MODELS:

SF310

SF370

SF310

SF370

Operator’s Manual

ENGLISH

-Original Instructions-

INTRODUCTION

1

1

INTRODUCTION

Thank you very much for purchasing an ISEKI front mower.

This operator’s manual provides the information necessary for operating and maintaining your front mower safely and

properly. The contents are mainly composed of the following two items:

SAFETY INSTRUCTION: Essential items which you should observe while operating the front mower.

TECHNICAL INSTRUCTION: Items which are necessary to operate, adjust, and service the front mower

properly.

Every time you see the words and symbols shown below in the manual and on the safety decals, you must take note of

their instructions and warning.

DANGER: This symbol together with the words DANGER indicates an imminently hazardous situation that, if

not avoided, will result in VERY SERIOUS INJURY OR EVEN DEATH.

WARNING: This symbol together with the word WARNING indicates a potentially hazardous situation that, if

not avoided, could result in SERIOUS INJURY OR EVEN DEATH.

CAUTION: This symbol together with the word CAUTION is used to indicate a potentially hazardous situation

that, if not avoided, may result in MINOR INJURY.

IMPORTANT: The word IMPORTANT is used to provide instructions or advice in order to let the front mower provide

the optimum performance.

NOTE: The word NOTE is used to indicate points of particular interest for more efficient and convenient repair or

operation.

Before starting to operate the front mower for the first time, you should read this operator’s manual thoroughly and

carefully until you are sufficiently familiar with the operation of the front mower in order to do jobs safely and properly.

You are advised to refer to it from time to time to refresh your understanding of the front mower.

The manual should be kept in a handy place so you can refer to it when required.

The parts employed in this front mower may be modified without notice for better performance and quality and for safe-

ty purposes, which may lead to some inconsistency found on your front mower with the contents of this manual.

The front mower is designed to be used on well-kept lawns. Using the front mower in other places is not authorized.

Besides, the manufacturer will not pay for any damage caused by unauthorized use and the risk is only borne by the

user. Proper use of the front mower also implies that the user follows the operational, adjusting, and servicing instructions indicated in the operator’s manual.

When you have any question about your front mower, you are always welcome to ask your dealers.

All information, illustrations, and specifications contained in this manual are based on the latest information available at

the time of publication. The right is reserved to make changes at any time without notice.

2

INTRODUCTION

3

INTRODUCTION .......................................................... 1

TABLE OF CONTENTS ............................................... 3

ABBREVIATION LIST ................................................... 5

UNIVERSAL SYMBOLS ............................................... 5

1. FOR SAFE OPERATION ........................................ 6

1. HOW TO BE A SAFE OPERATOR ..................... 6

2. BEFORE STARTING THE FRONT MOWER ...... 8

3. OPERATION OF THE FRONT MOWER ............. 10

4. OPERATION ON A SLOPE ................................. 13

5. DRIVING ON PUBLIC ROADS ........................... 14

6. LOADING ONTO OR UNLOADING

FROM A TRUCK ................................................. 15

7. WHEN FILLING WITH FUEL .............................. 16

8. MOUNTING AND DISMOUNTING OF

THE MOWER DRIVE SHAFT ............................. 16

9. INSPECTION AND MAINTENANCE................... 17

10. MAINTENANCE OF THE ELECTRIC

SYSTEM ............................................................. 20

10.1. TO MAINTAIN ELECTRIC WIRING ........... 20

10.2. TO HANDLE THE BATTERY ..................... 20

10.3. TO HANDLE BOOSTER CABLES ............ 20

11. TIRES AND WHEELS ......................................... 21

12. BEFORE STORING THE FRONT MOWER ....... 21

13. LONG TERM STORAGE .................................... 22

14. CAUTION LABELS & THEIR POSITIONS .......... 23

2. WARRANTY AND AFTER-SALE CARE ................ 28

1. WARRANTY ........................................................ 28

2. AFTER-SALE CARE ........................................... 28

3. SERIAL NUMBER PLATE ................................... 28

4. SUPPLY LIMIT OF SPARE PARTS..................... 28

3. SPECIFICATIONS ................................................... 29

1. OPTIONAL PARTS ............................................. 29

4. NAME OF MAJOR COMPONENTS ....................... 30

5. CONTROLS AND METERS .................................... 31

1. CONTROL PANEL .............................................. 31

1.1. STARTER SWITCH ................................... 32

1.2. WORK LAMP SWITCH .............................. 32

1.3. POSITION SWITCH (G type) .................... 32

1.4. PTO SWITCH ............................................ 32

1.5. COMBINATION SWITCH (G type) ............ 32

1.6. HAZARD SWITCH (G type) ....................... 33

1.7. MONITOR LAMP ARRAY .......................... 33

1.8. FUEL GAUGE ............................................ 34

1.9. HOUR / TACHOMETER ............................ 34

1.10. COOLANT TEMPERATURE GAUGE ........ 34

2. STEERING POST ............................................... 35

2.1. THROTTLE LEVER ................................... 35

2.2. AUTO / 4WD CHANGEOVER

LEVER (4WD LEVER) ............................... 35

2.3. TILT LOCK LEVER .................................... 36

3. FLOOR PEDALS AND LEVERS ......................... 36

3.1. MASTER BRAKE PEDAL .......................... 37

3.2. HST FORWARD TRAVEL PEDAL ............. 37

3.3. HST REVERSE TRAVEL PEDAL .............. 37

3.4. INDEPENDENT BRAKE

PEDAL (RH)(E6 type) ................................ 37

3.5. INDEPENDENT BRAKE

PEDAL (LH)(E6 type) ................................ 37

3.6. DIF-LOCK PEDAL ..................................... 37

3.7. PARKING BRAKE

LEVER (Except G type) ............................. 38

4. FENDER (WING) PANEL .................................... 38

4.1. TRANSMISSION RANGE

SHIFT LEVER ............................................ 38

4.2. LIFT LEVER ............................................... 38

4.3. CRUISE CONTROL LEVER ...................... 39

4.4. PARKING BRAKE LEVER (G type) ........... 39

5. SAFETY SWITCHES .......................................... 39

5.1. SAFETY SWITCH (except F type) ............. 39

5.2. SAFETY SWITCH (F type) ........................ 39

6. PRE-OPERATIONAL ROUTINE INSPECTION ...... 40

1. INSPECTION ITEMS .......................................... 40

2. WAY OF INSPECTION AND MAINTENANCE .... 40

7. OPERATION ........................................................... 41

1. BEFORE STARTING THE ENGINE.................... 41

2. STARTING THE ENGINE ................................... 41

3. STOPPING THE ENGINE ................................... 43

4. TRAVELLING ...................................................... 44

5. CRUISE CONTROL ............................................ 45

6. STOPPING .......................................................... 46

7. MOWING............................................................. 47

8. MAINTENANCE ...................................................... 49

1. SERVICE ACCESS ............................................. 49

2. ENGINE OIL LEVEL ............................................ 50

3. TRANSMISSION OIL LEVEL .............................. 51

4. REDUCTION GEAR CASE OIL LEVEL .............. 51

5. REAR AXLE OIL LEVEL ..................................... 52

6. COOLANT LEVEL ............................................... 53

7. FUEL LEVEL ....................................................... 53

TABLE OF CONTENTS

4

SF310,370

8. AIR-CLEANER .................................................... 54

9. FUEL STRAINER ................................................ 54

10. FUEL HOSES ..................................................... 55

11. FAN BELT ........................................................... 55

12. MASTER BRAKE PEDAL PLAY ......................... 56

13. NEUTRAL POSITION OF HST ........................... 56

14. INDEPENDENT BRAKE PEDALS (E6 type) ...... 58

15. WHEEL TIGHTENING BOLTS AND NUTS ......... 58

16. BATTERY ............................................................ 59

17. TIRE PRESSURE (INFLATION) ......................... 60

18. STEERING WHEEL (TOE-IN)............................. 61

19. ENGINE OIL REPLACEMENT ............................ 61

20. ENGINE OIL FILTER........................................... 62

21. TRANSMISSION OIL REPLACEMENT .............. 62

22. HYDRAULIC OIL FILTER.................................... 63

23. SUCTION FILTER ............................................... 63

24. REDUCTION GEAR CASE OIL

REPLACEMENT ................................................. 64

25. REAR AXLE OIL REPLACEMENT...................... 65

26. AIR-INTAKE OPENINGS .................................... 65

27. RADIATOR .......................................................... 66

28. COOLANT REPLACEMENT ............................... 66

29. FUSES AND WIRING ......................................... 67

30. HYDRAULIC SYSTEM PARTS ........................... 68

31. SAFETY SWITCHES .......................................... 68

32. FILLING DIAGRAM ............................................. 69

33. PERIODICAL INSPECTION TABLE ................... 70

34. WASHING THE MACHINE ................................. 71

35. MAJOR CONSUMABLES LIST .......................... 72

9. STORAGE ............................................................... 74

10. TROUBLESHOOTING ............................................ 75

1. ENGINE .............................................................. 75

2. BRAKE SYSTEM ................................................ 77

3. LIFT SYSTEM ..................................................... 77

4. STEERING SYSTEM .......................................... 78

5. HST (Hydrostatic transmission) .......................... 78

6. ELECTRICAL ACCESSORIES ........................... 79

NOISE & VIBRATION ................................................... 80

DECLARATION OF CONFORMITY ............................. 83

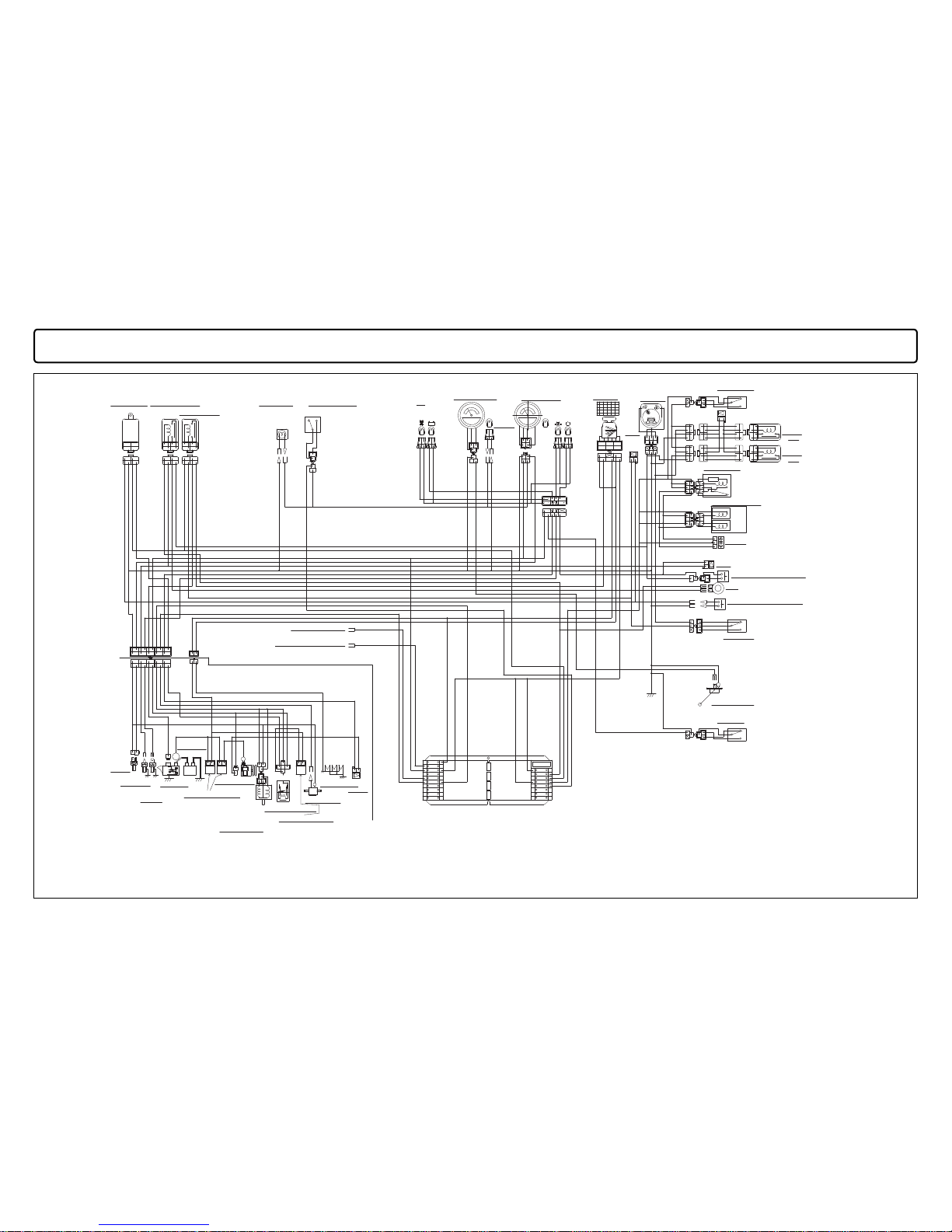

WIRING HARNESS CABLE ......................................... 85

INTRODUCTION

5

ABBREVIATION LIST

Abbreviations

PTO

PT

RH / LH

ROPS

RPM

SAE

SSM

Definitions

Power Take Off

Permanent Type

Right - hand and Left - hand sides are determined by facing in the direction of

forward travel

Roll - Over Protective Structure

Revolutions Per Minute

Society of Automotive Engineers

Side discharge Mower

UNIVERSAL SYMBOLS

Safety Alert Symbol

Operator’s manual

Preheat

Engine - Stop

Engine - Run

Starter Control

Engine - Revolution

Fast

Slow

Mower - deck

Mower -Lowered position

Mower - Raised position

Cutting Height

Power Take - Off Clutch Control - Off position

Power Take - Off Clutch Control - On position

Battery

Diesel Fuel

P

Parking Brake

6

SF310,370

DANGER : Failure to observe the following

safety instructions can result in serious injury or death. As the owner or operator of the

front mower,you are responsible for preventing accidents or injuries.

1. HOW TO BE A SAFE OPERATOR

1.1. Follow all the safety signs on the front mower and

all the manufacturer’s instructions before starting

the front mower. If you do not, it may result in body

injuries.

1.2. Pay attention to the caution labels on the front

mower and mower deck and observe the instructions they give to avoid physical injuries.

1.3. Ensure that all operators are responsible individuals

who have read the instructions or been fully trained

on the safe operation of the front mower.

1.4. All operators should evaluate their health and ability

to operate a front mower safely enough to protect

themselves and others from serious injury. Do not

operate the front mower while you are under the

influence of alcohol or drugs.

1.5. Understand how to properly and safely operate and

maintain the front mower. Seek and obtain practical

instruction on how to operate and maintain the front

mower properly.

1.6. Be sure to use necessary protective devices such

as headgear, safety glasses, safety shoes, ear

plugs, gloves, etc.

1.7. Wear appropriate protective clothing and equipment

when you are operating, adjusting, or servicing the

front mower, such as safety glasses, long pants,

substantial footwear, and ear protection. Long hair,

loose clothing, or jewellery can get tangled in moving parts.

1.8. Never permit the following persons to operate the

front mower:

- Persons not properly trained to operate the front

mower

- Persons who cannot understand the instructions

mentioned in this operator’s manual and on the

caution labels

- Pregnant women

- Children

Local regulations may restrict the age of the operator.

CHAPTER 1. FOR SAFE OPERATION

FIG. 1

FIG. 2

FIG. 3

CHAPTER 1. FOR SAFE OPERATION

77

1.9. Inspect the front mower periodically. If not, this may

not only shorten the front mower’s service life but

also make safe and efficient operation impossible.

1.10. Never use the front mower out of normal usage

even if it is not mentioned at this operator’s manual.

8

SF310,370

2. BEFORE STARTING THE FRONT MOWER

2.1. Set up an operation plan with sufficient time allowance. A tight plan may result in unexpected accidents. Especially when operating the front mower

under extremely hot, cold, or humid circumstances,

set up an operation schedule or method which will

ensure operational safety.

2.2. Mow only in daylight or good artificial light. Mowing

in the dark may cause unexpected accidents.

2.3. Thoroughly inspect the mowing area and remove all

objects from the mowing area that the front mower

can throw, such as stones, toys, sticks, and wires,

which may lead to serious accidents.

2.4. Ensure that there are no people or pets in the area

where you will mow. Keep children out of the mowing

area and under the watchful care of a responsible

adult.

2.5. Do not operate the front mower unless the operator’s

presence controls, safety switches, and guards are

attached and functioning properly .

2.6. Start the engine from the operating or designated

starting position.

2.7. Before starting the engine,make sure that everything

is safe around the front mower and put the traction

drive in neutral, set parking brake, and disengage

the cutting unit(s). Otherwise, unexpected accidents

may occur.

2.8. Start the engine with the starter switch only. Never

attempt to start the engine by shorting the terminals,

or the front mower may move abruptly, and result in

unexpected accidents.

2.9. Do not run the engine in an enclosed area where

dangerous carbon monoxide fumes can collect.

Sufficient ventilation should be provided when starting the engine in an enclosed area.

2.10. Make sure of safety around the front mower and

move slowly when starting. Abrupt starting may

cause unexpected accidents.

2.11. Become familiar with the operation, particularly, the

stopping of the front mower. You should be skilful

enough to be able to stop the front mower at will.

2.12. Use only attachments and accessories approved by

the manufacturer and install and operate them as

directed.

FIG. 4

CHAPTER 1. FOR SAFE OPERATION

9

2.13. When your front mower is equipped with an implement other than a standard mower deck, such as a

collector, a cabin, etc., never fail to ask your dealers

about machine balance. Always follow their advice.

2.14. Keep in mind that the operator or user is responsible

for the accidents or hazards caused by the front

mower to other people or their property.

2.15. Inspect the front mower for wear or damage.

Replace any worn or damaged parts.

2.16. Especially before starting the mower, be sure to perform advised pre-operation inspections especially

on the brakes and inspect visually to see that the

blade and blade tightening nuts are not worn, damaged or loose. Replace worn or damaged blade and

nuts as an assembly to preserve blade balance.

Otherwise, poor braking or scattered broken blades

may result, which is very dangerous.

FIG. 5

10

SF310,370

3. OPERATION OF THE FRONT MOWER

3.1. When the front mower is running, stay away from

the discharge opening, the cutting unit(s), and all

moving parts.

3.2. During operation, never allow anyone, especially

children, and animals to be in the vicinity of the front

mower. Do not direct the discharge at anyone.

3.3. When you are working with co-workers, be sure to

alert them by signalling before you take a new

action.

3.4. When operating the front mower, you should be

seated in the operator’s seat properly, hold the

steering wheel by both hands, and look in the direction in which the front mower advances. Avoid looking a side or holding the steering wheel by one hand

during operation.

3.5. Always be sure to operate the front mower from the

driver’s seat with seat belt. Never attempt to get on

or off the front mower while it is travelling.

3.6. Do not mow on wet grass. The front mower may

slide.

3.7. Slow down before turning the front mower. Turning

at high speed may cause the front mower to turn

over.

3.8. Never attempt to depress the dif-lock pedal while

turning around the front mower. Turning with the diflock on may cause the front mower to turn over.

3.9. Connect the independent brake pedal except necessary situation. Never operate the independent brake

pedal during travelling as this will cause the front

mower to skid sideways or turn over. When stopping, be sure to use the master brake pedal. (E6

type)

3.10. Look down and behind you and ensure a clear path

before you move the front mower backward.

3.11. Do not mow while moving backward unless it is

absolutely necessary.

FIG. 6

FIG. 7

FIG. 8

FIG. 9

CHAPTER 1. FOR SAFE OPERATION

11

3.12. Never operate the front mower in terrain where there

are ditches, holes, or steps easy to collapse. In such

a place, the front mower could turn over or fall.

3.13. Before making access to moving parts, stop the

engine, and keep your hands, feet, clothing, accessories and etc. away so as not to be caught in the

moving parts of the front mower.

3.14. Be alert when you approach blind corners and

objects that may obscure your vision. Watch for

holes, ruts, or bumps. Tall grass can hide obstacles.

3.15. Never rest a foot on the brake pedal. If so, the

brakes disc wear rapidly, which may lead to serious

accidents.

3.16. Travelling set with the cruise lever should be

restricted only to operations in specious, flat areas

with an unobstructed view and used with the range

shift lever always kept in the low speed position.

3.17. Never attempt to do the mowing operation without

the discharge cover in place or with the cover left

open.

3.18. Never attempt to operate without the drive shaft

cover in place.

3.19. Do not attempt to adjust the cutting height while the

engine is running.

3.20. Adjust the cutting height with the gauge wheels in

accordance with the condition of the ground surface

at the working site. Mowing on rough ground with

low cutting height may cause the blades to hit soil or

stones, which is very dangerous.

3.21. If you strike an object or if the front mower vibrates

abnormally, stop the front mower immediately, wait for

all moving parts to stop, and inspect the cutting unit(s).

Make all repairs before you resume operation.

3.22. Be sure to keep the grass discharging part clean. A

clogged discharging part may cause the discharge

cover to open, resulting in scattering of grass and

stones, which is very dangerous.

3.23. Never allow grass or leaves to accumulate around

heated parts such as the engine and the muffler, or

this may cause a fire.

3.24. Before moving the front mower to another place, be

sure to stop the mower blades and lift up the mower

deck. Otherwise, they may hit stones and scatter

them around, which is very dangerous.

FIG. 10

12

SF310,370

3.25. When driving over a levee or step, stop the mower

blades, lift up the mower deck, and move the front

mower straight to the levee and make it climb over

slowly. Avoid climbing over a levee too high, or the

front mower may fall sideways or turn over.

3.26. Stop the cutting unit(s) when you are crossing gravel

areas.

3.27. Watch for traffic when you are operating the front

mower near a roadway or when crossing a roadway .

3.28. Never attempt to use the front mower to draw

an implement or a trailer. It is not designed to draw a

load.

3.29. Stay alert and stop the front mower if people or pets

enter the area.

3.30. Do not carry passengers.

3.31. Never carry children, even when the cutting means

are not moving. Children may fall off the front mower

and become seriously injured or prevent you from

operating the front mower safely. Children who have

been given rides in the past may suddenly appear in

the mowing area for another ride and be run over or

backed over by the front mower.

3.32. If you use the lawn mower for long time, make

sure to take rest every 2 or 3 hours.

3.33. When you hear thunder, stop the lawn mower and

move indoors immediately. If you cannot move

indoors, get to low place. Otherwise, you can be

struck by lightning.

3.34. Before stopping the engine, be sure to lower the

mower deck onto the ground, apply the parking

brakes, shift the range shift lever in neutral and turn

the PTO switch to the OFF position.

3.35. Before leaving the operating position of the front

mower for any reason, always do the following:

- Stop the front mower on level ground.

- Stop the cutting unit(s), disengage PTO, and lower

the attachment(s).

- Disengage the drive(s).

- Set the parking brake.

- Stop the engine and wait for all moving parts to

stop.

FIG. 11

CHAPTER 1. FOR SAFE OPERATION

1313

4. OPERATION ON A SLOPE

DANGER : Slopes are a major factor related

to accidents with front mowers, resulting in

severe injuries.

We cannot recommend the front mower with mower deck

be operated on a slope. All slopes require extra caution;

no slope is safe.

You can lose control of the front mower on a slope

because of one of the following:

- the wheels lack traction; you are driving the front mower

too fast.

- you are not braking properly; the front mower type is not

suited for the task.

- you are unaware of the ground conditions (especially

slopes).

- you incorrectly hitch an attachment or distribute a load.

If the front mower has to be used on a slope, Never use it

on a slope of more than “10°”. Even if using it on a slope

of less than “10°”, be sure to abide by the following

instructions.

A slope angle of 10° is specified with the front mowers

equipped with the attachments mentioned respectively .

- The front mower is not equipped with any attachments or

a cabin.

- The front mower is equipped with a standard mower

deck.

Grass catchers and other attachments can change the

stability of the front mower. Follow the instructions for adding weight to improve the stability of the front mower.

When your front mower is equipped with an implement

other than standard, such as a collector, a cabin, etc.,

never fail to ask your dealers about machine balance.

Always follow their advice.

The ROPS is a safety device.

- Keep the ROPS in the vertical and locked position.

Always use the seat belt when you operate the mower.

Make sure the seat belt can be released quickly in an

emergency.

- The ROPS should only be folded if absolutely necessary

for storage. Do not operate the mower with the ROPS in

the folded position. There is no roll over protection with

the ROPS in the folded position.

- Do not use the seat belt with the ROPS in the folded

position.

- Do not remove the ROPS from the mower.

(Recommended seat: MSG83/521/GRAMMER)

4.1. Be sure to wear a helmet during operation.

4.2. If you feel uneasy operating your front mower on a

slope, do not mow it.

4.3. Evaluate the terrain to determine what accessories

and attachments you will need to be safe.

FIG. 12

14

SF310,370

14

4.4. Do not mow near drop-offs, ditches, or embankments.

You can tip the front mower over if a wheel is over the

edge of a drop-off or if an edge caves in. Uneven terrain can cause the front mower to overturn.

4.5. Never perform mowing operation on wet grass.

4.6. Be sure to shift the 4WD lever to the 4WD position.

4.7. Never use the cruise control during mowing operation.

4.8. Choose a low gear to prevent the need to stop or

shift gears on a slope.

4.9. Avoid sudden starting and stopping.

4.10. Mow up and down a slope; do not mow across it.

4.11. Mow a slope by moving slowly. Do not suddenly

change your speed or direction.

4.12. Do not turn on a slope unless it is necessary, and

then, turn slowly downhill, if possible.

4.13. If the tyres lose traction, disengage the cutting

unit(s) and proceed slowly, straight down the slope.

Do not apply the brake on a front mower that is sliding down a slope. Engage the clutch slowly and

always keep the front mower in gear, especially

when travelling downhill.

4.14. Do not use the grass catcher(s) while you are mow-

ing a steep slope.

4.15. Do not try to stabilize the front mower by putting

your foot on the ground.

4.16. Avoid stopping the front mower on a slope.

5. DRIVING ON PUBLIC ROADS

5.1. This front mower cannot be driven on a public road

without authorization by a local government agency,

etc. Therefore it may be illegal for the front mower

not only to travel on but also to cross a public road.

5.2. When transporting the front mower on a public road,

load it on a truck or trailer.

CHAPTER 1. FOR SAFE OPERATION

15

6. LOADING ONTO OR UNLOADING FROM A TRUCK

6.1. When loading the front mower onto a truck, turn off

the truck’s engine, apply the parking brakes to the

truck, and chock the wheels to avoid unexpected

moving of the truck or trailer.

6.2. Pay sufficient attention to safety conditions around

the front mower and have it guided by someone to

assist the operator. Never allow other persons to

approach the front mower, especially in front of or

behind it.

6.3. When loading the front mower onto a truck, lift up

the mower deck fully and advance it straight at sufficiently low speeds. Drive it rearward when unloading it from the truck or trailer.

6.4. If the engine stalls unexpectedly on the ramps,

depress the brake pedals immediately and roll the

front mower to the ground by releasing the brakes

gradually. Then start the engine and try again.

6.5. Use ramps with the same or better specifications

mentioned below. When the front mower is

equipped with the attachments other than those

included in the specifications mentioned below, ask

your dealers for advice.

Specifications of the ramps

6.6. Park the truck on hard level ground. Hook the ramps

securely on the platform of the truck with the top of

the ramp level with the platform.

6.7. Drive the front mower carefully at the moment the

front mower moves from the ramps onto the platform, for it changes angles abruptly.

6.8. When the front mower is loaded on the truck, lower

the mower deck onto the truck bed, stop the engine,

apply parking brakes, and withdraw the starter key,

chock the wheels, and rope it securely to the truck.

Refrain from unnecessary abrupt starting, stopping,

and turning during transportation, or the front mower

may shift position on the truck, which is very dangerous.

• Length ............. more than 4 times the height of the

platform of the truck

• Width (effective width) .................more than 30 cm

• Required quantity ......................................2 ramps

• Capacity (one ramp) ................... more than 750 kg

• Ramps should have anti-skid surfaces.

The above specifications are effective with the front

mower with the following configurations.

• The front mower is not equipped with any attachments or a cabin.

• The front mower is equipped with a standard

mower deck.

FIG. 13

FIG. 14

16

SF310,370

7. WHEN FILLING WITH FUEL

DANGER : Fuel is highly flammable and explosive. T ake the following precautions.

7.1. Do not add or drain fuel indoors, while smoking, or

near a source of flame.

7.2. Do not remove the fuel tank cap or add fuel to the

tank while the engine is running or hot. Wait until the

engine cools down sufficiently.

7.3. Do not completely fill the fuel tank. Add fuel to the

tank until the level inside the tank is just below the

bottom of the filler neck. The empty space allows

the fuel to expand.

7.4. If you spill fuel, clean it up and do not attempt to

start the engine until the vapour has dissipated.

7.5. When fuelling under certain circumstances, a static

charge may develop and ignite the fuel.

7.6. Use only an approved fuel container to store fuel.

7.7. Do not store the front mower or the fuel container

near a source of open flame, such as a water heater.

7.8. Replace all fuel tank and container caps securely.

7.9. To prevent personal injury and property damage, do

the following:

- Always place fuel containers on the ground and

away from the vehicle before fuelling.

- Do not fill the fuel container(s) inside a vehicle or

on a truck or trailer bed.

- When practical, remove a fuel-powered the front

mower from the truck or trailer and refuel it with its

wheels on the ground.

- If it is not practical to do this, refuel the front mower

on a truck or trailer from a portable container, not

fuel dispenser nozzle.

- If you must use a fuel dispenser nozzle, keep the

nozzle in contact with the rim of the fuel tank or

fuel container opening until you have completed

fuelling.

8. MOUNTING AND DISMOUNTING OF THE MOWER

DRIVE SHAFT

The mower gear box is driven through a drive shaft with

universal joints from the front mower. When connecting or

disconnecting the shaft, follow the next instructions.

8.1. Lower the mower deck onto the ground, stop the

engine, draw the engine key, and apply the parking

brakes before mounting or dismounting the drive shaft.

FIG. 15

CHAPTER 1. FOR SAFE OPERATION

17

8.2. Turn the PTO switch to the OFF position (

).

8.3. Make sure that the PTO shaft and mower blades

stop completely.

8.4. The drive shaft should be mounted or dismounted at

the front mower side. Never leave the shaft connected only at the mower side. If the PTO shaft be driven unexpectedly, the shaft will be swung around and

damage the front mower or cause serious accidents.

9. INSPECTION AND MAINTENANCE

9.1. Never start the engine in a closed place. Exhaust

fumes contain poisonous carbon monoxide, so sufficient ventilation should be provided when starting

the engine indoors.

9.2. Be sure to wear safety glasses and gloves when

servicing the front mower.

9.3. When servicing the front mower or mounting or dismounting the mower deck, place the front mower on

level, hard ground.

9.4. Service the front mower in a place sufficiently illuminated, or darkness may cause unexpected accidents.

9.5. Do not adjust or repair the front mower while the

engine is running.

9.6. When servicing the front mower or mounting or dismounting the mower deck, stop the engine and

Remove the key (if applicable) to prevent someone

from accidentally starting the engine and apply the

parking brakes

9.7. The engine, muffler, radiator, etc. are very hot just

after operation, so wait until those heated parts cool

down sufficiently to avoid burns.

9.8. Never remove the radiator cap while the engine is

hot or running. Wait until the engine cools down and

then relieve the radiator pressure by releasing the

radiator cap. Carelessly pouring cooling water into

the heated radiator can cause serious damage to

the radiator and the engine. Careless removal of the

radiator cap can cause serious injury because of

superheated water vapor.

9.9. Before servicing the front mower, be sure to turn the

PTO switch to the OFF position (

) and make sure

that the mower blades have stopped completely.

Rotating blades may cause serious accidents.

9.10. While adjusting the front mower, keep your fingers

away from all pinch points.

FIG. 16

FIG. 17

18

SF310,370

9.11. When servicing the front mower, use proper tools.

Using makeshift tools may lead to injuries or poor

service, which may result in unexpected accidents

during operation.

9.12. When removing a tire, chock other tires and support

the front mower securely. When installing tires, be

sure to tighten the wheel nuts to the specified

torque. Loose nuts may cause serious accidents.

9.13. When raising up the mower deck for service, raise

up it fully and apply the lift lock of hydraulic cylinder

to avoid lowering.

9.14. The cutting means(s) are sharp and can cut you.

Wrap the cutting means(s) or wear leather gloves

when you service them. On the front mower with two

or more cutting means, rotating one cutting means

may cause the other cutting means(s) to rotate.

9.15. Never step on the mower deck, or the mower deck

may be damaged or deformed, which may lead to

breakdown or accidents.

9.16. A first aid kit and a fire extinguisher should be kept

in a place always in instant access.

9.17. On the front mowers with hydraulic devices, hydraulic fluid escaping under pressure can penetrate and

seriously damage the skin, requiring immediate

medical assistance. Do not use your hand to check

for a hydraulic leak; use a piece of cardboard. Be

sure to consult your dealer about the hydraulic and

fuel injection system troubles.

9.18. If any hydraulic fluid is injected accidentally into the

skin, it must be removed within a few hours by a

doctor familiar with this type of injury.

9.19. Never allow grass or leaves to accumulate around

heated parts such as the engine and the muffler, or

this may cause a fire.

9.20. Replace any worn or damaged parts with the manufacturer’s recommended parts.

9.21. To reduce the fire hazard, keep the engine, muffler

(silencer), battery area, and fuel storage area free of

debris.

9.22. If fuel has to be drained, this should be done outdoors.

9.23. Check the brake(s) on the front mower frequently

and adjust and service the brake(s) as required.

9.24. Replace faulty mufflers (silencers).

FIG. 18

CHAPTER 1. FOR SAFE OPERATION

19

9.25. Do not change the engine governor settings or overspeed the engine. Operating an engine at an excessive speed can increase the risk of personal injury.

9.26. The grass catcher components are subject to wear

and damage, exposing you to moving parts or

thrown objects. Frequently check and replace them

with the manufacturer’s recommended parts when

necessary.

9.27. Be sure to reinstall the removed parts in place.

Never attempt to start the engine with any parts

removed.

9.28. Never attempt unauthorized modification of the front

mower as this could be very hazardous. Damaged

or worn parts should be replaced with ISEKI genuine spare parts. Unauthorized parts may cause

breakdown of the front mower, accidents, and ISEKI

warranty to expire.

9.29. Keep all fasteners tight, especially those that hold

the cutting means(s).

9.30. Check that all safety devices are in place and operating properly.

Parts code of blade

Punched ID

SSM60 8654-306-006-10

8654 C

SSM72 8655-306-003-10

8655 C

20

SF310,370

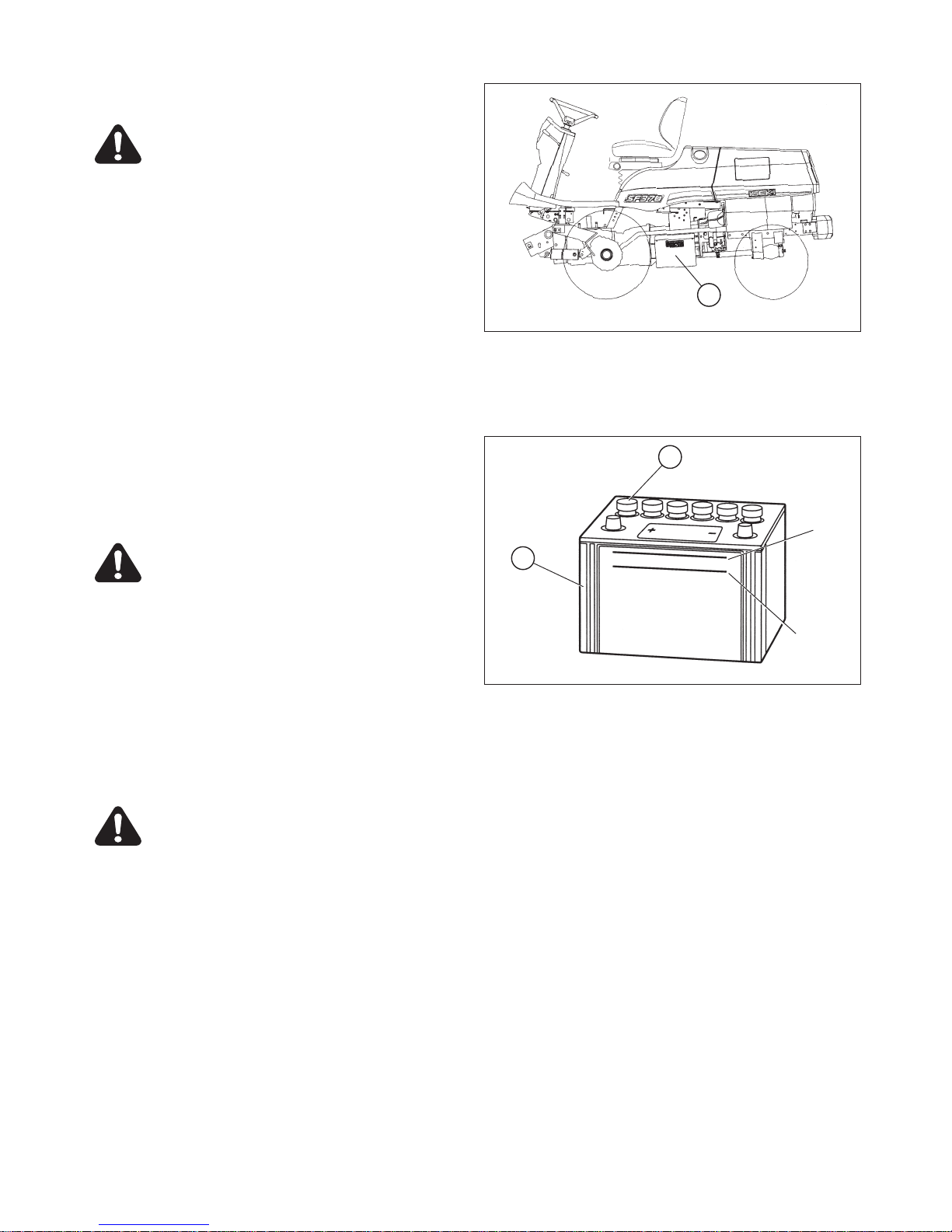

(1) Negative cord (2) Positive cord

FIG. 20

10. MAINTENANCE OF THE ELECTRIC SYSTEM

10.1. TO MAINTAIN ELECTRIC WIRING

(1) When servicing the electric wiring, stop the engine

without fail. Otherwise your hands or clothes may be

caught in or sandwiched between rotating parts.

(2) Before manipulating electric parts, be sure to dis-

connect the earth battery cable (-), or you may get

an electric shock or be injured by sparks.

(3) Loose electric terminals or connectors may not only

lower electrical performance but also cause short

circuit or leakage of electricity, which may lead to a

fire. Promptly repair or replace damaged wiring.

(4) Remove chaff or dust from the battery, wiring, muf-

fler or engine. Otherwise it could result a fire.

10.2. TO HANDLE THE BATTERY

(1) When working around the battery, avoid smoking.

The battery generates explosive hydrogen and oxygen gases when it is being charged. Keep the battery away from sparks or open flames.

(2) The battery should be inspected before starting the

engine. Be careful not to touch the electrolyte

makes contact with the skin or clothing, wash it off

immediately with water and then consult a doctor.

(3) When replacing or inspection the battery stop the

engine and turn the main switch off, or electrical

parts may be damaged or unexpected accident may

occur.

(4) When disconnecting the battery cables, disconnect

the earth cable (-) first without fail. When connecting

the battery cables, connect the positive cable (+)

first. Disconnecting or connecting in wrong order

may lead to a short circuit or sparks.

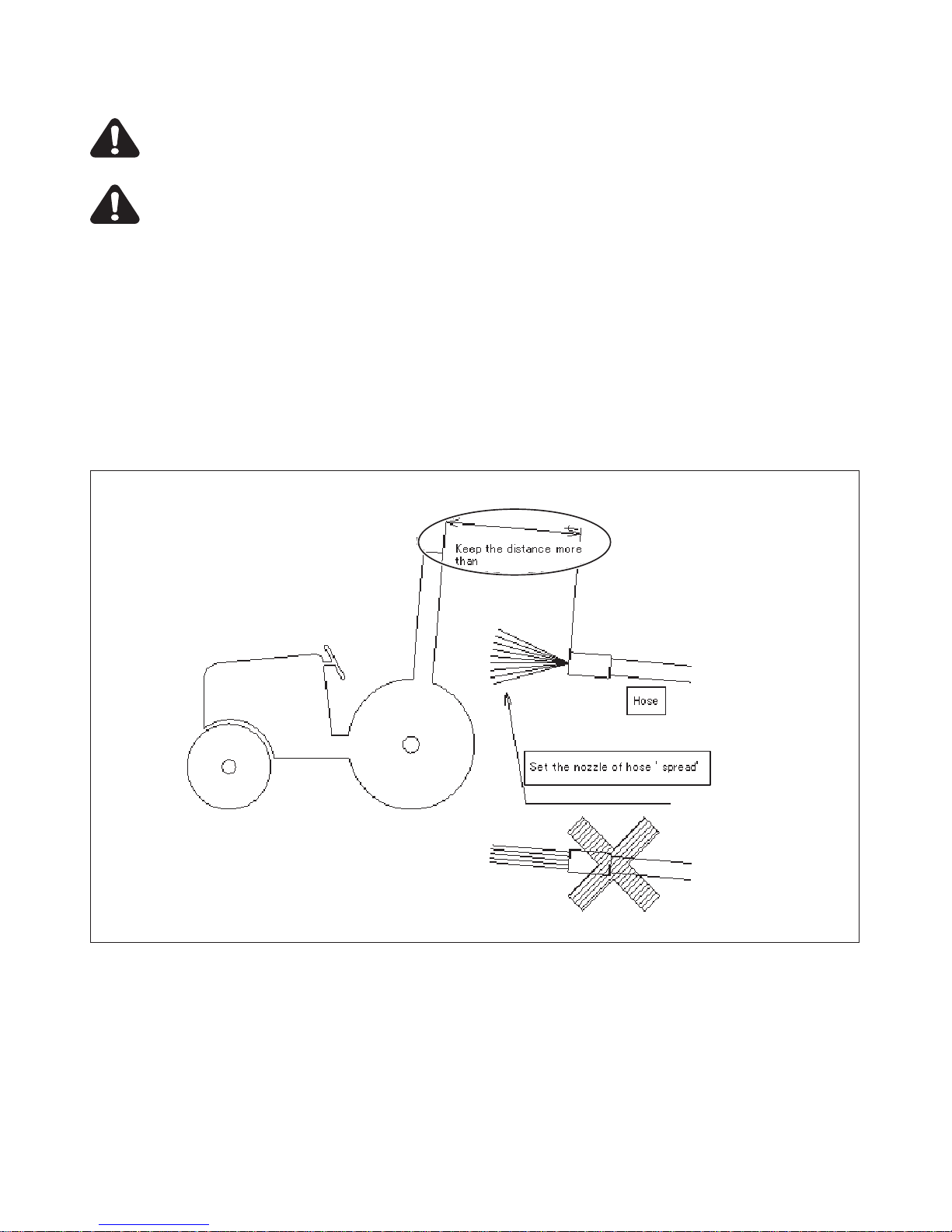

10.3. TO HANDLE BOOSTER CABLES

When using booster cables, pay attention to the fol-

lowing items for safe operation:

(1) Before connecting cables, remove the vent plugs.

This will lower the force in case of explosion.

(2) Before connecting cables, be sure to stop the

engines. Otherwise unexpected accidents may occur.

(3) Use booster cables with sufficient electrical capacity.

A cable of inadequate capacity will cause generation

of heat, which may lead to a fire.

FIG. 19

FIG. 21

CHAPTER 1. FOR SAFE OPERATION

21

11. TIRES AND WHEELS

11.1. Be sure to keep tire pressures at the levels specified

in this manual. Excessively high tire pressure

may result in explosion, which may lead to physical

accidents.

11.2. If a cut is found in a tire and the cut reaches the cords,

do not use it. Such a tire may explode.

11.3. Before replacing or repairing tires, tubes, or rims,

consult your dealers ahead of time. Such operation

should be performed by trained mechanics.

12. BEFORE STORING THE FRONT MOWER

12.1. After operation, be sure to close the fuel cock to prevent fuel from spilling, as spilled fuel may catch fire.

12.2. Never allow grass or leaves to accumulate around

heated parts such as the engine and the muffler, or

this may cause a fire.

12.3. Be sure to remove the ignition key to prevent unexpected accidents caused by engine starting by

untrained persons or children.

12.4. When storing the front mower with the mower deck

attached, be sure to lower the mower deck on the

ground. Otherwise manipulation of the lift lever by

untrained person or children may cause unexpected

accidents.

12.5. Store the front mower in a place provided with sufficient illumination. Inspection and moving of the front

mower in a dark place may lead to unexpected

accidents.

12.6. When the front mower is to be stored in a closed

place like a garage or a barn, provide sufficient ventilation for exhaust gases. Exhaust fumes can be lethal.

12.7. To avoid fire hazard, keep the engine, muffler, battery, and fuel storage area free of grass, leaves, or

excessive grease.

12.8. Never cover a hot front mower just after operation

with a tarpaulin or the like, or the heated engine and

related parts may cause a fire.

FIG. 22

22

SF310,370

(1) Negative cord

13. LONG TERM STORAGE

13.1. Never store the mower with fuel in the tank inside a

building where fumes can reach an open flame

or spark.

13.2. Lower the cutting unit(s) when you store the front

mower, unless you lock the cutting unit(s) into

position.

13.3. Allow the engine to cool before storing the front

mower in any enclosure.

13.4. Before storing the front mower for a long period of

time, disconnect the battery cables to prevent them,

in case they are gnawed by rats, from causing a

short circuit, which may lead to a fire. When disconnecting the battery, disconnect the negative (-) cable

first, while connecting the positive (+) cable first

when connecting the battery. Wrong order of disconnecting or connecting the battery will cause sparks,

which is very dangerous.

1

FIG. 23

CHAPTER 1. FOR SAFE OPERATION

23

14. CAUTION LABELS & THEIR POSITIONS

The following labels are stuck on the front mower and mower deck. You should of course read the caution instruc-

tions in the manual. But never fail to read the labels on the front mower as well. Their respective code numbers are

also mentioned below, so order them from your dealer if any of them are lost or damaged.

2

3

8

6

1

9

1705−902−007−0

1705−902−008−0

1705−902−006−0

1739−904−001−0

1674−904−008−0

4

7

5

1689−906−003−0

10°+

1.

2.

STOP

3.

1636−901−021−0

井関農機株式会社

ISEKI & CO.,LTD. MADE IN JAPAN

製造会社

946kg

SF370FH

UXWE4

MODEL

TYPE

WEIGHT

NO.

3−14 NISHI−NIPPORI 5−CHOME

ARAKAWA−KU TOKYO 116 JAPAN

06000001

井関農機株式会社

ISEKI & CO.,LTD. MADE IN JAPAN

製造会社

MODEL

TYPE

WEIGHT

NO.

3−14 NISHI−NIPPORI 5−CHOME

ARAKAWA−KU TOKYO 116 JAPAN

11

12

12

13

24

SF310,370

(1) Caution label

(Code No. 1689-906-003-0)

A. WARNING: BEFORE OPERATION

Read the safety and operating instructions in the oper-

ator’s manual before operating the front mower.

B. WARNING: BEFORE SERVICING

Read the technical instructions in the operator’s manu-

al before servicing the front mower. Remove the starter

key before servicing.

C. WARNING: RISK OF ELECTRIC SHOCK

When disconnecting the battery, detach the negative

terminal first and attach the positive terminal first when

connecting the battery.

D. WARNING: RISK OF ABRUPT MOVING

Before leaving the front mower unattended, apply the

parking brake, lower the implement, turn off the engine

and remove the starter key to avoid unexpected moving of the front mower.

E. WARNING: RISK OF ENTANGLEMENT

Stay clear of the belt while it is running.

F. WARNING: RISK OF INJURY

Stay away of the discharge opening of the mower deck

because stones or other hard objects ejected from the

mower may hit you.

G. WARNING: RISK OF RUNNING OVER A PERSON

Watch behind before reversing the front mower and

keep people from around the front mower before starting it.

H. WARNING: RISK OF RUNNING OVER A PERSON

Don’t allow any other person to ride on a wheel fender

or any place other than the driver’s seat of the front

mower.

I. WARNING: RISK OF OVERTURNING OR CRUSHING

Do not operate the front mower in any place where it

could slip or tip over.

J. WARNING: RISK OF OVERTURNING OR CRUSHING

Avoid operating the front mower on a slope of over

10°.

(2) Battery label

(Code No. 1705-904-002-1)

A. WARNING: RISK OF EXPLOSION

Keep away from sparks of flames, which could cause

explosion.

B. WARNING: WEAR AN EYE PROTECTION DEVICE

Battery electrolyte (sulphuric acid) may cause blind-

ness. Wear an eye protector to prevent contact with

the eyes.

CHAPTER 1. FOR SAFE OPERATION

25

C. WARNING: KEEP OUT OF REACH OF CHILDREN

D. WARNING: RISK OF BURNS

Battery electrolyte (sulphuric acid) may cause burns.

Avoid contact with skin or clothing. In case of an accident, flush attested part immediately with plenty of

water.

E. WARNING: RISK OF EXPLOSION

Never use the battery with the electrolyte surface

below the “LOWER” limit, or it may explode. Never

replenish exceeding “UPPER” limit or electrolyte may

leak out.

F. WARNING: READ OPERATOR’S MANUAL

Read the safety and operating instructions in the oper-

ator’s manual before operating the front mower.

Take care of handling the battery.

Improper handling may lead to explosion.

Never short the poles.

Charge the battery in well ventilated place.

(3) Battery disposal label

(Code No. 1728-903-003-0)

WARNING: Don’t throw away the battery to the garbage

can. Recycle it with observing the law of your community.

(4) Fuel label

(Code No. 1739-904-004-0)

DANGER: RISK OF EXPLOSION AND BURNS

Use only diesel fuel.

Before replenishing fuel, be sure to stop the engine and

wait until the engine and heated parts cool down sufficiently. Keep sparks, open flames, etc. away from the fuel

tank. No smoking!

(5) Hot-part warning label

(Code No. 1739-904-001-0)

WARNING: HOT SURFACES, RISK OF BURNS ON

HANDS AND FINGERS

Stay clear of the heated parts until they cool down sufficiently.

1739-904-001-0

26

SF310,370

(6) Fan warning label

(Code No. 1705-902-006-0)

WARNING: RISK OF ENTANGLEMENT

Stay clear of the fun while it is turning.

(7) Belt warning label

(Code No. 1674-904-008-0)

WARNING: RISK OF ENTANGLEMENT

Stay clear of the belt while it is running.

(8) Starter warning label

(Code No. 1705-902-007-0)

DANGER: RISK OF ELECTRIC SHOCK

Start the engine only from the seat using the key.

(9) Radiator warning label

(Code No. 1705-902-008-0)

WARNING: HIGH PRESSURE STEAM AND HOT WATER

Never remove the radiator cap during or just after operation. The water in the radiator is very hot and highly pressurized, which could cause burns.

(10) Lift lock label

(Code No. 1720-906-001-0)

WARNING: When raising up the mower deck for service,

apply the lift lock of hydraulic cylinder.

(11) PTO label

(Code No. 8654-901-002-0)

WARNING: Stay clear of the PTO shaft while the engine

is running.

CHAPTER 1. FOR SAFE OPERATION

27

(12) Brake warning label (E6 type)

(Code No. 1636-901-021-0)

WARNING: Do not use individual wheel brakes for transporting or operating at high speed. Always latch pedals

together using interlocking.

(13) ROPS label

(Code No. 1674-904-005-1)

WARNING: RISK OF INJURY

- Keep the ROPS in the upright position and fasten the

seat belt at all times. Do not jump from the seat if the

tractor starts to overturn, or you could be crushed under

the tractor. The ROPS should usually be kept in the

upright position during operation.

- However, when the ROPS has to be lowered, do not

wear the seat belt and operate the tractor with extreme

caution.

- Do not operate the tractor with a damaged or modified

ROPS.

• Maintenance of the caution labels

- The labels should always be clearly seen, that is, noth-

ing should obscure them.

- When they have become dirty, wash them with soapy

water and wipe off with soft cloth.

- If any of them are torn or lost, order new labels from

your dealer.

- A new label should be placed in the same place where

the old one was located.

- When sticking on a new label, clean the place to

enable the label to stick and squeeze out all air bubbles trapped under it.

- When replacing a part with a caution label stuck on, a

new caution label should also be ordered.

28

SF310,370

RH/LH independent brake pedal

Road homologation

For France

Type

UXWE4

UXWE6

UXWGE4

GE4F2

1. WARRANTY

On the warranty of this front mower and mower deck, refer to the warranty policy attached.

2. AFTER-SALE CARE

As for breakdown or question about the front mower and mower deck, consult with your dealers identifying the model

and serial number of your front mower.

3. SERIAL NUMBER PLATE

The model name and serial number for both machine and

engine are found in the serial number plates on the back

of the steering post.

This manual explains about several types of the front

mowers as listed below. Please confirm the type of yours

by referring to the name plate.

(1) Machine model name and serial number

(2) Engine model name and serial number

4. SUPPLY LIMIT OF SPARE PARTS

• The supply time limit of the spare parts for this model is 12 years after manufacture of the model is stopped. Even

within the supply limit, the delivery date of some parts have to be determined after negotiation.

• The supply of spare parts terminates when the limit mentioned above is exceeded. But orders for parts after the limit

may be met after negotiation about the delivery date, price etc.

CHAPTER 2. WARRANTY AND AFTER-SALE CARE

1

2

1689−906−003−0

10°+10°+

1.

2.

STOP

3.

1636−901−021−0

井関農機株式会社

ISEKI & CO.,LTD. MADE IN JAPAN

製造会社

946kg

SF370FH

UXWE4

MODEL

TYPE

WEIGHT

NO.

3−14 NISHI−NIPPORI 5−CHOME

ARAKAWA−KU TOKYO 116 JAPAN

06000001

井関農機株式会社

ISEKI & CO.,LTD. MADE IN JAPAN

製造会社

MODEL

TYPE

WEIGHT

NO.

3−14 NISHI−NIPPORI 5−CHOME

ARAKAWA−KU TOKYO 116 JAPAN

FIG. 24

Model

SF310FH

SF370FH

29

CHAPTER 3. SPECIFICATIONS

*

1 At the top of ROPS

*

2 When equipped with wide tire, seat, ROPS and full fuel tank

*

3 When equipped with wide tire, seat, and ROPS, and without full fuel tank

(Specifications and design subject to change without notice)

1. OPTIONAL PARTS

PARTS NAME PARTS CODE

CYLINDER/DOUBLE SET 1770-501-320-00

Dimensions

Weight

Engine

Generator capacity

Battery

Fuel

Fuel tank capacity

Transmission

Wheel base

Wheel tread

Driving system

Steering system

Min. un-cut radius

Brake system

Min. ground clearance

Tyre size

PTO

Overall length mm(in.)

Overall width mm(in.)

Overall height

mm(in.)

kg(lbs.)

Model

Type

No. of cylinders

Total displacement

cm3(cu.in)

Output (net)

kw(ps

)

Rated revolution rpm

amp.

liter

(gal)

Main transmission

Transmission range

Travelling speeds Forward

km/hr(mph)

Reverse

km/hr(mph)

mm(in)

Front mm(in)

Rear mm(in)

Mechanism

Steered wheels

mm(in)

mm(in)

Front

Rear

Location

Type

Drive

On-Off

Revolution mm(in)

CHAPTER 3. SPECIFICATIONS

Model SF310

SF370

1230/1330 wide (48.4/52.4 wide)

2180/2200 wide (85.8/86.6 wide)

*

1

2450 (96.5)

935/945 wide (2061/2083 wide)

*

2

895/905 wide (1975/1997 wide)

*

3

E3CD-VG03 E3CD-VTG

21.8(30) 26.0(35)

60

Vertical Water-cooled, 4-cycle Diesel

80D26R

Diesel fuel

48 (12.7)

HST (hydrostatic transmission)

Manual shift, 2 stages

1250 (49.2)

1000/1025 wide (39.4/40.4 wide)

960/1010 wide (37.8/39.8 wide)

2/4WD automatic shift - Permanent 4WD

Power

Rear wheels

1050 (41.3)

Wet,multi-disk

175/200 wide (6.9/7.9 wide)

23x10.5-12/26x12.0-12wide

20x8.0-10/22x8.50-12wide

Front

Wet multi disks

Shaft drive

Switch

2050

3

1498 (91.5)

2500

22.4/22.8 wide (14.0/14.2 wide)

12.1/12.3 wide (7.5/7.6 wide)

30

SF310,370

(1) Lift lever

(2) Cruise control lever

(3) Transmission range shift lever

(4) Floor open lever

(5) Dif-lock pedal

(6) Parking brake lever (G type)

(7) Throttle lever

(8) Independent brake pedal (LH) (E6 type)

(9) Independent brake pedal (RH) (E6 type)

(10) Parking brake lever (Except G type)

(11) Tilt lock lever

(12) Auto / 4WD changeover lever

(13) Control panel

(14) Master brake pedal

(15) HST forward travel pedal (Forward control)

(16) HST reverse travel pedal (Reverse control)

(17) Fuel tank filler

(18) Hood lock lever

CHAPTER 4. NAME OF MAJOR COMPONENTS

18

17

1

4

6

7

5

2

3

8

9

10

11

12

13

14

15

16

FIG. 25

31

CHAPTER 5. CONTROLS AND METERS

1. CONTROL PANEL

Except G type

G type

(1) Starter switch

(2) Work lamp switch

(3) Position switch

(4) PTO switch

(5) Combination switch

(6) Hazard switch

(7) Monitor lamp array

(8) Fuel gauge

(9) Hour / Tachometer

(10) Coolant temperature gauge

CHAPTER 5. CONTROLS AND METERS

2

8

9

10

1

4

7

FIG. 26

5

3

6

FIG. 27

32

SF310,370

1.1. STARTER SWITCH

: Glow position: the engine is pre-heated.

: OFF position: the engine stops and all electric cir-

cuits are turned off.

: ON position: the key turns to this position after start-

ing the engine and remains there during operation.

: START position: the starter motor is switched on.

1.2. WORK LAMP SWITCH

This switch turns the work lamp on and off.

: ON: Turn the switch lever towards this mark, and the

work lamps turn on and vice versa.

OFF:Off

1.3. POSITION SWITCH (G type)

The position light in combination lamp (Option) lights up

while this switch is ON.

: ON

○: Off

1.4. PTO SWITCH

With this switch the PTO can be either engaged to spin or

disengaged to stop.

: ON:Turn the switch to the position indicated by this

mark, and the PTO shaft starts spinning. To engage

PTO, first turn switch clockwise and then pull up it.

: OFF:Turn the switch to the position indicated by this

mark, and the PTO shaft stops spinning. Turn the

switch counter clockwise to disengage.

IMPORTANT: This front mower is equipped with UP-STOP

device for safety. PTO automatically stops

when the mower deck is raised while the

PTO switch is in the ON (

) position.

When the PTO stops by UP-STOP device,

lower the mower deck and reset the PTO

switch to the ON ( ) position to restart.

1.5. COMBINATION SWITCH (G type)

This switch incorporates the head lamp switch, turn signal

switch and horn button.

Head Lamp Switch

OFF: Off

: Low beam

: High beam

(1) Starter switch A: Glow position

B: OFF position

C: ON position

D: START position

(4) PTO switch

(5) Combination switch

A: Head lamp switch B: Turn signal switch

C: Horn switch

A

B

C

D

1

FIG. 28

FIG. 30

B

A

C

FIG. 29

4

33

CHAPTER 5. CONTROLS AND METERS

Turn Signal Switch

: Right-hand turn signal

○: Off

: Left-hand turn signal

NOTE: Turing indicator lamps will not self-cancel. Return

the turn signal switch lever to the center position

after completing turn.

Horn Switch

The horn is activated by pushing the horn mark with the

main switch is in the ON ( ) position.

1.6. HAZARD SWITCH (G type)

The turning signal lamps (Option) blink while hazard

switch is pushed on.

1.7. MONITOR LAMP ARRAY

: 4WD:The lamp lights up while 4WD lever is in the

LOCK (PERM) position and turns off while it is in the

AUTO (AUT.) position.

: Battery charge:The lamp lights up while the battery

is not being charged. It also lights up when the key

turns to the ON ( ) position or the START ( )

position while the engine stops, but turns off as soon

as the engine starts.

: Oil pressure:The lamp lights up when the engine oil

is not circulating normally. It also lights up when the

key turns to the ON ( ) position or the START ( )

position while the engine stops, but turns off as soon

as the engine starts.

: Grass collector:The lamp works only when the

machine is equipped with the grass collector. It

lights up and the buzzer also sounds when the collector is filled with grass with the PTO switch being

ON ( ).These turn off when the PTO switch is

turned to the OFF ( ) position. When the collector

is emptied, these turn off, too.

: High beam (G type):The lamp lights up while high

beam light of combination switch is ON.

: Trailer (G type):The lamp blinks when turn signal

switch is ON or when hazard switch is ON with

flasher lamps of trailer connected.

: Parking (G type):The lamp lights up with key switch

ON ( ) while parking lever is pulled upward to lock

brakes.

IMPORTANT: Always disengage the parking brake lever

and confirm that the lamp is OFF before

driving the front mower to prevent abnormal brake wear.

: Turning signal (G type):The lamp blinks while

turning signal switch is ON. Both lamps blink

while hazard switch is ON.

34

SF310,370

1.8. FUEL GAUGE

The gauge indicates fuel level in the fuel tank when the

main switch is in the ON (

) position.

E: Empty

F: Full

NOTE: The gauge can not indicate an accurate fuel level

when the front mower is on an incline. It takes a

little time to indicate an accurate level after the

front mower recovers its horizontal position.

1.9. HOUR / TACHOMETER

The hourmeter,A, counts operation hours of the front

mower and show them in 5-digit number. The least significant figure shows one tenth hour of operation.

The tachometer,B, shows current running speed of the

engine by one hundredth of engine speed (x 100).

1.10. COOLANT TEMPERATURE GAUGE

Gauge indicates engine coolant temperature when starter

switch is selected to ON (

).

C: - Shows too cool temperature for severe work. Allow to

warm (needle in mid position) before applying heavy

load.

H: - Indicates overheating. Reduce engine speed to idle,

allow to run at no load several minutes and investigate cause (refer to “Troubleshooting”).

IMPORTANT: When the engine coolant is over-heated,

the buzzer sounds while the PTO switch is

in the ON ( ) position. The buzzer turns

off when the PTO switch is turned to the

OFF ( ) position.

When the buzzer sounds, turn the PTO

switch to the OFF ( ) position, decelerated the engine to idling, and wait until the

buzzer turns off.

When the buzzer turns off, stop the engine

and correct the trouble (clogged grass or

dust around engine, radiator, etc.). Then

re-start operation.

WARNING: When inspecting the radiator, be

sure that the engine cools down sufficiently.

Never release the radiator cap while the coolant is hot, or boiling water will gush out.

(8) Fuel gauge

(9) Hour / Tachometer A: Hourmeter

B: Tachometer

(10) Coolant temperature gauge

A

B

FIG. 32

FIG. 33

FIG. 31

35

CHAPTER 5. CONTROLS AND METERS

2. STEERING POST

2.1. THROTTLE LEVER

With this lever, the engine speed is controlled.

: LOW: Shift (Pull) the lever towards the “turtle” mark,

the engine decelerates.

: HIGH: Shift (Push) the lever towards the “rabbit”

mark, the engine accelerates.

This front mower is equipped with Auto throttle system, it

raises up engine speed by depressing HST forward/

reverse travel pedal.

IMPORTANT: Don’t use Auto throttle for mowing opera-

tion. Set rated engine speed by hand

throttle lever.

2.2. AUTO / 4WD CHANGEOVER LEVER (4WD LEVER)

With this lever, 2WD/4WD automatic change-over and

permanent 4WD is selectable.

: 4WD PERM: Shift (push) the lever forward to

engage permanent 4WD mode.

4WD AUT: Shift (pull) the lever rearward to engage

AUTO 4WD mode.

In AUTO 4WD mode, 2WD and 4WD is selected automatically during operation on a level ground, so the lever operation is not required.

When operating on a slope, shift the changeover lever to

the 4WD position without fail.

IMPORTANT: Be sure to shift the 4WD lever to the

“AUTO” position when operating on level

ground, as level ground operation with the

4WD selected leads to a larger turning

radius and may cause turf damage.

IMPORTANT: When shifting the 4WD lever, slow down

the travelling speed below 1 km/h and

make the machine go straight.

WARNING: When operating the front mower

on a slope, be sure the 4WD lever is locked in

the 4WD position from the reasons mentioned below:

In the AUTO position the mechanism shifts to 2WD automatically when the peripheral speed of the front wheels

exceeds that of the rear wheels, which means loss of rear

wheel driving power.

(1) Throttle lever (2) 4WD lever (3) Tilt lock lever

(1) Throttle lever

(2) 4WD lever

1

2

3

FIG. 34

1

FIG. 35

2

FIG. 36

36

SF310,370

For example, when moving uphill if the front wheels slip,

the mechanism stays in 4WD. But moving downhill hill if

the front wheels slip and lose grip, and begin to slip down

the slope, it shifts to 2WD, that is, braking effect of the

HST unit is lost, which means loss of front mower control.

From another point of view, when you try to turn the front

mower on a slope, rear wheel driving power is lost and the

front mower may slip down the slope, which is also very

dangerous.

2.3. TILT LOCK LEVER

The steering wheel column is tiltable to gain the optimum

wheel angles. To adjust the angles, pull up the tilt lock

lever while holding the steering wheel with the other hand,

and the lock is released. Select the most adequate angle

within the four setting position. Then push down the lever

securely to lock the steering wheel column.

CAUTION: Only adjust steering tilt when the

machine is parked.

3. FLOOR PEDALS AND LEVERS

(1) Master brake pedal

(2) HST forward travel pedal

(3) HST reverse travel pedal

(4) Independent brake pedal (RH) (E6 type)

(5) Independent brake pedal (LH) (E6 type)

(6) Dif-lock pedal

(7) Parking brake lever (Except G type)

(3) Tilt lock lever

5

6

4

7 1

2

3

FIG. 38

3

FIG. 37

37

CHAPTER 5. CONTROLS AND METERS

3.1. MASTER BRAKE PEDAL

The front mower stops travelling by depressing this pedal,

which engage the right and left brakes at the same time.

3.2. HST FORWARD TRAVEL PEDAL

Depress this pedal, and the front mower starts moving forward. Forward travelling speed is controlled only by

depressing it: forward travel accelerates and decelerates

by the extent the pedal is depressed.

3.3. HST REVERSE TRAVEL PEDAL

Depress this pedal, and the front mower starts reversing.

Reverse travelling speed is controlled only by depressing

it: reverse travel accelerates and decelerates by the

extent the pedal is depressed.

3.4. INDEPENDENT BRAKE PEDAL (RH)(E6 type)

This pedal affects the right-hand front wheel brake alone.

3.5. INDEPENDENT BRAKE PEDAL (LH)(E6 type)

This pedal affects the left-hand front wheel brake alone.

WARNING:

• Never operate the independent brake pedal

during travelling as this will cause the front

mower to skid sideways or turn over. When

stopping, be sure to use the master brake

pedal.

• Connect the independent brake pedal except

necessary situation.

IMPORTANT: • Use of the independent brake may dam-

age the turf, so don’t use it during operation on turfs.

• When making a quick turn within a

garage or a barn, do this at sufficiently

slow speed.

3.6. DIF-LOCK PEDAL

To minimize the turning radius of the front mower, the differential is installed, which causes the right and left driving

wheels to turn at different speed when turning. On the

other hand, it causes the wheels to slip on wet grass or

soft ground. In such a case, lower engine speed and

depress the dif-lock pedal, and then the differential is

locked and both wheels turn at the same speed, which

results in straighter travelling.

WARNING:

• Never use the dif-lock when travelling at

high speeds.

• It is very dangerous to attempt to turn the front

mower with the dif-lock pedal depressed.

When turning the front mower, be sure to

release the dif-lock pedal.

• When the dif-lock is not released despite

releasing the dif-lock pedal, stop the front

mower immediately and ask your dealer to

repair.

(1) Master brake pedal

(2) HST forward travel pedal

(3) HST reverse travel pedal

(4) Independent brake pedal (RH) (E6 type)

(5) Independent brake pedal (LH) (E6 type)

(7) Parking brake lever (Except G type)

(6) Dif - lock pedal

5

4

7

1

2

3

FIG. 39

6

FIG. 40

38

SF310,370

3.7. PARKING BRAKE LEVER (Except G type)

While depressing the master brake pedal fully, move the

lever rearward and the parking brake is applied. To

release the parking brake, depress the master brake

pedal again.

IMPORTANT: Never start travelling with the parking

brake applied, or the brake performance

will deteriorate soon or, even worse, the

brake system could break down.

CAUTION: When leaving the front mower, be

sure to apply the parking brake.

4. FENDER (WING) PANEL

4.1. TRANSMISSION RANGE SHIFT LEVER

This lever shifts the transmission range into HIGH and

LOW speed ranges.

: LOW: Shift the lever forward, and the transmission

is shifted to the low speed range.

: HIGH: Shift the lever rearward, and the transmission

is shifted to the high speed range.

N

: NEUTRAL: The transmission is at the neutral posi-

tion.

IMPORTANT: Before shifting the range shift lever, be sure

to stop the front mower from travelling.

4.2. LIFT LEVER

With this lever, the lift link (mower deck) is raised or lowered.

: DOWN: Shift the lever forward to this mark, the lift is

lowered.

: UP: Shift the lever rearward to this mark, the lift is

raised.

CAUTION: When servicing or leaving the

front mower, be sure to lower the mower deck

to the ground.

IMPORTANT: Do not hold the lift lever too long in the

UP position( ), or it may damage the

hydraulic system.

LIFT LOCK: The lift cylinder is equipped with a lift locking

device.

WARNING: Be sure to raise the lift to its uppermost position and engage the lift lock when

servicing the mower deck.

IMPORTANT: Use the lift lock when servicing only with

the mower deck raised. Do not use when

travelling or transporting by truck, or it

may damage itself and hydraulic system.

(1) Transmission range shift lever

(2) Lift lever

(3) Cruise control lever

Released

Locked

A: Hydraulic cylinder

B: Lift lock

C: Lift link

1

2

3

FIG. 41

FIG. 43

FIG. 42

39

CHAPTER 5. CONTROLS AND METERS

4.3. CRUISE CONTROL LEVER

When this lever is shifted in the required position, the

cruising speed is held there without operating the HST forward travel pedal.

: LOW: Shaft the lever forward, cruising speed

becomes slow.

: HIGH: Shift the lever rearward, cruising speed

becomes fast.

4.4. PARKING BRAKE LEVER (G type)

Use this lever when parking the front mower.

Pull up the lever, and the parking brakes are applied.

Push in the top button and lower the lever to disengage

the brakes.

IMPORTANT: Never start travelling with the parking

brake applied, or the brake performance

will deteriorate soon or, even worse, the

brake system could break down.

The parking lamp light up with key switch ON while parking lever is pulled upward.

Relieve the parking lever before starting the front mower

and confirm the parking lamp is OFF.

CAUTION: When leaving the front mower, be

sure to apply the parking brake.

5. SAFETY SWITCHES

5.1. SAFETY SWITCHES (except F Type)

The operator’s seat, master brake pedal and PTO switch

are equipped with a safety device respectively. Before

starting the engine, the operator should be seated in the

operator’s seat, keep the master brake depress position

and turn the PTO switch to the OFF ( ) position.

5.2. SAFETY SWITCHES (F Type)

The operator’s seat, master brake pedal and PTO switch

and engine hood are equipped with a safety device

respectively. Before starting the engine, the operator

should be seated in the operator’s seat, keep the master

brake depress position and turn the PTO switch to the

OFF ( ) position.

CAUTION: When the engine does not start

due to a defective safety switch or does not

stop when the operator has left the operator’s

seat, consult your dealer at once without fail.

(E6 type) The engine keeps running even

when the operator has left the operator ’s

seat, provided that the PTO switch is in the

OFF ( ) position and the parking brake is

applied.

(4) Parking brake lever (G type)

4

FIG. 44

40

SF310,370

It is essential for avoiding accidents or breakdown during operation to keep the front mower in good condition. The following pre-operational checks should be performed without fail before starting daily operation.

WARNING:

• Before inspection, be sure to park the front

mower on a level and hard ground, stop the

engine, lower the mower deck onto the

ground, turn the PTO switch to the OFF position ( ), and check to see that the mower

blades have completely ceased rotating.

• Machine weight balance is a very important

factor for safe operation. When your machine

is equipped with an implement such as a

cabin, etc., never fail to ask your dealers

about machine balance. Always follow their

advice.

1. INSPECTION ITEMS

(1) Anything that was abnormal in the previous operations.

(2) While walking around the front mower.

• Tire inflation

• Exterior parts (broken or deformed covers or the like)

• Oil leakage (engine oil, transmission oil, fuel, etc.)

• Inspection and cleaning of air-intake port

• Inspection of engine oil level

• Inspection of coolant level

• Inspection of fan belt

• Inspection of fuel level

• Inspection of fuel filter

• Inspection of transmission oil level

• Inspection of front and rear wheel tightening bolts and

nuts

• Cleaning of radiator and radiator screen

• Inspection of electrical apparatus

• Inspection of mower blades

• Inspection of mower blade driving belt

• Inspection of mower exterior parts like covers for damage and deformation

• Oil leakage from mower gear case

• Inspection and cleaning of gauge wheels

• Inspection for loose, broken or lost pins and clips

(3) While sitting in the operator’s seat:

• Inspection of brakes

• Adjustment of seat

(4) After having started the engine:

• Confirmation of the operation of safety switches

2. WAY OF INSPECTION AND MAINTENANCE

Refer to the section of “MAINTENANCE.”

CHAPTER 6. PRE-OPERATIONAL ROUTINE INSPECTION

CHAPTER 7. OPERATION

41

1. BEFORE STARTING THE ENGINE

CAUTION:

•

Before sta rt ing the eng ine, be sure t o carr y out

the pre-operation inspection in accordance with

the periodical in spe ction tabl e.

• Follow instructions given in “I. FOR SAFE

OPERATION.”

• Observe instructions given on the caution

labels on the front mower and mower deck.

2. STARTING THE ENGINE

WARNING:

• Never attempt to start the engine in an

enclosed place with poor ventilation. Be sure

to provide sufficient ventilation, for exhaust

fumes can be lethal.

IMPORTANT: Before starting the engine, close the

engine hood securely, sit down in the operator’s seat properly, depress the master

brake pedal, and turn the PTO switch to

the OFF position ( ), or the engine cannot be started.

a. Close the engine hood securely.

b. Sit in the operator’s seat properly.

c. Apply the parking brakes,1 or 2, securely.

d. Shift the transmission range shift lever,3, to the neutral

position (N).

e. Turn the PTO switch,4, to the OFF position ( ).

f. Make sure the cruise control lever,5, is returned to the

LOW position ( ).

g. Shift the lift lever,6, to the DOWN position ( ).

h. Depress the master brake pedal,7, fully.

i. Insert the starter key into the starter switch,8, and turn

the key to the ON position ( ). Make sure that the

charge lamp and oil pressure lamp are both lit.

(1) Parking brake lever (Except G type)

(2) Parking brake lever (G type)

(3) Range shift lever

(5) Cruise control lever

(6) Lift lever

(7) Master brake pedal

(4) PTO switch A: OFF B: ON

CHAPTER 7. OPERATION

1

2 3

6

7

5

4

A B

FIG. 45

FIG. 46

SF310,370

42

i. Shift the throttle lever,9, to the high speed position (

).