2

Installation

and setting

up your

machine

Use and

care of your

machine

Advice, help

and troubleshooting

guide

ISE2v2 Washing Machine

user guide

ISE2 Washing Machine

Dear customer,

Thank you for choosing your ISE washing machine, we hope it offers you many years of

outstanding results and reliable service.

We would like you to be aware of how to correctly use the machine as it may differ from the

way that any previous machine you have owned may operate ISE appliances use the most

up to date technologies available to ensure that you receive the best possible wash results

whilst helping to protect and care for our environment along with saving you money in

detergent and energy use. It is both kind to your wallet and the planet.

We recommend that you read through this instruction manual even if you have used a

washing machine in the past and familiarise yourself with the machine and how it operates

before using the machine, paying careful attention to the installation section if you have

chosen to install the machine yourself.

We take great care in our products’ design and function, including this manual to ensure

that you get the best out of your new machine and we hope you enjoy how easy we try to

make life for you.

All contents © 2007 Independent Service Engineering Limited

Contents

Section1: Installation

Section5: Care & Maintenance

Section2: Programs

Section3: Using Your Machine

Section4: Safety & Security

Section6: Troubleshooting Guide

Pages 24-26

A guide to any general problems that you may encounter and how to resolve them

Pages 22-23

General care of your machine

Pages 20-21

The safety features of your ISE machine and how to use the security features

Pages 16-19

How to use the machine

Pages 5-15

A guide to programs available and the recommended uses

Pages 1-4

How to install the machine correctly and ensure optimum operation

transit

4

3

2

1

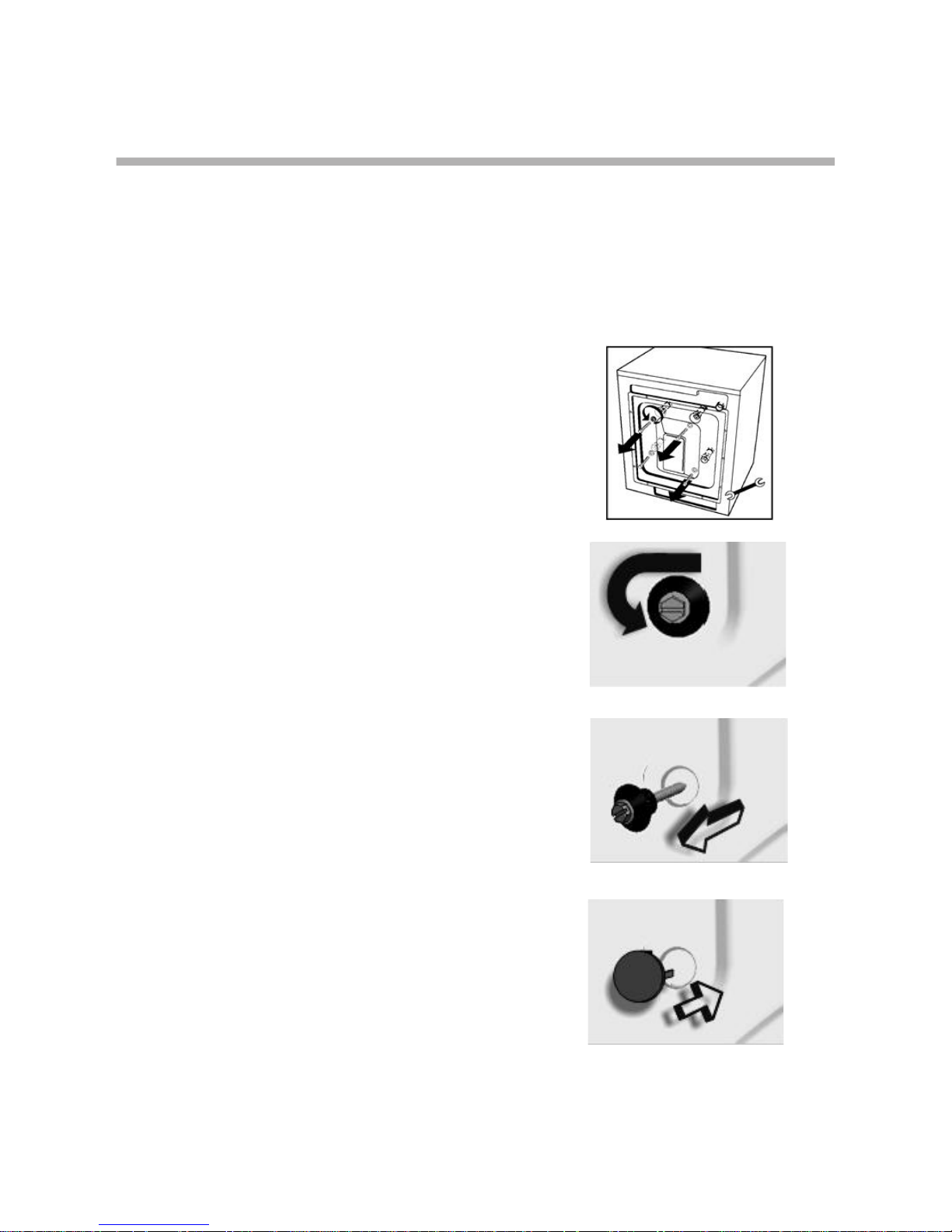

Section 1: Installation

Please pay attention to the following instructions before using your washing

machine.

Failure to install the machine correctly may result in irreperable damage which is not covered by your warranty. If you are unsure do not

proceed and call an appliance engineer or installer.

Loosen the screws by rotating counterclockwise

by a suitable wrench or spanner

Remove the screws by pulling them.

Often this may take a little force and manipulation to release the rubber mounts

To the holes where the transport screws have

been removed, insert the plastic transport screw

taps found in the accessories bag inside the

machine

The transportation screws that have been removed from the machine should be kept for any future transportationof the machine

Transportation screws, which are located at the

back of the machine, must be removed before

running the machine

1

water in

Suitable Installation Surroundings

It is important that you adhere to the following guidelines to get optimal noise and

vibration reduction from your machine:

The machine should be installed on a solid surface*•

The machine should not be installed on thick carpet or a loose carpet/flooring •

such as a rug, carpet tiles however are acceptable if properly fixed

The machine should be properly levelled•

Clearance should be allowed at either side and top for movement and ventilation •

purposes

Your machine is designed to be operated from UK mains votage only in a suitable •

area in accordance with legislation

* Installation to a “oating” oor or many types of wooden oor can cause excessive vibration if not installed and

levelled correctly

Connections

Your new machine requires three “connections” to operate as folows:

Cold water fill from a 3/4” BSP inlet connection•

Drain to either standpipe (ideal) or sink trap connection•

13A UK three-pin plug point•

Water Connection

The machine should be connected using the included 1.5M fill hose to a suitable water

outlet tap. Should you not have one avaibable please contact a plumber for further

assistance in fitting one.

The maximum recommended distance, with a suitable extended fill hose is 2.5M from

the outlet.

The fill hose should be connected using the washers supplied in order to prevent leaks

and should be tightened to “hand tight” to achive an optimal connection. Overtightening of this connection may result in the hose connection splitting so please be careful.

The machine will operate between 1 and 10 BAR pressure and the incoming water

pressure can greatly affect program times.

The water fill pipe should be connected to

the machine as shown in the diagram to the

right

CHECK AND ENSURE THERE ARE NO LEAKS AFTER CONNECTING!

2

water out

Drainage Connection

The machine should be connected using the fixed 1.5M drain hose to a suitable drainage point on your home plumbing. If this is not available or seems unsuitable you may

require a plumber to alter your drainage point to suit an automatic washing machine.

Should you require an extended drain hose to reach the drain point the maximum

advisable length of hose is 2.5M, extending any further than this may cause issues with

draining.

It is vital that the drain hose is elevated within the guidelines shown in the diagram below. Failure to do so can cause “backfilling” where the machine can fill from the home

plumbing causing malodourers and this is not covered by warranty

Be sure that water inlet and drain hoses are not folded, twisted, crushed or elon-•

gated by stretching

Water drain hose should be mounted at a height of minimum 60 cm, maximum •

100 cm from the ground

The end of the drain hose may directly be fitted to the dirty water outlet hole or a •

special apparatus mounted on the outlet bracket of the wash-stand

Never attempt to extend the water drain hose by adding extra parts without ad-•

vice from an engineer or installer, drain extension kits are strongly discouraged

3

levelling

power

Mains Votage Connection

Your machine requires a UK 13A standard plug point from which to draw power and

is pre-fitted with a standard 13A plugtop which is moulded onto the power lead.

Wherever possible this should be inserted directly to a suitable plug point and not an

extension lead or suchlike.

Your machine contains sensitive electronic components which, if fed a poor or irregular

power supply, can manifest “ghost” faults, that is, faults that are generated by an irregular or poor power supply that cause the electronics to become unstable. It is therefore

very important that the mains supply is good.

Should you wish or require to extend the power supply please contact your installer or

an appliance engineer for a suitable solution.

Levelling The Machine

One very important part of the installation is to ensure, after the machine is placed into

postion that it is level and solid. Failure to do so can lead to excessive vibration from

the machine and poor or no spin if the vibration reaches a level that it operates the

machine’s built in anti-balance circuitry.

To do this it is best advised to use a spirit level on the lid of the machine ensuring that

the top is level from front to back and side to side. This is not always possible where the

machine is installed beneath a worktop and, in this case, a thing spirit level placed on

the leading edge will allow you to ensure the machine is as level as possible from the

front.

Levelling is made easy by using the front feet as shown above.

Simply loosen the plastic locking ring, adjust the foor to the desired height by screwing

or unscrewing as usual to level the machine using your spirit level.

Once complete screw the locking plastic rings back to lock each foot into position and

to ensure that they remain as set.

4

use

Section 2: Programs

In this section we will deal with the various programs and functions of the washing

machine and take you through it step by step. Please feel free to use this guide as a

reference and doing so will ensure that you get the best possible results from your

machine.

The first part of the machine that we will explain is the program dial which you use to

set the various programs depending on the fabric type and level of soiling (how dirty

the clothes are). The choice of the proper program is very important if you wish to

receive the best possible results.

The program dial is divided into five main sections (detailed below) for each different

type of wash with one of those sections offering additional rinse, spin and drain functions.

Cottons Section

Programs 1-9

This section is for

cottons and mixed

fabrics

Synthetics Section

Programs 10-14

This section is for

synthetic fabrics

Delicates Section

Programs 15-17

This section is for

delicate fibres

Wool Section

Programs18-20

This section is for

woolen or handwash

only fibres

Drain/Spin Section

Programs 21-23

This section is to

allow an extra drain,

rinse or spin

As the above diagram shows how the control dial and programs are split into easy to

follow groupings making it far easier to select first by fabric type and then by wash

temperature or any other special requirements or programs which we shall explain

next.

These section symbols are shown on the soap drawer front in an easy to understand

visual guide to each program’s function for quick reference.

5

guide

Program Guide & Symbols

Now that you know what section of the dial is used for what type of fabric it becomes

easy to select the program that you desire to use within each section. On the ISE2 this

mainly falls down to simply selecting the temperature of wash that you require and

pressing the start button.

However, there are many special programs on the dial which we shall explain in this

section which may benefit you under certain circumstances or for special care fabrics.

It is worth taking heed of the fabric care labels on many modern garments as they can

use special fibre mixes and, if you use the wrong program, you can irreperably damage

these more delicate items.

Cycle Times

Throughout this guide we do give approximate cycle times which we have verified

under test. However it is very important to note that these can vary by a considerable

degree depending on local conditions and the time of year.

During the winter the incoming cold water temperature is often several degrees lower

than it is during the summer months and this leads to additional heating time so this

can affect these times.

Water pressure can also massively change the cycle times. A lower water pressure

would mean that on every fill the machine takes slightly longer and can lead to longer

than anticipated cycle times.

If the machine completes the cycle but takes longer than you would expect then there

is almost cerrtainly no fault with the machine it is just being affected by local conditions such as these.

Sorting Laundry

More than any other factor, sorting your laundry into whites/lights and coloured items

is essential to getting good results and we strongly advise that you do not mix light or

white items with coloured ones on any program. Doing so can lead to discolouration

and dye transfer which may well be irreversable.

It is also important that you use two detergents, one for whites/lights that is bleach

containing and one specifically for coloured items which does not contain any bleach.

Doing this will ensure that your machine remains in good order and that your clothes

last much longer.

6

cottons

Cotton Washes

Cotton and mixed fabric washes are the most common washes used in the UK, in

particular the 40°C wash. With modern energy saving methods it is possible to use very

little electricity and reduce the water consumption but this does mean that the wash

time is extended. To combat this the ISE2 has two programs that we recommend for

everday use which do complete faster, the ECO wash and the “40° mix” with the mixed

wash being the best choice for many everyday loads.

Where time is not such a concern please use the standard programs to achieve a

deeper clean and to reduce water and electricity consumption.

The Cotton 30°C wash is only recommended where a detergent such as Ariel or Simply

is used that supports the use of this program or results may be compromised.

It is worth noting that the wash agitagion is greater on all the cotton cycles than that of

synthetic or delicates cycles for a deeper and more intensive cleaning however, if you

repeatedly place delicate items in a cotton cycle it can cause damage to your clothing.

The following section details the uses and features of each cotton cycle.

This is the cotton 90°C cycle and is essentially a boil wash. It should be used for very

heavily soiled items that require to be effectively sterilised. It can also be used for

bleaching and dying items as instructed by the garment label.

Uses detergent compartment 2

Ideal for: Very heavily soiled cotton or linen textiles

Can be used with: Full load -

Approximate cycle time: 137 minutes

The cotton 60°C cycle with the bucket is a 60°C cycle with a pre-wash. It should be

used for very heavily soiled cotton or linen and gives a very strong wash. This temperature and above is ideal for bedding as it kills almost all mites.

Uses detergent compartment 1 and 2

Ideal for: Very heavily soiled cotton (bedding) or linen textiles including coloured items

Can be used with: Full load -

Approximate cycle time: 136 minutes

cotton 90°C

cotton 60°C with prewash

7

This is the standard cotton 60°C cycle and is the best program for most cottons,

especially if worn next to the skin or used in bedding which is not too dirty. Using this

program for bedding also ensures that almost all mites are destroyed.

Uses detergent compartment 2

Ideal for: Medium soiled cotton or linen textiles and bedding

Can be used with: Full load -

Approximate cycle time: 162 minutes

The 40°C cotton cycle is the most commonly used wash cycle in the UK as it copes

admirably with most everday washing and should prove efficient and effective for most

clothing. Most cottons or cotton mixes can be washed safely on this cycle and you will

have all the benefits of stain removal.

Uses detergent compartment 2

Ideal for: Medium soiled cotton or linen textiles including coloured items

Can be used with: Full load -

Approximate cycle time: 130 minutes

Our ecowash program is a specially developed variant of the common and popular

40°C cotton cycle which reduces the water and power useage still further and yet improves slightly on time performance without lessening the results. For most everyday

cotton clothing this cycle is ideal and will help you to further reduce your water and

electricity consumption.

Uses detergent compartment 2

Ideal for: Medium soiled cotton or linen textiles including coloured items

Can be used with: Full load -

Approximate cycle time: 121 minutes (40°C)

cotton 60°C

cotton 40°C

ecowash

8

The cotton 30°C cycle should only be used when suitablely rated detergents are used,

please see your detergent packaging too see if this is the case.

Uses detergent compartment 2

Ideal for: Slightly soiled cotton or linen textiles including coloured items

Can be used with: Full load -

Approximate cycle time: 117 minutes

The quickwash is designed to refresh garments and to clean very lightly soiled items

and we do not recommend it for more intense cleaning.

Uses detergent compartment 2

Ideal for: Very lightly soiled cotton or linen textiles including coloured items

Can be used with: Half load -

Approximate cycle time: 30 minutes (25°C)

This is the cottons cold cycle where cold water only is used and should be used as

directed by the garment labelling.

Uses detergent compartment 2

Ideal for: Slightly soiled cotton or linen textiles including coloured items

Can be used with: Full load -

Approximate cycle time: 105 minutes

The mixed wash program is an excellent balance between time and performance

for most people. This allows a mix of fabrics and colours to be washed effectively in a

much shorter time whilst retaining thebest possible stain removal characteristics. For

most everday washing you will find this program very effective and fast.

Uses detergent compartment 2

Ideal for: Medium soiled cotton or linen textiles including coloured items

Can be used with: Full load -

Approximate cycle time: 73 minutes (40°C)

cotton 30°C

quick wash

cold cotton

mixed wash

9

40° mix

synthetic

Synthetic Washes

Synthetic washes for man made fibres are also known as acrylics on some older garments and require a more gentle wash action than most cotton based fabrics. Therefore these washes have a lower agitation speed and are more gentle in the washing

process. It is important that you select the correct wash type as, should you wash for

example a synthetic printed t-shirt on a cottons wash by mistake, you can cause damage to the fabric of the garment and this can lead to a loss of qulaity in the print or the

fabric itself.

If you are unsure of what wash to use please refer to the wash labels section later in this

guide and, if this information is unavailable, we would advise that you select a gentle

wash to avoid damage to your clothes. Conversely, washing a cotton item that requires

a higher level of agitation on a synthetic program may not clean it properly.

This rest of this section will explain the various synthetic wash options and what they

are used for.

The synthetic 60°C cycle should only be used when the care label of the garment specifically states that it can be used for dirty synthetic or mixed synthetic garments.

Uses detergent compartment 2

Ideal for: Heavily soiled synthetic or mixed synthetic textiles including coloured items

Can be used with: Half load -

Approximate cycle time: 100 minutes

This program has been specifically designed to clean baby clothing by using a slightly

longer agitation stage and higher temperature to help remove stubborn staining and

at the same time remain gentle to the clothes and rinse well.

Uses detergent compartment 2

Ideal for: All baby clothing

Can be used with: Half load -

Approximate cycle time: 122 minutes (50°C)

synthetic 60°C

baby wash

10

The synthetic 40°C cycle is the most common synthetic cycle used and should suit

most everyday synthetic or mixed fibre garments.

Uses detergent compartment 2

Ideal for: Medium soiled synthetic or mixed synthetic textiles including coloured items

Can be used with: Half load -

Approximate cycle time: 81 minutes

Another special program that has been designed to clean sports wear such as tracksuits, jogging wear and gym wear to keep it looking good for longer.

Uses detergent compartment 2

Ideal for: All baby clothing

Can be used with: Half load -

Approximate cycle time: 91 minutes (40°C)

synthetic 40°C

sport wash

This is a program designed specifically to clean mixed fibre curtains which often have

delicate surfaces, specifically tuile, diolen and dralon curtains but it can be used for

other similar delicate items.

Uses detergent compartment 2

Ideal for: All synthetic curtains, other delicate items

Can be used with: Half load -

Approximate cycle time: 130 minutes (40°C)

curtain wash

Use this cycle where you have delicate synthetic or mixed fibre garments that may be

damaged by heat.

Uses detergent compartment 2

Ideal for: Lightly soiled synthetic or mixed synthetic textiles including coloured items

Can be used with: Half load -

Approximate cycle time: 83 minutes

synthetic cold

11

delicates

Delicate Washes

Often delicate items, especially machine washable wool or wool mixed fabrics, require

an even more gentle wash than the synthetic washes in order to give the best possible

care for you clothes. These programs have a still lower drum agitation and so are genteler to your clothes and none will heat above 30°C or offer the full spin speed, all these

programs will spin at the lower speed.

It is almost very important that, when washing wool or woolen mix items that you

use a detergent for that specific purpose. Failure to use the correct detergent will

almost certainly result in damage, primarily shrinkage, to your clothes which cannot be

reversed.

The delicate 30°C cycle is designed with a very gentle wash action to care for very delicate fibres such as silk mixtures, polyester, polimiads and so on. The need for this cycle

will be shown on your fabric care label.

Uses detergent compartment 2

Ideal for: Slightly soiled wool or delicate textiles including coloured items

Can be used with: Full load -

Approximate cycle time: 98 minutes

delicate 30°C

As above only with no heating of the water where it is not required.

Uses detergent compartment 2

Ideal for: Lightly soiled wool or mixed delicate textiles including coloured items

Can be used with: Less than half load -

Approximate cycle time: 83 minutes

delicate cold

12

The wool 30°C cycle is designed with a very gentle wash action to care for both hand

and machine washable woolen items. However it is extremely important to use the

correct “Wool” detergent when washing woolens as well as to use less than half the

drum capacity to allow these items to move freely around the drum.

Uses detergent compartment 2

Ideal for: Lightly soiled wool items

Can be used with: Less than half load -

Approximate cycle time: 65 minutes

wool 30°C

You can use the special handwash cycle to clean garments that are marked as being for

handwash only thus saving you the need to handwash any items. However, particular

care must be paid to the detergent requirments for each fabric type, please refer to the

fabric care label on the garment for more information.

With the above in mind with the detergent requirements, any fabric type can be

washed using this program except wool.

Uses detergent compartment 2

Ideal for: Lightly soiled synthetic or mixed synthetic textiles including coloured items

Can be used with: Half load -

Approximate cycle time: 89 minutes (30°C)

handwash

As above only with no heating of the water where it is not required.

Uses detergent compartment 2

Ideal for: Very lightly soiled wool items

Can be used with: Less than half load -

Approximate cycle time: 54 minutes

wool cold

Please remember that your choice of detergent is vital to get outstanding

results when using woolen and delicate cycles

13

additonal

Additional Programs

Often delicate items, especially machine washable wool or wool mixed fabrics, require

an even more gentle wash than the synthetic washes in order to give the best possible

care for you clothes. These programs have a still lower drum agitation and so are genteler to your clothes and none will heat above 30°C or offer the full spin speed, all these

programs will spin at the lower speed.

This feature allows you to do an additional rinse and spin cycle on it’s own

rinse

This program gives a spin at normal speed should you require only to spin some items.

spin only

This option will simply drain the machine.

drain only

14

options

Program Options

The program option buttons allow more flexability in the programs and for you to

tailor the programs to the way in which you want them to work. They are also required

for some fabrics, such as the “no-spin” option which is required for delicate silks and

suchlike. Please note the symbols below and, in the previous guide to each program,

you can quickly see which options are available on which programs as some options

are not available on all programs since either they are not required or they could prove

detrimental to the type of fabric that the program is designed to be used with.

This function, when selected as indicated by the indicator lamp, cancels any spin on

the program which you select.

The “no spin” function is especially useful for very delicate items that you do not wish to

spin or the clothing may be damaged such as fine wool, silk mix or handwash items.

no spin

The extra rinse is an option that adds one extra rinse to the program and this especially

useful for people with sensitive skin where you wish the clothes to be as detergent and

fragrance free as possible.

extra rinse

Easy iron reduces the creasing in your clothes making them easier to iron.

easy iron

15

symbols

Laundry Symbols

All clothing manufactured has laundry symbols on the garment’s labelling that will

give an indication of the recommendations for washing without causign damage to

the garments as well as extending the life of them. Washed incorrectly some items may

become damaged in a few washes or it could take many for the item to become damaged. It is important that you follow the labels as much as possible to ensure that your

clothes last as long as possible and remain looking new.

In normal circumstances the main five laundry symbols are shown below although

there are various options shown with these symbols as the maximum temperature suitable will be shown in the “bucket” where applicable.

Normal Wash Process

Any program can be used dependendent on the temperature indicated but

a vigorous wash process is recommended. Pre-treat stubborn stains.

Mild Wash Process

“Easy care” coloured wash: reduce the quantity of laundry. Pre-wash only if

the textiles are heavily soiled. Avoid spinning or do spin for short periods

only to minimise the risk of creasing. Maximum temperature will be indicated in the bucket.

Very Mild Wash Process

For articles e.g. in machine-washable wool. This washing cycle ensures a

low mechanical treatment. Reduce the quantity of laundry substantially, the

drum should be not more than on-third full. Select an appropriate delicates

washing program.

Pay particular attention to the detergent instructions as use of the wrong

detergent me irreparably damage delicate items.

Do Not Wash

Articles marked in this way must not be washed. They may be sensitive to

any kind of wet treatment or be unsuitable for washing in a washing machine because of their size.

Hand Wash Only

Garments with symbol can only be hand washed or washed in your machine using the special hand wash program at a water temperature between 30° C and a maximum of 40° C, depending on the particular article.

use

Section 3: Using You Machine

Your machine has been designed with great care and thought to be as simple to use as

possible and, now that you understand the various programs and how the timer dial is

arranged, you can see that it is as intuative as possible.

This section is all about how to use your machine and offers advice on getting the

most from your ISE.

First Use

When your machine is delivered you may find that there is some residual water from

factory testing in the machine, this is nothing to be concerned about and is perfectly

normal.

Although not absolutely necessary we do recommend that you run a “maintenance

wash” when the machine is first installed as it accomplishes several things at once:

You establish that the machine is operating normally•

That the machine is installed correctly •

That the machine is clear and clean internally•

It also allows you to see how the machine operates and become familiar with the controls and soap dispencer section.

To carry out a maintenance wash:

Place a normal dose of bleach containing detergent (see page 12 ) in compart-•

ment 2 of the soap drawer

Do not place any clothing in the drum•

Turn main control dial to the Cotton 90°C wash•

Ensure that the door is closed and latched•

Press the Start/Pause button•

Allow the program to complete•

This will clean and refresh the insides of the machine and a regular maintenance wash

is recommended about once a month to keep the inside of the machine clean, fresh

and operational. Should you ever encounter any malodour or smell from the machine

please run at least one maintenance wash to clear the smell.

16

use

Laundry Sorting & Detergents

The very first thing to do is sort your laundry into white/lights, separate coloured or

dark items and articles that require special treatments, such as wool or hand wash

clothing. This is essential to prevent dye transfer and to keep your clothes looking good

for longer.

It is also important that you use the correct detergent for these types of clothing and

this can be very confusing.

It is no more or less expensive than simply using the same detergent for all as many

people do, but it will ensure far superior results from your washing machine as well as

helping to retain your clothes good looks for much longer.

You will require a minimum of two detergents and possibly three if you wash delicates:

Normal detergent containing bleach•

Colour detergent that does not contain bleach•

Special detergents for wools and delicates•

From an environmental standpoint we recommend Simply by Aquados for both

normal biological detergent or non-biological and also for colour detergent. This is the

only detergent which will deliver excellent results and environmental benefits. This is

also the only detergent currently bearing the EU Eco Flower mark.

You can find out more at www.simplywashing.com

Should you wish to wash woolen, part woolen or other delicate items it is essential that

you use a mild detergent or you will damage the clothing. We would suggest that a

mild detergent such as Woolite is ideal for such garments.

Important Notes:

Bleach containing detergent is normal powder or tablets only and this includes both

biological and non-biological powders or tablets.

Colour detergent does not contain any bleach at all.

No liquid or liquid tablets contain bleach.

Normally no delicate detergents contain bleach.

WARNING!

Use only detergent that is recommended for domestic automatic (front loading)

washing machines as other detergents such as commercial or toploader/twin

tub detergents can cause damage that will not be covered by your warranty.

17

use

Detergent Drawer

For most washes all that is required is to use compartment “2” of the soap dispenser

and the middle fabric conditioner one if required. Compartment “1” is only used for prewash detergent where required by the cycle chosen.

Loading Laundry

In order for the washing machine to clean your clothing the garments placed in the

drum must have room to move. This means that you cannot cram the machine full and

effectively overload the drum. Should you do so then there is a risk of damage to the

machine and the clothing as well as inferior cleaning results so it is highly inadvisable.

To load correctly you should always have an approximate 10cm gap (roughly the width

of your hand) between the top of the laundry and the top of the door as shown in the

photograph below:

This shows the correct amount of space that is required to obtain the optimal results

from your ISE and, loaded correctly with the correct detergent being used your machine will deliver great washing results.

Compartment 2

Main Wash

Softener

Compartment

Compartment 1

Pre-Wash

18

use

Starting The Machine

Once you have loaded the machine and placed the detergent in the correct compartment of the soap drawer or placed the detergent in the drum you are ready to close

the door and select your desired program.

Should the door not be closed correctly or hindered in some way the safety features

of the machine will not allow it to start and if this should happen then the start/pause

light will blink to indicate that the door is not correctly closed. Once closed the program and options can be set.

Simply select the desired program using the main program selector knob. As you do

this the start indicator will illumiate.

Select any options that you wish to use on that program and the corresponding indicators will light.

To begin the program now press the Start/Pause button once and the program will

start.

Changing The Program

If you have selected a program and wish to change it follow this procedure:

Press the Start/Pause button•

Turn the program dial to the “O” (Off ) position•

Set the program dial to the desired program•

Press the Start/Pause button again to start the new selection•

Cancel A Program

Should you wish to cancle a program follow this procedure:

Press the Start/Pause button•

Turn the program dial to the “O” (Off ) position•

Set the program dial to the draining or spinning program•

The program ready light will illuminate•

Press the Start/Pause button again to drain and clear the program•

Program End

Once the Program has ended the machine will automatically stop and the program

end light will be lit. Turn the program selector to the “O” (Off ) position to switch the

machine off.

19

safety

Your ISE washing machine has several safety and security features built in in order to

protect your clothing, children and the machine itself. It is important that you familiarise yourself with these features

Balance Protection

The machine has a feature built into the electronics that will detect what is known as

an “out of balance” or OOB situation where the weight of clothing in the drum could

cause damage by being spun through excessive vibration. Things that are liable to

make this feature engage is where single items of clothing, especially heavy items such

as towels or jeans, would not distribute evenly around the drum before the machine

spins.

The machine will attempt, before entering into a spin cycle, to sort and distribute the

washing to give as even a balance as possible thereby minimising any vibrations and

making the machine smoother and quieter in operation.

However, should the machine not be able to evenly distribute the laundry to ensure

that the machine spins in a safe and controlled manner the spin cycle will abort after

several attempts to compensate.

In order to avoid this situation we would suggest washing several items at once or,

where this is not possible, add “ballast” to the machine so that it can spin safely. This

practise of not washing single items where it is avoidable is far more efficient and

environmentally friendly.

Overll & Overheat

Your machine is also equipped with sensors that will detect both an overfill and

overheat situation. Both of these features work in the background and require no user

intervention.

Should either of these features be activated an error message will be indicated by way

of a fault code and you should contact your nearest service centre for further assistance.

Section 4: Safety & Security

20

safety

Child Lock

All ISE washing machines feature a child lock for safety purposes.

On the ISE2 series the child lock prevents children from making any changes to the

program or settings whilst the machine is running.

Child lock is activated by pressing the first (Start/Pause) and third button (Extra Rinse)

on the control panel at the same time for more than 3 sec. When child lock is activated,

LEDs on the function buttons blink to indicate that child lock is active.

In order to deactive child lock, the same buttons (1st and 3rd) should be pressed again

for more than 3 seconds. Deactivation of child lock is shown by blinking of LED on

Start/Pause button.

WARNING!

This feature will deactivate all controls and function buttons whilst it is active!

Power Failure Protection

Your machine has a feature whereby if you suffer from a power loss or power cut, that

when power is restored the machine will continue operation from the point at which it

stopped.

This is not harmful to your machine.

Drain Protection

Your machine also has a safety feature that will prevent it from spinning when full of

water, for instance if the machine fails to drain for any reason.

This is to prevent possible damage to the machine by trying to spin too much weight

as well as to stop water leaking. Should this happen please contact your nearest service

centre for more assistance.

21

care

Taking a little care and regularly cleaning your machine will ensure a longer life and

better performance.

Soap Drawer

Section 5: Care & Maintenance

22

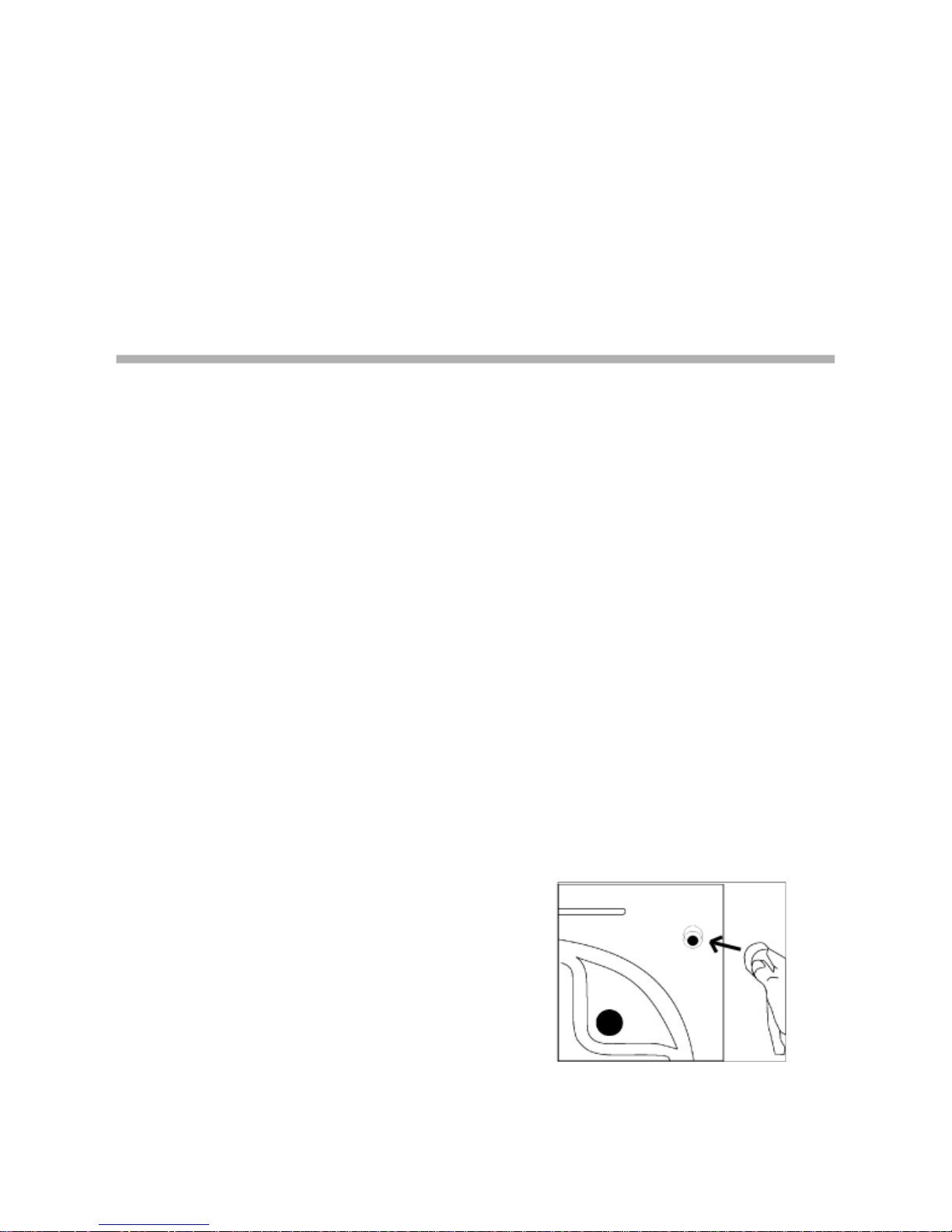

The soap drawer can easily be removed for cleaning purposes, simply press the blue lock in the softener compartment as shown and pull the drawer out.

It is advised that this is cleaned approximately once a

month as well as the inside of the drawer to prevent a

build up of excess detergent and softener which can lead

to mould or mildew forming in the drawer.

Pump Filter

The siphon plug can then be removed for cleaning as, if

this becomes blocked, the machine may not take fabric

conditioner correctly.

The filter is located at the bottom right hand side of the machine behind the lower

kickplate and can be easily accessed for cleaning. Please remember to clear this on a

failry regular basis as small items such as coins and pins inadvertanlty left in pockets

will end up here. However it is vital that pockets are checked as items left in clothing

can cause severe damage to the machine and any damage may not be covered by

your warranty if it is caused by external objects.

It is recommended that the filter is cleared on a monthly basis.

WARNING!

Failure to clear the lter on a regular basis can cause drainage and or noise

problems!

23

care

To access the filter the lower kickplate has to be

removed. To do this simply push gently upwards

and pull the kickplate toward you.

This should allow the kickplate to be removed easily

and without any damage.

Once the kickplate is removed the filter can be

unscrewed and removed to clean it.

Please note that there will be some water in the

sump at this point which will come out so before

you remove the filter runs a “Drain” cycle to clear as

much water as possible, however there may still be

up to 2-3 litres of water in the sump.

Once the filter is removed you will be able to see the blades of the drain pump and you

can see if these are clear with no objects blocking them or impairing their way.

The filter should be clear of all objects and any fluff, coins, pins or any other materials

should be removed to prevent damage or a failure to drain.

WARNING!

Always remember to place towelling on the oor to catch excess water!

Please note that damage caused by foreign objects or faults arising from these

being present may not be covered by your warranty.

24

help

Very often simple problems are easily rectified often without any need for a service

engineer to visit. Should you encounter any behaviour that you feel is unusual or not

normal in some way please pay particular attention to this section before contacting a

service centre.

The machine will not start or power on

Check the plug and fuse for the machine amking sure that power is available to the socket to

which ithe machine is plugged into.

Start/Pause button not pressed

Program knob set to “O” (Off) position

Door not closed

The machine will not ll with water

Is the water inlet tap switched on and the hose not bent or obstructed?

Door not closed

The machine will not drain water

Ensure that the drain hose is not obstructed or bent and that the drain is clear. This is especially inportant where connected to a sink trap.

Pump filter may be obstructed, please check that it is clear

The machine vibrates

Ensure that the transit straps have been removed (see Page 1)

Ensure that the feet have been adjusted and that the machine is level (See Page 4)

Ensure that the load is balanced as best as possible

Is the flooring that the machine is installed on solid? It is possible that installation on a

wooden “floating” floor can lead to vibration.

There is foam in the detergent drawer

Too much detergent has been used, please reduce the doseage.

Incorrect detergent used, please use a recommended detergent for domestic use automatic

washing machines only

The washing results are poor

The single biggest cause of this is overloading, please see page 18 of this guid for loading

advice and instruction.

Have you selected the suitable program for the laundry type?

Incorrect detergent used, please use a recommended detergent for domestic use automatic

washing machines only or insufficient detergent used to clean correctly.

Ensure that the detergent dose meets the criteria based on soil level (how dirty the clothing

is), the water hardness for the area and the amount of laundry being cleaned.

Section 5: Troubleshooting

help

25

Very often simple problems are easily rectified often without any need for a service

engineer to visit. Should you encounter any behaviour that you feel is unusual or not

normal in some way please pay particular attention to this section before contacting a

service centre.

The water drains as it lls

The drain hose is set too low and must be raised in accordance with the installation instructions on page 3

There is dirty water in the machine after use

The machine is filling with water from your drainage system. Very often this is a result of the

drain hose being too low and connected to a sink trap or a fault with your plumbing which

may require the attention of a plumber.

No water is seen in the drum

No fault, today’s energy efficient washing machines use much less water and the water will

rarely, if ever, be seen above the level of the door.

There are residues on the clothes

Invariably caused by overloading or overdosing detergent.

The machine does not spin

Imbalanced load, see page 20

Blocked or obstructed filter, see page 22-23 for instructions on cleaning the filter

help

26

Error Codes

Should a fault or error be detected your machine will display this by flashing the lights

as shown below.

Start/Pause FlashesError 01

The door is not detected as being closed, close the door.

Program Ready FlashesError 02

Low water level, ensure that water supply is okay

Start/Pause & Program Ready FlashError 03

Pump failed or pump blocked, clear filter

Start/Pause & Program End FlashError 05

Heater or heater sensor failure, power off the machine and call service centre

Program Ready & Program End FlashError 06

Motor fault detected, power off the machine and call service centre

Start/Pause, Ready & Program End OnError 07

Configuration error, power off the machine and call service centre

Start/Pause, Ready & Program End FlashError 08

Motor error detected, power off the machine and call service centre

Program Ready & Program End OnError 09

Over or under voltage supply detected once resolved the machine will restart

N.B.: Error code 04 not used on this model

WARNING!

Please ensure that the appliance should only be serviced by a competent service

engineer and that you should not attempt any repairs beyond maintenance

described in this manual.

There is a risk of electric shock from internal components even when mains voltage is removed.

ISE Limited

19-21 Nursery Street, Kilmarnock, Scotland

0845 226 1268

www.iseappliances.co.uk

Loading...

Loading...