D2

Installation— Fig 1

Rope adjustment device

User Instruction Manual

1. Side plates

2. Cam

3. Handle

Principal materials:

Aluminium (side plates, handle).

Stainless steel (cam, rivets)

Cleaning and maintenance

Max 40°C Dry naturally

Internaonal Safety Components Ltd.,

Unit1 Plot 2 Llandygai Ind. Est.,

Bangor, Gwynedd. UK. LL57 4YH

D2—product name / brand.

I|S|C—manufacturer identification.

0120—Body controlling the manufacture

of PPE

supplied by the manufacturer.

— Rope access systems—Rope adjustment devices. C—rope adjustment device:

working line descender. Max load 100kg.

- (non EN1891) ropes Ø 8mm

YY/BB BBB/X X— Year of manufactu re/

Production batch/Incremental number.

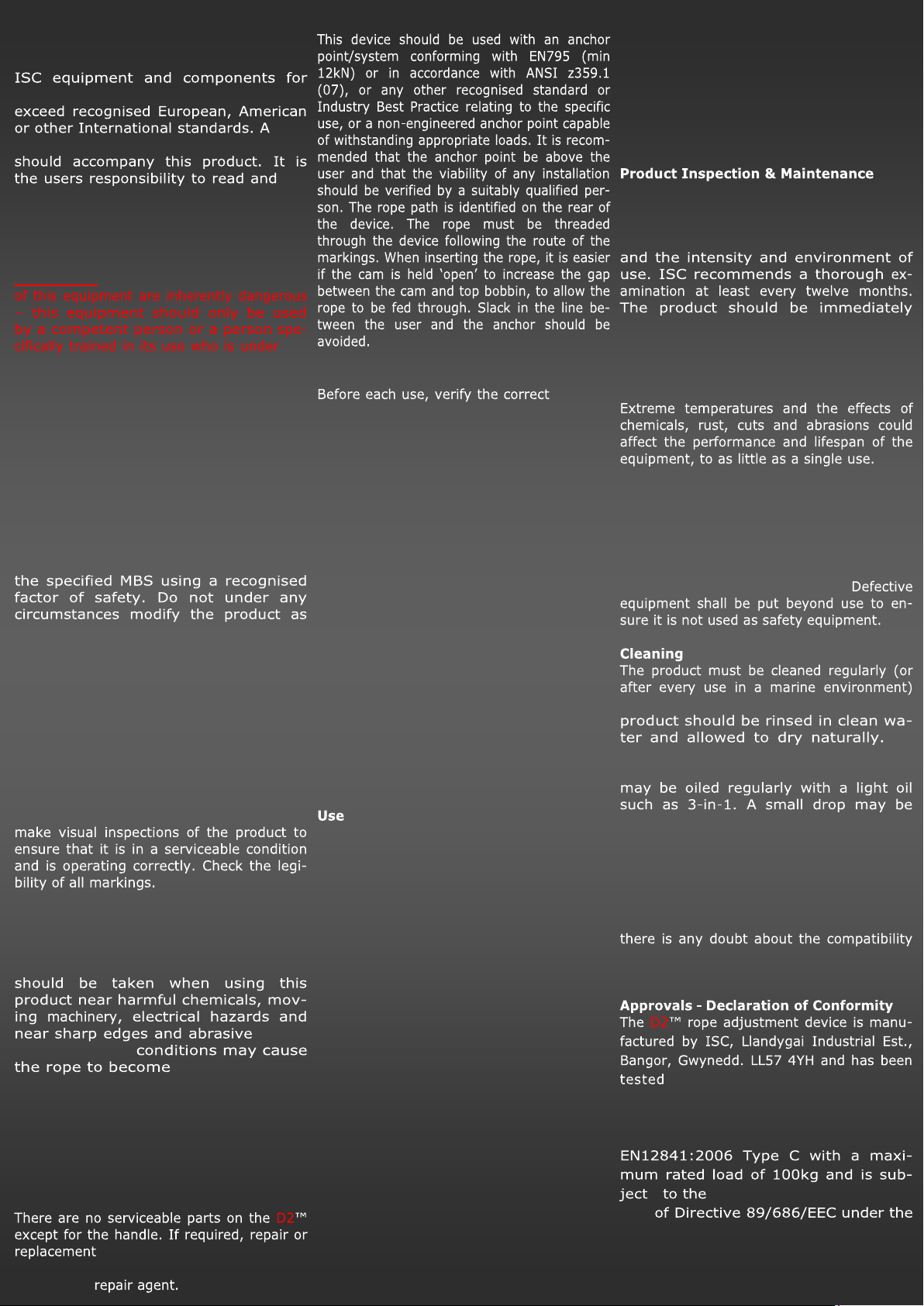

Operation— Fig 2

A—STOP

B—RESET (rotate clockwise)

C—DESCEND (pull handle down)

Modele & el Tipo / Modelleer & het Type / Modèle et type / Modello e tipo

Model & Type / Entwerfen Sie & Typ /

Serial Number / Seriennummer /

Número de serie / Het Serienummer / Numéro

de série / Numero di serie

Comprado de / Gekochte van / Acheté auprès

Purchase Date / Kaufen Sie Datum /

Compre la Fecha / Koop de Datum / Date

d'achat / Data di acquisto

Date first used / Datieren Sie zuerst benutzt /

Feche primero utilizado / Dateer eerst gebruikt /

Date de la première utilisation / Data primo

Purchased from / Gekauft von /

de / Acquistato a partire da

utilizzo

CETTE DOCUMENTATION DOIT ÊTRE DÉLIVRÉE AVEC CHAQUE ÉLÉMENT OU SYSTÈME ET CONSERVÉE AVEC CELUI-CI

PERIODIC THROUGH EXAMINATION AND REPAIR RECORD

Date /

Datum /

Fecha /

De datum /

Date / Data

Inspection details /

Detailinformationen zu Prüfungen /

Detalles de inspección /

Inspectiedetails /

Détails de l'inspection /

Dettagli ispezione

Name and signature /

Nennen Sie und Unterschrift /

Denomine y la firma /

Noem en handtekening /

Nom et signature / Nome e firma

RP860 series RP860UIM :Issue A: January 2014

Examen suivant / Prossimo esame

Next examination /

Nächste Untersuchung /

Próximo examen /

Het volgende onderzoek /

D2 Rope adjustment device.

General

prevention of falls from height meet or

mul-

ti-language user instruction manual

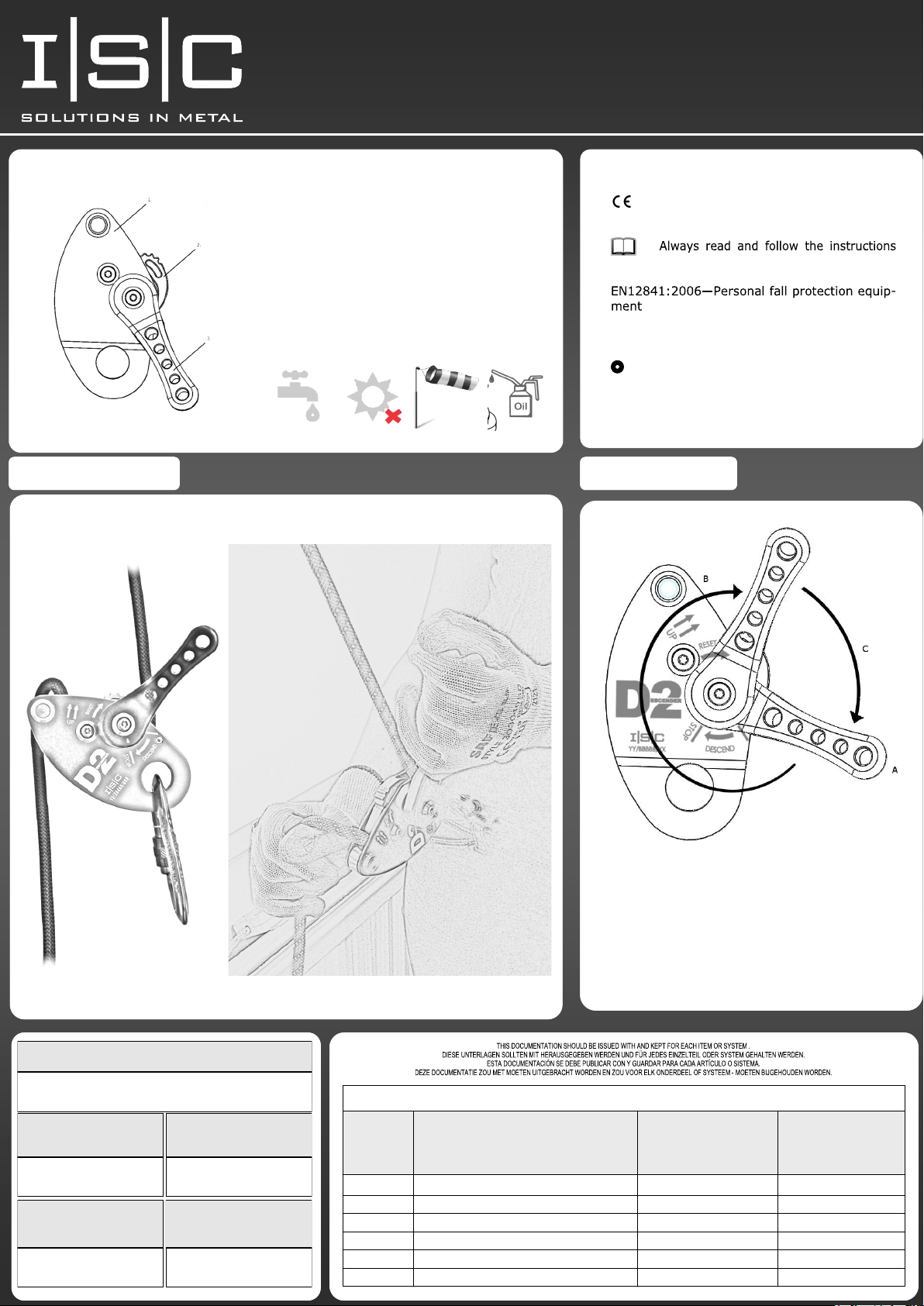

Figure 1 – Installation

Storage & Transportation

The product should be stored in a clean,

dry environment away from exposure to

UV, corrosive or chemical substances or

extreme heat sources. Care should be

taken to protect the product against

damage during transportation.

understand these instructions before use. If

this product is sold outside of the original

country of sale, it is the resellers responsibility to supply this document in the

language of re-sale.

WARNING - Activities involving the use

the

direct supervision of a competent person.

Responsibility

It is the user’s responsibility to ensure

understanding of the correct safe use of

this equipment, to use it only for the purposes for which it is designed, and to

practise all proper safety procedures. It is

mandatory that a Risk Assessment be

carried out prior to any use and a rescue

plan be in place for any work at height.

Do not exceed loads either specified by

the manufacturer or loads derived from

alterations may render it ineffective. This

equipment should not be used by persons

with a medical condition(s) that may affect the safety of the user.

Compatibility

Always ensure that all components within

a safety system are compatible and allow

the system to function safely.

Use Inspection

Immediately before, during and after use

Use Requirements

It is recommended that the viability of

any installation should be verified by a

suitably qualified person. Extreme care

surfac-

es. Wet and icy

slippery.

Testing

All testing for this device at ISC and the

Notified body, has been carried out using

Sterling PER 8mm and Sterling SAFETEC

8mm rope. One-man load 100kg.

Modifications, repair

of these items should only be

carried out by the manufacturer or its

recognised

Figure 2 – Operational check

installation on the rope. With the handle in STOP

position, carry out a pre-pull test to ensure the device does not slip down the

rope. If it is able to travel down the rope

the cam should be checked for wear by a

competent person. The device should still

be able to travel UP the rope, but should

not travel down the rope when in STOP

position. Ensure the device is attached

directly to your load bearing full body

harness (this is the only acceptable body

holding device in a fall arrest system)

attachment point (EN361) - marked ’A’

using a locking karabiner (EN362) with a

maximum overall length of 120mm (ISC

KH453 is recommended). When the adjustable anchor line is loaded by the full

weight of the user, this becomes a working line. Ensure that you have a fully

functional backup device (EN12841 Type

A) (e.g. ISC RED) on a separate rope.

The D2 is not suitable for use in an

EN363 fall arrest system.

To control the device in descent, your left

hand is used to position the handle, and

your right hand is used on the trailing

length of rope to give you extra security

and fine adjustments of speed control. –

see Fig 1. WARNING: Holding onto the

working line may result in loss of descent

control. If in the situation that you pull

the handle too far the device will STOP.

To RESET the device rotate the handle

clockwise, in the direction of the arrows.

This will allow you to continue to DESCEND. The use of an ISC karabiner

(KH453) is recommended (for handle

clearance). All rope adjustment devices

create heat when travelling along rope at

speed, which can cause damage to the

rope. Although this device is designed as

a single use system, always check the

rope for damage as well as the device.

When used with Technora rope the rope

must be disposed of after each descent.

When used with polyester rope the rope

must be inspected after each use.

In addition to the visual inspections (see

Inspection) a thorough examination

should be carried out by a competent

person in line with applicable legislation

withdrawn from use and not used again

until confirmed in writing by a competent

person that it is safe to do so, should any

doubt arise about its condition for safe

use or, if it has been used to arrest a fall.

The

potential lifetime of ISC products is up to 10

years for plastic or textile products, and indefinite for metal products. The actual lifetime of a

product depends on a variety of factors such

as, the intensity of use, the frequency of use,

the environment in which it has been used, the

competency of the user, and how well it has

been maintained and stored etc.

with a mild detergent. Afterwards the

Alternatively an air gun can be used to

clear debris from device. Moving parts

applied to the axle on the back frame.

Manufacturers’ responsibility

The manufacturer or distributor will not

be held responsible for any eventual

damages, injuries or death resulting from

an improper use of this equipment. If

of the products you have chosen please

consult the manufacturer

and approved by APAVE

SUDEUROPE SAS, CS60193, 13322 Marseille Cedex 16—France., notified body

number CE0082, in accordance with

procedures set out in Article

11b

supervision of SGS UK Ltd., Unit 202b,

Worle Parkway, Weston-super-mare.

BS22 6WA., notified body number 0120.

Loading...

Loading...