Italiana Camini ELLY IDRO Installation, Use And Maintenance Manual

®

Pellet boiler stove

ELLY IDRO

EN Installation, use and maintenance page 2

CONTENTS

Safety information 4

General information 5

Installation 7

Instructions for use 17

Maintenance 21

Troubleshooting 24

ENGLISH

2

The undersigned company with registered office in Via Vincenzo Monti 47 - 20123 Milan (Italy) - Tax ID Code and VAT

number 00192220192

Hereby declares, under its sole responsibility, that:

The pellet boiler stove mentioned below complies with EU

Regulation 305/2011 and harmonised EU standard

EN 14785:2006

PELLET Boiler Stove, bearing the

ITALIANA CAMINI trademark and called ELLY IDRO

SERIAL NO.: Rating plate reference

Performance declaration: (DoP - EK n° 092):

Rating plate reference

Moreover, the company hereby declares that:

the ELLY IDRO wood pellet boiler stove complies with the

requirements

of the European Directives:

2014/35/EC - Low Voltage Directive

2014/30/EC - Electromagnetic Compatibility Directive

Dear Sir/Madam

We thank you for and congratulate you on choosing our

product. Before using it, we ask that you read this manual

carefully, in order for you to be able to make the most of all

its functions in total safety.

This manual is an integral part of the product. We ask you

to keep it for the entire lifetime of the product. If you lose it,

you can request a copy from your dealer or download it from

www.italianacamini.com

The product is uniquely identified by a number, the

“counterfoil”, which is indicated on the warranty certificate.

Please keep:

• the warranty certificate accompanying the product

• the purchase receipt given to you by the retailer

• the declaration of conformity given to you by the installer.

The warranty conditions are given in the warranty certificate

accompanying the product.

After unpacking the product, check the condition and

completeness of the contents.

In the event of error, immediately contact the retailer where

the purchase was made, providing him with a copy of the

warranty booklet and the sales receipt.

The appliance must be installed and operated in compliance

with local and national law and European regulations. For the

installation, and for anything not specifically indicated in the

manual, observe local regulations.

The diagrams provided in this manual are for illustration

purposes only: they do not always strictly refer to your

specific model, and are not binding in any way.

In Italy, commissioning by an authorised technician is

required by UNI 10683, and is recommended in all countries

to ensure best results from the product.

This consists in:

• checking the installation documents (declaration of

conformity) and the quality of the installation itself

• calibrating the product to suit its actual application

• providing explanations to the end user and issuing

the complementary documentation (first ignition -

commissioning certificate)

Having the appliance commissioned properly ensures that it

will operate to best effect and in complete safety.

Proper commissioning is required for activation of the

manufacturer's warranty. The warranty is only valid in the

country where the product was bought.

If the appliance is not commissioned by an authorised

technician, the manufacturer will not provide warranty service.

See the warranty booklet for details. The above terms do not

affect the dealer's legal responsibility for the legal warranty.

ENGLISH

3

MEANING OF SYMBOLS

In some parts of the manual the following symbols are

used:

PLEASE NOTE:

carefully read and understand the

message in question, since failure to

follow the instructions in it could cause

serious damage to the product and put

the safety of those using it at risk.

INFORMATION:

failure to comply with these requirements

will compromise product use.

OPERATING SEQUENCE:

follow the instructions for the operations

described.

SEQUENZA OPERATIVA:

seguire le istruzioni procedurali per le

operazioni descritte

The warranty, however, covers only demonstrable

manufacturing defects and not, for instance, problems

resulting from improper installation or calibration.

SAFETY INFORMATION

®

• The product is not designed for use by people,

including children, with limited physical, sensory

and mental abilities.

• The appliance is not designed for cooking

purposes.

• The appliance is designed to burn UNI EN ISO

17225-2 category A1 wood pellets, in the amounts

and manner described in this manual.

• The appliance is designed for indoor use and in

areas with normal humidity conditions.

• Keep the product in a dry place out of the weather.

• For the legal and company warranties, refer to the

warranty certificate inside the product: specifically,

neither the manufacturer nor the dealer are liable

for damage resulting from incorrect installation or

maintenance.

Safety risks may be caused by:

• installation in unsuitable conditions. In particular,

conditions of fire hazard. DO NOT INSTALL THE

PRODUCT IN AREAS SUBJECT TO THE RISK OF

FIRE.

• contact with fire and hot parts (e.g. glass panel

and pipes). DO NOT TOUCH HOT PARTS and,

when the boiler stove is switched off and still hot,

ENGLISH

always wear the gloves supplied.

4

• contact with live electrical equipment (internal).

DO NOT ACCESS THE INTERNAL ELECTRICAL

EQUIPMENT WHILE THE APPLIANCE IS

POWERED ON. Electrocution hazard.

• use of improper ignition aids (e.g. alcohol). DO

NOT IGNITE OR BOOST THE FLAME WITH FLUID

SPRAYS OR A FLAME TORCH. Serious risk of

burns, damage and injury.

• use of fuel other than wood pellets. DO NOT

BURN WASTE MATTER, PLASTIC OR OTHER

MATERIALS THAN WOOD PELLETS IN THE

HEARTH. The product may become soiled, the

flue may catch fire, and environmental damage

may ensue.

• cleaning the hearth when hot. DO NOT CLEAN

THE HEARTH WITH A VACUUM CLEANER WHILE

IT IS HOT. Risk of damage to the cleaner and

smoke in the room.

• cleaning the fumes duct with cleaning products. DO

NOT CLEAN THE PRODUCT WITH FLAMMABLE

PRODUCTS. Risk of fire or blowback.

• cleaning the hot glass pane with unsuitable

cleaning products. DO NOT CLEAN HOT GLASS

WITH WATER. ONLY USE RECOMMENDED

GLASS CLEANING PRODUCTS. Risk of cracking

and permanent, irreparable damage to the glass.

• the storage of flammable materials at a distance

which is less than the safe distances listed in

this manual. DO NOT PLACE LAUNDRY ON

THE APPLIANCE. DO NOT PLACE DRYING

RACKS WITHIN THE SAFETY CLEARANCE. Keep

flammable fluids away from the appliance. Fire

hazard.

• blocking the aeration vents and air intakes in the

room. DO NOT BLOCK THE AERATION VENTS

OR FLUE. Risk of smoke returning into the room

with consequent damage and injury.

• use of the product as a support or ladder. DO NOT

CLIMB ONTO THE PRODUCT OR USE IT AS A

SUPPORT. Risk of damage and injury.

• use of the boiler stove with the hearth open. DO

NOT USE THE PRODUCT WITH ITS DOOR OPEN.

• incandescent material projected from the open

door. DO NOT throw incandescent material

outside the appliance. Fire hazard.

• use of water in case of fire. CALL THE AUTHORITIES

if a fire breaks out.

• The appliance must never be used without water

in the system; any “dry” lighting is likely to damage

the appliance.

If you have doubts, please do not take any action, but

contact the retailer or the installer.

For reasons of safety, read the user instructions

included in this manual.

®

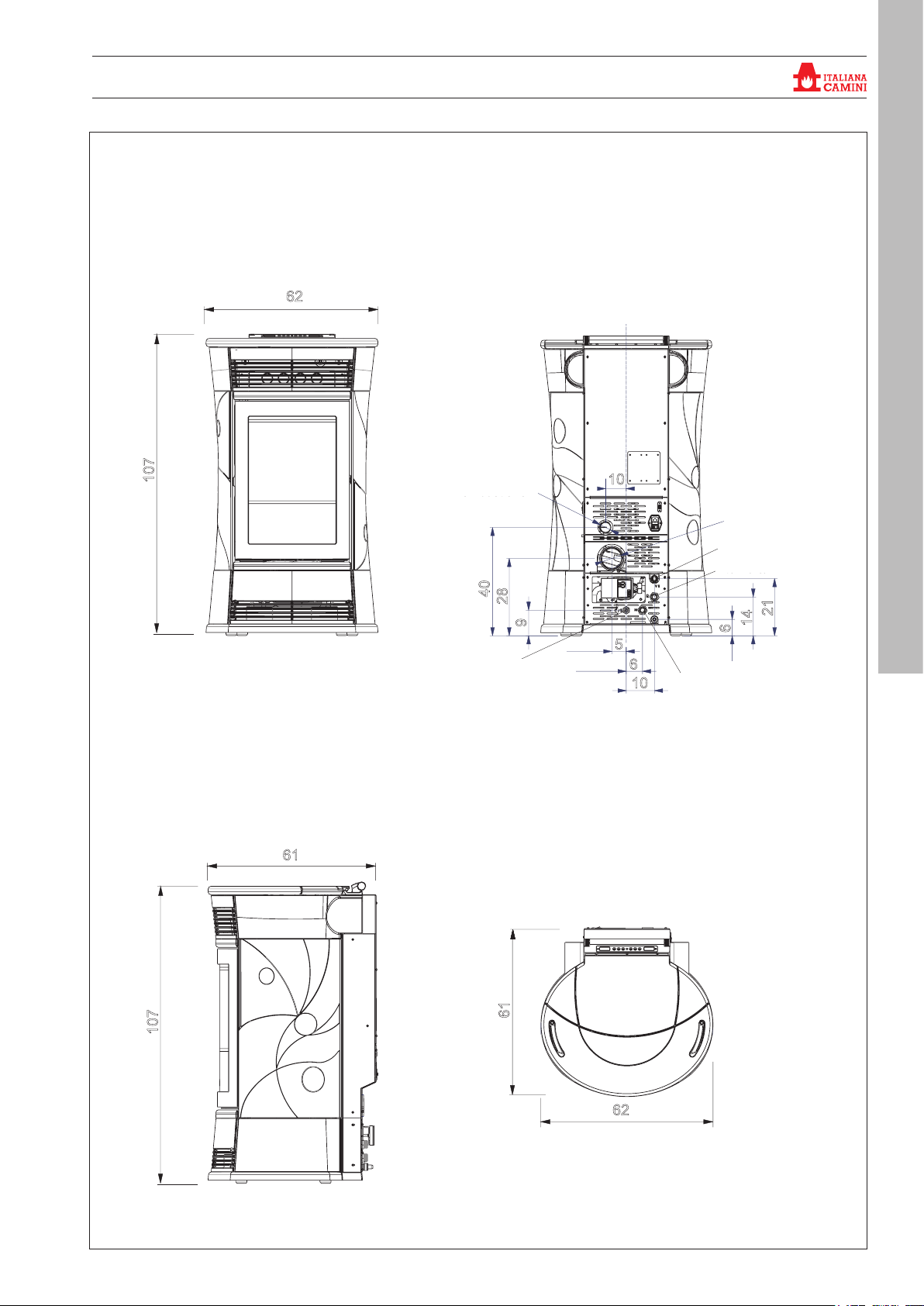

DIMENSIONS in cm

ritorno 3/4”

valvola sicurezza3bar

Ø8cm uscita fumi

Ø4cm aria

combustione

40

28

9

14

21

6

5

10

ritorno 3/4”

carico/scarico

mandata 3/4”

valvola sicurezza3bar

107

62

61

Ø8cm uscita fumi

Ø4cm aria

combustione

62

40

28

9

14

21

6

10

6

5

10

ritorno 3/4”

mandata 3/4”

valvola sicurezza3bar

Ø8cm uscita fumi

28

9

14

21

6

10

6

5

10

DIMENSIONS

62

107

61

Ø 4 (cm)

Ø4cm aria

combustion air

combustione

40

28

9

loading / unloading

carico/scarico

10

5

6

10

delivery 3/4”

mandata 3/4”

Ø 8 (cm) fume outlet

Ø8cm uscita fumi

safety valve 3 bar

valvola sicurezza3bar

return 3/4”

ritorno 3/4”

21

14

6

ENGLISH

5

61

107

62

INFORMAZIONI GENERALI

®

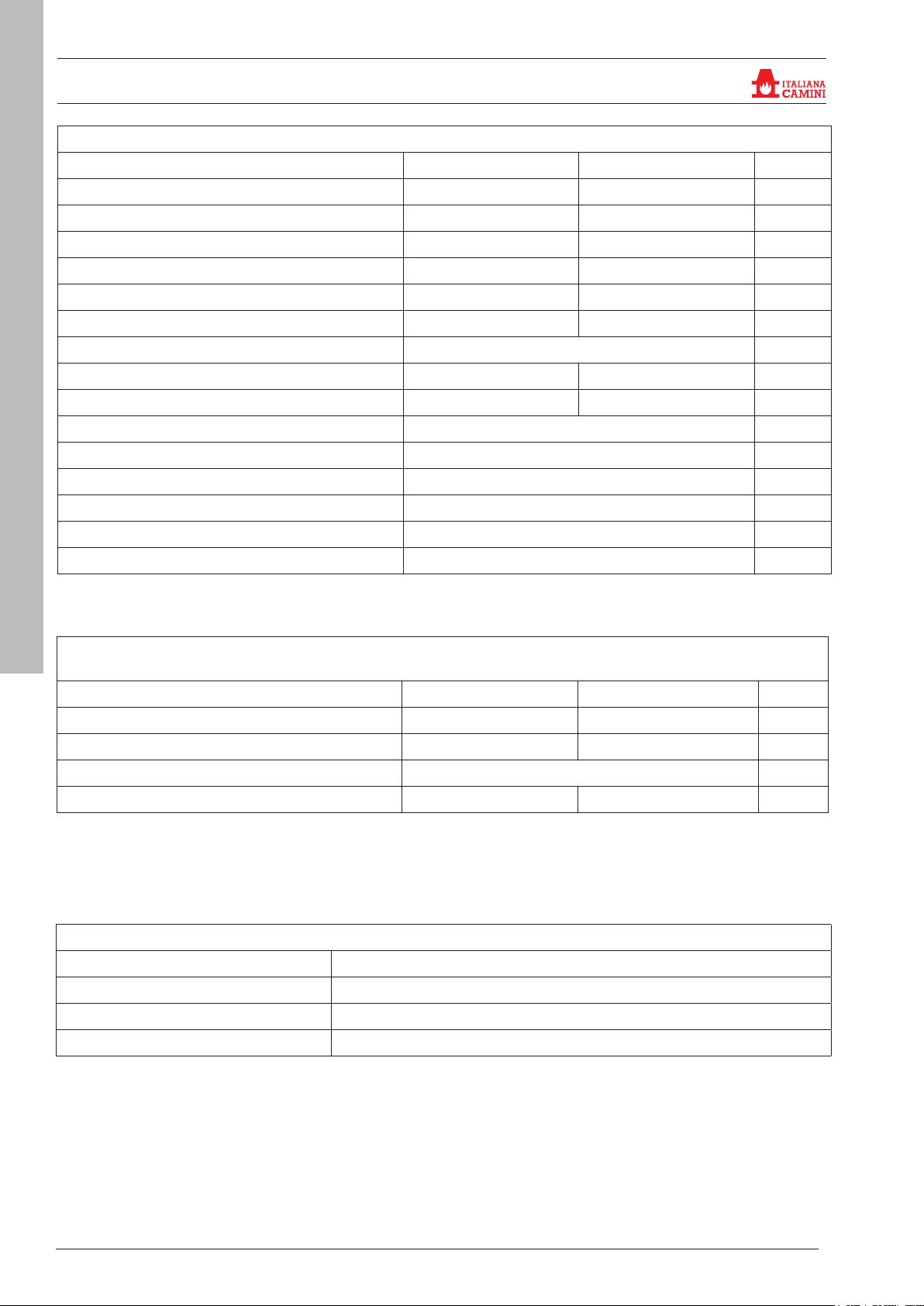

TECHNICAL CHARACTERISTICS in accordance with EN 14785

Nominal power Reduced power

Available power

Power for water

15 4.8 kW

12 3 kW

Efficiency 91.6 97.6 %

CO emissions at 13% O

2

0.010 0.025 %

Fumes temperature 129 56 °C

Fuel consumption 3.4 1 kg/h

Tank capacity 30 kg

Draw 12-5 10-3 Pa

Autonomy 8 27 hours

Heatable volume * 390 m

3

Water content 12 l

Maximum operating water pressure 1,5 bar

Fumes outlet diameter (male) 80 mm

Air intake diameter (male) 40 mm

Weight including packaging 246 / 248 kg

TECHNICAL DATA FOR RATING THE FLUE

ENGLISH

which must in any case satisfy the requirements of this sheet and the installation instructions for the product

6

Available power

Nominal power Reduced power

15 4.8 kW

Fumes temperature at outlet 155 67 °C

Minimum draw 0-5 Pa

Fumes flow rate 10.6 3.6 Rps

* The heatable volume is calculated for a house insulated pursuant to Italian Law 10/91 and subsequent amendments,

and a heating demand of 33 Kcal/m³ hour.

ELECTRICAL SPECIFICATIONS

Power supply 230 V AC +/- 10% 50 Hz

Mean absorbed power 120 W

Power absorption during ignition 400 W

Protection rating Fuse 2 AT 250 V AC 5x20

The manufacturer reserves the right to modify the product at his own discretion and without

notication.

®

INSTALLATION

GENERAL NOTES

All local and National laws and the European Standards

must be met in the installation and in the use of the

equipment. In Italy it is necessary to refer to Ministerial

Decree 37/2008 (formerly Law 46/90) and the UNI

10683 Standards.

In the case of installation in a multiple-tenancy building,

contact the building manager before installation.

VERIFY COMPATIBILITY WITH OTHER

DEVICES

In Italy the stove MUST NOT be installed in the same

space or in communicating environments as type B

gas heating equipment (e.g. gas boilers, stoves, and

equipment served by an extraction hood - ref. UNI

10683 and 7129).

In general, the stove could create low pressure in the

room, affecting the operation of such appliances or

being affected by them.

VERIFYTHE POWER SUPPLY CONNECTION

(the plug must be accessible)

The stove is supplied with a power cable that is to be

connected to a 230V 50 Hz socket, preferably fitted

with a magnetothermic switch.

Voltage variations exceeding 10% can damage

the stove (unless already installed, an appropriate

differential switch must be fitted).

The electrical system must comply with the law;

particularly verify the efficiency of the earthing system.

The power line must have a suitable cross-section for

the stove’s power. An inadequate earthing system can

cause anomalies for which Italiana Camini cannot be

held liable.

AIR INTAKE (mandatory to do)

The room where the stove is located must have

an air intake with cross section of at least 80cm

2

to ensurereplenishment of the air consumed by

combustion.

Alternatively, the stove air may be taken directly from

outside through a 4 cm steel extension of the pipe.

POSITIONING AND DISTANCES FOR FIRE

SAFETY

The stove must be installed in compliance with the

following safety conditions:

- minimum distance from flammable materials around

the sides and back of the stove: 10 cm

- flammable materials must not be placed less than 80

cm from the front of the stove.

If it is not possible to comply with the above-mentioned

distances, technical and construction-related

provisions must be taken to prevent fire hazards.

If connected to wooden walls or other flammable

materials, the smoke exhaust pipe must be insulated.

ENGLISH

7

One fuses (4 A) is inserted in the socket with switch,

located on the back of the stove.

®

46

Ø 4 cm aria

combustione

11

18

46

49

49

Ø 8 cm uscita fumi

39

6

46

Ø 4 cm aria

combustione

11

18

46

49

49

Ø 8 cm uscita fumi

39

6

SMOKE OUTLET

The stove must have its own smoke outlet (the smoke

cannot be discharged into a smoke flue used by other

devices).

The smoke is discharged through the 8 cm diameter

outlet at the back of the stove.

The smoke outlet must be connected to outside by

means of suitable steel pipes EN 1856 certified.

The pipe must be hermetically sealed.

The only horizontal section allowed may be up to 2 m

long up to three 90° bends (in relation to the vertical).

A vertical section of at least 1.5 m and an anti-wind

terminal is necessary (if the discharge outlet is not in a

chimney flue - reference UNI 10683).

The vertical duct can be internal or external.

If the smoke channel is outside, it must be appropriately

insulated.

If the smoke channel is fitted inside a chimney flue, the

latter must be suitable for solid fuel.

If it is wider than 150 mm in diameter it must be

improved by entering a pipe that has a suitable crosssection and is made of suitable material (e.g. 80 mm

diameter steel).

All sections of the smoke duct must be accessible for

inspection.

ENGLISH

The chimney pots and smoke ducts connected to the

solid fuel appliances must be cleaned once a year

8

(verify whether a specific legislation exists in your

country).

Failure to regularly inspect and clean the stove

increases the probability of a fire occurring in the

chimney pot. In that case, proceed as follows:

Do not use water to extinguish the fire; Empty the pellet

hopper; Contact specialist personnel before reigniting

INSTALLATION

the stove.

The stove is designed to work under any weather

conditions. In case of particular conditions, such as

strong wind, the safety system may be activated,

which results in the stove being extinguished.

If this happens, do not operate the stove with the safety

devices disabled.

If the problem persists, contact our Technical Service

Department.

CHIMNEY POT

The main characteristics are:

- an internal cross-section at the base, which is the

same as that of the chimney flue

- an outlet cross-section which is no smaller than twice

that of the chimney flue

- its position must be high enough to catch the wind

and avoid downdraft areas in turbulent wind, it must

be high enough to catch the wind and avoid downdraft

areas in turbulent wind.

TYPICAL EXAMPLES

FIG. 1 FIG. 2

A: flue in insulated steel compliant with EN 1856

B: minimum height of 1.5 m and in any case above the

height of the roof gutter

C-E: air intake from inside room

(minimum internal section: 80 cm²)

D: steel flue, inside existing brick-built chimney.

INSTALLATION

®

PLUMBING

Plumbing depends on the type of system.

However, there are some “general rules”:

• Plumbing must be carried out by qualified

personnel.

• The hydraulic system must operate at a pressure

between 1 and 1.5-2 bars at running temperature

(hot) in a closed vessel circuit.

• N.B.: The boiler SHOULD NOT be installed in place

of, for example, an open vessel installed kitchen

range without adjusting the expansion system to

closed vessel.

• The presence of an accumulator (tank) is

recommended but not mandatory. Its advantage is

that it releases the boiler from “sudden” requests

from the system and can be integrated with other

heat sources. It reduces fuel consumption and

increases the efficiency of the system.

• The return temperature of water to the boiler stove

must be higher than 50-55° C to prevent the forming

of condensation.

• An accumulator (tank) is needed to heat lowtemperature radiant panels and must be installed

according to the panel manufacturer's instructions.

• The material used in the circuit must be suitable to

withstand overheating.

• Check that the plumbing is carried out properly and

is fitted with an expansion vessel that is sufficient to

ensure safety.

•Thesafetyvalvebleedmustbereachableandvisible.

Waste water must be conveyed via a vertical pipe

through a funnel with backflow air vents, at a suitable

distance from the point of drainage.

This pipe must have the following characteristics:

- It must begin no more than 50 cm from the drainage

point of the valve and must be in the same room as the

appliance.

- It must be vertical for no less than 30 cm.

After this, the pipe can continue horizontally with a

slope that allows the flow of the water

- The pipe diameter should be at least one size larger

than the nominal size of the valve outlet.

- The end of the pipe must discharge into the sewage

system.

IT IS FORBIDDEN TO INTERCEPT THE DISCHARGE.

PRESSURE GAUGE

placed on the boiler stove enables you to read the

water pressure in the boiler stove.

ENGLISH

9

If the expansion tank is built into the boiler

stove, this does NOT ensure proper protection against the thermal expansion in-

curred by water in the entire system.

Therefore, installers should assess whether an additional expansion tank is needed,

depending on the type of system.

•

The installer must determine whether or not to use

conditioned products. In Italy, refer to UNI 8065-1989

(Water treatment in heating systems for civil use).

•

Direct plumbing to radiators prevents proper operation,

owing to the small diameter of their pipes.

Loading...

Loading...