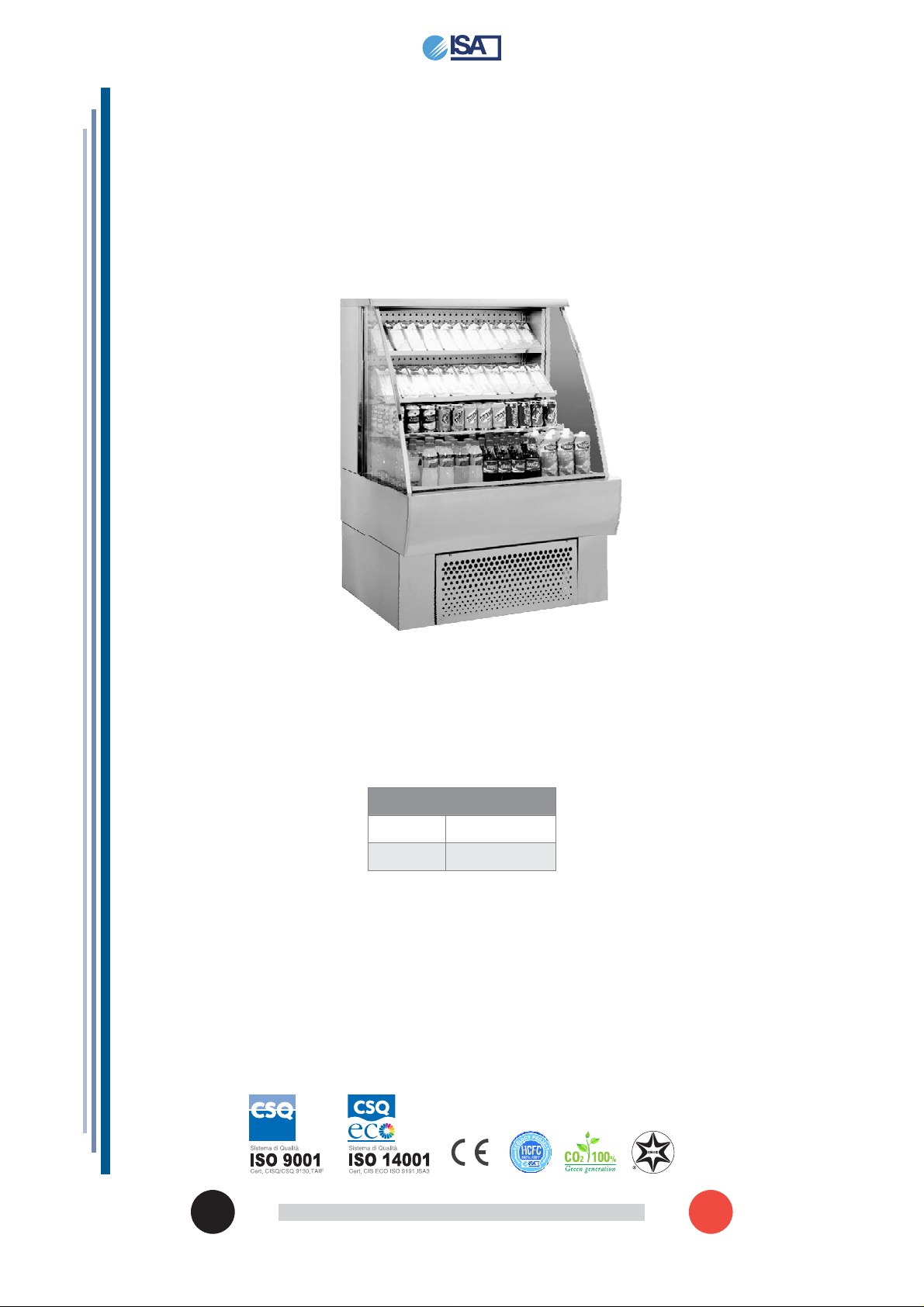

FOS INOX

EN

MODELS

60 RV TN

100 RV TN

ISA S.r.l.

Via del Lavoro, 5

06083 Bastia Umbra - Perugia - Italy

Tel. +39 075 80171 - Fax +39 075 8000900

www.isaitaly.com

FOS INOX

USE AND MAINTENANCE MANUAL

428000390037

R404A

1

CONTENTS

1. NOTES / IMPORTANT NOTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Manufacturer's contact details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2. SAFETY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 Personnel training. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Safety devices applied . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2.1 Safety devices present . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2.2 Fixed protective devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2.3 Sectioning the electrical power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Residual risks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3.1 Risk of contact with parts under stress . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3.2 Fire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3.3 Explosive atmosphere . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3.4 Slipping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3.5 Tripping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3.6 Circuit faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.4 Warning signs

3. WASTE DISPOSAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4. INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.1 Storage and unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.2 Installation, positioning and ambient conditions . . . . . . . . . . . . . . . . . . . . 10

4.3 Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5. TECHNICAL SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.1 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.2 Load limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6. EQUIPMENT DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

6.1 Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

6.2 Identifi cation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

7. CONTROL PANEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

7.1 Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

7.1.1 User Interface mod. 60 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

7.1.1.1 Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

7.1.2 User Interface mod. 100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

8. ROUTINE MAINTENANCE AND REGULAR CHECK . . . . . . . . . . . . . . . . . . 20

8.1 Chiller compartment inside cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

8.2 Accessing and cleaning the condensing unit . . . . . . . . . . . . . . . . . . . . . . . 20

8.3 External cleaning operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

9. MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

10. TECHNICAL ASSISTANCE CENTRE . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

10.1 Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

10.2 List of alarms on the electronic controller

11. WARRANTY TERMS AND CONDITIONS . . . . . . . . . . . . . . . . . . . . . . . . 24

12. ATTACHMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

(if any) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

(if any) . . . . . . . . . . . . . . . . . . . 24

EN

FOS INOX

USE AND MAINTENANCE MANUAL

428000390037

2

R404A

The manual contains symbols to attract the reader's attention

and highlight particularly important aspects. The table below

illustrates the meaning of the various symbols used.

Read the instructions manual

Use of protective clothing

Danger: Live electric parts

Request of maintenance or operations to be carried out by qualifi ed

personnel or technical assistance centre

Attention/Danger

Important information

Information

Operations to be performed by two persons

Visual check

Notes/Warnings

EN

FOS INOX

USE AND MAINTENANCE MANUAL

428000390037

3

R404A

1. NOTES / IMPORTANT NOTES

The content of this manual is of technical nature and is owned by ISA S.r.l.

It is forbidden to reproduce, circulate or modify all or part of its content without written

consent. Any infringement will be legally pursued.

The manual and the conformity certifi cate are an integral part of the equipment and should

always accompany the product in the event of transferral to a new location or to a new owner.

The user is responsible for the integrity of these documents, for their consultation during

the whole life cycle of the equipment itself. Keep this manual in a safe place. It should be

made available near the equipment for consultation at any time. If lost or destroyed, you

can request a copy of the manual to ISA S.r.l. by specifying the exact model, identifi cation

number and year of manufacturing. The manual refl ects the manufacturing technology at

the time of supply. The manufacturer reserves the right to modify its products in any way it

deems necessary, with no obligation to update manuals and machines relating to previous

manufacturing batches.

This equipment is not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities or by persons lacking the necessary experience and knowledge,

unless they are supervised by a person responsible for their safety who has instructed them

on how to use the cabinet. Children should be supervised to ensure that they do not play

with the equipment. Always refer to this manual before going ahead with any operation.

Before doing any type of work, disconnect the equipment from the power supply. Any work

on electric and electronic parts or cooling system components should only be carried out by

trained personnel in compliance with current laws.

The Manufacturer cannot be held liable for any injury to persons or animals, or damage to the

product itself in the event of:

• improper use of the equipment or use of the appliance by unqualifi ed or unauthorised

personnel;

• failure to comply with current legislation;

• incorrect installation and/or power supply faults;

• failure to observe the instructions contained in this Manual;

• failure to follow the maintenance programme;

• unauthorised modifi cations;

• installation of non-original spare parts in the equipment;

• installation and use of the equipment for purposes other than those for which the appliance

was designed and sold;

• tampering with or damage to the power supply cable.

Liability for applying the safety instructions contained in this manual is held by the technical

personnel responsible for the intended use of the equipment, who should ensure that

authorised personnel:

• are qualifi ed to carry out the requested activity;

• are aware of, and carefully comply with, the instructions contained in this document;

• are aware of, and apply, the general safety standards applicable to the equipment.

Failure to comply with safety standards may result in injury to personnel and damage to the

equipment components and control unit. The user can contact the dealer to request additional

information not contained in this document, or suggest improvements, at any time.

Before the product is delivered to the customer, it is essential that a trained technical

member of staff checks that the equipment is operating correctly in order to achieve

maximum performance.

FOS INOX

EN

USE AND MAINTENANCE MANUAL

428000390037

4

R404A

1.1 Introduction

ISA S.r.l. employs materials of the best quality and as they enter the company , we constantly

monitor their storage and the use as part of the manufacturing process to prevent damage,

deterioration and failure. All manufacturing elements are designed and manufactured in order

to guarantee reliability and high safety standards. All equipment is subjected to a strict testing

procedure before delivery. However, please bear in mind that product performance over time

depends on correct use and adequate maintenance. This manual contains the necessary

instructions to maintain the equipment's initial appearance and functions over time.

Note

So as not to compromise equipment operation and safety, particularly complex installation and

maintenance operations are not described in this manual and are carried out by the manufacturer's

specialised technical personnel.

The Use and Maintenance Manual contains the necessary information for understanding

how the equipment works and how to use it properly, namely: the technical description

of the various operational units, equipment and safety systems, operations, how to use

the instruments and the interpretation of any diagnostics reports, main procedures and

information relating to routine maintenance. For correct use of the equipment, the working

environment should comply with current health and safety standards.

The safety requirements, indications, standards and notes illustrated in the various chapters

of this manual are aimed at establishing a code of conduct and a series of obligations to

be observed when performing the various activities, in order to create safe conditions for

personnel, the equipment and the surrounding environment. The safety standards reported

in this document are intended for trained, authorised personnel responsible for:

- transport

- installation

- operation

- management

- maintenance

- cleaning, decommissioning and disposal which are the only intended uses of this equipment

Attention

Reading this manual, albeit in full, is no substitute for adequate user experience. therefore it should

only be considered a useful reminder of the technical features and the main operations to perform.

Warning

Installers and users are obliged to read and understand all the instructions contained in this document

before using the equipment.

1.2 Manufacturer's contact details

ISA S.r.l.

Via del Lavoro, 5

06083 - Bastia Umbra - Perugia - Italy

Tel. +39 075 80171

Fax +39 075 8000900

www.isaitaly.com

EN

FOS INOX

USE AND MAINTENANCE MANUAL

428000390037

5

R404A

2. SAFETY

The buyer is responsible for training personnel using the appliance on the risks, safety devices

and general health and safety rules required by the laws of the country where the equipment is

installed.

Users/operators should be aware of the position of all the controls and how they work, as well as

of the features of the equipment.

They should also read this manual in its entirely .

Maintenance work should be conducted by qualifi ed personnel after the equipment has been

prepared adequately .

Danger

Tampering with or unauthorised replacement of one or more parts of the equipment, applying

accessories that modify its use and fi tting spare parts other than recommended ones may result in

accident risks.

Danger

Before doing any type of work, the equipment must always be disconnected from the power supply.

Any work on electric parts or cooling system components should only be carried out by

trained personnel in compliance with current laws.

2.1 Personnel training

The buyer is responsible for ensuring personnel who will use the equipment and

maintenance technical staff are instructed and trained adequately.

The manufacturer is available for advice, clarifi cations, etc. so that the operator and

technical staff can use the equipment correctly.

Attention

The equipment is intended for professional use.

2.2 Safety devices applied

The Equipment is equipped with the following safety devices:

2.2.1 SAFETY DEVICES PRESENT

2.2.2 FIXED PROTECTIVE DEVICES

2.2.3 SECTIONING THE ELECTRICITY SUPPLY

2.2.1 Safety devices present

Devices which operation prevents risk situations in operation conditions verifying (e.g.

fuses, pressure switches, protective devices, circuit breakers, etc.).

2.2.2 Fixed protective devices

Fixed protective devices consist of fi xed perimeter shields, which are used to prevent

external parts from entering the equipment.

Danger

It is strictly forbidden to start up the equipment after maintenance work without refi tting the panelling

properly.

Attention

You should check the integrity of fi xed panels and corresponding fi xings to the frame, focusing in

particular on the protective panels.

FOS INOX

EN

USE AND MAINTENANCE MANUAL

428000390037

6

R404A

2.2.3 Sectioning the electricity supply

Before conducting any maintenance work on the equipment or part of it, it is necessary to

section the power supply that powers it.

Danger

Please remember to fully disconnect the equipment from the power supply in the event of maintenance

work during which the operator cannot prevent any accidental closure of the circuit by other people.

2.3 Residual risks

During design the manufacturer examined all the areas or parts at risk. Therefore, all

necessary precautions have been taken to prevent risks to persons and damage to the

equipment as mentioned earlier.

Attention

Periodically check that all safety devices are operating correctly.

Do not remove the fi xed protective devices.

Do not introduce foreign objects or tools into the operational and working area.

Although the equipment is fi tted with the aforementioned safety devices, there are still

some risks that cannot be eliminated, but reduced via corrective actions by the fi nal

integrator and correct operational procedures.

Below is a summary of the remaining risks associated with the equipment during:

- Normal operation

- Adjustments and tweaking

- Maintenance

- Cleaning

2.3.1 Risk of contact with live parts

Risk of breaking or damaging the electrical components of the equipment, with a possible

reduction in safety levels, following a short circuit.

Before connecting the electricity supply, make sure there is no ongoing maintenance work.

Attention

Before making the connection, check that the d/c electricity at the point of installation is no higher than

the value indicated on the protective switches on the fuse box. if it is, the user is responsible for fi tting

the relevant limiting devices.

It is strictly forbidden to conduct any electrical modifi cation, in order to prevent additional unforeseen

hazards and risks.

2.3.2 Fire

Danger

In the event of a fi re, immediately disconnect the master switch from the main power supply line.

EN

FOS INOX

USE AND MAINTENANCE MANUAL

428000390037

7

R404A

2.3.3 Explosive atmosphere

The equipment must not be located in an area classifi ed as an explosion risk according to

1999/92/EC such as:

Zone 0

An area in which there is a permanent, long-lasting or frequently explosive atmosphere

made up of a mixture of air and fl ammable substances in the form of gases, fumes or

steam.

Zone 1

An area in which the formation of an explosive atmosphere, made up of a mixture of air and

fl ammable substances in the form of gases, fumes or steam is occasionally probable during

normal activities.

Zone 20

An area in which there is a permanent, long-lasting or frequently explosive atmosphere in

the form of clouds of combustible dust in the air.

Zone 21

An area in which the formation of an explosive atmosphere in the form of clouds of

combustible dust is occasionally probable during normal activities.

2.3.4 Slipping

Any leaks in the areas surrounding the equipment may cause personnel to slip.

Check that there are no leaks and keep these areas clean at all times.

2.3.5 Tripping

Generally untidy deposits of material may constitute a tripping hazard and a total or partial

obstruction of emergency exit routes.

You should ensure that operating and transit areas and emergency exit routes are free from

obstacles in compliance with current legislation.

2.3.6 Circuit faults

Owing to potential faults, safety circuits may become less effective, which results in lower

safety levels.

You should check the oper ational condition of the present safety devices regularly.

2.4 Warning signs (if any)

Owing to the presence of various residual risks identifi ed, the equipment is fi tted with

hazard, warning and obligation signs devised in compliance with regulations relating to

graphical symbols for use on systems.

The signs are located in clearly visible positions.

Attention

It is strictly forbidden to remove the warning signs on the equipment.

The user is responsible for replacing warning signs that, owing to wear, become unreadable.

EN

FOS INOX

USE AND MAINTENANCE MANUAL

428000390037

8

R404A

3. WASTE DISPOSAL

During normal operation, the equipment does not generate any environmental

contamination. At the end of its life cycle, or if it is necessary to proceed to permanent

decommissioning, we recommend following the procedures below:

DISPOSAL (User)

The symbol, applied to either the product or its packaging, indicates that the product should

not be considered as normal domestic waste, but should be taken to a waste collection point

for the recycling of electrical and electronic appliances. The correct disposal of this product

helps to prevent potential negative consequences that might derive from inadequate product

disposal. For detailed information about recycling this product, contact your council, your local

waste collection service or the store where you purchased the product.

END-OF-LIFE DISPOSAL AND RECYCLING PROCEDURES

FOR THE EQUIPMENT

1. Switch off the equipment and unplug the power supply cable.

2. Remove the lamps (if installed). These should be disposed of separately.

3. Remove the control boards and the electronic cards. These should be disposed of

separately.

4. Remove all the independent parts (grids, casings, profi les, etc.) and group them

according to shared features in order to access the heat exchangers, pipes, cables, etc. and

be careful not to damage the cooling circuit.

5. Remove all mobile parts (doors, sliding doors, glass parts, etc.) and group the various

materials according to their features.

6. Check the type of coolant on the label located inside the counter. Remove the coolant

and dispose of it through authorised services.

7. Disconnect the evaporator, condenser, compressor, pipes and fans. These are made of

copper, aluminium, steel and plastic and should therefore disposed of separately.

8. Once all the guardings and the various parts of the frame have been removed, separate

the various types of material they are made from (plastic, metal sheets, polyurethane,

copper, etc.) into groups according to their features.

(Authorised Bodies)

All recyclable materials and waste should be processed and recycled by professionals, in

compliance with the laws of the country in question.

The company responsible for recycling the materials should be registered and certifi ed as a

waste disposal service in accordance with the specifi c directives of the country in question.

Attention

Illegal disposal of the product by the owner will result in administrative sanctions as required by

current laws.

Disposal of the product should comply with current laws on the disposal of coolant liquids and mineral

oils.

Important

If there is no symbol representing a barred dustbin on the equipment, this means that the

manufacturer is not responsible for taking care of the disposal of the product. In this case, again,

current waste disposal laws should be complied with.

Additional information

Further information on the disposal of liquid coolant, oils and other substances is available on the safety

data sheet corresponding to the substance itself.

EN

FOS INOX

USE AND MAINTENANCE MANUAL

428000390037

9

R404A

4. INSTALLATION

This manual provides information on how to unpack,

position and connect to the power supply.

4.1 Storage and unpacking

The equipment, with or without the packaging, should be carefully stored inside warehouses or

in areas away from the elements and direct sunlight, at a temperature between 0 and +40°C.

The equipment should only be moved by qualifi ed personnel operating forklift trucks, the

power of which should be suited to handling the weight of the product: during this operation

the equipment MUST be placed on the special pallet supplied.

Unpack the equipment by removing the screws fi xing it to the pallet.

All packaging materials are recyclable and should be disposed of in accordance with local

regulations. Please destroy "plastic" bags to prevent them from becoming hazardous to

children (suffocation).

4.2 Installation, positioning and ambient conditions

Attention

There should be a good air fl ow around the compressor and condensing unit. Therefore the area

around the unit should not be obstructed by boxes or other objects.

Position the equipment away from sources of heat (radiators, all types of ovens, etc.), and awa y from

draughts (generated for example by fans, air conditioning ducts, etc.).

Also avoid direct exposure to sunlight, or anything that causes the temperature inside the cabinet to

rise with detrimental results to unit operation and energy consumption. Do not use the equipment

outdoors and do not leave it exposed to rain.

4.3 Electrical connection

Attention

Check that the voltage indicated on the appliance is the same as the value on the appliance

identifi cation label and in the table provided in paragraph 2 of this manual, and check that the

required voltage is suitable.

Check on the socket that the power supply voltage provides rated voltage (±10%) when the

compressor is started.

The plug should be directly connected to the electrical socket. It is forbidden to connect the plug to

the socket by means of multiple socket extensions or adaptors.

The electrical system socket must be fi tted with a disconnecting device from the mains (rated for the

load and conform to current standards) to guarantee full disconnection in overloads category III (3)

and ensure protection of the circuits from earth faults, overloads and short circuits.

Do not route the electricity cable in passageways.

Attention

Earthing is necessary and mandatory by law.

EN

FOS INOX

USE AND MAINTENANCE MANUAL

428000390037

10

R404A

5. TECHNICAL SPECIFICATIONS

This equipment is exclusively intended to display and sell pre-packaged fresh products,

dairy ingredient and soft drinks.

The manufacturer is not liable for injury to persons or damage to property or the equipment

itself caused by the displaying of products other than those described above.

Attention

- Food preservation.

- Displaying and/or preserving non-food products (chemicals, pharmaceuticals, etc).

TECHNICAL

FEATURES

External dimensions (wxdxh) mm

Refrigeration

Defrosting

Climate class No.

Environmental conditions °C / % RH

Product class

Safety class (CEI EN 60335-2-89)

Refrigerant

Power supply V / ph / Hz

Electric absorption (at rated capacity) W / A

Electric absorption (during defrosting) W / A

Weight (net) Kg

No/°C (environment)

60 100

RV TN RV TN

STAINLESS STEEL STAINLESS STEEL

630 x 815 x 1400 1000 x 815 x 1400

Compressor

Stop

33

25 / 60 25 / 60

M2 M2

5 / 43 ± 2°C 5 / 43 ± 2°C

R404A R404A

230 / 1 / 50 230 / 1 / 50

680 / 3 1700 / 8

50 / 0.3 1200 / 5.2

78 130

Electrical

EN

FOS INOX

USE AND MAINTENANCE MANUAL

428000390037

11

R404A

5.1 Installation (Technical dimensions mm)

aaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

aa

Attention

The distances indicated for correct equipment installation must be respected.

5.2 Load limits

Attention

It is essential not to exceed the indicated load limits in order to prevent altering the correct air fl ow and

thus avoid higher product temperatures.

EN

FOS INOX

USE AND MAINTENANCE MANUAL

428000390037

12

R404A

6. EQUIPMENT DESCRIPTION

To ensure the operator's safety, equipment devices should be kept in constant working order. This

manual is intended to illustrate the use and maintenance

of the equipment. The operator has a responsibility and duty to carefully observe its instructions.

6.1 Structure

The equipment consist of a single piece of furniture which contains all the operational devices necessary

to make it a professional and effi cient product for its intended use.

The equipment consists of:

- Insulated structure in ecological polyurethane

- Cooling system

- Electronic commands panel

- Electrical system

- On board condensing unit

- Lighting

- Unidirectional movement wheels

6.2 Identifi cation

1 Symbols of Compliance

2

3 Production Order

4 Type

5 Model Name

6 Article

7 Serial Number

8 Production Date

9 - 10

11 Gross Capacity

12 Absorption at Rated Capacity

13 Absorption during Defrosting

14 Absorption of Heating Elements

15 Lamp Power

16 Fuse Value

17 Climate Class

18 Number of Motors

19 Type of Coolant

20 Amount of Coolant

21 Safety Class

22 - 23 Customer order

24 WEEE Mark

Identifi cation

of Company

Product Manager

Power supply voltage

and Frequency

EN

FOS INOX

USE AND MAINTENANCE MANUAL

428000390037

13

R404A

7. CONTROL PANEL

The control panel consists of the following components:

60

100

1 Electronic control unit

2 Chiller switch

3 Lighting switch

7.1 Start-up

Activate the mains system master switch.

mod. 60

Plug the socket supplied by the customer, ensuring that the plug is fi tted with an earth contact and that

there are no multiple sockets connected to it; the equipment automatically activates.

mod. 100

Plug in at the socket supplied by the customer, ensuring that the plug is fi tted with an earth contact and

that there are no multiple sockets connected to it.

Switch the equipment on by pressing the switch 2.

EN

FOS INOX

USE AND MAINTENANCE MANUAL

428000390037

14

R404A

7.1.1 User Interface mod. 60

To display or modify Set-Point.

Selects a parameter or confi rms a value when in programming.

To start defrosting.

To view data of a temperature alarm.

Scrolls parameters' codes or increases their value when in programming.

Attention

The electronic control board is installed already

programmed. Any changes to the control board

settings can be carried out exclusively by qualifi ed

technical personnel.

KEYS

To view data of a temperature alarm.

Scrolls parameters' codes or decreases their value when in programming.

Switches lighting on / off.

KEY COMBINATION

To lock and/or release keyboard.

To access programming.

To exit programming.

EN

FOS INOX

USE AND MAINTENANCE MANUAL

428000390037

15

R404A

LED

STATUS MEANING

On. Compressor(s) active

Flashing. Delay against close start-ups

On. Defrosting in progress

Flashing. Dripping in progress

On. Unit of measure

Flashing. Programming

On. Unit of measure

Flashing. Programming

On. Fan/s running

EN

FOS INOX

USE AND MAINTENANCE MANUAL

428000390037

16

R404A

7.1.1.1 PROGRAMMING

MINIMUM TEMPERATURE DISPLAY

1. Press and release key

2. The “Lo” message is displayed followed by minimum temperature reached.

3. Press or wait 5 seconds to go back to displaying normal temperature.

MAXIMUM TEMPERATURE DISPLAY

1. Press and release key

2. The “HI” message is displayed followed by minimum temperature reached.

3. Press or wait 5 seconds to go back to displaying normal temperature.

SET-POINT DISPLAY

1. Press and release , SET-POINT is immediately displayed.

2. Wait 5 seconds or press key again, to go back to temperature display

SET-POINT MODIFICATION

1. Press for at least two (2) seconds.

2. SET-POINT is displayed and LED °C starts fl ashing.

3. Modify value by acting on keys

4. Memorise new SET-POINT by pressing or wait 15 seconds to exit programming.

ACTIVATE MANUAL DEFROSTING CYCLE

1. Press for at least two (2) seconds.

KEYBOARD LOCK

1. Keep keys pressed for a few seconds until “POF” appears fl ashing.

The keyboard is now locked; only display of SET-POINT, maximum and minimum temperature is

possible.

“POF” appears if a key is pressed for more than three (3) seconds.

KEYBOARD RELEASE

1. Keep keys pressed for a few seconds until “POn” appears fl ashing.

FOS INOX

EN

USE AND MAINTENANCE MANUAL

428000390037

17

R404A

7.1.2 User Interface mod. 100

UP

Scrolls menu options

Increases the values

Activates manual defrosting

DOWN

Scrolls menu options

Decreases the values

Attention

The electronic control board is installed already

programmed. Any changes to the control board

settings can be carried out exclusively by qualifi ed

technical personnel.

At start-up, the instrument conducts a LAMP

TEST for a few seconds. The display and LEDS

fl ash to verify their integrity and to ensure they

are working correctly.

KEYS

STAND-BY (ESC)

Goes back one level compared to current menu

Confi rms parameter value

Activates the Stand-by function

SET (ENTER)

Accesses the Setpoint

Accesses the programming menu

Confi rms input commands

Displays alarms (if any)

LED

COMPRESSOR or RELAY 1

ON for compressor on

Flashing for delay, protection or blocked activation

DEFROST

ON for defrosting in progress

Flashing for manual activation

ALARM

ON for active alarm

Flashing for silenced alarm

EN

FANS

ON for operating fans

USE AND MAINTENANCE MANUAL

FOS INOX

428000390037

18

R404A

SET button

Press the SET (ENTER) button and release immediately.

The “Set” label appears.

To view the Setpoint value, press the SET (ENTER) button again.

The Setpoint value will appear on the display.

To change the Setpoint value, press the UP and DOWN buttons within 15 seconds.

To confi rm the new Setpoint value set, press the SET (ENTER) button again.

If 15 seconds passes without any of the buttons being pressed (time-out), or if the STAND-BY (ESC)

button is pressed just once, the last values viewed on the display will be confi rmed and the previous

display will be restored.

Check UP

Alarms are reported by the buzzer (if any) and the LED corresponding to the alarm icon.

Any alarms deriving from broken probe (probe 1) appear directly on the instrument's display and are

indicated by E1.

Any alarms deriving from broken evaporator probe (probe 2) appear directly on the instrument's display

and are indicated by E2.

Manual activation of the Defrosting cycle

To manually activate the defrosting cycle, press and hold the UP key for 5 seconds.

If defrosting conditions are not present (for instance the temperature of the evaporator probe is higher

than the temperature at the end of the defrosting process), the display will fl ash three (3) times to

indicate that the operation will not be performed.

EN

FOS INOX

USE AND MAINTENANCE MANUAL

428000390037

19

R404A

8. ROUTINE MAINTENANCE and REGULAR CHECK

8.1 Chiller compartment inside cleaning

a) Remove the product contained in the chiller compartment and place it immediately in a freezer to

ensure it is preserved correctly.

b) Switch off the equipment.

Wait at least 4 to 6 hours, until the ice on the evaporator has melted completely, before proceeding with

cleaning the equipment. We recommend waiting until the following day to make sure the product has

been completely defrosted.

c) Wash the bottom of the tank and the sides with a mild detergent, warm water and a cloth or a nonabrasive sponge.

Rinse well and dry using a cloth.

d) If the equipment is connected with a ground discharge, pour some warm water with a sanitising

solution suited for the intended use. In terms of quantity, the the amount of solution used should be

enough to remove any product residues and disinfect the whole drainage channel.

If the equipment is not connected to a drain channelled into the ground, follow the procedure described

in the previous paragraph. The water used to rinse the solution should be collected in the tray located

inside the base of the equipment. Clean and disinfect the tray.

8.2 Accessing and cleaning the Condensing Unit

Remove the rear protective grid by loosening the specifi c fi xing screws.

Attention

Clean the condensing unit using a suction brush.

Clean the CONDENSER with a soft bristle brush;

make sure you do not bend the condensing unit

springs whilst cleaning it.

EN

FOS INOX

USE AND MAINTENANCE MANUAL

428000390037

20

R404A

8.3 External cleaning operations

The external surfaces should be cleaned as follows:

STAINLESS STEEL

Wash with lukewarm water and mild detergents, rinse and dry using a soft cloth.

ACRYLIC OR POLYCARBONATE SURFACES

Wash with lukewarm water, using a soft cloth or a chamois cloth.

Do not use detergents, alcohol, acetone and solvents.

Do not use abrasive cloths or sponges.

GLASS SURFACES

Only use products specifi cally designed for cleaning glass.

We do not recommend using tap water, which may leave calcium deposits on the surface of the glass.

EN

FOS INOX

USE AND MAINTENANCE MANUAL

428000390037

21

R404A

9. MAINTENANCE

Any work conducted on the on the equipment MUST involve disconnection from the power socket and in

any case, none of the protective elements (grid, casing) should be removed by non-qualifi ed staff; the

equipment should not be operated when these protective elements have been removed.

The Equipment manager must check and respect the maintenance schedule in the table below by

calling the authorised Technical Assistance service when indicated.

ROUTINE

OPERATION FREQUENCY AUTHORISED

Cleaning the external surfaces Depending upon Use and Necessity User

Cleaning the accessible internal parts

(without the use of tools)

Power supply cable,

electric sockets and/or plugs check

Check the seal gaskets integrity Monthly User

Condenser cleaning Monthly/Six monthly Technical Assistance

Check the compressor oil level

(if present)

Air tank draining

(if present)

Check pneumatic connections

(if present)

Check the integrity of chiller system piping Six-monthly Technical Assistance

Inspect cables and internal power

connections

Cleaning of condensation absorbing sponges

(if present)

Depending upon Use and Necessity User

Monthly/Six monthly User

Six-monthly Technical Assistance

Six-monthly Technical Assistance

Six-monthly Technical Assistance

Six-monthly Technical Assistance

Six-monthly Technical Assistance

PERSONNEL

EXTRAORDINARY

OPERATION AUTHORISED

Replacing lamps/LED

(if present)

Replacing control panel

(electronic control board - thermostat - etc.)

Replacing power supply cable,

electric sockets and/or plugs check

FOS INOX

EN

USE AND MAINTENANCE MANUAL

428000390037

PERSONNEL

Technical Assistance

Technical Assistance

Technical Assistance

R404A

22

10. TECHNICAL ASSISTANCE

10.1 Faults

If the appliance is not working properly or stops working, before contacting the

Customer Support Centre, check the following:

FAILURE CAUSE SOLUTION

The

appliance is

not working

The internal

temperature

is not low

enough

The

compressor

does not

work or

works only

for a few

moments

Blown protective fuse Find what triggered the

The master switch is open Close the master switch.

Plug is not inserted Insert the plug.

Power cut If the power cut persists,

Evaporator(s) completely blocked

by ice

The wrong temperature has been

set on the electronic control board

The equipment is affected by

draughts or is exposed to direct or

refl ected sunlight

Insuffi cient cooling air fl ow in the

air condensing unit

The internal fans have stopped

or their blades are damaged

Internal ventilation is too high Contact the Technical Assistance service.

Low electronic control board

effi ciency

Air condensing unit blocked by dust

or debris

Insuffi cient coolant

in the cooling system

No power supply Check if there is a power cut.

The power supply voltage is too

low

The temperature set on the

thermostat is too high

The pressure switch

activated at maximum pressure

(if any) was

switch and subsequently replace the fuse.

transfer the product to a freezer.

Carry out an additional defrosting cycle.

Set the right temperature.

Eliminate any excessive draughts and prevent any direct or

refl ected sunlight.

Remove anything that may affect air fl ow inside the condensing

unit (paper sheets, cardboard, grids with an insuffi cient number

of holes, etc.).

Contact the Technical Assistance service.

Contact the Technical Assistance service.

Replace electronic control unit.

Replace the temperature probes only after checking which of the

two is not operating effi ciently .

Contact the Technical Assistance service.

Clean the condensing unit thoroughly.

Contact the Technical Assistance service

Find the cause behind the lower amounts of coolant and eliminate

it. Top up the coolant. If necessary, empty the system before

topping up.

Close the various switches on the power supply line.

Check that the mains voltage at the ends of the power supply

cable is 220V +/- 10%.

If the set temperature is higher than that of the air in the display

area, the compressor does not activate itself.

Set a more suitable temperature if the current value is not low

enough

Contact the Technical Assistance service.

Check the reasons why the pressure switch is operating at

maximum pressure levels, such as: air condensing unit blocked,

condensing unit fan stopped, ambient temperature too high,

pressure switch broken.

EN

FOS INOX

USE AND MAINTENANCE MANUAL

428000390037

23

R404A

10.2 List of alarms on the electronic controller (if any)

ALARM DESCRIPTION SOLUTIONS

P1

Broken thermostat probe.

Compressor trip with “CON” and “COF"

E0

P2

parameters.

Broken evaporator probe.

Set time for defrosting.

E1

HA

High temperature alarm.

HI

LA

Low temperature alarm.

LO

EA

External alarm.

IA

CB

ETc

Real time clock is broken.

RTF

EE Machine parameter error.

EF Operating parameters error.

Contact the Technical Assistance service.

The alarm starts a few seconds after the probe breaks

down; it stops a few seconds after the probe starts

working again properly.

We recommend checking the probe connections before

replacing it.

Contact the Technical Assistance service.

The alarm starts a few seconds after the probe breaks

down; it stops a few seconds after the probe starts

working again properly.

We recommend checking the probe connections before

replacing it.

Contact the Technical Assistance service.

The alarm stops automatically after reaching of set

temperature.

Check the settings.

Contact the Technical Assistance service.

The alarm stops automatically after reaching of set

temperature.

Check the settings.

Contact the Technical Assistance service.

The external alarm stops after the digital infeed is deactivated.

It should be automatically restarted.

The alarm is activated when the pressure switch and/or

the compressor's circuit breaker (if present) is activated.

Contact the Technical Assistance service.

Reset the clock.

If the alarm does not stop, replace the clock.

Contact the Technical Assistance service.

The instrument is damaged. It should be replaced.

Contact the Technical Assistance service.

The instrument is damaged. It should be replaced.

11. WARRANTY TERMS AND CONDITIONS

The seller's warranty on the equipment is valid for 12 (twelve) months from the date of

delivery.

The warranty includes repairs or replacements of any faulty parts due to manufacturing

processes or installation after written communication has been received, stating the

equipment serial number and date of installation.

All defects caused by incorrect use of the equipment, inappropriate electrical connection,

normal wear (for instance compressor failure and fl uorescent lamp malfunctioning that is

not due to manufacturing defects), as well as calls for installation, technical instructions,

adjustments and cleaning, are not included in the warranty.

If the seller's technical staff detect any tampering, unauthorised repairs or inappropriate use

of equipment the warranty will be invalidated.

Shipment of components covered by the warranty is freight collect only.

Any damage to the equipment detected at the time of delivery due to transport must be

reported on the same shipping note to claim compensation from the carrier.

The seller cannot be held liable in the event of damage to the preserved product due to

refrigerated cabinet failure.

EN

FOS INOX

USE AND MAINTENANCE MANUAL

428000390037

24

R404A

12. ATTACHMENTS

No.

1

Electrical diagram 412100024000 26

2

Electrical diagram 412129063200 27

3

Declaration of conformity 28

Page

EN

FOS INOX

USE AND MAINTENANCE MANUAL

428000390037

25

R404A

Attachment 1

MODELS

60 RV TN

EN

Code 412100024000

C5 Electronic control unit

F2 Fuse

L3 Single-lamp electronic reactor

L5 Fluorescent pipe T8

S1 Temperature probe

S2 Defrost probe

U1 Compressor

U2 Condenser fan

U3 Evaporator fan

U11 Antistatic fi lter

FOS INOX

USE AND MAINTENANCE MANUAL

428000390037

26

R404A

Attachment 2

EN

MODELS

100 RV TN

Code 412129063200

CE Electronic control unit

I1 Cabinet switch

I2 Lighting switch

K2 Klixon defrosting end

L1 Single-lamp magnetic reactor

L5 Fluorescent pipe T8

R1 Defrosting armoured resistor

R2 Condensation drying armoured resister

S1 Temperature probe

S2 Defrost probe

S5 Water level sensor

U1 Compressor

U2 Condensation fan

U3 Evaporator fan

U8 Starter

FOS INOX

USE AND MAINTENANCE MANUAL

428000390037

27

R404A

Attachment 3

DECLARATION OF CONFORMITY

We: ISA S.r.l.

Via del Lavoro, 5 - 06083 - Bastia Umbra (PG)

under out exclusive responsibility declare that the product:

Product: FOS INOX

Serial no.: XXXXXXXXXXXXXXXX

To which this declaration refers, is compliant with the following:

General Electrical Safety Standard EN 60335-1/Ed.2002+Modifi cations A11:2004,A1:2004,A12:2006,A2:2006,A13:2008 Special Safety

Requirements for Commercial Refrigeration Appliances EN 60335-2-89/Ed. 2010 Standard for the Measurement of Electromagnetic

Fields (EMF) of Electrical Appliances EN 62233:2008 Directive 2006/95/EC of the European Parliament and the Council of 12th December

2006 on the harmonisation of the Laws of Member States relating to electrical equipment for use within certain voltage limits. EN 62471/

Ed.2009 Photobiological safety lamps and lamp systems

ELECTROMAGNETIC COMPATIBILITY (EMC)

Limits and measurement methods for radio interference characteristics of household appliances and similar motor-operated and heating

appliances, tools, electrical appliances and similar apparatus EN 55014-1 (valid until 2009: Ed.2000+Amendments A1:2001, A2:2002

- or: Ed.2006)

Minimum requirements for household appliances, tools and similar electrical appliances. EN 55014-2 (Ed.1997+Amendment A1:2001)

Part 3: Limits – Section 2: Limits for harmonic current emissions (equipment input current=16A per phase)

EN61000-3-2 (valid until 2009:Ed.2000+Modifi cation A2:2005-or:Ed.2006) Part 3: Limits – Section 3: Limitation of voltage fl uctuations

and fl icker in low-voltage power supply systems for equipment with rated current=16A

EN61000-3-3 (Ed.1995+Modifi cations A1:2001,A2:2005) Part 4: T esting and measurement techniques Section 2: Electrostatic discharge

immunity test EN61000-4-2 (Ed.1995) Part 4: Testing and measurement techniques Section 4: Electrical fast transient/burst immunity

test EN61000-4-4 (Ed.1995)

PRESSURE EQUIPMENT DIRECTIVE (PED) 97/23/EC

As the equipment falls into a class lower than I, it is excluded from the PED’s application fi eld (art.1 par.3.6)

Regulation (EC) No.1935/2004 of the European Parliament and of the Council of 27th October 2004 Regulation (EC) No.2023/2006 of

the Commission of 22nd December Directive 2008/39/EC of the Commission of 6th March 2008 Directive 2007/19/EC of the Commission

of 30th March 2007 Directive 2005/79/EC of the Commission of 18th November 2005 Directive 2004/19/EC of the Commission of 10th

March 2004 Directive 2004/1/EC of the Commission of 6th January 2004 Regulation (EU) 10/2011 of the Commission of 14th January

2011

Directive 2002/95/EC of the European Parliament and of the Council of 27th January 2003

Directive 2002/96/EC of the European Parliament and of the Council of 27th January 2003

Regulation (EC) No.1907/2006 of the European Parliament and of the Council of 18th December 2006 on the recording, assessing,

authorising and restricting of chemical substances (REACH), implemented by a European agency for chemical substances, modifying

Directive 1999/45/EC and repeals Regulation (EEC) no. 793/93 of the Council and Regulation (EC) no. 1488/94 of the Commission

91/155/EEC, 93/105/EC and 2000/21/EC

SUBSTANCES REDUCING THE OZONE LAYER

Regulation (EC) No.1005/2009 of 16th September 2009 (G.U.U.E 31/10/2009 L286)

According to the requirements set by Directives: 2006/95/EC, 2004/108/EC, 2006/42/EC, 97/23/EC

SAFETY OF MACHINERY

FOOD COMPATIBILITY

ROHS AND WEEE

REACH

The person authorised to institute the Technical File is Mr. Maurizio Minelli (Technical Department Manager)

Bastia Umbra: 18 / 07 / 2012

(place and date of issue) Maurizio Minelli

EN

Via del Lavoro 5 - 06083 Bastia Umbra (PG)

FOS INOX

USE AND MAINTENANCE MANUAL

428000390037

28

R404A

Loading...

Loading...