Iso PT-450, PT-450M Owner's Manual

OWNER’S MANUAL

Important:Read these instructions before installing, operating or servicing this product.

MODEL: PT‒ 450 / PT‒ 450M

WELDING POSITIONER

Serial number:1506003 ~ and later

Revised date:May. 14th , 2015

RD-8450E

TABLE OF CONTENTS

Introduction

General Information

Operation Instruction

Service

Parts list

Circuit diagram

Appendix

Revision

Instruction ......................................................................................................... i

Safety precautions............................................................................................ ii

Limited warranty ................................................................ ............................... iii

1.1 Introduction ................................................................................................ 1

1.2 Specifications ............................................................................................. 2

2.1 Operation panel .......................................................................................... 4

3.1 Maintenance ............................................................................................... 6

3.2 Troubleshooting guide ................................................................................ 7

4.1 Parts list - machine .................................................................................... 10

4.2 Parts list - machine .................................................................................... 12

4.3 Parts list - control box (front) ...................................................................... 13

4.3 Parts list - control box (rear) ...................................................................... 14

5.1 control circuit diagram ............................................................................... 15

5.2 Diagram – tilting control box… ................................................................... 16

Wiring diagram .............................................................................................. 17

Revision.. ........................................................................................................ 18

i

INSTRUCTION

A procedure, which if not properly followed, may cause injury to the

operator or others in the operating area.

Equipment identification

Receipt of equipment

The identification number specification or part number, model, and serial

number of this unit usually appear on a nameplate attached to the control

panel; record these numbers for future reference.

When you receive the equipment, check it against the shipping documents.

Make sure it is complete and inspect the equipment for possible damage

during shipping. If there is any damage, notify the carrier immediately to file a

claim.

Move the equipment to the installation site before uncrating the unit. Use care

to avoid damaging the equipment when using bars, hammers, etc. to uncrate

the unit.

Falling machine due to lifting device failure may cause death or injury.

﹡ Lifting device may fail when overloaded.

﹡ Avoid sudden jerks, drops or swinging.

﹡

Check lifting device components visually for looseness and signs of metal

fatigue.

﹡

Before changing any hardware, check grade and size of bolts, and replace

with bolts of equal or higher size and grade.

WARNING

WARNING

ii

SAFETY PRECAUTIONS

Operation and maintenance involves potential hazards. All operators and

personnel should be alerted to possible hazards and precautions should

be taken to prevent possible injury.

Electrical safety

Maintenance

Individual safety

Machine:

﹡

The counter, safety device against excess current and electrical installation,

are compatible with its maximum power and its main voltage.

﹡

The connection, single-phase or three-phase, is possible on a stand

compatible with the plug of its cable link.

﹡

If the cable is connected with the electrical network, the earth, must never be

cut by the protection device against electrical shocks.

Work Place:

﹡

Be very careful to avoid contact between metal part and phase conductor

and the neutral of electric network.

﹡

Electrical messes of different electrical machine and apparatus are

connected between themselves and with the terminal of earth neutral wire.

Interventions:

﹡

Before control and repair, see the apparatus is switched off and insulated.

﹡

Connection with fixed installation cable is impossible.

﹡

It’s on “STOP” and connection is impossible.

﹡

Some apparatus are provided with starting circuit HT HF (with a plate). Never

enter into the corresponding switch cupboard.

﹡

Only qualified persons are authorized fo

r intervention concerning

electrical

installation.

﹡

Often check the insulation and connection good state of apparatus and

electrical accessories: taps, appliance cords, coatings, switch, extension

cords, etc.

﹡

Maintenance and repair of insulating coatings operations are very important.

﹡

Do repair with a specialist or better replace defective accessories.

﹡

Check regularly the right adjustment and the non-heating of electrical

connections.

﹡

The operator must be dressed and protected in relation with his work.

﹡

Avoid contacting metal parts connected or accidentally connected.

﹡

Wear leather gloves with gauntlet.

﹡

Safety clothes:gloves, apron, safety shoes protect the operator and his

assistants against burns of hot parts, projections and slag.

WARNING

iii

T

T

T

H

H

H

I

I

I

S

S

S

P

P

P

A

A

A

G

G

G

E

E

E

I

I

I

S

S

S

B

B

B

L

L

L

A

A

A

N

N

N

K

K

K

1

1.1 INTRODUCTION

Instruction

Main features

﹡ Welding positioned is normally used in the rotating and welding of the pipe or

round work pieces.

﹡ It can be applied on all kinds of welding: SMAW, MIG, TIG, Plasma, etc.

﹡ It can adopt different fixture to get the welding effects you require.

﹡ The table can be tilted for 0~135º, which is convenient for all angles of the pipe

welding or for adjusting welding angles. (It can adopt either manual or electrical

operation.)

﹡ The table has a through hole of 25 mm, which is convenient for the long pipe

welding or the purge shielding gas.

﹡ On the table, there are 4T- slots, suitable for all kinds of fixtures and grippers.

﹡ Ground current conduction:200Amps (400Amps option).

﹡ All units are high frequency protected.

2

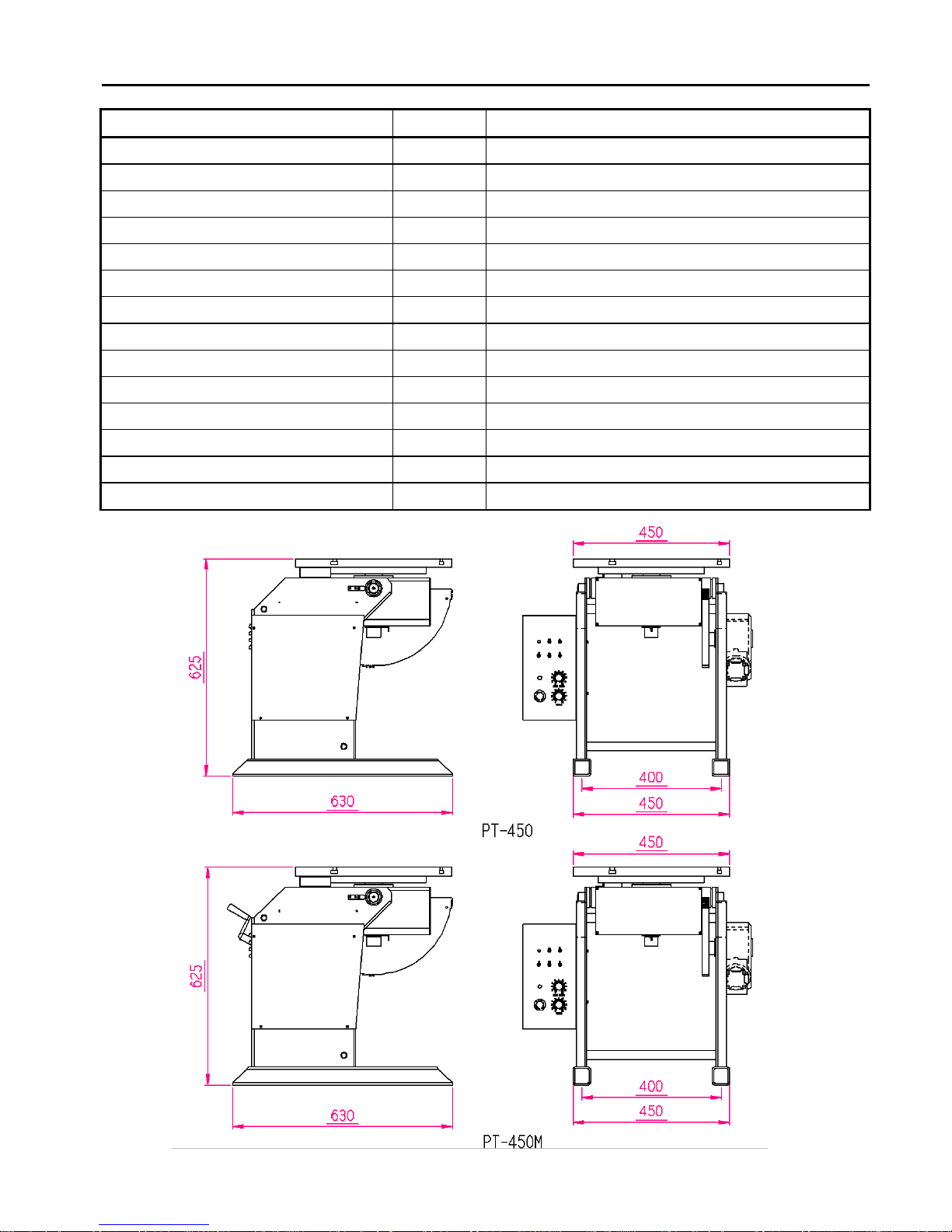

1.2 SPECIFICATIONS

Model

Unit

PT- 450 / PT- 450M

Power Input

~

1 Phase, 110V/220V, 50/60Hz

Capacity (Horizontal)

kg

450/300

Rated centre of gravity

mm

300

Rated eccentricity

mm

100

Table diameter

mm

450

Rotation speed

rpm

0.12-2.5

Spindle thru hole

mm

25

Earthing

Amp

200A (Max.400A)

Tilt range

deg.

0-135

Welding timer

sec.

0-60

Overall length

mm

630

Overall width

mm

650

Overall height

mm

625

Weight

Kg

134

Loading...

Loading...