Page 1

Operating & installation instructions

Anwendungs- & Einbauanleitung

Bruks- & installationsanvisning

Build-in boxes BI 40

Einbauboxen BI 40

Inbyggnadsboxar BI 40

Indel Webasto Marine S.r.l.

Zona Artigianale

IT-61019 S. Agata Feltria (PU), Italy

Tel: +39 0541 848 030

Fax: +39 0541 848 563

E-mail: info@indelwebastomarine.com

www.indelwebastomarine.com

Page 2

General

Specially designed to operate in tough marine environments, Isotherm fridge boxes are

outstanding in both performance and reliability. Fitted with a fully hermetic, leak-free compressor,

they offer the lowest possible power consumption and noise level. All models are extremely simple

to install. They will operate at a continuous angle-of-heel of up to 30° in all directions, for a short

time even more. To ensure that your Isotherm box operates as efficiently as possible, please follow

these general guidelines:

* Unnecessary opening of the lid will increase power consumption.

* Good ventilation of the compressor and condenser unit will reduce power consumption.

* The electrical system should be in good condition. Inspect batteries and charging levels

regularly. Always use a separate starter battery for the engine. Follow carefully the guide

lines regarding electrical cable areas and fuse placements.

* Keep the inside of the box clean and dry. Keep the lid slightly open to air the fridge box

when leaving the boat for any length of time.

Operation

Temperature setting

The 40L box is fitted with a manually operated, infinitely-variable thermostat. This is turned

clockwise to reduce temperature and anti-clockwise to both increase temperature and activate the

on-off switch at the end position. The switch position has a certain resistance to pass.

The thermostat knob is placed inside the box and allow setting within normal refrigeration

temperatures.

Defrosting

Defrosting shall be made when the frost layer is more than 4 mm thick. Set the thermostat in OFF

position. Store the foodstuff and the bottles as cold as possible during the defrosting. Do not use

sharp metal objects to remove frost or ice. Do not re-start until the box is completely defrosted and

dried.

BI 40 with ASU:

Control panel functions:

The refrigeration unit is switched off when the toggle switch is in the mid position.

“NORMAL-AUTO “ position:

The green light comes on indicating that power is being supplied and the refrigeration program is

activated.

When the engine is running and the power supply (measured at the compressor's control unit) is

more than 13.2 (26.4) volt, the compressor starts supply cooling energy to the holding plate. The

compressor starts within the first 30 seconds and operates at first at low speed with the yellow

indicator “Economy” on. After 30 seconds, the speed of the compressor increases by 75% and the

red “Freeze” indicator lights. This operating condition is maintained until the holding plate is

completely frozen at approximately –14°C (7°F) whic h can take between 30 and 45 minutes,

depending on ambient temperature. On reaching this temperature the compressor stops and red

the light goes out. When the temperature of the holding plate rises to –10°C (14°F) the compressor

re-starts to charge the holding plate and the red light comes on again. This process is repeated a

couple of times every hour to keep the holding plate at its optimum efficiency level. If the engine is

stopped, shortly afterwards the compressor also stops.

When the engine is not running and the battery voltage is below 12.7 (25.4) volt the surplus of

refrigeration energy stored in the holding plate is used first. Only when this has been consumed

does the compressor start and the yellow light comes on indicating that it is now running at its

“Economy” speed to top-up the holding plate. This condition starts when the temperature of the

Page 3

holding plate rises to –1°C (30°F) and stops when i t reaches economy level of –6°C (21°F).

“MAN-TEMP” position:

This position can be used when either shore-power is being used or if for some other

reason a higher or lower refrigerator temperature is desirable. The automatic function is

partially blocked and the temperature is regulated by means of the rheostat, clockwise for

colder and anti-clockwise for warmer. “A” indicates the holding plates temperature point for

“Accumulation”. In this mode the compressor starts but runs at low speed only to keep the

noise level as low as possible.

Indicator lights:

Green: Power and system on, but compressor at still-stand due to

Sufficiently low temperature of the holding plate.

Green + yellow: Compressor running within the higher temperature range.

Green + red: Compressor running on high speed within the lower temperature

range.

Green + yellow + red: Compressor running on lowest possible speed to reach selected

temperature in MAN-TEMP mode.

Flashing yellow + red: Error signal from the black electronic unit. Automatic restart after 1

minute. Select MAN-TEMP if necessary.

Flashing yellow: Low battery voltage sensor has switched off the system. Automatic

re- start occurs when the engine is running and batteries are

charged again.

Note:

After switching on, up to 30 sec. duration is required before the compressor starts. When

the engine is started, a duration of ½ to 10 minutes is required (depending on the boats

charging equipment and battery condition) before the system reacts. When the engine is

stopped, a duration of ½ - 5 minutes (depending on battery condition and level of charge) is

required before the system reacts.

Maintenance

The Isotherm boxes have a fully hermetic closed cooling system and do not require any

maintenance or refilling of refrigerant. The compressor is of domestic type and has a very

high

efficiency and an outstanding life-time. The build-in box shall be left in the boat during the

winter. (If the temperature is below freezing point, the compressor will not start).

The maintenance is reduced to periodically, not less than a year, cleaning of the condenser

from dust. Use a soft brush and no hard objects.

Keep clean inside the box. Use lukewarm water and a mild cleaner for the inside. Put the

lid, during not in operation periods, in a slightly open ventilation position.

Battery voltage sensor

To protect the batteries from becoming completely discharged, a battery voltage sensor

switches off the compressor automatically at the following levels:

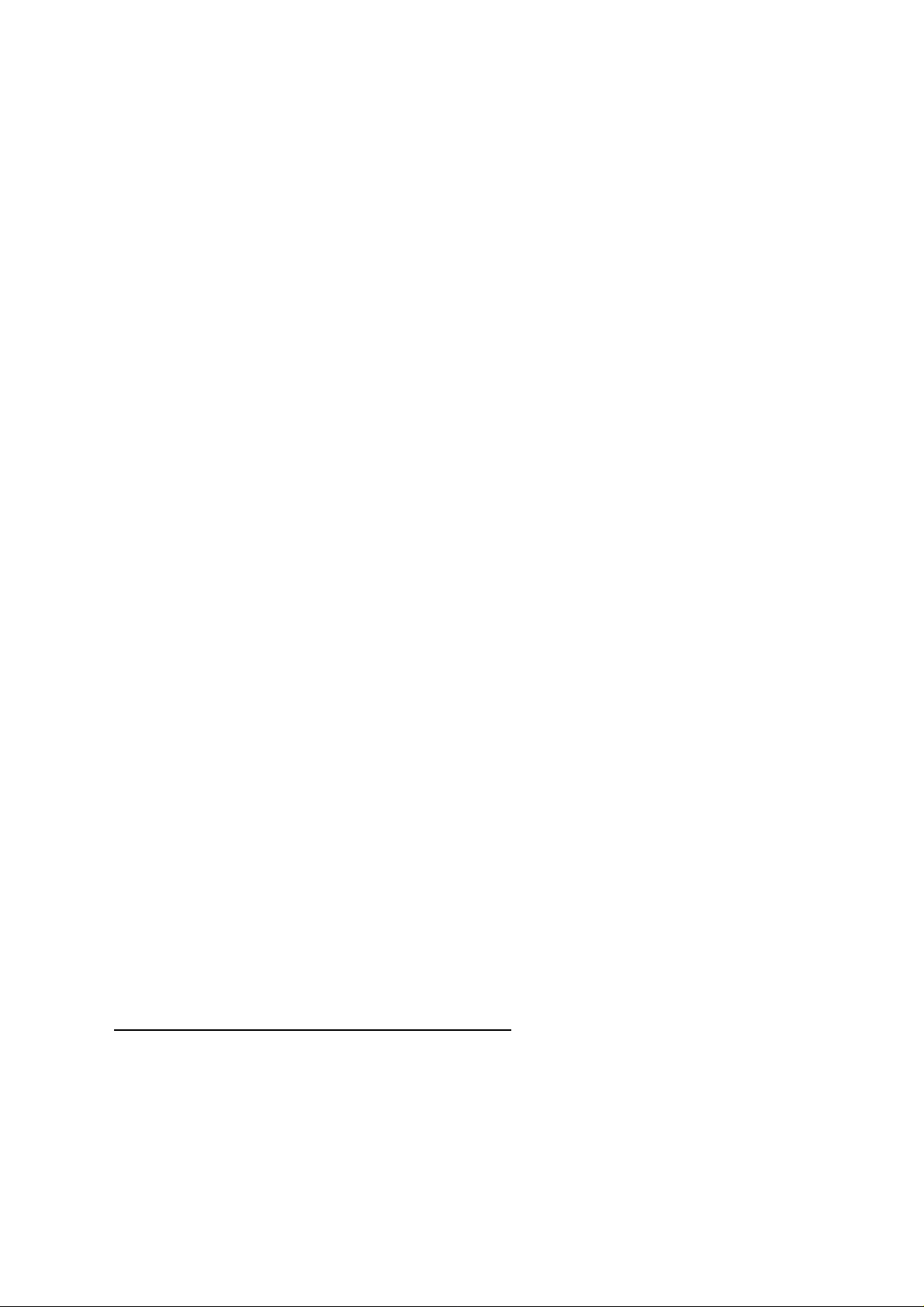

System voltage Cut-out Cut-in

12V 10.4V 11.7V

24V 22.8V 24.2V

Page 4

Safety instructions

When connected to shore power, ensure that the power supply is equipped with an automatic

earth leak switch. Danger!

Never tough bare electrical wiring connected to the mains supply. Danger!

Never connect battery charger direct to the refrigeration system. A battery charger must be

connected to the battery

In addition to acid, a newly-charged battery contains explosive gas. Danger!

Never cover up the ventilation systems for the compressor unit.

The refrigeration unit must be disposed by a refrigeration specialist for correct recycling of

components and care taking of the refrigerant.

Fault finding chart

Fault Possible cause Action

Box not cold. Compressor will not start. Check that power is present at

electronic unit.

Check fuse.

Reversed polarity.

Check all connections and cables.

Bridge the thermostat. See wiring

diagram.

If compressor starts this indicates a

faulty thermostat.

If the compressor does not start this

indicates a fault in the electronic unit

Compressor starts but does or the compressor.

Not cool the box. Contact an authorized service agent.

Installation instructions

Mount the box carefully and safe. It is vitally important that the compressor and the condenser

are well ventilated and that cold air can enter and warm air can leave the space around the

compressor unit. (Warm air is leaving upwards).

Do not install the box close to warm areas as the stove, heater or the engine.

Electrical connections

When connecting the box electrically, it is important that following points are considered:

* Always use cables of sufficient area. The area in the following table should be regarded

as a minimum.

Cable area mm² Max cable length in metres, 12 V Max cable length in metres, 24 V

2.5 2.5 5

4 4 8

6 6 12

10 10 20

* Always connect the box directly to the battery or to the battery main switch on the plus

circuit. Do not connect it via the boats own control panel or other diversions as this can

cause a voltage drop in the power supply. Use the included fuse holder with a 15A fuse.

The fuse shall be mounted on the plus cable.

Page 5

* Connect the red cable to the positive (+) terminal and the black to the negative (-)

terminal. Use tab type terminals for the connection to the electronic unit and other cable

connectors of sufficient size for the cable size selected.

* Do not connect the box direct to a battery charger. The battery charger must be connected

to the battery.

Technical data

Type designations: Thermostat: 3040EA2A00000

ASU: 3040EE2A00000

Volume: 40 litres

Voltage: 12/24 Volt

Power consumption: 2.5 - 5 A (12 volt) when compressor is running

Avarage consumption: 0.5 - 0.8 A (12 volt) at 6°C ( 43°F) boxtemp. and 22°C (72°F)

ambient temp.

Compressor: Danfoss BD35F

Refrigerant: R134a (Amount as per label on compressor)

Fuse: 15A/12V, 7.5A/24V

Measurements: Length 560 mm (400 mm without compressor)

Width 400 mm

Weight: 16 kgs

Height 420 mm

Wiring diagram

ASU

Automatic Speed Up

2008-02-26/LLG

BI 40-C eng

Page 6

Allgemeines

ISOTHERM Kühl/Gefrierboxen, speziell entworfen und produziert für die Anwendung im maritimen

Bericht, sind hervorragend in Leistung und Zuverlässigkeit.

Ausgestattet mit einem hermetisch abgeschlossenen Kompressor, bieten sie geringsten

Energieverbrauch und niedrigsten Geräuschpegel.

Alle Modelle sind leicht zu installieren. Sie können bei einem Krängungswinkel bis zu 30 grad

einwandfrei arbeiten, sogar über längere Zeit.

Damit Ihr Isotherm Kühl/Gefrierbox so effektiv wie möglich arbeitet, beachten Sie bitte die folgenden

Richtlinien:

* Unnötiges Öffnen die Box erhöht den Energieverbrauch.

* Eine gute Belüftung von Kompressor und Kondensator senkt den Energieverbrauch.

* Das elektrische System muß in einwandfreiem Zustand sein. Kontrollieren Sie regelmäßig den

Ladezustand der Batterien. Verwenden Sie immer eine separate Starter Batterie für den Motor. Beachten Sie die Vorschriften für das Verlegen elektrischer

Kabel und das Anbringen von Sicherungen.

* Halten Sie den Innenraum stets sauber und trocken.

Wenn Sie das Boot für längere Zeit verlassen, lassen Sie der Deckel leicht

offen, damit die Kühl/Gefrierbox ausgelüftet wird.

Betrieb

Temperatureinstellung

Die Kühlboxen sind mit einem manuellen, stufenlos einstellbaren Thermostat ausgerüstet.

Drehen in Uhrzeigerrichtung reduziert die Temperatur, drehen gegen den Uhrzeigersinn erhöht die

Temperatur und aktiviert den On-Off (Ein-Aus) Schalter.

Temperaturbereich: Normalen Kühlschranktemperatur.

Abtauen

Wenn die Eisschicht dicker als 3-4 mm ist, sollte abgetaut werden. Schalten Sie die Box aus. Lagern Sie

die Lebensmittel Während der Abtauphase so kalt wie möglich. Verwenden Sie keine scharfkantigen

Gegenstände, um das Eis zu entfernen. Schalten Sie die Kühlbox erst wieder ein, wenn er vollständig

abgetaut und getrocknet ist.

Box mit ASU

Bei mittlerer Schaltposition ist die Anlage ausgeschaltet.

Das Isotherm ASU Kühlsystem kann auf zwei Arten betrieben werden.

Schalter auf NORMAL-AUTO Position – die optimale Kühltemperatur wird automatisch eingehalten bei

absolut niedrigstem Batterieverbrauch.

MAN-TEMP Position – die automatische Funktion ist teilweise blockiert, die Kühltemperatur kann

manuell eingestellt werden.

NORMAL-AUTO Position:

Das grüne Licht leuchtet auf und zeigt an, daß Strom fließt und das Kühlprogramm aktiviert wurde.

Wenn der Motor läuft und die Spannungszufuhr (gemessen an der Steuereinheit am Kompressor) über

13,2 (26,4) Volt liegt, beginnt der Kompressor, Kühlenergie an den Kältespeicher zu liefern. Der

Kompressor startet innerhalb der ersten 30 Sekunden und arbeitet zuerst bei niedrigen Drehzahlen, die

gelbe Anzeige leuchtet auf „Economy”. Nach 30 Sekunden erhöht sich die Drehzahl von Kompressor

um 75%, das rote Licht leuchtet auf -„Freeze“. Diese Betriebszustand wird aufrecht gehalten, bis die

Freezer-Einheit vollständig gefroren ist bei ca. –14°C. Das kann zwischen 30 und 45 Minuten dauern.

Wenn die Freeze-Temperatur erricht ist, stoppt der Kompressor und das rote Licht geht aus.

Steigt die Temperatur des Kältespeichers auf -10°C, startet der Kompressor und das rote Licht geht

wieder an. Diese Vorgang wiederholt sich mehrere Male pro Stunde, damit der Kältespeicher immer auf

optimalen Kühlniveau ist.

Wird der Motor gestoppt, geht kurz darauf auch der Kompressor aus.

Wenn der Motor nicht läuft und die Batteriespannung unter 12,7 (25,4) Volt liegt, wird zuerst die im

Kältespeicher vorhandene, überschüssige Kühlenergie verbraucht. Erst wenn diese konsumiert

startet der Kompressor und das gelbe Licht geht an, was bedeutet, daß er nun auf „Economy“- stufe

läuft. Diese Vorgang beginnt, wenn die Temperatur des Kältespeichers auf -1°C gestiegen ist und endet,

wenn die „Economy“ – Stufe bei –6°C erreicht ist.

wurde,

Page 7

Kältespeicher vorhandene, überschüssige Kühlenergie verbraucht. Erst wenn diese konsumiert wurde,

startet der Kompressor und das gelbe Licht geht an, was bedeutet, daß er nun auf „Economy“- stufe

läuft. Diese Vorgang beginnt, wenn die Temperatur des Kältespeichers auf -1°C gestiegen ist und endet,

wenn die „Economy“ – Stufe bei –6°C erreicht ist.

MAN-TEMP Position

Diese Einstellung kann verwendet werden, wenn Landstrom benutzt wird oder wenn aus irgendeinen

anderen Grund eine höhere oder niedriger Kühltemperatur gewünscht wird.

Die Automatikfunktion ist dann teilweise blockiert und die Temperatur wird mit Hilfe des

Regelwiderstands eingestellt: im Uhrzeigsinn = wärmer, entgegen der Uhrzeigerrichtung = wärmer. „A“

steht für „Akkumulationstemperatur“ des Kältespeichers.

In dieser MAN-TEMP Einstellung startet der Kompressor und läuft bei niedrieger Drehzahl.

Bei gestopptem Motor (da Landstrom) wird dadurch der Geräuschpegel von Kompressor und Lüfter

extrem gesenkt, was als sehr angenehm empfunden wird.

Leuchtanzeigen

Grün: Strom liegt an, System ist an, aber Kompressor steht noch still, da die

Temperatur des Kältespeichers noch niedrig genug ist.

Grün + gelb: Kompressor läuft bei niedriger Drehzahl, um die Kältespeicher kühl zu

halten, ohne ihn „aufzuladen“.

Grün + rot: Kompressor läuft bei Maximaldrehzahl, um den Kältespeicher zu laden.

Grün + gelb + rot: Kompressor läuft bei niedriger Drehzahl im MAN-TEMP Modus.

Gelb + rot blinkt: Fehlersignal von Steuereinheit. Automatischer Neustart nach 1 Minute.

Gelb blinkt: Die Batteriespannung ist zu niedrig, der Sensor hat das System

abgeschaltet. Es erfolgt ein automatisches Neustarten, wenn der Motor

läuft, um die Batterien wieder aufzuladen.

Hinweis

Nach dem Einschalten dauert es ca. 5 – 30 Sekunden, bevor das System startet. Wenn der

Motor an ist, dauert es ½ bis 10 Minuten, bevor das System reagiert (abhängig von

Ladeausrüstung und Batteriezustand). Wird der Motor gestoppt, dauert es ½ bis 5 Minuten,

bevor das System Reaktion zeigt.

Wartung

Die Isotherm Kühlboxen besitzen ein hermetisch abgeschlossenes Kühlsystem und benötigen deshalb

keine Wartung, Kühlmittel muß nicht nachgefüllt werden. Der Kompressor ist sehr zuverlässig und

Leistungsstark und besitzt eine lange Lebensdauer. Über Winter sollte die Kühl/Gefrierbox im Boot

verbleiben. (Wenn die Temperatur unter 0 Grad C sinken, geht die Anlage nicht an).

Die Wartung beschränkt sich auf das Reinigen des Kondensators einmal pro Jahr. Verwenden

Sie dazu eine weiche Bürste. Halten Sie den Kühlboxinnenraum sauber. Nehmen Sie lauwarmes

Wasser und ein mildes Reinigungsmittel, um ihn zu saubern.

Halten sie der Deckel einen Spalt offen, wenn die Kühl/Gefrierbox nicht in Betrieb ist, damit sie auslüften

kann.

Batteriespannungssensor

Damit die Batterien nie ganz leer werden, schaltet ein Spannungssensor den Kompressor automatisch

ab bei folgenden Werten:

Systemspannung Ausschalten Einschalten

12 Volt / 24 Volt 10,4 Volt / 22,8 Volt 11,7 Volt / 24,2 Volt

Sicherheitshinweise

Wenn Sie Landstrom Anschließen, achten Sie darauf, daß die Stromzufuhr mit einer Sicherung über

einen F1-schalter abgesichert wird. Gefahr!

Berühren Sie niemals offene Wechselstromkabeln. Gefahr!

Schließen Sie nie ein Batterieladegerät direkt am Kühlschranksystem an.

Batterieladegeräte müssen an die Batterien angeschlossen werden!

Page 8

Beachten Sie, daß Batterien Säure enthalten.

Decken Sie die Belüftung der Kompressoreinheit niemals ab.

Eine spätere Verschrottung des Aggregates darf nur von Fachmann vorgenommen werden, der die

enthaltenen Bestandteile der Wiederverwertung zuführt und das Kühlmittel korrekt entsorgt.

Fehlersuche-Checkliste

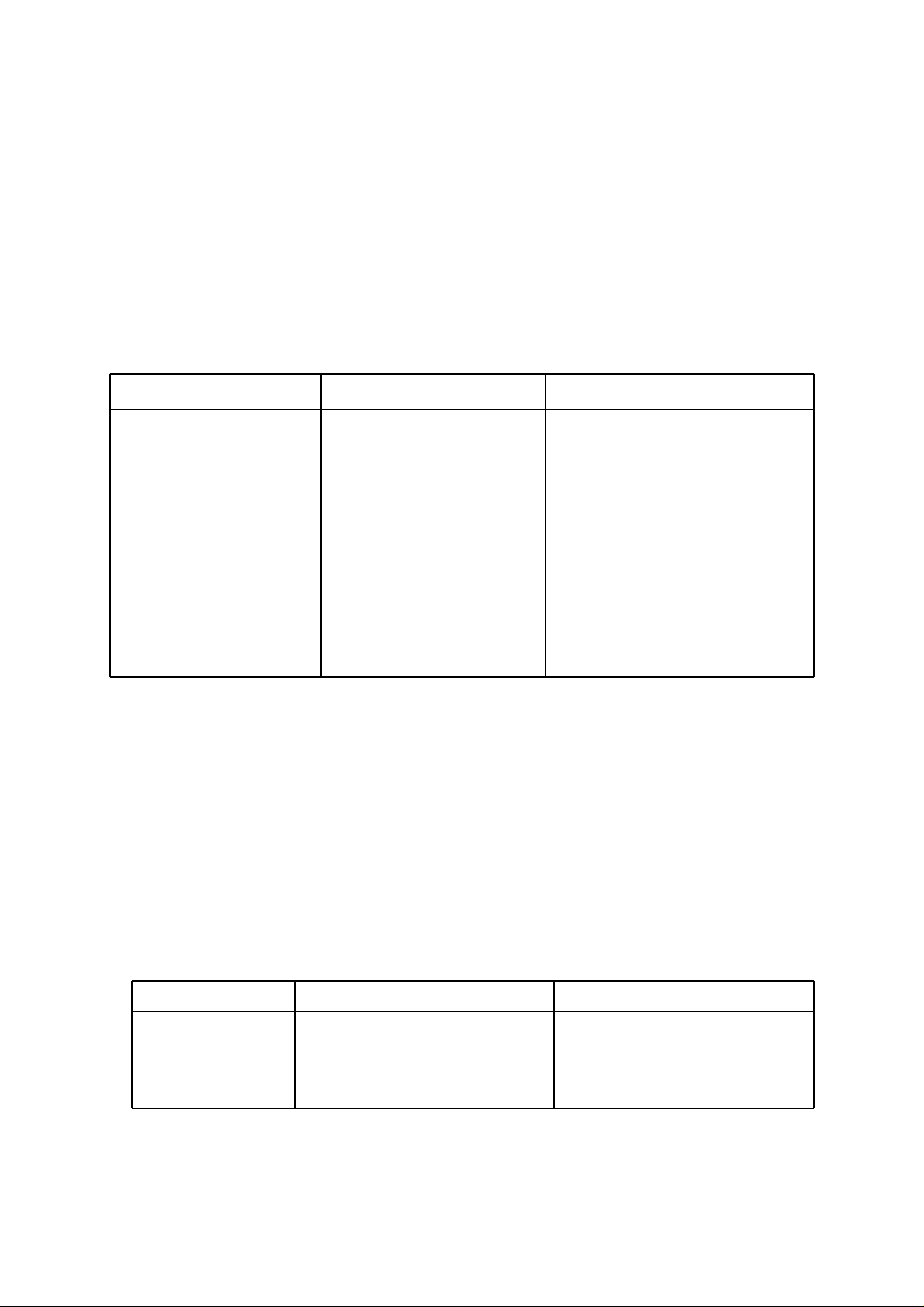

Fehler Möglische Ursache Maßnahmen

Kühlbox wird nicht kalt

Kompressor startet, aber

erfolgt keine Kühlung.

Kompressor startet nicht.

Überprüfen Sie, ob Strom fließt am Anschluß.

Kontrollieren Sie Polarität und Sicherung.

Prüfen Sie alle Anschlüße und Kabel.

Überbrücken Sie am Thermostat

Kabelanschlüsse.

Wenn der Kompressor startet, deutet dies auf

einen Defekt im Thermostat.

Wenn der Kompressor nicht startet, liegt ein

Fehler in der Elektronik oder am Kompressor vor.

Kontaktieren Sie Ihre Werkstatt.

Kontaktieren Sie Ihren Händler bzw. Ihre

zuständige Werkstatt.

Installationsanleitung

Die Box muss gut befestigt werden.

Es ist von größter Wichtigkeit, daß Kompressor und Kondensator gut belüftet werden und daß kalte Luft

am Boden einströmen und Warme oben entweichen kann.

Der Kompressor sollte senkrecht im Boot stehen, er arbeitet aber bei einem Krängungswinkel bis zu 30

Grad über einen gewissen Zeitraum einwandfrei.

Elektrische Anschlüsse

Wenn Sie die Kühl/Gefrierbox anschließen, müssen Sie folgendes beachten:

* Verwenden Sie immer die richtige Kabelgröße (korrekten Kabelquerschnitt).

Folgende Maße werden als Minimum verlangt:

Kabelquerschnitt in mm² Maximale Kabellänge in m

12 Volt 24 Volt

2,5 2,5 5

4 4 8

6 6 12

10 10 20

* Schließen Sie die Kühl/Gefrierbox immer direkt an der Batterie oder am Batteriehauptschalter,

positiver Stromkreis, an. Schließen Sie nicht über das Schaltbrett des Bootes oder andere

Umwege an, dies kann zu Spannungsabfall führen.

Verwenden Sie die beigefügte Sicherungsfassung mit 15A Sicherung.

Wird ein Schalter installiert, muss dieser auch für mind. 15 A ausgelegt sein.

* Schließen Sie das rote Kabel am positiven (+) und das schwarze Kabel am

negativen (-) Anschluß an. Verwenden Sie der Kabelgröße entsprechende

Kabelanschlüsse.

* Schließen Sie die Kühlbox niemals direkt am Batterieladegerät an. Der Batterielader muß an der

Batterie angeschlossen werden.

Page 9

Technische Daten

Typ: 3040EA2A00000 Thermostatmodell

3040EE2A00000 ASU Modell

Spannung: 12/24 Volt

Stromverbrauch: 2,5 - 5A in Betrieb (12 V)

Mittlerer Stromverbrauch: 0,5 - 0,8 A/h. (12 V) bei Temperatur in der Box +6°C, Umgebung +22°C.

Kompressor: Danfoss BD35F

Kältemittel: R134a (Füllmenge gemäß Schild am Kompressor).

Sicherung: 15 A Auto Flachsicherung

Abmessungen: Länge 565 mm (400 mm ohne Kompressor)

Breite 400 mm

Höhe 420 mm

Gewicht: 16 Kg

Elektrische Anschlüße

2008-02-26/LLG

BI 40-C ty

ASU

Automatic Speed Up

Page 10

Allmänt

Isotherm kylboxar är helt konstruerade efter de höga krav som ställs i marin miljö, både vad

gäller prestanda och utförande. De har en modern hermetisk helt läckagefri kompressor

som ger såväl lägsta strömförbrukning som i det närmaste ljudlös gång.

Kylboxarna är enkla att bygga in och installera. De tål en lutning på upp till 30º, tillfälligt mer.

Köldmediet är freonfritt, R 134a.

För bästa funktion är det viktigt att följande punkter beaktas:

* Undvik onödigt "spring" i kylboxen. Det höjer strömförbrukningen.

* God ventilation av kompressor och kondensor har också stor inverkan på

strömförbrukningen. Placera boxen där bra luftväxling finns till hands.

* Ett väl fungerande elsystem är en förutsättning. Se över batterier och laddning

regelbundet. Ha alltid ett separat startbatteri för motorn. Följ anvisningarna vad

gäller kabelarea och säkringsplacering.

•

Håll rent och torrt i boxen. Torka ur eventuellt kondensvatten som samlats i botten.

•

Ställ alltid upp locket i vädringsläge när Du lämnar båten ock kylboxen är avstängd.

Bruksanvisning

Temperaturreglering

Med kylboxens termostat kan man steglöst reglera temperaturen enligt följande:

vrids termostaten medurs blir det kallare och vrids den moturs blir det varmare

i boxen. Termostaten har en strömställare i sitt ändläge moturs, med vilken boxen

kan stängas av och sättas på, et distingt fjädermotstånd överbryggas när knappen vrides till avstängt läge.

Termostaten tillåter reglering av temperaturen inom normal kylskåps/kylbox temperatur.

Avfrostning

Avfrostning skall ske då en tjock (över 4 - 5mm) frostbeläggning finns på förångaren.

Stäng av boxen på termostatvredet. Förvara de matvaror och drycker som fanns i boxen så kallt

som möjligt t.ex. frysväskor el. dyl. under tiden avfrostningen äger rum. Använd inga vassa föremål för att avlägsna isen.

Starta ej boxen igen förrän det är fullständigt avfrostat och urtorkat.

Box med ASU

Manöverpanelens funktioner:

Aggregatet är avstängt med panelens strömställare i mittläge.

Läge “NORMAL-AUTO”:

Gröna lampan tänds omgående och visar att ström är tillkopplad och följande program kopplas

in:

- Då motorn går och spänningen i elsystemet, mätt vid kylkompressorns elektronikdel, är över

13,2 volt (26,4 volt) startar kompressorn och arbetar för att frysa ner och ladda kylmagasinet. Kompressorn startar inom 30 sek. och går den första halvminuten på lågt varvtal och

gul lampa "Economy” tänd. Efter 30 sek. varvar kompressorn upp 75% och röd lampa

“Freeze” tänds. Så kommer kompressorn att arbeta ända tills kylmagasinet är fulladdat vid

ca. –14°C, vilket tar mellan 30 – 45 min. Därefter stannar kylkompressorn, röd lampa slocknar och kompressorn återstartar vid ca. –10°C, någon gång i timmen för att hålla kylmagasinet fulladdat. Om båtmotorn stängs av, stannar också kompressorn.

- Då båtmotorn ej går och spänningen är lägre 12,7 volt (25,4 volt) används alltid i första hand

den lagrade kylan i kylmagasinet. Först när den är förbrukad kopplas kompressorn in och går

då på lågt varvtal med gula lampan “Economy” tänd, för att underhållskyla. Kompressorn

Page 11

startar då kylmagasinet är varmare än –1°C och stannar då kylmagasinet nått –6°C,

alltså innan kylmagasinet laddas.

Läge “MAN-TEMP”:

- Detta läge kan användas när man ligger på landström eller av annan anledning vill

åstadkomma kallare eller varmare temperatur i boxen. Automatiken är då urkopplad och

temperaturen regleras manuellt med reostaten på manöverpanelen. Medurs = kallare

och moturs = varmare. Vid “A” passeras kylmagasinets temperatur för “Ackumulering”.

Då kompressorn startar i MAN-TEMP går den företrädesvis på lågfart för att hålla ljudnivån så låg som möjligt. Om temperaturskillnaden mellan inställd och verklig då kompressorn startar, går den dock ett tag på högre varvtal för att snabbare kyla ner och jämna ut temperaturskillnaden.

Signaler:

Fast grön lampa: Aggregatet tillkopplat, får ström, kompressorn går ej.

Fast grön + gul: Kompressorn går på lågvarv inom det höga temperaturområdet.

Fast grön + röd: Kompressorn går på högvarv inom det låga temperaturområdet.

Fast grön + gul + röd: Kompressorn går på lägsta möjliga varvtal för att uppnå inställd tem-

peratur.

Blinkande gul + röd: Felsignal från elektroniken. Automatisk återstart inom 1 min.

Ställ strömställaren läge MAN-TEMP.

Blinkande gul: Batterivakten har löst ut och stängt av aggregatet. Starta motorn för

laddning och kompressorn återstartar automatiskt.

Obs! Då strömställaren slås till dröjer det ca. 30 sek. innan kompressorn startar. Då

båtmotorn startats dröjer det ½ - 10 min innan aggregatet reagerar, beroende på båtens

laddningsutrustning och batterikondition. Då båtmotorn slås av dröjer det ½ - 5 min innan

aggregatet reagerar, beroende på batteriernas kapacitet och laddningstillstånd.

Underhåll

Isotherm kylboxar har ett helt hermetiskt slutet kylsystem med lödda ledningar och

förslutningar och behöver inget underhåll och behöver ej påfyllning av köldmedium. Kompressorn är av hushållstyp och har förutom mycket hög verkningsgrad en

i särklass lång livslängd.

Kylboxen skall sitta kvar i båten under vintern (men förmår dock inte alltid starta vid

minusgrader). Underhållet inskränker sig till att regelbundet och vid behov göra rent

kompressorns kondensorgaller från damm med en pensel e.d.

Håll kylboxen ren invändigt, speciellt viktigt på hösten då boxen tömmes och stängs av.

Ställ luckan i vädringsläge under vintern.

Batterivakt

För att skydda batterierna mot urladdning slår en batterivakt ifrån kompressorn vid

för låg spänning enligt följande:

Systemspänning frånslag tillslag

12 volt 10,4 volt 11,7 volt

24 volt 22,8 volt 24,2 volt

Page 12

Säkerhetsföreskrifter

-Vid anslutning till landström måste strömförsörjningen vara jordad och ansluten till

jordfelsbrytare, annars föreligger stor risk för personskada. Kan medfara livsfara!

- Ingrepp i köldmediekretsen får absolut ej göras.

- Köldmedium får ej släppas ut i luften.

- Se till att boxens ventilationssystem ej blockeras.

- Anslut ej batteriladdare direkt till kylboxen. Batteriladdare måste kopplas till batteriet.

Felsökningsschema

Felindikering Möjlig orsak Åtgärd

Boxen blir ej kall. Kompressorn startar ej. Kontrollera att ström

finns fram till elboxen.

Kompressorn startar Kontrollera säkringen.

men ger ingen kyla. Kontrollera att plus och

minus ej förväxlats, el

kablar och kabelanslutningar.

Överbrygga termostaten, startar

kompressorn då, är termostaten

felaktig.

Om åtgärderna i övrigt inte av

hjälper felet, kontakta auktori

serad serviceverkstad.

Kontakta auktoriserad service

verkstad.

Installationsanvisning

Boxen skall sättas fast ordentligt i det utrymme som valts för montering.

Det är viktigt att god ventilation finns i utrymmet där boxen/kompressorn är monterad. Man

skall därför se till att kall luft kan tillföras undertill för att sedan släppas ut uppåt. (Varm luft

stiger uppåt). Installera ej boxen nära värmekällor såsom spis, värmare, motorn eller dyl.

Kompressorn skall i sitt normalläge sitta rakt/vågrätt i båten. Den klarar lutningar på 30°,

tillfälligt mer.

Elanslutning

Vid inkoppling till båtens elsystem är det mycket viktigt att hänsyn tas till följande punkter:

Använd väl tilltagen kabelarea, se tabellen.

Kabelarea mm² Max. kabellängd (m) vid 12V Max. kabellängd (m) vid 24V

2,5 2,5 5

4 4 8

6 6 12

10 10 20

Page 13

Tekniska data

Typbeteckning: 1381G Termostatstyrd

1383G ASU

Volym: 40 liter

Spänning: 12/24 volt

Strömförbrukning: ca. 2,5 - 5A i drift (12 volt)

Medelströmförbrukning: 0,5-0,8 A/tim (12 volt) vid 6°C i boxen och 22°C omgivningstemperatur.

Kompressor: Danfoss BD35F

Köldmedium: R134a (Fyllnadsmängd enligt dekal på kompressorn).

Säkring: 12V/15A alt. 24V/7,5A

Mått: Längd 560 mm (400 mm utan kompressor)

Bredd 400 mm

Höjd 420 mm

Vikt: 16 kg

Elinkoppling

ASU

Automatic Speed Up

2008-02-26/LLG

BI 40-C

Thermoprodukter AB

Dragonvägen 6

SE-392 39 Kalmar, Sweden

Tel: +46 480 425 880

Fax: +46 480 127 75

E-mail: info@isotherm.com

www.isotherm.se

Loading...

Loading...