Page 1

R

PLATO

Passive Infrared Detector

IR-580/580C/580CS

Installation Instructions

INTRODUCTION

Thank you for choosing PLATO series passive infrared

detector. This motion detector is designed to provide

reliable intruder detection for today’s security system.

To ensure optimum performance of this device, please

read all contents carefully before installing. Improper

installation may result in false operation.

INSTALLATION HINTS

Do not install the detector at

where faces direct or reflected

sunlight or windows with direct

car headlight.

Ensure that there are no

obstructions (plants, screens,

furniture etc.) in the field of view

that may cause incorrect

cover/operation of the detector.

Avoid locating the detector in

areas where contain equipment

that may change the environment temperature rapidly.

Install the detector at proper

height on a rigid surface. Do

not install the detector on

vibrating surface.

PIR detector is more sensitive to

the motions “across” the

detection zones than “toward”

or “away” the unit.

DESCRIPTION

PCB fixing screw

Corner mount knockout

s

Cable access

Wiring terminals

Tamper switch

PCB position pointer

Cover locking screw

Infrared sensor

(Do not touch!)

Alarm output selector

Pulse count selector

LED on-off switch

Mounting bracket fixing

INSTALLATION

DIRECT WALL/CORNER MOUNT

1. Open the front cover by releasing the cover

locking screw.

2. Carefully remove the PCB from the unit base.

3. Knock out the mounting holes with proper tool.

4. Drill the holes on wall. Lead the cable through

access hole and mounts the unit base firmly.

5. Replace the PCB to the unit base and complete

the wiring as the next paragraph described.

CEILING/WALL MOUNT WITH BRACKET

1. Mount the bracket base on ceiling or wall. Lead

the cable through central well.

2. Open the front cover of the detector by releasing

the cover locking screw.

3. Carefully remove the PCB from the unit base.

4. Fix the unit base of detector and the swivel arm of

mounting bracket with provided screws.

5. Lead the cable through the wire tunnel into the

unit base. Assemble the unit base with the bracket

base.

2.4m (8 feet)

(Approx)

6. Replace the PCB to the unit base and complete

the wiring as the next paragraph described.

WIRING CONNECTION

After the installation completed. Connect the wires to

the corresponding terminals according to the following

instructions.

+

, –

: 9 ~ 16 VDC power supply

ALARM : Zone input of control panel (N.C/N.O)

TAMPER : Tamper loop of control panel (N.C).

Replace the front cover, apply power supply to the

detector to conduct the walk test.

WALK TEST

The walk test should be carried out to ensure proper

detection coverage. Apply DC power to the detector

and wait at least 60 seconds for sensor to warm up.

Walk across the detection zones at normal speed. The

LED will light whenever it detects the movement. To

disable the LED, just remove the jumper head from the

pins marked “LED”.

Page 2

PULSE COUNT

The detector features an intelligent pulse count that

reduces the possibility of false alarm caused by

environmental and power line interference. The pulse

count can be set to count 2 or 3 pulses by placing the

jumper head on or off the corresponding pins. The

alarm signal will only be sent when the selected pulses

are generated within delay time of 20 seconds. IRTEC‘s intelligent pulse count circuitry analyzes the

width difference of pulse signal. When human motion

is detected a subsequent pulse signal

will over-ride the pulse count setting

and generate the alarm signal without

any delay.

ALARM OUTPUT SELECTION

The alarm output of this detector can be changed from

NC (normally closed) to NO (normally open) by

removing the jumper head from the pins. NC format is

generally used in the intruder alarm system; NO format

can be used for alarm event recording or other

automatic control applications.

RANGE ADJUSTMENT

The detection zones can be vertically adjusted by

sliding the PCB up or down. If the unit is mounted

higher than 2.7m (9 feet), it maybe necessary to slide

the PCB upwards to tilt the detection zones

downwards to obtain optimum detection coverage. If

the unit is mounted lower than 2.1 (6 feet), it maybe

necessary to move the PCB downwards to tilt the

detection zones upwards. Please refer to the following

table to get the adequate PCB position for the

respective maximum detection coverage with various

mounting heights.

For IR-580 w/o bracket

M/H 1.8m 2.0m 2.2m 2.4m 2.6m 2.8m 3.0m

B/P Maximum Detection Coverage(m)

+2 15 15 15 15 15 12 15

+1 15 15 15 15 13 15 15

0 15 15 15 15 15 15 15

-1 14 15 15 15 15 15 15

-2 13 14 14 15 15 15 14

-3 10 11 12 14 13 14 9

-4 8 9 11 11 12 13 8

M/H: Mounting Height B/P: PCB Position

Note: The detection range might be reduced under

high room temperature.

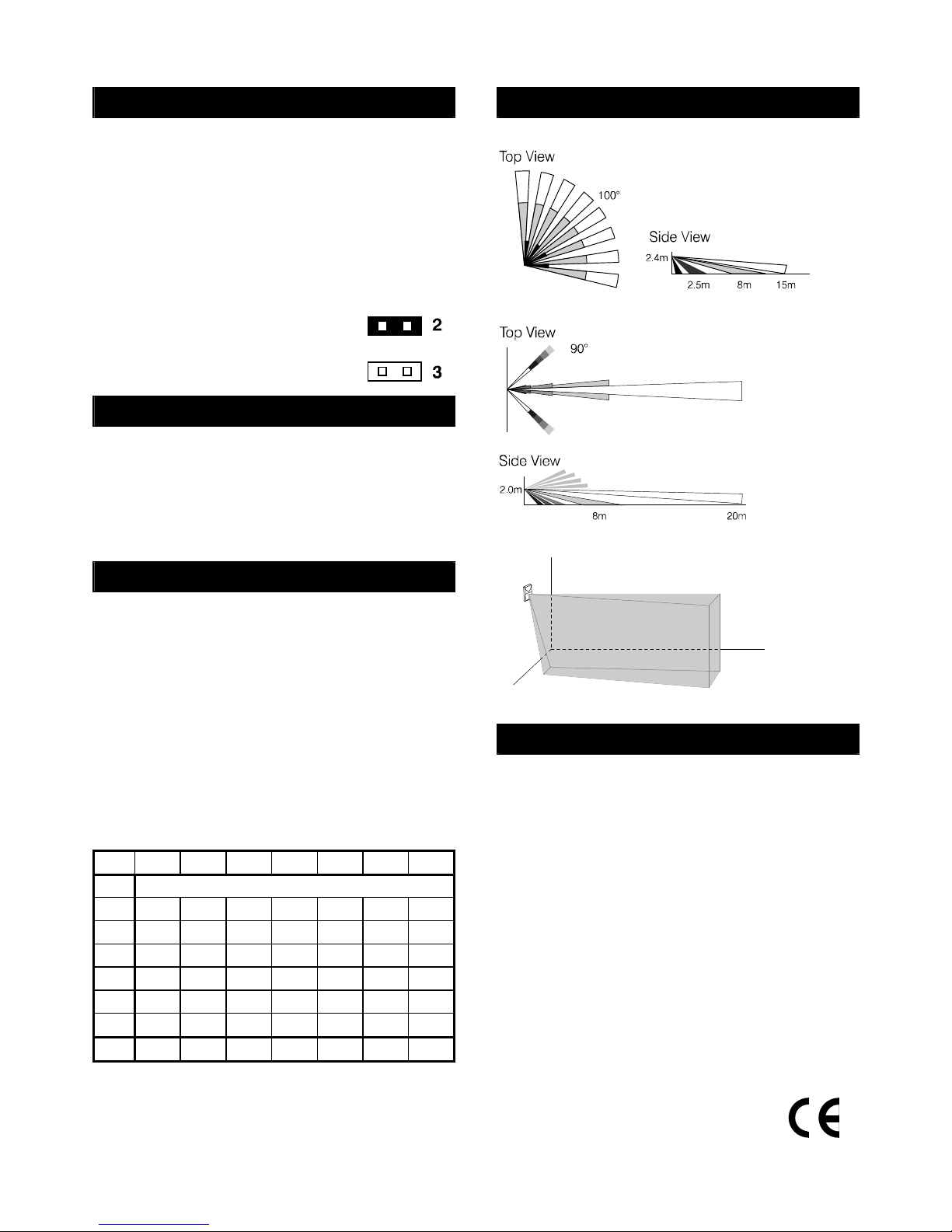

DETECTION PATTERN

IR-580

IR-580C

IR-580CS

15m

2.4m

SPECIFICATIONS

Infrared sensor..............Dual element

Power supply................9 ~ 16 VDC, 12V typical

Current drain.................NC: 15mA, NO: 8 mA, 12VDC

Alarm output .................NC/NO, 30VDC, 0.2A max.

Alarm period .................1.5 ~ 2.5 sec.

Pulse count...................2 / 3 selectable

Tamper switch ..............NC, cover open activates

Walk test LED ...............Blue, can be disabled

RFI immunity.................Ave. 25V/m (10~1000 MHz)

Detectable speed..........0.3 ~ 1.5m/sec.

Mounting height............W/o bracket: 1.8~3.0m

With bracket: 1.8~3.6m

Humidity........................95% RH maximum

Temperature .................-20°C ~ 60°C (-4°F ~ 140°F)

Dimensions...................100 x 60 X 42 mm

Unit weight....................68 grams

* Specifications are subject to change without prior notice.

06/29/05’ 058-58000-001

Loading...

Loading...