ISKRAEMECO ME382, MT382 User Manual

ME382 and MT382

Technical description

Technical description

ME382 and MT382

Document code:

EAD 020.615.810

Version:

V2.20

Language:

English

Date:

25.08.2016

COPYRIGHT

© 2016 ISKRAEMECO, d.d. All rights reserved.

No part of this document can be copied, reproduced, transferred, distributed, presented or stored in any

format without the prior written consent of Iskraemeco, d.d., except as otherwise provided in your license or

as expressly permitted in writing by Iskraemeco, d.d.

TRADEMARKS

The Iskraemeco logo, and all related trademarks are registered trademarks or trademarks of Iskraemeco,

d.d. All other trademarks are the property of their respective owners. All rights reserved.

DISCLAIMER AND LIMITATION OF LIABILITY

This Technical description was written for use of ME382 and MT382 meters. This manual, including all

documentation incorporated by reference herein such as documentation provided or made available at

Iskraemeco d.d. web site, is provided or made accessible "AS IS" and "AS AVAILABLE" and without

condition, endorsement, guarantee, representation, or warranty of any kind by Iskraemeco d.d. and its

affiliated companies (hereinafter collectively referred to as »Iskraemeco«). Iskraemeco assumes no

responsibility for any typographical, technical, or other inaccuracies, errors, or omissions in this

documentation, nor for any loss due to the use of this documentation. Iskraemeco reserves the right to

periodically change information that is contained in this documentation; however, Iskraemeco makes no

commitment to provide any such changes, updates, enhancements, or other additions to this documentation.

Iskraemeco shall not be liable for any type of damages related to this documentation or its use, or performance

or non-performance of any software, hardware, service, or any third party products and services.

SAVE AS EXPRESSLY PROVIDED IN YOUR CONTRACT WITH ISKRAEMECO, ISKRAEMECO

EXPRESSLY DISCLAIMS ALL WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED

TO THE IMPLIED WARRANTIES OF MERCHANTIBILITY OR FITNESS FOR A PARTICULARE PURPOSE

AND AGAINST INFRINGEMENT. ISKRAEMECO DOES NOT WARRANT THAT THE FUNCTIONS

CONTAINED IN THE PRODUCT WILL BE UNITERRUPTED OR ERROR-FREE, OR THAT DEFECTS IN

THE PRODUCT OR ERRORS IN THE DATA WILL BE CORRECTED. FURTHERMORE, ISKRAEMECO

DOES NOT WARRANT OR MAKE ANY REPRESENTATIONS REGARDING THE USE OR THE RESULTS

OF THE USE OF THE PRODUCT OR ITS DOCUMENTATION IN TERMS OF THEIR CORRECTNESS,

ACCURACY, RELIABILITY, OR OTHERWISE. NO ORAL OR WRITTEN INFORMATION OR ADVICE,

GIVEN BY ISKRAEMECO OR AN ISKRAEMECO AUTHORIZED REPRESENTATIVE SHALL CREATE A

WARRANTY OR IN ANY WAY INCREASE THE SCOPE OF THIS WARRANTY. SOME JURISDICTIONS

DO NOT ALLOW EXCLUSION OF THE IMPLIED WARRANTIES, SO THE ABOVE EXCLUSION MAY NOT

APPLY. UNDER NO CIRCUMSTANCES INCLUDING NEGLIGENCE, SHALL ISKRAEMECO, THEIR

DIRECTORS, OFFICERS, EMPLOYEES OR AGENTS BE LIABLE FOR ANY INCIDENTAL, SPECIAL OR

CONSEQUENTIAL DAMAGES (INCLUDING DAMAGES FOR LOSS OF BUSINESS, LOSS OF PROFITS,

BUSINESS INTERRUPTION, LOSS OF BUSINESS INFORMATION, ETC.) ARISING OUT OF THE USE

OR INABILITY TO USE THE PRODUCT OR ITS DOCUMENTATION, EVEN IF ISKRAEMECO OR AN

ISKRAEMECO AUTHORIZED REPRESENTATIVE HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH

DAMAGES. SOME JURISDICTIONS DO NOT ALLOW LIMITATION OR EXCLUSION OF LIABILITY FOR

INCIDENTAL OR CONSEQUENTIAL DAMAGES OR ALLOW EXCLUSION OR LIMITATION OF LIABILITY

ONLY FOR NEGLIGENCE, BUT NOT FOR GROSS NEGLIGENCE OR WILLFULL MISCONDUCT, SO

THIS LIMITATION MAY NOT APPLY. ISKRAEMECO'S TOTAL LIABILITY FOR ALL DAMAGES, LOSSES

AND CAUSES OF ACTION (WHETHER IN CONTRACT, TORT, INCLUDING NEGLIGENCE, OR

OTHERWISE) SHALL BE DEFINED WITH CONTRACT WITH WHICH YOU BOUGHT PRODUCT OR

SERVICE. IF LIABILITY IS NOT DEFINED WITHIN PREVIOUSLLY MENTIONED CONTRACT

ISKRAEMECO’S LIABILITY FOR ANY AND ALL DAMAGE EVER RELATED TO THIS DOCUMENTATION

SHALL NOT EXCEED (IF NOT OTHERWISE DEFINED WITH APPLICABLE LAW) THE AMOUNT:

1) PAID FOR THE PRODUCT/ SERVICE AND ITS DOCUMENTATION, 2) OF 20% OF THE VALUE OF

THE CUSTOMER’S ORDERS FROM THE LAST 12 MONTHS BEFORE OCCURENCE OF DAMAGE OR

3) 10.000 EUR, WHICHEVER THE LOWEST.

V2.20 – English i/xiv INTRODUCTION

Technical description

ME382 and MT382

ME382-D1

1x230 V, 5(85) A

ME382-D1

1x120 V, 5(85) A

ME382-D3

1x230 V, 10(100) A

ME382-D3

1x120 V, 10(100) A

MT382-D1

3x230/400 V, 5(85) A

MT382-D2

3x230/400 V, 5(120) A

MT382-D2

3x120/208 V, 5(100) A

MT382-T1

3x230/400 V, 5(6) A

ELECTRONIC SINGLE AND THREE-PHASE SYSTEM METER

with GSM/GPRS or UMTS communication module

Technical description

V2.20 – English ii/xiv INTRODUCTION

Technical description

ME382 and MT382

3GPP

3rd Generation Partnership Project

ABS

IA+I + IA-I

AC

Alternating Current

A/D

Analog to Digital

AES

Advanced Encryption Standard

AMM

Automatic Meter Management

APDU

Application Protocol Data Unit

APN

Access Point Name

ASCII

American Standard Code for Information Interchange

BS

British Standard

CAV

Current Average Value

CB

Circuit Breaker

CH

Channel

CII

Consumer Information Interface

CIP

Consumer Information Push

COSEM

COmpanion Specification for Energy Metering

CRC

Cyclic Redundancy Check

CS

Central Server

DCS

Data Coding Scheme

CSD

Circuit Switched Data

DC

Direct Current

DIN

Deutsches Institut für Normung

DLC

Data Line Carrier

DLMS

Device Language Message Specification

DLMS UA

DLMS User Association

DRO

Data ReadOut

DST

Daylight Saving Time

EC

Emergency Credit

EDIS

Energie Daten Identifikations System / Energy Data Identification System

EMC

ElectroMagnetic Compatibility

EN

European Norm

ESC

Escape

FF

Fatal Failure

FIFO

First In First Out

FIPS

Federal Information Processing Standard

FRAM

Ferroelectric Random Access Memory

GCM

Galois/Counter Mode

GIZ

Gesellschaft für Internationale Zusammenarbeit / Society for International Cooperation

i. About the Technical description

The Technical description is intended to present the Mx382 meters (x stands for E (single-phase

meters) or T (three-phase meters)).

The Technical description represents the purpose of the Mx382 meters, meter construction, the way

of deriving the measured quantities and meter functionalities.

The Technical description is intended for technically qualified personnel at energy supply companies,

responsible for system planning and system operation.

ii. Definitions, Acronyms and Abbreviations

V2.20 – English iii/xiv INTRODUCTION

Technical description

ME382 and MT382

GMAC

specialization of GCM for generating a MAC on data that is not encrypted

GMT

Greenwich Mean Time

GND

Ground

GPRS

General Packet Radio Service

GSM

Global System Mobile

HDLC

High-level Data Link Control

HES

Head End System

HEX

Hexadecimal

HHU

Hand Held Unit

HLS

High Level Security

HW

Hard Ware

ICCID

Integrated Circuit Card IDentifier

ID

Identification

IDIS

Interoperable Device Interface Specifications

IE

Iskraemeco

IEC

International Electrotechnical Commission

IEDL

Identity Element Data Length

IEI

Identity Element Identifier

IMEI

International Mobile station Equipment Identity

IP

Internet Protocol

IPv4

Internet Protocol version 4

IR

InfraRed

ISO

International Organization for Standardization

kWh

Kilo Watt-hours

LCD

Liquid Crystal Display

LCP

Link Control Protocol

LED

Light Emitting Diode

LLC

Logical Link Control

LLS

Low Level Security

MAC

Media Access Control address

MB

M-Bus

MC

Manufacturer Code

MCU

Micro Controller Unit

MD5

Message Digest algorithm 5

MDI

Maximum Demand Indicator

MP

Measurement Period

MSB

Most Significant Bit

NCT

No Connection Timeout

NET

IA+I - IA-I

NIST

National Institute of Standards and Technology

NV

Non-Volatile

OBIS

OBject Identification System

OSI

Open System Interconnection

OSM

Other Service Module

PAP

Password Authentication Protocol

PC

Personal Computer

PCB

Printed Circuit Board

PDP

Packet Data Protocol

PDA

Personal Digital Assistant

V2.20 – English iv/xiv INTRODUCTION

Technical description

ME382 and MT382

PDU

Protocol Data Unit

PHY

Physical

PLC

Power Line Carrier

PUP

Power UP

RAM

Random Access Memory

RF

Radio Frequency

RM

Register Monitor

RMS

Root Mean Square

RTC

Real Time Clock

SD

Switching Device (Disconnector, Disconnection device, Load switch)

SAP

Service Access Point

SCA

Service Centre Address

SHA-1

Secure Hash Algorithm

SME

Short Message Entity

SMSC

Short Message Service Centre

SN

Serial Number

SSR

Solid State Relay

SUM

Summation

SQ

Signal Quality

TCP

Transmission Control Protocol

TOU

Time Of Use

UDHI

User Data Header Indicator

UDHL

User Data Header Length

UMTS

Universal Mobile Telecommunications System

UTC

Coordinated Universal Time

UV

Ultra Violet

VDEW

Verband Der ElektrizitätsWirtschaft

WAN

Wireless Area Network

WEEE

Waste Electrical and Electronic Equipment

WIP

Wavecom Internet Protocol

WPDU

Wrapper Protocol Data Unit

NOTE

OBIS (Object Identification System) code (according to DLMS UA 1000-1:2001 standard)

is composed of 6 groups of digits (A-B:C.D.E*F; i.e. 0-0:1.0.0*255). In a case where the

last group of digits (group F) is not written, means the value of F is 255.

iii. Reference documents

Installation and maintenance manual

Iskraemeco’s general terms and condition

V2.20 – English v/xiv INTRODUCTION

Technical description

ME382 and MT382

Date

Version

Update

31.01.2014

1.00

Initial version of the document.

17.09.2014

1.01

Description of the meter type designation was changed.

17.03.2016

2.00

The subchapter 5.1. LCD: Table 20 was updated – new cursor meaning

In the subchapter 7.8. RTC backup: note was added

The subchapter 7.11. Switching device was renew, data changed in the Table 69

The subchapter 7.12.2. Advanced power limitation was added

In the chapter 11. TECHNICAL CHARACTERISTICS data was updated

In the subchapters 11.1. ME382 meter and 11.2. MT382 meter: Backup power

supply, the SuperCap charging time was changed

ME382 and MT382 object lists were updated (see chapters 12.2. Annex 2:

ME382 object list and 12.3. Annex 3: MT382 object list) – new objects in the

lists were added, firmware versions (core, module) were added

Detailed procedure description in the subchapter 6.4.9. Selecting the cellular

network (2G/3G) was added

In the subchapter 5.3.2.1. Data menu example of the register value reading on

the LCD was added

In the subchapter 3.5. Connection diagram connection diagrams were changed

03.05.2016

2.10

In the subchapter 7.7. Alarms two alarms in the Table 66 were added.

Next subchapters were added:

- 7.16.1.3. Asymmetrical voltage (optional)

- 7.16.1.7. Neutral fault (optional)

- 7.16.1.8. Time period for asymmetry voltage and neutral fault

- 7.16.1.9. Capturing of voltage values

New object list in the subchapter 12.3. Annex 3: MT382 object list with new

firmware module version

25.08.2016

2.20

In the subchapter 3.4. Main meter properties bullet modes of energy

measurement and registration at three-phase meters was supplemented with

descriptions of the methods, algebraic method was replaced with arithmetic

method and one new method (absolute) was added.

In the subchapter 3.6.1. Energy paragraph related to the active energy delta

registers was added

NOTE related to rollover in the subchapter 3.7.2.1. Transformer measurement

type was added

In the subchapter 3.7.9. Energy the Table 15 was updated (NET total tariff)

Description about rollover in the subchapter 5.1. LCD was added

The subchapter 5.1.1. Display configuration was added

In the subchapter 7.3. Main load profiles the Table 50 was updated (bit 6, PUP)

The subchapter 7.3.1. Load profiles options was added

The subchapter 7.6.2. Fraud detection log was updated (hold-off period)

In the subchapter 7.8. RTC backup two objects with their descriptions were added

The subchapters 7.10.4. Tariffication script table, 7.10.5. Tariff switch source

and 7.10.6. Manual tariffication script activation were added

The subchapter 7.13. Overvoltage monitor and load disconnection was added

The subchapter 7.16.2. Watchdog counter was added

In the subchapters 12.2. Annex 2: ME382 object list and 12.3. Annex 3: MT382

object list object lists were updated with new objects added

iv. Versioning

V2.20 – English vi/xiv INTRODUCTION

Technical description

ME382 and MT382

TABLE OF CONTENTS

1. SAFETY INFORMATION ........................................................................................................................... 1

1.1. Responsibilities ................................................................................................................................... 1

1.2. Safety instructions ............................................................................................................................... 2

1.2.1. Handling and mounting ................................................................................................................ 2

1.2.2. Meter installation procedure ......................................................................................................... 3

1.2.3. Meter maintenance ...................................................................................................................... 7

2. ENERGY METERING AND MX382 METERS ........................................................................................... 8

3. MX382 METERS INTRODUCTION ........................................................................................................... 9

3.1. Standards and references ................................................................................................................... 9

3.2. ME382 meter description .................................................................................................................. 11

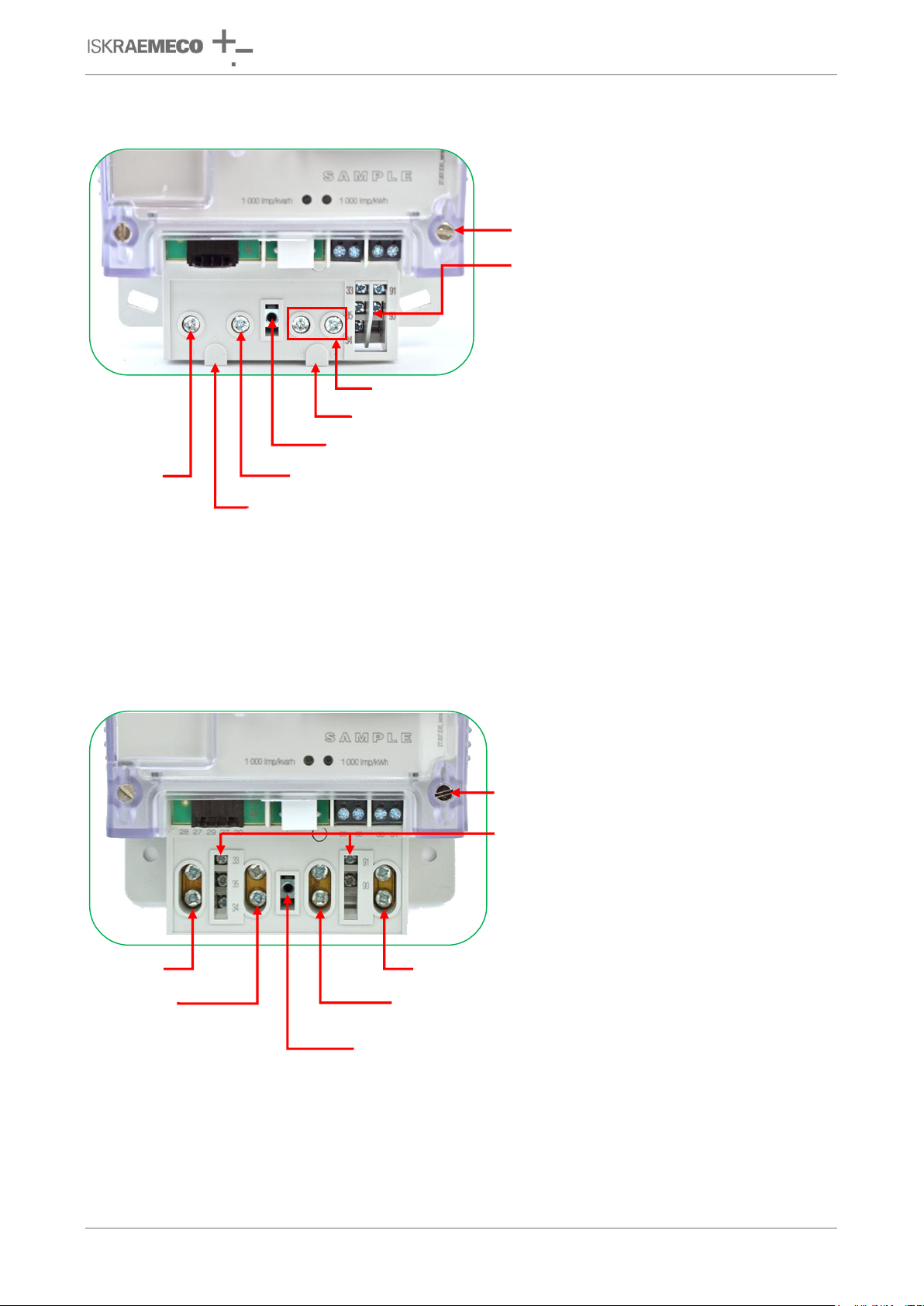

3.2.1. Terminal block constituent parts – ME382-D1 (85 A) DIN connection ...................................... 12

3.2.2. Terminal block constituent parts – ME382-D3 (100 A) BS connection...................................... 12

3.2.3. Terminal block constituent parts – common for D1 (DIN) and D3 (BS) type ............................. 13

3.3. MT382 meter description .................................................................................................................. 14

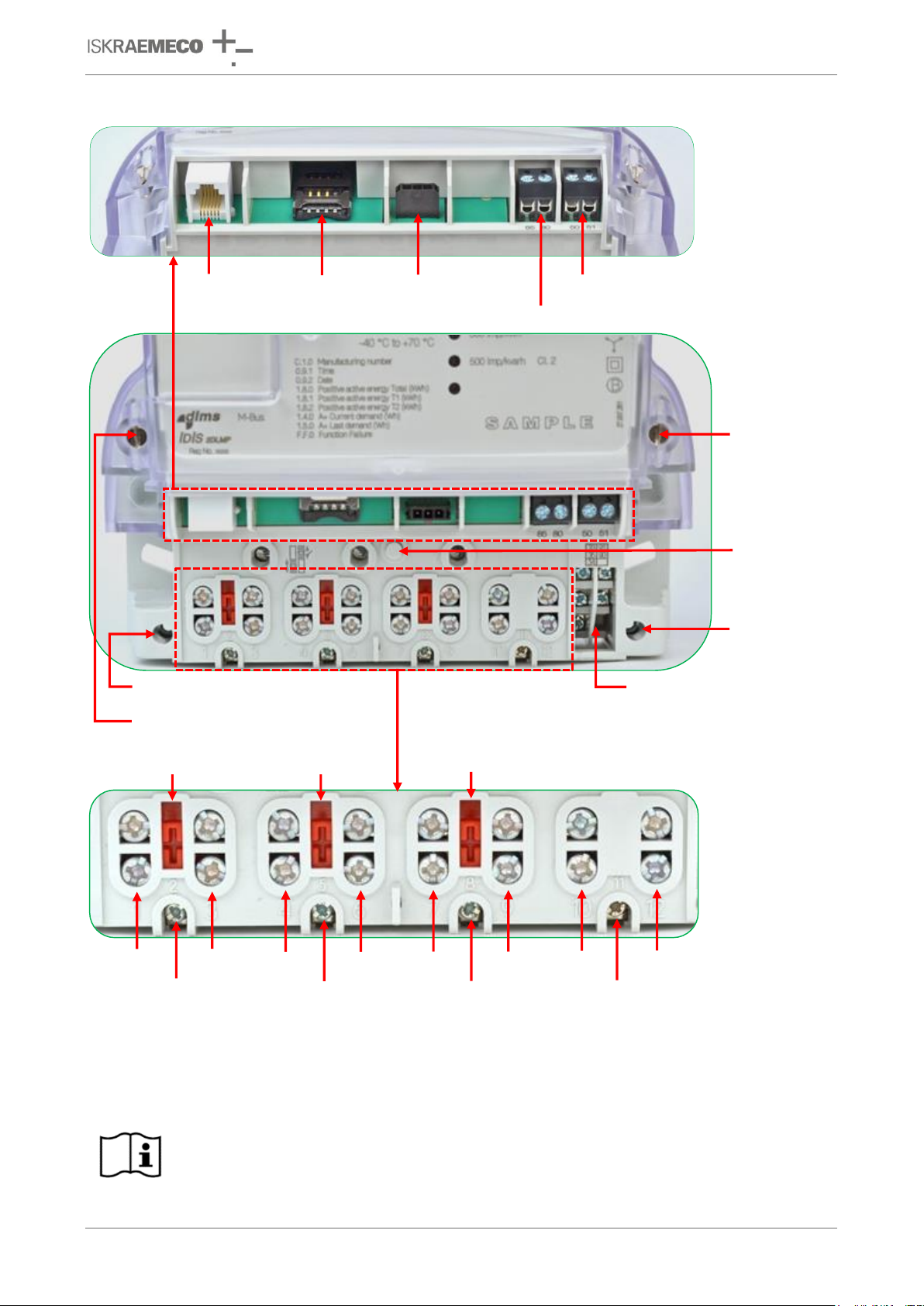

3.3.1. Terminal block constituent parts – MT382-D1/D2 ..................................................................... 15

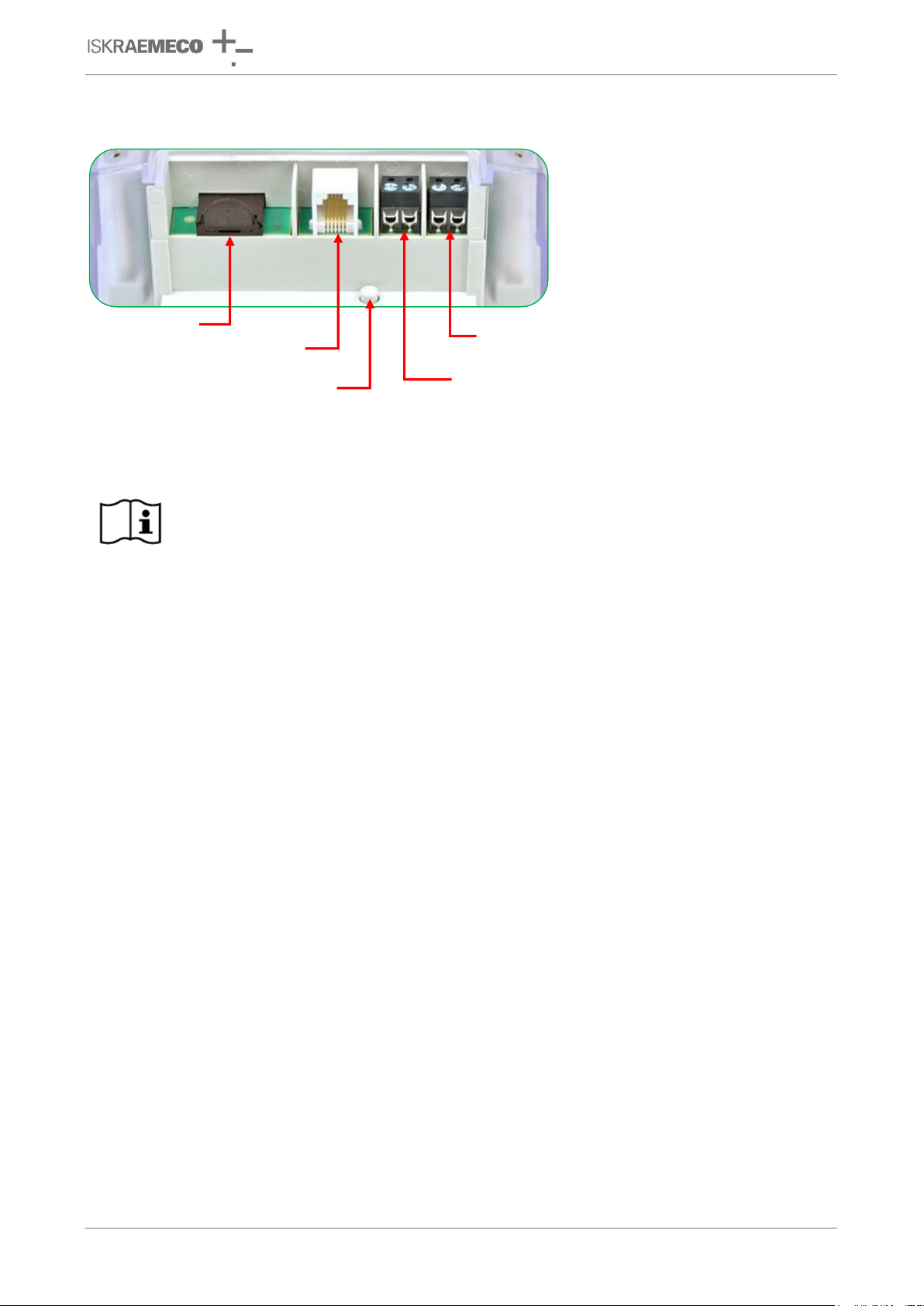

3.3.2. Terminal block constituent parts – MT382-T1 ........................................................................... 16

3.4. Main meter properties ....................................................................................................................... 17

3.5. Connection diagram .......................................................................................................................... 19

3.5.1. ME382-D1 meter ........................................................................................................................ 20

3.5.2. ME382- D3 meter ....................................................................................................................... 20

3.5.3. MT382 meter .............................................................................................................................. 21

3.6. Energy and demand registration ....................................................................................................... 22

3.6.1. Energy ........................................................................................................................................ 22

3.6.2. Demand ...................................................................................................................................... 23

3.6.2.1. Other demand registers ...................................................................................................... 25

3.6.2.2. Time management ............................................................................................................ 110

3.7. Measurement platform ...................................................................................................................... 26

3.7.1. Measuring configuration ............................................................................................................. 26

3.7.1.1. Rogowski coil ...................................................................................................................... 27

3.7.1.2. Shunt................................................................................................................................... 27

3.7.2. Energy metrological pulse output .............................................................................................. 27

3.7.2.1. Transformer measurement type ......................................................................................... 27

3.7.3. Measured quantities ................................................................................................................... 28

3.7.4. Voltage ....................................................................................................................................... 29

3.7.4.1. Instantaneous voltage ......................................................................................................... 29

3.7.4.2. Daily peak and minimum values ......................................................................................... 29

3.7.4.3. Average voltage .................................................................................................................. 29

3.7.4.4. Voltage levels ..................................................................................................................... 29

3.7.4.5. Voltage sags and swells ..................................................................................................... 29

3.7.5. Current ....................................................................................................................................... 30

3.7.5.1. Instantaneous current ......................................................................................................... 30

3.7.6. Net frequency ............................................................................................................................. 30

3.7.7. Power ......................................................................................................................................... 30

3.7.7.1. Instantaneous power .......................................................................................................... 30

3.7.7.2. Average power .................................................................................................................... 30

3.7.8. Power factor ............................................................................................................................... 30

3.7.9. Energy ........................................................................................................................................ 31

V2.20 – English vii/xiv INTRODUCTION

Technical description

ME382 and MT382

3.7.9.1. Total energy values ............................................................................................................ 31

3.7.10. Measurement period .............................................................................................................. 31

4. METER CONSTRUCTION ....................................................................................................................... 32

4.1. Technical figures and dimensions of the ME382 meter .................................................................... 32

4.2. Technical figures and dimensions of the MT382 meter .................................................................... 35

4.3. Meter case ......................................................................................................................................... 37

4.3.1. Terminal block ............................................................................................................................ 38

4.3.1.1. U-I link between voltage and current circuits ...................................................................... 38

4.3.1.2. Inputs and outputs .............................................................................................................. 39

4.3.1.2.1. Output for active switching device ................................................................................. 41

4.3.1.2.2. Input/output status .......................................................................................................... 41

4.3.2. Meter cover ................................................................................................................................ 42

4.3.3. Terminal cover ........................................................................................................................... 42

4.4. Name plate ........................................................................................................................................ 44

4.5. Mx382 meter type designation .......................................................................................................... 46

5. CONSOLE ................................................................................................................................................ 47

5.1. LCD ................................................................................................................................................... 47

5.1.1. Display configuration .................................................................................................................. 49

5.2. Metrological LEDs ............................................................................................................................. 50

5.3. Buttons .............................................................................................................................................. 51

5.3.1. Reduced console menu type ..................................................................................................... 52

5.3.1.1. General display readout mode ........................................................................................... 53

5.3.1.2. Alternate display readout mode .......................................................................................... 53

5.3.2. Normal console menu type ........................................................................................................ 54

5.3.2.1. Data menu .......................................................................................................................... 56

5.3.2.2. Set menu ............................................................................................................................ 59

5.3.3. Previous values on a display ..................................................................................................... 61

6. COMMUNICATION .................................................................................................................................. 62

6.1. Optical interface ................................................................................................................................ 62

6.2. P1 interface ....................................................................................................................................... 63

6.2.1. P1 functionality ........................................................................................................................... 64

6.2.2. P1 parameters ........................................................................................................................... 65

6.3. M-Bus ................................................................................................................................................ 65

6.4. GSM/GPRS/UMTS communication module ..................................................................................... 69

6.4.1. Modem initialization ................................................................................................................... 69

6.4.2. GSM/GPRS network diagnostic ................................................................................................. 70

6.4.3. CSD data connection (GSM) ..................................................................................................... 71

6.4.4. Packet data connection (GPRS) ................................................................................................ 72

6.4.5. Short message service (SMS) ................................................................................................... 74

6.4.5.1. SMS initialization ................................................................................................................ 74

6.4.5.2. SMS Application Protocol Data Unit (APDU)...................................................................... 75

6.4.5.3. Outgoing SMS .................................................................................................................... 76

6.4.5.4. Incoming SMS .................................................................................................................... 77

6.4.5.5. SMS Wake-up request (Empty incoming SMS).................................................................. 78

6.4.5.6. Concatenated SMS ............................................................................................................. 78

6.4.6. Modem reset .............................................................................................................................. 79

6.4.7. TCP/IP based COSEM communication profile .......................................................................... 82

6.4.8. GSM/GPRS connection management ....................................................................................... 84

6.4.8.1. Auto connect ....................................................................................................................... 84

V2.20 – English viii/xiv INTRODUCTION

Technical description

ME382 and MT382

6.4.8.2. Auto answer ........................................................................................................................ 85

6.4.9. Selecting the cellular network (2G/3G) ...................................................................................... 88

6.5. Push .................................................................................................................................................. 89

6.5.1. Push objects............................................................................................................................... 89

6.5.2. Data notification service ............................................................................................................. 90

6.5.3. Push process ............................................................................................................................. 90

6.5.4. Push related functionalities ........................................................................................................ 91

7. DESCRIPTION OF MAIN METER FUNCTIONALITIES ......................................................................... 92

7.1. Measurements ................................................................................................................................... 92

7.2. Sequences ........................................................................................................................................ 92

7.3. Main load profiles .............................................................................................................................. 92

7.3.1. Load profile options .................................................................................................................... 94

7.4. Billing ................................................................................................................................................. 94

7.4.1. Billing profile ............................................................................................................................... 95

7.5. Prepayment ....................................................................................................................................... 96

7.6. Event logs .......................................................................................................................................... 99

7.6.1. Standard event log ................................................................................................................... 100

7.6.2. Fraud detection log .................................................................................................................. 101

7.6.3. Disconnector control log .......................................................................................................... 102

7.6.4. M-Bus event log ....................................................................................................................... 103

7.6.5. Power quality log ...................................................................................................................... 104

7.6.6. Communication event log ........................................................................................................ 104

7.6.7. M-Bus master control logs ....................................................................................................... 105

7.6.8. Power failure event log ............................................................................................................ 106

7.6.9. Certification data log ................................................................................................................ 106

7.7. Alarms ............................................................................................................................................. 107

7.8. RTC backup .................................................................................................................................... 109

7.8.1. Time ......................................................................................................................................... 110

7.9. Errors ............................................................................................................................................... 111

7.9.1. Error filter ................................................................................................................................. 112

7.9.2. Error types................................................................................................................................ 112

7.10. Activity calendar and TOU registration ........................................................................................ 113

7.10.1. Activity calendar ................................................................................................................... 114

7.10.2. Tariff program ....................................................................................................................... 114

7.10.3. Tariff synchronization ........................................................................................................... 115

7.10.4. Tariffication script table ........................................................................................................ 115

7.10.5. Tariff switch source .............................................................................................................. 115

7.10.6. Manual tariffication script activation ..................................................................................... 115

7.11. Switching device .......................................................................................................................... 115

7.11.1. Switching device type designation ....................................................................................... 116

7.11.2. Disconnect control ................................................................................................................ 117

7.11.2.1. Manual option ................................................................................................................... 118

7.11.2.1.1. Manual reconnection .................................................................................................. 118

7.11.2.1.2. Manual disconnection ................................................................................................ 119

7.11.2.1.3. By the external button ................................................................................................ 120

7.11.2.2. Remote option .................................................................................................................. 120

7.11.2.2.1. Remote disconnection................................................................................................ 120

7.11.2.2.2. Remote reconnection ................................................................................................. 120

7.12. Limitation ..................................................................................................................................... 121

7.12.1. Limiter ................................................................................................................................... 121

V2.20 – English ix/xiv INTRODUCTION

Technical description

ME382 and MT382

7.12.2. Advanced power limitation ................................................................................................... 122

7.12.3. Supervision monitor – IDIS ................................................................................................... 123

7.12.4. Supervision monitor – GIZ .................................................................................................... 123

7.13. Overvoltage monitor and load disconnection .............................................................................. 124

7.14. Fraud detection ............................................................................................................................ 125

7.14.1. Meter cover open and terminal cover open .......................................................................... 125

7.14.2. Magnetic field detection ........................................................................................................ 125

7.15. Identification numbers ................................................................................................................. 125

7.15.1. COSEM logical device name ................................................................................................ 125

7.15.2. System title ........................................................................................................................... 126

7.15.3. Device number ..................................................................................................................... 126

7.15.4. Device ID .............................................................................................................................. 127

7.15.5. Meter software identification ................................................................................................. 127

7.15.5.1. Software architecture ........................................................................................................ 127

7.15.5.2. E-meter signatures ........................................................................................................... 128

7.16. Monitoring functions .................................................................................................................... 129

7.16.1. Power quality ........................................................................................................................ 129

7.16.1.1. Voltage level ..................................................................................................................... 129

7.16.1.2. Voltage asymmetry ........................................................................................................... 130

7.16.1.3. Asymmetrical voltage (optional) ....................................................................................... 131

7.16.1.4. Asymmetric current ........................................................................................................... 132

7.16.1.5. Unexpected consumption ................................................................................................. 132

7.16.1.6. Neutral missing detection ................................................................................................. 132

7.16.1.7. Neutral fault (optional) ...................................................................................................... 133

7.16.1.8. Time period for asymmetry voltage and neutral fault ....................................................... 133

7.16.1.9. Capturing of voltage values .............................................................................................. 134

7.16.1.10. Power failure ................................................................................................................... 134

7.16.1.11. Wrong phase sequence .................................................................................................. 134

7.16.2. Watchdog counter ................................................................................................................ 135

8. SECURITY ............................................................................................................................................. 136

8.1. Physical security.............................................................................................................................. 136

8.1.1. Seal protection ......................................................................................................................... 136

8.1.2. Parameter protection button .................................................................................................... 137

8.2. Logical security ................................................................................................................................ 137

8.2.1. DLMS/COSEM security ........................................................................................................... 137

9. FIRMWARE UPGRADE ......................................................................................................................... 140

10. APPLICATION ASSOCIATION ......................................................................................................... 142

10.1. SAP assignment .......................................................................................................................... 142

11. TECHNICAL CHARACTERISTICS .................................................................................................... 143

11.1. ME382 meter ............................................................................................................................... 143

11.2. MT382 meter ............................................................................................................................... 146

11.3. Switching device for the MT382 meter ........................................................................................ 149

12. ANNEX ............................................................................................................................................... 150

12.1. Annex 1: Relay, SD and M-Bus disconnect states and transitions ............................................. 150

12.2. Annex 2: ME382 object list .......................................................................................................... 151

12.3. Annex 3: MT382 object list .......................................................................................................... 165

V2.20 – English x/xiv INTRODUCTION

Technical description

ME382 and MT382

INDEX OF FIGURES

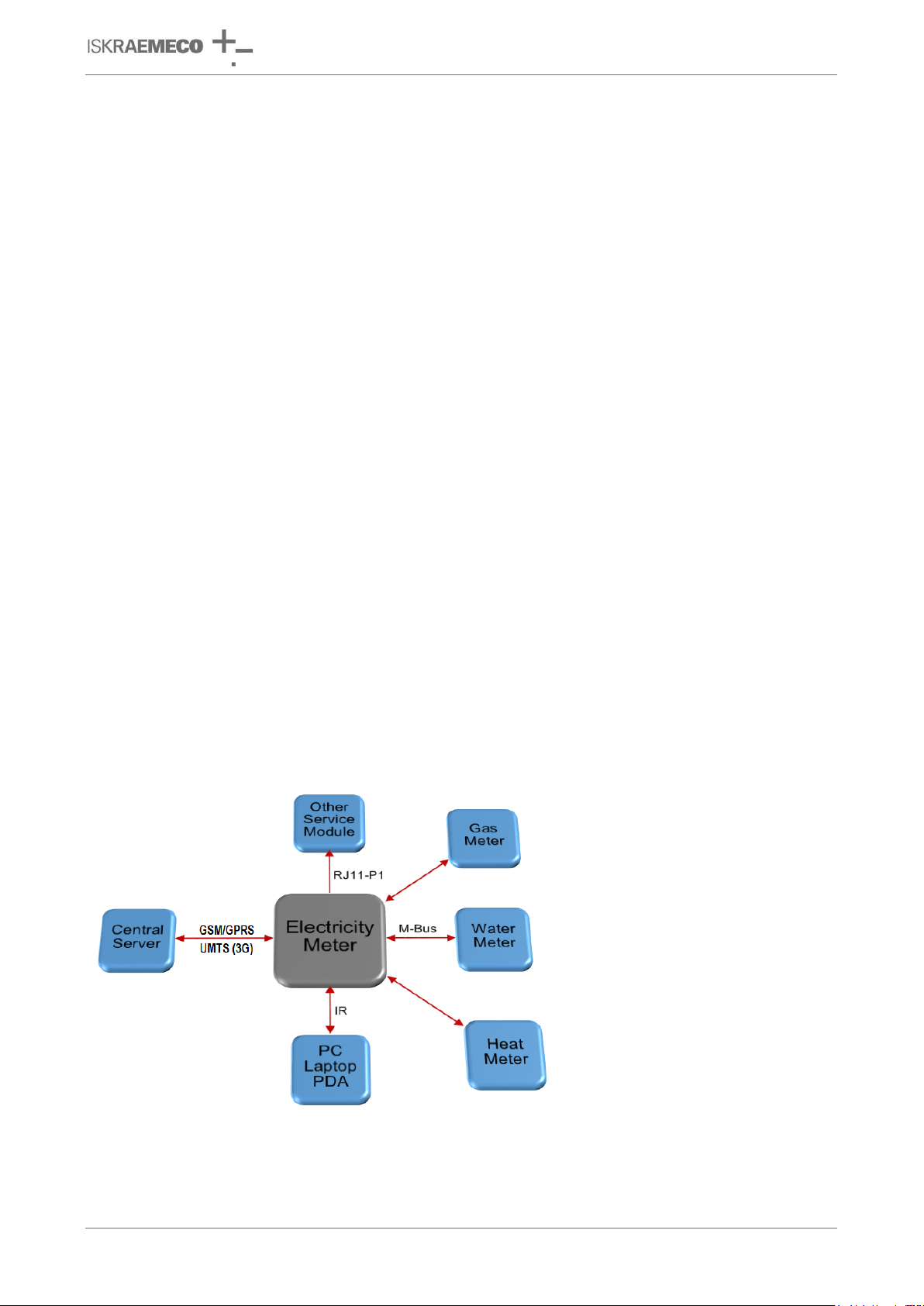

Figure 1: Smart metering system ........................................................................................................................................ 8

Figure 2: ME382 meter appearance – front view .............................................................................................................. 11

Figure 3: Terminal block – ME382-D1 (85 A) DIN connection ........................................................................................... 12

Figure 4: Terminal block – ME382-D3 (100 A) BS connection .......................................................................................... 12

Figure 5: Terminal block constituent parts – common for D1 (DIN) and D3 (BS) type ...................................................... 13

Figure 6: MT382 meter appearance – front view ............................................................................................................... 14

Figure 7: Terminal block – MT382-D1/D2 ......................................................................................................................... 15

Figure 8: Terminal block – MT382-T1 ............................................................................................................................... 16

Figure 9: ME38y-D1 meter connection diagram – DIN connection ................................................................................... 20

Figure 10: ME38y-D3 meter connection diagram – BS connection ................................................................................... 20

Figure 11: MT38y meter connection diagram – direct connection (left), transformer connection (right) ............................ 21

Figure 12: Measured energy and demand ........................................................................................................................ 22

Figure 13: Demand calculation sample ............................................................................................................................. 23

Figure 14: Measuring principle .......................................................................................................................................... 23

Figure 15: Attributes in the case of block demand (1 period) ............................................................................................ 24

Figure 16: Attributes in case of sliding demand ................................................................................................................. 24

Figure 17: Time attributes when measuring sliding demand ............................................................................................. 25

Figure 18: Overall and fixing dimensions of the ME382-D1 meter fitted with a regular terminal cover .............................. 32

Figure 19: Overall and fixing dimensions of the ME382-D3 meter fitted with a regular terminal cover .............................. 32

Figure 20: Overall and fixing dimensions of the ME382-D1 meter fitted with a short terminal cover ................................. 33

Figure 21: Overall and fixing dimensions of the ME382-D3 meter fitted with a short terminal cover ................................. 33

Figure 22: Overall and fixing dimensions of the ME382-D1 meter fitted with a P1+M-Bus terminal cover ........................ 34

Figure 23: Overall and fixing dimensions of the ME382-D3 meter fitted with a P1+M-Bus terminal cover ........................ 34

Figure 24: Overall and fixing dimensions of an MT382 meter fitted with a regular terminal cover ..................................... 35

Figure 25: Overall and fixing dimensions of an MT382 meter fitted with a short terminal cover ........................................ 35

Figure 26: Overall and fixing dimensions of the MT382 meter fitted with an external SD terminal cover .......................... 36

Figure 27: Overall and fixing dimensions of the MT382 meter fitted with a P1+M-Bus+SD terminal cover ....................... 37

Figure 28: Sliding U-I link (left: position down; right: position up) ...................................................................................... 39

Figure 29: Load control terminal ........................................................................................................................................ 39

Figure 30: Signal control terminal ...................................................................................................................................... 40

Figure 31: Mx382 input terminals ...................................................................................................................................... 41

Figure 32: Output for active SD ......................................................................................................................................... 41

Figure 33: Short terminal cover (left) and regular terminal cover (right) ............................................................................ 42

Figure 34: External SD terminal cover for the meter with SD unit (left) and P1+M-Bus+SD terminal cover (right)............ 43

Figure 35: P1+M-Bus terminal cover (left: with the sealable lid; right: without the sealable lid) ........................................ 43

Figure 36: Meter connection diagram on the inner side of the terminal cover ................................................................... 43

Figure 37: Name plate of the ME382 meter ...................................................................................................................... 44

Figure 38: Name plate of the MT382 meter ....................................................................................................................... 45

Figure 39: Full Mx382 LCD – display fields ....................................................................................................................... 47

Figure 40: Displaying value with format “60“ ..................................................................................................................... 48

Figure 41: Displaying value with format “82“ ..................................................................................................................... 48

Figure 42: Signature on the display ................................................................................................................................... 49

Figure 43: LEDs at the ME382 meter ................................................................................................................................ 50

Figure 44: LEDs at the MT382 meter ................................................................................................................................ 50

Figure 45: Scroll button (on the left) Reset and Scroll button (on the right) ....................................................................... 51

Figure 46: Menu navigation diagram – Reduced console menu type ................................................................................ 53

Figure 47: Entering the Data/Set menu ............................................................................................................................. 55

Figure 48: Data menu navigation ...................................................................................................................................... 56

Figure 49: Alternate display readout mode navigation in Normal console menu type ....................................................... 56

Figure 50: Load profile on display navigation .................................................................................................................... 58

Figure 51: Certification data log on display navigation ...................................................................................................... 59

Figure 52: Set menu navigation ........................................................................................................................................ 60

Figure 54: LCD test mode navigation ................................................................................................................................ 60

Figure 55: Previous values navigation in Alternate display readout mode ........................................................................ 61

Figure 56: Optical interface (left); optical sonda (right) ................................................................................................ ...... 62

Figure 57: Diagram for connecting devices to the P1 port................................................................................................. 63

V2.20 – English xi/xiv INTRODUCTION

Technical description

ME382 and MT382

Figure 58: P1 port connection ........................................................................................................................................... 64

Figure 59: M-Bus master-slave configuration and dongle interface .................................................................................. 66

Figure 60: Example for channel ........................................................................................................................................ 67

Figure 61: State transitions during a successful call establishment procedure ................................................................. 72

Figure 62: GPRS connection establishment process ........................................................................................................ 73

Figure 63: SMS short wrapper .......................................................................................................................................... 75

Figure 64: IDIS client and server model ............................................................................................................................ 76

Figure 65: State diagram during modem restart procedure ............................................................................................... 81

Figure 66: TCP/IP based COSEM communication profiles ............................................................................................... 82

Figure 67: The COSEM wrapper protocol data unit (WPDU) ............................................................................................ 82

Figure 68: Auto connect operation in »Always ON« modes during defined time window .................................................. 84

Figure 69: Auto connect operation in modes 103 and 104 when a connection method is invoked ................................... 85

Figure 70: Prepayment function with statuses ................................................................................................................... 96

Figure 71: Credit transfer data structure............................................................................................................................ 97

Figure 72: Token protocol data unit processing phases .................................................................................................... 97

Figure 73: Event handling ................................................................................................................................................. 99

Figure 74: Alarm reporting process ................................................................................................................................. 107

Figure 75: Time and Date Data Format ........................................................................................................................... 110

Figure 76: Error filtering................................................................................................................................................... 112

Figure 77: Graphical tariff program ................................................................................................................................. 113

Figure 78: Example of switching device for MT382 (left: top view; right: front view) ....................................................... 116

Figure 79: MT382 meter with switching device ............................................................................................................... 117

Figure 80: The “ConnEct” notice on the LCD .................................................................................................................. 118

Figure 81: The “EntEr” notice on the LCD ....................................................................................................................... 118

Figure 82: Switching device manual reconnection diagram ............................................................................................ 118

Figure 83: The “dISconn” notice on LCD ......................................................................................................................... 119

Figure 84: Switching device manual disconnection diagram ........................................................................................... 119

Figure 85: Limiter diagram .............................................................................................................................................. 121

Figure 86: Advanced power limitation diagram ............................................................................................................... 122

Figure 87: Terminal cover opening switch ....................................................................................................................... 125

Figure 88: COSEM Logical Device Name Structure ........................................................................................................ 125

Figure 89: Identification Structure ................................................................................................................................... 128

Figure 90: Revision Number Structure ............................................................................................................................ 128

Figure 91: Asymmetrical voltage detection...................................................................................................................... 131

Figure 92: Unexpected consumption ............................................................................................................................... 132

Figure 93: Intended neutral N-N' ..................................................................................................................................... 132

Figure 94: Neutral fault detection .................................................................................................................................... 133

Figure 95: Power fail example ......................................................................................................................................... 134

Figure 96: Positions of the seals at ME382 meter (left) and MT382 meter (right) ........................................................... 136

Figure 97: Encryption and decryption procedure ............................................................................................................. 137

Figure 98: Three-step upgrading procedure .................................................................................................................... 141

Figure 99: Firmware image transfer process ................................................................................................................... 141

Figure 100: Relay, switching device and M-Bus disconnect state transitions.................................................................. 150

V2.20 – English xii/xiv INTRODUCTION

Technical description

ME382 and MT382

INDEX OF TABLES

Table 1: Auxiliary terminals designation ............................................................................................................................ 19

Table 2: Last average demand registers ........................................................................................................................... 25

Table 3: Maximum demand registers – total ..................................................................................................................... 25

Table 4: Cumulative maximum demand registers ............................................................................................................. 26

Table 5: Average demand objects ..................................................................................................................................... 26

Table 6: Measuring configuration type .............................................................................................................................. 26

Table 7: List of a metropulse output functions ................................................................................................................... 27

Table 8: Peak and minimum values of voltage .................................................................................................................. 29

Table 9: Average values of voltage ................................................................................................................................... 29

Table 10: Voltage levels counters ..................................................................................................................................... 29

Table 11: Magnitude for voltage sags and swells .............................................................................................................. 29

Table 12: Magnitude of last voltage sag and swell ............................................................................................................ 29

Table 13: Instantaneous power objects ............................................................................................................................. 30

Table 14: Average power .................................................................................................................................................. 30

Table 15: Total and tariff energy objects ........................................................................................................................... 31

Table 16: Input state control register of ME382 and MT382 meter ................................................................................... 41

Table 17: Output state control register of single-phase (ME382) meter ............................................................................ 42

Table 18: Output state control register of three phase (MT382) meter .............................................................................. 42

Table 19: Meter type designation ................................ ................................ ................................................................ ...... 46

Table 20: LCD cursors ...................................................................................................................................................... 48

Table 21: Display Configuration for Octet 0 definition ....................................................................................................... 49

Table 22: Display Configuration for Octet 1 definition ....................................................................................................... 49

Table 23: LED constants recommendation ....................................................................................................................... 50

Table 24: Button labels...................................................................................................................................................... 51

Table 25: Use of Scroll button in Reduced console menu type ......................................................................................... 52

Table 26: Scroll button extended press ............................................................................................................................. 52

Table 27: Use of buttons in Normal console menu type .................................................................................................... 54

Table 28: Register reading procedure on the LCD when the Reduced console menu type is set ..................................... 57

Table 29: Register reading procedure on the LCD when the Normal console menu type is set........................................ 57

Table 30: RJ11 pins .......................................................................................................................................................... 64

Table 31: M-Bus profile status registers notifications ........................................................................................................ 67

Table 32: M-Bus alarms .................................................................................................................................................... 69

Table 33: GSM/GPRS modem diagnostics objects ........................................................................................................... 70

Table 34: Network signal strength ..................................................................................................................................... 70

Table 35: GSM status object bit assignment ..................................................................................................................... 71

Table 36: SMS centre address phone number setting ...................................................................................................... 74

Table 37: Phone number example .................................................................................................................................... 75

Table 38: Push setup list ................................................................................................................................................... 76

Table 39: DCS Settings ..................................................................................................................................................... 77

Table 40: VP Settings........................................................................................................................................................ 77

Table 41: Example of SMS PDU for setting object 0-0:96.13.0 ......................................................................................... 78

Table 42: Concatenated SMS ........................................................................................................................................... 78

Table 43: Modem reset triggers ........................................................................................................................................ 80

Table 44: COSEM Wrapper header information ................................................................................................................ 83

Table 45: Auto connect modes .......................................................................................................................................... 85

Table 46: Modem working mode ................................ ................................ ................................................................ ....... 86

Table 47: Window status ................................................................................................................................................... 86

Table 48: GSM status object bits B1 and B11 relation states and meaning ...................................................................... 87

Table 49: GSM network name ........................................................................................................................................... 88

Table 50: Profile status register ......................................................................................................................................... 93

Table 51: Load profile options bit values ........................................................................................................................... 94

Table 52: Event log objects ............................................................................................................................................. 100

Table 53: List of events in the Standard event log .......................................................................................................... 101

Table 54: List of events in the Fraud detection event log ................................................................................................ 102

Table 55: List of events in the Disconnector control log .................................................................................................. 102

Table 56: List of events in the M-Bus event log ............................................................................................................... 103

V2.20 – English xiii/xiv INTRODUCTION

Technical description

ME382 and MT382

Table 57: List of events in the Power quality event log ................................................................................................... 104

Table 58: List of events in the Communication event log ................................................................................................ 105

Table 59: List of events in the M-Bus control log ............................................................................................................. 105

Table 60: Power Failure Event Log ................................................................................................................................. 106

Table 61: Last Modified Secure Parameter Identifier ...................................................................................................... 106

Table 62: Last Modified Secure Parameter Old Value .................................................................................................... 106

Table 63: Last Modified Secure Parameter New Value ................................................................................................... 106

Table 64: Monitored critical parameters .......................................................................................................................... 107

Table 65: Alarm 1 codes ................................................................................................................................................. 108

Table 66: Alarm 2 codes (IDIS P2) .................................................................................................................................. 109

Table 67: IDIS error codes register ................................................................................................................................. 111

Table 68: IE error codes register ..................................................................................................................................... 112

Table 69: Type designation for ZO350-D1/D2 ................................................................................................................. 116

Table 70: The IDIS Device Type Meaning....................................................................................................................... 126

Table 71: The IDIS Function Type Meaning .................................................................................................................... 126

Table 72: COSEM logical device name example ............................................................................................................ 126

Table 73: Meter device IDs ............................................................................................................................................. 127

Table 74: Meaning of Revision Number Characters ........................................................................................................ 128

Table 75: Dip & swell detection model ............................................................................................................................ 129

Table 76: Daily peak and minimum counters .................................................................................................................. 130

Table 77: Set of supported clients ................................................................................................................................... 138

Table 78: Supported authentication mechanism names ................................................................................................. 138

Table 79: Application context names .............................................................................................................................. 139

Table 80: Security suite ................................................................................................................................................... 139

Table 81: COSEM SAP assignment example ................................................................................................................. 142

Table 82: Disconnect control modes ............................................................................................................................... 150

V2.20 – English xiv/xiv INTRODUCTION

Technical description

ME382 and MT382

DANGER: for a possibly dangerous situation, which could result in severe physical injury

or fatality – attention to high-risk hazards.

WARNING: attention to a medium risk hazards.

CAUTION: for a possibly dangerous situation, which could result in minor physical injury

or material damage - attention to a low risk hazards.

Operating instruction: for general details and other useful information.

1. SAFETY INFORMATION

Safety information used in this Technical description are described with the following symbols and pictograms:

All safety information in this Technical description describes the type and source of danger; it is possible

consequences and measures to avoid the danger.

1.1. Responsibilities

The owner of the meter is responsible to assure that all authorized persons who work with the meter read

and understand the parts of the Technical description and Installation and maintenance manual that explains

safe handling with the meter.

The personnel must be sufficiently qualified for the work that will be performed. The installation personnel

must possess the required electrical knowledge and skills, and must be authorised by the utility to perform

the installation procedure.

The personnel must strictly follow the safety regulations and operating instructions, written in the individual

chapters in the Installation and maintenance manual and the Technical description.

The owner of the meter is responsible specially for the protection of the persons, for prevention of material

damage and for training of personnel.

V2.20 – English 1/179 1. SAFETY INFORMATION

Technical description

ME382 and MT382

1.2. Safety instructions

1.2.1. Handling and mounting

At the beginning of installation at the metering point, the meter should be carefully taken out of the box

where it was packed. This should prevent the meter from falling as well as any other external or internal

damage to the device and personal injuries. Should such an incident occur despite all precautions the meter

may not be installed at the metering point as such damage may result in different hazards. In such case, the

meter needs to be sent back to the manufacturer for examination and testing.

CAUTION: The edges of the seals, sealing wires as well as some edges under (removed) terminal cover are

sharp!

CAUTION: The temperature of the terminal block of the connected and operating meter may rise, therefore

the temperature of the terminal cover may rise as well.

DANGER: In case of any damage inside the meter (fire, explosion...) do not open the meter.

CAUTION: The meter may be used only for the purpose of measurement for which it was produced.

Any misuse of the meter will lead to potential hazards.

WARNING: Safety measures should be observed at all times. Do not break the seals or open the meter at

any time!

It must be consulted in all cases where symbol is marked in order to find out the nature of the

potential hazards and any actions, which have to be taken to avoid them.

The meter installation procedure is described in the Installation and maintenance manual. For safety reasons

the following instructions should be followed.

See the complete Technical description for detailed technical features of ME382 and MT382 meters

and its intended use.

V2.20 – English 2/179 1. SAFETY INFORMATION

Technical description

ME382 and MT382

Only a properly connected meter can measure correctly! Every connection error could result in a

financial loss for the power company!

1.2.2. Meter installation procedure

DANGER: The ME382/MT382 electricity meter is a device connected into the electricity network. Any

unauthorized manipulation of the device is dangerous for life and prohibited according to the

applicable legislation. Any attempt to damage the seals as well as any unauthorized opening of the

terminal or meter cover is strictly forbidden.

Installation companies shall implement a training policy that ensures that all installers are adequately trained,

understand risk and safety issues and possess the relevant skills before they commence operational duties.

The installer will need to recognise and understand different metering installations, meter types and various

equipment associated with those installations applicable to the successful installation of the electricity meter.

The installer must consult and comply with local regulations and read the installation instructions

written in the Installation and maintenance manual before installation.

The Installation and maintenance manual provides the instructions for installing ME382/MT382 meters.

The document provides a short overview of the meter, details of device installation and set-up, installation

considerations, and health and safety considerations.

The installer will be considered as a public face by both the power company and its customers. The installer

shall adopt the highest standards of behaviour and be respectful to clients and members of the public.

Before the beginning of the installation procedure, check if the metering point is correctly prepared for meter

installation. The metering point must always be left clean and in order.

The work location shall be defined and clearly marked. Adequate working space as well as means of access

and lighting shall be provided at all parts of an electrical installation on, with, or near which any work activity

is to be carried out.

Where necessary, safe access to the work location shall be clearly marked.