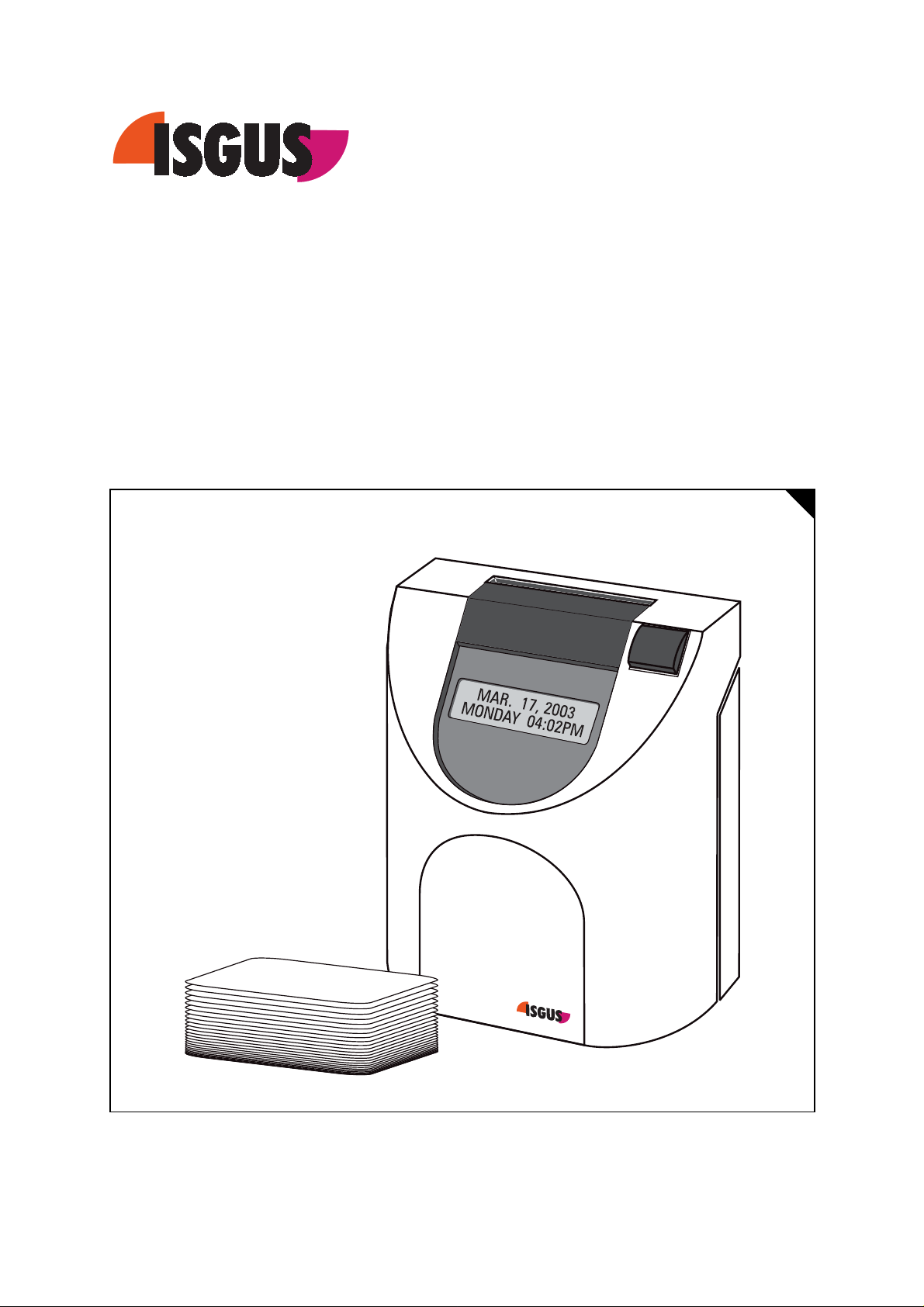

PERFECT 2040

Operating Manual

PERFECT 2040

Time recorder

Manual for the operation, installation, commissioning,

maintenance and troubleshooting of the time recorder.

Copyright © ISGUS GmbH 2008 - 2009

The company ISGUS GmbH claims copyright protection for

this documentation. No part of this documentation may be amended, extended,

reproduced or by any means of infringement on other legitimate interests without the

prior written permission of ISGUS.

With the exception of component parts changes, ISGUS has made every effort to

keep the contents of this manual current and correct at the time of publication.

However, we cannot guarantee the documentation to be 100% accurate.

Should you find any errors in this document, please let us know.

We are always grateful for suggestions and comments from our customers.

Edition 015CA. 0809 15 BA 2O

2.39

Printed in Federal Republic of Germany

Ref. no. 7169

ISGUS GmbH

Oberdorfstraße 18 - 22

DE - 78054 Villingen-Schwenningen

www.isgus.de

info@isgus.de

WARNING

This Equipment has been tested and found to comply with the limits for a

Class B digital device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against

harmful interference in a residential installation.

This equipment generates, uses and can radiate radio frequency energy

and, if not installed and used in accordance with the instructions, may

cause harmful interference to radio communications.

Only peripherals certified to comply with the Class B limits may be

attached to this equipment.

However, there is no guarantee that interference will not occur in a

particular installation.

If this equipment does cause harmful interference to radio or television

reception, which can be determined by tuning the equipment off and on,

the user is encouraged to try to correct the interference by one or more of

the following measures:

− Reorient or relocate the receiving antenna.

− Increase the separation between the

equipment and receiver.

− Connect the equipment into an outlet on a

circuit different from that to which the

receiver is connected.

− Consult the dealer or an experienced

radio/TV technician for help.

Safety instructions

Designated use

• The PERFECT 2040 time recorder is exclusively designed for the printing of

time and date information on manufacturer approved time cards, which is the

only designated use of this machine, as described in this manual.

• Using the time recorder for purposes other than that described above is

considered contrary to its designated use. The manufacturer cannot be held

liable for any damage resulting from such use. The risk of misuse of the time

recorder lies entirely with the user.

• The time recorder has no explosive environment protection. The use of the

recorder in an explosive hazardous area is contrary to its designated use. The

manufacturer and/or dealer cannot be held liable for any damage resulting

from installation and use of the time recorder in such areas.

• Operating the time recorder within the limits of its designated use requires that

you follow the instructions set out in the operating manual.

• All service work on the time recorder must be done by trained technicians who

are familiar with the time recorder and have been instructed in safety

precautions.

• All applicable local and national safety regulations must be observed in the

installation, use, and maintenance of the time recorder.

• Modifications to the time recorder made without the authorization of the

manufacturer will negate the manufacturer’s responsibility and liability.

Hints for the user

• Before installing and programming the time recorder, the operator must read

the operating instructions and safety notes.

• The time recorder should only be opened by competent and trained

personnel.

• The external power supply must be unplugged during maintenance and repair.

The person performing the service must also ensure that all wiring entering or

leaving the time recorder is electrical current-free before beginning work.

• Improper changing of the lithium battery may result in explosion. Do not use

batteries other than those specified by the manufacturer. Send the replaced

batteries to the recycling process available in your area.

• Any changes or service to the electrical components of the unit must be

carried out by a qualified electrical technician.

• In addition to reading the operating instructions, the user should be instructed

in all other generally applicable legal and other mandatory regulations relevant

to accident prevention and environment protection.

Hints for the recorder's safety

• The time recorder has been built to the highest standards and conforms to

recognized safety rules. Nevertheless, its use may constitute a risk to the user

or third parties, or cause damage to the unit and to other property.

• Operate the time recorder only with the power supply being part of the time

recorder package.

• The time recorder must only be used in a suitable environment, in accordance

with its designated use and the instructions set out in this operating manual.

Any equipment or functional problems, especially those affecting the safety of

the unit and users of the unit, should be repaired immediately.

• UL approval void if no approved batteries are installed.

• Replacement parts must comply with the technical requirements specified by

the manufacturer. This is guaranteed only when you use the manufacturer’s

original replacement parts. Use of non-conforming parts voids your warranty.

• Unplug and switch the unit off immediately if a problem occurs in the electrical

system.

• Installation and mounting of the unit must be done by trained personnel.

• Plug the time recorder power supply into a sufficiently grounded electrical

outlet.

• Ensure that all consumables and replaced parts are disposed of safely and

with minimum environmental impact.

Warning!

This symbol focuses the user's attention to special procedures

and in the handling of the time recorder that could cause serious

injuries if the instructions are not followed carefully.

Attention

This symbol indicates that there may be danger to the time

recorder if the text is not read or the procedure is not followed.

Data may be lost or the recorder may be damaged.

Hint

This symbol indicates useful information and recommendations

for the handling of the time recorder.

Chapter 0

Contents

Chap. 1 Introduction ........................................................ 1-1

Product Overview................................................ 1-2

How to Use This Manual ..................................... 1-3

Symbols and Abbreviations................................................ 1-4

Chap. 2 Features .............................................................. 2-1

PERFECT 2040..................................................... 2-2

Recorder Construction........................................ 2-4

Time Recorder Identification.............................. 2-5

Chap. 3 Installation............................................................ 3-1

Contents............................................................... 3-2

Selecting a Location............................................ 3-3

General Conditions............................................................ 3-3

Specific Conditions for the Time Recorder......................... 3-3

Time Recorder Installation.................................. 3-4

Installation for Table Operation...................................... 3-4

Wall Mounting................................................................... 3-5

Open the Recorder............................................................. 3-6

Close the Recorder............................................................ 3-7

Remove the Metal Back Plate............................................ 3-7

Wall Mounting.................................................................... 3-8

Connect the Power Supply................................................. 3-8

Connect Additional Functions............................................ 3-10

Chap. 4 Getting Started..................................................... 4-1

Preparations......................................................... 4-3

Preparations....................................................................... 4-3

Open the Recorder............................................................. 4-3

Powering Up The Time Recorder....................................... 4-3

Powering Down the Time Recorder................................... 4-4

Programming Panel............................................. 4-5

Date / Time............................................................ 4-7

Setting the Time only......................................................... 4-9

Set Time of Slave Clocks (optional)................................... 4-10

Chapter 0 Contents 0-1

Programming ....................................................... 4-13

Calling up the Programming Routine

for the Main Programming Menu........................................ 4-14

Print Format...................................................................... 4-15

Punch Rounding............................................................... 4-19

Totals Rounding............................................................... 4-22

IN Punch Revisions.......................................................... 4-25

Change or Delete Values for schedules

with IN Punch Revisions..................................................... 4-31

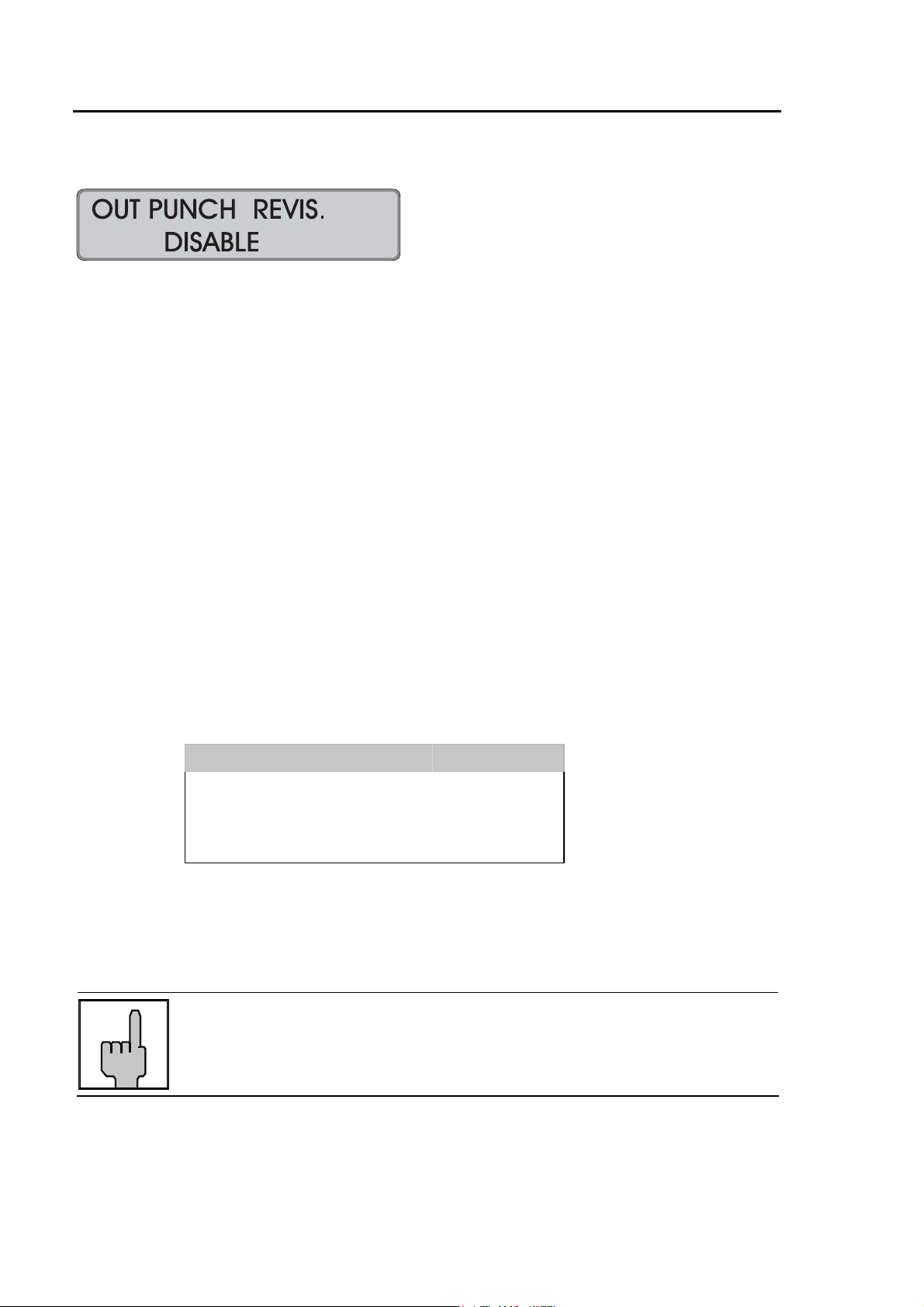

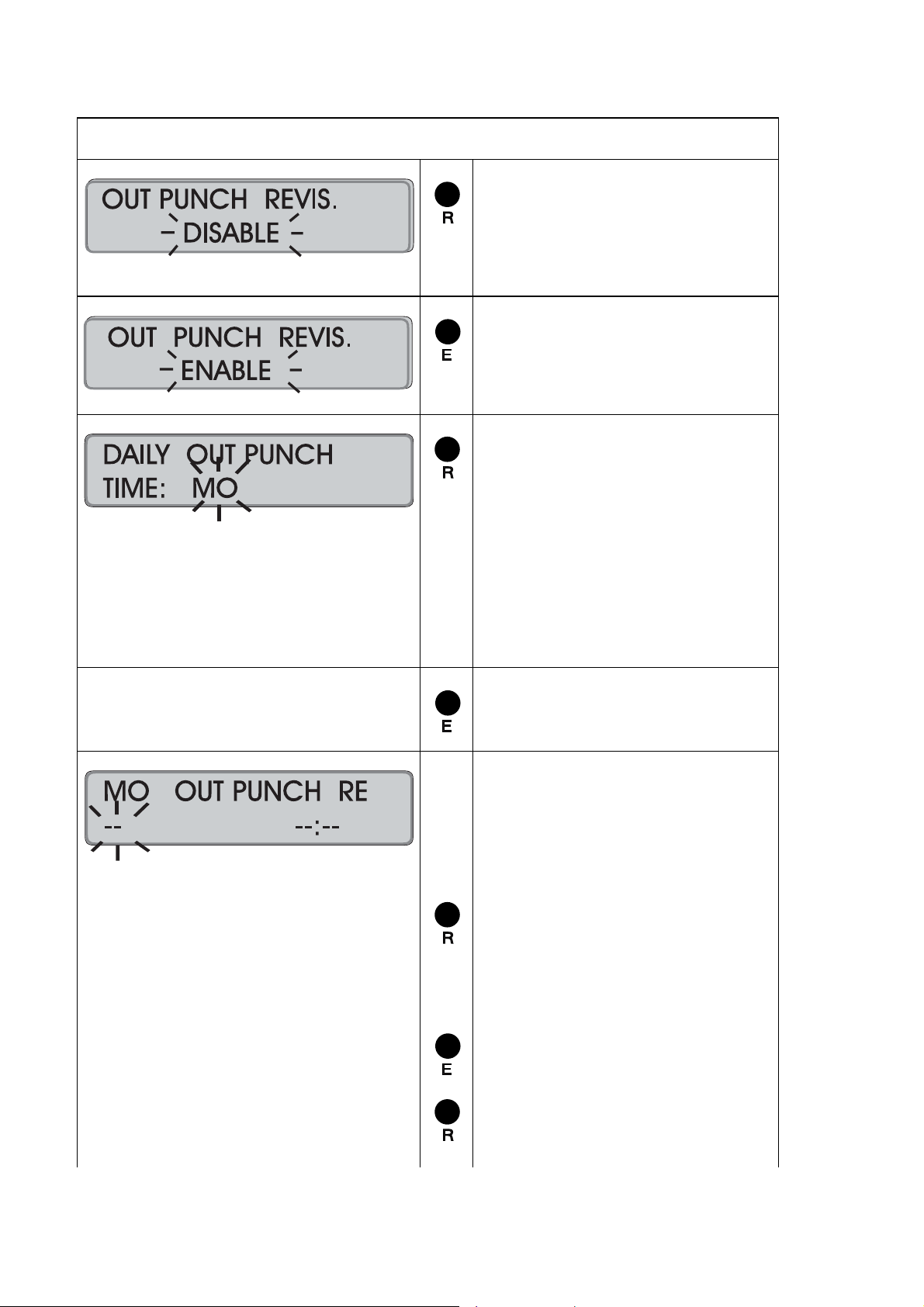

OUT Punch Revisions...................................................... 4-32

Change or Delete Values for schedules

with OUT Punch Revisions................................................. 4-38

Automatic Break............................................................... 4-39

Fixed Break (Non Accumulation Times.......................... 4-47

Change or Delete Values for Fixed Break

(no accumulation) Time Ranges......................................... 4-52

Red Print (Ribbon Color Change).................................... 4-53

Change or Delete Values for Red Print /

Ribbon Color Changes....................................................... 4-57

Overtime............................................................................ 4-58

Option Menu ........................................................ 4-63

Calling up the Programming Routine for

the Options Menu............................................................... 4-63

Daylight Savings Time..................................................... 4-65

Deleting Cards.................................................................. 4-69

Maximum Presence.......................................................... 4-70

Date Format....................................................................... 4-72

Day End............................................................................. 4-73

Day Extend........................................................................ 4-75

Overtime 2......................................................................... 4-77

Public Holidays................................................................. 4-82

Deleting Public Holidays..................................................... 4-84

Card Initialization................................................................ 4-85

Duplicate Punch................................................................ 4-87

Reproducing Card............................................................ 4-88

Summary by Cards........................................................... 4-88

Lock Out............................................................................ 4-89

Change or Delete Values for Lock Out Schedules............. 4-93

Signal Operation............................................................... 4-94

Change or Delete Values for Signal Operation................... 4-98

Slave clock function......................................................... 4-99

Master Clock Function..................................................... 4-100

Synchronize the Slave Clocks............................................ 4-101

Card Validity Duration...................................................... 4-103

Quit Programming Mode.................................................. 4-105

Commissioning after Power Failure................................ 4-105

Service Call....................................................................... 4-106

Print out of Program Settings.......................................... 4-108

Chap. 5 Operation............................................................. 5-1

Punching at the Recorder................................... 5-2

0-2 Contents Chapter 0

Card Structure / Card Print.............................................. 5-2

Requirements for Trouble Free Time Recording................ 5-4

IN / OUT Punches.............................................................. 5-5

Double Punch Disabling..................................................... 5-6

Forgotten OUT Punches (Max On).................................... 5-7

Card Full............................................................................. 5-8

Card Management / Card Organization.............. 5-9

What to Know about Card Usage....................................... 5-9

Card Management Options................................................ 5-10

Deleting Cards without Carryover...................................... 5-13

Deleting Cards with Carryover of Totals............................. 5-14

Deleting Cards with Carryover of Weekly Qualification

Hours and Deletion of Totals.............................................. 5-16

Reproducing Time Card..................................................... 5-19

Summary by Cards.............................................. 5-21

Standby operation ............................................... 5-24

Chap. 6 Trouble Shooting................................................. 6-1

Error Messages .................................................... 6-2

Change of Fuse for Signal Output...................... 6-3

Removing of the Battery Pack............................ 6-4

Adjustment of Card Sensor ................................ 6-5

Cleaning of the Card Sensor............................... 6-6

Service Call .......................................................... 6-8

Chap. 7 Maintenance......................................................... 7-1

Ribbon Change .................................................... 7-2

Cleaning the Time Recorder............................... 7-3

PERFECT Info Display......................................... 7-4

Service Call .......................................................... 7-4

App. A Technical Specifications..................................... A-1

App. B Default Program Settings.................................... B-1

App. C Program Settings................................................. C-1

App. D Conversion table for minute print formats........ D-1

App. E Local Sales and Service Dealer.......................... E-1

Chapter 0 Contents 0-3

0-4 Contents Chapter 0

Chapter 1

Introduction

Product Overview.............................................................. 1-2

How to Use This Manual................................................... 1-3

Symbols and Abbreviations..................................... 1-4

Chapter 1 Introduction 1-1

Product Overview

The PERFECT series of microprocessor based time recorders are available in

several configurations.

The series is separated into two classifications - non-calculating and

calculating.

The models P2005, and P2020 are non-calculating time recorders. They print

the time of daily arrivals and departures on time cards.

The models P2030 and P2040 are calculating time recorders. In addition to

printing daily arrival and departure times on a time card, they calculate the

elapsed time between punches (according to user defined workplace rules)

and print the various totals.

Common features of all PERFECT time recorders are their ease of

programming, user friendly interface and minimum maintenance requirements.

After programming, the time recorder’s operation is fully automatic. Each time

recorder is equipped with automatic daylight savings time change capability; a

perpetual calendar to adjust for leap years and month-end date changes; and

a reliable quartz time base with battery back-up during power failures. Many

PERFECT models can be equipped with additional features such as audible

signal control, synchronized time operation, and battery standby to allow time

recorder registrations during power failures.

This manual gives you step by step instructions on the operation of the

PERFECT 2040 time recorder. It documents all important functions which are

available to users.

We recommend that you carefully read this manual, before the commissioning

and use of the time recorder. To save time, please keep it in a handy location

for futu re refere nce.

All recorders are of utmost reliability and have passed thorough quality

assurance tests. Nevertheless, if there should be any problems which are not

covered by this manual, please contact your local dealer or e-mail us at:

support@ca.isgus.com

or

techsupport@isgus.com

1-2 Introduction Chapter 1

How to Use This Manual

This manual will help you become familiar with the time recorder, and how to use the

designated application possibilities with its many features.

Before using the time recorder, please read and study this manual. Pay particular

attention to the pages with safety instructions.

The manual provides you with all of the important information required for the safe

and efficient use of the time recorder. Following the instructions in this manual will

help you to avoid danger and maximize the benefits from the use of the time

recorder.

Chapter 1 "Introduction", contains general information about this recorder and

about the structure of this manual.

Chapter 2 "Features", describes the functions of the PERFECT 2040 time recorder

with illustrations and easy to understand explanations.

Chapter 3 "Installation", discusses how to assemble and connect the time

recorder. Before installin g the time recorder please pa y close attention to the

required installation conditions.

Chapter 4 "Getting Started", teaches you how to prepare and program the time

recorder for your application. This chapter takes you through a step by step

instruction guide on the programming panel, setting of the date and time, various

menu items and options, and how the programming routine works.

Chapter 5 "Operation", explains how to use the time recorder and provides a

description of how the recorder functions in standby operation.

Chapter 6 "Trouble Shooting", provides an explanation of the internal diagnostics

built into the PERFECT 2040 and the corresponding messages. The chapter

documents most service problems and lists possible solutions.

Chapter 7 "Maintenance", provides instruction on the periodic servicing of the time

recorder that is required to guarantee top performance. Due to environmental

conditions where the time recorder may be installed, the user is encouraged to

occasionally clean the machine and change the ink ribbon.

Appendix A "Technical Specifications", provides a summary of the time recorder’s

physical and electrical characteristics.

Appendix B "Default Program Settings", lists the time recorder’s standard program

that was pre-set at the factory.

Chapter 1 Introduction 1-3

Appendix C "Program Settings", is a blank document to assist you in the planning

and recording of your time recorder’s programming.

Appendix D contains a conversion table for the individual minute print formats.

Symbols and Abbreviations

To make the reading of this manual easier, symbols and pictures are used.

These symbols and pictures may be placed at the edge of a page or they may be

inserted into text or table areas of the manual.

Warning!

This symbol focuses the user's attention to special procedures in

the handling of the time recorder that could cause serious

personal injury if the instructions are not followed carefully .

Attention

This symbol indicates that there may be danger to the time

recorder if the text is not read or the procedure is not followed.

Data may be lost or the recorder may be damaged.

Hint

This symbol indicates useful information and recommendations

for the handling of the time recorder.

1-4 Introduction Chapter 1

Chapter 2

Features

PERFECT 2040 .................................................................. 2-2

Recorder Construction..................................................... 2-4

Time Recorder Identification............................................ 2-5

Chapter 2 Features 2-1

PERFECT 2040

The PERFECT 2040 is a calculating time recorder that records the time and date of

the arrival and departure of employees. The recorded time is printed on a bar-coded

time card with distinct, pre-printed “In / Out” columns.

The time recorder also has the ability to calculate the elapsed time between an “In”

and an “Out” punch and immediately print user defined totals in distinct columns that

are pre-printed on the time card. The totals printed are arrived at after the application

of certain global workplace rules that the user programs.

Employee use of the time recorder is very simple. When the employee inserts the

time card into the card receiver, the time recorder automatically pulls the time card

into the printer and aligns it for a precise print registration in the appropriate In / Out

column. Once the printing function is completed, the time recorder releases the card

and the employee can remove it for placing in a nearby card storage rack.

The dot matrix printer of the PERFECT is maintenance-free. In addition, bicolored

ribbons enable the time recorder to highlight in red ink any attendance irregularities.

The PERFECT 2040 time recorder is equipped with a large two-line backlit display.

The display shows the current date and time. The enhanced capabilities of this

display make the use of the time recorder extremely simple, especially when being

programmed.

Once the user has programmed the PERFECT 2040, the time recorder becomes

fully automatic.

The PERFECT time recorder has been designed for table mounting. However, wall

mounting is also possible.

You can find an overview of the features and flexibility of the PERFECT 2030 and

the advanced model PERFECT 2040, in the following table.

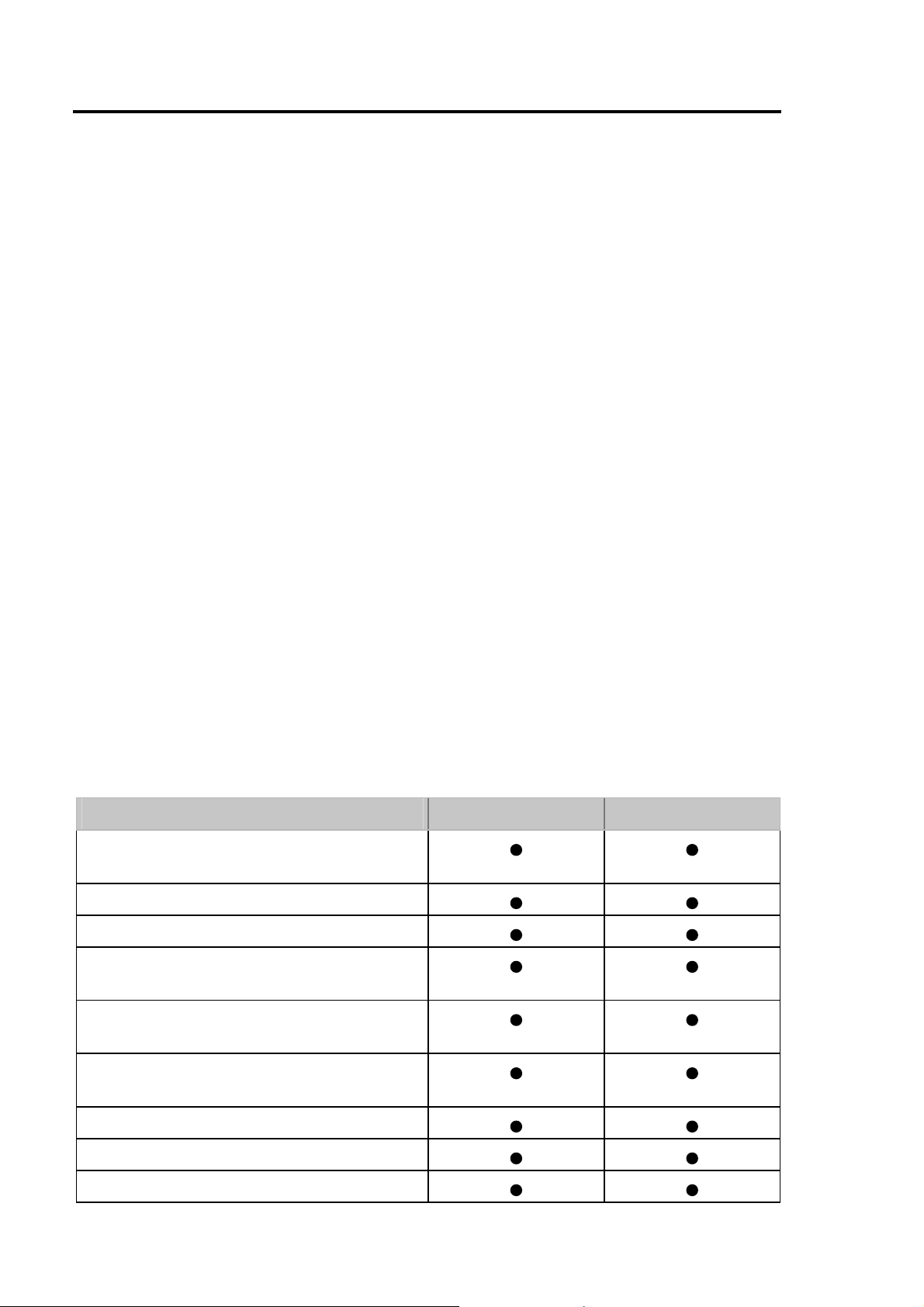

Features Model 2030 Model 2040

Quartz-clock controlled and battery-

buffered real-time clock

Power reserve

Time, Day & Date Display

Automatic Daylight Savings Time

Adjustment

Automatic end-of-month date correction,

including leap years (perpetual calendar)

Automatic punch placement eliminates

over-punching

User defined time card format

Elapsed time printout

Time card total printout

2-2 Features Chapter 2

User defined punch rounding

User defined totals rounding

Day end moveable to next day

Day extend

User programmable two color printing

Large time card capacity (max. 250

active time card running totals)

Time card initialization (limits which

numbered time cards the time recorder

will accept)

User programmable date format

Individual card close-out with or without

carry forward of totals

Lost or mutilated time card replacement

(last cumulative total only)

Automatic switch-over from day to day

Forgotten punch monitoring

Overtime calculation

Fixed break / non-accumulating time

schedule

IN punch revisions

Lock out schedule

Programmable print formats

Automatic break deduction after

minimum presence time

Automatic variable break deduction after

scaleable minimum presence time

Duplicate punch protection

PIN-Code protection of programming

functions

Slave clock function (payable option)

Master clock function (payable option)

Time card reports

Protocol print out

Programmable audible signal circuit for

signaling stop and start work times

Available printer battery back-up

(payable option)

Chapter 2 Features 2-3

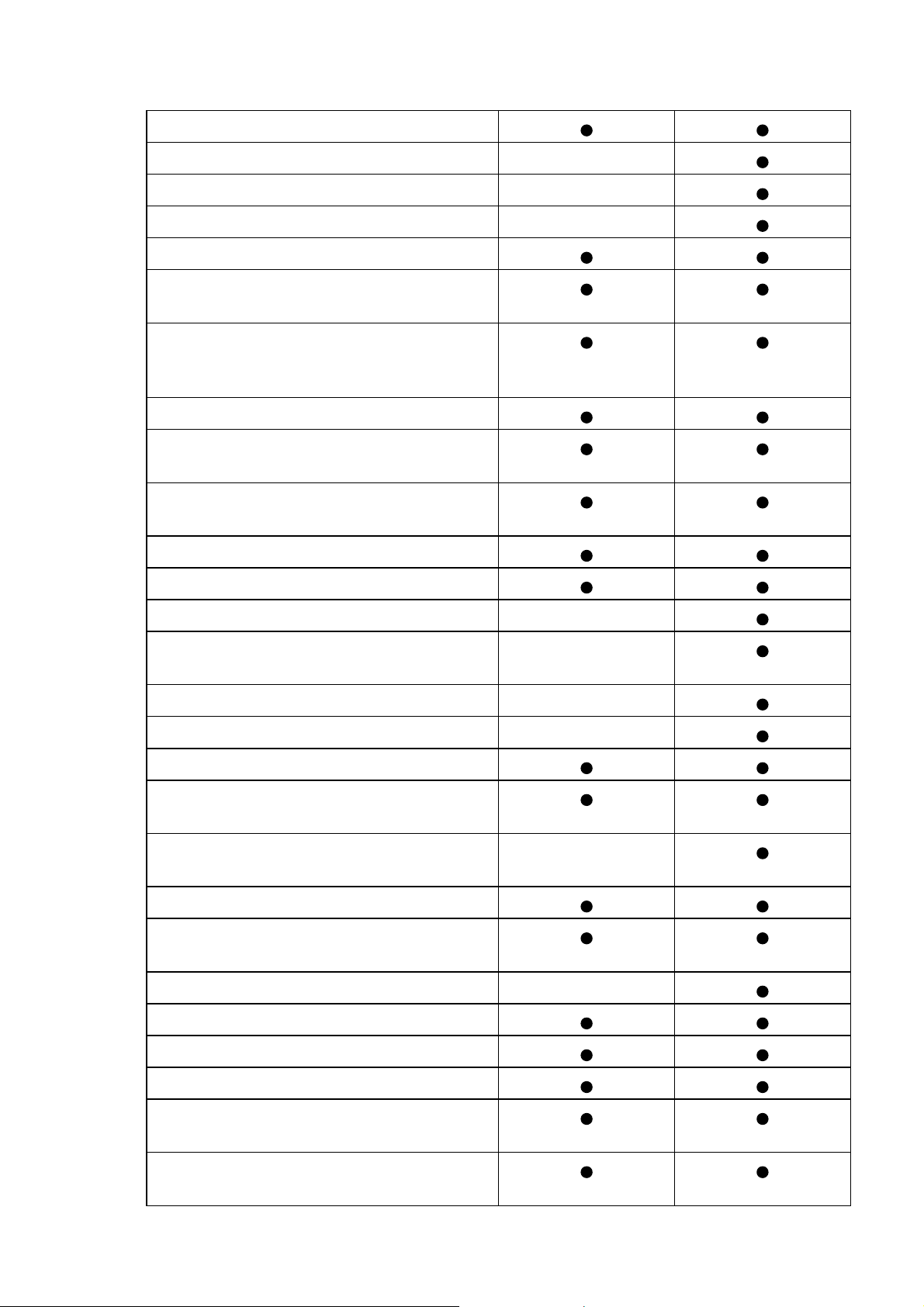

Recorder Construction

Fig. 1: Total view

(1) Display with day, date and time

(2) Card receiver

(3) Function key

(4) Removable front cover

(5) Rear cover

2-4 Features Chapter 2

Time Recorder Identification

• Electrical rating plate

• Program data

The name-plate is fixed on the bottom side of the cover.

The serial number is attached to the inside bottom of the unit.

Electrical data

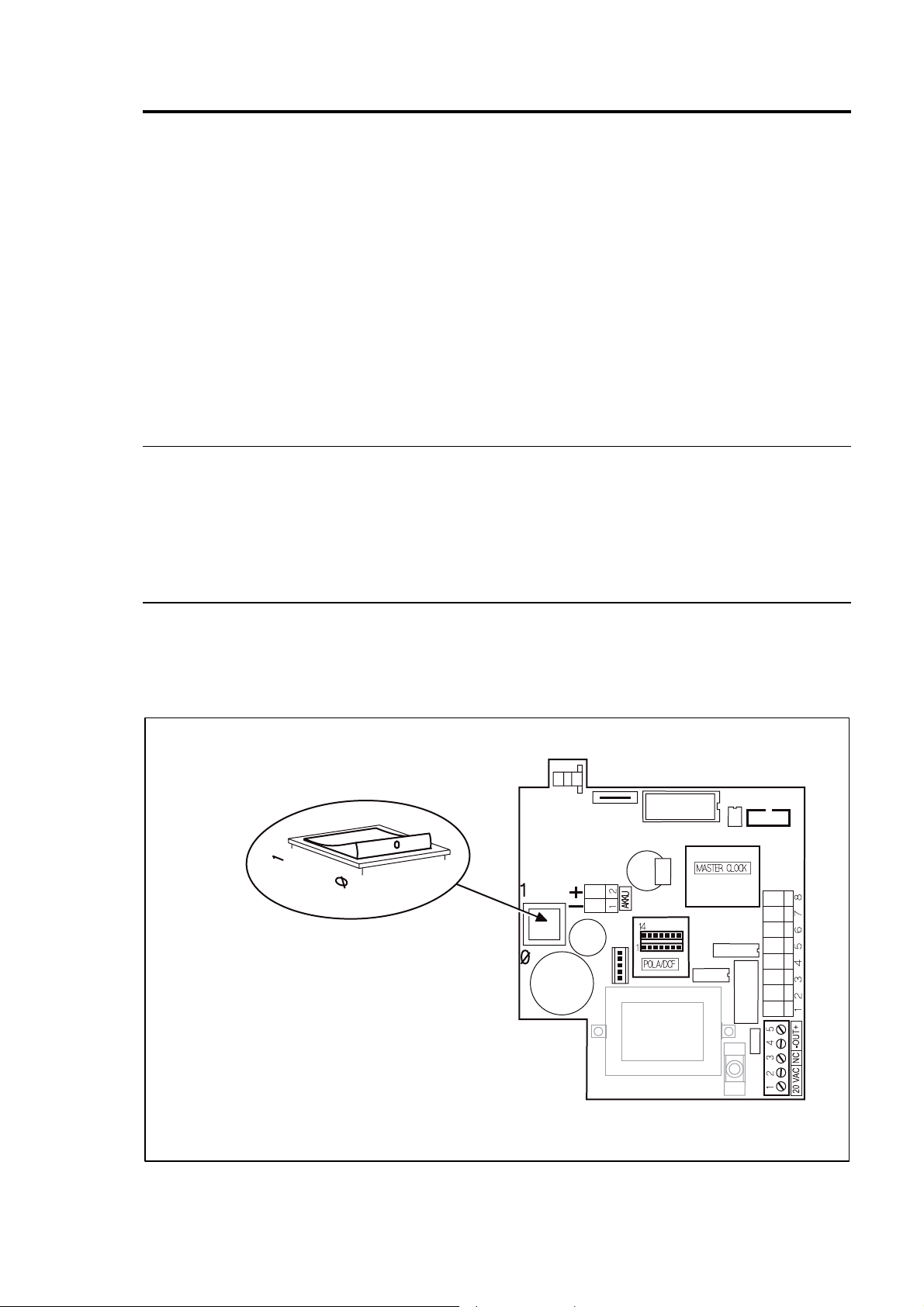

The label with the program data (1) can be found on the operating system PROM of

the CPU.

Example:

Type of recorder

P 2040 Type of recorder

V 2.20 Program release

Fig. 2: PC-Board

Chapter 2 Features 2-5

2-6 Features Chapter 2

Chapter 3

Installation

Contents............................................................................. 3-2

Selecting a Location ......................................................... 3-3

General Conditions............................................. 3-3

Specific Conditions for the Time Recorder......... 3-3

Time Recorder Installation............................................... 3-4

Installation for Table Operation............................... 3-4

Wall Mounting ........................................................... 3-5

Open the Recorder............................................. 3-6

Close the Recorder ............................................ 3-7

Remove the Metal Back Plate............................ 3-7

Wall Mounting .................................................... 3-8

Connect the Power Supply................................. 3-8

Connect Additional Functions............................. 3-10

Chapter 3 Installation 3-1

Contents

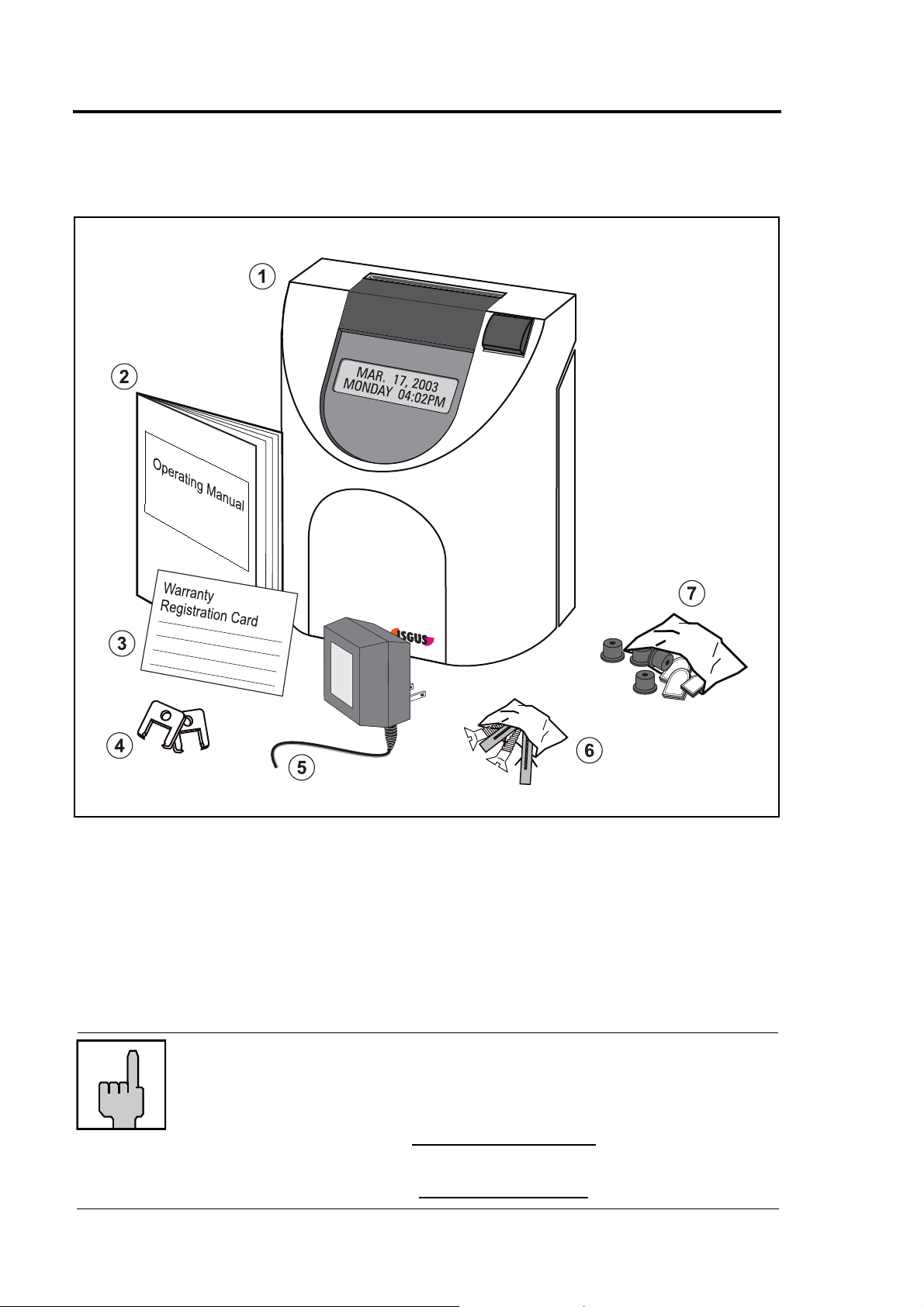

The following illustration shows the time recorder box contents without options.

Fig. 3: Supply

(1) Time recorder PERFECT 2040

(2) Operating manual

(3) Warranty Registration Card

(4) 2 keys

(5) Power supply unit

(6) Fixing elements for wall mounting (2 screws, 2 plugs)

(7) Set of accessories for table operation (4 rubber feet, 3 cover caps)

Hint

Time cards are not included with your time recorder and must be

ordered separately. Please contact your local dealer or e-mail us

at:

sales@ca.isgus.com

or

sales@isgus.com

3-2 Installation Chapter 3

Selecting a Location

Warning!

Proper installation of the time recorder is the responsibility of the

owner. All work must only be carried out by qualified personnel.

The installation must comply with the requirements of the

General Conditions

The installation location should have the following characteristics:

→ the time recorder is not exposed to electrical frequency transmissions

→ the time recorder is not exposed to direct sunlight.

→ the location’s environment is within the temperature and humidity limits

published in this manual.

authorities having jurisdiction and all applicable safety codes and

regulations that govern the installation of electrical appliances.

→ the location is free of airborne particles such as dust, dirt and fine powders

and there is no possibility of the time recorder being exposed to direct contact

with any kind of liquid or steam.

→ there are no dirty manufacturing processes that could contaminate the

location .

→ the location is isolated from electromagnetic noise sources such as motors,

electromagnets, and series reactors.

Specific Conditions for the Time Recorder

→ The time recorder is designed for continuous operation.

→ The time recorder is designed for indoor mounting only. Outdoor mounting is

not supported. Avoid direct sunlight and high humidity (refer to "Technical

Specifications, Appendix A".

→ Connection only to the mains voltage specified on the name-plate.

→ Cable connections must not be permanently installed.

→ Only use the recorder with the supplied power supply unit, both in table and

wall mount installations.

→ In the power supply installation in the building a separator, e.g. fuse, switch,

etc. must be integrated to allow a contact opening of at least 3 mm per pole.

→ Installation must be according to NEC requirements.

Chapter 3 Installation 3-3

Time Recorder Installation

Basically the PERFECT recorder is designed for table operation. No further settings

are required for this type of application. Please see the instructions in the following

section ”Installation for table operation”. If you have to connect additional functions

such as signal operation, master clock operation or standby operation refer to the

end of section "Wall mounting".

For wall mounting refer to the corresponding section "Wall mounting". When used as

wall-mounted recorder you have to carry out a number of installation steps described

in this chapter.

The connection of additional functions and the programming of the time recorder are

carried out with the time recorder’s case open. Below the time display panel you will

find a power switch and other electrical terminals and components. Please refer to

the section "Programming panel".

Warning!

All work must only be carried out by qualified and authorized

personal.

Installation for Table Operati on

When using the time recorder as a table model, the installation effort is reduced to a

minimum. Simply connect the power supply to the recorder and then plug it in to the

closest receptacle. Switch on the black power switch located on the PC board. For

instructions on how to switch the recorder on and how to program it for your

individual requirements see chapter "Getting Started".

Fig. 4: Bottom side of the recorder with rubber feet and mains cable s ocket

3-4 Installation Chapter 3

Select an easily accessible and vibration-free place of installation. The recorder may

only be placed on a stable, slip-resistant surface.

For the stability of the time recorder use the rubber feet included in the set of

accessories. For this purpose clip them on by following the arrow-head indications.

Also use the 3 cover caps for the metal back plate in order to seal the cable leadings.

The power outlet has to be close to the recorder and easily accessible. Lay the

power cable so that access is not obstructed and persons are not endangered.

Warning!

Only use the time recorder with the enclosed power supply both

in case of table operation and of wall mounting. Do not use

extension cords.

Wall Mounting

The PERFECT time recorder is designed for table mounting. However, power

connection and signal control terminals have been provided to meet the

requirements of eventual wall mounting applications.

Installation steps:

1. Open the time recorder

2. Remove the metal rear panel

3. Mount the time recorder on the wall

4. Connect the power supply

5. Connect any additional

functions (if required)

6. Commissioning

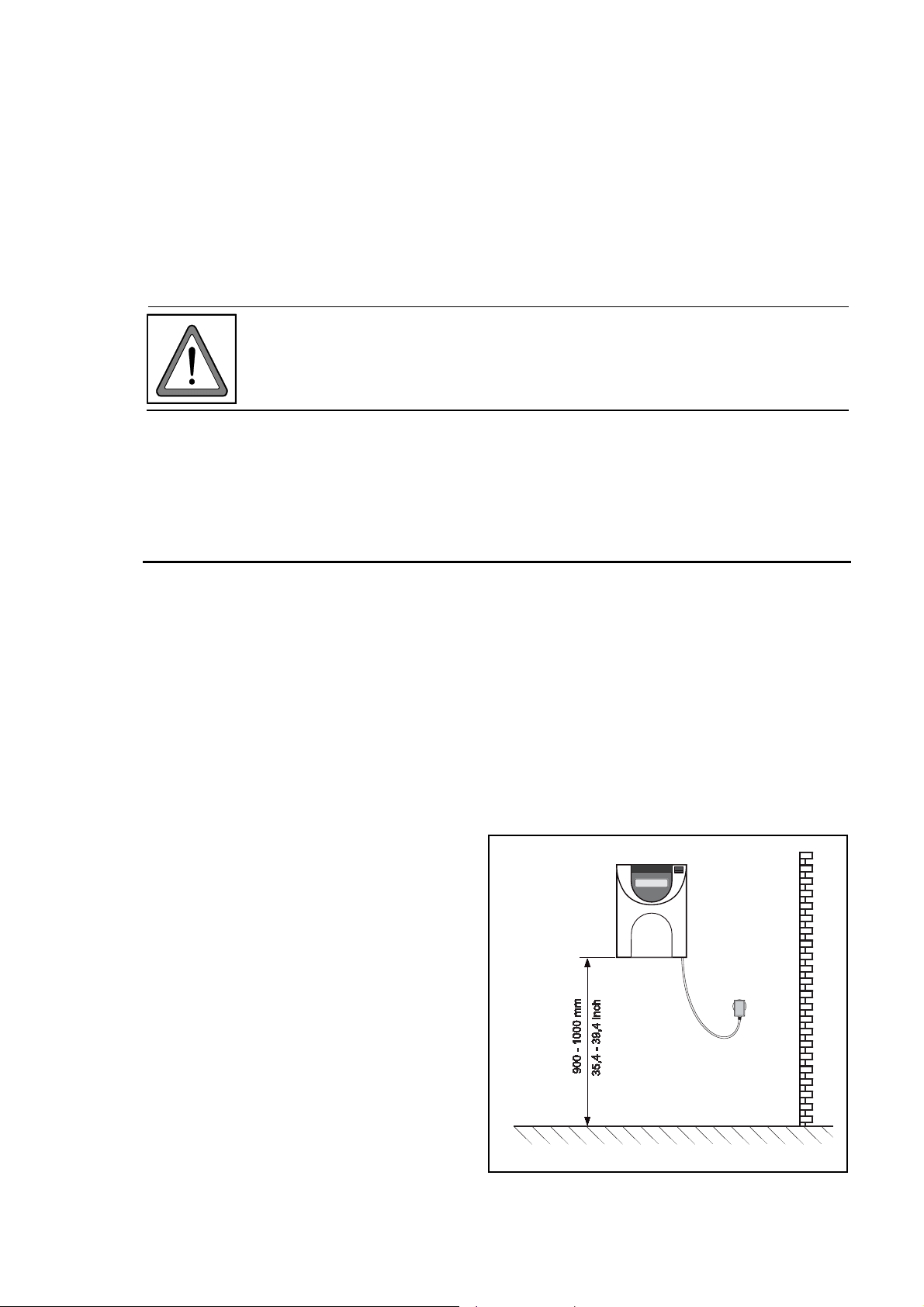

The location of the mounting holes

can be traced from the metal back

plate of the time recorder. The metal

back plate can be plugged in with the

plastic housing.

The installation dimensions shown in

the figure on the right are

recommendations which can be

adjusted to the local conditions. The

dimensions apply both for table

operation and for wall mounting.

Fig. 5: Installation dimensi ons

Chapter 3 Installation 3-5

Open the Recorder

1. Insert the key into the slot on the under side of the time recorder. Press the

key into the slot until the locking latch releases the front case cover.

Fig. 6: Unlock the recorder

2. Swing out the front case cover with the time recorder tilted away from you

(step 1) until it can be lifted up and off the time recorder (step 2).

Fig. 7: Open the recorder

3-6 Installation Chapter 3

Close the Recorder

1. Align and insert on an angle the two tabs at the top of the rear case cover into

the corresponding two slots at the top of the front case cover.

2. Swing the front case cover downwards until it meets the bottom of the rear

case cover. Push the bottom of the front case cover until it engages the

locking latch on the bottom of the rear case cover.

Hint

Do not close the time recorder until you have made all electrical

connections and completed all time recorder programming.

Remove the Metal Back Plate

1. To begin removing the metal back plate, press the two locking tabs located on

the top left and right hand sides of the rear case cover (step 1).

2. Keep the locking tabs pressed in and push the metal back plate back about ½

of an inch (step 2).

3. Pull the metal back plate away from the unit (step 3).

Fig. 8: Rear view of the rec order with metal back plate

Chapter 3 Installation 3-7

Wall Mounting

The location of the mounting holes can be traced from the metal back plate of the

time recorder. The metal back plate can be plugged in with the plastic housing.

See previous section. The installation dimensions mentioned in this manual are

recommendations which have to be adjusted for local conditions.

1. Position the metal back plate in the desired wall location. Make sure the back

plate is level by using a carpenter’s level

2. Using a pencil, trace the upper and lower mounting holes of the metal back

plate on the wall. Drill corresponding holes with a 5/16” drillbit . Insert the wall

plugs.

3. Mount the metal back plate starting first with the lower screw and then the top

screw. Make sure you do not fully tighten.

4. Using a carpenters level, align the time recorder once more and then tighten

both screws.

5. Hang the time recorder mechanism on the wall mounted metal back plate. The

four metal tabs (one on each corner of the metal back plate) must be aligned

and inserted into the corresponding slots of the rear case cover. When the

cover has been inserted correctly on the metal tabs, pull time recorder slightly

downwards until the locking mechanism engages.

Check your installation for good fits.

Connect the Power Supply

1. Make sure that the recorder has been switched off.

Fig. 9: PC-board with power switch

3-8 Installation Chapter 3

2. Check the connection of the power

cord to the screw-type terminal strip

of the CPU.

black

black

Attention

The power cord must be connected to the PC board

terminals that are electrically compatible with the supply

voltage of the electrical outlet that the power cord is plugged

into. Incorrect connections can cause the destruction of the

time recorder!

3. Connect the power cable of the power supply unit to the bottom side of your

PERFECT.

Fig. 10: Bottom side of the recorder with power cable socket

4. Insert the plug-in power supply unit into the provided socket.

Warning!

The power outlet must be close to the recorder and easily

accessible. Make sure, that a loose power cable does not

cause obstruction or risk to people.

Chapter 3 Installation 3-9

Connect Additional Functions

Only connect additional functions when they are required.

Additional functions:

− Signal operation

− Master clock operation (payable option)

− Slave clock operation (payable option)

− Standby operation (payable option)

All additional functions can be used for both types of installation, i.e. table or wall

mounted version.

When used as a table unit, the knockouts at the bottom of the metal rear back plate

have to be used for cable entry.

For wall mounted units the plastic knockouts on the bottom of the rear cover have to

be detached.

Attention

Units without the additional function "standby operation" only

operate with bridged standby clamp (Z-diode). See section

"Connection of battery pack" and chapter 6 "Trouble shooting".

Fig. 11: PC-board with additional functions

(1) Power connection terminals (2) Signal circuit connection terminals

(3) Master clock function (4) Battery, standby connector

(5) Slave clock function

Attention

Before installing additional functions switch off the unit and unplug

the power supply.

3-10 Installation Chapter 3

(2) Connect wiring for audible signal circuit control.

→ only if required.

→ low power signal output: 15V DC , 50 mA

3 4 5

NC - OUT +

Attention

This connection is polarity sensitive.

(3) Connect wiring for synchronized clock option

→ only if the recorder is equipped with the option module "MASTER CLOCK".

→ fused output rated at 12 V, max. 50 mA,

This connection is not polarity sensitive.

12

(4) Connect an optional battery pack for printer operation

during a power failure.

Attention

UL approval void if no approved batteries are installed!

1. Put the battery pack into the prepared battery

partition.

→ the battery partition is on the left side on the

bottom of the case.

2. Unplug bridge (Z-Diode, 12 V / 1 W) at clamp X5

of the PC board of the unit.

→ Hint: Keep the Z-Diode on hand.

The z-diode must be replaced, when removing

the battery pack.

3. Connect the cables of the battery pack to clamp

X5 of the PC board of the unit. + = red - = black

Attention

This connection is polarity sensitive.

Wrong connection causes a damage of the unit!

Chapter 3 Installation 3-11

(5) Connect impulse lines for slave clock connection.

→ Only if recorder is equipped with option module slave clock function/DCF"

→ unipolar and bipolar impulses, 12 V - 60 V, 2 - 10 mA.

This connection is not polarity sensitive.

12

The Installation is now finished.

To program the time recorder see chapter 4 "Getting Started".

If the recorder is to be programmed at a later date, insert the front cover and close

the recorder.

3-12 Installation Chapter 3

Chapter 4

Getting Started

Preparations...................................................................... 4-3

Open the Recorder............................................. 4-3

Powering Up The Time Recorder....................... 4-3

Powering Down the Time Recorder.................... 4-4

Programming Panel .......................................................... 4-5

Date / Time......................................................................... 4-7

Setting the Time only.......................................... 4-9

Set Time of Slave Clocks (optional)................... 4-10

Programming ..................................................................... 4-13

Calling up the Programming Routine

for the Main Programming Menu ........................ 4-14

Print Format .............................................................. 4-15

Punch Rounding....................................................... 4-19

Totals Rounding........................................................ 4-22

IN Punch Revisions .................................................. 4-25

Change or Delete Values for schedules

with IN Punch Revisions..................................... 4-31

OUT Punch Revisions .............................................. 4-32

Change or Delete Values for schedules

with OUT Punch Revisions................................. 4-38

Automatic Break....................................................... 4-39

Chapter 4 Getting Started 4-1

. continued

Fixed Break (Non Accumulation Times.................. 4-47

Change or Delete Values for Fixed Break

(no accumulation) Time Ranges........................ 4-52

Red Print (Ribbon Color Change)........................... 4-53

Change or Delete Values for Red Print /

Ribbon Color Changes....................................... 4-57

Overtime.................................................................... 4-58

Option Menu ............................................................. 4-63

Calling up the Programming Routine for

the Options Menu .............................................. 4-63

Daylight Savings Time............................................. 4-65

Deleting Cards.......................................................... 4-69

Maximum Presence .................................................. 4-70

Date Format .............................................................. 4-72

Day End..................................................................... 4-73

Day Extend................................................................ 4-75

Overtime 2................................................................. 4-77

Public Holidays......................................................... 4-82

Deleting Public Holidays.......................................... 4-84

Card Initialization ..................................................... 4-85

Duplicate Punch....................................................... 4-87

Reproducing Card.................................................... 4-88

Summary by Cards................................................... 4-88

Lock Out.................................................................... 4-89

Change or Delete Values for

Lock Out Schedules........................................... 4-93

Signal Operation....................................................... 4-94

Change or Delete Values for Signal Operation.. 4-98

Slave clock function................................................. 4-99

Master Clock Function............................................. 4-100

Synchronize the Slave Clocks ........................... 4-101

Card Validity Duration.............................................. 4-103

Quit Programming Mode ......................................... 4-105

Commissioning after Power Failure....................... 4-105

Service Call............................................................... 4-106

Print out of Program Settings ................................. 4-108

4-2 Getting Started Chapter 4

Preparations

Follow the instructions in this chapter and keep in the order the topics are presented.

Basic procedure and overview:

1. Open the recorder

2. Switch on recorder

3. Check date and time, and reset if necessary

4. Program the recorder

5. Close the recorder

6. Carry out test punches

Open the Recorder

If the recorder is not yet opened, remove the front cover as described in chapter 3,

"Installation".

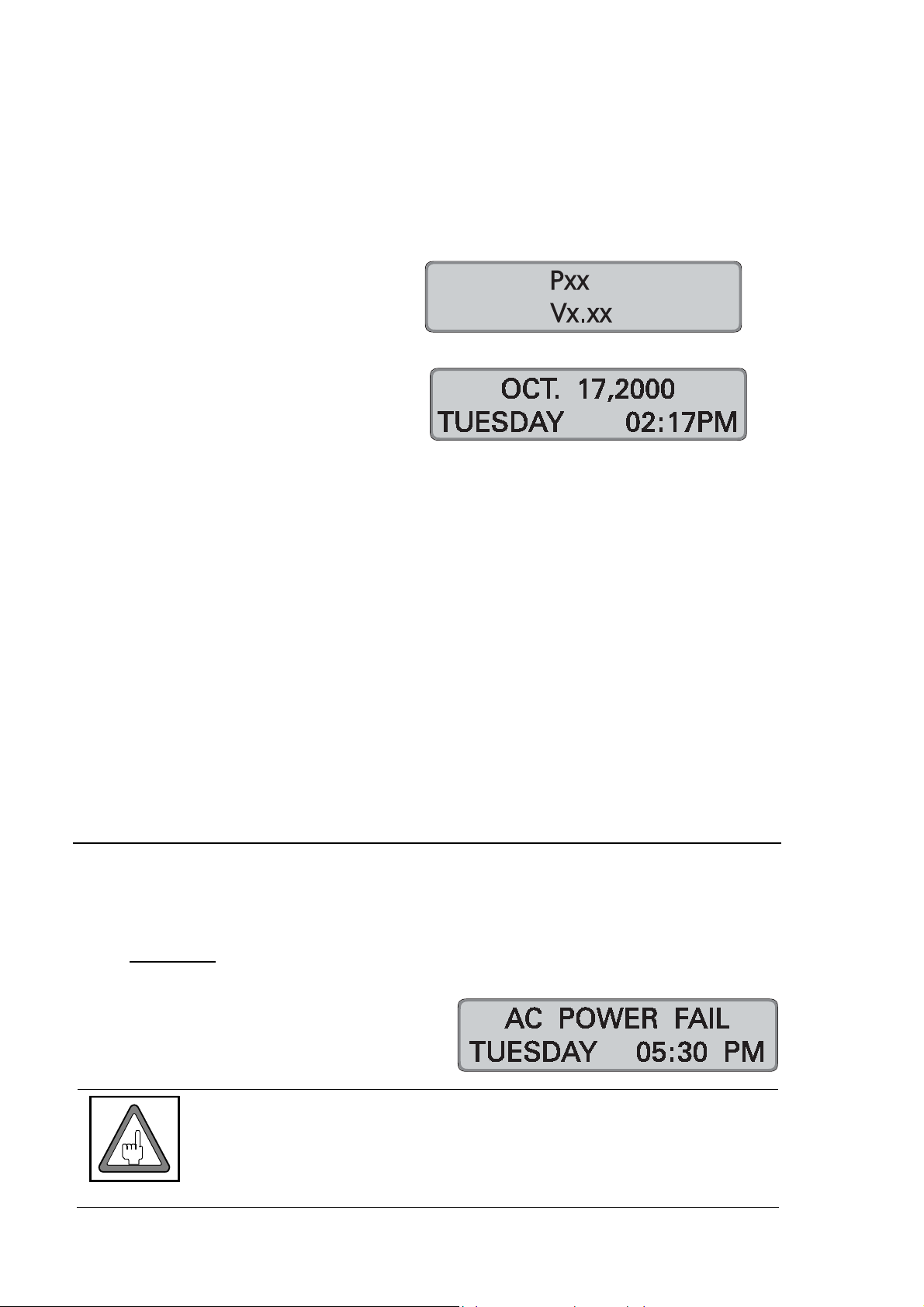

Powering Up The Time Recorder

The recorder is provided with a separate power switch. This power switch is located

inside the recorder, on the left hand side of the CPU-board.

Fig.12: PC-board with power switch

Chapter 4 Getting Started 4-3

Proceeding:

1. Make sure that the switch on the CPU board is in the off position (O).

2. Connect the time recorder’s power supply to the time recorder and then plug

the power supply into the closest AC power outlet.

3. Switch the power switch to position "1" (on).

→ Initialization is started

→ After a f ew seconds the

current date and time are

displayed.

Now the recorder is ready for operation. In some circumstances however, the

recorder may ask you to program the current time and date by displaying the

message "SET SYSTEM", and by flashing the hour digits.

→ For a detailed description of setting date and time, see "Time / Date" in

this chapter.

4. If the recorder has been programmed at our factory or by your dealer, close

the recorder by putting the front cover back on and locking it.

Now the recorder is ready for operation.

Familiarize yourself with the time recorder by punching a blank time card

several times. Additional information about using the time recorder is given in

chapter 5 "Punching at the Recorder“.

If the time recorder’s settings have not been previously programmed for your

application, you can now start to do so. Please refer to section "Programming"

in this chapter for a detailed description of programming procedures.

Powering Down the Time Recorder

1. Turn the time recorder off with the switch on the CPU board.

2. Observe the AC Power Fail message on the display.

3. Important

Wait a few seconds for the display to go blank.

4. Unplug the time recorder’s power

supply from the AC outlet.

Attention

Never plug or unplug the time recorder’s power supply with the

time recorder’s power switch in the On (1) position. This can

4-4 Getting Started Chapter 4

potentially create an electrical voltage spike that could damage

the time recorder’s CPU, which is not covered under warranty.

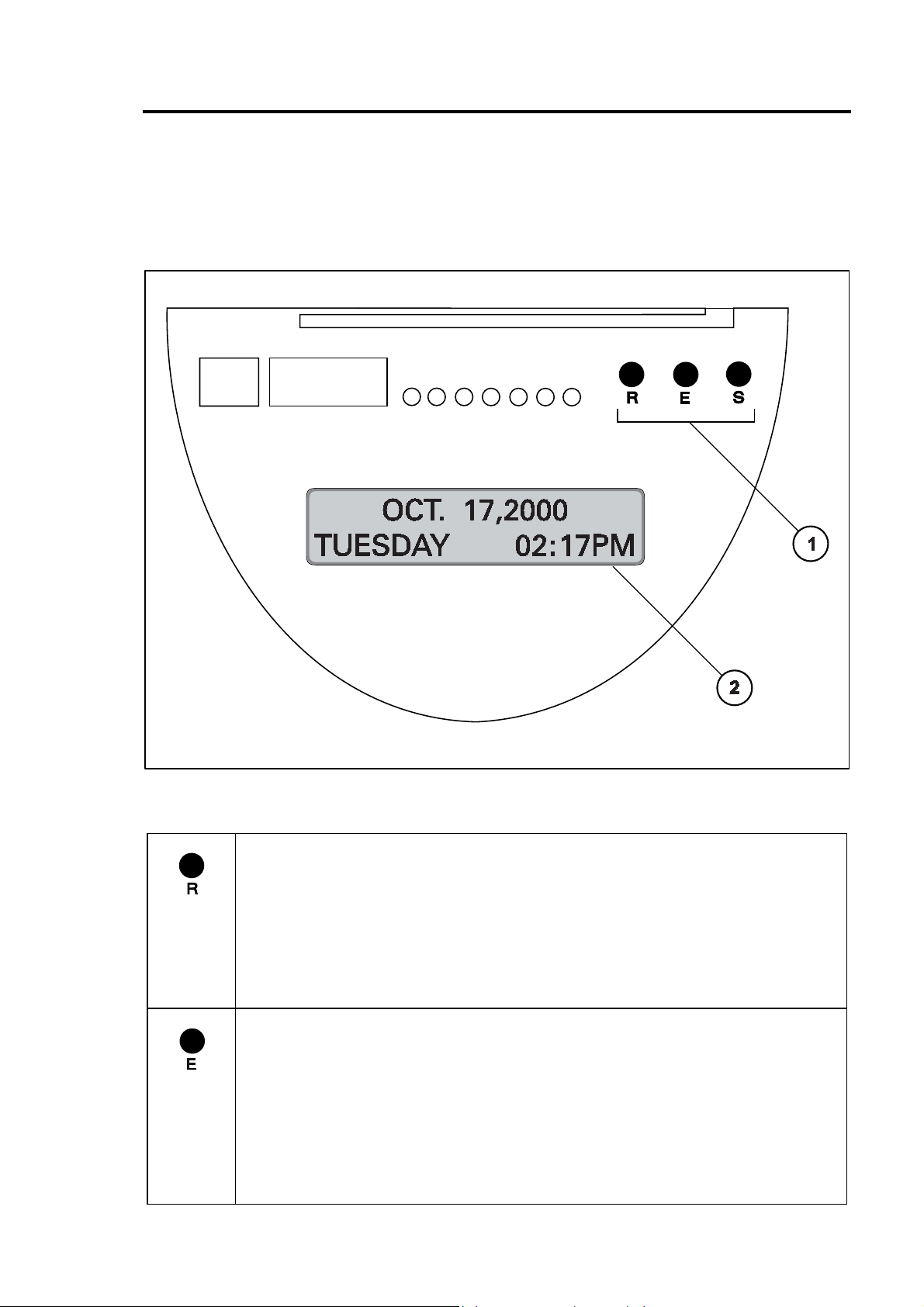

Programming Panel

For obvious security reasons, the time recorder’s programming panel is locked under

the front case cover and is not accessible to unauthorized users. To access the

panel, a user must have a key to unlock and remove the front cover.

Fig. 13: Programming panel

(1) Programming keys R, E and S (2) Two-line display

Key R 〈Revise value〉

→ Activates the programming routine when continually pressed for more

than two seconds.

→ Pressing the key once changes flashing displayed values in single

increments.

→ Keeping the key pressed changes displayed flashing values quickly

by scrolling through possible selections in a fast mode.

Key E 〈Enter〉

→ Activates the date and time setting routine.

→ When in the programming mode or in the time and date setting

mode, it enters into memory the values that the user selected with

the "R“ key. The display then switches to the next value in the current

programming field or to the next programming field. By repeated

pressing of the "E" key it is possible to scroll through and view

existing program settings.

Chapter 4 Getting Started 4-5

Key S 〈Skip〉

→ In the programming mode this key serves to sequentially skip from

the current programming field to the next field. However, for the "S“

key to perform this function, the user must have programmed all

values in the current field.

→ In the normal operating mode, this key serves to delete cards from

the time recorder’s memory (if the function Card Close Out is

enables)

Program display

→ Line 1 = program field

→ Line 2. = program value

The flashing character(s) is the

active value being programmed.

4-6 Getting Started Chapter 4

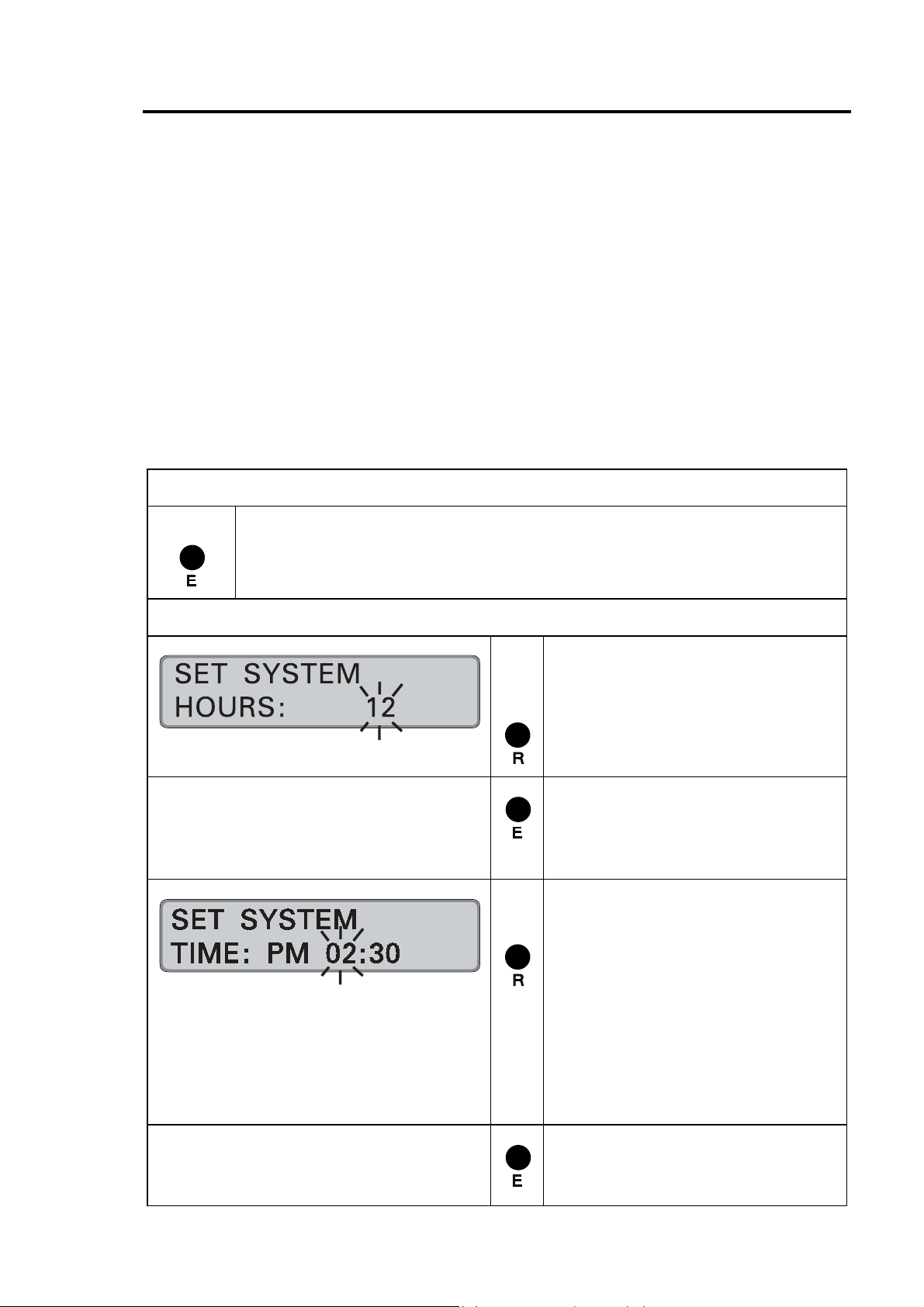

Date / Time

The recorder is provided with a battery-buffered quartz clock with power reserve. The

lithium battery stores the correct time for years in case of power failure.

Setting of date and time is usually necessary only during commissioning of the

recorder.

The exact display of the current date is guaranteed by an integrated “eternal

calendar“.

The PERFECT 2040 can be operated in two different time modes.

- 12 hour range with use of the AM/PM abbreviation for morning/afternoon

- 24 hour range from 0.00 to 24.00 hours.

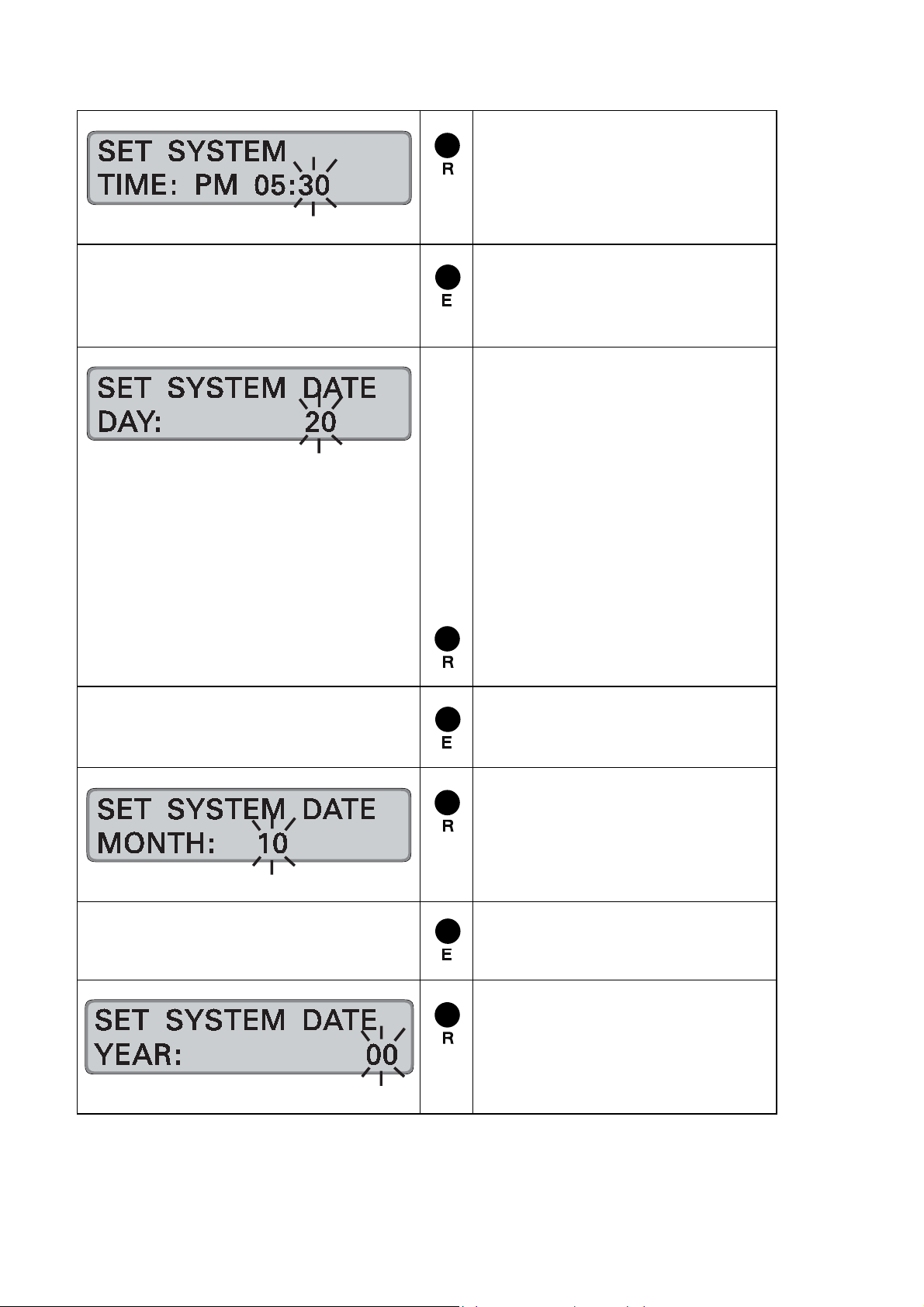

Calling up the setting routine

The recorder is switched on.

Press "E" (approx. 2 seconds) until display switches to "SET

SYSTEM".

Settings

The time mode has to be

determined before date and time

are set.

= Set the desired mode.

Range of values: 12 or 24

= Confirm setting.

Recorder changes to entry of

time.

Setting the time

Format: HH:MM

= Set desired hour

Range of values: 00 - 12

or 00 - 24

Hint: If the 12 hour time mode

is selected, a change from AM

to PM is to be achieved by

scrolling the hour value.

= Confirm setting.

Recorder changes to minutes.

Chapter 4 Getting Started 4-7

= Enter the desired minutes

Range of values: 00 - 59

Note: By keeping this key

pressed the value is scrolled.

= Confirm setting.

Recorder changes to date

input.

Date entry

Entry format: DD MM YY

The steps for setting the date are

divided into day, month, year.

Hint: The entry order does not

effect the display's date format

in normal operation mode.

First setting is the day

Range of values: 01 - 31

= Enter the desired day.

= Confirm setting.

Recorder changes to month.

= Set desired month.

Range of values: 01 - 12

Hint: By keeping this key

pressed the value is scrolled.

= Confirm setting.

Recorder changes to year.

= Set desired year.

Range of values: 00 - 99

Note: By keeping this key

pressed the value is scrolled.

4-8 Getting Started Chapter 4

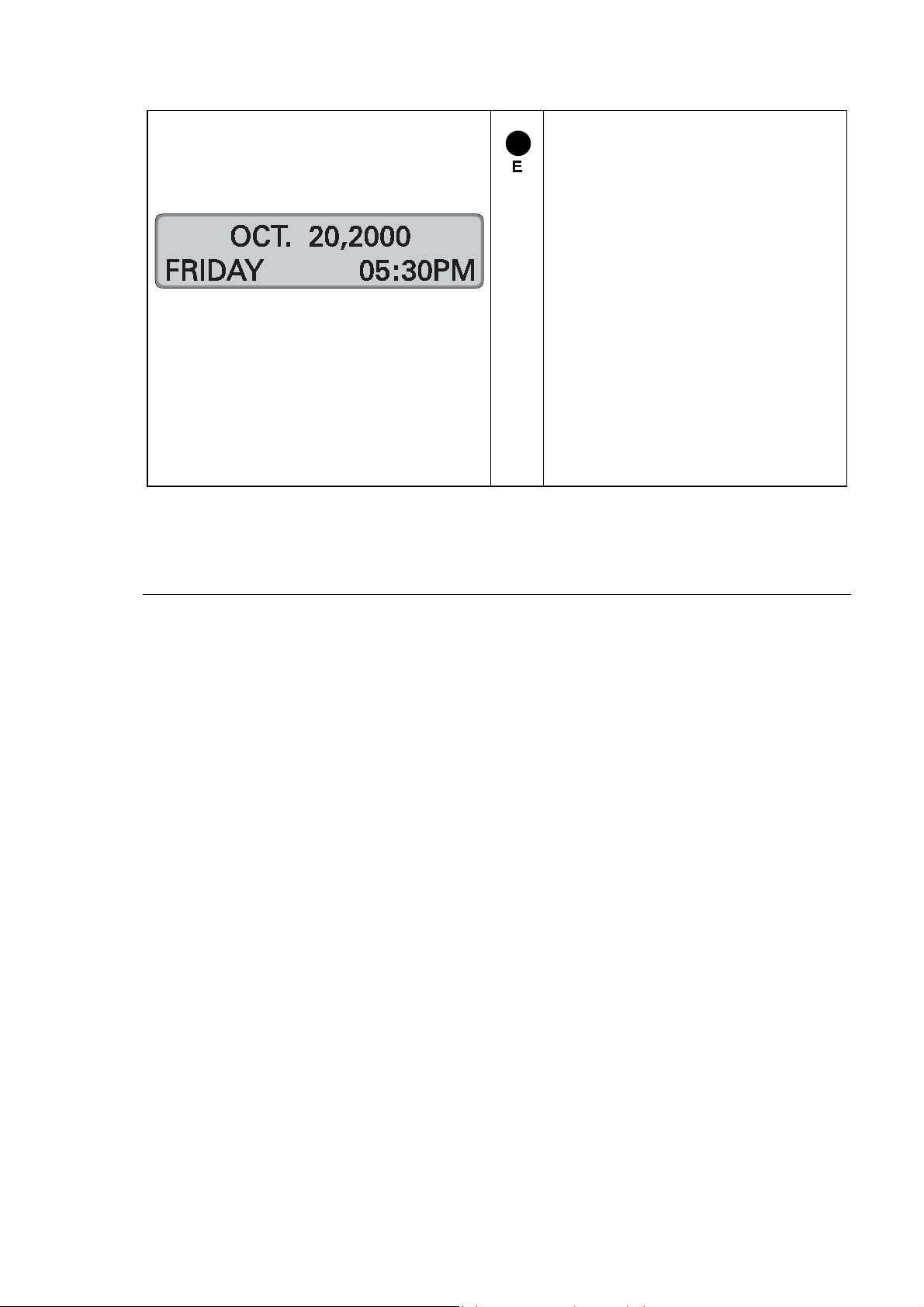

= Confirm the selection, setting

routine is completed.

The recorder changes to

operating display and shows

the current date and time.

Hint: If the "Master Clock"

option is enabled in the

function programming, the

time recorder will immediate ly

begin to transmit minute

impulses to connected slave

clocks. Refer to the

programming instructions "

"Setting time of slave clocks".

Setting the Time only

After setting the time, you can skip setting the date (if not required), by pressing the

"E" key until the recorder returns to its normal operating mode display.

Conversely, if you only want to set the date and do not wish to change the time, you

can jump ahead to the date entry fields by pressing the "S" key just once.

Chapter 4 Getting Started 4-9

Set Time of Slave Clocks (optional)

Hint

The following procedure is only performed when slave clocks are

connected to the time recorder. The default setting from the

"Slave clocks“ are clocks whose time is controlled by a "master clock“. These clocks

can be other time recorders or wall clocks mounted in common work areas such as

lunch rooms and offices. Configuring a master / slave clock system benefits users by

establishing one "official“ workplace time and by providing automatic resetting of

connected time devices after power failures or after Daylight Savings Time changes.

factory is to disable this option, therefore this routine should not

be done until after the initial start-up of the time recorder.

For further details please contact your local dealer where you

have purchased the time recorder or e-mail us at:

support@ca.isgus.com

or

techsupport@isgus.com

A master / slave clock system of synchronized workplace time has the following

pre-requisites:

• The "Master Clock“ hardware and software options have been installed in the

PERFECT time recorder.

• The "Slave Clock“ hardware and software options have been installed in those

time recorders designated as slave clocks.

• A 12“ diameter, 12 volt ISGUS system wall clock has been installed in those

locations (locker rooms, offices etc.) designated to be slave clocks.

• All slave clock locations have been wired and connected back to this time

recorder’s (the master clock) location with two #14 AWG copper conductors.

• All installation work must be performed and verified by qualified staff.

Proceed as follows:

1. Ensure that the hardware and installation prerequisites previously listed

have been met.

2. Check or set time and date for this recorder.

3. Carry out the complete programming routine of the time recorder.

→ By enabling the function "Master Clock" this recorder is defined

as a master clock.

4. Re-enter the "Set time and date“ program mode for this time recorder.

5. Follow the steps of the below sequence. A distinction is made between

slave clocks with:

− Straight Polarity operation

− Reverse Polarity operation

As to the operating mode of your slave clocks please refer to the

manufacturers specifications

4-10 Getting Started Chapter 4

Slave clock synchronization with unipolar activation

= Call up the set time and date

routine.

! Confirm time of master clock

with "S" and date with "E"

! If it is necessary to change

time and/or date of master

clock, see previous

instructions " setting routine

time and date"

! After having confirmed the

year with "E" the recorder

changes to slave clock

synchronization.

Set the slave clocks manually to

the same time

Set the slave clock time on the

master clock.

= Set the value.

= Confirm settings, continue with

Time setting, see previous

instructions

Slave clock synchronization with bipolar activation

= Call up the set time and date

! Confirm time of master clock

1. value = hours,

2. value = minutes

next value

routine.

with "S" and date with "E"

! If it is necessary to change

time and/or date of master

clock, see previous

instructions " setting routine

time and date"

Chapter 4 Getting Started 4-11

! After having confirmed the

year with "E" the recorder

changes to slave clock

synchronization.

Set slave clocks manually to the

same time

Hint: This display only appears

when the setting "Reverse Pola"

has been selected in the

parameter "Master Clock".

= Transmit single impulses to

the slave clocks.

1 = positive impulses

0 = negative impulses

Positive / negative impulse

selection alternates with each

key actuation.

Make sure that with each

impulse, all slave clocks advance

at even resp. odd numbered

minutes.

! Reverse the polarity

connection of the slave clocks

that do not advance

When all slave clocks advance in

After completing the entry by pressing "E" the slave clocks are set automatically to

the current time of the master clock.

The automatic resetting of the slave clock may take several minutes, after which the

time recorder returns immediately to the normal operating mode. Punching time

cards, at the time recorder is possible during slave clock synchronization.

unison, confirm the process with

"E".

Set the slave clock time on the

master clock.

= Set the value.

1. value = hours,

2. value = minutes

= Confirm settings, continue with

next value

Time setting, see previous

proceeding.

4-12 Getting Started Chapter 4

Programming

The programming of the PERFECT is made in 2 menus:

- Main Programming Menu

- Options Menu

Each menu is divided into menu items, which must be programmed in chronological

order. For each item, the current programming field is described on the first line of

the time recorder’s display.

Unless it is mandatory, a programming field can be skipped by pressing the "S“ key.

If you do not wish to change a value, simply press the "E“ key and you will advance

to the next field without changing that value.

Hint

The values used on the next pages are only examples and may

differ from your values.

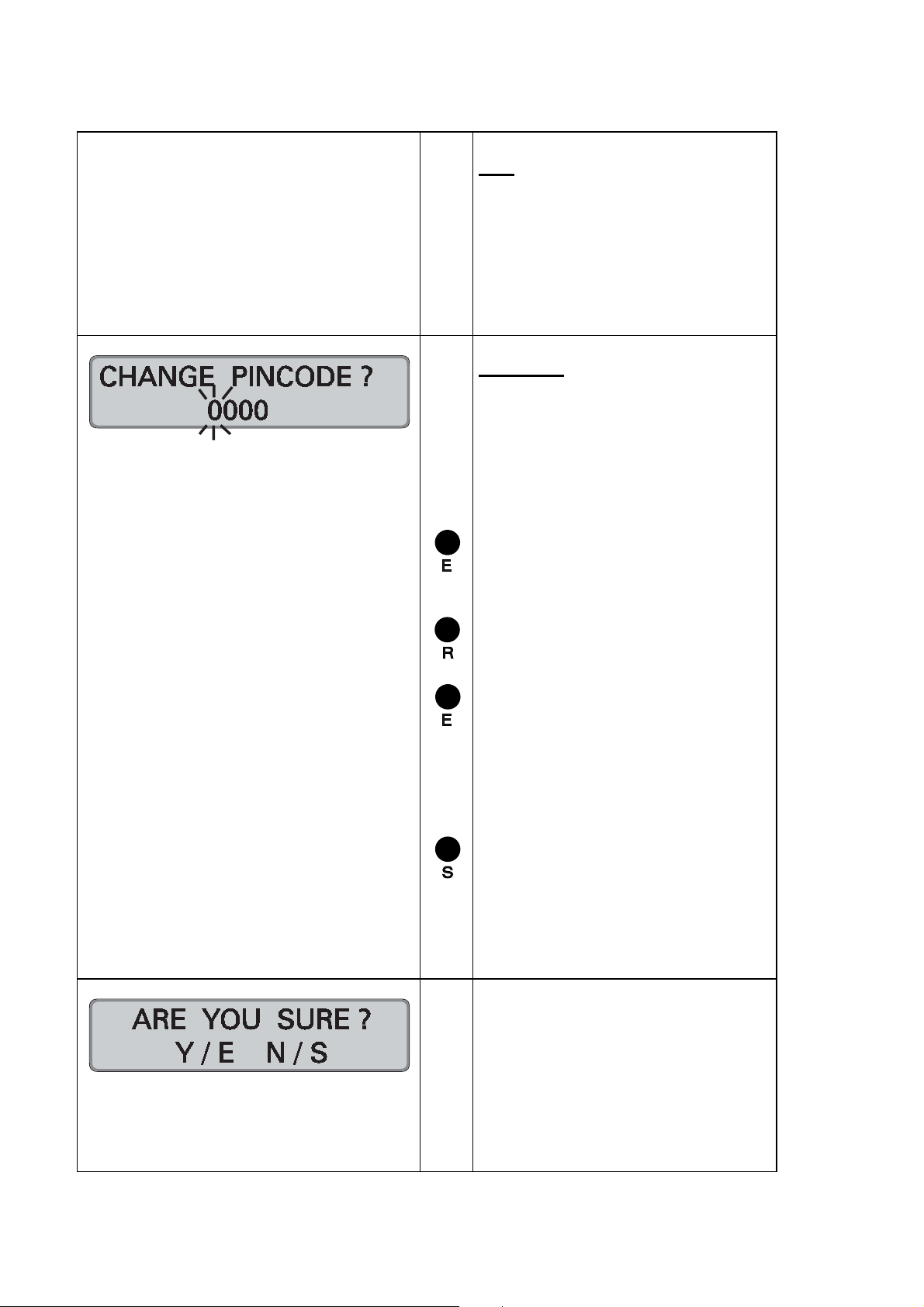

To ensure system integrity, access to the programming mode is protected by a 4 digit

numeric PIN code. An initial PIN is assigned to this PIN code ex factory.

If an incorrect PIN code is entered, the time recorder automatically exits the

programming mode.

In the examples, the 12 hour time mode is always used.

The factory set initial PIN code is : 0 0 0 0

Attention

Extreme caution is advised. It is recommended to replace the

factory-set initial PIN code with your own individual number.

However, if you forget your unique PIN code, you will have to

return the time recorder to ISGUS for reprogramming.

Chapter 4 Getting Started 4-13

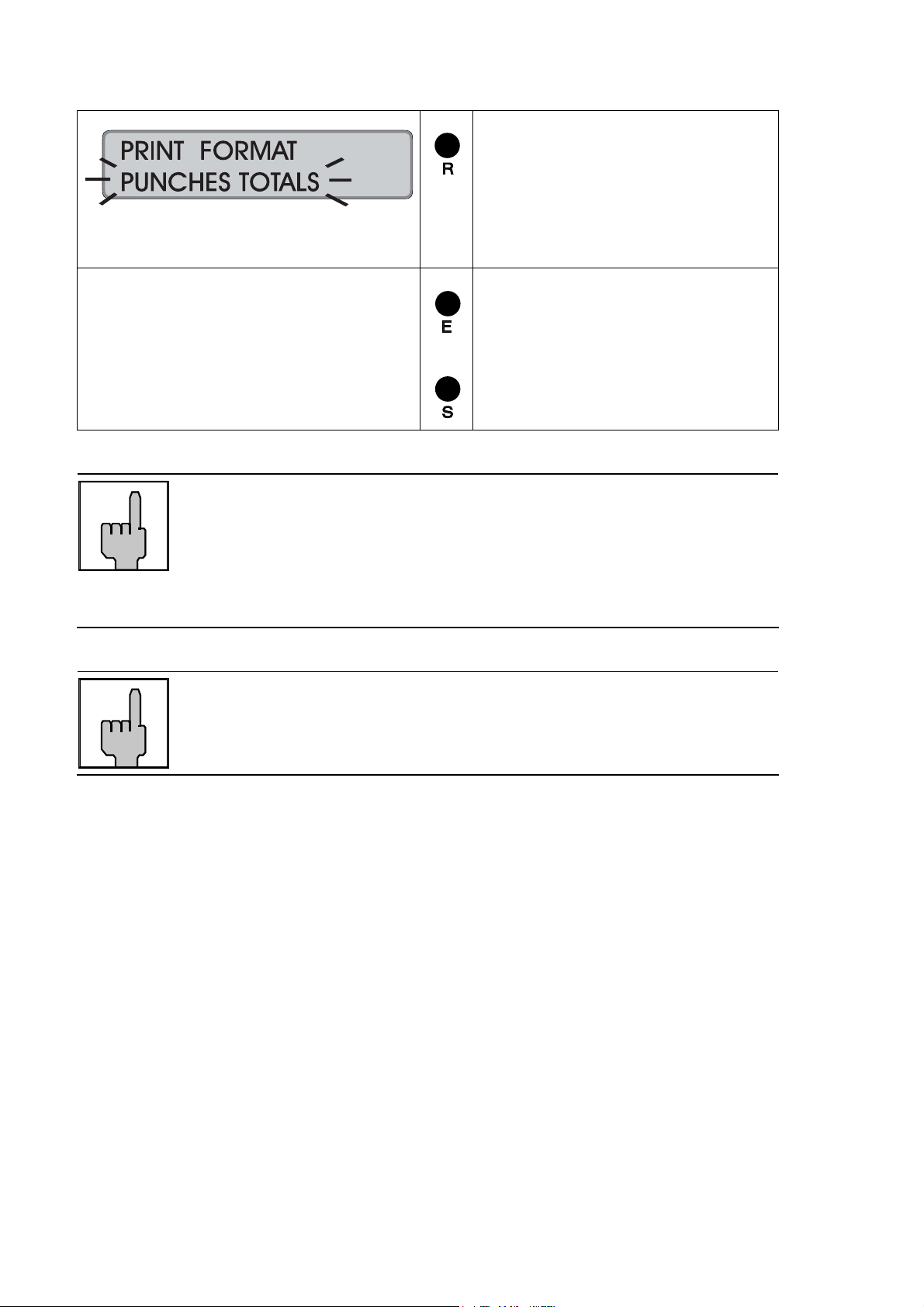

Calling up the Programming Routine for the Main Programming Menu

To call up the programming routine for the main programming menu, the front cover

of the recorder must be removed. If the recorder is switched off, you must switch it

on with the mains switch. Refer to section "Switch on recorder".

Calling up the programming routine

→ Recorder is switched on.

Press "R" (at least 2 seconds) until display switches to

"ENT.EXISTING PIN".

PIN-code input

Each PIN-code input is started with the

display of a 4-digit zero. The first digit

flashes.

For the first calling up and if the

PIN Code is not changed

the initial PIN = 0000

The entry of the code-number

begins with the left flashing digit.

If initial PIN is kept

The recorder continues with

function "PRINT FORMAT".

If individual PIN is entered

= enter each digit and

= confirm each digit

Recorder changes to next input

digit.

After having confirmed the last

digit with key "E" the recorder

continues with function "PRINT

FORMAT".

4-14 Getting Started Chapter 4

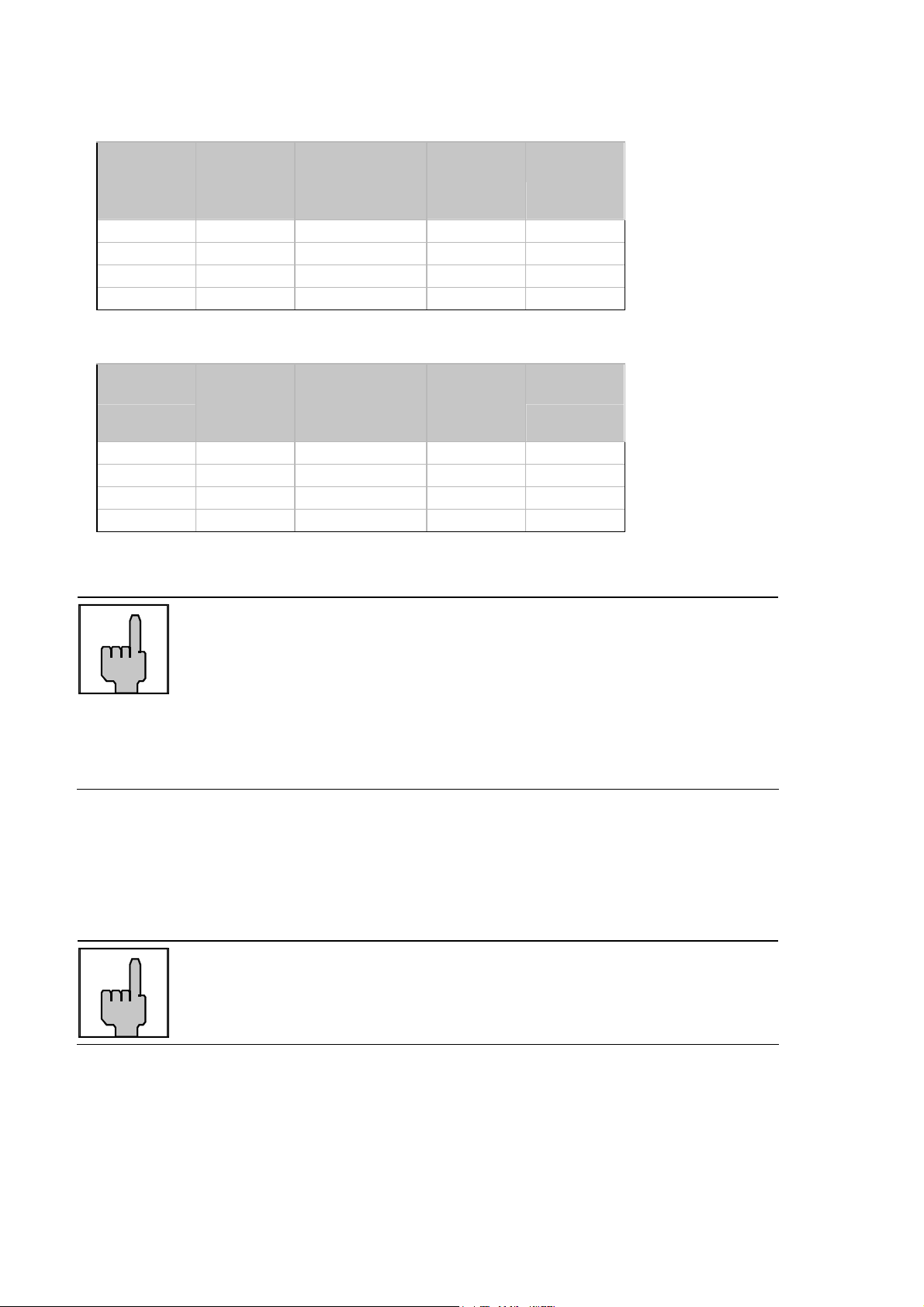

Print Format

Print formats determine how and where

"IN" punches, "OUT" punches, and various

combinations of hour totals are printed on

the time card.

With the aid of this function you can select

in addition the minutes printing format.

Format

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

Column 1 Column 2 Column 3 Column 4 Column 5 Column 6 Column 7 Column 8 Column

Date IN time OUT time Interval

Date IN time OUT time Interval

Date IN time OUT time Card

Date IN time OUT time IN time OUT time

Date IN time OUT time Interval

Date IN time OUT time Interval

Date IN time OUT time Card

Date IN time OUT time

Date IN time OUT time Reg Hrs

Date IN time OUT time Reg Hrs

Date IN time OUT time Reg Hrs

Date IN time OUT time Reg Hrs

Date IN time OUT time Reg Hrs

Card example

Total

Total

Total

Total

Interval

Total

Card

Total

Interval

Total

Interval

Total

Interval

Total

9

Card

Total

IN time OUT time Interval

Total

Card

Total

Total

OT Hrs

Interval

Total

OT Hrs

Card

Total

OT 1+ 2

Hrs

Interval

Total

OT 1 Hrs

Interval

Total

OT Hrs

Interval

Total

IN time OUT time Interval

Total

Total

IN time OUT time Card

Reg Hrs

Card

Total

IN Time Out Time Reg Hrs

Card

Total

Reg Hrs

Card

Total

OT 2 Hrs

Interval

Total

Reg Hrs

Card

Total

Reg Hrs

Card

Total

OT Hrs

Card

Total

OT 1 Hrs

Card

Total

OT 1 Hrs

Card

Total

Card

Total

Total

OT Hrs

Card

Total

OT Hrs

Card

Total

OT 2 Hrs

Card

Total

OT 2 Hrs

Card

Total

Chapter 4 Getting Started 4-15

Hint

With the unit you can use one of 2 possible standard card types.

The cards differ by their card width. The print formats 1 to 3 and

Formats 1-8

In columns 4 and 8 the clocking difference between IN and OUT punchings is

determined and printed.

In columns 5 and 9 the cumulative totals of the presence time are shown.

The totals are added until a new card without total carryover is used or the card is

deleted in the recorder.

Format 9

The normal time is printed out in column 4 and the ov er time i s pri nted out i n column 5.

The total from column 4 and column 5 produces the presence time.

Column 8 shows the cumulative total of normal time.

Column 9 shows the cumulative total of overtime.

The totals are added until a new card without total carryover is used or the card is

deleted in the recorder.

Format 10

The cumulative total values of normal time are printed out in columns 4 and 8.

9 to 12 are not suited for the small card type.

In columns 5 and 9 the cumulative totals of overtime are shown.

The totals are added until a new card without total carryover is used or the card is

deleted in the recorder.

Format 11

The normal time is printed out in column 4 and the ov erti me of account 1 and

account 2. is printed out in col umn 5. The total from column 4 and column 5 produces

the presence time.

Column 7 shows the cumulative total of normal time.

Column 8 shows the cumulative total of overtime account 1

Column 9 shows the cumulative total of overtime account 2

The totals are added until a new card without total carryover is used or the card is

deleted in the recorder.

Format 12

The cumulative total values of normal time are printed out in columns 4 and 7.

In columns 5 and 8 the cumulative totals of overtime account 1 are shown.

In columns 6 and 9 the cumulative totals of overtime account 2 are shown.

The totals are added until a new card without total carryover is used or the card is

deleted in the recorder.

4-16 Getting Started Chapter 4

Format 13

The normal time is printed out in column 4 and the ov er time i s pri nted out i n column 5.

The total from column 4 and column 5 produces the presence time.

Column 6 shows the cumulative total of normal time.

Column 7 shows the cumulative total of overtime.

The totals are added until a new card without total carryover is used or the card is

deleted in the recorder.

Hint

In order to be able to better understand how differences and

totals are determined and for reasons of clarity, we recommend

Factory setting: → Format 09 or 13 and

print format for minutes = 1/60 hours.

not to change the print format as long as printing is being carried

out on the same card.

Proceeding

= Select print format

or

= Confirm setting

= Print format for minutes

Range of values:

01MIN = 1/60 h

15MIN = 1/4 h

10THS = 1/10 h

100THS = 1/100 h

= Confirm selection and continue

with next parameter.

Hint! If 10THS or 100THS is

selected for the minutes

printout, the unit switches to

the next input level.

Chapter 4 Getting Started 4-17

= Select range of validity for

Hint

If 10THS or 100THS is selected as the format for the minutes

printout, a * is displayed to the right of the current time on the

display, e.g. Monday 07.49 A*.

A conversion table for the individual minute print formats is to be

found in Annex D.

or

minute printing format.

Range of values: Totals,

Punches

+ Totals

= Confirm selection and continue

with next parameter.

Hint

Differences and totals are always calculated in hours and

minutes, but they are always printed out in hours and the

selected minute print format.

4-18 Getting Started Chapter 4

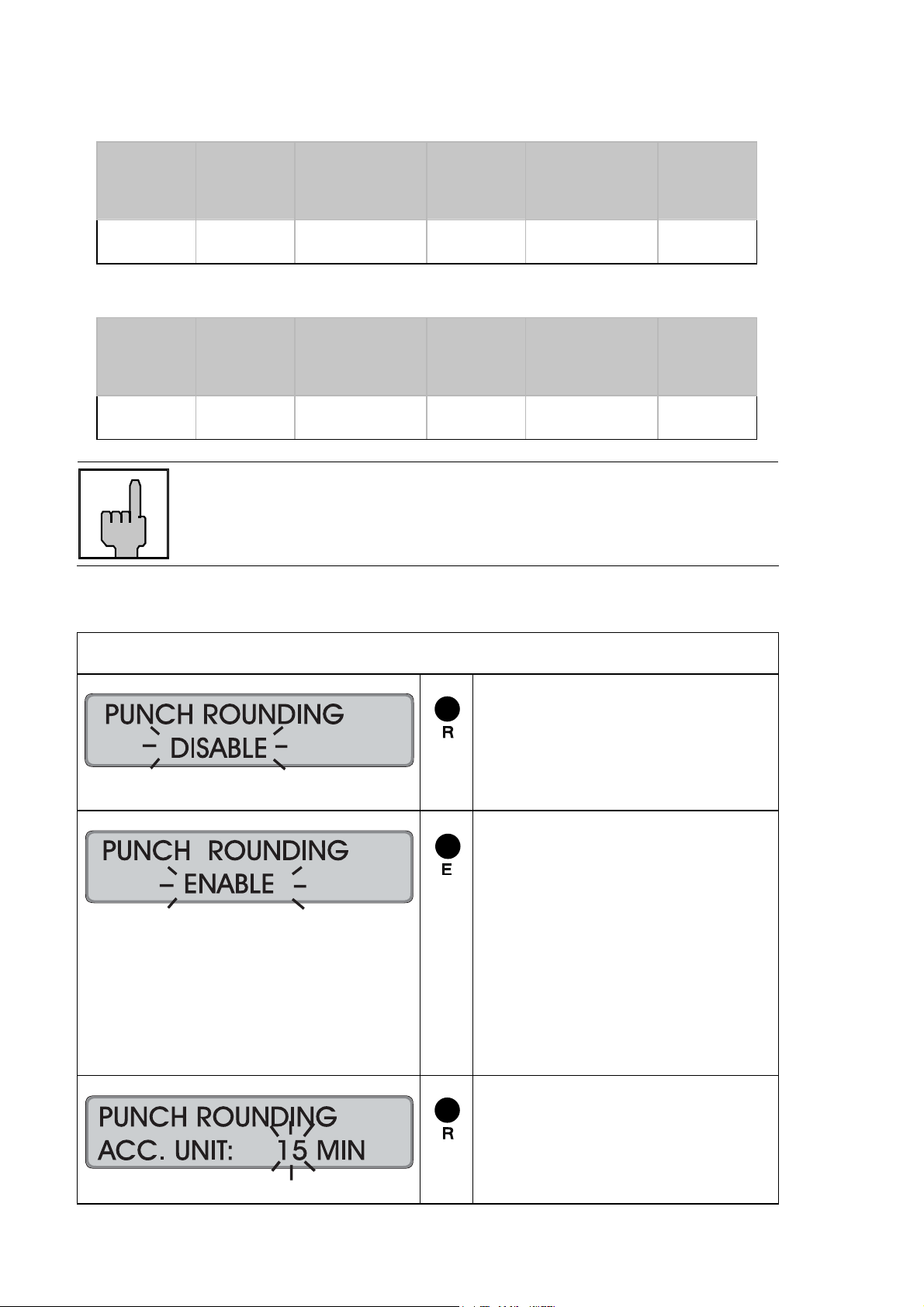

Punch Rounding

The PERFECT has the ability to round "In“ and "Out“ punches either forwards or

backwards depending on company defined qualification periods.

The first step in programming punch rounding is to establish the time intervals that

the time recorder will divide work hours into. We call these "time accounting units“.

The available time accounting units are: 2, 3, 5, 6, 10, 12, 15, 20 and 30 minutes.

Additionally, rounding qualifications can be determined separately for IN and OUT

punchings. The rounding qualification can be set and defines in which case a

punching is rounded up or down. These qualifications are called "Late IN" for IN

punchings and "Early OUT" for OUT punchings.

For IN punchings, the qualification always begins with the beginning of the interval.

For OUT punchings, the qualification is always considered retroactively from the end

of the interval.

If punchings are within the qualification, the recorder always rounds in favour of the

employee. That is to say, for IN punchings the recorder rounds down , for OUT

punchings the recorder rounds up.

If punchings are beyond the qualification or if they are equal to the qualification

value, the recorder always rounds not in favour of the employee. That is to say, for

IN punchings the recorder rounds up, for OUT punchings the recorder rounds down.

Example:

Rounding interval = Accounting Unit 15 minutes

Rounding qualification IN = Late IN 7 minutes

Rounding qualification OUT = Early OUT 10 minutes

Punching Time Rounded

IN 7:45 7:45

IN 7:51 7:45

IN 7:52 8:00

IN 8:00 8:00

OUT 11:45 11:45

OUT 11:50 11:45

OUT 11:51 12:00

OUT 12:00 12:00

In addition, it is possible to define whether the rounded or the not rounded original

time is to be printed on the time card.

Chapter 4 Getting Started 4-19

not rounded original punching time is printed

Date IN

(printed)

IN

(rounded and

not printed)

OUT

(printed)

OUT

(rounded and

not printed)

03.12.00 AM 7:51 AM 7:45 AM 11:50 AM 11:45 4.00

04.12.00 AM 7:52 AM 8:00 AM 11:51 PM 12:00 8.00

rounded punching time is printed

Date IN

(not printed)

IN

(rounded and

printed)

OUT

(not printed)

OUT

(rounded and

printed)

03.12.00 AM 7:51 AM 7:45 AM 11:50 AM 11:45 4.00

04.12.00 AM 7:52 AM 8:00 AM 11:51 PM 12:00 8.00

Hint

When determining the punching differences and the totals, the

recorder in both cases calculates with the rounded IN and OUT

punches.

Factory setting: → function deactivated

Total

Total

Proceeding

= Activate the function.

Or:

Switch to the next parameter

with "S".

= Confirm setting.

Recorder changes to the input

level.

1st setting = Rounding

interval

2nd setting = Rounding

qualification IN

3rd setting = Rounding

qualification

OUT

= Set rounding interval.

The intervals are fix and

defined in steps of 2, 3, 5, 6,

10, 12, 15, 20 and 30 minutes.

4-20 Getting Started Chapter 4

= Confirm selection.

= Set rounding qualification for

IN punching.

Range of values: 00 - 29 min.

Hint: By keeping this key

pressed the value is scrolled.

= Confirm selection.

= Set rounding qualification for

OUT punching.

Range of values: 0 - 29 min.

Note: By keeping this key

pressed the value is scrolled.

= Confirm selection.

Recorder changes to next

input level.

= Select time to be printed on

the card:

Range of values:

unrounded,

rounded.

= Confirm selection and return to

menu level.

= Continue with next parameter.

Hint: Use "E" to return to the

input level.

Hint

In order to be able to better understand how differences and

totals are determined and for reasons of clarity, we recommend

setting only one type of rounding in the recorder, either PUNCH

ROUNDING or TOTALS ROUNDING.

Chapter 4 Getting Started 4-21

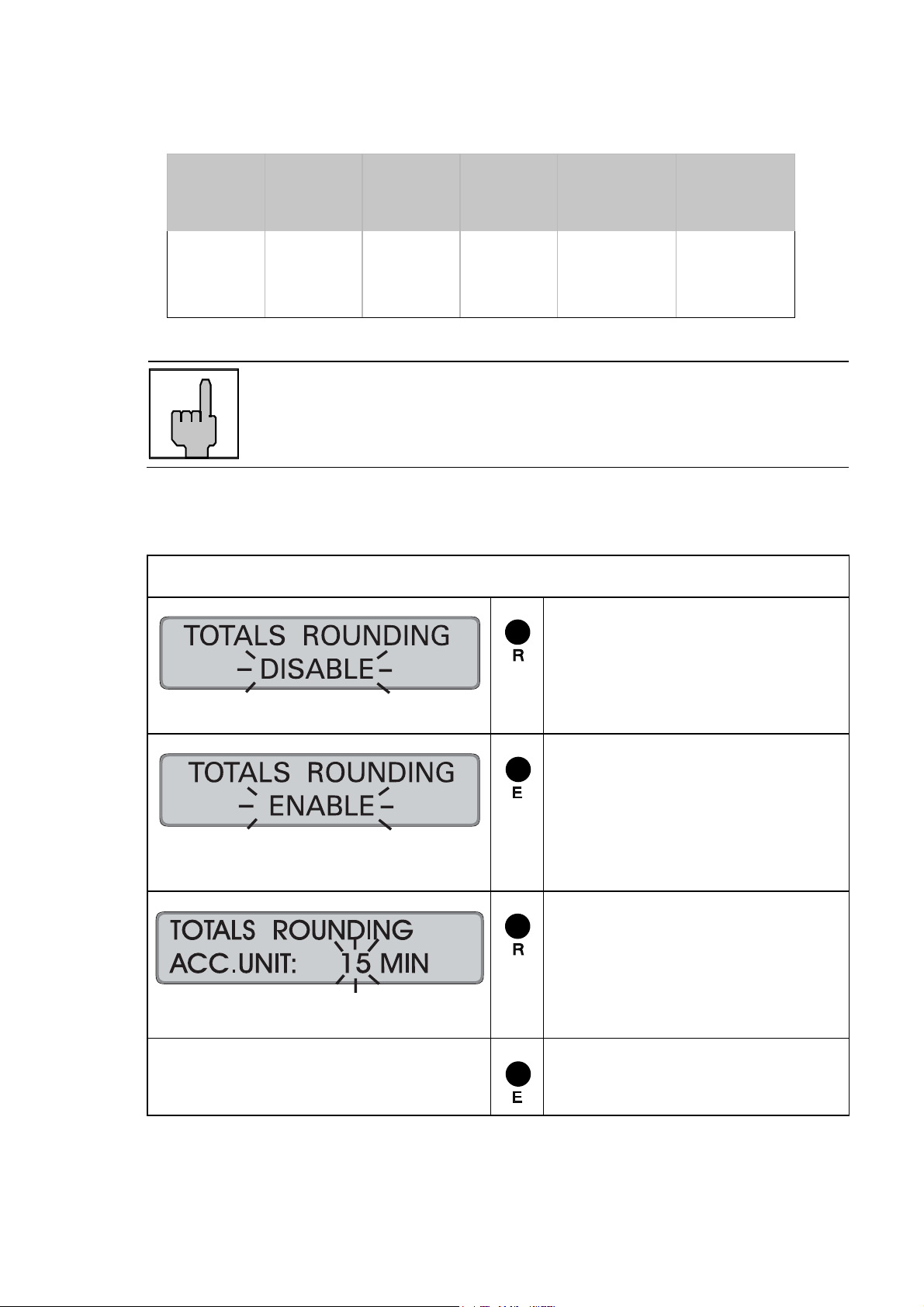

Totals Rounding

The recorder has a rounding function for results.

The intervals that the time recorder will divide work hours into are called "time

accounting units".

The time accounting units (rounding intervals) can be selected in steps of:

2, 3, 5, 6, 10, 12, 15, 20 and 30 minutes.

In addition a rounding qualification can be created. The rounding qualification can be

set and defines in which case a punching is rounded up or down.

The qualification is always regarded retroactively from the end of the interval.

If results are within the qualification, the recorder always rounds in favour of the

employee i.e. it rounds up.

If results are beyond the qualification or if they are equal to the qualification value,

the recorder always rounds not in favour of the employee, i.e. it rounds down.

Depending on the setting, the recorder rounds either totals (= exclude sub-totals) or

differences (= include sub-totals).

Examples

Rounding interval = Accounting Unit 15 minutes

Rounding qualification = Grace setting 7 minutes

Example 1 Rounding totals (= exclude sub-totals)

Date IN OUT Difference

(printed)

Total

(not printed)

01.12.00 AM 7:00 AM 11:08 4.08 4.08 4.00

01.12.00 PM 1:00 PM 5:16 4.16 8.24 8.30

02.12.00 AM 7:00 AM 11:15 4.15 12.39 12.45

02.12.00 PM 1:00 PM 5:14 4.14 16.53 16.45

Hint

With this setting the totals are determined by first adding the

differences and then rounding them.

4-22 Getting Started Chapter 4

Total

(rounded and

printed)

Example 2 Rounding differences (= include sub-totals)

Date IN OUT Difference

(not printed)

Difference

(rounded and

printed)

01.12.00 AM 7:00 AM 11:08 4.08 4.00 4.00

01.12.00 PM 1:00 PM 5:16 4.16 4.15 8.15

02.12.00 AM 7:00 AM 11:15 4.15 4.15 12.30

02.12.00 PM 1:00 PM 5:14 4.14 4.15 16.45

Hint

With this setting the totals are determined by first rounding the

differences and then adding them.

Factory setting: → function deactivated

Proceeding

= Activate the function.

Total

(printed)

Or:

Switch to the next parameter

with "S".

= Confirm setting.

Recorder changes to the input

level.

st

setting = R interval

1

nd

2

setting = R qualification

= Set rounding interval.

The intervals are fix and

defined in steps of 2, 3, 5, 6,

10, 12, 15, 20 and 30 minutes.

= Confirm selection.

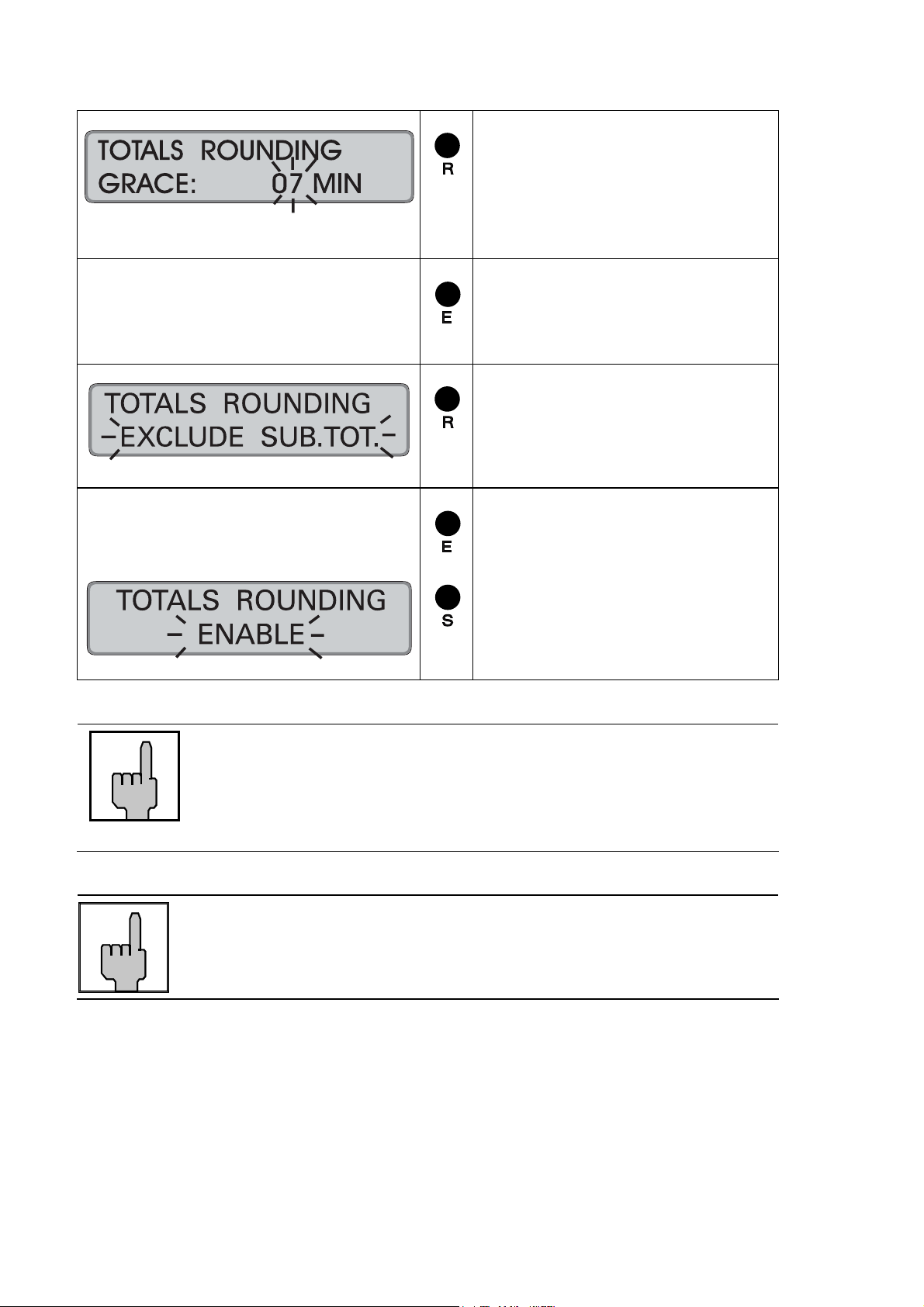

Chapter 4 Getting Started 4-23

= Set rounding qualification.

Range of values: 00 -14 min.

Hint: By keeping this key

pressed the value is scrolled.

= Confirm selection.

Recorder changes to input

level.

= Select function.

Selection:

- EXCLUDE SUB.TOT

- INCLUDE SUB.TOT

= Confirm selection and return to

menu level.

= Continue with next parameter.

Hint: Use "E" to return to the

input level.

Hint

In order to be able to better understand how differences and

totals are determined and for reasons of clarity, we recommend

setting only one type of rounding in the recorder, either PUNCH

ROUNDING or TOTALS ROUNDING.

Hint

If, in addition, the OVERTIME function is activated, also the

rounded values for overtime totals are printed.

4-24 Getting Started Chapter 4

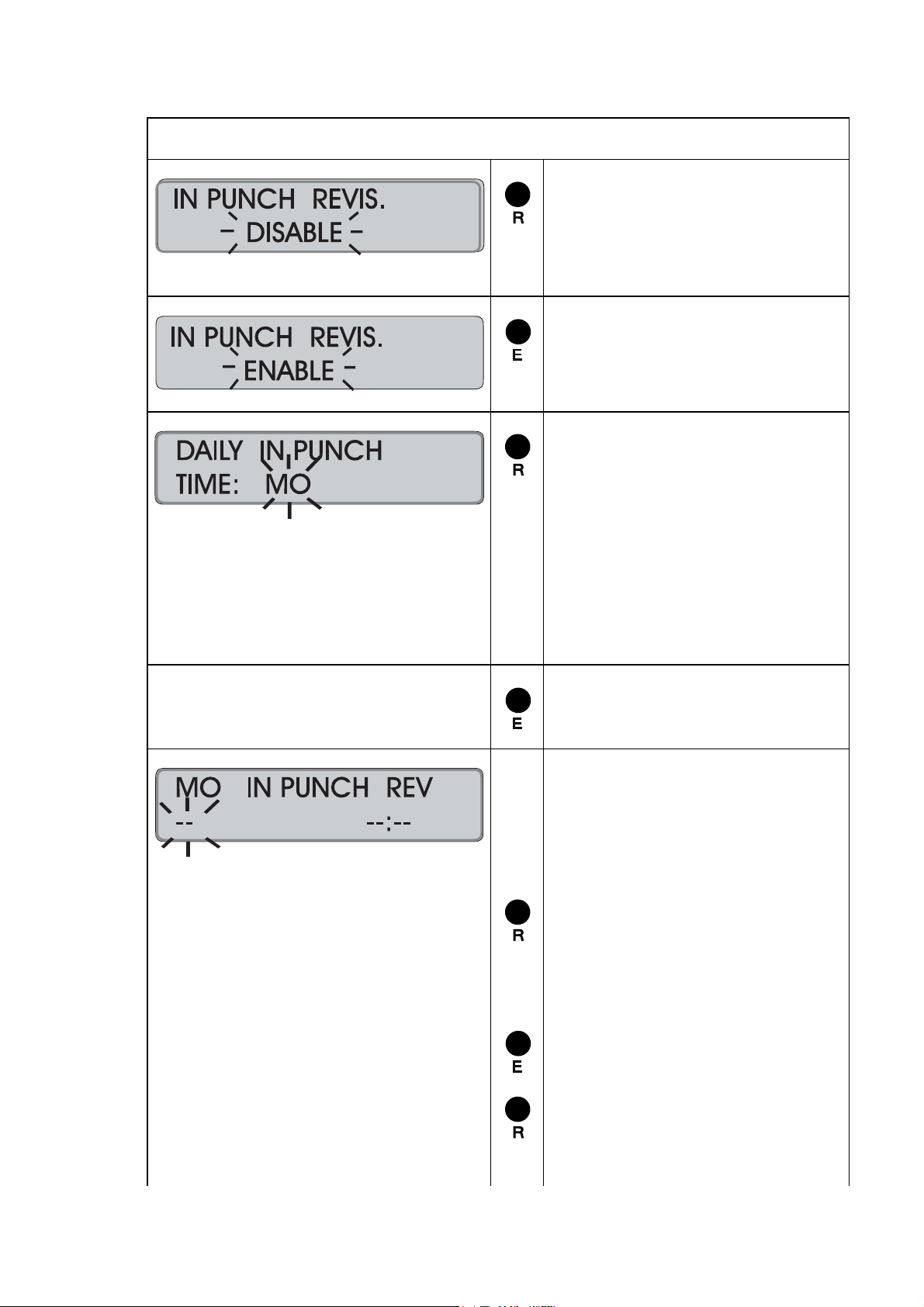

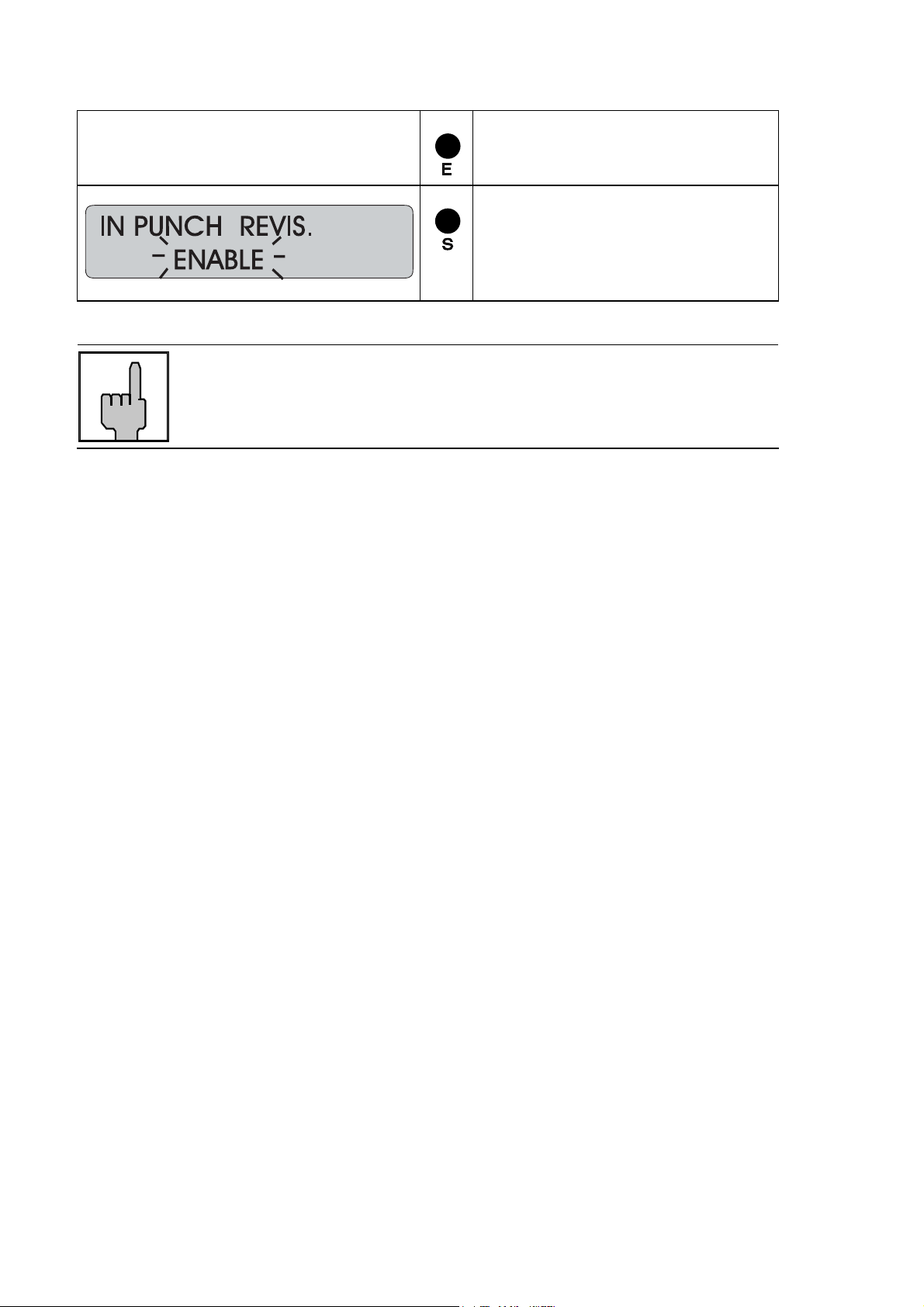

IN Punch Revisions

It is possible to set 4 time ranges per weekday within which the first IN punch of the

employees is rounded.

The definition of such revision time ranges makes it possible to

- round the first IN punch of an employee to the start of working time

e.g. for shifts

Additionally, it is possible to determine a rounding qualification, which is valid for all

revision time ranges of the week.

The qualification value (grace) is always considered retroactively from the end of the

interval.

Within the defined revision time range the first IN punch is rounded to the rounding

time. The rounding time results from revision time range end minus grace.

Punches at revision time range start are rounded to the rounding time,

punches at the revision time range end are not rounded.

Example A: Revision time range: from = AM 07:30 to = AM 08:07

Grace: 07 minutes

Rounding time: = revision time range end minus grace

= AM 08:07 - 00:07 = AM 08:00

Punching Time Rounded

IN AM 7:30 AM 8:00

IN AM 8:01 AM 8:00

IN AM 8:06 AM 8:00

IN AM 8:07 AM 8:07

In addition, it is possible to define whether the rounded or the not rounded original

time is to be printed on the time card.

Hint

When determining the punching differences and the totals, the

recorder calculates with the rounded IN punches.

Chapter 4 Getting Started 4-25

not rounded original punching time is printed

Date IN

(printed)

IN

(rounded and

not printed)

OUT

25.11.02 AM 7:30 AM 8:00 PM 12:00 4.00

26.11.02 AM 8:01 AM 8:00 PM 12:00 8.00

27.11.02 AM 8:06 AM 8:00 PM 12:00 12.00

28.11.02 AM 8:07 AM 8:07 PM 12:00 15:53

rounded punching time is printed

Date IN

(not printed)

IN

(rounded and

printed)

OUT

25.11.02 AM 7:30 AM 8:00 PM 12:00 4.00

26.11.02 AM 8:01 AM 8:00 PM 12:00 8.00

27.11.02 AM 8:06 AM 8:00 PM 12:00 12.00

28.11.02 AM 8:07 AM 8:07 PM 12:00 15:53

Total

Total

Hint

In order to use this function for punch pairs, where the first IN

punch is rounded up to a time after the date change, the IN

punch revision schedule must also be defined beyond the date

change.

In the input routine possible time settings for the following day

are automatically marked with "+" in the 12 hours mode as well

as in the 24 hours mode (see the following example)

Example B: Revision time range on Monday: from = PM 11:30 to = AM + 00:22

Grace: 07 minutes

Rounding time: = revision time range end minus grace

= AM + 00:22 - 00.07 = AM + 00:15

Hint

If IN punches on Tuesday in the revision time range AM 00:00 to

AM 00:22 should be rounded to AM 00:15, it is necessary to

enter a corresponding time schedule for Tuesday.

Factory setting: → function deactivated

4-26 Getting Started Chapter 4

Proceeding

= Activate the function

Or:

Switch to the next parameter

with "S".

= Confirm setting

Recorder changes to the next

input level.

= Select the day of the week to

program the IN punch revision

schedule.

Range of values: MO to SU

Example: MO;

It is also possible to start on

any other weekday.

Note: By keeping this key

pressed the value is scrolled.

= Confirm selection.

1st input field = Start or

end of the

range with

IN punch

revision

2nd input field = time value =

= Select function of the first input

field.

Range of values: FROM, TO,

−−,

= Confirm 1st input field

= Set the related time value in

the second input field.

Format: : hours, minutes

Chapter 4 Getting Started 4-27

Hint: If the 12 hour time mode

is selected, a change from AM

to PM is to be achieved by

scrolling the hour value.

Possible time indications for

the following day are

automatically marked with "+"

in the 12 hours mode as well

as in the 24 hours mode.

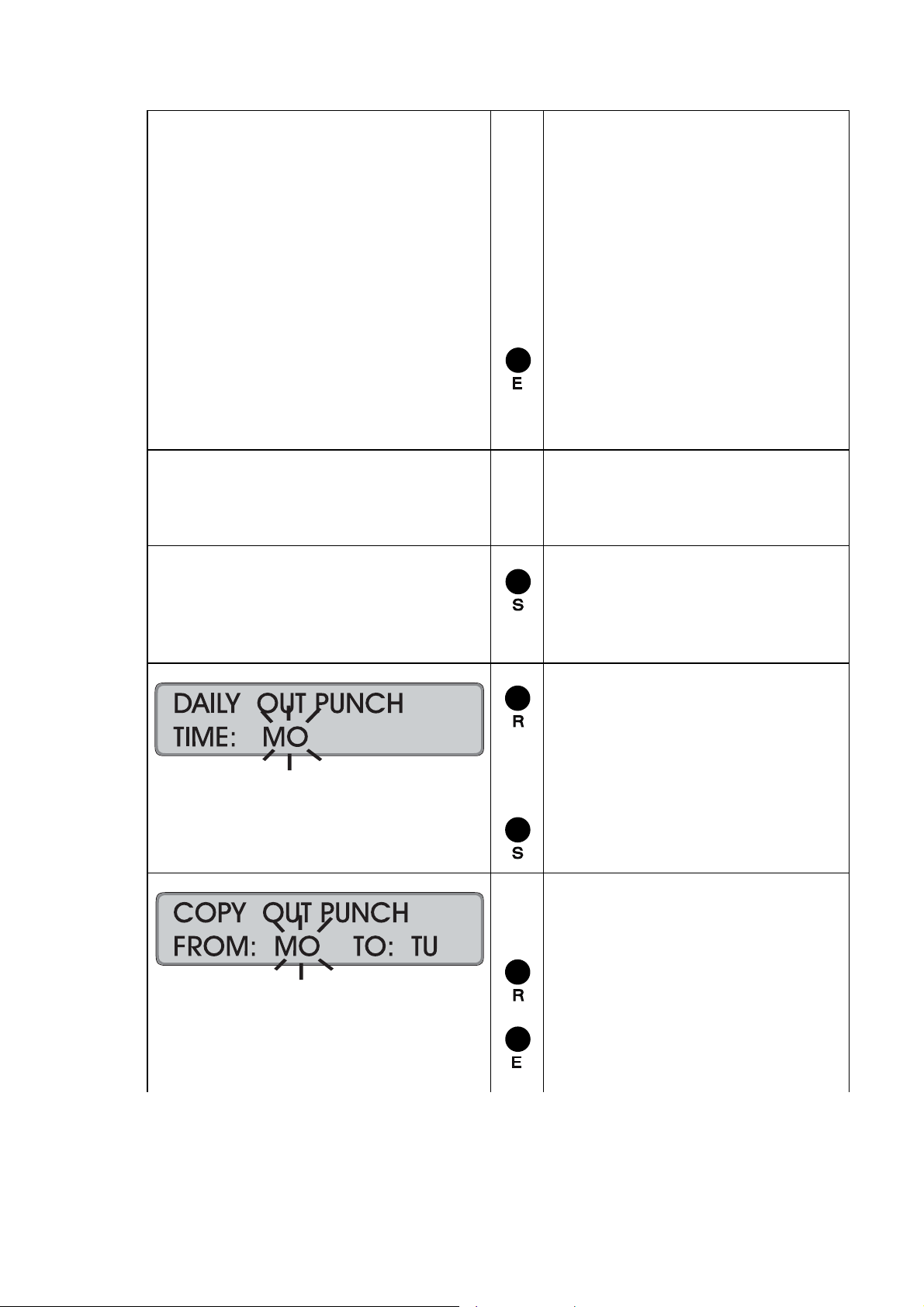

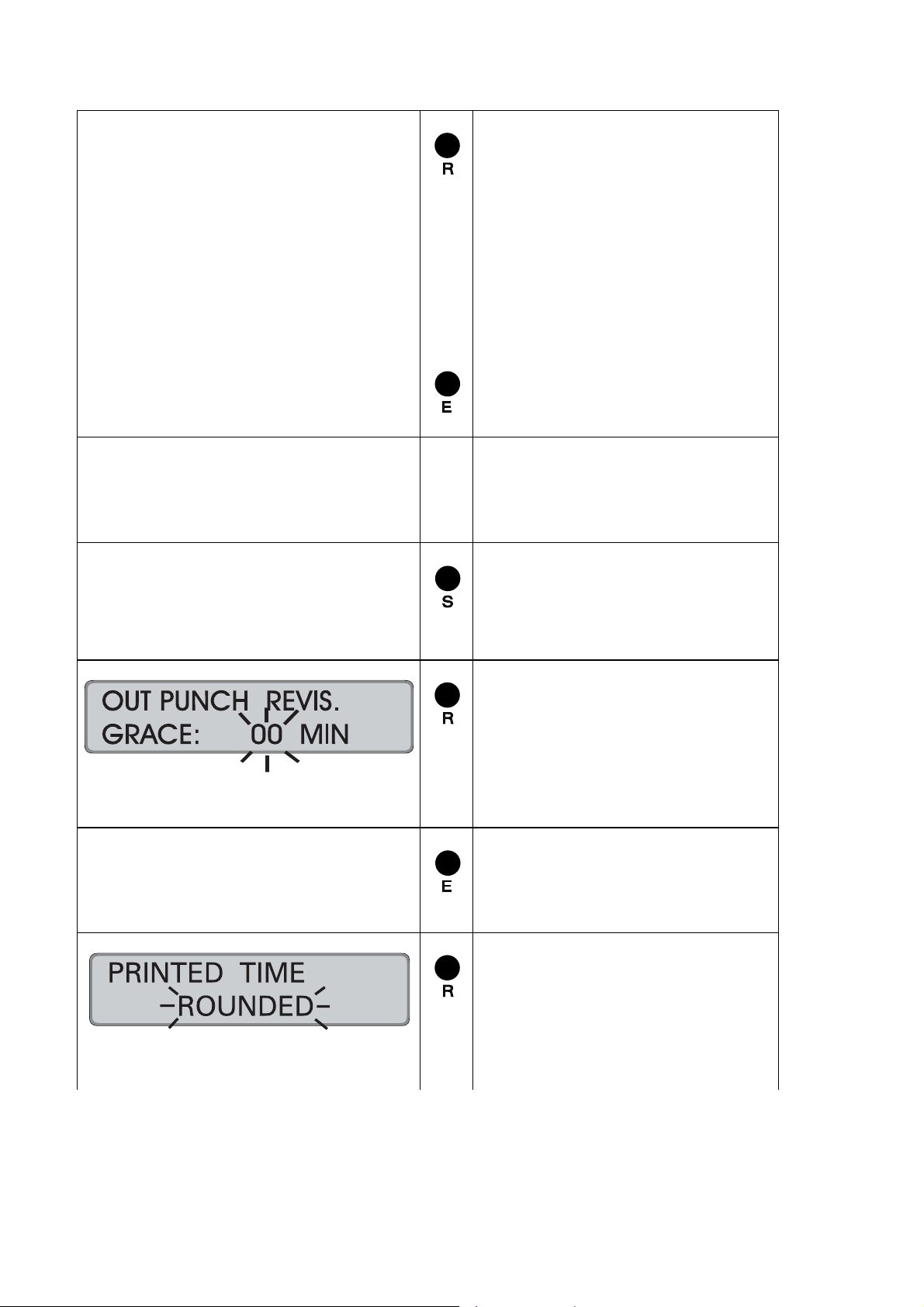

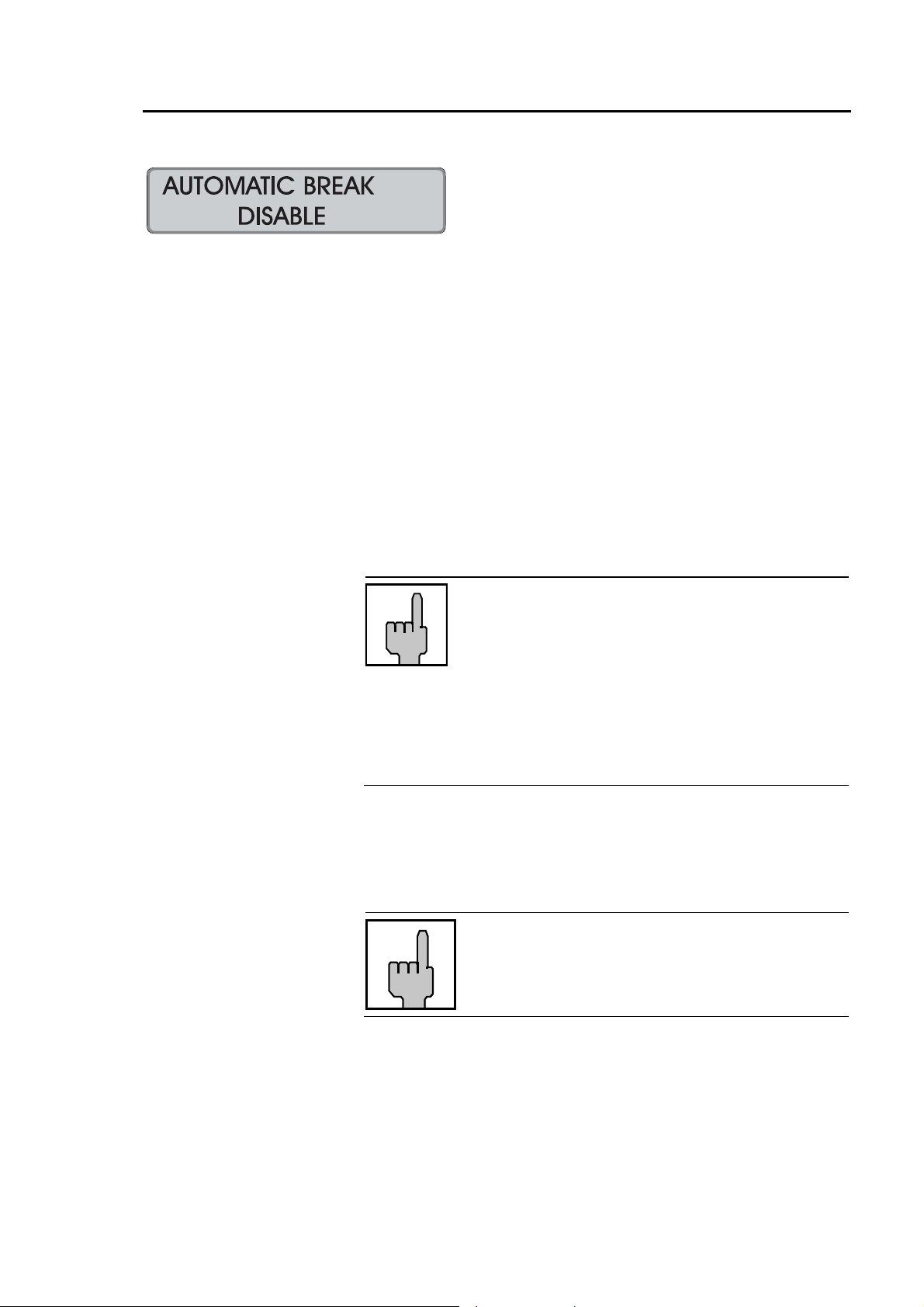

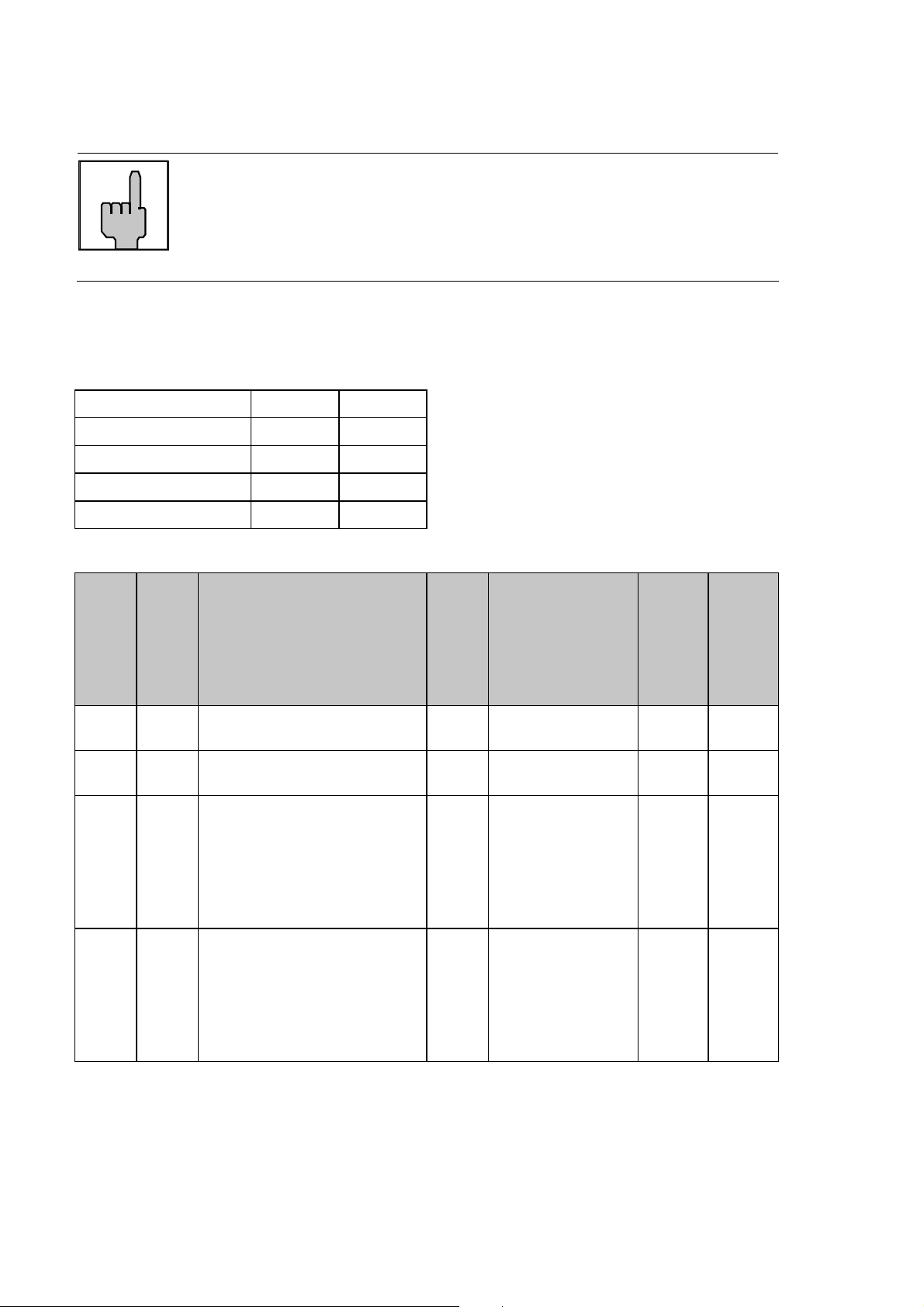

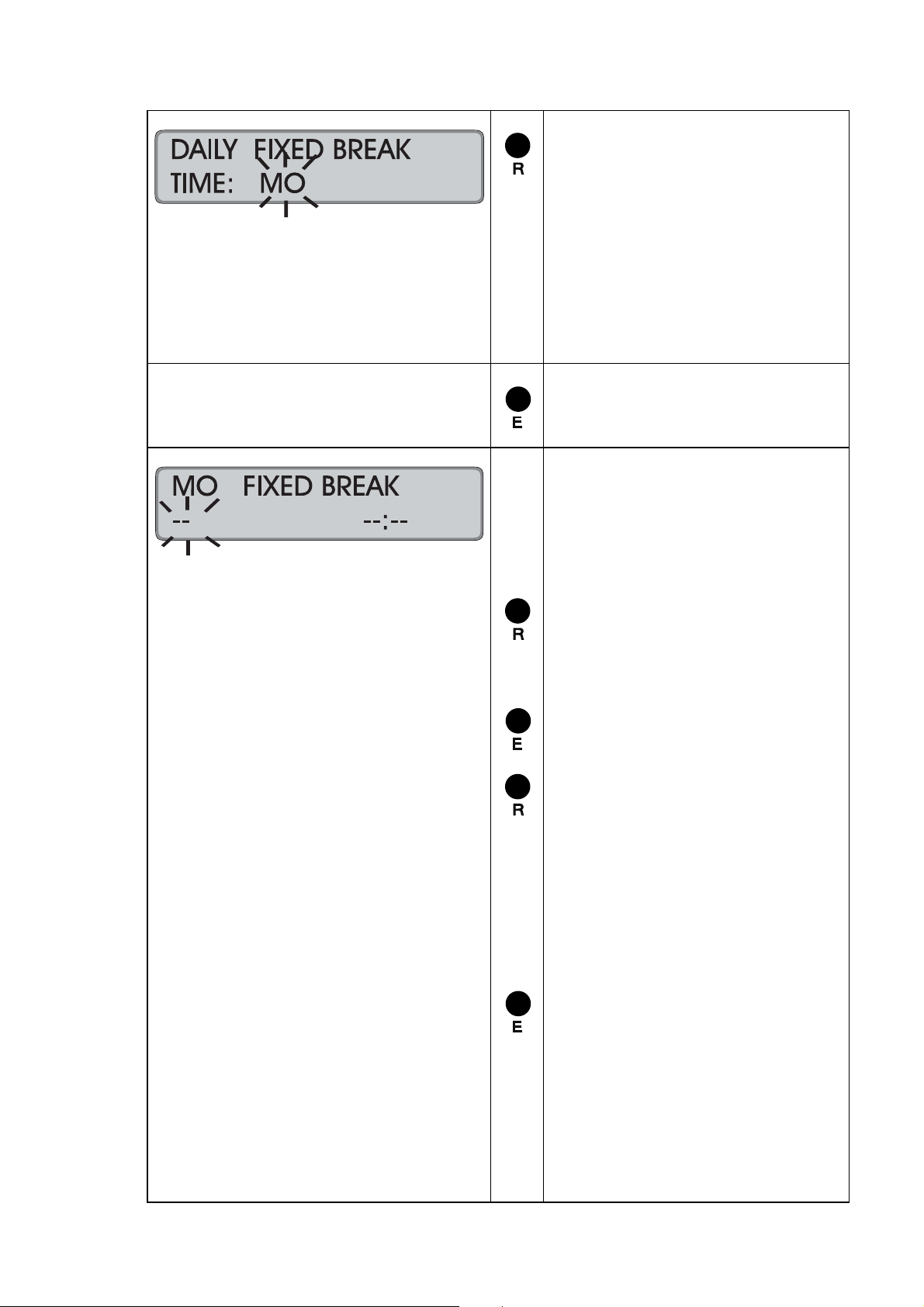

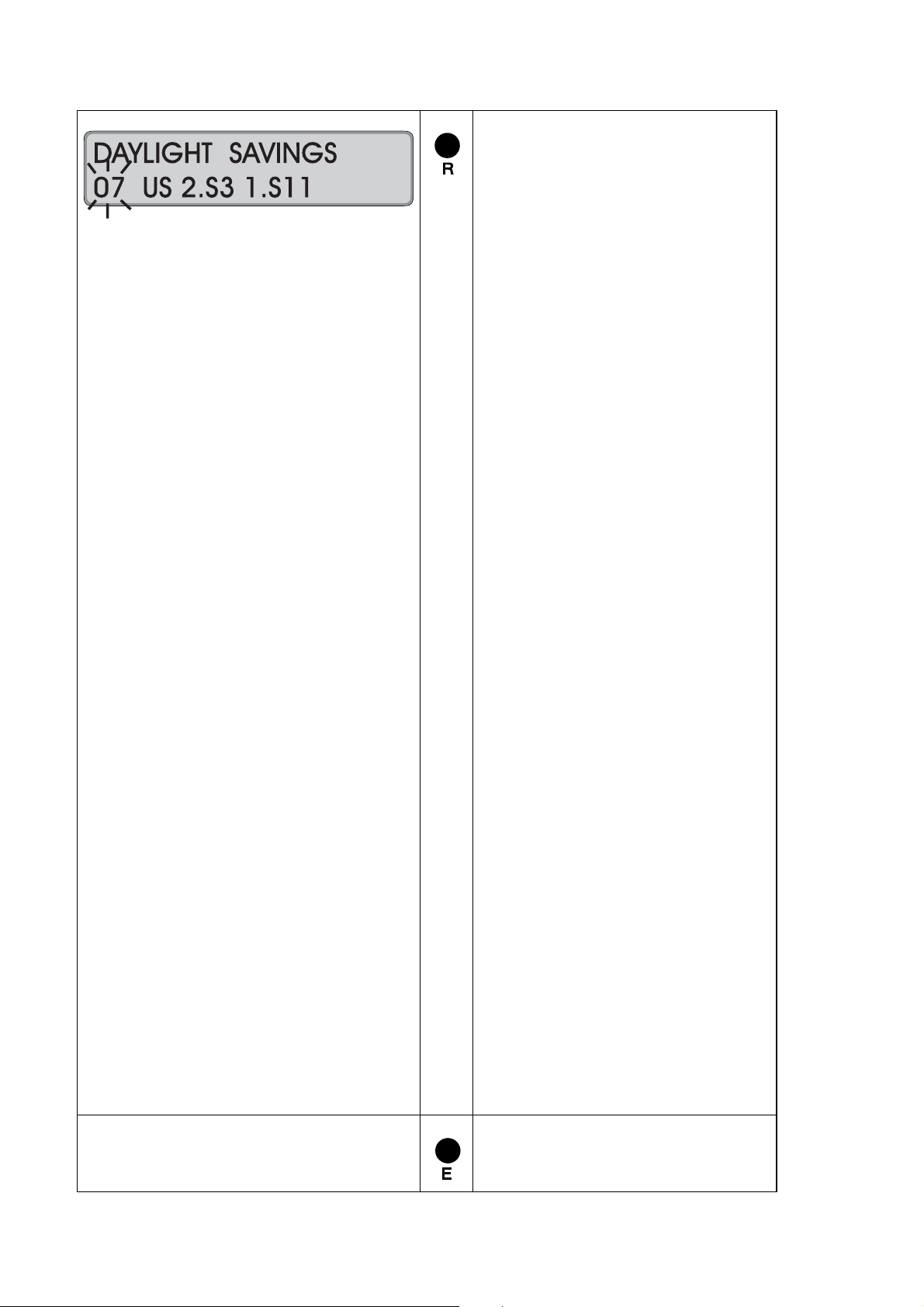

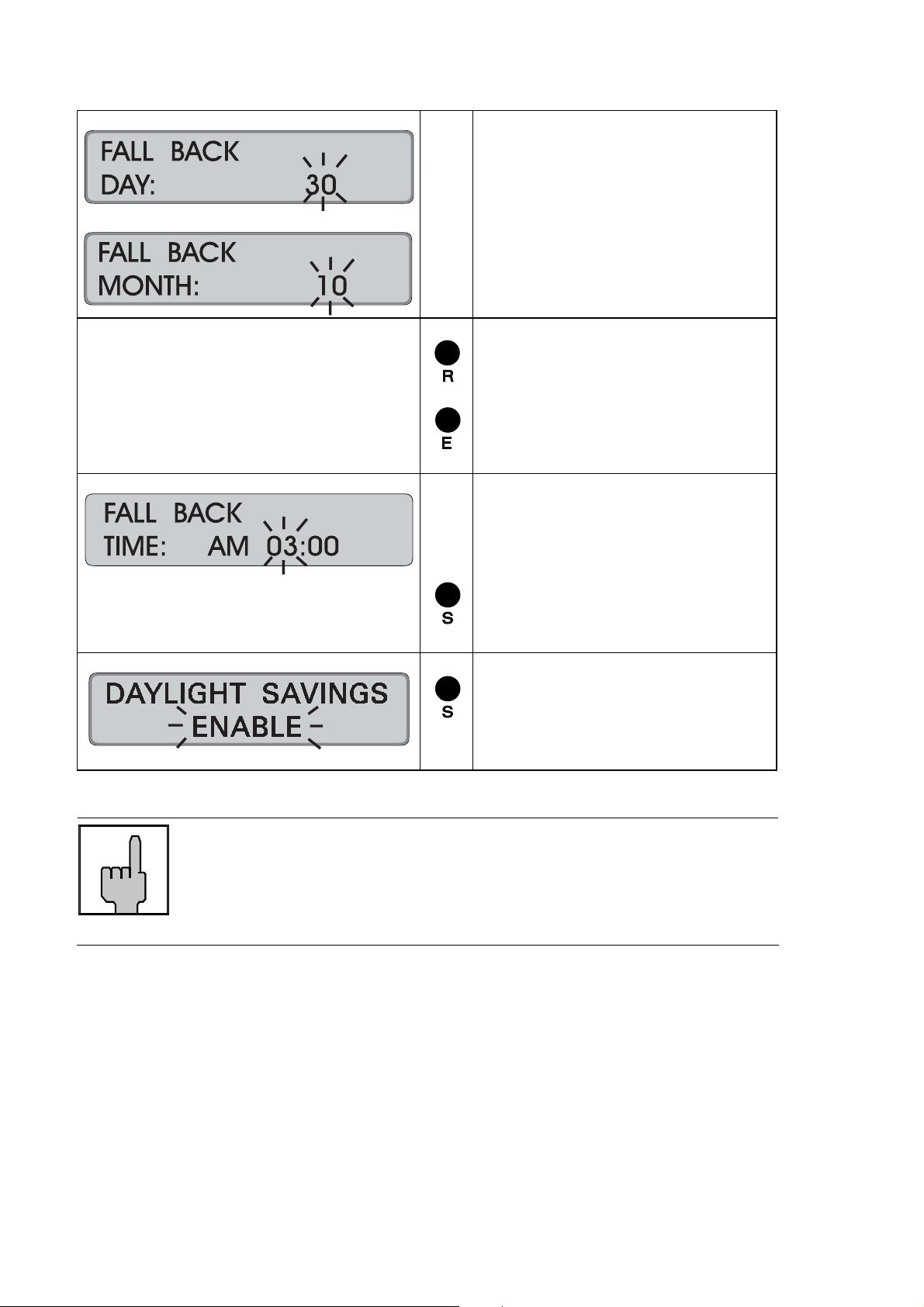

= Confirm 2nd input field.