iseg HPS 300 W series, HPS 800 W series, LPS 300 W series, LPS 800 W series Operator's Manual

Page 1

Spezialelektronik GmbH

19“ / 1U – High Voltage Power Supplies

HPS 300 W and 800 W series

19“ / 1U – C-Charger High Voltage Power Supplies

LPS 300 W and 800 W series

Operator’s manual

1 Safety instructions ........................................................................................................................ 3

2 Technical data .............................................................................................................................. 4

2.1 General technical data............................................................................................................ 6

3 Functional description ................................................................................................................... 7

3.1 Operation states ..................................................................................................................... 8

3.2 Safety loop (Interlock) ............................................................................................................ 8

Operating see the attachment point 4 to 7

!

Attention!

- The unit must not be operated with the cover removed

to avoid the possibility of lethal shock to the operator!

- We decline all responsibility for damages and injuries caused by an improper use of the

module. It is strongly recommended to read the operator’s manual before operation!

Note

All information in this document is subject to change without notice. We take no responsibility for any

error in this document. We reserve the right to make changes in the product design without any notification to the users.

Filename HPx-LPx_300-800W_HW01_eng.___; Version 5.19 as of 2009-07-15

iseg Spezialelektronik GmbH Email: sales@iseg-hv.de Tel ++ 49 (0)351 / 26 996 - 0

Bautzner Landstr. 23 http://www.iseg-hv.de Fax ++ 49 (0)351 / 26 996 - 21

D - 01454 Radeberg / Rossendorf

Page 2

Spezialelektronik GmbH

iseg Spezialelektronik GmbH Email: sales@iseg-hv.de Tel ++ 49 (0)351 / 26 996 - 0

Bautzner Landstr. 23 http://www.iseg-hv.de Fax ++ 49 (0)351 / 26 996 - 21

2 D - 01454 Radeberg / Rossendorf

Page 3

Spezialelektronik GmbH

1 Safety instructions

This High Voltage Power Supply has to be installed by skilled personnel only.

Following instructions are made for the personal safety of the operator, the safe use of this product

and the connected units.

!

Caution

Dangerous Voltage

This unit is supplied from line voltage of 85 to 260 V-AC and

generates an output voltage of up to 30 kV.

The disregard of this voltage condition can cause death, heavy injuries or material

damage.

Danger in case of missing connector at the HV output

The LEMO-HV connector will be used for units which generate output voltages > 6kV.

It is forbidden to switch on this unit without a suitable connector inclusive a cable which

is connected to the output connector and the load.

Before connecting to the local mains it must be proofed that the nominal line voltage of this unit is

equal to the local mains.

Caution: After system-assembly the guard connections have to be checked if they are con-

nected correctly!

The guard connection has to be proofed through a correct mains cable. An additional guard connection is possible via the green-yellow guard connector next to the HV Output ( ⊥⊥⊥⊥/PE-connector).

The shield of the HV output is always connected to the housing ( ⊥⊥⊥⊥/PE-connector).

If this shield is intended to use as “reverse line“ , then a jumper has to be plugged between the “0 V“

(reverse current) and the “ ⊥⊥⊥⊥/PE” connector.

If this jumper has been removed an additional “reverse line“ from the load to the “0 V“ connector must

been used and this connector close to ground can be float up to max. ± 300 V.

In this case the user is responsible that - due to the voltage between “0 V“ and “ ⊥⊥⊥⊥/PE“ connector - no

danger for the user may occur.

If the potential between “0 V“ and “ ⊥⊥⊥⊥/PE“ connector is > 300V then - in order to avoid damages for

the unit - the connections are short circuited with help of electronically protection circuits.

The unit is prepared to be mounted into a 19“-cabinet. In this case the necessary air flow conditions

through the according air input and output slots have to be guaranteed.

If the unit will be used as desk top instrument then the enclosed unit bases have to be glued on the

bottom sheet in order to guarantee a certain distance to the desk.

Before the cover of the unit will be removed the mains connection has to be disconnected, the discharge time of at least (> 15 s) of the output capacitance has to be kept and the discharge status has

to be checked afterwards.

Only skilled and authorised people are allowed to do any service, repair or maintenance for this unit.

iseg Spezialelektronik GmbH Email: sales@iseg-hv.de Tel ++ 49 (0) 351 / 26 996 - 0

Bautzner Landstr. 23 http://www.iseg-hv.de Fax ++ 49 (0) 351 / 26 996 - 21

D - 01454 Radeberg / Rossendorf 3

Page 4

Spezialelektronik GmbH

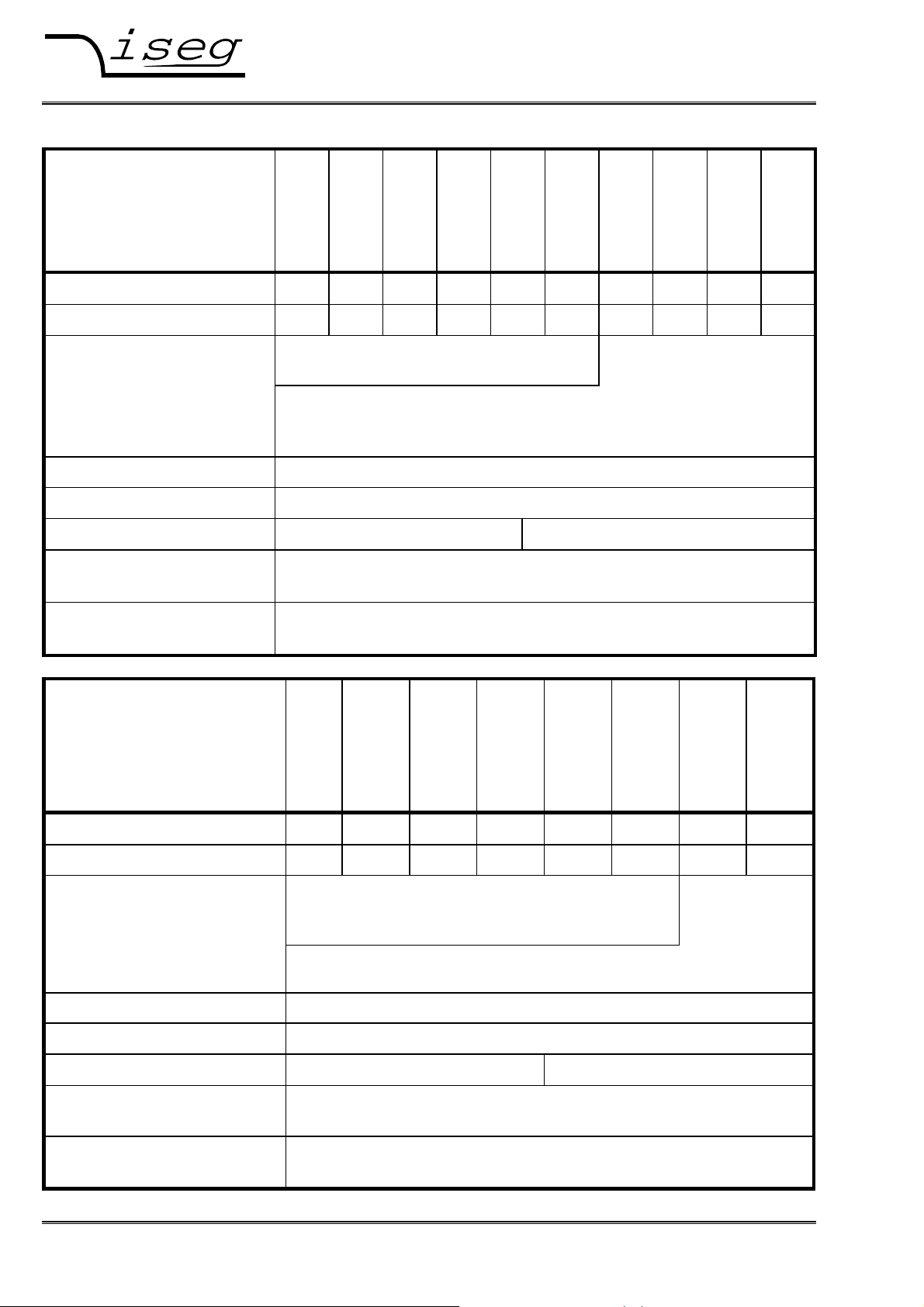

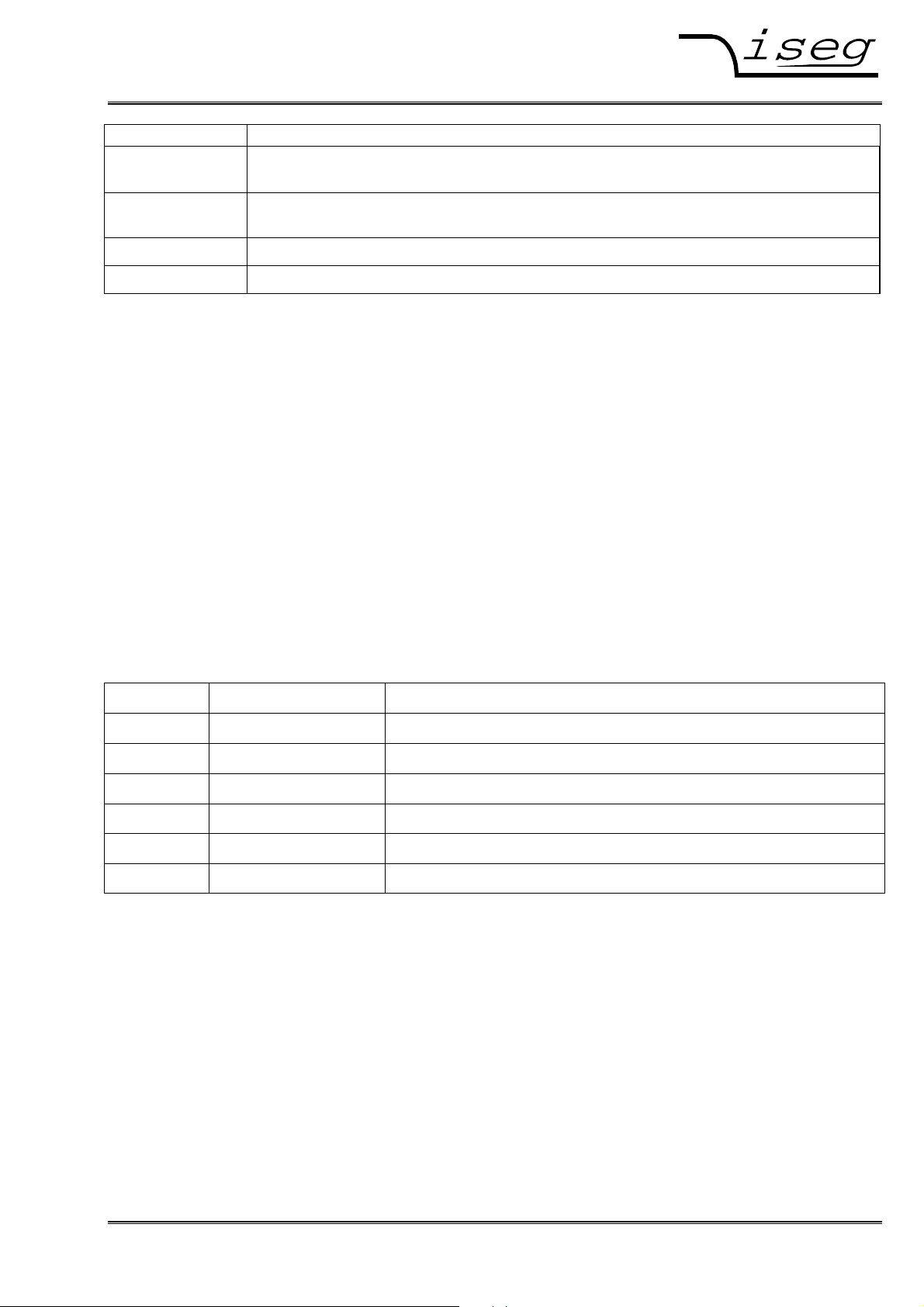

2 Technical data

19“ / 1U - series

HPx)1 300 W

10 307

)1

)1

HPx

Output voltage V

Output current I

HV connector

NOM

NOM

(kV)

(mA)

1 2 3 4 6 8 12 15 20 30

300 150 100 75 50 35 25 20 15 10

SHV front side, opt. rear side (SHV-R)

8 kV < V

V

Attention: Use with connected HV connector only !

Output power max. 300 W

Polarity

Ripple & noise [V

Voltage stability

P-P

]

factory fixed ⇒ )1x = p: positive ⇒ )1x = n: negative

V

≤ 8kV: < 1 • 10-4 • V

NOM

< 1 • 10-4 • V

in the output voltage range:

Current stability

< 2 • 10-3 • I

in the output voltage range:

20 157

HPx

30 107

)1

HPx

40 756

)1

HPx

60 506

)1

HPx

80 356

)1

HPx

120 256

)1

HPx

Lemo-HV-connector

rear side

≤ 16kV: Lemo ERA.1Y.416.CLL

NOM

> 16kV: Lemo ERA.3Y.425.CLL

NOM

V

NOM

(load to no load, ∆VIN and repeatability)

NOM

1% • V

( R

NOM

≤ RL < no load and ∆VIN)

Lmin

1% • V

> 8kV: < 5 • 10-4 • V

NOM

NOM

NOM

≤ V

≤ V

OUT

OUT

≤ V

≤ V

)1

NOM

NOM

150 206

HPx

200 156

)1

HPx

NOM

300 106

)1

HPx

19“ / 1U - series

HPx)1 800 W

Output voltage V

Output current I

HV connector

NOM

NOM

(kV)

(mA)

10 807

)1

HPx

20 407

)1

HPx

1 2 3 4 6 8 12 15

800 400 250 200 130 100 65 50

SHV front side, opt. rear side (SHV-R)

8 kV < V

Attention: Use with connected HV connector only !

Output power max. 800 W

Polarity

Ripple & noise [V

Voltage stability

P-P

]

factory fixed ⇒ )1x = p: positive ⇒ )1x = n: negative

V

≤ 8kV: < 1 • 10-4 • V

NOM

< 1 • 10-4 • V

in the output voltage range:

Current stability

< 2 • 10-3 • I

in the output voltage range:

30 257

)1

HPx

(load to no load, ∆VIN and repeatability)

NOM

( R

NOM

40 207

)1

HPx

NOM

V

NOM

1% • V

≤ RL < no load and ∆VIN)

Lmin

1% • V

60 137

)1

)1

HPx

≤ 16kV: Lemo ERA.1Y.416.CLL

> 8kV: < 5 • 10-4 • V

NOM

NOM

NOM

≤ V

≤ V

OUT

OUT

≤ V

≤ V

80 107

HPx

NOM

NOM

120 656

)1

HPx

Lemo-HVconnector

rear side

NOM

150 506

)1

HPx

iseg Spezialelektronik GmbH Email: sales@iseg-hv.de Tel ++ 49 (0)351 / 26 996 - 0

Bautzner Landstr. 23 http://www.iseg-hv.de Fax ++ 49 (0)351 / 26 996 - 21

4 D - 01454 Radeberg / Rossendorf

Page 5

Spezialelektronik GmbH

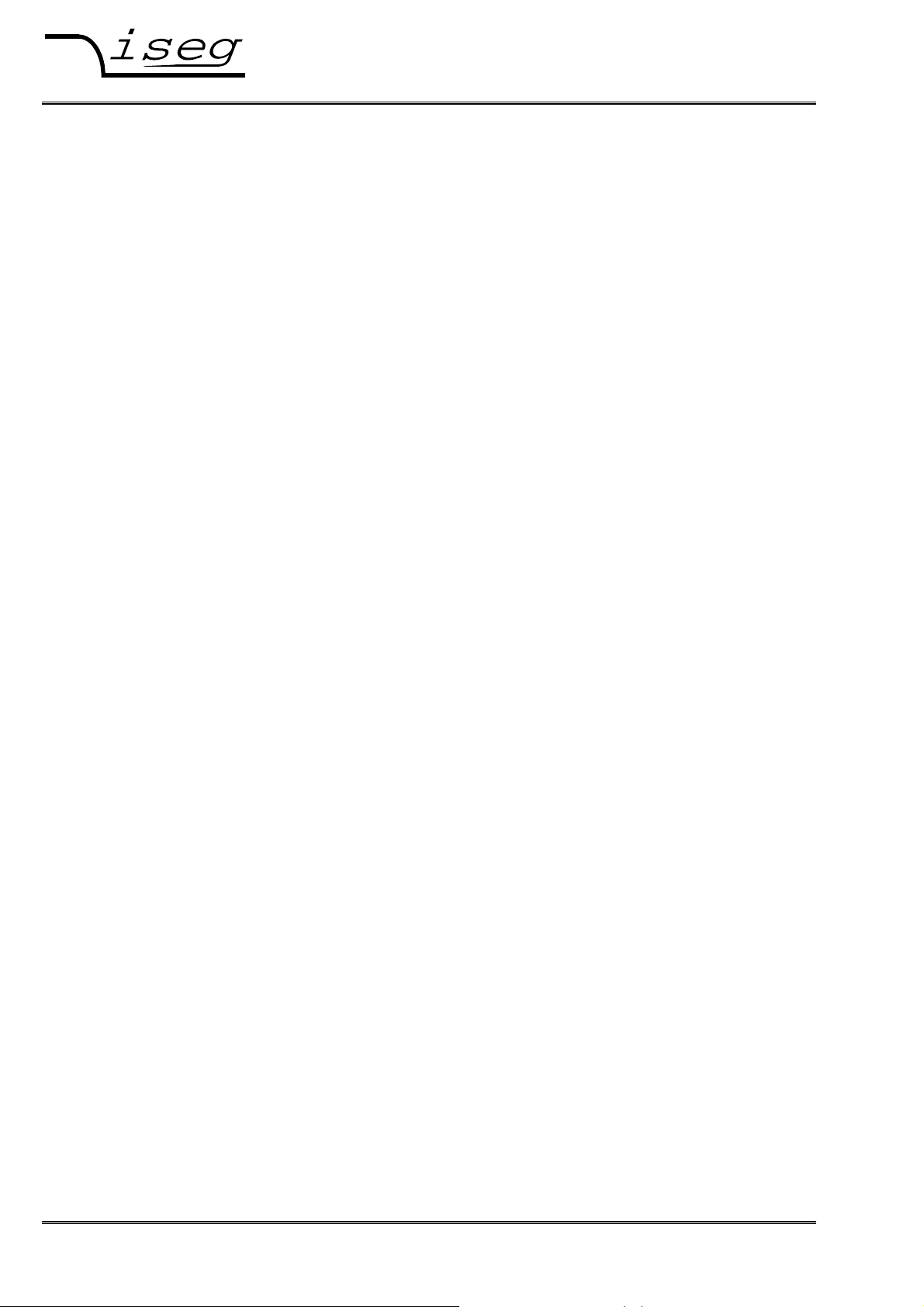

19“ / 1U - series LPx)1 300 W

Output voltage V

Output current I

HV connector

(kV) 1 2 3 4 6 8 12 15 20 30

NOM

(mA) 300 150 100 75 50 35 25 20 15 10

NOM

10 307

)1

LPx

SHV front side, opt. rear side (SHV-R)

8 kV < V

V

20 157

)1

LPx

30 107

)1

LPx

40 756

)1

LPx

60 506

)1

LPx

≤ 16kV: Lemo ERA.1Y.416.CLL

NOM

> 16kV: Lemo ERA.3Y.425.CLL

NOM

Attention: Use with connected HV connector only !

Output power max. 300 W

Discharge frequency Max. one complete discharge per second,

at discharging up to 2 kV against GND: up to 15 Hz

at discharging up to 1 kV against GND: up to 60 Hz

discharge current must be limited external to I

Polarity

Voltage stability

Current stability

factory fixed ⇒ )1x = p: positive ⇒ )1x = n: negative

< 1 • 10-3 • V

in the output voltage range: 5 V ≤ V

< 2 • 10-3 • I

in the output voltage range: 5 V ≤ V

(load to no load, ∆VIN and repeatability)

NOM

≤ V

OUT

(R

NOM

≤ RL < no load and ∆VIN)

Lmin

≤ V

OUT

80 356

)1

LPx

120 256

)1

LPx

150 206

)1

LPx

200 156

)1

LPx

300 106

)1

LPx

Lemo-HV-connector rear

side

otherwise

NOM

NOM

NOM

19“ / 1U - series LPx)1 800 W

Output voltage V

Output current I

HV connector

10 807

)1

LPx

(kV) 1 2 3 4 6 8 12 15

NOM

(mA) 800 400 250 200 130 100 65 50

NOM

20 407

)1

LPx

30 257

)1

LPx

40 207

)1

LPx

60 137

)1

LPx

SHV front side, opt. rear side (SHV-R)

80 107

)1

LPx

120 656

)1

LPx

150 506

)1

LPx

Lemo-HV-connector rear side ERA.1Y.416.CLL

Attention: Use with connected HV connector only !

Output power max. 800 W

Discharge frequency Max. one complete discharge per second,

at discharging up to 2 kV against GND: up to 15 Hz

at discharging up to 1 kV against GND: up to 60 Hz

Polarity

Voltage stability

Current stability

discharge current must be limited external to I

factory fixed ⇒ )1x = p: positive ⇒ )1x = n: negative

< 1 • 10-3 • V

in the output voltage range: 5 V ≤ V

< 2 • 10-3 • I

in the output voltage range: 5 V ≤ V

(load to no load, ∆VIN and repeatability)

NOM

≤ V

OUT

(R

NOM

≤ RL < no load and ∆VIN)

Lmin

≤ V

OUT

otherwise

NOM

NOM

NOM

iseg Spezialelektronik GmbH Email: sales@iseg-hv.de Tel ++ 49 (0) 351 / 26 996 - 0

Bautzner Landstr. 23 http://www.iseg-hv.de Fax ++ 49 (0) 351 / 26 996 - 21

D - 01454 Radeberg / Rossendorf 5

Page 6

Spezialelektronik GmbH

2.1 General technical data

19“ / 1U - series

HPx)1 300 W

Accuracy voltage measurement

current measurement

Temperature coefficient

19“ / 1U - series

HPx)1 800 W

± (0,5% • V

± (0,1% • I

< 2 • 10-4/

+ 0,3% • V

OUT

+ 0,05% • I

OUT

K

19“ / 1U – series

LPx)1 300 W

+ 1 digit) for one year

NOM

+ 1 digit) for one year

NOM

19“ / 1U – series

LPx)1 800 W

Display 8-digit LCD-Display for current and voltage

Resolution of voltage and current

4-digit

measurement

Resolution of settings LOCAL 4-digit

Voltage / Current REMote 4-digit

Switching of output voltage with button “ON/OFF” or via remote control

Control LOCAL rotary encoders for voltage and current

(REMote) CAN via CAN-Interface

USB via USB-Interface

optional: RS-232 via RS232-Interface

optional: AIF via indirect coupled analogue I/O additionally (male SUB-D-9)

optional: IEEE-488 via IEEE-Interface additionally (male Micro D25)

optional: ETH via Ethernet-Interface additionally (RJ45)

Efficiency up to 85%

Supply VIN = 85 up to 260 V AC with PFC

IIN = 1,7 A at 230V-AC / 3,5 A at 115 V-AC (300 W series),

IIN = 4,5 A at 230 V AC / 9 A at 115 V AC (600 W series)

via mains connector and switch “POWER“, isolated from HV-output,

fused with 2 • 6,3 A / slow (300 W series)

2 • 10 A / slow (800 W series).

Dimension 1U -19“ compatible / depth: 410 mm

Weight ca. 5,7 kg (300 W series) / ca. 6,5 kg (800 W series)

Cooling Internal fan

Protection Over load and short circuit , voltage supply and temperature

Environment conditions Operating temperature: 5 up to 35 °C

Humidity: 30% up to 80 %, no condensation

Storage temperature 0 up to 60 °C

iseg Spezialelektronik GmbH Email: sales@iseg-hv.de Tel ++ 49 (0)351 / 26 996 - 0

Bautzner Landstr. 23 http://www.iseg-hv.de Fax ++ 49 (0)351 / 26 996 - 21

6 D - 01454 Radeberg / Rossendorf

Page 7

Spezialelektronik GmbH

3 Functional description

The High Voltage PS of the HPx)1 - 300 W series provide an output voltage of 0 up to 30 kV-DC at

max. 300 W output power.

The High Voltage PS of the HPx)1 - 800 W series provide an output voltage of 0 up to 15 kV-DC at

max. 800 W output power.

The control loop is designed to provide a constant voltag or current.

The High Voltage PS of the LPx)1 - 300 W series provide an output voltage of 0 up to 30 kV-DC at

max. 300 W output power.

The High Voltage PS of the LPx)1 - 800 W series provide an output voltage of 0 up to 15 kV-DC at

max. 800 W output power. Mains voltage is 85 - 264 V -AC 50/60 Hz (PFC is standard).

The control loop is designed to charge a capacity in constant current control mode. This capacity will

discharge with the user circuit. You will find information to the discharge frequency dependence on

the discharge level in chapter 2.

On LPS devices, the Software voltage ramp (0…3000V/s) can be disabled. The device then ramps to

the choosen set voltages as fast as possible (see chapter 4 “Front panel operation” and 6 “Command

sets”).

Mains voltage is 85 to 260 V-AC 50/60 Hz.

The output voltage and current are limited due to the hardware circuitry. The polarity is factory fixed

)1

(

x=p: positive; )1x=n: negative).

The shield of the HV output is always connected to the housing ( ⊥⊥⊥⊥/PE-connector).

If this shield is intended to use as “reverse line“, then a jumper has to be plugged between the “0 V“

(reverse current) and the “⊥⊥⊥⊥/PE” connector.

If this jumper has been removed an additional “reverse line“ from the load to the “0 V“ connector must

been used and this connector close to ground can be float up to max. ± 300 V.

Attention: In this case the user is responsible that – due to the voltage between “0 V“ and

“⊥⊥⊥⊥/PE“ connector – no danger for the user may occur.

If the potential between “0 V“ and “⊥⊥⊥⊥/PE“ connector is > 300V then – in order to avoid damages for

the unit – the connections are short circuited with help of internal electronically protection circuits.

iseg Spezialelektronik GmbH Email: sales@iseg-hv.de Tel ++ 49 (0) 351 / 26 996 - 0

Bautzner Landstr. 23 http://www.iseg-hv.de Fax ++ 49 (0) 351 / 26 996 - 21

D - 01454 Radeberg / Rossendorf 7

Page 8

Spezialelektronik GmbH

3.1 Operation states

The device has the following operation states:

- POWER-ON Device initialises the connected Hardware (Booting)

- LOCAL Device is controlled with buttons and rotary encoders at the front panel

- REMOTE Device is remote controlled via interface (CAN, RS-232, IEEE-488)

The states LOCAL and REMOTE are further divided into:

- HV-OFF No high voltage is produced

- HV-ON High voltage according to Set values is produced

In the HV-ON state there are two modes for high voltage creation:

1. Voltage control CV:

Control of output voltage according to set value V

(Output current I

OUT

< I

), LED „CV“ lighting.

SET

2. Current control CC (only with “Kill disable”):

Control of output current according to set value I

(Output current V

OUT

< V

), LED „CC“ lighting.

SET

The KILL function is be set with the KILL/ESC button:

Disable: The output voltage will be limited after reaching I

Enable: The yellow LED „KILL ENABLE” is lighting.

The output voltage will be shut off permanently without ramp, if I

The re-setting of the output voltage is possible after pushing button HV ON again.

SET

SET

SET

≥ I

OUT

SET

.

3.2 Safety loop (Interlock)

The unit is equipped with a connector for a hardware safety loop (interlock) on the rear.

If the loop is closed an internal current source (open circuit voltage 15 V / short circuit current max.

40 mA) will drive a current of ca. 12 mA through the built-in safety relay.

That will work if the impedance of the closed loop is less than 200 Ohm.

If the safety loop is opened, the relay will be drop-out and the generation of high voltage will be

stopped without any semiconductor by the contacts of the safety relay only.

Caution: The internal and external capacities must be discharge about the load before the

output will be volt-free. The internal load is very high, so a very long discharging

time is possible according to the connected load.

The unit is not equipped with an active discharging circuit!

The safety loop is closed ex works with help of a wire strap.

It is not possible to switch on the high voltage generation if the loop is open.

If the loop will be closed again high voltage will be switch on with HV-ON on front panel or via the

digital interfaces only.

If chosen AIF ON in the menu F06 „Control with analogue I/O automatically“ it is able to switch

on high voltage with Low to High on the INHIBIT pin of the analogue I/O too.

iseg Spezialelektronik GmbH Email: sales@iseg-hv.de Tel ++ 49 (0)351 / 26 996 - 0

Bautzner Landstr. 23 http://www.iseg-hv.de Fax ++ 49 (0)351 / 26 996 - 21

8 D - 01454 Radeberg / Rossendorf

Page 9

Spezialelektronik GmbH

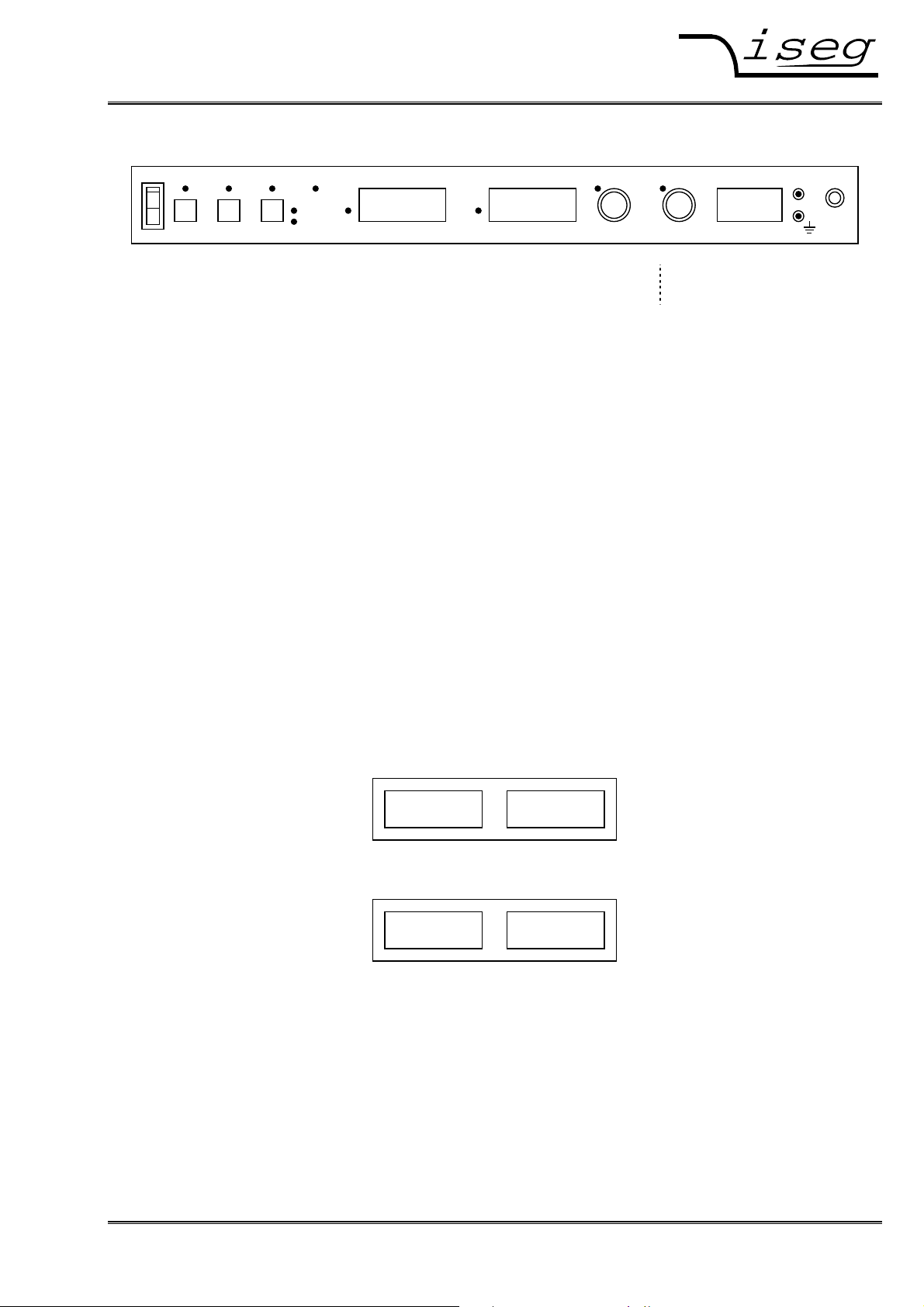

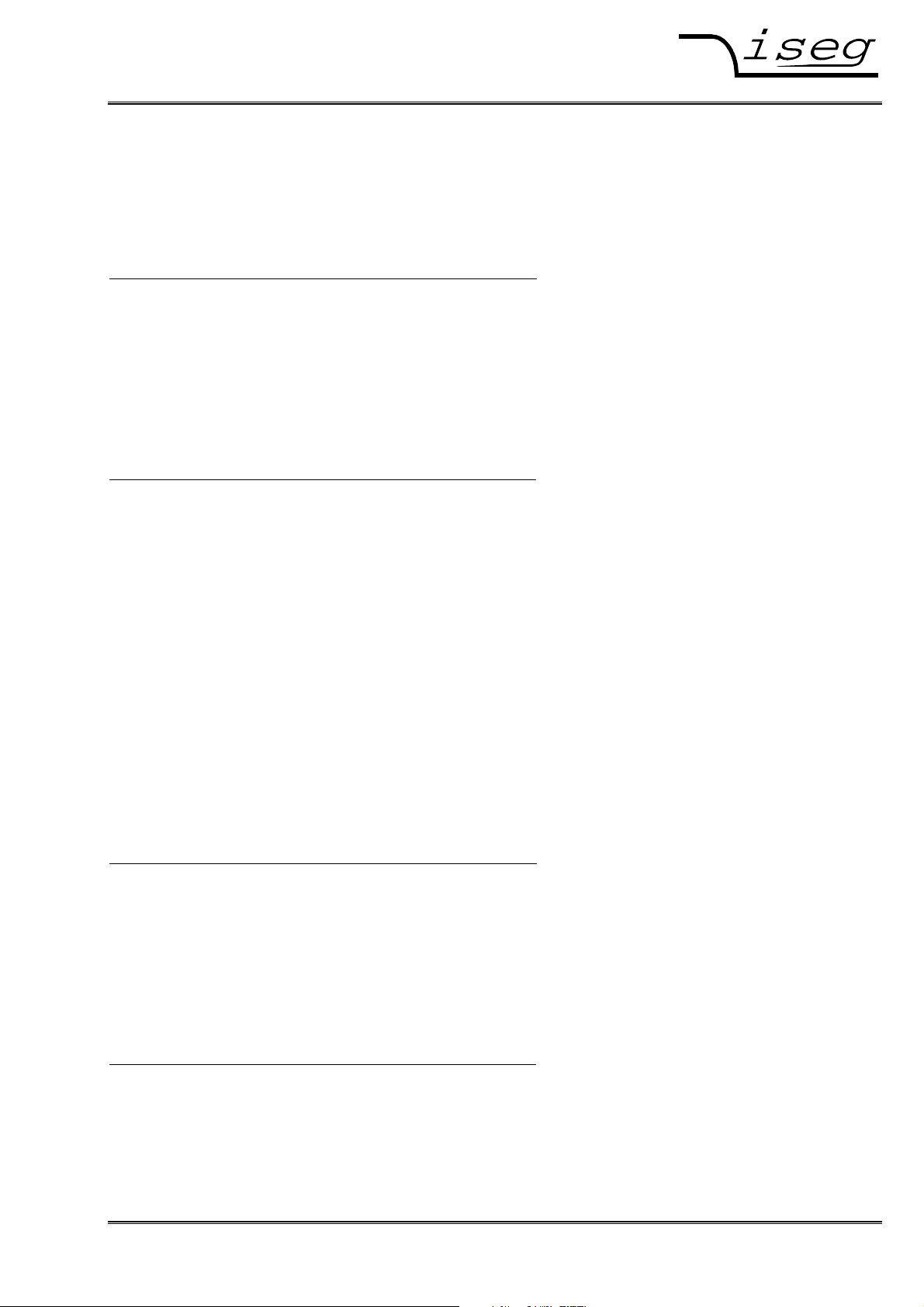

4 Front panel operation

POWER HV

1

O

KILL

REMOTE ERROR

ENABLE

ON

KILL

LOCAL

OFF

ESC

MENU

RxD

TxD

VOLTAGE CURRENT

CV CC

1.000kV 800.0mA

HIGH VOLTAGE POWER SUPPLY

VOLTAGE CURRENT HV OUT

iseg

HPp 10 807

1kV / 800mA

0 V

Picture: HPS/LPS front panel. Optional and if V

NOM

> 7 kV:

connections on the rear

After pushing the POWER button the device is booting. During boot, the integrated hardware is initialised. After start-up the device is working in LOCAL mode and the KILL function is “disable”.

In LOCAL mode, the set values for voltage and current can be adjusted with the rotary encoders

VOLTAGE for V

When trying to set V

and CURRENT for I

SET

SET

or I

beyond the adjusted limit, the corresponding LED is flashing for one

SET

. The yellow LEDs VOLTAGE and CURRENT are lighting.

SET

second.

Generation of high voltages starts by pushing the ON/OFF button. While generating high voltage, the

green LED “HV” is lighting.

Caution! The high voltage which has been selected with the rotary encoders is going to

ramp to the chosen voltage with the programmed ramp speed!

Factory setting for ramp speed is 0.2 •••• V

per second.

NOM

By pressing ON/OFF again, the high voltage generation is turned off, the green LED “HV” goes off.

The high voltage is ramped down with the programmed ramp speed.

4.1 Displays

The device has two eight digit displays for voltage and current as well as for Menu control.

In HV-OFF state, the set values are shown on display for easy changes with the rotary encoders

VOLTAGE and CURRENT. These set values are stored in processor’s EEPROM and reloaded at

next start-up.

While displaying the set values for voltage and current, a small ’s’ is flashing at the left display side:

s1.000kV s800.0mA

Picture: Set values on display in HV-OFF state

In HV-ON state the measured values of voltage and current are displayed:

0.995kV 752.3mA

Picture: Measured values on displays in HV-ON state

By pressing the rotary encoder VOLTAGE or CURRENT in HV-ON state, the corresponding set value

is displayed for a short time to allow exact adjustment.

If the set values aren’t changed, the device shows the measured values again after four seconds. By

pressing the corresponding rotary encoder again, this delay can be shortened.

After turning high voltage off, the displays show the measured values while ramping down. After four

seconds an with measured voltage lower than 60 V, the device shows the set values again.

iseg Spezialelektronik GmbH Email: sales@iseg-hv.de Tel ++ 49 (0) 351 / 26 996 - 0

Bautzner Landstr. 23 http://www.iseg-hv.de Fax ++ 49 (0) 351 / 26 996 - 21

D - 01454 Radeberg / Rossendorf 1

Page 10

Spezialelektronik GmbH

4.2 Menu

In HV-OFF mode the device menu is activated by pressing the button MENU.

If no button is pressed, the display switch back to HV-OFF mode after 30 seconds. The menu can

also be closed without changing any value by pressing the button ESC.

By turning the rotary encoder VOLTAGE you can scroll through the menu. By pressing the rotary encoder VOLTAGE the displayed menu point is selected. The setting can be changed by the active rotary encoder (shown by yellow LED). By pressing the active rotary encoder the changes are stored

and the main menu is displayed again.

Display Description

F01 Set Limit V

Adjust the Software voltage limit V

rotary encoder VOLTAGE. V

will be limited to this value.

SET

in the range of 0.02 • V

OUTmax

If the Limit gets smaller than the actual value of V

automatically.

SET

NOM

, V

will be decreased to V

SET

≤ V

OUTmax

≤ V

with

NOM

OUTmax

F02 Set Limit I

Adjust the Software current limit I

rotary encoder CURRENT. I

will be limited to this value.

SET

in the range of 0.02 • I

OUTmax

If the Limit gets smaller than the actual value of I

SET

≤ I

NOM

, I

will be decreased to I

SET

OUTmax

≤ I

with

NOM

OUTmax

auto-

matically.

F03 Set Ramp V Adjust voltage ramp speed with rotary encoder VOLTAGE in the range of 1…3000 V/s

(factory setting is 0.2 • V

NOM

/s).

On LPS devices, the software voltage ramp can be disabled. In this case, the device

changes it’s output voltage as fast as possible.

The software ramp can be disabled be setting the ramp speed greater than 3000 V/s:

“max.” will be displayed. To enable the software ramp again, set a ramp speed between

1…3000 V/s.

F04 Set Ramp I Adjust current ramp speed with rotary encoder CURRENT with the given values in the

range of 0.02 • I

NOM

/s up to I

/s (factory setting is I

NOM

NOM

/s)

F05 Auto Start Not implemented yet.

F06 Auto AIF AIF ON: Turn on HV by pushing the ON/OFF button or with

INHIBIT Low to High on analogue I/O

AIF OFF Turn on HV by pushing the ON/OFF button only

The INHIBIT signal on analogue I/O has priority in both cases!

INHIBIT High to Low: turn off HV

Low to High: turn on HV (KILL disable)

Low static: HV = 0

F07 Set Interfce Select external Interface with rotary encoder VOLTAGE:

“CAN” control via CAN-Interface

“RS-232” control via RS232-Interface

“USB“ control via USB-Interface

“IEEE 488” control via IEEE (GPIB)-Interface

“Ethernet“ control via Ethernet-Interface

“AIF” control via Analogue I/O

F08 Set Instruct Select instruction type for RS-232/USB/IEEE-488/Ethernet control with rotary encoder

VOLTAGE:

”EDCP” SCPI command set with EDCP (recommended)

“SCPI” old SCPI command set

“ET” old ET command set

F09 Addr IEEE Select IEEE address with rotary encoder VOLTAGE: 01 to 30. Factory setting is 17.

F10 Addr CAN Select CAN address with rotary encoder VOLTAGE: 00 to 63. Factory setting is 0.

iseg Spezialelektronik GmbH Email: sales@iseg-hv.de Tel ++ 49 (0)351 / 26 996 - 0

Bautzner Landstr. 23 http://www.iseg-hv.de Fax ++ 49 (0)351 / 26 996 - 21

2 D - 01454 Radeberg / Rossendorf

Page 11

Spezialelektronik GmbH

Display Description

F11 Set Echo

F12 Set Password The MENU settings are safed with 4 pin password. Setting position by position with rotary

Select Echo state for RS-232/USB control with rotary encoder VOLTAGE: “on” ⇒ “off” ⇒

“on”

encoder VOLTAGE. Given the code „0000“ the password function is not active (ex works).

F13 Show Power Change the display to V

and Power

OUT

(on/off)

OUT

F14 Quit Menu Close the menu.

4.3 Software limits

The device uses two software limits for voltage and current.

These limits consists of two functions:

1. Limit the set values to the adjusted limits: limit V

SET

to V

OUTmax

resp. I

SET

to I

OUTmax

.

2. Set the limit bits in Channel Status and Channel Event Status, if the measured values exceed

the limits:

- isVLIM and EVLIM if V

- isCLIM and ECLIM if I

OUT

OUT

≥ V

≥ I

OUTmax

OUTmax

+ 0.02 • V

+ 0.02 • I

NOM

NOM

In mode Kill enable, the bits EVLIM resp. ECLIM causes the High Voltage to shut down without ramp.

4.4 Error states

The following Events cause the High Voltage to shut down without ramp and have to be cleared with

Button KILL/ESC or a remote command (e. g. *CLS) before turning it on again.

Event Bit Display Description

EEMCY EMERGENCY OFF Emergency off via remote control

ETRIP CURRENT TRIP

Current trip (I

OUT

≥ I

) in mode Kill enable

SET

EVLIM VOLTAGE LIMIT Voltage limit exceeded in mode Kill enable

ECLIM CURRENT LIMIT Current limit exceeded in mode Kill enable

ESFLPngd SAFETYLOOP Safety loop was or is open

ETEMPngd OVERTEMPATURE Maximum allowed temperature was or is exceeded

iseg Spezialelektronik GmbH Email: sales@iseg-hv.de Tel ++ 49 (0) 351 / 26 996 - 0

Bautzner Landstr. 23 http://www.iseg-hv.de Fax ++ 49 (0) 351 / 26 996 - 21

D - 01454 Radeberg / Rossendorf 3

Page 12

Spezialelektronik GmbH

5 Interface control

For remote control, the corresponding interface (CAN, RS-232, USB, IEEE-488, Ethernet) has to be

selected first in Menu “F07 Set Interfce”. The device switches to REMOTE state when receiving the

first command from the selected interface. The yellow LED “REMOTE” is lighting. The yellow LEDs

VOLTAGE and CURRENT stop lighting to indicate that no local control is possible at the moment.

By pressing the LOCAL button the remote control is suspended. The device can now be controlled

via front panel. When receiving new commands via Interface, the device switches back to REMOTE

state.

If the device is in “HV-ON” state via interface, high voltage can be turned off by pressing the ON/OFF

button. In this case the device goes to LOCAL state as well.

Exception: If local control is disabled (Local Lockout, see chapter 6.3), the device can only

be turned off via mains switch POWER!

While receiving or transmitting data via RS-232 or IEEE-488, the LED’s RxD (Receiving) or TxD

(Transmitting) are flashing.

5.1 CAN Interface

Attention: Turn off the device with mains switch POWER before connecting/disconnecting

the interface cable.

The CAN interface is located at a male D-SUB-9 connector at the device rear. The pin assignment is

as follows:

Pin Signal

2 CAN_L (CAN Low)

3 CAN_GND (CAN Ground)

5 CAN_SHLD (CAN Shield)

7 CAN_H (CAN High)

For the CAN protocol, please see the description of the EDCP protocol in the manual

CAN-Interface

Multi-Channel High Voltage Power Supply Module

EHS xxx and EDS xxx

Thus, the device can be controlled with the program isegCANHVControl or with the iseg OPC server.

iseg Spezialelektronik GmbH Email: sales@iseg-hv.de Tel ++ 49 (0)351 / 26 996 - 0

Bautzner Landstr. 23 http://www.iseg-hv.de Fax ++ 49 (0)351 / 26 996 - 21

4 D - 01454 Radeberg / Rossendorf

Page 13

Spezialelektronik GmbH

5.2 RS-232- / USB Interface

Attention: Turn off the device with mains switch POWER before connecting/disconnecting

the interface cable.

Attention: If you device is equipped with RS-232 and USB Interface, only one of them must

be connected to the HPS at the same time.

RS-232

The RS-232 interface is located at a female D-SUB-9 connector at the device rear.

The electrical transfer is working indirectly coupled via RxD and TxD related to GND. The D-SUB-9

pin assignment is in the following table.

The cable connection to the computer is 1:1 (no zero modem-cable!). If no 9-pole cable is available,

then the connections shown in the table have to be made.

Signal HV-PS PC Connection

RS-232 D-SUB-9 Internal D-SUB-9 D-SUB-25 3-pol. cable

RxD 2 2 3

TxD 3 3 2

GND 5 5 7

4

6

8

─┐

─┤

─┘

4 20

6 6

8 5

─┐

─┤

─┘

USB

The USB interface is realized with a female USB-B connector at the device rear. Internal, the USB is

implemented as an USB-serial converter FTDI FT232R.

This device functions as virtual serial port in PC, and thus can be used with every program that supports a serial port, e. g. a terminal program or LabVIEW.

Programming

The following description applies both to RS-232 and USB interface.

For remote control, “RS-232” must be selected in Menu “F07 Set Interfce“. The device switches to

REMOTE state when receiving the first command via interface.

The (virtual) serial Interface is set to 9600 Bit/s, 8 Bit/character, no parity, 1 Stop-Bit.

The data transfer is character oriented, while the synchronization in direction "Computer to HV PS

unit” (Input direction) is made by echoes. The transfer direction “HV-PS to computer“ (Output direction) is free running.

The Echo can be permanently disabled (Factory setting is “Echo on“):

1. On front panel via Menu “F11 Set Echo“.

2. Via SCPI instruction set with EDCP

The command transfer works with ASCII code. Commands are terminated by <CR><LF> ($0D $0A

or 13 10). On input side, no leading zeros are needed. Output is fixed format without leading zero.

A minimum time delay of 20 ms between write and read instructions is needed.

iseg Spezialelektronik GmbH Email: sales@iseg-hv.de Tel ++ 49 (0) 351 / 26 996 - 0

Bautzner Landstr. 23 http://www.iseg-hv.de Fax ++ 49 (0) 351 / 26 996 - 21

D - 01454 Radeberg / Rossendorf 5

Page 14

Spezialelektronik GmbH

Windows USB driver installation

The FTDI VCP driver (Virtual COM Port) can be downloaded from:

http://www.iseg-hv.com Download Software USB driver for THQ/EHQ

The following steps are necessary for installation:

1. Extract the FTDI driver “CDM 2.04.16 WHQL Certified.zip“, e. g. to C:\Temp\

2. Connect the HV device to the computer via USB

3. The Found new Hardware wizard appears.

Please choose “No, not this time” in the first dialog and then click Next.

4. Choose “Install from a list or specific location” in the next dialog and then click Next:

iseg Spezialelektronik GmbH Email: sales@iseg-hv.de Tel ++ 49 (0)351 / 26 996 - 0

Bautzner Landstr. 23 http://www.iseg-hv.de Fax ++ 49 (0)351 / 26 996 - 21

6 D - 01454 Radeberg / Rossendorf

Page 15

Spezialelektronik GmbH

5. Please choose the directory you extracted the driver to and the click Next:

6. After some copying you get the final dialog:

It may be necessary to do the steps 3 to 6 again, before the device can be used

(the first time, a bus driver is installed, the second time, the virtual COM port driver is installed).

iseg Spezialelektronik GmbH Email: sales@iseg-hv.de Tel ++ 49 (0) 351 / 26 996 - 0

Bautzner Landstr. 23 http://www.iseg-hv.de Fax ++ 49 (0) 351 / 26 996 - 21

D - 01454 Radeberg / Rossendorf 7

Page 16

Spezialelektronik GmbH

RS-232/USB Interface Test under Windows

Determine the serial USB interface with Device Manager

Start the Device Manger with:

Start Settings Control Panel System Device Manager

All HPS devices with USB interface get an USB Serial Port assigned in section Ports (COM & LPT),

in this case COM3:

Test with HyperTerminal

HyperTerminal is included in Windows 2000 / XP and can be started with:

Start Programs Accessories Communications HyperTerminal

Create a new connection with menu „File New Connection“, name it e. g. “HPS” and click OK.

iseg Spezialelektronik GmbH Email: sales@iseg-hv.de Tel ++ 49 (0)351 / 26 996 - 0

Bautzner Landstr. 23 http://www.iseg-hv.de Fax ++ 49 (0)351 / 26 996 - 21

8 D - 01454 Radeberg / Rossendorf

Page 17

Spezialelektronik GmbH

The following dialog appears. Choose your serial port and click OK:

Please enter the interface parameters in the following dialog:

After clicking OK, the interface setup is finished.

iseg Spezialelektronik GmbH Email: sales@iseg-hv.de Tel ++ 49 (0) 351 / 26 996 - 0

Bautzner Landstr. 23 http://www.iseg-hv.de Fax ++ 49 (0) 351 / 26 996 - 21

D - 01454 Radeberg / Rossendorf 9

Page 18

Spezialelektronik GmbH

As last step, under:

File Properties Settings ASCII Setup

the setting “Send line ends with line feeds” has to be made (see following picture).

You can now test the communication with the device:

iseg Spezialelektronik GmbH Email: sales@iseg-hv.de Tel ++ 49 (0)351 / 26 996 - 0

Bautzner Landstr. 23 http://www.iseg-hv.de Fax ++ 49 (0)351 / 26 996 - 21

10 D - 01454 Radeberg / Rossendorf

Page 19

Spezialelektronik GmbH

5.4 IEEE-488 Interface (GPIB)

Attention: Turn off the device with mains switch POWER before connecting/disconnecting

the interface cable.

IEEE-488 Interface

The IEEE-488 bus interface was implemented with a NEC 7210 compatible IEEE controller. The following interface functions according to IEC 625 are available:

SH1 Source Handshake: all functions (no polling)

AH1 Acceptor Handshake: all functions (no polling)

T6 Talker: standard equipment

L4 Listener: standard equipment

To connect the device to the IEEE bus, a Micro-D25 male connector is located at the device rear. An

adapter cable with a 24 pin connector following IEEE-488.2 standard is available optional.

For remote control, the IEEE interface must be selected in Menu “F09 Set Interfce“ by choosing

“IEEE“. The IEEE address (0…30) can be selected in Menu “F11 Addr IEEE“. The device ships from

the factory with a IEEE address of 17.

When receiving control commands over IEEE, the device switches to REMOTE state and the yellow

LED “REMOTE” is lighting.

By pushing the LOCAL button, remote control is suspended and the device switches to LOCAL state.

If the device is in REMOTE state and high voltage is on, pushing ON/OFF turns off the HV generation

and the device switches to LOCAL state.

In both cases, when receiving new commands via interface, it switches back to REMOTE state.

Programming

The command transfer works with ASCII code. Commands are terminated by <CR><LF> ($0D $0A

or 13 10). Alternatively, the control line EOI (End or Identify) can be set together with the command’s

last character. On input side, no leading zeros are needed. Output is fixed format without leading

zero.

A minimum time delay of 5 ms between two IEEE commands is needed.

iseg Spezialelektronik GmbH Email: sales@iseg-hv.de Tel ++ 49 (0) 351 / 26 996 - 0

Bautzner Landstr. 23 http://www.iseg-hv.de Fax ++ 49 (0) 351 / 26 996 - 21

D - 01454 Radeberg / Rossendorf 11

Page 20

Spezialelektronik GmbH

5.5 Ethernet Interface

Attention: Turn off the device with mains switch POWER before connecting/disconnecting

the interface cable.

The Ethernet Interface with 10-MBit/s, Full-Duplex, is connected via RJ-45 socket on the device rear.

The device can be connected to a switch via patch cable. If it shall be connected to a PC directly, a

crossover cable has to be used.

“Ethernet” has to be set in menu “F09 Set Interfce“. The additional settings (IP address, net-mask,

default gateway) have to be made with the SCPI Instruction set with EDCP. This can be done over

Ethernet or RS-232. Ex works settings are as follows:

IP-address: 192.168.16.13

Net mask: 255.255.255.0

Default Gateway: 192.168.16.1

Command port: 10001 (fixed)

The connection can be tested with the ping command (Start programs accessories command).

C:\>ping 192.168.16.13

Ping will done for 192.168.16.13 with 32 bytes data:

Answer from 192.168.16.13: bytes=32 time=4ms TTL=128

Answer from 192.168.16.13: bytes=32 time=4ms TTL=128

Answer from 192.168.16.13: bytes=32 time=4ms TTL=128

Answer from 192.168.16.13: bytes=32 time=4ms TTL=128

Ping statistic for 192.168.16.13:

Package: sent = 4, received = 4, lost = 0

Time in millisecond:

minimum = 1ms, maximum = 4ms, average = 1ms

During communication the HV unit act as server, the control PC act as client. The following table

shows the principle sequence of communication PC to HV unit.

Step Function call Computer HV-Unit HV-Unit Computer

1. connect() SYN

2. SYN, ACK

3. ACK

4. send() "*IDN?\r\n"

5. recv() "iseg Spezialelektronik GmbH [...]"

6. closesocket() FIN, ACK

7. FIN, ACK

8. ACK

The first three packages are for the establishing of a TCP-Connection (three way handshake). Fourth

step is the inquiry from PC to HV unit. The order is ASCII coded in data field of the TCP packet. The

answer is also ASCII coded send to the PC in step 5. Package No. 6 confirms the receipt of the

packet and sends a FIN for termination of connection. Step 7 and 8 are the confirmation of termination of connection from HV unit and PC.

The communication can be monitored with a network sniffer (e. g. Wireshark). Control is done with

the instruction sets described later. The preferred command set for Ethernet is “SCPI with EDCP”, as

you can build longer Frames which reduces Ethernet Overhead.

iseg Spezialelektronik GmbH Email: sales@iseg-hv.de Tel ++ 49 (0)351 / 26 996 - 0

Bautzner Landstr. 23 http://www.iseg-hv.de Fax ++ 49 (0)351 / 26 996 - 21

12 D - 01454 Radeberg / Rossendorf

Page 21

Spezialelektronik GmbH

Programming

Simple programming example (without error handling) for communication with the HV device over

Ethernet. This program was compiled and tested with Microsoft Visual C++ 6.0 on Windows XP.

#include <stdio.h>

#include <winsock.h>

int main(int argc, char *argv[])

{

WSADATA wsadata;

SOCKET sock;

SOCKADDR_IN sockaddr_in;

int retcode;

char cmd[255] = "*IDN?\r\n";

char ans[255];

// init sockets (Berkeley style, UNIX compatible)

WSAStartup(2, &wsadata);

// create TCP socket

sock = socket(AF_INET, SOCK_STREAM, IPPROTO_TCP);

// bind socket to dynamic port

memset(&sockaddr_in, 0, sizeof(sockaddr_in));

sockaddr_in.sin_family = AF_INET; // UDP, TCP

sockaddr_in.sin_port = htons(10001); // Remote Port

sockaddr_in.sin_addr.S_un.S_un_b.s_b1 = 192; // IP address

sockaddr_in.sin_addr.S_un.S_un_b.s_b2 = 168;

sockaddr_in.sin_addr.S_un.S_un_b.s_b3 = 16;

sockaddr_in.sin_addr.S_un.S_un_b.s_b4 = 13;

// connect to server (three way handshake)

connect(sock, (SOCKADDR *)&sockaddr_in, sizeof(SOCKADDR_IN));

// send command to server

send(sock, cmd, strlen(cmd), 0);

// read answer from server

retcode = recv(sock, ans, sizeof(ans), 0);

// close socket (three way handshake) and clean up

closesocket(sock);

WSACleanup();

// print answer to screen

printf("%s\n", ans);

return 0;

}

iseg Spezialelektronik GmbH Email: sales@iseg-hv.de Tel ++ 49 (0) 351 / 26 996 - 0

Bautzner Landstr. 23 http://www.iseg-hv.de Fax ++ 49 (0) 351 / 26 996 - 21

D - 01454 Radeberg / Rossendorf 13

Page 22

Spezialelektronik GmbH

5.6 Analogue I/O Interface

Attention: Turn off the device with mains switch POWER before connecting/disconnecting

the interface cable.

Attention: All control inputs and outputs are indirect coupled to the HV-OUT.

All control inputs and outputs are available at the male D-SUB-9 connector on the rear side of the unit

according to the following table.

Analogue I/O with male SUB-D-9 connector

Pin 1 / 6 @GND Ground

Pin 2 V

Pin 3 INHIBIT TTL level / Input

Pin 4 V

Pin 5 Cmode TTL level / Output

Current monitor

I-MON

Current control

I-SET

Low = active: ⇒ V

High / offen: ⇒ V

= 0

OUT

according set values

OUT

Low = Current control (CC), High = Voltage control (CV)

reaction time < 100 ms

Pin 7 V

Pin 8 V

Pin 9 V

Voltage monitor

V-MON

Voltage control

V-SET

Internal reference voltage V

REF

= 5 V / 1 mA

REF

Operation with analogue I/O

You can choose control with the analogue interface “AIF” in the menu „F07 Set Interfce“ and then

switch push button “LOCAL” in order to switch to analogue remote control, the yellow LED “REM” is

lighting now (exception see “Auto AIF”).

By pushing LOCAL again the mode runs back to menu and „HV-OFF”. To use the unit in LOCAL

mode again you must choose an other interface in the menu „F07 Set Interfce” (e.g. RS-232).

The generation of high voltage will start with pushing “HV ON” (exception see “Auto AIF”) according

to the analogue set values and will stop with pushing “HV OFF” or with external INHIBIT (LOW = active).

The reaction to the active INHIBIT signal is according to the setting of the KILL function:

• KILL disable: generation of HV will be stopped, with Low to High on INHIBIT the output will be

ramp to the chosen voltage/current with the programmed ramp speed!

• KILL enable: generation of HV will be stopped, with Low to High on INHIBIT the output will be

volt-free. The generation of high voltage will start with pushing “HV ON” only

(exception see “Auto AIF”).

Automatic function “Auto AIF“

If the control mode is chosen with analogue interface “AIF” in the menu „F07 Set Interfce“ you can set

the automatic function “Auto AIF” in the menu „F06 Auto AIF“ to “ON”.

Now it is able to start the generation of HV according to the set values with the INHIBIT signal Low to

High, without pushing “HV ON”!

Caution! The high voltage generation will start with each Low to High Signal on INHIBIT!

If you choose an other interface in the menu „F07 Set Interfce“, the function “Auto AIF” will be set to

“OFF” automatically. If you will use „Auto AIF“ again, you must choose “AIF” in the menu „F07 Set

Interfce“ before and than set the automatic function “Auto AIF” in the menu „F06 Auto AIF“ to “ON”.

iseg Spezialelektronik GmbH Email: sales@iseg-hv.de Tel ++ 49 (0)351 / 26 996 - 0

Bautzner Landstr. 23 http://www.iseg-hv.de Fax ++ 49 (0)351 / 26 996 - 21

14 D - 01454 Radeberg / Rossendorf

Page 23

Spezialelektronik GmbH

Control inputs

• Remote Control Voltage (CV) V

= 0 to 5 V

V-SET

The output voltage is proportionally to the external control voltage of 0 to 5 V DC between

pin 8 (+ V

Example: HPp 40 357, maximum voltage = 4 kV

V

(V) Output voltage (kV)

V-SET

, indirect coupled) and pin 6 (@GND, indirect-coupled).

V-SET

5.0 corresponds to 4.0

2.5 corresponds to 2.0

1.0 corresponds to 0.8

• Remote Control Current (CC): V

The output current is proportionally to the external control voltage of 0 to 5 V DC between

pin 4 (+ V

, indirect coupled) and pin 6 (@GND, indirect-coupled).

I-SET

Example: HPp 40 357, maximum current = 350 mA

V

(V) Output current (mA)

I-SET

= 0 to 5 V

I-SET

5.0 corresponds to 350

2.5 corresponds to 175

1.0 corresponds to 70

• INHIBIT TTL level

High voltage generation will be shut off with help of the TTL-level LOW on pin 3 related to GND analogue (@GND-analogue indirect-coupled to GND-HV and metal box).

High voltage generation will be started according to the settings with TTL-level Low to High or open

on pin 3 in case of “KILL” is disabled. If “KILL” is enabled also the push button “HV-ON” has to be

pushed.

Monitor outputs

• Voltage monitor output V

An analogue monitor signal proportionally to the output voltage is available. This monitor voltage is

measured between pin 7 (V

, indirect-coupled) and pin 6 (@GND, indirect-coupled).

V-MON

Example: HPp 40 357, maximum output voltage = 4 kV

V

(V) Output voltage (kV)

V-MON

= 0 to 5 V

V-MON

5.0 corresponds to 4.0

2.5 corresponds to 2.0

1.0 corresponds to 0.8

• Current monitor output V

An analogue monitor signal proportionally to the output current is available. This monitor voltage is

measured between pin 2 (V

, indirect-coupled) and pin 6 (@GND, indirect-coupled).

I-MON

Example: HPp 40 357, maximum output current = 350 mA

V

(V) Output current (mA)

I-MON

= 0 to 5 V

I-MON

5.0 corresponds to 350

2.5 corresponds to 175

1.0 corresponds to 70

iseg Spezialelektronik GmbH Email: sales@iseg-hv.de Tel ++ 49 (0) 351 / 26 996 - 0

Bautzner Landstr. 23 http://www.iseg-hv.de Fax ++ 49 (0) 351 / 26 996 - 21

D - 01454 Radeberg / Rossendorf 15

Page 24

Spezialelektronik GmbH

6 Command sets

6.1 SCPI command set with EDCP

This is the recommended command Set.

To use this command set, choose “EDCP” in the menu or the *INSTR command. (EDCP = Enhanced

Device Communication Protocol). This command set is oriented on the iseg EDCP CAN Protocol with

Status and Event handling.

The Status and Event Status Fields are explained after the SCPI table.

Common Commands

*IDN?

*CLS

*RST

*LLO

*GTL

*INSTR?

*INSTR,EDCP

:VOLTage

<Voltage>[V] Set Channel Voltage

:LIMit <Voltage>[V]

:BOUnds <Voltage>[V]

{ ON | OFF }

EMCY OFF

EMCY CLR

:CURRent

<Current>[A] Set Channel Current

:LIMit <Current>[A]

:BOUnds <Current>[A]

:EVent

CLEAR

:MASK <Word>

:MEASure

:VOLTage?

:CURRent?

:CONFigure

:RAMP

:VOLTage <RampSpeed>[V/s]

:VOLTage MAX

:CURRent <RampSpeed>[A/s]

:EVent

:CLEAR

:MASK

:KILL?

:KILL { 0 | 1 }

)1, )2

If the high voltage is shut down with :VOLT EMCY OFF, the channel is hold in state Emergency Off. To turn

on the High Voltage again, the state Emergency Off must be leaved with :VOLT EMCY CLR. Furthermore, the

Channel EventStatus Bit EEMCY must be cleared e. g. with *CLS.

Query Module Identification

Clear Module (Event-)Status

Reset device to save values

(Turn HV off with ramp, Vset= 0, Iset= Inominal)

Local Lockout (disable front panel buttons)

Goto Local (enable front panel buttons)

Query instruction set

Switch to EDCP SCPI command set

SCPI Commands

Set Voltage Limit

Set Channel Voltage Bounds

Set Channel On / Off (with configured ramp speed)

Shut Channel Emergency Off (without ramp)

Leave state emergency off

Set Current Limit

Set Channel Current Bounds

Clear Channel Event Status

Set Channel Event Mask

Query Measured Channel Voltage (V)

Query Measured Channel Current (A)

Set/Get module configuration

Set Module Voltage Ramp Speed

LPS only: disable Software Voltage Ramp

Set Module Current Ramp Speed

Clear Module Event Status

Query Module Kill Status

Set Kill Disable (0) or Kill Enable (1)

iseg Spezialelektronik GmbH Email: sales@iseg-hv.de Tel ++ 49 (0)351 / 26 996 - 0

Bautzner Landstr. 23 http://www.iseg-hv.de Fax ++ 49 (0)351 / 26 996 - 21

16 D - 01454 Radeberg / Rossendorf

Page 25

Spezialelektronik GmbH

:CONFigure

:ETHernet

:ADDRess <xxx.xxx.xxx.xxx>

:ADDRess?

:NETmask <xxx.xxx.xxx.xxx>

:NETmask?

:GATEway <xxx.xxx.xxx.xxx>

:GATEway?

:MAC?

:SERIAL

:BAUDrate?

:ECHO { 0 | 1 }

:ECHO?

:GPIB

:ADDRess?

:CAN

:ADDRess?

:READ

:VOLTage?

:LIMit?

:NOMinal?

:BOUnds?

:CURRent?

:LIMit?

:NOMinal?

:BOUnds?

:RAMP

:VOLTage?

:CURRent?

:MODule

:STATus?

:EVent

:STATus?

:MASK?

:SUPply?

:TEMPerature?

:CHANnel

:STATus?

:EVent

:STATus?

:MASK?

Set Ethernet IP Address

Query Ethernet IP Address

Set Ethernet IP Netmask

Query Ethernet IP Netmask

Set Ethernet IP Default Gateway

Query Ethernet IP Default Gateway

Query Ethernet MAC Address

RS-232/USB Configuration

Query Serial Baudrate

Set Serial Echo Off (0) or Echo On (1)

Query Serial Echo

Query IEEE-488/GPIB Address

Query CAN Address

Query Set Voltage (V)

Query Voltage Limit (V)

Query Nominal Voltage (V)

Query Voltage Bounds (V)

Query Set Current (A)

Query Current Limit (A)

Query Nominal Current (A)

Query Current Bounds (A)

Query Voltage Ramp Speed (V/s)

Query Current Ramp Speed (A/s)

Query Module Status Word

Query Module Event Status

Query Module Event Mask

Query Module Supply State

(1 = good, 0 = not good)

Query measured Module Temperature (°C)

Query Channel Status Word

Query Channel Event Status Word

Query Channel Event Status Mask

iseg Spezialelektronik GmbH Email: sales@iseg-hv.de Tel ++ 49 (0) 351 / 26 996 - 0

Bautzner Landstr. 23 http://www.iseg-hv.de Fax ++ 49 (0) 351 / 26 996 - 21

D - 01454 Radeberg / Rossendorf 17

Page 26

Spezialelektronik GmbH

Output formats for voltage and current:

Vnominal Output format voltage values

100 V ≤ V

1 kV ≤ V

10 kV ≤ V

< 1 kV 123.456V

nom

< 10 kV 1.23456E3V

nom

< 100 kV 12.3456E3V

nom

Inominal Output format current values

1 mA ≤ I

10 mA ≤ I

100 mA ≤ I

1 A ≤ I

10 A ≤ I

< 10 mA 1.23456E-3A

nom

< 100 mA 12.3456E-3A

nom

< 1 A 123.456E-3A

nom

< 10 A 1.23456A

nom

< 100 A 12.3456A

nom

Examples:

Read Module Identification:

*IDN?

iseg Spezialelektronik GmbH,HPp 40 207,680001,5.24

Set Voltage to 1000.501 V

:VOLT 1000.501

Set Current to 1.58 mA

:CURR 0.00158

Set Voltage Ramp speed to 300 Volt per second

:CONF:RAMP:VOLT 300

Advanced Examples:

Set and read back Voltage and Current:

:VOLT 2000.5; :READ:VOLT?; :CURR 0.2; :READ:CURR?

2.00050E3V;200.000E-3A

Read actual measured Voltage and Current:

:MEAS:VOLT?; CURR?

2.00028E3V;19.997E-3A

iseg Spezialelektronik GmbH Email: sales@iseg-hv.de Tel ++ 49 (0)351 / 26 996 - 0

Bautzner Landstr. 23 http://www.iseg-hv.de Fax ++ 49 (0)351 / 26 996 - 21

18 D - 01454 Radeberg / Rossendorf

Page 27

Spezialelektronik GmbH

Channel status (read access)

:READ:CHANnel:STATus?

Bit15 Bit14 Bit13 Bit12 Bit11 Bit10 Bit9 Bit8

isVLIM isCLIM isTRP isEINH isVBND isCBND res res

Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

isCV isCC isEMCY isRAMP isON isIERR res res

The ChannelStatus register describes the actual status. Depending on the status of the channel the

bits will be set or reset.

Bit Name Bit is 1 Bit is 0

isVLIM IsVoltageLimitExceeded Voltage limit set by V

IsCLIM IsCurrentLimitExceeded Current limit set by I

Trip is set when Voltage or Current

isTRIP IsTripExceeded

isEINH IsExtInhibit External Inhibit active No External Inhibit

isVBND IsVoltageBoundsExceeded Voltage out of bounds Voltage in bounds

isCBND IsCurrentBoundsExceeded Current out of bounds Current in bounds

IsCV IsControlledVoltage

IsCC IsControlledCurrent

isEMCY IsEmergencyOff Emergency off without ramp No Emergency Off

isON IsOn HV is On HV is Off

isRAMP IsRamping Ramp is running No Ramp is running

isIERR InputError Input error No Input error

res Reserved

limit or Iset has been exceeded

(when KillEnable=1)

Voltage control active (evaluation is

guaranteed when no ramp is running)

Current control active (evaluation is

guaranteed when no ramp is running)

is exceeded Voltage limit not exceeded

max

is exceeded Current limit not exceeded

max

No Trip

Voltage control not active

Current control not active

iseg Spezialelektronik GmbH Email: sales@iseg-hv.de Tel ++ 49 (0) 351 / 26 996 - 0

Bautzner Landstr. 23 http://www.iseg-hv.de Fax ++ 49 (0) 351 / 26 996 - 21

D - 01454 Radeberg / Rossendorf 19

Page 28

Spezialelektronik GmbH

Channel event status (read/write access)

:READ:CHANnel:EVent:STATus?

Bit15 Bit14 Bit13 Bit12 Bit11 Bit10 Bit9 Bit8

EVLIM ECLIM ETRP EEINH EVBNDs ECBNDs res res

Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

ECV ECC EEMCY EEOR EOn2Off EIER res Res

The Channel EventStatus register describes the captured status. Depending on the status of the

channel the bits will be set but not reset. A reset has to be done by the user by writing an 1 to this

event bit. All Events can be cleared by :EVENT:CLEAR.

Bit Name

EVLIM EventVoltageLimit Event: Voltage limit has been exceeded

ECLIM EventCurrentLimit Event: Current limit has been exceeded

Description

ETRIP EventTrip

Event: Trip is set when Voltage or Current limit or Iset has been exceeded (when KillEnable=1)

EEINH EventExtInhibit Event: External Inhibit

EVBNDs EventVoltageBounds Event: Voltage out of bounds

ECBNDs EventCurrentBounds Event: Current out of bounds

ECV EventControlledVoltage Event: Voltage control

ECC EventControlledCurrent Event: Current control

EEMCY EventEmergencyOff Event: Emergency off

EEOR EventEndOfRamp Event: End of ramp

EOn2Off EventOnToOff Event: Change from state "On" to "Off" without ramp

EIER EventInputError Event: Input Error

res Reserved

An event bit is permanently set if the corresponding status bit is 1 or is changing to 1. Different to the

status bit an event bit isn't automatically reset. A reset has to be done by the user by writing an 1 to

this event bit.

If one of the EventStatus Bits EVLIM, ECLIM, ETRIP, EEINH, EVBNDs, ECBNDs, EEMCY is set, it

prevents turning on the High Voltage again until the corresponding bit is cleared.

iseg Spezialelektronik GmbH Email: sales@iseg-hv.de Tel ++ 49 (0)351 / 26 996 - 0

Bautzner Landstr. 23 http://www.iseg-hv.de Fax ++ 49 (0)351 / 26 996 - 21

20 D - 01454 Radeberg / Rossendorf

Page 29

Spezialelektronik GmbH

ModuleStatus (read access)

:READ:MODule:STATus?

Bit15 Bit14 Bit13 Bit12 Bit11 Bit10 Bit9 Bit8

isKILena isTEMPgd isSPLYgd isMODgd isEVNTact isSFLPgd isnoRAMP isnoSERR

Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

res res res isSrvc res res res isADJ

The status bits as there are IsTemperatureGood, IsSupplyGood, IsModuleGood, IsEventActive, IsSafetyLoopGood, IsNoRamp and IsNoSumError indicate the single status for the complete module.

Bit Name Bit is 1 Bit is 0

isKILena IsKillEnable Module is in state Kill enable Module is in state Kill disable

isTEMPgd IsTemperatureGood

isSPLYgd IsSupplyGood Power Supply is good Power Supply is not good

isMODgd IsModuleGood Module status is good Module status bad

isEVNTact IsEventActive At least one masked Event is active No masked Event is active

isSFLPgd IsSafetyLoopGood Safety Loop is closed Safety Loop is open

isnoRAMP IsNoRamp All channels stable, no ramp active. At least one channel is ramping

isnoSERR IsNoSumError No sum error Sum error active

isSrvc IsServiceNeeded

isADJ IsFineAdjustment Adjustment is on Adjustment is off

Res Reserved

Module Temperature < 55 °C Module temperature > 55°C

High voltage is turned off

Hardware failure detected:

consult manufacturer

No Hardware failure detected

iseg Spezialelektronik GmbH Email: sales@iseg-hv.de Tel ++ 49 (0) 351 / 26 996 - 0

Bautzner Landstr. 23 http://www.iseg-hv.de Fax ++ 49 (0) 351 / 26 996 - 21

D - 01454 Radeberg / Rossendorf 21

Page 30

Spezialelektronik GmbH

Module EventStatus (read/write access)

:READ:MODule:EVent:STATus?

The Module EventStatus register describes the captured status. Depending on the status of the module the bits will be set but not reset. A reset has to be done by the user by writing an 1 to this event

bit. All Events can be cleared by :CONFIGURE:EVENT:CLEAR.

Bit15 Bit14 Bit13 Bit12 Bit11 Bit10 Bit9 Bit8

Res ETMPngd ESPLYngd res res ESFLPngd res res

Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

res res res res ESrvc res res res

ETEMPngd EventTemperatureNotGood Event: Temperature is above 55°C

ESPLYngd EventSupplyNotGood Event: at least one of the supplies is not good

ESFLPngd EventSafetyLoopNotGood Event: Safety loop is open

Event: A hardware failure of the HV module has been detected. The HV is

ESrvs EventService

res Reserved

switched off without the possibility to switch on again. Please consult the

iseg Spezialelektronik GmbH.

iseg Spezialelektronik GmbH Email: sales@iseg-hv.de Tel ++ 49 (0)351 / 26 996 - 0

Bautzner Landstr. 23 http://www.iseg-hv.de Fax ++ 49 (0)351 / 26 996 - 21

22 D - 01454 Radeberg / Rossendorf

Page 31

Spezialelektronik GmbH

6.2 ET command set (Compatibility to old HPS)

This command set is selected via Menu “F10 Set Instruct” “ET”.

Setting commands

Command: Command example:

Command to set an output voltage:

U,<Voltage>kV U,1.000kV

Command to set a voltage limit:

UL,<Voltage>kV UL,1.000kV

Command to set an output current:

I,<Current>mA I,30mA

Command to set a current limit:

IL,<Current>mA IL,30mA

Command to set the Voltage ramp speed:

RAMP,<Rampspeed>V/s RAMP,3000V/s

Command to switch the high voltage on and off:

HV,ON

HV,OFF

Command for setting the KILL function „Enable“ or „Disable“:

KILL,ENable KILL,EN

KILL,DISable

Command for Emergency off (The HV generation is shut off permanently and the set values for voltage and current are set to Zero):

EMCY OFF

Read out the setting commands

Command: Response example:

Read out the set voltage:

STATUS,U U, RANGE=3.000kV, VALUE=2.458kV

Read out the voltage limit:

STATUS,UL UL, RANGE=3.000kV, VALUE=2.458kV

Read out the set current:

STATUS,I I, RANGE=100.0mA, VALUE=30.0mA

Read out the current limit:

STATUS,IL IL, RANGE=100.0mA, VALUE=30.0mA

Read out the voltage ramp speed:

STATUS,RAMP RAMP, RANGE=3000V/s, VALUE=1000V/s

iseg Spezialelektronik GmbH Email: sales@iseg-hv.de Tel ++ 49 (0) 351 / 26 996 - 0

Bautzner Landstr. 23 http://www.iseg-hv.de Fax ++ 49 (0) 351 / 26 996 - 21

D - 01454 Radeberg / Rossendorf 23

Page 32

Spezialelektronik GmbH

Read out the measurement values

Read measured output voltage:

STATUS,MU UM, RANGE=3.000kV, VALUE=2.458kV

Read measured output current:

STATUS,MI IM, RANGE=100.0mA, VALUE=25.3mA

Read out the device status

STATUS,DI DI, b

15 b14 b13 b12 b11 b10 b9 b8 b7 b6 b5 b4 b3 b2 b1 b0

0 1

#define IERR b15 no Input Error Input error

#define RAMP b14 no Ramp Ramp

#define EMCY b13 no Emergency Emergency

#define TRIP b12 no Trip error Trip error

#define RES5 b11 Reserved

#define RES4 b10 Reserved

#define RES3 b9 Reserved

#define RES2 b8 Reserved

#define SERR b7 no Sum error Sum error

#define IREG b6 no Current control Current control

#define VREG b5 no Voltage control Voltage control

#define POL b4 negative Polarity positive Polarity

#define INH b3 no external Inhibit external Inhibit

#define RES1 b2 Reserved

#define KILena b1 Kill disable Kill enable

#define ON b0 no High voltage active High voltage active

Read out the LAM status

STATUS,LAM

LAM,ERROR External Inhibit occurred during Kill enable

LAM,EMERGENCY High Voltage was shut down with Emergency Off

LAM,SAFETY LOOP Safety Loop was opened

LAM,INHIBIT External Inhibit occurred

LAM,TRIP ERROR Software current trip occurred

LAM,VOLTAGE LIMIT Voltage has exceeded set value

LAM,CURRENT LIMIT Current has exceeded set value

LAM,INPUT ERROR Wrong command received

LAM,OK Status OK

Read out the device identification

ID ID, iseg Spezialelektronik r5.01 sn.680041 Typ HPn 30 107

iseg Spezialelektronik GmbH Email: sales@iseg-hv.de Tel ++ 49 (0)351 / 26 996 - 0

Bautzner Landstr. 23 http://www.iseg-hv.de Fax ++ 49 (0)351 / 26 996 - 21

24 D - 01454 Radeberg / Rossendorf

Page 33

Spezialelektronik GmbH

6.3 SCPI command set (Compatibility to old HPS)

This instruction set ist selected with Menu “F10 Set Instruct“ “SCPI“.

Setting commands

Command: Command example:

Command to set an output voltage:

:VOLTage <Voltage>kV :VOLT 1.000kV

Command to set a voltage limit:

:LIMIT:VOLTage <Voltage>kV :LIMIT:VOLT 1.000kV

Command to set an output current:

:CURRent <Current>mA :CURR 30mA

Command to set a current limit:

:LIMIT:CURRent <Current>mA :LIMIT:CURR 30mA

Command to set a voltage ramp speed:

:CONFigure:RAMP <Rampspeed>V/s :CONF:RAMP 3000V/s

Command to turn high voltage on and off:

:VOLTage ON

:VOLTage OFF

Command for Emergency off (The HV generation is shut off permanently and the set values for voltage and current are set to Zero):

:VOLTage EMCY OFF

Command for setting KILL function “Enable“ or “Disable“:

:CONFigure:KILL ENable :CONF:KILL EN

:CONFigure:KILL DISable

Read out the setting commands

Command: Response example:

Command to read out the set voltage:

:READ:VOLTage? U, RANGE=3.000kV, VALUE=2.458kV

Command to read out the voltage limit:

:READ:LIMIT:VOLTage? UL, RANGE=3.000kV, VALUE=2.458kV

Command to read out the set current:

:READ:CURRent? I, RANGE=100.0mA, VALUE=30.0mA

Command to read out the current limit::

:READ:LIMIT:CURRent? IL, RANGE=100.0mA, VALUE=30.0mA

Command to read out the voltage ramp speed:

:READ:RAMP? Ramp, RANGE=3000V/s, VALUE=3000V/s

iseg Spezialelektronik GmbH Email: sales@iseg-hv.de Tel ++ 49 (0) 351 / 26 996 - 0

Bautzner Landstr. 23 http://www.iseg-hv.de Fax ++ 49 (0) 351 / 26 996 - 21

D - 01454 Radeberg / Rossendorf 25

Page 34

Spezialelektronik GmbH

Read out the measurement values

Read measured output voltage:

:MEASure:VOLTage? UM, RANGE=3.000kV, VALUE=2.458kV

Read measured output current:

:MEASure:CURRent? IM, RANGE=100.0mA, VALUE=25.3mA

Read out the device status

:READ:STATus? DI, b

15 b14 b13 b12 b11 b10 b9 b8 b7 b6 b5 b4 b3 b2 b1 b0

For status field description, see chapter 6.1, device status.

Read out the LAM status

:READ:LAM?

For LAM status description, see chapter 6.1, LAM status.

Read out the device identification

:READ:IDNT? ID, iseg Spezialelektronik r5.01 sn.680042 Typ HPn 30 107

6.4 Common command set (Compatibility to old HPS)

The Common commands can be used all the time, independently from selected instruction set (ET or

SCPI).

A response example for commands that returns an answer is shown at the right side (printed Italic).

Command Response example:

Read out the device identification

*IDN? ID, iseg Spezialelektronik r5.01 sn.680043 Typ HPn 30 107

Device control

*LLO Local Lockout: disable local buttons

*GTL Go to Local: enable local buttons

*CLS Clear Status: clear error status

*RST Reset: Device is rebooting

Read/change Instruction set

*INSTR? Query current instruction set Instruction type, SCPI

*INSTR,SCPI Change to SCPI instruction set

*INSTR,ET Change to ET instruction set

Read/change RS-232 Echo state

*ECHO? Query Echo status Echo off

*ECHO*ON Turn on Echo

*ECHO*OFF Turn off Echo

iseg Spezialelektronik GmbH Email: sales@iseg-hv.de Tel ++ 49 (0)351 / 26 996 - 0

Bautzner Landstr. 23 http://www.iseg-hv.de Fax ++ 49 (0)351 / 26 996 - 21

26 D - 01454 Radeberg / Rossendorf

Page 35

Spezialelektronik GmbH

7 Troubleshooting

7.1 Error messages on Displays

Error messages during operation

Display: Meaning:

SAFETYLOOP Safety loop (Interlock) is not closed. Device can’t create high voltage.

EXTERNAL INHIBIT No high voltage can be created because of external inhibit (analogue I/O).

EMERGENCY High voltage has been shut down without ramp due to Emergency Off.

CURRENT TRIP Current set value reached during Kill enable. High voltage has been shut

down without ramp.

VOLTAGE LIMIT Voltage Limit V

has been exceeded.

max

In Kill enable, the high voltage is shut down without ramp.

CURRENT LIMIT Current Limit I

has been exceeded.

max

In Kill enable, the high voltage is shut down without ramp.

OVERTEMPERATURE High voltage has been shut down because of over temperature.

Let device cool down.

ERROR SUPPLY Internal power supply is bad. Device must be shipped to service.

ERROR SERVICE High voltage generator is bad. Device must be shipped to service.

Error messages during boot

Display: Meaning:

ERROR RTC Real time clock battery is low. Contact service.

CONTACT SERVICE Device must be shipped to the factory for service.

ERROR AIF Analogue interface (optional) is not working. Contact service.

ERROR IEEE IEEE interface (optional) is not working. Contact service.

7.2 General errors

Unit does not provide output voltage, and

the displays are not lighting

⇒

- check mains voltage and connection

Unit does not provide output voltage but

the displays are ligthing.

During switch ON external fuses are

blowing

If these provisions do not lead to a good result, this unit has to be checked from an authorised

agent or must be shipped to the factory.

iseg Spezialelektronik GmbH Email: sales@iseg-hv.de Tel ++ 49 (0) 351 / 26 996 - 0

Bautzner Landstr. 23 http://www.iseg-hv.de Fax ++ 49 (0) 351 / 26 996 - 21

D - 01454 Radeberg / Rossendorf 27

⇒

⇒

- Check of environmental temperature

(TA ≤ 35 °C)

- Check of Control

- Replace to slow blow fuse (switch ON

current peak 25 A)

Loading...

Loading...