Page 1

EN

INSTRUCTIONS FOR USING, MAINTAINING AND INSTALLING THE HOOD

ISLAND AND ANGULAR HOODS

Page 2

INSTRUCTIONS FOR USING, MAINTAINING AND INSTALLING THE HOOD

ATTENTION: The hood must only be installed by a qualified technician.

The company accepts no liability if it is installed by an unauthorised person.

Please read these instructions carefully before beginning the installation. Conserve this handbook together with the

hood

WARNINGS

This appliance can be used by children aged from 8 years and above and persons with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge if they have been given supervision or

instruction concerning use of the appliance in a safe way and understand the hazards involved.

Children shall not play with the appliance. Cleaning and user maintenance shall not be made by children

without supervision.

Before cleaning or performing any periodic or urgent maintenance to the hood, ensure the power is turned

off by removing the plug from the socket and turning the main switch to 0 (off).

Do not connect the hood to any piping used for combustion appliances, such as burners, boilers or fireplaces.

Check that the main power supply corresponds to the voltage required by the hood, which is given on the

silver label stuck inside the hood. Ensure that the electric system is correctly earthed and that the earth

discharge works correctly.

When cooking do not use any materials that could form high or unusual flames. Oil that has been used

twice and fats are very dangerous and could easily catch fire. Do not prepare flambè dishes under the

hood.

Once the specialized technician has completed the installation of the hood equipped with a remote motor,

all the leads, connectors, ground connections and the remote motor must not be accessible to the user.

Only the installer is granted access by removing the screwed on panels.

Respect local legislation and regulations issued by the relative authorities regarding the exhaust air when

the suction is operating. Failure to respect and perform all the maintenance and cleaning operations described in this handbook could cause a fire hazard.

ATTENTION: Accessible parts may become hot when the hood is used with cooking appliances

INSTALLATION

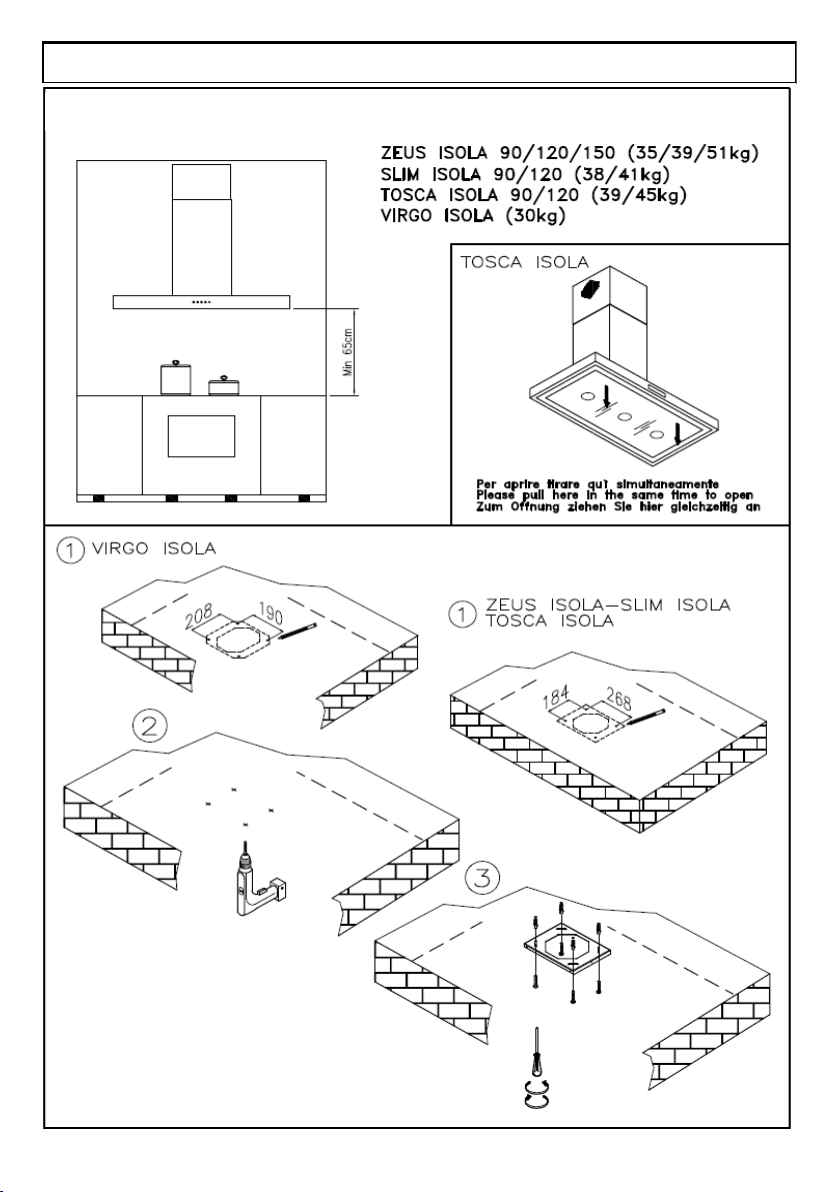

The minimum safety distance between the bottom of the hood and the top of the cooking hob must be 65 cm., smaller

distances must be previously authorised by the manufacturer. (see installation drawings)

The hood can be used for both filtering and suction.

When the filtering function is operating, i.e. with air recycle, carbon filters must be used (refer to the paragraph on

CARBON FILTERS).

When the suction function is operating, i.e. exhausting the filtered air on the outside, a suitable compensation system

must be used according to current standards in force. The diameter of the fume exhaust pipe must be the same or

greater than the diameter of the hood pipe union.

There must be sufficient ventilation in the room where the hood is installed, to allow the simultaneous use of other

appliances that use gas or other fuel.

Page 3

Hoods equipped for remote motors

The hoods equipped for remote motors have a specific connector for the remote motor lead connection. The connect-

or is situated inside the hood. Pass the remote motor lead into the hood through the aperture in the hood itself

(usually near the fume exit hole) and join the two connectors. Refer to the figures in the remote motor instruction

book when performing this operation.

Hoods without motor (Art.*0***) must only be installed and connected with extraction units with a max. output of

640W, as supplied and indicated by the manufacturer.

Once the specialized technician has completed the installation of the hood equipped with a remote motor, all the

leads, connectors, ground connections and the remote motor must not be accessible to the user. Only the installer is

granted access by removing the screwed on panels.

ASSEMBLY INSTRUCTIONS

Attention: Before proceeding with the installation, make sure that the screws and the anchors already sup-

plied, are suitable for the type of wall the hood must be fixed to.

To assemble the hood use the accessories that are supplied and follow the instructions given in the enclosed handbook.

ELECTRIC WIRING

The electric wiring must be performed by a specialised electrician fully respecting current standards and legislation

in force. Check that the power supply corresponds to the voltage requested by the hood, which is given on

the silver label stuck inside the hood. Ensure that the wiring system conforms to current standards and the earth

discharge works efficiently. Pay special attention to the hood power cable, ensure that it does not pass through any

holes without a cable clamp. For direct connection to the electrical mains is necessary to provide a device that en-

sures disconnection from the electrical mains, with an opening distance of the contacts that allows the complete

disconnection under the conditions ofovervoltage category III, in accordance with the rules of installation.

The plug or omnipolar switch must be accessible when the unit is installed

If the power cord is damaged, it must be replaced by a special cord or assembly available from the manufacturer or

its service agent. The cable used must be of type H05VV-F 3 x 0.75 mm2 minimum cross-section.

The manufacturer declines all responsibility if the current accident prevention standards in force are not

respected, which are needed for the wiring system to operate correctly

CONTROLS

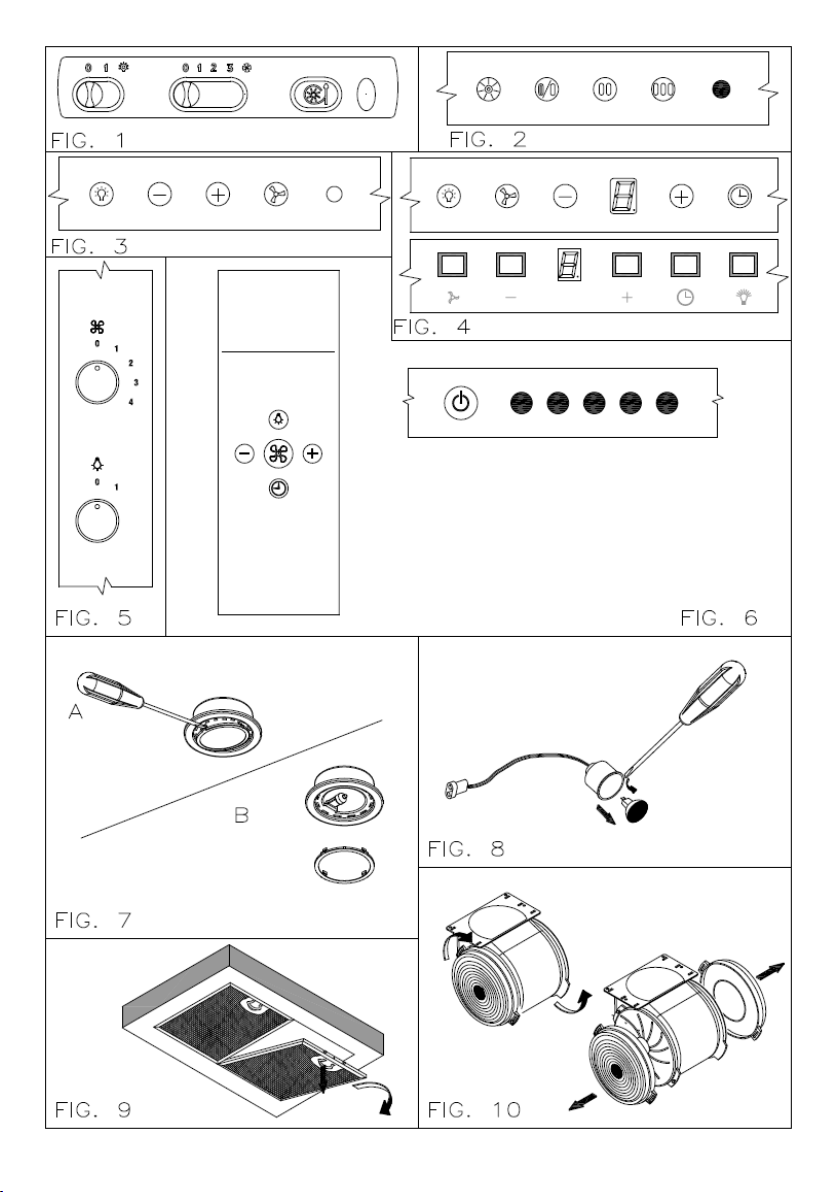

SLIDER CONTROL (Fig. 1)

There are two slider switches on the slider control version.

> One for turning the lights on and off.

> One for turning the motor on and off and for selecting 1^, 2^ or 3^ speed.

KEYBOARD CONTROLS (Fig. 2)

There are four buttons on the keyboard control version:

> One for turning the lights on and off.

> One for turning the motor on at 1st speed and for turning it off.

> One for turning it on at 2nd speed.

> One for turning it on at 3rd speed.

Page 4

SOFT TOUCH CONTROL (Fig. 3)

There are four soft touch buttons on this version and a variable colour led (green min. speed, red max. speed).

> One button for turning the lights on and off.

> One button for turning on at 2nd speed and for turning the motor off.

N.B. If this button is kept depressed for more than three seconds, the automatic function is activated to turn the

hood off function after 10 minutes, the led flashes slowly .

> Two buttons + and - for increasing and reducing the motor speed. At the 4th motor speed (intense) the led flashes

quickly and after 5 minutes the 2nd speed is automatically set.

DIGITAL CONTROLS \ TOUCH CONTROLS (Fig. 4)

In this version there are five soft touch buttons and a display

> One button for turning the lights on and off.

> One button for turning on at 2nd speed and for turning the motor off.

> Two buttons + and - for increasing and decreasing the motor speed. At the 4th motor speed (intense) the number

on the display flashes and after 5 minutes the 2nd speed is automatically set.

> A TIMER button for turning the motor off after 10 minutes. When the timer is activated, the number on the display

flashes.

Special functions:

After 100 hours use, a 0 or a letter A will start flashing on the DISPLAY to remind the user to clean the metal filters.

After washing the metal filters, reset the hour meter by pressing the TIMER button for more than three seconds with

the hood turned off. When the hour meter has been reset a dash appears on the display, with the hood turned off.

ROTARY CONTROL (Fig.5)

In the rotary control version there are three knobs:

> One knob for switching light decorative on and off

> One knob for switching lights on and off

> One knob for speed selection (1^,2^,3^,4^) and turning the motor off. At the 4th motor speed (intense) after 5

minutes the 2nd speed is automatically set.

RADIO- CONTROL (Fig. 6)

The button ON/OFF on the hood turn on simultaneously lights and the motor at the second speed or it turns off everything. After 100 working hours of the suction motor the red led will start to flash indicating the need to wash metals filters. To cancel the filters alarm, when the suction motor is switched off, you must press button ON/OFF long

enough.

Radio control:

At the first use it is necessary to start remote control learning. With the hood turned off, keep button “+” for a long

time. The remote control learning is indicated with the flashing alarm filters led. If within one minute arrive a valid

remote control code (sent by pressing any button of the remote control ) the led will be on continuously for 3 seconds and then it will turn off, indicating the proper learning.

Control buttons:

> One button for turning the lights on and off.

> One button for turning on at 2nd speed and for turning the motor off.

> Two buttons + and - for increasing and decreasing the motor speed. At the 4th motor speed (intense) the led flashes and after 5 minutes the 2nd speed is automatically set.

> A TIMER button for turning the motor off after 10 minutes.

Page 5

USE AND MAINTENANCE

Before beginning any sort of cleaning or maintenance work, turn power off to the hood by turning the main

switch to 0 (OFF).

Changing the light bulbs

12V halogen G4 attachment: Use a screwdriver to unscrew the glass support ring (Fig. 6). Remove the glass and change the light bulb with another identical. Replace the protective glass and screw back the ring. The light bulbs can be

purchased in any electrical supply shop.

Dichroic lamp G4 attachment: Use a screwdriver to remove and change the dichroic lamp with another identical (Fig.

7).

LED spotlight replacement should only be carried out by qualified technicians using only original spare parts.

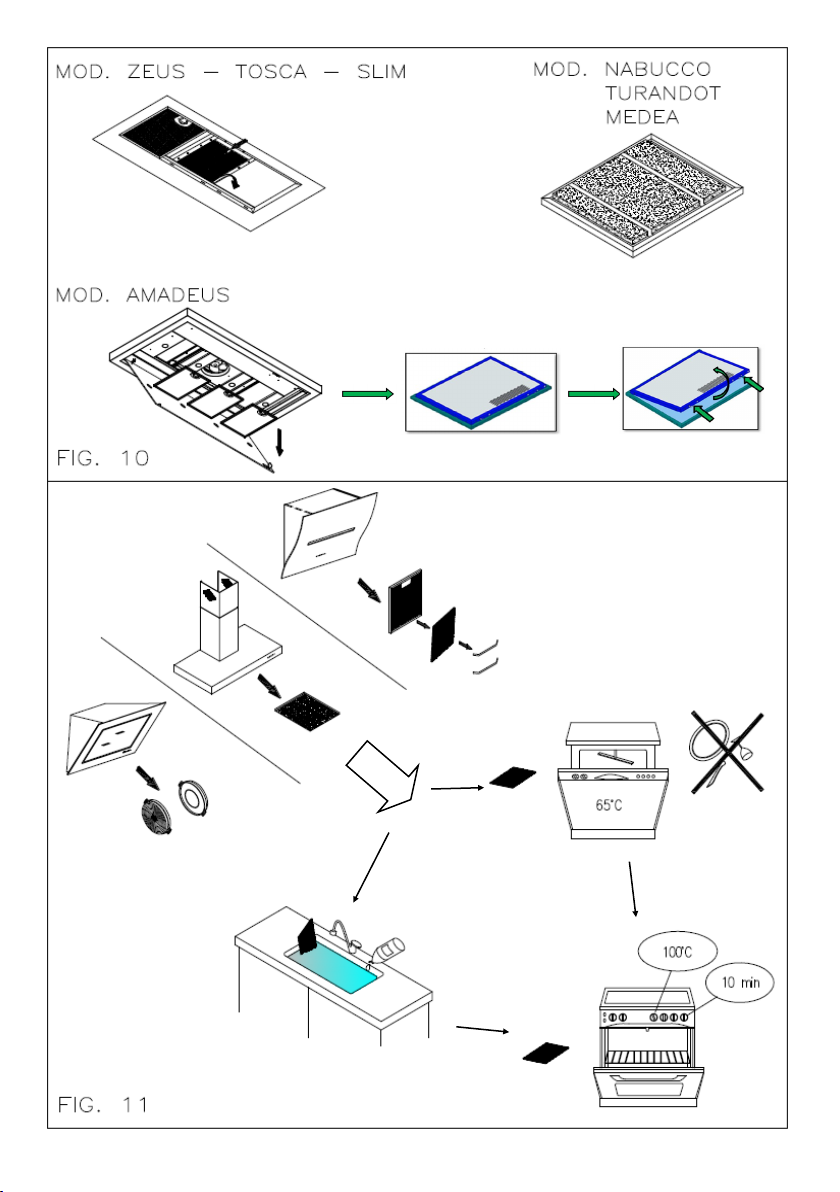

Cleaning the metal filters:

The metal filters fitted in the hood should be washed every 2-3 months, depending on how much the hood is used,

using hot water and a liquid detergent that is not too aggressive. The metal filters can be removed by the special

handle, unhooking the front part of the filter and pulling it downwards (Fig. 8)

Carbon filters

If the hood is used with an internal recycle filtering system, then active carbon filters must be used. The active carbon in the filters traps the cooking smells. To remove and change the filters, refer to fig. 9.

POLYESTER carbon filters cannot be reused or washed and must be periodically changed (every 4 months if the hood

is used for 2 hours every day). Saturate filters could be a fire hazard. Depending on the hood model, the carbon filters are round or rectangular.

LONG LIFE carbon filter can be cleaned and reactivated. The filter should be cleaned every other month if used normally. The filter is best cleaned in a dishwasher at the highest temperature using normal washer detergent. The filter

should be washed on its own to prevent particles of food from fastening in it and then causing an unpleasant smell

later on. To reactivate the carbon the filter should be dried in the oven. Chose upper/ lower heat and maximum 100 °

C and try the filter for 10 minutes. The filter must be changed when it no longer absorbs the cooking smells sufficiently. (fig.10)

Cleaning the hood

The surfaces of the hood should be cleaned frequently, to avoid the risk of having to remove built up and encrusted

deposits and stains.

For the painted or copper plated hoods just use a soft cloth with warm water and a neutral detergent. Do not pour the

detergent directly onto the hood or use powdery or abrasive products

For the stainless steel hood, use special products and cloths for satin finish stainless steel (not abrasive, corrosive

detergents or detergents containing chloride), ensuring to clean in the same direction as the satin finish.

Do not use aggressive products, chemical solvents or derivatives of oil distillates that could leave oily traces which

could cause oxidation and polymerisation.

Condensation in the hood

Induction or glass ceramic hobs heat food up very quickly, creating cooking steam before the glass or steel surface

of the hood has heated up, which causes condensation on the hood that then drips. Another cause for condensation

could be that the fume pipe is not the size we recommend (see INSTALLATION). The steam that remains inside the

hood while it is cooling down condensates and drips. Therefore it is advisable to turn the hood on ten minutes before

starting to cook and when you have finished, leave it on so that all the fumes in the pipe are expelled.

Furthermore, it is important to clean the filters frequently and if they are worn they should be replaced (see CLEANING THE METAL FILTERS).

The manufacturer accepts no responsibility for damage to the surface of the hood due to failure to respect

these instructions.

Page 6

33

Page 7

34

Page 8

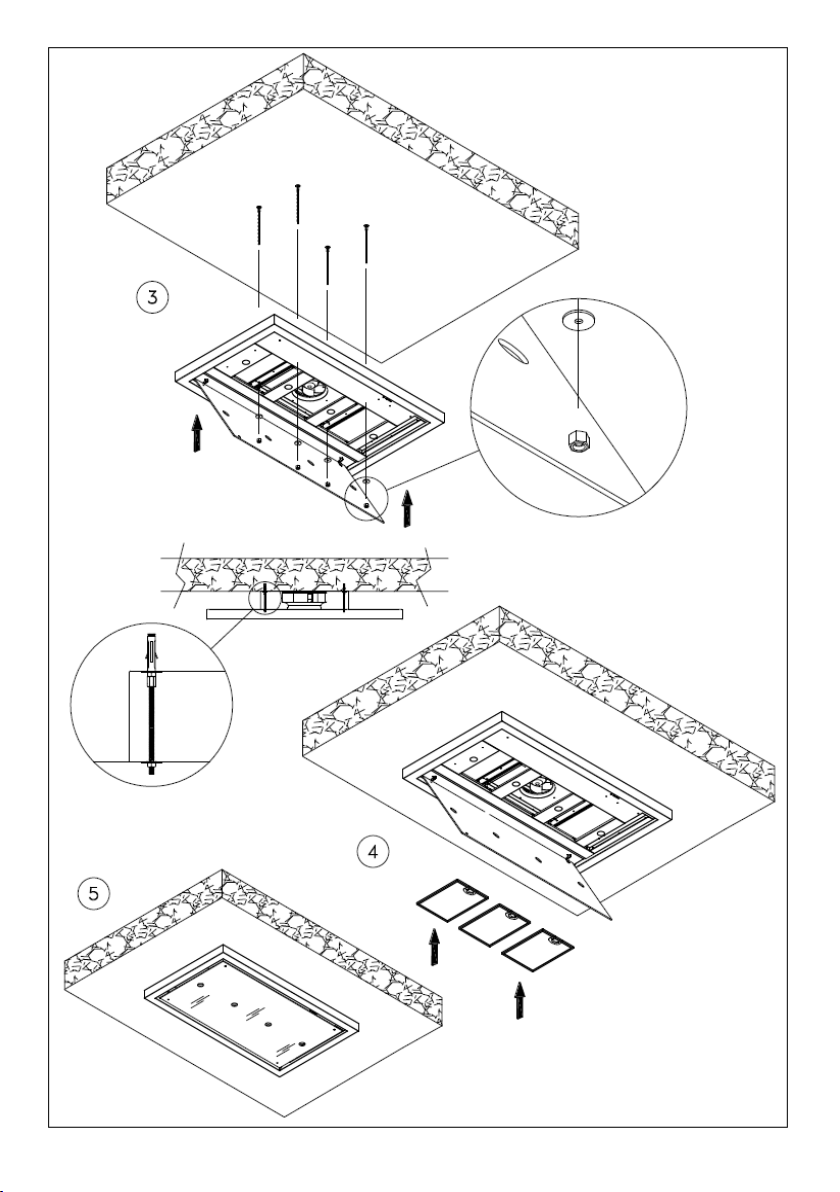

AMADEUS

35

Page 9

36

Page 10

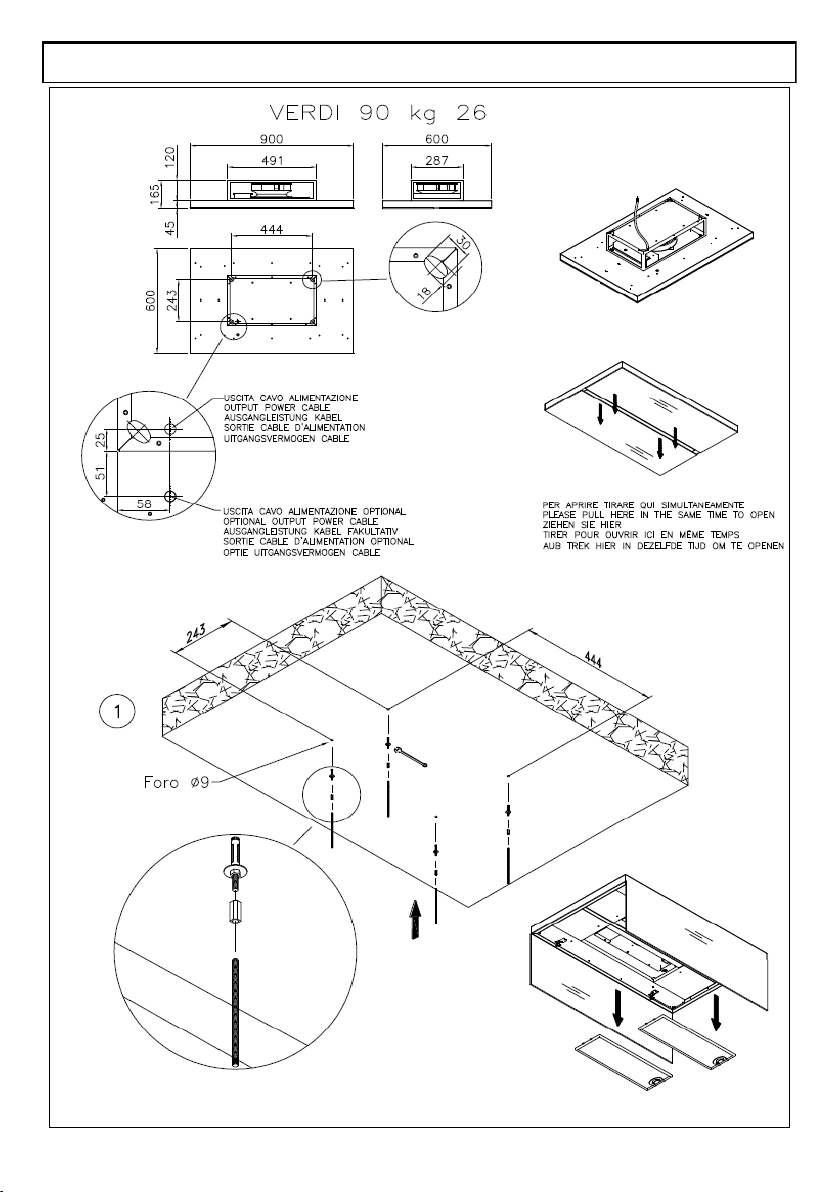

VERDI 90

37

Page 11

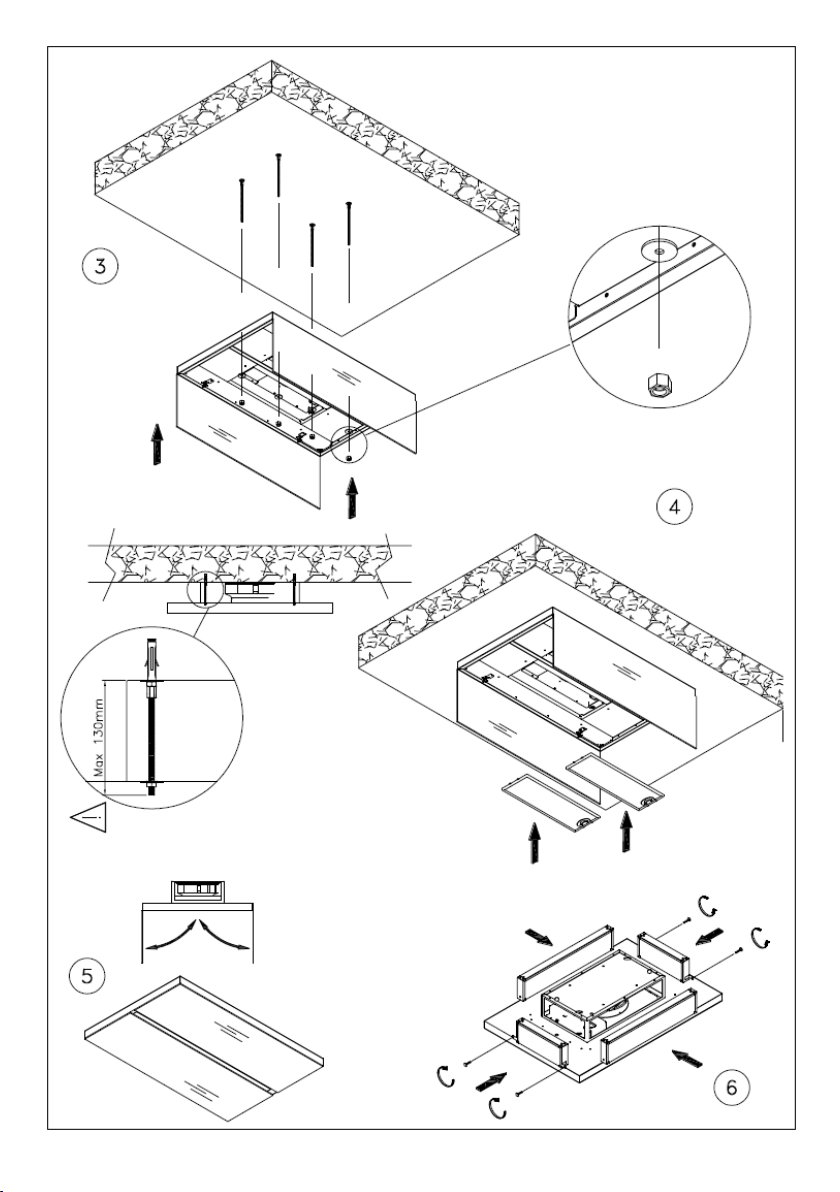

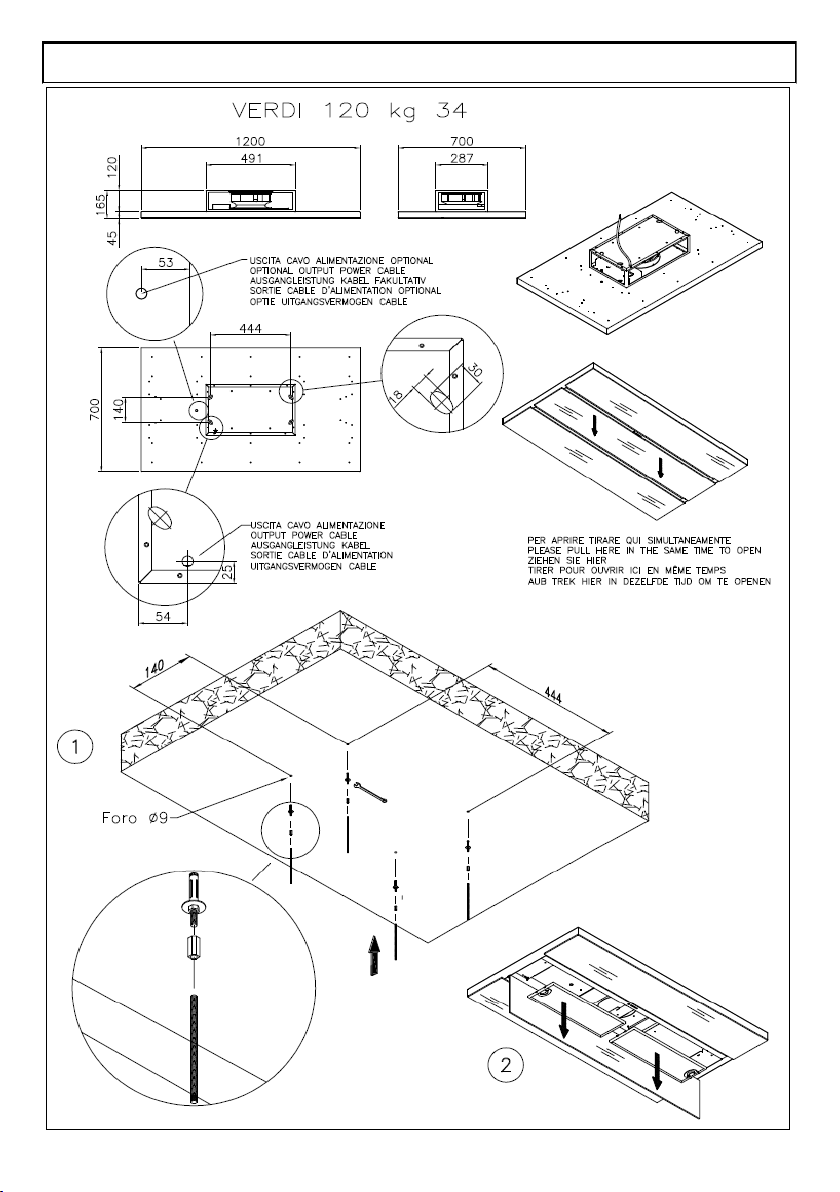

38 39

Page 12

VERDI 120

Page 13

40 41

Page 14

SLIM ISOLA - TOSCA ISOLA - VIRGO ISOLA - ZEUS ISOLA

Page 15

42

Page 16

MEDUSA ISOLA

43

Page 17

44

Page 18

ARIA ISOLA

45

Page 19

46

Page 20

ITACA ISOLA

47

Page 21

48

Page 22

RUBIK ISOLA 40-60

49

Page 23

50

Page 24

RUBIK ISOLA 90

51

Page 25

52

Page 26

NABUCCO ISOLA FULL LED

NABUCCO ISOLA FULL LED (16Kg)

53

Page 27

54

Page 28

MEDEA ISOLA - TURANDOT ISOLA FULL LED - HONSHU ISOLA

TURANDOT ISOLA 60 (23Kg)

TURANDOT ISOLA 90 (28Kg)

MEDEA ISOLA 60 (21KG)

HONSHU ISOLA (23Kg)

TURANDOT ISOLA 60

MEDEA ISOLA 60

TURANDOT ISOLA 90

55

Page 29

56

Page 30

ZEUS ANGOLARE

57

Page 31

58

Page 32

SLIM ANGOLARE

59

Page 33

60

Page 34

OPERA ANGOLARE

61

Page 35

62

Page 36

INDICE - INDEX:

AMADEUS….…………………………………………………………………………………………………………………………………….. pg.35

VERDI 90……...……………………………………………………...……………………………………………………………………..….. pg.37

VERDI 120…..………...…………………………………………………………………………………………………………………………. pg.39

SLIM ISOLA, TOSCA ISOLA, VIRGO ISOLA, ZEUS ISOLA…..……………………………………………………………….. pg.41

MEDUSA ISOLA…………………………………………………………………………………………………………………..………….... pg.43

ARIA ISOLA..……………………………………………………………………………………………………………………………….……. pg.45

ITACA ISOLA……….……...……………………………………………………………………………………………………………………. pg.47

RUBIK ISOLA 40-60...……………………………………………………………………………………………………………………… pg.49

RUBIK ISOLA 90….………………………………………………………………………………………………………………………….... pg.51

NABUCCO ISOLA FULL LED…..……………………………………………………………………………………………………….... pg.53

MEDEA ISOLA, TURANDOT ISOLA FULL LED, HONSHU ISOLA..………………………………..…………………….... pg.55

ZEUS ANGOLARE..………………………………………………………………………………………………………………………….... pg.57

SLIM ANGOLARE..……………………………………….………………………………………………………………………………….... pg.59

OPERA ANGOLARE…...…………………………………………………………………………………………………………………….... pg.61

63

Page 37

Page 38

WK21 Y2015 REL.10 COD.DOLIGARISOANG00004

Airone S.r.l. - Via Ghebo, 12 - 35017 Piombino Dese (PD) Italy

tel +39.049.9369333 fax +39.049.9369399

www.aironehoods.com

Loading...

Loading...