Page 1

Installation and operating instructions

Page 2

Table of Contents

1 Preface

2 Installation

2.1 Unpacking and Inspection

2.2 Safety Considerations

2.3 Tools and Materials Required

2.4 Getting Good Results

2.5 Plan Ahead

2.6 Location and Ventilation

2.7 General Electrical Installation

2.8 Shore Power

2.9 Electronic Unit

2.10 Locating and Installing the Compressor/Condenser Unit

2.11 Locating and Installing the Evaporator

2.12 Thermostat Control Box

2.13 Quick-Couplings

3 Maintenance

4 Operation

4.1 Start Up

4.2 Protection System

5 Troubleshooting Guide

Appendix A Building or Modifying an Icebox for Use with an Isotherm Refrig-

6

eration System

7 Appendix B Bending a Flat Evaporator

INSTALLATION AND OPERATING INSTRUCTIONS

PRODUCED BY

GREAT WATER, INC.

BRUNSWICK MAINE

WWW.GREAT-WATER.COM

207 729 8500 TEL 517 813 6509 FAX

INFO@GREAT-WATER.COM

Page 3

1 Preface

Isotherm Classic Compact refrigeration systems are designed and built to provide excellent performance and many years of trouble-free service. The system is pre-charged with environmentally

safe R-134a refrigerant and can be owner installed. This manual has been prepared to provide information needed for proper installation, operation and maintenance. Before beginning installation please read it carefully.

2 Installation

2.1 Unpacking and Inspection

Please examine the box and contents for signs of shipping damage. If there is any damage, contact the carrier immediately. All units are shipped with insurance but the carrier must be notified

immediately of any shipping damage in order to process a claim.

Each system consists of:

1. Compressor/condenser unit.

2. Click on mounting bracket.

3. Evaporator with 6 feet of flexible tubing.

4. Thermostat with control wiring.

5. Owners manual and warranty registration card.

2.2 Safety Considerations

Whenever working on the electrical system make certain that all circuits are off before opening

any electrical panels. Disconnect shore power cables and turn battery switches off. Follow ABYC

standards for electrical installations. If in doubt contact a certified technician.

2.3 Tools and Materials Required

• Electric drill and bits for pilot holes to attach compressor mounting bracket and evapora-

tor.

• Wire cutters and electrical terminal crimping tool.

• Good quality electrical wire of suitable gauge (usually 10/2).

• Screwdrivers.

• Wrenches.

2.4 Getting Good Results

Classic Compact refrigeration systems are designed for use in a marine environment and will operate efficiently for many years with a minimum of maintenance when installed properly. Plan the

installation carefully and choose a suitable location for the refrigerator. The insulation and construction of the refrigerator box are very important and will have a dramatic effect on the performance and power consumption of the refrigerator system.

A box with thicker insulation will require less power to maintain the proper temperature. Three to

four inches of a good quality insulation material with a value of R-5 per inch is recommended.

This will result in a box with an overall insulation value of R-15 to R-20.

The box must be well sealed. Lids must be airtight. Drains (if fitted) must be closed tightly.

Often boxes are pre installed by the manufacturer and modifications are not always easy to make.

If you are planning to build or modify a box please see Appendix A: “Building or Modifying an Icebox for Use with an Isotherm Refrigeration System.”

Page 4

Battery capacity should be at least 75 Ah to enable sufficient power to be stored during engine

F

D

C

P

T

101N0200

operation.

All the electrical power supply equipment such as alternator, regulator, cables, connectors and

batteries must be kept in good condition.

2.5 Plan Ahead

· Plan tubing and wire runs carefully before starting.

· Avoid getting dirt or moisture on coupling ends. Leave dust caps on until ready to connect.

· Provide sufficient air circulation for air-cooled condenser.

· Use a dedicated 15 amp circuit breaker.

2.6 Location and Ventilation

All refrigerators are heat-transfer machines. They

transfer the heat from the inside of the box to the

outside. If adequate ventilation is provided, the

compressor will operate more efficiently and use

F

less power.

Inlet vent should be located at the bottom (as low

D

C

P

T

101N0200

as possible) and the outlet vent at the top of the

refrigerator (as high as possible); this supports the

natural flow of convection of heat from cool

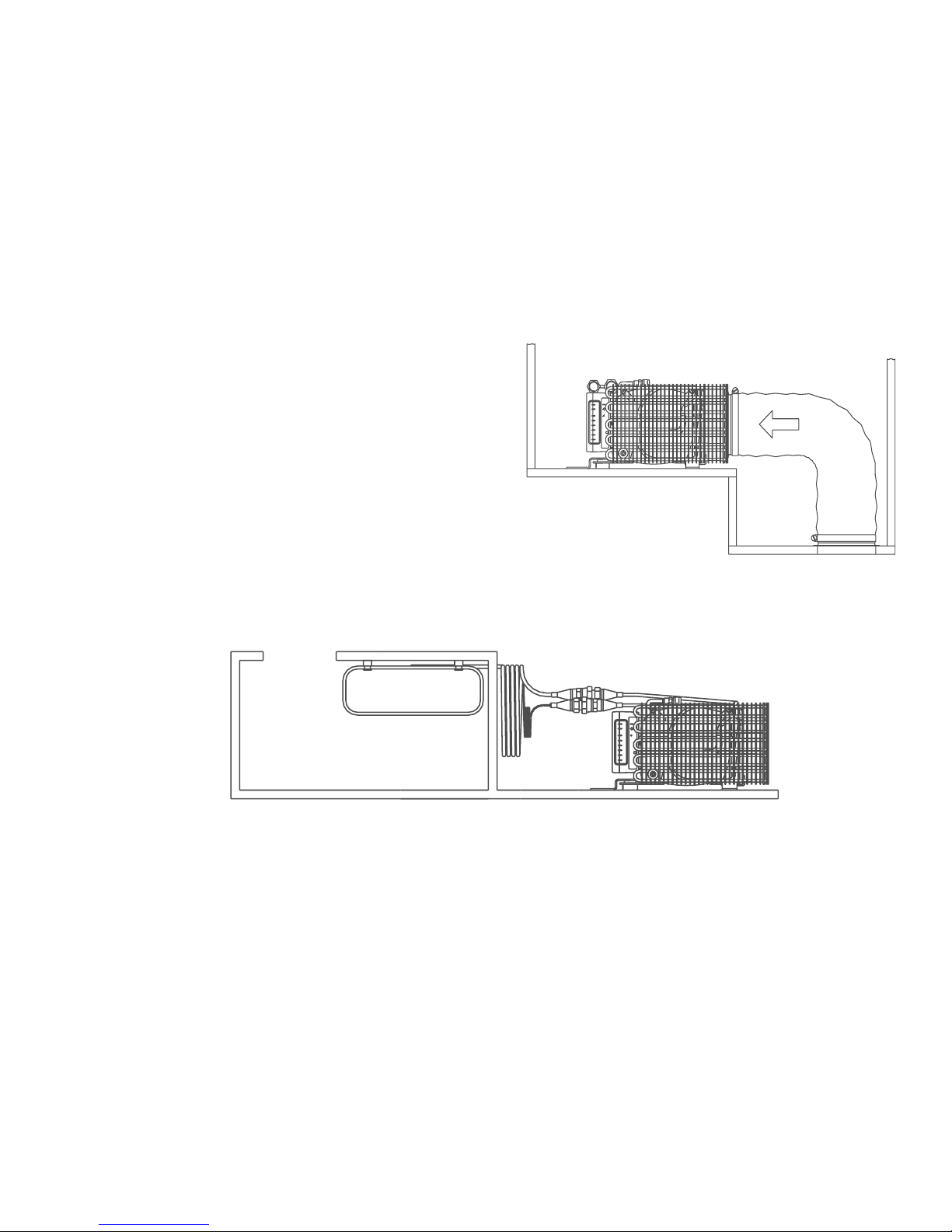

Fig. 1

(bottom) to warm (top).

A vent of 20 to 30 square inches is recommended at

top and bottom (fig. 1).

Make sure there is sufficient space around the compressor to connect and tighten the quickconnect couplings on the pipes (fig. 2).

Fig. 2

2.7 General Electrical Installation

Good performance and efficient operation of the refrigeration system depends on a good electrical installation that will deliver power to the system with a minimum of voltage loss. If the boat's

electrical panel cannot deliver the required power with no more than one half volt of loss the circuit may need to be connected directly to the boat’s main battery switch with the fuse supplied.

In either case the circuit that supplies the power to the refrigerator must be protected with either

a 15 Amp fuse or circuit breaker. Always use a separate dedicated circuit to power the refrigeration system. Remember that the negative connection is equally important in delivering power to

the unit.

Use a good quality marine duplex wire to make the connection between the unit and the power

source. Tinned cable is recommended because it will give better resistance to corrosion and long

service life.

Keep the length of the run as short as possible (less than 6 feet).

For runs up to 10 feet use 12 gauge wire (12/2 duplex).

For runs up to 30 feet use 10 gauge wire (10/2 duplex).

Make sure the circuit is not connected to the power source while making these connections.

Page 5

2.8 Shore Power

Battery Charger

Battery

Electronic Unit

When shore power is available the

electrical requirements of the refrigeration system can be supplied

by a regulated battery charger of

at least 5 amps capacity. This

battery charger must be connected to the battery and never

directly to the electronic unit (fig.

3).

2.9 Electronic Unit

The electronic unit must always be connected directly

to either the battery or the main switch (plus to plus –

minus to minus).

It is very important that cables of correct dimensions

are used for the power supply.

2.10 Locating and Installing the Compressor/

Condenser Unit

The compressor/condenser unit is air-cooled and must

be mounted in a well-ventilated location. The efficiency of the system will be greatly reduced if the

temperature of the cooling air rises above 95°F. Ideally the air supply should be drawn from a cool area

such as the bilge and the warmed exhaust air vented

out of the space. Avoid warm locations such as an engine room or closed spaces where the warm air will recirculate over the condenser. Make sure the ventilation to the space will not be restricted when the space

is packed for cruising.

The compressor/condenser must be located within 6

feet of the evaporator so that the refrigeration tubing

will reach.

The click–on bracket simplifies mounting the compressor. The bracket can be mounted on a bulkhead or on a

shelf. The compressor can be easily snapped onto the

bracket after it is screwed into position (fig. 4).

The compressor/condenser must be mounted in a horizontal position and will operate at a heeling angle up

to 30° (fig. 5).

The compressor/condenser is nearly silent in operation

so it can be mounted near sleeping cabins or even under a berth.

The compressor must be mounted in a dry location to

protect the electrical components.

Fig. 3

Fig. 4

Fig. 5

Page 6

2.11 Locating and Installing the Evaporator

The evaporator can be mounted horizontally or vertically on a sidewall near the top of the box, accessible from the box opening. In positioning the

evaporator consider the routing of the refrigerant

lines out of the box.

Mark the location of the mounting holes, drill and

attach the evaporator with the screws and the plastic standoff spacers provided. Do not use screws

longer than those provided, as they will penetrate

the insulation (fig. 6).

Note: It ma y be easie r if the t hermo stat’s se nsor i s

attached before final mounting of the evaporator.

When the evaporator mounting holes are completed, locate the hole for the refrigerant lines.

Use a 1 1/2 " diameter hole saw to make a passage

way through the box for the copper tubing. In locating the hole, consider the routing of the tubing,

both inside and outside the box. Avoid sharp bends

that will make it difficult to run the tubing to the

compressor/condensing unit. The aluminum tube

may be bent to a minimum of 1½" radius by hand.

Repeated bending should be avoided (fig. 7).

Note: It is possible to reshape an O-evaporator.

Remove the rivets holding it together and carefully

form it to the required shape required (fig. 8).

Flat evaporators can be bent, using a special bending tool. (See Appendix B.)

Fig. 6

Fig. 7

Fig. 8

Page 7

2.12 Thermostat Control Box

The thermostat control box can

be installed either inside or outside the refrigerator. When locating the thermostat make sure

it is in a dry area and will not be

subjected to damage. Check that

the thin capillary sensor tube is

long enough so that it may be attached to the evaporator, either

with a clip or with a special

screw on clamp (fig. 9). Uncoil

the required length of capillary

tubing and secure the excess in a

coil. Avoid bending or twisting

the capillary tube repeatedly to

prevent kinking or cracking the

tube. Connect the thermostat

wiring to the electronic unit connections “T” and “C” (fig. 10).

The polarity of these connections

is not important. On some models, the speed of the Danfoss

compressor is set with a resistor

that is part of a three inch

jumper that is connected to the

"C" terminal. Leave this wire in

place. Connect the free end of

this short wire to one of the thermostat wires.

After mounting the thermostat

housing, turn the control knob

completely counterclockwise to

the off position.

Fuse/

Circuit Breaker

Thermostat

Sensor Tube

Fig. 10

Fig. 9

F

D

C

P

T

Speed Setting Resistor

(on some models)

2.13 Quick-Couplings

The evaporator is supplied with 6 feet of pre-charged tubing with a pair of self-sealing quick connect couplings. The compressor/condensing unit has a mating pair of these fittings. Connecting

the quick-connect couplings together completes the refrigeration circuit without the loss of any

refrigerant.

All quick connect couplings must be kept free of dirt and moisture. Any contamination can

cause failures.

Save the caps in the event the system needs to be removed for service.

A suggestion: screw the caps together, place them in a small plastic bag and tape them to the

tubing near the fittings so they will be available if needed.

Page 8

Thread the couplings together by hand until you are sure the couplings are properly mated.

Tighten the couplings by turning the swivel nut on the female fitting while holding the male fitting

stationary.

It is important not to twist the tubing when

tightening the fittings. If the male fitting is

allowed to rotate the tubing may break

causing serious damage to the system.

Continue tightening the female fitting until

positive resistance is felt. Screw the couplings to the bottom of their threads and ,

tighten finally firmly using 21 and 24mm

wrenches (fig. 11). Tighten the female cou-

Fig. 11

pling another 1/6 to 1/4 rotation to insure a

leak-proof joint.

After the installation is complete and the system has been tested the 1½ inch hole in the box

must be filled and sealed with a polyurethane foam sealant.

3 Maintenance

Maintenance is not normally required and the refrigeration unit may remain in the boat during the

winter. To maintain efficiency, remove any dust that may have collected on the condenser tubes

every few years.

It is time to defrost when frost builds up to 1/4 inch.

4 Operation

4.1 Start Up

Make sure the circuit supplying the refrigerator is turned on. The compressor should start within

30 seconds and a low humming noise will be heard. The fan will start after a short delay. In a

few minutes the evaporator will begin to frost. The thermostat is adjustable and has an on/off

switch. Turning the control knob to the extreme counter clockwise position turns the unit

off. Turning the control to the right (clockwise) will turn the unit on. Turning the control clockwise lowers the temperature setting with the lowest temperature at the extreme clockwise position.

A good initial setting is mid-range. Positions “4” – “7” are recommended for making ice cubes.

4.2 Protection System

The compressor is equipped with an electronic protection system. The system is activated when

the compressor is overloaded and fails to start for any reason. It is also activated if the batteries

are under- or overcharged.

To prevent battery damage the protection system will shut off the compressor when the input

voltage at the electronic module falls below 10.3 volts. The compressor will not start again until

the input voltage rises to 11.5 volts.

Page 9

5 Troubleshooting Guide

Problem Possible Cause Action

Refrigerator isn’t cold. Compressor won't start.

Compressor starts but

doesn't cool refrigerator.

Compressor runs all the time. Air leak. Check gasket/seal of door. Make sure door

Condensor dirty. Clean condensor with soap, water, and a brush.

Insufficient ventilation.

System charge of refrigerant R-134a may be low.

Check that power is present at terminal box.

Check fuse. Check all connections and cables.

Check the thermostat connections. If the compressor still doesn't start this indicates a fault in

the electronic unit or compressor. Contact an

authorized service agent.*

Contact an authorized service agent.*

closes properly.

Improve ventilation. Refer to installation instructions.

Contact an authorized service agent.*

Refrigerator too cold inside. Faulty thermostat Turn thermostat to "off" position and make sure

unit turns off. Adjust to minimum setting and

check that sensing tube is properly attached to

evaporator.

* If a complicated fault does occur, such as those requiring specialist assistance, please contact Great Water, Inc. or your local marine distributor for advice. Great Water can be reached at: Phone: (814) 838-0786

Fax: (814) 838-8700 email: info@great-water.com.

6 Appendix A

Building or Modifying an Icebox for Use with an Isotherm Refrigeration System

Page 10

7 Appendix B Bending a Flat Evaporator

The following instructions should be used when bending a flat evaporator to install in a refrigerator or freezer box.

The evaporator should be bent to cover as many sides of the box as possible, with a minimum of

two sides for a refrigerator and three sides for a freezer. The evaporator should be placed as high

in the box as possible. Use the enclosed bending tool.

• Plan exactly where the evaporator should be located. Begin by selecting a position in the

box wall where a hole can be made through which the connection tube can be passed. The

hole should have a diameter of at least 1.25" (33 mm) to allow the quick couplings to pass

through. It is very important that the short length of tubing clamped to the outside of the

evaporator be protected. Be sure to leave enough space for this tubing inside the box because it must never be stressed or pulled through the clamp to alter its length.

• Begin measuring the interior of the box from the point where the edge of the evaporator

will be located. The first measurement should be for the end of the evaporator with ample

space to accommodate the tubing.

• Continue measuring around the inside corners of the box. Write down these measure-

ments.

• Calculate where the evaporator must be bent to fit into the box. It is important to account

for the extra length of evaporator needed to round the corners of the box. A 90-degree

bend requires 1.25" (33 mm) length of evaporator when the inner radius is .75" (20mm).

Remember also that the evaporator should be mounted .5" (13 mm) from the box wall using

the plastic stand-offs provided. These factors will affect your calculations. Refer to next

page for an example of how to calculate location of bends.

• Put a piece of plywood down on a workbench with an open space underneath so that there

will be room to accommodate the evaporator as you bend it.

• Mount the bending tool on the edge of the plywood for the evaporator to be screwed to in

order to keep it stationary while bending.

• Draw a line down the length of the bending tool to mark the center. This corresponds to

where the marks you have made on the evaporator for the start of each bend will line up.

• Begin bending the end of the evaporator farthest away from the end where the tubing is

coiled.

• Mark the location of the mounting holes, drill and attach the evaporator with the screws

and the plastic standoff spacers provided. Do not use screws longer than those provided as

they will penetrate the insulation.

• Install the evaporator in the box after it has been bent. If necessary, the evaporator can

be carefully bent further to fit through the opening and then bent back to 90˚ inside the

box.

Page 11

a = 0"

c = 12"

b = 10.75"

d = 28.25"

e = 29.5"

f = 40"

= 10.75"

Take length of first side (AB) 12.0"

Subtract width of first bend - 0.75"

add length of radius of bend + 1.25"

Subtract width of first stand-off - 0.5"

location of beginning of first bend is 10.75"

location of the end of the first bend is 12.0"

Calculate location of first bend:

C

e

d

= 28.25"

Subtract width of 2 stand-offs - 1.0"

Add length of second side (BC) + 18.0"

Subtract length of second bend - 0.75"

add length of radius of second bend + 1.25"

location of beginning of second bend is 28.25"

location of the end of the second bend is 29.5"

Calculate location of second bend:

D

f

drawings are not to scale

AB = 12"

The following example illustrates how to calculate

where the bends should be made in an evaporator.

Measure interior of box from the point where the

edge of the evaporator will be located. In this

example, the evaporator will cover three sides of the

box. The lengths of the box wall the evaporator will

cover are:

BC = 18"

CD = 12"

c

b

a

B

A

Page 12

Isotherm Classic Compact Technical Data

Model Max Box

Size

Cu. Ft.

2009 4.4 2.5 10.6 6.3 6.1 9.4 8.3 3.3 Small “O” 24 BD35F none

2309 5.3 4 10.6 6.3 6.1 12.6 9.1 3.9 Medium “O” 24 BD35F Black 698 Ohm

2503 7.1 6 10.6 6.3 6.1 15.0 11.0 5.5 Large “O” 24 BD50F Black 698 Ohm

2007 3.5 2.5 10.6 6.3 6.1 9.8 13.8 4.3 Small “L” 24 BD35F none

2010 4.4 4 10.6 6.3 6.1 15.7 8.3 6.7 Large “L” 24 BD35F Red 1.50 KO

2005 2.1 2.5 10.6 6.3 6.1 13.8 5.1 0.5 Small Flat 24 BD35F none

2013 14.1 6.5 10.6 6.3 6.1 55.0 12.0 0.5 V. Large Flat 24 BD50F Red 1.50 KO

2017 4.4 5 10.6 6.3 6.1 39.4 10.6 0.5 Large Flat 24 BD50F Red 1.50 KO

Dimensions in inches

Max

Current

Amps

Dimensions of

Compressor

L W H L W H

Dimensions of

Evaporator

Voltage

Fuse

12/24 volt

15 A Car type blade fuse.

Evaporator

Style

Weight

lbs

Danfoss

Compressor

Model

Resistor

Radiosuppression

Battery protection

Fulfills EMC directives CE-marked

Power cut-off at 10.4 (22.8) volt.

Re-start at 12 (24) volt.

Loading...

Loading...