RISE

Assembly Instructions

UPDATED

July 1, 2013

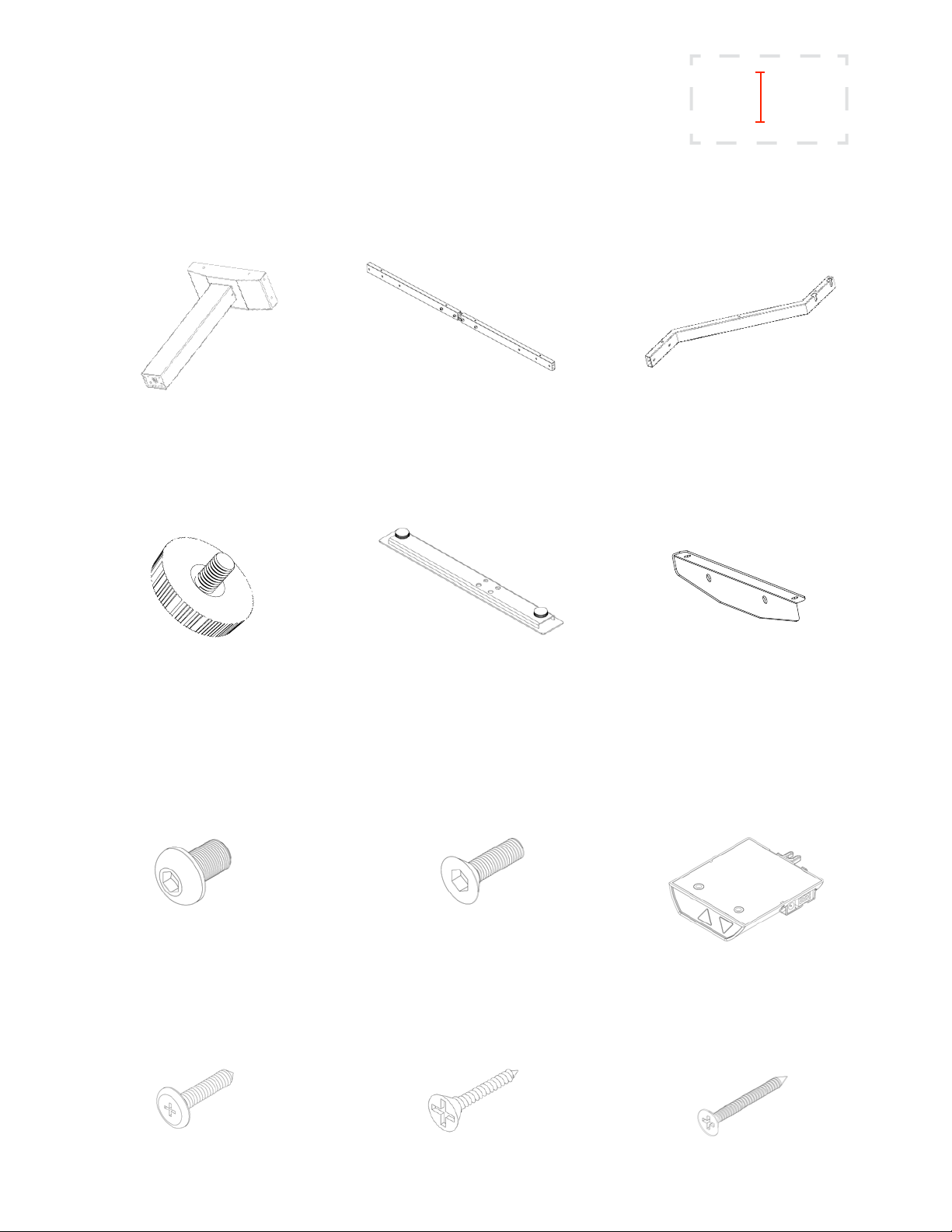

Part List: caution - only use the parts and hardware provided

[xx]

[93] - Silver

[01] - Black

68002348 [xx]

Height Adjustable Leg

2 pcs.

RISE - Glide

(attached to feet)

4 pcs.

68002547 [xx] - 29”- 45” or

54006700 [xx] - 44” - 75” or

68002513 [xx] - 76” - 90”

Adjustable Bar

1 pc.

68002505 [xx]

Foot

2 pcs.

68002509 [xx]

Kneesaver Z-Bar

2 pcs.

68001089

Side Support

2 pcs.

Fix-Kit- 1

M8 x 16mm

Panhead Bolt (Black)

8 pcs.

Fix-Kit- 4

3/16” x 3/4”

Panhead Wood Screw

6 pcs.

Fix-Kit- 2

M8 x 25mm

Countersunk Bolt (Silver)

8 pcs.

Fix-Kit- 5

1/8” x 5/8”

Countersunk Wood Screw

2 pcs.

68002462

Standard (2 leg)

Up/Down Switch

1 pcs.

Fix-Kit- 3

3/16” x 2-1/8”

Countersunk Wood Screw

8 pcs.

Fix-Kit- 6

Plastic Round Cap

12 pcs.

QKA - Tableclip

Plastic Wire Clip

6 pcs.

55750100

Plastic

Rectangular End-Cap

4 pcs.

68002462-PS

Leg Motor Cable

(attached to motors)

Power Adaptor

1 pc.

2 pcs.

Note: The hardware bag may contain extra components.

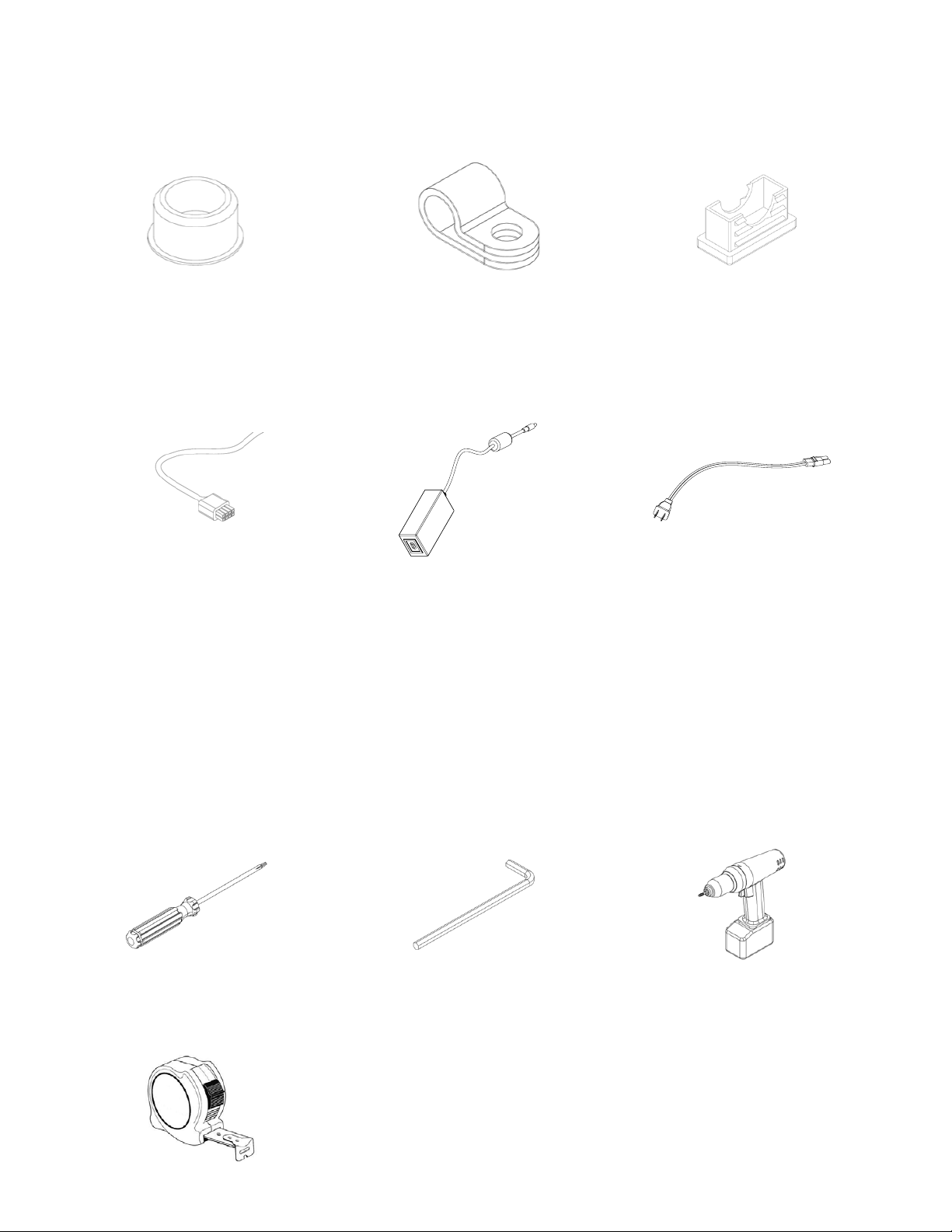

Tools Required:

68002462-PS-CABLE

Power Cable

1 pc.

Phillips Screwdriver M5 Hexagonal Wrench Electric Drill with

Phillips Head Bit

Tape Measure

Assembly Instructions: caution - please read notes carefully

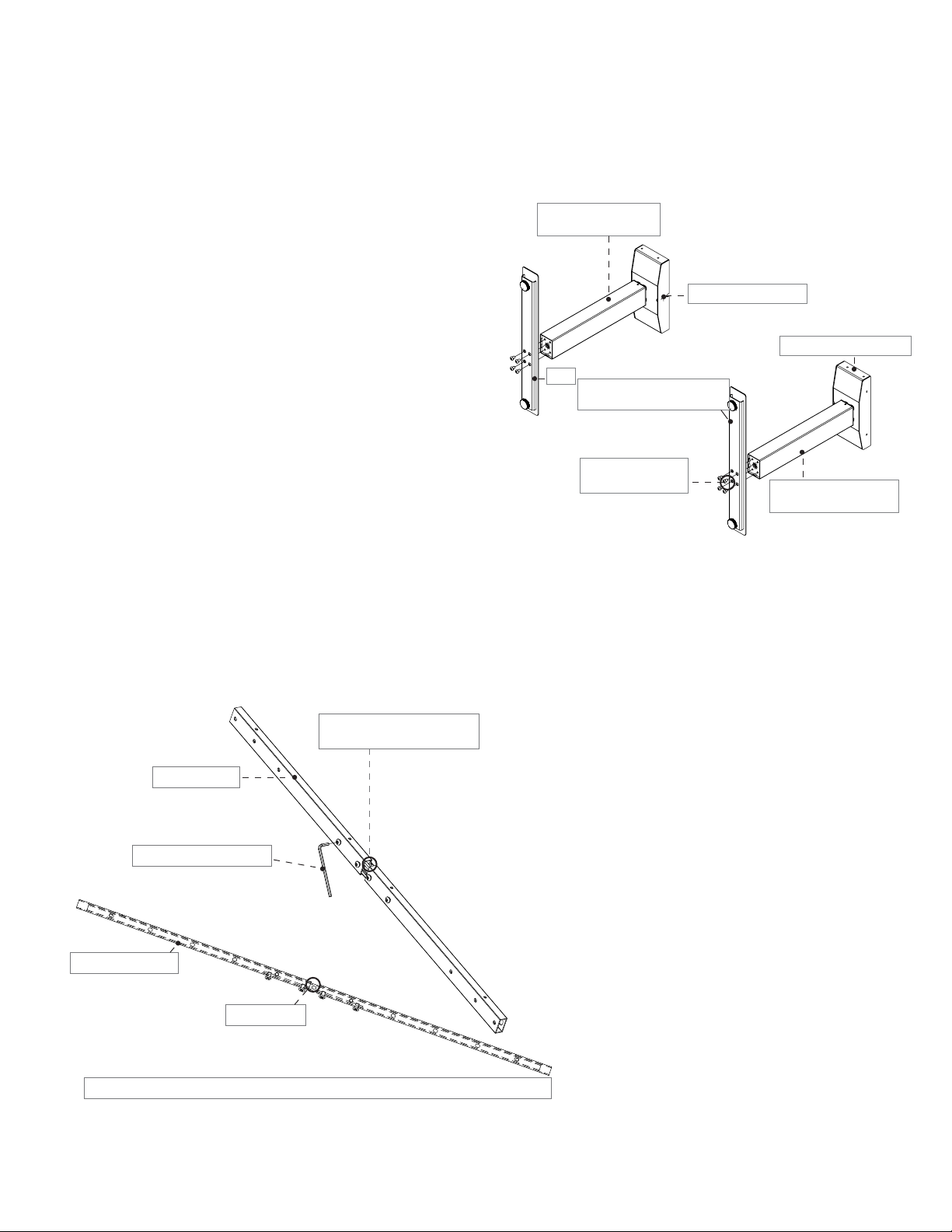

1. Attach Feet to Height Adjustable Legs

Position the 2 Height Adjustable Legs making sure

the wire cutouts on the Motor Housings are facing

each other.

Using an M5 Hexagonal Wrench attach the Feet to the

Height Adjustable Legs with 8 Black M8x16mm

Panhead Bolts. Make sure the longer sides of the Feet

are facing the front as shown in Figure 1.

Note: Both Height Adjustable Legs are identical.

Left Height Adjustable

Leg Sub-Assembly

Motor Housing Cutout

Foot

Longer side of the Feet to be

at the front of the desk

Black M8 x 16mm

Panhead Bolts

Figure 1. Attach Feet to Height Adjustable Legs

2. Adjust Adjustable Bar Width

Front of Motor Housing

Right Height Adjustable

Leg Sub-Assembly

Guiding hole for symmetrical

extension and retraction

Adjustable Bar

Loosen all 4 Center Bolts

Outer Square Tube

Inner Channel

Make sure all 4 holes on the Outer Square Tube align with the 4 holes of the Inner Channel

Figure 2. Adjust Adjustable Bar Width

Using an M5 Hexagonal Wrench, loosen the 4 Center

Bolts.

Expand or retract the Adjustable Bar to the desired

width while making sure the top holes of the Outer

Square Tube align with the holes of the Inner Channel.

Use the Center Hole of the Inner Channel as guide for

symmetry.

After achieving the desired width, tighten the 4 Center

Bolts to secure the Adjustable Bar subassembly. See

Figure 2.

Note: For Worksurfaces less than 48”, two crossbars

are provided.

3. Attach Adjustable Bar to Motor Housings

Facing the rear of the Height Adjustable Leg Assemblies, use an M5 Hexagonal Wrench to fasten the

Adjustable Bar with the 4 Silver M8x25mm Countersunk bolts onto the rear of the Motor Housings.

Make sure to use the 2 outer holes on each end of the Adjustable Bar.

The 4 Center Bolts of the Adjustable Bar should be facing forward towards the Motor Housings.

After fastening the Adjustable Bar, install the 2 Rectangular Plastic End-Caps on each end of the Adjustable

Bar. See Figure 3.

Rectangular Plastic End-Caps

Silver M8 x 25mm Countersunk Bolts

Adjustable Bar with 4 Center Bolts facing forwards

Rear of Motor Housing

Use Outer 2 holes

Figure 3. Attach Adjustable Bar to Motor Housings

Note: For worksurfaces less than 48”, attach crossbars to front and back of Motor Housing.

4. Attach the Kneesaver Z-Bars

Position the Sub-Assembly upright and face the front. The Adjustable Bar should be in the rear.

Loosen the 4 Adjusting Bolts in the middle of the Adjustable Bar while making sure to not change the width

alignment performed earlier.

Locate the slotted end of each Kneesaver Z-Bar and slide it between the Adjustable Bar and the back of the

Adjusting bolts. Tighten the bolts to secure the Kneesaver Z-Bars to the Adjustable Bar. Note: Both Kneesaver

Z-Bars are identical. See Figure 4.

Note: For worksurfaces less than 48”, Kneesaver Z-Bars are not provided.

Loosen Adjusting Bolts to

allow installation of Kneesaver

Z-Bars and tighten back after

positioning.

Figure 4. Attach Kneesaver Z-Bars to Adjustable Bar

After the Kneesaver Z-Bars have been fastened to the Adjustable Bar,

fasten the other ends of the Kneesaver Z-Bars to the front of the

Motor Housings using the 4 Silver M8x25mm Countersunk bolts.

Install the 2 Rectangular Plastic End-Caps. See Figure 5.

Silver M8 x 25mm

Countersunk Bolts

Figure 5. Attach Kneesaver Z-Bars to front of Motor Housings

Install the 8 Plastic Round Caps on the front of the Kneesaver Z-Bars.

See Figure 6.

Rectangular Plastic End-Caps

Plastic Round Caps

Figure 6. Attach Plastic Round Caps to front of Kneesaver Z-Bars

Install 6 Plastic Round Caps on the back of the Adjustable Bar.

See Figure 7.

Figure 7. Attach Plastic Round Caps to back of Adjustable Bar

Plastic Round Caps

NOTE:

· Ensure motor is properly positioned into the motor housing

· Ensure motor cable stain relief is positioned in the motor housing cut-out

· Ensure all motor connectors are properly connected

Connectors

Strain Relief

Motor Motor Housing

5. Install the Worksurface

Place the Worksurface on the oor with the bottom facing up. Make sure to lay it on a protective

layer to prevent scratching.

Using a tape measure, position the frame so that the distance between the back edge of the

Worksurface is 3” away from the back of the Adjustable Bar.

Depending on the size of the Worksurface selected, ensure to leave equal distances on both sides

of the frame.

Using an Electrical Drill with a Phillips Bit, fasten the frame onto the Worksurface with the 3/16” x

2-1/8” Countersunk Wood Screws. See Figure 8.

3/16” x 2-1/8” Countersunk

Wood Screws

Figure 8. Install the Worksurface

Note: For Bases 30” - 36” wide, refer to the last page for Side Support

Installation Instructions.

Note: For Digital Readout Memory Switch see seperate instruction guide.

6. Mount the Standard Up/Down Switch

Warning: Make sure the Power is disconnected until table is fully assembled

Select a convenient location on the underside of the Worksurface such that the Standard Up/Down

Switch can be easily accessed.

To mount the Standard Up/Down Switch use the 1/8” x 5/8” screws provided to fasten it on the

underside of the Worksurface in the location selected.

Connect the Motor Cables coming from each Height Adjustable Leg to the Standard Up/Down Switch.

Connect the Power Cable to the Standard Up/Down Switch.

Use the 6 Wire Clips and the 3/16”x3/4” Panhead Wood Screws to attach the Motor Cables and Power

Cable onto the underside of the Worksurface. See Figure 9.

1/8” x 5/8” Countersunk

Wood Screws

Figure 9. Mount the Standard Up/Down Switch

7. Initializing Instructions for Standard Up/Down Switch

Ensure the table is positioned in its nal location and that the Power Cord is plugged into an 110VAC

source.

Ensure all cables are properly connected.

1. Press and hold the UP and DOWN button at the same time on the Standard Up/Down Switch for

10 seconds

2. Press and hold the DOWN button to lower the table to its lowest point.

3. Table is ready to be used.

NOTE: It is sometimes necessary to press the DOWN button twice to start the

initialization as the system can be in dierent modes when initialization is

attempted.

Figure 10. Fully Assembled RISE Table

Side Support Installation Instructions - For bases 30” - 36” only

1. Install the two Side Supports with the four M8x25mm Countersunk Bolts onto the Left and Right

Motor Housings of the Rise base.

M8x25mm

Countersunk Bolt

Side Support

Figure 11. Installing Side Supports

Loading...

Loading...