROL POWER SUPPLY

4 3 2 1

CN3

F 1AT 250V

CN2

1 2

PP BATTERY HOLDER

SIT CONTROL BOARD

EA IGNITION ELECTRODE

ER DETECTION ELECTRODE

EV1 GAS SOLENOID VALVE

F “1AT 250V” FUSE

CL LINE CONNECTOR

EV2 POWER MODULATOR

L PHASE LINE

N NEUTRAL LINE

CRD DIGITAL REMOTE CONTROL

PS PRESSURE SWITCH

TL LIMIT THERMOSTA T

3 2 1

CN6

3 2 1

CN1

VC

LN

CL

230V~

10

GENERAL

CONTROL PANEL

12345

DESCRIPTION OF KEYS

a - Switch on the appliance (key 3);

b - Press MENU key (key 5);

c - Press DOWN key (key 2) to move the cursor onto the required menu line;

d - Press SELECT key (key 5);

note: keys 1, 2, 4 and 5 acquire different functions in the different menus.

• required setting

e - Press keys 1 and 2 to set the required parameter;

f - Press key 4 to store the parameter just set and pass onto the next;

g - Press OK key (key 5) to store all the set parameters and return to main menu;

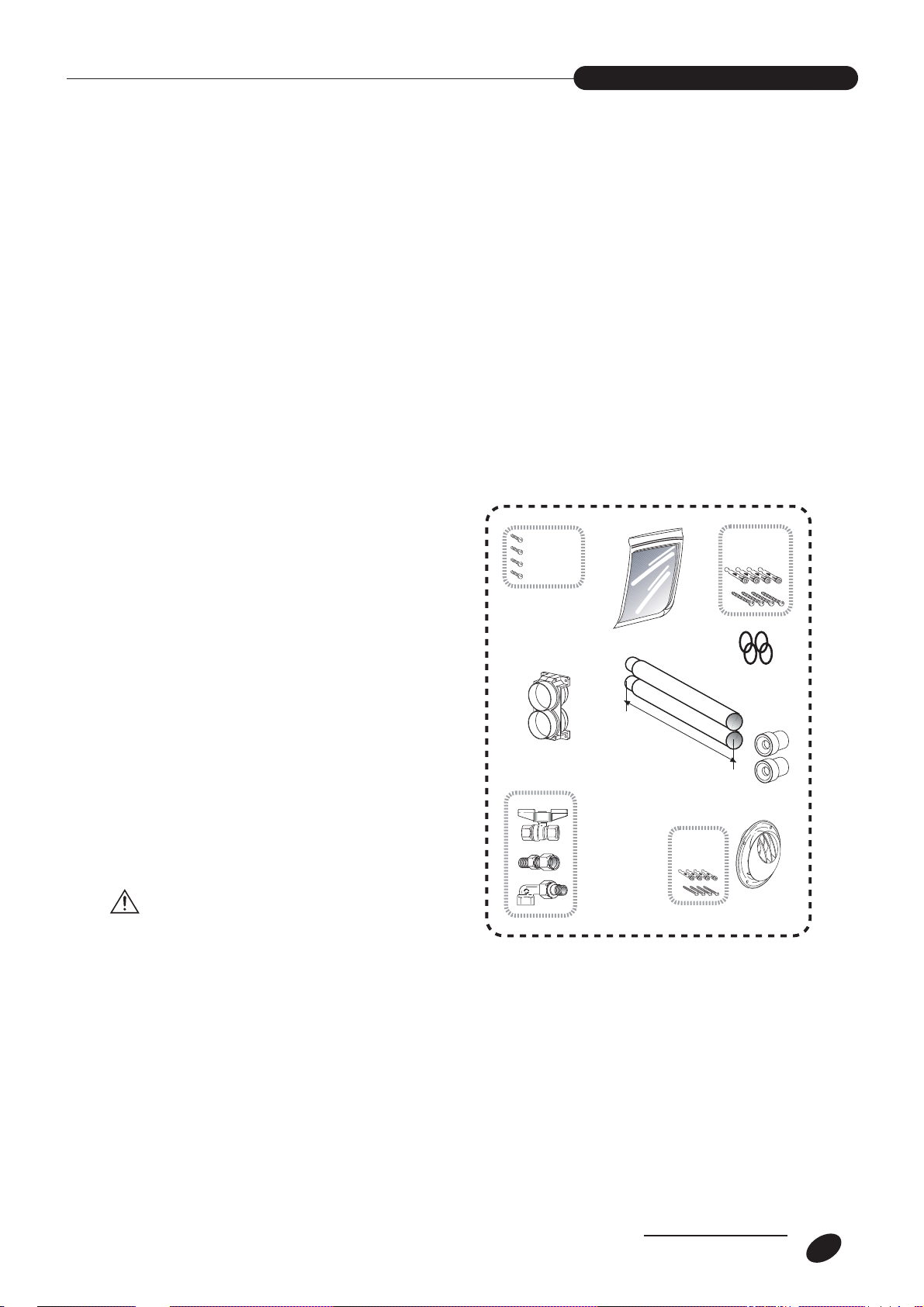

The appliance is supplied protected by cardboard

packaging containing:

n. 1 Appliance

n. 1 Digital chronothermostat

n. 1 STANDARD pipe kit

n. 1 Metal template

n. 2 Bracket

n. 1 Documents envelope:

n. 1 User instruction booklet

n. 1 Installer booklet

n. 1 Gas transformation KIT

n. 1 Spare parts catalogue

n. 1 Warranty certificate

n. 1 Warranty labels

n. 1 Power socket

- PARALLEL PIPE KIT WITH SINGLE END PIECE

(STANDARD)

- STANDARD Ø 54 pipe KIT with single end piece

The Kit consists of:

Q.ty Description

1 Gas tap with connections

1 Adapter union for Ø 54 mm pipes

4Ø 3.9 mm screws for fastening adapter

4Ø 8 mm screw anchors for fastening template

2Ø 54 mm pipes, L = 500 mm

1 Single end piece with integrated rosette

4Ø 6 mm screw anchors for fastening

single end piece

2 Diaphragms

4 O-Ring for pipes

For installation see INSTALLER section.

If the STANDARD Pipe KIT inside the appliance

packaging fails to satisfy the desired installation characteristics, new parts can be added (pipes, curves,

etc.) from the Manufacturer’s List.

To avoid any type of breakage or malfunc-

tion that could damage the appliance, we

suggest always using the Manufacturer’s original

accessories and spare parts.

11

INSTALLER

RECEIPT OF PRODUCT

nr. 4

3,9 x 9,5

500

nr. 4

(Ø 6mm)

nr. 4

(Ø 8mm)

nr. 4

O-Ring

Ø110

12

INSTALLER

Verify Tube kit

When the appliance is being installed be sure that all

the tubes are adjusted for the installation you want

done. The tube kits available are:

Cod. TP54OP 0000

Cod. TP5410A5 00

Cod. TP54SP 0000

MODEL CODE

fiammella

nr. 4

3,9 x 9,5

description

KIT std. EXHAUST & INTAKE Ø 54mm (1 INDIVIDUAL)

KIT special EXHAUST & INTAKE Ø 54mm (2 SINGLES)

KIT special EXHAUST & INTAKE Ø 54mm (1 INDIVIDUAL) INTERNAL Installation

TP540P 00000

TP54SP 00000

TP5410A5 00

nr. 4

(Ø 8mm)

nr. 4

O-Ring

nr. 4

3,9 x 9,5

nr. 8

O-Ring

500

mm

mm

1000

500

nr. 4

(Ø 6mm)

Ø110

nr. 4

(Ø 8mm)

500

mm

Loading...

Loading...