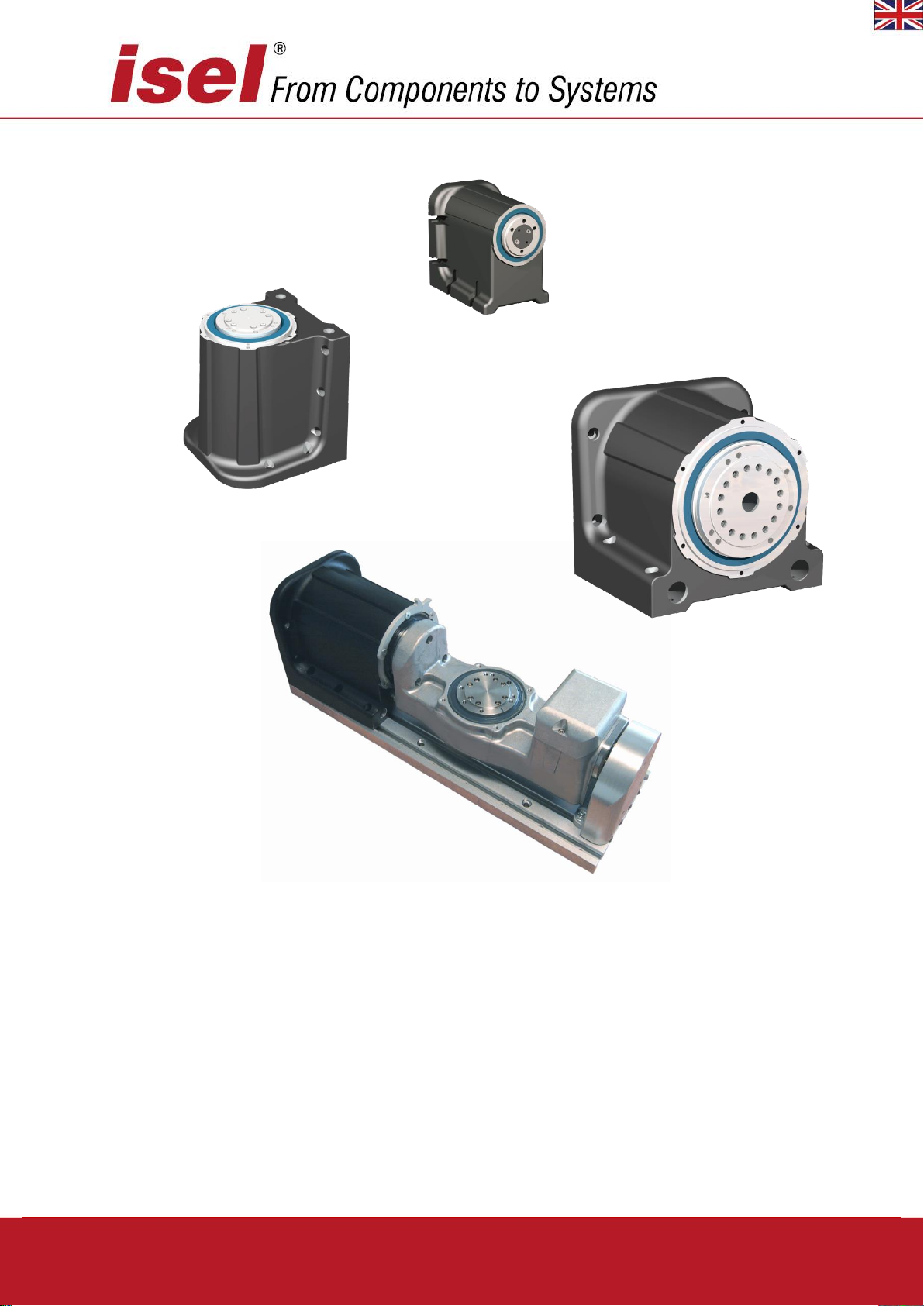

Rotary units with Harmonic Drive®

RDH-XS, RDH-S, RDH-M

RSH-S

Assembly instruction with:

- Installation instructions

- Maintenance instructions

- Declaration of incorporation

for a drive system

(A partly completed machine as defined in the Machine Directive 2006/42/EC)

© isel Germany AG, April 2019, english

RDH-XS, RDH-S, RDH-M, DSH-S

Symbol

Warning

Meaning

Danger

Warning of possible serious or fatal injuries to persons

Caution !

Fatal Voltage !

The flash symbol is a clear warning of danger from electric current!

Not heeding this warning can lead to personal injuries with fatal consequences.

Warning, caution !

Warning of possible minor injuries to persons, of possible faults or destruction of the product or possible damage to property.

Not heeding the facts following this symbol (text, picture or table) can

result in serious damage to property.

Important

information or

note

Important information or note on how the product works.

About these assembly instructions

Abbreviations

MD = MachineDirective 2006/42/EC

RDH = Rotary Index Table with Harmonic Drive® Motor

RSH = Rotary Swivel Unit with Harmonic Drive® Motor

AC = Alternating Current, AC servo motor (always synchronous motor)

BDC = Brushed DC, brush type Direct Current (DC) servo motor

BLDC = Brushless DC, brushless type direct current (DC) servo motor

PDF = Portable Document Format

Terminology

In these assembly instructions "product" always refers to a Rotary Unit with Harmonic Drive.

Symbols used

In these instructions you will find various symbols which are there to alert you to important information /

facts and hazards:

Readinig the safety guidelines

Before commissioning the Rotary Units (as partly completed machines), working with them, or making

any additions or modifications to the electrical installation, it is essential you read carefully:

the safety guidelines in these assembly instructions

the safety guidelines for electric drives and control systems in the instruction manual of the

positioning module, drive controller, drive module or drive controls used.

Copyright

© isel Germany AG, January 2013

All rights reserved

Although every care has been taken to avoid printing errors and mistakes, these cannot be ruled out.

We would be grateful for any suggestions for improvements or information on possible mistakes or unclear formulation of facts and illustrations.

2 / 44 April 2019

RDH-XS, RDH-S, RDH-M, DSH-S

Note on CE compliance for partly completed machines:

isel rotary units comply with CE guidelines. They are classed as partly completed machines as defined

in the Machinery Directive 2006/42/EC and therefore do not explicitly bear the CE mark.

Only after the compliance assessment procedures for the machine have been completed is the (complete) machine or system in which these linear units are installed awarded the CE mark by the manufacturer or distributor of the machine.

All other machine parts and/or machine components to which the CE safety guidelines apply must not

be commissioned until all the relevant requirements of Machinery Directive 2006/42/EC are met.

isel Germany AG does not accept any responsibility for any modifications you make to the rotary unit.

Manufacturer:

Processing date of this documentation: January 2013

More documents from isel Germany AG:

'Nothing is so good it can't be improved upon.' In accordance with this motto, as the manufacturer, we

are constantly improving all our manuals (including operating instructions and assembly instructions) at

considerable cost to ourselves.

We are committed to doing so since this is of benefit to both you as our customers and us:

We want you to be able to work efficiently with the relevant manuals and find the information you are

looking for quickly. Many details in the manuals are the result of information we have received from our

customers.

To support you, all the manuals are available to download in PDF format on our homepage:

https://www.isel.com/en/support-downloads/manuals.html

isel

Germany AG

Bürgermeister-Ebert-Straße 40

D-36124 Eichenzell

Tel.: (06659) 981-700

Fax: (06659) 981-776

E-Mail: automation@isel.com

http://www.isel.com

In your own interest:

Please read these assembly instructions carefully and keep them in a safe place. These instructions

form an integral part of the "Rotary Unit with Harmonic Drive" product, regardless of whether these instructions are supplied/available in the form of an electronic storage medium (as PDF file on a CD, DVD

or memory stick) or as a printed version.

Please read and follow the safety guidelines in these assembly instructions.

3 / 44 April 2019

RDH-XS, RDH-S, RDH-M, DSH-S

Contents

1 General information ....................................................................................................................... 5

1.1 Safety guidelines ....................................................................................................................... 6

1.2 Proper use ................................................................................................................................. 8

1.3 Deliverables .............................................................................................................................. 8

2 Installation instructions and overview of functions................................................................... 9

2.1 Functions ................................................................................................................................... 9

2.2 Assembly / of the rotary units /drive elements ........................................................................ 10

2.3 Connector pin assignment for rotary units .............................................................................. 27

3 Commissioning, general information ........................................................................................ 28

4 Assembly of the rotary unit ........................................................................................................ 29

4.1 Mounting and adjustment instructions .................................................................................... 29

4.2 Mounting the tailstock unit ...................................................................................................... 30

5 Fault list ........................................................................................................................................ 31

6 Technical specification ............................................................................................................... 32

6.1 Mechanical data ...................................................................................................................... 32

6.2 Electrical data .......................................................................................................................... 35

7 Maintenance and cleaning .......................................................................................................... 35

7.1 Maintenance instructions ........................................................................................................ 35

7.2 Cleaning .................................................................................................................................. 35

8 Decommissioning / disposal ...................................................................................................... 36

9 CE Conformity .............................................................................................................................. 36

10 Service .......................................................................................................................................... 37

11 Warranty ....................................................................................................................................... 37

12 Declaration of incorporation according to MD 2006/42/EC ..................................................... 38

13 Index .............................................................................................................................................. 39

14 Appendix ....................................................................................................................................... 40

14.1 A1: Accessories ................................................................................................................... 40

14.2 A2: Miscellaneous ............................................................................................................... 41

4 / 44 April 2019

RDH-XS, RDH-S, RDH-M, DSH-S

1 General information

This manual contains all important information about the assembly/installation, commissioning and

maintenance of your rotary units. In addition, it provides information and important notes for your safety.

The isel-rotary units RDH - RSH are rotary modules with Harmonic Drive® Motors, which are ready to

install. They are for use mainly in machining and positioning tasks in factory automation, handling technology and light machinery construction.

These rotary units are available in different standard sizes with various gear reductions.

The options for horizontal or vertical positioning of the rotary axis on the RDH series mean users can

build a wide variety of constructions to suit their requirements.

Please note:

The product is classed as 'partly completed machine' and not a (complete) machine according

to MD 2006/42/EC.

5 / 44 April 2019

RDH-XS, RDH-S, RDH-M, DSH-S

The following guidelines on safety and danger are intended to protect you, third parties

and the product. It is essential that you follow them.

1.1 Safety guidelines

Operating environment

The surrounding medium must not have a corrosive effect on aluminium alloys, stainless steels

(1.4305) or ABS plastics.

The product has achieved Protection Type IP65 if no corrosion has been caused on the surface

of the radial shaft seal by the operating environment.

When moving the product from cold to warm conditions, allow the product to adjust to the change

in temperature for a few hours, to avoid possible damage from condensation.

Do not install the product near devices which generate powerful magnetic fields. This could

disturb some products main functions.

Avoid environments exposed to direct solar radiation, considerable heat, cold, humidity or mois-

ture.

Power supply (only applies to products with multiphase motors, brushed DC/brushless DC or

AC servo motors and a suitable motor output stage/controller)

Only connect the power supply of the multiphase motor/servo motor output stage iMD10/iMD20,

the link to the servo motor output stage iMD40 (terminals L, N, PE) or the single-axis or multiaxis controller (e.g. iMC-P/iMC-S8, MC-1 series, iPU series…) to an earthed mains socket with

a mains voltage of 230 V AC/50…60 Hz (1-phase AC power supply).

It is preferable to use for the final stage of the mulitphase motor or the final stage of the

iMD10/iMD20 servomotor the original power supply recommended by isel Germany AG (primary

power supply: 230V AC, secondary: 48V DC). Using a different, inappropriate power supply

renders the warranty null and void. In addition, using an inappropriate power supply entails risks

caused by electric current, such as electric shock, fire or short circuits!

If you notice faults, activate the EMERGENCY STOP button on the (single axis) controller, the

CNC operating panel/CNC console, the control panel/control cabinet or a handheld device. Activating the EMERGENCY STOP button interrupts the power supply to the motor output stage.

If the power supply used is damaged you must not operate it. Have a qualified technician check

and if necessary repair the product.

The rotary unit

For safety reasons you must not convert and/or modify the rotary unit on your own.

In operation, the rotary unit must not be concealed by supplies (electricity or compressed air),

objects (e.g. tools) or tarpaulins, packaging or other materials etc. (e.g. clothing), because this

can lead to mechanical damage or heat obstruction and sometimes fire.

If using a single-axis/multi-axis controller to control a linear unit (equipped with an AC, brushed

DC (BDC) or a brushless DC (BLDC) servo motor), you need to ensure that the controller or

motor output stage used (in a control cabinet or on a mounting rack) is placed in a well-ventilated

environment.

6 / 44 April 2019

RDH-XS, RDH-S, RDH-M, DSH-S

Operation

(applies only to products supplied with a motor and a suitable motor output stage or a suitable

controller, e.g. a single-axis controller)

Only if the product is assembled correctly and the motor, the tactile or inductive limit switches, the brake

and the incremental measuring system (encoder) are correctly connected to the motor output stage/controller all further operations can be successful. Next operations are parameterization, commissioning

and operation/programming of the product as a fully-functioning drive system.

The technical details of special versions may differ from the following versions.

If the product malfunctions or you are unclear about its operational status, you should consult the relevant operating instructions/assembly instructions.

https://www.isel.com/en/support-downloads/manuals.html

Here you will find instructions and information on how to check the functions you require, remove the

causes of a possible malfunction or have these removed.

You must always carry out the instructions you find completely and correctly in order to ensure the

product functions correctly.

Never allow children or other persons who are vulnerable or at risk to operate the product unsupervised.

If you are still unclear about its operational status, it is highly recommended that you consult isel Germany, quoting the type and article number or serial number.

7 / 44 April 2019

RDH-XS, RDH-S, RDH-M, DSH-S

1.2 Proper use

The rotary units serve to rotate and position securely attached loads on the output flange in an environment where there is no danger of Exploded views and in accordance with the operational and environmental conditions specified for this product. The product can be installed as required (in a horizontal,

vertical or diagonal position).

The rotary units are a partly completed machine (compare Article 2g in the MD 2006/42/EC). Here a

partly completed machine is defined as follows (quote):

'A partly completed machine is a unit which almost forms a machine but which cannot fulfil any specific

function on its own.

A drive system is a partly completed machine.

A partly completed machine is only intended to be installed into other machines or other partly completed

machines or equipment or joined together with these to form a machine as defined in this directive.'

The rotary units RDH - RSH are intended for installation into a machine or into other partly completed

machines.

The product should not be used to transport people.

Any other use than those described above is not considered correct and can lead to personal injuries

and damage to property.

1.3 Deliverables

The deliverables include:

Assembly instructions and installation explanation according to MD 2006/42/EC

Mounting materials

Accessories if required

8 / 44 April 2019

RDH-XS, RDH-S, RDH-M, DSH-S

2 Installation instructions and overview of functions

Firstly, this section provides an overview of the mechanical structure, installation or assembly of the

rotary units and a description of their functions.

The instructions for commissioning/configuring the rotary unit and its programming by users depend on

the motors used and the relevant controllers with output stages; they can be found in their documentation.

2.1 Functions

The rotary units in the series RDH and RSH have a modular design.

These rotary units are based on extremely durable Harmonic Drive® motors with their well-known high

degree of precision.

These are housed in sealed aluminum molded shell and linked to a drive directly (solid shaft) or via a

drive belt (hollow shaft).

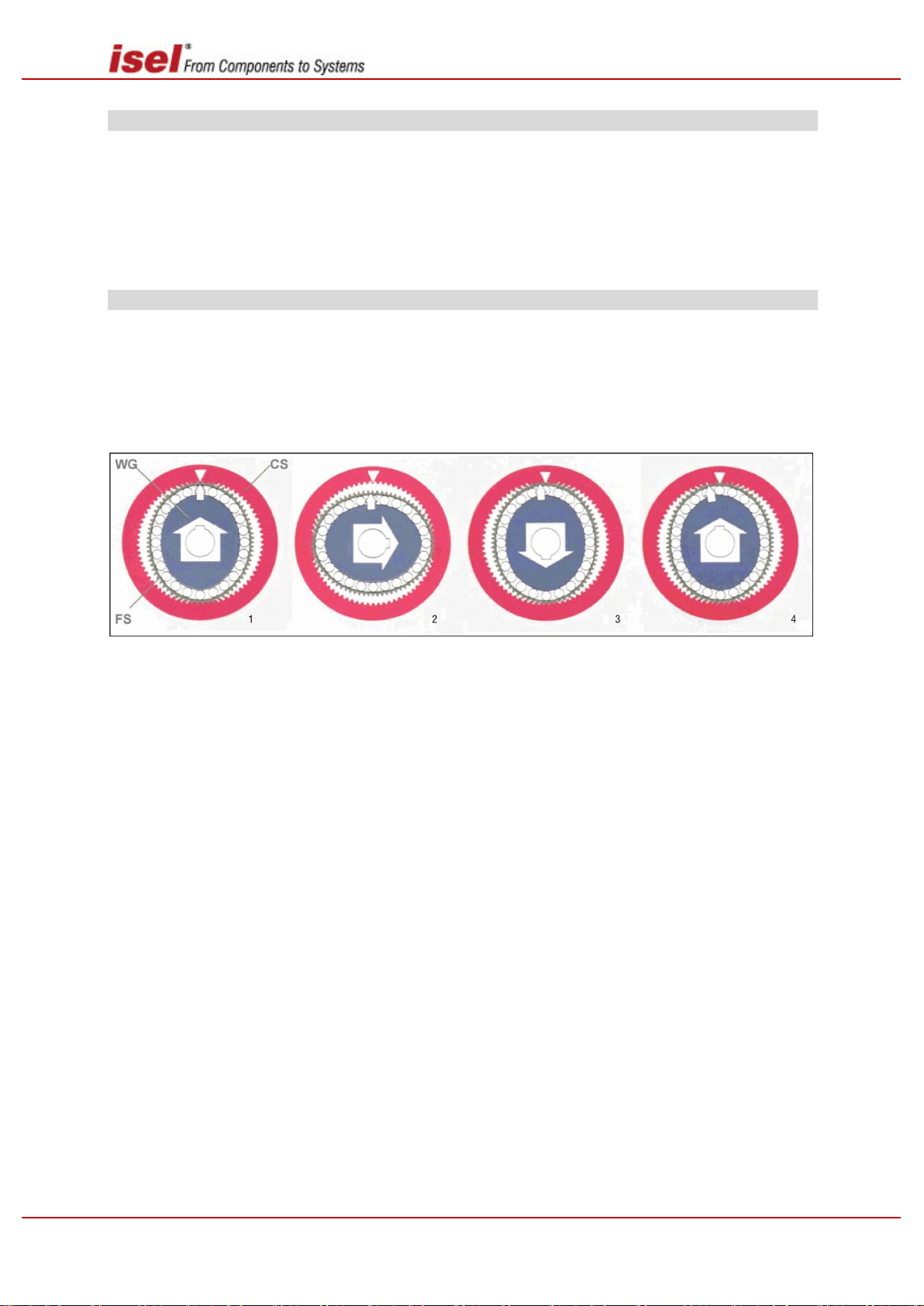

Operating principle of the Harmonic Drive-Transmission

Harmonic Drive motors are comprised of only three concentric components:

The Circular Spline (CS), a rigid cylindrical ring with internal gearing

The Flexspline (FS), a malleable cylindrical steel bushing with external gearing

The Wave Generator (WG), an elliptical steel disk with a centric hub and thin section ball bear-

ings

The powered elliptical Wave Generator (WG) deflects the Flexspline (FS), which is engaged with the

internal gearing of the fixed Circular Spline (CS) across the ball bearings.

In turning, the WG shifts the major axis of the ellipse axis and hence the position of tooth engagement.

The FS has two teeth less than the CS, so after half a WG rotary, a relative movement the size of one

tooth occurs between FS and CS (after a complete rotary this is equal to two teeth).

Where the CS is fixed, the FS is the output element and rotates in the opposite direction.

The following advantages result from this operating principle:

Reduction ratios of 30:1 to 320:1 with a minimal construction space

Peak torque values of 0.5 to 15000 Nm

Efficiencies of over 90% under rated operating conditions

Total positioning accuracy to less than one minute of an angle

Repeatability is only a few minutes of an angle

Freedom of movement in the tooth system

Very low tooth abrasion thanks to low sliding speed between the teeth

9 / 44 April 2019

RDH-XS, RDH-S, RDH-M, DSH-S

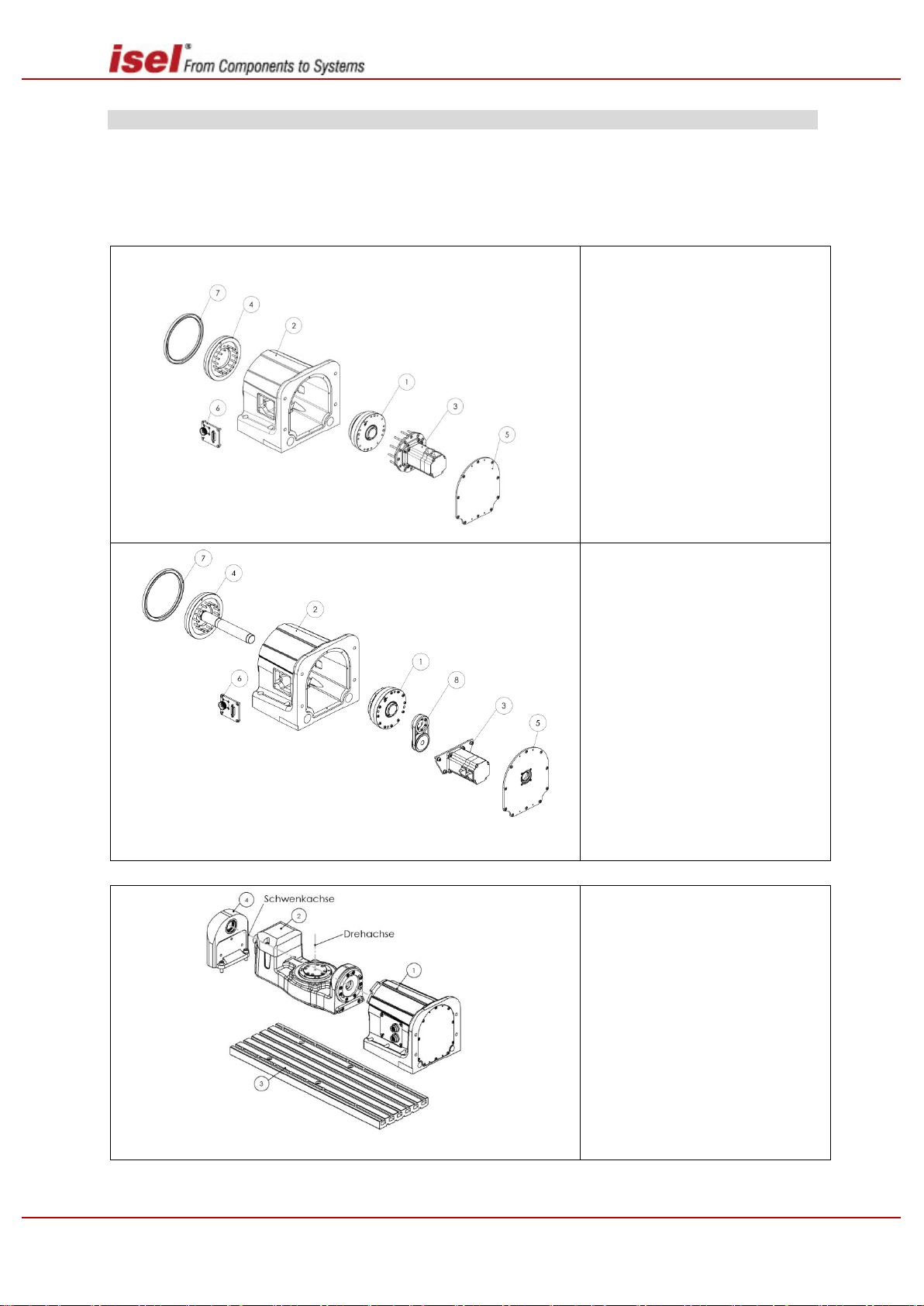

Solid shaft

(1) Harmonic Drive Motor

(2) Aluminiummoulding shell

(3) Drive module

(4) Output flange solid shaft

(5) Cover

(6) Connection panel

(7) Rotary shaft seal

Hollow shaft

(1) Harmonic Drive Motor

(2) Aluminiummoulding shell

(3) Drive module

(4) Output flange hollow shaft

with pipe penetration

(5) Cover with penetration

and shaft seal

(6) Connection panel

(7) Rotary shaft seal

(8) Toothedbeltstage

Overview of the functions of DSH-S

* Schwenkachse = swivelaxis / Drehachse = rotationaxis

(1) Swivel module (RDH-S)

(2) Rotary axis

(3) Base plate

(4) Counterbearings

2.2 Assembly / of the rotary units /drive elements

The following illustrations, drawings and item lists illustrate the structure of the rotary units.

Options

Rotary units RDH – RSH are usually supplied ready for connection and with an integrated drive module.

The RDH-S and RDH-M units are also available as hollow shafts.

Overview of the functions using RDH-M as an example

10 / 44 April 2019

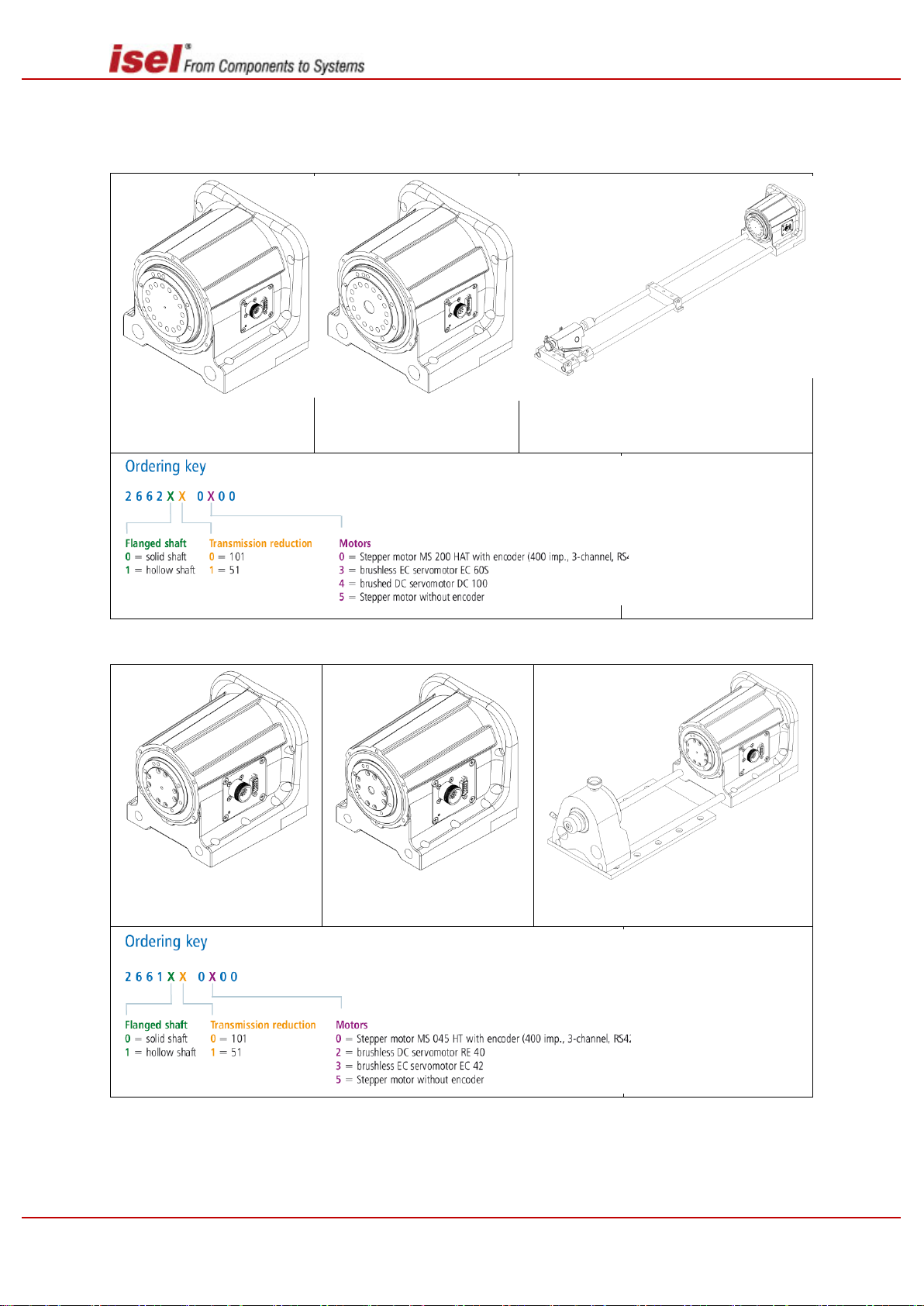

Options

RDH-M (Solid shaftoption)

RDH-M (Hollow shaft option)

RDH-M with tailstock unit RE M

Tailstock unit RE M

Art. No.: 269100 2100

(1000 mm)

Art. No.: 269100 2150

(1500 mm)

Art. No.: 269100 2200

(2000 mm)

RDH-S (Solid shaft option)

RDH-S (Hollow shaft option)

RDH-S with tailstock unit RE S

Tailstock unit RE S

Art. No.: 269100 1020

(200 mm)

Art. No.: 269100 1030

(300 mm)

Art. No.: 269100 1040

(400 mm)

Art. No.: 269100 1050

(500 mm)

RDH-M

RDH-XS, RDH-S, RDH-M, DSH-S

RDH-S

11 / 44 April 2019

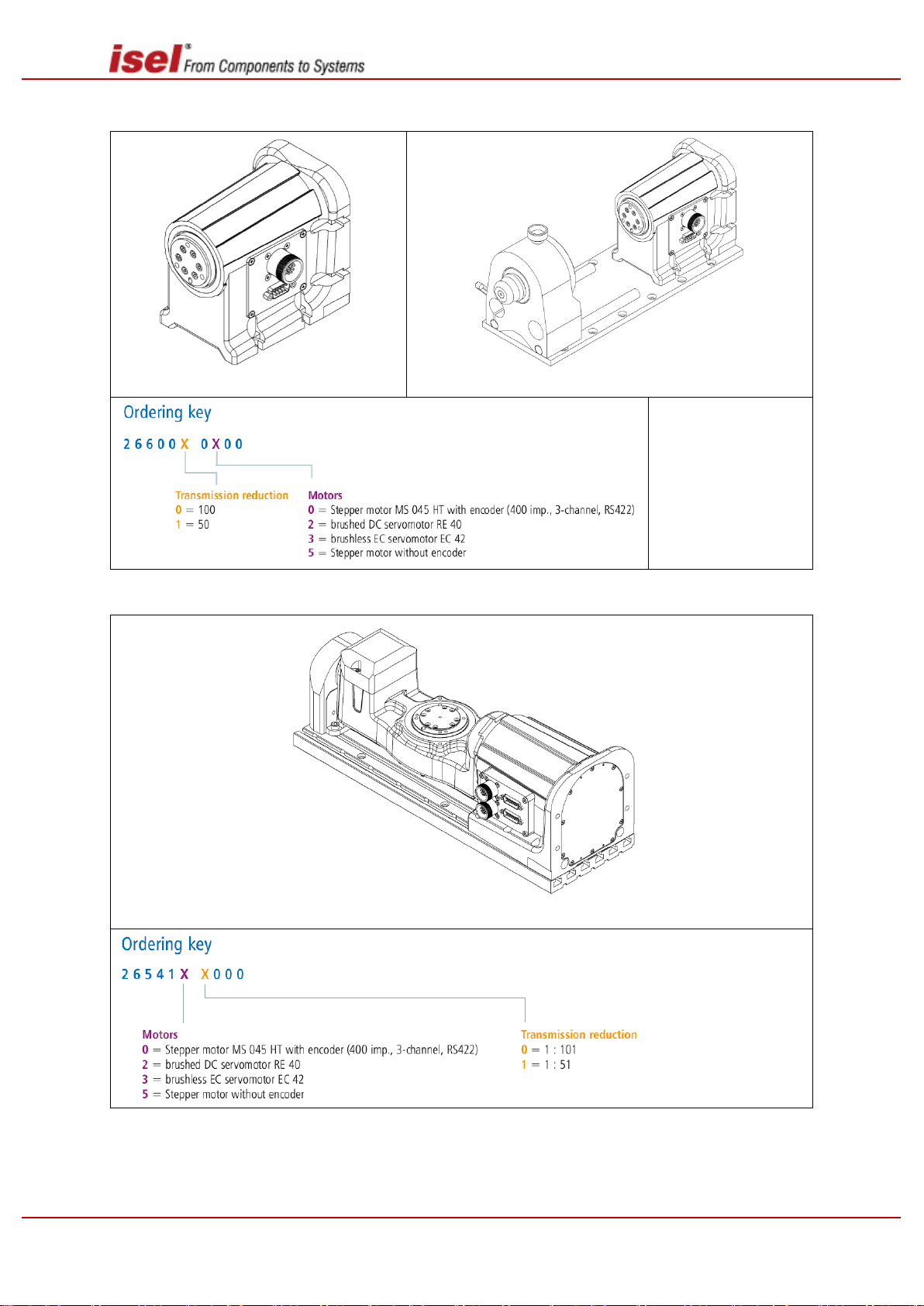

RDH-XS

RDH-XS (Solid shaftoption)

RDH-XS with tailstock unit RE XS

Tailstock unit RE S

Art. No.: 269100 0020

(200 mm)

Art. No.: 269100 0030

(300 mm)

Art. No.: 269100 0040

(400 mm)

Art. No.: 269100 0050

(500 mm)

RDH-XS with tailstock unit RE XS

RDH-XS, RDH-S, RDH-M, DSH-S

RSH-S

12 / 44 April 2019

RDH-XS, RDH-S, RDH-M, DSH-S

*Raster = grid / Spannfutter = chuck

Options L A

Tailstock unit RE-XS 200 mmm

325

117

Tailstock unit RE-XS 300 mmm

425

217

Tailstock unit RE-XS 400 mmm

525

317

Tailstock unit RE-XS 500 mmm

625

417

Dimension sheetfor RDH-XS

Dimension sheet for RDH-XS tailstock unit RE XS

13 / 44 April 2019

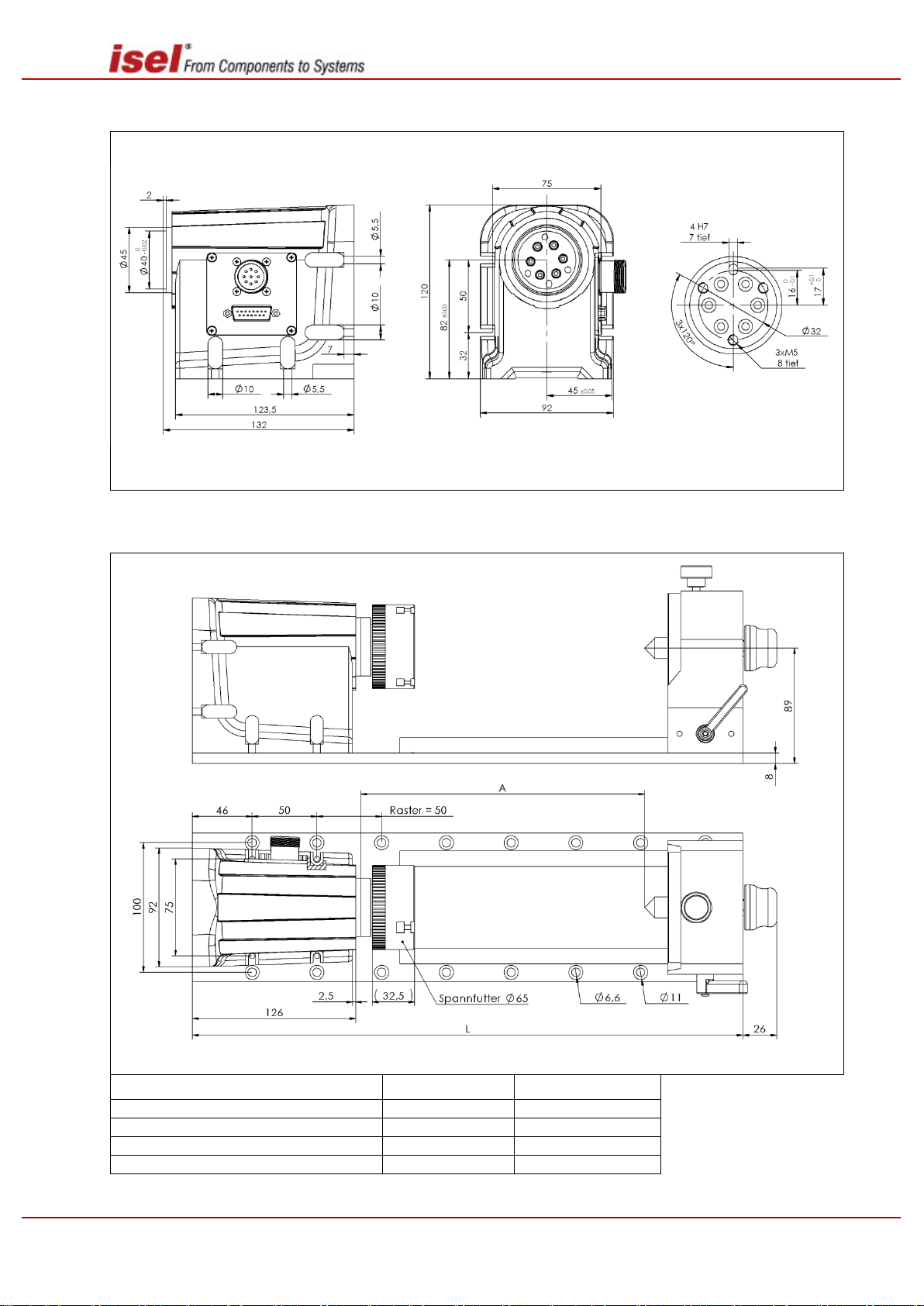

Explodedview RDH-XS

18

30

34

Servo motorstructure

19

20

22

multiphasemotorstructure

Item list RDH-XS

Pos No.

Item number

Quantity

Name

Drawing no. 1 660500 0000

1

EZ4150 - base body - XS - processed

EZ4150

2

660500 4152

1

EZ4152 – Adapter flange XS

EZ4152 3 660500 4156

1

EZ4156 – Cover at back

EZ4156

4

660500 28782 / 660500 28783

1

DZ2878 - Connector panel - RDH-XS

DZ2878

5

660500 41582 / 660500 41583

1

EZ4158 - toothed belt disk HTD3 - Z40

EZ4158

6

660500 39432

1

EZ4159 - toothed belt disk HTD3 - Z40 with flanged wheel

EZ4159 7 898081 8201

1

Clampingbushing 8-18-11(Mädler 615708 00)

8

660500 4153

1

EZ4153 - Transmission attachment

EZ4153 9 660500 4154

1

EZ4154 - Transmission mounting

EZ4154

10

660500 4155

1

EZ4155 – Shaft Transmission entry

EZ4155

11

660500 4164

1

EZ4164 - Clamping ring

EZ4164

12

660500 41512 / 660500 41511

1

EZ4151 - Motor mounting

EZ4151

13

660500 1000 /650200 0010

1

Harmonic Drive Motor HDUC-14-xx-1U-CC (i=100 / i=50)

14

XXXXXX XXXX *

1

Motor module

15

896010 8224

2

Single-row groove ball bearings with sealing pads 608-2RS1

16

843400 0030

1

Shaft seal BABSL 45-58-7 Simrit 72 NBR902

17

616504 0722

1

Toothed belt HTD 3M CXP b=6 L216 (Z=72)

18

562015 4000

1

Inductive proximity switch Baumer IFFM08P37A6_L

19

582132

1

Magneticsensormounting

20

563005

1

Magneticsensor

21

898120 1218

1

Spieth pressure sleeve AK 12-18 L12

22

632501 0002

1

Neodymium block magnet 3 mm

23

891101 0161

6

Pan head screw DIN 912 8.8 VZ M3 x 16

24

891101 0251

6

Pan head screw DIN 912 8.8 VZ M3 x 25

25

891102 0081

6

Pan head screw DIN 912 8.8 VZ M4 x 8

26

891053 0101

1

Allen screw DIN 933 M5x10

27

891191 0065

10

Countersunk screw DIN 965 4.8 VA M 3 x 6

28

891191 0085

8

Countersunk screw DIN 965 4.8 VA M 3 x 8

29

891530 0051

2

Self-tapping screw DIN 7981 VZ 2,2 x 4,5

30

891131 0101

5

Countersunk screw DIN 7991 M 3 x 10

31

893051 0001

6

Disk DIN 125 ST 4,3

32

891378 0025

4

Grubscrew DIN 913 VA M 2 x 2

33

891371 0041

2

Grubscrew DIN 913 M 3 x 4

34

891373 0051

1

Grubscrew DIN 913 M 5 x 5

35

891375 0085

1

Grubscrew DIN 913 VA M 8 x 8

RDH-XS, RDH-S, RDH-M, DSH-S

* Item number see page 26

14 / 44 April 2019

RDH-XS, RDH-S, RDH-M, DSH-S

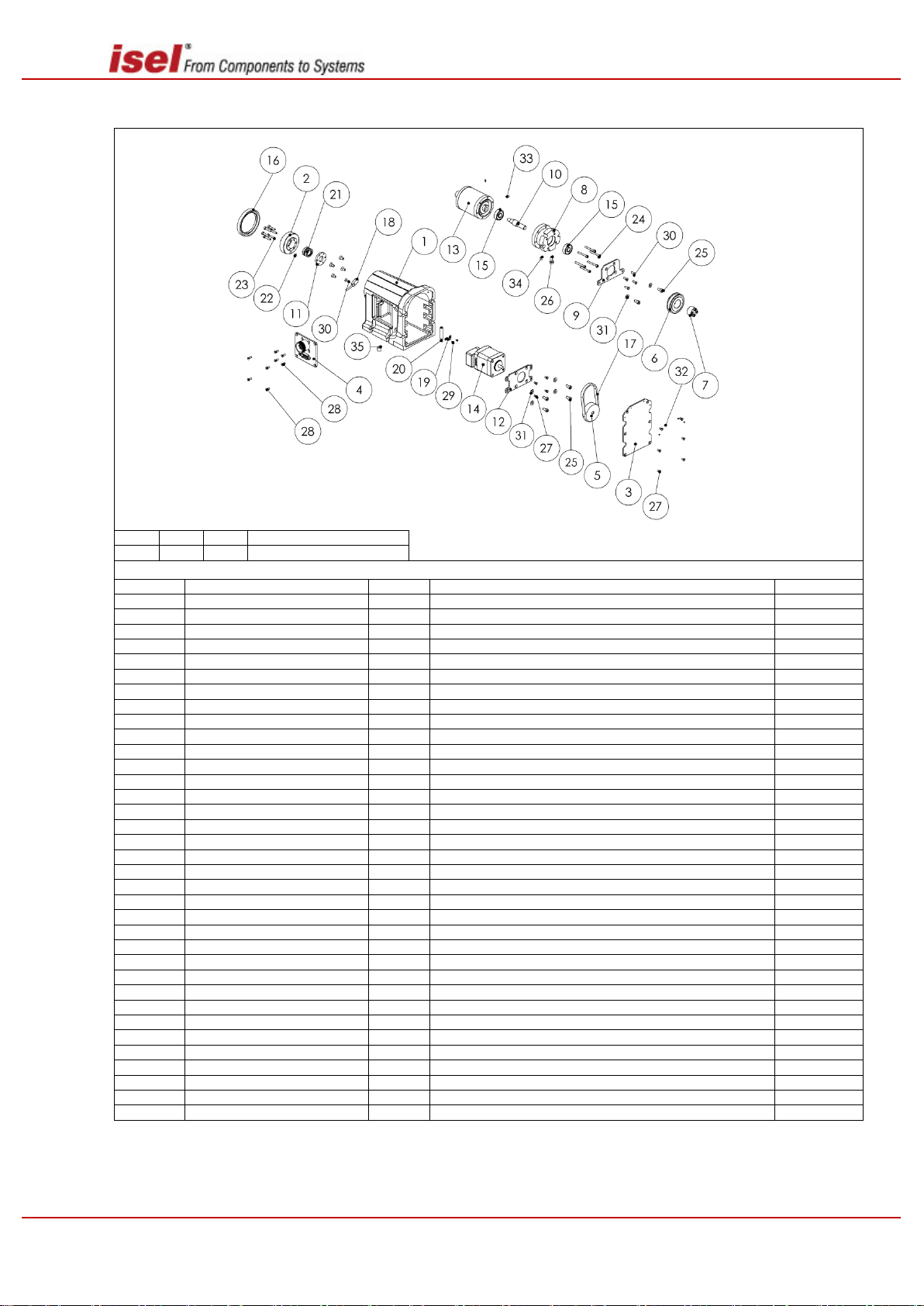

*Abtriebsflansch = outputflangeHohlwelle = hollowshaft tief = deep

Zentrieransatz Gehäuse = centeringspigotcasing Lochkreis = boltcircle

*Raster = grid / Spannfutter = chuck

Options L A

Tailstock unit RE-S 200 mm

370

128

Tailstock unit RE-S 300 mm

470

228

Tailstock unit RE-S 400 mm

570

328

Tailstock unit RE-S 500 mm

670

428

Dimension sheet for RDH-S

Dimension sheet for RDH-S tailstock unit RE S

15 / 44 April 2019

Exploded view RDH-S - Solid shaft

11

13

14

23

Servo motorstructure

12

21

27 multiphasemotorstructure

Item list RDH-S - Solid shaft

Pos No.

Item number

Quantity

Name

Drawing no.

1

660500 0001

1

EZ3937 - basebody - 14

EZ3937 2 660500 3930

1

EZ3930 - Adapter flange - 14

EZ3930 3 660500 3932

1

EZ3932 - Motor adapter_14

EZ3932

4

660500 39331 / 660500 39332

1

EZ3933 - Motor adapter 14

EZ3933

5

660500 39454 / 660500 39452

1

EZ3945 - Couplingpart

EZ3945 6 660500 39382

1

EZ3938 - Cover - below

EZ3938

7

660510 3919 / 660510 39191

1

EZ3919 - Cover

EZ3919 8 893400 0027

1

Shaft seal BABSL 90-70-7 Simrit 72 NBR902

9

665330 1000 / 650200 0002

1

HarmDrive Motor HFUS-14-xx-2UH (i=101 / i=51)

10

XXXXXX XXXX *

Motor module

11

632501 0002

1

Neodymium Block magnet 3 mm

12

562015 4000

1

Inductive proximity switch Baumer IFFM08P37A6_L

13

660510 3934

1

EZ3934 - Magneticswitchmounting

14

563005

1

Magneticsensor

15

891101 0105

8

Pan head screw DIN 912 8.8 VA M3 x 10

16

891101 0101

8

Pan head screw DIN 912 8.8 VZ M3 x 10

17

891101 0301

8

Pan head screw DIN 912 8.8 VZ M3 x 30

18

891191 0065

10

Countersunk screw DIN 965 4.8 VA M 3 x 6

19

891191 0061

4

Countersunk screw DIN 965 4.8 VZ M 3 x 6

20

891191 0085

4

Countersunk screw DIN 965 4.8 VA M 3 x 8

21

891191 0101

1

Countersunk screw DIN 965 4.8 VZ M 3 x 10

22

891192 0085

4

Countersunk screw DIN 965 4.8 VA M 4 x 8

23

891541 0095

1

Self-tapping screw DIN 7982 VA 2,9 x 9,5

24

891371 0031

3

Grubscrew DIN 913 M 3 x 3

25

891371 0035

4

Grubscrew DIN 913 VA M 3 x 3

26

891372 0045

1

Grubscrew DIN 913 VA M 4 x 4

27

891373 0061

1

Grubscrew DIN 913 M 5 x 6

RDH-XS, RDH-S, RDH-M, DSH-S

* Item number see page 26

16 / 44 April 2019

RDH-XS, RDH-S, RDH-M, DSH-S

17

19

20

30

Servo motorstructure

18

28

35 multiphasemotorstructure

Item list RDH-S - Hollow shaft

Pos

No.

Item number

Quantity

Name

Drawing

no.

1

660500 0001

1

EZ3937 basebody - 14

EZ3937

2

660500 3931

1

EZ3931 Adapter flange - 14 Hollow shaft

EZ3930

3

660500 39381

1

EZ3938 Cover - below hollow shaft structure

EZ3938

4

660510 3919

1

EZ3919-3 Cover - Connector - Option Sub-D 15

EZ3919 5 660500 3944

1

EZ3944 Toothed belt disk HTD3 - Z34

EZ3944

6

660510 3957 / 660510 39431

1

Toothed belt disk HTD3 - Z34 with flanged wheel

7 660500 3941

1

EZ3941 Flange - Pipe seal_14

EZ3941

8

660500 3956

1

EZ3956 Bearing for RE40 Maxon Motor - 14

EZ3956

9

660500 3958 / 660500 3942

1

Motor mounting

EZ3942

10

660500 3940

1

EZ3940 Internal pipe

EZ3940

11

893400 0027

1

Shaft seal BABSL 90-70-7 Simrit 72 NBR902

12

893400 0028

1

Shaft seal BABSL 12-22-6 Simrit 72 NBR902

13

616504 0660

1

Toothed belt CXP HTD 180 -3M - 6 (Z60)

14

896010 6194

1

Single-row groove ball bearings with sealing pads 626-2RS1

15

665330 1000 / 650200 0002

1

HarmDrive Motor HFUS-14-xx-2UH (i=101 / i=51)

16

XXXXXX XXXX *

1

Motor module

17

632501 0002

1

Neodymium Block magnet 3 mm

18

562015 4000

1

Inductive proximity switch Baumer IFFM08P37A6_L

19

660510 3934

1

EZ3934 Magneticswitchmounting

EZ3934

20

563005

1

Magneticsensor

21

891101 0061

6

Pan head screw DIN 912 8.8 VZ M3 x 6

22

891101 0251

8

Pan head screw DIN 912 8.8 VZ M3 x 25

23

891101 0105

8

Pan head screw DIN 912 8.8 VA M3 x 10

24

891102 0101

4

Pan head screw DIN 912 8.8 VZ M4 x 10

25

891191 0065

10

Countersunk screw DIN 965 4.8 VA M 3 x 6

26

891191 0085

8

Countersunk screw DIN 965 4.8 VA M 3 x 8

27

891191 0081

6

Countersunk screw DIN 965 4.8 VZ M 3 x 8

28

891191 0101

1

Countersunk screw DIN 965 4.8 VZ M 3 x 10

29

891192 0085

4

Countersunk screw DIN 965 4.8 VA M 4 x 8

30

891541 0095

1

Self-tapping screw DIN 7982 VA 2.9 x 9.5

31

893050 0001

6

Disk DIN 125 ST 3.2

32

893051 0001

4

Disk DIN 125 ST 4.3

33

891371 0031

3

Grubscrew DIN 913 M 3 x 3

34

891371 0035

4

Grubscrew DIN 913 VA M 3 x 3

35

891373 0061

1

Grubscrew DIN 913 M 5 x 6

Exploded view RDH-S - Hollow shaft

* Item number see page 26

17 / 44 April 2019

RDH-XS, RDH-S, RDH-M, DSH-S

*Abtriebsflansch = outputflange Hohlwelle = hollowshaft tief = deep

Zentrieransatz Gehäuse = centering spigot casing Lochkreis = boltcircle

*Raster = grid / Spannfutter = chuck

Options L A

Tailstock unit RE-M 1000 mmm

1110

624.5

Tailstock unit RE-M 1500 mmm

1610

1124.5

Tailstock unit RE-M 2000 mmm

2110

1624.5

Dimension sheet for RDH-M

Dimension sheet for RDH-M tailstock unit RE M

18 / 44 April 2019

Exploded view RDH-M - Solid shaft

14

15

16

25

Servo motor structure

17

23

31 Multiphase motor structure

Item list RDH-M - Solid shaft

Pos No.

Item number

Quan-

tity

Name

Drawing no.

1

660510 0001

1

EZ3917 - basebody - 25

EZ3917

2

660510 3909

1

EZ3909 - Adapter flange 25

EZ3909

3

660510 3905

1

EZ3905 - Motor mounting 1

EZ3905

4

660510 3906

1

EZ3906 - Motor mounting 2

EZ3906

5

660510 1158

1

EZ1158 - Coupling part for HD motor - Male collet

EZ1158

6

635003 1101 / 635003 1200

1

EZ1160 - Collet Type S

EZ1160

7

660510 39182

1

EZ3918 - Cover - below option Standard

EZ3918

8

660510 3919 /660510 39191

1

EZ3919 - Cover - Connector

EZ3919

9

660510 39072 / 660510

39074 / 660510 39075

1

EZ3907 - Motor adapter

EZ3907

10

66051039253 / 660510

1

EZ3925 - Adapter - Motor shaft

EZ3925

11

893400 0025

1

Shaft seal BABSL 130-150-7.5 Simrit 72 NBR902

12

660510 1000 / 660510 1001

1

HarmDrive Motor HFSU-14-xx-2UH (i=101 / i=51)

13

XXXXXX XXXX *

1

Motor module

14

632501 0002

1

Neodymium Block magnet 3 mm

15

660510 3934

1

EZ3934 – Magneticswitch mounting

EZ3934

16

563005

1

Magneticsensor

17

562015 4000

1

Inductiveproximityswitch

18

891102 0101

8

Pan head screw DIN 912 8.8 VZ M4 x 10

19

891102 0141

4

Pan head screw DIN 912 8.8 VZ M4 x 14

20

891102 0255

16

Pan head screw DIN 912 8.8 VA M4 x 25

21

891191 0081

6

Countersunk screw DIN 965 4.8 VZ M 3 x 8

22

891191 0085

4

Countersunk screw DIN 965 4.8 VA M 3 x 8

23

891191 0101

1

Countersunk screw DIN 965 4.8 VZ M 3 x 10

24

891192 0085

14

Countersunk screw DIN 965 4.8 VA M 4 x 8

25

891541 0095

1

Self-tapping screw DIN 7982 VA 2.9 x 9

26

891132 0161

4

Countersunk screw DIN 7991 M4 x 16

27

891132 0401

12

Countersunk screw DIN 7991 M4 x 40

28

892023 0002

4

Hexagonal flangenut DIN 934 8 M 4

29

891372 0045

5

Grubscrew DIN 913 VA M 4 x 4

30

891373 0161

1

Grubscrew DIN 913 M 5 x 16

31

895025 0126

1

Grubscrew DIN 6325 d6x 12

RDH-XS, RDH-S, RDH-M, DSH-S

* Item number see page 26

19 / 44 April 2019

RDH-XS, RDH-S, RDH-M, DSH-S

15

16

17

27

Servo motor structure

18

23

30 Multiphase motor structure

Item list RDH-M - Hollow shaft

Pos No.

Item number

Quantity

Name

Drawing no.

1

660510 0001

1

EZ3917 - basebody - 25

EZ3917 2 660510 3915

1

EZ3915 - Adapter flange 25

EZ3915 3 660510 39181

1

EZ3918 - Cover - below option hollow shaft

EZ3918

4

660510 3919 / 660510 39191

1

EZ3919 - Cover Connector

EZ3919

5

660510 3924

1

EZ3924 - Toothed belt disk HTD3 - Z52

EZ3924

6

660510 39233 / 660510 39231

660510 39234

1

EZ3923 - Toothed belt disk HTD3 - Z52 with flanged

wheel

EZ3923

7

660510 3921

1

EZ3921 - Flange - Pipe seal

EZ3921

8

660510 39223 / 66051 39222

1

EZ3922 - Motor mountingplate

EZ3922 9 660510 3920

1

EZ3920 - Internal pipe

EZ3920

10

893400 0025

1

Shaft seal BABSL 130-150-7.5 Simrit 72 NBR902

11

893400 0026

1

Shaft seal BABSL 25-35-6 Simrit 72 NBR902

12

616510 0267

1

Toothed belt CXP HTD 267 -3M - 9 (Z89)

13

660510 1001 / 660510 1000

1

HarmDrive Motor HFSU-14-xx-2UH (i=101 / i=51)

14

XXXXXX XXXX *

1

Motor module

15

632501 0002

1

Neodymium Block magnet 3 mm

16

660510 3934

1

EZ3934 - Magneticswitchmounting

EZ3934

17

563005

1

Magneticsensor

18

562015 4000

1

Inductive proximity switch Baumer IFFM08P37A6_L

19

891101 0141

6

Pan head screw DIN 912 8.8 VZ M3 x 14

20

891102 0255

16

Pan head screw DIN 912 8.8 VA M4 x 25

21

891103 0145

4

Pan head screw DIN 912 8.8 VZ M5 x 14

22

891191 0085

8

Countersunk screw DIN 965 4.8 VA M 3 x 8

23

891191 0101

1

Countersunk screw DIN 965 4.8 VZ M 3 x 10

24

891192 0085

14

Countersunk screw DIN 965 4.8 VA M 4 x 8

25

891122 0351

12

Pan head screw DIN 6912 8.8 M 4 x 35

26

891132 0161

4

Countersunk screw DIN 7991 M 4 x 16

27

891541 0095

1

Self-tapping screw DIN 7982 VA 2.9 x 9.5

28

893053 0001

4

Disk DIN 125 ST 5.3

29

892023 0002

4

Hexagonal flangenut DIN 934 8 M 4

30

895025 0126

1

Grubscrew DIN 6325 d6x 12

31

891372 0045

5

Grubscrew DIN 913 VA M 4 x 4

32

891373 0161

1

Grubscrew DIN 913 M 5 x 16

Exploded view RDH-M - Hollow shaft

* Item number see page 26

20 / 44 April 2019

Dimension sheet for RSH-S

*Schritt = steppermotorSchwenkbereich = turingarea tief = deep

Servo = servomotor Grundplatte = baseplate

Item list RDH-S - Hollow shaft

Pos

No.

Item number

Quan-

tity

Name

Drawing no.

1 / 1

R5H-S Counter bearing

/

2 / 1

R5H-S Swivel unit

/

3 / 1

Rotary indexing table RDH-S (for RSH-S)

/

RDH-XS, RDH-S, RDH-M, DSH-S

Exploded view DSH-S

21 / 44 April 2019

RDH-XS, RDH-S, RDH-M, DSH-S

Item list R5H-S Counter bearing

Pos No.

Item number

Quan-

tity

Name

Drawing no.

1

665320 4331

1

EZ4331 Counter bearing block - S

EZ4331

2

665320 4385

1

EZ4385 Cover Counter bearing - S

EZ4385 3 665320 4369

1

EZ4369 Mount for counter bearing block - S

EZ4369

4

893400 0026

1

Shaft seal BABSL 25-35-6 Simrit 72 NBR902

5 1

Needle bearings NKI 20-16

6

891104 0205

5

Pan head screw DIN 912 8.8 VA M6 x 20

7 891054 0201

2

Allen screw DIN 933 M6x20

8

891190 0045

1

Countersunk screw DIN 965 4.8 VA M 2.5 x 4

9

891191 0065

2

Countersunk screw DIN 965 4.8 VA M 3 x 6

Exploded view R5H-S Counter bearing

22 / 44 April 2019

RDH-XS, RDH-S, RDH-M, DSH-S

4

20

22

41

Servo motor structure

21

37

Multiphase motor structure

Item list RDH-S (for Swivel unit RSH-S)

Pos No.

Item number

Quantity

Name

Drawing

no.

1

660500 0012

1

DZ2869 - Processing RSH-S - Servo

DZ2869 2 665320 28681

1

DZ2868 - Connector - RSH-S

DZ2868 3 660500 3931

1

EZ3931 Adapter flange - 14 Hollow shaft

EZ3930

4

660510 3934

1

EZ3934 Magnetic switch mounting

EZ3934

5

660500 39382

1

EZ3938 Cover - below Standard option

EZ3938 6 660500 3944

1

EZ3944 Toothed belt disk HTD3 - Z34

EZ3944 7 660500 3956

1

Bearing for motor module

8

660500 3957 /660500 39431

1

Toothed belt disk HTD3 - Z34 with flanged wheel for motor module

EZ3957

9

660500 3958 / 660500 3942

1

EZ3958 Motor adapter hollow shaft motor module

EZ3958

10

665320 42511

1

EZ4251-4 Stopcollar - right

EZ4251

11

See table

1

EZ4252 Internal pipe_14 Axis combinationL=112.5

EZ4252

12

665320 4256

1

EZ4256 Limit switch module ring LS

EZ4256

13

665320 4257

2

EZ4257 Adjustment ring LS with control disk

EZ4257

14

665320 4258

2

EZ4258 Control disk

EZ4258

15

665320 4259

1

EZ4259 Divider plate

EZ5249

16 / 1

EZ4262 Cable fastening

17 / 2

EZ4263 Cable fastening - Pipe

18

XXXXXX XXXX *

1

Motor module

19

665330 1000 / 650200 0002

1

HarmDrive Motor HFSU-14-xx-2UH (i=101 / i=51)

20

632501 0002

1

Neodymium block magnet 3 mm

21

562015 4000

1

Inductive proximity switch Baumer IFFM08P37A6_L

22

563005

1

Magnetic sensor

23

896010 6194

1

Single-row groove ball bearings with sealing pads 626-2RS1

24

893400 0027

1

Shaft seal BABSL 90-70-7 Simrit 72 NBR902

25

616504 0660

1

Toothed belt CXP HTD 180 -3M - 6 (Z60)

26

665320 0001

2

Fork light barrier PM-T54P

27

891371 0035

4

Grub screw DIN 913 VA M 3 x 3

28

891373 0061

1

Grub screw DIN 913 M 5 x 6

29

89114x 0061

4

Pan head screw DIN 84 4.8 VG M 2 x 6

30

891101 0061

6

Pan head screw DIN 912 8.8 VZ M3 x 6

31

891101 0081

4

Pan head screw DIN 912 8.8 VZ M3 x 8

32

891101 0105

8

Pan head screw DIN 912 8.8 VA M3 x 10

Exploded view RDH-S (for swivel unit)

23 / 44 April 2019

33

891101 0251

8

Pan head screw DIN 912 8.8 VZ M3 x 25

34

891102 0101

4

Pan head screw DIN 912 8.8 VZ M4 x 10

35

891191 0065

10

Countersunk screw DIN 965 4.8 VA M 3 x 6

36

891191 0081

6

Countersunk screw DIN 965 4.8 VZ M 3 x 8

37

891191 0101

1

Countersunk screw DIN 965 4.8 VZ M 3 x 10

38

891122 0251

4

Pan head screw DIN 6912 A2 M 4 x 25

39

891591 0101

2

Roundhead screw DIN 7380 M 3 x 10

40

891592 0101

2

Roundhead screw DIN 7380 M 4 x 10

41

891541 0095

1

Self-tapping screw DIN 7982 VA 2.9 x 9.5

42

893050 0001

6

Disk DIN 125 ST 3.2

43

893051 0001

4

Disk DIN 125 ST 4.3

44

891132 0085

2

Countersunk screw DIN 7991 VA, M 4 x 8

* Item number see page 26

10

16

18

36

Servo motor structure

17

32

41 Multiphase motor structure

Exploded view R5H-S Swivel unit

RDH-XS, RDH-S, RDH-M, DSH-S

24 / 44 April 2019

RDH-XS, RDH-S, RDH-M, DSH-S

Item list for R5H-S Swivel unit

Pos No.

Item number

Quan-

tity

Name

Drawing

no.

1

665320 4340

1

EZ4340 Pin fixing

EZ4340

2

665320 4343

1

EZ4343 Base body - Cover for Swivel unit - S

EZ4343 3 665320 4345

1

EZ4345 Divider plate - S

EZ4345

4

660500 3956

1

EZ4357 Bearing for motor module

EZ3956

5

665320 4366

1

EZ4366 Flange - S Drive side

EZ4366 6 665320 4367

1

EZ4367 Flange - S Counter bearing side

EZ4367

7

665320 4375

1

EZ4375 Base body Swivel unit - S Finishing

EZ4375 8

1

EZ4384 Cover Swivel unit - S

EZ4384 9 660500 3930

1

EZ3930 - Adapter flange - 14

EZ3930

10

660510 3934

1

EZ3934 Magnetic switch mounting

EZ3934

11

660500 3944

1

EZ3944 Toothed belt disk HTD3 - Z34

EZ3944

12

660500 3957

1

Toothed belt disk HTD3 - Z34 with flanged wheel for motor

module

EZ3957

13

660500 3958

1

EZ3958 Motor adapter hollow shaft motor module

EZ3958

14

XXXXXX XXXX *

1

Motor module

15

665330 1000 / 650200 0002

1

HarmDrive Motor HFSU-14-xx-2UH (i=101 / i=51)

16

632501 0002

1

Neodymium block magnet 3 mm

17

562015 4000

1

Inductive proximity switch Baumer IFFM08P37A6_L

18

563005

1

Magnetic sensor

19

896010 6194

1

Single-row groove ball bearings with sealing pads 626-2RS1

20

893400 0027

1

Shaft seal BABSL 90-70-7 Simrit 72 NBR902

21

616504 0660

1

Toothed belt CXP HTD 318 -3M - 6 (Z106)

22 1

Pipe D10 d5 L=40

23

890365 0101

1

TE2770-4 Grubscrew M8x0.75 with 60 point

TE2770

24

891371 0031

3

Grubscrew DIN 913 M 3 x 3

25

891101 0061

6

Pan head screw DIN 912 8.8 VZ M3 x 6

26

891101 0105

8

Pan head screw DIN 912 8.8 VA M3 x 10

27

891101 0251

8

Pan head screw DIN 912 8.8 VZ M3 x 25

28

891101 0305

2

Pan head screw DIN 912 8.8 VA M3 x 30

29

891102 0061

2

Pan head screw DIN 912 8.8 VZ M4 x 6

30

891103 0125

3

Pan head screw DIN 912 8.8 VA M5 x 12

31

891191 0081

6

Countersunk screw DIN 965 4.8 VZ M 3 x 8

32

891191 0101

1

Countersunk screw DIN 965 4.8 VZ M 3 x 10

33 16

Pan head screw DIN 6912 A2 M 3 x 6

34

891122 0101

3

Pan head screw DIN 6912 8.8 M 4 x 10

35

891122 0101

16

Pan head screw DIN 6912 A2 M 4 x 10

36

891541 0095

1

Self-tapping screw DIN 7982 VA 2.9 x 9.5

37

891132 0451

1

Countersunk screw DIN 7991, M 4 x 45

38

893050 0001

6

Disk DIN 125 ST 3.2

39

893050 0005

16

Disk DIN 125 ST 3.2

40

893051 0001

3

Disk DIN 125 ST 4.3

41

895024 0126

1

Grubscrew DIN 6325 d5x 12

42

895025 0126

2

Grubscrew DIN 6325 d6x 12

* Item number see page 26

25 / 44 April 2019

RDH-XS, RDH-S, RDH-M, DSH-S

Drive module

RDH-XS

RDH-S

RDH-M

RSH-S

Item no.

multiphase-

motor

MS-045 HT

X X X 398702 0002

MS-200 HT

X 398701 0002

EC

servo-

motor

EC 42 (brushless)

X X X 398703 0005

EC 60S (brushless)

X 398703 0003

DC servo-

motor

RE 40 (brushed)

X X X 398700 0001

DC 100 (brushed)

X 398700 0012

Drive module

Various drive modules with multiphase motors, brushed servo motors (BDC) and brushless servo motors

(BLDC) are available for the rotary units RDH - RSH as standard.

26 / 44 April 2019

RDH-XS, RDH-S, RDH-M, DSH-S

Motor connector

M23 9-pol. (8+1) pin

Encoder connector

Sub-D 15-pin Pin

View of pin insertion

on the plug-in side

1

Motor phase U

2

Motor phase V

3

Motor phase W

4

---

5

+24V brake

6

GND brake

7

8

9

Protectiveconductor

PE

Casing – cableshield

View of pin insertion

on the plug-in side

1

Hall signal A

2

+5V encoder/Hall

3

Encoder track /Z

4

Encoder track /B

5

Encoder track /A

6

+24V Switch

7

Limit switch 1

8

GND switch

9

Hall signal B

10

GND encoder

11

Encoder track Z

12

Encoder track B

13

Encoder track A

14

Hall signal C

15

Limit switch 2

Casing – cableshield

Motor connector

M23 9 pin (8+1) pin

Encoder connector

D-sub 15 pin

View of pin insertion

on the plug-in side

1

Motor phase U

2

Motor phase V

3

Motor phase W

4

+24 V brake

5

GND brake

6

Protective earth PE

Housing - cable shield

View of pin insertion

on the plug-in side

1

Hall signal A

2

+5 V encoder/Hall

3

Encoder track /Z

4

Encoder track /B

5

Encoder track /A

6

+24 V switch

7

Limit switch 1

8

GND switch

9

Hall signal B

10

GND encoder

11

Encoder track Z

12

Encoder track B

13

Encoder track A

14

Hall signal C

15

Limit switch 2

Housing - cable shield

Motor connector

M23 12 pin Pin

View of pin insertion

on the plug-in side

1

Motor phase 1A

2

Motor phase 1B

3

Motor phase 2A

4

Motor phase 2B

5

+24V Switch

6

+24V brake

7

GND switch

8

GND brake

9

Limit switch 1

10

Limit switch 2

11

---

12

---

Casing – cableshield

2.3 Connector pin assignment for rotary units

Connector pin assignment for brushless DC servo motors (BLDC) 48V

Connector pin assignment for brushless DC servo motors (BLDC) 48 V, 400W

Connector pin assignment for M23 12 pin for multiphase motors

27 / 44 April 2019

RDH-XS, RDH-S, RDH-M, DSH-S

3 Commissioning, general information

The rotary unit is commissioned after mounting the relevant drive modules and any necessary cables.

Follow the relevant instructions in the documentation of the motor modules, output stages or controls

used.

Procedure:

Switch off the controls and ensure that they are secured.

Mount the rotary unit / rotary-swivel unit securely to a suitable work surface

Connect the encoder cable.

Connect the motor cable.

Switch the controls on and check that the rotary unit / rotary-swivel unit is working correctly

Conduct a test run

- First with slow movement,

- Then under operating conditions

Incorrect assembly (including loading on the axis system), cabling or commissioning

increases the risks.

Unauthorized individuals should not be given access to the controls or the switch cabinet.

There is a risk of electric current causing injuries. This is the responsibility of the individual

who installed the machinery.

28 / 44 April 2019

RDH-XS, RDH-S, RDH-M, DSH-S

A: Alignmentsurface

B: Free-stationary

C: Rack mounting

4 Assembly of the rotary unit

Before you can assemble your new rotary unit, you must remove any securing devices used in transport.

4.1 Mounting and adjustment instructions

You have several options for mounting the components individually:

A) Alignment surface

The rotary units RDH / RSH have a stop face on the connector side of the casing with a clearly defined

distance from the axis of rotary. (Distances are given in the respective dimensioned drawings).

In addition, the rotary units have two plane installation surfaces parallel to the axis of rotary, which allows

the rotary unit to be used as a rotary axis as well as a rotary indexing table.

B) Free-stationary rotary unit

You can place the rotary unit on a rack, a work table or any other suitable, i.e. sturdy base.

Choose the location carefully so that the product cannot fall or be knocked over by

any impact or tug on the cables.

C) Rack mounting (recommended)

Use the depression in the base body of the rotary unit to mount the rotary unit on your rack. Use appropriate Pan head screws and the matching T-nuts / threaded rails (accessories) to secure it.

Make sure the mounting surfaces are sufficiently clean.

The base bodies used in the rotary units are castings which can deviate in terms of their tolerance as a

result of the manufacturing process.

The surface areas of these base bodies are plane-milled to achieve a high degree of precision.

However, to achieve the desired guide accuracies and running performance, the rotary unit must either

be laid out over an appropriately flat surface or arranged over levelling plates. This achieves round tolerances or axial run-out tolerances of maximum 0.03 mm in the Transmission flange.

Make sure the fixing surfaces are sufficiently clean and sufficiently level.

29 / 44 April 2019

RDH-XS, RDH-S, RDH-M, DSH-S

A: Mounting tailstock unit RE M / RE S

B: Mounting tailstock unit RE XS

4.2 Mounting the tailstock unit

A) Position both guide shafts of the tailstock unit RE S / RE M in the two through bores of the rotary unit

RDH-S / RDH-M so that these can be secured on the underside of the rotary unit with the appropriate

grubscrews.

For tailstock unit RE M, place the guide shafts (facing the rotary unit) in a middle position between the

rotary unit and the pinole. Secure the two guide shafts to the work surface with suitable screws.

Secure the position of tailstock unit RE S by also screwing the base plate of the tailstock unit to the work

surface.

B) First secure rotary unit RDH-XS to the base plate of the tailstock unit (4x M5). Leave the screws loose

at this stage. Turn the rotary unit axial to the tailstock unit and tighten the screws securely.

Now secure the entire unit to your work surface (if you are using T-nut plates use T-nus and the

appropriate matching screws, see accessories). Leave the screws loose at this stage. Align the unit

precisely with the existing axis system and secure the screws.

30 / 44 April 2019

5 Fault list

Problem/fault

Possible cause(s)

Help

Louder running

sounds

Dirt

Lack of lubricating film

Clean the rotary unit

in the area around the seals

Stiffness

Dirt

Incorrect tension

Clean the rotary unit

Alignment, adjustment

Impaired positioning

accuracy or

repeatability

Overload

Reduce load

Important: In unfavourable electromagnetic conditions the effects of EMC can cause faults.

Only allow qualified technicians to carry out repairs on the electric components of the product.

Otherwise there is a risk of electric current causing fatal injuries.

RDH-XS, RDH-S, RDH-M, DSH-S

Do not attempt to manipulate the controller or output stage of the rotary unit.

31 / 44 April 2019

6 Technical specification

Technical specification RDH-XS

Multiphase motor

MS 045HT*

EC servo motor

EC 42

DC servo motor

RE 40

Reduction ratio

1 : 50

1 : 100

1 : 50

1 : 100

1 : 50

1 : 100

Nominal output speed [rpm]

5 2 22

11

22

11

at 1500 Hz (225 rpm)

at 1100 rpm

at 1100 rpm

Max. output speed

[rpm]

24

12

59

30

70

35

at 8000 Hz (1200 rpm)

--

Nominal torque

[Nm]

5

7 5 7 5 7

at 1500 Hz (225 rpm)

--

Max. Torque(short)

[Nm]

--

-- 5 7 5 7

Nominal holding torque (static load)

[Nm] 5 7 5 7 5 7

Max drive load

[Nm]

9

14 9 14 9 14

Limit for repeatable peak torque

Dynamic loading capacity C

[N]

392

Static loading capacity C

0

[N]

392

Weight

[Kg]

2.3

* Values for half-step-

ping mode

Technical specification

RDH-S

Multiphase motor

MS 045HT*

EC servo motor

EC 42 (brushless)

DC servo motor

RE 40 (brushed)

Reduction ratio

1 : 51

1 : 101

1 : 51

1 : 101

1 : 51

1 : 101

Nominal output speed

[rpm]

4 2 22

11

22

11

at 1500 Hz (225 rpm)

at 1100 rpm

at 1100 rpm

Max. output speed

[rpm]

24

12

59

30

69

35

at 8000 Hz

--

Nominal torque

[Nm]

7

11

4.8

9.2

4.6

9

at 1500 Hz

--

Max. Torque (short-term)

[Nm]

--

-- 7 11 7 11

Nominal holding torque (static load)

[Nm] 7 11 7 11 7 11

Max driveload

[Nm]

18

28

18

28

18

28

Limit for repeatable peak torque

Dynamic loading capacity C

[N]

5800

Static loading capacity C0

[N]

8600

Weight

[Kg]

4.6

* Values for half-step-

ping mode

6.1 Mechanical data

RDH-XS, RDH-S, RDH-M, DSH-S

32 / 44 April 2019

RDH-XS, RDH-S, RDH-M, DSH-S

Technical specification

RDH-M

Multiphase motor

MS 200HT*

EC servo motor

EC 60S (brushless)

DC servo motor

DC 100 (brushed)

Reduction ratio

1 : 51

1 : 101

1 : 51

1 : 101

1 : 51

1 : 101

Nominal output speed

[rpm]

4 2 22

11

22

11

at 1500 Hz (225 rpm)

at 1100 rpm

at 1100 rpm

Max. output speed

[rpm]

24

12

59

30

59

30

at 8000 Hz

--

--

Nominal torque

[Nm]

24

46 9 17 7 14

at 1500 Hz

--

--

Max. Torque (short-term)

[Nm]

--

--

42

80

39

73

Nominal holding torque (static load)

[Nm]

55

108

26

51

15

30

Max drive load

[Nm]

98

157

98

157

98

157

Limit for repeatable peak torque

Dynamic loading capacity C

[N]

21800

Static loading capacity C

0

[N]

35800

Weight

[Kg]

13,7

* Values for half-step-

ping mode

Technical specification

RSH-S

Multiphase motor

MS 045HT*

EC servo motor

EC 42

DC servo motor

RE 40

Reduction ratio

1 : 51

1 : 101

1 : 51

1 : 101

1 : 51

1 : 101

Nominal output speed

[rpm]

4 2 22

11

22

11

at 1500 Hz (225 rpm)

at 1100 rpm

at 1100 rpm

Max. output speed

[rpm]

24

12

59

30

69

35

at 8000 Hz

--

Nominal torque

[Nm]

7

11

4.8

9.2

4.6

9

at 1500 Hz

--

Max. Torque (short-term)

[Nm]

--

-- 7 11 7 11

Nominal holding torque (static load)

[Nm] 7 11 7 11 7 11

Max drive load

[Nm]

18

28

18

28

18

28

Limit for repeatable peak torque

Dynamic loading capacity C

[N]

5800

Static loading capacity C

0

[N]

8600

Weight

[Kg]

12

* Values for half-step-

ping mode

33 / 44 April 2019

RDH-XS, RDH-S, RDH-M, DSH-S

Transport load, processing forces, feed rate

Rotary unit

1*

2* 3 4 5 6

7

RDH-M (step)

100kg

45kg

55Nm

24Nm

24Nm

4 rpm

1 : 51

RDH-M (step)

160kg

70kg

108Nm

45Nm

45Nm

2 rpm

1 : 101

RDH-M (EC servo/brushless)

110kg

50kg

26Nm

9Nm

9Nm

22 rpm

1 : 51

RDH-M (EC servo/brushless)

180kg

80kg

51Nm

17Nm

17Nm

11 rpm

1 : 101

RDH-M (DC servo/brushed)

110kg

50kg

15Nm

7Nm

7Nm

22 rpm

1 : 51

RDH-M (DC servo/brushed)

180kg

80kg

30Nm

14Nm

14Nm

11 rpm

1 : 101

RDH-S (step)

30kg

15kg

7Nm

7Nm

7Nm

4 rpm

1 : 51

RDH-S (step)

48kg

24kg

11Nm

11Nm

11Nm

2 rpm

1 : 101

RDH-S (EC servo /brushless)

30kg

15kg

7Nm

4.6Nm

4.6Nm

22 rpm

1 : 51

RDH-S (EC servo/brushless)

48kg

24kg

11Nm

4.6Nm

9.2Nm

11 rpm

1 : 101

RDH-S (DC servo/brushed)

25kg

13kg

7Nm

4.6Nm

4.6Nm

22 rpm

1 : 51

RDH-S (DC servo/brushed)

40kg

20kg

11Nm

8.7Nm

8.7Nm

11 rpm

1 : 101

RDH-XS (step)

30kg

10kg

5Nm

5Nm

5Nm

24 rpm

1 : 50

RDH-XS (step)

30kg

10kg

7Nm

7Nm

7Nm

12 rpm

1 : 100

RDH-XS (EC servo/brushless)

30kg

10kg

5Nm

5Nm

5Nm

59 rpm

1 : 50

RDH-XS (EC servo/brushless)

30kg

10kg

7Nm

7Nm

7Nm

30 rpm

1 : 100

RDH-XS (DC servo/brushed)

30kg

10kg

5Nm

5Nm

5Nm

70 rpm

1 : 50

RDH-XS (DC servo/brushed)

30kg

10kg

7Nm

7Nm

7Nm

35 rpm

1 : 100

* Standard values may deviate depending on the application

Performance data for drive bearing

Rotary units RDH

RDH-M

RDH-S /

RSH-S

RDH-XS

Dynamic loading capacity

C

[N]

21800

5800

-

Static loading capacity

C0

[N]

35800

8600

-

Added dynamic breakdown torque

1

M

[Nm]

258

74

5

Added static breakdown torque

2

M0

[Nm]

1070

144

5

Tilting rigidity

Kb

[Nm/arcmin]

114

25

-

Added axial load

3

Fa

[N]

11504

3044

392

Added radial load

3

Fr

[N]

7708

2039

392

1

applies to turning drives

2

applies to stationary drives with static safeguard 1.5

3

is on the basis of a normal load, average rotational speed 15 rpm, working life 15000h

These data only apply for a load

M, M0 Fa=Fr=0

Fa Fr=0, M=0

Fr Fa=0, M=0

working life is calculated similarly to the roller bearings through the dynamic equivalent load, load factors, the average output

speed and the service factor to the load ratings

34 / 44 April 2019

RDH-XS, RDH-S, RDH-M, DSH-S

Maintenance interval

Maintenance work

When necessary

Clean the rotary unit

300 – 700 operating hours

Visual check of seals, attachments

2 years

Replace toothed belts (when available)

Replace shaft seal rings

6.2 Electrical data

You can find the motor data, output stages mains values and connection values and controller data in

the documentation

https://www.isel.com/en/support-downloads/manuals.html

7 Maintenance and cleaning

7.1 Maintenance instructions

The RDH - RSH rotary units function extremely accurately and reliably. Maintenance costs are therefore

relatively low.

Maintenance of the rotary units is limited to cleaning them of coarse dirt particles and contaminants.

The Harmonic Drive Motors are ex works lubricated with special isel grease. No further basic lubrication

is necessary before the axis system is started up.

7.2 Cleaning

Clean the surface of the rotary unit's cast housing and the output flange with a lint-free, dry/slightly damp

cloth. Do not use harsh cleaning agents or abrasive cleaners.

35 / 44 April 2019

RDH-XS, RDH-S, RDH-M, DSH-S

8 Decommissioning / disposal

The symbol on the product or its packaging indicates that the product must not be disposed of with

normal household waste. Users must deliver the products/used devices to a collection point for used

electrical and electronic devices. The separate collection and proper disposal of your products/used

devices helps to conserve natural resources and guarantees recycling, which in turn protects people's

health and the environment. You can get information on where to find collection points for your used

devices from your local borough council, local waste disposal companies or on the Internet.

9 CE Conformity

The rotary units RDH - RSH are classified as 'partly completed machines' according to MD 2006/42/EC

and therefore comply with CE guidelines (see installation explanation of the manufacturer, isel Germany

AG).

As a 'partly completed machine' the product does not carry the CE mark, although it still conforms to the

relevant European guidelines.

isel Germany AG hereby confirms that the product complies with the following directives:

EC Directive 2006/42/EC 'Machinery Directive'

EC Directive 2006/95/EC 'Electrical Equipment Designed for Use within certain Voltage Limits'/'Low

Voltage Directive'

EC Directive 2004/108/EC 'Electromagnetic Compatibility (EMC)'

The installation explanation for the product rotary unit RDH - RSH is an integral part of these assembly

instructions.

36 / 44 April 2019

RDH-XS, RDH-S, RDH-M, DSH-S

10 Service

If you need customer service or have any questions regarding parameterization of the controllers/motor

output stages (if they are included in the scope of the delivery), please consult:

Mr. Frank Hecht (Dermbach - Thüringen plant):

Tel: +49 (0)6659 981-763

Email: support@isel.com

Mr. Frank Jansen (Eichenzell – Hessen plant):

Tel: +49 (0)6659 981-765

Email: support@isel.com

11 Warranty

Warranty:

Over and above the seller's statutory liability for material defects and according to the following conditions, as the manufacturer we guarantee flawless working life of products from isel Germany AG if used

properly.

This guarantee extends to the functioning of isel Germany AG products and includes any fault which can

be proved to have been caused by the manufacturing process or material defects.

Warranty exclusions:

All replaceable individual components, e.g. screws, connecting pins etc. are excluded from this warranty.

Furthermore, we accept no liability for damage caused by:

Inappropriate or improper use

Faulty or negligent handling

Failure to observe installation instructions and instructions on care, as well as modifications or repairs

carried out by users themselves

The effects of chemical and physical influences and improper use on the surface of the materials, e.g.

damage from sharp objects.

We do not accept any liability for consequential damage.

We do not accept any liability for damage to persons and property caused by improper handling or failure

to observe the safety guidelines. In cases such as these no claim can be made against the warranty.

Warranty conditions:

Our warranty only covers at our discretion the repair or replacement of the product free of charge for

first/end users within the warranty period.

Warranty period:

In accordance with our General Terms and Conditions (AGB of isel Germany AG, Section VI) our warranty lasts one year.

For claims please contact the seller or the manufacturer directly, quoting the number of your invoice/delivery note.

Manufacturer:

isel

Germany AG

Bürgermeister-Ebert-Straße 40

D-36124 Eichenzell

Tel.: (06659) 981-700

Fax: (06659) 981-776

E-Mail: automation@isel.com

http://www.isel.com

37 / 44 April 2019

RDH-XS, RDH-S, RDH-M, DSH-S

EN ISO 12100:2010

Safety of Machinery - Safety of machinery -- General principles for design -- Risk

assessment and risk reduction

EN 349:1993+A1:2008

Safety of Machinery - Minimum distances to avoid the Bruising of body parts

EN 60204-1:2006

Safety of machinery. Electrical equipment of machines

- Part 1: General requirements

12 Declaration of incorporation according to MD 2006/42/EC

Installation explanation according to EC Machinery Directive (MD) 2006/42/EC, Appendix II B

The manufacturer isel Germany AG

Bürgermeister-Ebert-Straße 40

D-36124 Eichenzell, Germany

hereby declares that the product (incomplete machine)

Product description: Rotary unit RDH-XS Item number: 26600x 0x00

Rotary unit RDH-S Item number: 2661xx 0x00

Rotary unit RDH-M Item number: 2662xx 0x00

Rotary unit DSH-S Item number: 26541x x000

complies with the fundamental health and safety requirements of EC Machinery Directive 2006/42/EC

Appendix I.

The following harmonised standards were applied:

The following additional EC Directives relevant to this product were applied:

Low Voltage Directive 2014/35/EC

The technical documentation for this incomplete machine was produced according to Appendix VII Part

B. The manufacturer undertakes to pass on these technical documents to national authorities in electronic form on request.

Member of staff responsible for producing the technical documents or assembly instructions/installation

explanation is: Christian Bley (CE coordinator, isel Germany AG)

The product (incomplete machine) is intended for installation into a machine or combining with other

incomplete machines to form a machine as defined in MD 2006/42/EC, Article 1, Section (1) a.

This incomplete machine (product) must not be commissioned until the machine in which this product is

installed or of which it forms a component meets the provisions of all the relevant directives (especially

MD 2006/42/EC) and this (complete) machine carries a CE mark.

Place, date: Dermbach, 21 April 2016

_____________________________

Werner Kister, Member of the Management Board

38 / 44 April 2019

13 Index

RDH-XS, RDH-S, RDH-M, DSH-S

A

Abbreviations ........................................................... 2

Appendix with Accessories ................................. 43

Assembly ................................................................ 29

C

CE Conformity ........................................................ 38

Cleaning .................................................................. 36

Copyright .................................................................. 2

D

Decommissioning .................................................. 37

Deliverables .............................................................. 8

drive elements ........................................................ 10

F

Fault list ................................................................... 31

Functions .................................................................. 9

O

Operating environment ........................................... 6

P

Proper use ................................................................ 8

S

Safety guidelines ..................................................... 6

Service ..................................................................... 39

Symbols used ........................................................... 2

T

Technical specification ......................................... 32

W

Warranty .................................................................. 40

I

Installation instructions .......................................... 9

39 / 44 April 2019

14 Appendix

RDH-XS

Chuck

• 3-jaw chuck Ø 65

Item no.: 269060 4065*

* includingflange

Tailstockunit RE XS

• for RDH-SX

Item no.: 269100 0020 (200mm)

Item no.: 269100 0030 (300mm)

Item no.: 269100 0040 (400mm)

Item no.: 269100 0050 (500mm)

RDH-S

Chuck

• 3-jaw chuck Ø 65

Item no.: 269060 3065*

• 3-jaw chuck Ø 80

Item no.: 269063 2080*

• 3-jaw chuck Ø 100

Item no.: 269063 2100*

Chuck

• 4-jaw chuck Ø 100

Item no.: 269061 2100*

* includingflange

Tailstockunit RE S

• for RDH-SX

Item no.: 269100 1020 (200mm)

Item no.: 269100 1030 (300mm)

Item no.: 269100 1040 (400mm)

Item no.: 269100 1050 (500mm)

RDH-M

Chuck

• 3-jaw chuck Ø 125

Item no.: 269062 2125

• 4-jaw chuck Ø 125

Item no.: 269061 0125*

* including flange

Aluminium T-nut disk

• Ø 240 mm / PT 25

Item no.: 269050 0240

• Ø 365 mm / PT 25

Item no.: 269050 0365

Aluminium rotarydisk

• Ø 490 mm, anchor points

drilled at extra charge on customer request

Item no.: 269051 0500

Tailstock unit RE S

• for RDH-SX

Item no.: 269100 2100

(1000mm)

Item no.: 269100 2150

(1500mm)

Item no.: 269100 2200

(2000mm)

14.1 A1: Accessories

RDH-XS, RDH-S, RDH-M, DSH-S

40 / 44 April 2019

RDH-XS, RDH-S, RDH-M, DSH-S

RSH-S

Chuck

• 3-jaw chuck Ø 65

Item no.: 269060 3065*

• 3-jaw chuck Ø 80

Item no.: 269063 2080*

• 3-jaw chuck Ø 100

Item no.: 269063 2100*

Chuck

• 4-jaw chuck Ø 100

Item no.: 269061

2100*

* includingflange

Rotary table

• Ø 150 mm

Item no.: 269050 0150

Threadedinserts/slidingnut

Item number

Comments

Threadedinsert M6 (Grid 50)

209011

VE 3 piece x 1m

Slidingnut M6

209001 0005

VE 100 pieces

Slidingnut 2x M6

209002 0004

VE 50 pieces

Slidingnut M5

209006 0001

VE 20 pieces

Angled sliding nut 2x M6

209021 0003

VE 25 pieces

Special angled gliding nut 3x M6

209022 0003

VE 25 pieces

14.2 A2: Miscellaneous

Assembly instructions [product] identification no.: 970261 BE 0001 / 11-2011

41 / 44 April 2019

RDH-XS, RDH-S, RDH-M, DSH-S

Space for notes

42 / 44 April 2019

RDH-XS, RDH-S, RDH-M, DSH-S

Space for notes

43 / 44 April 2019

Loading...

Loading...