Rev. 0128/01

TRONIC

SERVICE MANUAL

SYSTEMS

1

CONTENTS

1.0) CALIBRATION AND TEST MENU

1.1) CALIBRATION MENU ACCESSING PROCEDURE

1.2) REFRIGERANT SCALE CALIBRATION

1.3) MAINTENANCE METER CALIBRATION (RESET)

1.4) COMPONENTS AND FUNCTIONS TEST MENU

1.5) OPERATION PARAMETERS SETTING MENU

1.6) TABLE OF COMPONENT CODES

2.0) LIST OF COMPONENTS VIEW

2.1) GENERAL OVERVIEW

2.2) CONTROL PANEL VIEW

2.3) REAR VIEW

2.4) REFRIGERANT CONTAINER SAFETY VALVES

2.5) FRONT PART, INSIDE VIEW

2.6) UPPER PART, INSIDE VIEW

2.7) POWER BOARD VIEW

2.8) LOGIC BOARD VIEW

2.9) FLOW DIAGRAM

2.10) ELECTRICAL DIAGRAM

2.11) TABLE OF CONNECTIONS

Rev. 0128/01

TRONIC

SERVICE MANUAL

SYSTEMS

2

1.0) CALIBRATION AND TEST MENU

1.1) CALIBRATION MENU ACCESSING PROCEDURE

WARNING: PERFORM THIS PROCEDURE ONLY AFTER HAVING READ THE

FOLLOWING INSTRUCTIONS CAREFULLY. IF NOT PERFORMED PROPERLY, THIS

PROCEDURE CAN CAUSE MALFUNCTIONING AND DAMAGE THE UNIT.

Supply power to the unit.

With the display showing the net weight available (Stand-by mode), proceed as descri be d

below:

Press the UP Key and keep it pressed.

Press the S Key and keep it pressed.

Release the UP Key.

Press the DOWN Key and keep it pressed.

Release the S Key.

Release the DOWN Key.

The display shows 0000.

Use the UP-DOWN keys to access the following menus:

0001 Refrigerant scale calibration.

0005 Maintenance meter calibration (reset).

0015 Components and fu nctions test menu.

0050 Printer enabling.

0567 Operation parameter setting menu.

Set the desired menu.

Use the S key to confirm.

See the chapters on the individual menus.

Rev. 0128/01

TRONIC

SERVICE MANUAL

SYSTEMS

3

1.2) REFRIGERANT SCALE CALIBR ATIO N

Required equipment:

1 Phillips screwdriver, PH 2.

1 Hexagonal spanner no.13.

1 Sample weight, 5 Kg.

2 Sample weights, 2 Kg.

1 Sample weight, 1 Kg.

Or, alternatively:

1 Sample weight, min. 10 Kg.

1 Known weight, 9 Kg.

After removing the front panel, remove the M8 screw that fastens the container (34) to the

scale plate (18). Remove the container (34).

Note: it is not necessary to disconnect the hoses from the internal container (34).

Set menu 0001 (see Chap.1.1), confirm with the S Key.

The display shows P- - - 0.

With the scale plate (18) completely empty, press the S Key.

The display shows P- - - F.

Position the 10-Kg sample weight (or weights) on the scale plate (18).

Confirm with the S Key.

The display shows the theoretical weight read by the scale.

Use the UP-DOWN Keys to set the sample weight value.

Confirm with the S Key.

Remove the 10-Kg sample weight.

The display shows P- - - t.

Position 9-Kg sample weight (or weights) on the scale plate (18).

Confirm with the S Key.

The display shows –End–.

Press the S Key to exit. The display shows the Stand-by mode.

End of procedure.

Rev. 0128/01

TRONIC

SERVICE MANUAL

SYSTEMS

4

1.3) MAINTENANCE METER CALIBRATIO N ( RE S ET)

Set menu 0005 (see Chap.1.1), confirm with the S Key.

The display shows cont.

Press the S Key.

The display shows the work time (maximum time of 3600).

Press the S Key and keep it pressed.

The display shows cont – rESEt alternately.

When the display shows 0000, release the S Key.

The display shows –End–.

Press the S Key to exit. The display shows the Stand-by mode.

End of procedure.

Rev. 0128/01

TRONIC

SERVICE MANUAL

SYSTEMS

5

1.4) COMPONENTS AND FUNCTIONS TEST MENU

This procedure can be used to check the operation of the unit’s component s.

Set menu 0015 (see Chap.1.1), confirm with the S Key.

The display shows tESt 1.

When the F Key is pressed repeatedly, the following tests can be selected sequentially:

Test 1 All display segments check.

Test 2 All leds check.

Test 4 Out C and keys check.

Test 5 Refrigerant scale net weight visualization.

Test 6 Pressure transducer visualization (mV).

Test 7 Not used

Test 8 Not used

Test 9 Printer test. (If installed)

–End– Exit.

Use the F Key to select the desired menu.

Confirm with the S Key.

Use the S Key to exit from the individual tests.

With the display showing –End–, press the S Key to exit. The display shows the Stand-by

mode.

End of procedure.

Rev. 0128/01

TRONIC

SERVICE MANUAL

SYSTEMS

6

1.5) OPERATION PARAMETER SETTING MENU

WARNING: PERFORM THIS PROCEDURE ONLY AFTER HAVING READ THE

FOLLOWING INSTRUCTIONS CAREFULLY. IF NOT PERFORMED PROPERLY, THIS

PROCEDURE CAN CAUSE MALFUNCTIONING AND DAMAGE THE UNIT.

Set menu 0567 (see chap. 1.1),confirm with the S Key.

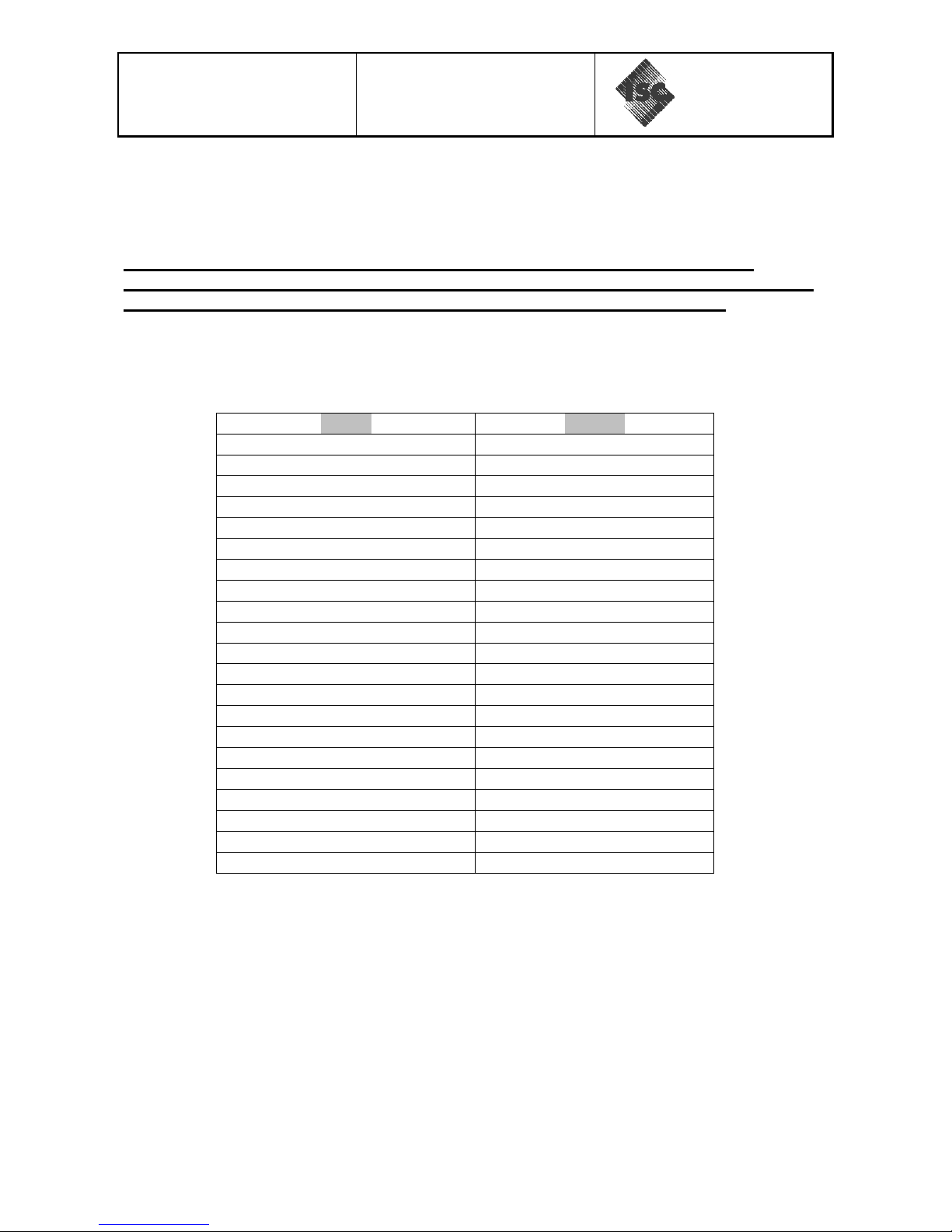

Press the F key repeatedly to select the following operation parameters in sequence:

CODE

VALUE

P-t02

60

P-t03

180

P-t04

60

P-t05

45

P-t06

04

P-t07

05

P-t08

02

P-t09

60

P-t10

00

P-t11

09

P-t12

60

P-t13

05

P-t14

240

P-t15

05

P-udL

0.700

P-udH

1.400

P-ud1

0.120

P--Fd

1.000

rES

P--Lb

10.000

t--AL

3600

When the display shows u---F, the pressure transducer can be calibrated.

Disconnect the quick connectors from the high and low pressure hoses.

Open the LP-HP valves on the control panel to connect the pressure transducer to the

atmospheric pressure.

With the display showing u---F, confirm with the S key.

The display shows the theorical weight measured.

Digit the value 0.960. Confirm with the S key.

Rev. 0128/01

TRONIC

SERVICE MANUAL

SYSTEMS

7

The display shows the following parameters:

P---M

19.500

rES

P-CFd

00.700

-End-

OUT

Use the F key to select the desired parameter and confirm by pressing the S key.

Use the UP-DOWN keys to set the value shown in the table.

Confirm with the S key.

Select the parameter -End- and confirm with the S key to exit.

The display shows the net weight available (standby).

End of procedure.

Rev. 0128/01

TRONIC

SERVICE MANUAL

SYSTEMS

8

1.6) TABLE OF COMPONENT CODES

1

TRONIC 2K1 LOGIC BOARD

2

POWER CABLE

3

LP BALL VALVE

4

HP BALL VALVE

5

2200 mm BLUE CHARGING HOSE

6

2200 mm RED CHARGING HOSE

7

LP QUICK CONNECTOR

8

HP QUICK CONNECTOR

10

HP D80 GAUGE

11

LP D80 GAUGE

12

–1/10 bar PRESSURE SENSOR

13

DISTILLATOR

14

OIL SEPARATOR

15

DRYING FILTER

16

140 KPL COMPRESSOR

17

4,3 m3/h VACUUM PUMP

18

60 Kg LOAD CELL

20/21

OIL INJECTION/DRAIN CONTAI NER

22

EXPANSION VALVE

25

500mm STRAIGHT+STRAIGHT HOSE

26

500 mm 90°+STRAIGHT HOSE

27

FAN CONDENSER

28

HP PRESSURE SWITCH

29

PROTECTION WIRE

30

500 mm 90°+STRAIGHT HOSE

31

CHECK VALVE M/F

32

CHECK VALVE

33

11,8 bar UNCONDENSABLES DISCHARGE VAL VE

34

INTERNAL REFRIGERANT CONTAI NER

39

500 mm STRAIGHT+STRAIGHT HOSE

40

PRINTER SET (OPTIONAL)

41

PAPER WIND KEY (OPTIONAL)

42

KPL DOUBL E POLE SWITCH

43

UPPER PANEL

45

FRONT PANEL

46

A200 REAR WHEEL

47

ROTATING FRONT WHEEL WITH BRAKE

48

SIDE POCKET

49

IDENTITY LABEL

50

KPL MANIFOLD

53

15 bar SAFETY VALVE

60

6 OUT 2K1 POWER BOARD

Rev. 0128/01

TRONIC

SERVICE MANUAL

SYSTEMS

9

2.0) LIST OF COMPONENTS VIEW

2.1) GENERAL OVERVIEW (Picture. 1)

41

40 43

OPTIONAL

20

1

21

48

46

4

10

11

3

8

6

7

5

45

47

Rev. 0128/01

TRONIC

SERVICE MANUAL

SYSTEMS

10

2.2) CONTROL PANEL VIEW (Picture.2)

10

11

S LED S

DOWN

UP

LED G

LED T

LED W

LED P

LED C

LED D

LED B

LED A

LED F

F

3

4

Rev. 0128/01

TRONIC

SERVICE MANUAL

SYSTEMS

11

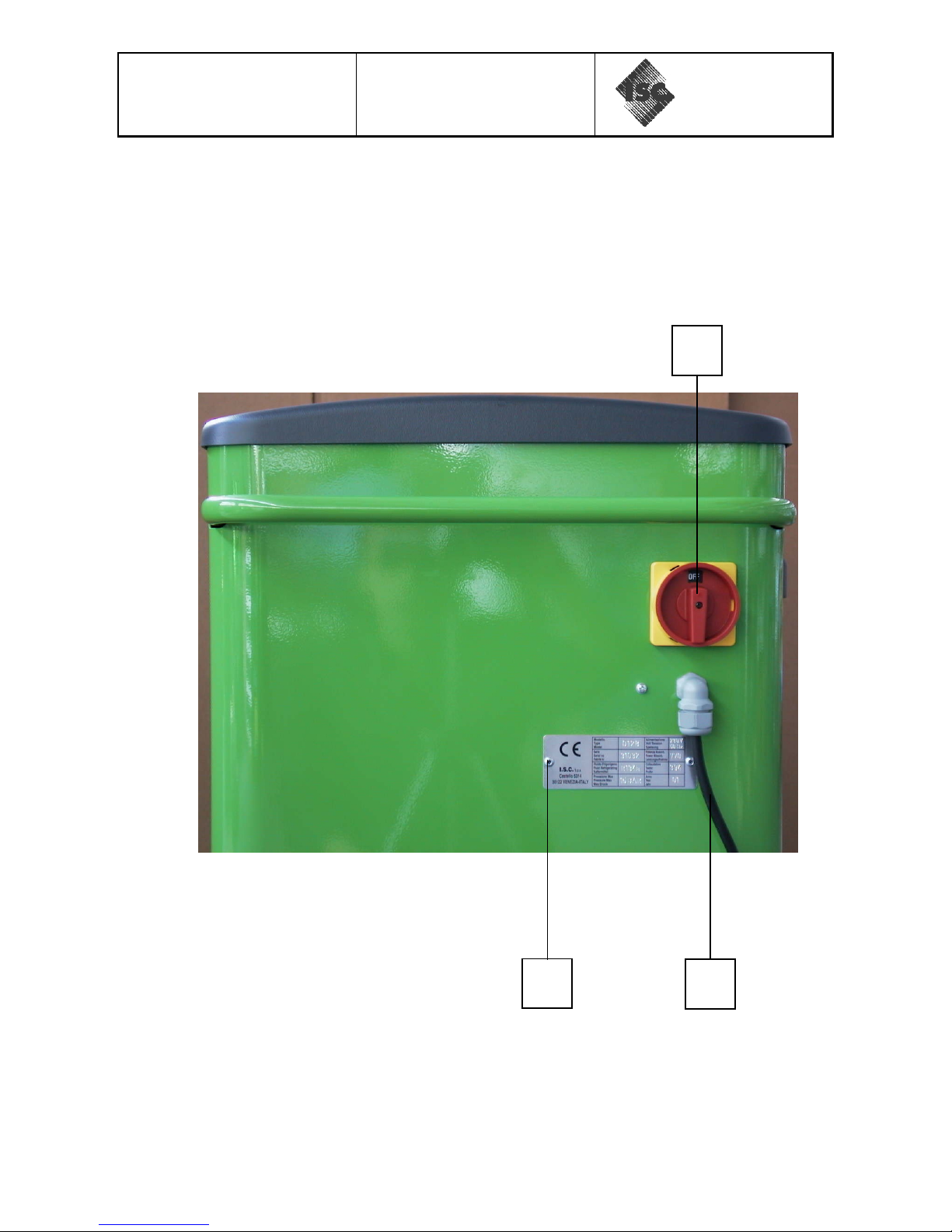

2.3) REAR VIEW (Picture. 3)

42

2

49

Rev. 0128/01

TRONIC

SERVICE MANUAL

SYSTEMS

12

2.4) REFRIGERANT CONTAINER SAFETY VALVES (Picture. 4)

31

53

33

34

25

39

Rev. 0128/01

TRONIC

SERVICE MANUAL

SYSTEMS

13

2.5) FRONT PART, INSIDE VIEW (Pictur e. 5 )

29

22

28

30

25

34

18

17

16

27

65

15

13/14

39

Rev. 0128/01

TRONIC

SERVICE MANUAL

SYSTEMS

14

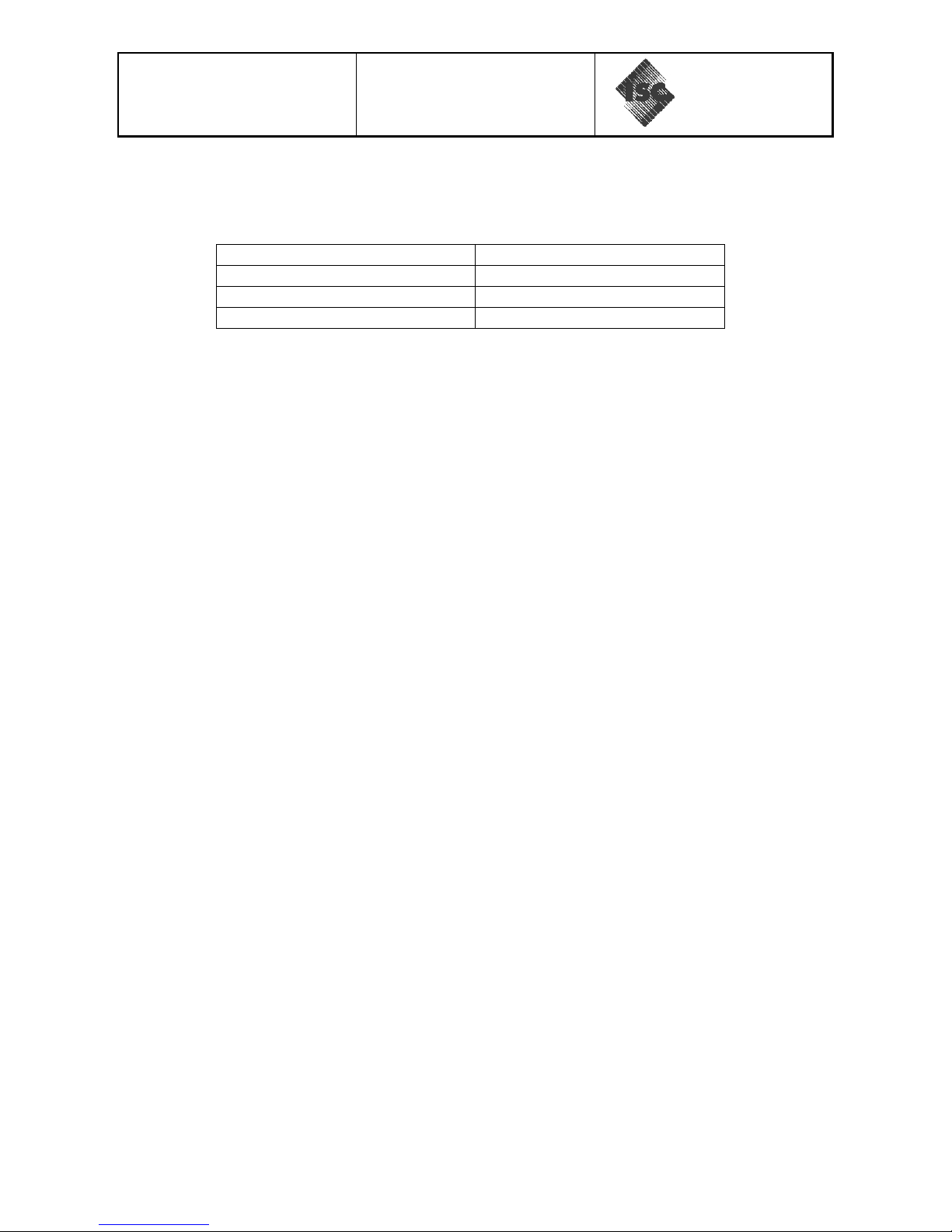

2.6) UPPER PART, INSIDE VIEW (Pictur e.6 )

POS

NAME

DESCRIPTION

61A

OUT B

SOLENOID VALVE ø4.5 mm

61B

OUT B

SOLENOID VALVE ø4.5 mm

62A

OUT A

SOLENOID VALVE ø3mm

62B

OUT A

SOLENOID VALVE ø4.5 mm

63

OUT R

SOLENOID VALVE ø2.5 mm

64

OUT L

SOLENOID VALVE ø2.5 mm

60

CHECK VALVE

42

12

50

61A

61B

62B

62A

63

64

Rev. 0128/01

TRONIC

SERVICE MANUAL

SYSTEMS

15

2.7) POWER BOARD VIEW (Picture.7)

71

81

80

72

74

75

76

73

79

78

77

70

Rev. 0128/01

TRONIC

SERVICE MANUAL

SYSTEMS

16

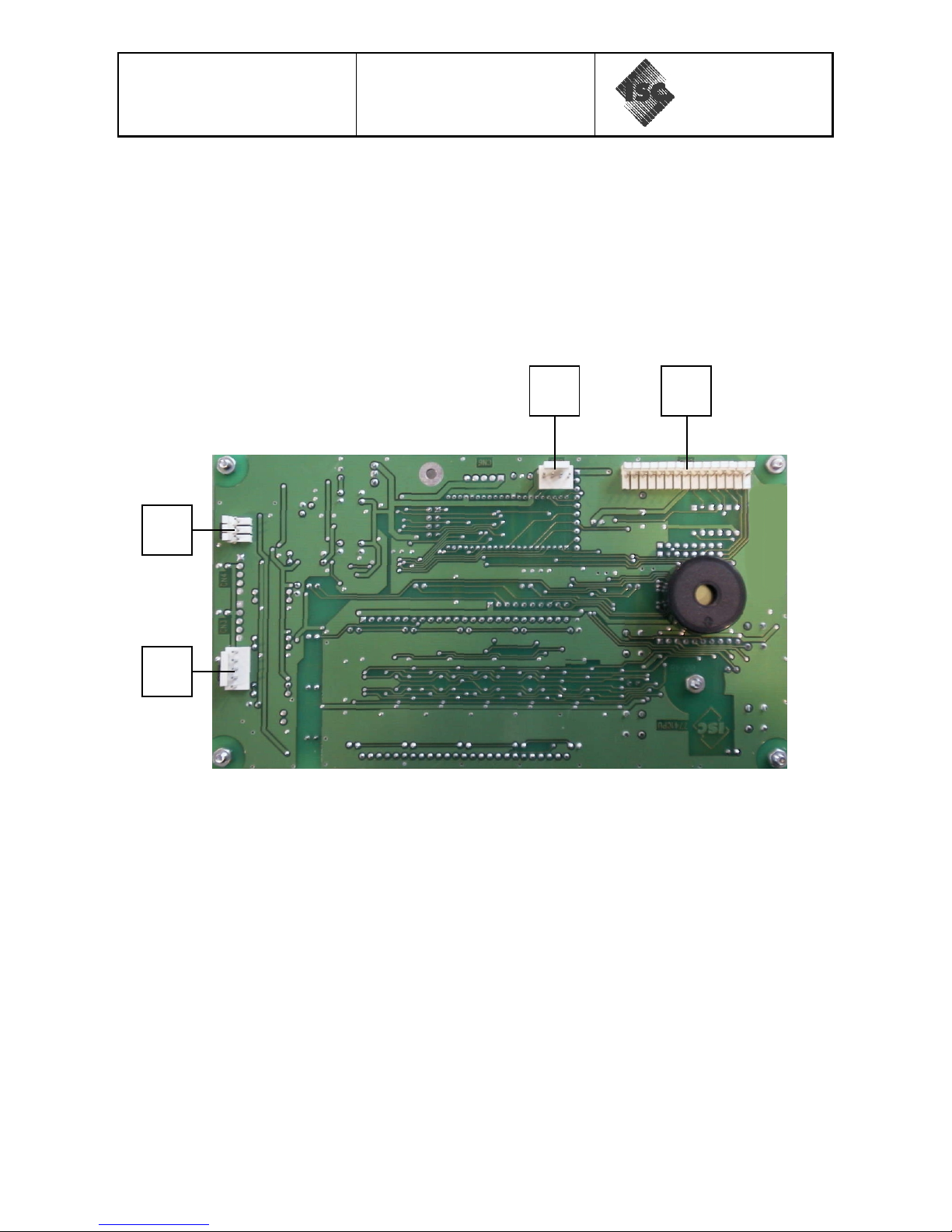

2.8) LOGIC BOARD VIEW (Picture.8)

82

83

85

84

Rev. 0128/01

TRONIC

SERVICE MANUAL

SYSTEMS

17

2.9) FLOW DIAGRAM

Rev. 0128/01

TRONIC

SERVICE MANUAL

SYSTEMS

18

2.10) ELECTRICAL DIAGRAM

Rev. 0128/01

TRONIC

SERVICE MANUAL

SYSTEMS

19

2.11) TABLE OF CONNECTIONS

PIC.

POS.

NAME

N°PIN

DESCRIPTION

DESTINATION

6

61

OUT B

-

VACUUM SV

-

6

62

OUT A

-

RECOVERY SV

-

6

63

OUT R

-

FILLING SV

-

6

64

OUT L

-

INJECT. SV OIL

-

6

65

OUT S

-

DRAIN OIL SV

-

6

12

PRESS.SENSOR.

-

PRESS.SENSOR.

-

6

42

SWITCH

-

SWITCH

-

7

70

PRINTER

2

POWER. PRINTER

PRINTER (40)

7

71

J2

10

DATA LINE

LOGIC BOARD (1)

7 72 PROTECT 2

PRESSURE

SWITCH INPUT

PRESSURE SWITCH

(28)

7 73 COMPRESS 3

POWER. COMP

(OUT C)

COMPRESSOR (16)

7 74 PUMP 3

POWER. PUMP

(OUT P)

VACUUM PUMP (17)

7 75 PUMP 3

POWER. VACUUM

SV (OUT B)

OUT B

7 76 OUT 1 3

POWER.

RECOVERY SV

(OUT A).

OUT A

7 77 OUT 3 3

POWER. INJECT.

OIL SV (OUT L)

OUT L

7 78 OUT 4 3

POWER. FILLING

SV (OUT R)

OUT R

7 79 OUT 6 3

POWER. OIL DRAIN

SV (OUT S)

OUT S

7

80

LINE OUT

3

220V 50 Hz LINE

NOT USED

7

81

LINE IN

3

POWER IN.

-

8

82

CN 8

15

DATA LINE

POWER BOARD (60)

8 83 CN 7 4

OUT. PRINTER

DATA

PRINTER (40)

8

84

CN 2

5

IN. REFRIG. CELL.

REFRIG. CELL. (18)

8 85 CN 5 3

IN. PRESSURE

SENSOR

PRESSURE SENSOR

(12)

Rev. 0128/01

TRONIC

SERVICE MANUAL

SYSTEMS

20

CONTROL PANEL

SFUP

DOWN

Loading...

Loading...