Isel iCU-DC, iCU-EC Operating Instructions Manual

isel Germany AG, D-36124 Eichenzell, Bürgermeister-Ebert-Str. 40 (06659)981-0 (06659)981-776

CNC Servo Controller

iCU-DC

iCU-EC

Operating Instructions

iCU-DC / iCU-EC Operating Instructions

The information, technical data and measurements in these printed materials conform

to the latest technological advances at the time of publication. However, the possibility

of printing errors and mistakes cannot be excluded. We would be grateful if you

suggest improvements or point out errors.

We note that the software and hardware brand names used in our printed materials

are generally subject to trademark, brand name or patent protection belonging to each

respective company.

All rights reserved. No part of our printed materials may be reproduced in any form

(print, photocopy or any other process) or processed, duplicated or disseminated via

electronic systems without written permission from isel Germany AG.

Manufacturer: isel Germany AG

Bürgermeister-Ebert-Straße 40

D-36124 Eichenzell

Tel.: +49 (0)6659 981-0

Fax: +49 (0)6659 981-776

Email: automation@isel.com

http://www.isel.com

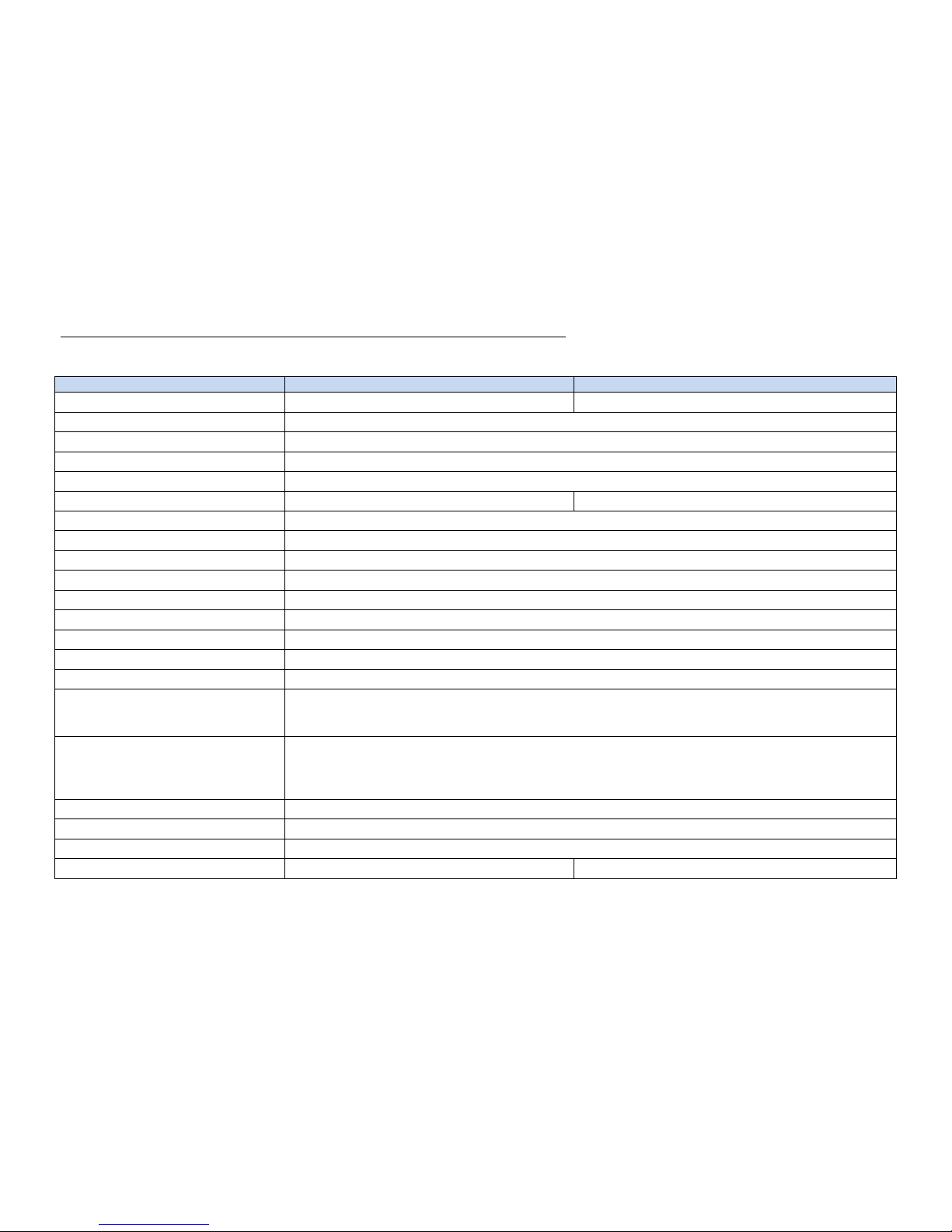

Revisions

Date of

change

Reason for change

Changed by

b

04/07/2018

Page 15 changed, E/A ports

CB

a

05/01/2015

Serial number

RL 2014

First print

We reserve the right to make technical changes.

Current operating instructions and manuals can be downloaded at:

www.isel-data.de/manuals

iCU-DC / iCU-EC Operating Instructions

Contents

1 Introduction .......................................................................................................... 4

1.1 Safety symbols ................................................................................................ 4

1.2 Safety information ............................................................................................ 5

2 Variants ................................................................................................................. 7

3 Technical data ...................................................................................................... 8

4 Hardware description ........................................................................................... 9

4.1 Front side ......................................................................................................... 9

4.2 Back side of iCU-DC / iCU-EC ........................................................................11

4.3 Structure of iCU-DC / iCU-EC .........................................................................18

5 Initialisation ........................................................................................................ 19

6 Software .............................................................................................................. 20

6.1 Installation of the initialisation software ...........................................................20

6.2 Installing ProNC / Remote and first steps .......................................................22

7 EC Declaration of Conformity ........................................................................... 26

8 List of sources .................................................................................................... 27

9 Index .................................................................................................................... 27

iCU-DC / iCU-EC Operating Instructions

Page - 4

1 Introduction

The CAN Controllers of the iCU Series are compact, high-performance drive

controllers for 2 to 6 linear or rotational axles. The table housing integrates all control

components required for solving various automation tasks.

The table housing integrates all control components required for solving widely

varying automation tasks. These range from the output stage to the I/O component

group to safety controlling.

The control computer interface is a CANopen PCI card which serves as a CAN

master for the drive regulators and the I/O component group. External expansions

for up to 128 CAN nodes are also easily possible. The connections on the back side

of the control computer make it possible to easily connect a monitor, among other

things. USB sockets are available for attaching various peripheral equipment such as

mouse and keyboard. A LAN connection allows for integration into an existing

network and can also be used for remote maintenance.

The NC controller core makes it possible to interpolate up to 6 axles (linear, circular,

or helix), and online and Lock Ahead belt processing are also available. Using the

software ProNC, individual axles can be controlled as handling axles (besides the

interplating axles).

The iCU-DC CAN Controllers can drive up to 6 brushed DC servo motors. The

iMD10 output stages in use have automatic jerk limitation and standstill monitoring

(up to safety category 3).

Controllers in the iCU-EC Series can drive up to 6 brushless DC servo motors. The

iMD20 output stages in use have automatic jerk limitation and standstill monitoring

(up to safety category 3).

1.1 Safety symbols

Warning!

Warning of dangers which can lead to adverse effects on health, physical

injury, or death.

Warning! Life-threatening voltage

Warning of danger from electrical current. Non-compliance can result in

severe injury or death.

Attention!

This symbol is for notices, non-observance of which can lead to damage

or faults.

Information:

This symbol is for important information and notices.

iCU-DC / iCU-EC Operating Instructions

Page - 5

1.2 Safety information

▪ The iCU-DC and iCU-EC CNC Controllers are constructed according

to current technological advances and recognised safety regulations.

▪ The machine must only be operated when it is in perfect technical

condition. Faults must be dealt with immediately. Children, and

anyone who has not been trained, are not permitted to operate the

machine.

▪ The machine must only be used according to its intended purpose.

Control of 2 to 6 linear or rotational axles with brushed DC servo

motors (iCU-DC) or brushless DC servo motors (iCU-EC) and

incremental measurement system (encoder).

▪ All work must only be done by authorised specialist personnel with

regard to the regulations of the electrical industry as well as accident

prevention regulations. Before opening the housing or doing any work

on the electrical installation, you must unplug the power cable.

▪ Assembly and use of equipment must be carried out according to the

norms of the Declaration of Conformity. The regulations and

threshold values observed by the manufacturer are not sufficient to

protect from improper use of the equipment.

▪ The device must not be exposed to high air humidity or high levels of

vibration.

▪ Keep this manual in a safe place and oblige each user to comply with

it!

▪ Failure to observe these operating instructions can cause property

damage, severe physical injuries, and death.

iCU-DC / iCU-EC Operating Instructions

Page - 6

▪ Warning! High earth leakage current (ground discharge current,

protection conductor current). Before connecting to the AC supply

network, it is necessarily required an additional protective

grounding. Before connecting the CNC controller to the AC supply

network, an additional protective grounding (cross section: 2.5 mm2

or 4 mm2, see below) has to be connected! Before the electrical startop of the controllers a protective grounding of 2.5 mm2 (protected

installation) or a protective conductor of 4 mm2 (unprotected

installation) has to be connected durably to the marked clamping point

at the back of the housing where the cross section of the protective

grounding shall not be less than 10 mm2 copper or 16 mm2 aluminum

has (e.g. electrical distribution of the building). Please instruct an

electrician with these implementation. When using the Residual

Current circuit Device (RCD) for line fuses/fault current delimitation: Do

not use an RCD with AC characteristics. Using a frequency inverter

and choppered power stages in the power units may cause

superimposed AC fault units with pulsating direct current and direct

current apart from AC fault currents. Please consult your electrician.

▪ The term leakage is understood here as grounding discharge

current. This is defined in the standard EN 60204-1:2006 section

8.2.8, note 1

▪ If the CNC machine (ideal) is set up isolated from the reference

potential, the grounding discharge current is equal to the

protective grounding stream.

iCU-DC / iCU-EC Operating Instructions

Page - 7

2 Variants

Type

Motor

Output

stages

max. Number of

axles

iCU-DC

BDC Servo motors (brushed)

iMD10

6

iCU-EC

BLDC Servo motors (brushless)

iMD20

6

Scope of delivery iCU-DC (Art.-No. 354002 10X10)

• iCU-DC servo controller as a tabletop device with the following components:

o max. 6 integrated iMD10 performance output stages for brushed DC

servo motors /1/

o Control computer iPC25 with CAN PCI card iCC10

o CAN IO 8/12-4/1 Module

o Safety circuit module iSM5

• Power cable 230VAC (Safety contact plug, IEC-60320 appliance connector

plug)

• RS232 communications cable for firmware updates, 9 pin sub-D (socket) to

RJ45 (plug)

• Accessories kit (appliance plug connector, strapping plug, etc.)

• Remote control software from Version 1.46.6.6 (optional: ProNC)

• Operating Instructions

• Optional: Frequency converter SKC750, SKC1500 for main spindle drive,

max. 4 axles possible

Scope of delivery iCU-EC (Art.-No. 354002 20X10)

• iCU-EC servo controller as a tabletop device with the following components:

o max. 6 integrated iMD20 performance output stages for brushless DC

servo motors /2/

o Control computer iPC25 with CAN PCI card iCC10

o CAN IO 8/12-4/1 Module

o Safety circuit module iSM5

• Power cable 230VAC (Safety contact plug, IEC-60320 appliance connector

plug)

• RS232 communications cable for firmware updates, 9 pole sub-D (socket) to

RJ45 (plug)

• Accessories kit (appliance plug connector, strapping plug, etc.)

• Remote control software from Version 1.46.6.6 (optional: ProNC)

• Operating Instructions

• Optional: Frequency converter SKC750, SKC1500 for main spindle drive,

max. 4 axles possible

1

X … Number of axles, 2-6

iCU-DC / iCU-EC Operating Instructions

Page - 8

3 Technical data

Controller

iCU-DC

iCU-EC

Servo motor type

BDC Servo motors (DC brushed)

BLDC Servo motors (DC brushless, EC)

Max. Number of axles

6

Power input

115 - 230 VAC, 50 … 60 Hz

Fuses

2 x 6.3A (inert)

Power supply performance

1000 W

Performance output stage

iMD10

iMD20

Intermediate circuit voltage

48 VDC

Max. Nominal motor current

12 A

Max. Peak motor current

25 A

Descriptive code for safety data

EN ISO 13849-1:2006 Category 3, PL d

Protection type

IP20

Environment temperature

0°C to 50°C

Storage temperature

-20°C to +65°C

Air humidity

max. 90%, non-condensating

Safety functions

Can be integrated into higher-level emergency stop circuits, hood control, spindle control

I/O component group

4 digital inputs

8 digital outputs (4 relay outputs, 4 electrical outputs

1 x 115-230 V relay output (max. 6A)

Control computer

1.8 GHz processor

RAM ≥ 1 GB

Hard drive 2.5” SATA ≥ 120 GB

2 x USB 2.0 on the front

Operation

Function keys, emergency stop

Operating system

Windows Embedded standard 7 (64Bit)

Control software

Remote (Optional: ProNC, isyCAD/CAM)

Measurements, W x H x D

630 x 230 x 400

630 x 230 x 400

iCU-DC / iCU-EC Operating Instructions

Page - 9

4 Hardware description

4.1 Front side

1 - Emergency stop switch

The emergency stop switch is for switching off the power supply to the stepping

motor output stage in case of danger.

By this we are referring to dangers which could affect the health of the operator or

the safety of the machine.

2 - Power button

Using the you can switch on the voltage supply to the output stages. The prerequirements for this are:

- The power source must be switched on using the backwards “on” switch.

- The emergency stop switch must be “pulled out”.

When the main voltage is successfully switchted on, this is signalled by the lighted

power button.

3 - Mode Selection Switch (Key switch)

This key switch selects Automatic or Setup mode.

When the emergency stop switch is activated, axle movement is

braked in a controlled manner and the main voltage is switched off

according to Stop Category 1 with a time delay (DIN EN 60204-1).

The 115/230VAC power supply is still connected to the machine.

Only the power supply to the output stage is switched off.

Loading...

Loading...