Content

FPC 200

USER MANUAL

Mar 2017

Feeder F1 and F3

Motor M1 and M3

Busbar B2 and B3

Transformer T1 and T3

1 USER MANUAL FPC 200 - 3/2017

Content

This product complies with the Low Voltage Directive 2014/35/EU and EMC Directive 2014/30/EU. This

conformity has been proved by tests according to product standards IEC 60255-26 (for EMC directive)

and IEC 60255-27 (for Low Voltage Directive).

Preface

Copyright

Copyright © Iskra d.d. Ljubljana, Slovenia 2016. All rights reserved. Dissemination or reproduction of this document, or

evaluation and communication of its contents is not authorized except where expressly permitted.

Purpose of this manual

The manual describes the functionality, as well as operation, installation and commissioning instructions for the FPC 200

types F1, F3, M1, M3, B2, B3, T1 and T3.

Target audience

Protection engineers, mechatronic engineers, commissioning engineers, personnel concerned with setting, monitoring

and service of protection equipment, industrial automatic and control facilities and personnel of electrical facilities and

power plants.

Applicability

This manual is valid for all FPC 200 type multifunctional numerical relays.

Conformity

Liability statement

Specialists and responsible persons of Iskra d.d. has checked the contents of this manual to ensure the description of both

hardware and software are as accurate as possible. However, deviations from the description cannot be completely ruled

out, so that no liability can be accepted for any errors or failures contained in the given manual. The content of this

manual is reviewed regularly. Corrections will be included in following editions. Any suggested improvements are highly

appreciated. We reserve the right to make technical improvements without notice.

2 USER MANUAL FPC 200 - 3/2017

Content

Contact

If there are any questions or comments related to this document or product please contact us at:

Iskra d.d.

Stegne 21,

1000 Ljubljana

Slovenia – EU

Tel: +386 1 500 4282

Email: sales.energy@iskra.eu

Webpage: www.Iskra.eu/fpc200/

USER MANUAL FPC 200 - 3/2017 3

Content

Indicates an imminently hazardous

situation which, if not avoided, will result

in death, serious injury or property

damage.

Indicates a potentially hazardous situation

which, if not avoided, could result in death,

serious injury or property damage.

Indicates a potentially hazardous situation

which, if not avoided, could result in

minor or moderate injury of property

damage.

Indicates information about the device or

respective part of instruction manual

which is essential to highlight.

WARNING!

Risk of electrical shock!

CAUTION!

Refer to product technical documentation!

Protective and functional ground terminal.

Waste Electrical and Electronic Equipment (WEEE) Directive 2002/96/EC; the affixed

product label indicates that you must not discard this electrical / electronic product in a

domestic household waste.

Safety symbols and messages

The warnings and notes contained in this manual serve for your own safety as well as safety of people and property

around you. Please observe them!

The following indicators and standard definitions are used:

DANGER

WARNING

CAUTION

NOTE

Explanation of device safety symbols

Depending on the device layout, the following labels and symbols can be used on device itself or in the

corresponding technical documentation:

4 USER MANUAL FPC 200 - 3/2017

Content

QUALIFIED PERSONNEL

For the purpose of this manual and product, a qualified person is the one who is familiar with the

installation, construction and operation of the equipment and hazards involved. Following qualifications are

needed:

Knowledge to energize, de-energize, clear, ground and tag circuits and equipment in accordance

with established safety practices.

Knowledge of proper care and use of protective equipment in accordance with established safety

practices.

Proficiency in rendering first aid.

NOTE

This is a class A product. In a domestic environment this product may cause radio

interference in which case the user may be required to take adequate measures.

Warning

Only qualified personnel can work on this device. Certain parts of the device inevitably have dangerous voltage. Thorough

familiarity with all warnings and safety notices of this manual along with applicable safety regulations is required. Failure

to observe these precautions can result in fatality, personal injury or extensive material damage. The successful and safe

operation of this device is dependent on proper handling, installation, operation and maintenance by qualified personnel.

USER MANUAL FPC 200 - 3/2017 5

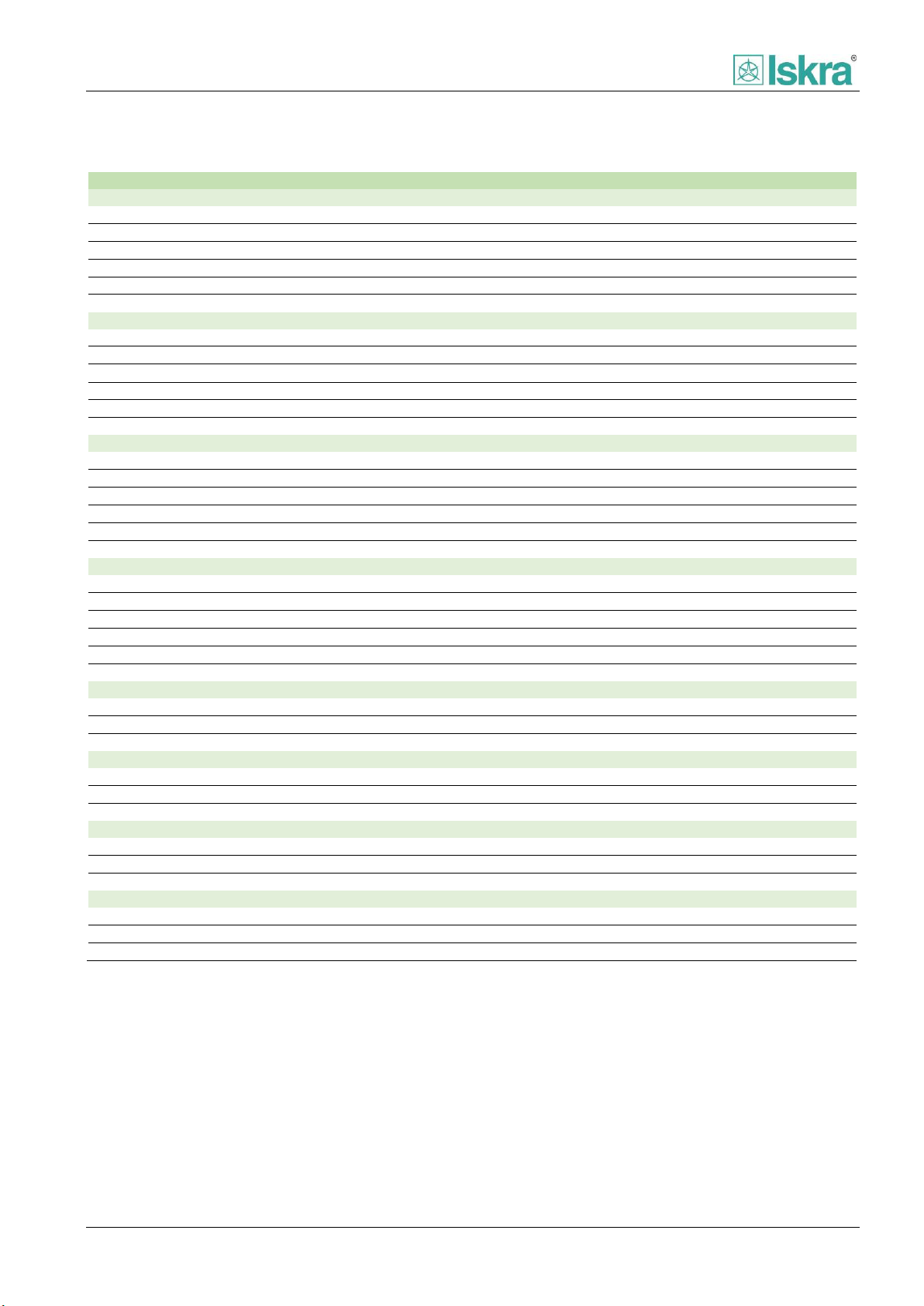

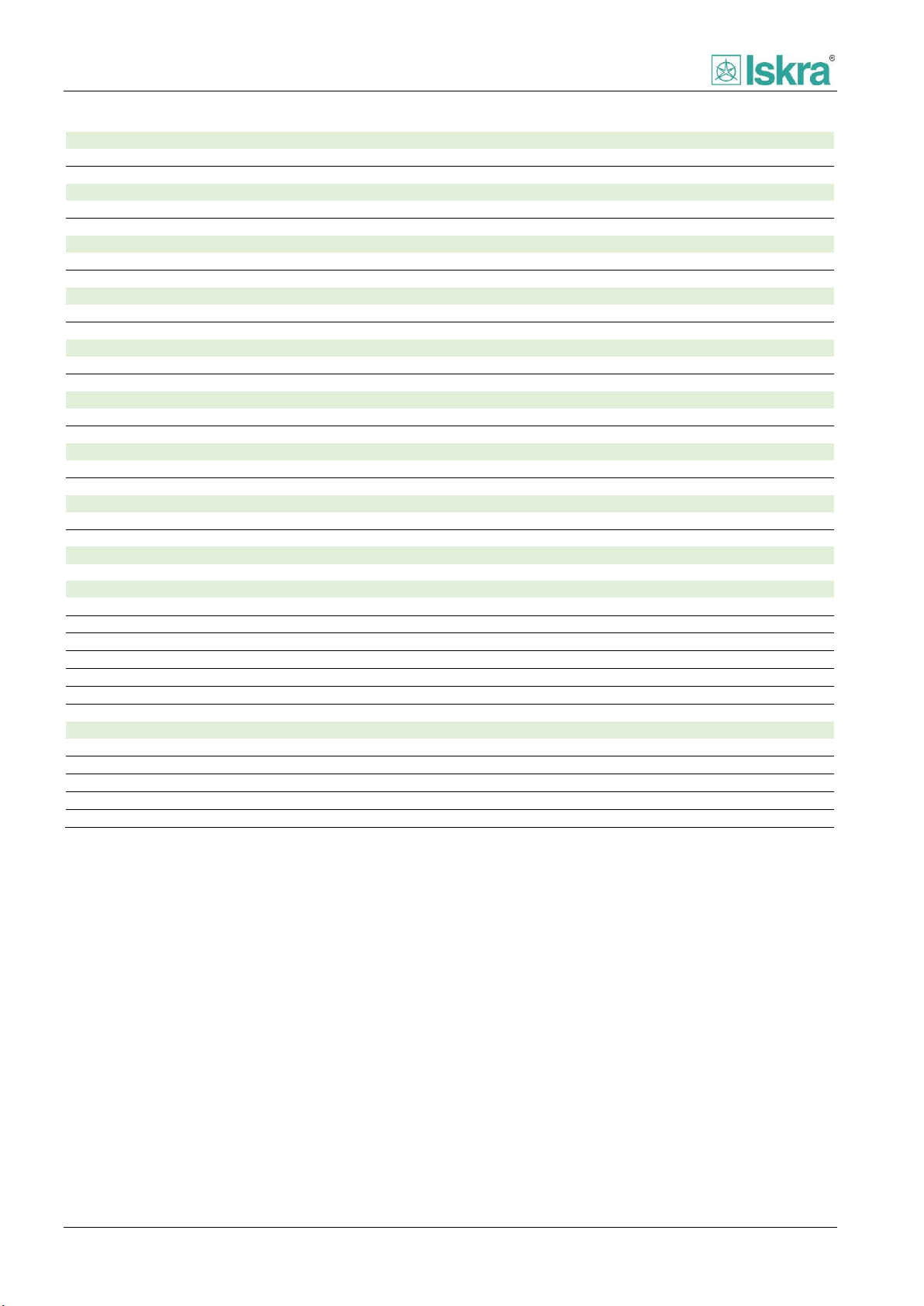

Content

Content

Preface ..................................................................................................................................................................................... 2

Copyright .............................................................................................................................................................................. 2

Purpose of this manual ........................................................................................................................................................ 2

Target audience ................................................................................................................................................................... 2

Applicability ......................................................................................................................................................................... 2

Conformity ........................................................................................................................................................................... 2

Liability statement ............................................................................................................................................................... 2

Contact ................................................................................................................................................................................. 3

Safety symbols and messages .............................................................................................................................................. 4

DANGER ........................................................................................................................................................................... 4

WARNING ........................................................................................................................................................................ 4

CAUTION .......................................................................................................................................................................... 4

NOTE ................................................................................................................................................................................ 4

Explanation of device safety symbols .............................................................................................................................. 4

Warning ............................................................................................................................................................................... 5

Content ..................................................................................................................................................................................... 6

1 Introduction ................................................................................................................................................................... 10

1.1 Presentation ......................................................................................................................................................... 11

1.2 Selection table ...................................................................................................................................................... 12

1.3 Device description ................................................................................................................................................ 13

Connection configuration ................................................................................................................................. 13

2 Functionality .................................................................................................................................................................. 14

2.1 Protections in general ........................................................................................................................................... 15

Default values ................................................................................................................................................... 15

Protection operation range .............................................................................................................................. 15

Time characteristics .......................................................................................................................................... 17

2.2 Current based protections .................................................................................................................................... 20

Overcurrent protection - ANSI code 50/51 ...................................................................................................... 20

Earth fault overcurrent protection - ANSI code 50/51|N/G ............................................................................. 22

Negative sequence/unbalance overcurrent protection - ANSI code 46 ........................................................... 24

Restricted earth fault protection - ANSI code 64REF ....................................................................................... 26

Phase undercurrent protection - ANSI code 37 ................................................................................................ 28

Inrush restraint ................................................................................................................................................. 30

6 USER MANUAL FPC 200 - 3/2017

Content

2.3 Voltage based protections .................................................................................................................................... 32

Phase to phase overvoltage protection - ANSI code 59 .................................................................................... 32

Neutral voltage displacement - ANSI code 59N ................................................................................................ 34

Phase to phase undervoltage protection - ANSI code 27 ................................................................................. 36

Positive sequence undervoltage protection - ANSI code 27D .......................................................................... 38

Remanent undervoltage protection - ANSI code 27R ....................................................................................... 40

2.4 Frequency based protections ................................................................................................................................ 42

Overfrequency protection - ANSI code 81H ..................................................................................................... 42

Underfrequency protection - ANSI code 81L .................................................................................................... 44

Rate of change of frequency protection - ANSI code 81R ................................................................................ 46

2.5 Power and machine protections ........................................................................................................................... 48

Thermal overload protection – ANSI code 49T ................................................................................................. 48

Machine Thermal Overload Protection - ANSI code 49M ................................................................................. 50

Temperature monitoring - ANSI code 38/49T .................................................................................................. 53

Locked rotor protection, excessive starting time - ANSI code 48/51LR/14 ...................................................... 55

Starts per hour - ANSI code 66 .......................................................................................................................... 57

Buchholz relay protection – ANSI code 63 ........................................................................................................ 58

Thermal switch protection – ANSI code 26 ....................................................................................................... 59

2.6 Automation and diagnostic ................................................................................................................................... 60

Circuit breaker control and monitoring - ANSI 94/69 with integrated circuit breaker failure - ANSI 50BF/62BF

function. ......................................................................................................................................................................... 60

Trip circuit supervision - ANSI 74 - TCS ............................................................................................................. 66

Auto-reclosing function - ANSI 79 - AR ............................................................................................................. 69

Machine control ................................................................................................................................................ 72

External trip – EXT-T ......................................................................................................................................... 74

2.7 User defined signals .............................................................................................................................................. 75

Description ........................................................................................................................................................ 75

Assigning user defined signals to digital outputs .............................................................................................. 75

Blocking of individual protection ...................................................................................................................... 75

2.8 Disturbance recording ........................................................................................................................................... 76

Description ........................................................................................................................................................ 76

USB stick ........................................................................................................................................................... 76

Trigger ............................................................................................................................................................... 76

Recorded data ................................................................................................................................................... 76

Clearing disturbance records ............................................................................................................................ 76

Setting parameters ........................................................................................................................................... 77

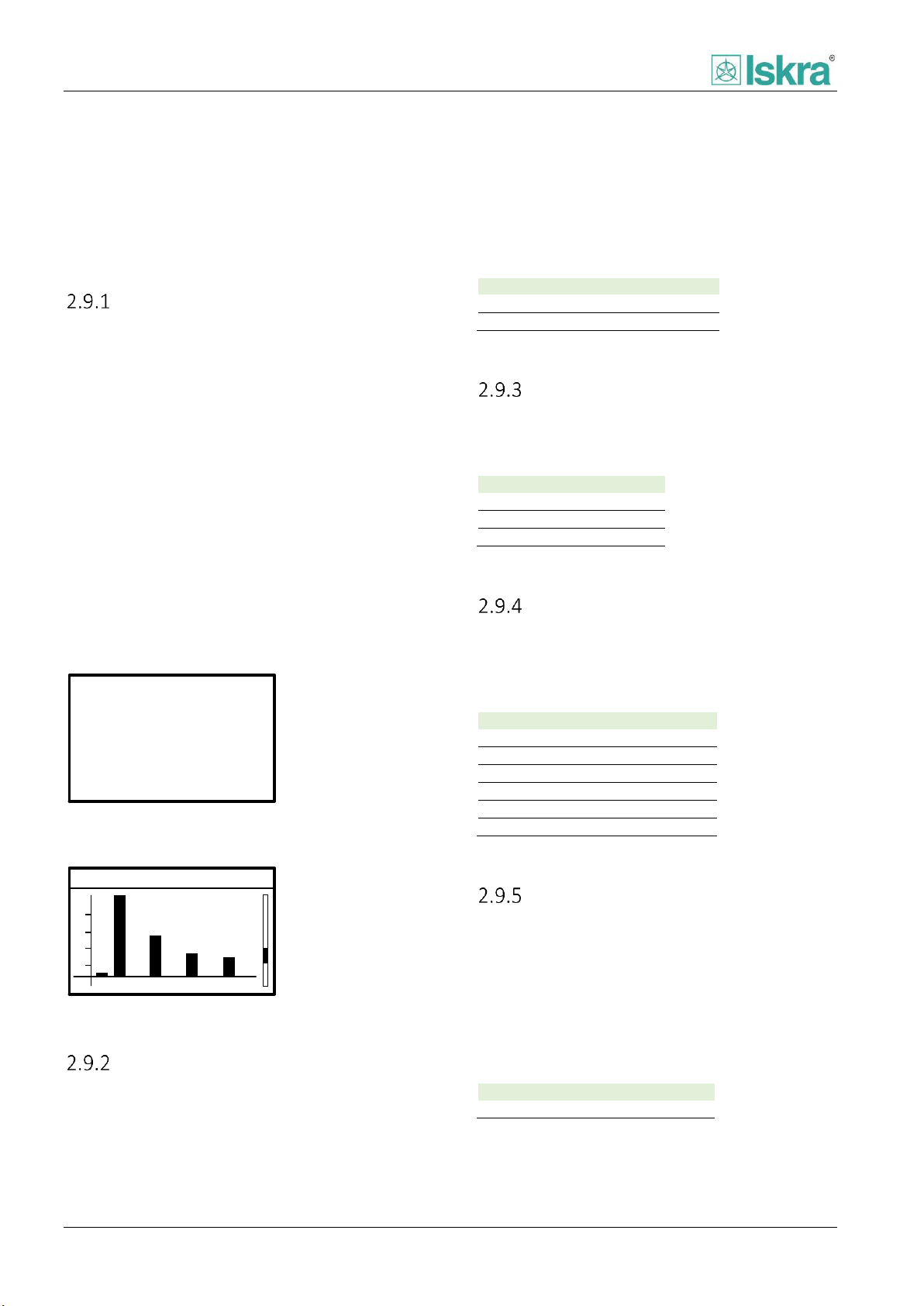

2.9 Measurements ...................................................................................................................................................... 78

Presented measured values .............................................................................................................................. 78

USER MANUAL FPC 200 - 3/2017 7

Content

Nominal values ................................................................................................................................................. 78

Current measurement ...................................................................................................................................... 78

Voltage measurement ...................................................................................................................................... 78

Frequency measurement ................................................................................................................................. 78

Symmetrical components ................................................................................................................................. 79

Temperature ..................................................................................................................................................... 79

2.10 Self-diagnostic ....................................................................................................................................................... 80

System status register .................................................................................................................................. 80

Operating states ........................................................................................................................................... 80

Internal faults description ............................................................................................................................ 81

3 Communication ............................................................................................................................................................. 82

3.1 Modbus RTU ......................................................................................................................................................... 82

General description .......................................................................................................................................... 82

Modbus PDU (protocol data unit) .................................................................................................................... 82

Modbus function supported ............................................................................................................................. 82

Time synchronization ....................................................................................................................................... 82

Events ............................................................................................................................................................... 83

Parameters ....................................................................................................................................................... 84

Address table .................................................................................................................................................... 85

3.2 Protocol IEC60870-5-103 ...................................................................................................................................... 98

General description .......................................................................................................................................... 98

Acronyms and Terms ........................................................................................................................................ 98

Protocol data transfer ...................................................................................................................................... 98

Supported standard options and functions .................................................................................................... 100

8 Interoperability ......................................................................................................................................................... 100

Parameters ..................................................................................................................................................... 107

Data table – Monitor direction ....................................................................................................................... 108

Data table – Control direction ........................................................................................................................ 111

4 Settings ........................................................................................................................................................................ 112

4.1 Introduction ........................................................................................................................................................ 113

4.2 Human machine interface (HMI) ........................................................................................................................ 113

User interface ................................................................................................................................................. 113

LCD .................................................................................................................................................................. 114

Menu overview ............................................................................................................................................... 116

Submenus overview ....................................................................................................................................... 119

4.3 PC based graphical interface MiQen Setting Studio ........................................................................................... 130

Installation ...................................................................................................................................................... 131

Using MiQen software .................................................................................................................................... 132

8 USER MANUAL FPC 200 - 3/2017

Content

5 Mounting and commissioning ..................................................................................................................................... 148

5.1 Safety instructions ............................................................................................................................................... 149

5.2 Precautions ......................................................................................................................................................... 149

Device stored in its original packaging ............................................................................................................ 149

Device installed in a cubicle ............................................................................................................................ 150

Working environment ..................................................................................................................................... 150

5.3 Equipment identification and unpacking ............................................................................................................ 151

Package specification ...................................................................................................................................... 151

Device identification ....................................................................................................................................... 151

5.4 Device installation ............................................................................................................................................... 152

Service conditions ........................................................................................................................................... 152

Dimensions ..................................................................................................................................................... 152

Cut-out dimensions ......................................................................................................................................... 153

Assembly ......................................................................................................................................................... 154

Spacing ............................................................................................................................................................ 155

Recommended external protection elements ................................................................................................ 155

5.5 Connection .......................................................................................................................................................... 156

Grounding wire ............................................................................................................................................... 157

Connection scheme ........................................................................................................................................ 158

Serial connection ............................................................................................................................................ 159

5.6 External module .................................................................................................................................................. 160

EX 408 Temperature module .......................................................................................................................... 160

5.7 Commissioning .................................................................................................................................................... 162

Handling conditions ........................................................................................................................................ 162

Testing equipment required ........................................................................................................................... 162

Device overall check ....................................................................................................................................... 162

Checking parameter and protection setting ................................................................................................... 163

Start-up ........................................................................................................................................................... 163

Hardware overview ......................................................................................................................................... 163

Protection validation ...................................................................................................................................... 166

6 Technical data .............................................................................................................................................................. 167

6.1 Type tests ............................................................................................................................................................ 168

6.2 Technical characteristics ..................................................................................................................................... 170

7 Appendix A: Ordering code .......................................................................................................................................... 173

8 Appendix B: Analog inputs configuration .................................................................................................................... 174

9 Glossary ........................................................................................................................................................................ 175

USER MANUAL FPC 200 - 3/2017 9

Introduction

1 Introduction

The chapter introduces FPC 200 device. Provided information can help you to pick device type which covers specific needs

of your project.

1.1 Presentation ........................................................................................................................................................... 8

1.2 Selection table ........................................................................................................................................................ 9

1.3 Device description ................................................................................................................................................ 10

10 USER MANUAL FPC 200 - 3/2017

Introduction

1.1 Presentation

FPC 200 is a family of current and voltage numerical protection relays with easy to use interface meant for variety of

solutions in industry and power distribution.

Its robust design enables it to be placed in demanding industrial environments.

Setting can be done completely through user friendly Human Machine Interface (HMI) unit. Visual experience is enhanced

through PC based interface software MiQen featuring specially designed menus where electrical attributes of power

system are graphically and numerically displayed in real time.

Transferring settings between different devices is easily done thanks to front panel USB port. Same settings are

transferred from one device to another using USB stick which can also be used to save fault recordings, counters and

software updates.

FPC 200 is a member of NEO3000 Substation system and can be integrated to any other new or existing substation or

automation protection and control system.

Figure 1.1: FPC 200 protection relay.

Main features are:

- Robust design for industrial usage

- Fast and simple commissioning

- Fault and event recording

- Intuitive user interface

- Multiple communication capabilities

- Numerical and graphical MiQen software tool

- Easy data transfer using USB stick

- Low power consumption

USER MANUAL FPC 200 - 3/2017 11

Introduction

Feeder

Busbar

Motor

Transformer

ANSI code

F1

F3

B2

B3

M1

M3

T1

T3

Current protections

Overcurrent DT/IDMT with Inrush restraint and Cold

Load Pick-up

50/51

4 4 4 4 4

4

Earth fault overcurrent DT/IDMT with Inrush restraint

and Cold Load Pick-up

50/51|N/G

4 4 4 4 4

4

Restricted earth-fault

64REF

2 2 2

Negative sequence overcurrent / unbalance

46 1 1 1 1 1 1

Phase undercurrent

37 1 1

Voltage protections

Phase-to-phase under voltage

27

2 2

Remanent under voltage

27R

1 1 Positive sequence under voltage

27D

2 2

Phase-to-phase overvoltage

59 2 2

Neutral voltage displacement/Residual overvoltage

59N 2 2

Over frequency

81H 2 2

Under frequency

81L 2 2

Rate of change (ROCOF)

81R 1

Power and machine protections and diagnostic

3 phase thermal overload (transformers)

49

Temperature monitoring (up to 8 sensors)

38/49T

Locked rotor, excessive starting time

48/51LR/14

Starts per hour

66

Thermostat / Buchholz switch

26/63

External trip

2 2 2 2 2 2 2

2

Automation and diagnostic

Circuit breaker control and monitoring

94/69

Circuit breaker failure

50BF/62BF

Trip circuit supervision (TCS)

74TC

Auto-reclosing

79

Lockout Relay

86LR/94

Cumulative breaking current

Metering

Phase current, RMS, THD, Harm., Residual c. 3I0

Earth current sensitive

Opt.

Opt.

Opt.

Opt.

Opt.

Opt.

Ph. & PPV voltages, RMS, THD, Harmonics

Frequency

Running hours

Communication protocols

Modbus

Optional

IEC 60870-5-103

Optional

1.2 Selection table

Table 1: Selection table Opt. Optional, included.

12 USER MANUAL FPC 200 - 3/2017

Introduction

1.3 Device description

Design of FPC 200 is modular. Base unit consists of housing, human machine interface (HMI), analog measurement card

(AMC) and six digital outputs (DO) with power supply (PS). AMC provides current or voltage measurements. Optional cards

extends the input/output and communication capabilities. Further extension is possible with external modules.

Base unit with maximum configuration includes:

Front panel with HMI and USB interface

rear panel with 10 digital inputs

8 digital outputs

2 serial communication ports

3 analog outputs

4 analog inputs

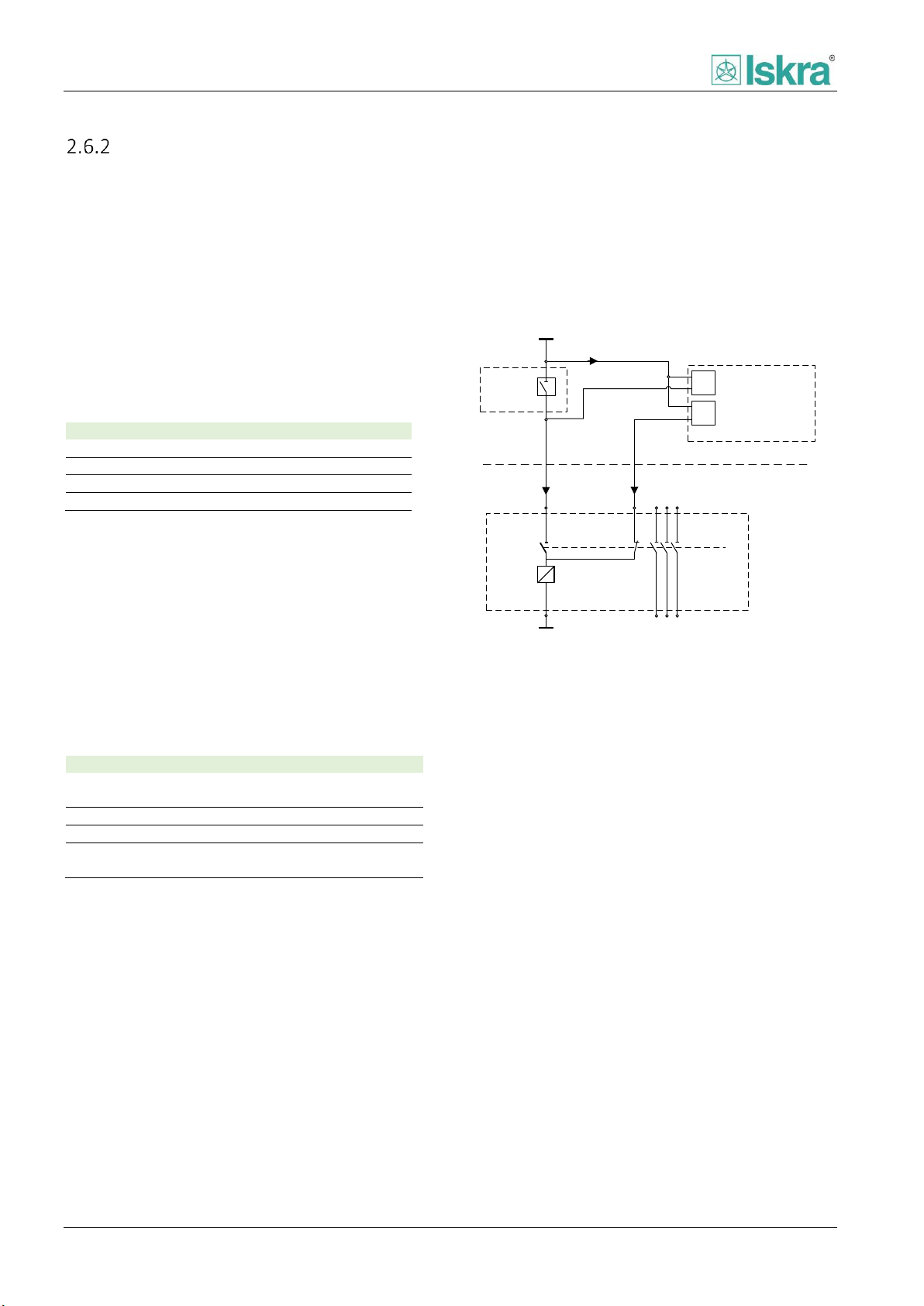

Connection configuration

Two connection configurations exist based on device type. Current measuring configuration is shown on Figure 1.2

whereas voltage version is shown on Figure 1.3.

Figure 1.2: Current measurements configuration.

Figure 1.3: Voltage measurements configuration.

USER MANUAL FPC 200 - 3/2017 13

Functionality

2 Functionality

This chapter describes various functions of the FPC 200 device. It explains options of each function in maximum

configuration and provides information on how to determine the setting values and, if required, corresponding formulas.

The following information also allows you to specify which of the available functions to use.

2.1 Protections in general ........................................................................................................................................... 15

2.2 Current based protections .................................................................................................................................... 20

2.3 Voltage based protections .................................................................................................................................... 32

2.4 Frequency based protections ............................................................................................................................... 42

2.5 Power and machine protections ........................................................................................................................... 48

2.6 Automation and diagnostic ................................................................................................................................... 60

2.7 User defined signals .............................................................................................................................................. 75

2.8 Disturbance recording .......................................................................................................................................... 76

2.9 Measurements ...................................................................................................................................................... 78

2.10 Self-diagnostic ....................................................................................................................................................... 80

3 Communication ............................................................................................................................................................. 82

3.1 Modbus RTU ......................................................................................................................................................... 82

14 USER MANUAL FPC 200 - 3/2017

Functionality

Parameter

Range

Pickup delay

0 … 5 … 1000 ms

Minimum value of pickup delay is 0 ms, maximum

value is 1000 ms. Default value is set to 5 ms.

Pickup value

Drop-out value

Fault detection

Monitored value

Fault area

Pickup signal

Fault detection

Trip signal

Pickup

delay

Trip delay

Drop-out

delay

Drop-out

delay

Fault

detection

Pickup

Blocking

Pickup

Delay

Pickup

&

2.1 Protections in general

Within this chapter the general theory of protection functions is described. For clear understanding several time

characteristics for different scenarios are presented.

Default values

Default values are presented as bold.

Example:

Table 2 Example of default parameter setting.

Protection operation range

Fault is detected when monitored value exceeds the

chosen threshold (pickup value). At that point the

protection enters into protection operation range or

fault area. To prevent unwanted switching a hysteresis

characteristic is introduced. Drop-out value is set

relative to pickup value.

When the monitored value enters the protection

operating range the protections picks up. On the other

hand when the value falls below the operating range the

protection drops or resets.

Protection operation range is shown on Figure 2.1.

short period of time. It is usually used when very long

time characteristics are used. In case the protection

trips, drop out delay is not accounted for and other

means of delaying trip signal are used.

Figure 2.2: Pickup signal and Trip signal when fault duration is

shorter than trip delay.

2.1.2.1 Pickup logic

The pickup signal indicates that monitored value

exceeded the set value and indicates that a fault

occurred (Figure 2.2). The pickup delay is intended for

fault signalling stabilization to prevent the short-lived

disturbances in the measuring part of the system from

being reported as faults (Figure 2.4).

Figure 2.1: Protection operation range - fault area.

Example: Nominal current of protected element I

set to 300 A, pickup value is set to 1,1 I

is 0,95 Ip. The protection will pick up when current

exceeds 330 A. It will drop out when the current drops

below 313,5 A.

Operational scenario is illustrated on Figure 2.2. Dropout delay prevents the timer of protection function to

reset in case the fault falls below the pickup value for a

USER MANUAL FPC 200 - 3/2017 15

and Drop-out

n_obj

n_obj

is

The pickup is set (Figure 2.3):

When a fault is detected and

Pickup delay confirmation time runs out and

There is no blocking

Figure 2.3: Pickup set logic.

Functionality

Pickup signal

Fault detection

Trip signal

Drop-out

delay

Pickup

delay

Pickup

delay

Trip

delay

Trip

Delay

&

Blocking

Pickup

Fault

detection

Trip

Pickup

Pickup block

Fault

Pickup blocked

Pickup

delay

Pickup

delay

Trip

delay

Trip

Trip

delay

Pickup drops when:

Fault is not present anymore, the drop-out

delay runs out and the Trip signal has not set

yet or

fault is not present anymore and Trip signal is

already set or

a blocking occurs.

Figure 2.4: Fault confirmation.

2.1.2.2 Trip logic

The Trip signal is intended for opening of circuit breaker,

which eliminates faulty element from power system.

Majority of faults have transient character and

disappear spontaneously. The duration of such faults is

relatively short. In order to avoid unnecessary opening

of circuit breaker the Trip signal can be delayed. Among

others the delaying of Trip signal may be used to ensure

selectivity along the power system network. The delay is

set with Trip delay parameter. In case the protection is

blocked the Trip signal will not set.

The Trip is set (Figure 2.5):

When a fault is detected and

when the pickup signal is stated and

trip delay time runs out and

no blocking is present.

Figure 2.5: Trip set logic.

Trip signal drops:

when the pickup drops or Blocking appears

When the protection trips there are some particular

delays on detection and trip execution levels. Several

milliseconds can pass during transfer of the signal to

external output relay and forward to the circuit breaker

switch of the circuit. The compensation of lost time is

solved with default value.

2.1.2.3 Blocking

Function is blocked when any pickup Block input is set. It can be set through digital input port or it can be set internally in

combination with different functions. When the protection is blocked the pickup signal drops and pickup blocked signal is

stated. Consequently after the pickup signal drops the Trip delay timer resets. After the blocking is reset and if the fault is

still present the protection function starts again. Protection operation with blocking signal turned on for a certain amount

of time is shown on Figure 2.6.

Figure 2.6: Protection operation with blocking signal turned on for a certain duration.

16 USER MANUAL FPC 200 - 3/2017

Functionality

0 1,0

drop

out

20 x Pickup

Trip

delay

Fault area

Fault

amplitude

1,1

Name of curve

IEC Normal inverse

IEC Very inverse

IEC Extremely inverse

IEC Long time inverse

IEEE Moderately inverse

IEEE Very inverse

IEEE Extremely inverse

RI curve

Name of characteristic

α

β

Normal inverse

0,02

0,14

Very inverse

1

13.5

Extremely inverse

2

80

Long time inverse

1

120

Name of characteristic

α

β

Moderately inverse

0,02

0,114

0,0515

Very inverse

2

0,491

19,61

Extremely inverse

2

0,1217

28,2

T …

protection trip time

k …

IDMT coefficient factor

α, β, …

Coefficient values

I …

Fault current amplitude

…

set limit of fault range, pickup value

Time characteristics

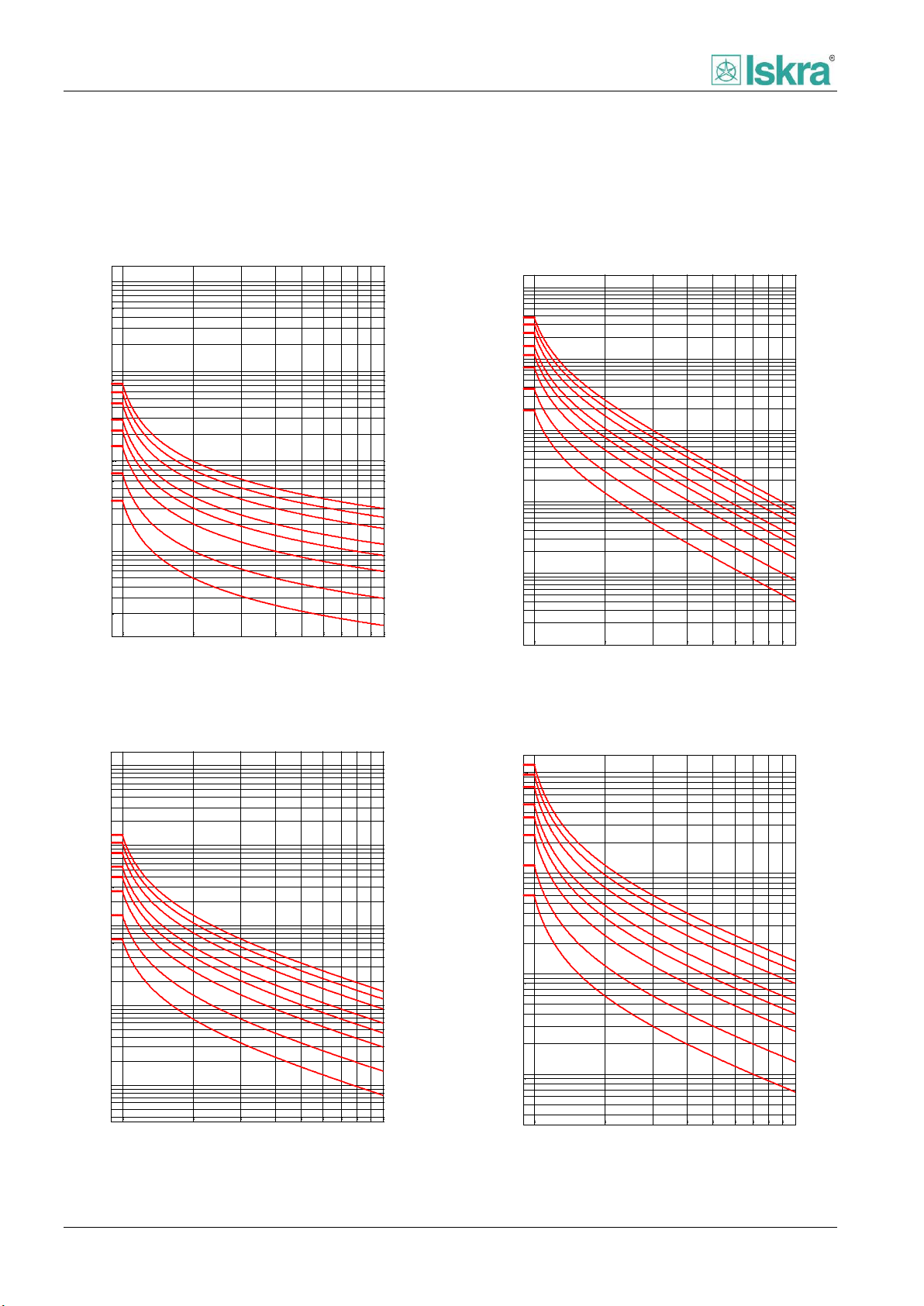

The main purpose of inverse time characteristics (IDMT

– Inverse Definite Minimum Time) is to enable shorter

time of protection trip when the fault current amplitude

is greater. At a set fault value the protection must trip in

time that can be read out from a characteristic. The

operation time depends on the measured current value

in accordance with standards IEC 60255-3 and IEEE C-

37112.

The available area of inverse time characteristic is

defined in a range between 1,1 and 20 Ip, where Ip

stands for pickup value. Amplitudes above 20 Ip have an

equal trip delay as the amplitude at 20 Ip. Amplitudes

from 1,1 Ip and lower have an equal trip delay as the

amplitude at 1,1 Ip.

The type of time characteristic can be chosen with the

mode parameter. It is necessary to set the pickup value

and IDMT coefficient parameters. Values are used with

all types of time characteristics. The IDMT coefficient

factor defines the time delay level. Lower values

indicate faster operation at equal fault values.

The fault current amplitude is not always constant and

can change during fault duration. For this reason the

algorithm dynamically integrates parts of time during

the fault according to particular characteristic and when

the sum reaches the switch off limit the protection trips.

2.1.3.1 IEC characteristics

Equation 1 Time to trip for IEC inverse characteristics.

Table 4: Coefficients of IEC characteristics.

2.1.3.2 RI curve

Equation 2 Time to trip for RI inverse characteristics.

2.1.3.3 IEEE characteristics

Equation 3 Time to trip for IEEE inverse characteristics

equation.

Figure 2.7: Time inverse characteristic.

Table 3 Time inverse curve types.

Table 5: Coefficients of IEEE characteristics.

USER MANUAL FPC 200 - 3/2017 17

Functionality

1.1 2 3 4 5 6 7 8 9 10

1

10

100

1000

1500

IEC Normal inverse

I / In

t [s]

0.05

IDMT

0.1

IDMT

0.2

IDMT

0.3

IDMT

0.4

IDMT

0.6

IDMT

0.8

IDMT

1

IDMT

1.1 2 3 4 5 6 7 8 9 10

0.1

1

10

100

1000

1500

IEC Very inverse

I / In

t [s]

0.05

IDMT

0.1

IDMT

0.2

IDMT

0.3

IDMT

0.4

IDMT

0.6

IDMT

0.8

IDMT

1

IDMT

1.1 2 3 4 5 6 7 8 9 10

0.1

1

10

100

1000

1500

IEC Extremely inverse

I / In

t [s]

0.05

IDMT

0.1

IDMT

0.2

IDMT

0.3

IDMT

0.4

IDMT

0.6

IDMT

0.8

IDMT

1

IDMT

1.1 2 3 4 5 6 7 8 9 10

1

10

100

1000

1500

IEC Long time inverse

I / In

t [s]

0.05

IDMT

0.1

IDMT

0.2

IDMT

0.3

IDMT

0.4

IDMT

0.6

IDMT

0.8

IDMT

1

IDMT

2.1.3.4 Graphs of inverse characteristics

Graphs below represent time to trip depending on current and user defined IDMT setting for each of the inverse time

characteristics.

Figure 8 IEC Normal inverse characteristics.

Figure 9 IEC Very inverse characteristics.

18 USER MANUAL FPC 200 - 3/2017

Figure 10IEC Extremely inverse characteristics.

Figure 11 IEC Long time inverse characteristics.

Functionality

1.1 2 3 4 5 6 7 8 9 10

0.1

1

10

100

150

IEEE MI

I / In

t [s]

0.05

IDMT

0.1

IDMT

0.2

IDMT

0.3

IDMT

0.4

IDMT

0.6

IDMT

0.8

IDMT

1

IDMT

1.1 2 3 4 5 6 7 8 9 10

0.1

1

10

100

150

IEEE EI

I / In

t [s]

0.05

IDMT

0.1

IDMT

0.2

IDMT

0.3

IDMT

0.4

IDMT

0.6

IDMT

0.8

IDMT

1

IDMT

1.1 2 3 4 5 6 7 8 9 10

0.1

1

10

100

150

IEEE VI

I / In

t [s]

0.05

IDMT

0.1

IDMT

0.2

IDMT

0.3

IDMT

0.4

IDMT

0.6

IDMT

0.8

IDMT

1

IDMT

1.1 2 3 4 5 6 7 8 9 10

1

10

100

150

RI

I / In

t [s]

0.05

IDMT

0.1

IDMT

0.2

IDMT

0.3

IDMT

0.4

IDMT

0.6

IDMT

0.8

IDMT

1

IDMT

Figure 12 IEEE moderately inverse characteristics.

Figure 13 IEEE Extremely inverse characteristics.

USER MANUAL FPC 200 - 3/2017 19

Figure 14 IEEE Very inverse characteristics.

Figure 15 RI inverse time characteristics.

Functionality

50/51 Over current

Mode:

Enable:

IDMT coeficient:

0,02

ON

Pickup value: 1,2xIn

A

Trip delay: 0,4s

Ext. inverse

1A 1B 2A 2B 3A 3B 4A

Pickup value

Drop-out value

CLP activated

Monitored value

Fault area

Fault detection

2.2 Current based protections

Overcurrent protection - ANSI code 50/51

Overcurrent protection is one of the basic functions of FPC 200 numerical relays. It protects the feeder or other elements

of the power system from overcurrent when fault occurs. It comprises of various time-delayed characteristics. Protective

function includes Inrush restraint [2.2.5] and Cold load pickup (CLP) protection.

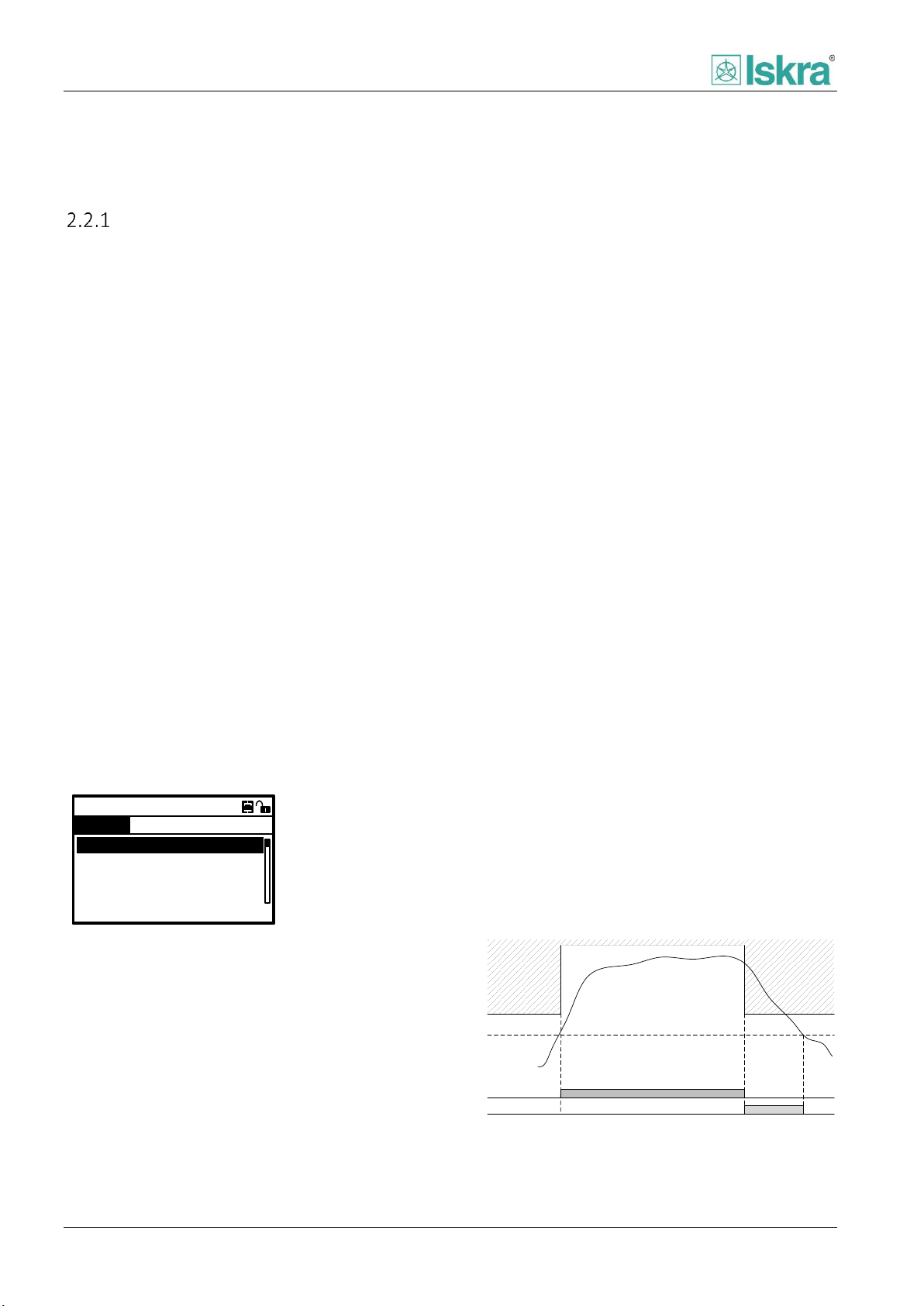

2.2.1.1 Functionality

Overcurrent protection is used as non-directional time

delayed overcurrent and short-circuit protection. It picks

up when current in one, two or three phases exceeds

the set threshold. The function can be enabled or

disabled through corresponding menu. The trip time

characteristics can be selected to be Instantaneous,

definite time (DT) or inverse definite minimum time

(IDMT). When instantaneous operation mode is selected

the trip signal is stated as the DT characteristic. The

settings of this function are applied to each of the three

phases to produce pickup and trip signals per each

phase.

Several overcurrent protection instances with different

settings can run independently at the same time.

The selection of pickup value, pickup delay as well as

drop-out ratio and drop-out delay helps the user to fine

tune the protection according to the project

specifications.

2.2.1.3 Delays

Function includes following delays explained in Chapter

2.1:

Pickup delay

Trip delay

Drop-out delay

2.2.1.4 Cold load pickup

A temporary increased starting current can appear

when energizing feeders with loads that had a long zero

voltage period (e.g. air-conditioning systems, heating

installations, motors...). Its value can be up to several

times higher than the nominal current. To avoid

unwanted protection operation the pickup limit has to

be raised temporarily. The function is set with

parameter Enable. It triggers through the activation of

corresponding digital input or when current raises

above

5 % of I

of time has passed.

in at least one phase after certain amount

n_obj

Figure 2.16: Overcurrent protection setting.

2.2.1.2 Measurements

The value of each phase current is acquired through

separate input current transformer. The measured

phase currents are compared with the set pickup value.

20 USER MANUAL FPC 200 - 3/2017

The dynamic pickup value changeover is common to all

overcurrent elements. With inverse characteristics, the

CLP influences only the fault detection limit, whereas

the time calculation of the selected inverse

characteristic is not affected.

Figure 2.17: Operation with CLP activated for a shorter than

fault time duration.

Functionality

Parameter

Range

Description

Enabled

No

Yes

Enabling protection function.

Operate mode

Instantaneous

Definite time

IEC Normal inverse

IEC Very inverse

IEC Extremely inverse

IEC Long-time inverse

IEEE Moderately inverse

IEEE Very inverse

IEEE Extremely inverse

RI

Protection operation mode:

Definite time – constant time of operation

Inverse characteristics – selected IDMT characteristic

IDMT coefficient

0,05 … 1,00

Coefficient of selected IDMT characteristic

Pickup value

0,05 … 1,00 … 40,00 I

n_obj

Limit of monitored current.

Trip delay

0,00 ... 0,50 … 300,00 s

Delay of trip signal

Inrush restraint source

None

Inrush-1

Inrush-2

Input source of Inrush restraint [Chapter 2.2.5] blocking function.

Pickup delay

0 … 5,00 … 1000 ms

Time stabilization of fault detection. As a filter of short

disturbances on measuring circuits. Time before protection starts.

Drop-out delay

0,00 … 0,20 … 60,00 s

Time stabilization of pickup signal. Time when the monitored value

is outside the operating range, but the protection does not stop

yet.

Drop-out ratio

0,80 … 0,95 … 1,00 Ip

Drop-out value below which the protection drops.

Cold load pickup Enabled

No

Yes

Enabling CLP function.

Cold load pickup Level

1,01 … 1,50 … 10,00 Ip

Pickup and drop-out value increase.

Cold load pickup Duration

0 … 60 … 3600 s

Pickup value increase duration time.

Pickup block

None

Variable 1

Variable 2

Variable 3

Variable 4

Source of blocking signal.

Name

Description

Pickup

Total consecutive number of pickup signals.

Trip

Consecutive number of trip signals.

Pickup L1

Consecutive number of pickup signals detected in phase L1

Pickup L2

Consecutive number of pickup signals detected in phase L2

Pickup L3

Consecutive number of pickup signals detected in phase L3

CLP

Consecutive number of cold load pickup

2.2.1.5 Setting parameters

Table 6: Overcurrent protection function parameters.

2.2.1.6 Counters

Table 7: Counters presented in overcurrent protection.

21 USER MANUAL FPC 200 - 3/2017

Functionality

50N/51N Ground prot

Mode:

Enable:

IDMT coeficient:

0,02

ON

Pickup value: 1,2xIn

A

Trip delay: 0,4s

Ext. inverse

1A 1B 2A 2B 3A 3B 4A

Pickup value

Drop-out value

CLP activated

Monitored value

Fault area

Fault detection

Earth fault overcurrent protection - ANSI code 50/51|N/G

Earth fault overcurrent protection is one of the basic functions of FPC 200 numerical relay. It comprises of various timedelayed characteristics. Protective function includes CLP and inhibition by Inrush restraint [2.2.5] function.

2.2.2.1 Functionality

Earth fault overcurrent function is used as nondirectional earth fault protection. Pickup value of this

function is normally set lower than pickup value of

phase overcurrent protection. Protection picks up when

the earth fault current exceeds the set threshold value.

The function can be enabled or disabled through

corresponding menu. Trip time characteristics can be

selected to be Instantaneous, Definite time (DT) or

Inverse definite minimum time (IDMT). When

instantaneous operation mode is selected the trip signal

is stated as the DT characteristic.

Several earth fault protection instances with different

settings can run independently at the same time.

The selection of pickup value, pickup delay as well as

drop-out ratio and drop-out delay helps the user to fine

tune the protection according to the project

specifications.

2.2.2.3 Delays

Function includes following delays explained in Chapter

2.1:

Pickup delay

Trip delay

Drop-out delay

2.2.2.4 Cold load pickup

A temporary increased starting current can appear

when energizing feeder loads that had a long zero

voltage period (e.g. air-conditioning systems, heating

installations, motors...). Its value can be up to several

times higher than the nominal current. To avoid

unwanted protection operation the pickup limit has to

be raised temporarily. The function is set with

parameter Enable. It triggers only when CB Close

command is executed manually.

Figure 2.18: Earth fault overcurrent setting.

2.2.2.2 Measurements

Earth fault current is acquired directly through analog

measurement or calculated.

Sensitive current input can be selected for direct earth

fault measurement. When sensitive analog input Ie is

not present earth current 3I0 is calculated using phase

currents analog measurements.

The dynamic pickup value changeover is common to all

overcurrent elements. With inverse characteristics, the

CLP influences only the fault detection limit, whereas

the time calculation of the selected inverse

characteristic is not affected.

Figure 2.19: Operation with CLP activated for a shorter than

fault time duration.

22 USER MANUAL FPC 200 - 3/2017

Functionality

Parameter

Range

Description

Enabled

No

Yes

Enabling protection function.

Operate mode

Instantaneous

Definite time

IEC Normal inverse

IEC Very inverse

IEC Extremely inverse

IEC Long-time inverse

IEEE Moderately inverse

IEEE Very inverse

IEEE Extremely inverse

RI

Protection operation mode:

Definite time – constant time of operation

Inverse characteristics – selected IDMT characteristic

Pickup value

0,005 … 0,10 … 1,25 I

n_e

Limit of monitored current.

Trip delay

0,00 … 2,00 … 300,00 s

Delay of trip signal

IDMT coefficient

0,05 … 1,00

Coefficient of selected IDMT characteristic

Inrush restraint source

None

Inrush-1

Inrush-2

Input source of Inrush restraint [Chapter 2.2.5] blocking

function.

Pickup delay

0 … 5,00 … 1000 ms

Time stabilization of fault detection. As a filter of short

disturbances on measuring circuits. Time before protection

starts.

Drop-out delay

0,00 … 0,20 … 60,00 s

Time stabilization of pickup signal. Time when the monitored

value is outside the operating range, but the protection does

not stop yet.

Drop-out ratio

0,80 … 0,95 … 1,00 Ip

Drop-out value below which the protection drops.

Input current

3I0

Ie

Selector for protection to account for calculated residual

current (3I0) for 50N/51N function or measured residual

current (Ie) for 50G/51G function.

Cold load pickup Enabled

No

Yes

Enabling CLP function.

Cold load pickup Level

1,01 … 1,50 … 10,00 Ip

Pickup and drop-out value increase.

Cold load pickup Duration

0 … 60 … 3600 s

Pickup value increase duration time.

Pickup block

None

Variable 1

Variable 2

Variable 3

Variable 4

Source of blocking signal.

Name

Description

Pickup

Total consecutive number of pickup signals.

Trip

Consecutive number of trip signals.

CLP

Consecutive number of cold load pickup

2.2.2.5 Setting parameters

Table 8: Earth fault overcurrent protection function parameters.

2.2.2.6 Counters

Table 9: Counters presented in earth fault overcurrent protection.

USER MANUAL FPC 200 - 3/2017 23

Functionality

Definite time

46 Negative sequence

Mode:

Enabled:

IDMT coeficient:

0.05

Yes

Pickup value: 0.1In

Trip delay: 1.5s

A B

Negative sequence/unbalance overcurrent protection - ANSI code 46

Uneven distribution of currents is caused by asymmetrical loads, single or two phase earth faults, line disconnections or

irregular switching operations. Negative sequence/unbalance overcurrent protection function calculates negative

sequence current of symmetrical components in three phase system.

2.2.3.1 Functionality

Function is used for detecting unbalanced loads in the

power system. Negative sequence value is defined by

the asymmetry of power system. Asymmetrical faults

selectivity is achieved by considering negative sequence

value.

In order to prevent malfunction of the protection and to

achieve better selectivity additional operational

conditions must be applied:

All phase currents have to be below the set

Maximum current value and

At least one phase current has to be above the

set Minimum current value

Protection selectivity is further improved with trip delay

time value set higher than the one set in main

protections (e.g. Overcurrent protection).

The trip time characteristics can be selected to be

Instantaneous, definite time (DT) or inverse definite

minimum time (IDMT). When instantaneous operation

mode is selected the trip signal is stated as the DT

characteristic with zero trip delay parameter.

The selection of pickup value, pickup delay as well as

drop-out ratio and drop-out delay helps the user to fine

tune the protection according to the project

specifications.

Figure 2.20 Example of parameter settings on HMI.

2.2.3.2 Delays

Function includes following delays explained in Chapter

2.1:

Pickup delay

Trip delay

Drop-out delay

24 USER MANUAL FPC 200 - 3/2017

Functionality

Parameter

Range

Description

Enabled

No

Yes

Enabling protection function.

Operate mode

Instantaneous

Definite time

IEC Normal inverse

IEC Very inverse

IEC Extremely inverse

IEC Long-time inverse

IEEE Moderately inverse

IEEE Very inverse

IEEE Extremely inverse

RI

Protection operation mode:

Definite time – constant time of operation

Inverse characteristics – selected IDMT characteristic

IDMT coefficient

0,05 … 1,00

Coefficient of selected IDMT characteristic

Pickup value

0,01 … 0,10 … 3,00 I

n_obj

Limit of monitored current.

Trip delay

0,00 … 1,50 … 300,00 s

Delay of trip signal.

Pickup delay

0 … 5,00 … 1000 ms

Time stabilization of fault detection. As a filter of short disturbances on

measuring circuits. Time before protection starts.

Drop-out delay

0,00 … 0,20 … 60,00 s

Time stabilization of pickup signal. Time when the monitored value is

outside the operating range, but the protection does not stop yet.

Drop-out ratio

0,80 … 0,95 … 1,00 Ip

Drop-out value below which the protection drops.

Pickup block

None

Variable 1

Variable 2

Variable 3

Variable 4

Source of blocking signal.

Minimal current

0,01 … 0,10 … 2,00 I

n_obj

Minimal current above which the protection operates. Protection is

blocked if all phase currents are below the set value.

Maximum current

0,10 … 4,00 … 10,00 I

n_obj

Maximum current below which the protection still operates. Protection is

blocked if any of the phase currents is above the set value.

Name

Description

Pickup

Total consecutive number of pickup signals.

Trip

Consecutive number of trip signals.

2.2.3.3 Setting parameters

Table 10: Negative/unbalance sequence protection function parameters.

2.2.3.4 Counters

Table 11: Counters presented in negative sequence protection.

USER MANUAL FPC 200 - 3/2017 25

Functionality

Off

64 Res. Earth fault

Mode:

Enabled:

Pickup value:

0.1In

Yes

Trip delay: 2s

A

1A 1B 2A 2B

CONTROL SETTINGS

L1

L2

L3

3Io=I1+I2+I3

FPC 200

Ie

I1I2I3

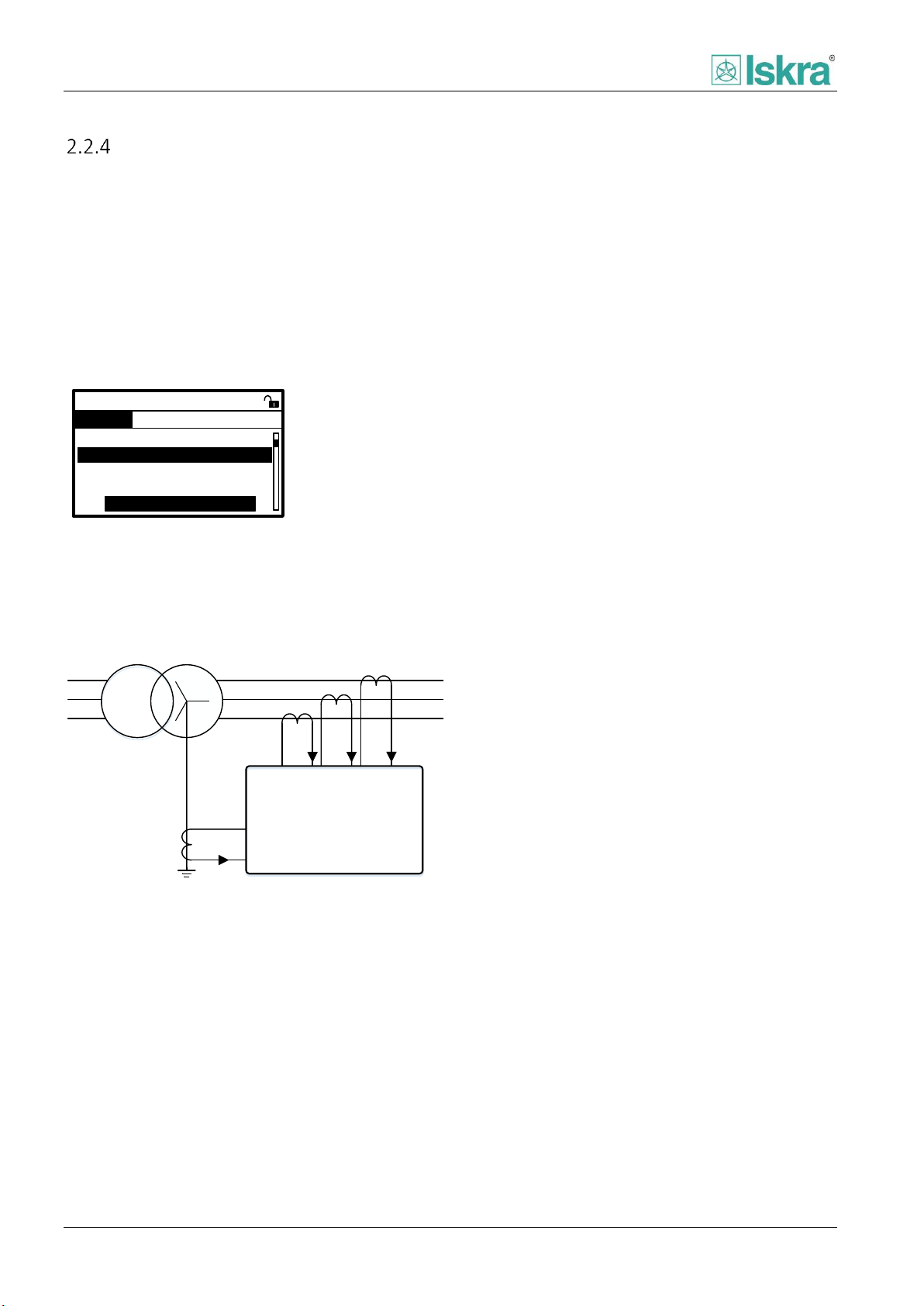

Restricted earth fault protection - ANSI code 64REF

Restricted Earth Fault function is one of advanced protection functions installed in FPC 200 protection relay. Protection

detects earth faults in power transformers, shunt reactors, neutral earthing transformers/reactors, or rotating machines.

Starpoint of protected element should be earthed. The starpoint CT and the phase CTs define the limits of absolutely

selective protection. Restricted earth fault protection is not applicable to busbar, type B of FPC 200 protection relay.

2.2.4.1 Functionality

Function compares calculated residual phase current

(3I0) with measured neutral point current Ie.

Figure 2.21 Example of parameter settings on HMI.

2.2.4.3 Connection scheme

Typical Connection scheme is shown on Figure 2.22.

2.2.4.2 Delays

Function includes following delays explained in Chapter

2.1:

Pickup delay

Trip delay

Drop-out delay

Figure 2.22: Connection scheme.

26 USER MANUAL FPC 200 - 3/2017

Functionality

Parameter

Range

Description

Enabled

No

Yes

Enabling protection function.

Operate mode

Off

Definitive time

Enabling protection function separately for each group level.

Pickup value

0,005 … 0,10 … 2,00 I

n_e

Limit of monitored current.

Trip delay

0,00 … 2,00 … 300,00 s

Delay of trip signal.

Pickup delay

0 … 5,00 … 1000 ms

Time stabilization of fault detection. As a filter of short disturbances on

measuring circuits. Time before protection starts.

Drop-out delay

0,00 … 0,20 … 60,00 s

Time stabilization of pickup signal. Time when the monitored value is

outside the operating range, but the protection does not stop yet.

Drop-out ratio

0,80 … 0,95 … 1,00 Ip

Drop-out value below which the protection drops.

Pickup block

None

Variable 1

Variable 2

Variable 3

Variable 4

Source of blocking signal.

Name

Description

Pickup

Total consecutive number of pickup signals.

Trip

Consecutive number of trip signals.

2.2.4.4 Setting parameters

Table 12: Restricted earth fault function parameters.

2.2.4.5 Counters

Table 13: Counters presented in restricted earth fault protection.

USER MANUAL FPC 200 - 3/2017 27

Functionality

37 Undercurrent

Enabled:

No

Pickup value: 0.7In

A

Trip delay: 0.4s

1A 1B

CONTROL SETTINGS

Pickup delay:

0.4s

A

Phase undercurrent protection - ANSI code 37

Phase to phase undercurrent is a function that protects the rotating machine or other elements of the power system from

low current.

2.2.5.1 Functionality

Undercurrent protection is used as time delayed

protection. It picks up when one of the phase currents

drops below the selected threshold. The function can be

enabled or disabled through corresponding menu.

The selection of pickup value, pickup delay as well as

drop-out ratio and drop-out delay helps the user to fine

tune the protection according to the project

specifications.

Figure 2.23: Phase undercurrent protection setting as seen on

HMI.

2.2.5.2 Delays

Function includes following delays explained in Chapter

2.1:

Pickup delay

Trip delay

Drop-out delay

2.2.5.3 Block settings

Pickup of any instance separately of protection can be

individually blocked by:

Any user defined signal [2.6.5].

Defined zero current level.

In addition the individual protection trip exhibits pulse

type if connected to trip relay [4.2.4.5.7, relay mapping

section], to ensure correct CBFP [2.6.1.10] functionality.

28 USER MANUAL FPC 200 - 3/2017

Functionality

Parameter

Range

Description

Enabled

No

Yes

Enabling protection function.

Operate mode

Off

On

Enabling protection function separately for each group level.

Pickup value

0,1 … 0,75 … 2,00 I

n_obj

Value at which fault conditions are considered.

Trip delay

0,00 … 1,50 … 300,00 s

Delay of trip signal

Pickup delay

10 … 20 … 1000 ms

Time stabilization of fault detection. As a filter of short

disturbances on measuring circuits. Time before protection starts.

Drop-out delay

0,00 … 0,20 … 60,00 s

Time stabilization of pickup signal. Time when the monitored value

is outside the operating range, but the protection does not stop

yet.

Drop-out ratio

1,01 … 1,20 … 3,00 Ip

Drop-out value below which the protection drops.

Current Supervision

Enabled

No

Yes

Enabling Current Supervision.

Zero I level

0,04 … 0,10 … 1

Level of current below which operation of protection is blocked.

Operation is blocked only in case of all three current amplitude Lx

are below Zero I level.

Recovery time

0,00 … 60 … 100 ms

Time of blocked protection after reaching Zero I level for Recovery

time.

Pickup block

None

Variable 1

Variable 2

Variable 3

Variable 4

Source of blocking signal.

Name

Description

Pickup

Total consecutive number of pickup signals.

Trip

Consecutive number of trip signals.

Pickup L1

Consecutive number of pickup signals detected in phase L1

Pickup L2

Consecutive number of pickup signals detected in phase L2

Pickup L3

Consecutive number of pickup signals detected in phase L3

2.2.5.4 Setting parameters

Table 14: Phase undercurrent protection function parameters.

2.2.5.5 Counters

Table 15: Counters presented in phase undercurrent protection.

USER MANUAL FPC 200 - 3/2017 29

Functionality

Protection function

Monitored currents

Overcurrent protection

Phase currents

Inrush detection

Inrush pickup

Inrush block

Max. inrush time

t < 20 ms

Inrush restraint

Inrush restraint function is a blocking function. The function can block overcurrent or earth fault overcurrent protection

from operating for pre-defined period of time.

2.2.6.1 Functionality

Transformer inrush current includes high 2nd harmonic

component. The Inrush restraint function is based on

evaluation of 2nd harmonic component present in the

inrush current. Inrush current detection is set for each

monitored current separately as defined in Table 16.

When transformer is energized high amount of 2

nd

harmonic component is present. In order to prevent

unwanted tripping Inrush restraint function can be used.

Another example is in combination with 50N/51N

protection function. When large object (e.g.

Transformer) is energized large amount of transients are

present. Because of that a large zero sequence can be

calculated which can trigger unwanted tripping of

50N/51N protection function. To once again prevent

unwanted tripping Inrush restraint should be used.

In order for inrush restraint to inhibit desired protection

its output should be assigned in parameter Inrush

restraint source which is present in all types of

overcurrent protection [2.2.1, 2.2.2].

2.2.6.2 Monitoring

Monitored currents are different for each protection

function.

Table 16: Monitored currents.

Figure 2.24: Inrush Restrain characteristic.

30 USER MANUAL FPC 200 - 3/2017

Functionality

Parameter

Range

Description

Enabled

No

Yes

Enabling of function.

Inrush pickup

1 … 15 … 70 %

Higher 2nd harmonic current limit in comparison to fundamental current, above

which the detection of inrush current is enabled.

Dropout delay

0 … 0,20 … 10 s

Max time

0 … 5,00 … 60 s

Max current

0,30 … 7,50 … 30,00 I

n_obj

Maximum value of fundamental current above which the protection is disabled.

Constant

Value

Description

Inrush drop-out delay

0,20 s

Time stabilization of pickup signal. Predefined time when the monitored

harmonic component value is outside the operating range, but the protection

does not stop yet.

Max inrush time

5,00 s

Predefined time when inrush restraint function is disabled.

Name

Description

Inrush counter

Total consecutive number of detected inrush signals.

2.2.6.3 Setting parameters

Table 17: Inrush restraint function parameters.

2.2.6.4 Predefined values

Table 18: Inrush restraint predefined values.

2.2.6.5 Counters

Table 19: counter presented in inrush restraint function.

USER MANUAL FPC 200 - 3/2017 31

Functionality

59 Overvoltage

Enabled:

Yes

Pickup value: 1.2Un

A

Trip delay: 0.4s

1A 1B 2A 2B 3A 3B

A

CONTROL SETTINGS

Pickup delay:

0.4s

2.3 Voltage based protections

Phase to phase overvoltage protection - ANSI code 59

Phase to phase overvoltage protection is one of the basic functions of FPC 200 numerical relays. It protects the feeder or

other elements of the power system from overvoltage. It comprises of time-delayed characteristics.

2.3.1.1 Functionality

Overvoltage protection is used as time delayed

protection. It picks up when voltage in one, two or three

phases exceeds the set threshold. The function can be

enabled or disabled through corresponding menu. The

settings of this function are applied to each of the three

phases to produce pickup and per each phase and

common trip signal.

Several overvoltage protection instances with different

settings can run independently at the same time.

The selection of pickup value, pickup delay as well as

drop-out ratio and drop-out delay helps the user to fine

tune the protection according to the project

specifications.

2.3.1.2 Measurements

The value of each phase to phase voltages is calculated

through measured phase voltages of measurement

voltage transformers. The input voltage is compared to

rated pickup voltage.

2.3.1.3 Delays

Function includes following delays explained in Chapter

2.1:

Pickup delay

Trip delay

Drop-out delay

2.3.1.4 Block settings

Pickup of any instance separately of protection can be

individually blocked by any user defined signal [2.6.5.].

Figure 2.25: Overvoltage protection setting as seen on HMI.

32 USER MANUAL FPC 200 - 3/2017

Functionality

Parameter

Range

Description

Enabled

No

Yes

Enabling protection function.

Operate mode

Off

On

Enabling protection function separately for each group level.

Pickup value

0,05 … 1,10 … 2,00 Un

Value at which fault conditions are considered.

Trip delay

0,00 … 2,00 … 300,00 s

Delay of trip signal

Pickup delay

0 … 5 … 1000 ms

Time stabilization of fault detection. As a filter of short

disturbances on measuring circuits. Time before protection starts.

Drop-out delay

0,00 … 0,20 … 60,00 s

Time stabilization of pickup signal. Time when the monitored value

is outside the operating range, but the protection does not stop

yet.

Drop-out ratio

0,80 … 0,95 … 0,99 Up

Drop-out value below which the protection drops.

Pickup block

None

Variable 1

Variable 2

Variable 3

Variable 4

Source of blocking signal.

Name

Description

Pickup

Total consecutive number of pickup signals.

Trip

Consecutive number of trip signals.

Pickup L12

Consecutive number of pickup signals detected in phase L12.

Pickup L23

Consecutive number of pickup signals detected in phase L23.

Pickup L31

Consecutive number of pickup signals detected in phase L31.

2.3.1.5 Setting parameters

Table 20: Overvoltage protection function parameters.

2.3.1.6 Counters

Table 21: Counters presented in overvoltage protection.

USER MANUAL FPC 200 - 3/2017 33

Functionality

Neut. voltage displ.

COUNTERS

0

Enabled:

1A 1B 2A 2B

No

Pickup:

Pickup value: 0,75

Trip delay:

1,5s

0

Trip:

CONTROL SETTINGS

Pickup delay:

5ms

Drop-out delay:

0,2s

0,95 Drop-out ratio:

BLOCK SETTINGS

Input: none

Input voltage:

Sum3U

Neutral voltage displacement - ANSI code 59N

Neutral voltage displacement protection is a function that detects residual overvoltage. It comprises of time-delayed

characteristics.

2.3.2.1 Functionality

Neutral voltage displacement protection is used as time

delayed protection. As voltage input this function can

use measured Ue or calculated 3U0 source. It picks up

when voltage from selected source exceed the selected

threshold. The function can be enabled or disabled

through corresponding menu.

Several voltage displacement protection instances with

different settings can run independently at the same

time.

The selection of pickup value, pickup delay as well as

drop-out ratio and drop-out delay helps the user to fine

tune the protection according to the project

specifications.

2.3.2.2 Measurements