ISHIDA BC-300 Service Manual

Retail Scale

BC-3000

SERVICE MANUAL

Manual No. 0141A

ISHIDA CO., LTD.

48775

Contents

HARDWARE SECTION

1. INTRODUCTION ................................................................................................. 1-1

1.1 Main Components .................................................................................................. 1-1

1.2 Characteristics........................................................................................................ 1-2

2. SET UP................................................................................................................ 2-1

2.1 Parts Check ............................................................................................................ 2-1

2.2 Installation Site Check ............................................................................................ 2-1

2.3 Assembly ................................................................................................................ 2-1

2.4 Set Up Sequence ................................................................................................... 2-2

3. PARTS DISASSEMBLY & REPLACEMENT ...................................................... 3-1

3.1 Disassembly View and Part Names ....................................................................... 3-1

3.2 Upper Cover Removal ............................................................................................3-3

3.3 Circuit Board Replacement.....................................................................................3-6

3.4 Display Unit Replacement ...................................................................................... 3-7

3.5 Load Cell Replacement .......................................................................................... 3-8

4. ELECTRONIC CONFIGURATIONS.................................................................... 4-1

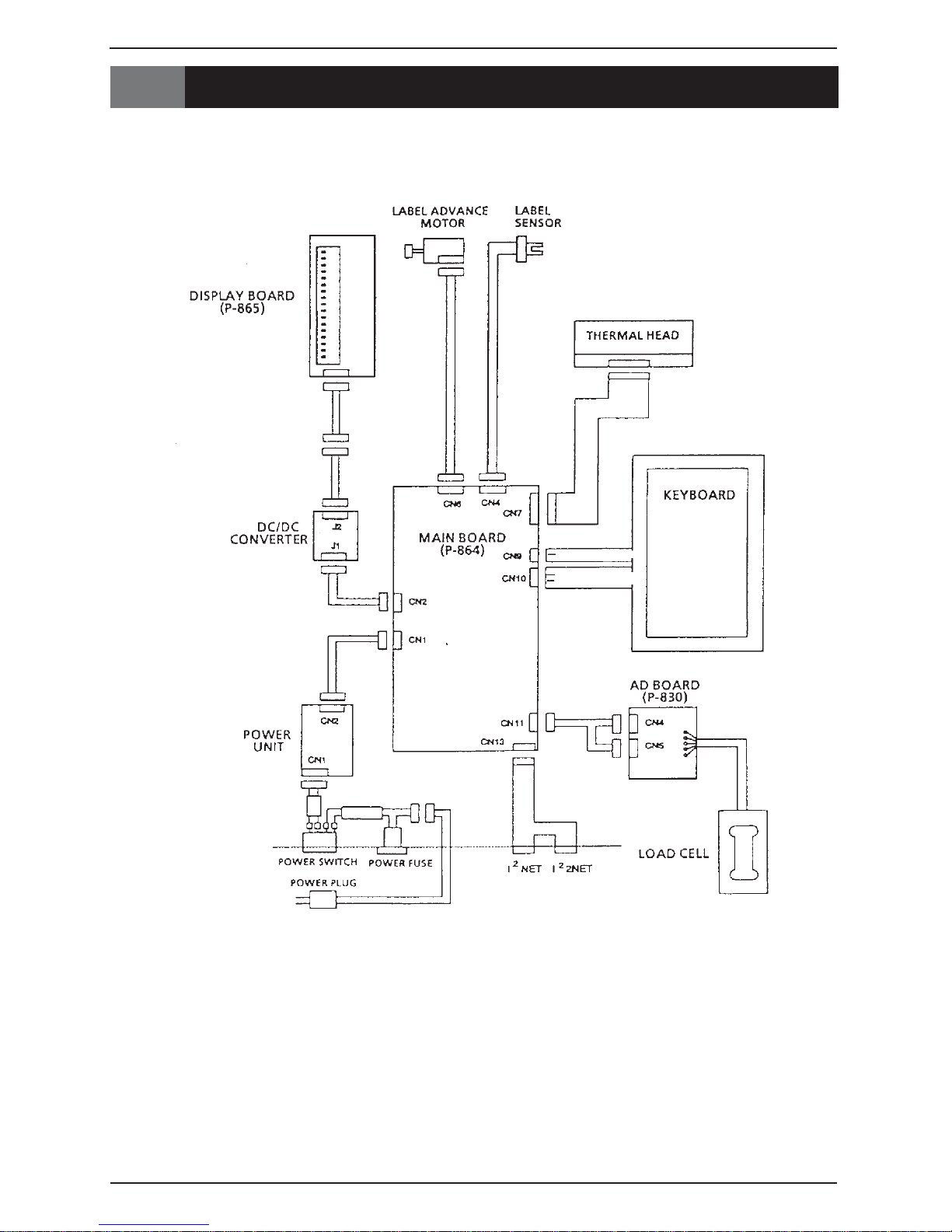

4.1 Connector Configuration.........................................................................................4-1

4.2 Power Unit .............................................................................................................. 4-2

4.3 Main Board (P-864) ................................................................................................ 4-3

4.4 A/D Board (P-830) .................................................................................................. 4-5

4.5 Keyboard ................................................................................................................ 4-5

4.6 Display Unit (P-856) ............................................................................................... 4-6

4.7 DC/DC Converter ................................................................................................... 4-7

4.8 Connector Bracket.................................................................................................. 4-7

4.9 Label Sensor .......................................................................................................... 4-8

5. THERMAL HEAD ................................................................................................ 5-1

5.1 Overview.................................................................................................................5-1

5.2 Specifications ......................................................................................................... 5-1

5.3 Thermal Head Adjustment...................................................................................... 5-2

5.4 Thermal Head Cleaning.......................................................................................... 5-3

5.5 Other Adjustments (Label sensor).......................................................................... 5-3

6. TROUBLESHOOTING ........................................................................................ 6-1

6.1 Periodic Parts Replacement (MTBF*) .................................................................... 6-1

6.2 Malfunction Troubleshooting Chart......................................................................... 6-2

6.3 Error Messages ...................................................................................................... 6-3

BC-3000

• Service Manual • Rev. 1 Contents - i

SOFTWARE SECTION

S1. OUTLINE OF SOFTWARE................................................................................ S1-1

S1.1 Memory Map.........................................................................................................S1-1

S2. PRINT FORMAT MODIFICATION..................................................................... S2-1

S2.1 Print Format Overview..........................................................................................S2-1

S2.2 Label Format Modification Range.........................................................................S2-1

S2.3 Format Modification Method .................................................................................S2-1

S3. DISPLAY MODULE ........................................................................................... S3-1

S3.1 Display Module Overview .....................................................................................S3-1

S3.2 Root and SUB Menu Selection.............................................................................S3-1

S4. SETTING MODE ............................................................................................... S4-1

S4.1 Menu Schematic...................................................................................................S4-1

S4.2 Setting Procedures ...............................................................................................S4-3

1. Label Format (b01) ........................................................................................S4-3

2. Bar Code (b02) ..............................................................................................S4-4

3. Code (b03).....................................................................................................S4-4

4. Initial Data Setting (b04) ................................................................................S4-5

5. PLU File (b08) ...............................................................................................S4-6

6. Registration Select (b11) ...............................................................................S4-7

7. Total Mode Select (b12).................................................................................S4-8

8. Password (b13) .............................................................................................S4-8

9. Default PLU (b14)..........................................................................................S4-8

S5. TEST MODE...................................................................................................... S5-1

S5.1 Menu Schematic...................................................................................................S5-1

S5.2 Test Mode Procedures..........................................................................................S5-2

1. Hardware Test (C01) (Calibration) .................................................................S5-2

2. RAM Clear (C02) ...........................................................................................S5-6

3. Thermal Head (C03)......................................................................................S5-7

4. Sensor Check (C04) ......................................................................................S5-8

5. Memory Check (C05) ....................................................................................S5-9

6. ROM Switch Number Select (C06)................................................................S5-9

7. Label Format (C07) .....................................................................................S5-10

8. Sales Mode (C08)........................................................................................S5-11

10. Preset Function Key (C10) ..........................................................................S5-12

99. Data Send/Load (C99).................................................................................S5-13

S6. IF-21FD ERRORS .............................................................................................S6-1

A1. DC/DC Converter Schematic Diagram............................................... Appendix-1

A2. P-864A Circuit Diagram....................................................................... Appendix-3

A3. BC to BC System Setup...................................................................... Appendix-5

A4. Korean Language Firmware ............................................................... Appendix-7

A5. Chinese/Japanese Language Firmware ............................................Appendix-9

A6. Label Format Worksheets ................................................................. Appendix-11

A7. Dual Weight Range Notice................................................................ Appendix-19

Contents - ii

BC-3000

• Service Manual • Rev. 1

HARDWARE SECTION

1INTRODUCTION

1.1 MAIN COMPONENTS

Chapter 1. Introduction

BC-3000

• Service Manual • Rev. 1 1 - 1

Chapter 1. Introduction

1.2 CHARACTERISTICS

■ 16-Bit microprocessor

The BC-3000 scale is equipped with a 16-bit microprocessor unit (V-40) which enables processing of large

quantities of data.

■ E2ROM

The use of E2ROM ensures that important data is not lost.

■ Resistance value and printing density settable via key entry

The thermal head resistance value as well as printing density can be set by key entry.

■ Settable sales mode

For supermarket specifications, there are operator and non-operator selections.

Differences from the AC-2000

• Data transmission to the IF-21FD is via I2NET (9P) instead of RS-232C used by the AC-2000.

• An inspection mode has been added. Verification can be made during totaling.

Mode Key Function

Enter the pass code (4 digits), then press MODE to change modes. If MODE is pressed without

entering a pass code, then normal operation mode is returned.

Pass Code Mode

9000 Registration

8000 Totals

7000 Subtraction

6000* Setting

5000* Checking

*Fixed

1 - 2

BC-3000

• Service Manual • Rev. 1

2 SET UP

2.1 PARTS CHECK

Open the shipping carton and confirm the following:

• No parts are missing.

• No parts are damaged.

2.2 INSTALLATION SITE CHECK

Check that the installation site conforms to the following conditions:

• Site is stable and level.

• Scale will not be exposed to water or other liquids.

• Scale will not be exposed to direct sunlight for long periods.

• Scale will not be exposed to wind or strong vibration.

• Installation site should be sufficiently spacious.

• Dedicated, grounded circuit is available.

Chapter 2. Set Up

2.3 ASSEMBLY

Assemble the display components as follows:

1. Thread the display connector cable through the display pole.

2. Attach display pole to the plastic display housing with 2 screws (M4).

3. Connect cables.

4. Attach the display to the main body with 2 screws (M4).

5. Cover the screws with the plastic screw caps.

BC-3000

• Service Manual • Rev. 1 2 - 1

Chapter 2. Set Up

2.4 SET UP SEQUENCE

1. Perform RAM clear sequence.

Insert the power plug into an outlet. Referring to Chapter S5 (Test Mode 2: RAM Clear), initialize all the

RAM data.

2. Set print format, label length and sales mode according to user's specifications.

Service manual reference sections:

• Print format setting : Chapter S5 (Test Mode7: Label Format)

• Label length setting : Chapter S4 (Setting Mode 1: Label Format)

• Sales mode setting : Chapter S5 (Test Mode 8: Sales Mode)

3. Register date and time.

Referring to the programming manual, enter the date and time.

4. Register PLU.

Referring to the programming manual, enter PLU data registration in Registration mode.

5. Perform print test.

Load a roll of labels or receipts, and confirm that printing is correct. Refer to Chapter S5 (Test Mode 3:

Thermal Head).

6. Perform totals clear.

Refer to the operation manual.

7. Back up data.

Back up the registration data on a floppy disk. Refer to Chapter S5 (Test Mode 99: Data Transmission.)

2 - 2

BC-3000

• Service Manual • Rev. 1

Chapter 3. Parts Disassembly & Replacement

3PARTS DISASSEMBLY & REPLACEMENT

This chapter explains the procedures for disassembling and replacing the main components. Please be

careful not to drop or strongly impact fragile parts such as the display unit and circuit boards. Also, before

disassembly, be sure to turn off the power switch and unplug the power cord.

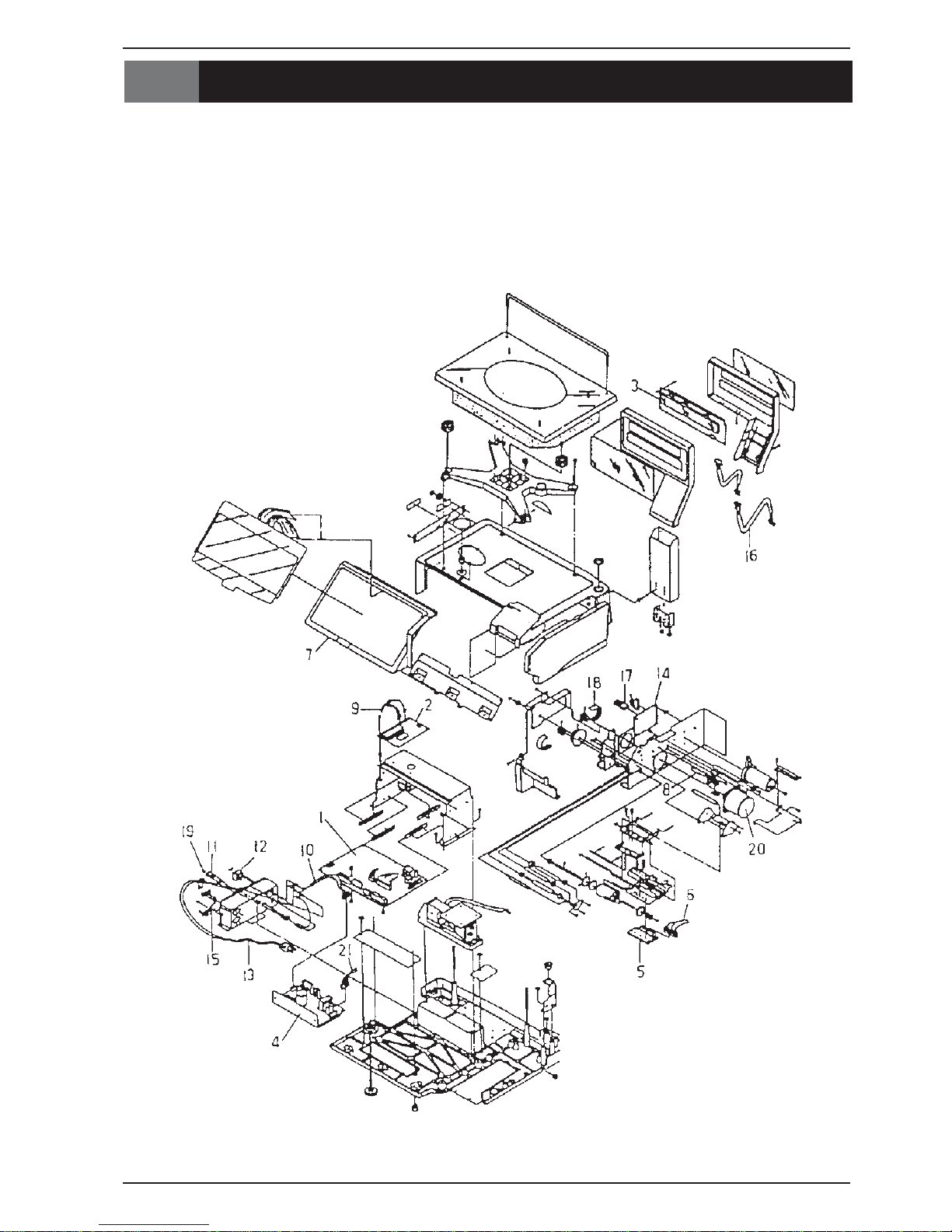

3.1 DISASSEMBLY VIEW AND PART NAMES

BC-3000

• Service Manual • Rev. 1 3 - 1

Chapter 3. Parts Disassembly & Replacement

*1UPC:468-P:BWP

2D/A:038-P:BWP

3yalpsiD:568-P:BWP

*4gnihctiwS:ylppuSrewoP

5daehlamrehT

6daehlamrehT:2S:ssenraH

7draobyeK:lenaP

8SA:rosneSlebaL

9elacS:3C:ssenraH

01rewoP:3C:ssenraH

11SA:esuF

21waseeS:hctiwS

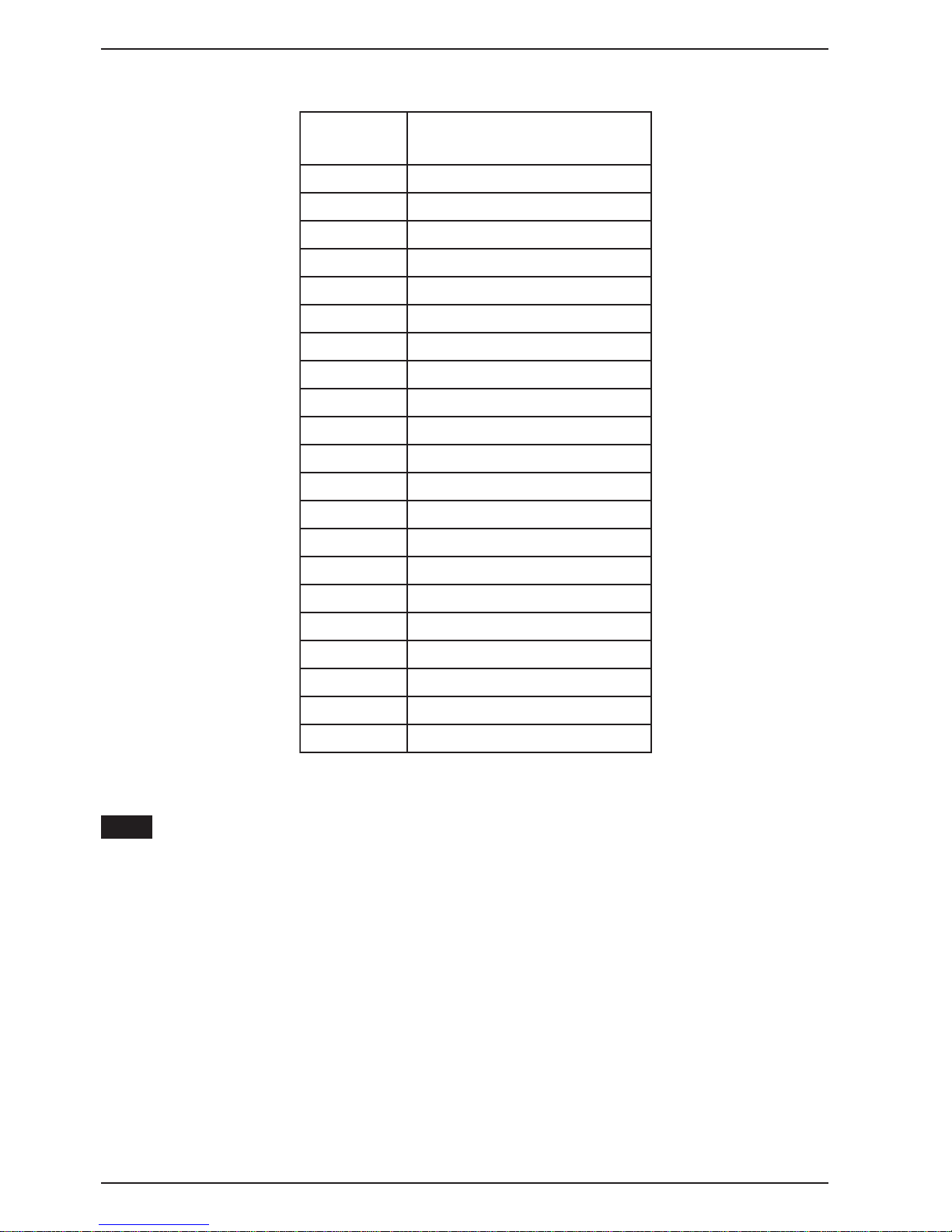

Part Name Key

.oNtraPemaNtraP

*31drocrewoP:3C:ssenraH

41CD/CD:ylppuSrewoP

51I:3C:ssenraH

2

TEN

611yalpsiD:2C:ssenraH

711CD/CD:2S:ssenraH

81)Lx421(LX:tleBgnimiT

*91ebutssalG:esuF

02gnippetS:SA:rotoM

12rewoP:3S:ssenraH

* These parts vary with country. (Only the software of PWB: P-864 varies; the board itself is

common to all countries.)

Note: Only the main parts are listed here. For a complete listing of parts and their corresponding parts

numbers, refer to the BC-3000 parts list.

3 - 2

BC-3000

• Service Manual • Rev. 1

3.2 UPPER COVER REMOVAL

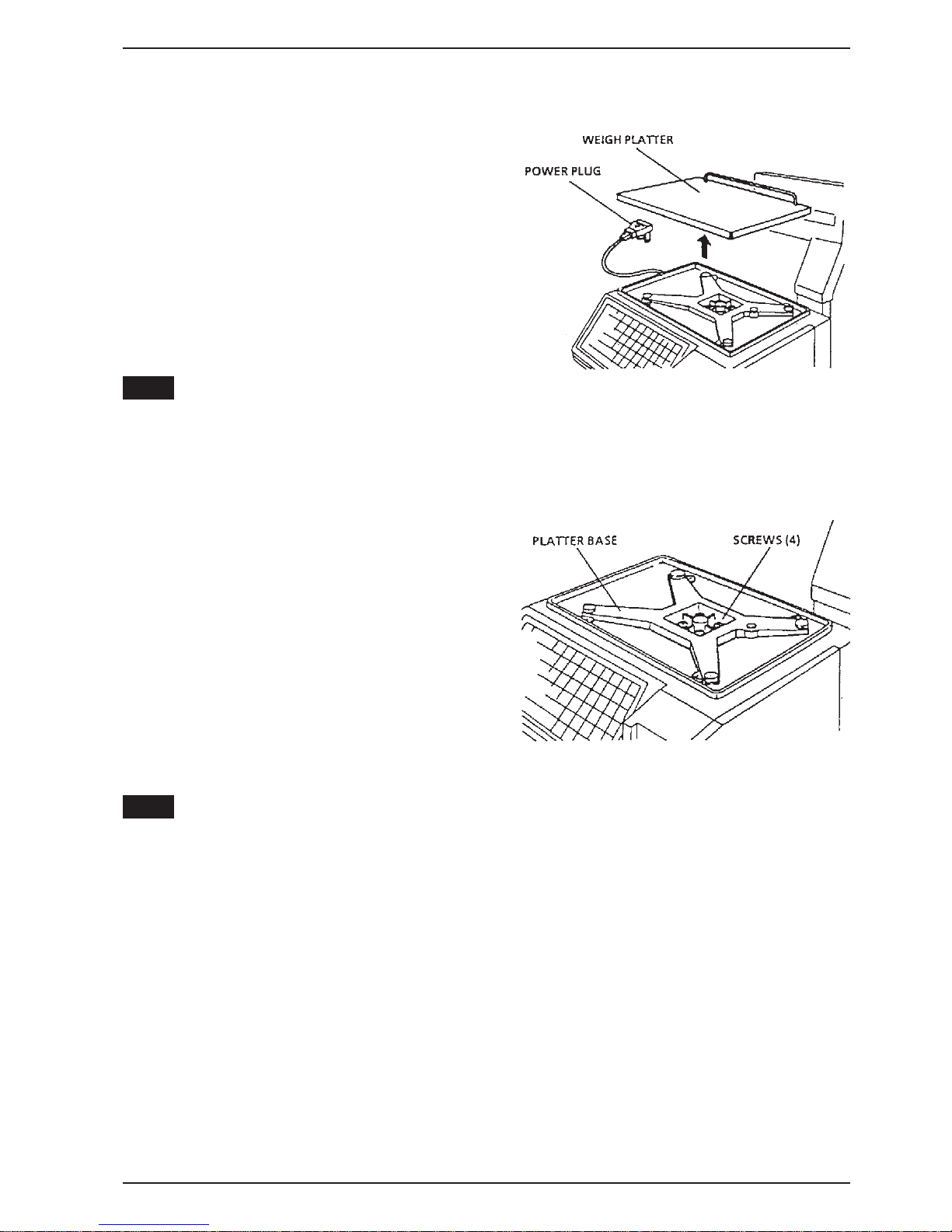

1. Remove the weigh platter.

1) Place the scale on a level surface.

Rotate the adjustment feet to level the scale if

necessary.

2) Unplug the power plug from its outlet.

3) Lift off the weigh platter, keeping it horizontal.

Chapter 3. Parts Disassembly & Replacement

Note:

2. Remove the platter base.

Note:

When replacing the weigh platter, align the platter pins with the rubber inserts on the platter base.

Remove the four attachment screws, then lift off the

platter base.

After replacing the platter base, perform four corner adjustment (Refer to Section 5.5).

BC-3000

• Service Manual • Rev. 1 3 - 3

Chapter 3. Parts Disassembly & Replacement

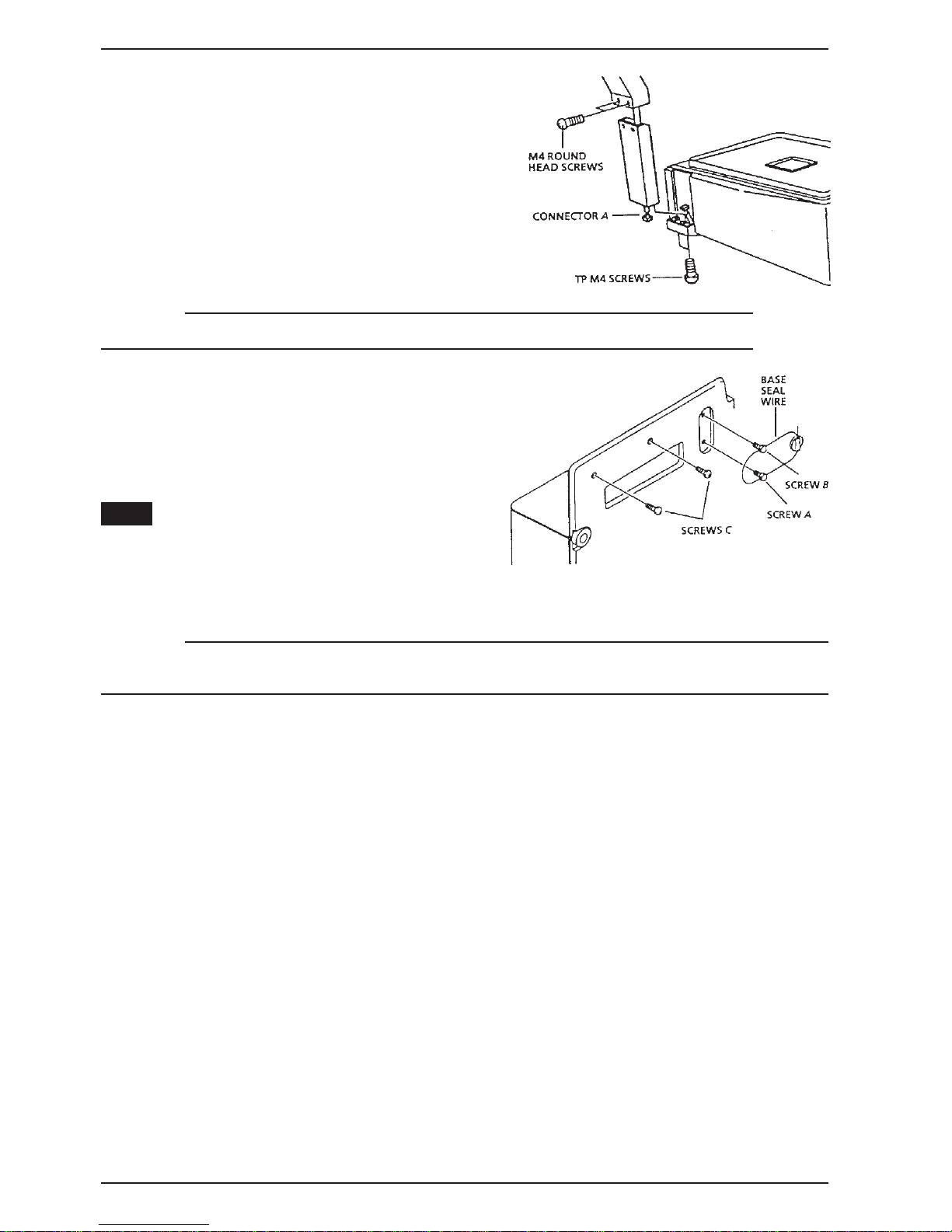

3. Remove display unit.

1) Remove the two screws (M4) that secure the

display pole to the main body.

2) Carefully lift up the display unit and disconnect

connector A.

3) Remove the two screws (M4) which secure the

plastic display housing to the display pole.

CAUTION!

In order to avoid damage to fragile components, be careful not to drop or strongly impact them.

4. Remove the operation keyboard panel.

1) Cut the base seal wire.

2) Remove base seal wire screw B.

3) Remove both screws C.

Note:

The base seal wire is only used for countries

requiring a base seal. For other specifications, remove

only screws B & C.

CAUTION!

After the base seal wire is cut, it is necessary to have the scale re-inspected and the seal replaced. Nev er cut

the base seal unless required.

3 - 4

BC-3000

• Service Manual • Rev. 1

Chapter 3. Parts Disassembly & Replacement

5. Remove the upper case.

1) Lower the side panel in the direction of the

arrow.

2) Cut the seal wire, and remove the seal wire

screws.

3) Remove the four screws which secure the

upper case, then carefully lift the cover off

the main body.

CAUTION!

After the base seal wire has been cut, it is necessary to have the scale re-inspected and the seal replaced.

Never cut the base seal unless required.

BC-3000

• Service Manual • Rev. 1 3 - 5

Chapter 3. Parts Disassembly & Replacement

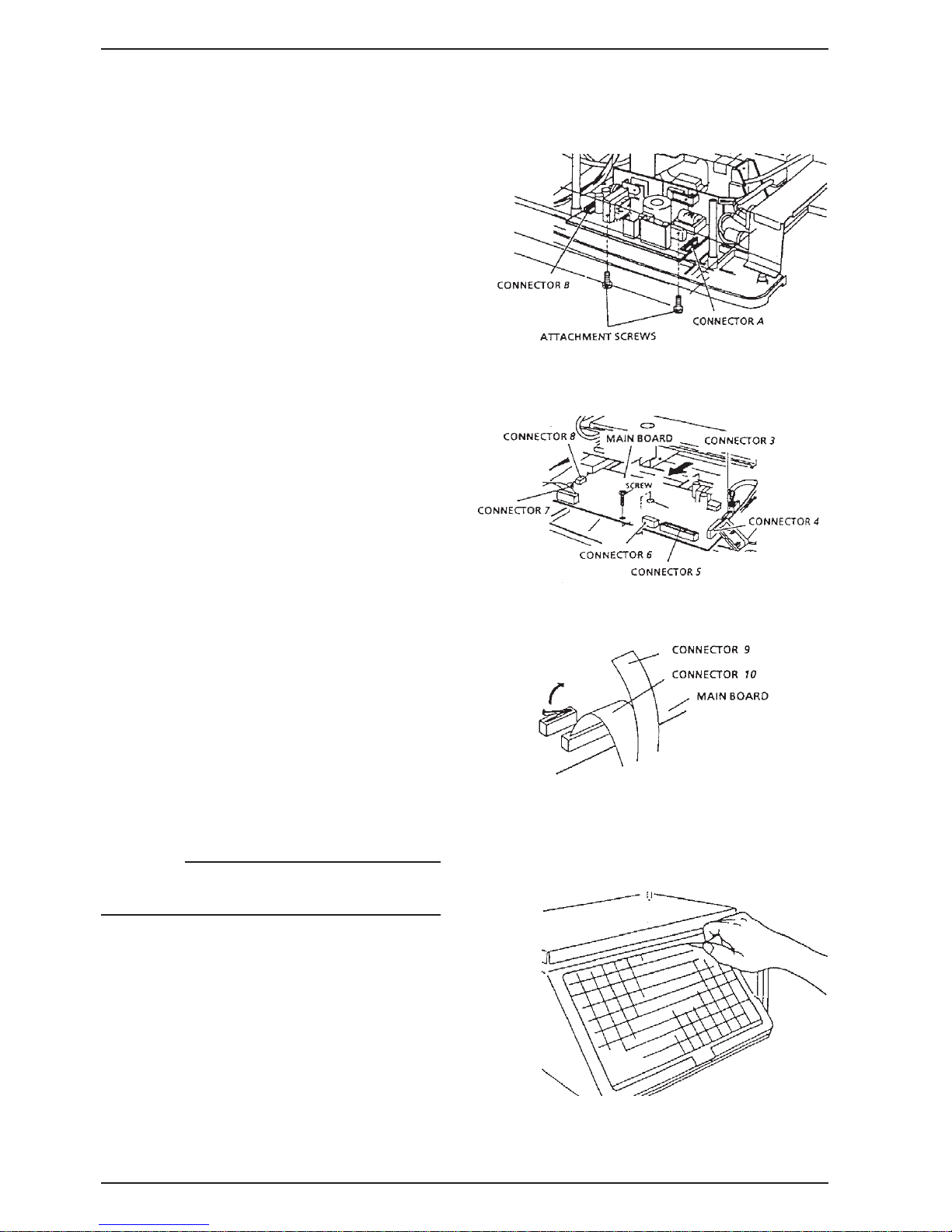

3.3 CIRCUIT BOARD REPLACEMENT

1. Remove the power unit.

1) Remove the two attachment screws from

the power unit located in the lower part of

the scale.

2) Remove connectors A & B.

2. Remove the main board.

1) Remove the attachment screw from the

main board.

2) Slide the main board toward you, and

remove connectors 3~8.

3. Remove the keyboard.

1) Remove connectors 9 and 10 located on

the main board beside the keyboard.

2) Peel off the keyboard starting from the

corner.

CAUTION!

If the keyboard is removed even once, it becomes

unusable. Never remove unless necessary.

4. Remove the A/D board.

Remove the A/D board referring to the

procedures described in Load Cell

Replacement section of this manual (Section

3.5).

3 - 6

BC-3000

• Service Manual • Rev. 1

3.4 DISPLAY UNIT REPLACEMENT

Replace display unit.

1) Carefully remove the cover.

2) Remove the four screws which secure the

display unit.

CAUTION!

•

To avoid damage to the cover, open it slowly and carefully.

•

Avoid touching the display unit.

Chapter 3. Parts Disassembly & Replacement

BC-3000

• Service Manual • Rev. 1 3 - 7

Chapter 3. Parts Disassembly & Replacement

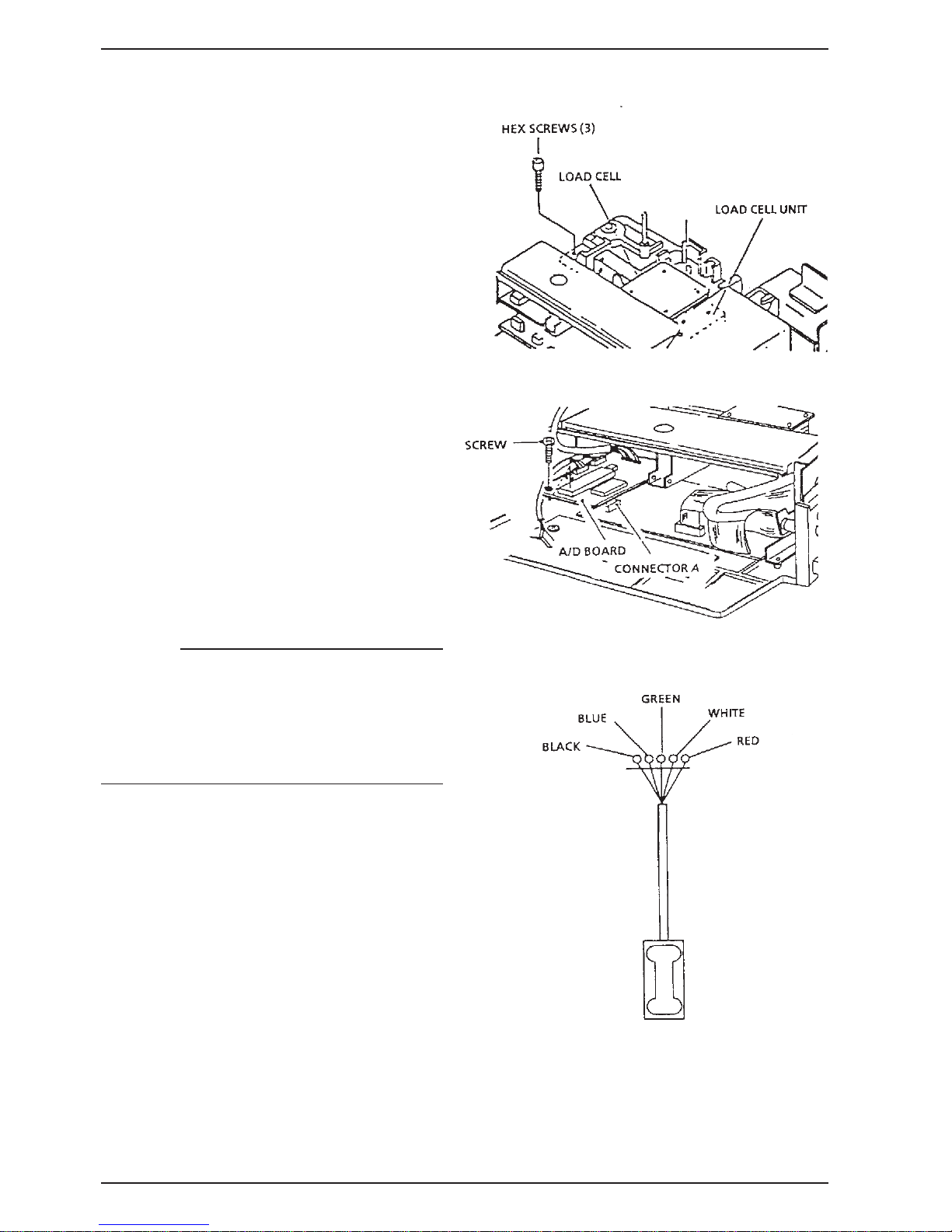

3.5 LOAD CELL REPLACEMENT

1. Remove the upper cover.

Refer to Section 3.2 of this manual for upper

cover removal procedure.

2. Remove the load cell unit.

1) Remove the three screws which secure

the load cell unit.

2) Remove the load cell unit.

3. Remove the A/D board.

1) Remove the screw which secures the A/D

board.

2) Slide the A/D board from its plastic bracket

and disconnect Connector A.

3) Remove the load cell output cable

(soldered in five places).

CAUTION!

•

The load cell output cable has five soldered

points. When replacing be sure that the wires

are in the correct order.

•

After replacing the load cell unit, perform a fourcorner test. (Reference: Section 5.5 of this

manual)

3 - 8

BC-3000

• Service Manual • Rev. 1

4 ELECTRONIC CONFIGURA TIONS

4.1 CONNECTOR CONFIGURATION

Chapter 4. Electronic Configurations

BC-3000

• Service Manual • Rev. 1 4 - 1

Chapter 4. Electronic Configurations

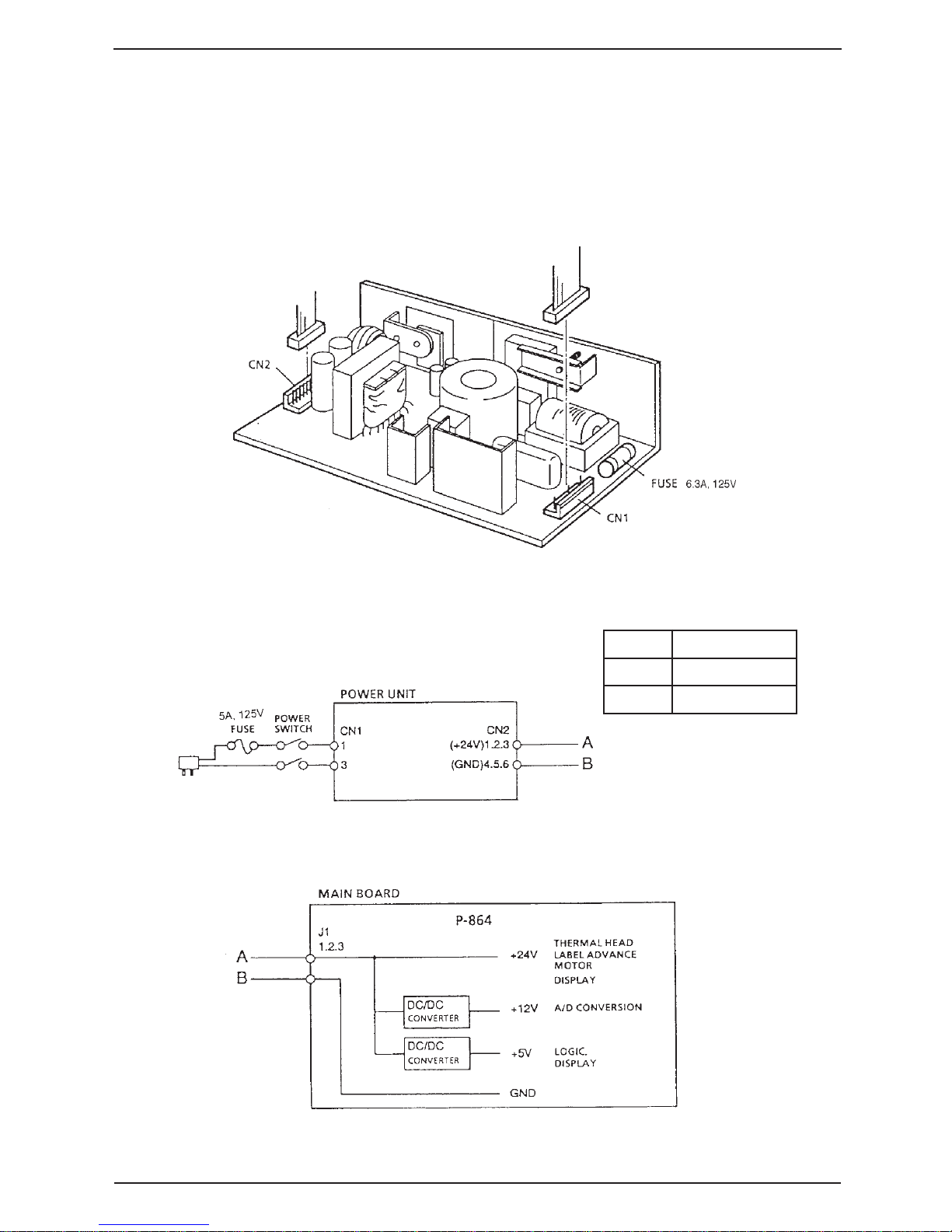

4.2 POWER UNIT

The power unit performs efficient voltage conversion, stabilizes low voltage, and supplies power to the

various units.

External View

Block Diagram

1NCP001SLS

1V511ot001CA

3V511ot001CA

4 - 2

BC-3000

• Service Manual • Rev. 1

Chapter 4. Electronic Configurations

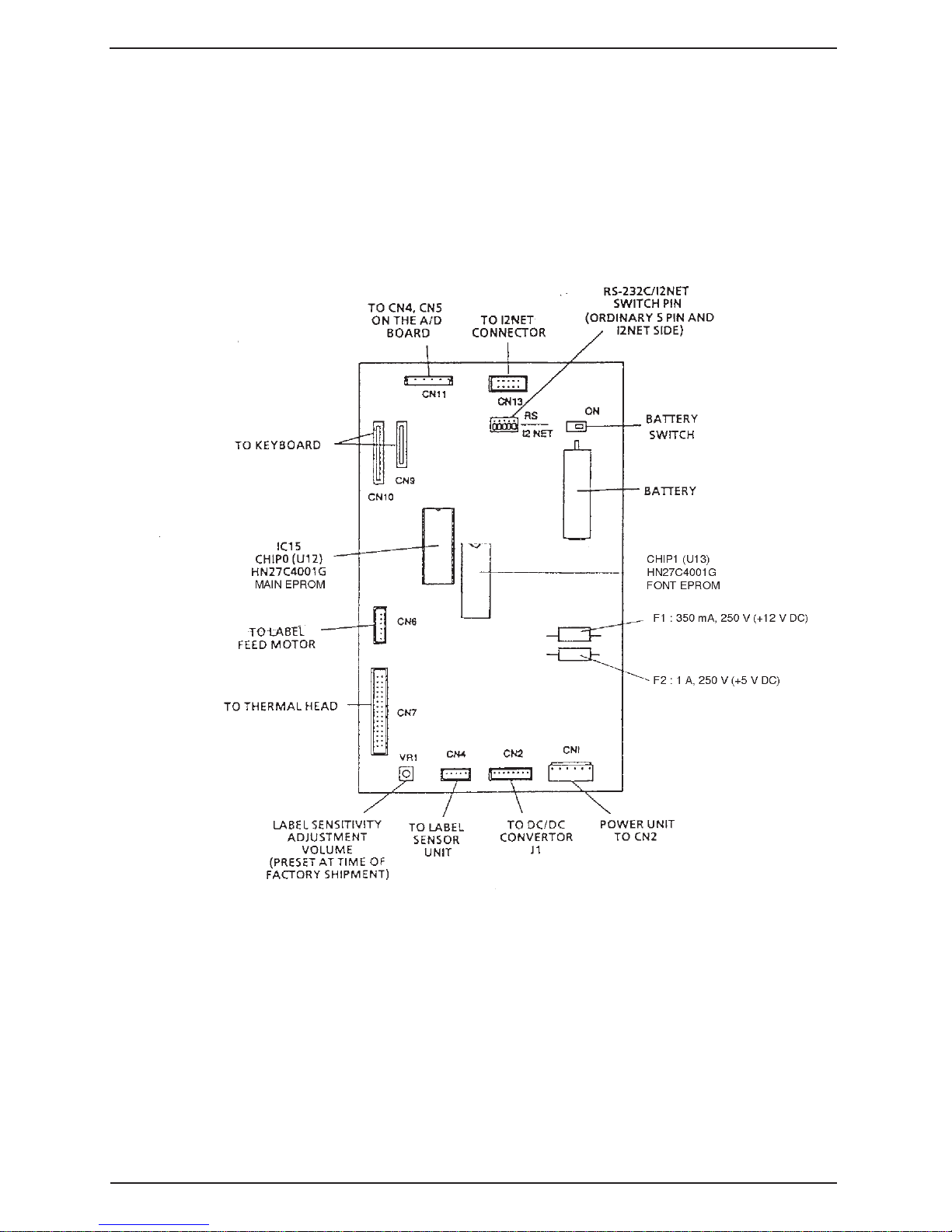

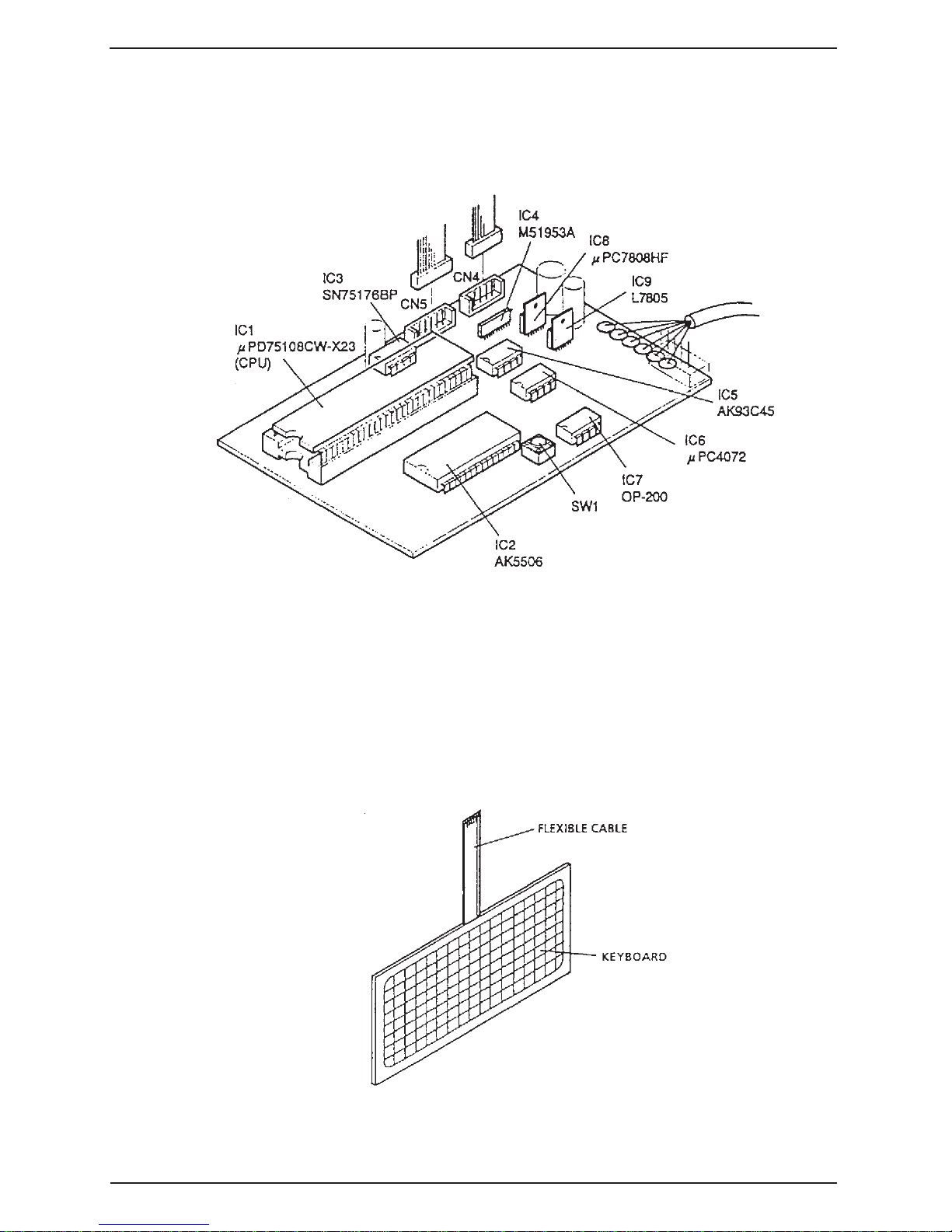

4.3 MAIN BOARD (P-864)

This board is equipped with a 16-bit microprocessor and is used to process scale data. The board is multilayered, and its high precision construction is designed to reduce electrical impedance, electrical noise, and

static electricity.

External View

BC-3000

• Service Manual • Rev. 1 4 - 3

Chapter 4. Electronic Configurations

Board Functions

• Control of overall unit via CPU (V40)

*EPROM (Program memory) 4 Meg type (2) are installed

• Process weight data from A/D board

• Key data input

• Price calculation

• Display of weight, price and unit price data

• Label advance motor output

• Thermal head printing output

2

• I

NET output

• Label sensor input

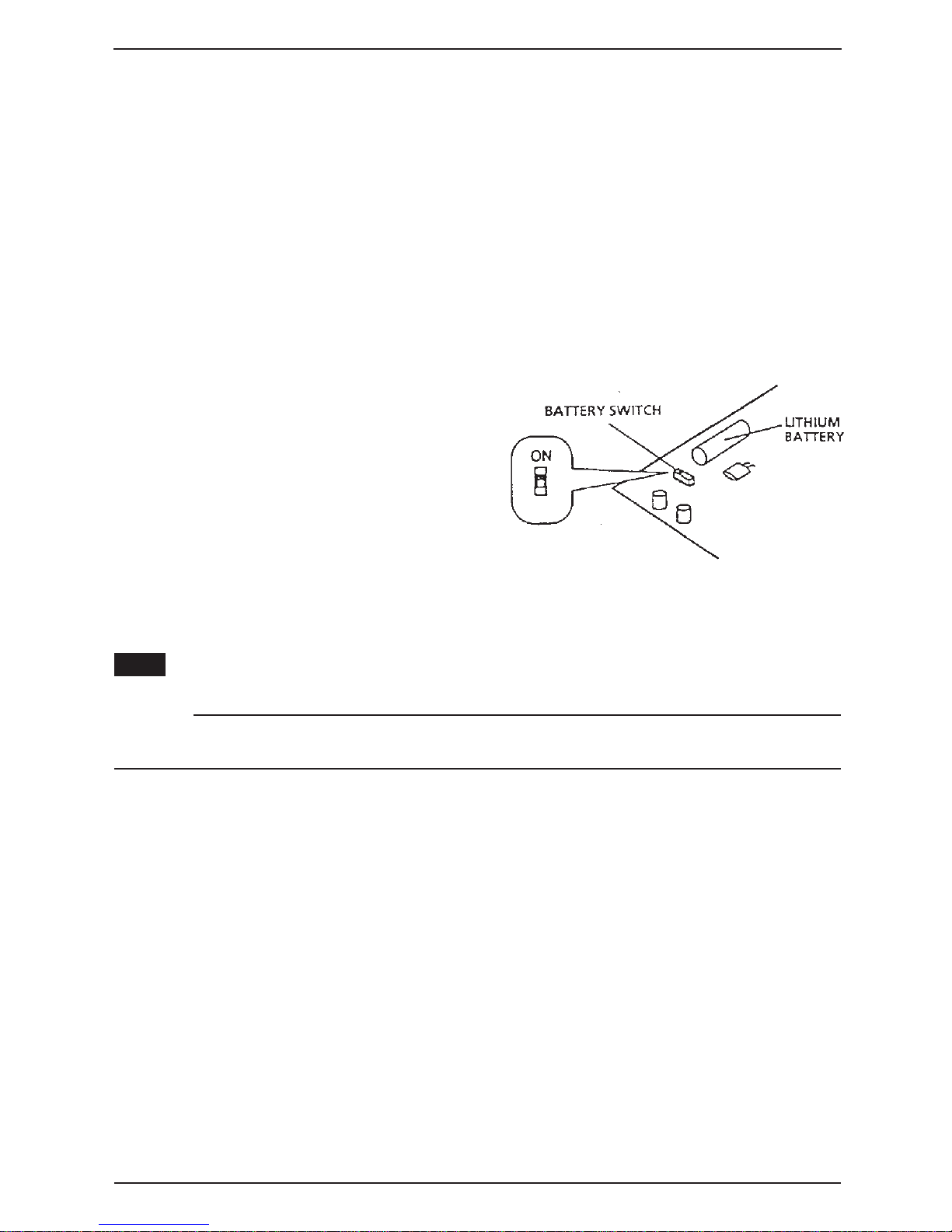

Battery Switch

A lithium memory backup battery is included

in these units.

After installation, make sure the battery switch

is set to ON.

Note:

This scale uses a rechargeable lithium battery . Normal charge is 3.6V . Battery switch is set to ON at

time of shipment from factory.

CAUTION!

There is danger of explosion if this battery is incorrectly replaced. Replace only with the same or equivalent

type recommended by the manufacturer . Discard used batteries according to the manufacturer's instructions .

4 - 4

BC-3000

• Service Manual • Rev. 1

Chapter 4. Electronic Configurations

4.4 A/D BOARD (P-830)

The A/D board converts analog weight data from the load cell into digital data, and performs automatic span

control and zero compensation.

External View

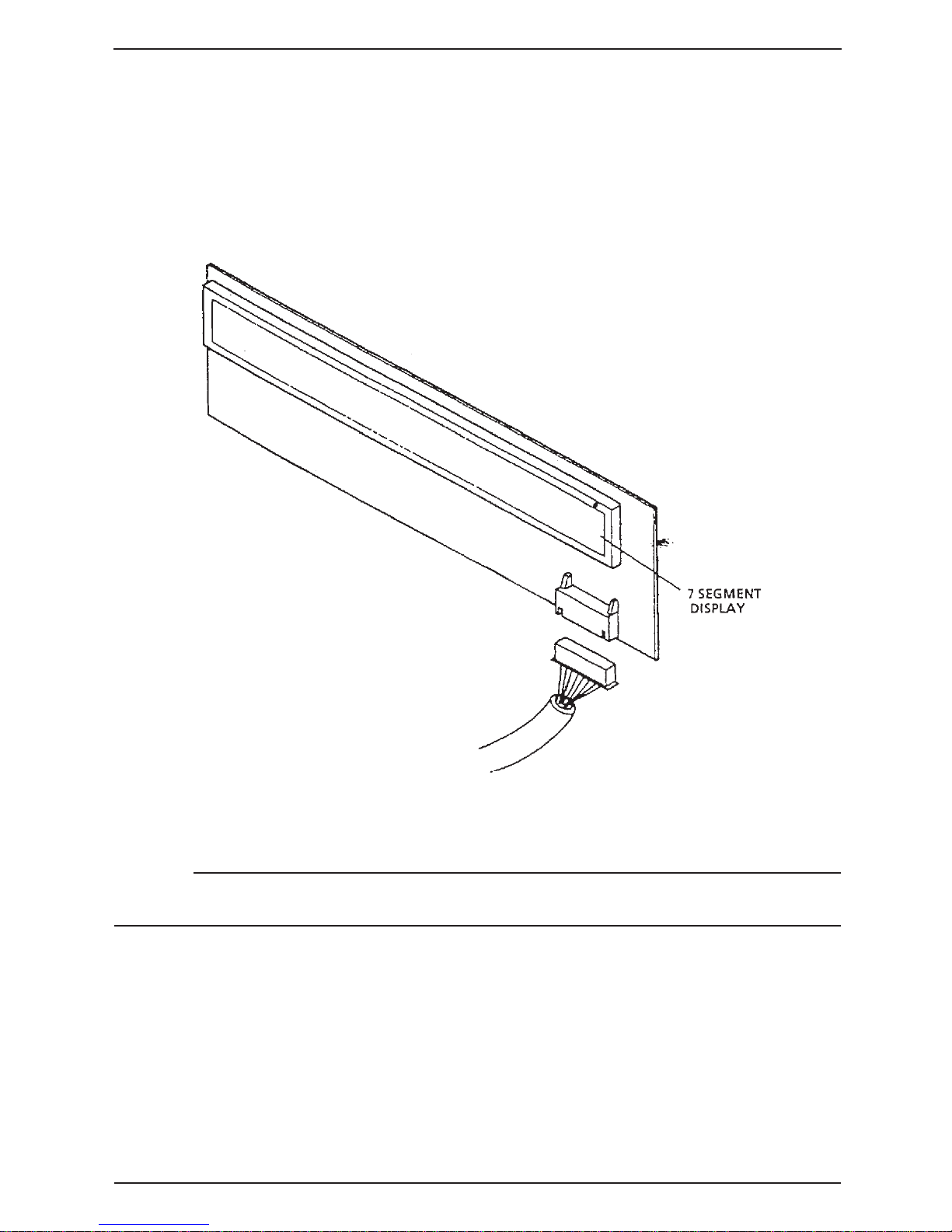

4.5 KEYBOARD

This is a panel type keyboard.

A flexible cable connects it to the main keyboard (CN9 and CN10).

External View

BC-3000

• Service Manual • Rev. 1 4 - 5

Chapter 4. Electronic Configurations

4.6 DISPLAY UNIT (P-856)

• The BC-3000 is equipped with a 7-segment display module.

• Weight, price, and unit price data are displayed.

External View

CAUTION!

•

The display modules are made of glass so care should be taken not to touch or impact the units.

•

Do not remove the connectors with the power ON.

4 - 6

BC-3000

• Service Manual • Rev. 1

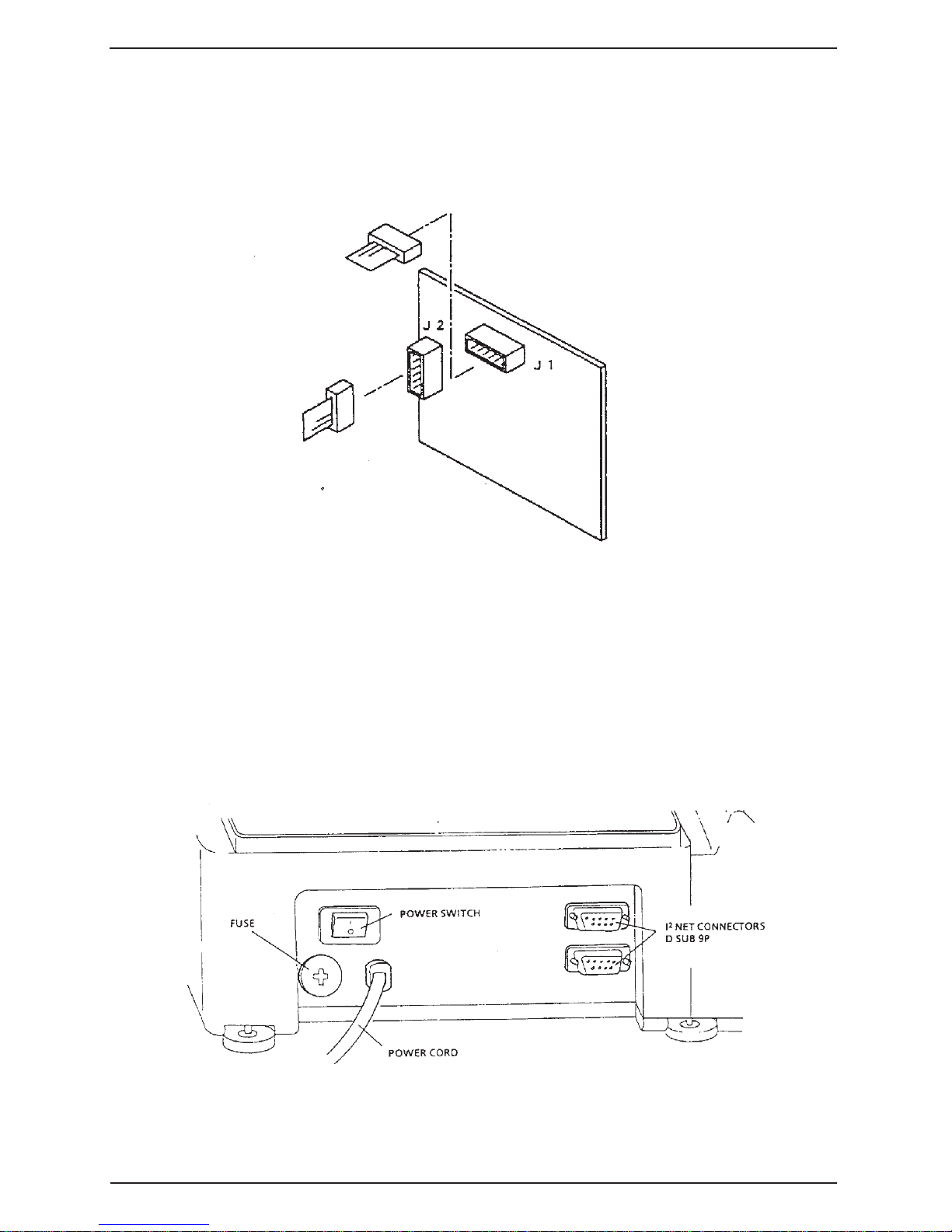

4.7 DC/DC CONVERTER

The DC/DC converter transfers the voltage supplied to the display board.

External View

Chapter 4. Electronic Configurations

4.8 CONNECTOR BRACKET

Includes the power switch, power cord, fuse, and I2NET connectors.

External View

BC-3000

• Service Manual • Rev. 1 4 - 7

Chapter 4. Electronic Configurations

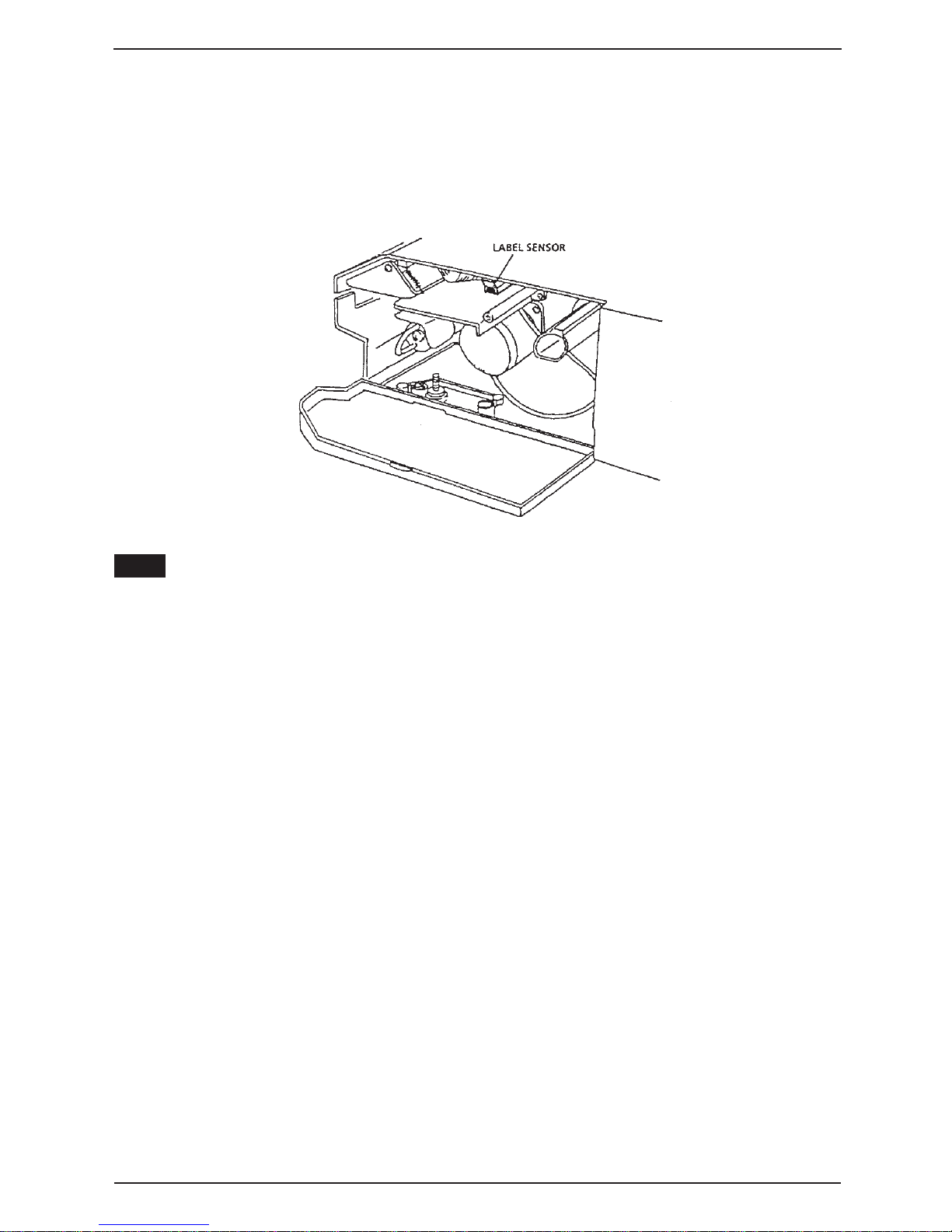

4.9 LABEL SENSOR

The label sensor utilizes a photo-interrupter to detect the gap between labels, and functions to ensure that

labels are printed correctly one at a time.

External View

Note:

See Section 5.5 for adjustment procedures.

4 - 8

BC-3000

• Service Manual • Rev. 1

5 THERMAL HEAD

5.1 OVERVIEW

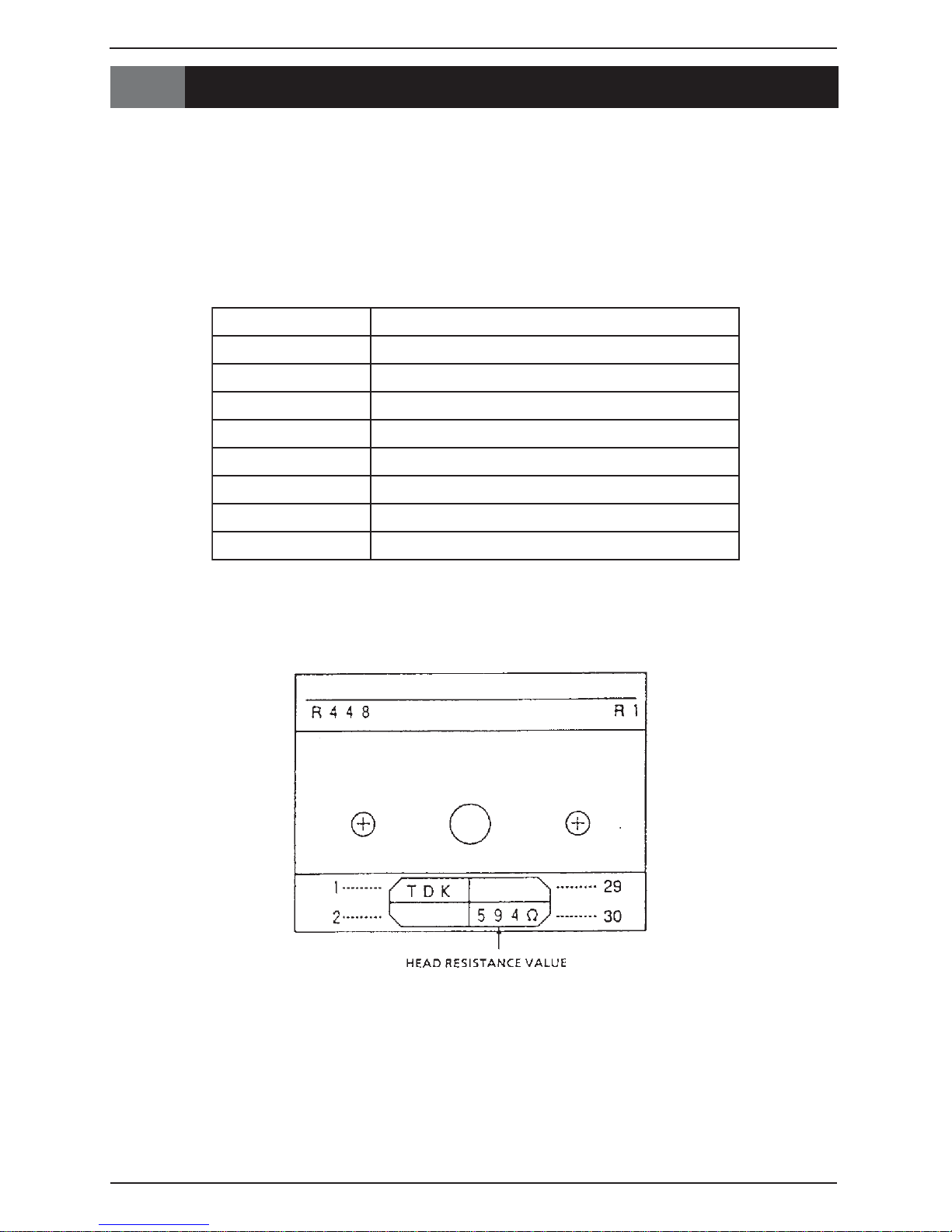

This 448 dot thermal head is specifically intended for use with label printers.

5.2 SPECIFICATIONS

Specification Sheet

epyTKDT)daehlamrehtytisnedelbuoD(I4213HL

tnuoctodllarevOstod844

hctiptoD)H(mm51.0x)W(531.0

ecnatsiserdaeH276ot825=R Ω

rewopderiuqeRtod/W88.0

egatlovdeilppAV42

Chapter 5. Thermal Head

Configuration

htdiwtnirpmumixaMmm5.06

noituloseR)mm/stod4.7(hcni/stod881

deepstnirP)ces/mm07(ces/hcni8.2

BC-3000

• Service Manual • Rev. 1 5 - 1

Loading...

Loading...