isel Germany AG

isel Germany AGisel Germany AG

isel Germany AG, D-

36124 Eichenzell, Buergermeister

CNC control panel iOP

Operating

-Ebert-Str. 40 +49 (0)6659 981-0

-19-

TFT

instructions

+49 (0)6659 981-776

Abbreviations used in these

operating instructions

MRL

Machinery Directive 2006/42/EC

ERL

EMC Directive 2004/108/EC

NRL

Low Voltage Directive 2006/95/EC

Symbols used

The operating instructions contain important information / issue and danger symbols, which

must be noted and complied with:

Warning!

This symbol warns of potential danger to health, life and limb.

Warning! Potentially lethal voltage

This sign warns of danger to life and limb due to the presence of high-voltage

electrical circuits. Failure to observe the danger can result in severe injury or

death.

Attention!

This symbol means important instructions are being given. Failure to observe the

instructions may result in equipment malfunction or damage to machinery.

Information:

This symbol means important information or advice is being given.

Complying with safety information

Prior to using the iOP-19-TFT CNC control panel or making any alterations to

the electrical installations in or on your machinery, please ensure that you have

carefully read through the safety information in these operating instructions.

The information, technical specifications and dimensions contained in this booklet represent the

latest available data at the time of going to print. The occurrence of misprints and other errors

cannot, however, be completely ruled out. We thank you in advance for bringing such errors to

our notice and we welcome any improvement suggestions you may have.

We are obliged to draw your attention to the fact that the software and hardware brand names

and trade marks appearing in this booklet are protected under patent.

All rights reserved. No part of this booklet may be reproduced, electronically processed,

duplicated or distributed in any form whatsoever (printed out, photocopied, etc.) without the

written permission of isel Germany AG.

isel Germany AG

isel Germany AG isel Germany AG

isel Germany AG

machines and controllers are CE compliant and labelled

accordingly. This equipment must not be operated until the CE safety guidelines

applying to all associated machinery parts and components have been

fully complied with.

isel Germany AG

isel Germany AG isel Germany AG

isel Germany AG accepts no liability for damage to equipment or malfunction

where modification has been made to the controller.

The EMC test is only valid for CNC control panels with original ex-works

configurations.

Manufacturer: isel Germany AG

Buergermeister-Ebert-Straße 40

D-36124 Eichenzell

Tel.: +49 (0) 6659 981-0

Fax: +49 (0) 6659 981-776

Email: automation@isel.com

http://www.isel.com

Article No. : 371100 1000 (original operating instructions)

Date of issue: 06/2014_RL

Technical specifications may change without prior notification.

Current operating instructions and equipment manuals can be downloaded at:

www.isel-data.de/manuals

Table of contents

1 General Information ........................................................................................................... 5

1.1 Safety information .............................................................................. …………………5

2 Product description ............................................................................................................. 6

2.1 Versions .......................................................................................................................... 6

2.1.1 CNC control panel iOP-19-TFT with 19“ touch screen ....................................................... 6

2.2 Description of control elements ..................................................................................... 7

3 Connections of the control elements ................................................................................ 10

3.1 Connection of the controls for the control PC .............................................................. 10

3.2 Power supply for the CNC control panel ..................................................................... 11

3.3 Connection of machine controls ................................................................................... 12

4 Faults .................................................................................................................................. 13

5 Service and maintenance .................................................................................................. 13

6 Technical Data ................................................................................................................... 14

6.1 Technical Data iOP-19-TFT ......................................................................................... 14

7 EC Declaration of Conformity ......................................................................................... 15

CNC control panel iOP-19-TFT

Page - 5

1 General

Please read these operating instructions through to the end and carefully follow the

instructions given. Failure to comply with these operating instructions can result in damage

to property, personal injury or death.

1.1 Safety note

The iOP-19-TFT CNC control panel is designed in

accordance with state of the art technology and in full

compliance with recognised safety standards.

This equipment must only be operated in a fault-free

condition. Any observed defect must be removed before

the equipment is used. This equipment must only be

operated by trained personnel. Children should not be

allowed in the vicinity of the equipment.

This equipment must only be used in accordance with its

intended purpose, i.e. for the monitoring and control of

CNC machinery linked to a separate iSR/iPC series

control computer.

Equipment operations must only be carried out by

authorised, qualified personnel and in full compliance

with electrical industry regulations and safety standards.

Ensure the equipment is fully disconnected from the mains

supply before opening the cover and carrying out any

electrical installation work.

Ensure there is sufficient ventilation in the immediate

vicinity of the monitor. Ensure the equipment is mounted

in a safe and stable position and that the ventilation ports

in the monitor housing are left open and unobstructed.

Equipment assembly and operation must be undertaken in

compliance with all relevant conformity declaration

standards. The guidelines and threshold values issued by

the manufacturer do not provide protection in the event of

improper use of the equipment.

The equipment must not be exposed to excessive levels of

humidity or vibration.

Ensure that all operators are familiar with the content of

these operating instructions and that such content is

strictly adhered to at all times!

CNC control panel iOP-19-TFT

Page - 6

2 Product description

2.1 Versions

Type Description Article No.

iOP-19-TFT

without keyboard, RAL

3011

371100 1000

with German keyboard,

(optional)

with silicon keyboard,

RAL 3011

371200 0001

with English keyboard,

(optional)

Silicon keyboard, RAL

3011

371200 0002

2.1.1 CNC control panel iOP-19-TFT with 19“ touch screen

standard

optional

robust aluminium housing

Aluminium "stainless steel-look" front

panel

Simple assembly using VESA 100/100

mounting

Integrated machinery control elements

19“ TFT with touch screen

Max. resolution: 1280 x 1024 pixels

3 USB connections

pull-out connecting cable, compatible

with isel control computer

Stand

Swivel arm for connection to PS

profile

Simple keyboard / mouse storage

compartment

Superior quality, built-in 105-key

silicon German / English keyboard

with touch pad

Two-handed operation

Override potentiometer

Available in 3 colours, RAL 3011,

RAL

CNC control panel iOP-19-TFT

Page - 7

2.2 Description of control elements

In the standard version, the most important control elements (buttons, switches) are mounted

on the CNC control panel.

Machinery control elements

CNC control panel iOP-19-TFT

Page - 8

No. Element Description

1 Power ON button Switches the power amplifiers on.

2 Fault indicator

The fault indicator signals the presence of a fault in the safety

circuit.

3 STOP button

Interrupts the NC program currently being executed. Pressing

the STOP button a second time terminates the NC program

currently being executed (does not apply to all control

configurations, only to the ProNC setting).

4 START button

Pressing the START button initiates execution of the current

NC program or, where the program has been interrupted,

allows the current program execution to be continued.

5

ACK (acknowledge)

button

The ACK button is used in Set Up mode and must be pressed

to allow the shafts to be driven when the cover is open.

6 COVER button

The COVER button is pressed to allow the cover to be opened

(where a cover has been provided). The cover can only be

opened when the conditions listed under "Operating Mode

Selector Switch" have been fulfilled. Once the white signal

lamp on the COVER button is illuminated, the cover can be

opened.

7

Operating Mode

Selector Switch

This key switch allows the unit to be switched between the

Automatic Operation and Set Up modes. In Automatic

Operation, the cover (or door) of the machine can only be

opened when the shafts are not in motion and the cutting

spindle has been switched off. In the Set Up mode, the cover

(or door) of the machine can only be opened when the working

spindle has been switched off. In the Set Up mode, the shafts

can be activated with the cover open by pressing the ACK

acknowledgement button.

8

EMERGENCY

STOP button

Pressing this button immediately disconnects the power supply

to the motor, converter and working spindle.

Switching into the AUTO ->TEST operating mode whilst the workpiece is

being machined brings the working spindle to a halt. Switching back to the

AUTO mode restarts the working spindle. Before switching back to the

AUTO operating mode, ensure that all moving parts are in the stop

position. Failure to do this can result in damage to the working spindle or

workpiece.

No. Element Description

9 PC START button Switches the computer "on" and "off".

10

Two-handed

operation

Control buttons for two-handed operation (optional)

CNC control panel iOP-19-TFT

Page - 9

Control computer control elements

No. Element Description

11 USB connections

The iOP-19-TFT is fitted with an integrated USB hub. This

provides integrated touch screen connection. The three USB

ports allow equipment such as USB sticks, a USB keypad, a

WIBU dongle or an external CD ROM drive to be connected.

The USB hub is provided with its own +24V power

supply (active USB hub). Power is fed to the hub via

the machinery control element connecting cable

(see Chapter 3).

If the CNC control panel has been connected to an isel

computer not fitted with a +24V supply (e.g. iPC15), the

touch screen and USB ports will remain inoperative.

CNC control panel iOP-19-TFT

Page - 10

Screen control elements

The screen control elements are located in the service hatch

3 Control element connection

All CNC control panel connecting cables are optimised for use with isel

iSR/iPC series control computers. These connecting cables should not be

extended. Doing so may impair the performance of the CNC control panel.

Ensure the protective earth conductor is adequate with a diameter of at

least 2.5mm2 (screened cable) or 4mm2 (un-screened cable) and

connected between the iOP-19 terminal and the safety bus bar of

your machine!

3.1 Connecting the control PC control elements

DVI connecting cable

This cable is fitted with a DVI plug for connection to the graphic card of

your computer.

No. Element

Description

1 Menu (top) Use the menu to navigate to the top

2 Menu (bottom) Use the menu to navigate to the bottom

3 ON / OFF Switches the monitor "on" and "off"

4 Menu (enter) Opens the menu / confirms settings

5 Menu (back) Steps the menu back one level

6 LED Indicates operating condition: redoff, greenon

1

2

3

4

5

6

12

CNC control panel iOP-19-TFT

Page - 11

USB hub connecting cable

Plug this cable into any free USB port on the control computer.

Connecting the cable allows the integrated keyboard, in-built LCD touch

screen and the two side-mounted USB ports to be used.

The USB hard drive cannot be used without first connecting

an external power supply to the USB ports. This is because the

USB ports alone are unable to supply sufficient power.

3.2 Power supply to the CNC control panel

D-sub 9-pin plug

This plug must be used with the isel iSR/iPC series control computer. It

allows the power button connecting cable to be plugged into the righthand side of the CNC control panel, the indicator LEDs into the front

panel of the equipment cover and the TFT power supply into the socket

provided on the control computer. Insert the plug into the D-sub socket

provided on the control computer in the switching cabinet.

Pin Labeling Description

1 PWR BTN + Power button connection +

2 PWR BTN GND Power switch connection GND

3 PWR LED +5V DC LED indicator lamp connection +

4 PWR LED GND LED GND indicator lamp connection

5 HDD LED +5V DC HDD LED indicator lamp connection +

6 +12V DC Power supply for the 19“ TFT +12V

7 GND Power supply for the 19“ TFT GND

8 not available

9 HDD LED GND HDD LED indicator lamp connection GND

Jack plug connection when using an external power supply unit

12V DC/60W power supply

Always make sure that only one power connection

is provided. Use either the D-sub 9-pin plug or the

jack.

+ 12V

GND, – 12V

CNC control panel iOP-19-TFT

Page - 12

3.3 Machine control element connection

Pin assignment for the D-sub 25-pin plug

Pin Signal Labeling

1 EMERGENCY

STOP_1

EMERGENCY Stop Channel 1, Connection 1.1

2 EMERGENCY

STOP_1

EMERGENCY Stop Channel 1, Connection 1.2

3 EMERGENCY

STOP_2

EMERGENCY Stop Channel 2, Connection 2.1

4 EMERGENCY

STOP_2

EMERGENCY Stop Channel 2, Connection 2.2

5 24V +24V DC

6 POWER BTN Power button input

7 POWER LAMP Power lamp output

8 24V +24V DC

9 KEY SWITCH Test Key switch input test mode

10 KEY SWITCH Auto Key switch input automatic operating mode

11 24V +24V DC

12 ACK_1 Channel 1 enabling switch input

13 24V +24V DC

14 ACK_2 Channel 2 enabling switch input

15 COVER SWITCH Cover switch input

16 COVER SWITCH Cover switch output

17 GND

18

19

20 FAULT LAMP Control panel fault lamp output

21 START BTN Start button (closing contact)

22 STOP BTN Stop button input (opening contact)

23 START LAMP Start lamp output

24 STOP LAMP Stop lamp output

25 not available

D-sub 25-pin plug control element

This cable allows the control elements (buttons and switches) on the front

cover of the CNC control panel to be connected to the corresponding

safety circuit modules in the switching cabinet.

Power (+24V DC) to the USB hub on the control panel is provided by

this cable.

Make sure that the keyboard, touch screen and USB interfaces only

function when connected to the safety circuit modules.

CNC control panel iOP-19-TFT

Page - 13

4 Malfunctions

Fault Action

No screen display

on the monitor

1 Check that the control computer is switched on.

2 Check the PC START button connecting cable and make sure

the computer is switched on.

3 Check the power supply (D-sub 9-pin plug at the iPC)

4 Check the POWER ON control lamp is illuminated. If not,

switch the monitor on with the Power On/Off button.

5 Check whether the resolution setting can actually be

displayed by the monitor. If necessary, reset the resolution by

starting the computer in safety mode and then adjusting the

screen resolution.

The screen image is

blurred or distorted.

1 Use the button provided to automatically calibrate the

monitor.

The equipment cannot be

controlled using the

control panel.

1 Check the D-sub 25-pin plug connection to the safety circuit

module.

2 Check the software signal settings (these affect the START /

STOP button)

The integrated touch

screen and keyboard do

not function

1 Check that power is provided to the integrated USB hub.

Power is being provided to the safety module via the

machinery control element cable and D-sub 25-pin plug.

2 Check that the USB cable is properly connected to the

control computer.

5 Maintenance and servicing

Maintenance

The iOP 19-TFT CNC control panel is maintenance free.

Cleaning

Switch off the control computer and all other components connected to

the CNC control panel. Disconnect the power supply.

Clean with a soft, damp cloth. Do not use any cleaning fluids or

abrasive compounds. Using abrasives may result in the surface of the

monitor screen becoming scratched. Make sure that no liquid

penetrates the ventilation ports and gets inside the equipment cover.

CNC control panel iOP-19-TFT

Page - 14

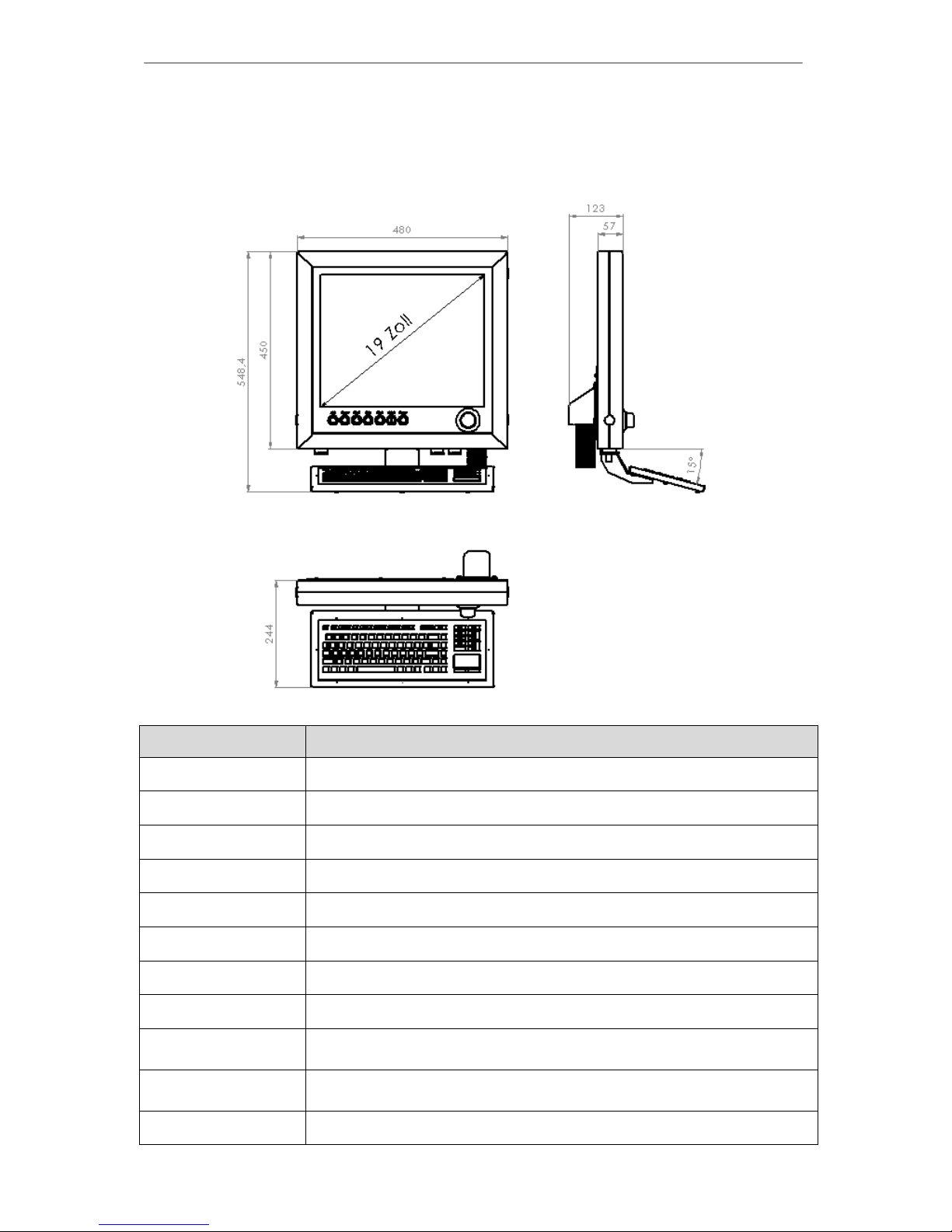

6 Technical specifications

Dimensions

6.1 Technical specifications of the iOP-19-TFT

Properties

Driver 19” TFT Active Matrix

Viewing angle 75°(horizontal) 60°(vertical)

Pixel size 0.264(H) x 0.264(W)

Viewing area 337 x 270 mm

max. pixel number 1280 x 1024

Colour 24-Bit colour depth 16.2 million

Connections 3 USB ports Pull-out USB 2.0 connection

Power supply: 12V DC, min. 60W, separate power unit required

Degree of protection

iOP-19-TFT IP 50

Keyboard IP 68

Ambient temperature

Storage temperature

5°C – 35°C

-25°C – 55°C

Weight approx. 15 kg

CNC control panel iOP-19-TFT

Page - 15

7 EC Declaration of Conformity

Der Hersteller

The manufacturer

isel Germany AG

Bürgermeister-Ebert-Str. 40

D-36124 Eichenzell

erklärt hiermit, dass folgendes Produkt

hereby declares that the following product

Geräteart: CNC-Bedienpanel iOP-19-TFT

Device: CNC-Control-Panel iOP- 19-TFT

Typ: iOP-19-TFT

Type:

Art.-Nr.: iOP-19-TFT: 371100 1000

Product - No.:

mit den Vorschriften folgender Europäischer Richtlinien übereinstimmt:

complies with the requirements of the European Directives:

EG-Richtlinie 2004/108/EG

EC-Directive 2004/108/EC

EMV Richtlinie

EMC directive

EG-Richtlinie 2006/95/EG

EC-Directive 2006/95/EC

Niederspannungsrichtlinie

low voltage directive

Folgende harmonisierte Normen wurden angewandt:

Following harmonized standards have been applied:

EN 61000-6-2:2006 EMV - Fachgrundnorm - Störfestigkeit für Industriebereich

EMC - Generic standards - Immunity for industrial environments

EN 61000-4-2:2008 EMV - Prüf- und Messverfahren - Prüfung der Störfestigkeit gegen Entladung

statischer Elektrizität (ESD)

EMC - Testing and measurement techniques; Electrostatic discharge immunity test

EN 61000-4-4:2012 EMV - Prüf- und Messverfahren - Prüfung der Störfestigkeit gegen schnelle

transiente elektrische Störgrößen (Burst)

EMC - Testing and measurement techniques - Electrical fast transient/burst immunity test

EN 61000-4-5:2007 EMV - Prüf- und Messverfahren - Prüfung der Störfestigkeit gegen energiereiche

Impulse (Surge)

EMC - Testing and measurement techniques - Surge immunity test

EN 61000-4-11:2005 EMV - Prüf- und Messverfahren - Prüfung der Störfestigkeit gegen Spannungs-

einbrüche / Spannungsunterbrechungen

EMC - Testing and measurement techniques - Voltage dips, short interruptions and voltage

variations immunity tests

EN 61000-6-4:2011 EMV - Fachgrundnorm - Störaussendung Industriebereich

EMC - Generic standards - Emission standard for industrial environments

DIN EN 55011:2011 Industrielle, wissenschaftliche und medizinische Hochfrequenzgeräte (ISM-Geräte) -

Funkstörungen - Grenzwerte und Messverfahren

Industrial scientific and medical (ISM) radio-frequency equipment - Electromagnetic

disturbance characteristics - Limits and methods of measurement

Dermbach, 17.06.2014

___________________________

Werner Kister, Vorstand / managing board

Loading...

Loading...