Page 1

BI 41

Installation and operation manual

Einbau- und Bedienungsanleitung

Installations- och bruksanvisning

Indel Webasto Marine S.r.l.

Zona Artigianale

IT-61019 S. Agata Feltria (PU), Italy

Te l: +39 0541 848 030

Fax: +39 0541 848 563

E-mail: info@indelwebastomarine.com

www.indelwebastomarine.com

Page 2

Notes:

Page 3

Isotherm built-in box

41 litres

General

Specially designed to operate in tough marine

environments, Isotherm fridge and freezer boxes are

outstanding in both performance and reliability. Fitted

with a fully hermetic, leak-free compressor, they offer

the lowest possible power consumption and noise

level. All models are easy to install. BI41 is used in

the fi rst hand as a refrigeration box, but can reach

temperatures down to -10°C/14°F. The box can stand

an angle of heel up to 30°, for a short time even

more. To ensure that your Isotherm box operates as

effi ciently as possible, please follow these general

guidelines:

* Unnecessary opening of the lid will increase

power consumption.

* Good ventilation of the compressor and

condenser unit will reduce power

consumption.

* The electrical system should be in good

condition. Inspect batteries and charging

level regularly. Always use a separate starter

battery for the engine. Follow carefully the

guidelines regarding electrical cable areas and

fuse placements.

* Keep the inside of the box clean and dry.

Keep the lid slightly open, to air the box when

leaving the boat for any length of time.

* Keep the drainage in the box closed during

normal operation, if such is mounted.

Operation

Te mperature setting

The boxes are fi tted with a manually operated,

infi nitely-variable thermostat to operate the box within

refrigeration temperatures. This is turned clockwise

to reduce temperature and anti-clockwise to increase

temperature.

Turn the thermostat knob to the off-position, maximum

anti-clockwise, to stop the unit working.

The thermostat knob is placed inside the box.

Defrosting

Defrosting shall be made when the frost layer is more

than 3-4 mm thick. Turn off the unit with the thermostat

put into off-position. Store the foodstuff and the bottles

as cold as possible during the defrosting. Do not use

sharp metal objects to remove frost or ice. Do not restart until the box is completely defrosted and dried. Do

not forget to close the drainage if such is mounted,

Maintenance

The Isotherm boxes have a fully hermetic closed

cooling system and do not require any maintenance or

refi lling of refrigerant. The compressor is of domestic

type and has a very higheffi ciency and an outstanding

life-time. The box shall be left in the boat during the

winter. (If the temperature is below freezing point, the

compressor will not start).

The maintenance is reduced to periodically, not less

than a year, cleaning of the condenser from dust, on air

cooled units. Use a soft brush and no hard objects.

Keep the inside of the box. Use lukewarm water and

a mild cleaner for the inside. Put the lid, during not in

operation periods, in a slightly open ventilation position.

See also the Isotherm SP and Magnum installation

instructions.

Battery voltage sensor

To protect the batteries from becoming completely

discharged, a battery voltage sensor switches off the

compressor automatically at the following levels:

System voltage Cut-out Cut-in

12 9.6 alt. 10.4 10.9 alt. 11.7

24 21.3 alt. 22.8 22.7 alt. 24.2

Safety instructions and environment

- When connected to shore power, ensure that the

power supply is equipped with an automatic earth

leak switch. Danger!

- Never touch bare electric wiring connected to the

mains supply. Danger!

- Never connect a battery charger direct to the

refrigeration system. A battery charger must be

connected to the battery.

- In addition to acid, a newly-charged battery contains

explosive gas. Danger!

- Never open the refrigerant circuit except by the re operable quick couplings which are of self sealing

types and designed for this purpose.

- Never cover up the ventilation system for the

compressor unit.

- The refrigeration unit must be disposed by a

refrigeration specialist for correct recycling of

components and care taking of the refrigerant.

This appliance is marked according to the European

directive 2002/96/EC on Waste Electric and Electronic

equipment /WEEE). By ensuring this product is

disposed of correctly, you will help prevent potential

negative consequences for the environment and

human health, which could otherwise be caused by

inappropriate waste handling of this product.

The symbol on the product, or on the

documents accompanying the product, indicates that

this product may not be treated as household waste.

Instead it shall be handed over to the applicable

collection point for recycling of electrical and electronic

equipment. Disposal must be carried out in accordance

with local environmental regulations for waste disposal.

For more detailed information about treatment,

recovery and recycling of this product, please contact

your local city offi ce, your household waste disposal

service or the shop where you purchased the product.

GB

Page 4

Fault fi nding chart

Fault Possible cause Action

Box not cold. Compressor will not start.

Compressor starts but does not cool

the box.

Check that power is present at electronic unit.

Chech fuse.

Check polarity on connectors and cables.

Bridge the thermostat over T-C, see wiring diagram.

If compressor starts, this indicates a faulty thermostat.

If the compressor does nopt start, this indicates a faulty electronic

unit or compressor.

Contact an authorized service agent.

A possible leak in the cooling system, contact an autorized service

agent.

If a complicated fault does occur, such as those requiring specialist assitance, pleas contact Indel Marine S.r.l. Italy or your

local marine distributor for advise.

Indel Webasto Marine S.r.l.

Te l. +39 0541 848 030

Fax +39 0541 848 563

E-mail: info@indelwebastomarine.com

Installation instructions

Mount the box carefully and safe. It is vitally important,

on air cooled units, that the compressor and the

condenser are well ventilated and that cold air can

enter from below and warm air can leave the space

around the compressor unit. (Warm air is leaving

upwards).

Do not install the box close to warm areas as the stove,

heater or the engine.

See the separate additional installation instructions for

Isotherm SP when the refrigeration unit is equipped

with an SP through hull fi tting/heat exchanger and also

the separate installation instructions valid for boxes

having a “Magnum” compressor unit water cooled with

water pump.

Electrical connections

When connecting the box electrically, it is important

that following points are considered:

Always use cables of suffi cient area. The area in the

following table should be regarded as a minimum.

Wire area

mm² AWG

Max wire length

12V m / ft

Max wire length

24V m / ft

2.5 12 2.5 / 8 5 / 16

4 10 6 / 18 12 / 32

6 10 10 / 32 20 / 64

* Always connect the box directly to the battery or

to the battery main switch on the plus circuit. Do not

connect it via the boats own control panel or other

diversions as this can cause a voltage drop in the

power supply. Use the included fuse holder with a 15A

fuse. Use 7.5A fuse in a 24 volt system. The fuse

shall be mounted on the plus cable.

* Connect the red cable to the positive (+) terminal

and the black to the negative (-) terminal. Use tab

type terminals for the connection to the electronic

unit and other cable

connectors of suffi cient size for the cable size

selected.

* Do not connect the box direct to a battery charger.

The battery charger must be connected to the

battery.

Page 5

Technical data

Voltage: 12/24 Volt

Power consumption: Running compressor: 4 A (half for 24 V system).

Average consumption: 12 Volt: approx. 0.7 A (half for 24 V system) at +6°C in the

box and 22°C ambient temperature.

Compressor: Danfoss BD35F

Refrigerant: R134a

Fuse: 15 A for 12 V/7.5A for 24 V

Type designations: 3041BA2A00000 Air cooled compressor

3041BA2A00006 Air cooled compressor, Pipe with couplings and Click-on bracket

3041CA2B00000 SP-water cooled

Dimensions: Height 465 mm (625 incl. compressor), Width 340 mm, Deep 500 mm

Weight: 19 kg

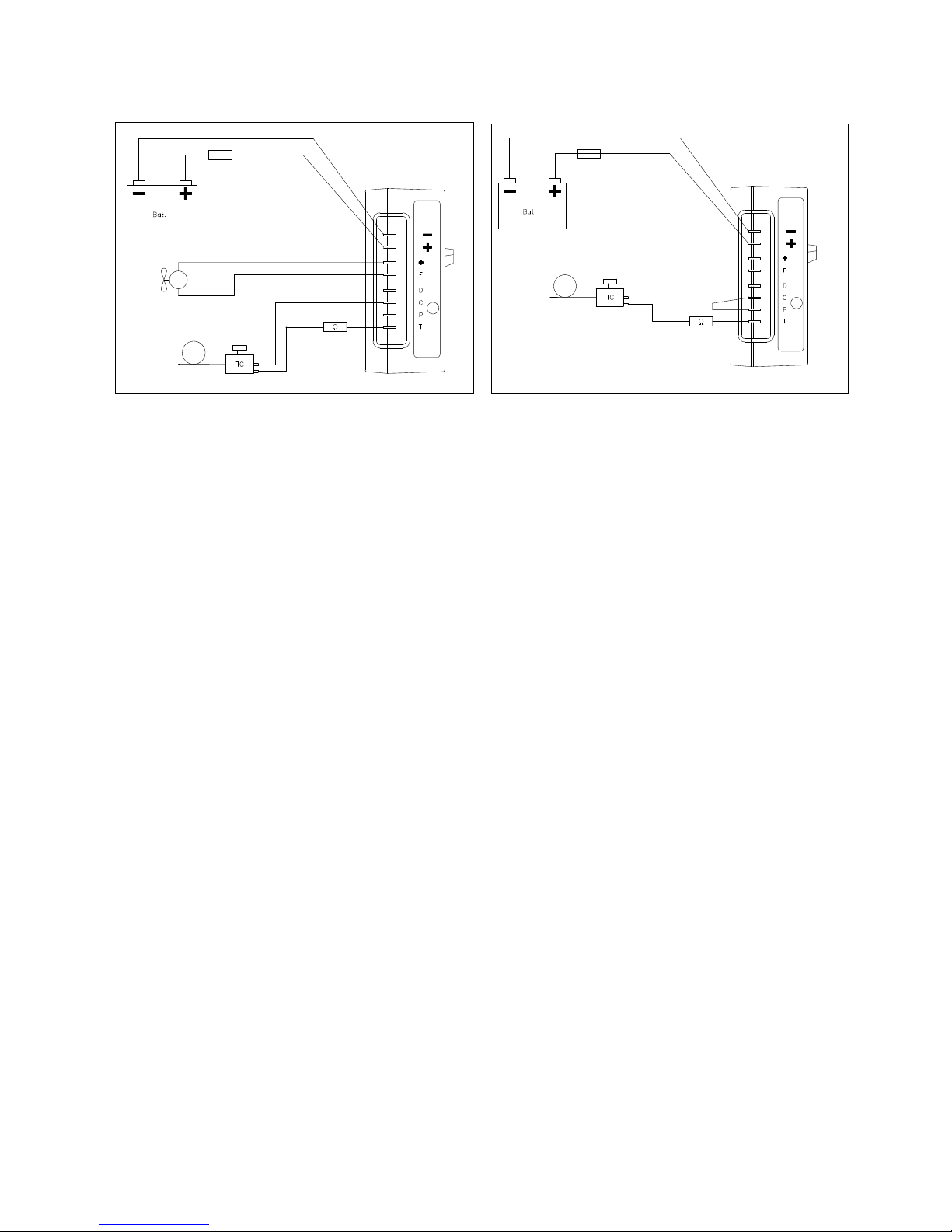

Wiring diagram

Air cooled Water cooled SP

Brown

Blue

Black

Red

Red

Black

Red

Black

Brown

Blue

000889-2

000890-2

Page 6

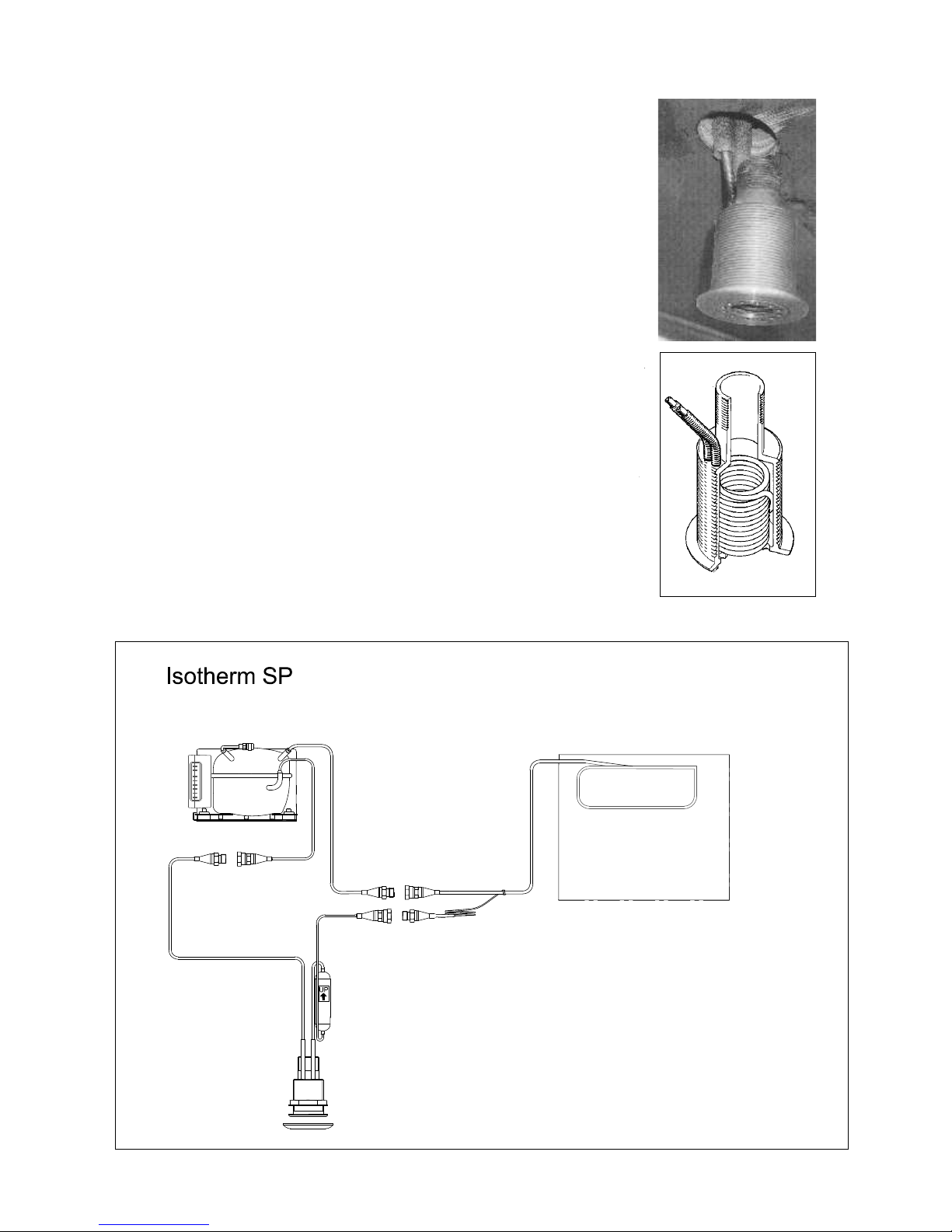

Isotherm SP Installation instructions

General

Isotherm SP is a sea water cooled refrigeration system for

sailing yachts and power boats. This unique system means

reduced power consumption and noise level. It has no fan

or pump. The sea water cooled skin fi tting/heat exchanger

replaces the air cooled condenser and cooling fan. The

heat is transferred directly to the surrounding water instead

of being circulated as hot air inside the boat.

Description

The special skin fi tting with its integrated condenser/heat

exchanger is mounted in the hull and is made of salt water

resistant brass with the heat exchanger coil in copper-nickel

alloy and replaces the existing skin fi tting for the sink drainage.

The connection pipes to the compressor have a length of 1

meter and are equipped with quick couplings. The couplings

can be opened and closed without loss of refrigerant. A fi lter

dryer is mounted approx. 20 cm (7¾”) above the skin fi tting

on the return pipe. A 1¼” ball valve should be mounted on

the skin fi tting.

Important! The hose between the sink and the ball valve shall be a minimum

of ø 38 mm (1½”). The skin fi tting is normally kept clean due to the constant

movement of the water and lack of sunlight. During sailing or motoring the

water will fl ash the fi tting and the heat exchanger coil rapidly, which will keep

it clean from marine growth. The skin fi tting shall be equipped with the zinc

anode on the outside and which is included in the delivery.

Operation

Always keep the ball valve open to ensure a satisfactory function.

If the ball valve is closed and the boat is in harbour, the fridge will operate at

a reduced cooling level.

During sailing or motoring the fridge will operate better but not to its full

potential with a closed valve. When the boat is on shore, the fridge system

will operate at a reduced level, in this case the ball valve must be kept open

to allow air ventilation through the hose and the sink.

Maintenance

When necessary clean the through hull fi tting, do not use sharp or hard tools, a brush will be enough. In a tropical

environment, cleaning of the fi tting has to be made more often. If necessary, the threaded bottom entrance

washer can be removed for better access to the heat exchanger coil.

Corrosion: Galvanic corrosion can often take place on board when the boat is surrounded by salt water and

should be carefully checked. This type of corrosion takes place depending on various electrical potential between

different devices. When two different metals are placed under water and connected to each other, electricity will

start to run. To prevent metal damages on parts under water, sacrifi ced anodes made of zinc are installed. Zinc is

a less noble metal compared to other materials used and will therefore be sacrifi ced.

All Isotherm refrigeration units have the plus and minus power supply separated from all chassis parts. Isotherm

SP has a skin fi tting in direct contact with the sea water and has as standard a zinz anode. The brass in the fi tting

is dezincifi cation and salt water resistant as well as the Cu/Ni condenser pipes and the soldering silver. The zinc

anode on the fi tting shall be inspected regularly and replaced as soon as half or more of the zinc is used. If it

is affected to a high degree and not lasting more than one season or part of a season, the electrical system on

board must be carefully checked to fi nd the reason for the galvanic or stray-current corrosion.

Make sure that the refrigeration system is connected to the electrical system in such a way, it cannot be

connected to the shore grounding when shore power is connected.

It is recommended to use an insulation transformer in the shore power system, to always be sure, boat and shore

grounding is separated.

When the boat is equipped with a central bonding system, the SP skin fi tting shall be connected to this with a 6

mm² copper cable. On the skin fi tting, there is a M5 hole for this purpose.

Page 7

Mounting

First of all, plan the installation!

The skin fi tting is to be mounted in the hull instead of existing fi tting for

the galley sink waste water. The hole in the hull shall have a diameter of

60 mm (2½”). When an existing skin fi tting is to be replaced, it is taken

away by the following method. Place a wooden plug in the fi tting from

outside, use a 60 mm (2½”) hole saw with a centre drill and cut out the

complete skin fi tting at the same time as the new hole is made. Put

through the connecting pipes and the fi tting from the outside, seal

carefully using Sikafl ex 291 or equivalent. The skin fi tting has a 32 mm

wrench grip on the inside part for easy tightening of the counter nut.

Bend aside the connection pipes to allow the 1¼” ball valve to be mounted,

which on the galley sink side shall have a hose serrated tail ø38 mm (1½”)

hose to be installed. As an option, there is a kit available, consisting of

a 1¼ ball valve, ø38 mm (1½”) hose adaptor and modifi cation kit for the

sink hose connection.

Part no. SFD 00008 AA.

Remember to use twin hose clamps below the water line level.

The compressor unit is most likely to be placed in the compartment

below the sink, in a suitable distance from the skin fi tting, not more

than one meter (3 ft.). The compressor shall be mounted horizontally.

The bracket allows a choice of mounting positions, standing or

bulkhead mounting. The compressor needs to be protected from

splashed water or water leaking from the sink at all times.

Connection diagram

Page 8

Installation Isotherm Magnum

compressor unit

Compressor unit

The compressor unit should be fi tted in a horizontal

position in a suitable place. The unit will operate

continuously at angles of up to 30° and should

therefore be fi tted horizontally so as nor to exceed this

at full angle of heel. The unit should be screwed down

well to withstand all possible sea conditions.

Installation can often be simplifi ed if the quick-coupling

connections on the piping and the compressor unit

are screwed up tight before the compressor unit is

fi n ally tightened down in its position. Do not remove

the protective caps until immediately before this is

about to be done and save them for future use if the

compressor unit for some reason must be moved. The

quick coupling connections can be turned by hand into

open position and fi rmly tightened after that with fi xed

spanners 21 and 24 mm. During the tightening, hold

the male coupling with the 21 mm spanner in position

and turn the other part, not to damage the thin capillary

tube. Tighten the couplings up hard.

Water pump

The water pump is self priming up to 2 m (6 ft.) suction

height. The power supply for the pump is reduced

down to 5 volt for low noise and long lifetime operation.

The voltage reducer set the speed of the pump

depending on water condenser temperature. after

the refrigeration system has been installed, the water

pump will at the fi rst start up run on a higher speed for

90 seconds to pick up water faster. This will happen

also when the unit has been powerless.

Sea water connection

The cooling water inlet to the pump must be connected

to a hull fi tting which allow cooling water to be fed to

the pump also when sailing in heavy weather. Suitable

hose dimension is 13 mm / ½”. A water fi lter is mounted

on the suction side. The strainer has an easy

replaceable cartridge. Clean this cartridge with short

intervals. The water outlet from the heat exchanger can

be connected to an existing hull fi tting, but must always

be open to allow a free fl ow through the system when

the pump is working.

Separate fi ttings for both in- and outlet for the

refrigeration system is always the best.

As an alternative to the sea water connection, the

fresh water tank on board can be used for cooling

the condenser/heat exchanger. If there is a fresh

water capacity of about 400 litres or more , the water

pump/condenser unit can be connected to the tank.

The heat exchange will not infl uence the fresh water

temperature, as long as the tank has 170-180 litres

or more. With less water a temperature rise of a few

degree C can be recognized.

Minimum water volume can be recommended to 140150 litres.

Water out

Water in

Zinc Anode

Water out

Water in

Maintenance

Maintenance of the compressor assembly is limited to

regular check-up and replacvement of the zinc anode,

cleaning water strainer and watwer pump. Change the

zinc anode at least once a year.

Drain the water system, including pump and fi lter, if

temperatures below freezing point are expected, or fi ll

up properly with anti-freeze.

001102

001103

Page 9

Wiring diagram Magnum compressor unit

Blue

Brown

Blue

Red

Black

Zona Artigianale sn

IT-61019 S. Agata Feltria (PU) - Italy

Phone +39 0541 848030 Fax +39 0541 848563

info@indelwebastomarine.com

www.indelwebastomarine.com

For service and technical support:

Indel Webasto Marine USA

Phone +1 954 772 8355

Fax +1 954 772 3839

Mail:info@indelwebastomarineusa.com

Thermoprodukter AB, Sweden

Phone +46 480 425 880

Fax +46 480 127 75 Mail:info@isotherm.se

Red

Black

Red

Te mp. sensor

001222

Black

Brown

Page 10

Isotherm Einbaubox 41 Liter

Allgemeines

ISOTHERM Kühlboxen, speziell entworfen und

produziert für die Anwendung im maritimen Bereich,

sind hervorragend in Leistung und Zuverlässigkeit.

Ausgestattet mit einem hermetisch abgeschlossenen

Kompressor, bieten sie geringsten

Energieverbrauch und niedrigsten Geräuschpegel. Alle

Modelle sind leicht zu installieren. BI 41. Sie können

bei einem Krängungswinkel bis zu 30 grad einwandfrei

arbeiten, sogar über längere Zeit. Damit Ihr Isotherm

Kühl so effektiv wie möglich arbeitet, beachten Sie bitte

die folgenden Richtlinien:

Unnötiges Öffnen die Box erhöht den

Energieverbrauch.

Eine gute Belüftung von Kompressor und

Kondensator an Luftgekühlte Anlagen, senkt den

Energieverbrauch.

Das elektrische System muss in einwandfreiem

Zustand sein. Kontrollieren Sie regelmäßig den

Ladezustand der Batterien. Verwenden Sie immer eine

separate Starter-Batterie für den Motor.

Beachten Sie die Vorschriften für das Verlegen

elektrischer Kabel und das Anbringen von

Sicherungen.

Halten Sie den Innenraum stets sauber und trocken.

Wenn Sie das Boot für längere Zeit verlassen,

lassen Sie der Deckel leicht offen, damit die Kühlbox

ausgelüftet wird.

Die Entwässerung in Normalbetrieb immer zu.

Betrieb

Te mperatureinstellung

Die Kühl/Gefrierboxen sind mit einem manuellen,

stufenlos einstellbaren Thermostat ausgerüstet.

Drehen in gegen den Uhrzeigerrichtung erhöht die

Te mperatur, drehen in Uhrzeigersinn reduziert die

Te mperatur.

Wenn der Thermostatschalter zurück auf die STOPStellung gedreht wird, is das Aggregat abgeschaltet.

Abtauen

Wenn die Eisschicht dicker als 4 mm ist, sollte

abgetaut werden. Lagern Sie die Lebensmittel

Während der Abtauphase so kalt wie möglich.

Verwenden Sie keine scharfkantigen Gegenstände,

um das Eis zu entfernen. Schalten Sie die Kühlbox

erst wieder ein, wenn er vollständig abgetaut und

getrocknet ist.

Wartung

Die Isotherm Kühlboxen besitzen ein hermetisch

abgeschlossenes Kühlsystem und benötigen deshalb

keine Wartung, Kühlmittel muss nicht nachgefüllt

werden. Der Kompressor ist sehr zuverlässig und

leistungsstark und besitzt eine lange Lebensdauer.

Über Winter sollte die Kühl/Gefrierbox im Boot

verbleiben. (Wenn die Tem peratur unter 0 Grad C

sinken, geht die Anlage nicht an).

Die Wartung beschränkt sich auf das Reinigen des

Kondensators einmal pro Jahr. (Nicht Wassergekühlte

Modellen). Verwenden Sie dazu eine weiche Bürste.

Halten Sie den Kühlboxinnenraum sauber. Nehmen Sie

lauwarmes Wasser und ein mildes Reinigungsmittel,

um ihn zu saubern.

Halten sie der Deckel einen Spalt offen, wenn die Kühlbox nicht in Betrieb ist, damit sie auslüften kann.

Sehe auch SP und Magnum Einbaueinweisungen.

Batteriespannungssensor

Damit die Batterien nie ganz leer werden, schaltet ein

Spannungssensor den Kompressor automatisch ab bei

folgenden Werten:

Stystemspannung Ausschalten Einschalten

12 V 9,6 Alt. 10,4 10,9 Alt. 11 ,7

24 V 21,3 Alt. 22,8 22,7 Alt. 24,2

Sicherheitshinweise

Beim Anschluss an Landstrom muss die

Stromversorgung geerdet und an einen Erdschluss

Schalter angeschlossen sein. Falsch ausgeführte

Elektroinstallationen können Lebensgefahr

bedeuten.

Berühren Sie niemals nichtisolierte oder beschädigte

Elektrokabel, die an das

Wechselstromnetz angeschlossen sind. Es besteht

Lebensgefahr!

Es dürfen keine Eingriffe in den Kühlmittelkreislauf

vorgenommen werden, außer an den

Schnellkupplungen, die sich wieder öffnen lassen.

Es muss verhindert werden, dass Kühlmittel in die

Atmosphäre entweichen kann.

Decken Sie die Belüftung der Kompressoreinheit

niemals ab.

Das Kühlwassersystem des Kühlaggregats darf

während des Betriebs nicht abgestellt oder

blockiert werden. (Gilt nur für wassergekühlte

Aggregate.)

Schließen Sie kein Batterieladegerät direkt an das

Kühlaggregat an. Batterieladegeräte

müssen immer an die Batterie angeschlossen werden.

Eine neugeladene Batterie enthält außer ätzender

Batteriesäure auch explosive Gase.

Eine spätere Verschrottung des Aggregates darf nur

vom Fachmann vorgenommen werden,

der die enthaltenen Bestandteile der

Wiederverwertung zuführt und das Kühlmittel korrekt

entsorgt.

In Übereinstimmung mit den Anforderungen der

Europäischen Richtlinie 2002/96/EG über

Elektro- und Elektronik-Altgeräte (WEEE) ist

vorliegendes Gerät mit einer Markierung

versehen. Sie leisten einen positiven Beitrag für

den Schutz der Umwelt und die Gesundheit des

Menschen, wenn Sie dieses Gerät einer gesonderten

Abfallsammlung zuführen.

D

Page 11

In unsortierten Siedlungsmüll könnte ein solches

Gerät durch unsachgemäße Entsorgung negative

Konsequenzen nach sich ziehen.

Auf dem Produkt oder der beiliegenden

Produktdokumentation ist folgendes Symbol

Einer durchgestrichenen Abfalltonne abgebildet. Es

weist darauf hin, dass eine

Entsorgung im normalen Haushaltsabfall nicht zulässig

ist. Entsorgen Sie dieses Produkt im

Recyclinghof mit einer getrennten Sammlung für

Elektro- und Elektronikgeräte.

Die Entsorgung muss gemäß den örtlichen

Bestimmungen zur Abfallbeseitigung erfolgen.

Bitte wenden Sie sich an die zuständigen Behörden

Ihrer Gemeindeverwaltung, an den lokalen

Recyclinghof für Haushaltsmüll oder an den Händler,

bei dem Sie dieses Gerät erworben haben, um weiter

Informationen über Behandlung, Verwertung und

Wiederverwendung dieses Produkt zu erhalten.

Fehler Möglische Ursache Maßnahmen

Kühlbox wird nicht kalt. Kompressor startet nicht.

Kompressor startet, aber

es erfolgt keine Kühlung.

Überprüfen Sie, ob Strom fl ießt am Anschluss.

Kontrollieren Sie Polarität und Sicherung.

Prüfen Sie alle Anshlüsse und Kabel.

Verbinden Sie an Elektronikteil Anschluss T und C.

Wenn der Kompressor startet, deutet dies auf einen Defekt im Thermostat.

Wenn der Kompressor nicht startet, liegt ein Fehler in der Elektronik

oder am Kompressor vor.

Kontaktieren Sie Ihre Werkstatt.

Kontaktieren Sie Ihren Händler bzw. Ihre zuständige Werkstatt.

Bei komplizierten Defekten, die einen Fachmann erfordert, Wenden Sie sich bitte an Indel Marine S.r.l. Italia, oder den entsprechenden Lieferanten.

Indel Webasto Marine S.r.l.

Te l. +39 0541 848 030

Fax +39 0541 848 563

E-mail: info@indelwebastomarine.com

Installationsanleitung

Die Box muss gut befestigt werden.

Es ist von größter Wichtigkeit, dass Kompressor und

Kondensator gut belüftet werden und daß kalte Luft am

Boden einströmen und Warme oben entweichen kann

(nicht für SP und Magnum Modellen).

Der Kompressor sollte senkrecht im Boot stehen, er

arbeitet aber bei einem Krängungswinkel bis zu 30

Grad über einen gewissen Zeitraum einwandfrei.

Sehe auch Montageanweisungen für SP und Magnum

Ausführungen.

Elektrische Anschlüsse

Wenn Sie die Kühlbox anschließen, müssen Sie

folgendes beachten:

Verwenden Sie immer die richtige Kabelgröße

(korrekten Kabelquerschnitt).

Folgende Maße werden als Minimum verlangt:

Kabelquerschnitt

mm²

Maximale Kabellänge in m - 12V

Maximale Kabel-

länge in m - 24V

2,5 2,5 5

4 4 8

6 6 12

Schließen Sie die Kühlbox immer direkt an

der Batterie oder am Batteriehauptschalter, positiver

Stromkreis, an. Schließen Sie nicht über das

Schaltbrett des Bootes oder andere Umwege an, dies

kann zu Spannungsabfall führen.

Verwenden Sie die beigefügte Sicherungsfassung mit

15A Sicherung.

Wird ein Schalter installiert, muss dieser auch für mind.

15 A ausgelegt sein.

Schließen Sie das rote Kabel am positiven (+) und

das schwarze Kabel am negativen (-) Anschluss an.

Verwenden Sie der Kabelgröße entsprechende

Kabelanschlüsse.

Schließen Sie die Kühlbox niemals direkt am

Batterieladegerät an. Der Batterielader

muss an der Batterie angeschlossen werden.

Page 12

Schaltplan

Kompressor luftgekühlt Kompressor wassergekült SP

Technische Daten

Spannung: 12/24 Volt

Stromverbrauch: 4 A wenn Kompressor läuft (die Hälfte für 24 V),

Mittlerer verbrauch: 12 V: 0,7A, (die Hälfte für 24 V) bei Tem peratur in der Box +6°C,

Umgebungstemperatur +22°C.

Kompressor: Danfoss BD35F

Kältemittel: R134a (Füllmenge gemäß Etikette am Kompressor).

Sicherung: 15A für 12 V bzw. 7,5A für 24 V

Bezeichnungen: 3041BA2A00000 - 12/24 V Kühlbox, Luftgekühlt

3041BA2A00006 - 12/24 V Kühlbox Luftgekühlt, längere Rohre mit Kupplungen.

3041CA2B00000 - 12/24 V Kühlbox, SP Wassergekühlt

Abmessungen: Höhe 465 mm (625 mit Kompressor unten), Breite 340 mm, Tiefe 500 mm

Gewicht: 19 Kg

Rot

Rot

Schwarz

Braun

Blau

Schwarz

Rot

Braun

Blau

Schwarz

Page 13

Isotherm SP Montageanleitung

Allgemein

Isotherm SP ist ein Seewassergekühltes, besonders

energiesparendes Kühlaggregat zum Einbau in Booten.

Der übliche luftgekühlte Kondensator und der zuweilen

darin angebrachte Kühlventilator werden hier durch einen

Seewassergekühlten Borddurchlass/Wärmetauscher ersetz.

Ausführung

Der Borddurchlass mit dem integrierten wassergekühlten

Kondensator/Wärmetauscher wird in den Rumpf montiert.

Er besteht aus salzwasserbeständigem Messing. Die

Rohrschlange des Wärmetauschers ist aus einer KupferNickel-Legierung gefertigt.

Der Kühldurchlass ersetzt den vorhandenen Borddurchlass

für den Spülbeckenablauf in der Pantry.

Die Verbindungsrohre zum Kompressor sind 1 m lag und

mit Schnellkupplungen versehen. In einer Höhe von ca. 20

cm ist ein Filter/Trockner am Retourrohr montiert. Am

Borddurchlass wird ein 1¼“-Kugelventil an- gebracht.

Wichtig: Der Schlauch zwischen Spülbecken und Kugelventil sollte

mindestens einen Durchmesser von 38 mm haben. Der Borddurchlass ist

normalerweise selbstreinigend. Der ständige Wasseraustausch und die

Dunkelheit bilden ein ungünstiges Klima für Bewuchs.

Beim segeln oder laufen unter Motor entstehen interne Kaskaden, die den

Durchlass sauber halten. Der Borddurchlass soll auf der Außenseite mit

einer Opferanode versehen werden. Es ist in der Lieferung mit.

Funktion

Das Kugelventil muss immer geöffnet sein, damit Kühlsystem zufrieden

stellend arbeitet.

Wenn das Ventil geschlossen ist, funktioniert die Kühlung beim Liegen

am Steg mangelhaft, da das Wasser um die Rohrschlange stillsteht. Beim

segeln oder laufen unter Motor mit geschlossenem Ventil funktioniert die

Kühlung befriedigend, da das Wasser zumindest bei SeegangTurbulenzen

im Borddurchlass bildet. Steht das Boot auf Land, funktioniert die Kühlung,

jedoch nicht optimal. Das Kugelventil muss in diesem Fall geöffnet sein,

damit der erwärmte Luft hindurchströmen und hinauf in das Spülbecken

gelangen kann.

Wartung

Die Wartung beschränkt sich auf eine Reinigung der Rohrschlange

des Borddurchlasses bei Bedarf. Bitte vermeiden Sie Gewalt und harte

Werkzeuge. Verwenden Sie stattdessen eine Weiche Bürste. Bei Bedarf

kann die Mündungsscheibe abgeschraubt werden. Die Opferanode soll

regelmäßig nach Bedarf ausgetauscht werden. Zink Anode Teilnummer:

SBE00006AA

Korrosionsangriff:

Galvanische Korrosion kann oft auf Booten in Salzwasser passieren, durch

die unterschiedlichen elektrischen Potentiale von verwendete Materialen.

Dafür soll die Opferanode (Zink) immer auf dem Borddurchlass als

Korrosionsschutz montiert werden.

Kontrollieren Sie, dass das Kühlaggregat im Elektrosystem abgetrennt

ist, so dass keine Erdung zum Land, sondern nur zum Boot besteht.

Wenn ein zentral Masseschwamm im Rumpf montiert ist, soll auch die SP

Borddurchlass an diesen angeschlossen werden. (M 5 Schraub)

Page 14

Alle Isotherm Kühlaggregate haben Stromversorgung, + und -, separiert von

Metallteilen. Der Isotherm SP Borddurchlass hat direkte Verbindung mit Wasser und

die Zinkanode wird vor allem bei der Neuinstallation von Isotherm SP empfohlen.

Nach der ersten Saison besteht Klarheit darüber, ob auch in Zukunft eine Zinkanode

benötigt wird. Wenn diese nach der ersten Saison stark korrodiert ist, gilt das als

Warnsignal! Fehler aufweist, die galvanische Ströme über den Borddurchlass

verursachen. Zeigt die Zinkanode nach der ersten Saison keine nennenswerte

Korrosion, ist alles in Ordnung.

Eine montierte Zinkanode ist jedoch ein guter Indikator für den Zustand des

Elektrosystems.

Kontrollieren Sie, dass das Kühlaggregat im Elektrosystem abgetrennt ist, so

dass keine Erdung zum Land, sondern nur zum Boot besteht. Wenn ein zentral

Masseschwamm im Rumpf montiert ist, soll auch die SP Borddurchlass an diesen

angeschlossen wird. Verwenden Sie mindestens

6 mm² Kupferkabel. (M 5 Schraub)

Verwendung von eine Isolations-Transformator in der Landstromanlage ist zu

empfehlen. Galvanische Trennung wird durch den Einbau eines

Isolations-Transformators erreicht.

Montage

Beginnen Sie mit der Planung der Installation!

Der Borddurchlass wird statt des vorhandenen Durchlasses für den Spül-ablauf der

Pantry im Rumpf montiert. Die Öffnung im Rumpf muss 60 mm im Durchmesser

betragen. Wenn ein vorhandener Durchlass ersetzt werden soll, wird der alte

Durchlass entfernt wie folgt: Drücken Sie einen Holzpropfen in den Durchlass, so

dass Sie mit einer Lochsäge Ø 60 mm mit Zentrumbohrer den alten Durchlass

vollständig wegbohren können. Gleichzeitig erhalten Sie eine Öffnung mit den

richtigen Maßen für den neuen Durchlass. Die Verbindungsrohre mit Kupplungen

und Filter werden von außen durch die Öffnung im Rumpf geführt. Dichten Sie

Sorgfältig mit Sikafl ex o.ä., wenn Sie den neuen Durchlass festziehen. Dieser ist auf

der Innenseite mit einem Schlüsselgriff, 42 mm, versehen, damit Sie beim Anziehen der Mutter auf der

Innenseite dagegenhalten können. Biegen Sie danach die Rohre so weit zur Seite, dass Sie ein 1¼“-Kugelventil

montieren können. Bringen Sie einen Schlauchnippel für einen Ø 38 mm Schlauch auf dem Kugelventil an und

montieren Sie dieses am Durchlass.

Gegebenenfalls muss der Spülablauf für einen Ø 38 mm Schlauch angepasst werden. Ändern Sie den

Spülablauf mit helfe von Adapter und Rohr.

Als Zubehör: Einbausatz mit Kugelventil und Spülablaufumbausatz,

Te il Nr. SFD00008AA.

Bitte denken Sie daran, unterhalb der Wasserlinie doppelte Schlauch-Klemmen zu verwenden.

Der Kompressor wird am besten in der Nähe des Borddurchlasses montiert, normalerweise unter der Spüle. Er

wird waagerecht mit den Befestigungsfüßen nach unten angebracht. Die Konsole ist so geformt, dass sie auf

eine ebene Unterlage gestellt, an ein Schott gehängt werden kann. Montieren Sie die Kompressoreinheit so,

dass sie gegen Spritzwasser und eventuelle Ausfl üsse von einer undichten Spüle geschützt ist.

Isotherm SP

Einkupplungsplan

Page 15

Montage Isotherm Magnum

Kompressoreinheit

Kompressor

Die Kompressoreinheit soll in einem geeigneten

Raum waagerecht montiert werden. Schrauben Sie

die Bodenplatte ordentlich auf einer Unterlage fest.

Benutzen Sie alle mit Gummifüßen versehenen

Montageöffnungen.

Die Kompressoreinheit muss gut verankert werden und

darf sich auch bei jedem erdenklichen Seegang und

Schräglagen nicht lösen.

Oft ist es am einfachsten, erst die Schnellkupplungen

des Anschlussrohres und der Kompressoreinheit

zusammenzuziehen, bevor die Kompressoreinheit

endgültig angebracht wird. Die Schnellkupplungen

werden erst per Hand zusammengeführt und dann

mit festen 21 und 24 mm Schlüsseln nachgezogen.

Halten Sie auf der Steckerseite immer dagegen, damit

das dünne Kapillarrohr nicht rotieren und beschädigt

werden kann. Nehmen Sie die Schutzkappen erst

ab, wenn die Kupplungen miteinander verbunden

werden sollen. Sorgen Sie dafür, dass die Kupplungen

sauber und trocken sind, bevor sie zusammengezogen

werden. Heben Sie die Schutzkappen auf, falls das

Aggregat aus irgendeinem Grund später umgesetzt

oder demontiert werden soll. Achten Sie darauf, dass

die Elektronikteile und Kabel an der Kompressoreinheit

gegen mechanische Einwirkung geschützt sind.

Seewasseranschluss

Der wassergekühlte Kondensator der KompressorEinheit soll an das Seewasser angeschlossen werden..

Der Borddurchlass zum Einlauf sollte so placiert

werden, dass der Wasserzufl uss auch beim Segeln

störungsfrei funktioniert. Wenn der Wasserzufl uss

nicht funktioniert, tritt eine Fehlfunktion auf, und der

Kompressor haltet an. Es startet erneut, wenn der

Wasserfl uss wieder störungsfrei funktioniert. Der

Auslauf muss so gestaltet werden, dass er nie blockiert

werden kann, wenn er mit einem anderen Auslauf

zum selben Borddurchführung kombiniert wurde. Der

Auslauf darf nicht an der Spühlablauf oberhalb des

Schließventils angeschlossen werden. Am bestens

ist es, für das Kühlaggregat immer separate Einund Ausläufe zu montieren. Die Pumpe leistet eine

Saughöhe von 2 m.

Der Stromzuführ der Wasserpumpe hat einen

Spannungsreduzierer, um die Drehzahl der Pumpe zu

senken und damit leiseren Betrieb zu ermöglichen.

Wenn nach der Installation Schwierigkeiten in der

Kühlwasserzirkulation auftreten, weil die Pumpe

trocken oder das System geleert worden war, läuft

die Pumpe 90 Sekunden automaitsht schneller. Der

Spannungsregler gibt 5 bis 9,5 Volt unabhängig davon,

dass der Eingang 10 - 30 Volt hat. Die Spannung

(Pumpendrehzahl) ist von Kondensatortemperatur

geregelt. Reiningen Sie gerne mit kurz Intervall das

Wasserfi lter auf der Kühlwasserpumpe. Schmutz im

Kühlwasserkreislauf reduziert die Kühlleistung.

Wartung

Wenn die Schnellkupplungen während der

Installation korrekt angezogen wurden, braucht

das abgeschlossene Isotherm System nie mehr mit

Kühlmittel aufgefüllt werden. Wartung ersteckt sich

im Prinzip nur auf das Wegbürsten von Staub und

Schmutz an der Kompressoreinheit und regelmäßig

(mindestens einmal pro Jahr) die Zinkanode des

Wasserkondensators zu überprüfen und bei Bedarf

auszutauschen. Spülen Sie den Kondensator gründlich

aus, bevor Sie die neue Zinkanode montieren.

Entwässern Sie die Wasserpumpe, den WasserKondensator und die Wasserleitungen bei FrostGefahr und Winterlagerung bzw. füllen Sie mit FrostSchutzmittel.

Wasser aus

Wasser ein

Zinkanode

Wasser aus

Wasser ein

001102

001103

Page 16

Anschlussplan Magnum Kompressoreinheit

Blau

Braun

Blau

Rot

Schwarz

Rot

Schwarz

Schwarz

Rot

Te mp. Sensor

Zona Artigianale sn

IT-61019 S. Agata Feltria (PU) - Italy

Phone +39 0541 848030 Fax +39 0541 848563

info@indelwebastomarine.com

www.indelwebastomarine.com

Für kundendienst auch:

Thermoprodukter AB, Schweden

Phone +46 480 425 880

Fax +46 480 127 75

E-mail:info@isotherm.se

Braun

001222

Page 17

Isotherm Inbyggnadsbox BI 41

Allmänt

Isotherm kylboxar är helt konstruerade efter de

höga krav som ställs i marin miljö, både vad gäller

prestanda och utförande. De har en modern hermetisk

helt läckagefri kompressor som ger såväl lägsta

strömförbrukning som i det närmaste ljudlös gång.

Boxarna är enkla att bygga in och installera. De tål

en lutning på upp till 30º, tillfälligt mer. Köldmediet är

freonfritt, R 134a.

För bästa funktion är det viktigt att följande punkter

beaktas:

Undvik onödigt ”spring” i boxen. Det höjer

strömförbrukningen.

God ventilation av kompressor och kondensor på

de luftkylda aggregaten har också stor inverkan på

strömförbrukningen.

Ett väl fungerande elsystem är en förutsättning.

Se över batterier och laddning regelbundet. Ha alltid ett

separat startbatteri för motorn. Följ anvisningarna

vad gäller kabelarea och säkringsplacering.

Håll rent och torrt i boxen. Öppna locket på glänt för

vädring under vintern, eller då boxen lämnas avstängd.

Dräneringen i botten på boxen, om sådan fi nns

monterad, skall vara stängd vid normal drift.

Bruksanvisning

Temperaturreglering

Med termostaten kan man steglöst reglera

temperaturen i boxen inom normala kyltemperaturer

enligt följande: vrids termostaten medurs blir det

kallare och vrids den moturs blir det varmare i boxen.

Te rmostaten är placerad på insidan av boxen. För

att stänga av boxen, vrid termostaten till O-läget max

motsols. Ett tydligt motstånd ska passeras till avstängt

läge.

Te mperaturer ner till ca. −10°C kan nås med

termostaten inställd på max kyla, men boxen är i första

hand avsedd att användas som kylbox.

Avfrostning

Avfrostning skall ske då en tjock (över 4 mm)

beläggning fi nns på boxens väggar. Stäng av

på termostatvredet, genom att vrida det till varmaste

läget. Förvara de matvaror och drycker som fanns

i boxen så kallt som möjligt i t.ex. frysväskor el. dyl.

under tiden avfrostningen äger rum. Använd inga vassa

föremål för att avlägsna isen.

Starta inte boxen igen förrän den är fullständigt

avfrostad och urtorkad.

Glöm ej att stänga igen dräneringen efter

avfrostningen, om sådan är monterad.

Underhåll

Isotherm kylboxar har ett helt hermetiskt slutet

kylsystem med lödda ledningar och förslutningar

och behöver inget underhåll och behöver heller

aldrig påfyllning av köldmedium. Kompressorn är av

hushållstyp och har förutom mycket hög verkningsgrad

en i särklass lång livslängd.

Boxen skall sitta kvar i båten under vintern (men förmår

dock inte alltid starta vid minusgrader). Underhållet

inskränker sig till att regelbundet och vid behov på

de luftkylda aggregaten göra rent kompressorns

kondensorgaller från damm med en pensel el. dyl.

Håll boxen ren invändigt, speciellt viktigt då boxen

tömmes och stängs av. Använd ej rengöringsmedel

som innehåller lösningsmedel. Ställ upp luckan i

vädringsläge då kylsystemet är avstängt under en

längre tid.

Se också monteringsanvisningarna för Isotherm SP

och Magnum.

Batterivakt

För att skydda batterierna mot urladdning slår en

batterivakt ifrån kompressorn vid för låg spänning enligt

följande:

Systemspänning Frånslag volt Tillslag volt

12 V 9,6 (alt. 10,4) 10,9 (alt. 11,7)

24 V 21,3 (alt 22,8) 22,7 (alt 24,2)

Om bygling mellan C & P tas bort gäller värden inom

parantes.

Säkerhetsföreskrifter

Vid anslutning till landström måste strömförsörjningen

vara jordad och ansluten till jordfelsbrytare, annars

föreligger stor risk för personskada. Fel kan medföra

livsfara!

Vidrör ej frilagda kablar från nätanslutningar. Fel kan

medföra livsfara!

Ingrepp i köldmediekretsen får absolut inte göras.

Köldmedium får ej släppas ut i luften.

Se till att ventilationssystemet inte blockeras.

Anslut inte batteriladdare direkt till kylaggregatet.

Batteriladdare måste kopplas till batteriet.

Vid skrotning av anläggningen i framtiden, skall den

lämnas till fackman för korrekt återvinning av ingående

komponenter och omhändertagande av köldmedium.

Denna produkt är märkt enligt EG-direktiv 2002/96/

EEC beträffande elektriskt och elektroniskt avfall

(WEEE).

Genom att säkerställa en korrekt kassering av denna

produkt bidrar du till att förhindra potentiella, negativa

konsekvenser för vår miljö och vår hälsa, som annars

kan bli följden om produkten inte hanteras på rätt sätt.

Symbolen på produkten, eller i medföljande

dokumentation, indikerar att denna produkt inte

får behandlas som vanligt hushållsavfall. Den skall

istället lämnas in på en lämplig uppsamlingsplats

för återvinning av elektrisk och elektronisk

utrustning. Produkten måste kasseras enligt lokala

miljöbestämmelser för avfallshantering.

För mer information om hantering, återvinning och

återanvändning av denna produkt, var god kontakta de

lokala myndigheterna, ortens sophanteringstjänst eller

butiken/företaget där produkten inhandlades.

S

Page 18

Felsökningsschema

Felindikering Möjlig orsak Åtgärd

Boxen blir ej kall. Kompressorn startar inte.

Kompressorn startar

men ger ingen kyla.

Kontrollera att ström fi nns fram till elboxen. Kontrollera

säkringen. Kon-trollera att + och - ej förväxlats och

elkablar och kabelanslutningar.

Överbrygga termostaten, startar kom-pressorn då, är

termostaten felaktig.

Om åtgärderna i övrigt inte avhjälpt felet, kontakta

auktoriserad serviceverkstad.

Kontakta auktoriserad serviceverkstad.

Vid komplicerade fel, som ofta fordrar specialist, kontakta gärna Thermoprodukter AB, Kalmar, eller

aktuell importör.

Thermoprodukter AB,

Tel . 0480-425 880

Fax 0480-127 75

E-post: service@isotherm.com

www.isotherm.se

Installationsanvisning

Boxen skall sättas fast ordentligt i det utrymme som

valts för monteringen. Det är viktigt att kompressorn

och dess kondensor får bra ventilation (gäller ej

vattenkylda boxar i SP-utförande eller med vattenkyld

kompressordel typ Magnum). Man skall därför se till

att kall luft kan tillföras undertill för att sedan släppas

ut upptill (varm luft stiger uppåt). Installera inte boxen

nära värmekällor såsom spis, värmare, motor eller

dylikt. Kompressorn skall i sitt normala läge stå rakt i

båten. Den klarar lutningar upp till 30°, tillfälligt mer.

Se också de separata installationsanvisningarna för

Isotherm SP och Magnum.

Elanslutning

Vid inkoppling till båtens elsystem är det mycket viktigt

att hänsyn tas till följande punkter:

- Använd väl tilltagen kabelarea, se tabellen:

Kabelarea mm² Max längd m 12V Max längd 24V

2,5 2,5 5

4 4 8

6 6 12

Anslut alltid pluskabeln direkt till batteriet alternativt via

huvudströmbrytaren. Undvik anslutning till

standardmonterad elpanel eller dyl. då dessa ofta kan

förorsaka spänningsfall.

Använd den medlevererade säkringshållaren.

Elsystemet avsäkras med en 15 Amp säkring för 12 V

och 7.5 Amp för 24 V.

Koppla röd kabel till elsystemets plussida och den

svarta kabeln till minussidan.

Använd rejäla kabelskor anpassade för den valda

kabelarean.

Boxen får inte anslutas direkt till batteriladdare, utan att

ha ett batteri kopplat parallellt.

Page 19

Tekniska Data

Spänning: 12/24 volt

Strömförbrukning: 4 A (hälften vid 24 volt) då kompressorn går.

Medelförbrukning: 0,7 A (hälften vid 24 volt) vid +6°C i boxen och 22°C omgivningstemperatur.

Kompressor: Danfoss BD35F

Köldmedium: R 134a (Fyllnadsmängd enligt etikett på kompressorn).

Säkring: 15 A-12V/7.5 A-24V

Typ beteckningar: 1410G - 12/24 V Kylbox med luftkyld kompressor

1411G - 12/24 V Kylbox luftkyld med förlängt anslutningsrör och kopplingar

1415G - 12/24V Kylbox med SP-kyld kompressor

1416G - 12/24 V Kylbox vattenkyld med Magnum kompressordel

Dimensioner: Höjd 465 mm (625 med kompressor monterad under), bredd 340 mm, djup 500 mm

Vikt: 19 kg

Elschema

Luftkyld Vattenkyld SP

Svart

Röd

Svart

Röd

Brun

Blå

Svart

Röd

Brun

Blå

Page 20

Isotherm SP Monteringsanvisning

Allmänt

Isotherm SP är ett vattenkylt speciellt energisnålt kylaggregat

avsett för inbyggnad i båtar. Den sjövattenkylda bordgenomföringen/värmeväxlaren ersätter den normalt luftkylda

kondensorn och i förekommande fall kylfl äkten, placerad på

kondensorn.

Utförande

Bordgenomföringen med den integrerade vattenkylda

kondensorn

monteras genom skrovet. Den är utförd i saltvattenbeständig mässing med värmeväxlarens rörslinga i kopparnickel legering.

Den ersätter den befi ntliga bordgenomföringen till vaskavloppet i pentryt. Förbindelserören till kompressorn är 1 m

långa och försedda med snabbkopplingar som kan öppnas

och förslutas utan att köldmedium går förlorad.

Ett torkfi lter är monterat ca 20 cm upp på returröret. En 11/4”

kulventil skall monteras på bordgenomgföringen.

Viktigt: Slangen mellan vasken och kulventilen ska ha en

innerdiameter på minst 38 mm. Bordgenomföringen är normalt

självrensande, det är ständig vattenväxling och mörkt, vilket är

ogynnsamt för beväxning. Vid segling eller motorgång blir det

interna ”kaskader” som håller rent. Bordgenomföringen ska

förses med den medlevererade offeranoden på utsidan. En

offeranod ingår i leveransen.

Funktion

Kulventilen skall alltid vara öppen för att kylsystemet skall fungera

tillfredsställande. Med ventilen stängd fungerar kylen dålig om båten

ligger stilla, då vattnet kring rörslingan inne i genomföringen i så fall

blir stillastående. Vid segling eller motorgång med stängd ventil

fungerar den hyggligt eftersom vattnet kommer att bli turbulent i bordgenomföringen, i varje fall i sjögång. Med båten på land fungerar kylen, men ej optimalt. Kulventilen ska då vara

öppen så att uppvärmd luft kan strömma igenom och komma upp i vasken.

Underhåll

Underhållet inskränker sig till att vid behov göra ren bordgenomföringens rörslinga. I tropiska klimatområden

måste detta göras med tätare intervall. Använd inte våld och hårda verktyg, använd mjuk borste. Vi behov kan

mynningsbrickan (med de små hålen) gängas bort, för bättre åtkomlighet kring rörslingan.

Korrosionsangrepp: Galvanisk korrosion kan ofta uppstå ombord i en båt som omges av saltvatten och skall

ägnas särskild uppmärksamhet. Denna typ av korrosion uppstår som en följd av elektrisk potentialskillnad som

orsakar materialvandring. För att förhindra materialangrepp på de metalldelar som är i kontakt med saltvatten,

direkt, eller bara genom miljön, så monteras offeranoder. Dessa är av zink som befi nner sig långt ner på

metallers spänningsskala och får korrodera och lämna ifrån sig material under kontrollerade former och som

därför regelbundet måste bytas ut. Om den angrips snabbt och inte räcker mer än en eller två säsonger, skall

båtens elsystem undersökas för att avslöja eventuella krypströmmar som orsakar s.k. läckströmskorrosion.

Zinkanodens reservdelsnummer är: 39051

Om båten är utrustad med ett centralt jordplan (jordplatta) monterat i skrovet, där samtliga genomföringar är

anslutna till gods, skall också SP-genomföringen anslutas. Det fi nns ett M5 skruvhål på genomföringen för detta

ändamål. Använd minst 6 mm² kabel.

Om båten har landströmsanslutning, rekommenderas att denna är försedd med en skiljetransformator eller

likvärdig utrustning för att förhindra potentialskillnad mellan landjord och båt.

Alla Isotherm kylanläggningar har strömtillförselns plus och minus separerad från alla chassidetaljer. Isotherm

SP som har en bordgenomföring i direkt kontakt med havsvatten har som standard en offeranod av zink.

Bordgenomföringen är gjord i avzinkningshärdad och saltvattenbeständig mässing. Kondensorröret som är av

Cu/Ni, liksom silvret i lödningarna offeranoden på Isotherm SP ska kontrolleras regelbundet och byts ut då mer

än hälften av materialet är förbrukat. Om den angrips snabbt och inte räcker mer än en eller två säsonger, skall

man undersöka båtens elsystem för att avslöja eventuella krypströmmar som orsakar läckströmskorrosion.

Page 21

Montering

Planera först installationen!

Bordgenomföringen monteras i skrovet i stället för den befi ntliga genomföringen

för avloppet från vasken i pentryt. Hålet i skrovet skall vara ø 60 mm. När den

befi ntliga genomföringen skall ersättas tas den gamla bort genom att en

träplugg trycks in i genomföringen från utsidan, så att en hålsåg ø 60 mm med

centrumborr kan användas för att borra bort den gamla genomföringen helt

och hållet, samtidigt som ett hål med rätt diameter erhålles för den nya

genomföringen. Förbindelserören med kopplingar och fi lter träs utifrån upp

genom hålet i skrovet. Täta noggrant med Sikafl ex 291 eller motsvarande

då den nya genomföringen dras fast. Den har ett nyckelgrepp (NV42) på

insidan så att man kan hålla emot då muttern dras åt på insidan.

En 1¼” kulventil skall monteras på genomföringen. Montera först en rak

slangnippel för ø 38 mm slang på kulventilen, täta ordentligt, t.ex. med

LocTite 577. Vik undan rören på genomföringen tillräckligt för att kunna

montera kulventilen. Täta ordentligt. Vaskavloppet måste också i

förekommande fall ändras för att passa mot ø 38 mm slangen. Som tillbehör

fi n ns en monteringssats med en kulventil 1¼”, ø 38 mm slangnippel och

adapter till vasken. Artikelnummer: 39052.

Kom ihåg att använda dubbla slangklammer under vattenlinjenivån!

Slangen från bordgenomföringen upp till vasken ska dras så vertikalt som

möjligt, så att vattnet har fri rörelseförmåga upp och ner i slangen.

Kompressorn monteras lämpligen i närheten av bordgenomföringen,

normalt i utrymmet under vasken. Kompressorn monteras vågrätt med

gummifötterna nedåt. Konsolen är utformad så att den kan stå på ett plant

underlag eller hängas på ett skott. Montera kompressorn så att främst

elektronikdelarna skyddas från fukt och stänkvatten.

Hopkopplingsschema

Page 22

Kompressor

Kompressordelen skall monteras vågrätt med bottenplattan nedåt i något lämpligt utrymme. Kompressorn

kan arbeta kontinuerligt i lutningar upp till 30°. I segelbåtar skall därför kompressordelen monteras i helt

vågrätt läge för att under segling tåla lutningar i alla

riktningar. Kompressordelen skall vara väl fastsatt och

förankrad i underlaget i den rostfria bottenplattans

samtliga fästhål för att klara alla tänkbara skakningar

och stampningar. Många gånger kan det vara enklast

att dra ihop kompressordelens och anslutningsrörets

snabbkopplingar innan kompressorn slutgiltigt satts

på plats. Snabbkopplingarna kan dras ihop helt och

hållet för hand och sedan efterdras ordentligt med

fasta nycklar 21 och 24 mm. Håll alltid emot med

21:an på hankopplingen, så att denna inte tillåts

rotera och skada det tunna kapillärröret. Tag inte

bort kopplingarnas skyddshattar förrän det är dags

att dra ihop kopplingarna. Det är av största vikt att

kopplingarna är rena och torra när de dras ihop.

Spara skyddshattarna ifall ni senare av någon

anledning skall dela systemet igen.

Om kompressordelen monteras i t.ex. något

stuvutrymme kan det vara nödvändigt att skydda

den så att den inte skadas mekaniskt av annat som

förvaras på samma ställe.

Sjövattenanslutning

Den sjövattenkylda kondensorn på kompressordelen

skall anslutas till sjövattnet. Bordgenomföringen till

inloppet ska vara så placerad att vattentillströmningen

också fungerar störningsfritt under segling. Om

vattentillströmningen inte fungerar uppstår en

felfunktion och kompressorn stannar, men återstartar

när kylvattenfl ödet åter fungerar. Utloppet måste vara

så utfört att det inte vid något tillfälle kan blockeras,

om det kombineras med annat utlopp till samma

bordgenomföring. Bäst är alltid separata in- och utlopp

enbart för kyl-aggregatet. Kompressorenheten kan

placeras upp till 2 m över vattennivån.

För att åstadkomma en så tyst drift som möjligt är

elsystemet försett med en spänningsänkare som matar

vattenpumpen med ström. Spänningssänkaren lämnar

5 - 9,5 volt till pumpen vid en spänning in på 10-32 volt.

Pumpen är varvtalsstyrd efter kylbehov med

variabel spänning, och styrs av temperaturen i

vattenkondensorn. Vid elektrisk inkoppling av

aggregatet första gången eller efter ett spänningslöst

tillstånd, varvar pumpen upp automatiskt under 90

sekunder för att snabbare ta upp vatten.

Rengör fi ltret med täta intervall. Det är viktigt att hålla

vattenkondensorn fri från smuts och föroreningar som

kan reducera vattengenomströmningen och försämra

kyleffekten.

Alternativ till sjövattenanslutning är att i stället

ansluta vattenpumpen till färskvattentanken och

låta färskvattnet också fungera som kylvatten till

kondensorn/värmeväxlaren.

Om färskvatten- tanken har en kapacitet på 400 liter

eller mer påverkas inte vattentemperaturen. Först

Montering Isotherm Magnum kompressordel

när vattenvolymen kommer ner till 170-180 liter kan

temperaturhöjning på några grader mätas upp.

Mindre vatteninnehåll än 120-140 liter ska undvikas.

Underhåll

Isotherm har ett helt hermetiskt slutet kylsystem med

lödda ledningar och förslutningar och är underhållsfritt

samt behöver aldrig påfyllning av köldmedium

förutsatt att snabbkopplingarna är dragna ordentligt

vid installationen. Aggregatet kan sitta kvar i båten

under vintern men förmår dock inte starta vid låga

temperaturer.

Underhållet är begränsat till att hålla aggregatet

rent och snyggt för att förhindra korrosionsangrepp,

säsongvis kontrollera och vid behov byta zinkanoden

och regelbundet göra rent vattenfi ltret för det

inkommande vattnet.

Då zinkanoden byts, passa på att spola ur vattenkondensorn och ledningarna ordentligt.

Dränera, alternativt fyll på med frostskyddsvätska i

vattenpumpen och vattensystemet i övrigt, då det fi nns

risk för frost och för vinterförvaring.

Vat ten ut

Vat ten in

Zinkanod

Vat ten ut

Vat ten in

001103

001102

Page 23

SE-392 39 Kalmar - Sweden

Phone +46 480 425880

Fax +46 480 12775

E-mail: info@isotherm.com

www.isotherm.se

Kopplinsschema Magnum kompressorenhet

Brun

Blå

Brun

Blå

Röd

Svart

Röd

Svart

Svart

Röd

Te mp. sensor

2007-04-24/LLG

001222

Loading...

Loading...