Page 1

isel

Germany AG, D-36124 Eichenzell, Bürgermeister-Ebert-Str. 40 (06659)981-0 (06659)981-776

CAN I/O 16/16

CAN I/O 8/12 – 4/1

Operating Instruction

isel - CAN - I/O - Modules

CAN I/O 16/16

CAN I/O 8/12 - 4/1

Page 2

About this manual:

The information, technical data and dimensions contained in this print are up-to-date

when published. Any possible misprints and mistakes cannot be excluded however.

We are thankful for any suggestion for improvement and indication of mistakes.

Please note that the used software- and hardware descriptions of each individual

company are generally subject to protection of trademarks and patent law.

All rights reserved. It is not permitted to reproduce or electronically process, duplicate

or spread any part of our prints in any way (print, copy etc.) without written

permission of isel Germany AG.

Manufacturer: isel Germany AG

Bürgermeister-Ebert-Straße 40

D-36124 Eichenzell

Tel.: (06659) 981-0

Fax: (06659) 981-776

Email: automation@isel.com

http://www.isel-germany.de

Part.-No.: 970321 BE004

Status: 03/2013

Page 3

Contents

1 Introduction ......................................................................................................... 2

1.1 General function, benefit in application ........................................................ 2

1.2 Intended use................................................................................................. 3

1.3 Safety symbols ............................................................................................. 3

1.4 Safety guidelines .......................................................................................... 4

2 Technical specifications .................................................................................... 5

2.1 General, process - and logic power supply .................................................. 5

2.2 Module overview .......................................................................................... 7

2.3 Plug allocation .............................................................................................. 8

2.4 DIP Switches .............................................................................................. 12

2.5 Assembly, installation, connection .............................................................. 13

2.5.1 Base connection (Logic voltage and CAN bus) 13

2.5.2 Digital inputs 13

2.5.3 Digital outputs (relay outputs) 14

2.5.4 Digital electronic outputs (switching transistors) 15

2.5.5 Analog output 16

2.5.6 Analog input 18

2.5.7 Diagnosis, signalization, fault states 18

3 Integration into the control software (ProNC, Remote) ................................. 19

3.1 Settings in the module management .......................................................... 19

3.2 Settings within the Contro administration ................................................... 21

3.3 Version information .................................................................................... 24

3.4 Diagnosis function ...................................................................................... 25

3.5 Status information ...................................................................................... 26

4 Index .................................................................................................................. 27

Page 4

isel - CAN - I/O – Modules: Operating Instruction

Page - 2

1 Introduction

1.1 General function, benefit in application

The CAN-I/O-Module is an Input/output-module for peripheral automation by

linking intelligent modules to the CAN bus (Controller Area Network).

Such modules are:

Positioning modules for numerical axes, e.g. IMD10, IMD20, IMD40 or CPC12

interface from isel Germany AG

HF-Inverter for working spindles

I/O-Modules for binary (analog) input/output, e.g. CAN-I/O-Modules from isel

Germany AG

All CAN-Modules are intelligent, that means they have at least one microprocessor

with integrated on chip or separate CAN-Controller. The CAN-I/O-Modules follow the

CANopen- Standard Device profile for I/O-Modules: CiA Draft Standard Proposal

DS301 V4.0 und DS401 V2.0.

The advantages of using I/O-Modules with CAN interface are:

The binary (analog) Inputs and Outputs are available close to the process

sensors (inputs) as well as to the actuators (outputs). A costly, susceptible and

EMC sensitive cabling to the (central) CNC-Controller (CNC-Master, CNC-

Control) will be cancelled.

Additional modules can be integrated and configured in a simply way:

1. Plug node to CAN-Bus

2. Set a new node address for the I/O module

3. Assign the respective software driver (DLL) to the application software (ProNC

or Remote)

There are extensive diagnostic- and test-possibilities because every CAN-I/O-

Module is intelligent. That means, that the modules are able to give status and

error information to the CNC-Master (this is also the CAN Master) on demand.

Page 5

isel - CAN - I/O – Modules: Operating Instruction

Page - 3

1.2 Intended use

The CAN-I/O module is intended to be used as a peripheral Input / Output module

and therewith to connect sensors and actuators from an industrial process to this

module:

binary or analog sensors (Inputs)

binary or analog actuators (Outputs)

1.3 Safety symbols

Danger

This symbol indicates dangers that cause damages for person’s

health, physical injury or death.

Attention

This Symbol indicates important notes. Ignoring this symbol

leads to damages and malfunctions of the module.

Information

This symbol indicates important information and notes.

.

Page 6

isel - CAN - I/O – Modules: Operating Instruction

Page - 4

1.4 Safety guidelines

The CAN-I/O-Modules 16/16 resp. 8/12-4/1 are designed due to current technical

and recognized rules.

Do not expose the device to high humidity or high vibrations.

Admissible ambient temperature : +5°C bis +40°C

Storage temperature : –25°C bis +70°C

The device may only be used if it is in correct condition. Any faults have to be

eliminated immediately. Neither children nor non-authorized persons are allowed

to put the device into operation.

The device may only be used for the intended use, i.e. I/O operations.

All work on the module must be executed from authorized personal regarding

electrical industry rules and accident prevention regulations.

Assembly and use of operating material has to be according to the appointments

of Machinery Directive 2006/42/EU resp. the Low Voltage Directive

2006/95/EU.

In case of improper, incorrect use even the compliance of the respective rules

and standards does not protect against physical damages and damage to

property.

Please take care of the instruction manual. Be sure that all users know the

instructions.

Ignoring the instruction manual can lead to damage, heavy physical damage or to

death.

Page 7

isel - CAN - I/O – Modules: Operating Instruction

Page - 5

2 Technical specifications

2.1 General, process - and logic power supply

box size:

85mm (B) x 180mm (H) x 28mm (T)

weight:

260 g

safety class:

IP20

power supply 1:

(logic voltage)

24VDC

The logic voltage supplies the module internal logic like

the CANopen microcontroller, DA and AD converters,

optocouplers, relays and the CAN bus drivers.

The logic voltage is feeded to the module via connector

X1 from an external 24VDC power supply device.

power supply 2:

(process voltage)

24VDC

The process voltage supplies sensors and actuators that

are connected to the CAN-I/O module:

binary process sensors like switches or inductive

sensors

binary process actuators like Ohm or inductive loads

The process voltage is feeded to the module via

connector X4 (+24V) resp. connector X6 (GND) from an

external 24VDC power supply device.

power consumption 1:

(from / over logic voltage)

160mA

power consumption 2:

(from / over process

voltage)

Power consumption (from / over process voltage)

depends from the external loads, e.g. especially from the

binary process actuators connected to the module.

Dimensioning the 24VDC power supply device for

process voltage with a sufficient value is very important.

The customer is responsible to do this dimensioning

correctly.

ambient temperature:

5°C bis +40°C

storage temperature:

-25°C bis +70°C

relative humidity:

max. 95%

Page 8

isel - CAN - I/O – Modules: Operating Instruction

Page - 6

CAN – I/O - 16/16

digital inputs:

16 In1.1 to In1.8 and In2.1 to In2.8

using optocouplers (input current about 8mA)

digital outputs:

16 Out1.1 to Out1.8 and Out2.1 to Out2.8

8 relay outputs Out1.1 to Out1.8, Imax < 5A

8 electronic outputs (switching transistors)

Out2.1 to Out2.8, Imax < 350mA,

switching delay about 100µs,

thermic protection,

short-circuit protection

catch diode for digital

outputs

Each inductive load plugged to digital outputs requires

a separate external catch diode.

analog output:

1 0V – 10V over 8 Bit D/A converter

(if the analog output is used the eight electronic digital outputs Out2.1 to Out2.8

can not be used for binary output)

fuse:

630 mA / 250V fast

CAN – I/O - 8/12 - 4/1

digital inputs:

8 In1.1 to In1.8

using optocouplers (input current about 8mA)

digital outputs:

12 Out1.1 to Out1.8 and Out2.1 to Out2.4

4 relays outputs Out2.1 to Out2.4, Imax < 5A

8 electronic outputs (switching transistors)

Out1.1 to Out1.8, Imax < 350mA,

switching delay about 100µs,

thermic protection,

short-circuit protection

catch diode for digital

outputs

Each inductive load plugged to digital outputs requires

a separate external catch diode.

analog output:

1 0V – 10V over 8Bit D/A transformer

analog inputs:

4 Ana In1 bis Ana In4, 0V – 10V, 16 Bit resolution

fuse:

630mA / 250V fast

Page 9

isel - CAN - I/O – Modules: Operating Instruction

Page - 7

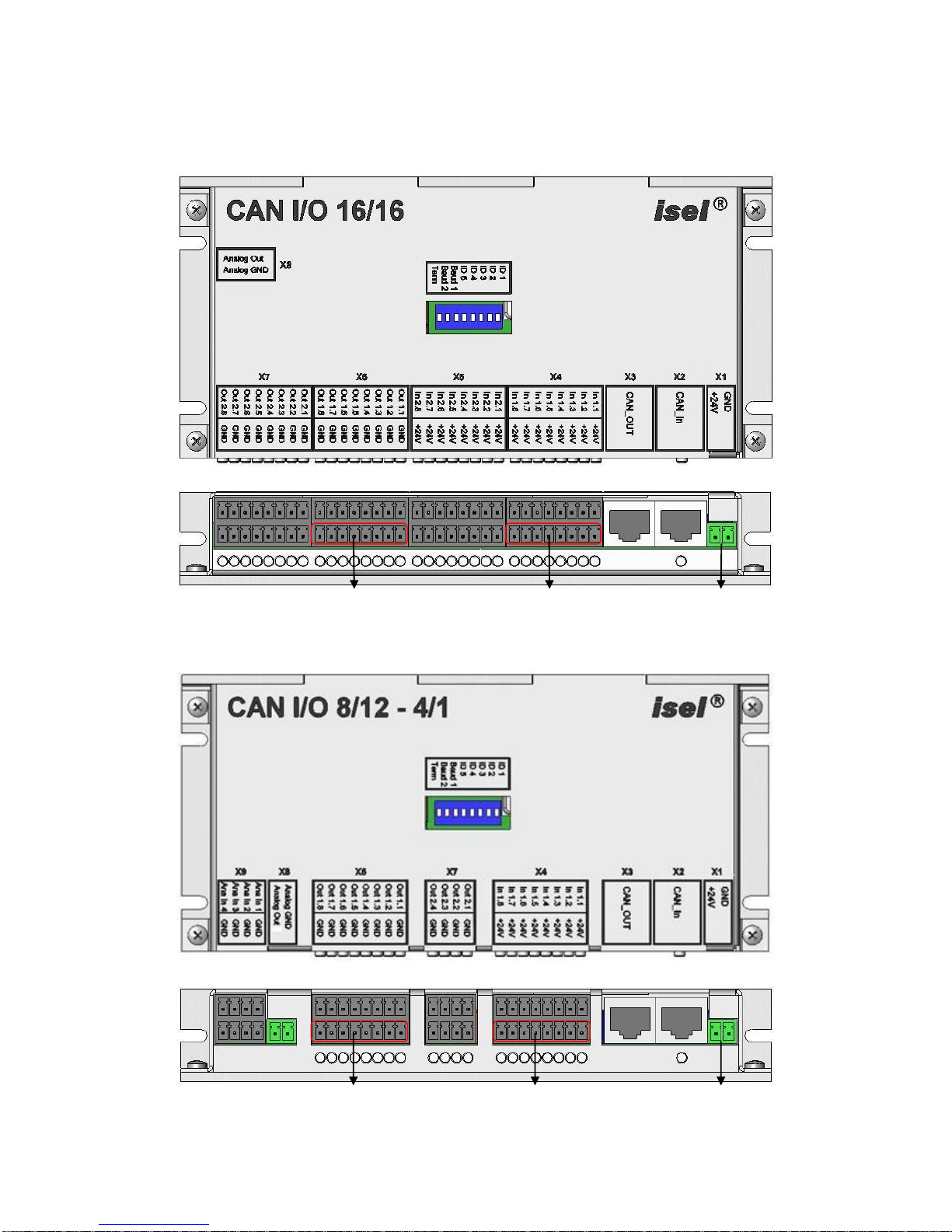

2.2 Module overview

CAN-IO-16/16

Process voltage: GND 24VDC Logic voltage

CAN-IO-8/12- 4/1

Process voltage: GND 24VDC Logic voltage

Page 10

isel - CAN - I/O – Modules: Operating Instruction

Page - 8

2.3 Plug allocation

Supply voltage (Logic voltage)

Phoenix Mini Combicon 2 pins

modul

connector

pin

signal

description

CAN-IO 16/16

X1

1 2 GND

+24V

supply voltage GND

supply voltage +24V

CAN-IO 8/12-4/1

X1

1 2 GND

+24V

supply voltage GND

supply voltage +24V

CAN In, CAN Out

RJ45 connector

modul

connector

pin

signal

description

CAN- IO 16/16

X2 CAN In

X3 CAN Out

1

2

3

4

5

6

7

8

n.c.

n.c.

n.c.

CAN_H

CAN_L

CAN_GND

n.c.

n.c.

not connected

not connected

not connected

signal CAN high

signal CAN low

GND

not connected

not connected

CAN-IO 8/12-4/1

X2 CAN In

X3 CAN Out

1

2

3

4

5

6

7

8

n.c.

n.c.

n.c.

CAN_H

CAN_L

CAN_GND

n.c.

n.c.

not connected

not connected

not connected

signal CAN high

Signal CAN low

GND

not connected

not connected

Page 11

isel - CAN - I/O – Modules: Operating Instruction

Page - 9

Input ports

Phoenix Mini Combicon 8 x 2 pins

module

connector

pin bottom

signal

description

CAN- IO

16/16

X4 In 1

and

X5 In 2

1

2

3

4

5

6

7

8

+24V

+24V

+24V

+24V

+24V

+24V

+24V

+24V

pin top

signal

description

9

10

11

12

13

14

15

16

In 1

In 2

In 3

In 4

In 5

In 6

In 7

In 8

bit 0

bit 1

bit 2

bit 3

bit 4

bit 5

bit 6

bit 7

pin bottom

signal

description

CAN-IO

8/12-4/1

X4 In 1

1

2

3

4

5

6

7

8

+24V

+24V

+24V

+24V

+24V

+24V

+24V

+24V

pin top

signal

description

9

10

11

12

13

14

15

16

In 1

In 2

In 3

In 4

In 5

In 6

In 7

In 8

bit 0

bit 1

bit 2

bit 3

bit 4

bit 5

bit 6

bit 7

Page 12

isel - CAN - I/O – Modules: Operating Instruction

Page - 10

Output ports

Phoenix Mini Combicon 8 x 2pol.

module

connector

pin bottom

signal

description

CAN- IO

16/16

X6 Out 1

X7 Out 2

1

2

3

4

5

6

7

8

GND

GND

GND

GND

GND

GND

GND

GND

pin top

signal

description

9

10

11

12

13

14

15

16

Out 1

Out 2

Out 3

Out 4

Out 5

Out 6

Out 7

Out 8

bit 0

bit 1

bit 2

bit 3

bit 4

bit 5

bit 6

bit 7

pin bottom

CAN-IO

8/12-4/1

X6 Out 1

X7 Out 2

1

2

3

4

5

6

7

8

GND

GND

GND

GND

GND

GND

GND

GND

pin top

9

10

11

12

13

14

15

16

Out 1

Out 2

Out 3

Out 4

Out 5

Out 6

Out 7

Out 8

bit 0

bit 1

bit 2

bit 3

bit 4 (not on X7)

bit 5 (not on X7)

bit 6 (not on X7)

bit 7 (not on X7)

Page 13

isel - CAN - I/O – Modules: Operating Instruction

Page - 11

Analog output

Phoenix Mini Combicon 2 pins

module

connector

pin

signal

description

CAN-IO

16/16

X8 AnaOut

1 2 analog Out GND

analog Out

reference for analog output

analog output (0 – 10V)

CAN-IO

8/12-4/1

X8 AnaOut

1 2 analog Out GND

analog Out

reference for analog output

analog output (0 – 10V)

Analog inputs

Phoenix Mini Combicon 2 pins

module

connector

pin bottom

signal

description

CAN- IO

16/16

-

-

-

pin bottom

signal

description

CAN-IO

8/12-4/1

X9 AnaIn

1

2

3

4

GND

GND

GND

GND

reference for analog input 1

reference for analog input 2

reference for analog input 3

reference for analog input 4

pin top

5

6

7

8

Analog In 1

Analog In 2

Analog In 3

Analog In 4

analog input 1

analog input 2

analog input 3

analog input 4

Page 14

isel - CAN - I/O – Modules: Operating Instruction

Page - 12

2.4 DIP Switches

The node address of a CAN module is used to clearly identify the device on the CAN

bus.

We submit the following assignment of the modules node address:

Module

Node address

1. positioning module

Node address 1

2. positioning module

Node address 2

3. positioning module

Node address 3

additional positioning module

Node address 4-9

4. I/O-module (firstt)

Node address 16

5. I/O-module (second)

Node address 17

additional I/O-modules

Node address 18 and 19

6. HF- converter

Node address 10

additional HF-converter

Node address 11,12 or 13

CAN Node address (S1 – S5)

The switches S1 – S5 are used to set the CAN node address. Possible values are 1

to 31.

Node address

S1

S2

S3

S4

S5

16

off

off

off

off

on

17

on

off

off

off

on

…

31

on

on

on

on

on

Baud rate (S6 – S7)

The switches S6 and S7 are used to set the baud rate.

Following values are possible:

Baud rate

S6

S7

1 MBit/s

off

off

500 kBit/s

on

off

125 kBit/s

off

on

20 kBit/s

on

on

Terminating resistor (S8)

Switch S8 is used to switch a CAN bus termination resistor on or off. If the switch is

on a 120 Ω resistor is enabled.

Page 15

isel - CAN - I/O – Modules: Operating Instruction

Page - 13

2.5 Assembly, installation, connection

Be sure that the jumper settings are correct before you build in the CAN-I/O

module into a Control cabinet or another device (refer to chapter 2.4).

2.5.1 Base connection (Logic voltage and CAN bus)

If you have configured the DIP switches the module can be built in to the intended

mounting place.

Now the 24V-power supply (logic voltage) must be connected with X1 (see

connection assignment). Also the CAN- bus interface connection must be plugged in

(CAN In must be connected)

If the CAN-I/O-module is the last device in the CAN-topology the DIP-switch 8

must be set to “on” to enable the terminating resistor.

2.5.2 Digital inputs

The digital inputs of the CAN-I/O-modules are realized using 24V-DC process

voltage. They can be connected to process sensors as follows:

The reference potential (+24VDC, GND) for the external sensor (in the principle

drawing a simple switch) is the process voltage.

The input load is about 8mA.

Page 16

isel - CAN - I/O – Modules: Operating Instruction

Page - 14

2.5.3 Digital outputs (relay outputs)

The digital relay outputs of the CAN-I/O-modules switch 24V-DC process voltage.

Integrate the outputs as follows:

The reference potential (+24VDC, GND) for the external actuator (in the principle

drawing a simple resistor) is the process voltage.

The relay outputs

Out1.1 to Out1.8 at CAN-I/O-Module CAN-IO 16/16 = port1 (X6)

Out2.1 to Out2.4 at CAN-I/O-Module CAN-IO 8/12-4/1 = port2 (X7)

can be rated with 5A for each output.

Driving inductive loads on digital outputs (for example relays) put parallel to

every load (relay) a catch diode (anode to GND).

Page 17

isel - CAN - I/O – Modules: Operating Instruction

Page - 15

2.5.4 Digital electronic outputs (switching transistors)

The digital electronic outputs (switching transistors, P channel, 24V switching) of the

CAN-I/O-modules switch 24 VDC process voltage. Integrate the outputs as follows:

The reference potential (+24VDC, GND) for the external actuator (in the principle

drawing a simple resistor) is the process voltage.

The digital electronic outputs

Out2.1 to Out2.8 at CAN-I/O-Module CAN-IO 16/16 = port2 (X7)

Out1.1 to Out1.8 at CAN-I/O-Module CAN-IO 8/12-4/1 = port1 (X6)

can be loaded with max. 350mA on each output.

IMPORTANT when using the CAN-I/O-Module CAN-IO 16/16,

here obtains for digital electronic outputs Out2.1 bis Out2.8 = Port2 (X7):

If the integrated D/A converter is used for analog output then port2 is reserved. That

means port2 is not longer available for digital outputs. To prevent confusions you can

deactivate port2 by removing Jumper1 (refer the next chapter Analog output).

Through this the port2 LEDs are also deactivated.

Driving inductive loads on digital outputs (for example relays) put parallel to

every load (relay) a catch diode (anode to GND).

Page 18

isel - CAN - I/O – Modules: Operating Instruction

Page - 16

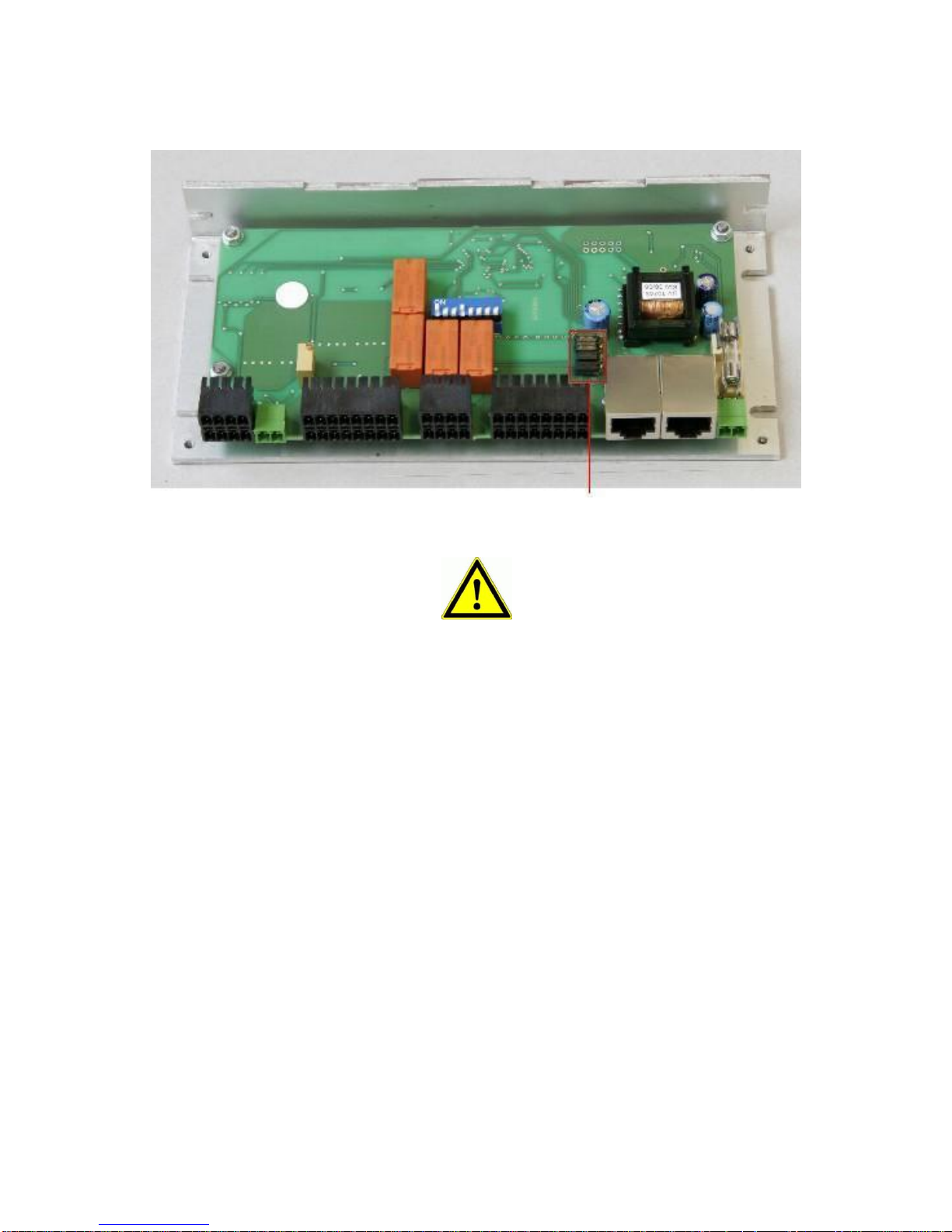

2.5.5 Analog output

You can use this output for controlling an external device with 0 to 10V interface /

input (e.g. the target velocity for HF converter).

If the analog output ist used, port2 is no longer available for digital outputs.

Output current not more than 15mA!

CAN-I/O 16/16 Jumper settings

Jumper 1 plugged:

- if the analog output is in use the LEDs

from output Port A2 signalize the binary

analog output value.

Delivery state:

Jumper 2 (4 pieces) not plugged.

Galvanic separation the 24DCV

process voltage from 24VDC logic

voltage is guaranteed.

If you plug the jumpers 2 then there is no galvanic separation between 24VDC

process voltage and 24VDC logic voltage!

This may be effects damages on the CAN-I/O-Module.

Page 19

isel - CAN - I/O – Modules: Operating Instruction

Page - 17

CAN-I/O 8/12 - 4/1 Jumper settings

Delivery state: Jumper 1 (4 pieces)

Jumper 1 is not plugged. Galvanic separation the 24VDC process voltage from

24VDC logic voltage is guaranteed.

If you plug the jumper 1 then there is no galvanic separation between 24VDC

process voltage and 24VDC logic voltage!

This may be effects damages on the CAN-I/O-Module

Page 20

isel - CAN - I/O – Modules: Operating Instruction

Page - 18

2.5.6 Analog input

The module CAN-I/O-8/12-4/1 has 4 analog Inputs with an input voltage range from

0V to10V and a resolution of 16 Bit. On these inputs you can directly connect e.g.

sensors. These inputs have an input impedance of 2kΩ and provides an internal RC

filter.

2.5.7 Diagnosis, signalization, fault states

Diagnosis of the CAN-I/O modules is possible by observing the status LED.

CAN-IO-16/16

Status-LED

CAN-IO-8/12- 4/1

Status-LED

This LED signals 4 different states:

LED duty cycle

State

0%, off

Error: CAN I/O module is not in operational state,

logic voltage is not available or the internal power

supply (DC/DC: 24 VDC to 5,0 V) is damaged

10%

No error normal operation

50%

Uncritical error or warning

90%

Critical error (NMT error, output error)

Page 21

isel - CAN - I/O – Modules: Operating Instruction

Page - 19

3 Integration into the control software (ProNC, Remote)

3.1 Settings in the module management

At first the Interface-DLL which opens the connection between ProNC/Remote and

CAN-IO-Device must be set-up.

If not already available, copy the files

IoCan.DLL

and

IoCan.INI

into a new sub-directory of the CNCworkbench - directory.

Our suggestion for the new directory:

{ProgramPath}\CNCWorkbench\Control\Can\

After the files are copied the application must get to know the new IO-deviceTherefore start ProNC/Remote and open the Setup-dialog for the control with the

help of the command "Setup – Control…". The following dialog will be appear:

Page 22

isel - CAN - I/O – Modules: Operating Instruction

Page - 20

Follow the commands to get the USB-IO device into the modul management:

Choose in the tree view the IO-Modul which is not in use and name it e.g”CAN-IO-

16/16 Node address is 16" or only "CAN IO".

Click on ">>" next to the Edit field "Modul DLL". Choose the "IoCan.DLL" in the

"\CNCWorkbench\Control\Can" directory. The Edit field "Modul initialisation file"

shows automatically the “CNCWorkbench\Control\Can\IoCan.INI" file. You don’t

need to rename the file.

Click on button (in case nothing will happen, choose another IO-

Modul from the tree view and after that choose the IO-Modul for the CAN-IO).

Click on to open the Setup dialog.

In this dialog

you can set

different

settings for the

module. The

most important

setting are the

node address

of the module.

The default

value for the

address is 16.

Furthermore

you can set

initialization

values for

digital and

analog output

ports. If you

start the

software

(ProNC /

Remote) these

values will be

set.

Page 23

isel - CAN - I/O – Modules: Operating Instruction

Page - 21

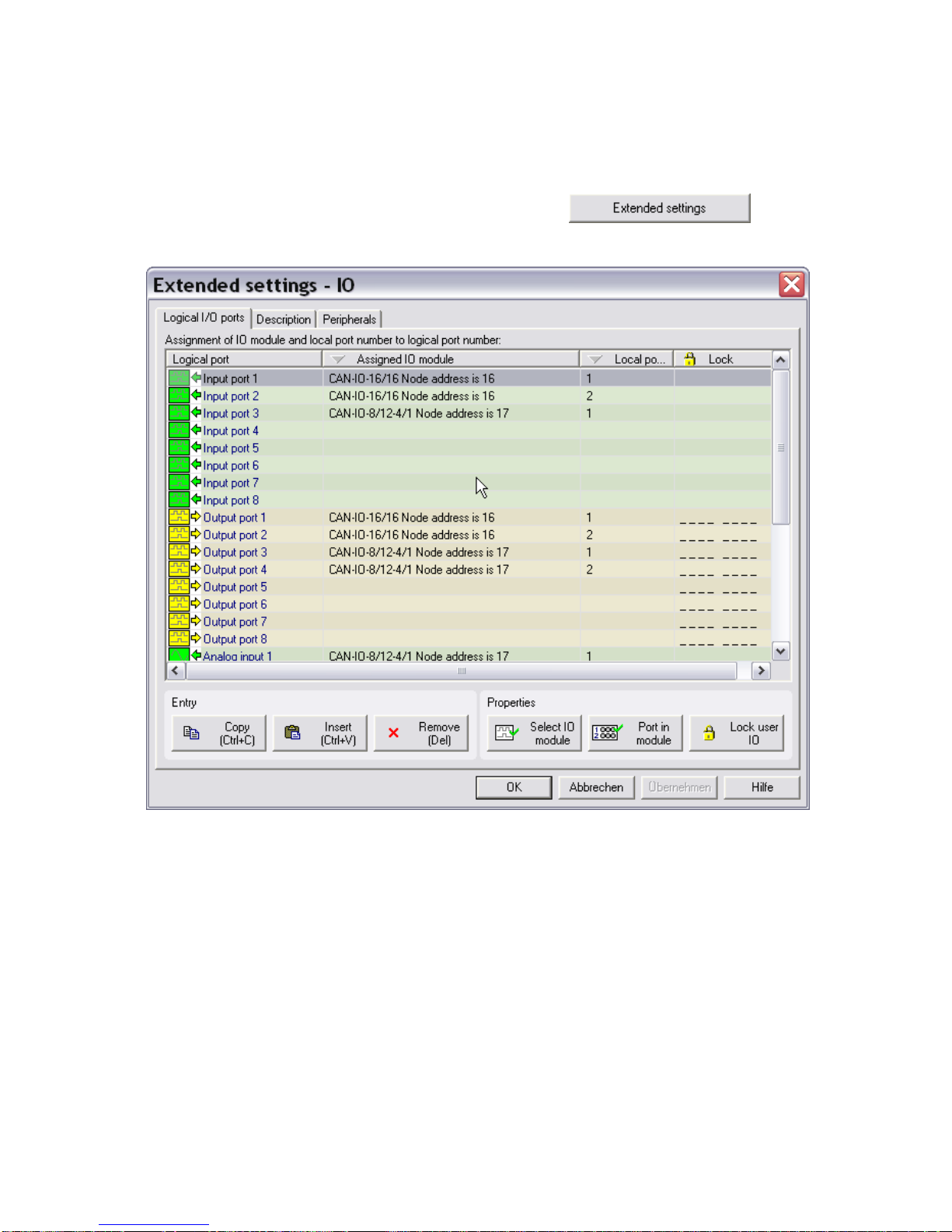

3.2 Settings within the Contro administration

To get access to the IO-module within the Control administration one setting in the

top level must be changed. Open the "Extended settings-IO" - Dialog as follows.

Highlight in the tree structure "IO modules". Click on on the

right side. You can see the following dialog:

The IO-module " CAN-IO-16/16 Node address is 16" needs a logical Input / Output

port number to access the Input / Output-functions from the CNC control software

ProNC resp. Remote.

Page 24

isel - CAN - I/O – Modules: Operating Instruction

Page - 22

Mind the following notes:

Highlight a free logical port, for example: Input port 1

Choose in the button band

the button "▼Assigned IO module" by mouse click, then the element

"[1] CAN IO 16/16 Node address is 16":

Choose in the button band

the button “▼ Local port in module" by mouse click, then the element

“Local Port 1”:

Click on “OK” to close the dialog

Now you must do the described steps for all logical output ports, analog output and

analog input. You find these entries by scrolling down in the list field.

Close the dialog “Control modules and settings” over the button “Close & Initialize” to

reinitialize the new modules.

Page 25

isel - CAN - I/O – Modules: Operating Instruction

Page - 23

The following lines show the use of local input ports, output ports, analog output and

analog input of the different modules.

CAN- IO- 16/16

Local input ports: Port 1 and Port 2

Local output ports: Port 1 and Port 2

Local analog output: Port 1 (alternatively with the local output port Port 2)

If the analog output is used, Port 2 (X7) is no longer available for digital

outputs. You must clear the entry for this port in the list.

CAN- IO- 8/12- 4/1

Local input ports: Port 1

Local output ports: Port 1 and Port 2

Local analog output: Port 1

Local analog inputs: Port 1 - Port 4

At the local output port 2 you can only use the outputs 1-4:

A2.1 = Out 2.1

A2.2 = Out 2.2

A2.3 = Out 2.3

A2.4 = Out 2.4

Page 26

isel - CAN - I/O – Modules: Operating Instruction

Page - 24

3.3 Version information

Inside the module management you can show version information of the used

module DLL and the connected device type by pressing the button .

Page 27

isel - CAN - I/O – Modules: Operating Instruction

Page - 25

3.4 Diagnosis function

The button allows you to access input / output functions of the connected

CAN-I/O-module. In this dialog you can e.g. switch outputs separately or you can

check the state of inputs.

Page 28

isel - CAN - I/O – Modules: Operating Instruction

Page - 26

3.5 Status information

Using the button you can check whether the process voltage is

connected to the CAN I/O module.

If there is no process voltage connected to the CAN I/O module you can not

measure 24VDC potential between the load connectors X4 (24VDC) and X6

(GND).

Page 29

isel - CAN - I/O – Modules: Operating Instruction

Page - 27

4 Index

A

actuators ...................................................................... 3

ambient temperature ................................................... 4

C

CAN bus ....................................................................... 2

CANopen ...................................................................... 2

catch diode ............................................................ 6, 14

CNC-Controller ............................................................. 2

G

galvanic separation .............................................. 16, 17

I

intended use ................................................................ 4

IoCan.DLL ................................................................... 20

J

Jumper 1 .............................................................. 16, 17

Jumper 2 .................................................................... 16

L

logic voltage ................................................................. 5

M

module management ................................................. 24

N

node address.......................................................... 2, 20

P

process voltage ...................................................... 5, 26

R

resolution..................................................................... 6

S

sensors......................................................................... 3

short-circuit protection ................................................ 6

Status-LED ................................................................. 18

Storage temperature .................................................... 4

switching delay............................................................. 6

T

terminating resistor .................................................... 13

termination resistor.................................................... 12

thermic protection ....................................................... 6

Loading...

Loading...