Mod. 12 kW

0694

BR0969

Decorative outdoor gas heater.

Decorative outdoor-Heizofen.

Decorative outdoor gaskachel.

Décoratif extérieur chauf fage au gaz.

UK - USER MANUAL AND ASSEMBLY INSTRUCTIONS

DE - GEBRAUCHSANLEITUNG UND DIE AUFBAUANLEITUNG

NL - INSTALLATIE-INSTRUCTIES EN GEBRUIK

FRA - INSTRUCTIONS D'INST ALLATION ET D'UTILISA TION

Manuale h MAX 736, Ø MAX 310

Manual

1

20

18

Telecomandato h MAX 706, Ø MAX 310

Remote

2

3

56

7

16

9

10

11

12

13

14

15

17

19

4

8

Fig.3

1

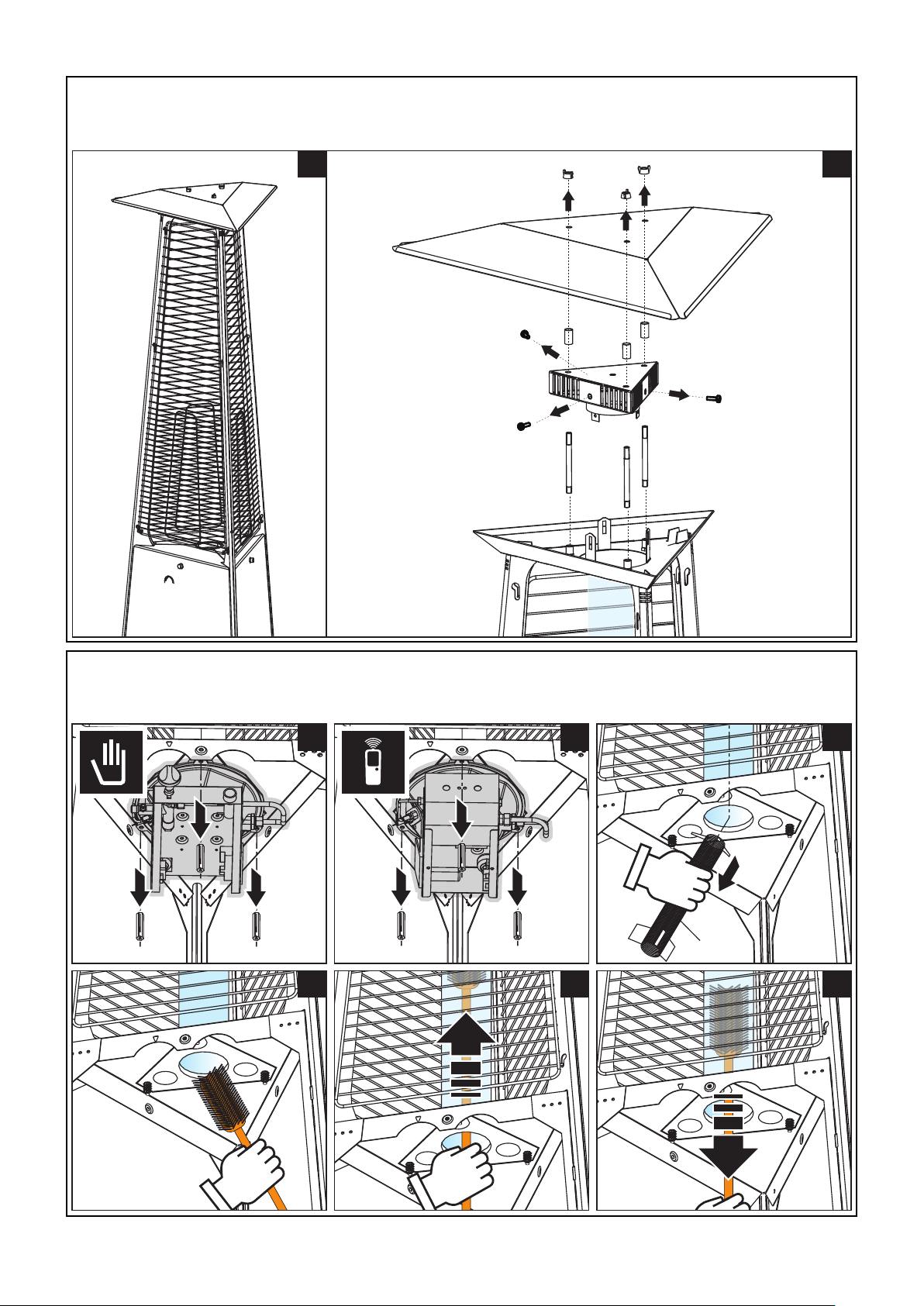

KEY: 1) fastening knob, 2) cover dish, 3) exchanger head, 4) net cylinder (optional), 5) structure upright, 6)

1 2 3 4

5 6 7 8

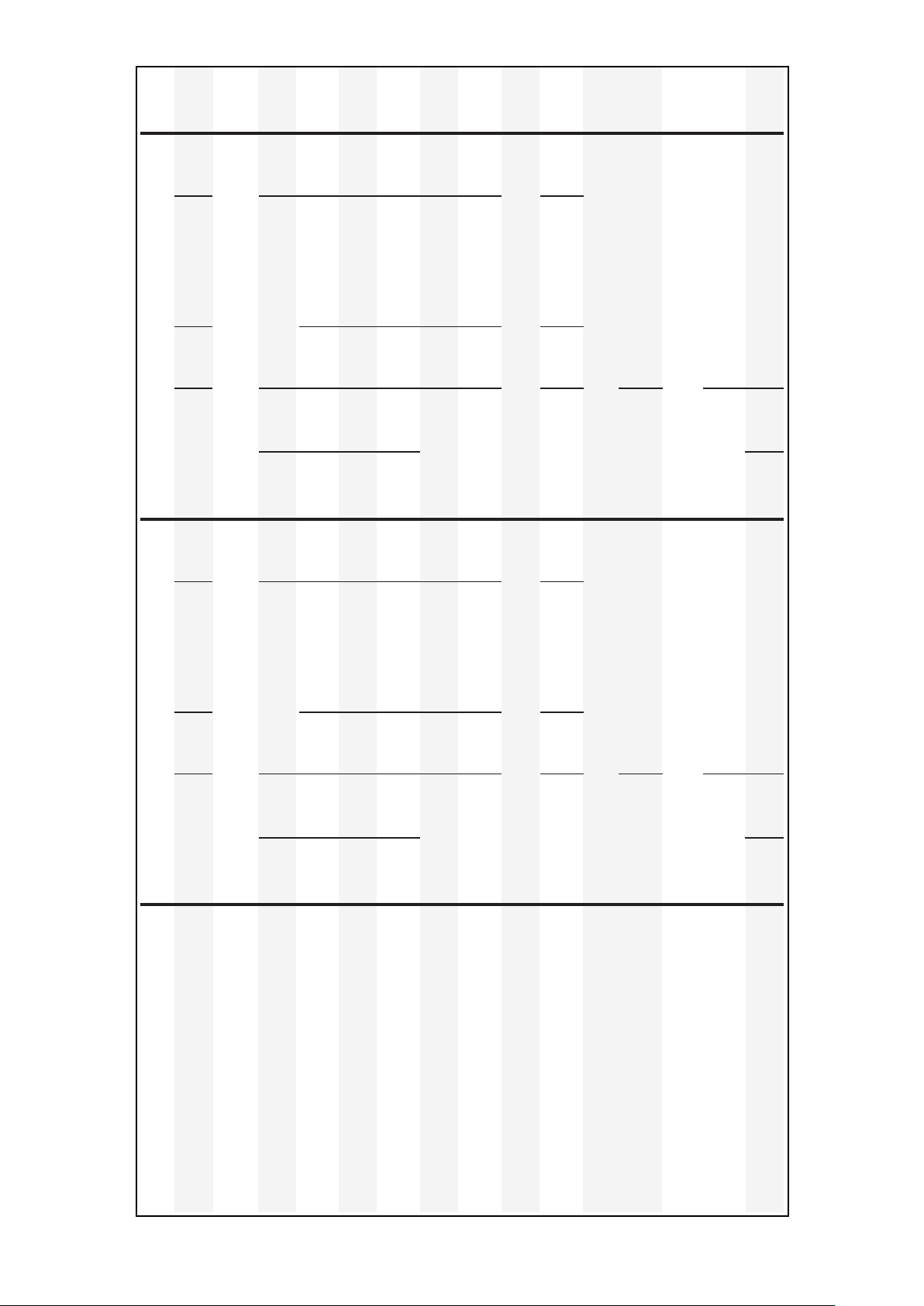

Aria compressa

Compressed air

nr.

19

nr.

8

protection grid, 7) glass pipe, 8) retention screw, 9) burner, 10) ignition/adjustment knob, 11) battery holder,

12) control unit (remote control Mod.), 13) tank support base, 14) side panel, 15) control cover panel, 16)

fastening knob, 17) control unit display slot (remote control Mod.), 18) trolley (optional), 19) Hurricane KIT,

20) SMALL remote control (remote control Mod.).

ZEICHENERKLÄRUNG: 1) Befestigungsknopf, 2) Abdeckungsschirm 3) Wärmeaustauscherkopf, 4) Walze netz

Option), 5) Strukturpfosten, 6) Schutzgitter, 7) Glasrohr, 8) Befestigungsschraube, 9) Brenner, 10) Einschalt-

(

/Einstellknopf, 11) Batteriefach, 12) Steuereinheit (Mod. Mit Fernbedienung), 13) Gasflaschenstützfläche, 14)

seitliche Verkleidungstafel, 15) Verkleidungstafel der Bedienelemente, 16) Befestigungsknopf, 17) Aussparung

Display Steuereinheit (Mod. Mit Fernbedienung), 18) Schlitten (Option), 19) Gegen wind, 20) klein

Fernbedienung (Mod. Fernbedienung).

1) Schroeven, 2) Reflector, 3) branderkop, 4) warmteverdeler 5) rechte structuur, 6) beschermingsroosters, 7)

glazen buis, 8) aanhoudperiode schroef 9) brander, 10) ontsteking / aanpassing knop, 11) batterij houder,

12) controle-eenheid (afstandsbediening Mod.), 13) gasfles draagvlak, 14) zij paneel, 15) paneel van de

gascontrole kant, 16) bevestigings knop, 17) controle-eenheid met sleuf (afstandsbediening Mod .), 18) wielset

(optioneel), 19) afstandsbediening (afstandsbediening Mod.).

LÉGENDE: 1) bouton de fixation, 2) la parabole de couverture, 3) l'échangeur, 4) l'échangeur de chaleur, 5)

Structure verticale, 6) la grille de sécurité, 7) tube de verre, 8) vis de fixation, 9) brûleur, 10) le bouton on /

cadre, 11) batterie, 12) unité de contrôle (à distance), 13) appui de base du cylindre, 14) le panneau latéral,

15) panneau de couverture, 16) de fixation mâle, 17) slot unité d'affichage (Mod . télécommande), 18) chariot

(facultatif), 19) Télécommande (mode à distance).

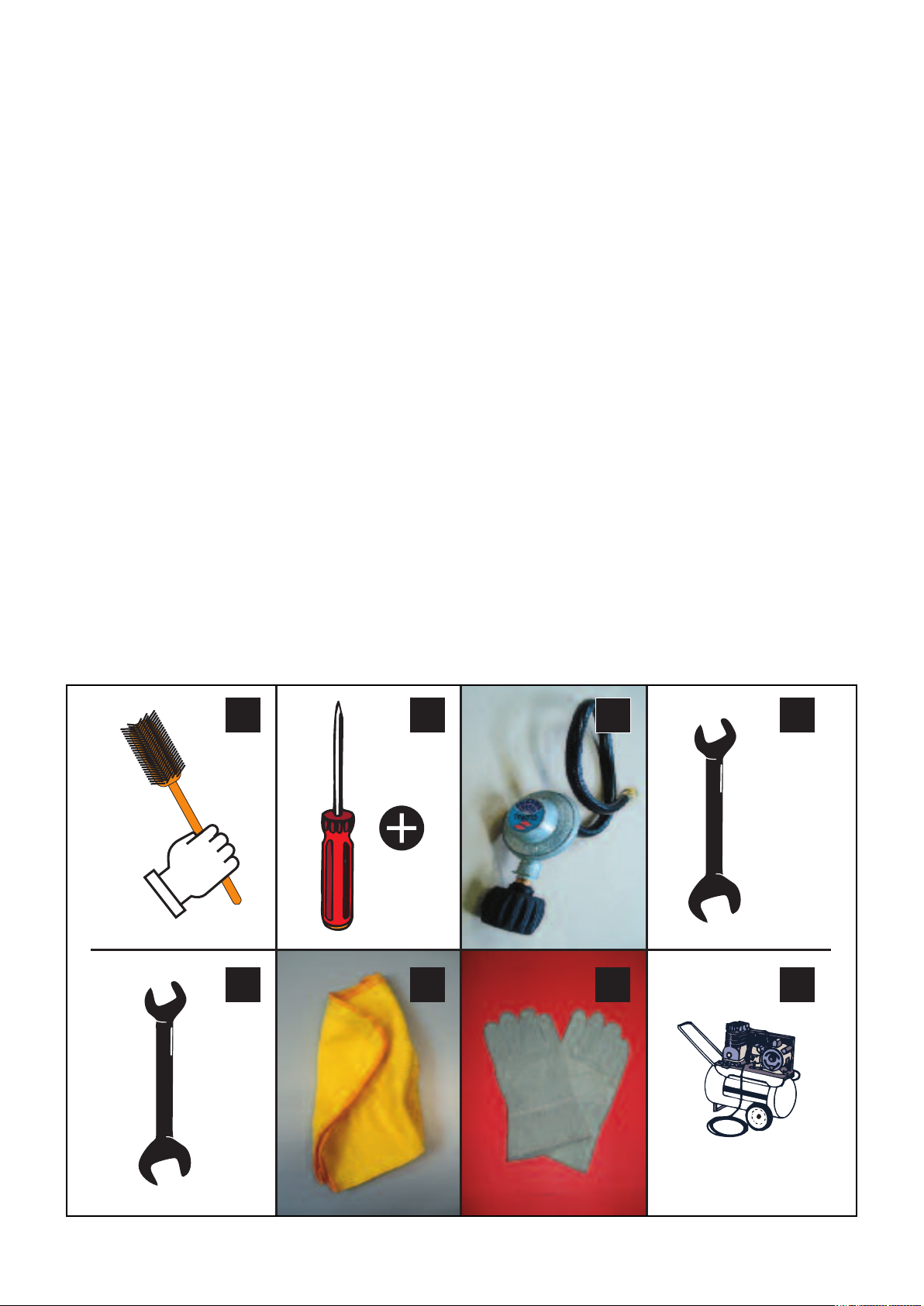

TOOLS recommended for fitting and/or maintenance (not supplied by the Manufacturer): 1) brush for cleaning the glass pipe, 2)

cross-headed tip screwdriver, 3) LPG pressure regulator, 4) 19 fixed wrench for regulator, 5) 8 fixed wrench, 6) scratchproof soft cloth for outside cleaning, 7) protection gloves for transport, 8) compressed air for inside cleaning.

Empfohlene WERKZEUGE für Montage und Wartung (nicht vom Hersteller geliefert): 1) Bürste zum Reinigen des Glasrohrs, 2)

Kreuzschraubenzieher, 3) LPG-Druckregler; 4) 19-Maulschlüssel für den Regler; 5) 8,6-Maulschlüssel; 6) weiches, nicht

scheuerndes Tuch zur externen Reinigung; 7) Schutzhandschuhe für den Transport; 8) Druckluft zur internen Reinigung.

2

F

MIN

500

680

L 640

range of action 2m

h 2180

1436

raggio azione 2m

MIN

500

ig.1

Fig.2

3

1

3

2

1

2

3

1,5Volt

torcia

KD

D

AM1

R14

1,5Volt

ministilo

K3A

AAA

AM4

1,5Volt

stilo

KAA

AA

AM3

Fig.4

1

2

3

4

1

2

3

4

Fig.5

Fig.6

4

1

1

1

2

4

5

8

7

10

11

9

12

Fig.7

1

1

2

10

11

9

5

13

7

12

14

15

16

1

4

1

2

3

5

6

7

8

4

Fig.8

Fig.9

5

Fig.10

1

2

2

Fig.11

Fig.12

6

2

1

UK - HURRICANE KIT ASSEMBLY

1 2

4 5 6

3

optional

E - MONTAGE GEGEN WIND

D

ig.13

F

UK - TUBE MAINTENANCE

DE - WARTUNG TUBE

Fig.14

7

centralina/control unit

telecomando/remote control

Fig.15

UK - DUNP-SWITCH SAFETY DEVICE

DE - SAFETY DEVICE ANTI-KIPPEN

Fig.16

8

1 2 3

4 5 6

1 2 3

UK - REPLACING BROKEN PIPE

DE - ERSATZ GEBROCHEN TUBE

ig.17

F

UK - FIXING THE TANK

DE - FESTSETZUNG DER TANK

Fig.18

8a

G30 • G31

model

Power supply

Thermal capacity Nom.

Thermal capacity Red.

Pressure Nom. supply

Pressure Nom. nozzle

Gas consumption (Qn) (15°C)

Consumption G30

Consumption G31

Tipo apparecchio

Gas category

Burner nozzle

Ø

Pilot nozzle

Ø

Ø Diaphragm

G20 G20 • G25 G25

kW

kW

mbar

mbar

m3/h

Kg/h

Kg/h

nr.

mm

nr.

mm

mm

Manual performant Remote performant

12,00

4,50 6,40 6,00

28-30 • 37

20 20 • 25

20

50 • 50

5,20

28-30 • 37

20 20 • 25

20

50 • 50

-

1,14 1,14 • 1,33 1,33

- - -0,872

- - -0,858

A1

I2H I2E

I2E+ I2LI3+ I3B/P

1

1,65 2,50

1

0,25 0,35

np

np

1,75

G30 • G31 G20 G20 • G25 G25

12,00

5,20 6,40 6,00

28-30 • 37

20 20 • 25

20

50 • 50

6,20

28-30 • 37

20 20 • 25

20

50 • 50

-

1,14 1,14 • 1,33 1,33

- - -0,872

- - -0,858

A1

I2H I2E

I2E+ I2LI3+ I3B/P

1

2,10 3,30

1

0,25 0,35

np

np

1,75

- -

8b

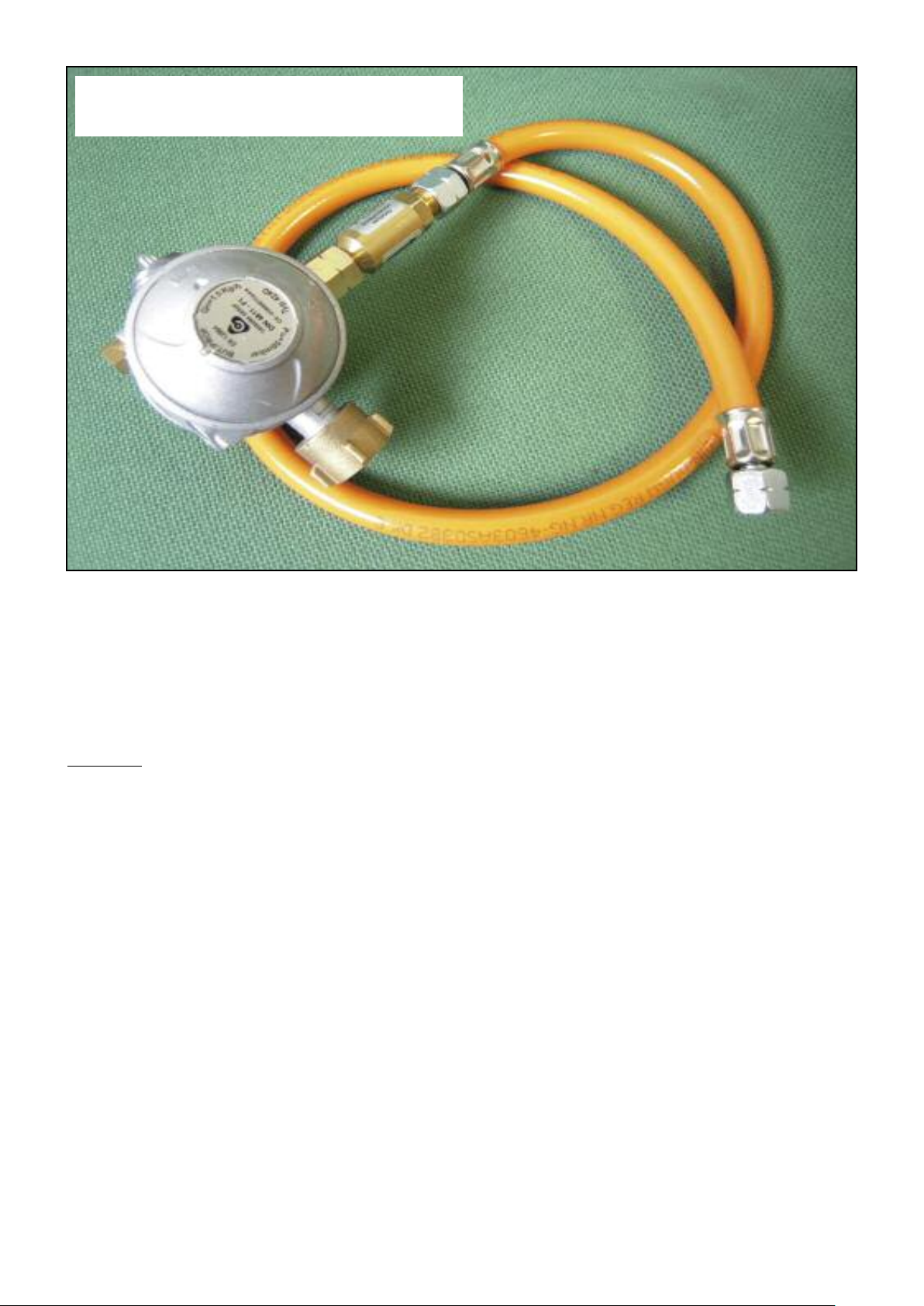

ITA - REGOLATORE PER GERMANIA (50 mbar)

UK - GAS GOVERNOR FOR GERMANY (50 mbar)

DE - DRUCKGAS REGLER FUR DEUTSCHLAND (50 mbar)

UK - REGULATOR: Capacity MAX 1000 g / h, Max pressure 37mbar.

UK - The gas pipe must be of a flexible type and of a length such as to allow an easy replacement of the cylinder.

- UK -

Contents

THE REMOTE CONTROL

GENERAL DESCRIPTION

ASSEMBLY

START-UP

SWITCH-OFF

MAINTENANCE

STORAGE

WARRANTY

TROUBLESHOOTING

9

CAREFULLY LOOK AFTER THIS BOOKLET FOR THE ENTIRE LIFE OF THE APPLIANCE

AND REQUEST A NEW ONE IN CASE OF DAMAGE OR LOSS!

IMPORTANT! SHOULD THE PARTS BE DAMAGED, DO NOT GO AHEAD WITH ASSEMBLY!

IMPORTANT! This appliance must be installed in compliance with the Regulations, Laws and

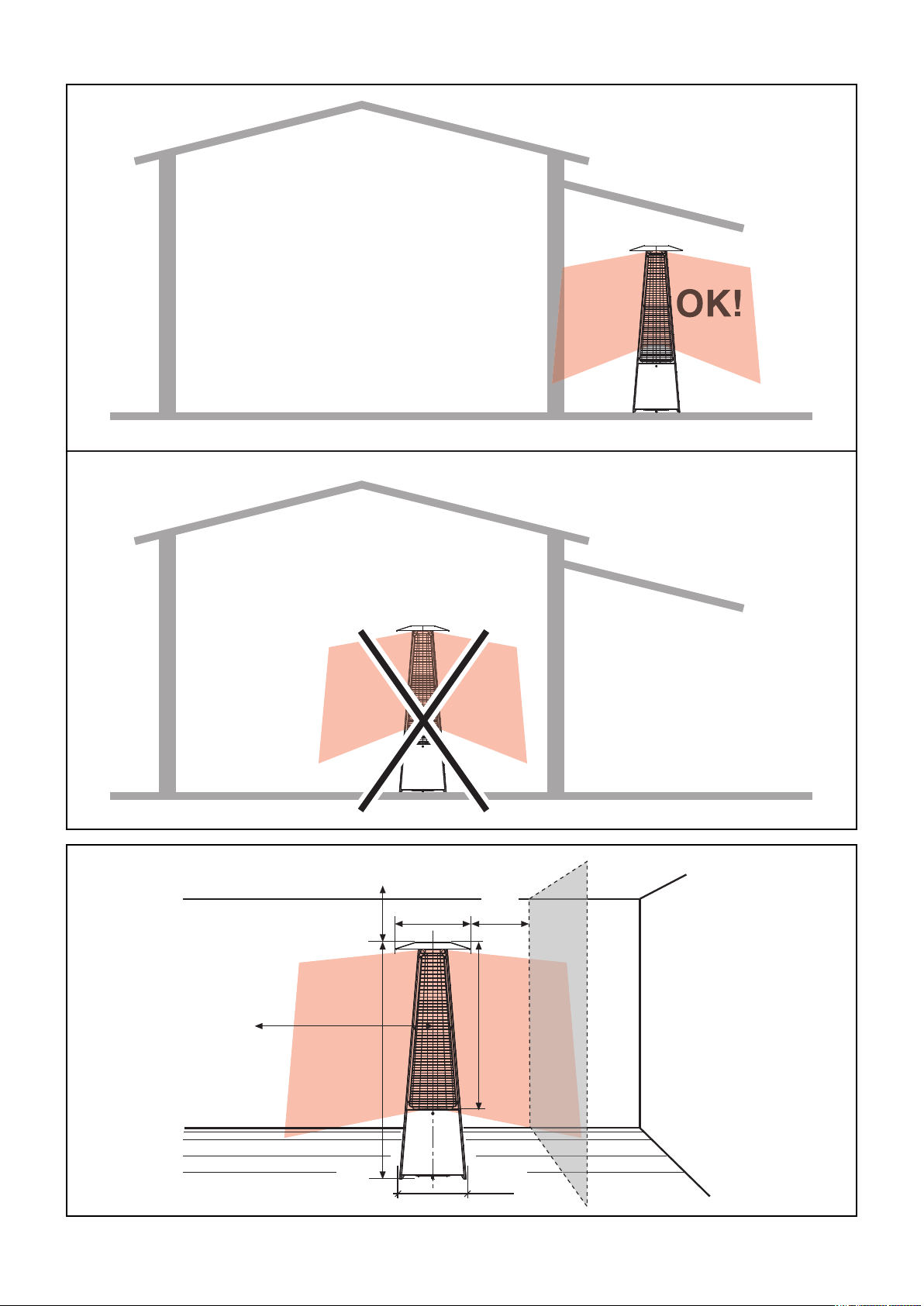

Standards applicable in the Country of use. Install the appliance outdoors in a well ventilated

area, the area around the appliance must have an open side of MIN 25% of the total area, the

use must comply with the instructions provided by the manufacturer. Refer to the instructions before installing and using the appliance.

IMPORTANT! ALL the maintenance, repair or modification operations MUST be performed

by professionally qualified and certified personnel and always using the Manufacturer’s

original spare parts.

IMPORTANT! This gas-fuelled appliance is a heat generator intended only for the use for which

it was designed and certified (with room temperature NOT below 0°C for Remote-controlled

mod.), or as an appliance for heating open, ventilated or outdoor environments. All other

uses are to be deemed improper and therefore hazardous. The Manufacturer disclaims all

liability for any injury to persons or animals or damage to things caused by improper use.

IMPORTANT! If exposed to violent gusts of wind, provide adequate anchorage to the slab.

IMPORTANT! OPERATION IN CLOSED ENVIRONMENTS IS FORBIDDEN: OFFICES, INSIDE HOMES, STABLES, ANIMAL FARMS, PLACES NEAR GAS VAPOURS OR POTENTIALLY INFLAMMABLE DUSTS AND/OR EXPLOSIVES, ETC.

IMPORTANT! Carefully follow ALL the instructions and precautions indicated in this

booklet (concerning INSTALLATION, USE and MAINTENANCE). Failure to abide by these

instructions could cause malfunctions and or endanger people, animal and things.

IMPORTANT! THIS APPLIANCE IS GAS FUELLED AND PARTS OF IT BECOME HEATED.

CONSEQUENTLY, KEEP IT OUT OF REACH OF CHILDREN.

IMPORTANT! NEVER move the appliance with the burner still operating.

IMPORTANT! ALWAYS COMPLY WITH SAFETY DISTANCES FROM OBJECTS OR

INFLAMMABLE MATERIALS(Fig. 2).

IMPORTANT! TO ASSEMBLE AND USE, ABIDE BY THE FIRE-FIGHTING AND ACCIDENTPREVENTION REGULATIONS OF THE COUNTRY WHERE THE APPLIANCE IS USED.

IMPORTANT! DO NOT use the appliance set for LPG in basements or cellars.

IMPORTANT! The appliance made to use LPG, CANNOT be fed with or modified to use

natural gas and vice versa.

IMPORTANT! MODIFYING the appliance is absolutely forbidden except ONLY in those cases

indicated and authorised by the Manufacturer.

IMPORTANT! Fit the gas pressure regulator on the cylinder (fixed-setting type) in conformity with the TECHNICAL DATA and GAS SETTING plates on the appliance (Tab. 1).

IMPORTANT! Every time the cylinder is changed and periodically, using soapy water or

equivalent, make sure there are NO gas leaks from the pipes, from the cylinder connections, gas distribution connections and gas connection with the appliance. Replace the

seal every time the cylinder is changed and periodically check the state of wear, efficiency,

tube expiry data and all the connections.

IMPORTANT! Before making the connection, make sure the hose connector provided is in

conformity with the Regulations applicable in the Country of use.

IMPORTANT! Before proceeding with assembly operations, make sure all the parts making up

the appliance are suitable for the type of gas and pressures according to the Regulations applicable in the Country of use.

10

GENERAL DESCRIPTION

Due to its specific type of operation with direct and reflected irradiance, this appliance approximately heat up a surface of 13 m

2

with a range of action of 2 meters. The weather of your specific region could influence the device efficiency, as the appliance position (totally or in part

open space) as your subjective heating feelings. The heating feeling substaintially increases

close to the appliance.

The appliance is very simple to use and built according to CE safety standards. It has been

tested, approved and controlled by the Notified Approval Institute to which the Manufacturer has

always entrusted most of its certifications in the gas industry.

Types of installation:

- MOBILE, with the base free of restraints using the trolley (optional), with LPG fuel only (tank).

- FIXED, with the base fastened to the floor (this type of installation must be carried out only by

professionally skilled personnel), using Propane/Butane gas (large tank) or natural mains gas.

ASSEMBLY

Take all the parts making up the appliance out of the packaging, with special care given to the

burner unit (Fig. 3: 3, 4, 7, 9, 10).

Check the integrity and the conformity of the contents of the packaging (the latter must be

disposed of according to applicable regulations):

A - Mod. FALO’ with manual controls

- Appliance with carrying structure and special-glass pipe;

- Hose connection (make sure this complies with applicable regulations);

- Cover dish;

- Multilingual instruction booklet;

- Warranty Certificate.

B - Mod. FALO’ with Remote Control

- Appliance with carrying structure and special-glass pipe;

- Hose connection (make sure this complies with applicable regulations);

- Cover dish;

- Multilingual instruction booklet;

- Warranty Certificate.

IMPORTANT! Always wear individual hand protection gear during appliance assembly and

positioning. Use the special accessory for moving (Fig. 3:18) to prevent cuts and burns.

ASSEMBLY OPERATIONS (MOBILE type with LPG tank):

Before starting assembly operations, remove any guards.

1 – Delicately place the structure on the ground and fit the cover dish (Fig. 3: 2).

2 – Remove the side panels (Fig. 3: 14, 15) and position the tank on the base plate (Fig. 3: 13).

3 – Fit the gas pressure regulator on the cylinder (fixed-setting type) in conformity with

the TECHNICAL DATA and GAS SETTING plates on the appliance (Tab. 1 or 2).

4 – Purchase the connector and the rubber connection hose separately. These must be of the type

and materials required by the Regulations of the Country of use (if those already provided do NOT

conform).

11

The threaded end part, meaning the adapter (Fig. 9: 4) permits various kinds of connections.

IMPORTANT! two types of adapters exist, one left turning (SWITZERLAND, AUSTRIA, GERMANY and LUXEMBOURG) and one right turning (all other countries).

CASE A (Fig. 9: A) 1/4” gas left turning: fit the rubber hose (1), featuring a specific threaded

connector (SUPPLIED). This solution is suitable for SWITZERLAND, AUSTRIA, GERMANY

and LUXEMBOURG.

CASE B (Fig. 9: B) 1/4” right turning: fit the rubber hose (6) purchased separately (if that already

provided does NOT comply) directly on the threaded 1/4” GAS right turning connection (4) of the

end part ; now fit the rubber hose (8- MAX Length = 1.5 m) using the clamp provided (6).

5 – Fasten the lower part of the gas connection hose to the regulator (Fig. 9: 2) on the tank (Fig.

9: 3). Connect the other end of the gas hose to the connection.

6 – Before making the connection, check to see whether the gas diaphragm (Fig. 9: 5) must be

fitted on the entry connector (Fig. 9: 4) (solution valid for SWITZERLAND, AUSTRIA, GERMANY and LUXEMBOURG - see Tab. 1 or 2).

IMPORTANT! DO NOT FIT the diaphragm on appliances fuelled with gas G30/G31 at 29÷37 mbar.

IMPORTANT! ONLY FIT the diaphragm in case of operation with supply pressure 50 mbar

(Switzerland, Austria, Germany, Luxembourg). Check the correct type as specified and

shown on Tab. 1 or 2.

7 – Delicately tilt the appliance, position the cover dish (Fig. 3: 2) and fasten in position with the

knobs provided (Fig. 3: 1) and return the appliance to vertical position.

IMPORTANT! NEVER rest the top end of the appliance on the ground, especially when the

cover dish is fitted to avoid damaging the gas seals, the glass pipe or obstructing the gas pipe.

8 – Connect the gas supply pipe to the bottom part of the connection (already fitted) (Fig. 7 and 8: 12).

ASSEMBLY PHASES (FIXED type, on ground or floor, with LPG tank or mains gas supply):

IMPORTANT! If the appliance is used with LPG at 50 mbar (for SWITZERLAND, AUSTRIA,

GERMANY and LUXEMBOURG), fit the conforming diaphragm, see Technical Data table.

1 – Delicately rest the structure on the ground and fit the cover dish (Fig. 3: 2).

IMPORTANT! NEVER rest the top end of the appliance on the ground, especially when the

cover dish is fitted, to prevent damaging the gas seals, the glass pipe or obstructing the gas pipe.

2 – Position the appliance taking into account the position of the supply pipe and remove the

side panels (Fig. 3: 14, 15).

3 – Mark the position of the fastening holes on the ground.

4 – Fasten the structure to the ground using anchor bolts (Fig. 11: 1, NOT provided) suitable for

the type of floor, making use of the holes (Fig. 11: 2) made in the tank support base.

5 – Separately purchase the connector and connection pipe, of a type and material suitable for

the Regulations of the Country of use, and connect directly on the _” right-threaded GAS connector (4) on the end part of the coupling, and then fasten the rubber hose (8 with MAX length =

1.5 m) using a clamp (7).

6 – Before making the connection, check to see whether the gas diaphragm (Fig. 9: 5) needs

fitting on the inlet connection (Fig. 9: 4) (solution valid for SWITZERLAND, AUSTRIA, GERMANY and LUXEMBOURG - see Tab. 1 or 2).

IMPORTANT! DO NOT FIT the diaphragm on appliances fuelled with gas G30/G31 at 29÷37 mbar.

IMPORTANT! ONLY FIT the diaphragm in case of operation with supply pressure at 50 mbar

(Switzerland, Austria, Germany, Luxembourg). Now check the correct type as indicated and

illustrated in Tab. 1 or 2.

7 – Make sure the type of gas and the supply pressure correspond to those on the plate (see

Table), if necessary fit a pressure reducer/regulator (NOT supplied).

8 - Purchase the connector and the rubber connection hose separately. These must be of the

12

type and materials required by the Regulations of the Country of use (if those already provided

do NOT conform).

IMPORTANT! MAKE SURE THE SUPPLY PIPE AND GAS CONNECTOR COMPLY WITH

THE STANDARDS REQUIRED BY THE COUNTRY OF USE.

9 – Connect the gas supply pipe to the lower part of the connector (already fitted) (Fig. 7 and 8: 12).

Fitting the battery (for electronic Pilot ignition):

1 – remove the tank cover side panel (Fig. 3: 14) by loosening the screw (Fig. 3: 8);

2 – after locating the battery cylinder (Fig. 4: 1), remove the cover (Fig. 4: 2) and fit the battery

Type AA (Fig .4: 3) respecting the right polarity.

3 – fit everything back correctly in the opposite sequence.

START-UP

IMPORTANT! USE OF THIS PRODUCT IN CLOSED CAN 'BE A SOURCE OF DANGER

AND' PROHIBITED.

IMPORTANT! Remove all the protective films if fitted.

IMPORTANT! Use LPG tanks taking into account the size of the tank compartment (Fig. 3: 13).

IMPORTANT! To prevent any blaze-ups due to gas accumulation, allow 1 or 2 minutes to pass

before repeating the ignition procedure.

NOTE: when first igniting, due to the air in the pipes, the pilot flame tends to go out.

Wait a while before attempting to ignite again (at most 2 or 3 times) until the flame stabilises! If the fault continues, try and identify the cause, see Troubleshooting Section.

- If the pilot should accidentally go out, the incorporated safety device will automatically interrupt the gas supply.

- If the flame goes out for want of gas, the gas flow is interrupted (for example when the gas

cylinder is empty).

- In both cases, you must wait a few minutes before restarting the heater. Then repeat the operations mentioned in points 1 and 2.

- Do not try to restart the heater time and again; if the heater does not work, you should check

whether ALL operations have been carried out correctly.

IMPORTANT! NEVER start the appliance without first fitting the cover dish and fully completing

assembly. The burner unit and the glass pipe must NEVER be covered or partially covered.

IMPORTANT! DO NOT cover the appliance if this has only just been switched off. Wait for it to

cool down.

IMPORTANT! Protect the appliance against knocks. Always place the appliance on fairly flat

surfaces to prevent it overturning (gradient < 10°) and on non-inflammable surfaces (wood, linoleum, synthetic floors, etc).

IMPORTANT! The appliance is equipped with a safety device (Fig. 16) that extinguishes the

flame in case of surface with slope greater than 15°.

IMPORTANT! WHEN FIRST STARTED – IN THE OPEN AIR OR WELL-VENTILATED ENVIRONMENT – THE APPLIANCE COULD GIVE OFF VAPOURS OR SMELLS FOR A SHORT TIME.

IMPORTANT! Do not block the openings provided for ventilation of the cylinder holder and the

burner assembly.

IMPORTANT! CLOSE VALVE MAIL ON THE BOTTLE AFTER USE.

Ignition – MANUAL mod.

Regulation sequence, turn knob: OFF, spark ON, MIN and MAX;

1 – Make sure the ignition/regulation knob (Fig. 3: 10) is in OFF position (Fig. 5: 1) and open

13

the gas supply tap.

2 – Push and turn the ignition/regulation knob (Fig. 5) anticlockwise. The spark discharge and

gas opening for pilot ignition will start automatically.

Once the flame has ignited, continue to press the knob for about 15 seconds to allow the thermocouple to heat up and keep the valve open. At this point, simply regulate the burner power:

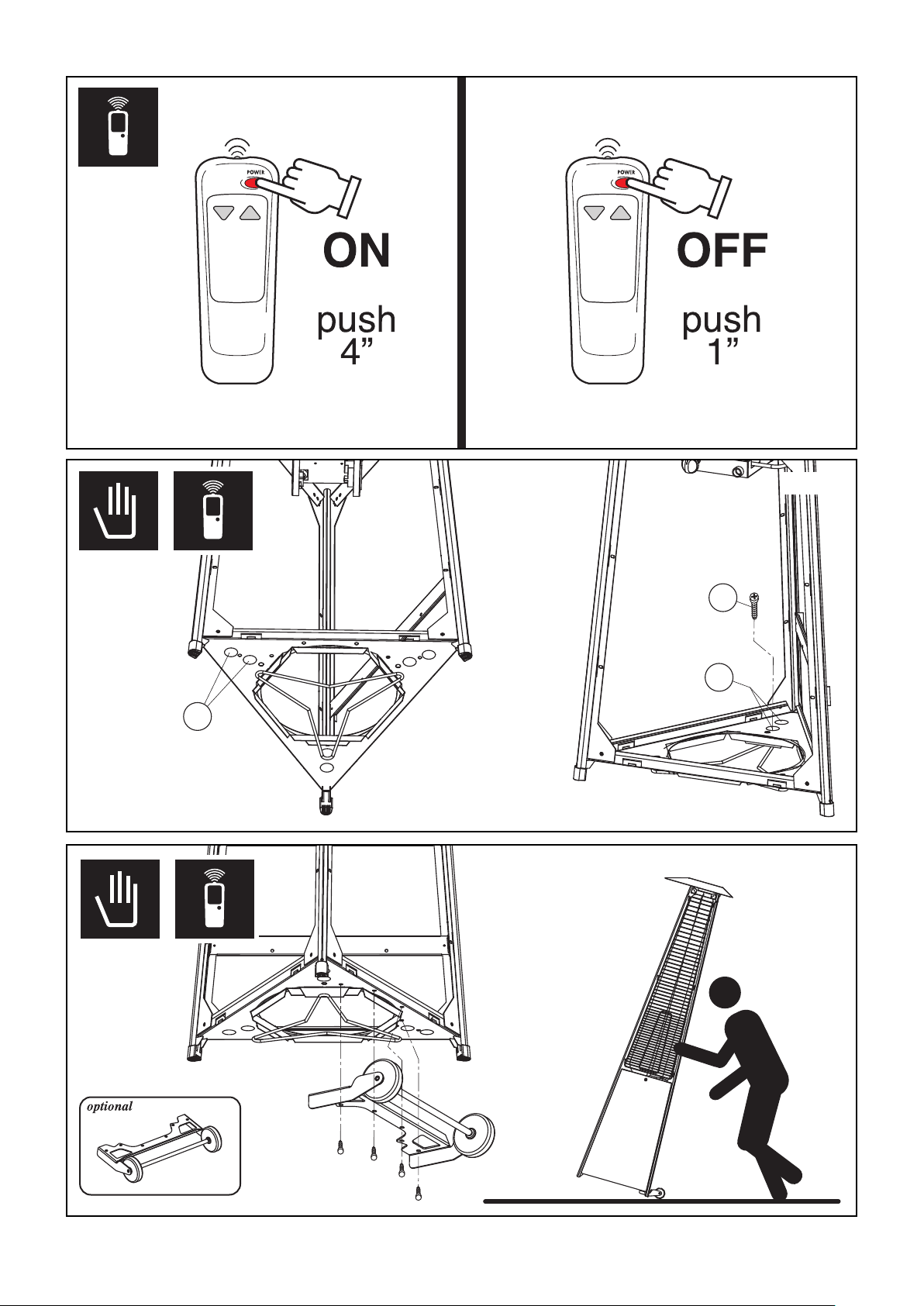

Ignition – REMOTE CONTROL mod.

WARNING! Some infrared remote controls, if pointed directly to the appliance may interfere

with its operation.

Regulation sequence, by pressing the button on the remote control or directly on the control

unit: ON, MAX, MEDIUM, MIN and OFF.

1 – Keep the ON/OFF button on the control unit (Fig. 6) pressed for about 4” until ignition

occurs. Once ignited, every time the ON/OFF button is pressed the appliance switches from

MAX to MEDIUM to MIN flame and finally OFF.

IMPORTANT! This ignition delay is not a “fault” in the electronic control unit but has been purposely designed by the Manufacturer to ensure appliance safety and prevent accidental ignition.

IMPORTANT! If the pilot flame goes out, accidentally or due to lack of gas, the gas supply will

be automatically interrupted by means of the installed safety device.

IMPORTANT! Avoid repeated ignition attempts: if the appliance does not operate immediately, make sure ALL the installation operations have been performed correctly.

IMPORTANT! During operation and also after switch off, DO NOT TOUCH the protection gril-

les, the burner unit, the glass pipe and the cover dish. These are hot and could cause burns.

Power adjustment can also be made during appliance operation:

- MANUAL mod. (Fig. 5), by means of the ignition and adjustment knob.

- REMOTE CONTROL mod. (Fig. 6), by means of the remote control and with the button located on the control unit.

IMPORTANT! If the appliance is fuelled by LPG in the open air and with temperatures below

2°C the use of Propane gas is recommended.

SWITCHING OFF

A - MANUAL mod.:

1 – Remove the side cover (Fig. 3: 15).

2 – Turn the control knob clockwise, returning this to position "0" (Fig. 5: 1).

3 – Correctly fit the side cover back on in reverse sequence.

B – REMOTE CONTROL Mod.:

1 – Press the ON/OFF button on the remote control (Fig. 6) or on the control unit on board the

appliance (Fig. 6).

2 – Remove the side cover (Fig. 3: 14 - 15) and close the gas supply tap.

IMPORTANT! IF THE APPLIANCE IS NOT USED FOR A LONG PERIOD, REMOVE THE

IGNITION BATTERIES (Fig. 4: 3), OF THE REMOTE CONTROL AND OF THE REMOTE

CONTROL UNIT (Fig. 4: 3) FROM THEIR HOUSING, TO PREVENT CORROSIVE LIQUID

LEAKING OUT AND CAUSING DAMAGE.

14

MAINTENANCE

IMPORTANT! BEFORE PERFORMING ANY TYPE OF MAINTENANCE, MAKE SURE THE

GAS SUPPLY TAP AND/OR BURNER SUPPLY TAP ARE CLOSED.

REPLACING THE BOTTLE

1 - Make sure the appliance is completely cold;

2 - Remove the tank cover side panel (Fig 3: 15);

3 - Remove the cylinder from the cylinder holder;

4 - Disconnect the pressure regulator from the cylinder valve;

5 - Check the state of efficiency of the gas supply pipe visually (presence of cracks) and

checking the expiration date stamped;

6 - Check the efficiency of the regulator while verifying the presence and condition of the seal

gas (if replacement is recommended at each change cylinder);

7 - Connect the new bottle and store it in the compartment;

8 - Check the perfect gas circuit with soapy water or specific products;

9 - Replace the side panel.

IMPORTANT! After replacement of the cylinder, the first attempts at ignition may occur with longer times due to the possible presence of air in the pipeline.

Maintenance concerns:

Cleaning the inside of the glass pipes: use a non-metal pipe-brush (optional) to remove traces

of dirt and/or soot.

IMPORTANT! Dry clean with a soft cloth. The use of liquid products could create deposits and/or encrustations that are hard to eliminate.

- Cleaning the outside of the appliance (use a soft cloth and neutral cleaning products and

avoid pouring these directly on the part to be cleaned).

- Control or replacement of the rubber gas hose (max L = 1.5m), whenever damaged and

according to the schedule provided by Laws and Standards applicable in the Country of use.

- Checking the integrity of all the parts making up the appliance; in case of wear or breakage,

only replace with the Manufacturer’s original spare parts.

- replacing batteries for electronic ignition (Fig. 4: 3) or in the Remote Control unit (Fig. 4: 3).

NOZZLE REPLACEMENT (by professionally qualified personnel)

1 – Remove the tank cover side panel (Fig. 3: 15);

2 – Loosen the retention screws (Fig. 7: 1) of the tap and burner drawer (Fig. 7: 2).

3 – Move the burner unit (Fig. 7: 4) so as to make the nozzle accessible.

4 – locate the nozzle (Fig. 7: 5), unscrew it delicately from its housing, and replace it, being

VERY CAREFUL NOT TO DAMAGE THE THREADED PARTS.

5 – Fit the new nozzle back on (always for the same type of gas) and delicately fully tighten.

6 – Fit everything back on in the reverse sequence.

IMPORTANT! The appliance MUST NOT under any circumstances, be transformed from Natural

Gas to LPG or vice versa. Any attempt at transformation is hazardous and the Manufacturer

disclaims all liability in the event of any injury to persons or damage to things deriving from this

operation or any other tampering. The appliance must therefore ONLY be assembled by the

Manufacturer and ordered by the user directly for the type of gas to be used to fuel it.

15

STORAGE AND HANDLING

IMPORTANT! Moving the unit (Fig. 12) just after turning it off, let it cool completely closed and the gas supply.

If the appliance is not used for a long time (change of season or other reasons), follow the

instructions below:

- Store the appliance in a dry place, protected against any possible damage.

- ALWAYS cover the burner unit and base to avoid obstructions (cobwebs, dust) or damage

(denting, weather conditions, etc.).

IMPORTANT! NEVER store the appliance together with one or more gas tanks. These must

always be kept in outside premises and in conformity with the Law and Regulations applicable

in the Country of use.

WARRANTY

Your appliance is covered by a two-year warranty starting on the day of purchase.

The warranty covers all manufacturing faults except those caused by use of the appliance in a

way different to that specified and intended by the Manufacturer.

The warranty starts on the date indicated on the purchase and cash receipt.

This appliance is not intended for professional uses.

Wear, corrosion, any deformation, decolouring or burnishing (especially of aluminium, satin-finish parts or the glass pipe) due to contact with the flame and continuous heat radiation are to be

considered normal and under no circumstances can be considered manufacturing defects.

These are caused by normal wear and tear.

It is also normal, after prolonged use, for worn parts to be replaced ALWAYS using the

Manufacturer’s original spare parts and having maintenance/repairs done by professionally-qualified personnel authorised by the Manufacturer.

16

TROUBLESHOOTING: with remote control.

FAULT CAUSE REMEDY

When ignited the appliance does not work,

The POWER indicator does not come on.

1-Battery charge too low, battery pack

faulty (B1) or poles loose.

2-Infra-red receiver (D) covered.

3-The POWER button of the remote control

has not been pressed for 2 seconds.

4-Remote control faulty or batteries low.

5-Connection cables between front and

rear control boards loose or faulty.

6-Control boards faulty.

7-Dump-switch failure or the floor with

inclination greater than 15¡.

1-Replace batteries, tighten poles

2-Make hole for receiver.

3-Press POWER for 2 seconds, release and

press again.

4-Replace Remote Control or Batteries

5-Remedy or replace.

6-Replace.

7-Replace, change position (floor with

inclination less than 15¡).

No spark when the appliance is started.

1-Distance between the ignition device

(HV1) and th e ear th connection or the dist ance

between the electrodes (HD) is excessive.

2-The ceramic p art of the ignition devi ce (H V1)

is broken or faulty.

3-High-voltage cable loose, broken or shortcircuited.

4-No earth connection in pilot set.

5-Rear control board faulty.

1-Regulate the distance to 4 __0.5 mm.

(Th e cable resistan ce mus t be connected close

to the ignition device).

2-Replace the ceramic part.

3-Repair or replace.

4-Make earth connection.

5-Replace.

No flame

1- Not en ough gas sup ply (bad LPG ga sifi cat ion

or dirt in system) or pressure regulator not set

properly or faulty.

2-No gas flow (tank empty or interruption in

supply) or pressure regulator faulty.

3-Sudden gust of wind (above 3 m/s) with

gas tank panels removed.

4-Dirt in gas circuit.

5-Gas leaks.

6-cylinder connection, air in pipe

1-Clean, set / replace.

2-Check / replace.

3-Replace panels.

4-Check / clean.

5-Ch eck/ tigh ten connec tion s/re place se als o r pip es.

6-repeat ignition to eliminate air.

Spark ok but pilot flame does not come on.

1-No gas supply.

2-Connection faulty between front and rear

connection boards or power cables loose.

3-Pilot injector blocked.

4-Rear control board faulty.

5-Valves G1 and G2 faulty.

1-Check.

2-Reposition or replace cables.

3-Check or replace.

Nozzle diameter: LPG: 0.35 mm; NATURAL

GAS: 0.55 mm.

4-Replace.

5-Replace.

Pilot flame on, sparks continue without stop

(no flame detection).

1-Flame sensor cables (S) and ignition device

(HV) switched over or loose.

2-Flame sensor (S1) and earth short circuited.

3-Flame sensor (S1) fails to detect flame.

4-Pilot flame burns inside pilot pipe.

5-Rear control board faulty.

1-Put right.

2-Restore correct position.

3-Restore correct position.

4-Replace.

5-Replace.

Pilot flame on, the main burner does not

come on.

1-Cables faulty or terminals loosened.

2-Main burner nozzle blocked.

3-ÒMÓ and ÒLÓ valves faulty.

4-Front and rear control boards faulty.

5-Faulty remote control.

1-Repair or replace.

2-Check gas pressure, replace pilot set or

perforate injector again.

3-Check gas pressure, replace ÒMÓ and ÒLÓ

valves.

4-Replace.

5-Replace.

The low flame comes on; the medium flame

does not.

1-Cables faulty or terminals loose.

2-ÒMÓ valve faulty or ÒMÓ valve nozzle

blocked.

3-Front control board faulty.

4-Faulty remote control.

1-Repair or replace.

2-Replace.

3-Replace.

4-Replace.

The medium flame comes on; the low flame

does not.

1-Cables faulty or terminals loose.

2-ÒLÓ valv e fau lty o r ÒLÓ valve nozzle bloc ked.

3-Front control board faulty.

4-Remote control faulty.

1-Repair or replace.

2-Replace.

3-Replace.

4-Replace.

During the ignition cycles, the appliance does

not go off in 25 seconds.

1-Front control board faulty. 1-Replace.

The remote control battery is down. 1-The battery is failing. 1-Replace.

Blackening of glass pipe

1-poor quality gas or gas unsuitable for winter

2-bad draught.

3-

mains cylinder (optional) out of

position/deformed

.

4-exchanger head dirty/damaged.

5-burner dirty/damaged.

1-use quality gas, preferably pure propane.

2-particularly windy or no wind-protection KIT.

3-reposition/replace/eliminate.

4-clean/replace.

5-clean/replace.

Glass pipe breakage

- excessive thermal shock due to particular

weather conditions.

- cleaning with unsuitable instruments.

- accidental fall of appliance.

- Replace.

- Replace.

- Replace.

17

TROUBLESHOOTING: manual controls.

FAULT CAUSE REMEDY

No flame

1 – non enough gas supply flow:

- bad LPG gasification;

- bad LPG gasification with low temperature.

- pressure regulator wrongly set or faulty.

2 – sudden gust of wind (above 3 m/s).

3 – thermocouple interrupted.

4 – valve magnet faulty.

5 - Dump-switch failure or the floor with

inclination greater than 15°.

6 – dirt in gas circuit.

7 – gas leaks.

8 – battery low.

9 – isolation of electrodes and/or faulty

cables.

1- Check:

- Check and replace empty tank;

- Replace with Propane gas tank.

- Regulate or replace.

2 – keep appliance out of wind.

3 - Replace.

4 - Replace.

5 - Replace, change position (floor with

inclination less than 15°).

6 - Check and clean carefully.

7 - Check and eliminate leak.

8 - Replace.

9 - Replace.

Blackening of glass pipe

1-poor quality gas or gas unsuitable for winter

2-bad draught.

3-

mains cylinder (optional) out of

position/deformed

.

4-exchanger head dirty/damaged.

5-burner dirty/damaged.

1-use quality gas, preferably pure propane.

2-particularly windy or no wind-protection KIT.

3-reposition/replace/eliminate.

4-clean/replace.

5-clean/replace.

Glass pipe breakage

1 - excessive thermal shock due to particular

weather conditions.

2 - cleaning with unsuitable instruments.

3 - accidental fall of appliance.

1 - Replace.

2 - Replace.

3 - Replace.

* Glass pipe breakage

The technical features of the glass pipe are particular and such as to permit resistance to thermal shocks caused by normal temperature fluctuations, rain or damp.

Despite the choice of this material (Borosilicate), sudden pipe breakages can occur as a result

of particular weather conditions and/or excessively concentrated temperature fluctuations.

IMPORTANT! This pipe breakage (crack) does not cause injury to people or damage to

things in the immediate vicinity of the appliance.

IMPORTANT! Any pipe breakage does not, in the short term, prevent the appliance from

operating, but being a damaged part, it must be replaced to ensure correct operation.

18

UK - GAS GOVERNOR FOR GERMANY (50 mbar)

E - DRUCKGAS REGLER FUR DEUTSCHLAND (50 mbar)

D

ITA - REGLER: Kapazität MAX 1000 g / h, Max Druck 37mbar.

ITA - der Gasleitung muß einer flexiblen Art und mit einer Länge, wie beispielsweise sein, einen

einfachen Austausch des Zylinders zu ermöglichen.

- DE -

Inhaltsverzeichnis

FERNBEDIENUNG

ALLGEMEINE BESCHREIBUNG

MONTAGE

INBETRIEBSETZUNG

AUSSCHALTUNG

WARTUNG

AUFBEWAHRUNG

GARANTIE

EVENTUELLE STÖRUNGEN UND ABHILFEN

19

DIESES HANDBUCH FÜR DIE GANZE LEBENSDAUER DES GERÄTS AUFBEWAHREN

UND EIN NEUES ANFORDERN, FALLS ES ZERSTÖRT WERDEN ODER VERLOREN

GEHEN SOLLTE!

WICHTIG! FALLS DIE BAUTEILE BESCHÄDIGT SEIN SOLLTEN, KEINESFALLS DIE

ZUSAMMENFÜGUNG VORNEHMEN!

WICHTIG! Dieses Gerät ist in Übereinstimmung mit den im Bestimmungsland geltenden

Regelungen, Gesetzen und Vorschriften aufzustellen. Stellen Sie das Gerät im Freien in einem

gut belüfteten Raum, muss der Bereich um das Gerät eine offene Seite der MIN 25% der gesamten Fläche zu haben, muss die Verwendung mit den Anweisungen des Herstellers beachten. Vor

der Gerätaufstellung und-Verwendung diese Anleitung lesen.

WICHTIG! ALLE Wartungs-, Reparatur- und Abänderungsarbeiten HABEN durch qualifiziertes

und anerkanntes Fachpersonal unter ausschließlichem Gebrauch der Originalersatzteile des

Herstellers zu erfolgen.

WICHTIG! Dieses mit Gas gespeiste Gerät ist ein Wärmeerzeuger, der nur für den Zweck

bestimmt ist, für den er konzipiert und zertifiziert wurde (bei Umgebungstemperatur von NICHT

weniger als 0°C im Falle der Version mit Fernbedienung), sprich als Gerät zur Erwärmung

von Umfeldern, die offen und belüftet sind oder sich im Freien befinden. Jeder anderweitige Gebrauch ist als unsachgemäß und demzufolge gefährlich zu betrachten. Der

Hersteller kann nicht für eventuelle, durch unsachgemäßen Gebrauch hervorgerufene

Personen- und Sachschäden verantwortlich gemacht werden.

WICHTIG! Wenn zu heftigen Windböen ausgesetzt ist, eine angemessene Verankerung an

der Platte.

WICHTIG! DER BETRIEB IN GESCHLOSSENEN RÄUMEN IST VERBOTEN: BÜROS, WOHNUNGEN, STÄLLEN, VIEHZUCHTEN, ÖRTLICHKEITEN IN NÄHE VON GASDÄMPFEN

ODER STÄUBEN, DIE POTENTIELL ENTFLAMMBAR UND/ODER EXPLOSIV SIND.

WICHTIG! Genau ALLE in diesem Handbuch angeführten Anweisungen und Warnungen

(betreffs AUFSTELLUNG, GEBRAUCH und WARTUNG) befolgen; deren Nichtbefolgung

könnte Ursache von Betriebsstörungen und/oder Gefahren für Personen, Tiere und

Sachen sein.

WICHTIG! DIESES GERÄT FUNKTIONIERT MIT GAS UND HAT HEISSE TEILE, WESHALB

ES AUSSERHALB DER REICHWEITE VON KINDERN GEHALTEN WERDEN MUSS.

WICHTIG! Das Gerät NIEMALS versetzen, wenn der Brenner noch in Betrieb ist.

WICHTIG! ES SIND UNBEDINGT DIE SICHERHEITSABSTÄNDE VON GEGENSTÄNDEN

UND ENTFLAMMBAREN STOFFEN EINZUHALTEN (Abb.2).

WICHTIG! BEI DER MONTAGE UND VERWENDUNG SIND DIE IM BESTIMMUNGSLAND GELTENDEN BRANDSCHUTZ- UND UNFALLVERHÜTUNGSVORSCHRIFTEN ZU BEFOLGEN.

WICHTIG! Das für Flüssiggas vorbereitete Gerät NICHT in Kellern oder unterirdischen Geschoßen

verwenden.

WICHTIG! Das vom Hersteller zur Versorgung mit Flüssiggas erzeugte Gerät, darf NICHT

zur Versorgung oder zum Betrieb mit Methan und umgekehrt umgerüstet werden.

WICHTIG! Mit ALLEINIGER Ausnahme der vom Hersteller vorgesehenen und angegebenen Fälle ist es strikt verboten, das Gerät ABZUÄNDERN.

WICHTIG! (Nicht verstellbaren) Gasdruckregler gemäß den am Gerät befindlichen

Schildern TECHNISCHE DATEN und GASVOREINSTELLUNG (Tab. 1) an der Gasflasche

montieren.

WICHTIG! Bei jedem Flaschenwechsel muss mit Seifenwasser oder entsprechenden

Mitteln überprüft werden, dass aus den Leitungen, den Flaschenanschlüssen oder jenen

der Gasverteilungsanlage sowie aus dem Geräteanschluss kein Gas austritt. Bei jedem

Flaschenwechsel ist die Dichtung zu ersetzen, und periodisch sind alle Verbindungen

20

auf ihre Abnutzung, Effizienz, werfalltermin von der schlauch und reife zu kontrollieren.

WICHTIG! Vor dem Anschließen überprüfen, dass der mitgelieferte Schlauchanschluss den im

Bestimmungsland geltenden Vorschriften entspricht.

WICHTIG! Bevor man mit den Montagevorgängen beginnt, überprüfen, dass alle Gerätbauteile

für den Gastyp und den Druck vorbereitet sind, die für den Gebrauch laut geltender Vorschriften

des Bestimmungslandes vorgesehen sind.

ALLGEMEINE BESCHREIBUNG

Für seine besondere Art des Betriebs, um direkte Sonneneinstrahlung und Reflexion, übt dieses

Gerät seinen Einfluss in einer Fläche von etwa 13 m

2

mit einem Bereich von etwa 2 m. Das

betroffene Gebiet und die Heizleistung variiert je nach Klima-und Wetterbedingungen in der

Region der endgültigen Bestimmung der Position des Geräts (Umweltschutz völlig offen oder

teilweise durch eine oder mehrere Seiten überdacht) und der subjektiven Wahrnehmung von

Wärme.

Das Gefühl von Wärme, völlig subjektiv und nicht messbar steigt deutlich näher an der Flamme.

Das gemäß den CE Sicherheitsvorschriften gebaute Gerät ist leicht zu verwenden; es wurde

erprobt und zugelassen und wird von der angegebenen Zulassungseinrichtung überwacht, welcher der Hersteller bereits den größten Teil seiner Zertifizierungen im Gasbereich anvertraut hat.

Aufstellungsarten:

- BEWEGLICH mit nicht verankertem Unterbau und Gebrauch des Wagens (Option), allein mit

Flüssiggasversorgung (Gasflasche).

- STATIONÄR mit am Boden befestigtem Unterbau (diese Art der Aufstellung darf nur von qualifiziertem Fachpersonal vorgenommen werden) und Versorgung mit Propan-/Butangas (Tank

oder Gasnetz) oder durch das Erdgasnetz.

MONTAGE

Alle Gerätteile aus der Verpackung nehmen und dabei besonders auf das Brenneraggregat

achten (Abb.3: 3, 4, 7, 9, 10).

Die Unversehrtheit und Konformität des Inhalts der Packungen (die den geltenden Vorschriften

entsprechend zu entsorgen sind) überprüfen:

A - Modell FALO’ mit manuellen Bedienelementen

- Gerät mit Trägerstruktur und Rohr aus Spezialglas

- Schlauchanschluss (überprüfen ob er den geltenden Vorschriften entspricht)

- Abdeckschirm

- Betriebshandbuch in verschiedenen Sprachen

- Garantieschein

B - Modell FALO’ mit Fernbedienung

- Gerät mit Trägerstruktur und Rohr aus Spezialglas

- Schlauchanschluss (überprüfen ob er den geltenden Vorschriften entspricht)

- Abdeckschirm

- Betriebshandbuch in verschiedenen Sprachen

- Garantieschein

WICHTIG! Zur Vermeidung von Schnittwunden und Verbrennungen besonders vorsichtig sein

und während aller Vorgänge zur Montage und Aufstellung des Geräts die persönlichen

Schutzausrüstungen für die Hände und das spezielle Zubehörteil zum Verschieben (Abb. 3: 18)

verwenden.

21

MONTAGEPHASEN (BEWEGLICHER Typ mit Gasflasche, Flüssiggas):

Vor dem Beginn der Montage, eventuelle Schutzelemente beseitigen.

1 – Die Struktur vorsichtig auf den Boden stellen und den Abdeckschirm anbringen (Abb.3: 2).

2 – Die seitlichen Tafeln entfernen (Abb.3: 14, 15) und die Gasflasche auf die Stützfläche stellen (Abb.3: 13).

3 – (Nicht verstellbaren) Gasdruckregler gemäß den am Gerät befindlichen Schildern

TECHNISCHE DATEN und GASVOREINSTELLUNG (Tab. 1 oder 2) an der Gasflasche

montieren.

4 – Getrennt den Anschluss und den Verbindungsschlauch aus Gummi erwerben (falls die

bereits mitgelieferten NICHT geeignet sind), deren Art und Material den Vorschriften des

Bestimmungslandes zu entsprechen haben.

Das Endteil mit Gewinde sprich der Adapter (Abb. 9:4) erlaubt verschiedene Arten von

Anschlüssen:

WICHTIG! Es gibt zwei Arten von Adaptern, einen linksgängigen (SCHWEIZ, ÖSTERREICH,

DEUTSCHLAND und LUXEMBURG) und einen rechtsgängigen (alle anderen Länder).

FALL A (Abb. 9: A) 1/4” Gas, linksgängig: Den Gummischlauch (1) anbringen, der mit dem

(MITGELIEFERTEN) speziellen Gewindeanschluss ausgestattet ist; in den Ländern SCHWEIZ,

ÖSTERREICH, DEUTSCHLAND und LUXEMBURG zulässige Lösung.

FALL B (Abb. 9: B) 1/4” Gas, rechtsgängig: Den getrennt erworbenen (wenn der bereits mitgelieferte NICHT geeignet ist) Schlauchanschluss (6) direkt am Gewindeanschluss 1/4” GAS

rechtsgängig (4) des Endteils der Kopplung anbringen, und dann den Gummischlauch (8- max.

Länge = 1,5 m) mit der speziellen Schelle (6) befestigen.

5 – Den Unterteil des Gasanschlussschlauches am Regler (Abb. 9: 2) an der Gasflasche (Abb.

9: 3) befestigen. Das andere Ende des Gasschlauches am Anschluss befestigen.

6 – Vor dem Anschließen überprüfen, ob am Eingangsanschluss (Abb. 9: 4) die Gasblende

(Abb. 9: 5) angebracht werden muss (in den Ländern SCHWEIZ, ÖSTERREICH, DEUTSCHLAND und LUXEMBURG zulässige Lösung – siehe Tab.1 oder 2).

ACHTUNG! Die Blende NICHT an Geräten anbringen, die mit Gas G30/G31, 29÷37 mb

gespeist werden.

WICHTIG! Die Blende nur in den Fällen anbringen, in denen der Betrieb mit einem

Versorgungsdruck von 50 mb (Schweiz, Österreich, Deutschland, Luxemburg) vorgesehen ist. Dann überprüfen, ob sie vom richten Typ ist (siehe Tab. 1 oder 2).

7 – Das Gerät vorsichtig neigen, den Abdeckschirm (Abb. 3:2) aufsetzen und anhand der mitgelieferten Drehknöpfe (Abb. 3: 1) befestigen. Das Gerät wieder gerade stellen.

WICHTIG! Das obere Ende des Geräts NIEMALS am Boden auflegen, vor allem wenn der

Abdeckschirm angebracht ist, um Beschädigungen der Gasdichtungen und des Glasrohrs oder

eventuelle Verschlüsse der Gasleitung zu vermeiden.

8 – Den Gasversorgungsschlauch mit dem Unterteil des (bereits angebrachten) Anschlusses

verbinden (Abb. 7 und 8: 12).

MONTAGEPHASEN (STATIONÄRER Typ, am Boden oder Fußboden, Versorgung durch

Flüssiggas-Tank oder Gasnetz):

WICHTIG! Wird das Gerät mit Flüssiggas, 50 mb verwendet (SCHWEIZ, ÖSTERREICH, DEUT-

SCHLAND und LUXEMBURG), die Blende laut der Tabelle Technische Angaben anbringen.

1 - Die Struktur vorsichtig auf den Boden stellen und den Abdeckschirm montieren (Abb.3: 2).

WICHTIG! Das obere Ende des Geräts NIEMALS am Boden auflegen, vor allem wenn der

Abdeckschirm angebracht ist, um Beschädigungen der Gasdichtungen und des Glasrohrs oder

eventuelle Verschlüsse der Gasleitung zu vermeiden.

22

2 – Das Gerät platzieren, wobei die Position des Versorgungsschlauches zu berücksichtigen ist,

und die seitlichen Tafeln entfernen (Abb. 3: 14, 15).

3 – Am Boden die Position der Befestigungslöcher markieren.

4 – Die Struktur mit für die Art des Fußbodens geeigneten Dübeln (Abb. 11:1, NICHT mitgeliefert)

am Boden befestigen und dazu die an der Gasflaschenstützfläche vorbereiteten Löcher (Abb. 11: 2)

benützen.

5 - Getrennt den Anschluss und den Verbindungsschlauch erwerben, deren Art und Material

den Vorschriften des Bestimmungslandes zu entsprechen haben; direkt am Gewindeanschluss

1/4” GAS, rechtsgängig (4) des Endstücks der Kopplung anbringen und dann mit Hilfe einer

Schelle (7) den Gummischlauch (8, MAX. Länge = 1,5 m) befestigen.

6 - Vor dem Anschließen überprüfen ob am Eingangsanschluss (Abb. 9: 4) die Gasblende (Abb.

9: 5) angebracht werden muss (in den Ländern SCHWEIZ, ÖSTERREICH, DEUTSCHLAND

und LUXEMBURG zulässige Lösung – siehe Tab.1 oder 2).

ACHTUNG! Die Blende NICHT an Geräten anbringen, die mit Gas G30/G31, 29÷37 mb

gespeist werden.

WICHTIG! Die Blende nur in den Fällen anbringen, in denen der Betrieb mit einem

Versorgungsdruck von 50 mb (Schweiz, Österreich, Deutschland, Luxemburg) vorgesehen ist. Dann überprüfen, ob sie vom richtigen Typ ist (siehe Tab. 1 oder 2).

7 – Überprüfen dass die Art des Gases und der Versorgungsdruck den Schildangaben (siehe

Tabelle) entsprechen und gegebenenfalls einen Reduzierer/Druckregler (NICHT mitgeliefert)

anbringen.

8 – Getrennt den Anschluss und den Verbindungsschlauch erwerben, deren Art und Material

den geltenden Vorschriften des Bestimmungslandes zu entsprechen haben.

WICHTIG! ÜBERPRUFEN, DASS DER ANGEBRACHTE VERSORGUNGSSCHLAUCH UND

GASANSCHLUSS DEN IM BESTIMMUNGSLAND GELTENDEN VORSCHRIFTEN GERECHT WERDEN.

9 – Den Gasversorgungsschlauch mit dem Unterteil des (bereits angebrachten) Anschlusses

verbinden) (Abb. 7 und 8: 12).

Anbringung der Batterie (zur elektronischen Anzündung der Leitflamme):

1 – Die seitliche Gasflaschen-Verkleidungstafel (Abb. 3: 14) abnehmen, indem man die

Schraube (Abb. 3: 8) abschraubt.

2 – Das Batteriefach (Abb. 4: 1) auffinden, den Deckel (Abb. 4: 2) abnehmen und unter

Beachtung der richtigen Polung eine Batterie Typ AA (Abb. 4: 3) einsetzen.

3 – Alles auf umgekehrte Weise wieder richtig zusammenfügen.

INBETRIEBSETZUNG

WICHTIG! NUTZUNG DIESER Produkt in geschlossenen CAN "eine Quelle der GEFAHR

UND 'VERBOTEN.

WICHTIG! Alle eventuell vorhandenen Schutzfolien beseitigen.

WICHTIG! Flüssiggasflaschen verwenden, die in den Gasflaschenraum (Abb. 3: 13).

WICHTIG! Um ein eventuelles Aufflackern wegen angesammelten Gases zu vermeiden, circa 1

oder 2 Minuten lange warten, bevor man das Anzündverfahren wiederholt.

BEACHTE: Bei der ersten Einschaltung geht die Pilotflamme aufgrund der in den

Leitungen befindlichen Luft leicht aus. Daher kurz abwarten und erneut anzünden (MAX.

2 oder 3 Mal), bis die Flamme sich stabilisiert hat! Bei Fortdauer des Problems auf

Störungen überprüfen, siehe hierzu den Abschnitt Eventuelle Störungen und ihre

Behebung.

23

- Sollte die Sparflamme versehentlich ausgehen, so wird die Gaszufuhr unmittelbar durch das

eingebaute Sicherheitssystem unterbrochen.

- Sollte die Sparflamme durch Gasmangel ausgehen, so wird die Gaszufuhr abgeschlossen

(z.B. wenn die Gasflasche leer ist).

- In beiden Fällen sollten Sie eine Weile warten, bevor Sie das Gerät wieder in Betrieb nehmen

und danach die Schritte 1 und 2 wiederholen.

- Versuchen Sie nicht, das Gerät immer wieder anzuzünden. Wenn das Gerät nicht sofort funktioniert, kontrollieren Sie, ob ALLE Schritte korrekt ausgeführt wurden.

WICHTIG! Das Gerät NIEMALS in Betrieb setzen, bevor es ganz zusammengebaut und der

Abdeckschirm angebracht wurde. Das Brenneraggregat und das Glasrohr dürfen NICHT abge-

deckt oder teilweise abgedeckt werden.

WICHTIG! Das soeben ausgegangene Gerät NICHT abdecken; warten bis es abgekühlt ist.

WICHTIG! Das Gerät gegen Stöße sichern. Damit es nicht umkippt, das Gerät stets auf ausrei-

chend ebenen Flächen (Neigung < 10°) aufstellen, die nicht entflammbar (Fußböden aus Holz,

Linoleum, Kunststoff, usw.) sein dürfen.

WICHTIG! Das Gerät ist mit einer Sicherheitsvorrichtung ausgestattet (Abb. 16,

Kippsicherung), dass bei Kippen des Heizgerätes um 15° die Gaszufuhr unterbricht.

WICHTIG! NUR BEI DER 1. ANZÜNDUNG, DIE IM FREIEN ODER IN EINEM GUT

BELÜFTETEN UMFELD ZU ERFOLGEN HAT, KÖNNTE DAS GERÄT FÜR KURZE ZEIT

DÜNSTE ODER GERÜCHE ABGEBEN.

WICHTIG! Blockieren Sie nicht die Belüftungsöffnungen des Zylinderhalter und der

Brenneranordnung vorgesehen.

WICHTIG! SCHLIESSEN VENTIL MAIL auf der Flasche nach dem Gebrauch.

Anzündung MANUELLES Modell

Einstellungsabfolge durch Drehen des Drehknopfes: OFF, Funke ON, MIN und MAX.

1 – Überprüfen, dass der Zünd-/Einstellknopf (Abb. 3: 10) auf ausgeschaltet OFF (Abb. 5: 1)

gestellt ist und den Gasversorgungshahn öffnen.

2 – Den Zünd-/Einstellknopf hineindrücken und gegen Uhrzeigersinn (Abb. 5) drehen. Auf diese

Weise wird automatisch die Funkenentladung gestartet und das Gas zur Anzündung der

Leitflamme geöffnet.

Wenn die Flamme brennt, den Knopf noch circa 15 Sekunden lang gedrückt halten, damit das

Thermoelement heiß wird und das Ventil offen hält. Jetzt nur noch die Brennerleistung einstellen:

Anzündung Modell mit FERNBEDIENUNG

WARNUNG! Einige Infrarot-Fernbedienungen können unter Umständen den Betrieb des

Gerätes beeinflussen, wenn sie direkt auf das Gerät gerichtet werden.

Einstellungsabfolge indem die Fernbedienung oder direkt die Steuereinheit betätigt wird: ON,

MAX, MITTEL, MIN und OFF.

1 – Den Knopf ON/OFF an der Steuereinheit (Abb. 6) circa 4” lang gedrückt halten, bis die

Zündung erfolgt; nach erfolgter Anzündung geht das Gerät bei jeder Betätigung des Knopfes

ON/OFF von Flamme MAX auf MITTEL auf MIN und dann auf OFF.

WICHTIG! Diese Verzögerung der Anzündung ist kein “Defekt” der elektronischen

Steuereinheit, sondern sie wurde eigens vom Hersteller konzipiert, um die Sicherheit des

Geräts zu garantieren und etwaige unvorhergesehene Zündungen zu vermeiden.

WICHTIG! Sollte die Leitflamme aus unvorhergesehenen Gründen oder Gasmangel ausgehen,

wird die Gaszufuhr automatisch durch die installierte Sicherheitsvorrichtung unterbrochen.

WICHTIG! Mehrfache Anzündungsversuche vermeiden: Sollte das Gerät nicht sofort

funktionieren, überprüfen, ob ALLE Aufstellungsvorgänge richtig getätigt wurden.

WICHTIG! Während des Betriebs und auch nach dem Erlöschen NICHT die Schutzgitter, die

Brennereinheit, das Gasrohr und den Abdeckschirm berühren, weil sie sehr heiß sind und

24

Verbrennungen verursachen könnten.

Die Einstellung der Leistung kann auch während des Gerätbetriebs erfolgen:

- MANUELLES Modell (Abb. 5): Anhand des Zünd-/Einstellknopfes.

- Modell mit FERNBEDIENUNG (Abb. 6): Anhand der Fernbedienung oder mit dem Knopf an der

Steuereinheit.

WICHTIG! Für den Betrieb des Geräts mit Flüssiggas im Freien und bei Temperaturen von

weniger als 2°C empfiehlt es sich, Propangas zu verwenden.

AUSSCHALTUNG

A – MANUELLES MODELL:

1 – Die seitliche Verkleidung (Abb. 3: 15) entfernen.

2 – Den Bedienungsknopf im Uhrzeigersinn drehen und wieder auf "0" (Abb. 5: 1) stellen.

3 – Die seitliche Verkleidung auf umgekehrte Weise wieder anbringen.

B – Modell mit FERNBEDIENUNG:

1 – Auf den Knopf ON/OFF der Fernbedienung (Abb. 6) oder der Steuereinheit an Bord des

Geräts drücken (Abb. 6).

2 – Die seitliche Verkleidung (Abb. 3: 14 - 15) entfernen und den Gasversorgungshahn schließen.

WICHTIG! WIRD DAS GERÄT LÄNGERE ZEIT NICHT VERWENDET, DIE BATTERIEN DER

ZÜNDUNG (Abb. 4: 3), DER FERNBEDIENUNG UND DER FERNBEDIENUNGS-STEUEREINHEIT (Abb. 4: 3) ENTFERNEN, UM DEN AUSTRITT KORROSIVER FLÜSSIGKEIT ZU

VERMEIDEN, DIE SCHÄDEN VERURSACHEN KÖNNTE.

WARTUNG

WICHTIG! Bevor man irgendeine Wartung tätigt, sicherstellen, dass der

Gasversorgungshahn und/oder Brennerhahn geschlossen sind.

AUSTAUSCH DER FLASCHE

1 - Stellen Sie sicher, das Gerät vollständig abgekühlt ist;

2 - Entfernen Sie die Tankabdeckung Seitenabdeckung (Abb 3: 15);

3 - Entfernen Sie den Zylinder vom Zylinderhalter;

4 - Ziehen Sie den Druckregler aus dem Flaschenventil;

5 - den Zustand der Wirkungsgrad der Gasversorgungsleitung visuell prüfen (das

Vorhandensein der Risse) und Prüfen Sie das Ablaufdatum gestempelt;

6 - Prüfen Sie die Effizienz der Regler beim Überprüfen der Anwesenheit und den Zustand des

Sperrgas (wenn ein Austausch bei jedem Wechsel Zylinder empfohlen);

7 - Schließen Sie die neue Flasche und speichern sie in der Kammer;

8 - Prüfen Sie die perfekte Gaskreislauf mit Seifenwasser oder bestimmte Produkte;

9 - Bringen Sie die Seitenabdeckung.

WICHTIG! Nach Ersatz des Zylinders können die ersten Zündversuche wobei längere Zeiten

aufgrund der möglichen Anwesenheit von Luft in der Rohrleitung auftreten.

Die Wartung umfasst:

Interne Reinigung der Glasrohre: Mit einer nicht aus Metall bestehenden Rohrbürste (Option)

Schmutz- und/oder Rußspuren entfernen.

WICHTIG! Mit einem weichen, trockenen Tuch reinigen. Die Verwendung flüssiger

Produkte kann schwer entfernbare Ablagerungen und/oder Verkrustungen verursachen.

- Äußere Reinigung des Geräts (mit einem weichen Tuch und mildem Reinigungsmittel, das

nicht direkt auf die zu reinigenden Teile aufgetragen werden darf).

- Kontrolle und Ersatz des Gasschlauches aus Gummi (max. Länge = 1,5m) gemäß den Fristen

und Modalitäten, die laut den Gesetzen und Vorschriften des Bestimmungslandes vorgesehen

sind, sowie im Falle von Beschädigungen.

25

- Überprüfung aller Gerätteile auf Unversehrtheit und Sauberkeit; im Falle von Abnützung oder

Schäden nur durch Originalersatzteile des Herstellers ersetzen.

- Ersatz der Batterien für die elektronische Zündung (Abb. 4: 3) oder die FernbedienungsSteuereinheit (Abb. 4: 3).

DÜSENAUSTAUSCH (durch qualifiziertes Fachpersonal)

1 – Die seitliche Gasflaschen-Verkleidungstafel entfernen (Abb. 3: 15).

2 – Die Halterschrauben (Abb. 7: 1) des Hahnträger- und Brennerkastens (Abb. 7: 2) abschrauben.

3 – Brenneraggregat (Abb. 7: 4) so verschieben, dass man die Düse erreichen kann.

4 – Die Düse (Abb. 7: 5) auffinden, vorsichtig herausschrauben und ersetzen, wobei BESONDERS DARAUF ZU ACHTEN IST, DASS DIE GEWINDETEILE NICHT BESCHÄDIGT WERDEN.

5 – Die neue Düse (stets für dieselbe Gasart) einsetzen und vorsichtig bis zum Anschlag

hineinschrauben.

6 – Alles auf umgekehrte Weise wieder zusammenfügen.

WICHTIG! Das Gerät darf auf KEINE Weise von Methan auf Flüssiggas oder umgekehrt

umgerüstet werden. Jeglicher Umrüstungsversuch ist als gefährlich zu betrachten und der

Hersteller lehnt jegliche Haftung für eventuelle Personen- und Sachschäden aufgrund derartiger oder anderweitiger Fremdeingriffe ab. Das Gerät darf deshalb NUR vom Hersteller zusammengebaut werden und der Anwender muss es direkt für die Art des zum Betrieb verwendenden Gases bestellen.

AUFBEWAHRUNG

WICHTIG! Transport des Gerätes (Abb. 12) nur nach dem Ausschalten, abkühlen lassen

vollständig geschlossen und die Gaszufuhr.

Falls ein längerer Gerätstillstand vorgesehen ist (Wechsel der Jahreszeit oder andere Gründe),

nachstehende Anweisungen befolgen:

- Das Gerät an einem trockenen Ort und geschützt gegen etwaige Beschädigungen aufbewahren.

- STETS das Brenneraggregat und den Unterbau abdecken um Verschlüsse (Spinnennetze,

Staub) oder Beschädigungen (Dellen, Witterungseinflüsse, usw.) zu vermeiden.

WICHTIG! NIEMALS gemeinsam mit dem Gerät eine oder mehrere Gasflaschen aufbewahren.

Diese sind stets im Freien und gemäß den im Bestimmungsland geltenden Gesetzen und

Vorschriften zu lagern.

GARANTIE

Ihr Gerät hat 2 Jahre Garantie ab Kaufdatum.

Die Garantie deckt alle Herstellungsfehler mit Ausnahme von Defekten aufgrund anderer als

der vom Hersteller für dieses Gerät angegebenen und vorgesehenen Verwendungen. Die durch

den Garantieschein gedeckte Garantiezeit läuft ab dem Datum der Kaufquittung oder des

Kassenbelegs. Dieses Gerät ist nicht für professionellen Gebrauch geeignet.

Abnützung, Korrosion, eventuelle Verformung, Verfärbung oder Bräunung (insbesondere der

matt glänzenden Teile oder des Glasrohres) aufgrund des Kontakts mit der Flamme und der

kontinuierlichen Strahlung sind als normal zu betrachten und können keinesfalls als

Herstellungsfehler angesehen werden, weil sie durch die normalen Gebrauchsbedingungen

bedingt sind.

Des weiteren ist es normal, dass es nach längerem Gebrauch erforderlich ist, einige abgenützte

Teile zu ersetzen, wozu STETS Originalersatzteile des Herstellers zu verwenden sind.

„Bei Austausch von Teilen, die auf Garantie ersetzt werden sollen, muss das reklamierte Teil nach Ausbau zur Mängelprüfung dem zuständigen Lieferanten zurückgeschickt werden.“

26

EVENTUELLE STÖRUNGEN UND ABHILFEN: mit Fernbedienung.

STRUNG URSACHE ABHILFE

Das Gert funktioniert beim Einschalten nicht,

die Anzeige POWER leuchtet nicht auf.

1-Zu schwache Batterieladung, defektes

Batteriepaket (B1) oder lockere Pole.

2

-Infrarotempfnger (D) bedeckt.

3-Knopf POWER der Fernbedienung wurde

nicht 2 Sekunden lang gedrckt gehalten.

4-Defekte Fernbedienung, erschpfte

Batterien.

5-Verbindungskabel zwischen vorderer und

hinterer Steuerplatine sind locker oder defekt.

6-Defekte Steuerplatinen.

7-Anti-Kippen Ausfall oder den Boden mit

Neigung von mehr als 15¡.

1-Batterien ersetzen, Pole anziehen.

2

-Loch fr den Empfnger machen.

3-2 Sekunden lang auf POWER drcken,

loslassen, und erneut darauf drcken.

4-Fernbedienung oder Batterien ersetzen.

5-In Ordnung bringen oder ersetzen.

6-Ersetzen.

7-Ersetzen, ndern Position Gert (Boden

mit Neigung weniger als 15¡).

Kein Funke beim Anznden des Gerts.

1-Zu gro§er Abstand zwischen Zndvorrichtung

(HV1) und Erdung oder zu gro§er Abstand

zwischen den Elektroden (HD).

2-Der K eramikteil der Zndvo rrichtung (HV1)

ist beschdigt oder defekt.

3-Hochspannungskabel locker, beschdigt

oder kurzgeschlossen.

4-Leitflammenset hat keine Erdung.

5-Hintere Steuerplatine defekt.

1-Den Abstand auf 4 __0,5 mm einstellen.

(Der Kabelwiderstand ist in Nhe der

Zndvorrichtung anzuschlie§en).

2-Den Keramikteil ersetzen.

3-Reparieren oder ersetzen.

4-An die Erdung anschlie§en.

5-Ersetzen.

Keine Flamme

1-Ungengende Gasversorgung (schlechte

Flssiggasvergasung, Schmutz in der Anlage),

oder falsch eingestellter bzw. defekter Gasregler.

2-Keine Gasversorgung (leere Gasflasche

oder unterbrochene Gaslieferung), oder

defekter Druckregler.

3-Pltzliche Windstsse (strker als 3

m/s) bei beseitigten Verkleidungstafeln.

4-Schmutz im Gaskreis.

5-Gaslecks.

6-Gasflaschenanschluss, Luft in der Leitung

1-Reinigen, einstellen / ersetzen.

2-berprfen / ersetzen.

3-Verkleidungen wieder anbringen.

4-berprfen / reinigen.

5-Verschr aubu ngen kontr olli eren/na chzi ehen;

Dichtungen oder Leitungen ersetzen.

6-Zndung wi ederhole n, damit d ie Luft en tweichen kann.

Funke vorhanden, aber die Leitflamme geht

nicht an.

1-Keine Gasversorgung.

2-Defekte Verb indung zw ischen vo rderer un d

hinterer Steuerplatine oder lockere

Ver bin dung ska bel .

3-Leitflammen-Einspritzer ist blockiert.

4-Hintere Steuerplatine ist defekt

5-Ventile G1 und G2 sind defekt.

1-berprfen.

2-In Ordnung bringen oder Kabel ersetzen.

3-berprfen oder ersetzen.

Dsendurchmesser: Flssiggas: 0,35 mm;

ERDGAS: 0,55 mm.

4-Ersetzen.

5-Ersetzen.

Lei tflamme brennt , kontinuierliche Fu nken, die

nic ht aufhren (e s wird keine Flamme erfasst) .

1-Kabel des Flammensensors (S) und der

Zndvorrichtung (HV) verkehrt oder locker

(HV).

2-Flammensensor (S1) und Erdung sind

kurzgeschlossen.

3-Flammensensor (S1) erfasst die Flamme nicht.

4-Leitflamme brennt im Leitflammenrohr.

5-Hintere Steuerplatine defekt.

1-In Ordnung bringen.

2-Wieder in die richtige Position bringen.

3-Wieder in die richtige Position bringen.

4-Ersetzen.

5-Ersetzen.

Leitflamme brennt, der Hauptbrenner geht

nicht an.

1-Defekte Kabel oder lockere Enden.

2-Hauptbrennerdse blockiert.

3- Ventile ÒMÓ und ÒLÓ defekt.

4-Vordere und hintere Steuerplatine defekt.

5-Fernbedienung defekt.

1-Reparieren oder ersetzen.

2-berprfen ob Gasdruck vorhanden ist.

Le itfl amm ense t er setz en o der E ins prit zer erne ut

durchbohren.

3-berprfen, ob kein Gasdruck besteht;

die Ventile ÒMÓ und ÒLÓ ersetzen.

4-Ersetzen.

5-Ersetzen.

Die kleine Flamme geht an; die mittlere

Flamme geht nicht an.

1-Defekte Kabel oder lockere Enden.

2-Ventil ÒMÓ defekt oder Dse Ventil ÒMÓ

blockiert.

3-Vordere Steuerplatine defekt.

4-Fernbedienung defekt.

1-Reparieren oder ersetzen.

2-Ersetzen.

3-Ersetzen.

4-Ersetzen.

Di e mit tle re Fl amm e geh t an ; die kle ine F lam me

geht nicht an.

1-Defekte Kabel oder lockere Enden.

2-Ventil ÒLÓ defekt oder Dse Ventil ÒLÓ

blockiert.

3-Vordere Steuerplatine defekt.

4-Fernbedienung defekt.

1-Reparieren oder ersetzen.

2-Ersetzen.

3-Ersetzen.

4-Ersetzen.

Whrend der Zndungsablufe geht das

Gert nicht in 25 Sekunden aus.

1-Vordere Steuerplatine defekt. 1-Ersetzen.

Batterie der Fernbedienung ist erschpft. 1-Die Batterie ist fast erschpft. 1-Ersetzen.

Glasrohr geschwrzt.

1-Schlechte oder fr den Winter

ungeeignete Gasqualitt.

2-schlechter Zug.

3-Netzzylinder (Option) falsch positioniert/verformt.

4-Wrmetauscherkopf verschmutzt/beschdigt.

5-Brenner verschmutzt/beschdigt.

1-Gas von guter Qualitt verwenden;

vorzugsweise reines Propan.

2-Starker Wind oder Fehlen des Windschutz-Kits.

3-rNeu positionieren/ersetzen/entfernen.

4-Reinigen/ersetzen.

5-Reinigen/ersetzen.

Bruch der Glasrhre

1 - Zu starker Temperaturschock aufgrund

besonderer Witterungsbedingungen.

2 - Reinigung mit unangebrachten Mitteln.

3 - Zuflliger Fall des Gerts.

1 - Ersetzen.

2 - Ersetzen.

3 - Ersetzen.

27

EVENTUELLE STÖRUNGEN UND ABHILFEN: mit manuellen Bedienelementen.

STRUNG URSACHE ABHILFE

Keine Flamme

1 – Ungenügende Gasversorgung:

- schlechte Flüssiggasvergasung;

- schlechte Flüssiggasvergasung bei

niedriger Temperatur;

- falsch eingestellter oder defekter

Druckregler.

2 – Plötzlicher Windstoß (stärker als 3 m/s).

3 – Thermoelement unterbrochen.

4 – Ventilmagnet defekt.

5 - Anti-Kippen Ausfall oder den Boden

mit Neigung von mehr als 15°.

6 – Schmutz im Gaskreis.

7 - Gaslecks

8 – Erschöpfte Batterie.

9 – Defekte Elektrodenisolierung und/oder

Kabel.

1- Überprüfen:

- Überprüfen und leere Gasflasche ersetzen.

- Mit Propangasflasche ersetzen.

- Einstellen oder ersetzen.

2 – Das Gerät gegen Wind schützen.

3 - Ersetzen.

4 - Ersetzen.

5 - Ersetzen, ändern Position Gerät (Boden

mit Neigung weniger als 15°).

6 - Überprüfen und sorgfältig reinigen.

7 - Überprüfen und das Leck beheben.

8 - Ersetzen.

9 - Ersetzen.

Glasrohr geschwärzt.

1-Schlechte oder für den Winter

ungeeignete Gasqualität.

2-schlechter Zug.

3-Netzzylinder (Option) falsch positioniert/verformt.

4-Wärmetauscherkopf verschmutzt/beschädigt.

5-Brenner verschmutzt/beschädigt.

1-Gas von guter Qualität verwenden;

vorzugsweise reines Propan.

2-Starker Wind oder Fehlen des Windschutz-Kits.

3-rNeu positionieren/ersetzen/entfernen.

4-Reinigen/ersetzen.

5-Reinigen/ersetzen.

Bruch der Glasrhre

1 - Zu starker Temperaturschock aufgrund

besonderer Witterungsbedingungen.

2 - Reinigung mit unangebrachten Mitteln.

3 - Zuflliger Fall des Gerts.

1 - Ersetzen.

2 - Ersetzen.

3 - Ersetzen.

*Bruch der Glasröhre

Die Glasröhre haben besondere technischen Merkmale, dank derer sie den, durch normale

Temperaturschwankungen, Regen und Feuchtigkeit verursachten Temperaturschocks widerstehen.

Obwohl dieses Material (Borsilikat) gewählt wurde, können aber trotzdem plötzliche Brüche der

Glasröhre aufgrund besonderer klimatischer Ereignisse und/oder zu starker

Temperaturschwankungen auftreten.

WICHTIG! Dieser Röhrenbruch (Sprung) verursacht keine Schäden der in unmittelbarer

Nähe befindlichen Personen und Sachen.

WICHTIG! Ein etwaiger Bruch der Röhre stellt momentan kein Hindernis für den

Gerätbetrieb dar, da es sich aber um ein beschädigtes Bauteil handelt, ist es jedoch

stets zu ersetzen, um den einwandfreien Betrieb zu garantieren.

28

NL - REGULATOR: Capaciteit MAX 1000 g / h, Max druk 37 mbar.

NL - De gasleiding moet uit een flexibel soort en lengte als om een eenvoudige vervanging van

de cilinder toe.

- NEDERLANDS -

Inhoud

ALGEMENE BESCHRIJVING

MONTAGE

START-UP

Uitschakeling

ONDERHOUD

OPSLAG EN BEHANDELING

GARANTIE

DE AFSTANDSBEDIENING

PROBLEEMOPLOSSING

29

Kijk aandachtig dit boekje na voor de volledige levensduur van het toestel en om een

nieuwe aan te schaffen IN GEVAL VAN SCHADE OF VERLIES!

BELANGRIJK! Indien onderdelen beschadigd zijn, GA NIET VERDER MET MONTAGE!

BELANGRIJK! Dit apparaat moet worden geïnstalleerd in overeenstemming met de

verordeningen, wetten en normen die gelden in het land van gebruik. Installeer het apparaat buiten in een goed geventileerde ruimte, moet het gebied rond het apparaat een

open zijde van MIN 25% van de totale oppervlakte, moet het gebruik voldoen aan de

instructies van de fabrikant. Raadpleeg de instructies voor de installatie en het gebruik

van het apparaat.

BELANGRIJK! ALLE onderhoud, herstelling of wijziging moet worden uitgevoerd door

professioneel gekwalificeerd en gecertificeerd personeel en altijd met de originele onderdelen van de fabrikant.

BELANGRIJK! Dit gasapparaat is een warmte-generator die alleen bedoeld is voor het

gebruik waarvoor het is ontworpen en gecertificeerd (met ruimte temperatuur niet lager

dan 0 ° C voor Remote-gecontroleerde mod.), Of als een apparaat voor de verwarming

open, geventileerde of outdoor omgevingen . Alle andere toepassingen worden geacht

onjuist en daarom gevaarlijk. De fabrikant wijst alle aansprakelijkheid af, voor eventuele

schade aan personen of dieren of schade aan zaken veroorzaakt door oneigenlijk

gebruik.

BELANGRIJK! Indien blootgesteld aan hevige windstoten, adequate verankering van de plaat.

BELANGRIJK! GEBRUIK IN GESLOTEN OMGEVINGEN is verboden: kantoren, in huizen,

stallen, STALLINGEN, PLAATSEN IN DE BUURT VAN GAS OF POTENTIEEL BRANDBARE

stoffen / of explosieven, ENZ.

BELANGRIJK! Volg zorgvuldig alle instructies en de voorzorgsmaatregelen die in dit boekje

(met betrekking tot installatie, gebruik en onderhoud). Niet-naleving van deze instructies

kan leiden tot storingen en / of gevaar opleveren voor mensen, dieren en dingen.

BELANGRIJK! Dit toestel is op gas EN DELEN ERVAN WORDEN WARM. BIJGEVOLG:

buiten bereik van kinderen houden.

BELANGRIJK! NOOIT het apparaat verplaatsen met de brander nog steeds actief.

BELANGRIJK! ALTIJD EENN VEILIGE afstand van voorwerpen of brandbare materialen

(afb. 2) behouden.

BELANGRIJK! Bij GEBRUIK, zich houden aan de brandbestrijding en

preventieVERORDENINGEN VAN HET LAND WAAR het apparaat wordt gebruikt.

BELANGRIJK! GEEN gebruik van het apparaat dat ingesteld is voor LPG, in kelders.

BELANGRIJK! Het apparaat, gemaakt voor het gebruik van LPG, kan niet worden aangepast voor het gebruik van aardgas en omgekeerd.

BELANGRIJK! WIJZIGEN van het apparaat is volstrekt verboden behalve in die gevallen

aangegeven en door de fabrikant.

BELANGRIJK! Periodiek controleren voor gas lekken in leidingen, aansluitingen en de

gas / apparaat verbinding met behulp van zeepsop. Controleer of er geen lekken van de

verbindingen met tanks of gasdistributiesystemen.

BELANGRIJK! Alvorens te verbinden, zorg ervoor dat de slang in overeenstemming is

met de verordeningen die van toepassing zijn in het land van gebruik.

BELANGRIJK! Alvorens over te gaan tot assemblage, zorg ervoor dat alle onderdelen

van het apparaat geschikt zijn voor het type van gas en de druk volgens de verordeningen die van toepassing zijn in het land van gebruik.

30

ALGEMENE BESCHRIJVING

Voor zijn bepaald type operatie aan direct zonlicht en reflectie, dit apparaat zijn invloed uitoefent in een gebied van ongeveer 13 m

2

met een bereik van ongeveer 2m. Het getroffen gebied

en het verwarmen efficiency varieert afhankelijk van het klimaat en de weersomstandigheden in

de regio van eindbestemming, de locatie van het apparaat (milieu volledig open of gedeeltelijk

door een of meer zijden) en de subjectieve perceptie van warmte. Het gevoel van warmte,

totaal subjectief en niet meetbaar verhoogt aanzienlijk dichter bij de vlam.

Het apparaat is zeer eenvoudig te gebruiken en gebouwd volgens de CE-veiligheidsnormen.

Het is getest, goedgekeurd en gecontroleerd door de aangemelde Goedkeuring Instituut waarvan de fabrikant de meeste van haar certificeringen in de gasindustrie heeft toevertrouwd.

Soorten installatie:

- MOBIELE, met het basisstation vrij van beperkingen het gebruik van de wielenset (optioneel),

met LPG-brandstof alleen (tank).

- Vaste, met de basis vastgemaakt aan de vloer (dit type installatie moet alleen worden uitgevoerd door professioneel geschoolde personeel), met een propaan / butaan gas (grote tank).

MONTAGE

Neem alle onderdelen uit het apparaat uit de verpakking, met speciale aandacht te geven aan

de brander eenheid (afb. 3: 3, 4, 7, 9, 10).

Controleer de integriteit en de conformiteit van de inhoud van de verpakking (de laatste moet

worden verwijderd volgens de geldende regelgeving):

A - Mod. FALO 'met handmatige controle

- Apparaat met de structuur en bijzondere glazen buis;

- Slangverbinding (zorg ervoor dat deze voldoet aan de geldende voorschriften);

- Plaats de alu-kap;

- Meertalig instructie boekje;

- Garantie Certificaat.

B - Mod. FALO 'met Remote Control

- Afstandsbediening + batterijen;

- Apparaat met de structuur en bijzondere glazen buis;

- Slangenverbinding (zorg ervoor dat deze voldoet aan de geldende voorschriften);

- Plaats de alu-kap ;

- Meertalige instructie boekje;

- Garantie Certificaat.

BELANGRIJK! Draag altijd individuele handbescherming tijdens de montage en de positionering van het apparaat. Gebruik de speciale accessoire (wielenset) voor het verplaatsen (fig.

3:18) ter voorkoming van snij-en brandwonden.

Assemblage (mobiele type met LPG-tank):

Voordat u begint a/d assemblage, verwijder alle bescherming en folie.

1 - plaats voorzichtig de structuur op de grond en breng de alu kap aan. (afb. 3: 2).

2 - Verwijder de zijpanelen (Fig. 3: 14, 15) en plaats de tank op de basisplaat (afb. 3: 13).

3 - Bevestig de gasdruk regelaar op de tank. Die moet voldoen aan de technische details

en GAS SETTING vermeld op het label in het apparaat (Tab. 1 of 2).

4 – Schaf een drukregelaar en de rubberen slang verbinding apart aan. Deze moeten van het

31

type en de materialen zijn, die door de verordeningen van het land van gebruik zijn vooropgesteld. (indien deze reeds niet beantwoorden).

De schroefdraad van de adapter (Fig. 9: 4) in acht nemen. ( verschillende soorten verbindingen).

BELANGRIJK! Er bestaan twee soorten adapters, een links draaien (Oostenrijk, Duitsland en

Luxemburg) en een rechts draaien (alle andere landen).

CASE A (Fig. 9: A) 1 / 4 "gas linksdraaiend: past de rubberen slang (1), met een specifieke

schroefdraad aansluiting (meegeleverd). Deze oplossing is geschikt voor Oostenrijk, Duitsland

en Luxemburg.

CASE B (Fig. 9: B) 1 / 4 "rechts draaien: past de rubberen slang (6) gekocht afzonderlijk (indien

reeds verstrekt niet voldoet) direct op de schroefdraad 1 / 4" GAS rechts draaien aansluiting (4)

van het einde onderdeel; nu past de rubberen slang (8 - MAX Lengte = 1,5 m) met behulp van

de klem bepaald (6).

5 - Bevestig het onderste gedeelte van de gas-aansluiting slang aan de regulator (Fig. 9: 2) op

de tank (Fig. 9: 3). Sluit het andere uiteinde van de gas-slang aan de verbinding.

6 - Voor het maken van de verbinding, controleren of het gas middenrif (Fig. 9: 5) moet worden

gemonteerd op het item connector (Fig. 9: 4) (geldig oplossing voor Oostenrijk, Duitsland en

Luxemburg - zie Tab. 1 of 2).

BELANGRIJK! Passen niet in het middenrif van toestellen gevoed met gas G30/G31 op

29 ÷ 37 mbar.

BELANGRIJK! ALLEEN diafragma verbinden in het geval van een druk van 50 mbar

(Oostenrijk, Duitsland, Luxemburg). Controleer of het juiste type zoals aangegeven en op

Tab. 1 of 2.

7 - voorzichtig kantelen van het apparaat, plaats de alu schotel (afb. 3: 2) en zet in positie met

de knoppen op voorwaarde (afb. 3: 1) en zet het apparaat op verticale positie.

BELANGRIJK! NOOIT de bovenkant van het apparaat op de grond leggen, wanneer de schotel gemonteerd is, dit om beschadiging van de vlamverdeler of de glazen buis te voorkomen, of

de gasdoorlaat te belemmeren.

8 - Sluit de gasvoorziening aan het onderste gedeelte van de verbinding (reeds gemonteerd)

(Fig. 7 en 8: 12).

1)MONTAGE FASES (VAST type, op de begane grond of verdieping, met LPG-tank of

hoofdbrandblusleidingen gasvoorziening):

BELANGRIJK! Als het apparaat wordt gebruikt met LPG op 50 mbar (voor Oostenrijk,

Duitsland en Luxemburg), zie Technische gegevens tabel.

1 - VOORZICHTIG de structuur op de grond leggen en de alu schotel bevestigen(afb. 3: 2).

BELANGRIJK! NOOIT rest van de bovenkant van het apparaat op de grond leggen, vooral

wanneer de alu schotel is gemonteerd, om te schade te voorkomen of gasdoorvoer te belemmeren.

2 - Plaats het toestel recht, rekening houdend met de positie van de buizen en verwijder de

zijkanten (Fig. 3: 14, 15).

3 - Markeer de positie van de bevestiging gaten op de grond.

4 - Bevestig de structuur in het wegdek met behulp van anker bouten (afb. 11: 1, niet meegeleverd) geschikt voor het type vloer, gebruik te maken van de gaatjes (afb. 11: 2) in de tank

draagvlak.

5 – Schaf een gasdrukregelaar en slang apart aan, van een type en materiaal dat geschikt is

volgens de verordeningen van het land van gebruik, en sluit direct aan de ¼ "rechtse GAS-aansluiting (4) op het einde een deel van de koppeling, en verbind vervolgens de rubberen slang (8

met max. lengte = 1,5 m) met behulp van een klem (7).

6 - Voor het maken van de verbinding, controleren of het gas middenrif (Fig. 9: 5) moet aan-

32