Page 1

Hot

Black

White

Red

Red

Black

Brown

Green

White

Red

Black

Blue

Red

Neut

Relay

Relay

DC24V

GND

COM

AC/DC

NO

NC

MS

DIM

Control

Hot

120~277V

Neutral

OS-551DT

PPU-301

Load

Hot

Neut

Yellow

Orange

Violet

Grey

OVERVIEW

The OS-551DT comes with pigtail wires for

connection to the corresponding wires of IR-TEC

power pack or BMS control. Each IR-TEC

PPU-300/301 power pack can supply power for up to

6 OS-551DT sensors. When more sensors are

connected, multiple power packs may be required.

Low Voltage Dual-Tech Occupancy Sensor

OS-551DT

INSTALLATION INSTRUCTIONS

APPLICATION NOTES

PIR sensor is more sensitive to the movements

“crossing” the detection zones than “toward” or

“away” the sensor unit. Avoid placing the sensor in

line with the path of occupant, if possible. In general,

mounting the sensor at corner area gives better

detection.

PIR sensor cannot “see” the movements behind

obstacles, such as furniture, shelf, glass or partitions.

As a general rule, ensure to place the sensor at where

the occupant could have clear view of the sensor.

HFD sensor may penetrate through certain types of

non-metallic partition material (glass, plaster,

plywood…etc) and detects the traffics outside of

desired range. Ensure to adjust the HFD sensitivity to

achieve optimal detection range.

Place the sensor at least at 5 ft. (1.5m) away from air

supply duct and fluorescent lighting to avoid false

activating.

For open office areas with partition which could block

the sensor view to occupant movements, it is

recommended to place the sensors over the

intersection of multiple workstations. For large areas of

open office or space, place multiple sensors so that

there is overlap coverage with each adjacent sensor.

1.

2.

3.

4.

5.

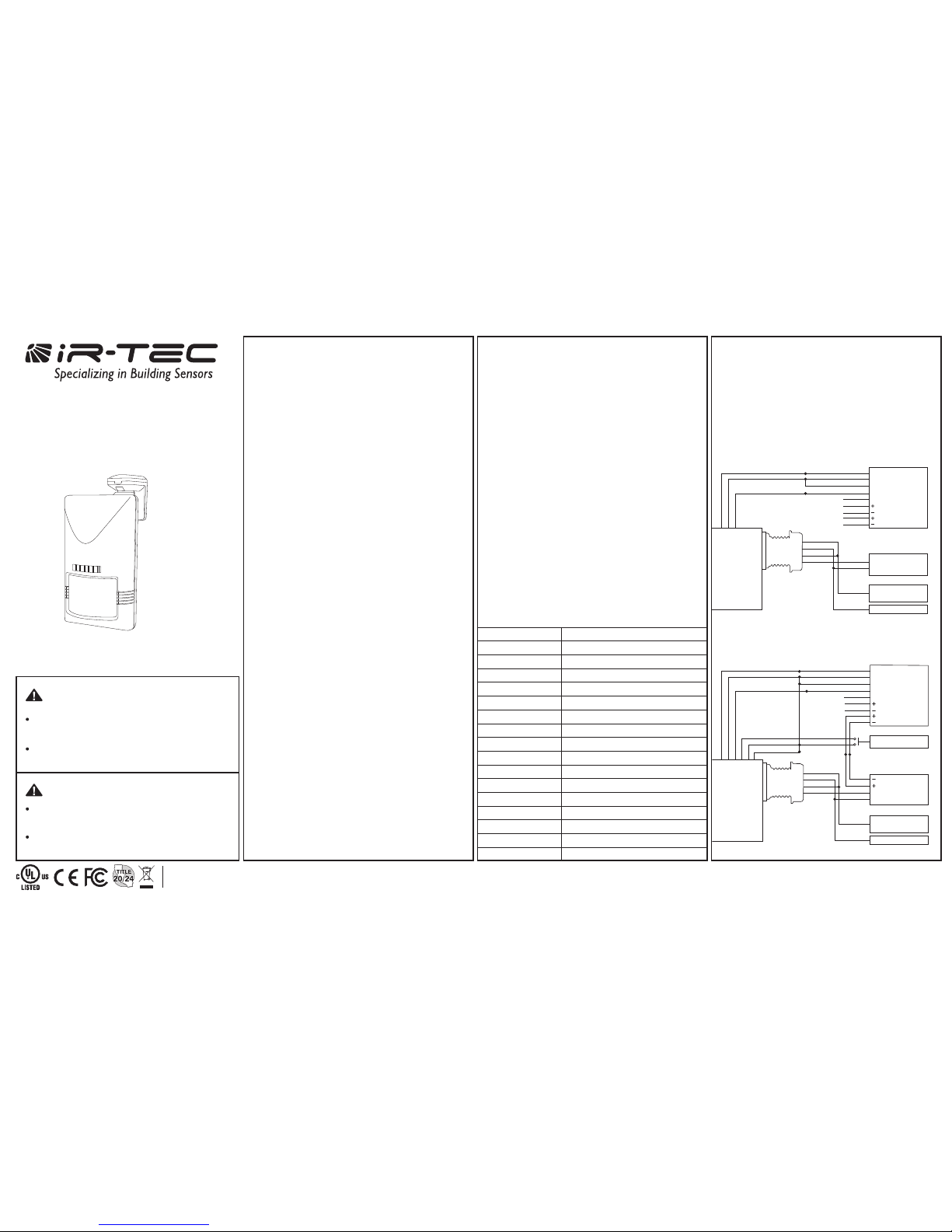

WIRING DIAGRAM

A. Auto-ON/Auto-OFF with PPU-301

B. Manual-ON/Auto-OFF and Auto-DIM

with PPU-300

Hot

Black

White

Red

Red

Black

Brown

Green

White

Red

Black

Blue

Red

Neut

Relay

Relay

DC24V

COM

AC/DC

NO

NC

MS

DIM

Control

Manual

Hold ON

Hold OFF

Hot

120~277V

Neutral

OS-551DT

DIM

Dimmable light

1-10V

Hot

Neut

Yellow

Orange

Violet

Violet

Grey

Grey

Momentary Button

PPU-300

DC24V

GND

Control

Manual

Hold ON

Hold OFF

Orange

Grey

Brown

The OS-551DT is a low voltage dual technology

occupancy sensor designed to signal the occupancy

status for area lighting, or HVAC control, for energy

efficient building management. The sensor combines a

cutting edge Passive Infrared (PIR) sensor, a

state-of-the-art High Frequency Doppler (HFD) sensor,

and advanced signal processing firmware into one unit

to perform superior occupancy sensing capability. The

OS-551DT is ideal for the areas where motion may not

be easily detectable by a single technology sensor.

The OS-551DT is operated by 24V low voltage power.

When PIR sensor detects the presence of occupant

within its coverage, the sensor will activate a form C

dry contact for a period of OFF-delay time as

programmed. The delay timer will be reset if any

motion is detected by either PIR or HFD sensor before

delay time elapsed. An ON-delay can be enabled to

prohibit short-cycle restart or unwanted load activation

if the sensor is used to control HVAC operation. Both

ON and OFF delays can be easily set via two rotary

DIP switches on board. A potentiometer allows the

HFD sensitivity adjustment. The sensor output can be

set to inhibit when ambient light level is higher than the

threshold programmed. The ECG analog output is

available for constant level lighting control.

This sensor offers numerous control options which can

be enabled, or disabled via a 6-pole DIP switch on

board. 3 LED’s are available to indicate the sensing

status which can be disabled if necessary. A built-in

buzzer can be enabled to provide audible Delay-End

Warning (DEW) at the end of OFF-delay. The

SmartDelay can be enabled to automatically adjust the

OFF-delay based on the duration of previous

occupancies. Walk-Through mode can be enabled to

turn the light off 3 minutes after the area is initially

occupied but with no motion detected in the next 30

seconds. The FORCE-OFF delay can also be applied if

HFD sensor may detect the out-of-range motions thus

result in unwanted OFF-delay extensions. The

sensitivity of PIR sensor can be reduced for harsh

environment.

SPECIFICATIONS

Power supply

Current drain

Output contact

Infrared sensor

HFD sensor

Detectable speed

Mounting height

Detection range

ON-delay setting

OFF-delay setting

ALS level setting

Manual override

FORCE-OFF delay

Walk-thru mode

Op. humidity

Op. temperature

Dimensions

22~26 VAC/DC

20 mA @ 24 VAC, standby mode

Form C, max. 5A resistive load

Dual element pyroelectric sensor

X-band DRO type, patch antenna

0.33 ~ 10 ft/sec. (0.1 ~ 3 m/sec.)

6 ~ 12 ft (1.8 ~ 3.6 m)

110°, 50 ft @ 77°F (25°C)

0(disabled)/5”/10”/20”/30”/1’/3‘/5’

10”/1’/3’/5’/10’/20’/30’/60’

4-level, 2~2,000 lux

Momentary contact

5 times of OFF-delay set, if enabled

3 min. if no motion within 30 sec.

Max. 95% RH

-14°F ~ 122°F (-10°C ~ 50°C)

4.4”x2.6”x1.8” (112 x 66 x 45 mm)

P/N: 058-55100-005 Printed in Taiwanwww.irtec.com

This product may be covered by one or more U.S. patents or patent applications.

Please visit www.irtec.com for more information.

Turn power OFF at circuit breaker before connecting

Power Pack or Sensor.

CAUTION

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1)This device may not cause harmful interference, (2)This device must accept any interference received,

Including interference that may cause undesired operation.

FCC NOTES:

FCC ID: NRIOS-551DT

Wire all Class 2 circuits using types CL3, CL3P, CL3R,

or equivalent conductors.

Coupez l'alimentation au disjoncteur avant

d'installer Power Pack ou capteurs.

PRUDENCE

Câble toute classes 2 circuits CL3, CL39, CL3R ou

conducteur équivalent

Install the sensor at least 1ft. away from any occupant.

INDOOR USE ONLY

Utilisation a L'interieur Uniquement

Page 2

DETECTION PATTERNS

Top View

Side View

110°

7.2’

16’ 32’ 50’

HFD Range

HFD Range

The OS-551DT offers numerous function controls and

operation settings available on board. To set the sensor

operation, remove the front cover by loosening the

locking screw at the sensor bottom.

SENSOR SETTINGS

Function Control Switch

1

ON-delay Selector

2

The Function Control Switch is a 6-pole DIP switch for

controlling the sensor operations as below.

3 LED’s are available on sensor board to indicate the

status of sensor operation. The LEFT one indicates HFD

sensor detection, the RIGHT one indicates PIR sensor

detection, and the CENTER one indicates sensor output

active.

No. Control OFF ON

1 LED indication

2 Buzzer output

3 SmartDelay

4 Walk-Through

5 FORCE-OFF

6 PIR sensitivity

disabled

disabled

disabled

disabled

disabled

Normal

enabled

enabled

enabled

enabled

enabled

Low

1. LED indication

The buzzer on board can be enabled to provide audible

indication for Delay-End Warning (DEW) and TEST mode.

TESTING THE SENSOR

After the sensor is mounted and wiring completed, it is

necessary to conduct a walk test to verify sensor

operation normal and detection coverage optimum.

When power is first applied to the sensor, the RIGHT LED

will blink about 1 minute for PIR sensor to warm up. The

sensor will be ready for testing after warm up expires.

Walk around within the desired coverage and observe

the LED indicators. The CENTER one should remain ON

as long as the relay is activated. The RIGHT one will light

on when PIR sensor detects the movement, and the

LEFT one will light on when HFD sensor detects.

Adjust the PIR sensor angle or apply the masking label

supplied on the lens to block the unwanted detection.

Adjust the HFD sensitivity as above-instructed to achieve

optimal coverage.

2. Buzzer output

SmartDelay can be enabled to automatically adjust the

OFF-delay from 3 to 30 minutes according to the duration

of previous occupancies. The OFF-delay time will be

constantly calibrated based on the history data collected.

3. SmartDelay

With Walk-Through (WT) mode enabled, the sensor will

deactivate its relay 3 minutes after the area is initially

occupied, if no activity is detected after the first 30

seconds. If activity is detected within the first 30 seconds,

the selected OFF-delay applies.

NOTE: The WT mode will not operate if OFF-delay is set

shorter than 3 minutes. ON-delay will be inhibited if the

WT mode is enabled.

4. Walk-Through

As HFD sensor may detect traffics behind certain type of

partition and result in unwanted OFF-delay extension.

Thus, the FORCE-OFF function can be enabled to

disengage the relay at 5 times of OFF-delay set, if only

the HFD sensor detects the movements during

OFF-delay duration.

5. FORCE-OFF

Lower PIR sensitivity can be achieved by setting the DIP

switch to ON position to eliminate unwanted activation.

ON-delay is the time given for sensor to avoid unwanted

load activation caused by short occupancy or pass

through traffics. Factory set ON-delay is disabled at “0”.

OFF-delay Selector

3

OFF-delay is the duration that relay contacts remain

engaged after the last motion sensed. Factory set is 10

minutes at “4”.

LUX Level Setting

5

4 different LUX levels can be set by placing the jumper

head at respective position, to inhibit the relay output if

ambient light level is higher than the threshold set.

ECG Adjustment

6

The ECG output can be used to achieve constant level

lighting control. This miniature potentiometer can be

adjusted to regulate the output of connected ECG lighting

fixture to the desired level.

HFD Sensitivity Adjustment

7

HFD sensor could detect the out-of-view traffics behind

partition. Ensure to adjust the potentiometer

counterclockwise to reduce the sensitivity if any of the

following situations occurred;

TEST Mode Switch

4

Pressing this button will activate a 5-minute TEST mode

(buzzer will beep twice). During TEST mode, the

ON-delay will be inhibited and the OFF-delay will be

shortened to 10 seconds for test convenience. Sensor will

return to normal operation automatically after times up.

6. PIR sensitivity

Set 0 1 2 3 4 5 6 7

0 5” 10” 20” 30” 1’ 3’ 5’

10” 1’ 3’ 5’ 10’ 20’ 30’ 60’

ON Delay

OFF Delay

A

10 lux (approx. 1 fc)

B

C

D

30 lux (approx. 3 fc)

50 lux (approx. 5 fc)

24H (ALS disabled)

Walk around outside of desired range and the LEFT

LED is ON.

If the sensor is installed in a small room, and the

LEFT LED remains ON all the time even with no any

movement outside of desired range.

1.

2.

The OS-551DT comes with the bracket assembled

which allows it to be mounted on wall or ceiling with

two screws. To achieve optimal coverage, sensor angle

can be adjusted horizontally or vertically by loosening

the tightening screw on the bracket. Ensure to tighten

the tightening screw to hold the sensor position.

Mount the bracket base to the mounting surface with

screws.

Drill a proper hole on the mounting surface to lead

the sensor wires through.

Refer to the wiring diagram and connect the sensor

wires to the power pack or BMS control.

MOUNTING THE SENSOR

Ceiling mount

Wall mount

0.3”

1

2

1.

2.

3.

2

3

1

0.9”

Tightening Screw

End-cap

It is best to leave

approximately 6

inches between the

sensor and the wall

so that the tightening

screw can be

accessed.

Mount the first screw with approximately

0.3” head-off the wall for ease of base mounting.

Note: An end-cap

can be snap-in to

cover the back of

bracket.

3

5

4

6

End-cap

1 2

3

Sensor Internal

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1)This device may not cause harmful interference, (2)This device must accept any interference received,

Including interference that may cause undesired operation.

Loading...

Loading...