INSTRUCTION MANUAL

MS 1000

START UP AND MAINTENANCE OF THE INSTRUMENTS _____________ 1

INTRODUCTION ___________________________________________ 1

SAFETY __________________________________________________ 2

GENERAL INFORMATION ON THE SENSORS INSTALLATION _________ 2

OVERALL DIMENSIONS _____________________________________ 3

OPERATING TEMPERATURES _________________________________ 4

ELECTRICAL CONNECTIONS OF SENSOR TO CONVERTER ___________ 5

GROUNDING INSTRUCTIONS ________________________________ 6

TORQUES (NM) FOR WAFER SENSOR’S BOLTS ___________________ 7

NOTES FOR PED DIRECTIVE FOR SENSOR ______________________ 8

DECLARATION OF CONFORMITY TO EUROPEAN

DIRECTIVE PED – 97/23/CE _________________________________ 9

1

MS1000 – SENSOR MANUAL

1000_EN_IT_IS_R0_PED

INTRODUCTION

– This manual is integral part of the product. Read carefully the instructions contained since

it contains important indications for the safety of use and of maintenance.

– The technical information and the relative products of this manual could be modied

without any previous notice.

– The ow meter must be used for the use it has been built for. The improper use, possible

tampering of the instrument or parts of it and substitutions of any components not original,

makes the warranty to decay automatically.

– The manufacturer is considered responsible only if the instrument is used in its original

conguration and setting.

– The owmeter makes measures of liquids with conductivity greater than 5µS/cm; it consists

of a sensor (described in this manual) and a converter, for it see the manual provided.

– If the sensor is supplied in compact version to the converter, consider the operating

temperatures more restrictive, otherwise refer to the respective manuals (page 5).).

– When transporting, unpacking and handling the owmeter, be careful and care.

– In the case of prolonged storage and of transport, use and store in the original container

in a dry place, do not place more than 3 packs one above the other.

– It is possible pallets storage and transport (in case of wooden crates do not place one

above the other).

– For the cleaning of the device use only a damp cloth, and for the maintenance/repairs,

contact the customer service.

– For the disposal of the device and of the packaging make strict reference to the regulations

– It is forbidden the reproduction of the present manual and of possible software supplied

with the instrument.

START UP AND MAINTENANCE OF THE INSTRUMENTS

– Before starting up the instrument, always make a sure connection to ground as suitable

to page 6.

– Verify periodically: the cables integrity, the tightening of the sealing elements (cable glands,

covers, etc.), the mechanical xing of the instrument on the pipe or on the wall stand

2

MS1000 – SENSOR MANUAL

1000_EN_IT_IS_R0_PED

Before using the instrument, always make a sure connection to the ground

Avoid any attempt to repair the instrument. If the instrument is not

functioning properly, please call the nearest assistance service

Pay maximum attention during the operations

ATTENTION !!!

DANGER !!!

SAFETY

GENERAL INFORMATION ON THE SENSORS INSTALLATION

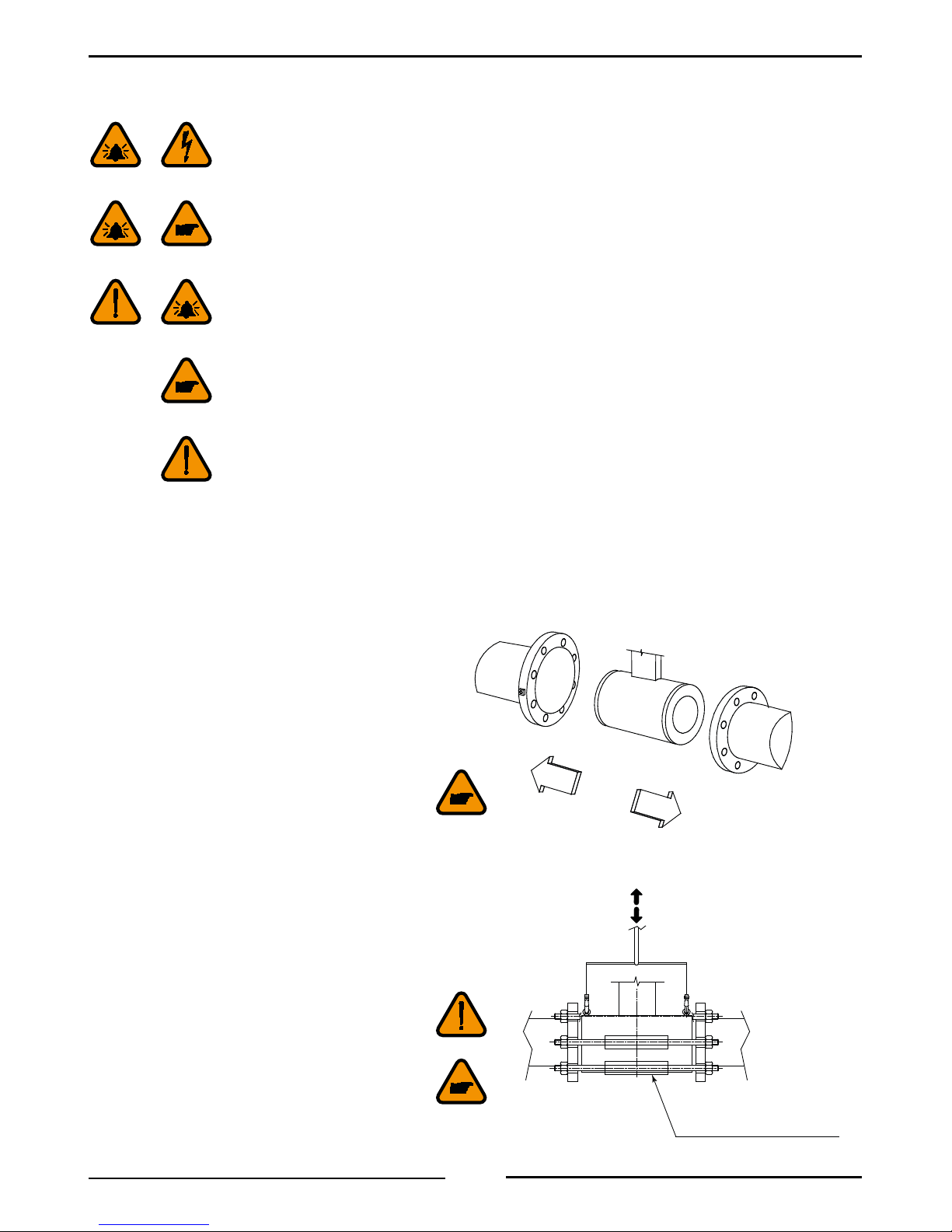

Lifting sensors

The sensors with eyebolts must be

lifted by the method shown below.

The eye-bolt are measured to sustain

exclusively the weight of the meter

?

-

+

Before install the sensor locate the

direction of the liquid in the piping

The sign of the ow rate is positive,

when the ow direction is from – to +

as printed on the tag plate.

If after the installation, for plant request

becomes necessary reverse the sign of

the ow, it is enough reverse the sign

of the coefcient KA

fLow direction

Centring cylinders

3

MS1000 – SENSOR MANUAL

1000_EN_IT_IS_R0_PED

OVERALL DIMENSIONS

DN

G

L

D

H

70

25

mm

(inches)

DN

25

(1”)32(1” 1/4)40(1” 1/2)50(2”)65(2” 1/2)80(3”)

100

(4”)

125

(5”)

150

(6”)

200

(8”)

250

(10”)

300

(12”)

350

(14”)

400

(16”)

L

+0 +0 +0 +0 +0 +0 +0 +0 +0 +0 +0 +0 +0 +0

-3

(-0.12)

-3

(-0.12)

-3

(-0.12)

-3

(-0.12)

-3

(-0.12)

-3

(-0.12)

-3

(-0.12)

-3

(-0.12)

-3

(-0.12)

-3

(-0.12)-5(-0.20)

-5

(-0.20)

-5

(-0.20)

-5

(-0.20)

100

(3.94)

100

(3.94)

100

(3.94)

100

(3.94)

150

(5.90)

150

(5.90)

150

(5.90)

180

(7.09)

180

(7.09)

200

(7.87)

250

(9.84)

300

(11.81)

350

(13.78)

400

(15.75)

H

147

(5.79)

153

(6.02)

161

(6.34)

177

(6.97)

199

(7.83)

209

(8.23)

235

(9.25)

263

(10.35)

291

(11.46)

362

(14.25)

417

(16.42)

467

(18.39)

527

(20.75)

579

(22.80)

D

62

(2.20)67(2.44)78(2.76)92(3.39)

108

(4.25)

118

(4.65)

144

(5.67)

172

(6.77)

200

(7.87)

271

(10.67)

326

(12.83)

376

(14.80)

436

(17.17)

488

(19.21)

G - - - - - - - - -

144

(5.67)

194

(7.64)

244

(9.60)

294

(11.57)

344

(13.54)

Weight

kg (lbs)

1.2

(2.64)

1.6

(3.52)

1.8

(3.96)2(4.4)

3.6

(7.92)

3.8

(8.36)5(11)

7.8

(17.16)

8.2

(18)

18.2

(40)24(53)27(59)32(70)39(86)

Usable

anges

PTFE-EBONITE: PN10, PN16, PN25, PN40, ANSI150, ANSI,300 PP: PN10,

PN16, ANSI150

PTFE-EBONITE: PN10, PN16, ANSI150

4

MS1000 – SENSOR MANUAL

1000_EN_IT_IS_R0_PED

shrewdness and Precautions

NO YES

OPERATING TEMPERATURES

EBONITE LINING PP LINING PTFE LINING

Liquid

temperature

Ambient

temperature

Liquid

temperature

Ambient

temperature

Liquid

temperature

Ambient

temperature

Min. Max Min. Max Min. Max Min. Max Min. Max Min. Max

°C 0 80 -5 60 0 60 0 60 -20 130 -10 60

°F 30 176 23 140 32 140 32 140 -4 266 14 140

LONG PIPE

LONG PIPE

ANTI VIBRATION JOINTS

3 DN

2 DN

GASKET THICKNESS +4mm

For vertical installations

with descending ow

direction contact the

manufacturer

Avoid the installation of

the sensor in a long pipe

line,without any support

of the same

Avoid the functioning

with the pipe partially

empty

Avoid the installation

near curves or hydraulic

accessories

Avoid the approach of

the ange and counter

ange using the closing

force of the nuts

For vertical installations is

preferable an ascending

ow

For installations on long

pipe line, please use the

anti vibration joints

During the functioning the

pipe must be completely

full of liquid, or completely

empty

Install the sensor away

from curves and hydraulic

accessories

Before tightening the nuts

approach as more possible

the ange of the piping to

the ange of the sensor

5

MS1000 – SENSOR MANUAL

1000_EN_IT_IS_R0_PED

ELECTRICAL CONNECTIONS OF SENSOR TO CONVERTER

connections to converter: see ProPer manuaL

VERSION SUITABLE FOR

SENSOR’S

CONNECTION

COMPACT ALL SENSORS MODEL NO CONNECTIONS

SEPARATE WITHOUT

JUNCTIONS-BOX

STAINLESS STEEL MODEL

NO CONNECTIONS REQUIRED

(CABLE ALREADY CONNECTED

AND POTTED)

SEPARATE WITH JUNCTIONS-

BOX

(WITH OR WITHOUT

PREAMPLIFIER)

ALL CARBON STEEL MODELS

NO CONNECTIONS REQUIRED

(CABLE ALREADY CONNECTED

AND POTTED)

SEPARATE WITH

PREAMPLIFIER

ALL STAINLESS STEEL MODEL

NO CONNECTIONS REQUIRED

(CABLE ALREADY CONNECTED

AND POTTED)

6

MS1000 – SENSOR MANUAL

1000_EN_IT_IS_R0_PED

GROUNDING INSTRUCTIONS

For correct operation of the meter is NECESSARY that the sensor and the liquid are equipotential,

so ALWAYS connect the sensor and converter to ground:

grounding with metaLLic PiPe

grounding with insuLating PiPe

g

rounding when there is a cathodic Protection over the PiPe

INSULATING GASKET

METALLIC RING

If the sensor must be install in the piping with a

cathodic protection, is necessary:

• using insulating bushes to isolate the bolts

• Grounding metallic rings should be provided

to ground the liquid using insulating gasket

between the rings

IMPORTANT: The ripple of DC power source

used for cathodic protection shall be = 0

INSULATING GASKET

METALLIC RING

If the sensor has to be mounted on a pipe made of

an insulating materials necessary:

• Install two metallic ring between the sensor

anges and the counter anges of the pipe line

or

• Use a sensor with the additional grounding

electrode

7

MS1000 – SENSOR MANUAL

1000_EN_IT_IS_R0_PED

TORQUES (NM) FOR WAFER SENSOR’S BOLTS

OPERATIVE PRESSURE

Kpa 1600 4000

psi 260 600

DN EBON. PP PTFE

25 19

25

[32]

32 28

43

[40]

40 36

53

[63]

50 52

68

[35]

65 75

45

[53]

80 41

53

[68]

100 56

83

[94]

125 71

112

[130]

150 106

135

[113]

200

288

(433)

250

408

(455)

300

510

(683)

350

598

(946)

400

821

(911)

• Tighten uniformly in diagonally opposite sequence

• The torque listed in tab are applicable to anges: EN1092-1, DIN2501, BS4504, ANSI

B16.5, JIS

• Is recommended the use of gaskets DIN 2690

• (***)= FOR SENSORS ON ANSI 150 FLANGES

• [***]= FOR SENSORS ANSI 300 FLANGES

8

MS1000 – SENSOR MANUAL

1000_EN_IT_IS_R0_PED

NOTES FOR PED DIRECTIVE FOR SENSOR

Here below the tables of products subject to Directive 97/23/EC.

The models are : MS1000/MS2410/MS2500.

The tables show which category of PED is applicable according to the water operating

temperature (TAB A T <110 ° C TAB B T> = 110 ° C), sensor’s DN and its nominal pressure.

DN

NOMINAL PRESSURE (PN)

10 16 25 40

25

USE PN 40

E

32 E

40 E

50

USE

PN 16

E

USE

PN 40

E

65 E E

80 E E

100 E E

125 E E

150 E E

200 E E E E

250 I I I I

300 I I I I

350 I I I I

400 I I I I

450 I I I I

500 I I I I

600 I I I I

700 I I I I

800 I I I I

900 I I I I

1000 I I I I

1200 I I I I

1300 I I I I

1400 I I I I

1500 I I I I

1600 I I I I

1700 I I I I

1800 I I I I

2000 I I I I

2400 I I I I

tab. a

Ped

directive for water with

temPerature <110°c

aLL

Lining : PP, ebonite,Ptfe

DN

NOMINAL PRESSURE (PN)

10 16 25 40

25

USE PN 40

E

32 E

40 II

50

USE

PN 16

I

USE

PN 40

II

65 I II

80 I II

100 I II

125 I II

150 I II

200 I I II II

250 I II II II

300 I II III III

350 I III III III

400 II III III III

450 II III III III

500 II III III III

tab. b

Ped

directive for water with

temPerature >=110°c

onLy

Ptfe Lining

Legenda

E OUT OF DIRECTIVE

I PED CAT. I

II PED CAT. II

III PED CAT. III

For products that falls in category I, is valid the declaration of conformity available on the

following page; the products in Category II and III are supplied with a specic declaration of

conformity for each instrument

9

MS1000 – SENSOR MANUAL

1000_EN_IT_IS_R0_PED

DECLARATION OF CONFORMITY TO EUROPEAN

DIRECTIVE PED – 97/23/CE

Prepared in accordance with Annex VII Legislative Decree no. 93 of 25 February 2000

transposing Directive no. 97/23/EC

Description of the

product

Misuratore di portata di liquidi del gruppo 2

Temperatura massima del liquido 110°C

Model family MS 2500 – MS1000 – MS2410

Conformity assessment

procedure applied

Allegato II - categoria I - Modulo A

Standard reference UNI EN 13480-3

Hemina declares that the equipment specied above model should fall within the scope

of the Directive, are:

¾ comply with the requirements of Directive 97/23/EC - PED and DL 93/2000 which

transposes in Italy

Identication and signature of the legal representative:

Roberto Guazzoni – President of Board of Directors

Service

Isoil Industria spa

20092 Cinisello Balsamo (MI) Italy

27, via F.lli Gracchi

Phone +39-02-66027.1

Fax +39-02-6123202

E-mail: isomagservice@isoil.it

Isoil Industria spa

Head ofce

20092 Cinisello Balsamo (MI) Italy

27, via F.lli Gracchi

Phone +39-02-66027.1

Fax +39-02-6123202

E-mail: sales@isoil.it

Web: www.isoil.com

Loading...

Loading...