Page 1

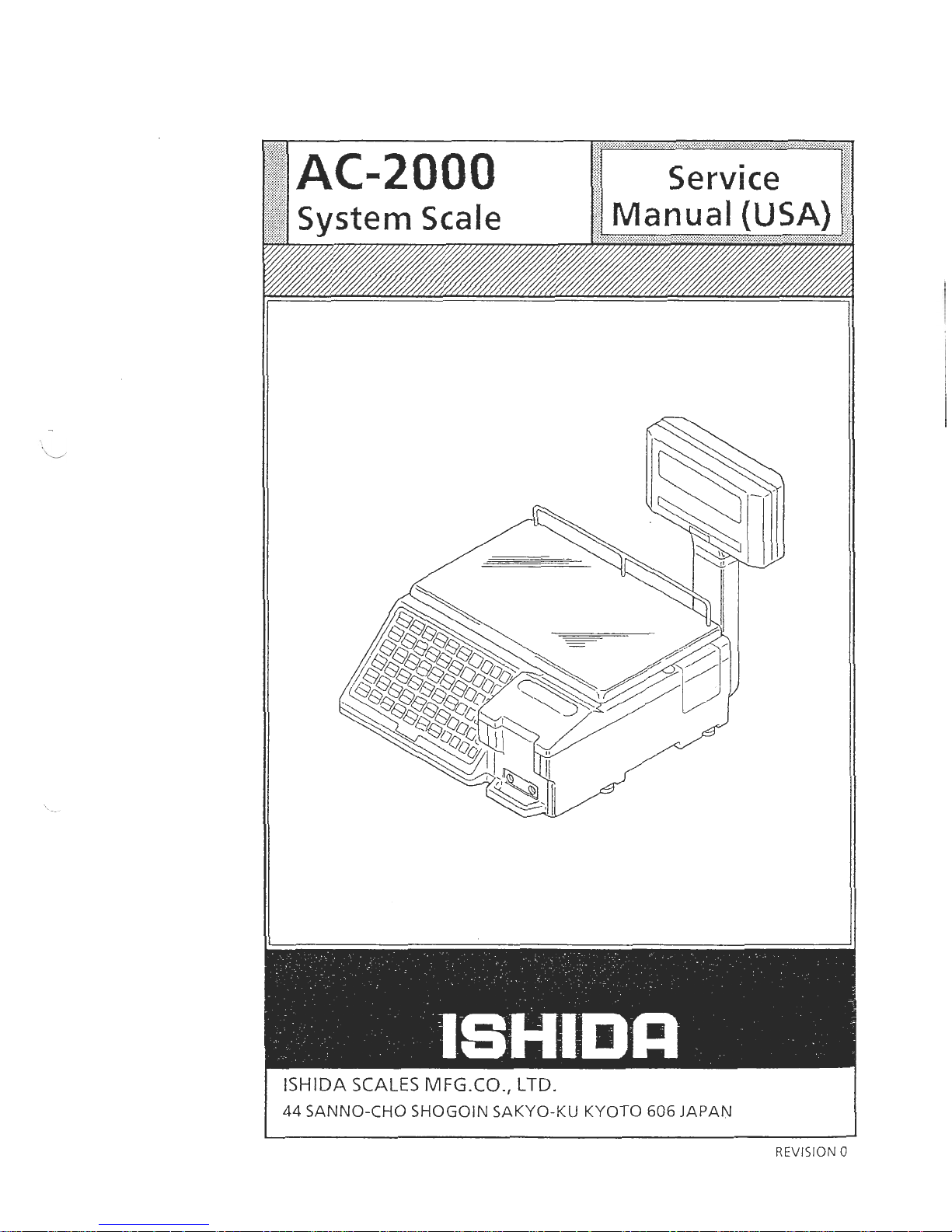

ISHIDA SCALES MFG.CO., LTD.

44

SANNO-CHO SHOGOIN SAKYO-KU KYOTO

606

JAPAN

REVISION

0

Page 2

You can help improve this manual by calling attention to errors and recommending improvements. Please convey your comments to the

nearest Ish ida Scales regional representative.

Thank

You!

Copyright0

1991

by

lshida Scales

Mf

.

Co., Ltd.

All

Rights Reserved.

No part of this manual may be repro

d

uced in any form, by mimeograph or any

other means, without permission in writing from the publisher.

Page 3

TABLE OF CONTENTS

H1 INTRODUCTION

1.1 External Views

1.2 Dimensions

1.3 Features

1.5 Key Switch and Reset Key

H2 MECHANICAL CONFIGURATION

2.1 Mechani'cal Components

2.2

Internal Components

H3 REPLACEMENT PROCEDURE

3.1 Outer Case Removal

3.2 Load Cell Replacement

3.3 Electrical Component Replacement

3.4 Display Panel Replacement

3.5 Cassette

'>d

H4 ELECTRICAL CONFIGURATION

Block Diagram

Connector Diagram

Power Unit

A/D Board (P704)

Main Board (P750)

Rom/Ram Board

(

P7

51

)

Battery Switch Check

Sensor Signal Relay Board (P755)

Display Unit

Peeling Sensor

Label Sensor

Cassette Sensor

B5

THERMAL

IIEAD

5.1 Outline

5.2 Specifications

5.3 Configuration

5.4 Adjustments

I16 ADJUSTMENTS

6.1 Overview

6.2 Adjustment Items

6.3 Four-Corner Limit Adjustments

6.4 Initial A/D Value Adjustment

6.5 Span Adjustment

6.6 Ad jus tlnent Sequence

6.7 Peeling Sensor Adjustment

H7 INSTALLAT'ION

7.1 Procedure For Installation

Page 4

MA1N1.L'ENANCJ<

8.1 Outline

8.2 When Replacing

A

Defective Unit

8.3

Cleaning

8.4 Daily Inspection

8.5 Preventive Maintenance

8.6 Troubleshooting

PARTS

9.1 Ovcrvicw

9.2 Parts List

OUTLINE OF SOPTWRRE

1.1 Memory

1.2 PLU File

1.3 Label Formatting

1.4

Non-Keyboard Characters

LABEL

F0KMATTING:USA

TOTALS

SET

UP

MODE

TEST MODE

Page 5

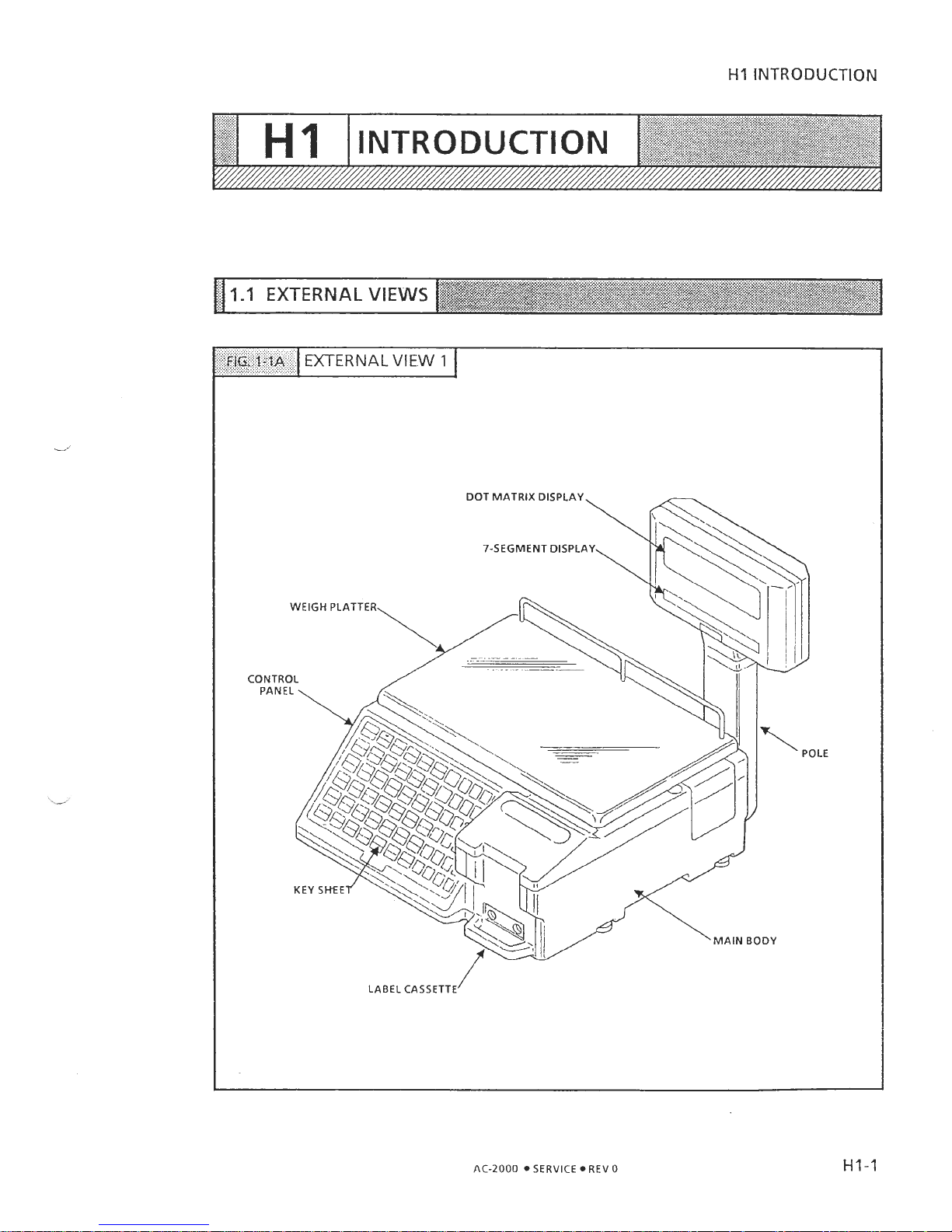

HI

INTRODUCTION

FIG.

1-1.4

EXTERNAL

VIEW

1

AC-2000 SERVICE REV 0

Page 6

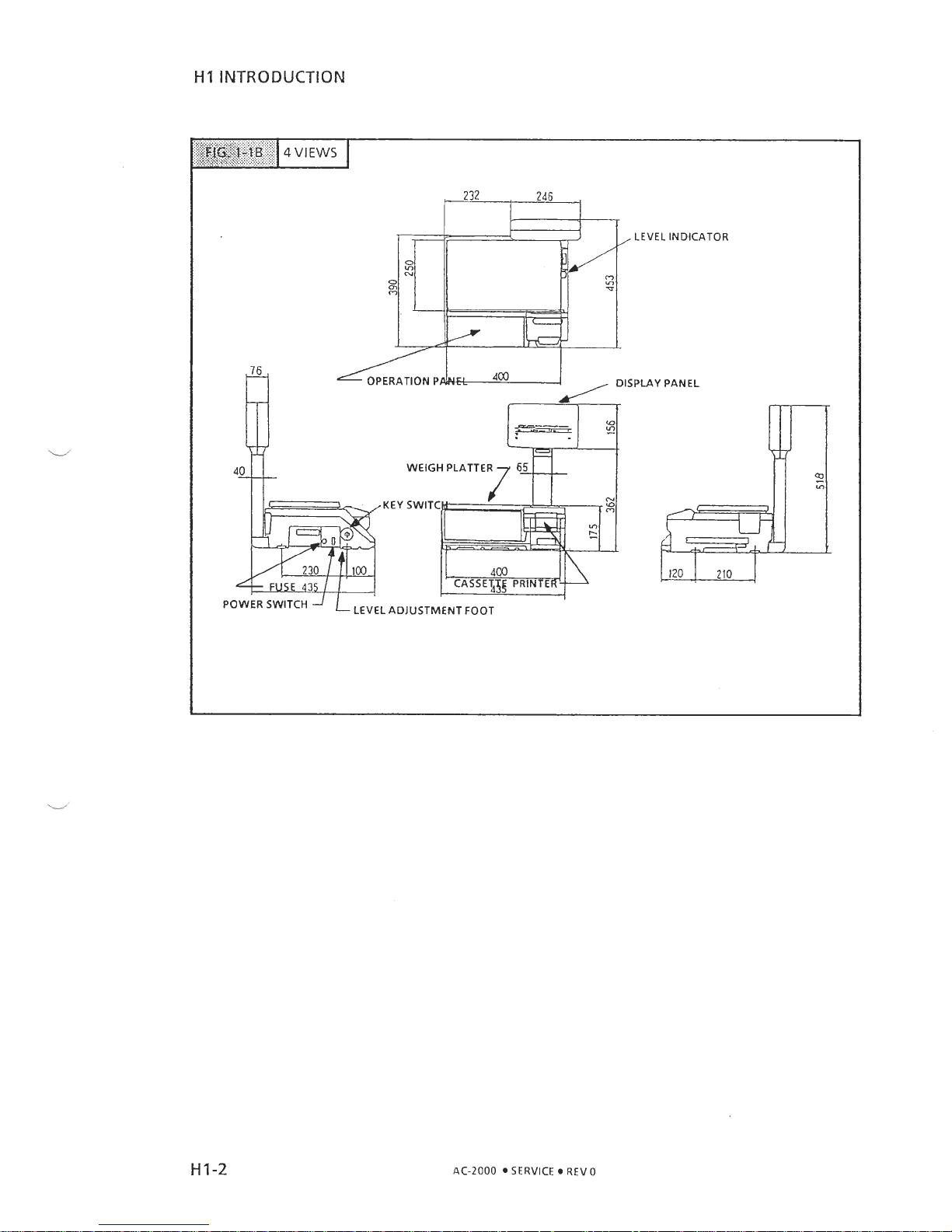

HI INTRODUCTION

LEVEL INDICATOR

DISPLAY PANEL

WEIGH PLATTE

P

AC-2000 SERVICE 0 REV 0

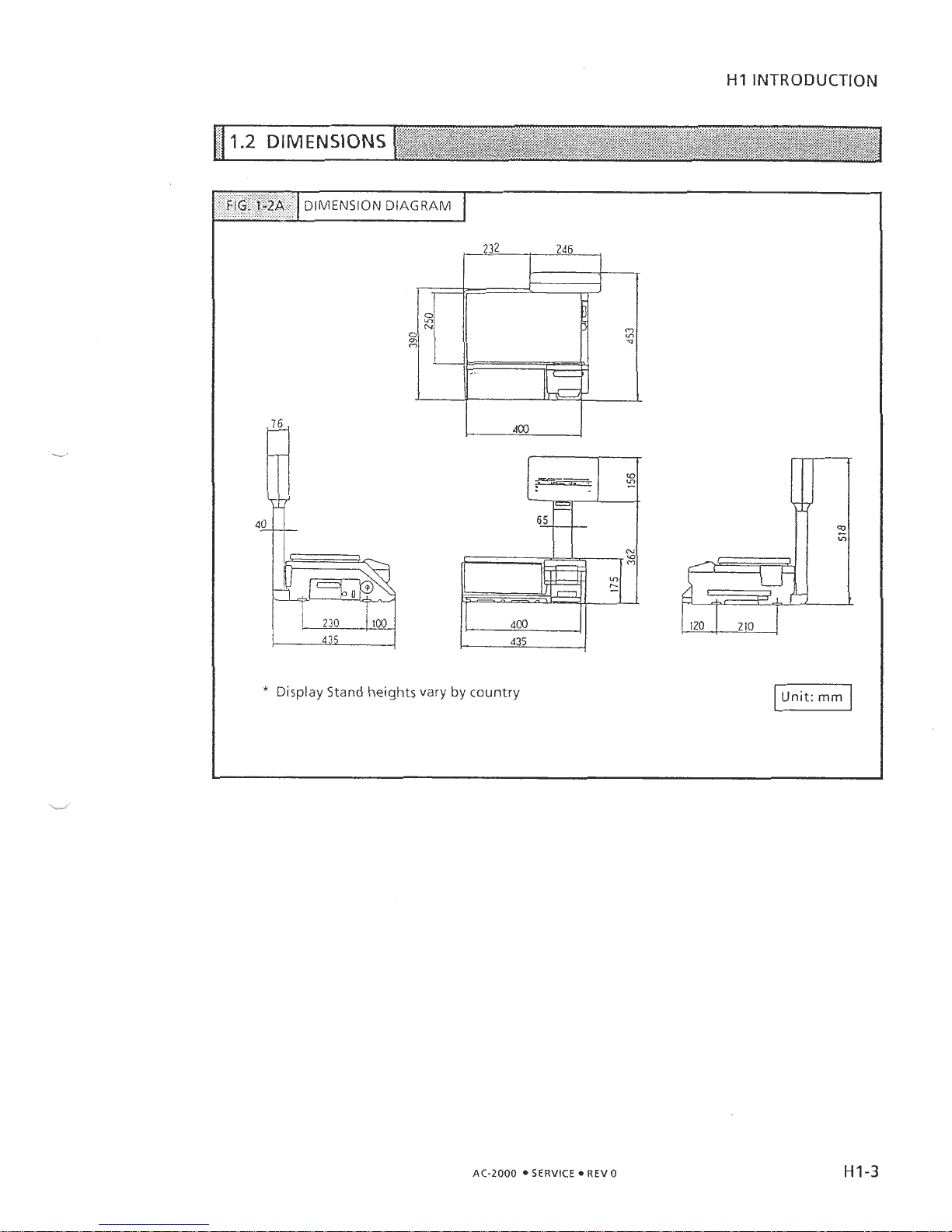

Page 7

H1

INTRODUCTION

*

Display Stand heights vary by country

FIG,

t*2A

AC-2000

SERVICE REV

0

DIMENSION DIAGRAM

Page 8

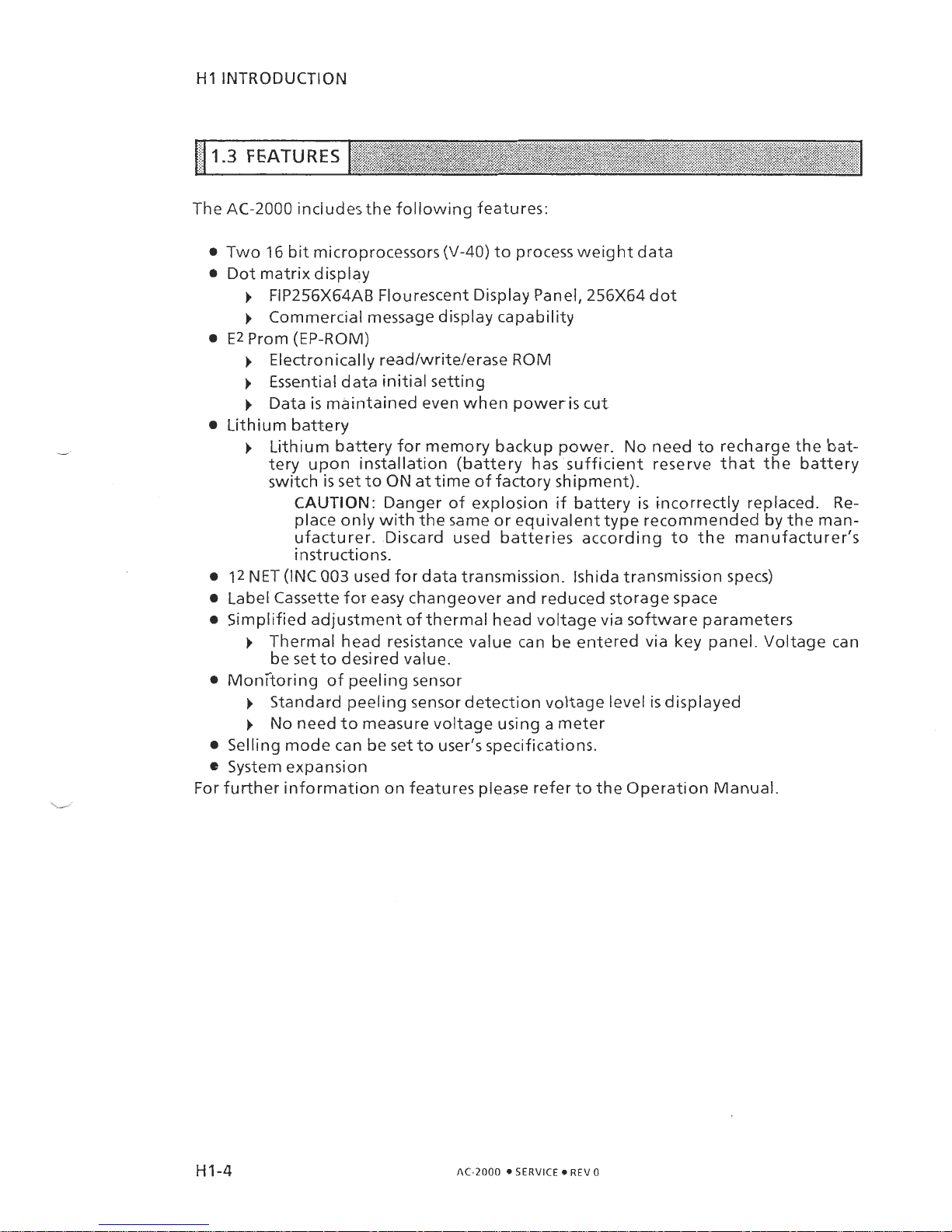

HI

INTRODUCTION

The

AC-2000

includes the following features:

Two

16

bit microprocessors

(V-40)

to process weight data

Dot matrix display

)

FIP256X64AB Flourescent Display Panel, 256x64 dot

)

Commercial message display capability

E2

Prom (EP-ROM)

)

Electronically readlwritelerase ROM

)

Essential data initial setting

)

Data is maintained even when power is cut

Lithium battery

)

Lithium battery for memory backup power. No need to recharge the battery upon installation (battery has'sufficient reserve that the battery

switch

is

set to

ON

at time of factory shipment).

CAUTION: Danger of explosion if battery

is

incorrectly replaced. Replace only with the same or equivalent type recommended by the manufacturer. Discard used batteries according to the manufacturer's

instructions.

12

NET (INC

003

used for data transmission. lshida transmission specs)

Label Cassette for easy changeover and reduced storage space

Simplified adjustment of thermal head voltage via software parameters

)

Thermal head resistance value can be entered via key panel. Voltage can

be set to desired value.

Monitoring of peeling sensor

)

Standard peeling sensor detection voltage level is displayed

)

No need to measure voltage using a meter

Selling mode can be set to user's specifications.

e

System expansion

For further information on features please refer to the Operation Manual.

AC-2000

SERVICE REV

0

Page 9

HI INTRODUCTION

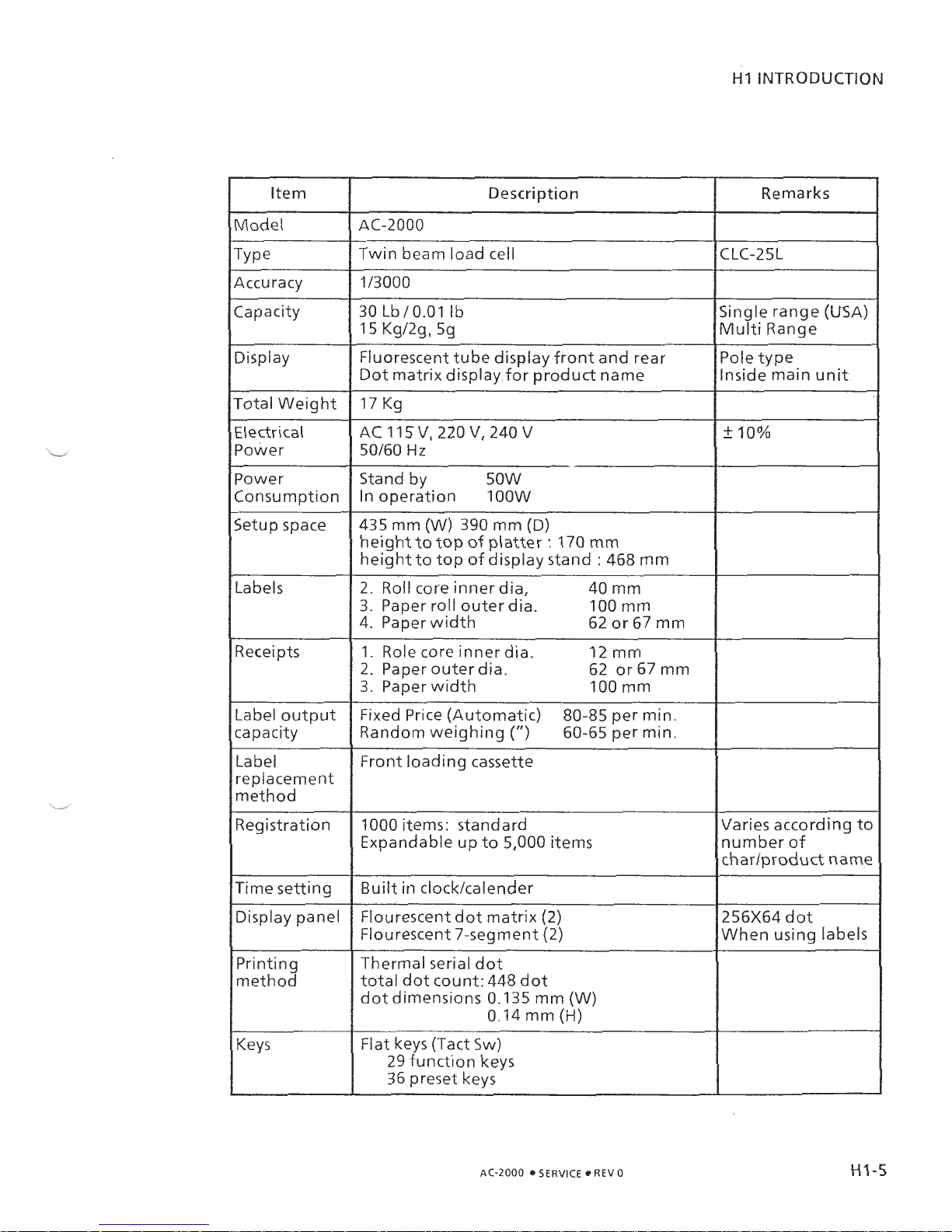

Item

Model

Description Remarks

Twin beam load cell

Accuracy

Capacity jingle range (USA)

Vlulti Range

Display Fluorescent tube display front and rear

Dot matrix display,for product name

I7 Kg

'ole type

nside main unit..

Total Weight

Electrical

Power

Power

Consumption

AC 1 15

V,

220

V,

240

V

50160

Hz

Stand by 50W

In operation 100W

Setup space 435 mm (W) 390 mm

(D)

height to top of platter : 170 mm

height to top of display stand

:

468 mm

Labels

2. Roll core inner dia,

40 mm

3.

Paper roll outer dia. 100 mm

4. Paper width

62 or 67 mm

Receipts

1. Role core inner dia. 12 mm

2.

Paper outer dia. 62 or 67 mm

3.

Paper width 100 mm

Label output

capacity

Fixed Price (Automatic)

80-85 per min.

Random weighing

(")

60-65 per min.

Label

replacement

method

Registration

Front loading cassette

1000 items: standard

Expandable up to 5,000 items

Varies according to

number of

charlproduct name

Time setting

Display panel

Built in clocklcalender

Flourescent dot matrix

(2)

Flourescent 7-segment (2)

256x64 dot

When using labels

Printing

method

Thermal serial dot

total dot count: 448 dot

dot dimensions 0.1 35 mm (W)

0.14 mm

(H)

Keys

Flat keys (Tact Sw)

29 function keys

36 preset keys

AC-2000

SERVICE

REV

0

Page 10

HI

INTRODUCTION

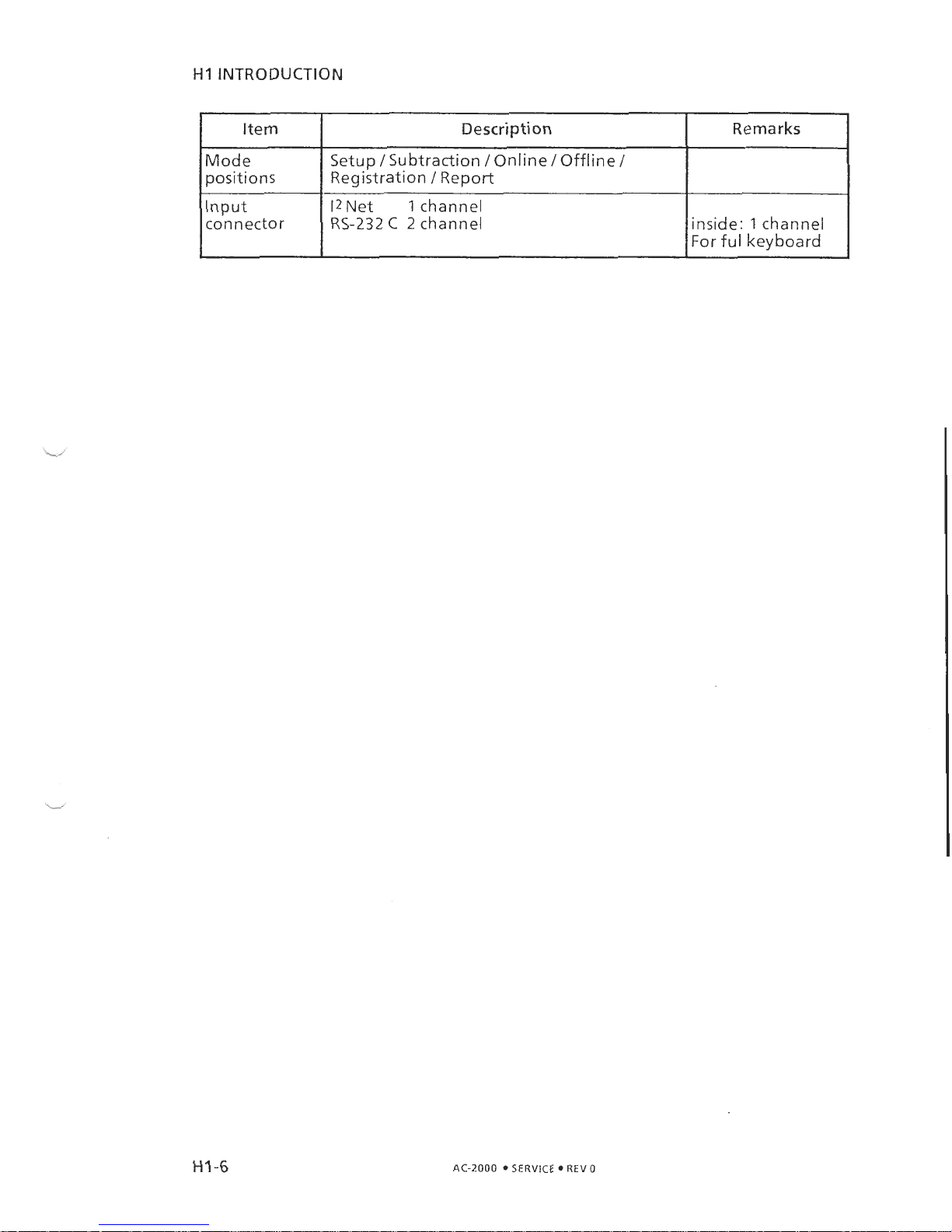

Mode

positions

Input

connector

Description

Setup

/

Subtraction /Online / Offline

/

Registration / Report

12

Net

1

channel

RS-232

C

2

channel

AC-2000 SERVICE REV 0

Remarks

_i

inside: 1 channel

For ful keyboard

Page 11

H1

INTRODUCTION

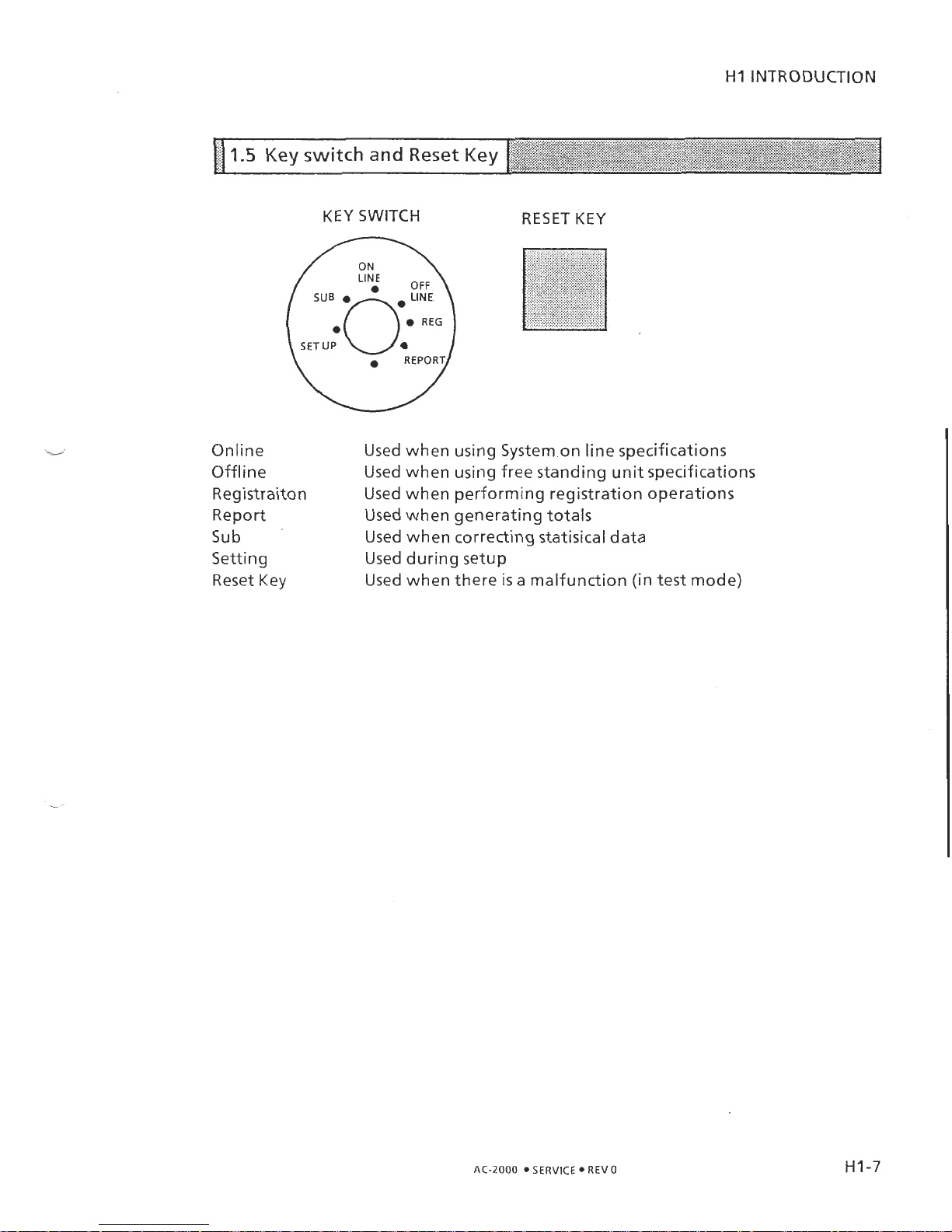

KEY

SWITCH RESET

KEY

Online

Used when using System.on line specifications

Offline Used when using free standing unit specifications

Registraiton Used when performing registration operations

Report Used when generating totals

Sub

Used when correcting statisical data

Setting Used during setup

Reset Key Used when there

is

a malfunction (in

test

mode)

AC-2000

SERVICE

REV

0

Page 12

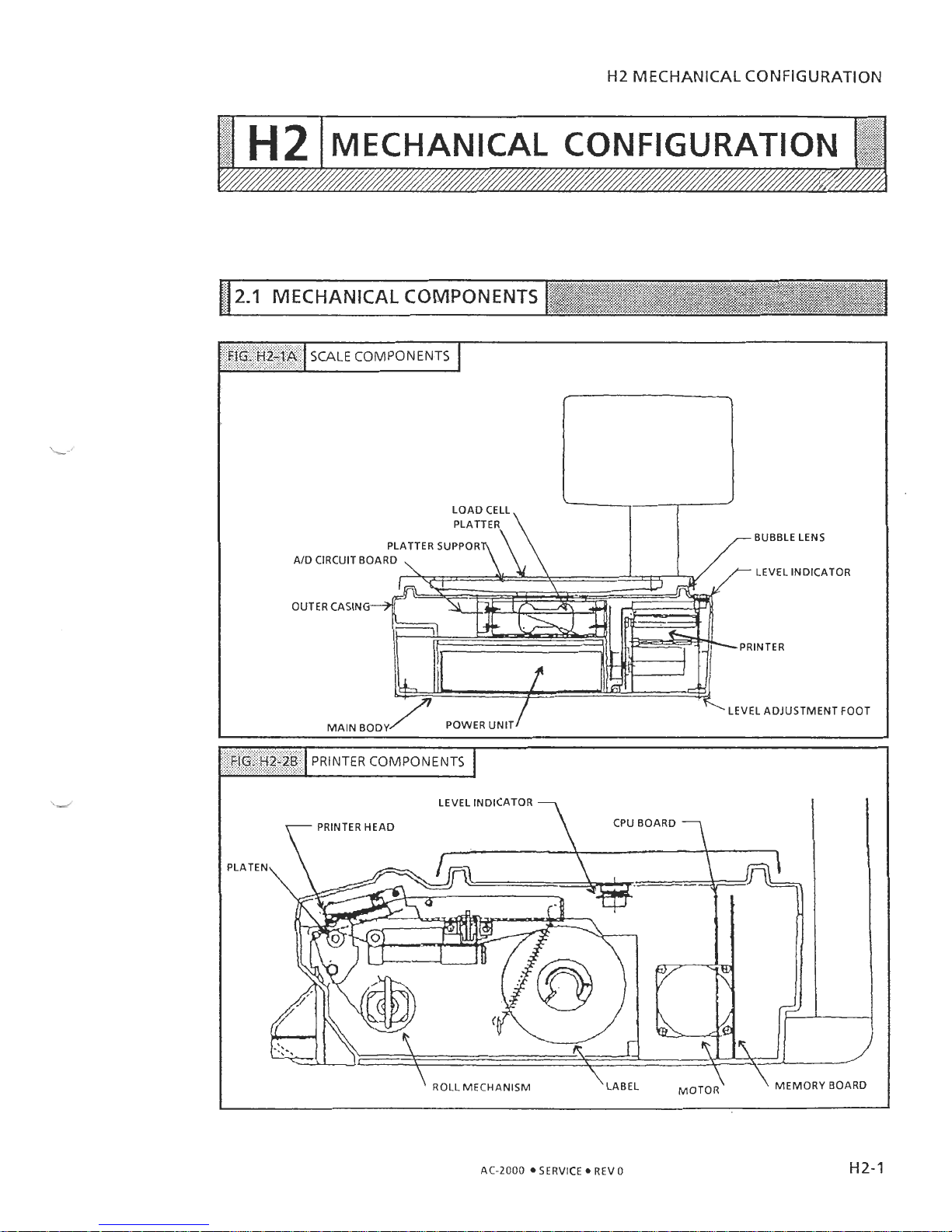

H2 MECHANICAL CONFIGURATION

SCALE COMPONENTS

BUBBLE LENS

AID CIRCUIT BOARD

LEVEL INDICATOR

OUTER CASIN

'

ROLL MECHANISM

\

\

MEMORY BOARD

AC-2000

SERVICE REV

0

Page 13

H2 MECHANICAL CONFIGURATION

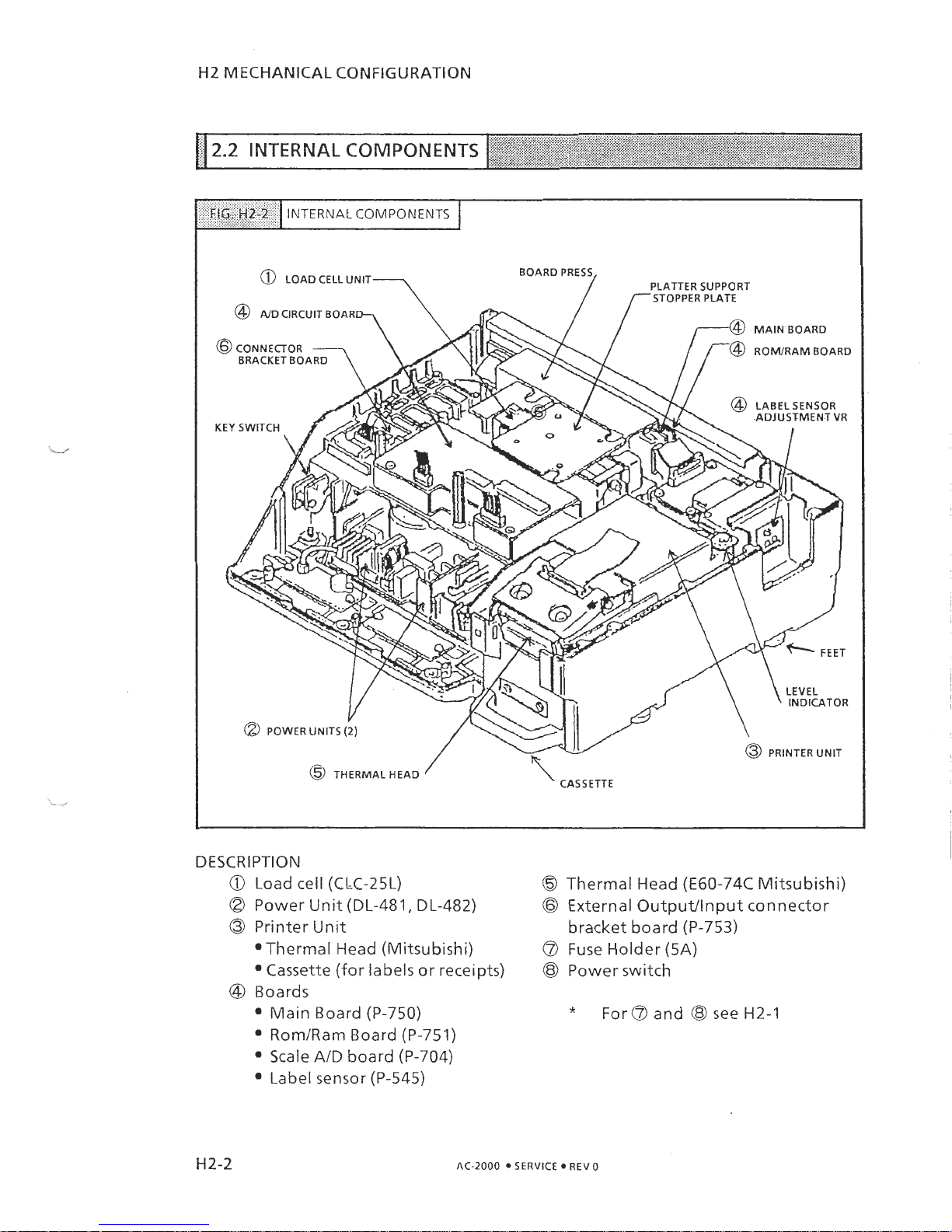

DESCRIPTION

0

Load cell (CLC-25L)

O

Thermal Head (E60-74C Mitsubishi)

Power Unit (DL-481, DL-482)

@

External Output/lnput connector

a

Printer Unit

bracket board (P-753)

@Thermal Head (Mitsubishi)

@

Fuse Holder (5A)

Cassette (for labels or receipts)

@

Power switch

@

Boards

Main Board (P-750)

*

For @ and @ see H2-1

RomIRam Board (P-751)

Scale AID board (P-704)

Label sensor (P-545)

AC-2000

SERVICE

REV

0

Page 14

H3

REPLACEMENT PROCEDURE

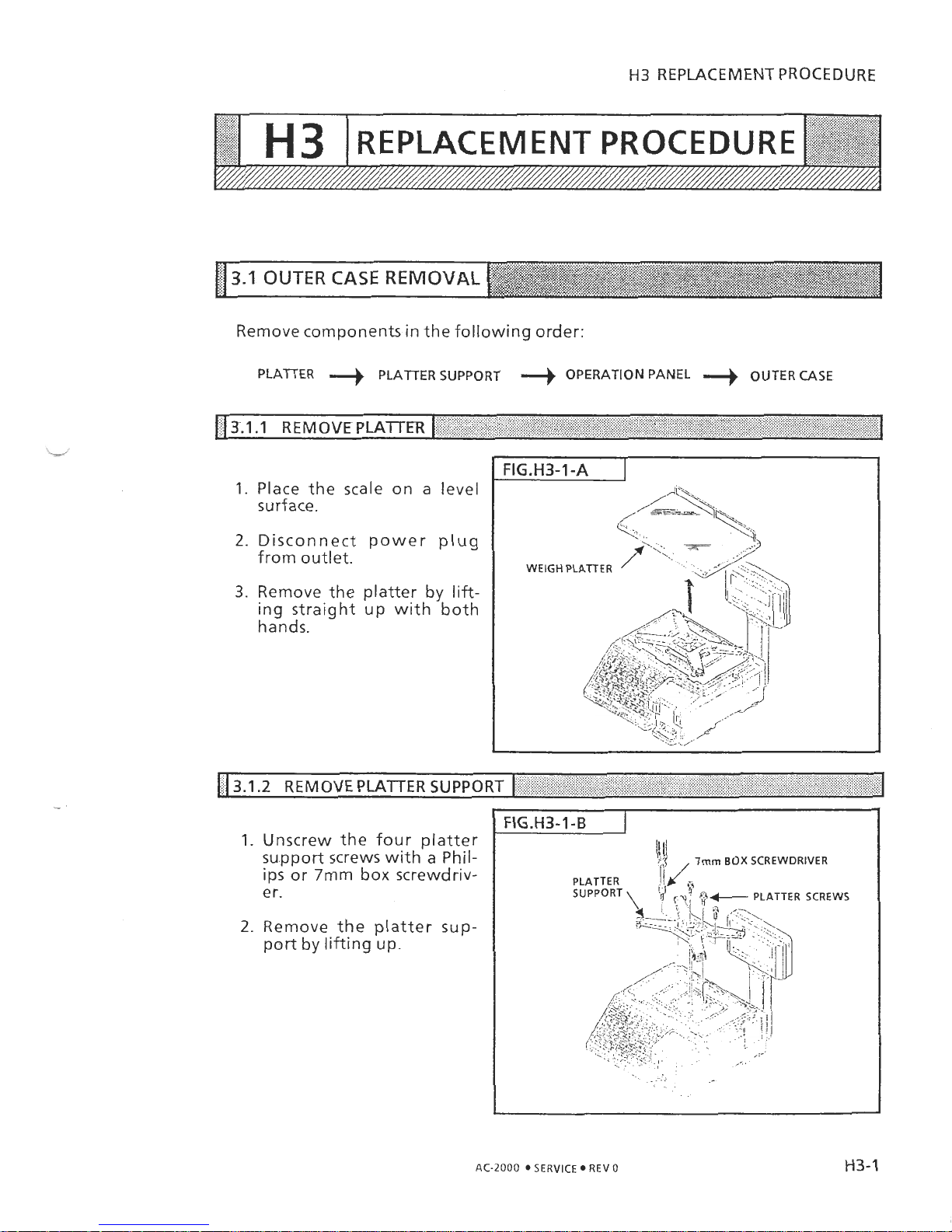

Remove components in the following order:

PLATTER

II)

PLA'ITER SUPPORT

II)

OPERATION PANEL

II)

OUTER CASE

.

,

,

.

,

,

,,,,

\

,

,

,,

..

.

%.,

<

*",

:;'

*,

,

,

[

3.1 1

REMOVE PLAITER

(

,,

1.

Place the scale on a level

surface.

2.

Disconnect power plug

from outlet.

3.

Remove the platter

by

lifting straight up with both

hands.

113.1.2

REMOVE PLATTER SUPPORT

I

,,

+<

I

1.

Unscrew the four platter

su.pport screws with a Philips or

7mm

box screwdriv-

er.

2.

Remove the platter sup-

port by lifting up.

&j

,

lmm

BOX

SCREWDRIVER

AC-2000 SERVICE REV0

H3-1

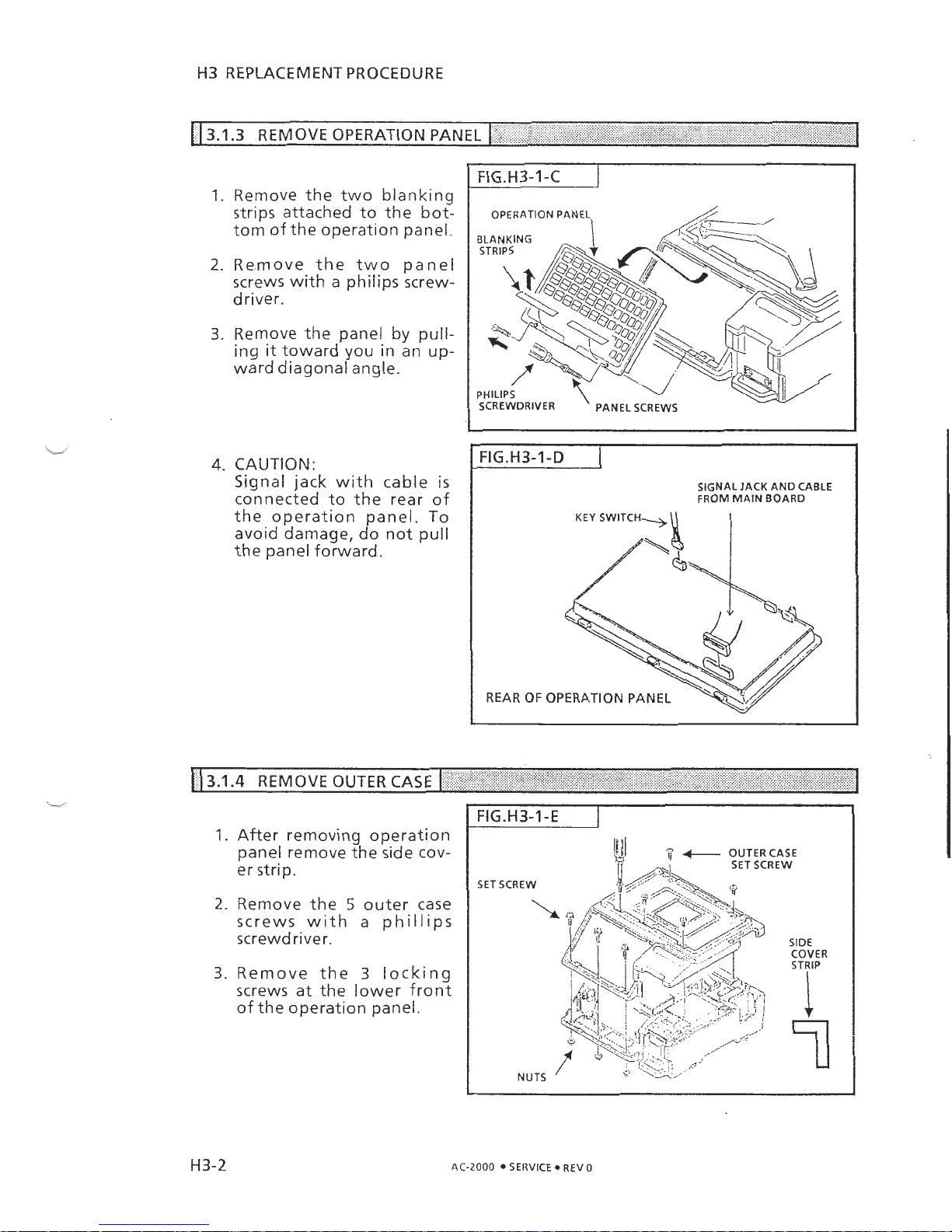

Page 15

H3

REPLACEMENT PROCEDURE

4. CAUTION:

Signal jack with cable

is

connected to the rear of

the operation panel. To

avoid damage, do not pull

the panel forward.

1.

Remove the two blanking

strips attached to the bot-

tom of the operation panel.

2.

Remove the two panel

screws with

a

philips screw-

driver.

3.

Remove the panel

by

pull-

ing it toward you in an up-

ward diagonal angle.

SIGNAL JACK AND CABLE

FROM MAIN BOARD

\

>'

<

13.1.4

REMOVE OUTER CASE

I

I

1.

After removing operation

panel remove the side cover strip.

2.

Remove the 5 outer case

screws with a phillips

screwdriver.

3.

Remove the 3 locking

screws at the lower front

of the operation panel.

SET

Page 16

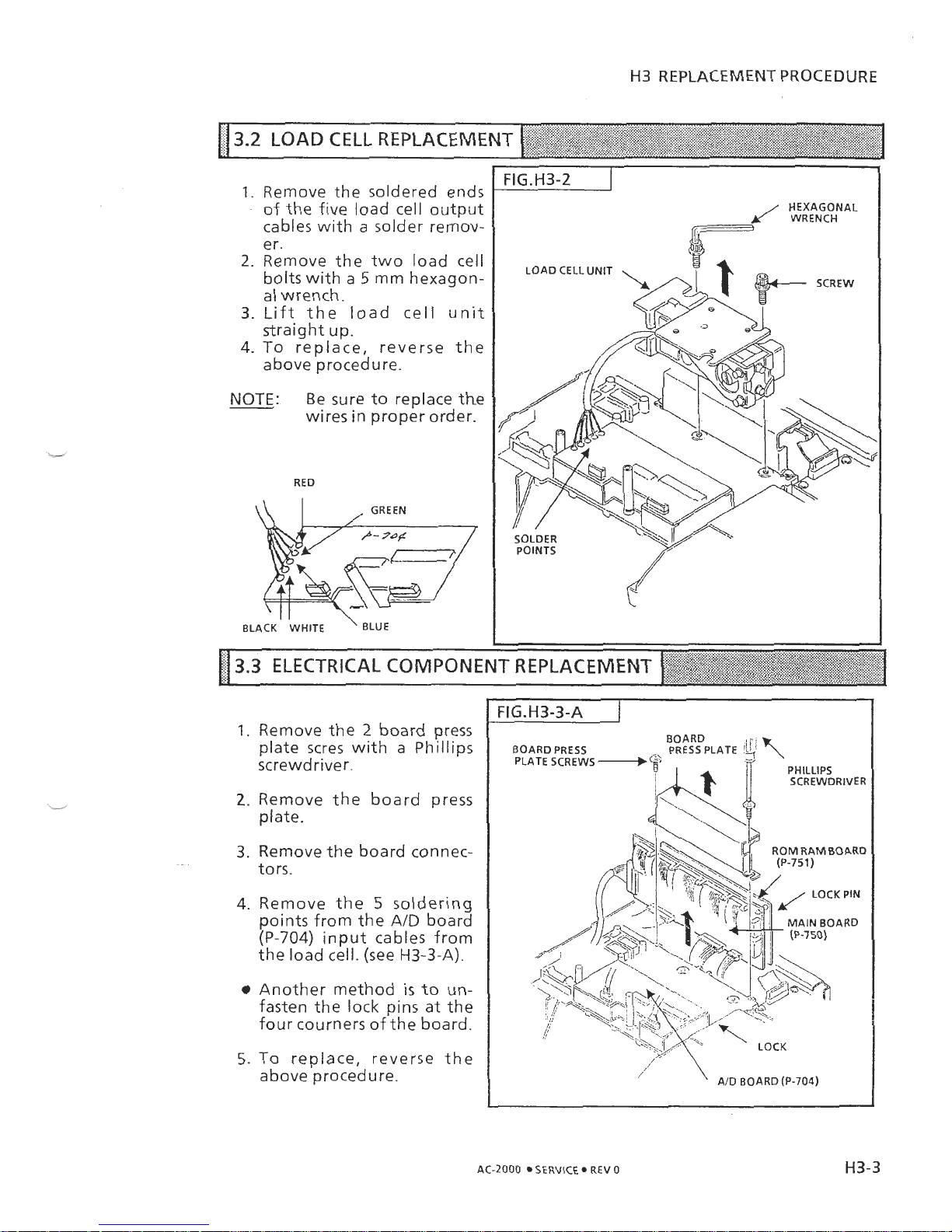

H3

REPLACEMENT PROCEDURE

1.

Remove the soldered ends

of the five load cell output

cables with a solder remov-

er.

2.

Remove the two load cell

bolts with

a

5

mm hexagon-

al wrench.

3.

Lift the load cell unit

straight up.

4.

To replace, reverse the

above procedure.

NOTE:

Be sure to replace the

wires in proper order.

RED

.

.

BLACK WHITE ' BLUE

1.

Remove the 2 board press

plate scres with a Phillips

screwdriver.

2.

Remove the board press

plate.

.

-

3.

Remove the board connec-

tors.

4.

Remove the 5 soldering

points from the

AID

board

(P-704)

input cables from

the load cell. (see

H3-3-A).

Another method

is

to

un-

fasten the lock pins at the

four courners of the board.

5.

To replace, reverse the

above procedure.

AC-2000

SERVICE

REV

o

H3-3

Page 17

H3

REPLACEMENT PROCEDURE

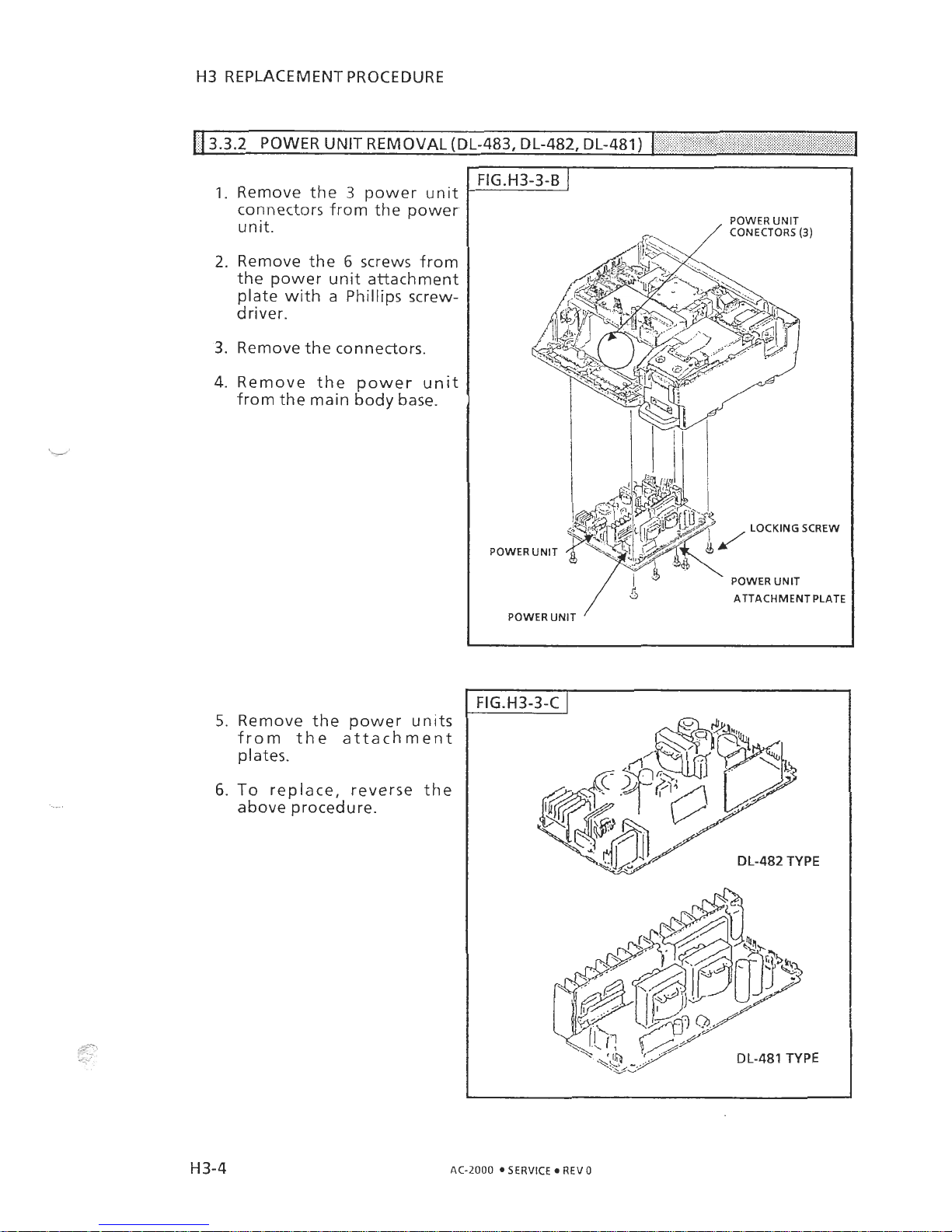

n

3.3.2

POWER UNIT REMOVAL(DL-483, DL-482, DL-481)

I

',,

,,

%.

.

1.

Remove the 3 power unit

connectors from the power-

unit.

2.

Remove the 6 screws from

the power unit attachment

plate with a Phillips screw-

driver.

3.

Remove the connectors.

4.

Remove the power unit

from the main body base.

5.

Remove the power units

from the attachment

plates.

6.

To

replace, reverse the

above procedure.

POWER UNlT

/

CONECTORS

(3)

LOCKING SCREW

POWER UNlT

POWER UNlT

ATTACHMENT PLATE

POWER UNlT

-

-

DL-482

TYPE

DL-481

TYPE

AC-2000

SERVICE REV

0

Page 18

H3

REPLACEMENT PROCEDURE

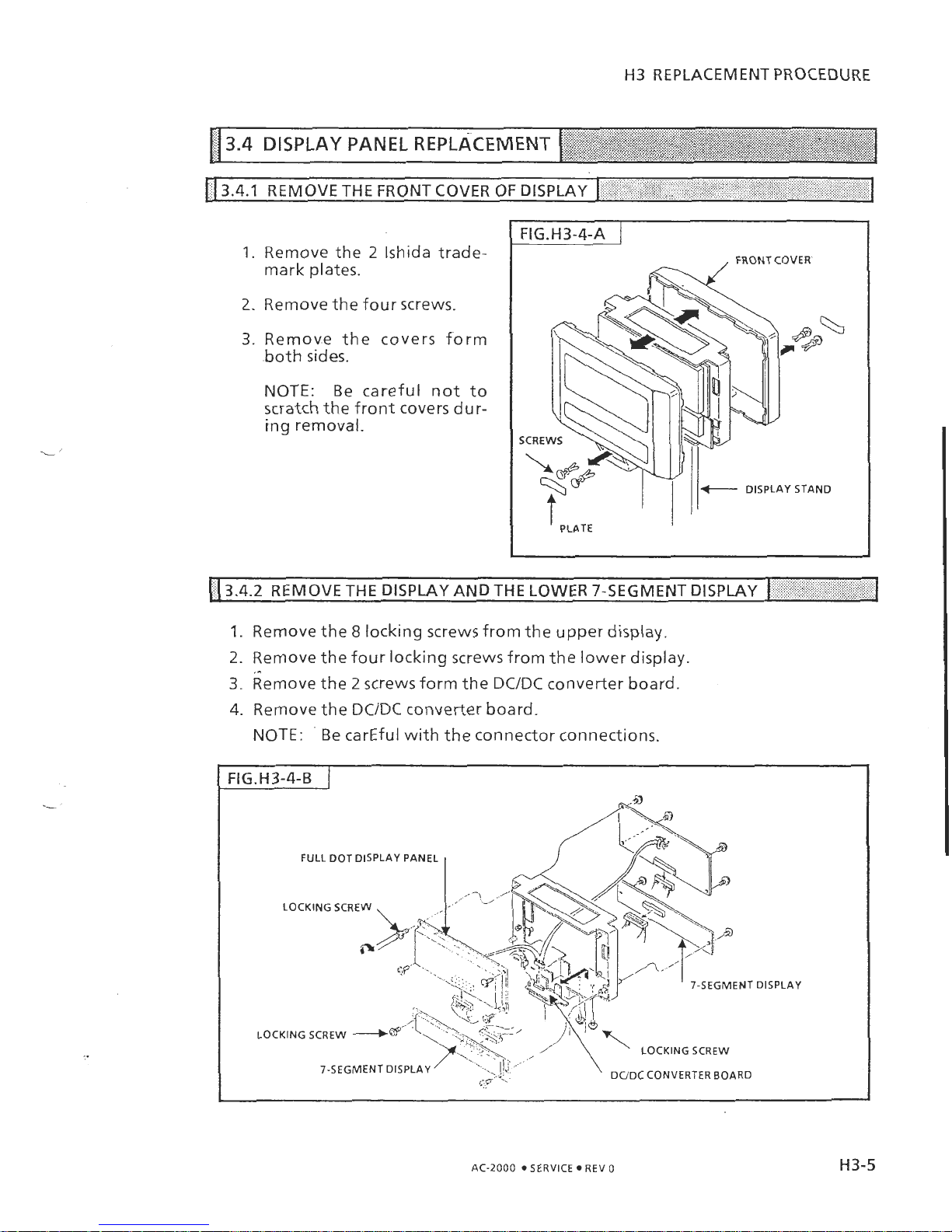

13.4.1

REMOVE THE FRONT COVER OF DISPLAY

I

I

1.

Remove the 2 lshida trademark plates.

2.

Remove the four screws.

3.

Remove the covers form

.both sides.

NOTE: Be careful not to

scratch the front covers dur-

ing removal.

1.

Remove the 8 locking screws from the upper display.

2.

Remove the four locking screws from the lower display.

3.

~emove the 2 screws form the

DC/DC

converter board.

4.

Remove the

DC/DC

converter board.

NOTE:

'

Be carEful with the connector connections.

FULL DOT DISPLAY PANEL

LOCKING SCREW

7-SEGMENT DIS

LOCKING SCREW

7-SEGMENT DISPLAY

&-,a

.

'.

'

DUDC CONVERTER BOARD

PLAY

AC-2000

SERVICE REV

0

Page 19

H3 REPLACEMENT PROCEDURE

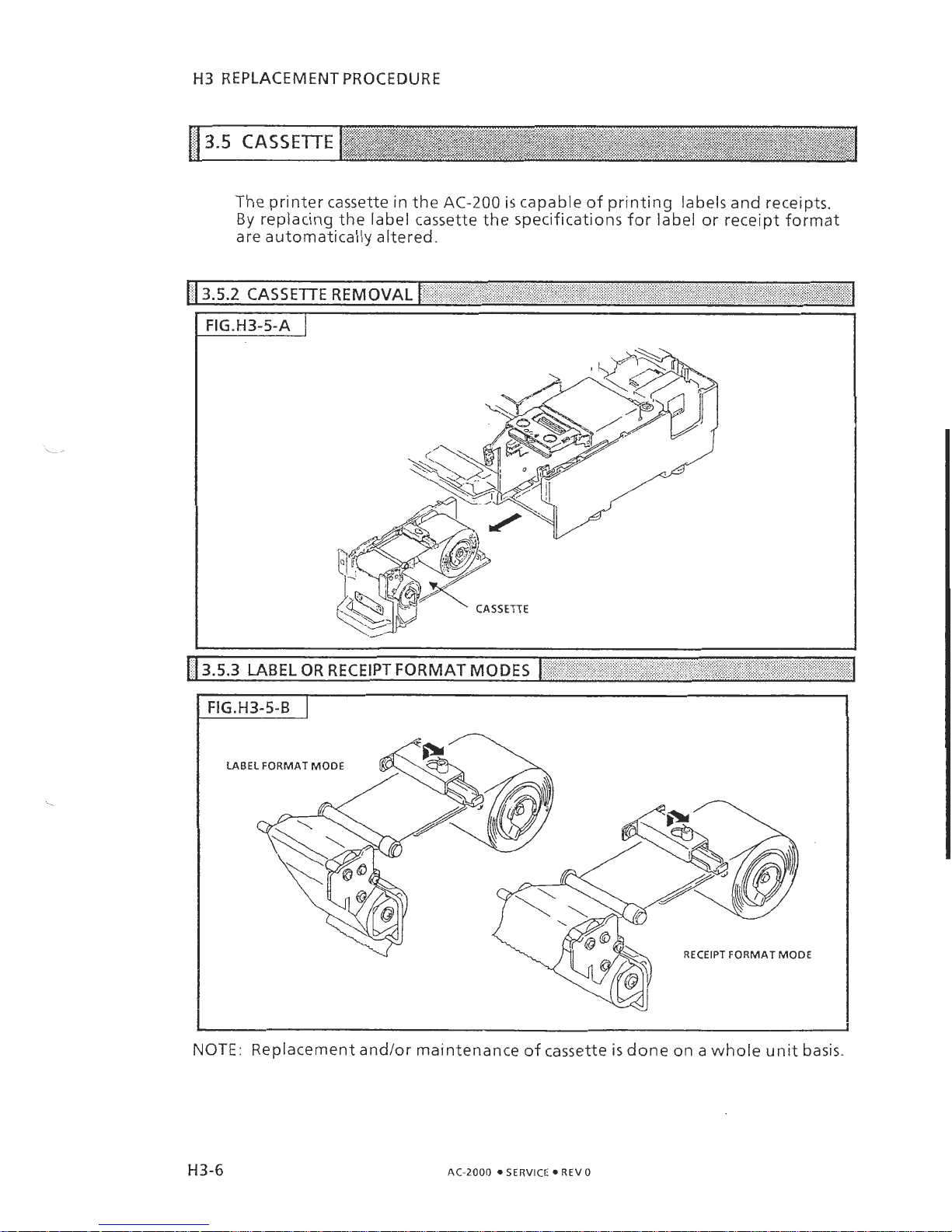

The printer cassette in the

AC-200

is

capable of printing labels and receipts.

By

replacing the label cassette the specifications for label or receipt format

are automatically altered.

NOTE:

Replacement andlor maintenance of cassette is done on

2

whnf~

llnit

ha&

AC-2000

SERVICE REV

0

Page 20

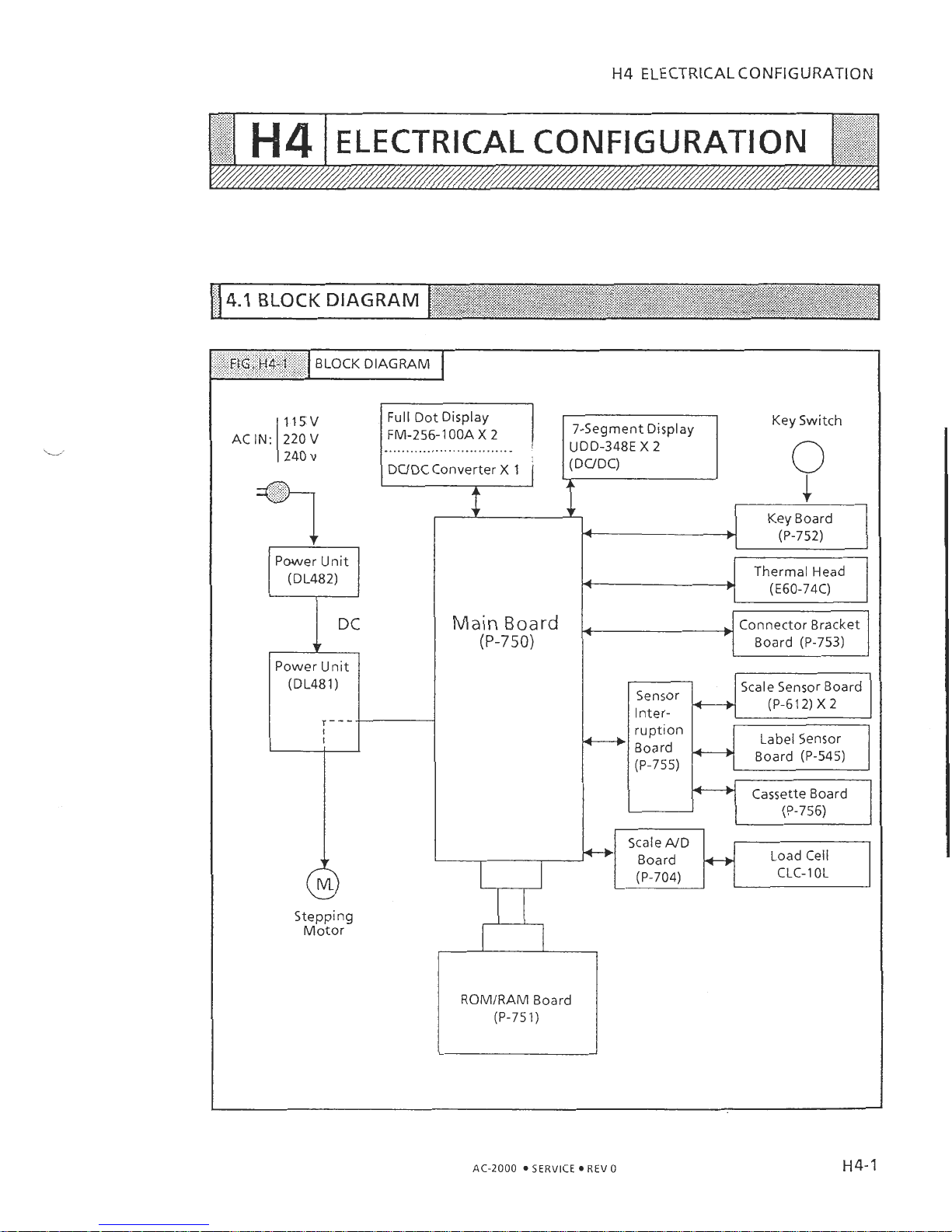

H4

ELECTRICAL CONFIGURATION

Power Unit

(DL482)

(DL481)

FM-256-1

OOA

X

2

..............................

I

DUDC Converter X 1

7-Segment Display

UDD-348E

X

2

(DUDC)

Key Switch

1

?

f

Key Board

b

(P-752)

Stepping

Motor

ROMIRAM

Board

(P-75

1)

Main Board

(P-750)

Connector Bracket

Board (P-753)

Scale Sensor Board

Sensor

Inter-

*

(P-612) X 2

Label Sensor

Board (P-545)

Cassette Board

Scale

AID

Load Cell

-1

Board

hy

(P-704) CLC- 1 OL

AC-2000

SERVICE

REV

0

Page 21

H4

ELECTRICAL

CONFIGURATION

,,,,.

%x

,

,>A,

.,,;,

,,',,

:

4.2

CONNECTOR DIAGRAM

, ,, . ,

I

,

'FiG.ti4-1'5

,A

(CONNECTORDIAGRAM

I

u,

u,

.a

.a

3

AC-2000 SERVICE REV 0

Page 22

H4

ELECTRICAL CONFIGURATION

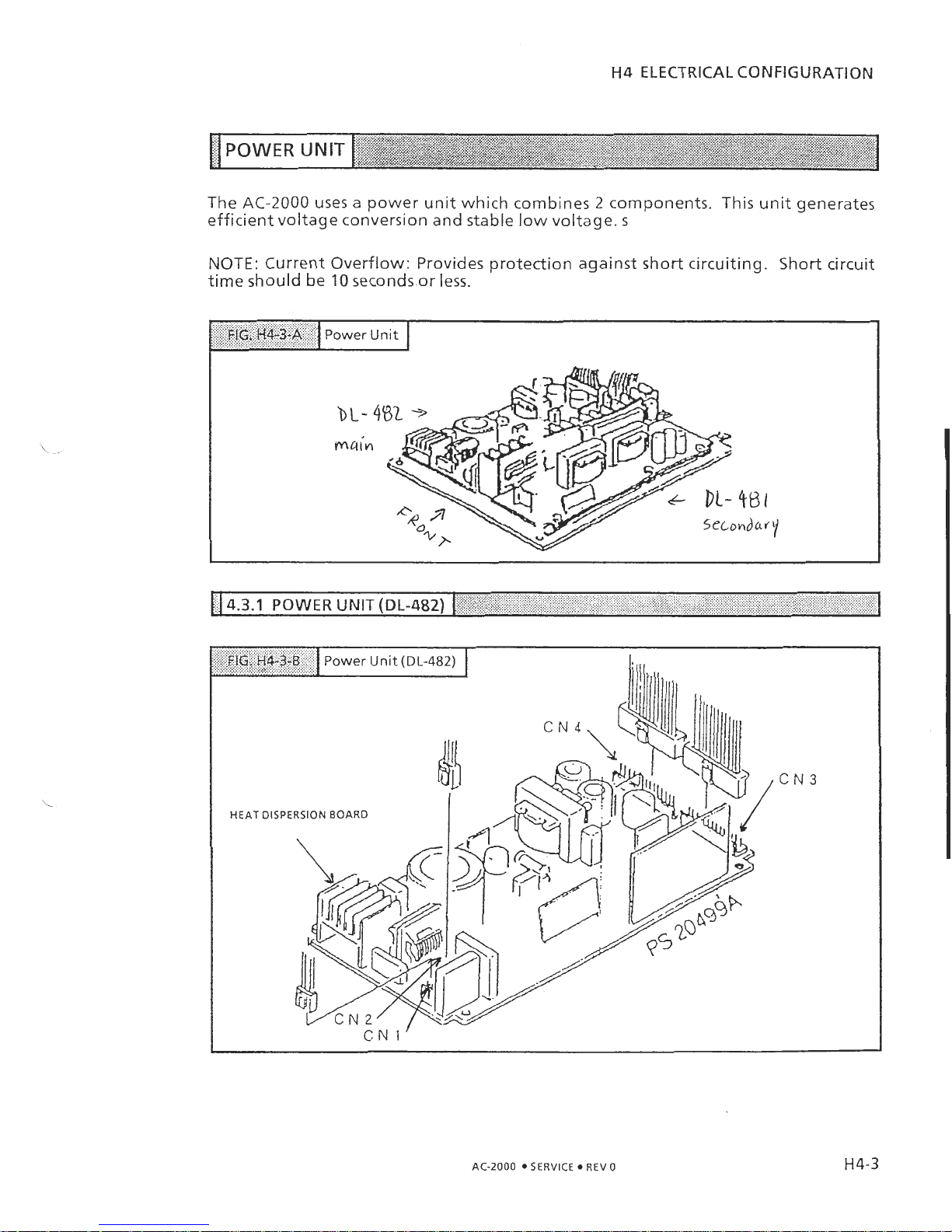

The AC-2000 uses

a

power unit which combines 2 components. This unit generates

efficient voltage conversion and stable low voltage.

s

NOTE: Current Overflow: Provides protection against short circuiting. Short circuit

time should be 10 seconds.or less.

1)

4.3.1

POWER UNIT

(DL-482)

(-

1

AC-2000

SERVICE

REV

0

Page 23

H4

ELECTRICAL CONFIGURATION

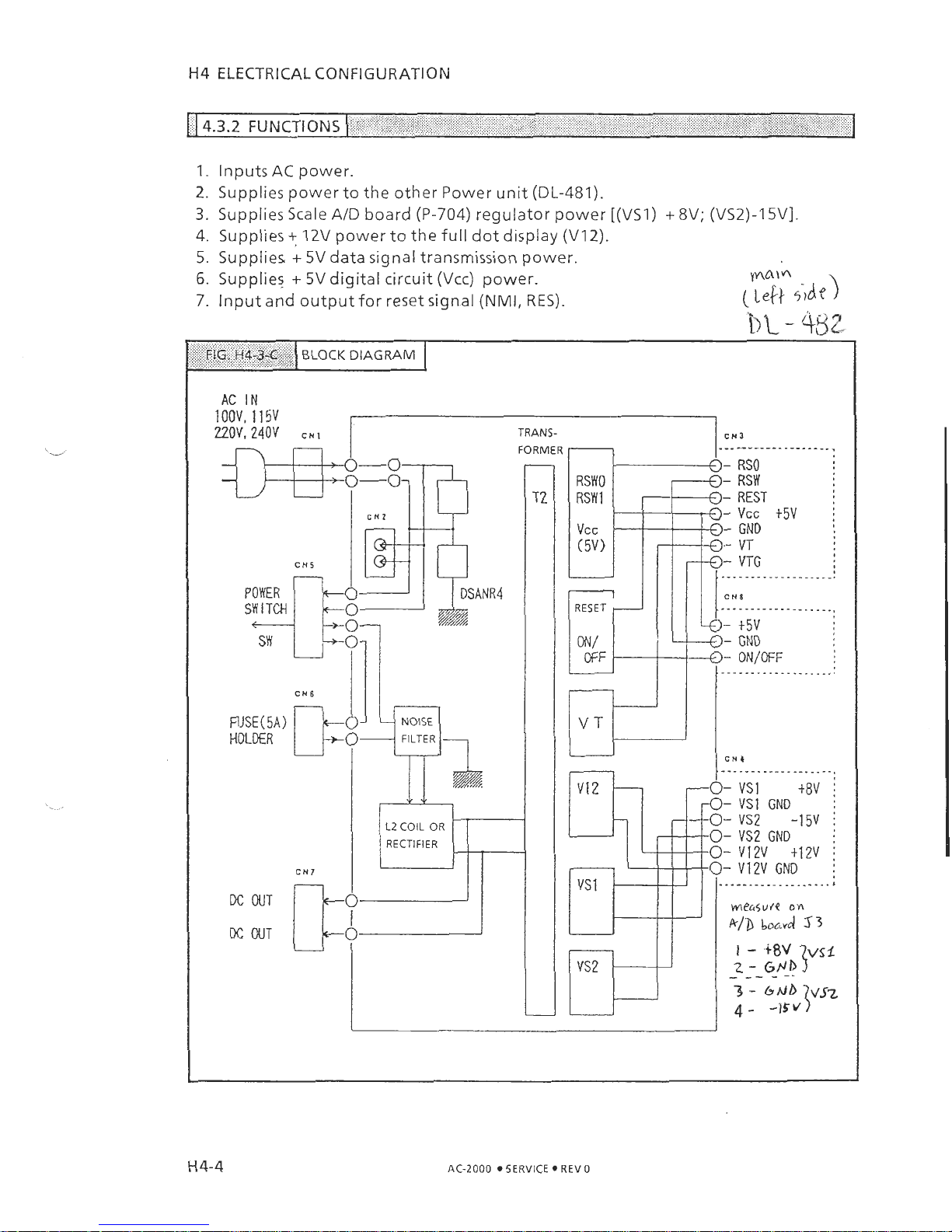

14.3.2

FUNCTIONS

(

,

,

,\%

,

I.

Inputs

AC

power.

2.

Supplies power to the other Power unit (DL-481).

3.

Supplies Scale AID board (P-704) regulator power [(VSI) + 8V; (VS2)-15Vl.

4.

Supplies

+

12V

power to the full dot display

(V12).

5.

Supplies + 5V data signal transmission power.

6.

Supplies + 5Vdigital circuit (Vcc) power.

yv\a\a

7.

Input and output for reset signal

(NMI,

RES).

(~e[/-

side)

1

OOV,

1

1

5v

220V,

240V

CH5

POWER

SW

ITCH

RJSE(5A)

HOLDER

FILTER

-

L2

COIL

OR

RECTIFIER

I

RSWO

1

i

H

4-4

AC-2000

05ERVICE

REV

0

Page 24

H4

ELECTRICAL CONFIGURATION

FIG.

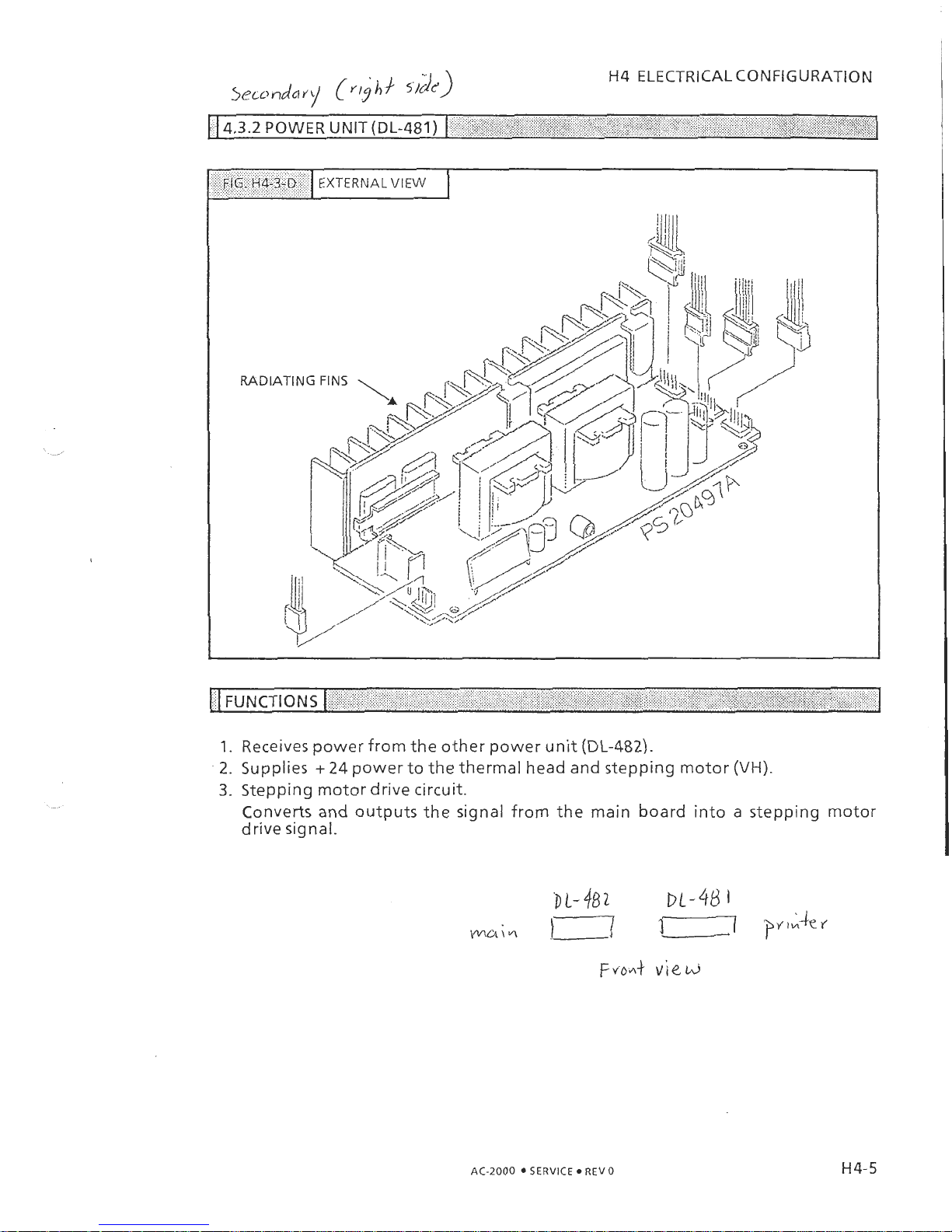

H4-3-D

EXTERNAL

VIEW

1.

Receives power from the other power unit (DL-482).

2.

Supplies + 24 power to the thermal head and stepping motor

(VH).

3.

Stepping motor drive circuit.

Converts and outputs the signal from the main board into a stepping motor

drive signal.

AC-2000

SERVICE REV0

Page 25

H4

ELECTRICAL CONFIGURATION

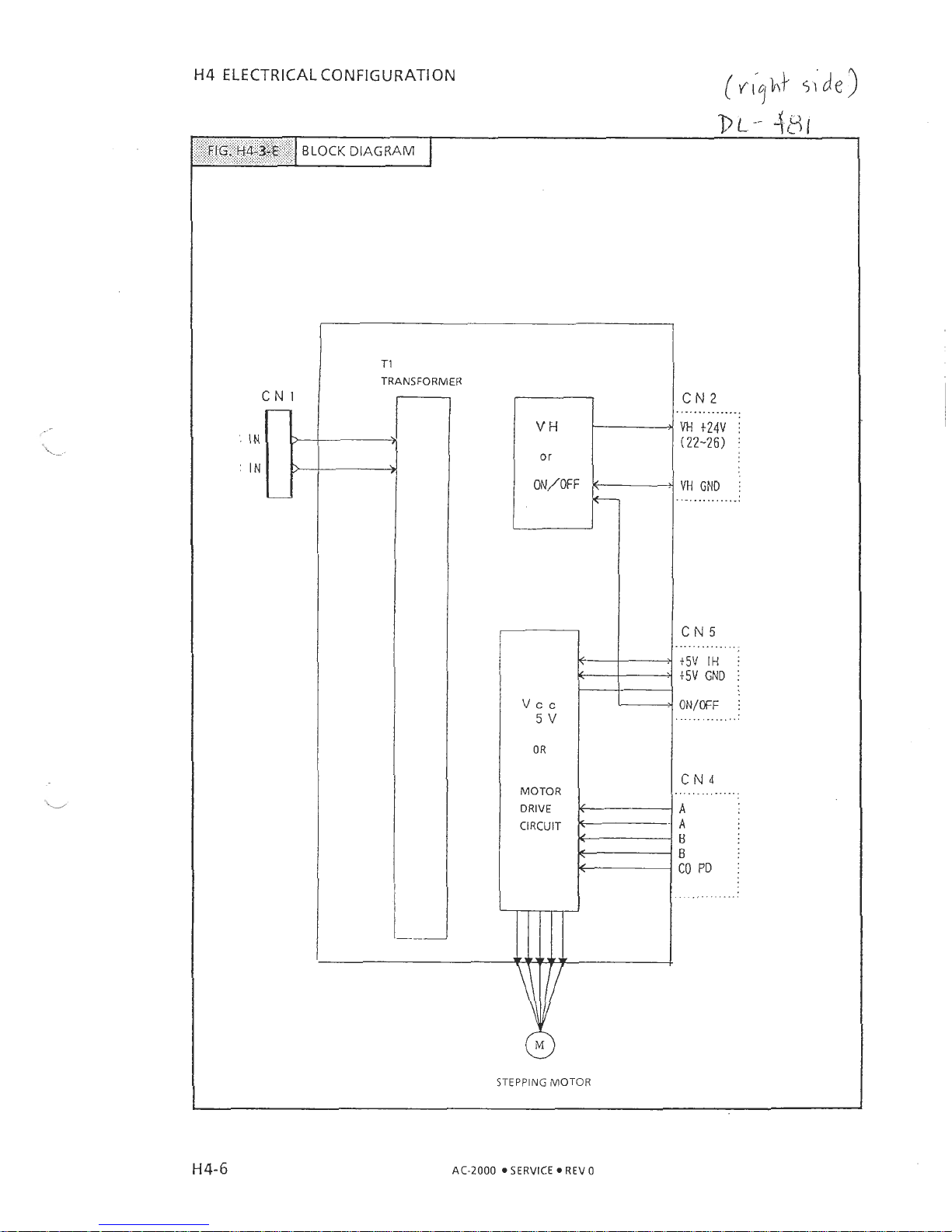

(i.ljhi.

de3

TI

TRANSFORMER

DL--

481

MOTOR

DRIVE

CIRCUIT

FIG.

H4-3-E

VH

GND

i

..............

CN5

BLOCK

DIAGRAM

t5V

IH

i

t5V

GND

i

ON/OFF

i

..............

STEPPING

MOTOR

AC-2000

SERVICE REV 0

Page 26

H4

ELECTRICAL CONFIGURATION

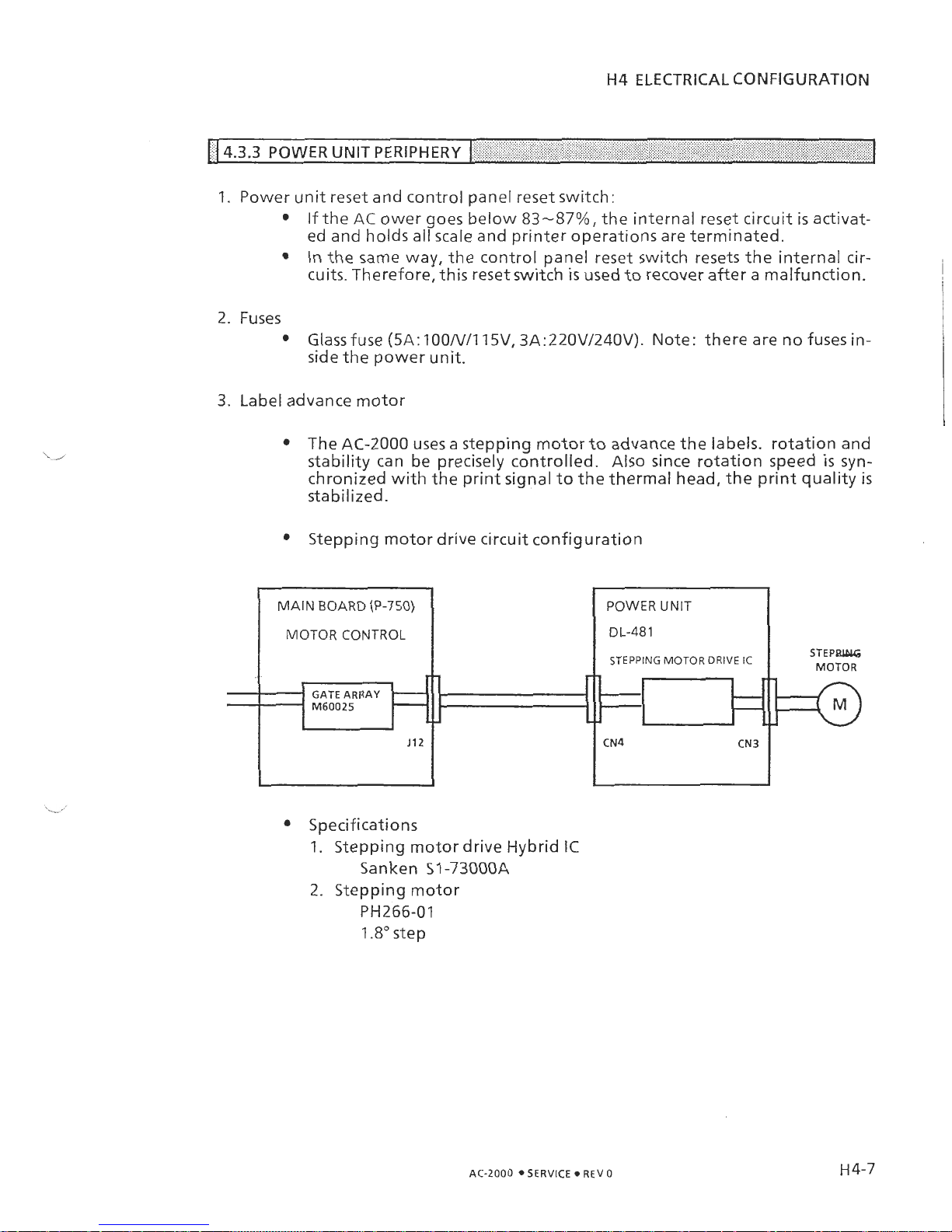

14.3.3

POWER UNIT PERIPHERY

I

,

1. Power unit reset and control panel reset switch:

If the

AC

ower goes below

83-87%,

the internal reset circuit is activat-

ed and holds all scale and printer operations are terminated.

In the same way, the control panel reset switch resets the internal circuits. Therefore, this reset switch is used to recover after a malfunction.

2. Fuses

Glass fuse (5A: 100N/115V, 3A:220V/240V). Note: there are no fuse.s in-

side the power unit.

3.

Label advance motor

The AC-2000 uses a stepping motor to advance the labels. rotation and

stability can be precisely controlled.

Also since rotation speed

is

syn-

chronized with the print signal to the thermal head, the print quality

is

stabilized.

Stepping motor drive circuit configuration

Specifications

1. Stepping motor drive Hybrid

IC

San ken 51 -73OOOA

2.

Stepping motor

PH266-01

1.8" step

AC-2000 SERVICE REV

0

.

MAIN BOARD (P-750)

MOTOR CONTROL

--

4

.

GATE ARRAY

M60025

-

_

STEPBLDLG

MOTOR

-,

L

POWER UNIT

DL-48

1

STEPPING MOTOR DRIVE IC

J12

-,

*

-

CN4

CN3

A

-

-

Page 27

H4

ELECTRICAL CONFIGURATION

\,

i

',

11

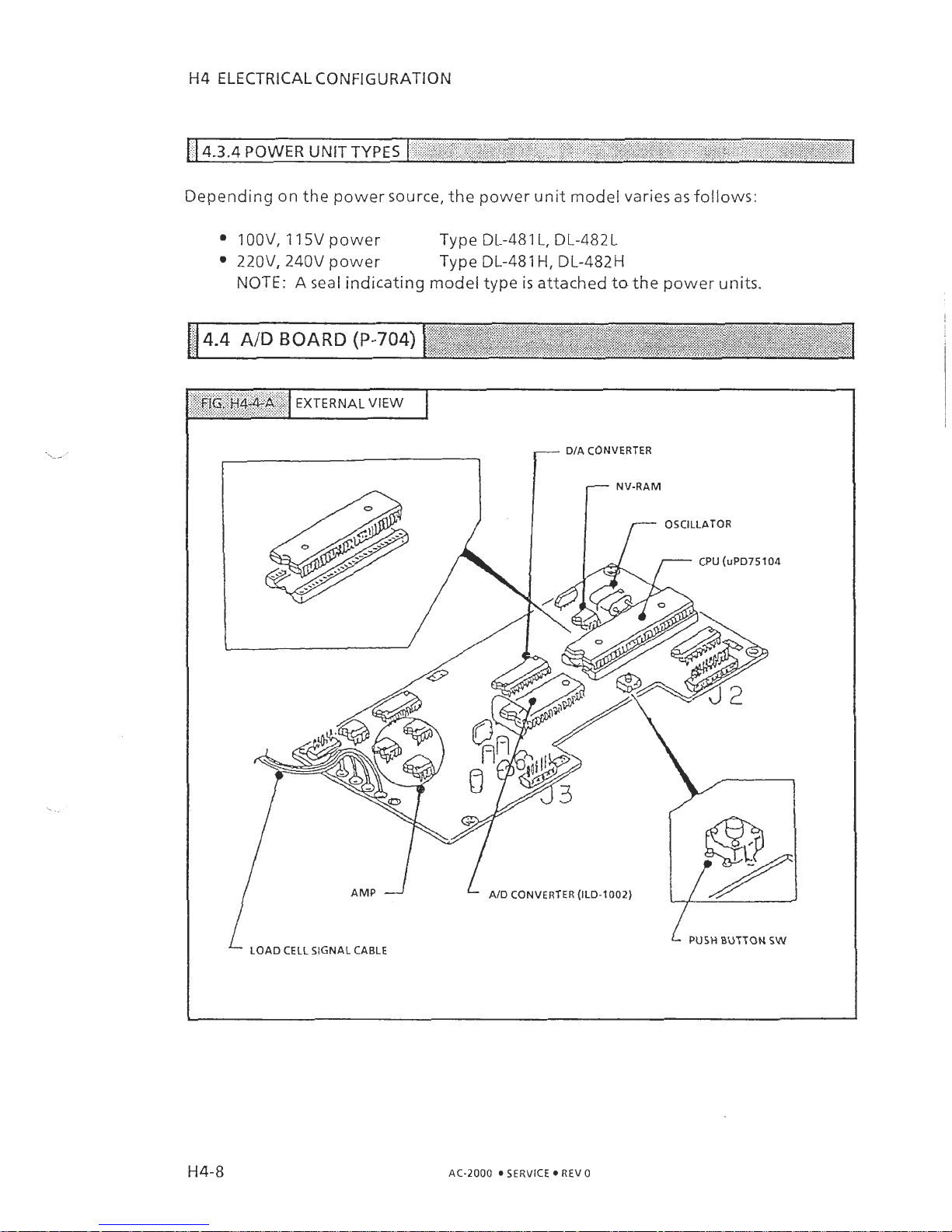

4.3.4

POWER

UNIT TYPES

I

,

,

, ,

I

Depending on the power source, the power unit model varies asfollows:

1

OOV,

11

5V power Type DL-481 L, DL-482L

22OV, 240V power

Type DL-481

H,

DL-482H

NOTE:

A

seal indicating model type

is

attached tothe power units.

-

DIA

CONVERTER

r

N;

oswAToR

CPU

(uPD75104

AMP

1

AID

CONVERTER

(ILD-1002)

L

LOAD

CELL

SIGNAL

CABLE

1

PUSH

BUTTON

SW

AC-2000

SERVICE

REV

0

Page 28

H4

ELECTRICAL CONFIGURATION

% %

. .

,

\

...

%.

%.

I

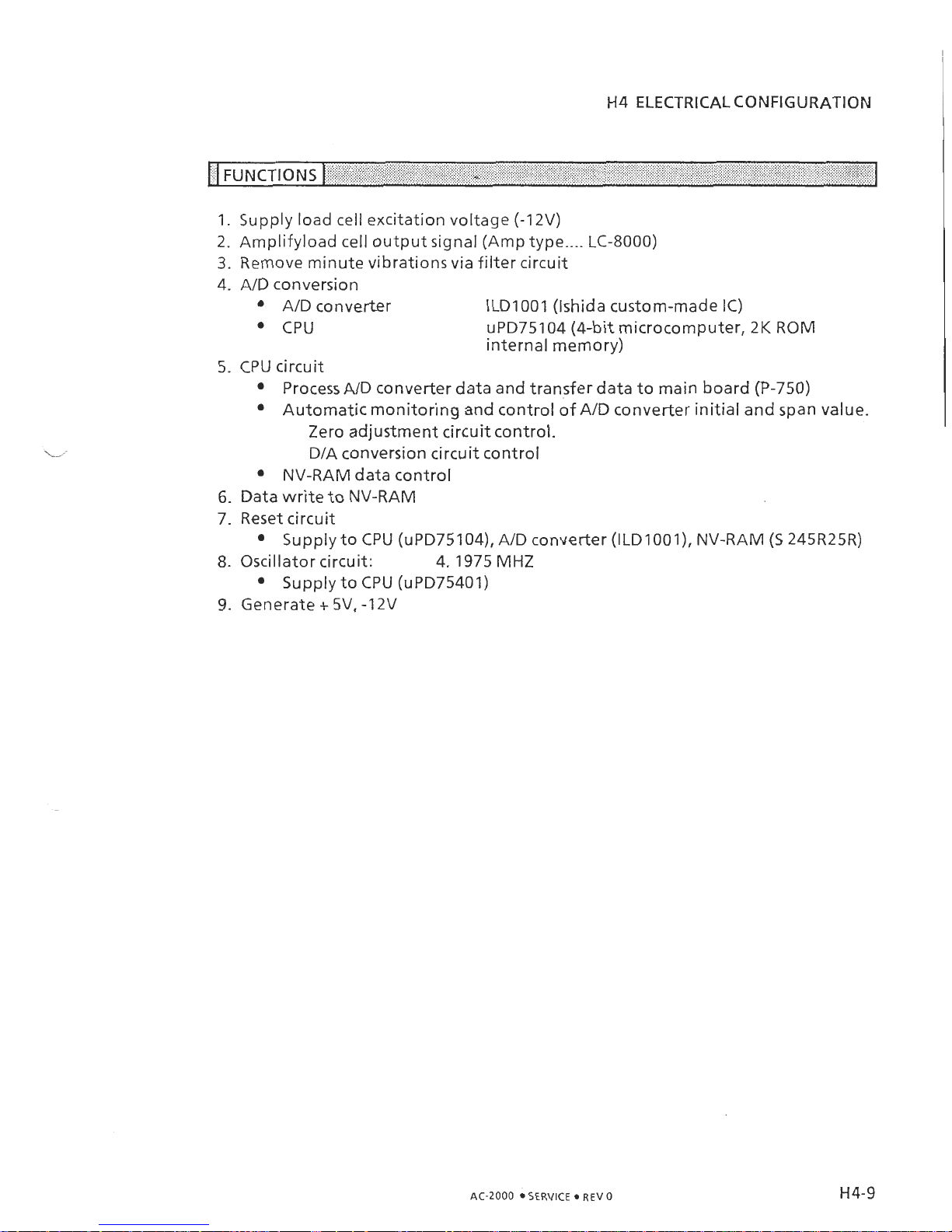

FUNCTIONS

[

"

A\'

I

1. Supply load cell excitation voltage (-12V)

2. Amplifyload cell output signal (Amp type

....

LC-8000)

3.

Remove minute vibrations via filter circuit

4. AID conversion

AID converter ILDl001 (Ishida custom-made IC)

CPU

uPD75104 (4-bit microcomputer, 2K ROM

internal memory)

5.

CPU circuit

Process AID converter data and transfer data to main board (P-750)

Automatic monitoring and control of AID converter initial and span value.

Zero adjustment circuit control.

DIA conversion circuit control

NV-RAM data control

6.

Data write to NV-RAM

7. Reset circuit

Supply to CPU (uPD75104), AID converter (ILDlOOl), NV-RAM (5 245R25R)

8.

Oscillator circuit: 4.1975 MHz

Supply to CPU (uPD75401)

9. Generate

+

5V,

-1

2V

AC-2000

SERVICE REV

0

Page 29

H4

ELECTRICAL CONFIGURATION

16-bit microprocessors (V40)

(2),

control all data processing for AC-2000.

Multi-layered type, higly condensed component mounting, with lowered

electrical impedance to improve endurance against electrical noise and

static electricity.

ON

OFF

14

IC1

}

uPD71051G

IC4

J

2

J

1

TO

SCALE

AID

NOT

IN

USE

BOARD

P-704

H'4-10

AC-2000

SERVICE

REV

0

Page 30

H4

ELECTRICAL CONFIGURATION

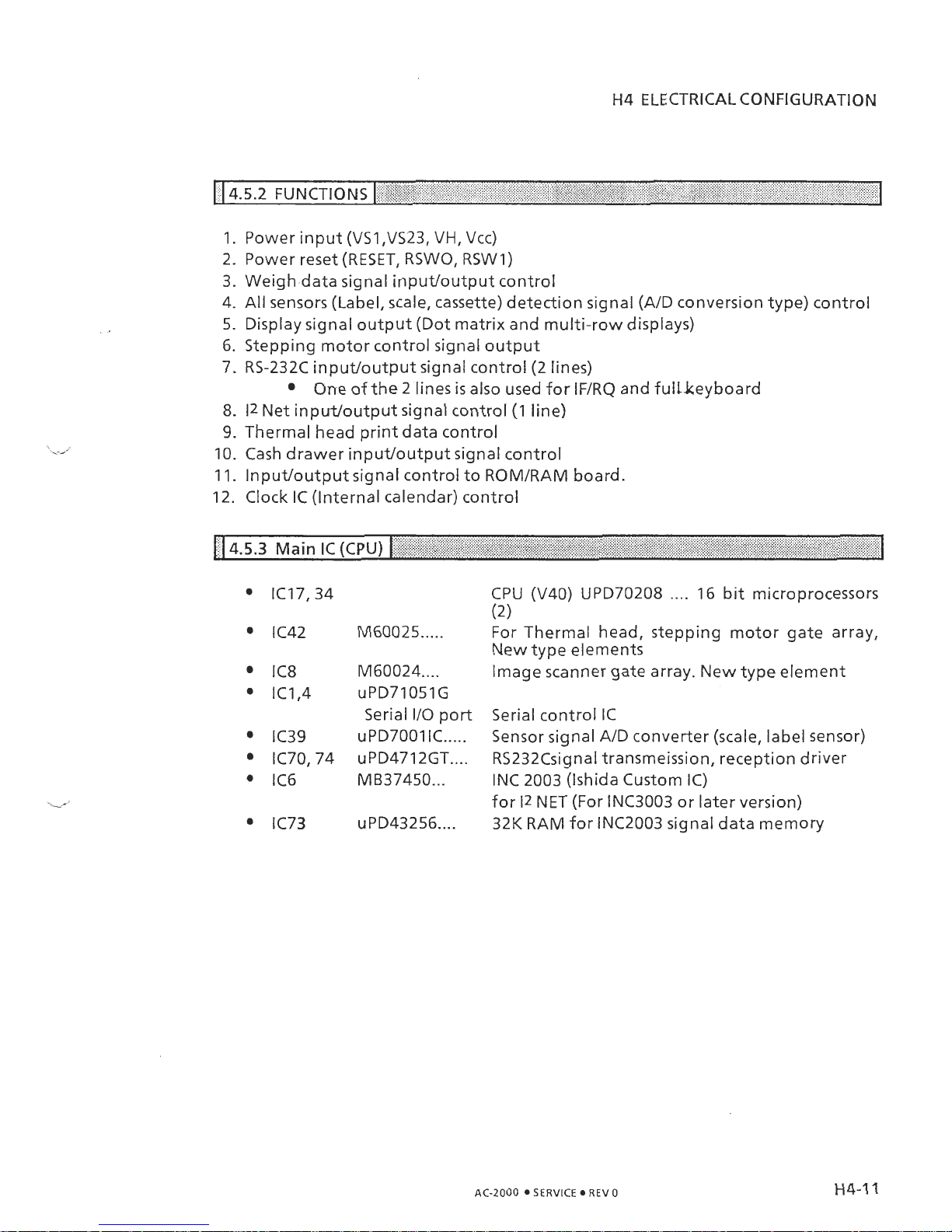

14.5.2 FUNCTIONS

I

'

,

,

>"

I

Power input (VSI ,VS23, VH, Vcc)

Power reset (RESET, RSWO, RSW 1)

Weigh.data signal inputloutput control

All sensors (Label, scale, cassette) detection signal (AID conversion type) control

Display signal output (Dot matrix and multi-row displays)

Stepping motor control signal output

RS-232C inputloutput signal control (2 lines)

One of the 2 lines is also used for IFIRQ and fullkeyboard

12

Net inputloutput signal control (1 line)

Thermal head print data control

Cash drawer inputloutput signal control

Input/output signal control to ROMIRAM board.

Clock IC (Internal calendar) control

,

%%

,%

J*

,

.I

4.5.3

Main

IC (CPU)

I

,,

,2-,

.

,

.:

",

,

.

M6OO24

....

uPD71051G

Serial I10 port

uPD7001

1C

.....

uPD471 2GT

....

MB3745O

...

CPU (V40) UPD70208

....

16 bit microprocessors

(2)

For Thermal head, stepping motor gate array,

New type elements

Image scanner gate array. New type element

Serial control IC

Sensor signal AID converter (scale, label sensor)

RS232CsignaI transmeission, reception driver

INC 2003 (Ishida Custom IC)

for

12

NET (For INC3003 or later version)

32K RAM for INC2003 signal data memory

AC-2000 SERVICE REV 0

Page 31

H4

ELECTRICAL CONFIGURATION

~I,G.'HL~z~~

1

P-751

COMPONENTS

I

ROMiRAM SWlTCrilNG

IO

(CHiP2)RAM

11

ROlUTdNl

JP(IPI-IPS)

FOR

OPT~DNS

I~(CHIPI)

ROM

MAIN PROGRAM

ROM 12BK

IATTERY SW

LITHIUM EAT

3.8

V

ICI

(CHIPO)

MAIN PROGRAM

ROM 128K

IClO (CHIPO)

THERMAL

PROGRAM ROM

(12BK)

-

lCll (CHIP

5)

ROMIRAM

ROWRAM

SWITCHING

2

IP(IP6-JP10)

IC19 MN62a12

CHARACTER ROM (16x16) 115

CAUTION: Danger of explosion if battery

is

incorrectly replaced. Replace only with

the same or equivalent type recommended by the manufacturer. Discard used batteries according to the manufacturer's instructions.

AC-2000 SERVICE REV0

Page 32

H4 ELECTRICAL CONFIGURATION

,FIG.

H4-6-B

ROMlRAM BOARD EXTERNAL

VIEW

IC41 €2 PROM (8K)

IC42 RAM (128K)

Ill.,"

AC-2000 SERVICE REV

0

Page 33

H4

ELECTRICAL CONFIGURATION

>.

14.6.1

DESCRIPTION

I

, ,

1

1. This main board performst all contol functons for the AC-2000 software programs via ROM, character table ROM, Memory RAM (256 bite),

E2

PROM (8K

byte)

etc.

AID

converter data processing, totals data, thermal print data, sensor

data, keyboard input and output control and data backup functions are per-

formed here.

2. Program

Main Proqram

ROM Chip 0 (IC1) 128K bite (1 M bit) D27C100A 1 pc.

Chip 1 (IC2) 128K bite (lM bit) D27C100A 1 pc.

RAM Chip 2 (IC3) 128K bite (1 M bit) Available (option)

Chip 3 (IC4) 128K bite (1 M bit) Available (option)

Thermal Proqram

ROM Chip 4 (IC10) 128K bite (lM bit) D27C1001A 1 PC.

Chip 5 (IC11) 128K bite (lM bit)

ROWRAM

Available (option) 1 pc.

3. Ram staNdard package (POS type) soldered

HN62818L (IC42) 128K bite (1 M bit)

1

pc.

HN62818L (IC27) 128K bite (1 M bit) 1 pc.

4.

E2

PROM electonically programmable and erasable.

HN58C65 (IC41) 8K bite (lM bit) 1 PC.

5.

Character ROM (16x16) JIS standard

HN62412 (IC19) Hitachi

6. Clock circuit

Clock IC

MSM62X42

BRS

(IC9) CalendAr included (with leap year)

1

pc.

AC-2000

SERVICE 0 REV

0

Page 34

H4 ELECTRICAL CONFIGURATION

7.

ROMIRAM Switching (JP) setting

Location

NO.

Chip 3 (IC4)

Location No. Chip

5

(ICI

1)

[ROMIRAM switching available for socketted

chip]

JP

Switchinq Method

1

1

+

for

Switchirqlack

(JP)

2

;;::;:;:::

...

. . . .

2

Ill

1,Z

jumpersfor

RAM

)

JP Switching Range

CHIP

3

(IC4) sockets: JP1 -JP5

CHIP 5 (ICll) sockets: JP6-JP10

NOTE: This switching operation applies when options are being used.

At factory shipment, the

JP

swithcing position

is

on the RAM

side.

8.

Data Backup

Battery

Switch

Make sure the battery switch for memory backup

is

set to

ON

at time of de-

livery.

NOTE: This scale uses a rechargeable lithium battery; normal charge:

3.8

V.

Average life: 10 years. Battery switch

is

set to ON at time

of shipment from factory.

CAUTION: Danger of explosion if battery is incorrectly replaced. Replace only with

the same or equivalent type recommended by the manufacturer. Discard used batteries according to the manufacturer's instructions.

AC-2000 SERVICE REV 0

Page 35

H4

ELECTRICAL CONFIGURATION

1.

Remove the two main body casing screws at the rear of the scale.

2.

ROMIRAM board

(P-751)

is mounted here. 'The lithium battery and switch

1

are located

at

the lower center area.

#

1-

DISPLAY POLE

/

ROM/RAM BOARD

REAR COVER

3.

Remove the rear cover. Check that the battery switch is ON.

LITHIUM

BAUERY

(3L.W)

AC-2000

SERVICE REV 0

Page 36

14.8.1

FUNCTIONS

1

.

I

Each sensor (peeling, label, cassette) signal is communicated to the main board

(P-750) J8 via J5 jack, and flat cable.

CIRCUIT DIAGRAM

J

4

CASSETTE SENSOR

JST 81

4P-SHF-l AA

(NHCN)

13

LABEL SENSOR

JST

B6P-SHF-l AA

(NHCN)

12

PEELING SENSOR

JST 847-SHF-1AA (NHCN)

11

LCD

JST

87P-SHF-l AA

(NHCN)

AC-2000

SERVtCE REV

O

Page 37

H4

ELECTRICAL CONFIGURATION

THE AC-2000 uses

2

types of fluorescent displays: full dot matrix and 7-segment.

The full dot matrix display is used for displaying' alphabetical messages. The

7-

segment display is used to numerically display weight, price etc. For electrical conversion, a DC/DC converter

is

used.

(SV,

12

V)

0""

\

POWER DUDC CONVERTER

CAUTION

i

1.

Do not plug the cable in or pull out with the power switch turned on.

I

I

1

2.

Be careful toa-void applying shock or pressure to the display. When handling

I

I

the display with bare hands, be catfeful to avoid injury.

I

I

I

I

AC-2000 SERVICE REV0

Page 38

H4

ELECTRICAL CONFIGURATION

The peeling sensor controls label issue. The set cassette no. and label size determines tahe amount of label advance.

NOTE:

During label printing, if there is no label pqeling operation, the next label will not be printed. Label peeling

is

only activated during label

printing (according to cassette number). During receipt printing the

signal

is

disregarded.

PROJECT

14.1

0.1

FUNCTION

1

,

,

,

,

,,

^

When label advance starts and the label interrupts the light axis, the label

is

ad-

vanced the distance set. Therefore,

if

the label size are misset, the proper label ad-

vance cannot be executed.

AC-2000 SERVICE REV 0

Page 39

H4 ELECTRICAL CONFIGURATION

,

,

_(\

14.10.2 POLARITY

I

,,

,

,

-<

CI'

1

The sensor has polarity: take note when replacing.

P-612A face (Projectorside)

JP

P-612A face (receptorr side1

CATHODE

EMITTER

ANODE

Sensor Type: SE

307

COLLECTOR

Sensor

Type:

H

1

10

SENSOR RELAY BOARD

(P-755)

SENDER SIDE: ANODE To J2

1

pin

CATHODE ToJ2 2

pin

RECEIVER SIDE: COLLECTOR To

J2

3

pin

EMITTER

TO

J2

4

pin

AC-2000 SERVICE REV0

Page 40

H4

ELECTRICAL CONFIGURATION

The label sensor controls a stepping motor, which regulates label advance.

LABEL SENSOR EXTERNAL VIEW

The label sensitivity adjustment device with a flashing

LED

is located at the right rear

side

of

the main body.

ADJUSTMENT POINTS

AC-2000

8

SERVICE

REV

0

Page 41

H4

ELECTRICAL CONFIGURATION

*\

,

.

I.

\,

(4.1 1.1

LABEL

SENSOR UNIT

1

;

.

I

FUNCTIONS

I.

Sensor unit

The reqistered liqht siqnal is output to the sensor sensitivitv adiustment

< <

.,

,

board (P-545).

1

Sensor sensitivity adjustment board

(P-545)

For adjustment instructions refer to

H6.10

I

Output jack

Connected to the sensor interruption board

(P-755)

J3

jack

.:

....

..:.:.:.:.:<.:.:

........

.;.:>..

...

:.:.:.:.:

.:.::

:6f%Bi/ifS$-~~$fi:1:;:

........

LAB EL SENSOR EXTERNAL. VIEW

::,:::::;:,'::':'.:i(':jr;.jj.

.:.,,:

I.

Sensor:

Detects the lighting volume difference at label gap area, and

output signal to Sensitivity ad-

jurtrnent Board (P-545)

I

2.

Sensitivity Adjustment Board

(P-545):

To adjust proper sensitivity.

Refer

H6

6-10

,Sensor Adjust-

ment

3.

Output connector

TO SENSOR INTERRUP-

TOR BOARD

(P-755)

J3

,:.:

..;.

:i.,:::::.:j:':.

.......................

~~I~~~,B$-z~~z:<:I

.:...:.:..'

......

:.:

...

......................

...

.:

::

....

SENSOR INTERRUPTION BOARD (P-545)

1

.......

BROWN,

,

BLANK

LED

BLACK

CONNECTOR COLOR

I

P-545

I

1

BROWN

1

2

RED

2

3

ORANGE

I

3

4 YELLOW

1

4

5

GREEN

I

5

AC-2000

SERVICE

REV

0

Page 42

H4

ELECTRICAL CONFIGURATION

FIG.

H4-23;A

CASSETTE SENSOR AND SENSOR SEAL LOCATION

SEAL

INDICATING NO.

CASSETTE

-

-

CASETTE SENSOR

SEAL ATTACHED TO REAR OF THIS PART

I

.,

,

.

CASETTE SENSOR AND CASS.ETTE

NO.

1

,'

1

The sensor is equipped with a photo interupto. When the sensor seal interrupts the

light beam the cassete sinal is dettected.

By

combinations of the cassette signals, the

cassete number is determined. Sensors

1-4

are combinations of

1,2,4,

and 8 for

a

total of

15

possible combinations.

NOTE:

Cassete no.

0

is

not available.

SENSOR

1

(2')

=

2

SENSOR

1

(20)

=

1

SENSOR 1 (22)=4

SENSOR

1

(23)=8

AC-2000 SERVICE REV

0

Page 43

H4

ELECTRICAL CONFIGURATION

Note the following points:

1.

Cassette

number and sensor number must be correct

2.

Cassete seals at front and rear must match

3.

Take care that the seal does not fall off

CASETTE

(2-1

5)

I

I

LABEL

WIDTH

ADJUSTMENT

I

9

I

n

f7

Set

the label width

to conform

with the users

requirements.

LABEL

GUIDE

LABEL

GUIDE

I

Align the 2 label

gu~des

with the width of the roll

SCREL;,

\-d

SCREW

AC-2000

SERVICE REV

0

Page 44

H4

ELECTRICAL CONFIGURATION

FIG.

~4:25-~.

I

EXTERNALVIEW OF

SIDE

PANEL CONNECTOR

-.

CONECTOR

4

'

'

CAP

CONNECTOR

1

:

Available at time of System start-up (i2 NET)

2:

R

I1 I1

,I

3

:

Cassette Loading (RS-232C)

4

:

Option (RS-232C)

NOTE: Please cover unused connectors with caps

AC-2000

SERVICE REV

0

Page 45

H

5

THERMAL

HEAD

This chapter describes the mechanical confi uration and electrical adjustment of the

thermal head as well as information relate to its function. The following items are

covered

:

3

Specifications

Thermal head configuration

Function

Adjustment

)

Mechanical adjustment

)

Head resistance and print density adjustment

This thermal head

(€60-74C

Mitsubishi) used

is a 448

dot high resolution type with

7.4

dotlmm. The printing is configured one row at a time.

NOTE:

Do not use a different type of thermal head in the

AC-2000.

I

I~oltaqe

0.84

W or less

I

Total Dot count

Dot dimensions

Resistance

Voltage dropdown

1

V

Head Print Volt. Max VH

+

Rx0.84

+

1

V

448

dots

0.135

mm

(W)

X

0.155

mm

(H)

R

=

600-700

ohms

AC-)000

SERVICE

8

REV

0

Page 46

H5

THERMAL HEAD

FI~.

H-5-3-A

I

HEAD RESISTANCE

1

Head

resistance

value

-b

RXXX

Surface Pattern:

rear view

Head resistance

(Q)

1

RG.

5-i-0

I

CIRCUIT DIAGRAM

I

I

1

I

CATCH

I

I

I

DATA

0

448-------

--I

1

CLKo

I

J

AC-2000

SERVICE REV

0

Page 47

H

5

THERMAL HEAD

,

U

5.4.1

ADJUSTMENT ITEMS

I

I

1.

Mechanical adjustment

2.

Thermal head resistance value adjustment

3.

Strobe pulse duty ratio adjustment

[I

5.4.2

MECHANICAL ADJUSTMENT

I

,

,

,,

,

,

A,

I

1.

Purpose

In order for the thermal head to print out a line, the head's line and the top line

of the print roller must be aligned to the same position. If misaligned ,the entire width of the line will not be printedclearly. By adjusting the installation position of the thermal head, this adjustment can be made.

2.

Adjustment Method

Loosen the

head screws, and align the thermal head and sii htly retighten

3

the screws. The head should be aligned so that the the printe characters are

sufficiently and consistently darkthroughtout a line. Finally, tighten the head

screw.

[::FIG.

54-A

1

ADJUSTMENT POINTS

Y'

""

-

'

%.;.

'

.

NOTE:

The print roller is made slighly wider in diameter compared with previous

models so that clear, consistent printing

is

still

maintained even

if

roller and head is

slightly misaligned. To ensure correct adjustment, change the Head resistance value

higher, only for adjustment purposes.

AC-2000..4

S~RVICE

4 REV 0

Page 48

H5

THERMAL HEAD

15.4.3 THERMAL HEAD RESISTANCE ADJUSTMENT

I

%

,<

,

I

Purpose: To compensate for variations of head resister value and ambient tempera-

ture variations. AC-2000 controls the apply voltage duration timning in-

stead of varying head voltage.

Applied voltage

is

fixed at 24V.

The method of adjustment

is

as follows:

1.

Press number 3 in the test mode

2.

Press the DOWNISET key.

3.

The

Head

Check

display appears.

4.

Align cursor with the resistance value setting position

5. With the key switch in the SET UP position enter the resistance value (inscribed

on the thermal head) via the ten-key pad and press the DOWNISET Key.

6..

Press the PRINT key to print the test.

7-

Ln

th.isconditim.d.ensity

can

be fine adjusted via-the up and down cursor keys

NOTE: For details on the Test Mode, see Chapter 55.

KEY

SWITCH

AND

TEST PRINT

LABEL

I

KEY

SWITCH

I

TEST

PRINT

LABEL

To clear the PRINT USAGE value:

Align cursor with the PRlNT USAGE item and press the ZERO Key

2

times. The

cursor will shift simultaneously with clearing. Always perform this procedure

when replacing the head.

AC-2000

SERVICE

REV

0

Page 49

H

5

THERMAL

HEAD

15.4.4 STROBE PULSE DUTY RATIO ADJUSTMENT

(

*',

,

'*

,

I

Depending on the printing frequency and the ambient temperature, the thermal

head temperature will vary. This means that printing quality may vary when using

high-sensitivity labels or receipts. For this reason the pulse duty ratio is adjusted.

MAIN

BOARD

P-750

TP1 is set to 3.3 V at time of factory shipment (VR1). Do not

set

to other than the

prescribed level.

To adjust:

1. Measure the voltage between TP1 and TP3

(GND).

2.

Adjust to 3.3 V.

3.

The normal temperature can be diagramed as the following wave pattern.

0.8

msec

l-1

NOTE: There

is

normally

no need to set the strobe

pulse ratio

(64%).

When

needed set via (VR1) only.

I+-+

1.25

msec

AC-2000 SERVICE REV 0

Page 50

H6

ADJUSTMENTS

This chapter deals with mechanical and electrical adjustment points. For thermal

head-adjustments, refer to Chapter

H5.

1.

Four-corner limit adjustment

2.

AID

converter initialization value and span adjustment

3.

Peeling sensor and label sensor adjustment.

A limit is provided

by

the platter stand to protect the load cell from excessive

external load. Adjustment

is

made at each corner of the platter supporter.

AC-2000

SERVICE

REV

0

Page 51

H6

ADJUSTMENTS

€l6:,&3-5

I

ADJUSTMENT POINTS

I

,

,,>

I

CUSTOMER SIDE

I

I

SHOP CLERK SIDE

I

1. For each corner

A-D

consecutively, place a capacity weight + 1Kg on the

corner.

2.

Loosen the fixed nut and turn the limit adjustment screw so that

it

contacts the

upper case set screw.

3.

Tighten the fixed nut.

NOTE: This adjustment

is

necessary when replaing load cell or excessive load

is

applied to the load cell.

If

the

AID

value falls outside a certain range, the scale cannot compute the weight.

The initial value adjustment ensures that this range

is

maintained.

1

ADJUSTMENT PROCEDURE

1

I

1. Press the RESET Key then immediately press any key. The

TEST

MENU

display

will

appear:

I

TEST

MENU

[PAGE]

113

1

:

HARDWARE TEST

2.

RAM CLEAR

3:

THERMAL HEAD

4.

SENSOR CHECK

(

0)

AC-2000 SERVICE REV 0

Page 52

H6

ADJUSTMENTS

2.

Enter

#1

and press the DOWNISET Key. The Hardware Test Menu display will

appear:

[PAGE]

113

1

:

AID

CHECK

2.

KEY CHECK

13:

DISPLAY CHECK

4.

PROGRAM

No.

I

3-

Enter#l and pres the DOWNISET Key.

The AID Check Display will appear.

AID CHECK

FIGURE

(9)

[PAGE]

113

*AREA+(SET] ZERO POINT+[ZEROI

I

The AID value will be displayed. In this mode the AID check, AID initial value adjustment, span adjustment etc.

is

performed.

NOTE: Refer to Chapter

55

for more detailed information onTest Mode.

AC-2000 *'SERVICE REV

0

Page 53

H6

ADJUSTMENTS

1.

Press the

ZERO

Key. The

AID

value display will show "0",

2.

Place the span weight specified below on the weigh platter

130

LbISingle Range

I

30~b

I

CAPACITYIRANG E

*

15 KgISingle Range

Press the

UP/T

Key.

Verify that the

AID

display shows 3Q,000 count during span adjustment,

Remove the span weight from the platter.

To perform fine span adjustment, place the span weight on the platter and

press the up and down cursor'keys

AV.

After span adjustment or initial

AID

adjustment is completed, press the button

on the

AID

board.

SPAN ADJUST WEIGHT

15

Kg

AC-2000

SERVICE

REV

0

Page 54

Page 55

H6

ADJUSTMENTS

Purpose: The adjustment is made to prevent notch feeding of label in case the axis

of sensor

is

misaligned by external interference

SENDER SIDE

PLATE

SENSOR LIGHT SHAFT

-

-\

SENSOR ATTACHMENT SCREW

I

'

SENSOR ATTACHMENT PLATE

16.7.1 ADJUSTMENT METHODS

1

',

1.

Loosen the sensor attachment screw and align the light axis.

2.

Move the sensor attachment plate and align the light axis.

3.

Align the light axis by bending the plate on the label sensor receiver side.

8,

,,

,

.

16.7.2 ADJUSTMENT VERIFICATION

1

, ,

A)

, ,

.

A,z,

*-A

,,.

%

I

See Chapter

55:

5.6

Test Mode.

AC-2000 SERVICE *REV 0

Page 56

H6

ADJUSTMENTS

1

(

6.7.3

PEELING SENSOR SENSITIVITY LEVEL VALUES

I

,

,,

Y

,

The sensitivity count show. Therefore the peeling sensor value which

is

displayed in

test mode

4

corresponds to the count as shown below.

Count standard value

(Count

+

0.02V.)

Peeling sensor voltage at time of light transmission

........

1 volt or less

Peeling sensor at time of light interrupt

....-...

4

volts or less

Therefore the Peeling sensor count is:

Peeling sensor voltage at time of light transmission

........

50

count (1 volt) or less

Peeling sensor attirne of light interrupt

........

200 count

(4

volts) or less

,

,

11

6.7.4

CAUTION POINTS

I

:\

Make sure there

is

no foreign matter on the sensor components

Verify power activated condition (Test Mode)

.A.

In the test mode menu enter

'4'

and press the +Down Set Button

2. The sensor check screen will appear:

SENSOR CHECK

[PAGE]

113

LABEL [255]

CASSETTE

[I]

CHECK

PEELING

[01

AC-2000 SERVICE REV 0

Page 57

H6

ADJUSTMENTS

~djustment Method A

1.

Turn the Fine Adjustment

VR

all the way counterclockwise.

2.

Press the Feed Key lightly one time, and turn the fine adjustment

VR

clockwise

until it corresponds with the position of one label advance. This

is

position A.

3.

Turn the Feed VR all the way clockwise.

4.

Press the Feed Key lightly one time, and turn the fine adjustment VR counterclockwise until it corresponds with the position of one label advance. This

is

posi-

tion

B.

5.

Set the VR halfway between positions A and

B.

NOTE:

If

B

cannot be determined, rotate the rough adjustment

VR

clockwise a lit-

tle and perform procedure again from

1.

Adjustment Method B (When range cannot be determined via fine adjustment VR)

1.

Align the Fine Adjustment VR to the center position.

2.

Turn the Rough Adjustment

VR

all the way cou&erclockwise.

3.

Press the Feed Key lightly one time, and turn the rough VR counterclockwise until

it

corresponds with the position of one label advance. This is position

C.

4.

Turn the Rough Adjustment VR all the way clockwise.

5.

Press the Feed Key lightly one time, and turn the Rough Adjustment

VR

counter-

clockwise until

it

corresponds with the position of one label advance. This is posi-

tion

D

.

6.

Set the VR halfway between positions C and

D.

7.

Perform Method A again.

NOTE: Upon delivery or during regular check of the scale, set

B

after setting A.

AC-2000 SERVICE REV 0

Page 58

H7

INSTALLATION

1.

Open the carton and check the scale and

its

components for damage.

2. Attach the weight platter and the display unit (including the pole).

3.

Insert power plug into a power outlet.

4.

Perform the Initial Set Up procedure in Test Mode 2 (page 212).

5.

Perform RAM clearin Test Mode 2 (page 112).

6.

Set the scale to conform to the users requirements:

Label format, label advance distance etc.

7.

Register the day and time.

8.

Register PLU Master Files etc.

9.

Insert the label or the receipt cassette, and determine if printing quality is nor-

mal.

10.

Clear Totals.

11.

Download all registered data to cassete or floppy disk as back-up.

12. Perform aging with the power

SW

still on.

NOTE: The installed lithium battery requires no aging

(10

year life-span).

AC-2000 SERVICE

REV

0

Page 59

H8

MAINTENANCE

This chapter contains cleaning, inspection, maintenance, and troubleshooting pro-

cedures for the dealer and user so that the scale

is

kept in its best operating condi-

tion.

When there

is

a malfunctioning unit reported by the user, unit replacement

is

the

usual countermeasure. The following table shows the necessary specifications for

the components used in the AC-2000.

PART NO. PARTNAME

I

SPECS

I

NOTES

I

I

1

PWB, P-750' B l~ain Board

I

I

I

PWB, P-751' A

1

RAM

board

1

I

PWB, P-752' A Keyboard

PWB, P-753' A Connector BKT

PWB, P-755'

Sensor interrupt

1

board

PWB, P-756'

Cassette sensor

1

board

I

PWB, P-704' D AID board

LC

Unit, CLC-25L 15 Kg130 lb

Stepping motor AS Orental PH266-01-C48

Fluorescent display URA

UDD-348E

Power supply

Sanken Main

D L-482

L

switchinq

1

OOVl115V

Power supply Isanken Main

I

DL-482

H

switching 22OVl24OV

Power supply

switching

I

Sanken Thermal

100V1l

5V

I

DL-481

AC-2000 SERVICE 0 REV 0

Page 60

H8

MAINTENANCE

AC-2000 SERVICE 0 REV 0

No-

"

16

17

18

PARTNO.

16-6527-01

18-3003-00

18-3004-03

09-2755-1 1

PART NAME

Power supply

switching

Fluorescent display

panel

Fluorescentdisplay

panel

Label sensor unit

SPECS

Sanken

Thermal

NEC

NEC

NOTES

DL-481

H

ZZOV,240V

FM256GX64

AB-100A

FM-PIS-001

P-545C, PN 150

(C)

Matsushita

Page 61

H8

MAINTENANCE

1.

Thermal head printing surface

If ink, glue or dust from the label gets stuck to the thermal head print surface,

heat will not be properly transferred to the label causing poor print quality.

2.

Print roller

The print roller drives the label feed. If dust from the label gets stuck to the

roller,

it

could cause improper label feed.

NOTE:

Clean with the attached cleaning pen dipped in filtercleaner.

When the cleaning pen and filter cleaner are not available, wipe with a

clean cloth moistened with benzene.

When cleaning the head be.very careful not to scratch or damage it.

Never use thinner for cleaning the head.

3.

Label sensor

-

Do not clean the label sensor with hard or abrasive materials

If foreign matter attaches to the sensor sensitivity will be reduced and

malfunction may result.

AC-2000 SERVICE

REV

0

Page 62

H8

MAINTENANCE

The inspection points listed below should be performed by the operator as a habit.

Early detection of

a

problem not only ensures proper machine operation but

extends machine life

as

well.

Be sure to turn power off when performing inspection. Turn power on only when

required to check operation.

-

No.

-

1

-

2

-

3

Inspection kern

Remove scrap prod"&

from and clean scale

surface

Remove scrap product

from and clean inside

scale.

Check installation and

operation

Location

I

Rernarl

Weigh Platter

Upper Case

Main Unit Base

Front Cover

Side Cover

Keyboard Sheet

Display

Level Window

Use

dry

cloth.

Underneath Platter

Label sensor

Cassette

Thermal Head surface

Print Roller

Use dry

clothlcleanin!

Check level (visually).

Touch scale; check that it

is

affixed securely.

Check that label feed

is

smooth.

Check each key function.

Check display.

CAUTION

-

I

f

Be

sure to turn power off when performing inspection. Turn power on only

1

when

it

is

requred-to check operation

I

I

L-----------------------------------------------------------------------------A

AC-2000 SERVICE REV

0

Page 63

H8

MAINTENANCE

Pre-maintenance procedures should be performed every 3-4 months.

8.5

PREVENTIVE MAINTENANCE

-

lo.

-

1

2

-

3

-

4

-

5

-

6

-

%

,

,,,

%,,

,,"$,,

'C

,

:,

Inspection Item

I

Location

lemove scrap product

rom and clean scale

urface

Weigh Platter

Upper Case

Main Unit Base

Front Cover

Side Cover

Keyboard Sheet

Display

Level Window

temove scrap product

rom and

clean

inside

cale.

:heck installation and

)peration

Underneath Platter

Label set location

~hermal Head surface

print Roller

Check level (visually).

Touch scale check that

it

is

affixed securely.

Check that label feed

is

smooth.

Feed should be quiet

Check la be1 sensitivity

adjustment

Check print position

etc.

Check display on store and

customer sides.

Check A/D value output

including initial and span

values.

Check label take up.

Inspect friction plate for

dirt.

Check print quality.

Zheck parts functions

Check that screws are

tight and connectors

are plugged in securely

Check function keys for

intermittence, chattering,

Thermal head cable.

External output connect01

rust (for cassette loading).

Printer.

Remarks

Ise

dry cloth

Other

Jse

dry cloth

Four corner load cell limit

adjustment.

Print roller damage.

Jse

cleaning pen

Use span weight.

Visual inspection

AC-2000

SERVICE REV

0

Page 64

H8

MAINTENANCE

[I

8.5.1

MAINTENANCE CAUTIONARY INSTRUCTIONS

I

z

:,,

A

,

'

.,

,

,

,"

,

..,,

,

,

I

Be

sure to follow the items below to ensure personnel safety when performing

maintenance, disassembly, assembly, adjustment and pre-maintenance.

1.

Turn power

OFF

and unplug power cable from socket and detach completely.

2.

Clear surrounding work area. Remove label set on printer.

Be sure that no parts, screws or papers fall into the internal mechanisms or

electronics during maintenance.

3.

When plugging in or unplugging connectors, be sure to rip the connector and

not pull by

the

cable wire. In particular, malfunction oft

8,

e thermal head cable

can result in temperature detection failure resulting

in

overheating.

4.

Take extra care when cleaning the thermal head and print roller to avoid

scratching their surfaces.

5.

Be sure to follow all instructions for assembly and adjustment procedures

completely.

AC-2000 SERVICE REV 0

Page 65

H8

MAINTENANCE

p,

9,'

5, %

2"

.

..

.:g

'

,,

,

<..

,

,

...,

8.6

TROUBLESHOOTING

,

I

The following causes for malfunction are the most probable and common ones.

Other factors may lead to abnormal functioning of the scale.

AC-2000 SERVICE REV 0

Page 66

H8

MAINTENANCE

-

No.

-

1

-

2

Condition

llank display when

lower turned

ON

kale enters Test Mode

after power switch is

urned on

'Just a moment! Scale

swarming up!"

lisplay does not extnguish

'Just a moment! Scale

swarming up!"Dis)lay appears when

3ower turned on.

Neight, price. unit price

jisplays read "0".

Neigh reading in error

3

r

Nei h reading varies by

tse

I

9

I

display column or

;egment doesn't light

3r does not extinguish

Probable Cause and Checkpoints

1.

Power cable not plugged in.

2.

Main fuse is blown.

3.

Voltages absent on

JlO,

Jl,

J14on Main

Board (P-750)

a. Connector unplugged.

+Check power unit side, too.

b. Connector miscontact.

+Check power unit side too.

c.

Faulty power supply unit

+Check

Vcc

(

+

5V) 7-segment display.

+Check Display drive V12 (Dot display)

(+

SV)..

+Check RST

is

<3V

4.

Main board defect

5. ROM, RAM board defect

6.

Power Switch defect

7. Power switch connector defect

1.

Key board short circuit

2.

Main board defect

-his indicates that the initial AID value

is

most

ikely unstable;

1.

Load cell defective

2.

External vibration influencing weigh

components

3.

Defective main board amp circuit

4.

Defective power unit (unstable

+

8V,

-1

5v)

1.

Check Key switch cable and its connection

2.

Key SW defect

3.

J2

connector on Key board (P-752) contact

defect

4. J4 connector on Main board (P-750) contact

defect

1.

Mechanical fault.

a. Lo-ad cell or

its

mount

is

hitting limiter.

b.

Foreign object stuck under or contacting

platter.

2.

Electrical Fault.

a. Defective Load Cell

b. Main board amp circuit defect

1.

Program not running

2.

J5 connector on Main board (P-750) contact

defect.

3.

Main board (P-750) defect

4.

Display board defect

AC-2000

SERVICE

REV

0

Page 67

H8

MAINTENANCE

-

'lo.

-

7

Condition

i<ey fault

3egisttered information

altered

Display goes out

completely during

operation

Label or receipts not

printed

Prints only on left or

right half of paper

"Check Label Cassette"

message appears

"Remove The Item on

the Platter" message

appears

NV

RAM Data Lost"

message appears

"RAM Data Lost"

message appears

"Mark Down Price

Over" message appears

Probable Cause and Checkpoints

1. All keys fail to operate.

a.

J4

connector on Main board (P-750) pulled

out

b. Main board (P-750) defect

2. Specific key fails to operate.

a. Key or key matrix problem.

+Cable open or poor connection.

+

Main board (P-750) defect

+

Key board (P-752) defect

--

1. Battery defect

2. ROMI Ram board defect

3.

Influence from external noise, static

electricity

1. Drop in AC input voltage.

2. Power unit reset circuit defect.

1. Contact defect in thermal head cable

2. Thermal head print voltage out

a. Power unit defect

b.

Check thermal head resistance value

(Head Check) via Test Mode

3

3.

Main board (P-750) defect

4. Thermal head defect

1. Main board (P-750) defect

2. Thermal head defect

3.

Strobe signal (either STB1 or STB2) not active

4. Thermal head connector cable defect

1. Cassette mis-inserted

2. Label or receipt specifications misset

a. Check Set up mode, Label Format.

b.

Check cassette sticker

3.

Cassette sensor defect

a. Check Test Mode 4, Sensor Check

4. Main board (P-750) defect

1. Check that platter is clear

1. Reset initial value data

2.

NV

RAM defect

3.

AID board (P-704) defect

1. RAM data lost, Clear RAM data (Test Mode 2)

2. ROM, RAM board (P-751) defect

3.

Main board (P-750) defect

1. Check mark down price

AC-2000 SERVICE REV 0

Page 68

H8 MAINTENANCE

\lo. Condition

17

"Memory Over"

message appears

I1'Over Character1'

message appears

"Over CharacterIPOP"

message appears

20 "Over CharacterIReg."

message appears

21

"Label End" message

appears

-

22 "Label Size Error"

message appears

"Label Size Set Error"

message appears

Probable Cause and Checkpoints

1.

During operation: Remove totals report and

clear totals

2.

During registration: Remove totals report

and clear totals. Or Delete unnecessary; PLU.

If necessary take backup via IFIRQ, and Clear

ram

(

Test Mode

2)

1. Re-register (Too many characters in

registration item.)

1.

Re-register (Time of ad messagetoo long.)

1. Re-register (Excessive Reg. code)

1.

Label paper end.

.2.

Cassette defect

a. Label advance mechanism defective

3.

Motor not rotatin (stepping motor)

a. Cable contact efect or connector contact

defect

3

b. Motor defect

c. Main board (P-750) defect

d. power unit (DL-481 side defect

4. Peeling sensor defect (Test Mode 4)

Only when label

is

not inserted after

peeling sensor catches the label end

1.

Check label format setting

2. Set to

1

via Key Switch

1.

Check labelformat setting

2.

Set to 1 via Key Switch

AC-2000

SERVICE

0

REV

0

Page 69

H9

PARTS

This chapter contains the principle parts used in the AC-2000.

SPECIFICATION.

OPERA TlON UNlT

--

I

Keyboard

Key Sheets (Normal, Totals, [Test Mode])

P-752

one of each

Switch Key (Operator's, Supervisor's)

I

one of each

LOAD

CELL

UNlT

I

Load Cell

1

CLC-25L (1 5Kgl301b)

Rated Capacity 25 Kg

I

.,

Rated Output 1.95 mvN

Input Resistance 405

2

1OQ

Output resistance 350

2

5R

A l D BOARD

(P-

704)

I

AD converter

CPU

I

ILD1001 (Ishida custommade IC)

uPD75104 (4 bit microprocessor;

2

KROM internal)

DIA converter

Analog SW (M-ultiplexor)

CPU (V40)

1

uPD75208

DAC0832

D4053

Power Regulator

NV-RAM

MAIN BOARD (P-750)

Gate array

1

.M60025

,70L05,79L12

S2444R (S24S45R)

AC-2000

SERVICE REV

0

I

12

NET transmission

M37450 (INC2003 lshida

custom-made IC)

Page 70

H9

PARTS

U

NITIPART

I

SPECIFICATION.

I

RS

232C Buffer

1

uPD47129

AID Convert

RS

232C Signal Transmission.

ROM I RAM BOARDS

(P-751)

I

uPD7001C

uPD71051G

I

Clock IC board

I

MSM62 X 42 BRS

Character Table ROM (1 6x1 6)

RAM (POS type) soldered installation

HN62412FPW01 (Hitachi)

HN628128L (128K) (Hitachi)

ROM (program)

Data switchover board

DISPLA Y UNIT

I

Fluorescent display DCIDC converter

I

UDD-348E

uPD27C100A

(1

28K)

HC541 P (Tri-State)

7-Segment display

X-Y Matrix fluorescent display module

CASSE77E SENSOR

I

FNI-PIS-00 1

.FM256GX64AB-l00A

PEELING SENSOR

I

Photointerruptor

LABEL SENSOR UNIT

PS4005 (NEC)

P-545C; PN 150 (Matsushita)

MOTOR

1

Projector side (on P-612)

Receiver side (on P-612)

SE

307 (NEC)

PH 110 (NEC)

AC-2000

SERVICE REV

0

Stepping motor

THERMAL HEAD

PH266-01 (Oleander)

E60-74C (Mitsubishi)

Page 71

S1

OUTLINE OF SOFTWARE

I

1

.I .I

MEMORY

MAPS

I

,

\

,

,*~

I

The memory map below refers to the main side memory data and Test Mode 6 described

in

Chapter

5.

ADDRESS

FFFFF

EOOOO

DFFFF

C0000

BFFFF

AOOOO

81

FFF

80000

5FFFF

40000

3FFFF

20000

IFFFF

0000

ROM (Ic1)

STANDARD FITTING

ROM (w

STANDARD FITTING

E2

PROM (IC41)

ROMIRAM (IC4)

(Option: RAM mode

at shipment

RAM (Ic3)

(OPTION)

RAM (Ic4)

STANDARD FITTING

ADDRESS

FFFFF

EOOOO

BFFFF

80000

5FFFF

40000

IFFFF

0000

(IClO)

STANDARD FITTING

STANDARD FITTING

I

I

1

ROMIRAM (IC11)

(Option: RAM mode

at shipment

1

RAM (IC27)

STANDARD FITTING

AC-2000 SERVICE REV 0

Page 72

51

OUTLINE OF SOFTWARE

RAM (IC

27)

is

used for printing (Initiated from the Main CPU side)

I

ROMIRAM

board

(P-750) Part

Side

1

I

ROMIRAM

board

(P-750)

Soldering

Diagram

E2

PROM

THERMAL

I...{

*,

'

I,

1

1.1.2

RAM

EXPANSION

.

~,

.

To increase RAM to add PLU, add in this order: IC3, IC4.

USE ONLY RAM PROVIDED BY ISHIDA'S SERVICE CENTER.

IF OTHER RAM ARE UTI-

LIZED, ISHIDA CANNOT BE RESPONSIBLE FOR MALFUNCTION.

AC-2000 SERVICE 0 REV 0

Page 73

51 OUTLINE OF SOFTWARE

PLU' NO.

ITEM

'CODE

POS CODE FLAG

.DESCRIPTION

ITEM LENGTH

POS CODE

UNIT PRICEIFIXED PRICE

FIXED WEIGHT

BITE COUNT

2

I

TARE

I

2

I

MARK DOWN FLAG

MARK DOWN DATA

1

3

POS FLAG

DATEfllM

E

MESSAGE 1-6

SHELF LIFE

USE

BY

PERIOD

FIXED PRICENVEIGHT FLAG

2

2

1

I

1 Character:

I

1

Bite

TAX

TAX RATE

FIXED LENGTH

46

BITES

1

2

MAX 1001 BlTE

(including

header

1

bite)

NOTE:

1. Start address for PLU Master is E000.

2.

No totals data is contained in PLU master file. The totals data

is

contained in the

area subsequent to the PLU master file (See 53).

AC-2000 SERVICE *,REV 0

Page 74

51 OUTLINE OF SOFTWARE

Fixed length

is

42

bites (totals are in separate area).

Product code is different from the POS code.

When the POS code

is

the same as the product, POS code registration

is

unnece-

sary.

Cost can only be registered as product information (not yet in use)

Mark down flag: 00

:

SPCL

01

:

-$

02

:

-%

03 : UIPrice

Expiry date/

Use by date

FF,

FF

:

Refer to

Set

Up

Mode

0

:

Prohibited

PRlNTlNG

1-998

:

Pack time, Shelf Llfe

999

:

Packtime only

1001-1998

:

Shelf Life only

Fixed pricelweig

ht

flag

00

:

Random weight

01

:

Fixedprice

02

:

Random weight WITH fixed price

POS flag

FF : Conform to Set Up Mode

01

:

13 digit Non-PLU

01

:

I3 digit PLU

Daterrime 00: Non printing

1-11

:

Manual print AM

**

I

PM**

12-23

:

24

:

AM) NOTE:

98

:

Internal timer print

It

is

necessary to modify format to print out Daterrime.

PLU file: Characters: One character bite (ASC 1 lcode)

Dictionary Word

:

2 bites per word

Example: A dictionary word

starting with the letter

"A"

C1H **H

Word reg. sequence No.

Code indicatin word

configutration

starts with

'4".

8

added

and contents

may

to

ASCII

bit (upper

---.A:--\

I

vary by country

I

puslLlurl,.

AC-2000

SERVICE REV

0

Page 75

S1 OUTLINE OF SOFTWARE

,I

[I

ITEM CODE AND POS CODE

1

,

,

1.

If the POS code registered in PLU item is

0,

the Item code

is

as shown here:

1

1

XX XXXXXXXXXX

POS

CODE

-

10

DIGITS

POS CODE

FLAG

POS CODE

2.

When PLU file POS code flag is SET FF

Conforms to setting input

in

Set UP Mode. When not FF, The POS code for the

PLU file takes precedence.

3.

When PLU file POS code is

"0"

Print according to the ITEM code. When not

"Ow,

the POS code for the PLU

file takes.precedence. The POS code for PLU items all take precedence.

AC-2000

SERVICE REV

0

Page 76

S1 OUTLINE OF SOFTWARE

1

1.3.1 CHARACTER TABLE

I

%

,

<,

,,

,,,

I

Three types of font, two of which have

X2

&

X4

size are available. (Total character

styles:

7)'

Type

3

15x30

I

30x60 1 650x120

dot

I

dot

I

dot

I

I

------------,-------------------------

I

I

I

I

I

I

I

I

I

I

I

I

1OX2.0

1

20x40 ( 4OX 80

dot

I

I

dot dot

......................................

I

I

7x14

I

dot

I

I

I

I

I

NOTE:

1.

The dimensions of one dot are:

0.15

mm

2.

Character selection may be limited

0.135

mm

according to the registration item.

AC-2000

SERVICE REV

0

Page 77

S1

OUTLINE OF SOFTWARE

The characters shown in the following chart do not appear on the keyboard but are

available.

METHOD:

Example: To access the exclamation mark:

1.

Press the

FEED~SHIFT

~e~.

2.

Press21.

3.

Press the

PLU

Key.

AC-2000 SERVICE REV

0

Page 78

S2

LABEL FORMATTING: USA

It is possible to modify label formats or move printed contents to comply with the

customer's requirements. The location data

is

stored in

E2

PROM so there

is

no need

to change

it

via.PROM Writer.

NOTE: Transaction labels or total label printing formats are subject to Weights and

Measures approval.

A

change of format or deletion of printed information may re-

sult in non-compliance with Weights and Measures regulations. Please use the ut-

most caution when changing or modifying the printing format.

This section will describe the actual dot printing size and coordinate setting.

The

AC-2000

is

equipped with a double density type thermal head, but labels are

printed at double density. Printing coordinates are

set

using double density specifi-

cations. Single density dot

size

is as shown below:

AC-2000 SERVICE REV 0

Page 79

S2 LABEL FORMATTING: USA

COORDINATES AND PRINT FORMAT LAYOUT

f

\

<,

,,,,X.

I

Labels are configured into four data columns as shown here. Only the upper and

lower column data can be modified.

Y axis

i

Origin of

Cooridnates

+

(0,O)

____+

X

axis

Table

Upper data column

Product Name column

Lower data column

Store name and address

column

Product name column

Column name

Upper data column

Product name. Number of lines

is

entered

via setup mode.

1

line

=

8

dots = 2.5mm

Data

is

cleared when a new PLU name is

called up

Specifications

Data which appears above the product

name (digits, bar code). This area is

cleared each time a label is printed.

Lower data column

AC-2000

SERVICE

REV

0

Digits and bar code printed between the

Store name and address and the product

name columns. Data

is

cleared when a

new PLU name

is

called up

Store name and address

column

Pre-printed store name and address print

area

Fixed at 2.65 dots (7.5MM)

Page 80

S2

LABEL

FORMATTING: USA

For entering actual cooridinates, think of the data columns as adjacent.

Y

axis

Upper data

Lower data

Origin of column

Cooridnates

+

(0,O)

X

axis

I

Upper data column

Dot count

Data column

Dot count

i

[(DATA

COORDINATE

STARTING

POINTS

I

%:I-*

'

%

,

.,..

"

+,v,..,

"

-,

*

,

*",

I

Y

axis

k-7

Data

I

COORDINATE DATATABLES

I

',

.,,

1

Oriain of

The coordinates for label formats

1-4

are shown in the following tables. Label for-

mat items vary by country. Charts reflect U.S.A. specifications

Print locations can be changed using the E2 PROM WRITER (See Test Mode

6),

for us-

ers using a largenumber of AC-2000 units of the same format, it

is

also possible to

change the ROM initial values

For this purpose, the data in the 0 chip of the Main Program

is

changed:

For Print Prohibit enter [FF.FF] as the

X

coordinate.

For Markdown price (lines

1

and 2) refer to this pattern:

starting

point

0000

1

980

-

Markdown Price

Line

1

*@&

Line

2

AC-2000

SERVICE

REV

0

Page 81

52 LABEL FORMATTING: USA

/

TEST

ITEPl

DATA

1

l

SHl

OA

SCALES

nFG.

SRrYO-KU

WOlO

JRrRN

I

Label Width

80602H 0602H

ChartS2-A

60mm

JLabel

Data line dot count

(above

&

below line)

1

80604H

1

0604H

Upper data line dot

count

1

80608H

1

0608H

DATA ITEM

Weight value

8062DH 062DH

MAIN

PROGRAM

ADDRESS

E2

ADDRESS

Unit price

1

8063AH

(

063~~

X-AXIS DATA

Line

2

I

8066EH

(

066EH

1

01.65

1

00.06

Y-AXIS DATA

Price

Special Price

Line

1

I

I

I

1

Pack day

I

80695H 0695H 00.76 00.69

80647H

80654H

80661 H

Markdown

Pack month

I

I

1

I

Shelf life day

806BCH 06BCH 00.23 00.69

0647H

0654H

0661 H

Pack year

Shelf life month

8067BH

80688H

I

@PCS data

I

806E3H

I

06E3H

1

01.26

1

-

00.69

0 1.47

0 1.65

01.65

01.65

00.59

067BH

0688H

806A2H

806AFH

Shelf life year

PCS

data

52-4

AC-2000 SERVICE REV 0

00.20

00.12

00.09

00.24

00.69

06A2H

06AFH

806C9H

806D6H

00.94

00.06

06C9H

06D6H

00.69

00.69

00.41

00.76

00.69

00.69

Page 82

S2 LABEL FORMATTING: USA

Chart

52-A

60rnrn

J

Label

AC-2000 SERVICE REV 0

.