Isoplam L030002 User Manual

1

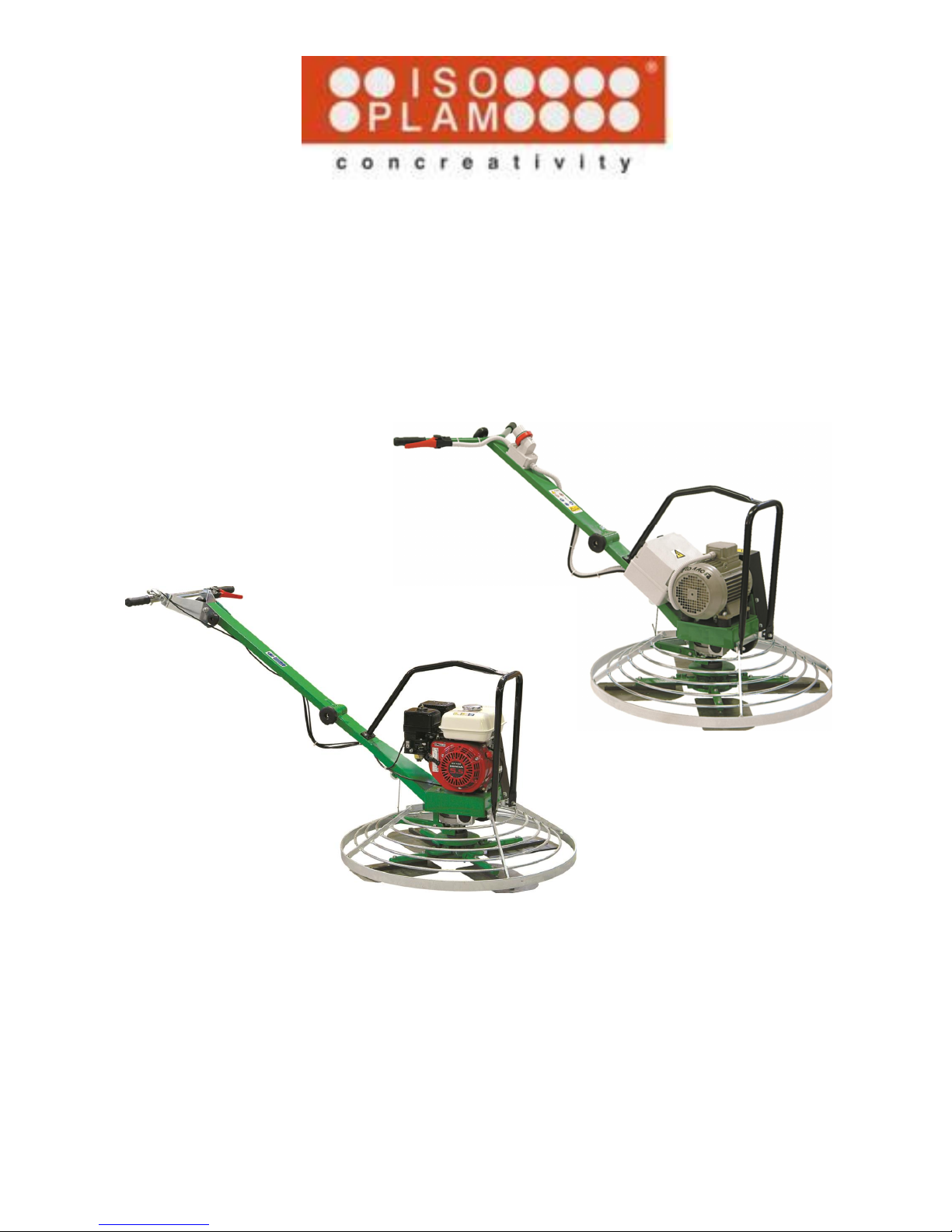

CONCRETE POWER TROWEL L030002

USER MANUAL AND SPARE PARTS LIST

2

Business Man Manual – Parts book

Isoplam s.r.l.

Building and road equipments

Address:

Via E.Mattei, 4

31010 Maser (TV) Italy

Phone 039 0423 925023

Fax number 039 0423 926119

E-mail: info@isoplam.it

Web: www.isoplam.it

CONCRETE POWER

TROWEL L030002

SERIAL NUMBER …………….

3

1. General precaution’s

2. Machine’s presentation

3. Machine’s identification

4. Instructions for the unpack of the machine

5. Instructions for the machine installation

6. Mounting and dismounting of the blades and

smoothing plate

7. Security working instructions

8. Working

9. Controls before starting

10. Starter

11. Instructions for use

12. Stopping

13. Maintenance

14. Guide to the search of anomalies and remedies

15. Transport

16. Technical data

17. Spare parts list

18. CE European Conformity Declaration

4

Introduction

Isoplam thanks to have purchased the L030002 Power Trowel. This manual must be considered

an integral part of the machine and it must follow every stage of sale until the last user.

Every machine is perfectly checked before it leaves the factory.

Warning!

THIS SYMBOL WILL BE USED EVERY TIME THERE IS A PARTICULAR

DANGER FOR THE USER.

Warning!

TO READ CAREFULLY THIS USER MANUAL

This manual has been written in order to help the user for the correct use of the

machine, to explain the safety norms in force in the European Community and to

eliminate the possible risks for a wrong use.

This machine must be utilised only at the use for which has been designed and that is

for the levelling and finishing of the concrete floors. Every other use is considered

improper and dangerous.

Consequently the manufacturer not is responsible for possible damages at persons or at

things coming from improper and wrong uses made on the same machine.

In addition, at these norms, please observe the safety instructions into force in the

building sites and in the workshops.

The ISOPLAM S.r.l. can make any modifications or improvements to its products

manufactured, without to inform the users in advance.

Warning!

IT IS FORBIDDEN TO REPRODUCE ANY PART OF THIS USER MANUAL.

To contact our Zone Dealer more near to You or our Assistance Service

Department for any questions or problems you need.

ISOPLAM S.R.L.

Via E.Mattei, 4 – 31010 Maser (TV) ITALY

tel. : 039 0423 925023 Fax : 039 0423 926119

Email : info@isoplam.it

WEB: www.isoplam.it

5

Instructions for use the L030002 Power Trowel

1. General precaution’s

·

Warning!

To move away the children from the job area. When the job is

completed please to put the machine in a safe place.

· The Isoplam Trowels are started with gasoline, diesel and electric motors and they

give the most safety if they are used according to the instructions. To read

carefully this user manual before starting the machine. A misuse can cause

damages to persons and the equipment.

· The buyer must entrust the use of this machine only to adults, who are both

physically and mentally suitable. He must make sure that these persons are able

to use correctly the machine.

· The Trowels can be started only if all performances and safety norms into force

are observed.

· The persons who work with these machines must know all safety norms for the

use.

· The use of this machine can expose the operator to a level of the superior noise to

the 85 dB (A). In fact, the resonant power of this machine is equal to the 101 dB

(A); whereas the emission level of sound pressure in the operator position is equal

to the 101 dB (A). Consequently, the users who use this machine must use all

protection accessory, as for example the crash helmet and stoppers for hearing

(D.L. 9 April 2008 n°81).

6

2. Machine’s presentation

· The ISOPLAM TROWEL is used to smooth the concrete backgrounds, prefabricated

panels and for small and large industrial flooring.

· To use 4 floating blades to level the floor or the smoothing plate (only in the LS60 and

L030002 versions).

· The finishing work can be started immediately after at job of levelling. In the winter,

when the climate is damp or cold, it is necessary to increase waiting time for the finish

smoothing.

· The essential controls have been put on the guide rudder for the user, so that the

ISOPLAM TROWEL is very easy to manipulate. The excellent balancing allows

without to strive the correct working.

· The rudder is adjustable to height, so that the operator can work in a more

comfortable position or to facilitate the transport, reducing the encumbrance.

· The handle is part of the safety device, which when realest will turn of the motor.

· The inclination of the four blades with the flooring surface is adjusted by a wheel that

is situated at the centre of rudder.

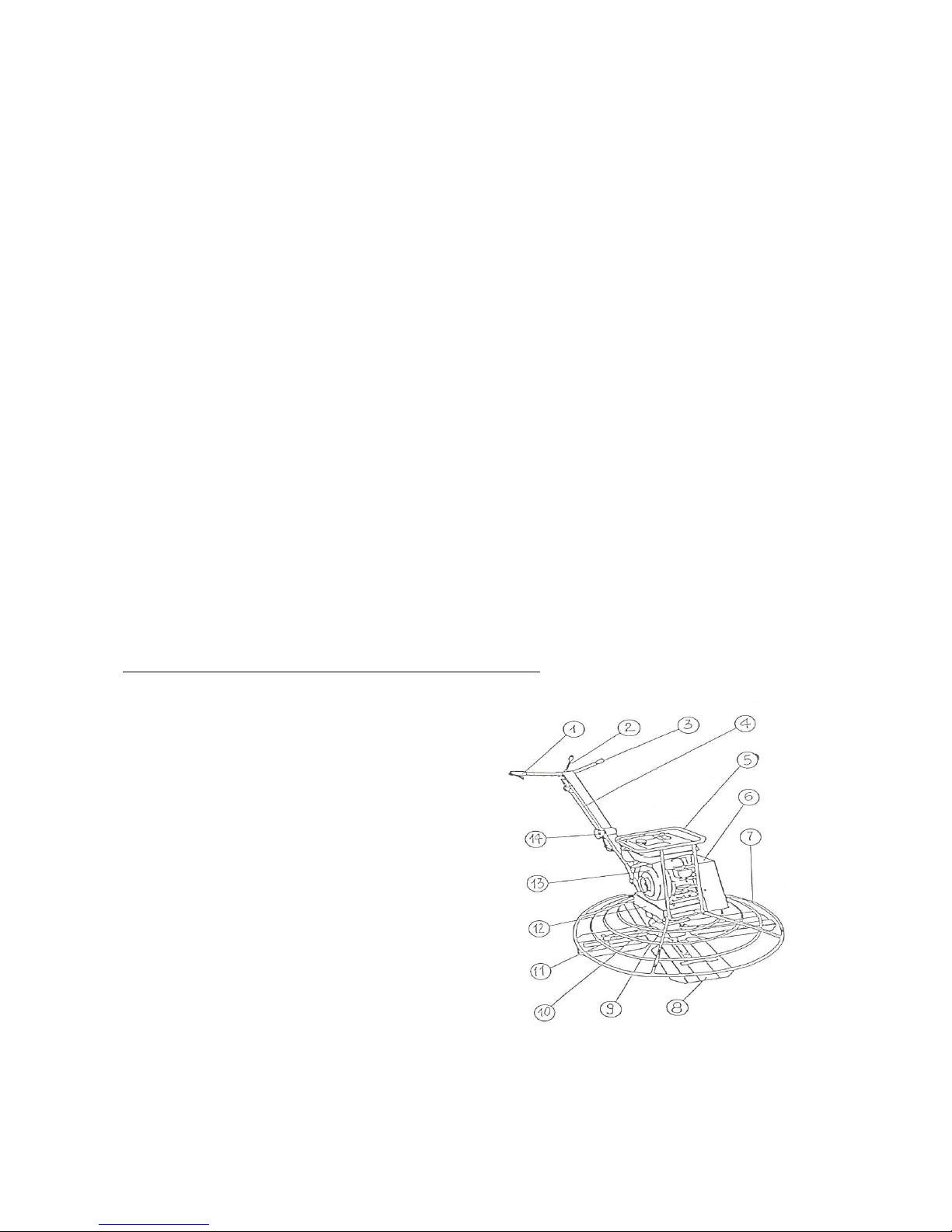

· THE MACHINE IS EQUIPPED OF THE FOLLOWING PARTS: (see the picture 01)

1. Security lever;

2. Wheel or lever for blades adjustment;

3. Handle;

4. Guide rudder;

5. Motor guard;

6. Belts guard;

7. Finishing or combination blades;

8. Cruise;

9. Pivots for blades;

10. Floating blades;

11. Circle of protection;

12. Motor plate;

13. Recoil starter of the motor;

14. Wheel to regulate the guide rudder;

Picture 01

7

3. Machine`s Identification

All the necessary data to identify the machine are on the nameplate “A” (see the picture 02)

situated on belts guard “B”.

4. Instructions for the unpack of the machine

The accessories supplied to the buyer with the machine are the following:

N. 01 USER MANUAL, SPARE PARTS LIST AND EUROPEAN CONFORMITY DECLARATIONS.

N. 01 TESTS AND WARRANTY CERTIFICATES

N. 01 PLASTIC ENVELOPE WITH N.17 KEY FOR THE MOUNTING AND DISMOUNTING OF THE BLADES

To execute with caution the outside packing elimination, so to avoid any damage to the

machine, above all at the rubber pipes and at the electrical connections.

5. Instructions for the machine installation

· The machine arrives completely mounted; it is ready for the use.

· The ISOPLAM TROWEL is delivered to the buyer full of fuel in the motor and in

the reduction gear, ready for the use.

· To loosen the joint wheel “C” (see the picture 03). To regulate the handle height

and to tighten the wheel “C”.

Picture 02 Picture 03

8

6. Mounting and dismantling blades

and smoothing plate

·

Warning!

To manipulate carefully the blades to avoid damages and lesions.

It is obligatory to use the protection gloves against cuts.

· To switch off the motor (to disconnect the socket from the electric system).

·

Warning!

To verify the springs connection "A" in the mounting of floating

blades and of smoothing plate, to avoid damages to the user (see the picture 04).

· To loosen the tightening screws “B” with the proper key in the mounting of the

finishing and of the combination blades (see the picture 05).

· To clean the blades pivots and the blades.

7. Security working instructions

· The work place must be perfectly in order without risks and well-lit.

·

Warning!

To remove the foreign persons from the neighbourhoods, before to

begin the levelling work.

· To wear always all proper protections, which spectacles, leather gloves, close-

fitting clothes, helmet and proper footwear to protect oneself against the sparks

and splinters of materials during the work.

· In case of job in the places closed: like rooms, galleries, etc… To make sure that

there is sufficient air for the health, because the exhaust gas contain the carbon

monoxide (they can cause a consciousness leak and be mortal).

· It is forbidden the use of machine in the places exposed to the explosions or with

dangerous products in the neighbourhoods.

Picture 04 Picture 05

9

8. Working

· To move backwards and forwards the machine at circular arches in the

longitudinal direction of the floor.

· It recommend itself to keep away from the surface just worked, moving itself at

small footprints.

· THE LEVELLING CAN BE MADE GENERALLY IN TWO PHASES:

Ø The FLOATING JOB: it is the hand finishing with a wooden tool. It becomes

a flat surface, without due irregularity to the concrete flowing.

Ø The FINISHING WORK: it is the hand finishing with a metal tool. It becomes

a perfect flat and uniform surface.

· With the machine complete of floating blades executes itself the FLOATING JOB.

You can start when the concrete hardened, so that it is possible to walk over

without leaving the too evident footprints. It is possible to make this operation with

a good yield, using also smoothing plate.

· If it forms itself a concrete roll around at the diameter of the blades rotation, this

means the working has been started too soon.

· To not stay long in the same place to not cause potholes of the machine.

· The FINISHING JOB follows the FLOATING JOB using only the finishing or the

combination blades, it is possible to start the FINISHING JOB when from the

concrete floor every humidity trace are disappearance. To obtain a good result in

the cold or damp environments, it is necessary to increase the waiting time before

to start the FINISHING JOB. To ascertain oneself the correct moment to begin

the FINISHING JOB, it is sufficient to press the hand palm on the surface and start

when it not sticks more to the skin. To have a good finishing it is necessary to

make at least two passes. During the first passage, the blades must have a few

degrees of inclination, to not make a too strong pressure on the surface. While the

second passage must start at the latest possible, but before the concrete is

hardened, naturally increasing also the blades inclination.

· The excellent results of the levelling operations much depend on the quality of the

equipments and the ability of the user.

Loading...

Loading...